Patents

Literature

586results about How to "Easy mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for rotating a shaft

ActiveUS20100095791A1Facilitate selective engagementReducing structural loading requirementGearingMachines/enginesRotational axisGear wheel

Turning gear apparatus for rotating a shaft comprises a rotary drive arrangement and a transmission system including a pivot arm. The rotary drive arrangement is fixed, for example to a vessel hull, and the pivot arm is pivotable between a first, shaft-disengaged, position and a second, shaft-engaged position where the rotary drive arrangement is operably coupled to the shaft, thereby permitting control over rotation of the shaft by the rotary drive arrangement.

Owner:GALLOWAY ERIC

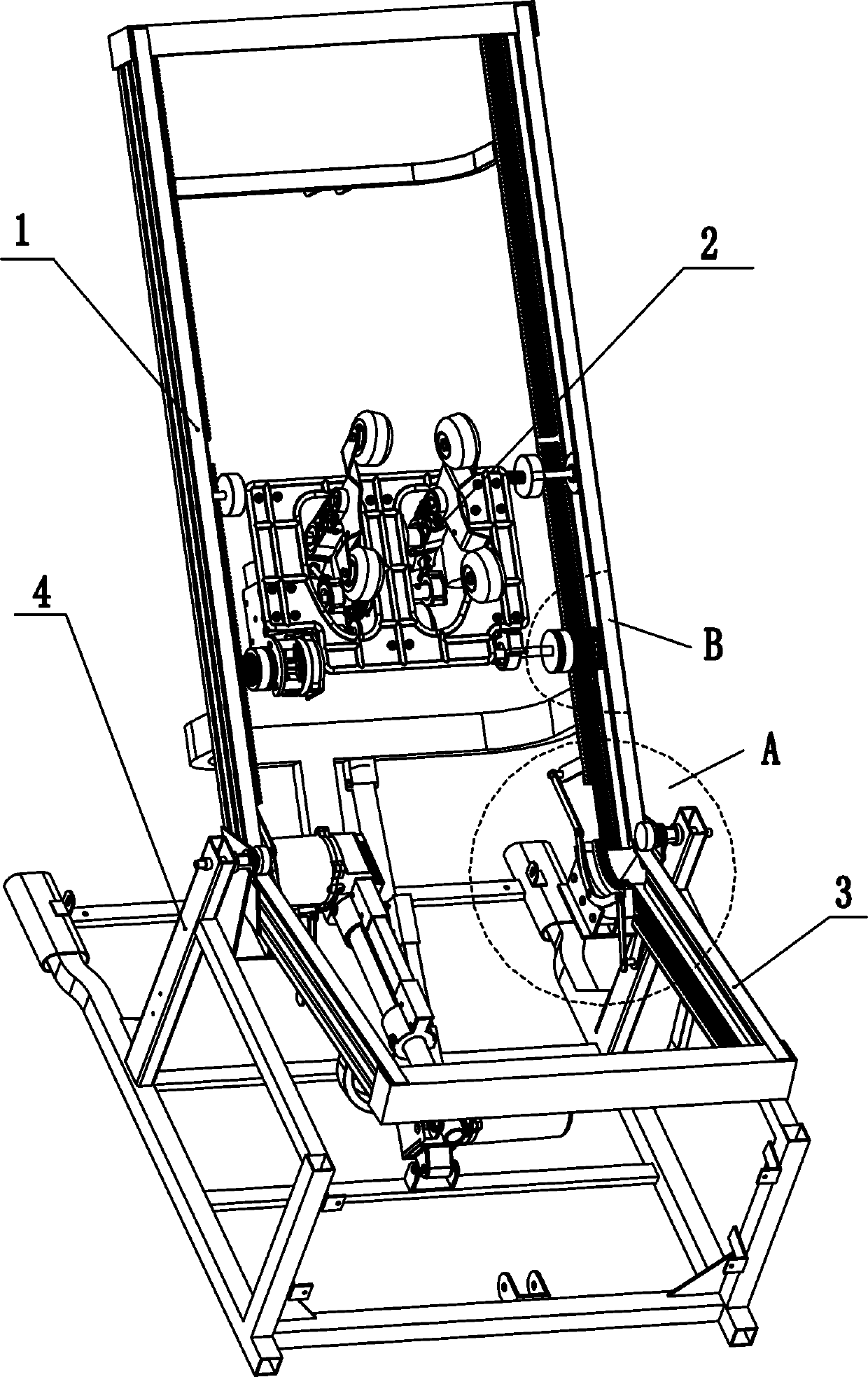

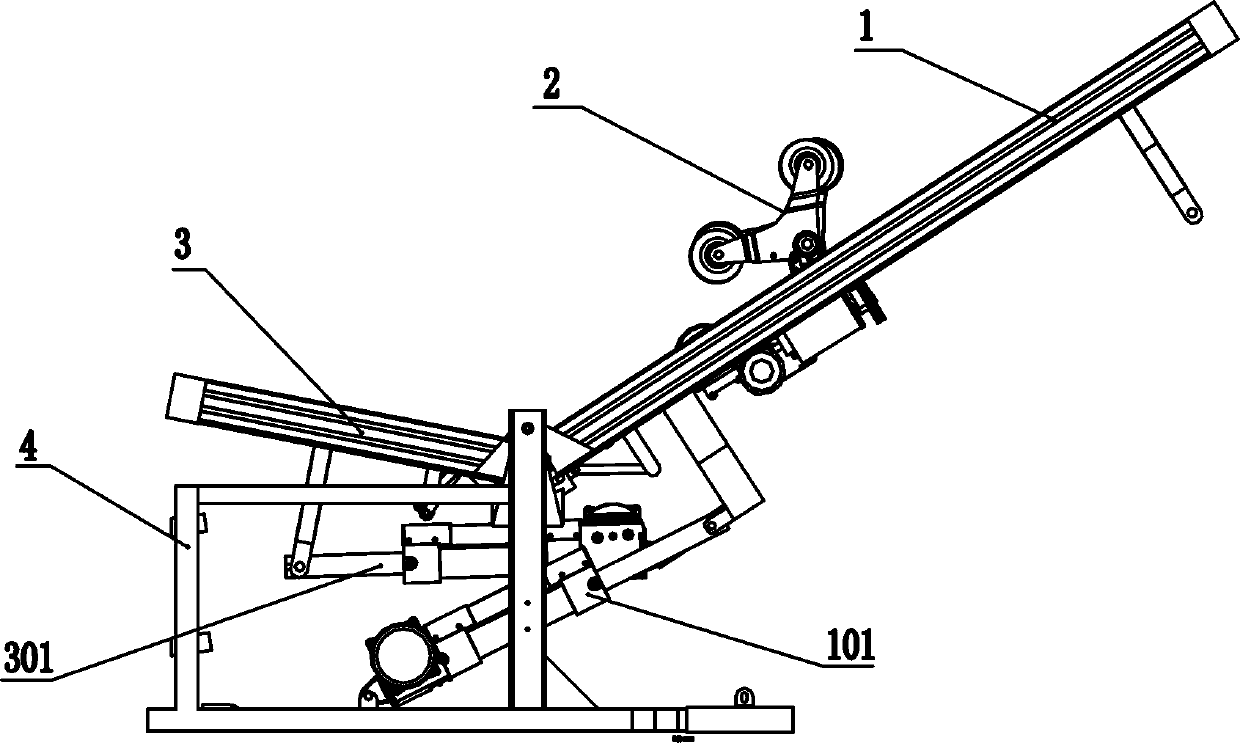

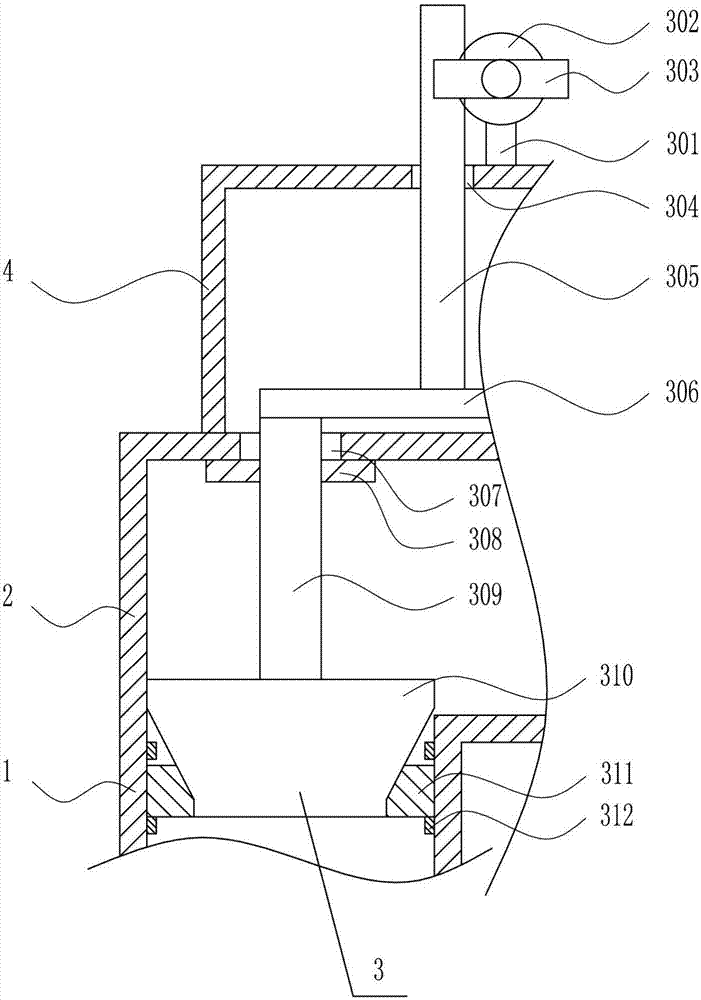

Chair type full-body massaging machine

The invention relates to a chair type full-body massaging machine. The chair type full-body massaging machine comprises a massaging machine core, a chair frame, a seat frame and a base, wherein the chair frame is movably hinged to the base; the seat frame is arranged on the base; the massaging machine core is provided with a traveling device; the chair frame is provided with a back guide track by which the massaging machine core walks on the back of a user; the seat frame is provided with a seat guide track by which the massaging machine core walks on legs of the user; the traveling device comprises traveling wheels matched with the back guide track and the seat guide track; a spaced gap is formed in a position at which the back guide track is connected with the seat guide track; a transitional guide track which is connected to adjacent ends of the back guide track and the seat guide track is arranged at the spaced gap and is movable; limiting chutes are formed in the transitional guide track; the chair frame and the seat frame are respectively provided with limiting guide columns extending in the limiting chutes; the limiting guide columns are matched with the limiting chutes in a sliding manner; and the traveling wheels pass through the spaced gap from the transitional guide track. The chair type full-body massaging machine has a full-body massaging function.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD +1

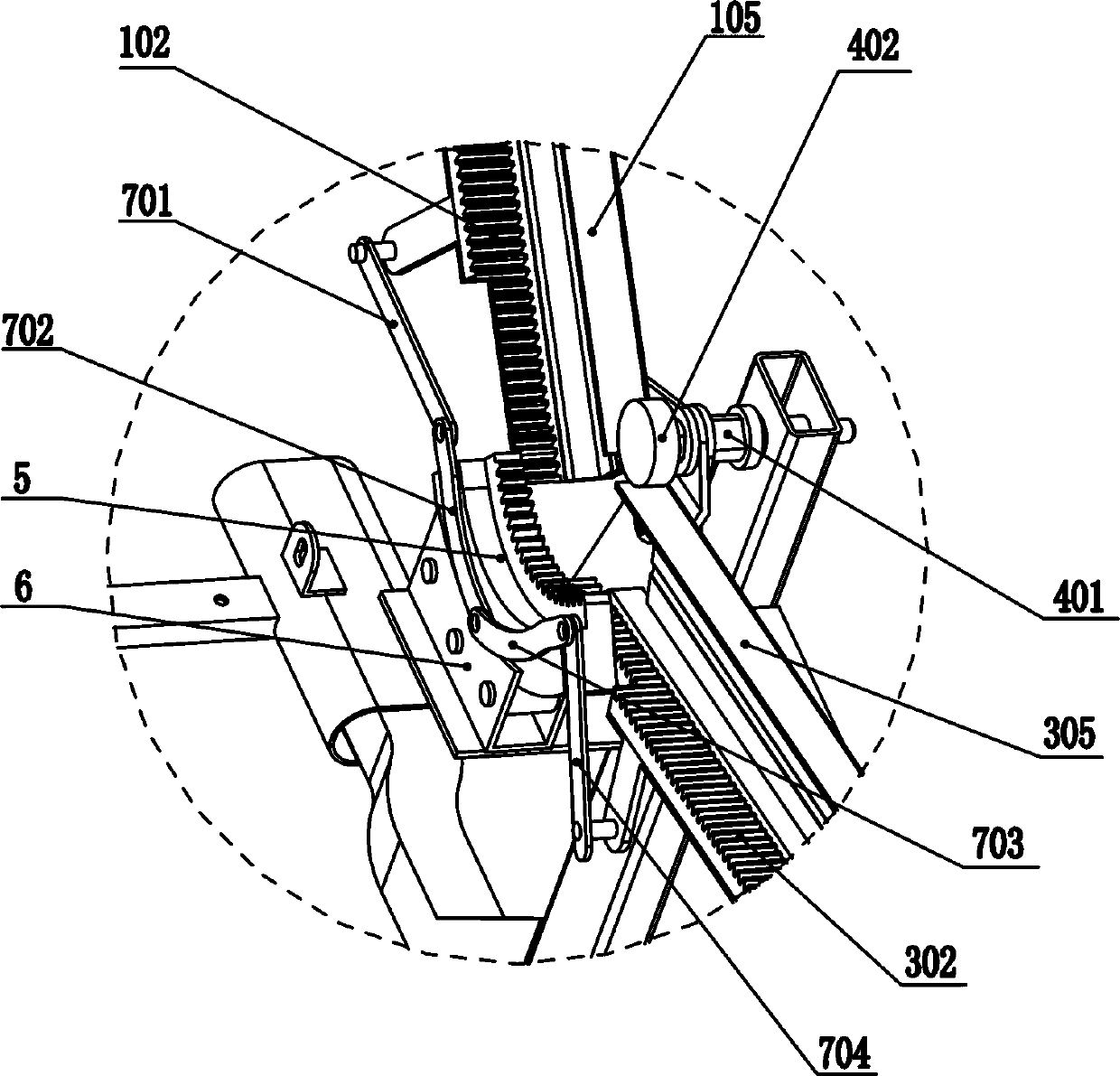

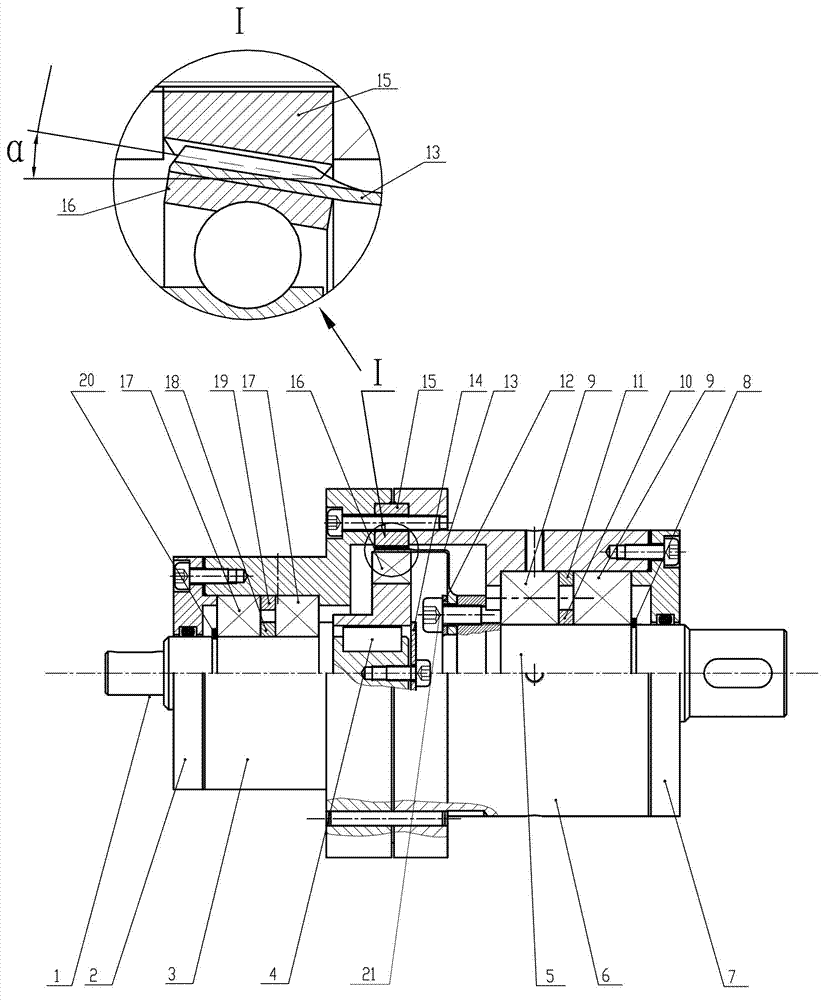

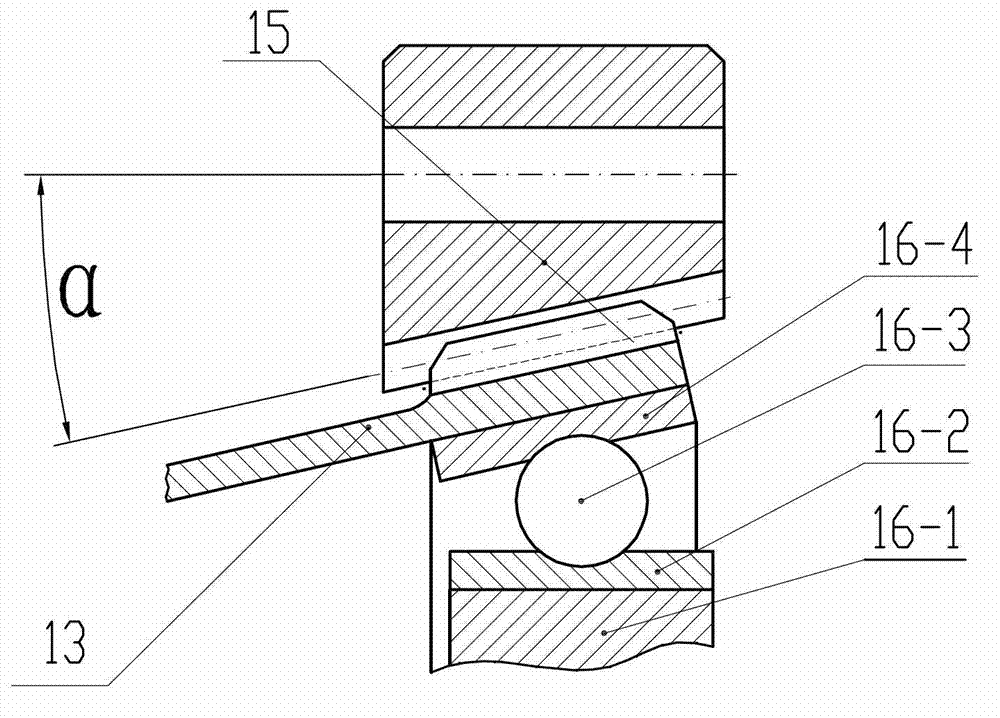

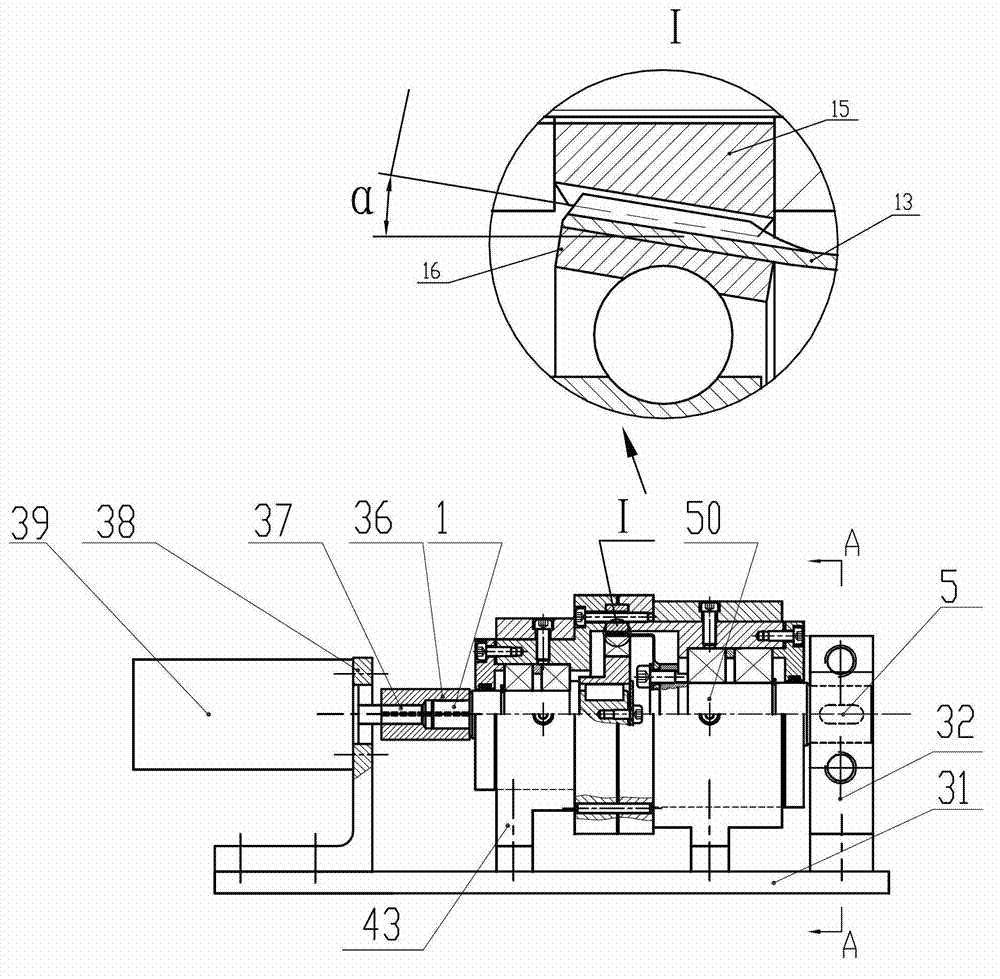

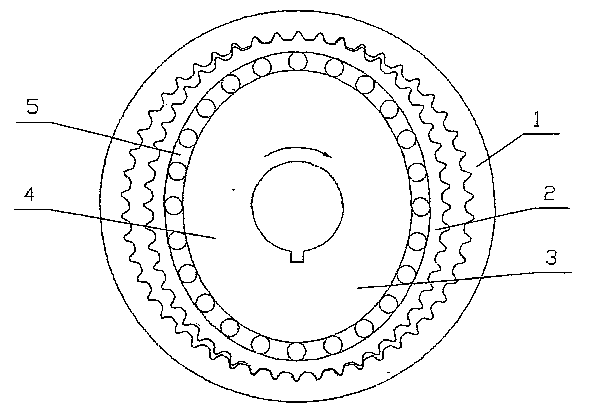

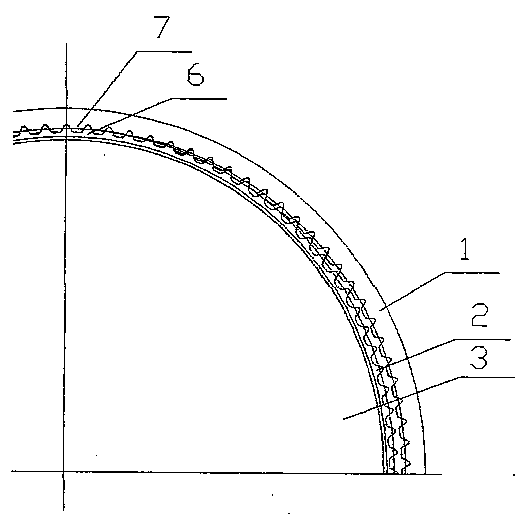

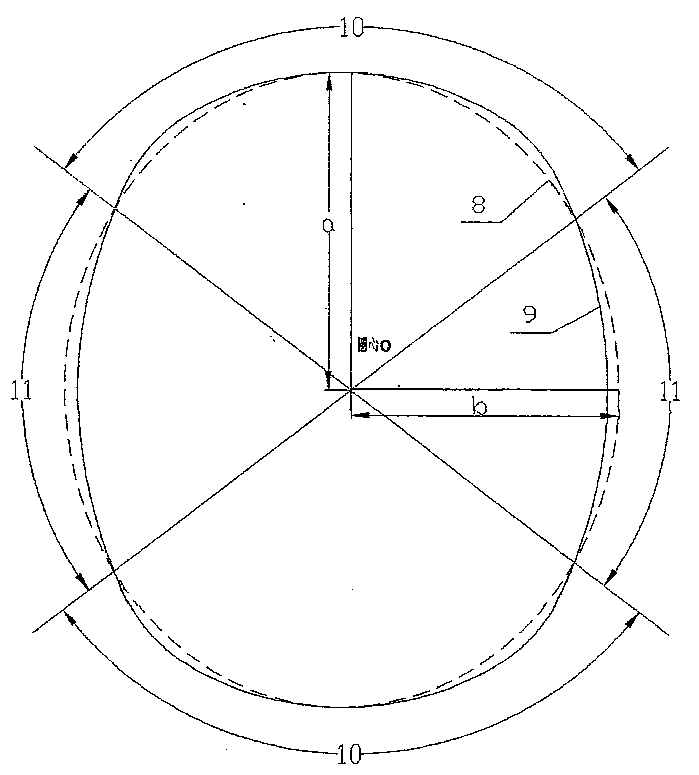

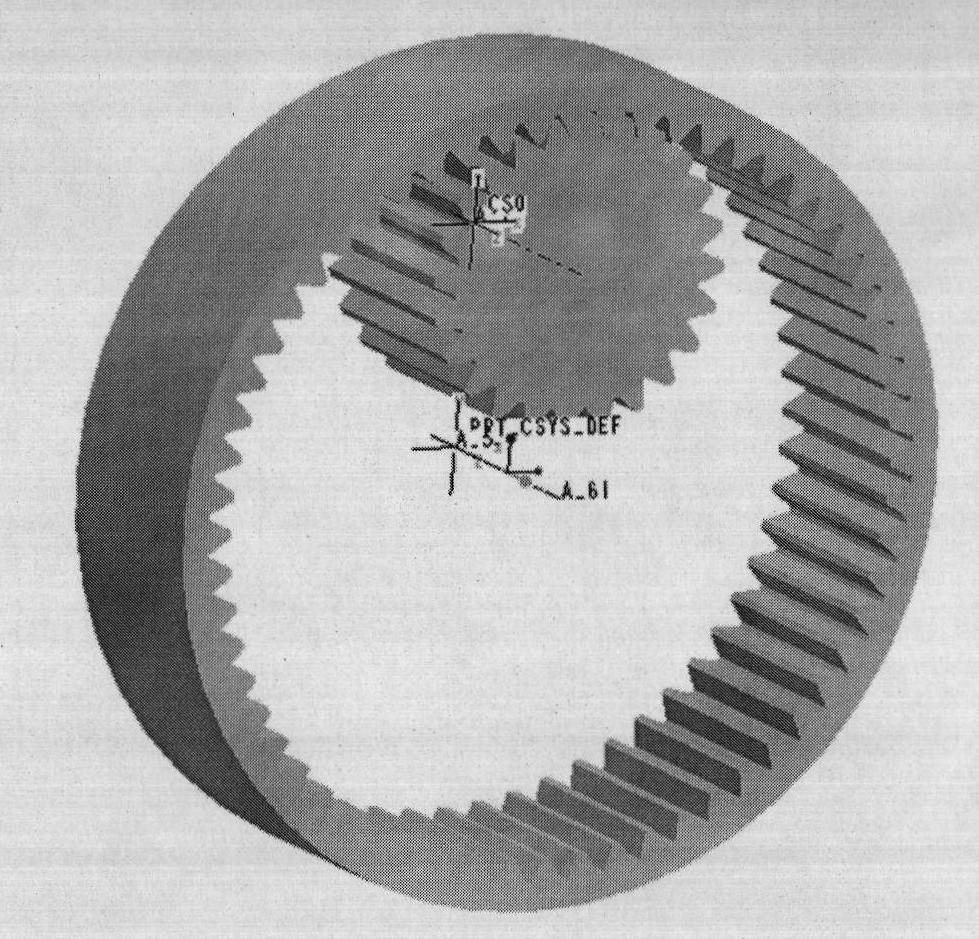

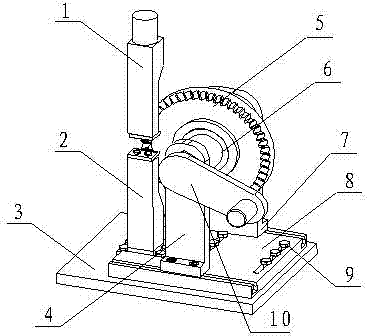

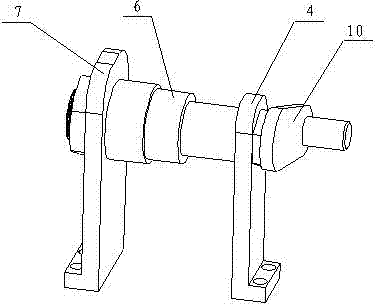

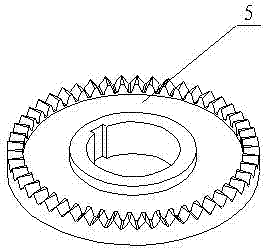

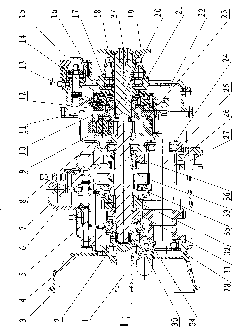

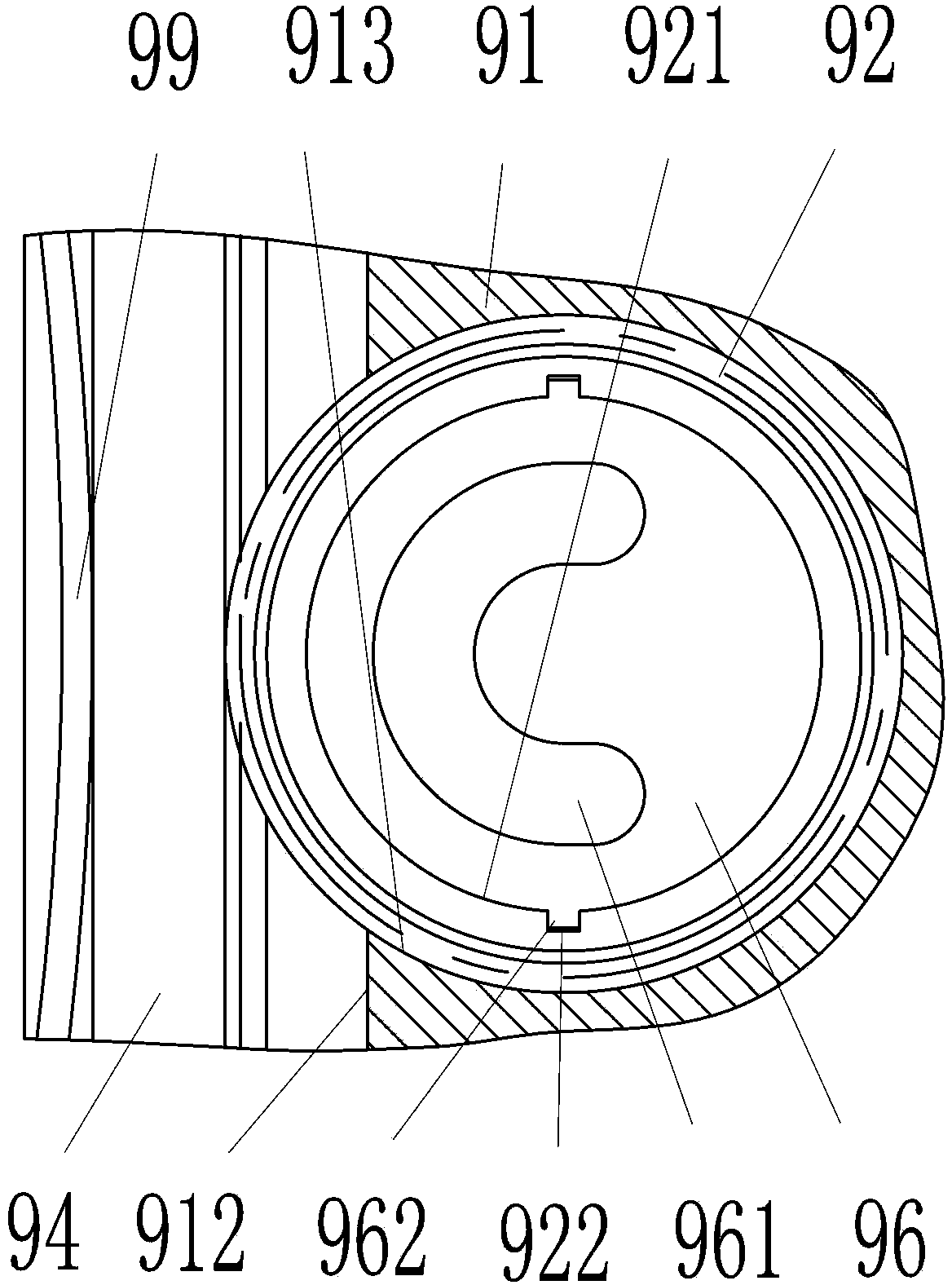

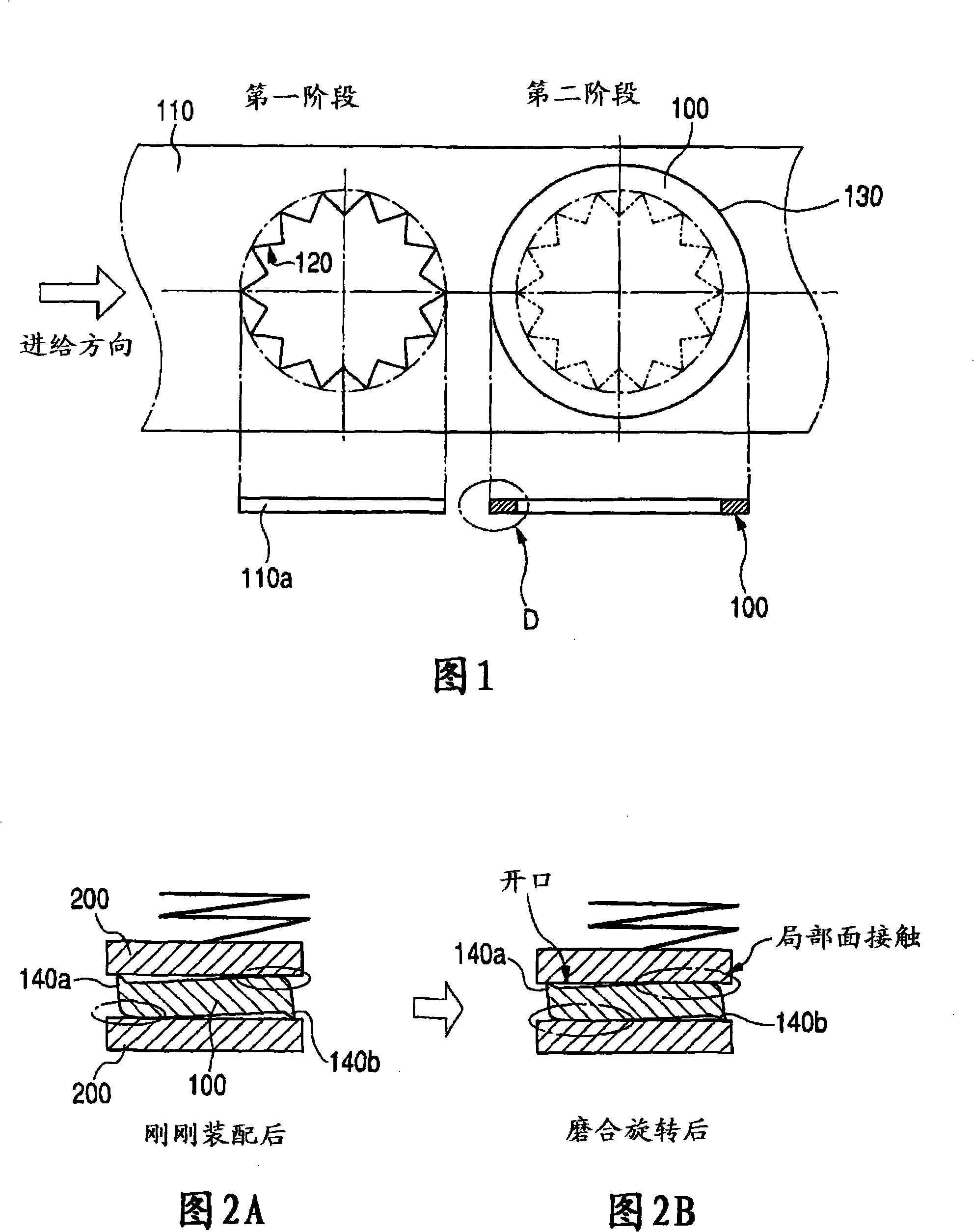

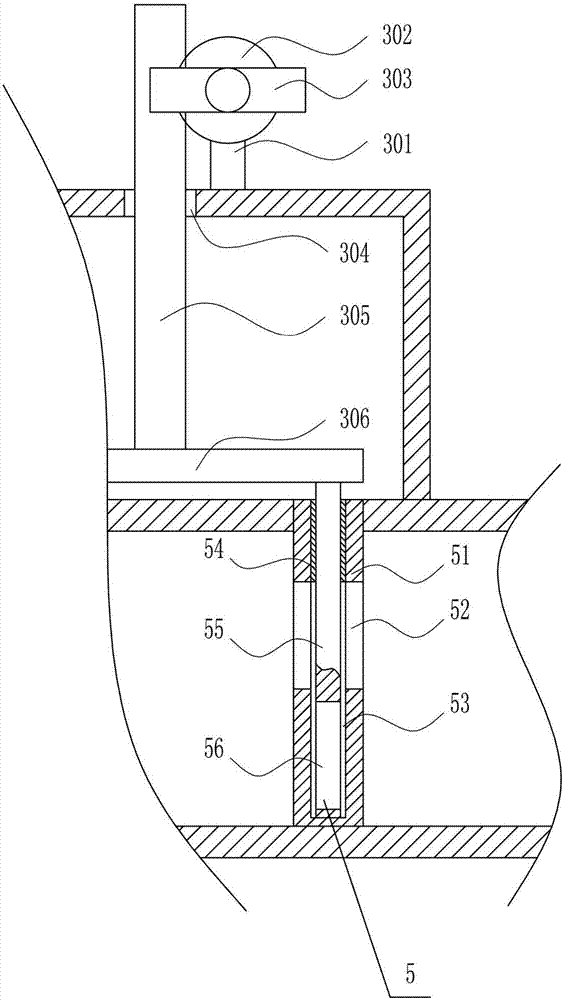

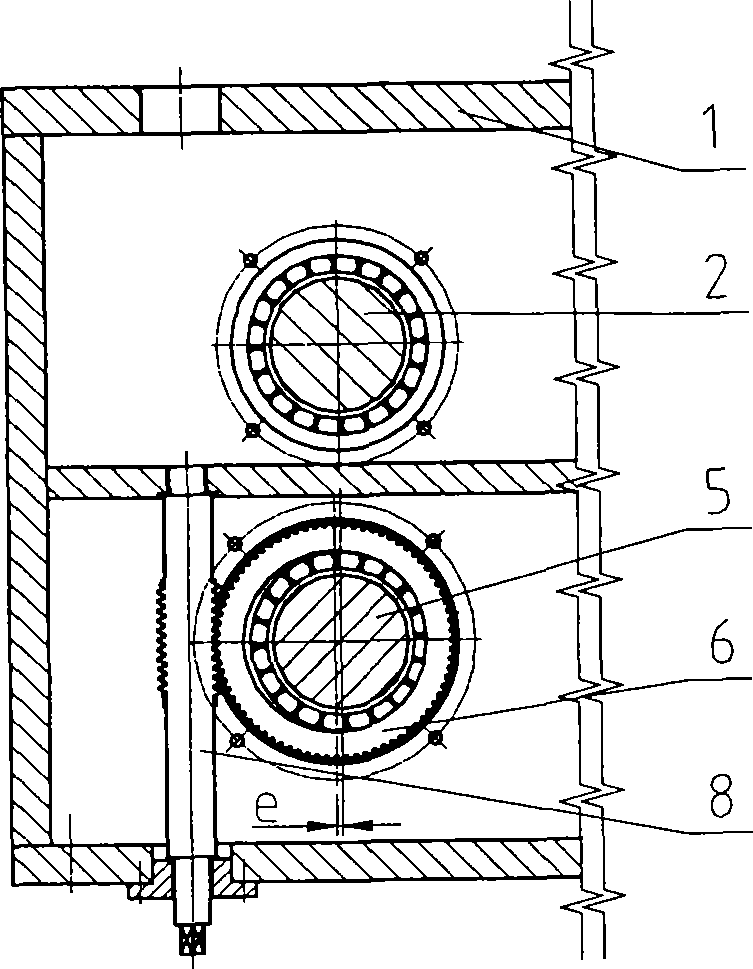

Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

ActiveCN102777546AEasy meshImprove transmission stiffnessMachine gearing/transmission testingToothed gearingsDiameter ratioEngineering

The invention discloses a short tube flexible gear harmonic reducer of a rigid wheel tooth dip angle and a transmission rigidity testing device thereof, and relates to the technical field of harmonic reducers. According to the invention, the deflection of the flexible wheel gear teeth is caused by the reduction of the axial size of the short tube flexible gear harmonic reducer, so as to realize the reduction of the surface area between the rigid wheel gear teeth and the flexible wheel gear teeth, and to realize the lowering of the transmission rigidity; the problem of complicated operating process of the existing harmonic drive rigidity experiment testing device is solved; and the length diameter ratio of a soft wheel is 1 / 4 to 3 / 5 of a short tube wheel, the inner wheel of the rigid wheel with a dip angle is the wheel teeth with the dip angle alpha along the rigid wheel axial direction, and the deflection direction and the field angle direction of the soft wheel on a long shaft are coincident. The transmission rigidity testing device of the short tube flexible gear harmonic reducer implements current control namely torque control through a computer and a servo driver, and the harmonic drive output end realizes continuous loading unloading; and the harmonic drive rigidity of the short tube soft wheel is obtained, and the transmission rigidity is serially, rapidly accurately obtained.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

Active bio piezoelectric ceramic coating layer and method of preparing said coating layer on titanium base body surface

InactiveCN1785439AReduce bond strengthHigh bonding strengthAnodisationImpression capsPlasma electrolytic oxidationMicro arc oxidation

A coated active biologic piezoelectric layer on Ti substrate is prepared from fluorohydroxy apatite (FHA) and barium titanate (BT) through cleaning the surface of Ti substrate, microarc oxidizing to form a porous oxide film layer, and electrophoretic deposition to form a FHABT layer on the surface of Ti substrate. Its advantages are easy control to content of F, high implantation stability, binding power to interface, biocompatibility and bioactivity, and high effect to promote generation of biologic bone and taking part energy conversion in human body.

Owner:HARBIN ENG UNIV

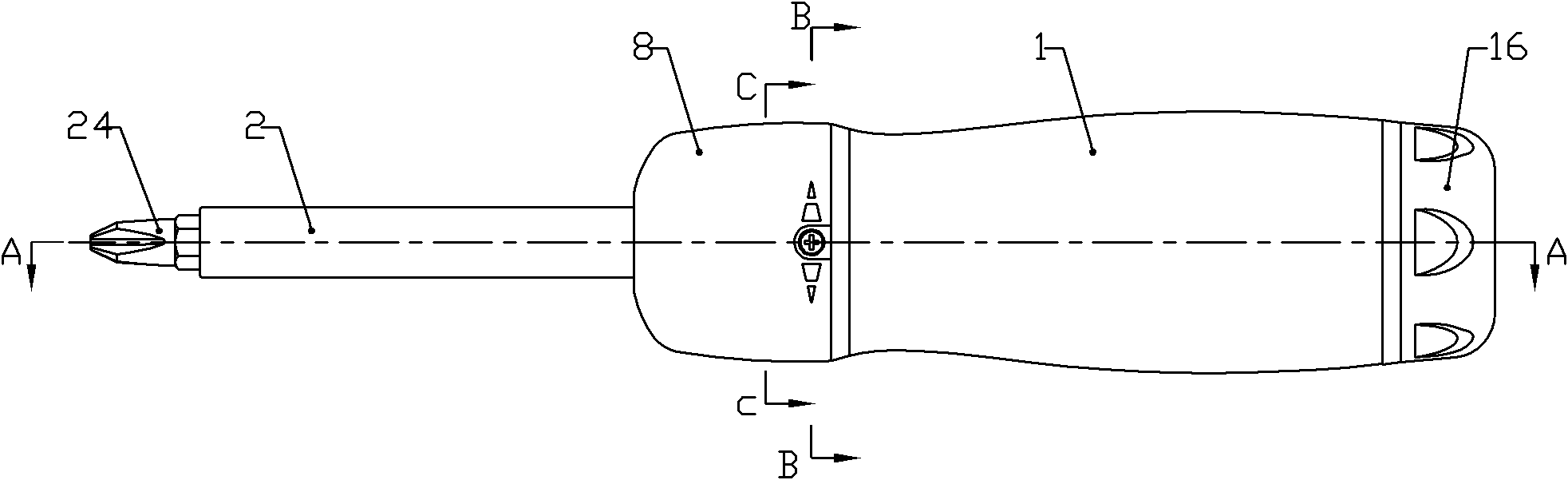

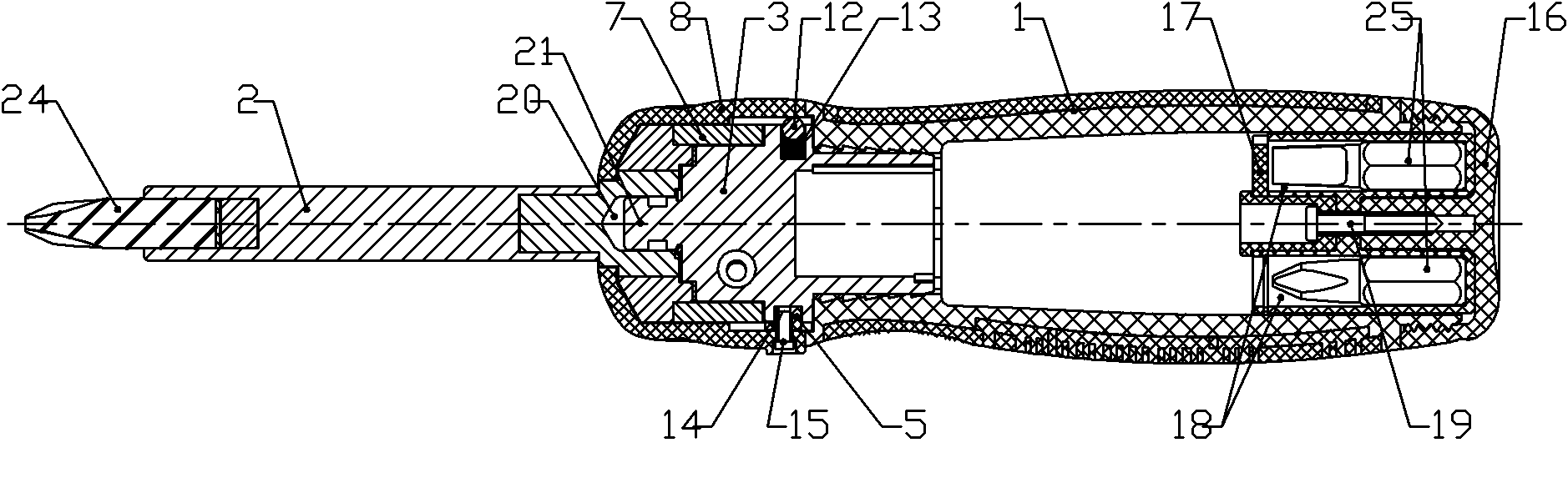

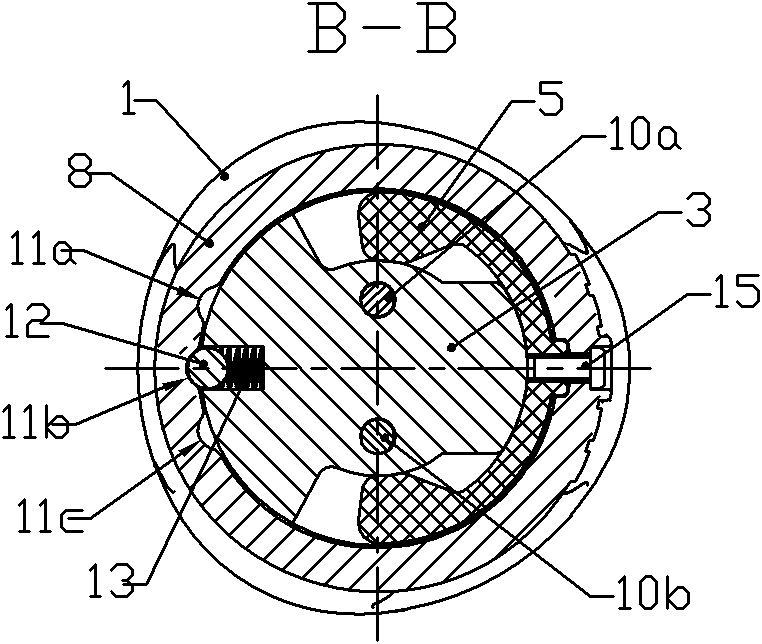

Ratchet screw driver

The invention discloses a ratchet screw driver which aims at solving the problems that the existing orienting screw driver is inconvenient to hold by hand and has a complicated structure. The ratchet screw driver comprises a handle and a driver rod and is characterized in that the front end of the handle is provided with a pawl bed, wherein the pawl bed is provided with two pendular pawls arranged in the opposite directions and a shift part for controlling the position states of the two pawls, and the shift part is provided with two shift blocks which respectively correspond to the two pawls;the tail of the driver rod is provided with a ratchet sleeve, and the ratchet sleeve is sheathed on the pawl bed and is at least meshed with one of the two pawls; and an operating part which can be positioned on the handle is arranged and is used for changing the position of the shift part. By integrating all orienting structures at the front end of the handle, the ratchet screw driver has the advantages of simple and compact structure and convenient assembly and disassembly. Since a rotating sleeve is adapted to the outline wheel of the handle, the ratchet screw driver is kept adapted to thehandle in shape in addition to facilitating gear shift, thereby facilitating being holden by hand for usage.

Owner:HANGZHOU GREAT STAR IND CO LTD

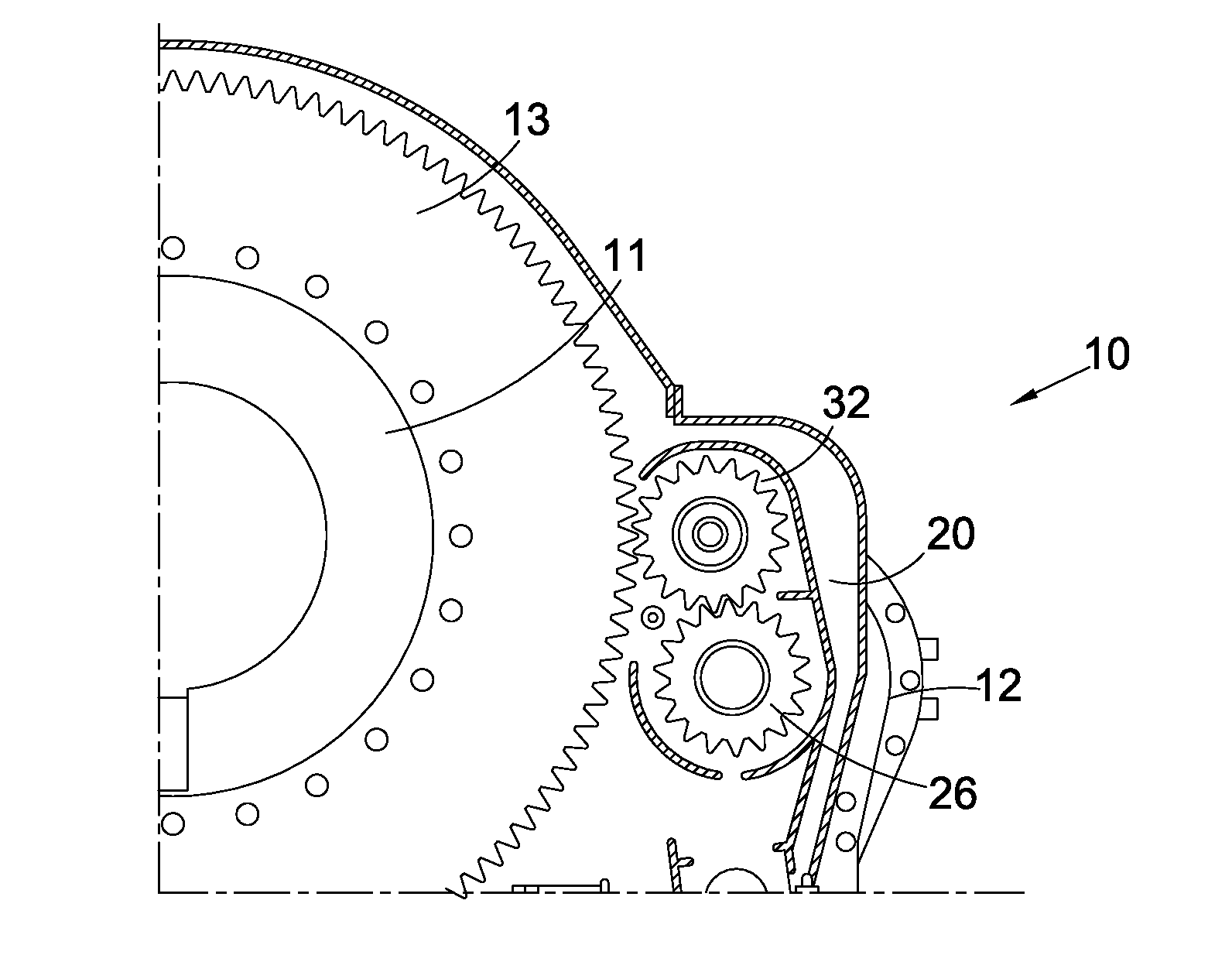

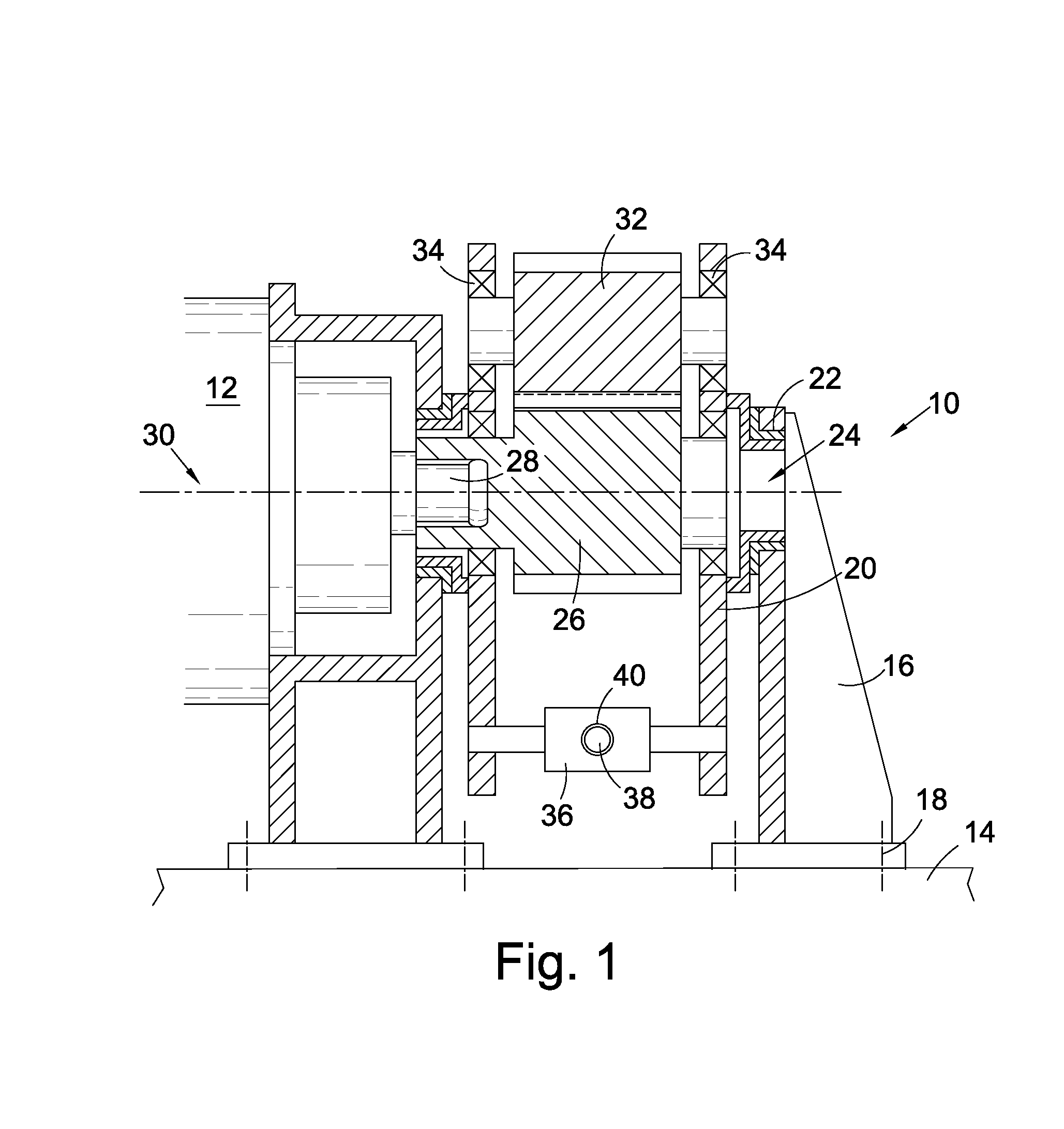

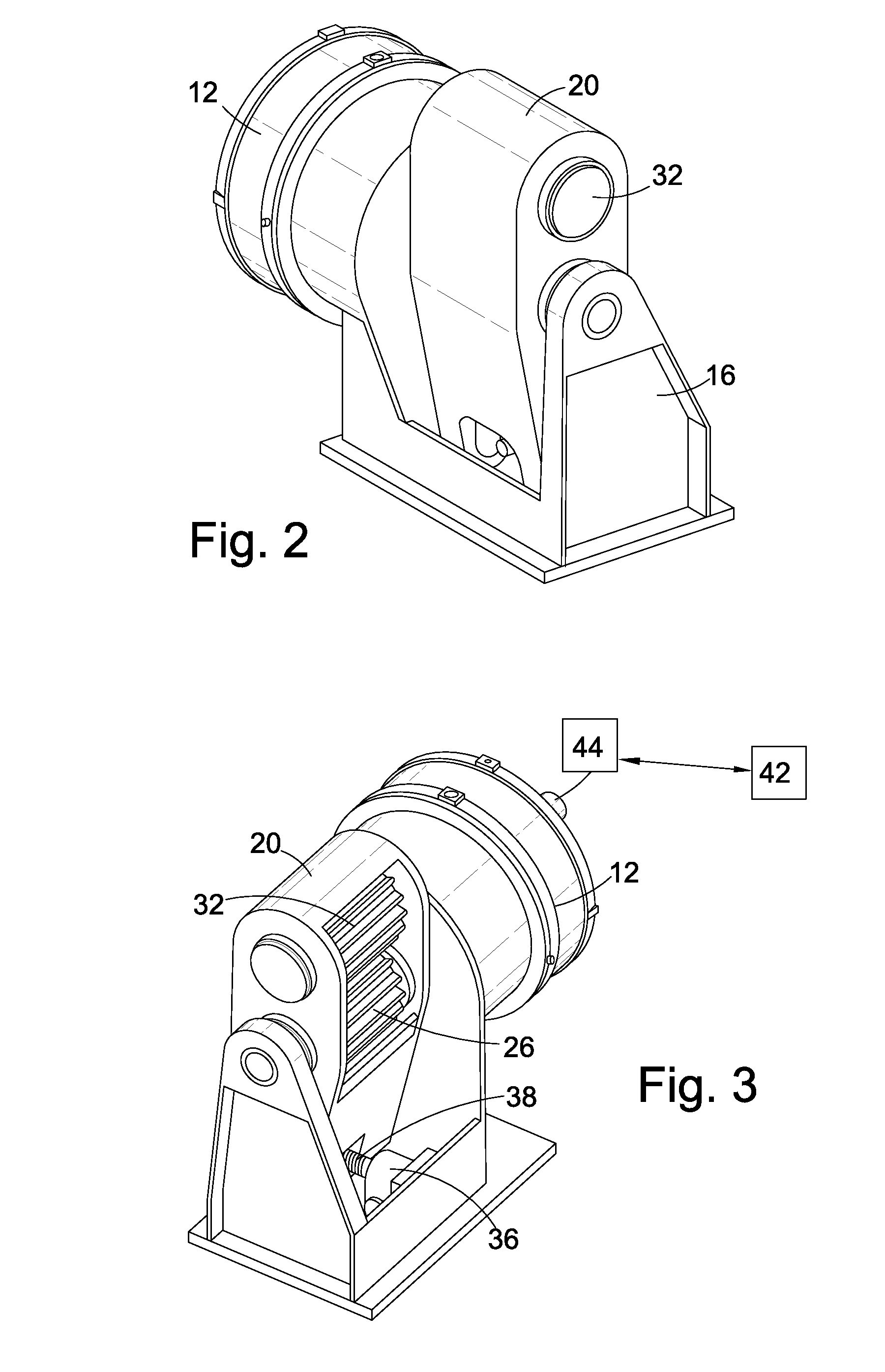

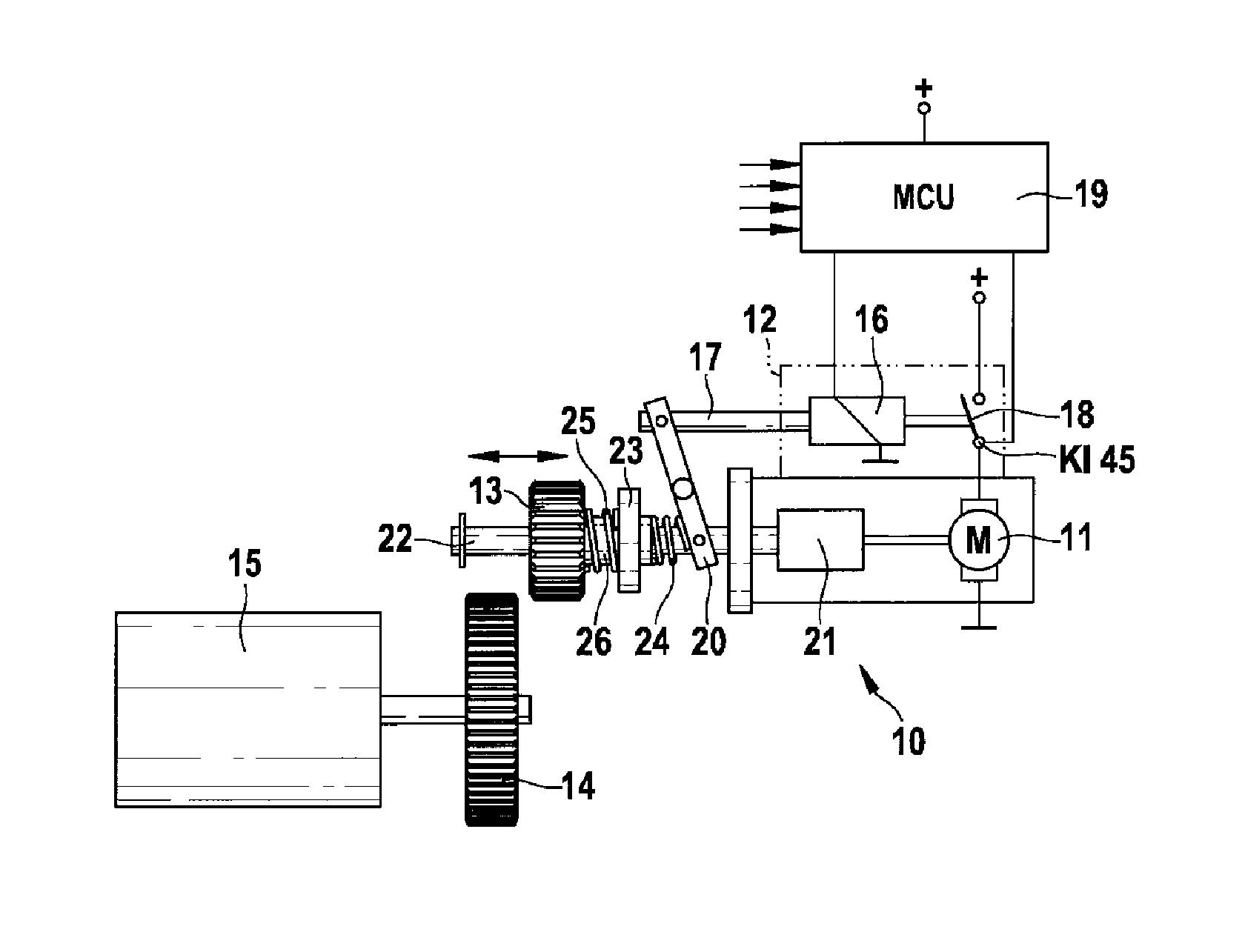

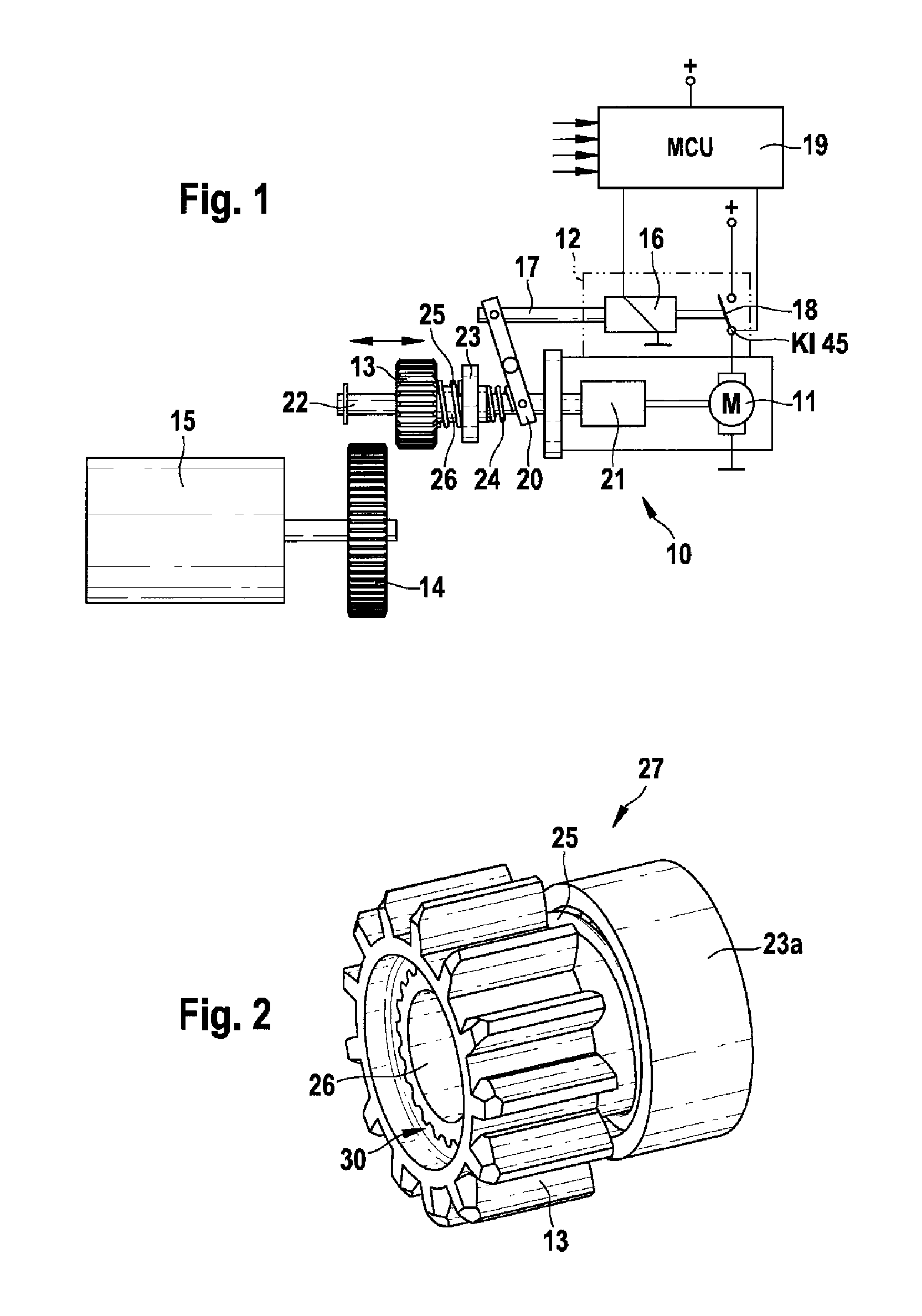

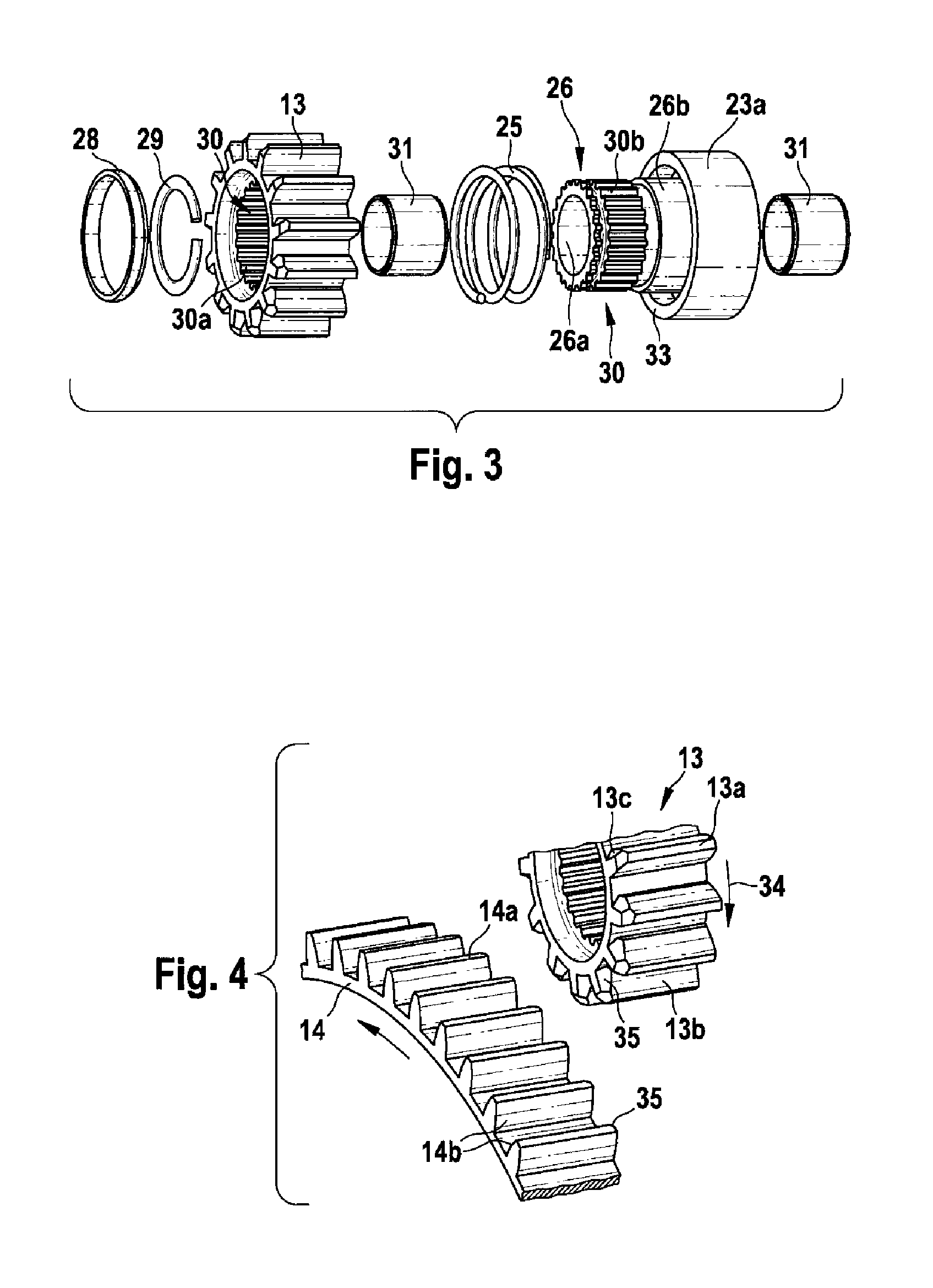

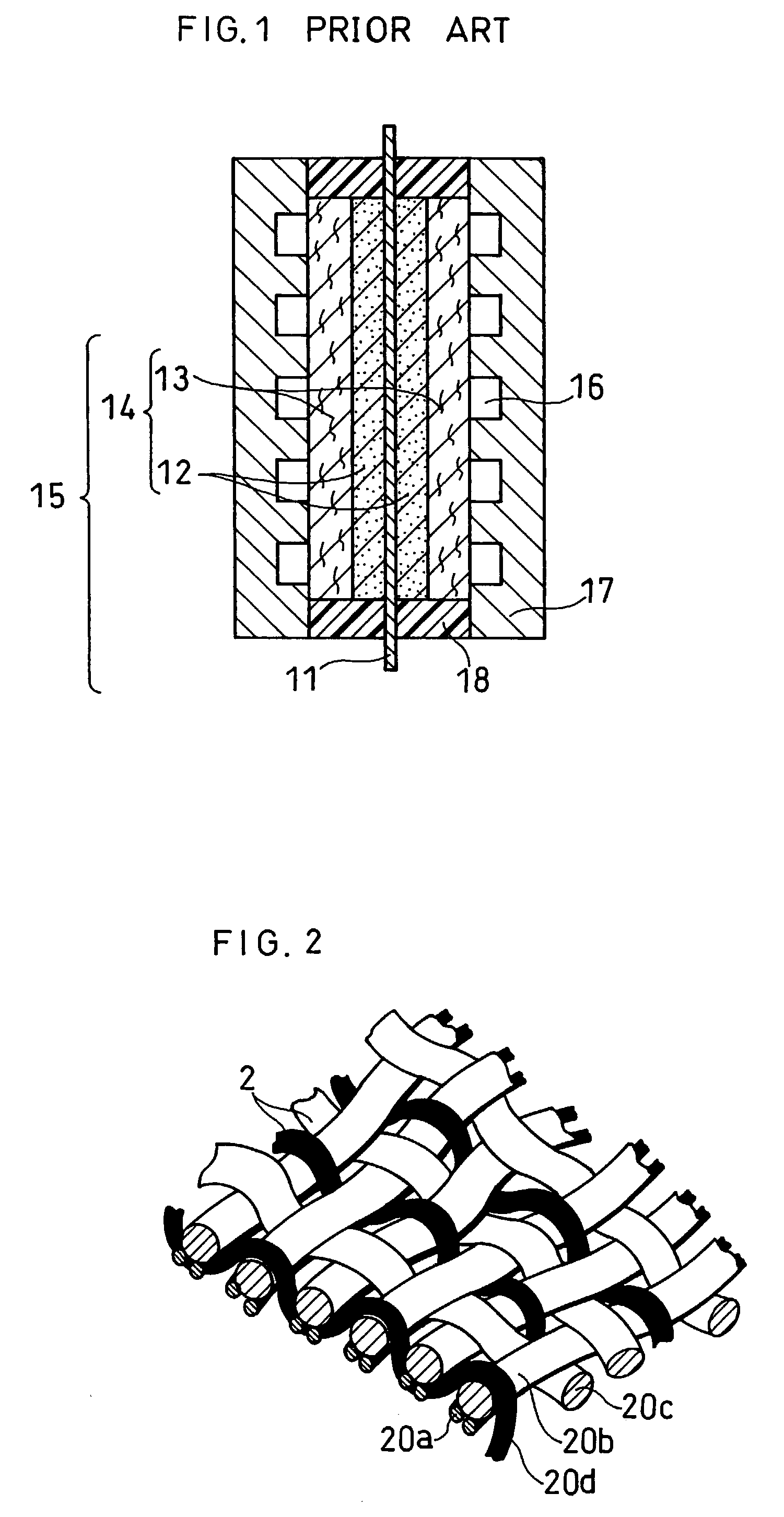

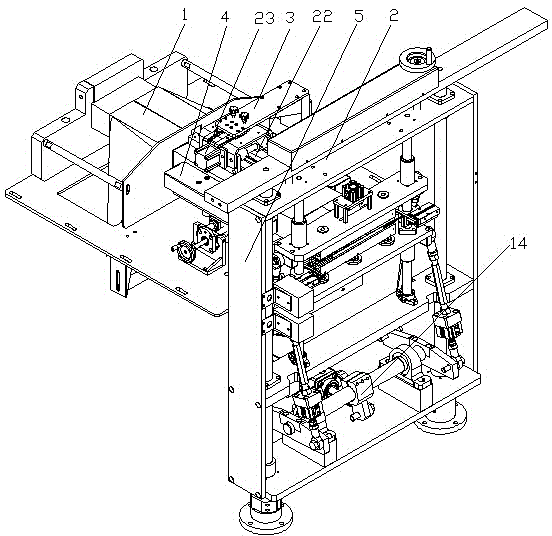

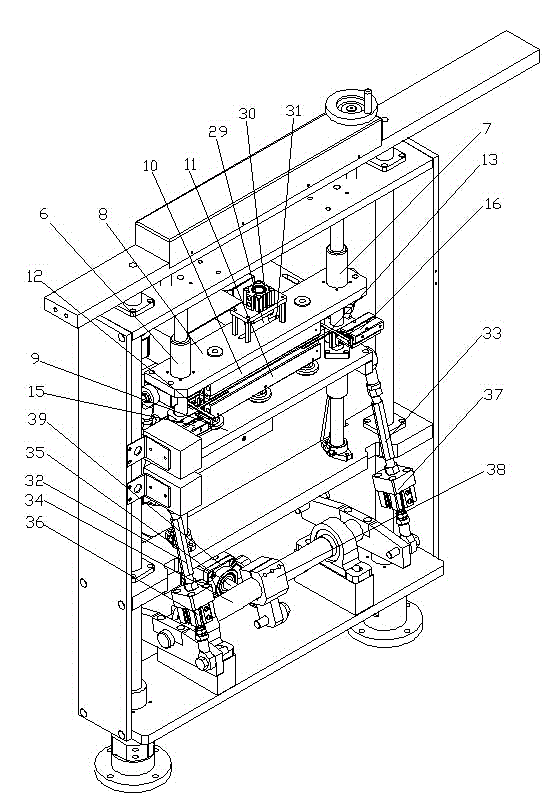

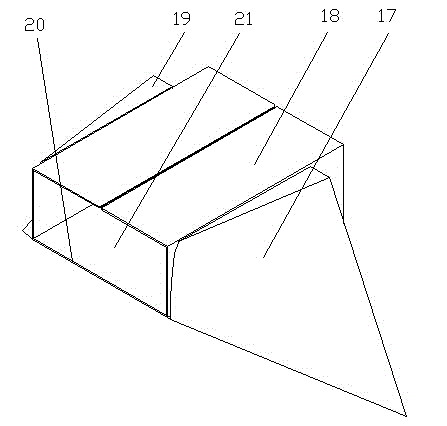

Method And Device For Start-Stop Systems Of Internal Combustion Engines In Motor Vehicles

ActiveUS20110308490A1Reduce stepsMechanically simplePower operated startersElectric motor startersStart stopCombustion

The invention relates to a starting method for internal combustion engines in motor vehicles, comprising a start-stop system, and to a starting device (10) for carrying out said method, said starting device comprising a starter motor (11) and an insertion device (12, 20) which axially inserts a slip-on pinion (13) into a crown gear (14) of the internal combustion engine when a stop cycle begins. In order to minimize the period until the engine can be restarted, the pinion (13) is resiliently inserted into the still rotating crown gear (14) by means of a pressure spring (25) when the stop phase begins, once the internal combustion engine (15) is switched off but before it comes to a standstill and with the starter motor (11) switched off.

Owner:SEG AUTOMOTIVE GERMANY GMBH

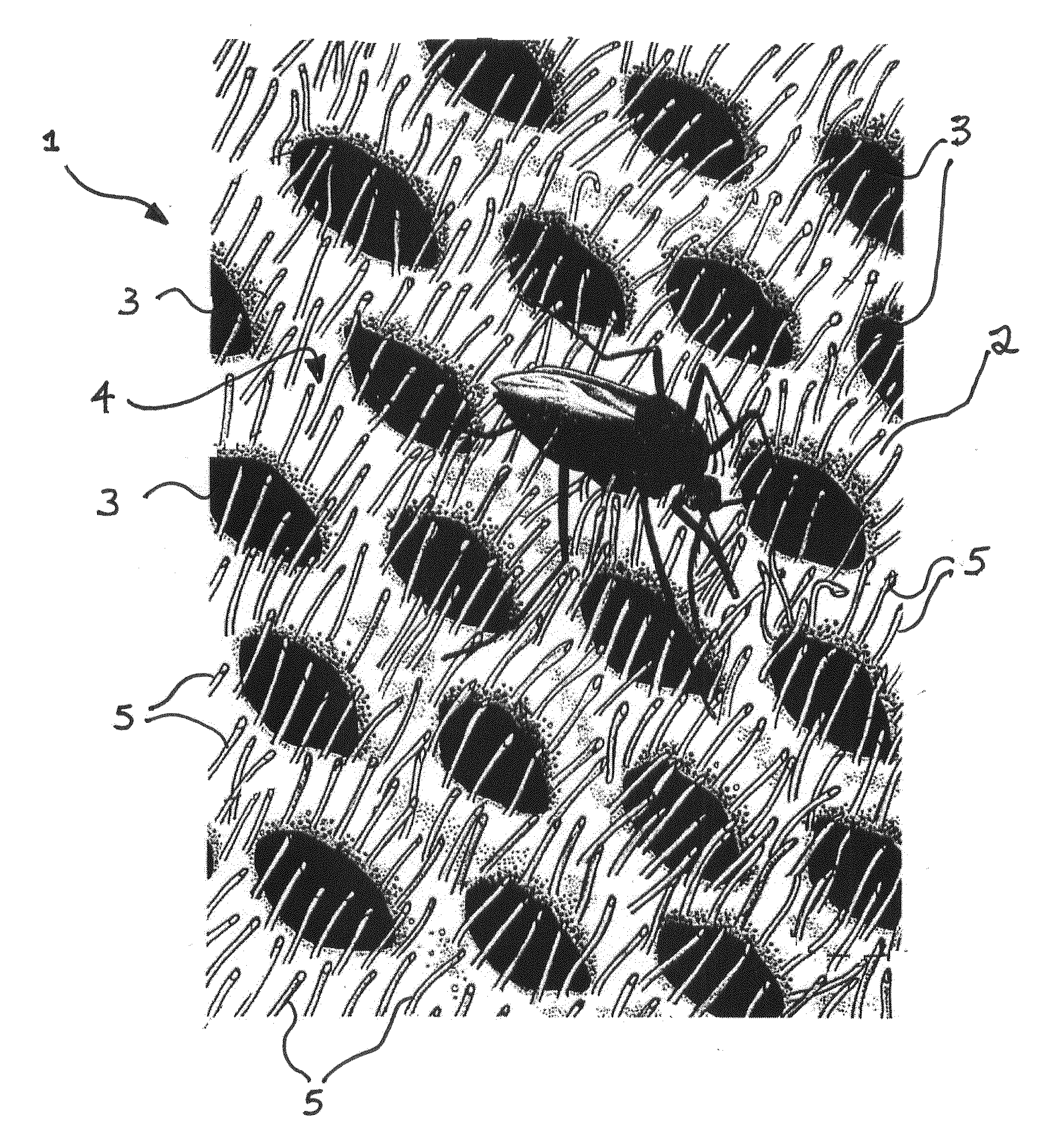

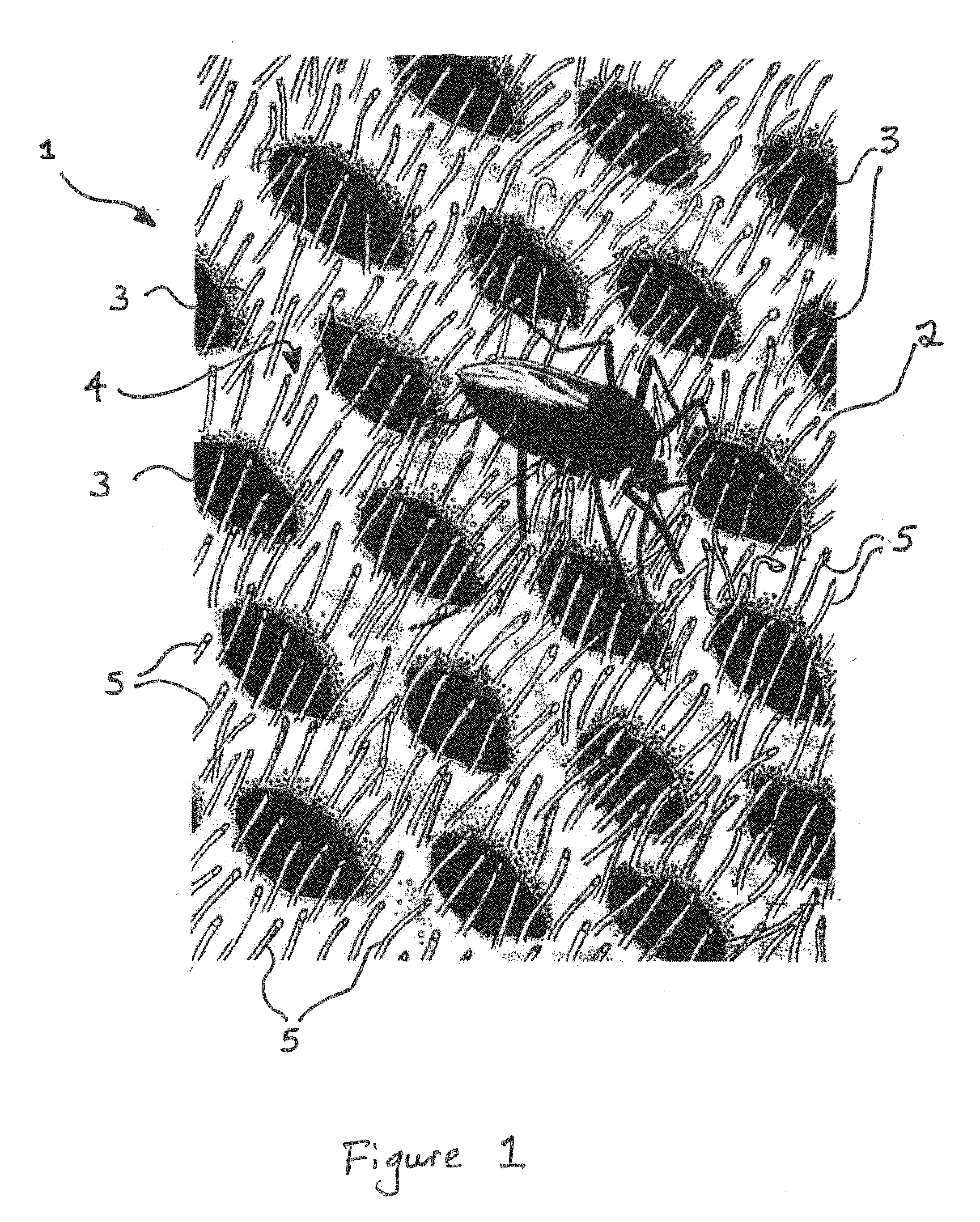

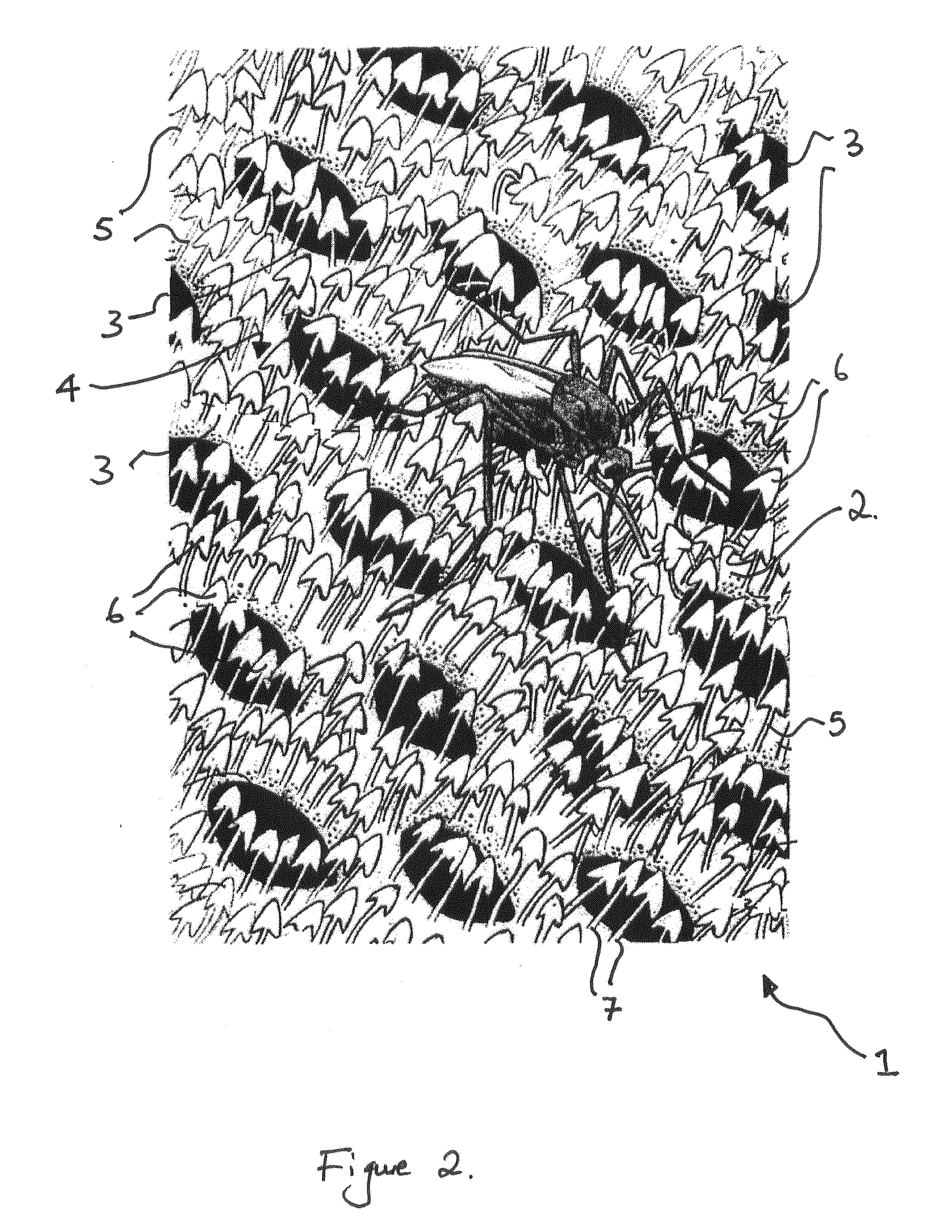

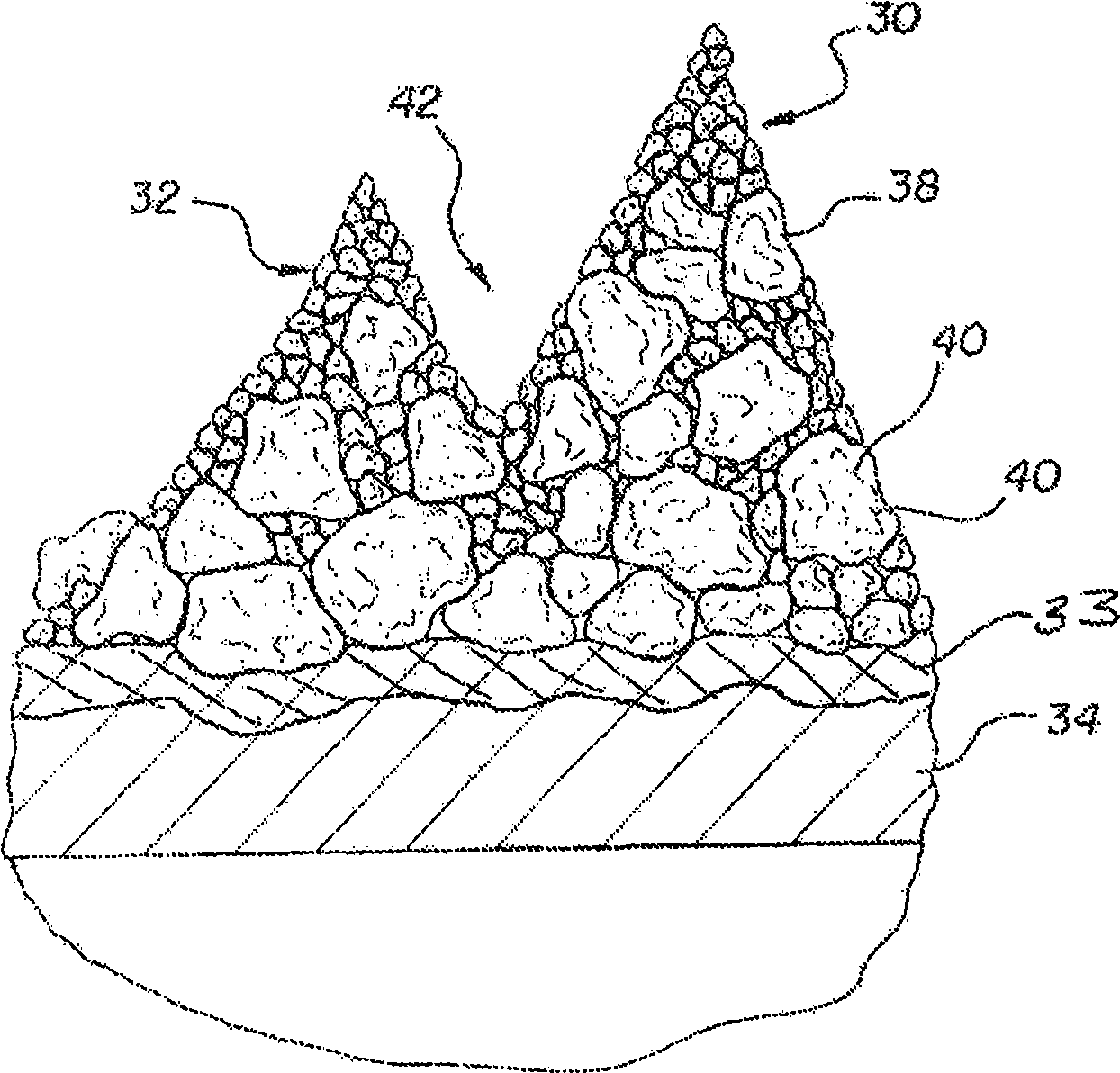

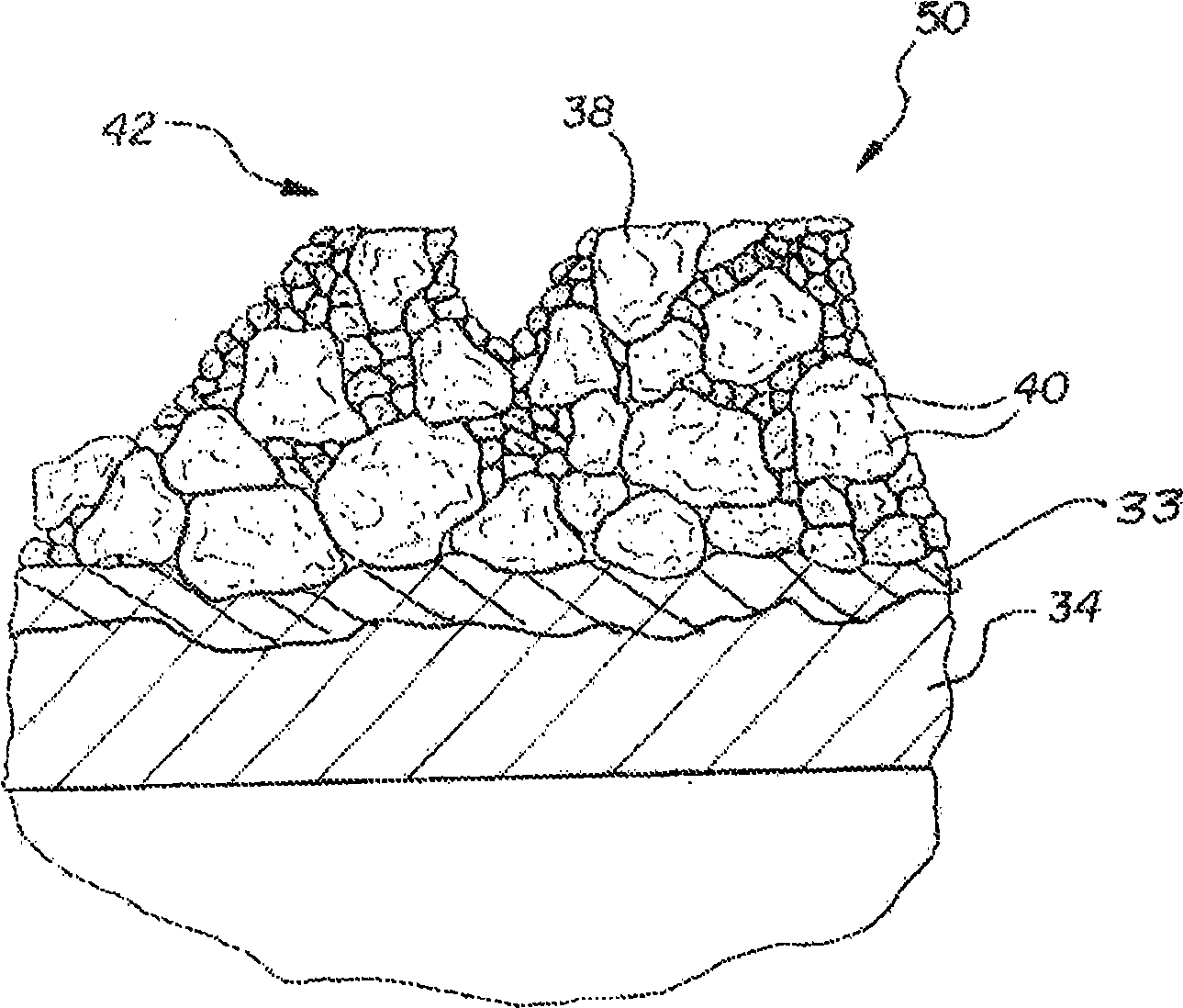

Pest control materials

InactiveUS20140041285A1Facilitate abrasionFacilitate mechanical interactionCrochetingTravelling sacksPaleontologyPest control

An open mesh insect control material is described which includes an insect contact surface, an internal surface, apertures communicating both surfaces and a plurality of filamentous projections protruding from the insect contact surface the projections at least partly occlude the apertures. The structure is suitable for use in pest control especially as a mosquito net.

Owner:INSECTSHIELD

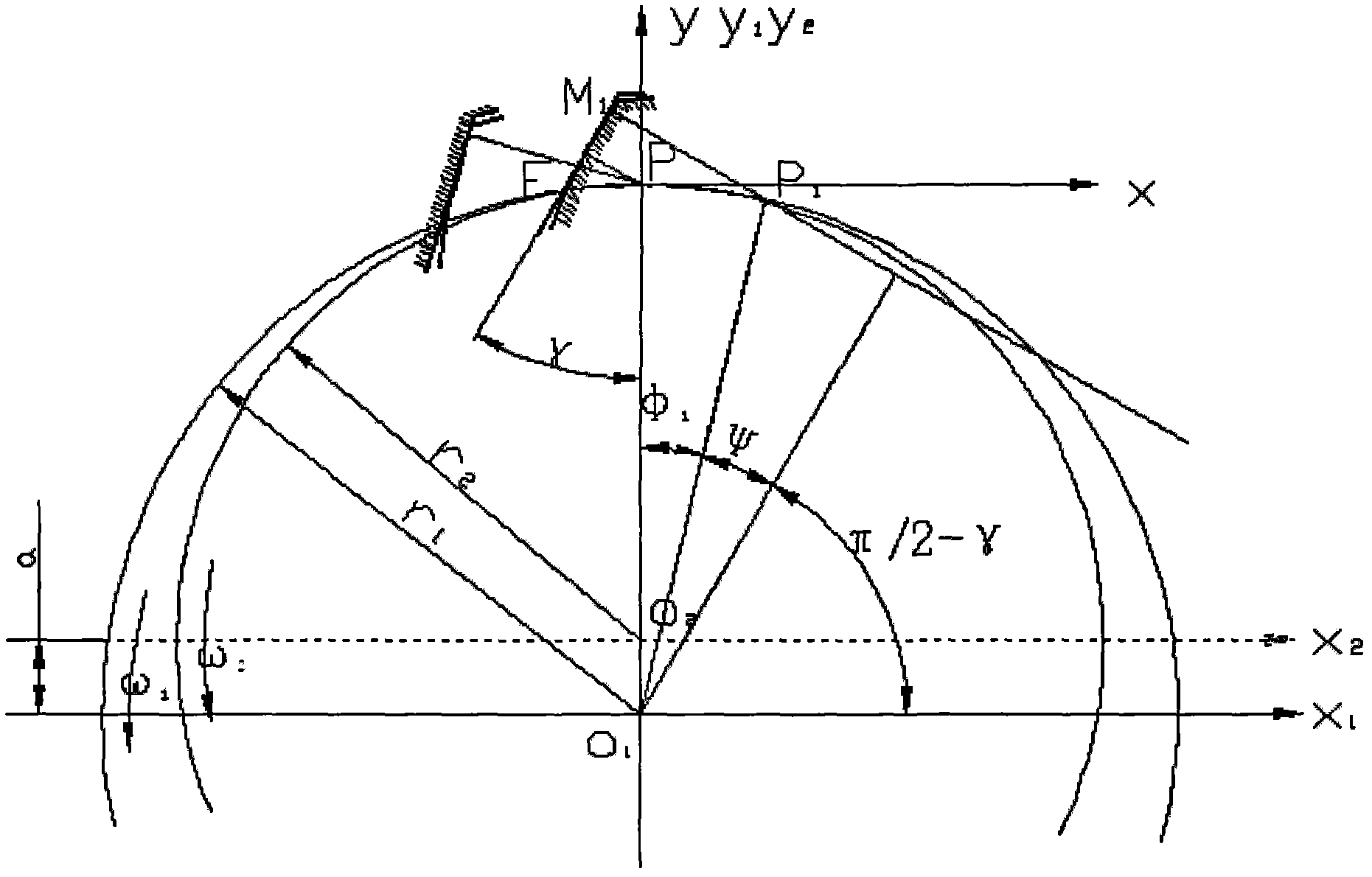

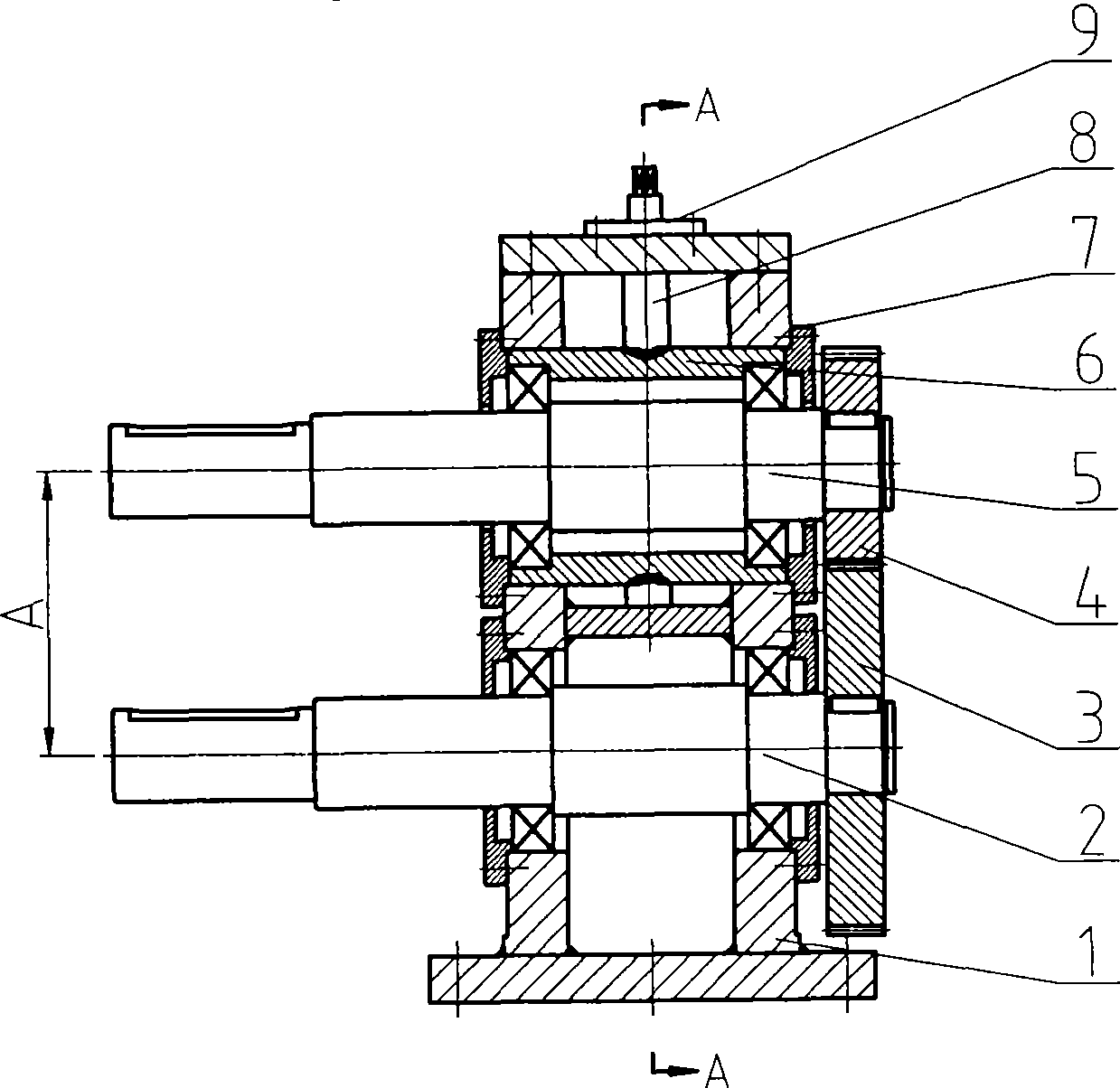

Novel harmonic speed reducer of wave generator

The invention discloses a novel harmonic speed reducer of a wave generator. The inner surface of a circular rigid wheel is provided with rigid internal teeth; a wave generator is arranged in the circular rigid wheel; the wave generator consists of an oval rigid cam and a flexible bearing embedded into the outer ring of the rigid cam; a flexible wheel is sleeved on the outer circle of the bearing of the wave generator; the outer surface of the flexible wheel is provided with outer teeth which are matched with the inner teeth of the circular rigid wheel; the flexible wheel and a circular rigid gear are configured coaxially; the wave generator is driven by a motor, and is taken as a rotary driving source; and the shape curve of the wave generator cam has a specific expression. According to the novel harmonic speed reducer, the specific expression of the shape curve of the wave generator cam is provided, and the flexible wheel and the rigid wheel are better meshed via the wave generator, so that the stress distribution on a meshed tooth surface between the flexible bearing and the gear is improved, and the bottom stress of the flexible gear is reduced.

Owner:上海鑫君传动科技有限公司

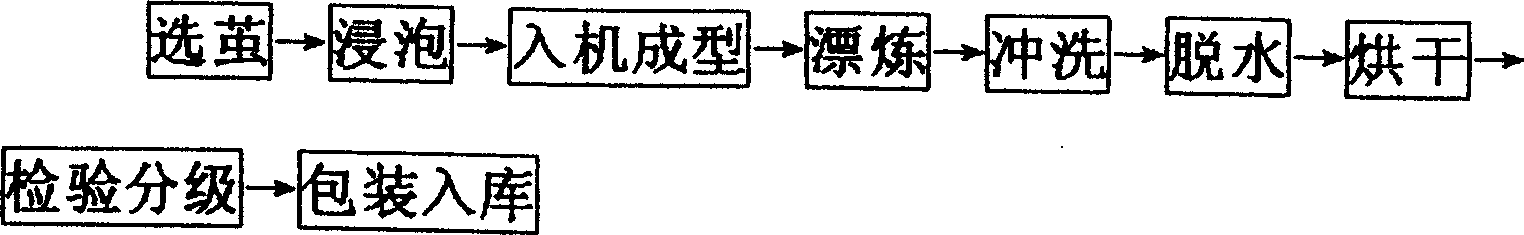

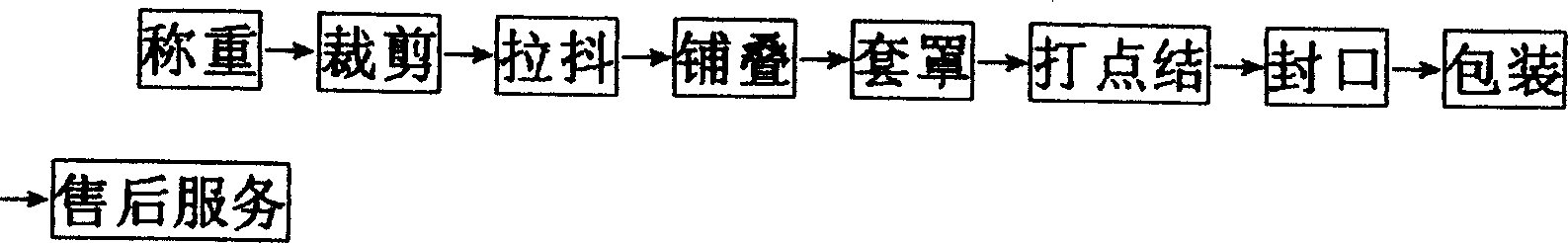

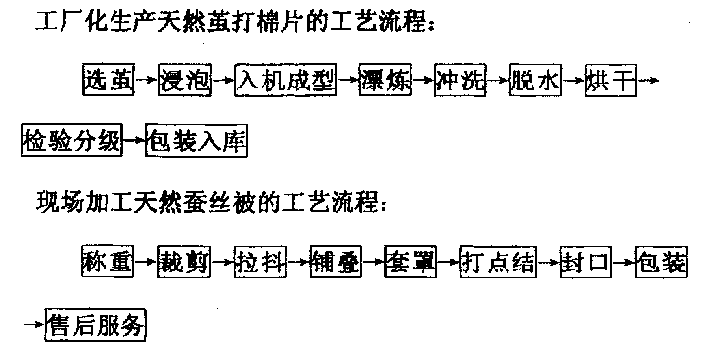

Industrial production of natural cocoon sheet and method of in situ processing natural cocoon silk quilt

A technology for industrially preparing the natural cocoon wool sheet includes choosing cocoon, immersing in warm water, adding caustic soda in the water tank of beating machine, heating the water to80 deg.C, cyclically scalding the cocoon by hot water while pulling silks while removing pupa to become cocoon wool sheet, rinsing in clean water at 90 deg.C for 4-5 hr, flushing, dewatering, baking and packing. A method for in-situ processing the natural silk quilt is also disclosed.

Owner:许景峰

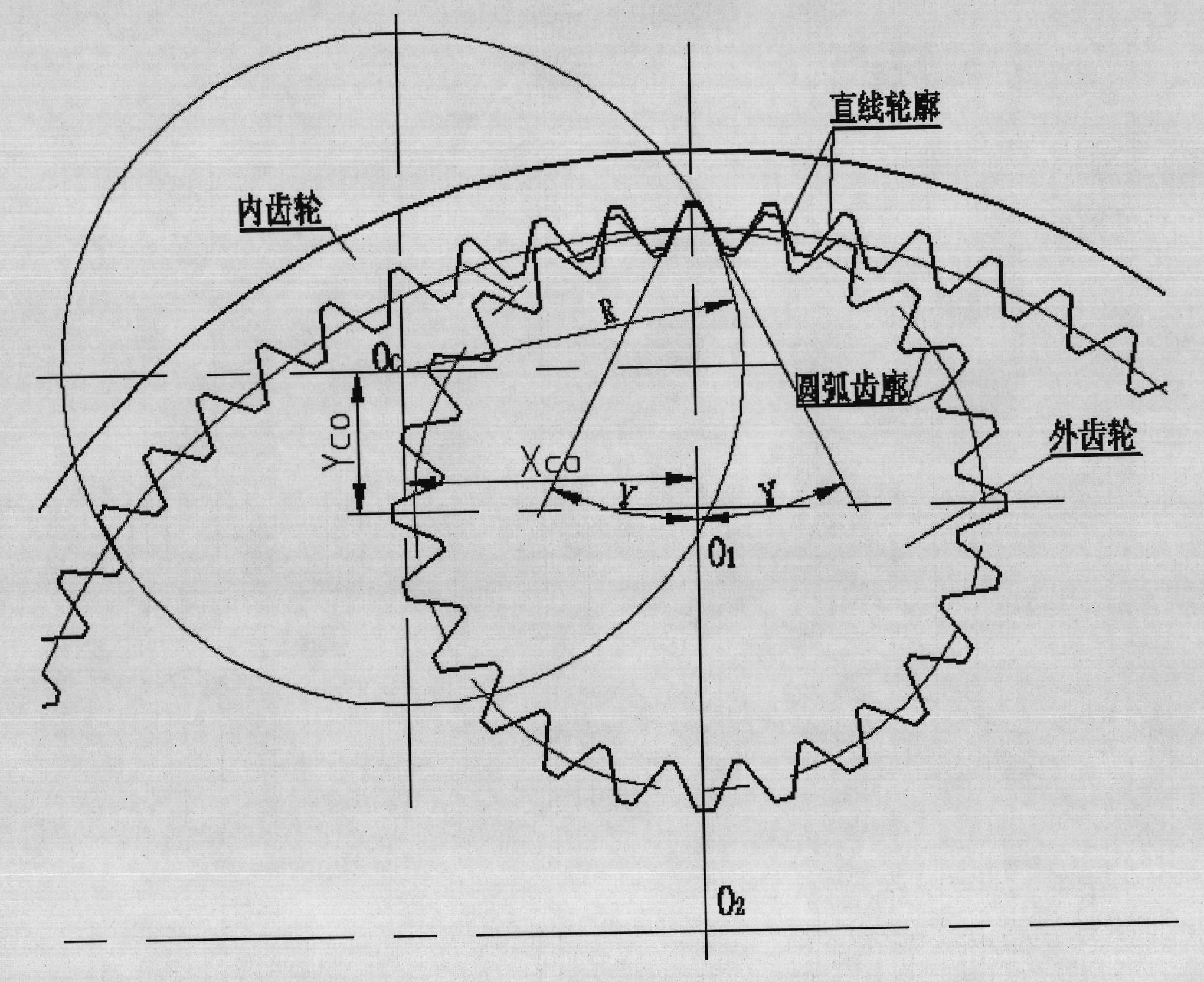

Tooth shape optimization design method for linear-circular arc tooth outline internal engaged cylindrical gear pair

InactiveCN101943245AIncrease in sizeIncrease manufacturing costPortable liftingToothed gearingsShape optimizationEngineering

The invention discloses a tooth shape optimization design method for a linear-circular arc tooth outline internal engaged cylindrical gear pair. The designed gear pair consists of a linear tooth outline internal gear ring and a circular arc tooth outline external gear, wherein the internal gear pair is a cylindrical straight gear. The method comprises the following steps of: determining the modulus and the tooth number of the gear pair according to the working condition of the gear pair, determining tooth tip circles, reference circles and tooth root circles of the internal and external gears of the gear pair, then designing the tooth outline of the internal gear as a simple linear tooth outline, and determining the tooth shape parameters of the circular arc tooth outline of the external gear, namely circular arc radius and circular arc center position of the circular arc tooth outline by using an optimization design method for replacing the circular arc tooth outline for minimum engaged transmission error caused by the conjugate tooth outline of the external gear. The method has the advantages that: the conjugate tooth outline of the external gear can be fully replaced by the circular arc tooth outline, hard tooth faces of the internal and external gears of the internal gear pair can be ground and processed by a mold grinding process and a grinding process of the circular arc gear respectively, and the precision can reach the sixth level.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

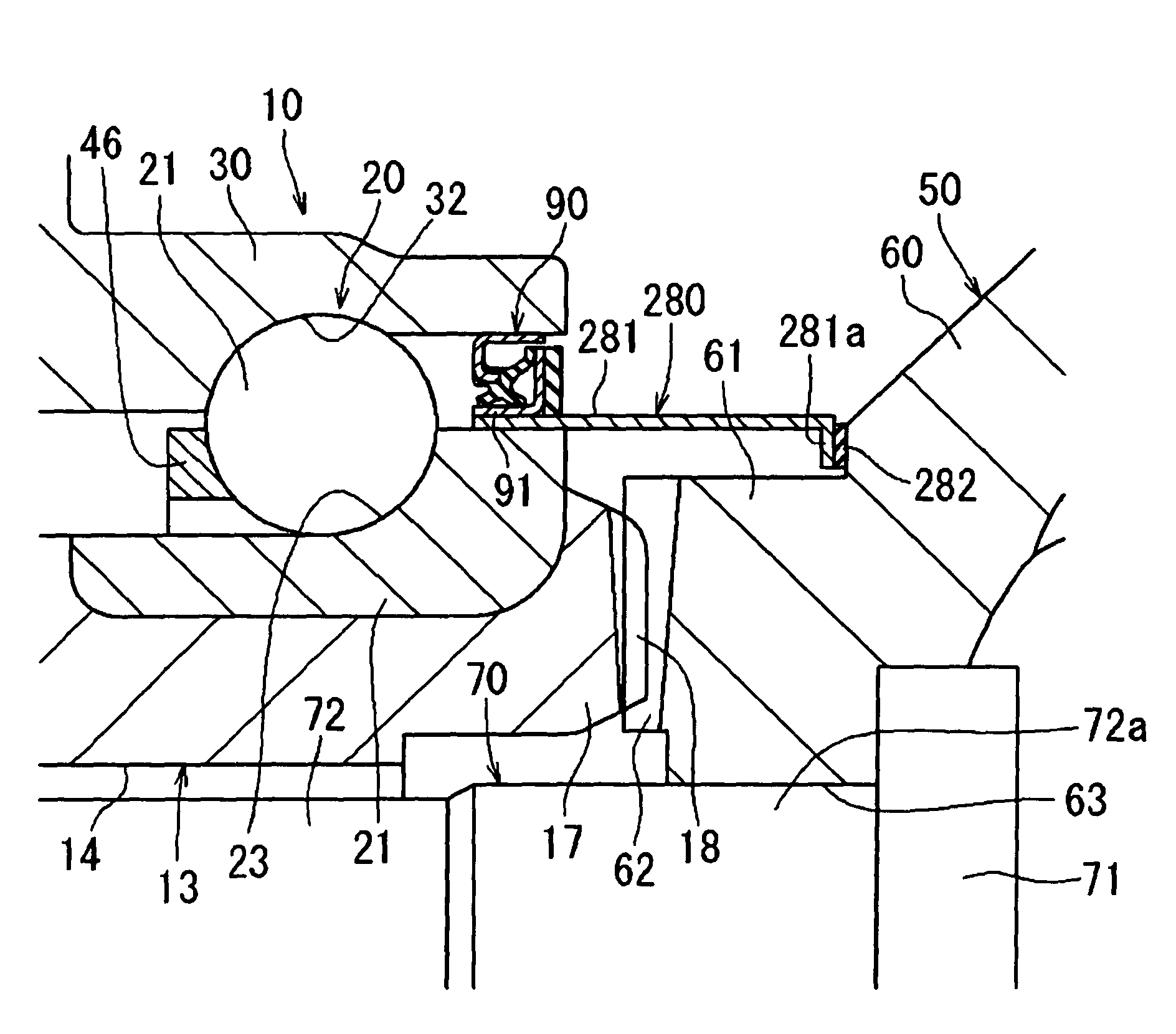

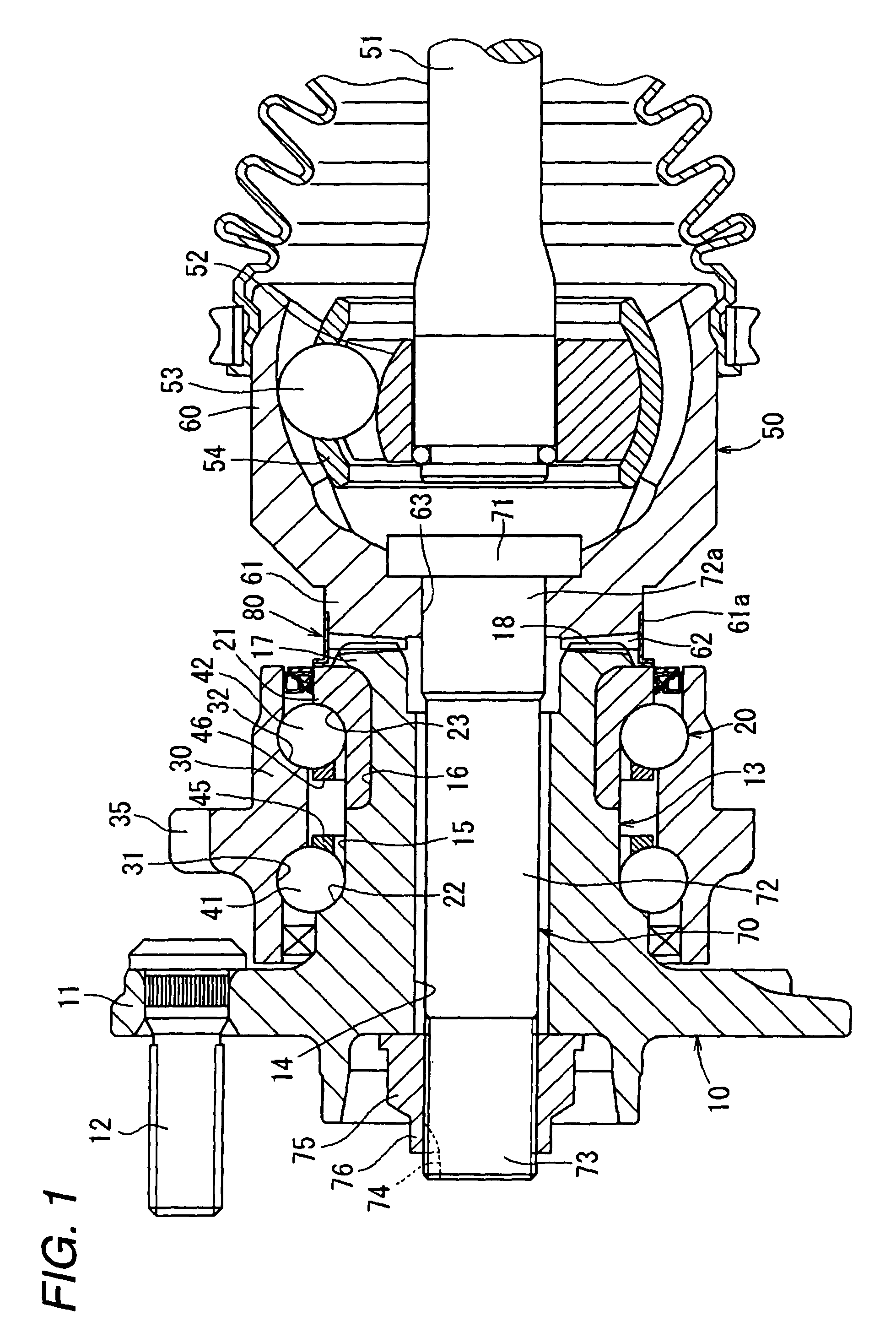

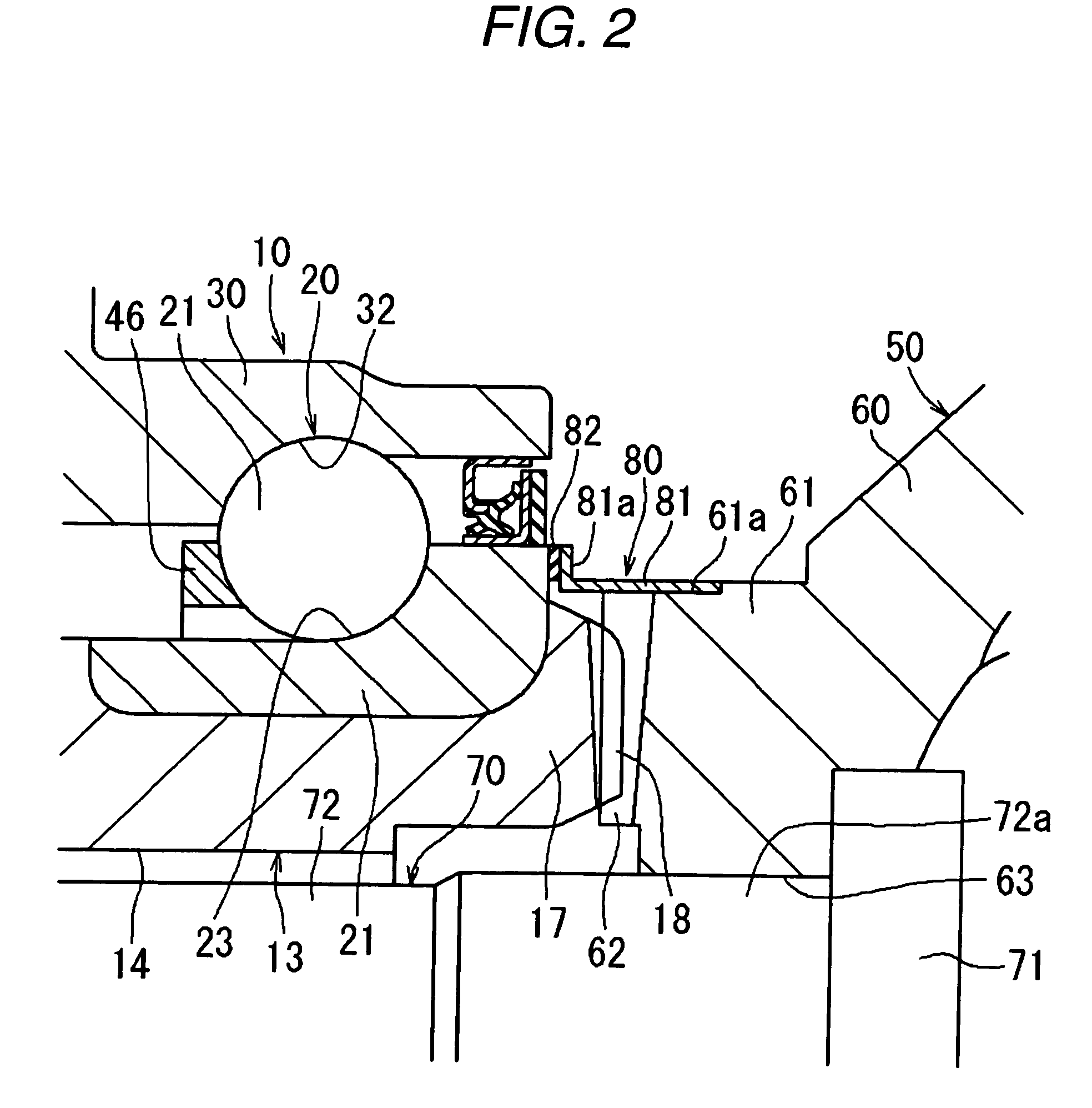

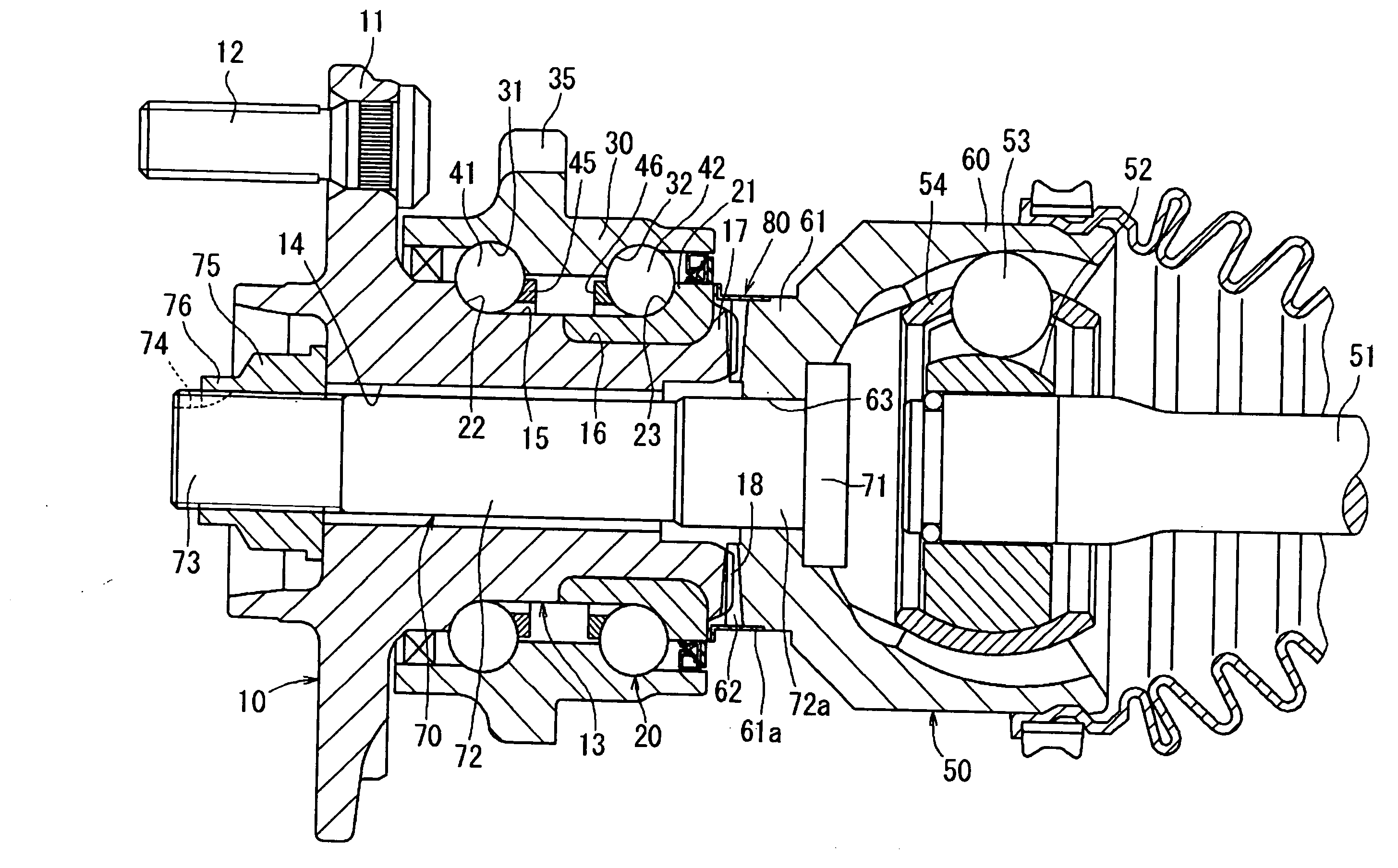

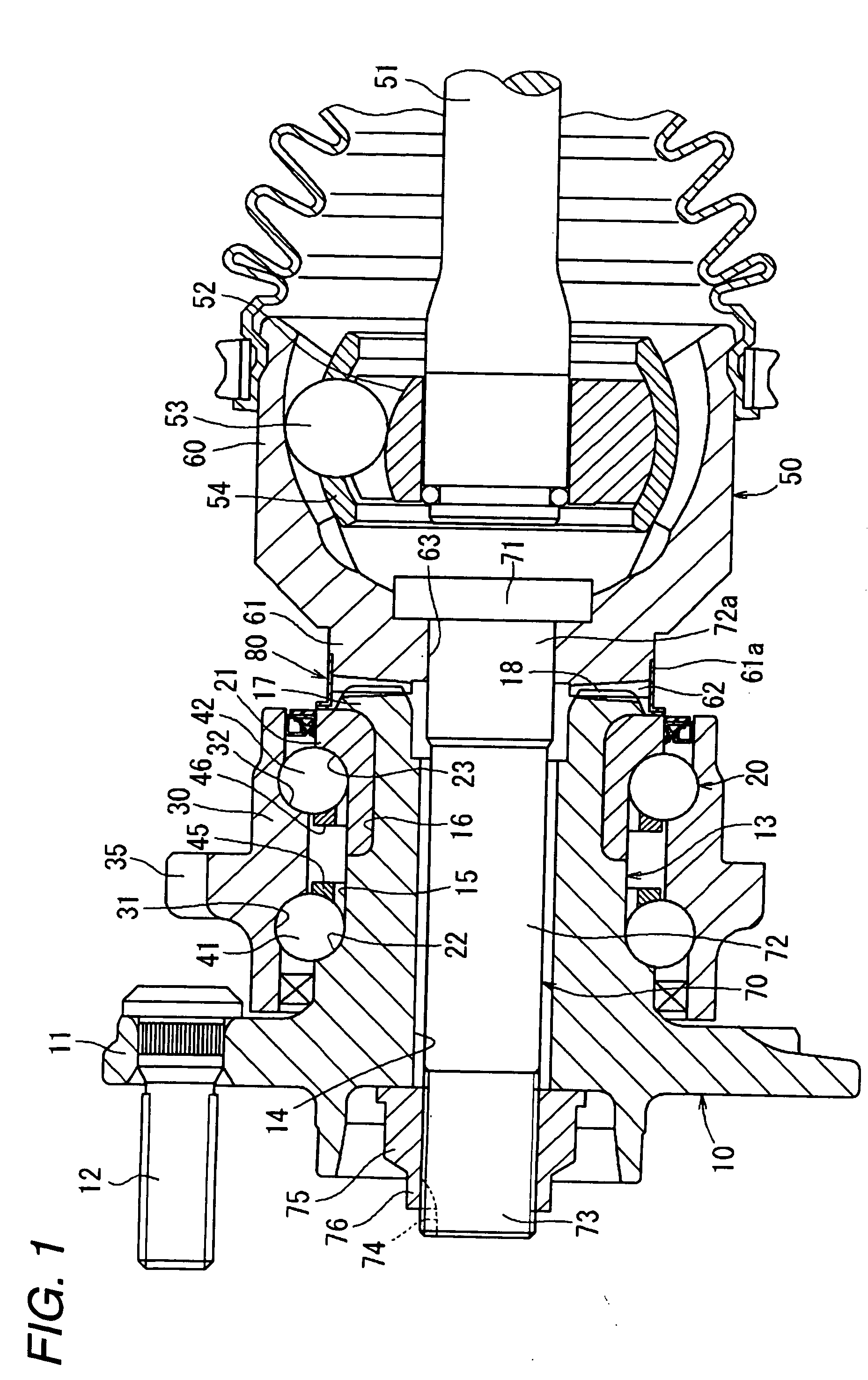

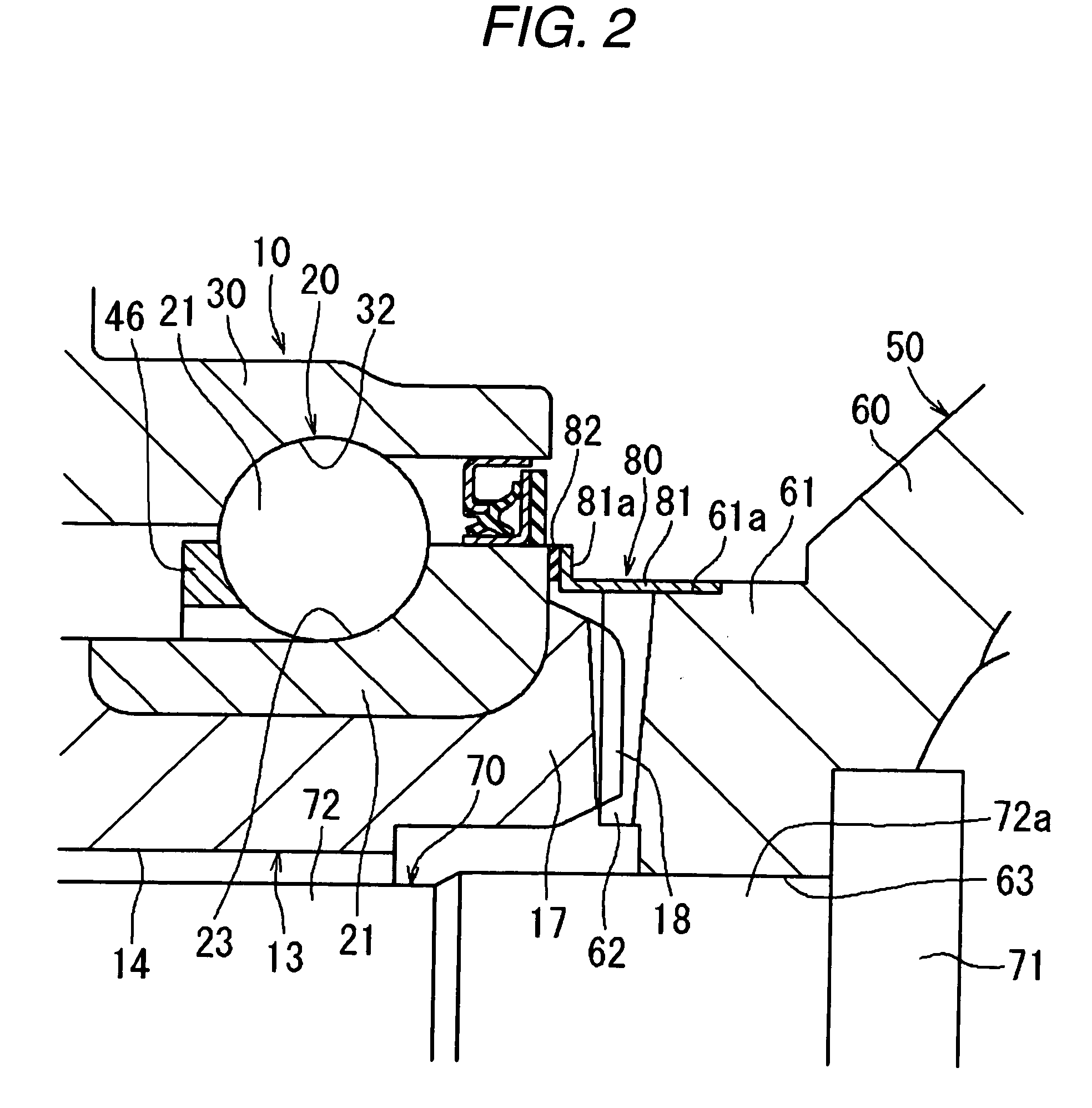

Wheel supporting device

A rolling bearing is provided on an outer peripheral surface of a hub spindle of a hub wheel on which a wheel is mounted. Opposite side face splines, which, by meshing with each other, couple the hub spindle and an outer ring of a constant velocity joint torque-transmittably, are respectively formed on an end face of the hub spindle and on an end face of the outer ring of the constant velocity joint which is abutted against this end face. A tubular seal member for covering outer peripheries of the opposite side face splines is disposed so as to straddle an inner ring of the rolling bearing and the outer ring of the constant velocity joint, while maintaining a sealing state.

Owner:JTEKT CORP

Wheel supporting device

InactiveUS20090097792A1Shorten the axial lengthReduce weightYielding couplingRolling contact bearingsConstant-velocity jointWheel and axle

A rolling bearing is provided on an outer peripheral surface of a hub spindle of a hub wheel on which a wheel is mounted. Opposite side face splines, which, by meshing with each other, couple the hub spindle and an outer ring of a constant velocity joint torque-transmittably, are respectively formed on an end face of the hub spindle and on an end face of the outer ring of the constant velocity joint which is abutted against this end face. A tubular seal member for covering outer peripheries of the opposite side face splines is disposed so as to straddle an inner ring of the rolling bearing and the outer ring of the constant velocity joint, while maintaining a sealing state.

Owner:JTEKT CORP

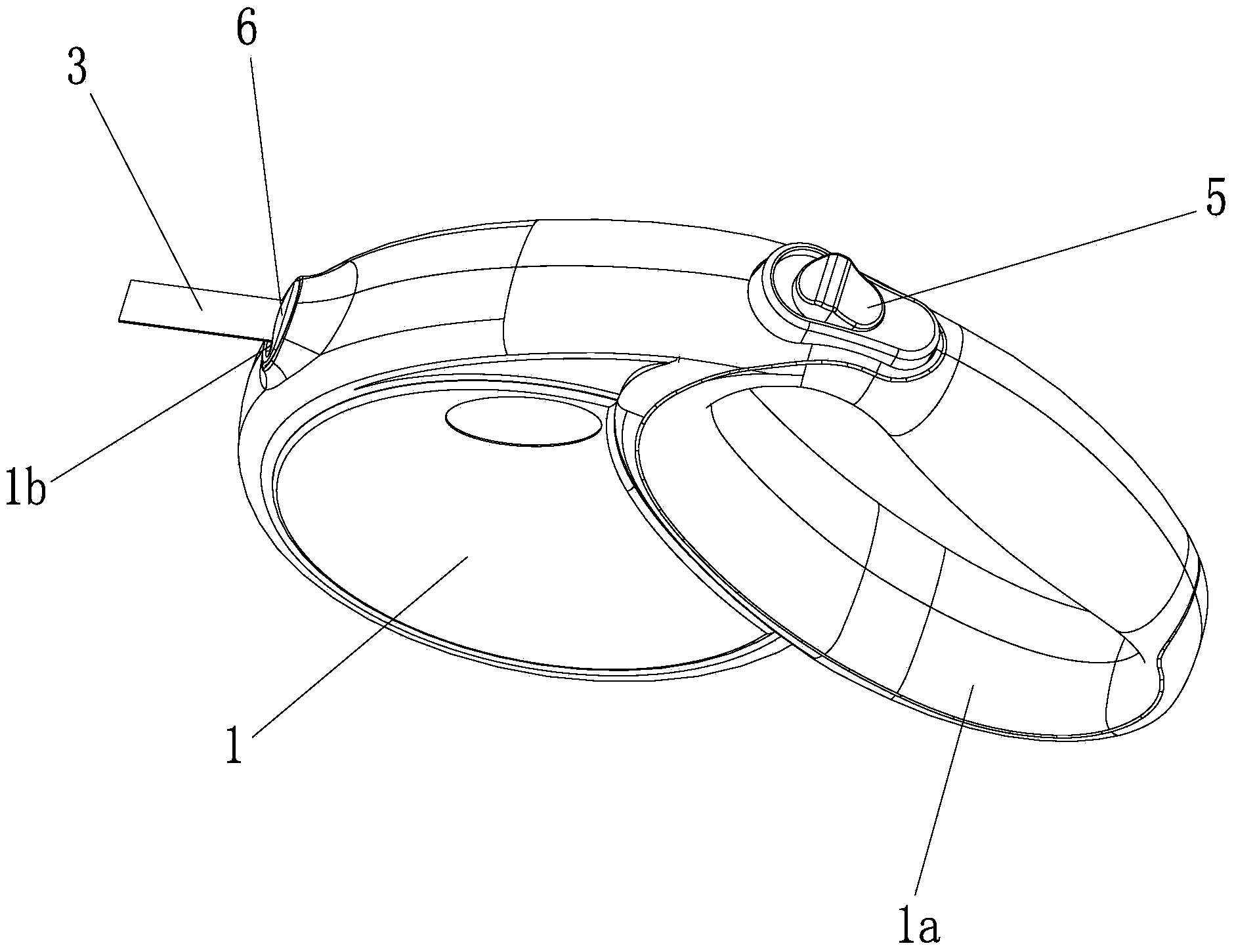

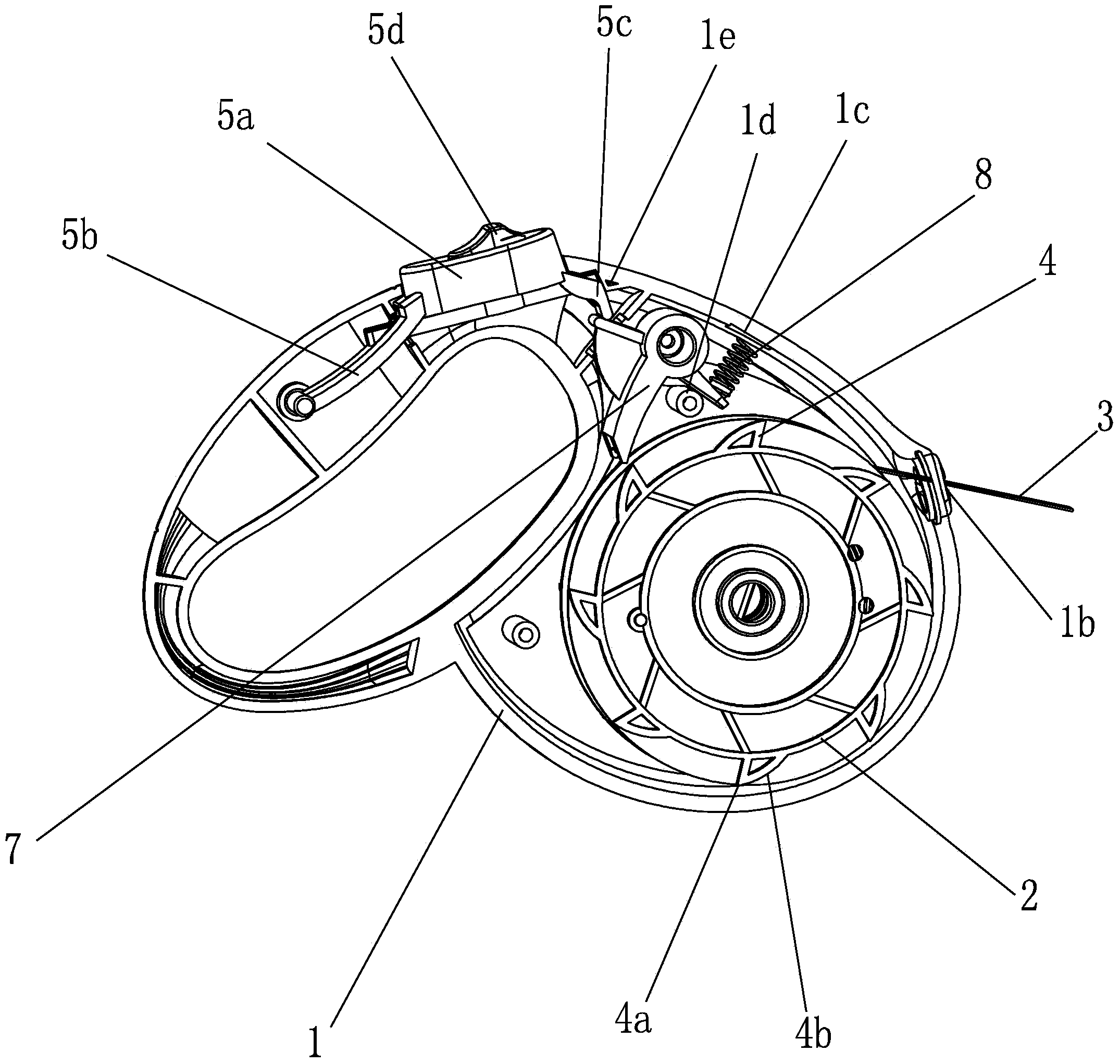

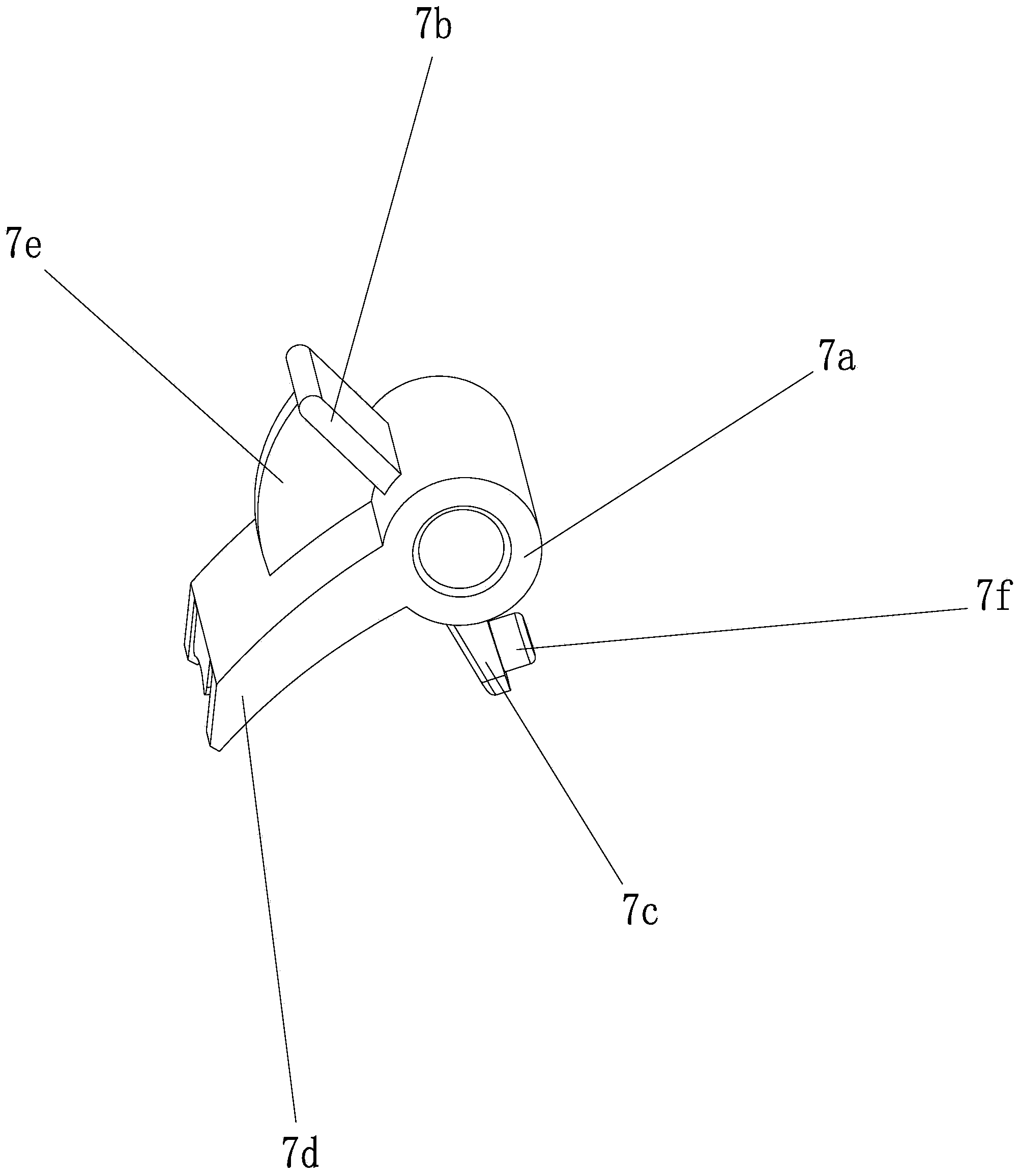

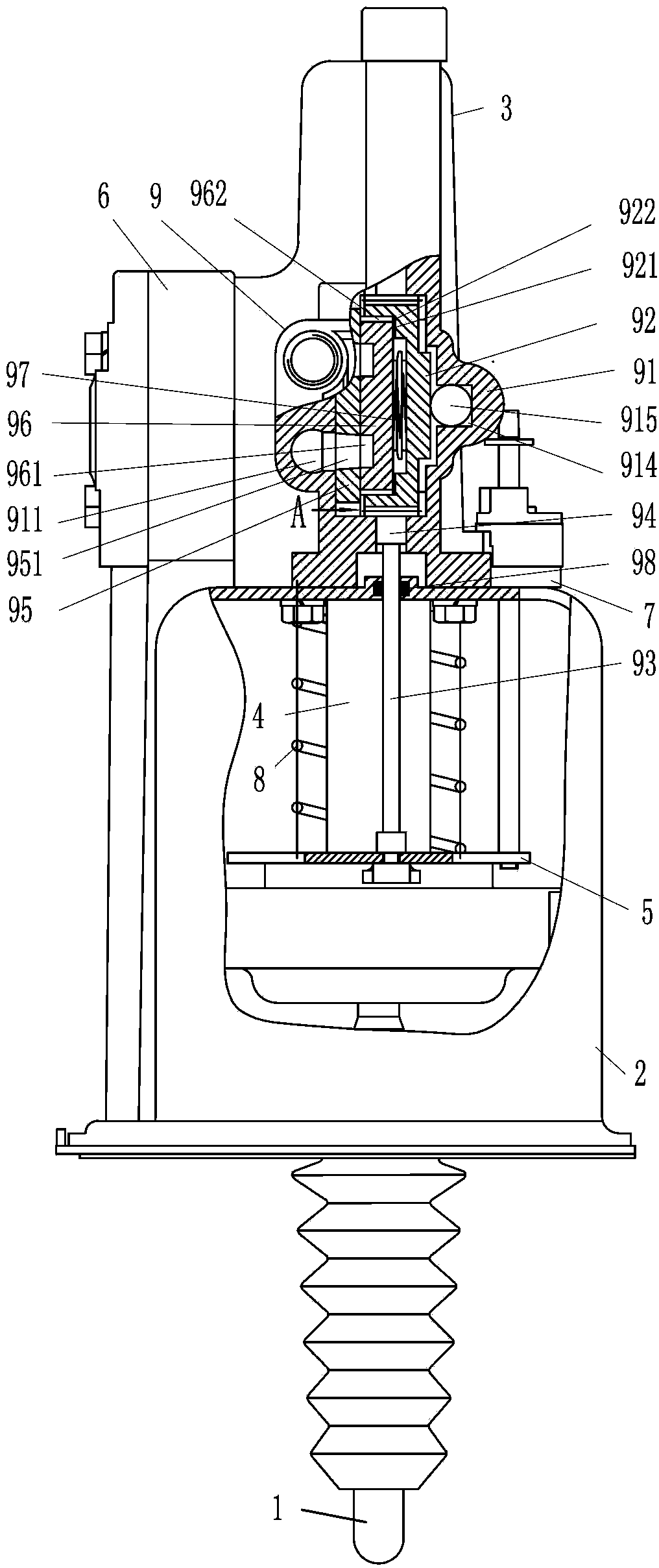

Pet tractor

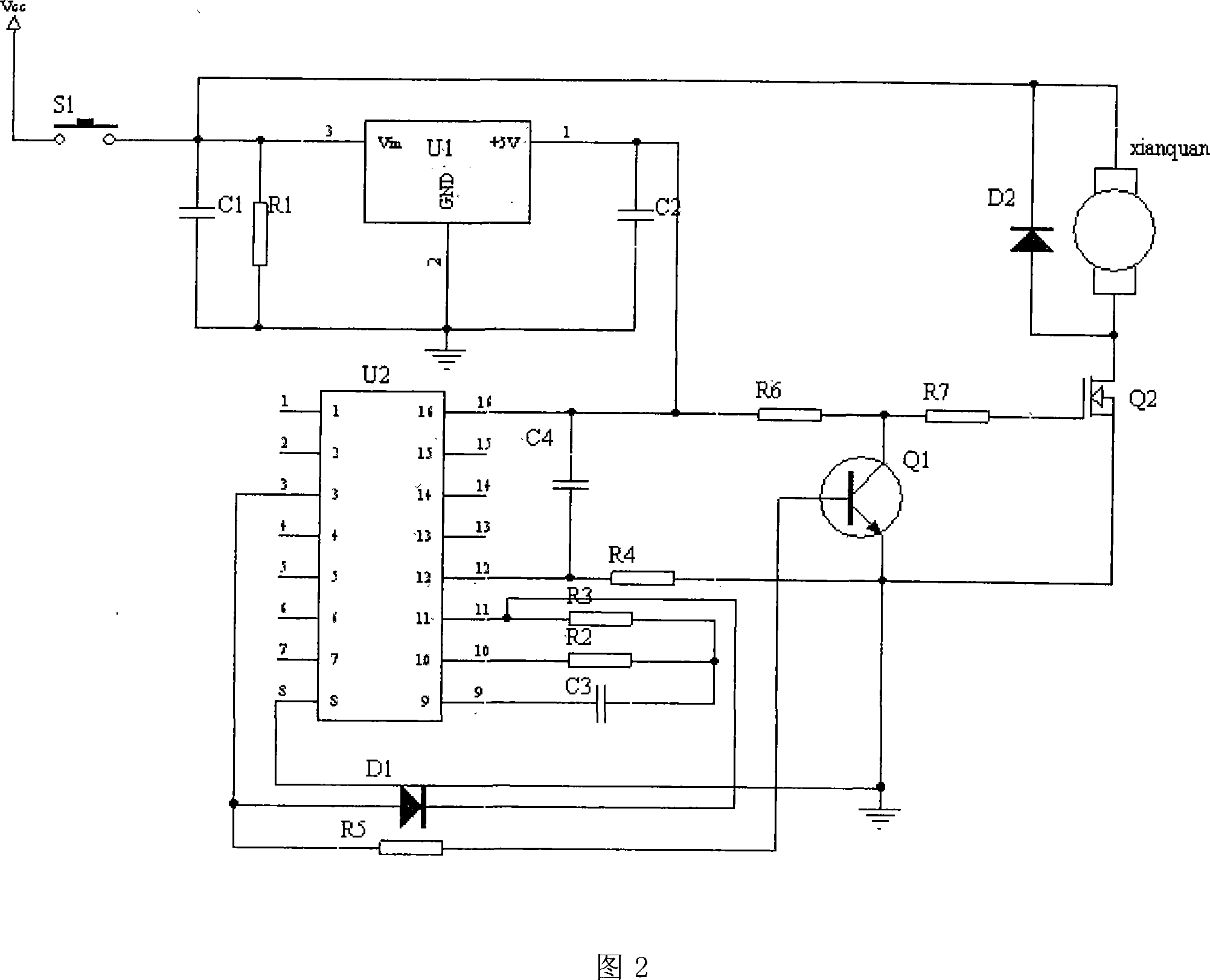

ActiveCN104351077ALimited movementImprove structural strengthTaming and training devicesUser needsNatural state

The invention discloses a pet tractor which comprises a housing on which a handle is formed, a rotary plate rotationally arranged in the housing, and a traction rope wound on the rotary plate, wherein a rope outlet for the leading-out of the traction rope is formed in the housing, a button exposed out of the housing is arranged at the handle, a clamping block linked and matched with the button is mounted in the housing, a return spring is arranged between the clamping block and the housing, and a plurality of clamping teeth matched with the clamping block are formed on the rotary plate; in a natural state, the clamping block is separated from the clamping teeth under the action of elastic force of the return spring, and the rotary plate can freely rotate; after the button is pressed, the clamping block generates a linked action and is clamped with the clamping teeth, and the rotary plate is circumferentially locked. According to the pet tractor, a user can quickly pull and hold a pet running away by only slightly pressing the button on the tractor, so that the pet is limited within a certain controllable adjustable rang and the accident is avoided; meanwhile, when the user needs to lock the state, the state can be locked by only moving a push button built in the button, and on the contrary, the state can be unlocked.

Owner:SUZHOU PETMATE IND & TRADE

Face-gear bending fatigue test mechanism and method

ActiveCN102967509AMeet the meshing principleTest stress distributionMaterial strength using steady bending forcesGear toothBending fatigue test

The invention relates to face-gear bending fatigue test mechanism and method, and belongs to the field of measurement of gear bearing capacity. The face-gear bending fatigue test mechanism disclosed by the invention meets the meshing relation of face-gears by using an involute profile loading press head and an involute profile supporting press head and can be used for loading any loading points positioned on the face-gears, thereby solving the problem that the traditional loading head can not meet the meshing relation and complicatedly transmits loading force; and besides, the face-gear bending fatigue test mechanism disclosed by the invention has adjustability and is suitable for a face-gear tooth bending fatigue test with different parameters by adjusting the positions of a supporting assembly and a loading assembly which are positioned in the face-gear bending fatigue test mechanism, thereby achieving obvious substantiality characteristics and outstanding advancement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mid-size vehicle speed changer with main tank and auxiliary tank

ActiveCN101799062AMeet development needsWith multi-speedToothed gearingsGearing controlCarrying capacityEngineering

The invention mainly discloses a mid-size vehicle speed changer with a main tank and an auxiliary tank. In the auxiliary tank, an epicyclic transmission structure is adopted and has a high gear and a lower gear; a locking ring type high-capacity synchronizer is adopted to shift gears and switch between a high-gear area and a low-gear area, and gear shifts are controlled by using a pneumatic gear shift mechanism; and the auxiliary tank is combined with the main tank and can form a plurality gears. The invention has the advantages of large carrying capacity, more gears, total synchronizer gear shift, speed ratio matching distribution according to a bias geometric progression, linkage operation of the main tank and the auxiliary tank, light and convenient gear shift, environmental protection, energy saving, and the like, has stronger adaptability to various working conditions and road conditions and can better meet the development requirements of domestic vehicles at present.

Owner:浙江绍齿传动股份有限公司

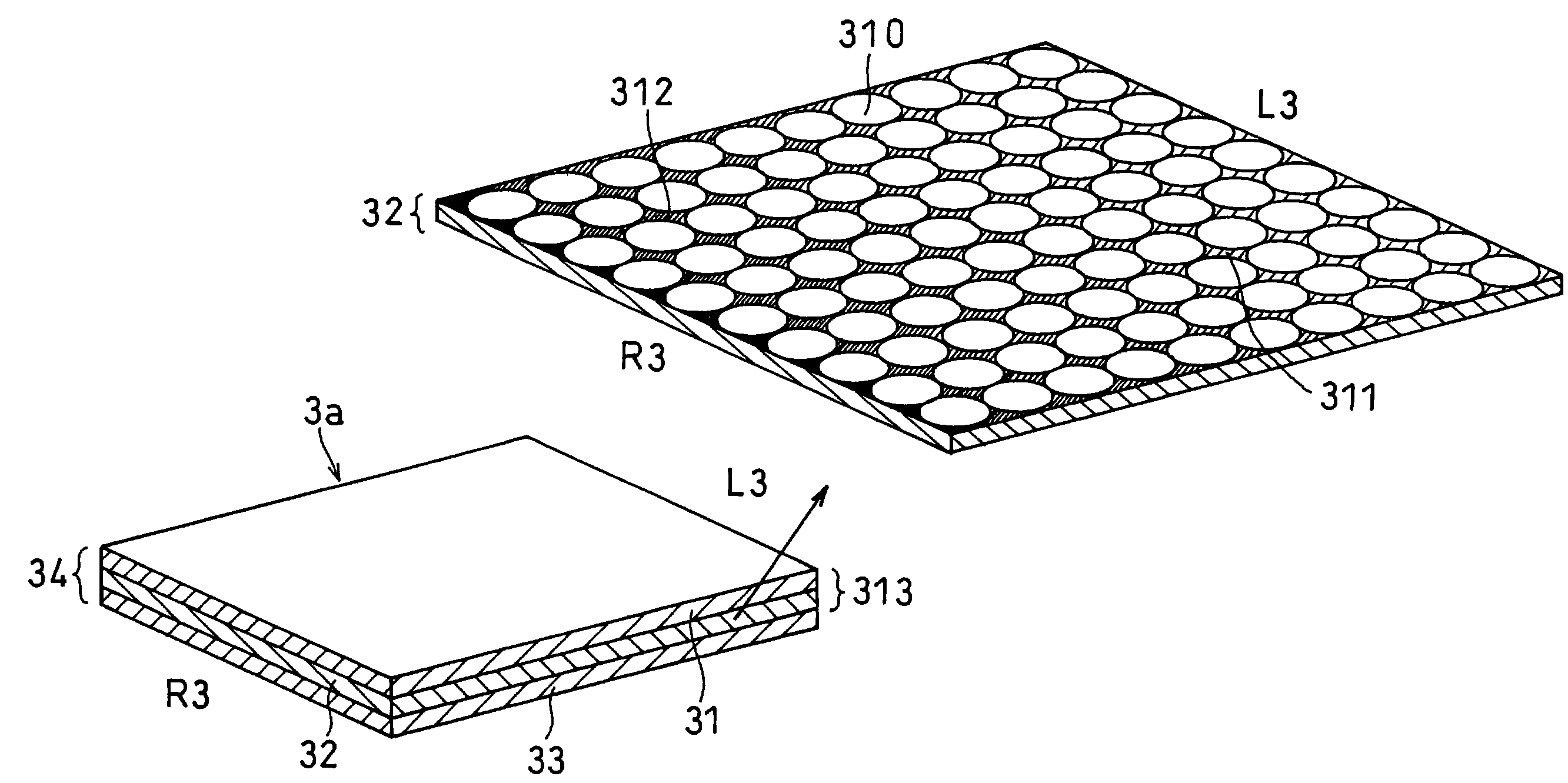

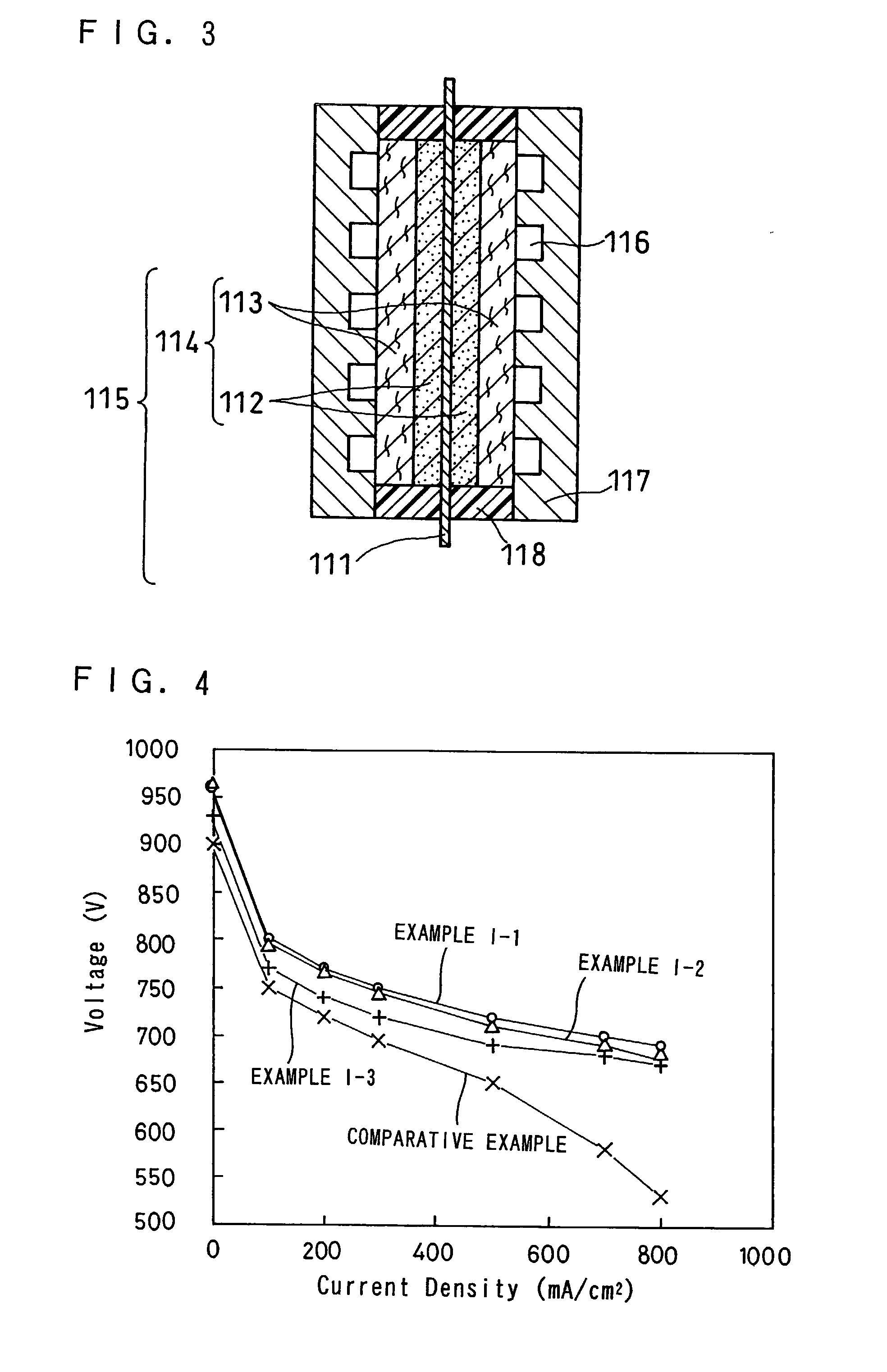

Polymer electrolyte fuel cell

InactiveUS7060384B2Improve performanceImprove basic performanceFuel cell auxillariesActive material electrodesChemistryLarge pore

A porous supporting carbon body of a gas diffusion layer is provided with a larger number of smaller pores at its catalyst layer side and a smaller number of larger pores at the other side, particularly with an appropriate distribution of finer mesh at its catalyst layer side and coarser mesh at the other side. As a result, a high performance polymer electrolyte fuel cell is obtained in which water generated at the catalyst layer is quickly sucked out to the gas diffusion layer, and is evaporated at the gas diffusion layer to be effectively exhausted to outside the fuel cell, so that excessive water can be prevented from retaining in the gas diffusion electrode, with the polymer electrolyte membrane being maintained at an appropriately wet condition.

Owner:PANASONIC CORP

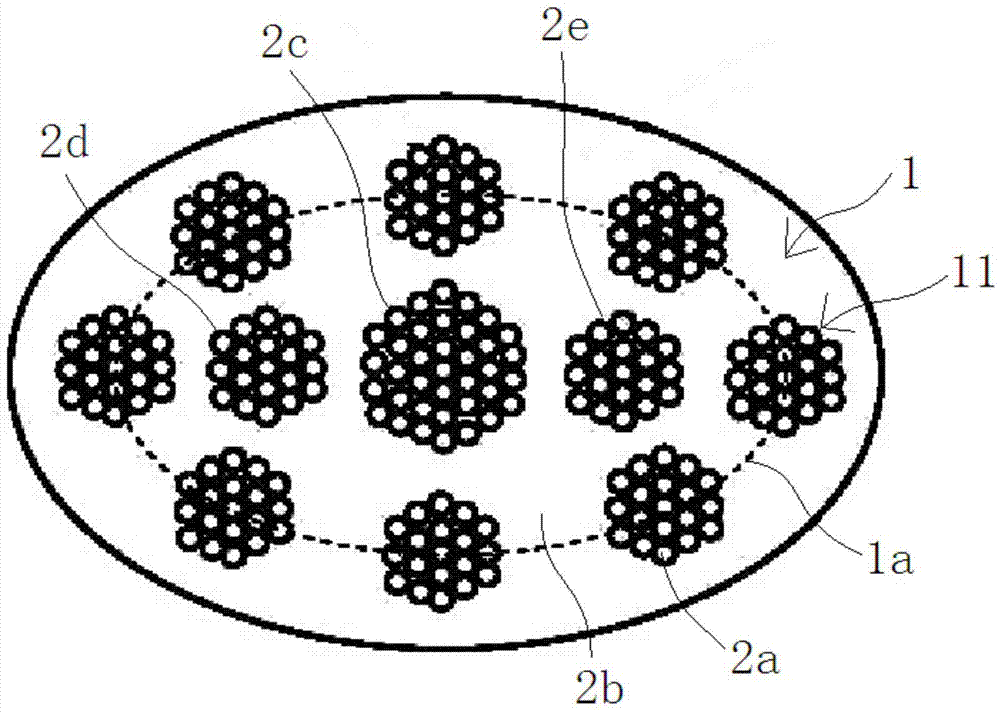

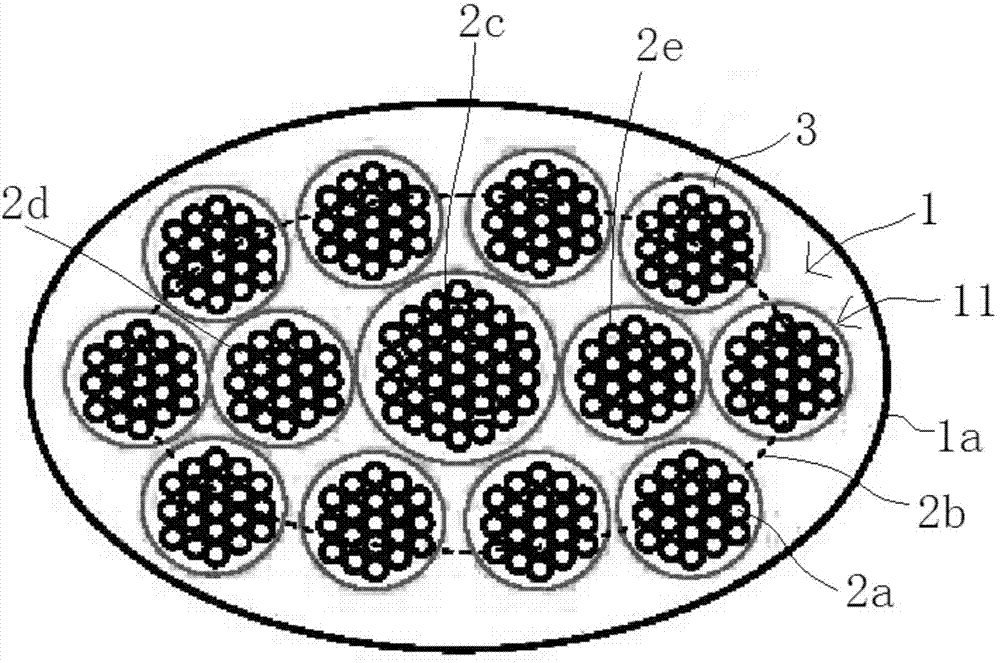

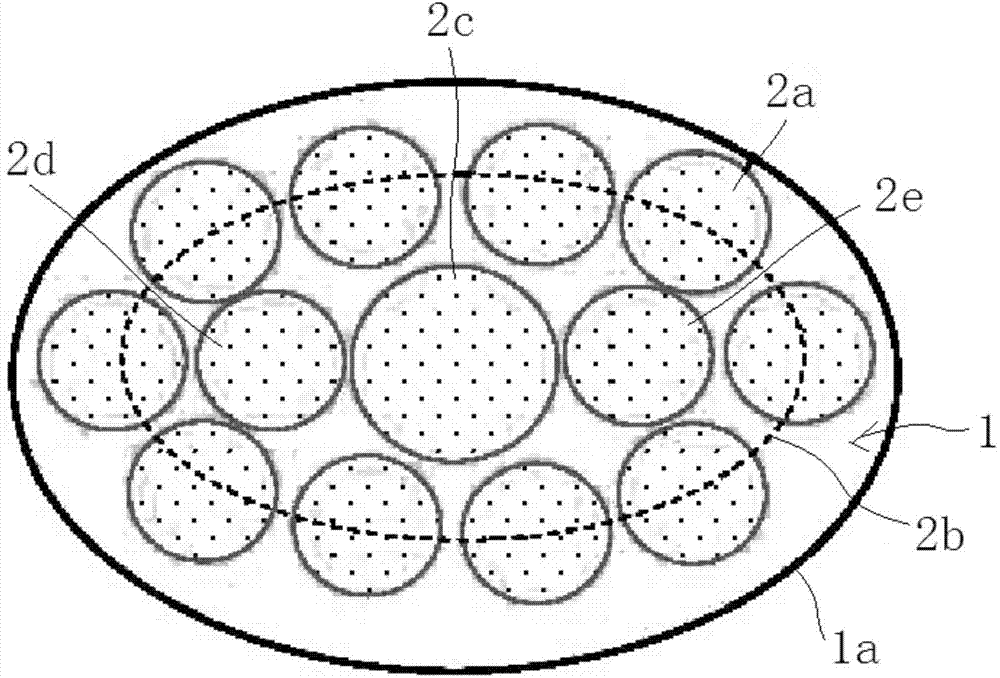

Retractable rope used for elevator

ActiveCN103663057AImprove carrying capacityHigh resistance to torsional deformationElevatorsTextile cablesDiameter ratioEngineering

The invention discloses a retractable rope used for an elevator. The retractable rope is characterized by being composed of at least one bearing body capable of bearing independently and a wrapping layer, wherein the cross section of the retractable rope is oval, and the short axis of the oval is vertical to the retracting direction of the retractable rope. Compared with a plastic coated wire rope with a circular section, the retractable rope mainly has two advantages that (1) on the condition that the bearing force is the same, the contact area of the retractable rope and a running wheel is increased, the retractable rope is evenly stressed, and service life of a coated layer is prolonged; (2) a plurality of independent bearing bodies in the retractable rope are distributed in parallel, the diameter of each bearing body is 2 mm, according to the requirement in GB7588 that the rope diameter ratio can not be smaller than 40, and the diameter of the running wheel can be reduced to 100m. When the retractable rope is used, a traction pulley needs to have a groove type which is complementary with the appearance of the retractable rope so that the traction pulley can be well meshed with the rope when the elevator operates, the guide performance of the rope is improved and eccentric wear is restrained.

Owner:YUNGTAY ELEVATOR EQUIP CHINA

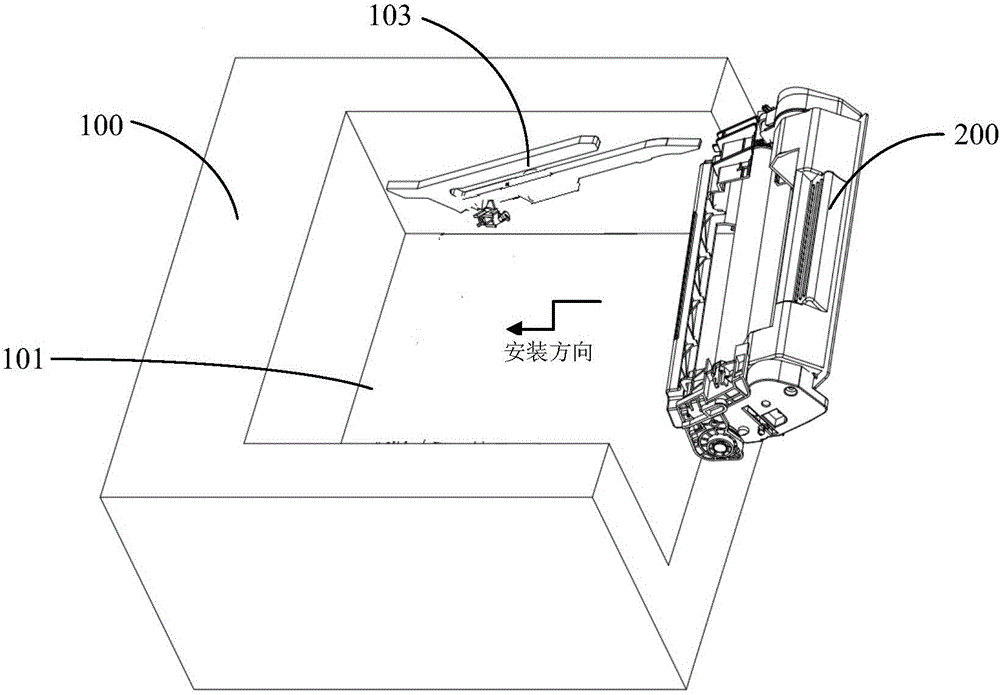

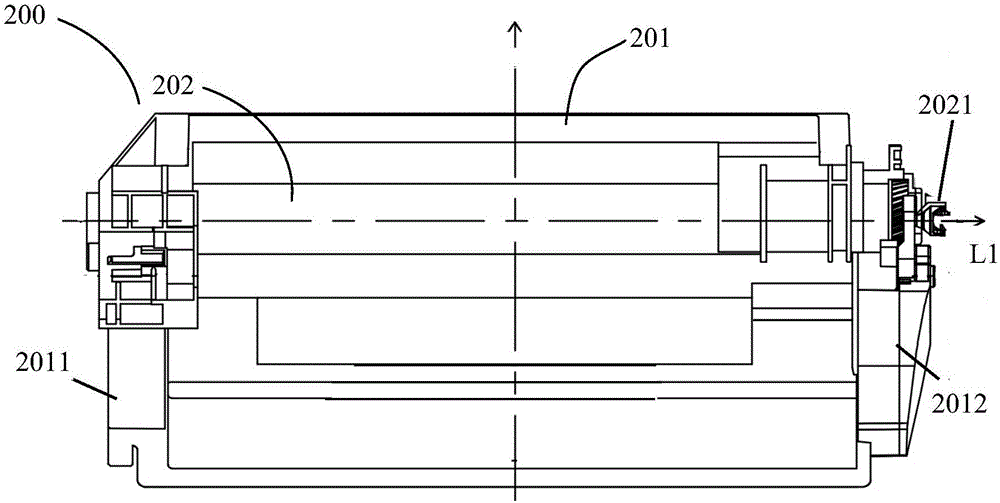

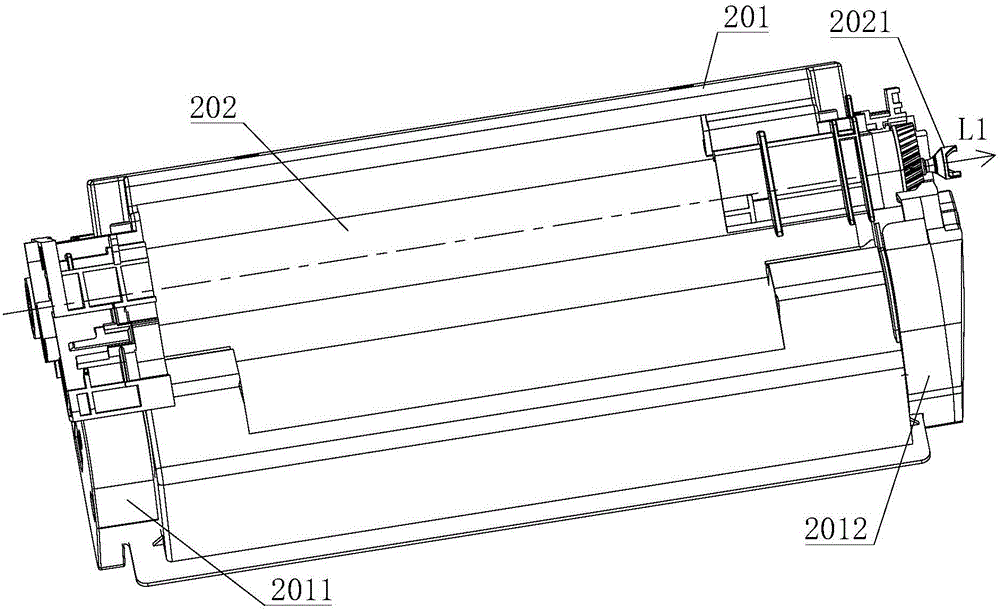

Processing box

The invention relates to a processing box, which is detachably arranged in an image forming device host. The processing box comprises a casing and a photosensitive drum, wherein the photosensitive drum is arranged in the casing; one end of the photosensitive drum is provided with a driving shaft coupler used for receiving the driving force of a driving head of the image forming device host; the casing comprises a first end plate and a second end plate which are positioned at the two opposite ends of the casing; an installing guide part protruded out of the end plate is arranged on the first end plate and / or the second end plate; through the installing guide part, the rotating axial line of the photosensitive drum can form an included angle with the rotating axial line of the driving head in the mounting and dismounting process of the processing box. The installing guide part protruded out of the end plate is arranged on the first end plate and / or the second end plate which are arranged at the two opposite ends of the casing of the processing box; the installing guide part can enable the rotating axial line of the photosensitive drum to form the included angle with the rotating axial line of the driving head in the mounting or dismounting process of the processing box; the installation of the processing box is convenient; the engagement of the driving shaft coupler and the driving head of the image forming device host is convenient.

Owner:NINESTAR CORP +1

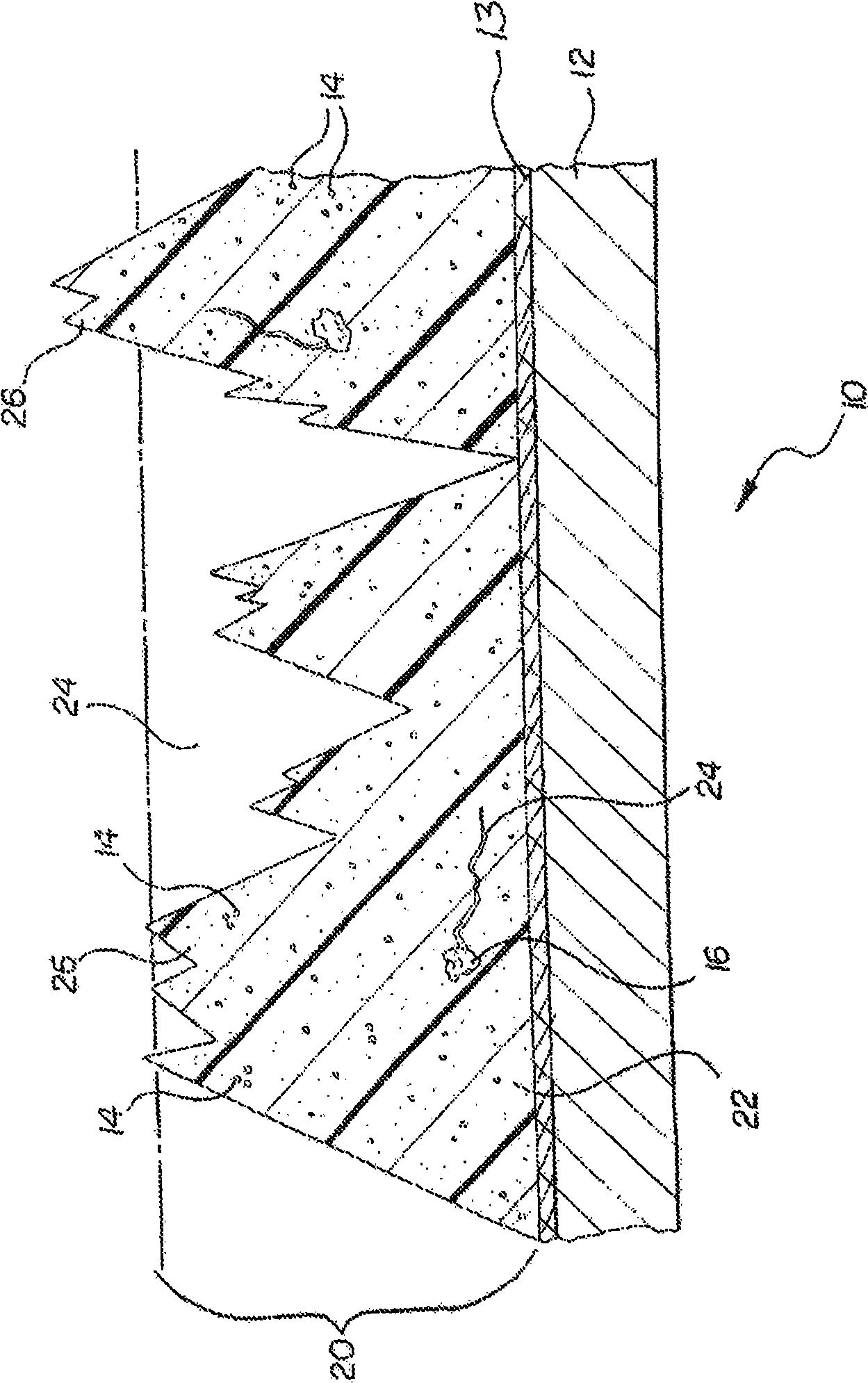

Abradable dry film lubricant and the method for applying same and article made therefrom

InactiveCN101535420AEasy meshReduce contact stressShaftsBearing componentsSubstrate surfaceLubricant

An article with an abradable dry powder coating thereon comprises an abradably coated article with a substrate surface and having at least one coating of a liquid primer on the substrate surface and then coating with at least one abradable dry powder coating on the surface of the liquid primer. The sequence of layers may also be reversed, or additional layers may be useful. The abradable dry powder coating is formed of a dry powder coating composition including a thermoset resin having a cure temperature combined with at least one filler material, wherein the filler is formed of a material which does not melt substantially at or below the cure temperature of the resin, whereby an abradable coating results employing a filler to make the coating. A method of making a composition for coating an article with a coating curable into an abradable coating is also disclosed, comprising melt- mixing an evaporative carrier-free mixture of a dry powder thermoset resin having a cure temperature, to form a mass composite, wherein the filler is formed of a material which does not substantially melt at or below the cure temperature of the resin, cooling the mass composite, and breaking the cooled mass composite into powder particles, thereby forming the composite powder composition.

Owner:安德鲁·W·苏曼

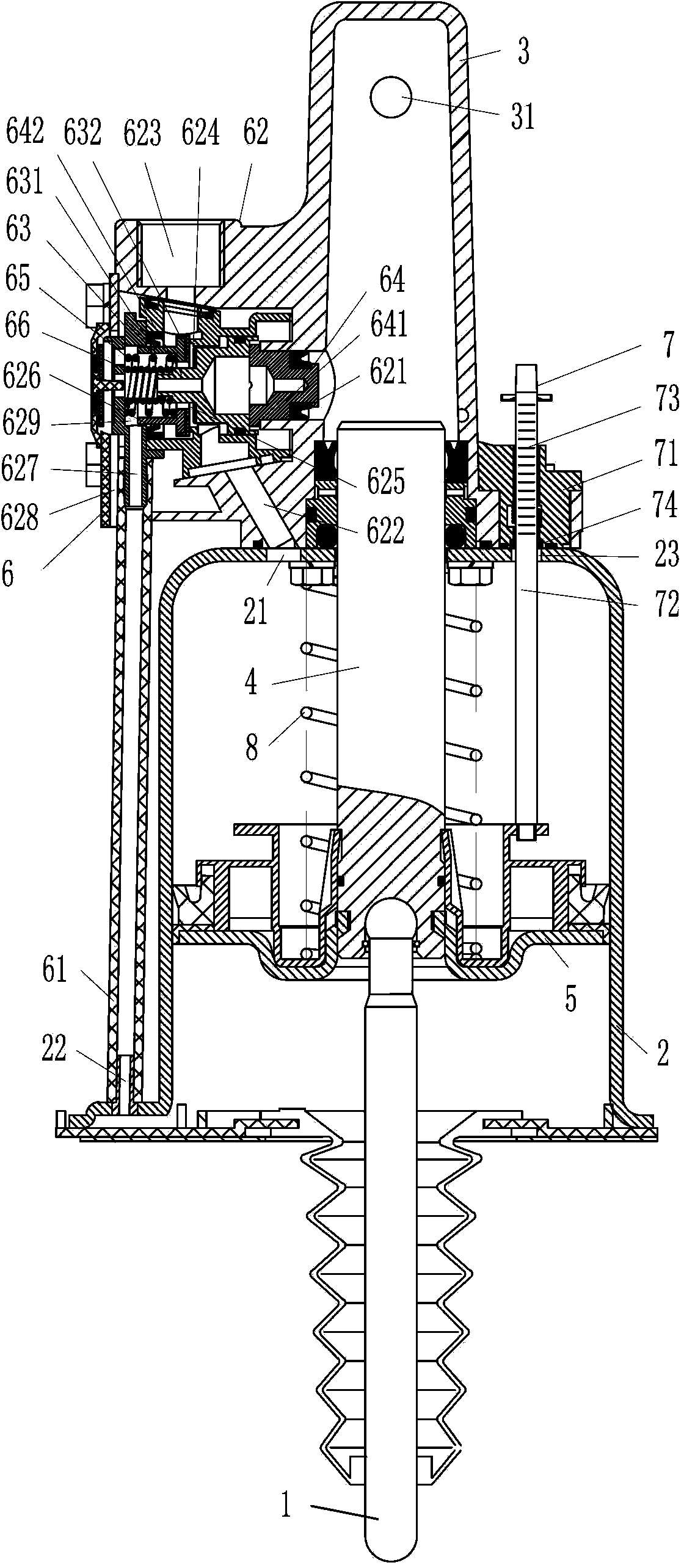

Clutch booster

InactiveCN103375512ATimely replacementReduce frictional resistanceClutchesHydraulic cylinderControl valves

The invention relates to the field of automobile clutches, in particular to a clutch booster which comprises a pneumatic cylinder, a hydraulic cylinder, a piston of a piston rod, an intake and exhaust control valve and a friction plate wear measuring device. An air inlet and an air outlet are arranged at the rear end and the front end of the pneumatic cylinder respectively, the hydraulic cylinder is provided with a liquid inlet and connected with the rear end of the pneumatic cylinder, the piston is positioned in the pneumatic cylinder, two ends of the piston are connected with push rods respectively, the rear end of the piston extends into the hydraulic cylinder, the intake and exhaust control valve is arranged on the side wall of the hydraulic cylinder, and a reset spring is positioned between one end of the piston and the pneumatic cylinder. The clutch booster can timely and quantitatively reflect wear conditions of a friction plate, so that the friction plate about to lose effectiveness can be timely replaced.

Owner:宁波神丰汽车部件有限公司

Diamond resin binder abrasive disc and preparation method and application thereof

ActiveCN110842800AImprove stabilityThe polishing process is environmentally friendlyAbrasion apparatusGrinding devicesA diamondAbrasive

The invention provides a diamond resin binder abrasive disc and a preparation method and an application thereof and belongs to the technical field of polishing grinding apparatuses. The diamond resinbinder abrasive disc is prepared from the following raw materials in parts by mass: 20-40 parts of thermosetting resin, 4-30 parts of a curing agent, 15-30 parts of a diamond, 10-20 parts of an auxiliary grinding material, 10-30 parts of micro filler, 1-10 parts of nano filler and 1-5 parts of a coupling agent. The diamond resin binder abrasive disc is used for polishing a marble and has the advantages of being good in polishing effect, high in efficiency, environmental-friendly and safe and the like.

Owner:惠安宇信金刚石工具有限公司 +1

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

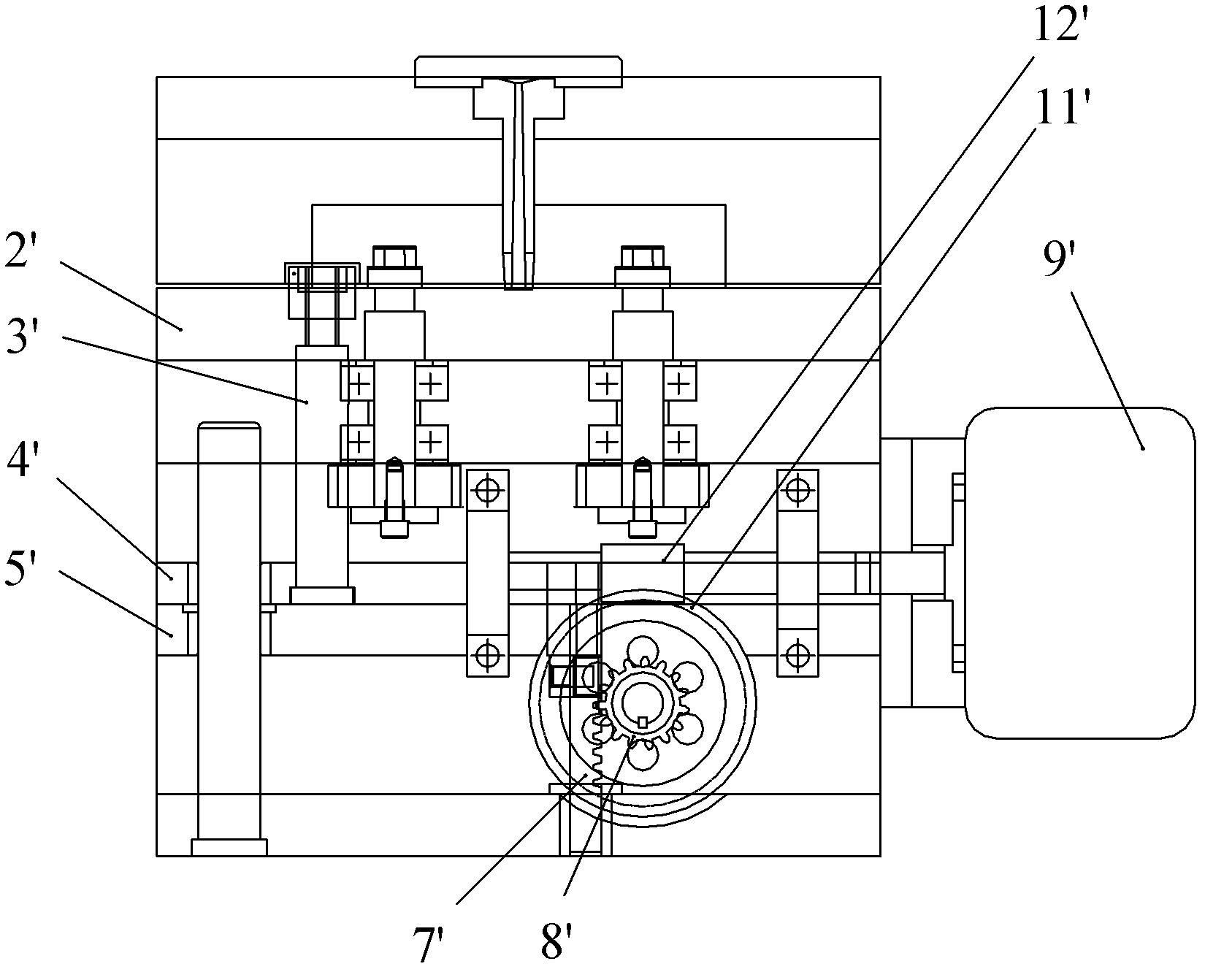

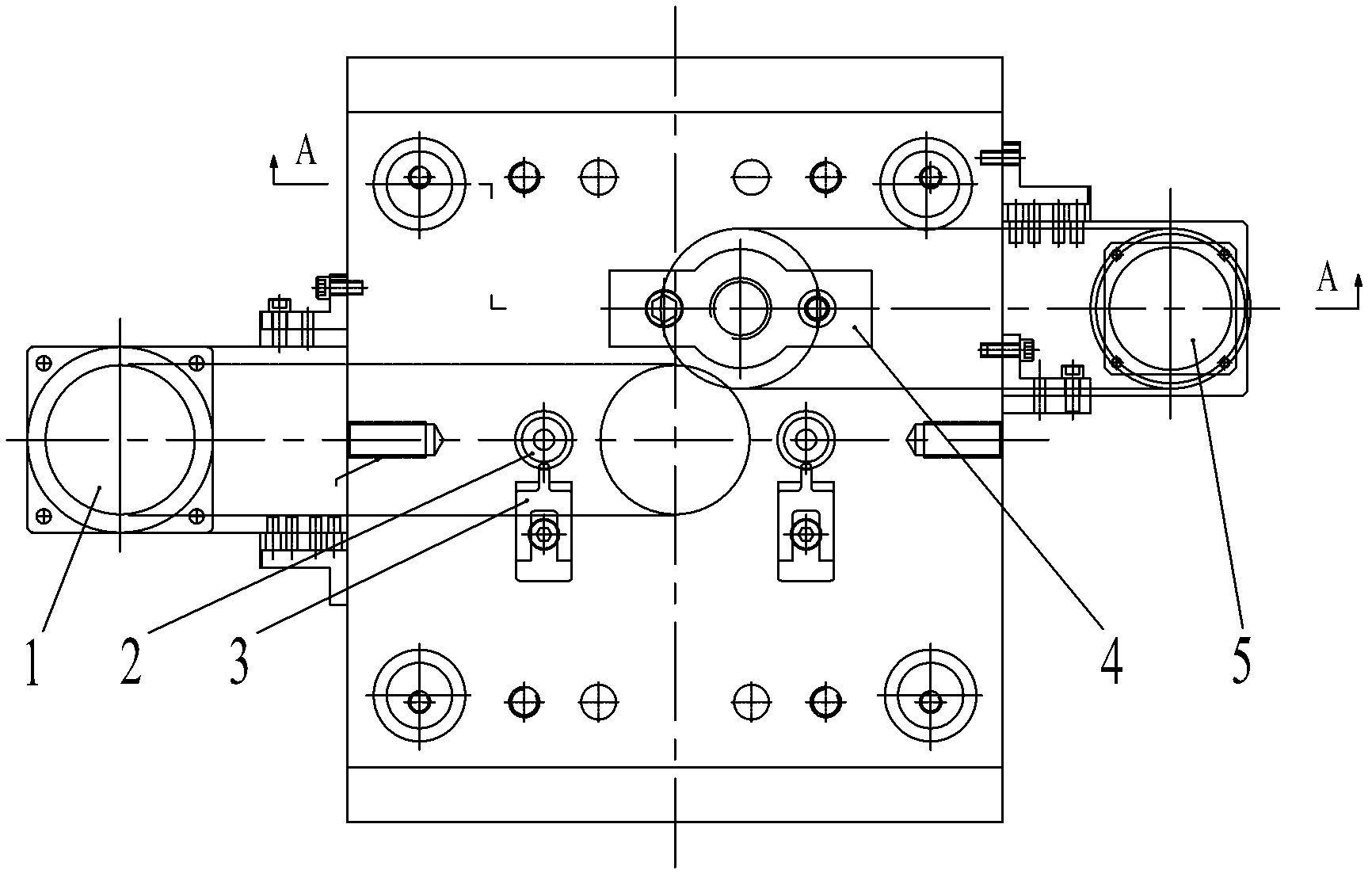

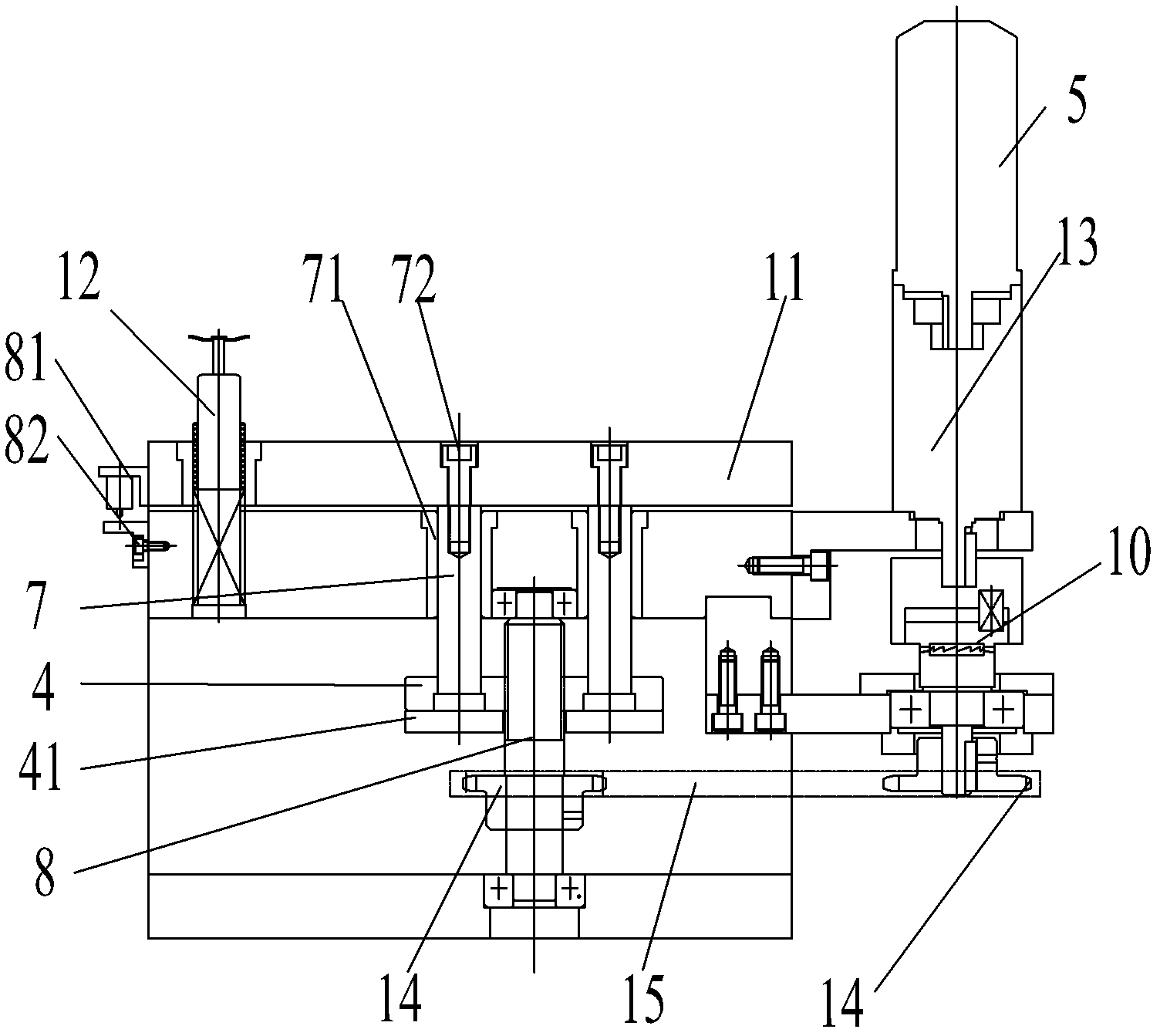

Reset mechanism of mold push plate

InactiveCN102328411ASolve the problem of zero driftMake sure the return trip is in placeLinear motionSynchronous control

The invention provides a reset mechanism of a mold push plate, and the reset mechanism comprises a fixed mold plate, a movable mold plate, a push plate, a threaded mold core, a rotating loose core connected with the threaded mold core and a push plate ejection mechanism connected with the push plate, as well as a PLC (programmable logic controller) synchronous control system for driving the rotating loose core mechanism and the push plate ejection mechanism, wherein the push plate ejection mechanism comprises a servo motor and a transmission pair for transforming the rotational motion of the servo motor to the ejection and withdrawal linear motion of the push plate, the PLC synchronous control system comprises a push plate ejection impulse stroke and a push plate reset impulse stroke, the servo motor of the push plate ejection mechanism is connected with a ratchet mechanism, the ratchet mechanism is connected with the transmission pair, and the push plate reset impulse stroke is larger than the push plate ejection impulse stroke. By additionally arranging the ratchet mechanism in a servo system, the zero drift problem of the servo system is solved in a simple and effective way, and the reset mechanism of the mold push plate has the advantages of reasonable structure, effective control and accurate reset.

Owner:SHUNDE POLYTECHNIC

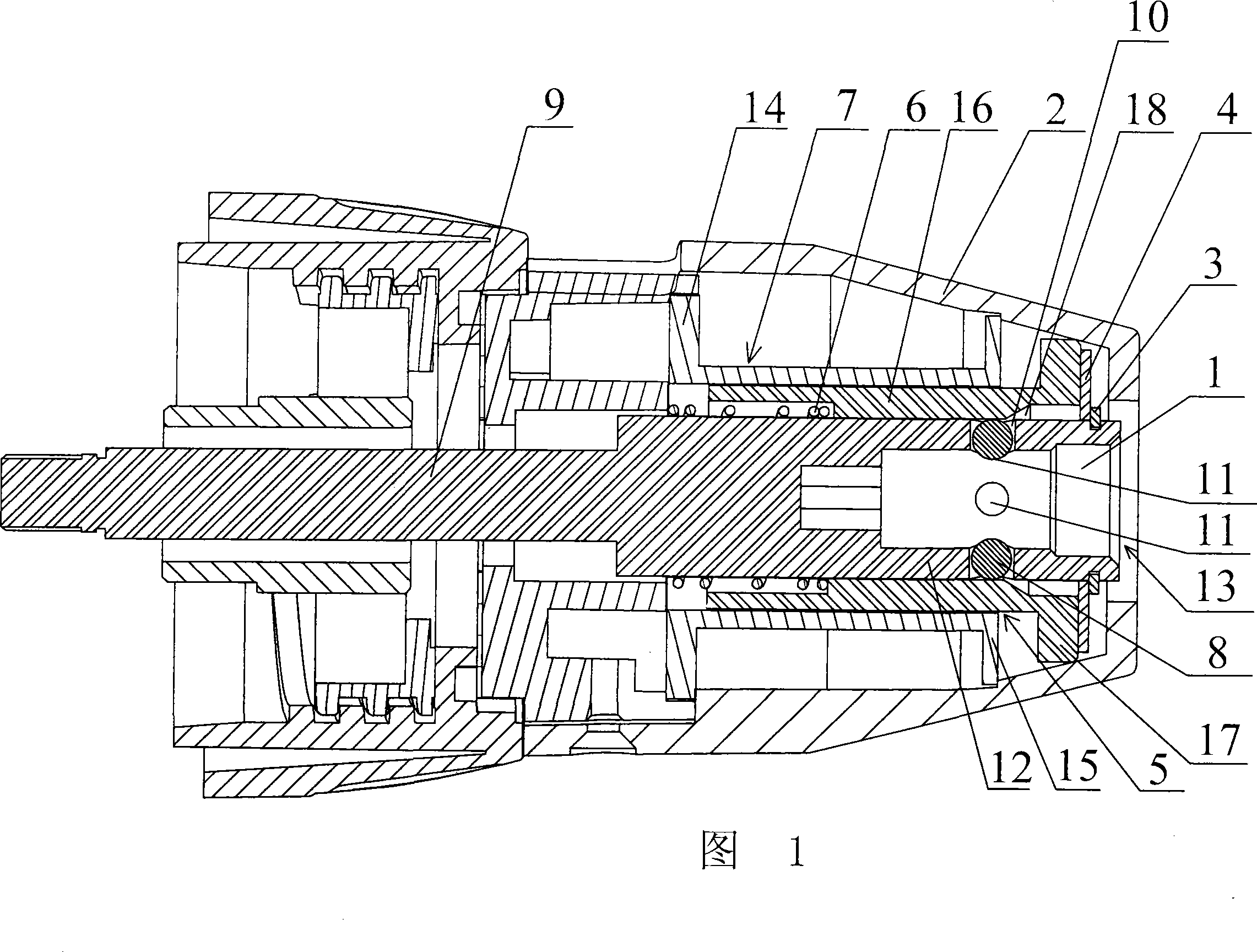

Quick change chuck of electric tool

InactiveCN101049639AAvoid overall overheatingEasy meshChucksPositioning apparatusEngineeringPower tool

A fast exchange clamping chuck for electric tool, especially the electric drill has an axial hole for installing the axle of drill bit, a detachable axle sleeve in said axial hole, and a fast exchange unit for fast exchanging axle sleeve and composed of a spherical locating mechanism and an axial drive mechanism for driving the locating ball in spherical locating mechanism.

Owner:孙延新

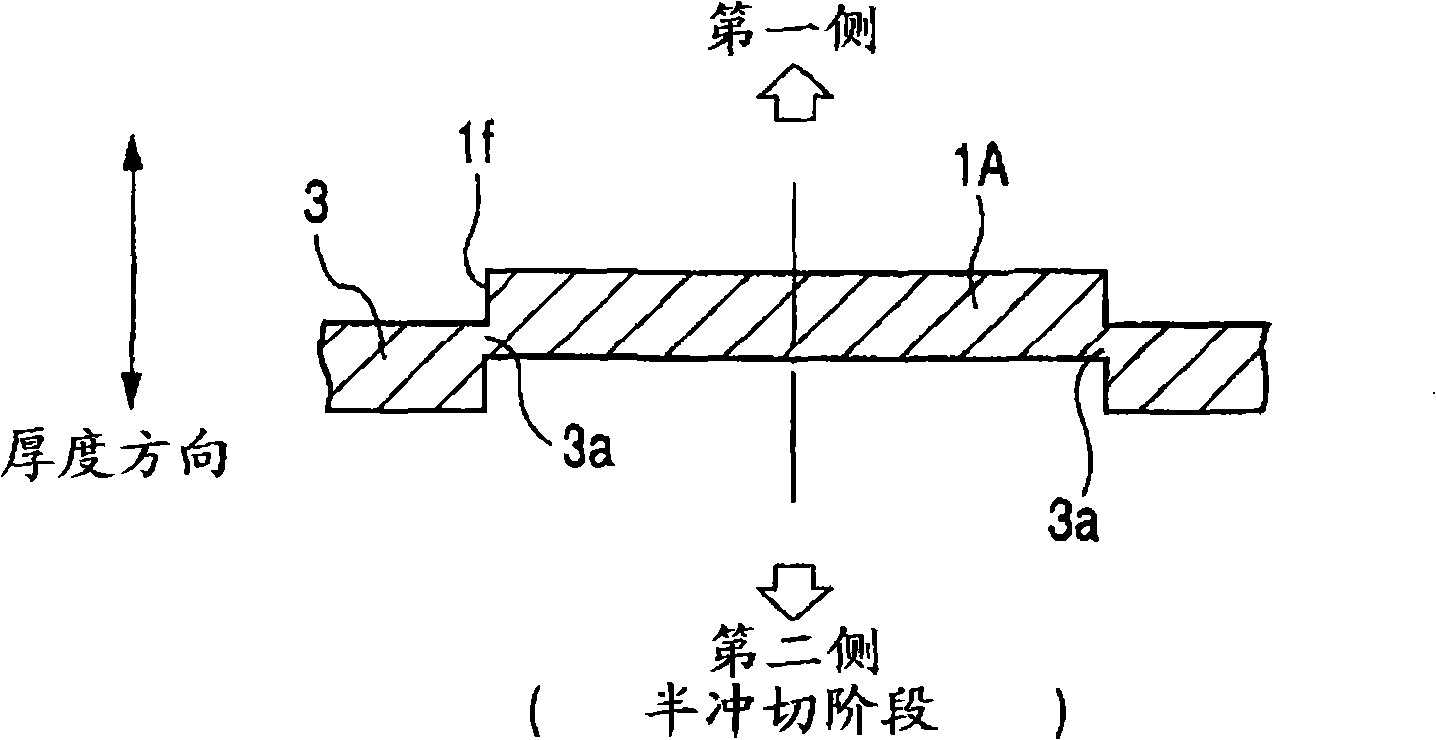

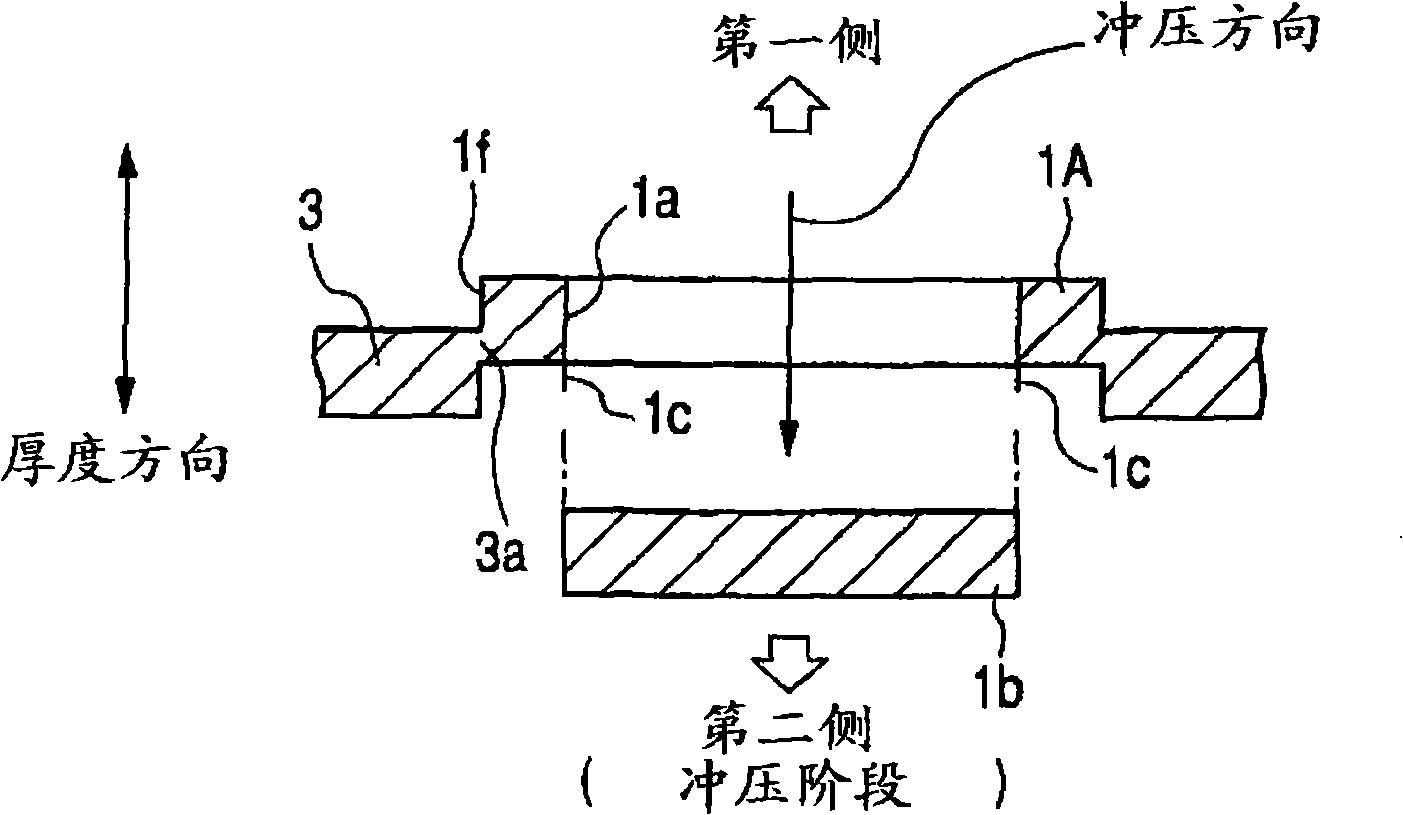

Method of manufacturing gear from metal sheet and the gear manufactured by the method

Owner:DENSO CORP

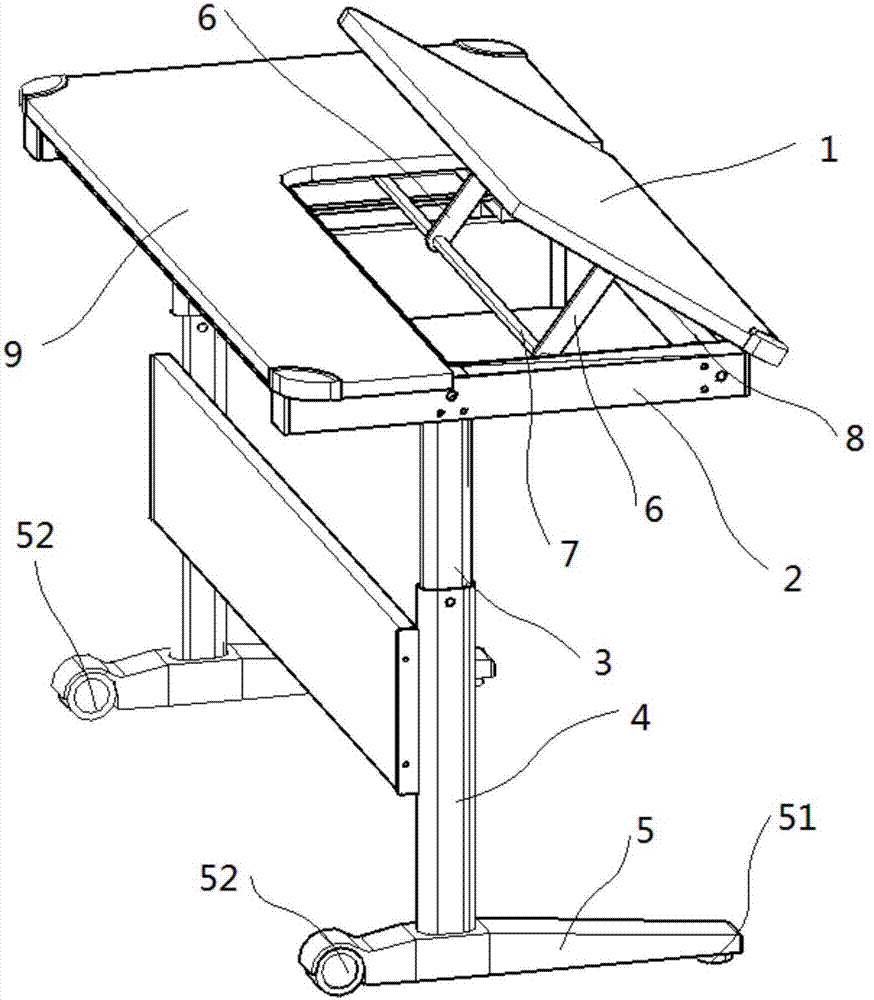

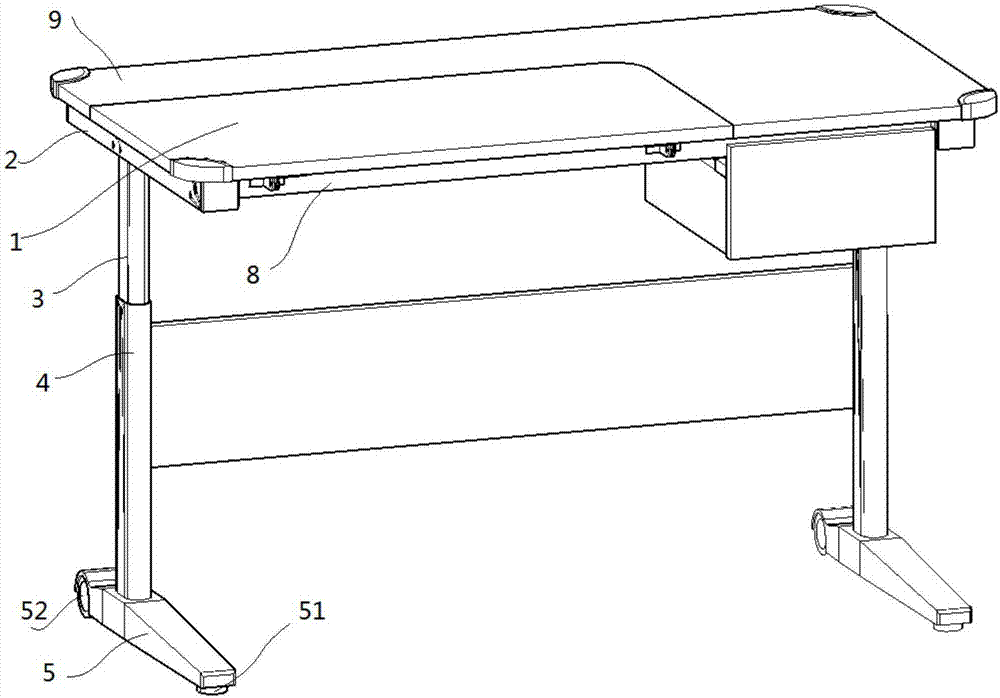

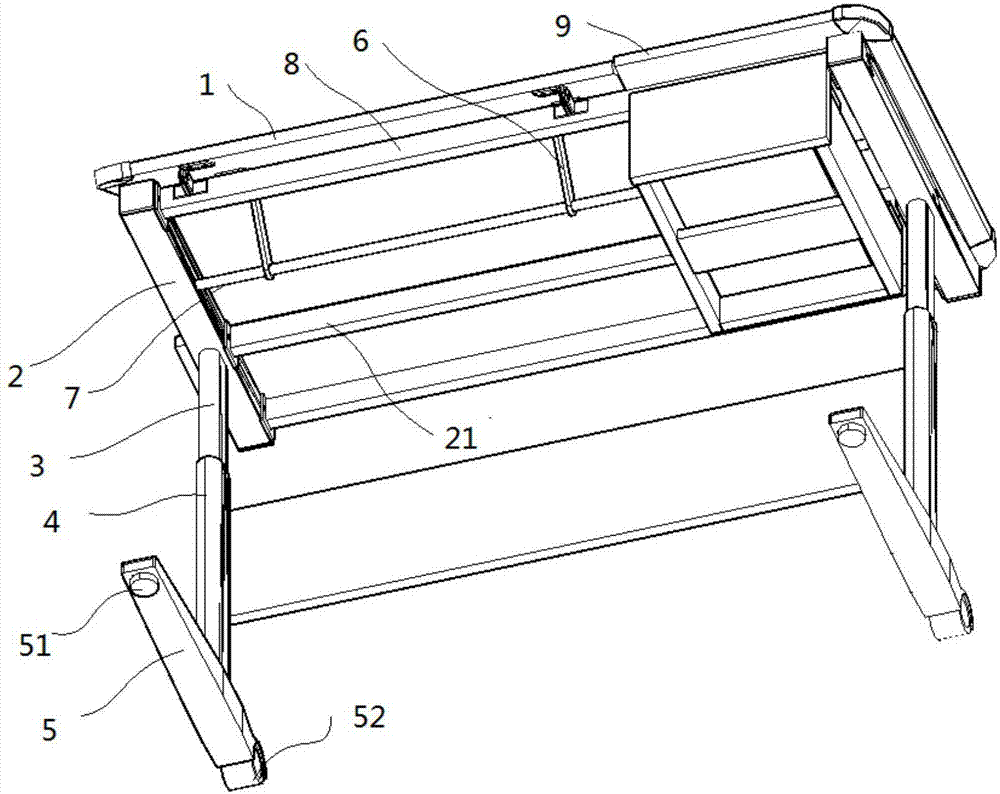

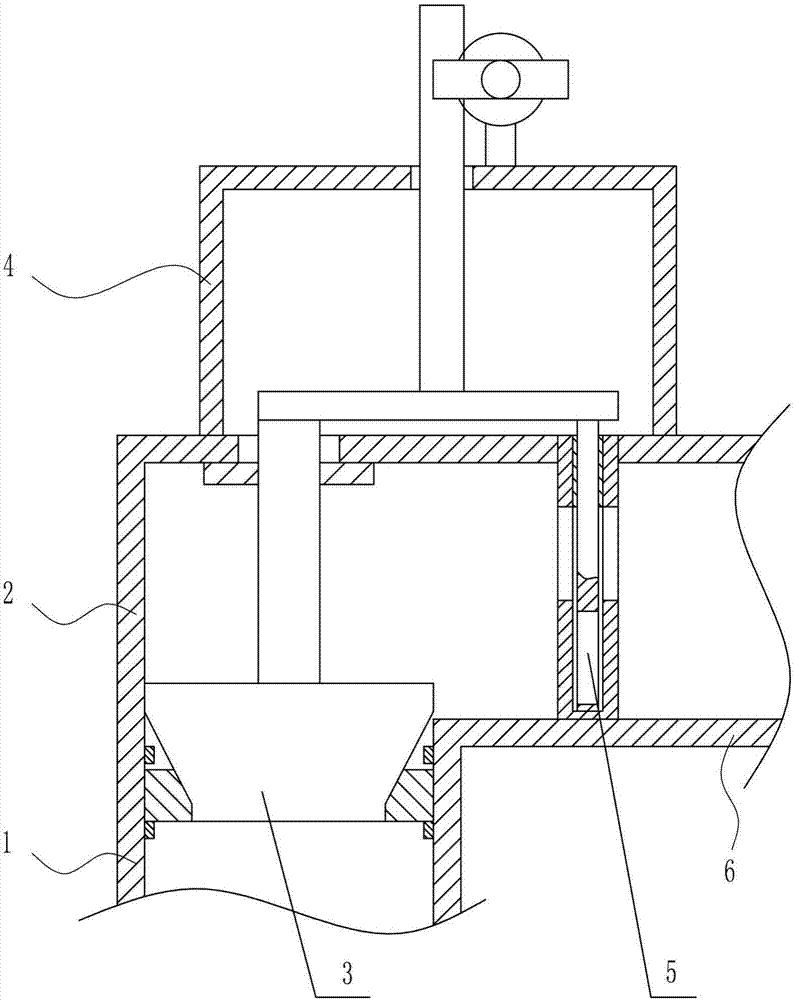

Multi-functional table

PendingCN107280230AStable supportWon't flip over and collapseBook-restsBed-tablesGear wheelEngineering

The invention relates to the technical field of living and learning furniture and concretely relates to a multi-functional table. The multi-functional table comprises table legs and support pipes connected to the table legs. A first transverse rod is hinged onto a table top board capable of turning over. The lower side surface of the table top board is connected with a movable rod through connecting parts. The support pipes are internally provided with two gear pairs axially vertical to each other. The gear pairs are connected with screw rods and first driving rods. Nut parts are in spiral and driving linkage with the screw rods. The nut parts are in spiral and driving linkage with the screw rods. The nut parts are connected to two ends of a movable rod through openings in one side of the two support pipes. A hand crank rocks the first driving rods such that active cone bevel gear wheels connected to two ends can rotate in sync. A gear mechanism transmits motion to the nut pats through the screw rods. The nut parts move such that the table top board turns over. The matching of gears can reduce rocking force and the screw rods have self-locking functions. Therefore, the table top board can conveniently turn over, make adjustments and is fixed better. A user can have better experience in using the multi-functional table and the multi-functional table is used stably for a longer period of time.

Owner:ZHEJIANG RONGHUA FURNITURE

Precise and heavy-load type involute beveloid gear-enveloping hourglass worm transmission

ActiveCN103742601AGood meshing performanceImprove carrying capacityToothed gearingsGearing elementsTransmission ratioMachine tool

The invention discloses a precise and heavy-load type involute beveloid gear-enveloping hourglass worm transmission. The precise and heavy-load type involute beveloid gear-enveloping hourglass worm transmission comprises a gear and a hourglass worm, wherein the gear is made of a hard-tooth-surface wear-resistant material, the tooth surface of the gear is an involute surface, and gear teeth are wedge-shaped along the axial direction thereof; the hourglass worm is made of a medium-hard material, and the tooth surfaces of the both sides of the hourglass worm are enveloping surfaces taking the involute spiral tooth surfaces of the two corresponding sides of the gear as generatrices respectively, and formed by performing generating motion according to the engagement relationship between the gear and the hourglass worm. The precise and heavy-load type involute beveloid gear-enveloping hourglass worm transmission disclosed by the invention is large in transmission ratio range, high in bearing capacity, high in transmission reliability, easy for realize high-accuracy machining, capable of performing tooth side gap adjustment and tooth surface wear amount compensation by virtue of the movement of the axial position of the involute beveloid gear, and suitable for precise and heavy-load equipment such as elevator traction machines, machine tool indexing tables, industrial robots, radars and gun pitching and rotating systems.

Owner:XIHUA UNIV

High-performance adjusting valve for floating valve seat

InactiveCN107504196AAvoid blockingPrevent fallingOperating means/releasing devices for valvesCleaning using toolsEngineeringValve seat

The invention relates to an adjusting valve for a floating valve seat, in particular to a high-performance adjusting valve for a floating valve seat, and aims to provide the high-performance adjusting valve for the floating valve seat, which can not only control the flow rate of a liquid but also be prevented from dust to ensure better application. In order to solve the technical problem, the provided high-performance adjusting valve for the floating valve seat comprises a liquid inlet pipe and the like, wherein a liquid outlet pipe is connected to the right side of the valve body; the liquid inlet pipe is connected to the lower part of the valve body; a support is mounted between the outer top of the valve body and the outer top of the liquid outlet pipe; a sealing device is mounted between the inside of the support and the liquid inlet pipe; and a volume control device is arranged in the liquid outlet pipe and connected with the sealing device. The high-performance adjusting valve achieves the effects that not only is the flow rate of the liquid controlled, but also dust prevention is performed, and further the adjusting valve can be better used.

Owner:林彬

Coating and conductive resin of film zinc coat

ActiveCN103265661AImprove bindingIncrease roughnessAnti-corrosive paints(Hydroxyethyl)methacrylateHydrazine compound

The invention discloses a coating and conductive resin of a film zinc coat, which is prepared by the following steps of: weighing an organic solvent, methyl methacrylate, hydroxybutyl acrylate, hydroxyethyl methylacrylate, hydroxyethyl methacrylate phosphate, tert-butyl peroxy-2-ethylhexanoate and graphene oxide; adding 3 / 4 of the organic solvent and the graphene oxide into a reaction kettle A and mixing uniformly; uniformly mixing the methyl methacrylate, hydroxybutyl acrylate, hydroxyethyl methylacrylate, hydroxyethyl methacrylate phosphate and 3 / 4 of the tert-butyl peroxy-2-ethylhexanoate, dropwise adding the mixture into a dropwise adding tank B, and then dropwise adding into the reaction kettle A; uniformly mixing the residual organic solvent and tert-butyl peroxy-2-ethylhexanoate, dropwise adding the mixture into the dropwise adding tank B, then dropwise adding into the reaction kettle A at 113-118 DEG C, preserving heat for 0.8-1.2 hours, cooling and filtering; and performing ultrasonic treatment, adding hydrazine hydrate for reaction, filtering, washing and drying. The prepared film zinc coat has better corrosion resistance.

Owner:HUNAN JINPAN NEW MATERIAL TECH CO LTD

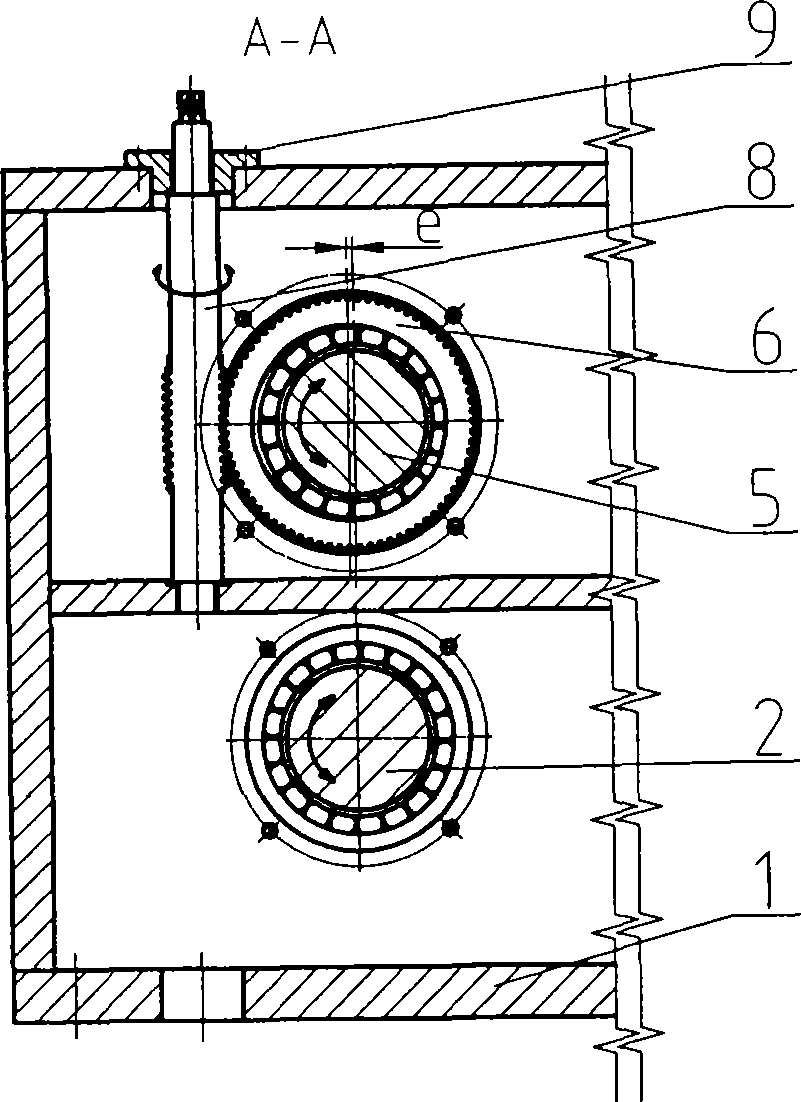

Center distance-regulating mechanism for steel plate-forming machine

ActiveCN101439353AEasy to adjustWith self-locking abilityMetal rolling stand detailsMetal rolling arrangementsManufacturing technologySheet steel

A shaft distance adjusting mechanism for a steel plate forming machine belongs to the manufacturing technical field of the matched parts of machines, building material forming machines and other devices. The adjusting mechanism mainly comprises a machine frame (1), a fixed rotating shaft (2) which is arranged on the machine frame (1) and provided with a lower gear (3), an adjusting rotating shaft (5) which is also arranged on the machine frame (1) and provided with an upper gear, an eccentric sleeve (6) sleeved on the adjusting rotating shaft (5), an adjusting rod (8) arranged on the machine frame (1) and connected with the eccentric sleeve (6), and an end cover (7) arranged at two axial ends of the eccentric sleeve (6); and bearing saddle bores at both ends of the eccentric sleeve (6) share one axis, and an eccentric distance e ranging from 1 mm to 10 mm exists between the bearing saddle bores and an axle center. The shaft distance adjusting mechanism has the advantages of reasonable design of an integral structure, simple structure, stable work and convenient adjustment.

Owner:ZHEJIANG JINGGONG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com