Tooth shape optimization design method for linear-circular arc tooth outline internal engaged cylindrical gear pair

An optimized design, cylindrical gear technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of external gear conjugate tooth profile error, difficult processing, not using and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

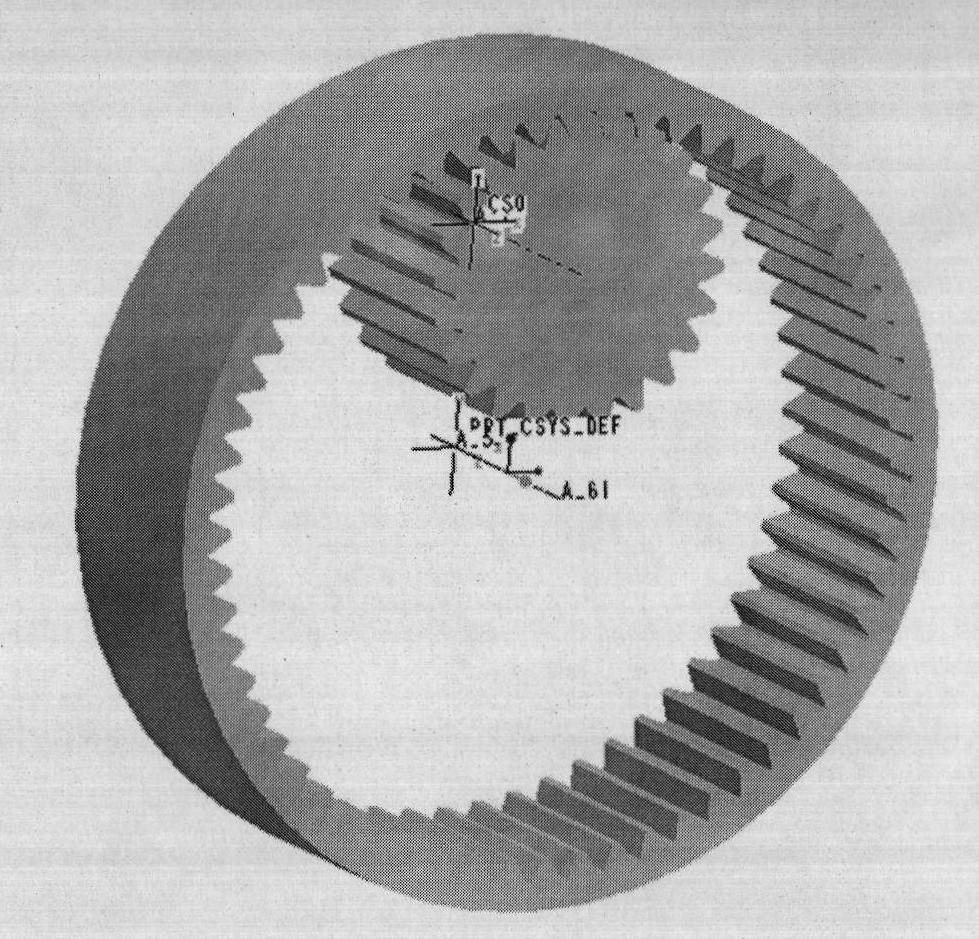

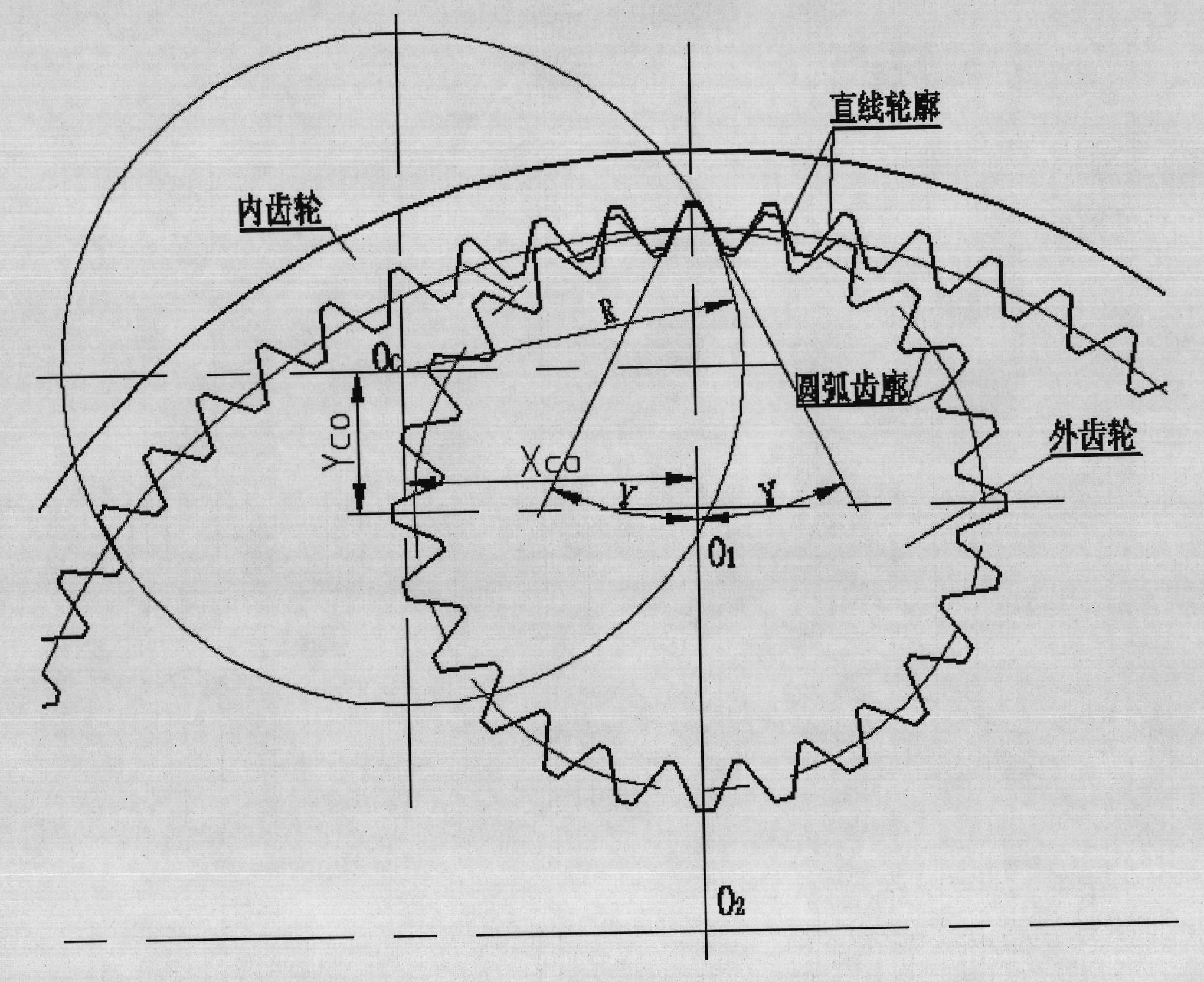

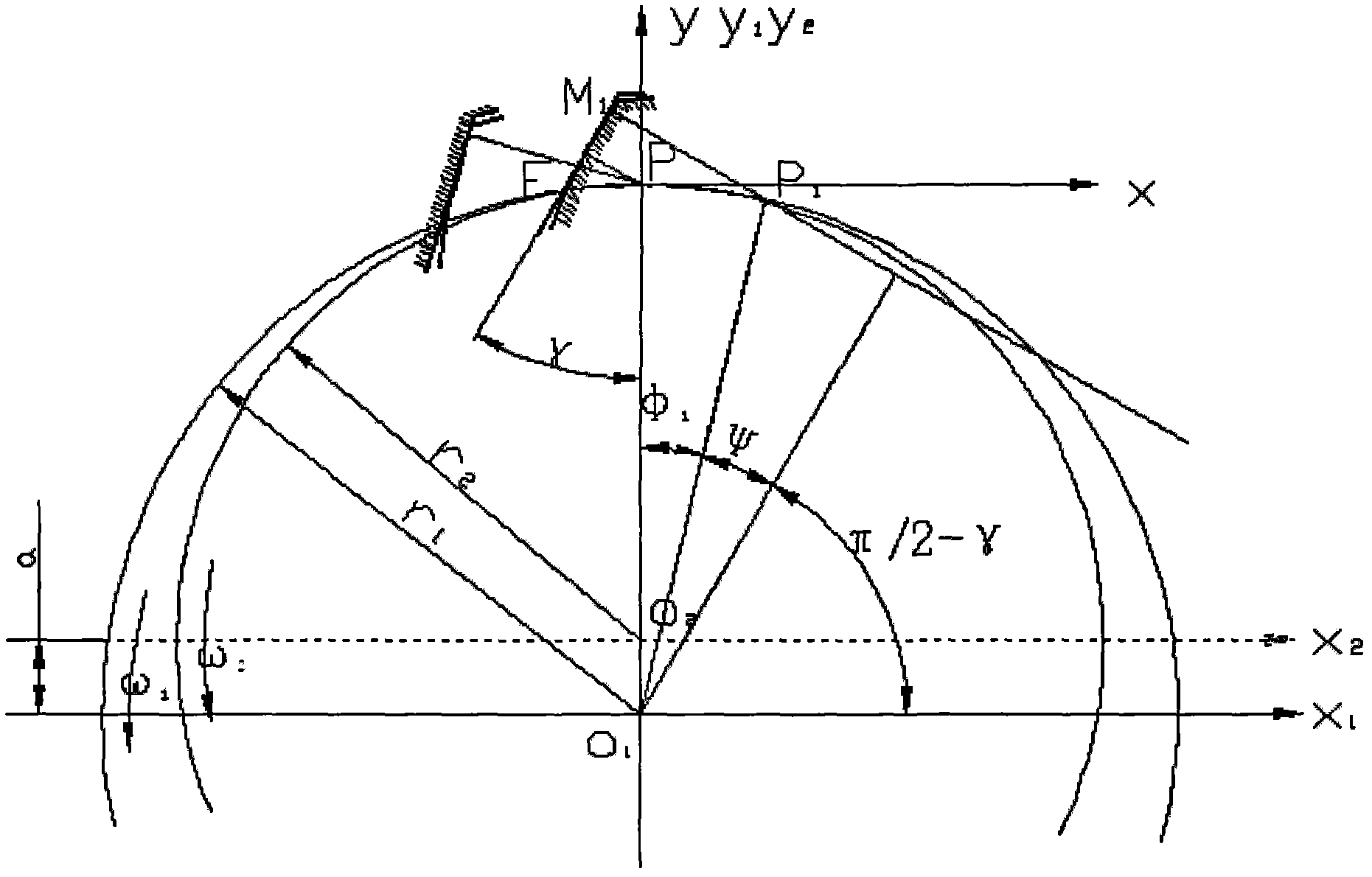

Image

Examples

Embodiment Construction

[0056] According to the transmission requirements of the internal gear pair, the parameters of a certain internal gear pair tooth shape are set before the tooth shape is optimized: the gear modulus m is 3, the number of teeth of the outer and inner gears z 1 ,z 2 24 and 60 respectively, preselected internal gear tooth profile half angle γ is 26°, addendum height coefficient root height factor Root transition arc radius ρ f = 0.2m. Then, the tooth profile of the internal gear in the internal gear pair is determined by formula (1).

[0057] The initial value of the design variable is X 0 =[25,25] T . When using MATLAB language programming for optimization calculations, pay attention to the parameters in the objective function is the rotation angle of the internal gear, a pair of tooth profiles from meshing to meshing, from -α 1 change to alpha 2 , first use the half angle of the tooth shape γ=25° to substitute into formulas (11) and (12) to calculate α 1 、α 2 val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com