Patents

Literature

931 results about "Tooth number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

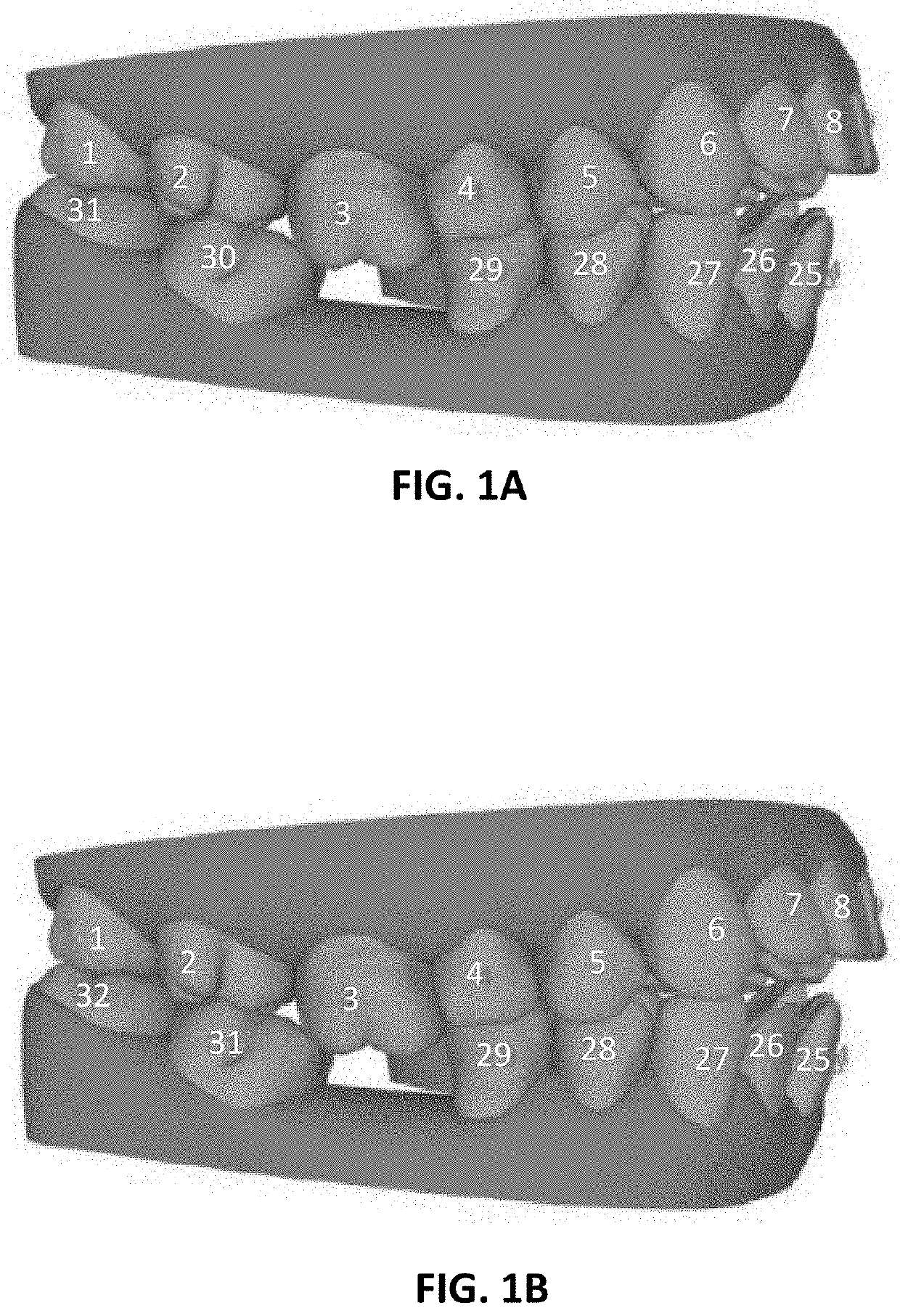

In the universal tooth numbering system, tooth number 1 is the patient's upper right third molar, on the right side of the mouth in the upper (maxillary) jaw. Numbering of teeth continues along the upper teeth toward the front and across to the last molar tooth back on the top left side (number 16).

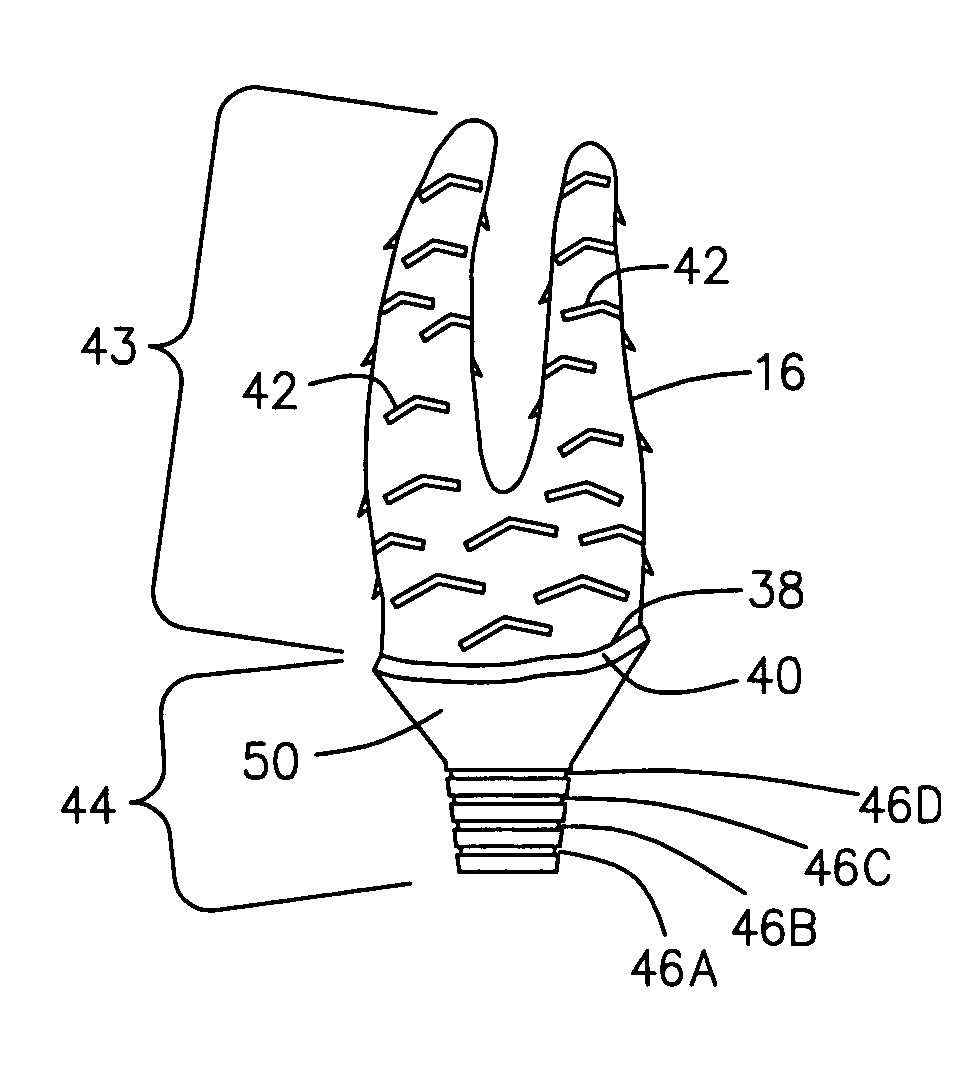

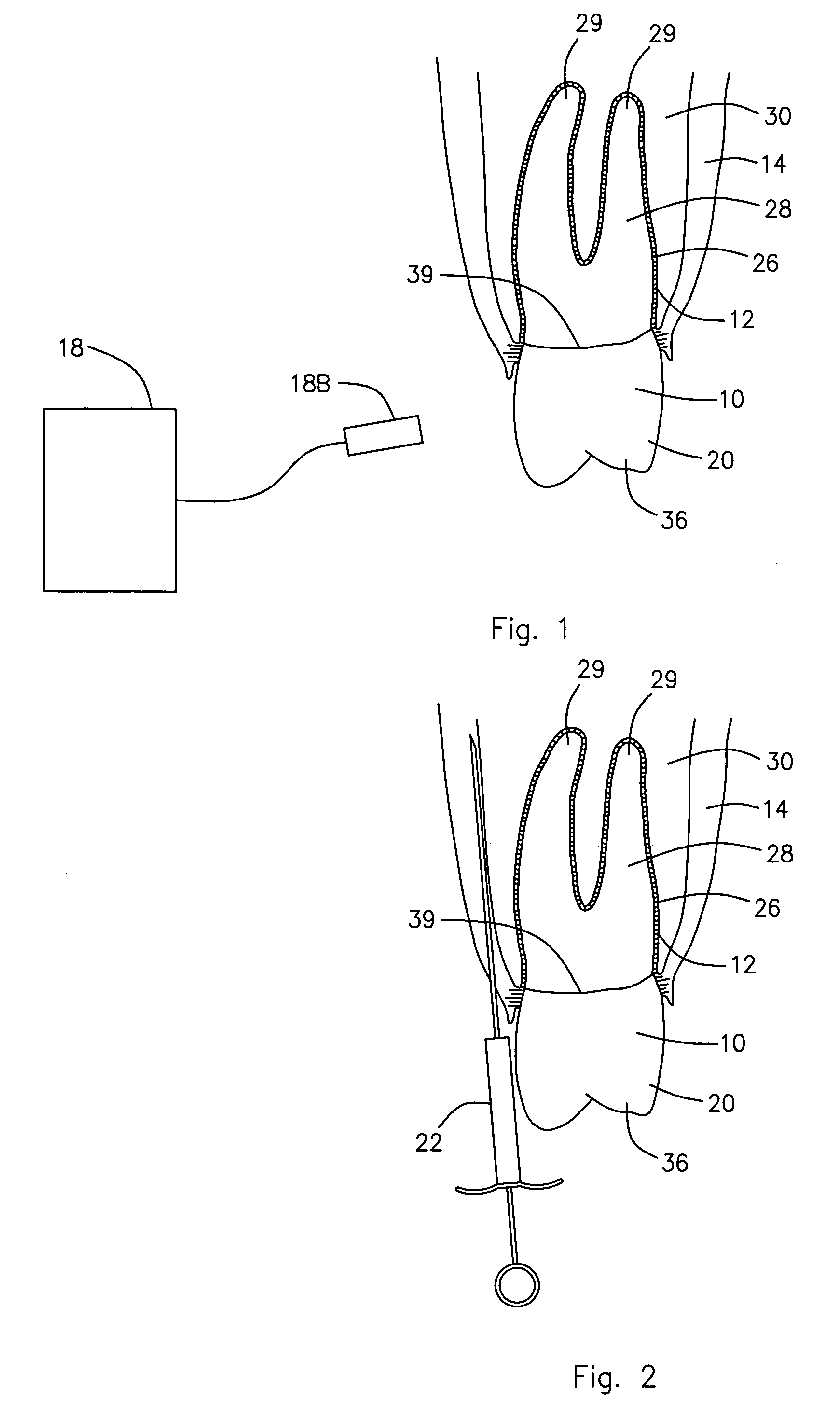

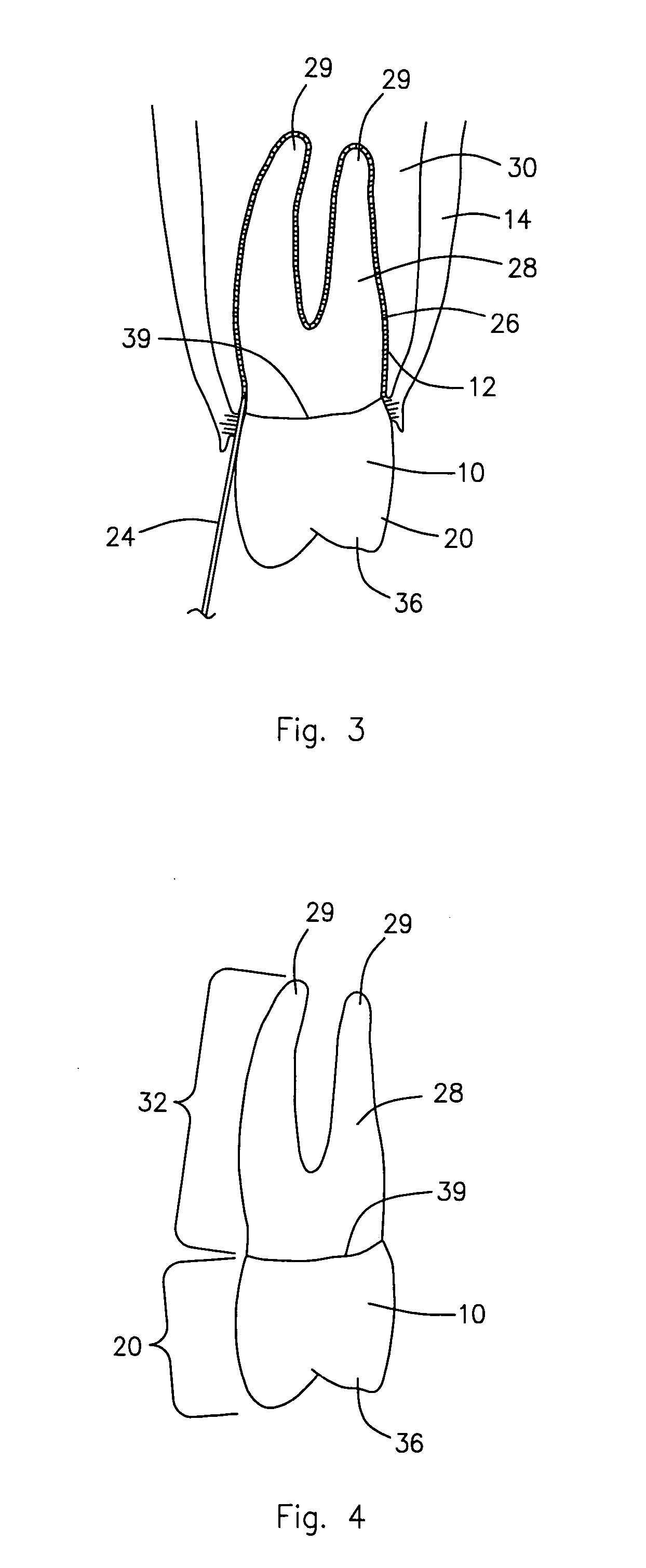

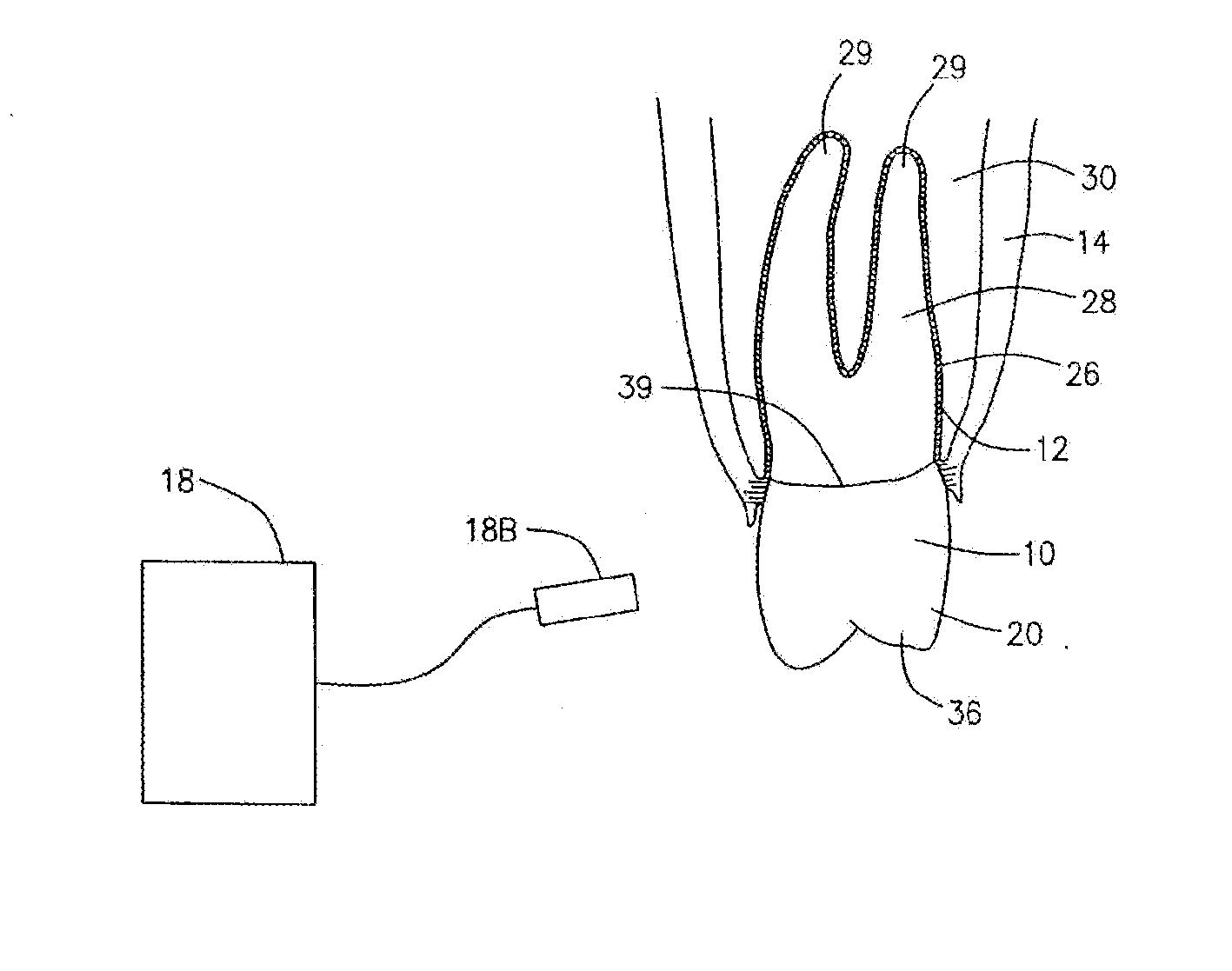

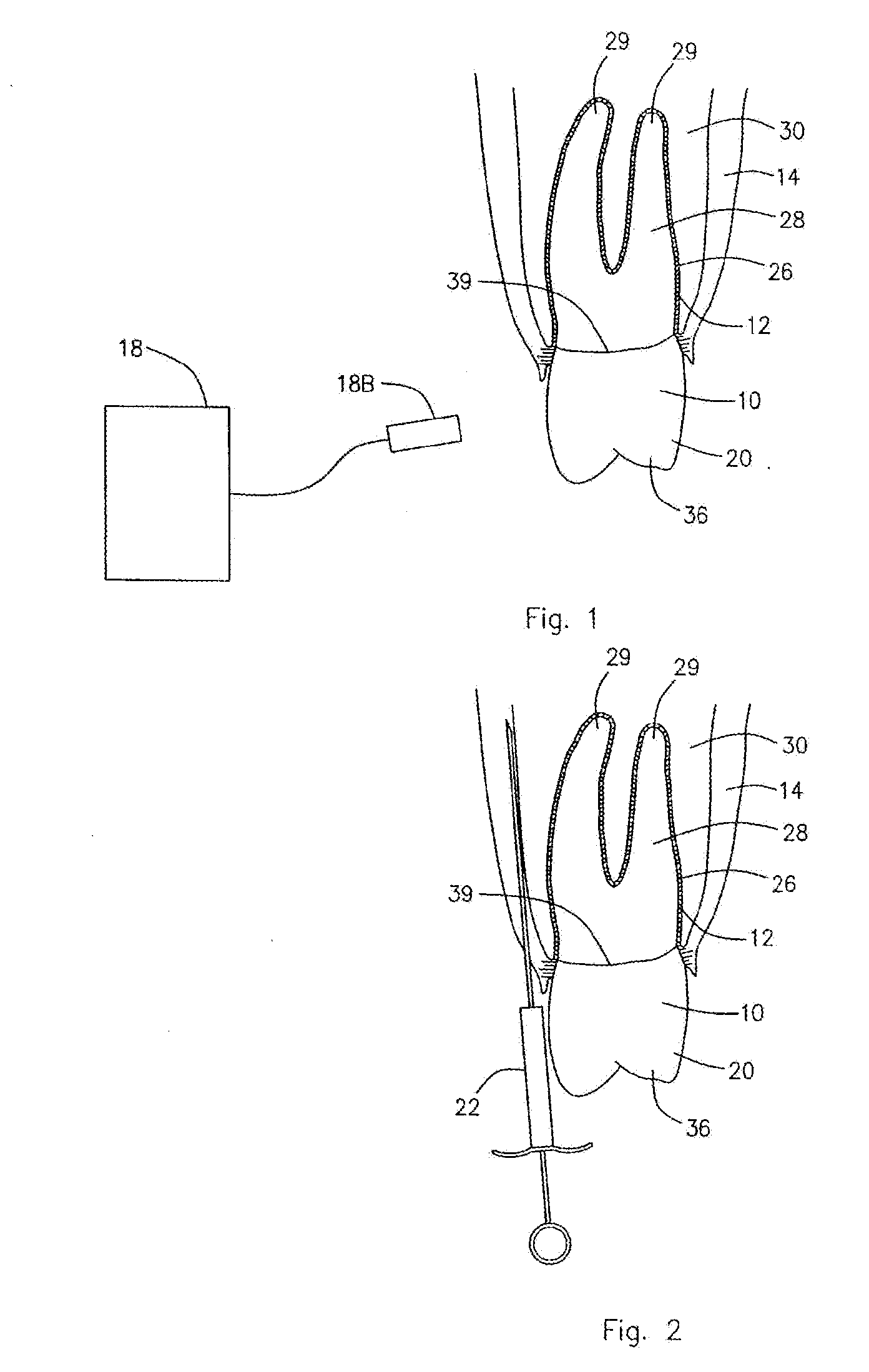

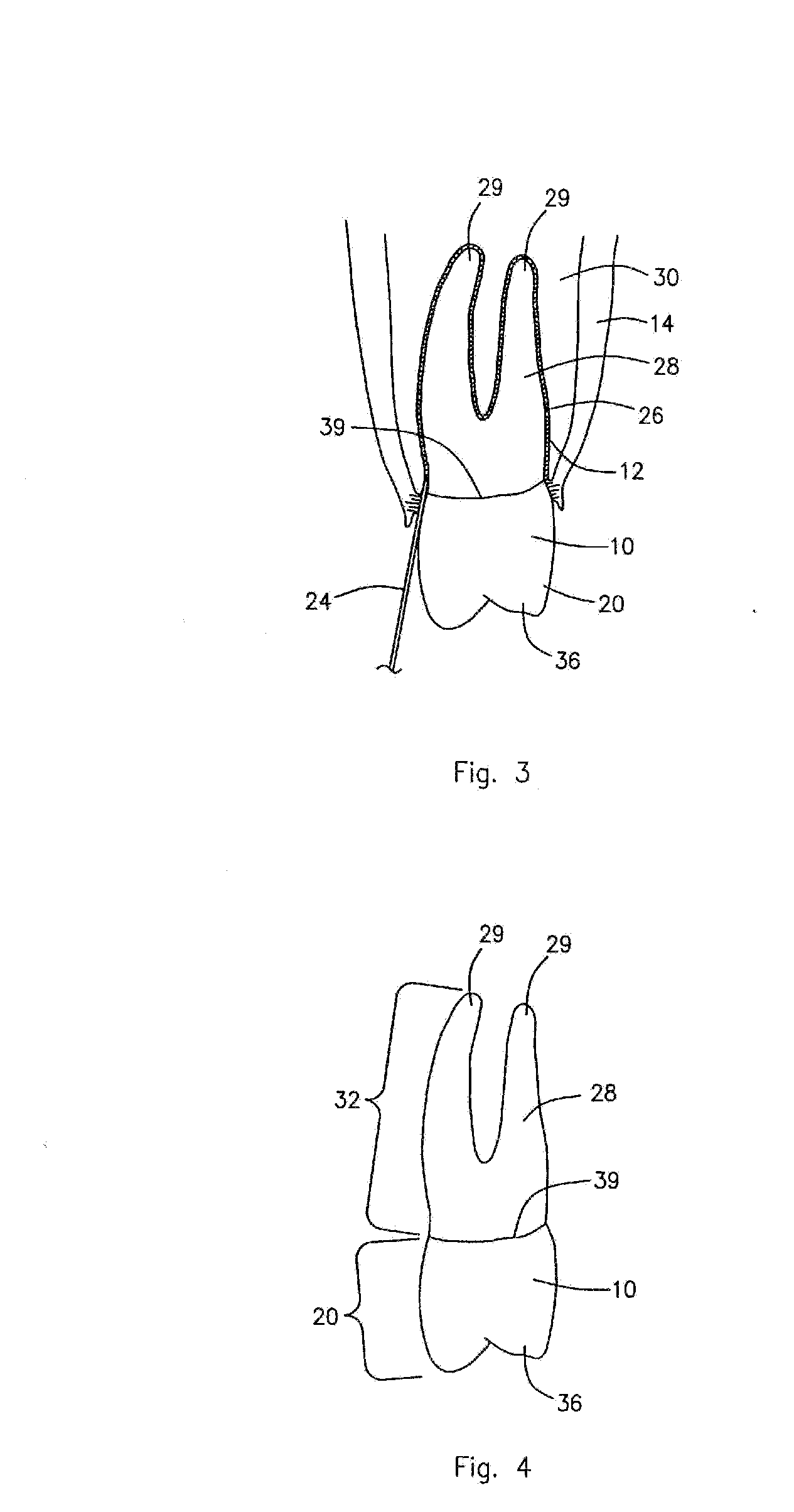

Dental implant and method for making and installing same

InactiveUS20070264612A1Promote bone growthEasy to disassembleDental implantsMechanical/radiation/invasive therapiesCementoenamel junctionReplacement implant

A method for making a dental implant by obtaining images of the tooth pre-atraumatic tooth extraction and post extraction and using those images to computer generate and mill a titanium replacement implant employing CAD / CAM equipment. The implant includes a scalloped neck interface similar to the replaced tooth's scalloped cementoenamel junction, a polished neck area between a root portion and a crown portion, and the numeral for the tooth number imprinted on the implant's facial surface. Chevron retention fins are provided on the root portion for engaging the bone of the tooth socket or osteotomy when the implant is tapped into position. Retention grooves are provided on the crown portion to which a provisional crown is cemented slightly out of occlusion at the time the implant is placed. The provisional crown will be replaced with a permanent crown after osteointegration of the implant has occurred.

Owner:MOUNT K TIM

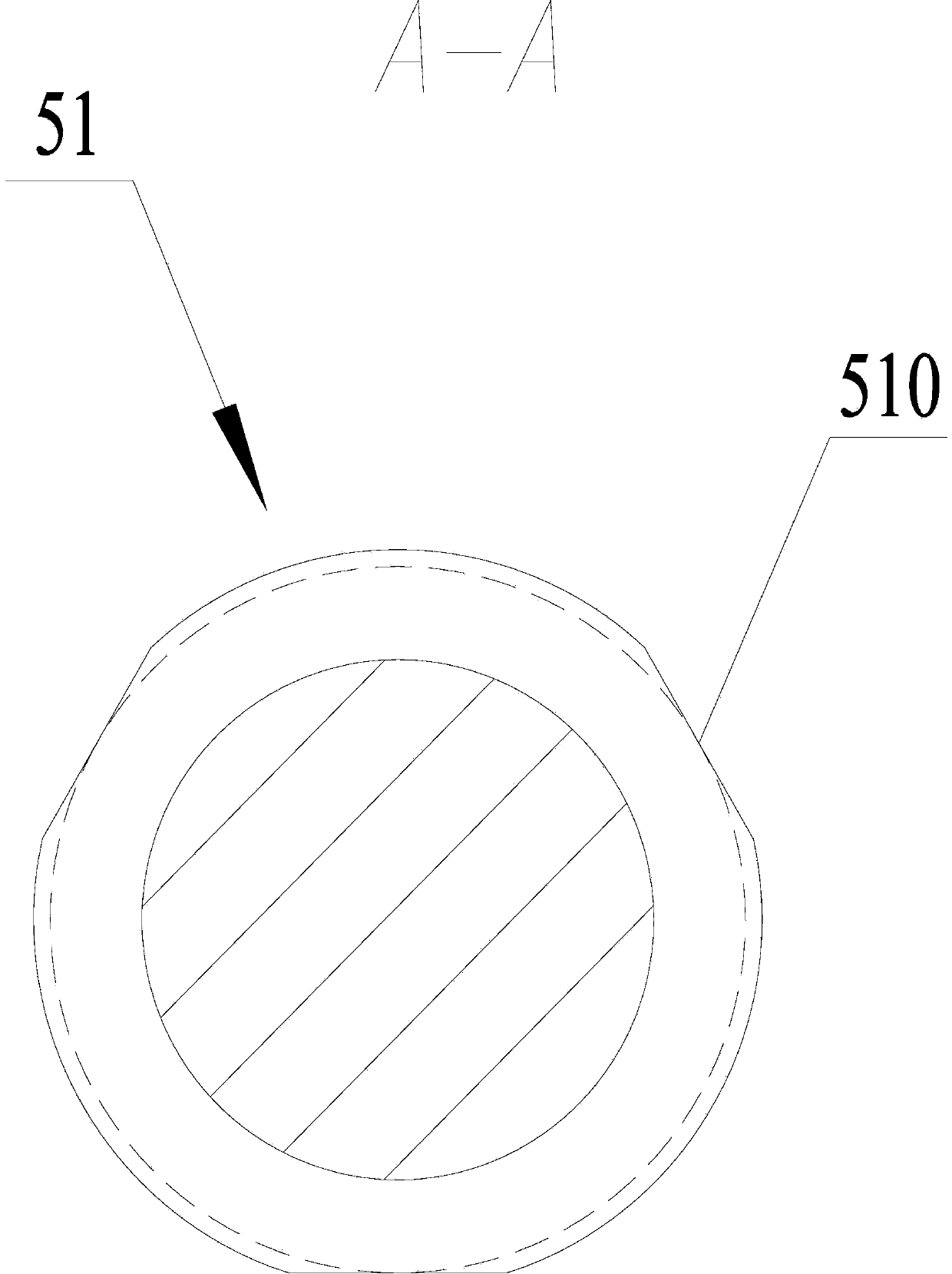

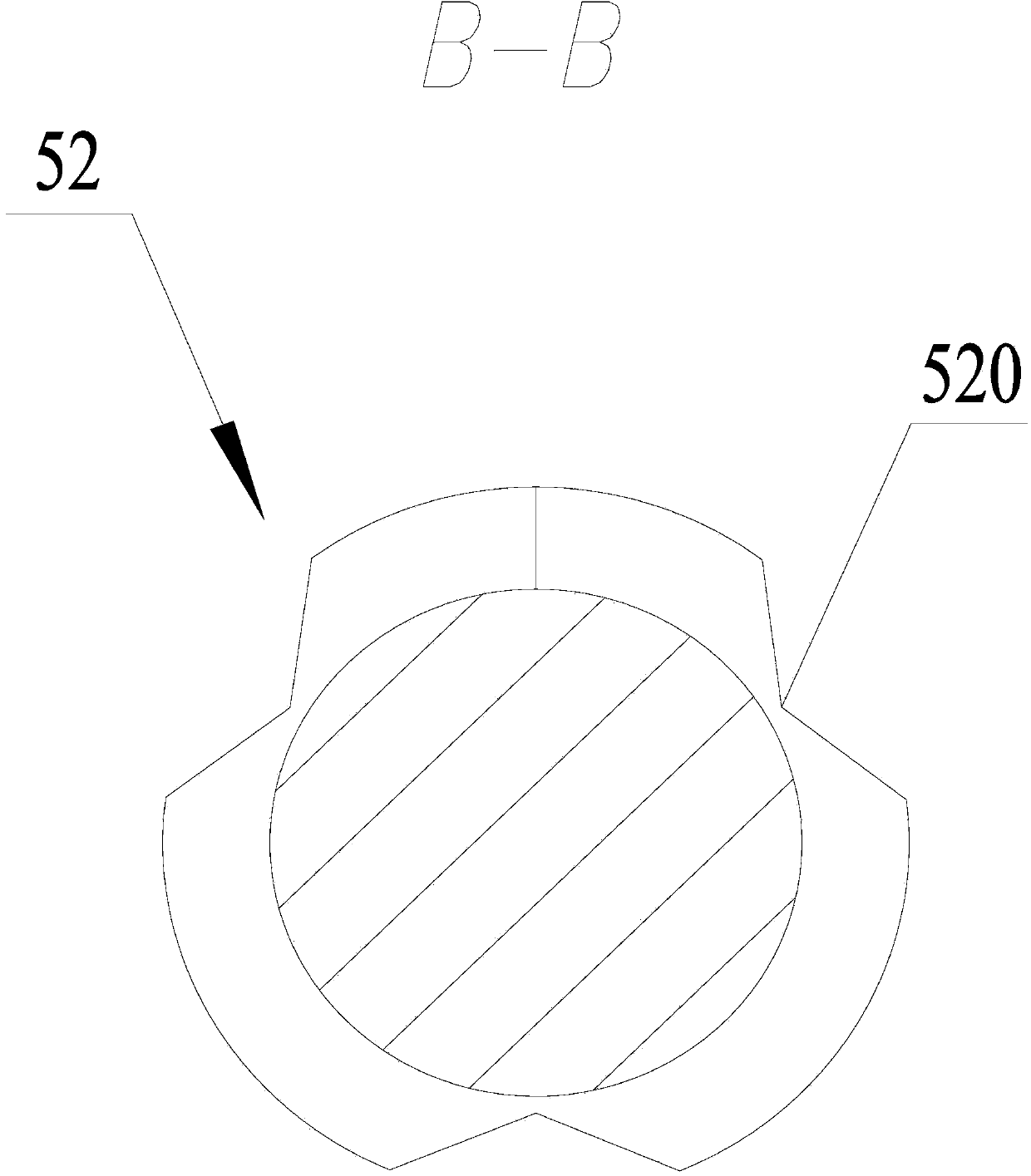

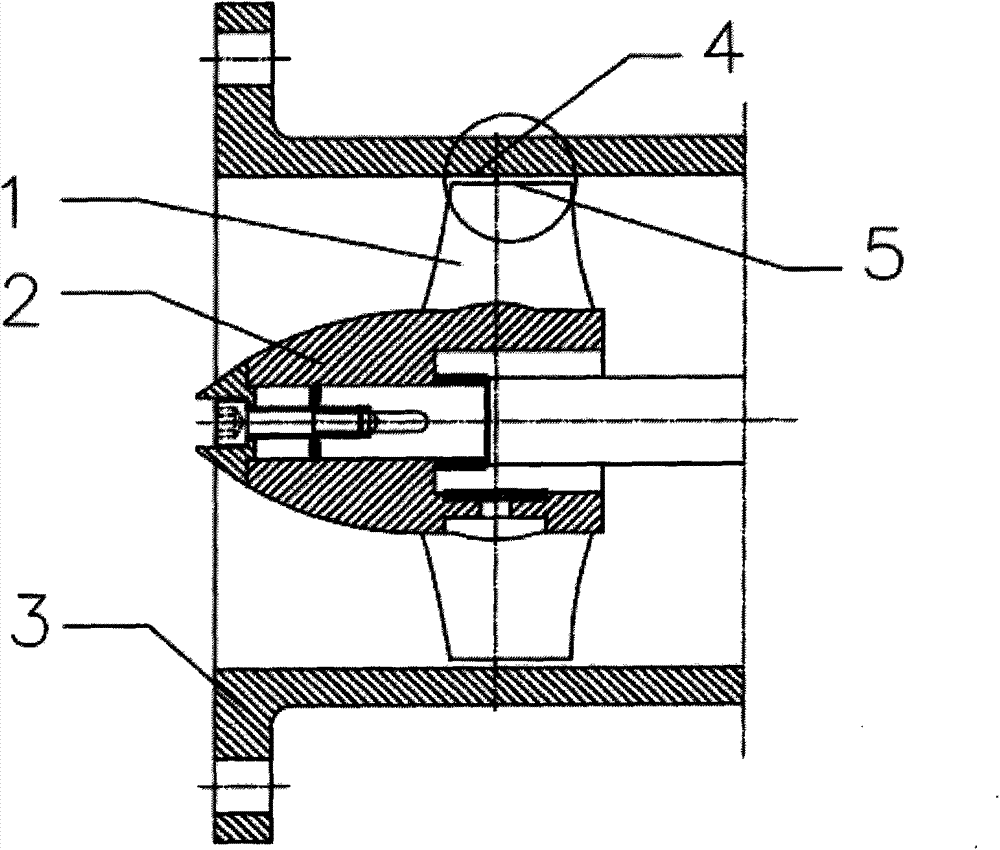

Heat transfer pipe with internal threads

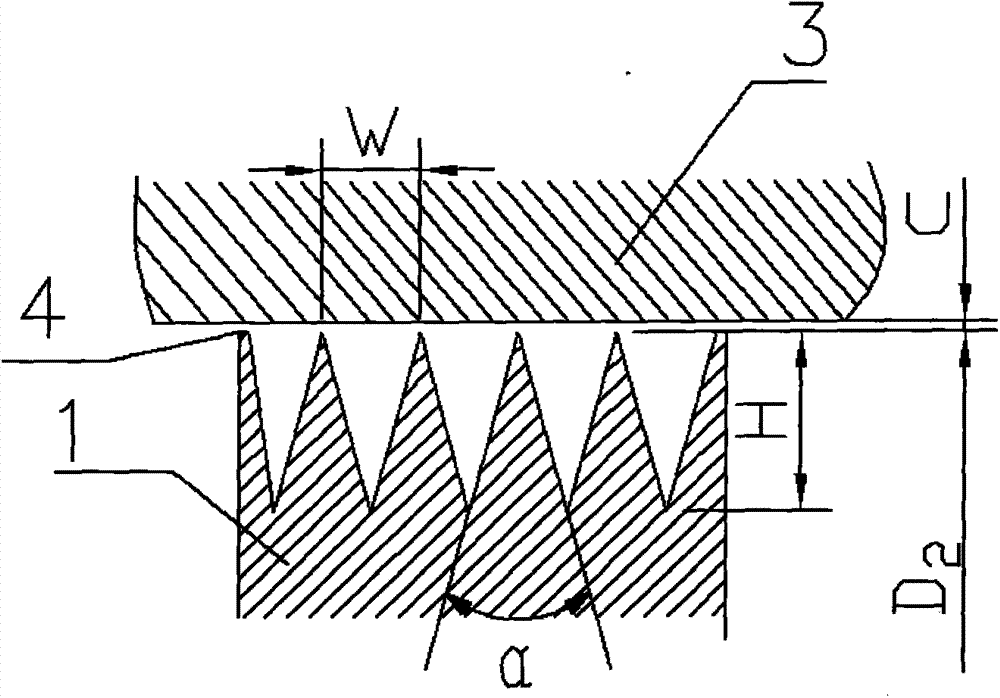

ActiveCN100365370CImprove heat exchange capacityEvaporators/condensersTubular elementsHeat transmissionEvaporation

The invention relates to an inner screw heat transmission pipe, belonging to the heat transmission element. The invention is purposed to realize high heat transmission efficiency in condensation and high heat transmission efficiency in evaporation. The invention comprises: the inner surface of said pipe has screw teeth whose sections are in Y-shape and the nearby two teeth have an open chamber; the heights of two side wall of tooth are different or same while the biggest width between nearby two chambers is bigger than the width of chamber; the screw angle beta of screw tooth ranges between 0-30 degrees; The number of screw teeth of inner surface ranges from 30-200; and the width between nearby chamber opens ranges from 0.01-0.25mm. The invention can apply cold-warm indoor air conditioner.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

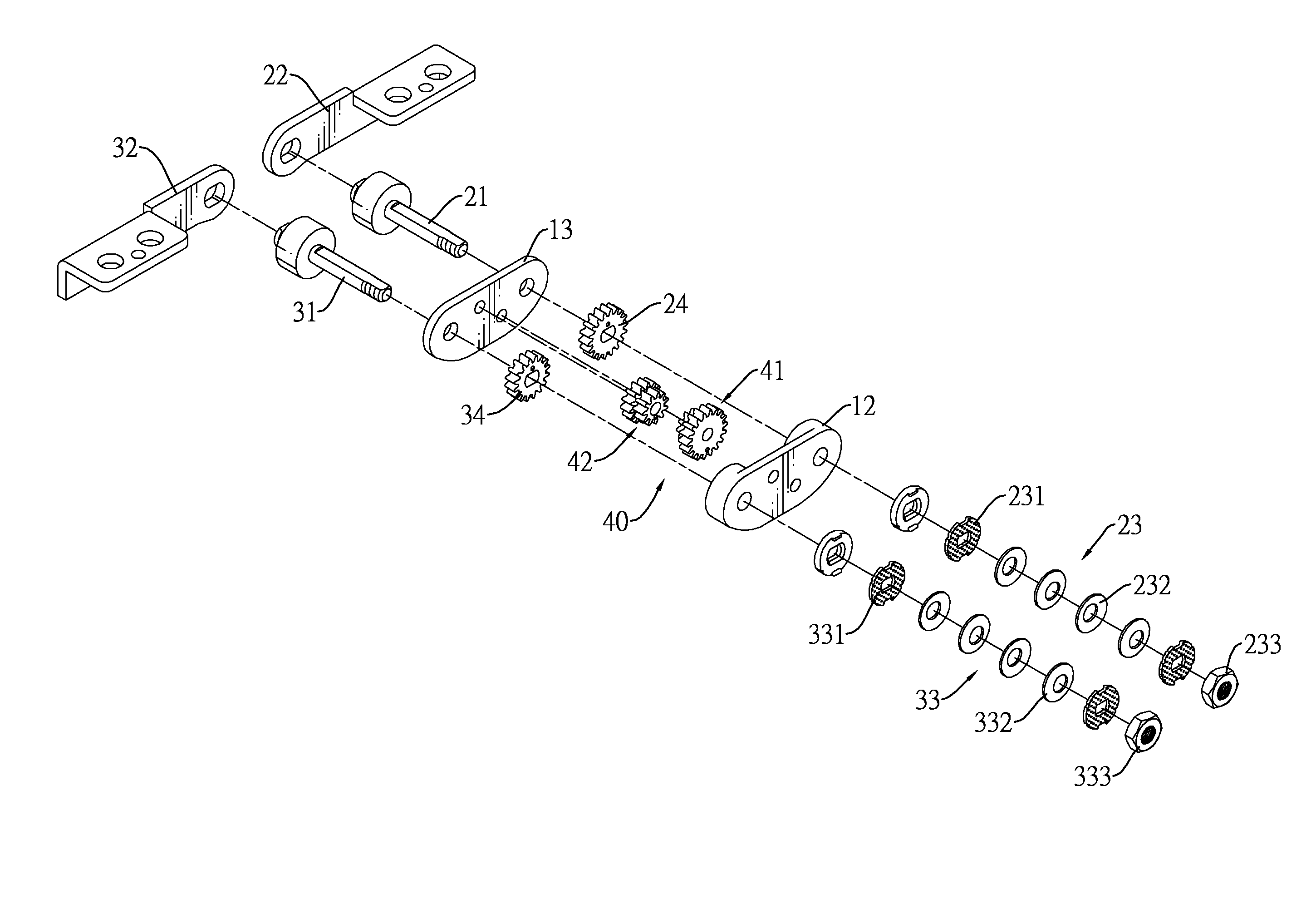

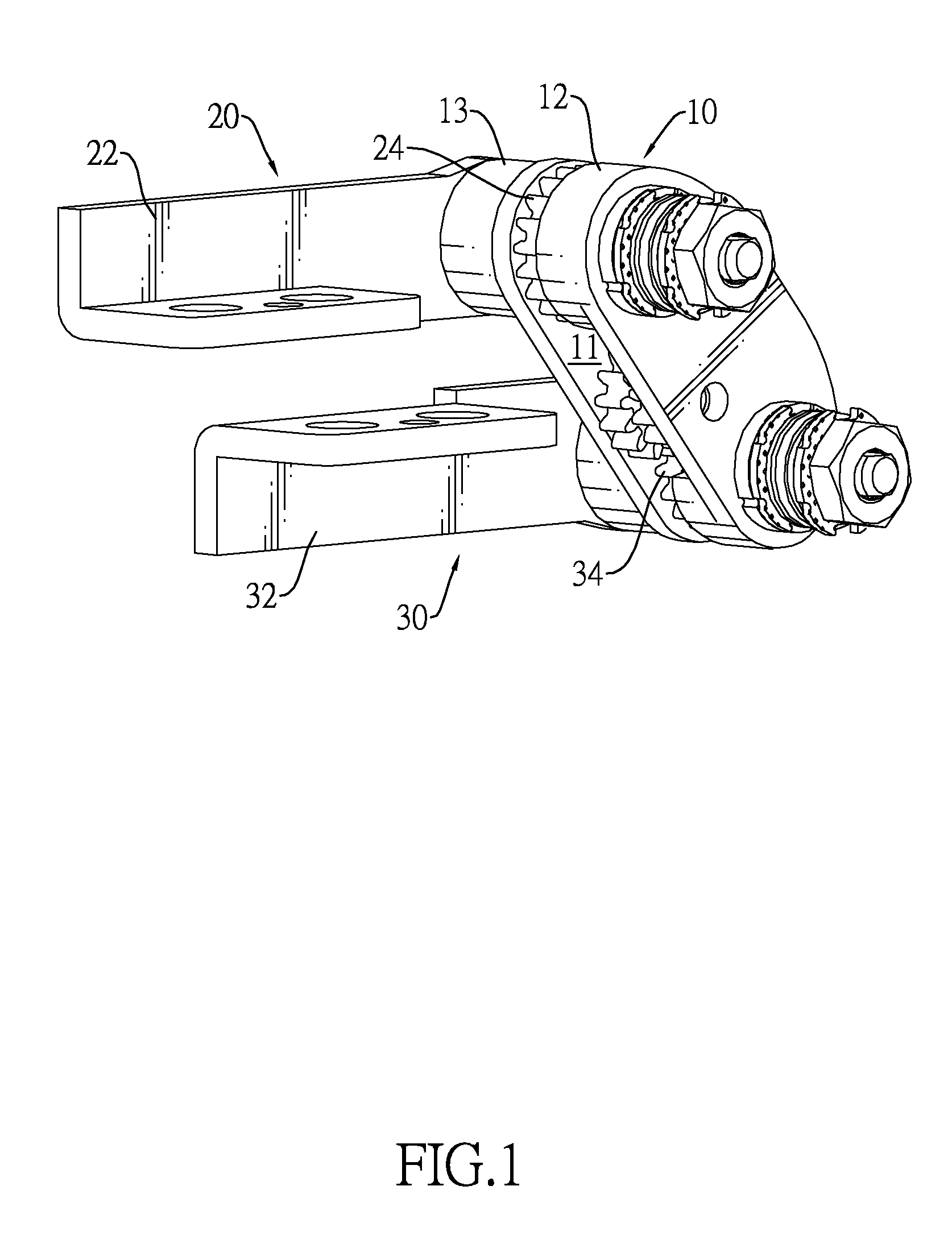

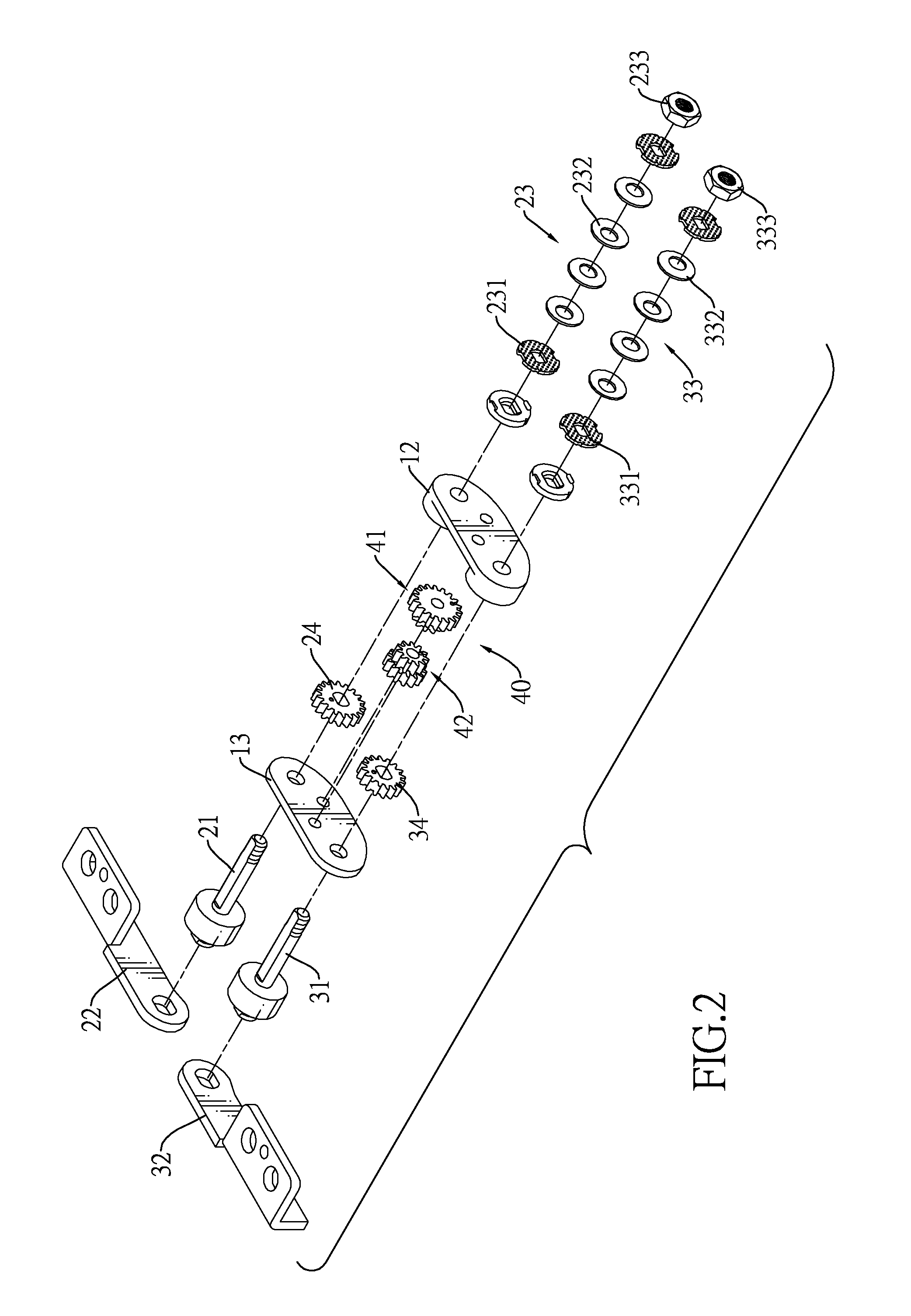

Dual-axis hinge and portable device with the same

A dual-axis hinge is mounted between a cover and a base of a portable device and has a connecting bracket, an upper rotating bracket, a lower rotating bracket, an upper active gear, a lower active gear and a transmission gear assembly. The connecting bracket is mounted between the upper and lower rotating brackets. The upper and lower active gears are connected respectively to the upper and lower rotating brackets. The transmission gear assembly is connected between the upper and lower active gears to adjust a velocity ratio of the upper and lower active gears. Therefore, the cover and the base align with each other without a drop whether or not the upper and lower active gears are the same in teeth number or whether or not the included angles between the upper and lower rotating brackets with the connecting bracket are the same.

Owner:SHIN ZU SHING

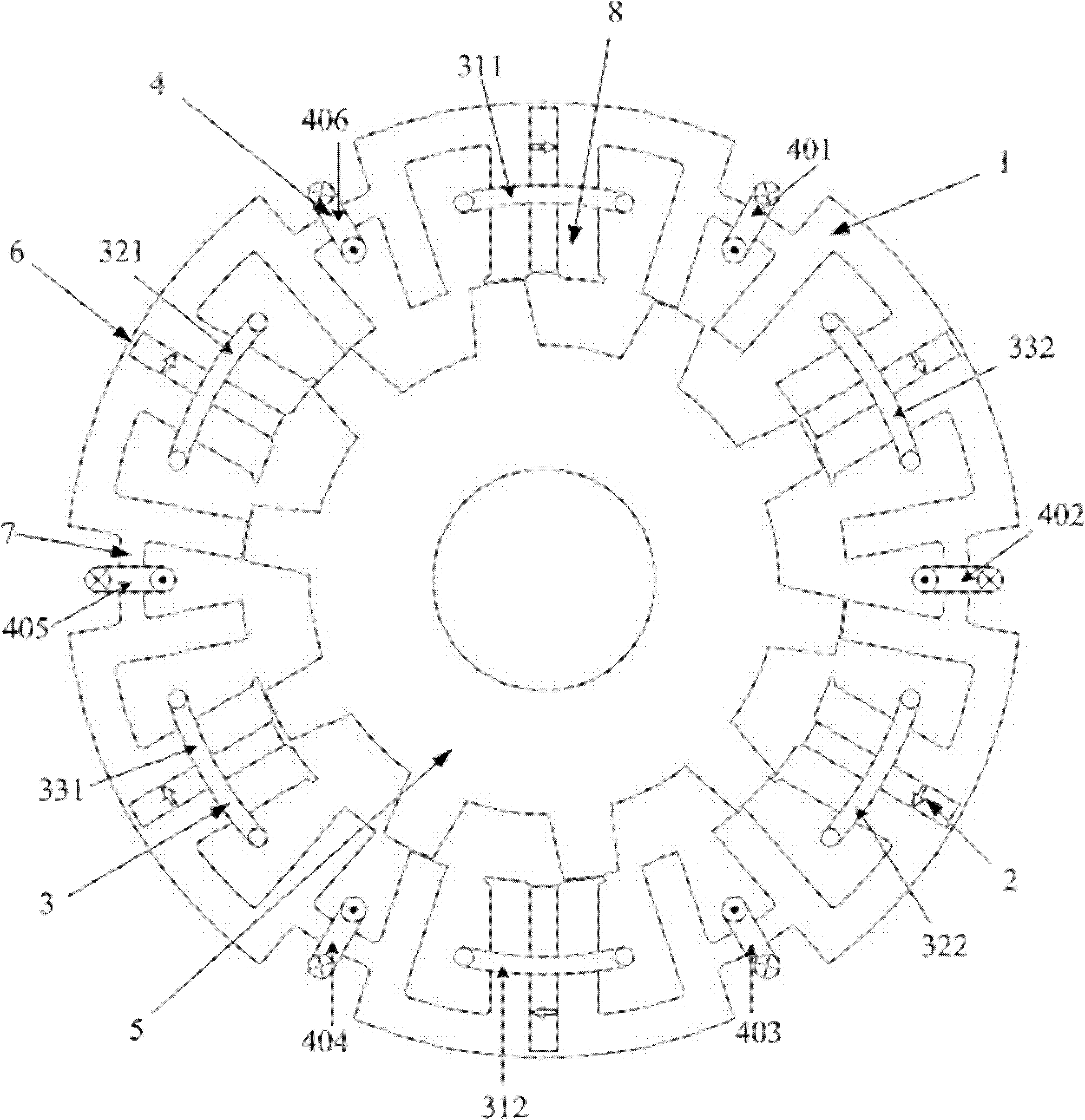

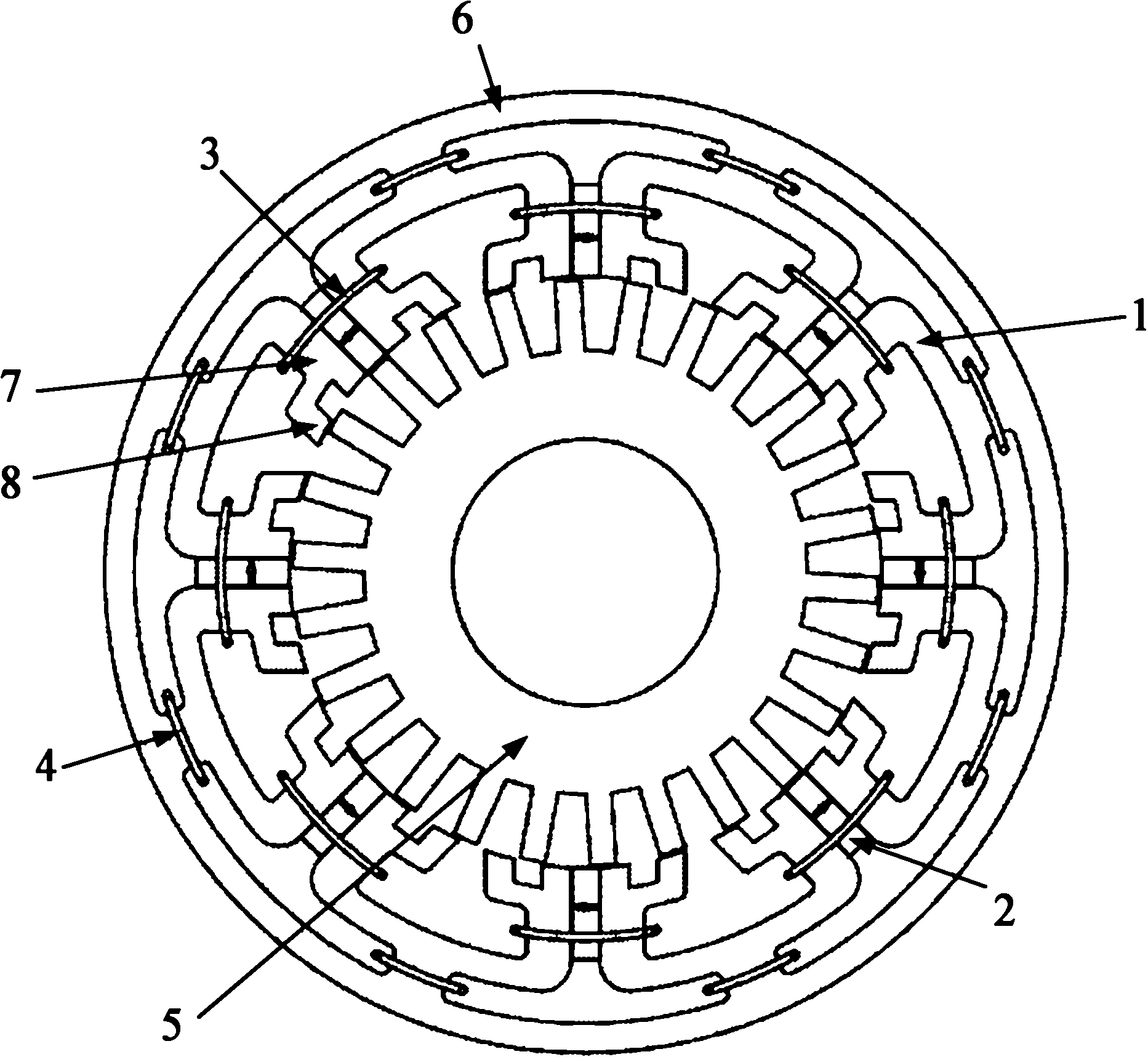

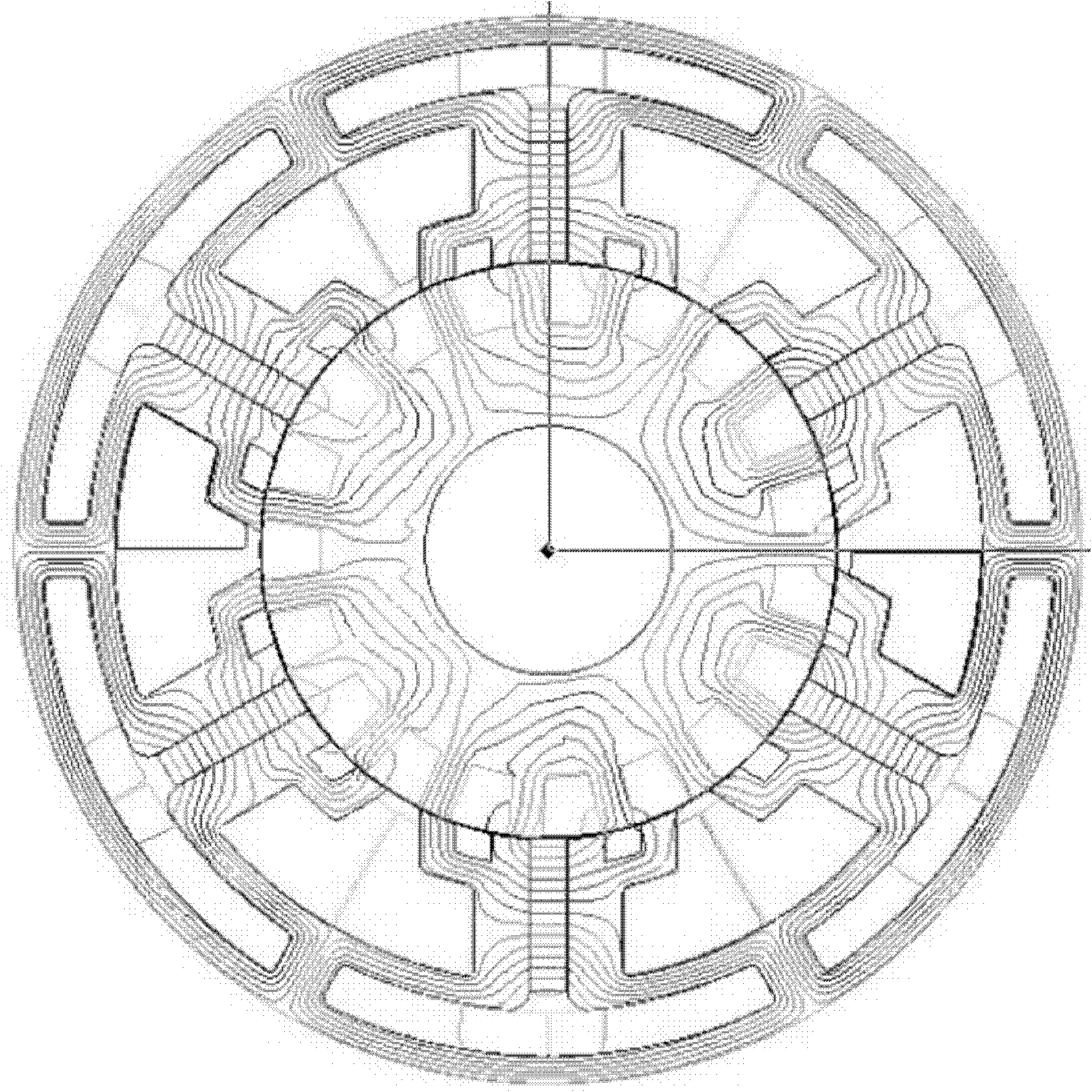

Mixed excitation permanent magnet flux switching motor

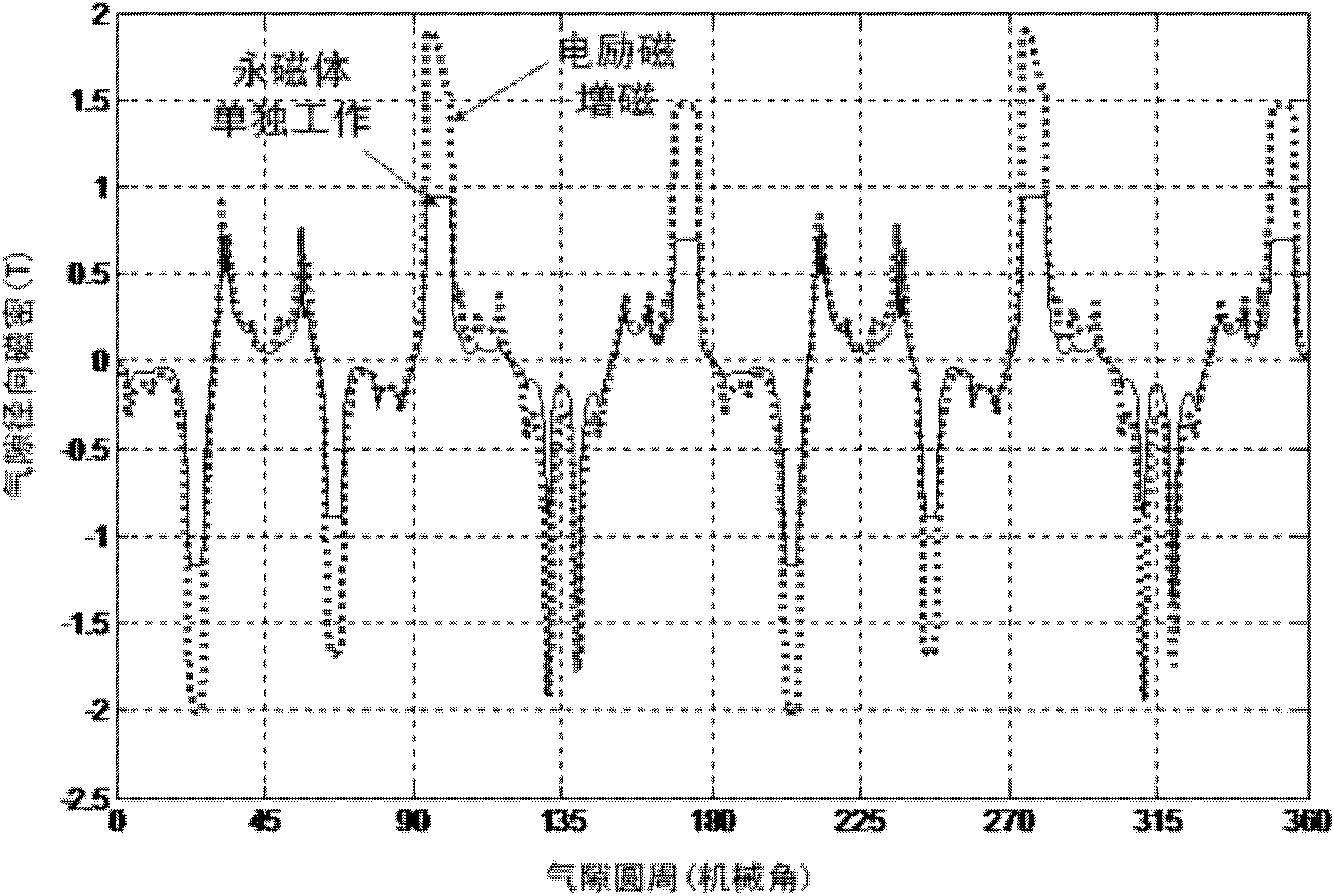

InactiveCN101820192AImprove tuning performanceReduced ampere-turnsMagnetic circuit rotating partsMagnetic circuit stationary partsTooth numberConductor Coil

The invention discloses a mixed excitation permanent magnet flux switching motor which comprises permanent magnets, three-phase armature windings and single-phase excitation windings, wherein the single-phase excitation windings are arranged on a stator, the tooth number of the stator is 4 times number of permanent magnets; and a rotor is in a salient pole structure and has no windings or permanent magnets, thereby having high mechanical strength and being suitable for high-speed operation. An air-gap field comprises an electric excitation magnetic field generated by the excitation windings and a magnetic field generated by the permanent magnets, and is flexibly adjusted by changing an excitation current. An electric excitation magnetic line of force is closed by using an iron core connecting magnetic bridge, which is beneficial to reducing the electric field ampere-turns and lowering the electric excitation copper loss. The armature windings and the excitation windings are distributed in different stator grooves at intervals, which is beneficial to increasing the self-inductance of the armature windings and the mutual inductance of the windings and effectively inhibiting the short circuit current of a motor.

Owner:CHANGZHOU INST OF TECH

Planetary-harmonic motor

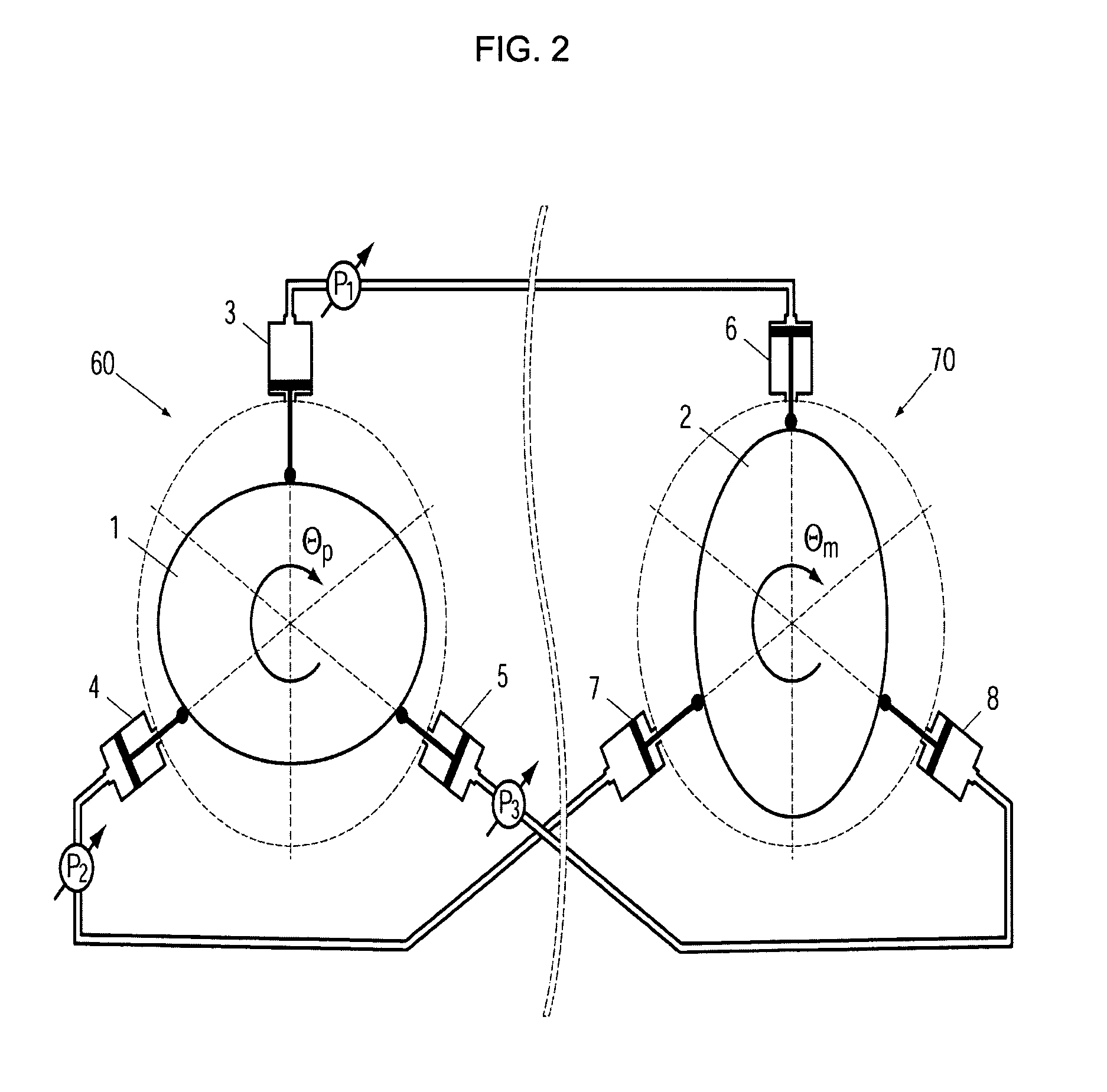

A motor suitable for use in a medical imaging environment has (a) a centrally located means for actuating a radial wave, (b) a deformable flexspline having an inner surface and a toothed outer surface with a first specified number of teeth, and (c) a circular spline having a toothed inner surface with a second specified number of teeth which is different than the first specified number of teeth in the flexspline, wherein the actuation means is operable so that the action of its radial wave causes at least one of the flexspline teeth to engage at a point the toothed side of the circular spline in such a manner that an engagement point passes as a wave around the inner perimeter of the circular spine, with the movement of this engagement point causing the flexspline to rotate around its central axis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

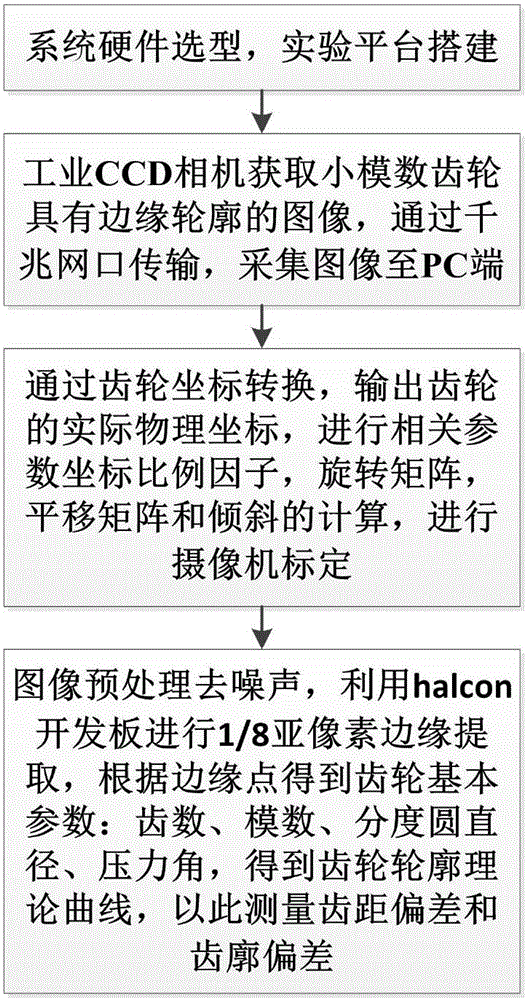

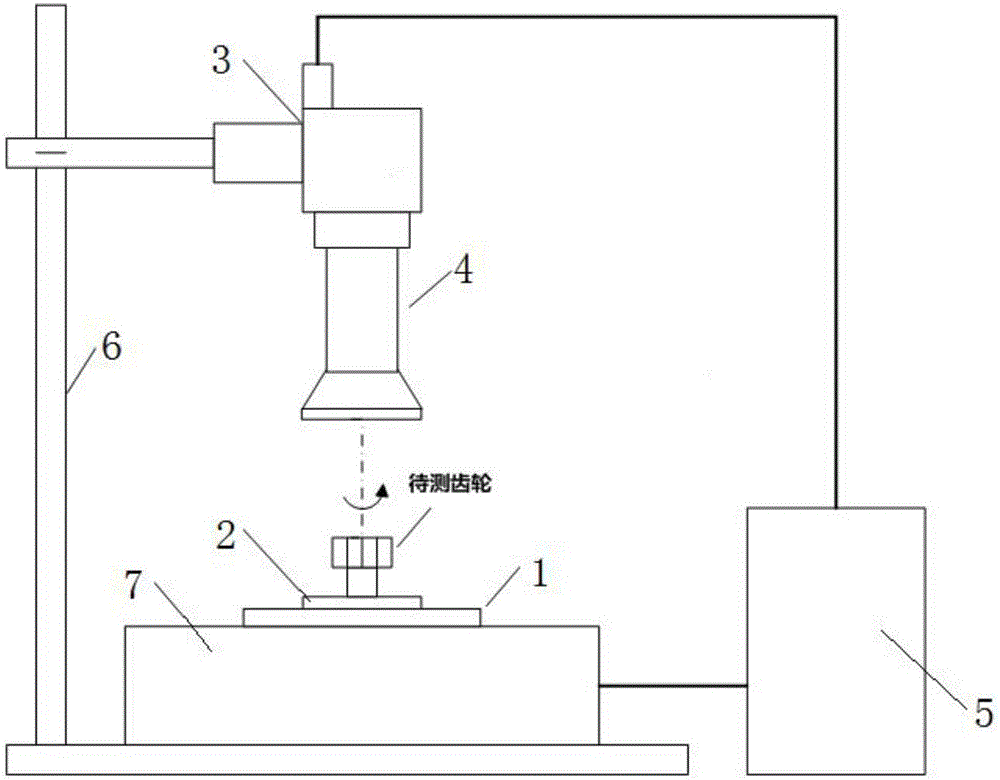

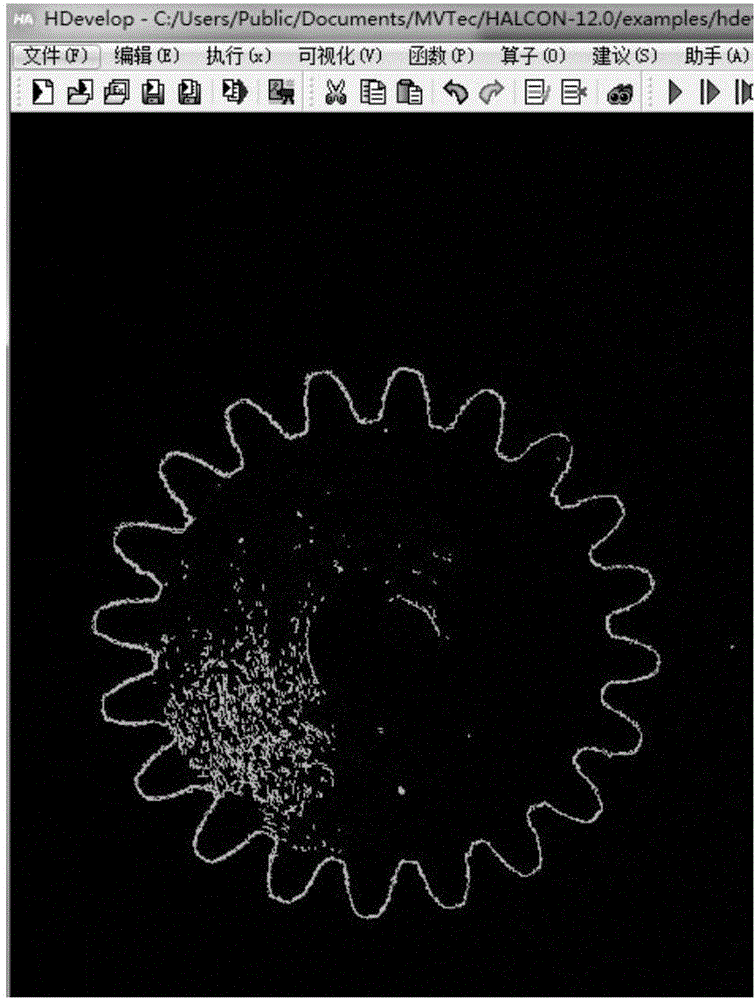

High-precision small modulus gear vision measurement method

A high-precision small modulus gear vision measurement method is disclosed. The method is characterized by after a CCD camera is calibrated, carrying out small modulus gear coordinate conversion, outputting an actual physical coordinate of a small modulus gear and calculating a correlation parameter coordinate scale factor, a rotation matrix and a translation matrix; reflecting a space position relation between a gear to be measured and a measurement system in the measurement system; carrying out image processing, wherein a processed object is a small modulus gear edge contour image acquired from a CCD camera 3; and carrying out denoising; then using and carrying out 1 / 8 sub-pixel edge extraction, extracting an edge point coordinate, carrying out center fitting and acquiring a center coordinate of the image; according to an edge point, acquiring a basic gear parameter, wherein the basic parameter is a tooth number, a mode number, a reference circle diameter and a pressure angle; fitting a standard gear contour curve; and comparing an actually-acquired edge contour curve with a theoretical contour curve so as to acquire a pitch deviation and a tooth profile deviation. The basic gear parameter and quality can be comprehensively analyzed and evaluated.

Owner:BEIJING UNIV OF TECH

Planetary-harmonic motor

A motor suitable for use in a medical imaging environment has (a) a centrally located means for actuating a radial wave, (b) a deformable flexspline having an inner surface and a toothed outer surface, with the flexspline coaxially aligned with the central axis of the radial wave actuating means and oriented such that the flexspline inner surface is proximate the outer boundary surface of the actuation means, and with the flexspline toothed outer surface having a first specified number of teeth, and (c) a circular spline having a toothed inner surface, this spline having an outer boundary surface and being coaxially aligned with the central axis and oriented such that the spline toothed inner surface is proximate the flexspline's toothed outer surface, with the spline inner surface having a second specified number of teeth which is different than the first specified number of teeth in the flexspline, wherein the actuation means is operable so that the action of its radial wave causes at least one of the flexspline teeth to engage at a point the toothed side of the circular spline in such a manner that an engagement point passes as a wave around the inner perimeter of the circular spine, with the movement of this engagement point causing the flexspline to rotate around its central axis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

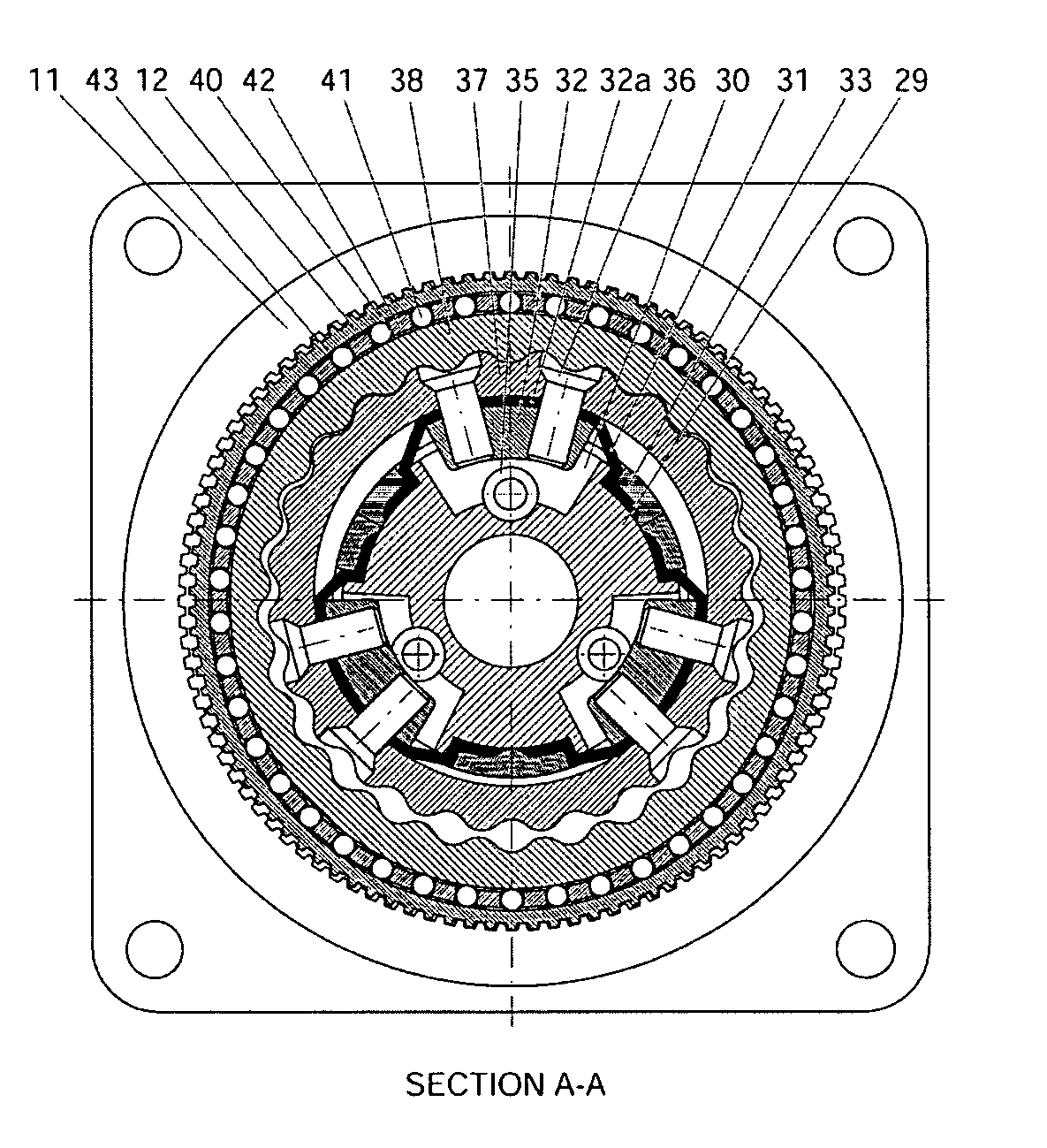

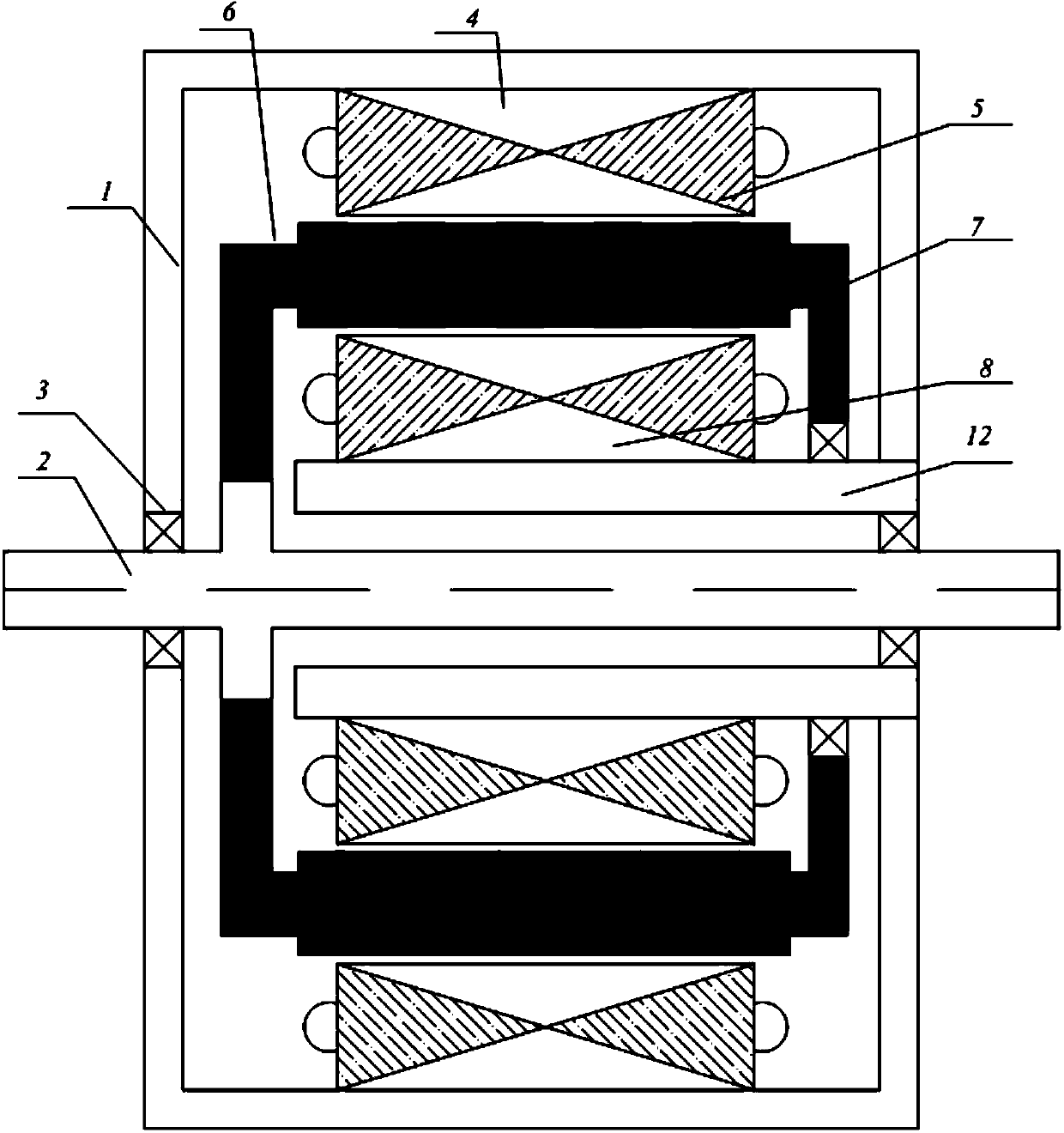

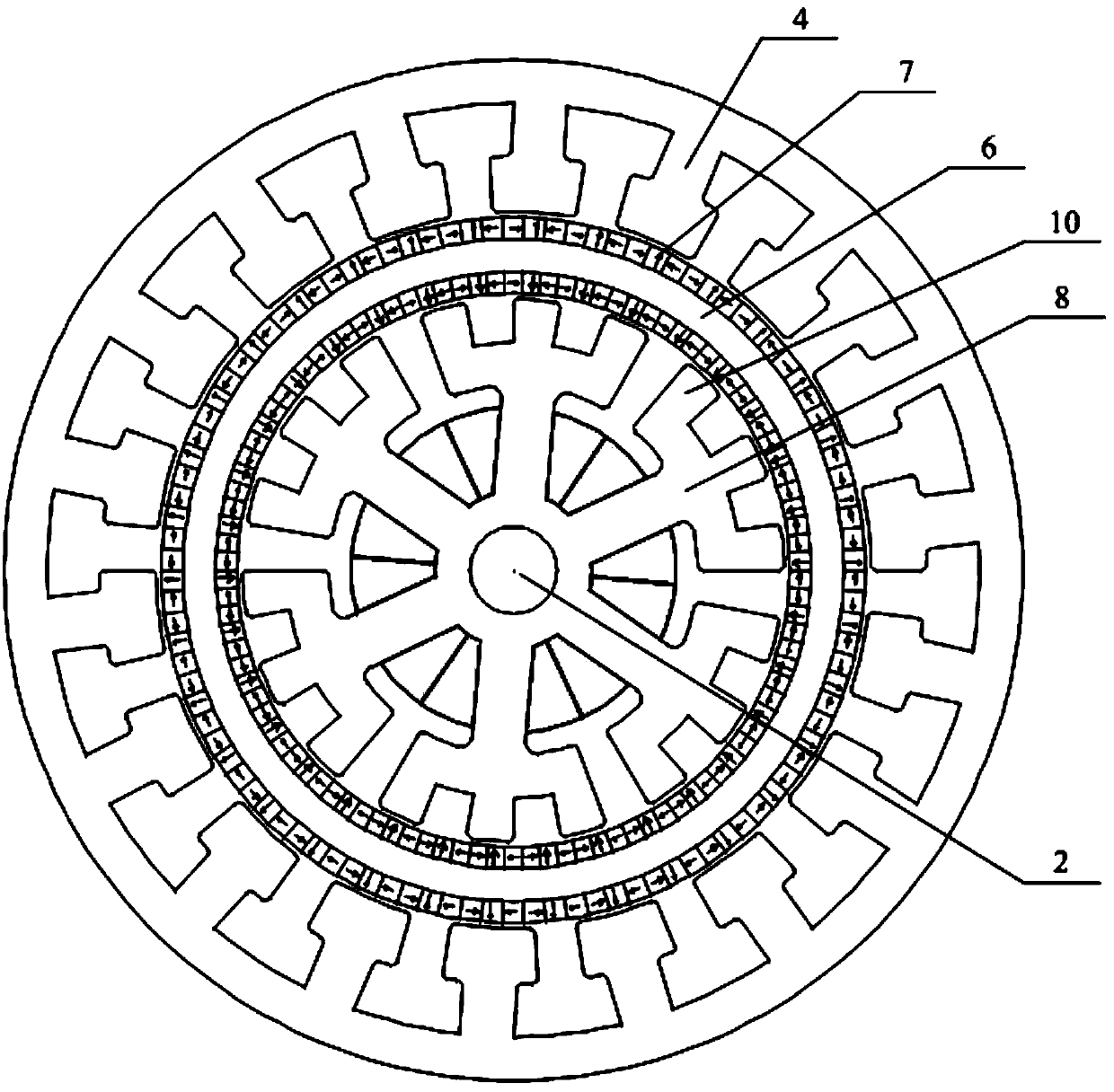

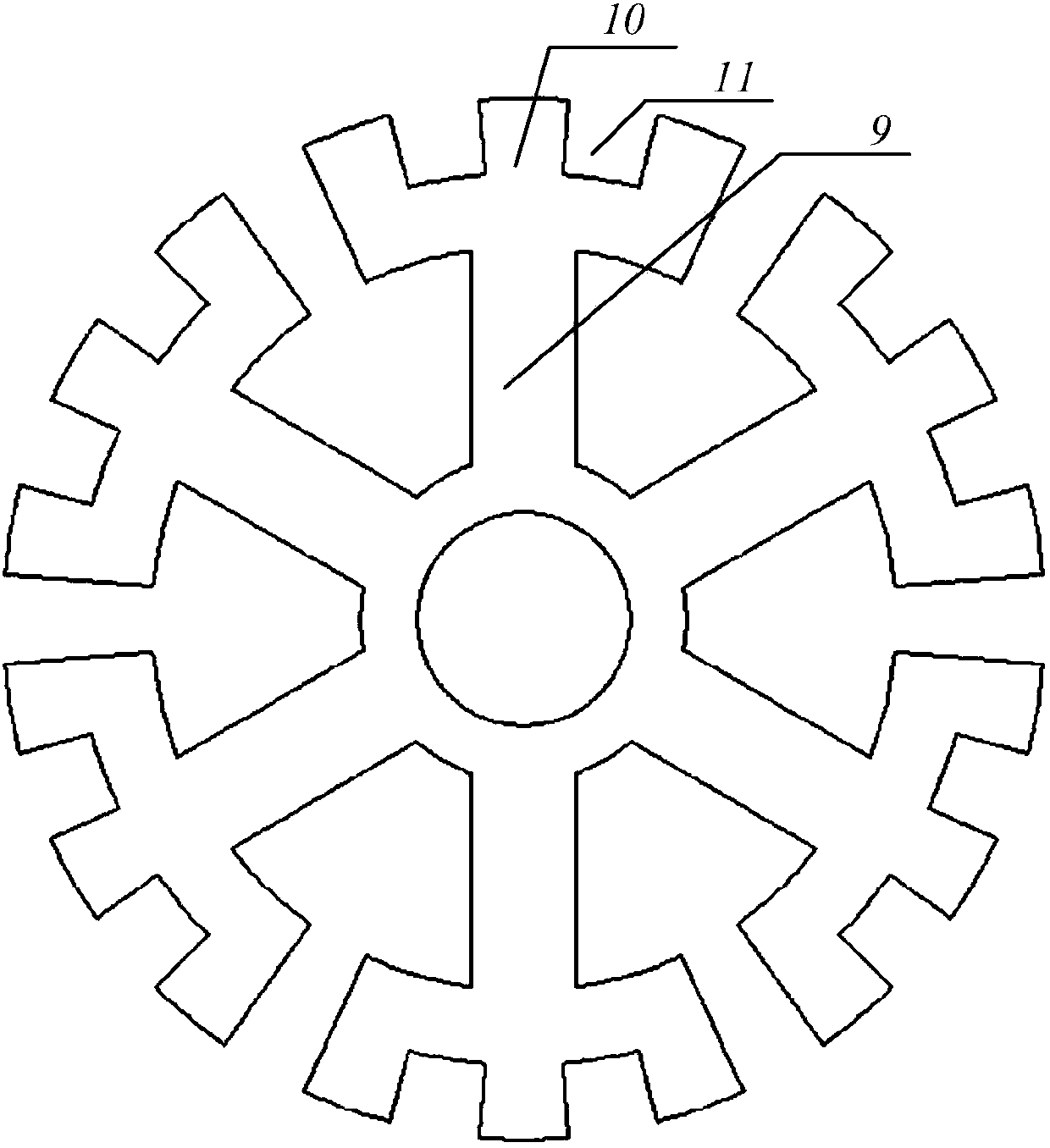

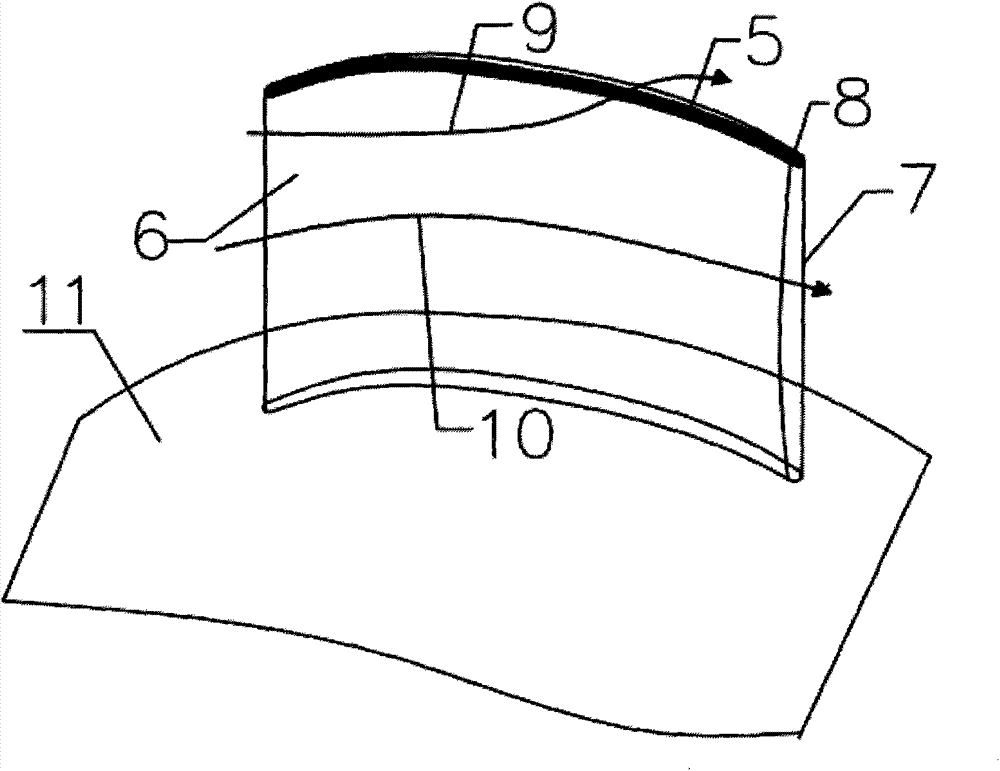

Double-stator permanent-magnet vernier wind driven generator

ActiveCN104201848AIncreased torque densityIncrease sineMagnetic circuit rotating partsMagnetic circuit stationary partsWind drivenThermodynamics

The invention discloses a double-stator permanent-magnet vernier wind driven generator, and belongs to the field of motor manufacturing. The double-stator permanent-magnet vernier wind driven generator comprises an outer stator (4), an inner stator (8) and a rotor (6), wherein the outer stator is provided with a pear-shaped groove and first stator teeth; the inner stator (8) is provided with second stator teeth (9), and each second stator tooth (9) is provided with a flux modulation electrode (10) and a flux modulation electrode groove (11); the rotor (6) is of a cup-shaped structure, and a Halbach-structure permanent magnet (7) is arranged on the rotor; the tooth number of the first stator teeth of the outer stator (4) is equal to that of the teeth of the flux modulation electrode (10); moreover, the pear-shaped groove of the outer stator (4) and the flux modulation electrode (10) are oppositely distributed and arranged, and the first stator teeth of the outer stator (4) and the flux modulation electrode groove (11) are oppositely distributed and arranged. The double-stator permanent-magnet vernier wind driven generator disclosed by the invention is capable of generating a high-sine air-gap magnetic field, and has the characteristic of a high output torque.

Owner:SOUTHEAST UNIV

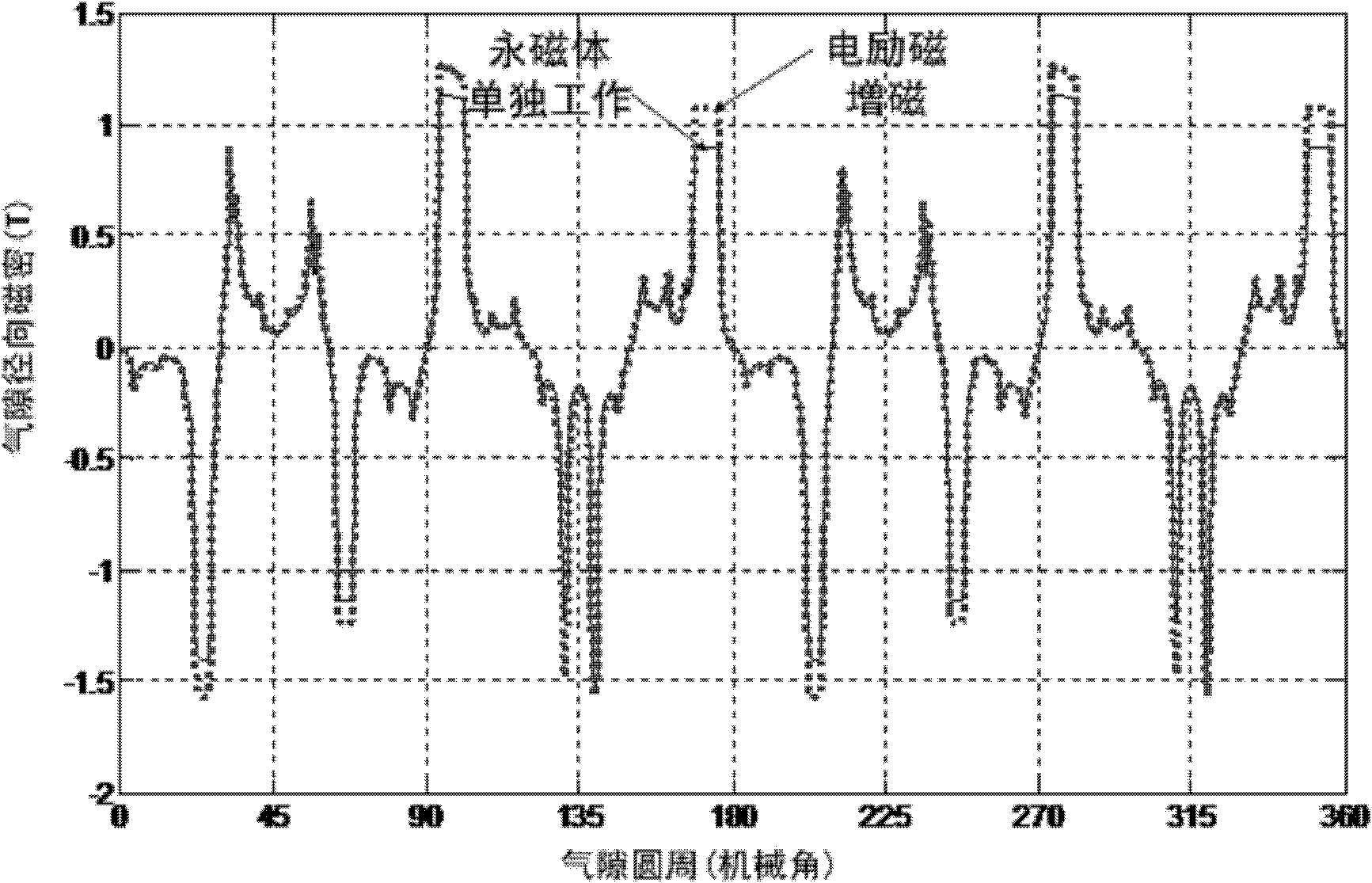

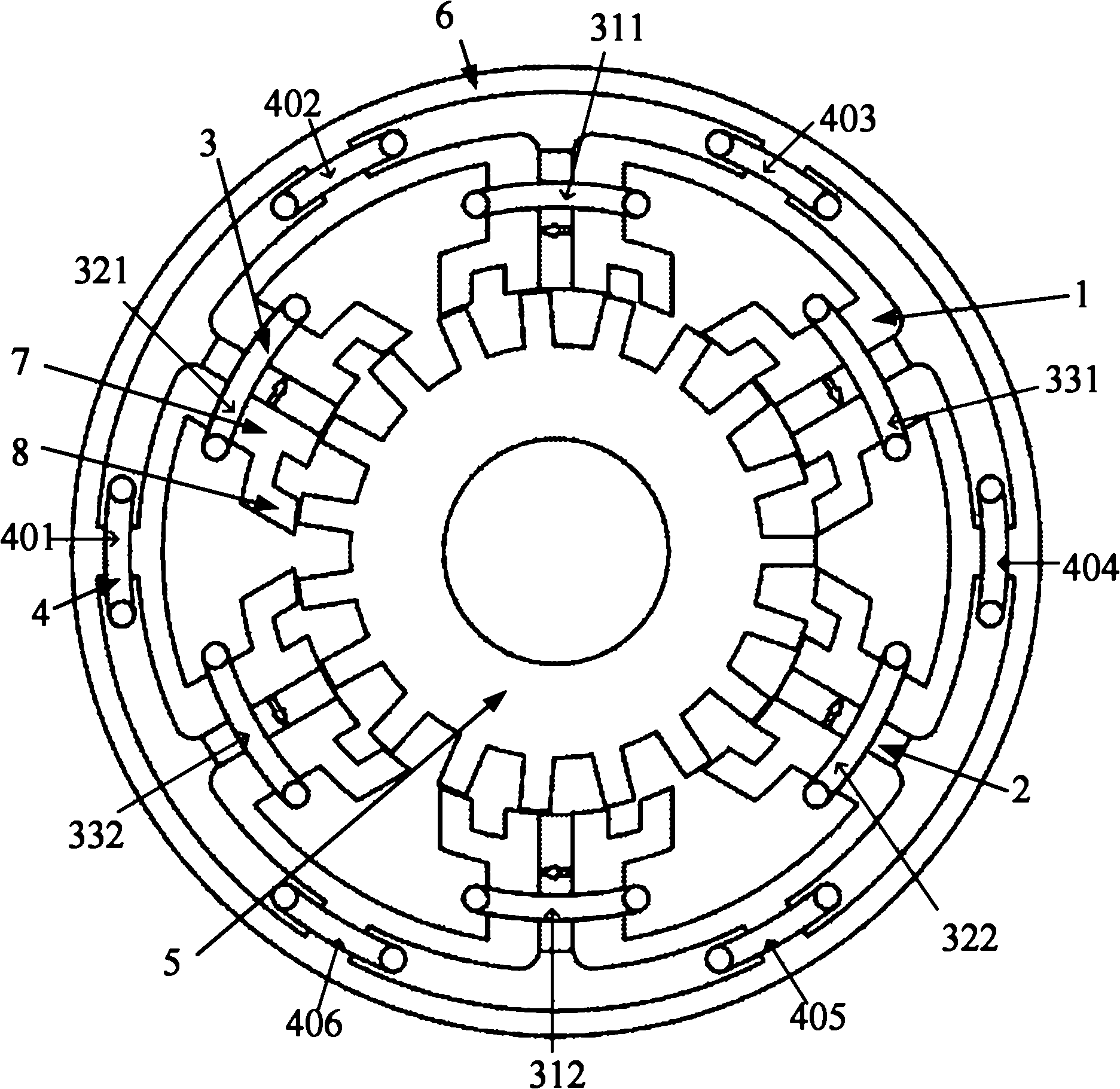

Multitooth magnetic bridge type hybrid excitation magnetic flux switching motor

InactiveCN101834474AReduced risk of irreversible demagnetizationReduce lossMagnetic circuit stationary partsLow speedTooth number

The invention discloses a multitooth magnetic bridge type hybrid excitation magnetic flux switching motor. Permanent magnets, an armature winding and a single-phase excitation winding are installed on a stator; the tooth number of the stator is four times of the number of the permanent magnets; and part of a rotor part is a salient pole, and a rotor has no winding or permanent magnets and has simple and firm structure. An air gap magnetic field comprises an electric excitation magnetic field generated by the excitation winding and a magnetic field generated by the permanent magnets and is adjusted by changing the magnitude and the direction of excitation current, thereby improving the rotating speed operating range and the magnetic weakening capability of the motor. An electric excitation magnetic force line is connected with a magnetic bridge for closing after penetrating through an iron core at the top of the permanent magnets, which is beneficial to reducing the electric excitation ampere turns. The invention has parallel connecting structure of the excitation winding and the permanent magnet in space, bipolarity of phase magnetic flux, large magnetic chain change amplitude value and higher torque output capability and power density and is suitable for a low-speed straight application occasion.

Owner:CHANGZHOU INST OF TECH

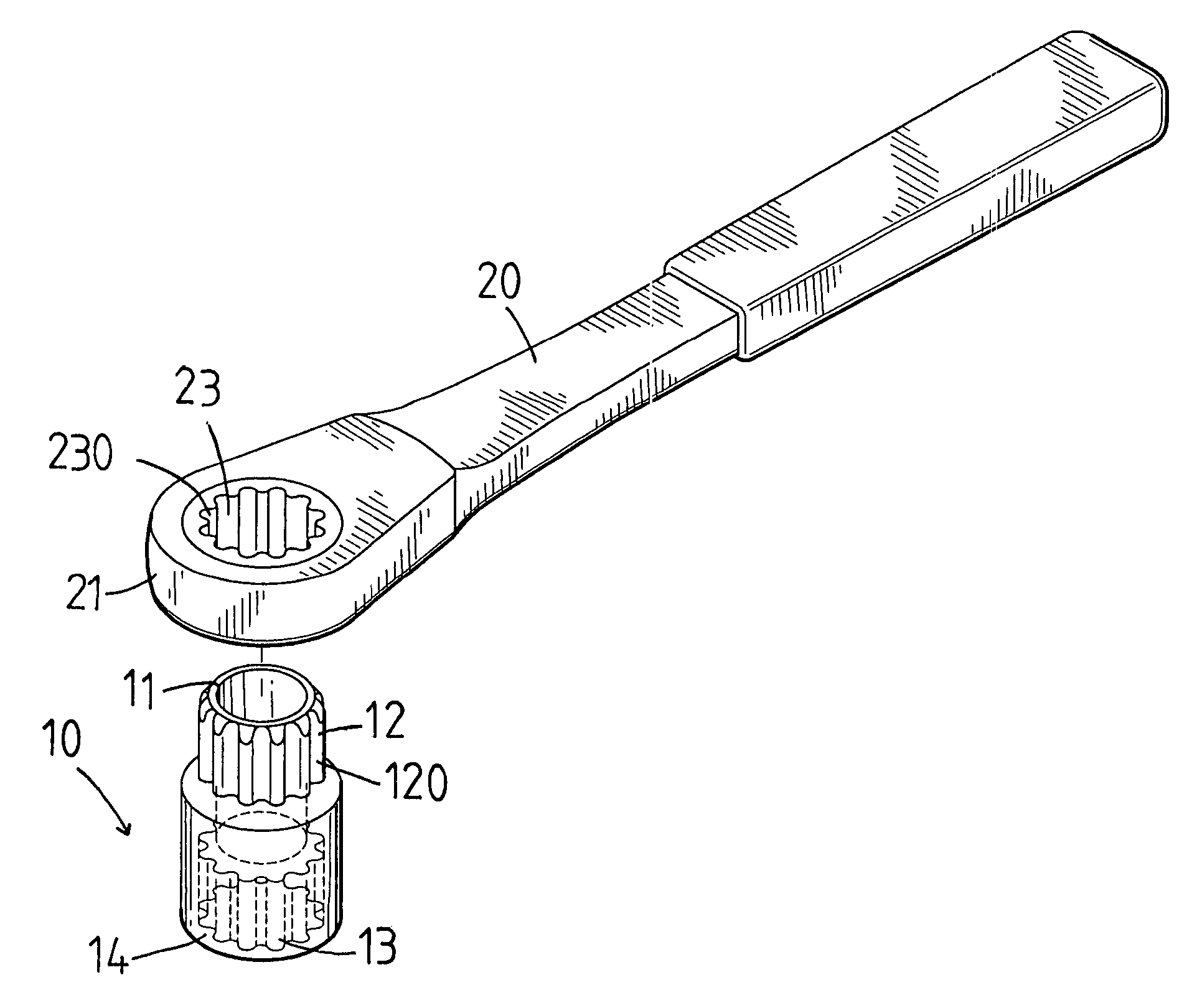

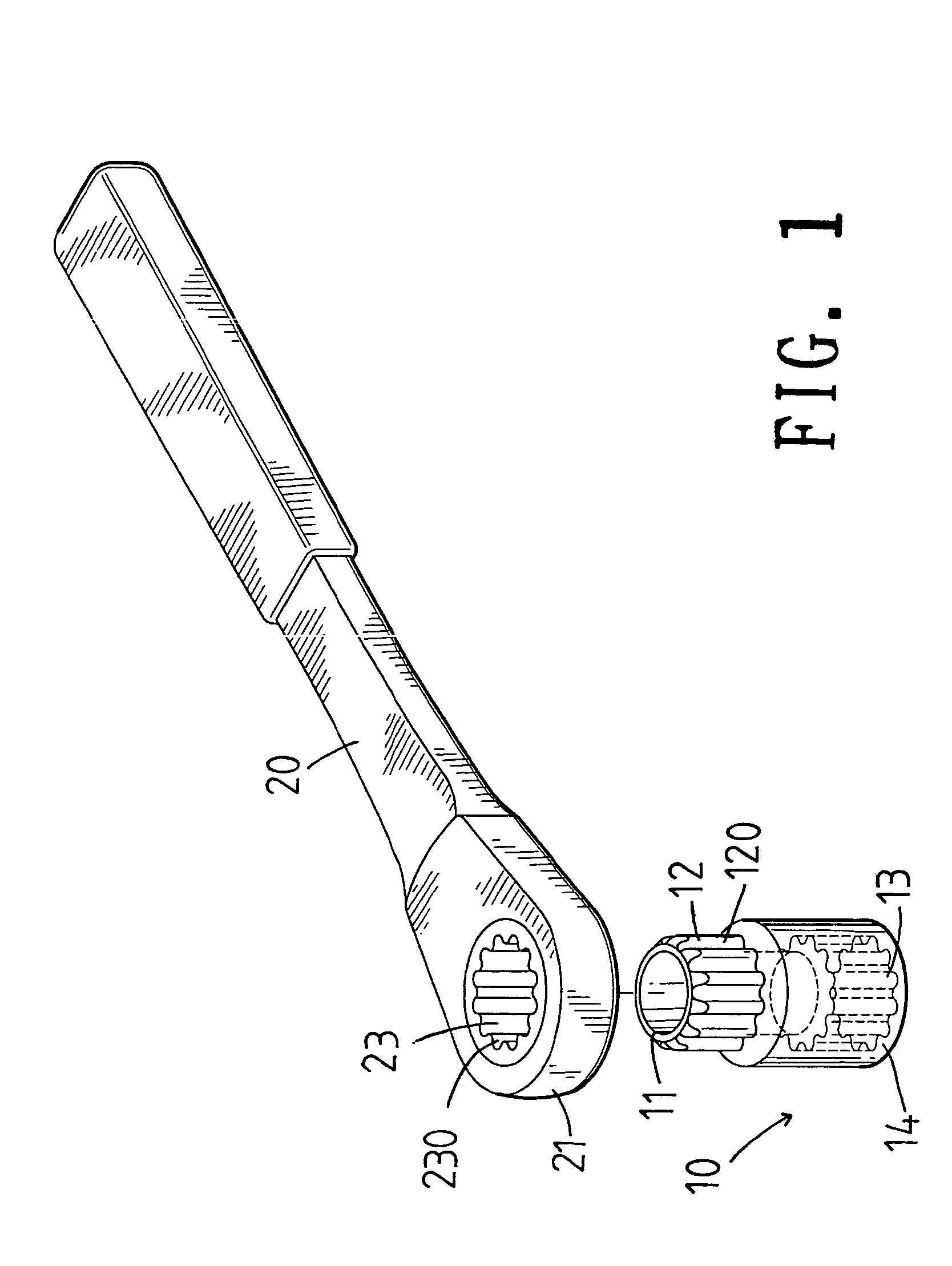

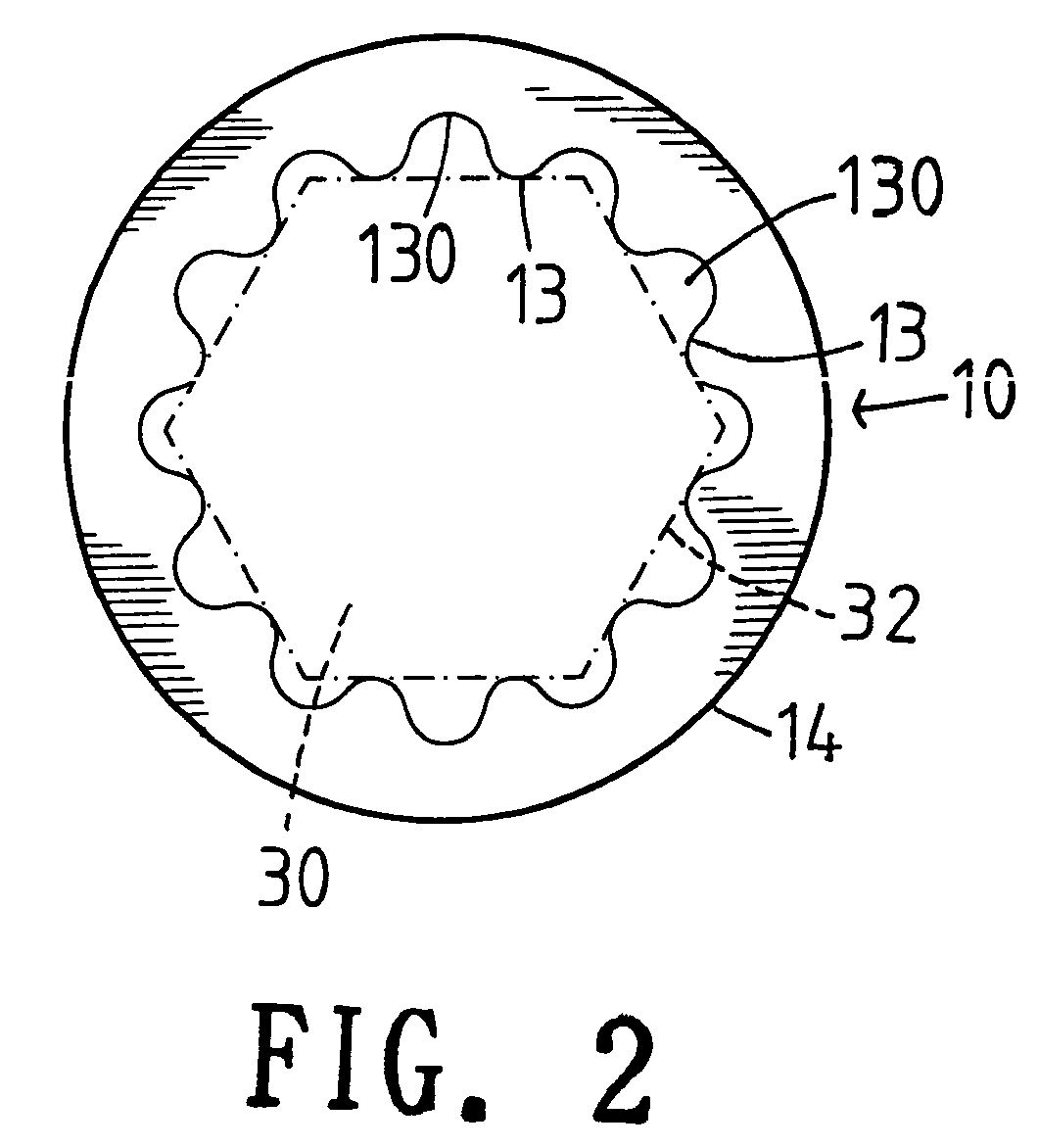

Socket

A socket includes a main body including a first cylinder having an outer periphery formed with a plurality of outer teeth, and a second cylinder having an inner periphery formed with a plurality of inner teeth. The inner teeth of the main body and the outer teeth of the main body have the same tooth number and have the corresponding tooth shape. Thus, the sockets can co-operate with each other to increase the working length, and the sockets co-operating with the ratchet wrench can be used in an elongated shallower space.

Owner:HSIEN CHIH CHING

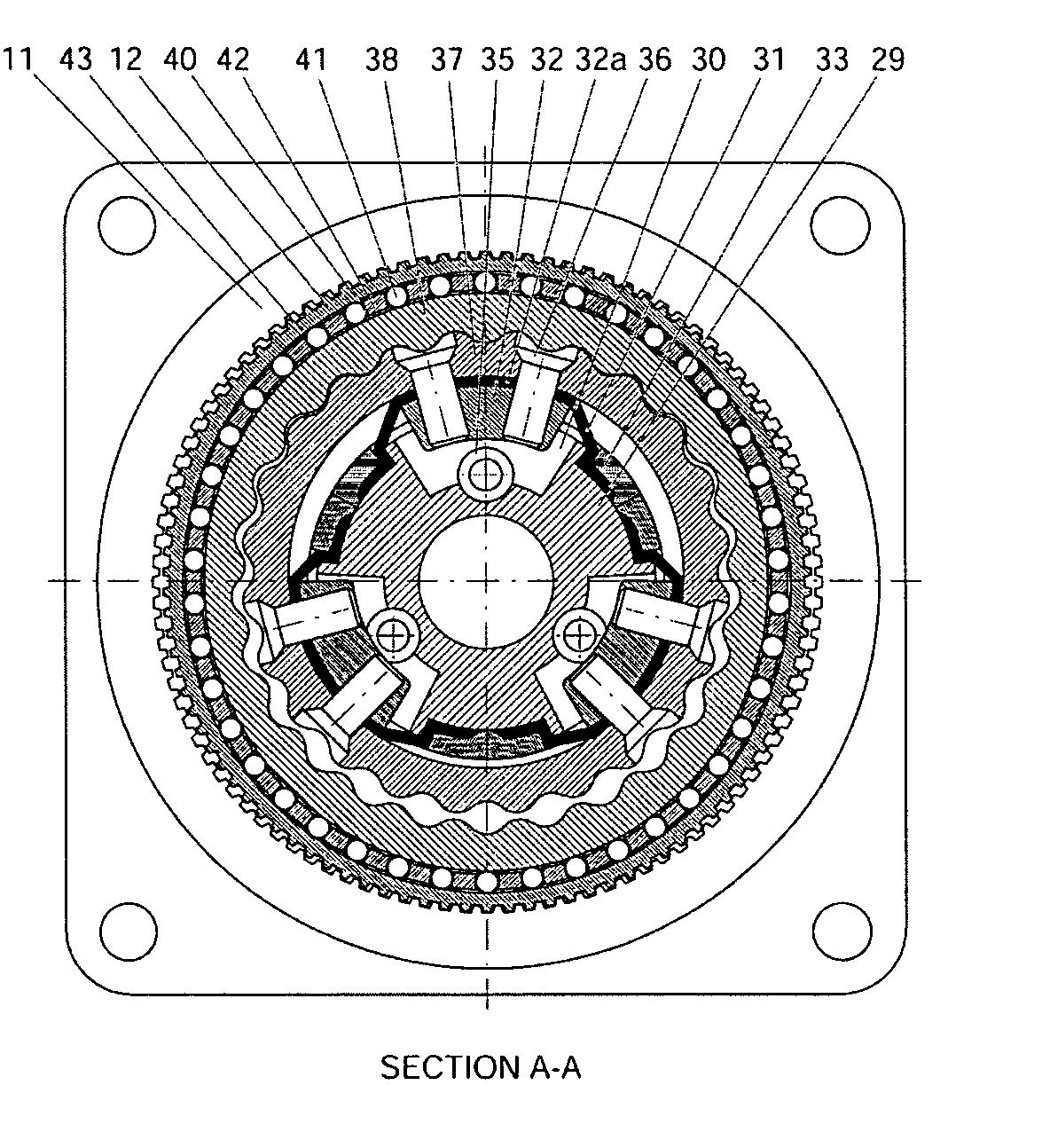

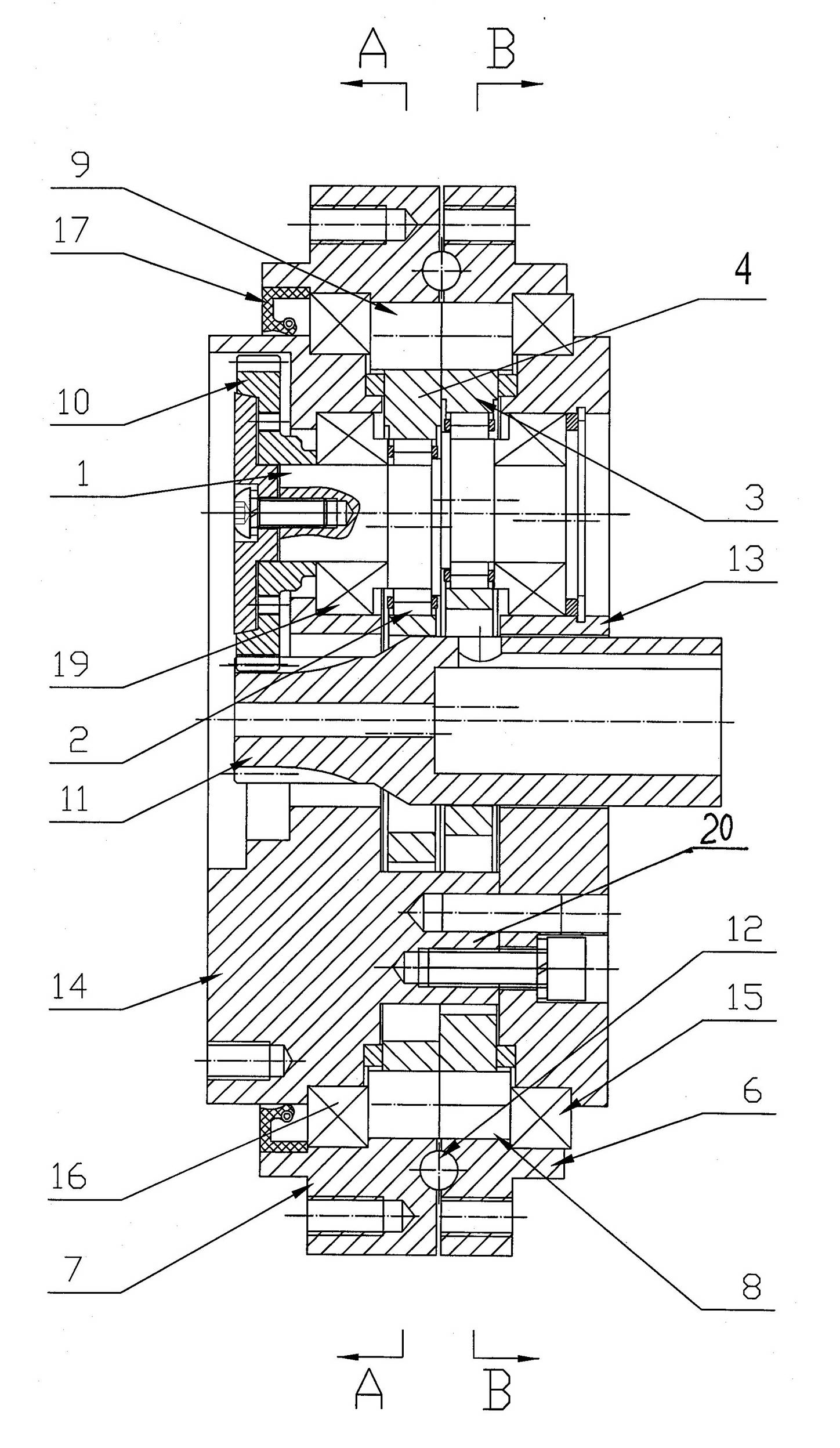

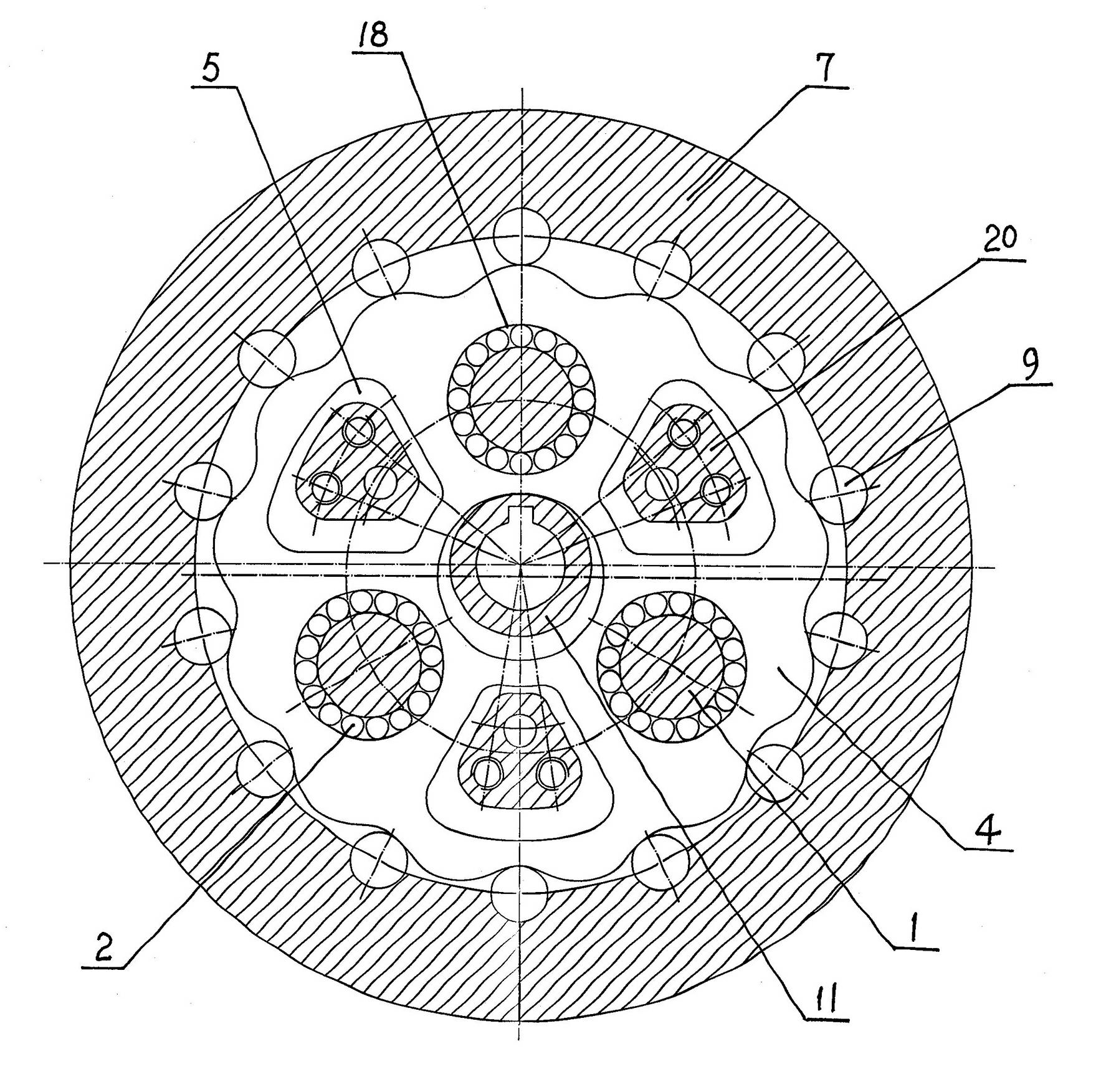

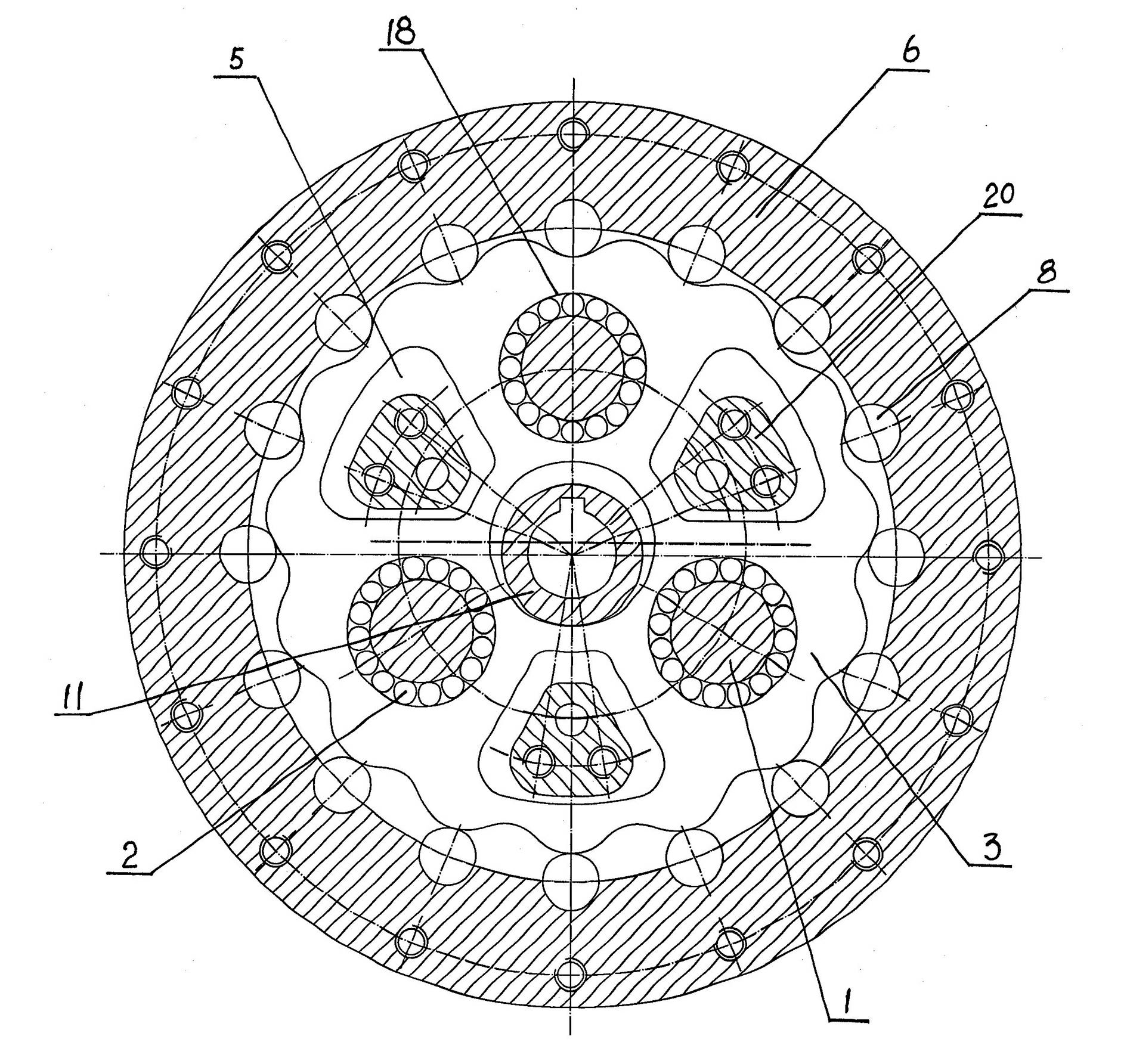

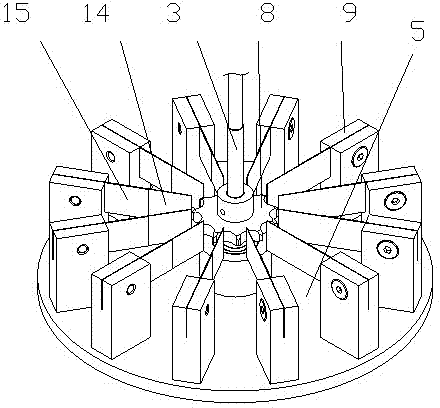

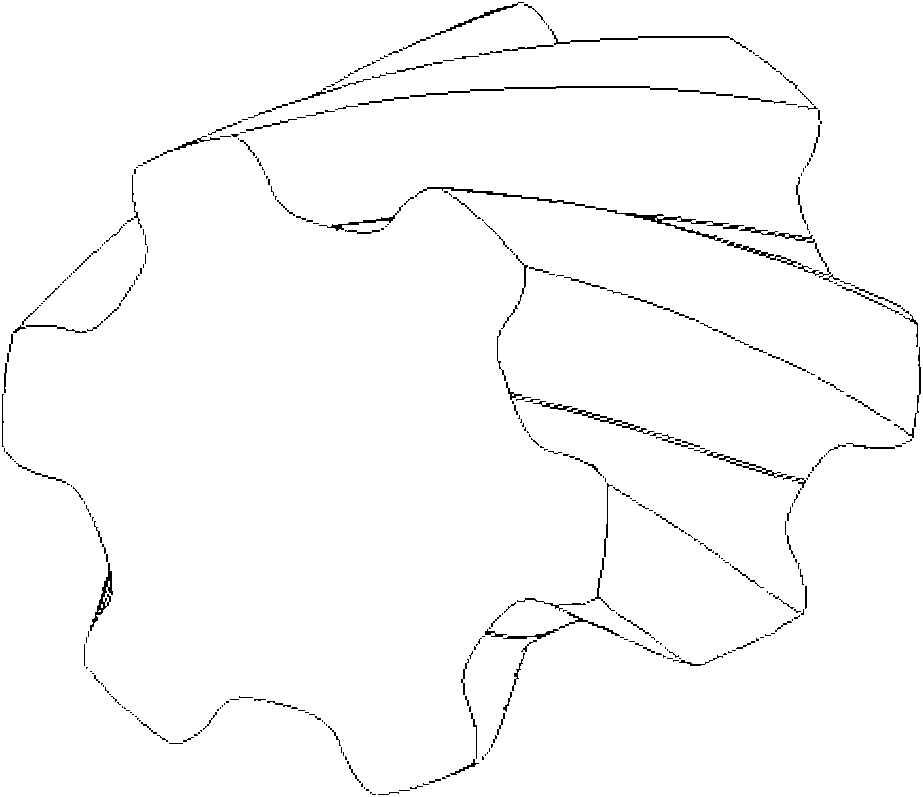

Complex precise cycloidal speed reducer

ActiveCN102252062AReduced number of teethImprove transmission efficiencyToothed gearingsEngineeringTooth number

The invention relates to a complex precise cycloidal speed reducer, which comprises an eccentric shaft, wherein the eccentric parts of the eccentric shaft are connected with cycloidal gears through turning arm bearings, the cycloidal gears are matched with pin tooth pins fixed on pin tooth shells, the eccentric shaft is provided with a plurality of staggered eccentric positions, the cycloidal gears outside the eccentric positions are divided into a group of negative cycloidal gears and a group of positive cycloidal gears, the negative cycloidal gears and the positive cycloidal gears have different tooth number and are provided with connecting transmission holes, the pin tooth shells are divided into static pin tooth shells and output pin tooth shells, the negative cycloidal gears are matched with the static pin tooth pins fixed on the static pin tooth shells, the positive cycloidal gears are matched with the follow-up pin tooth pins fixed on the output pin tooth shells, the eccentric shaft is connected with a gearwheel, and the gearwheel is engaged with an input shaft gear. By composite design of a primary involute planetary gear transmission and cycloidal pin wheel epicyclic gear train, the complex precise cycloidal speed reducer has the advantages of high precision, high efficiency, high rigidity, high bearing and long service life and is particularly suitable to be used in a heavy-duty industrial robot.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

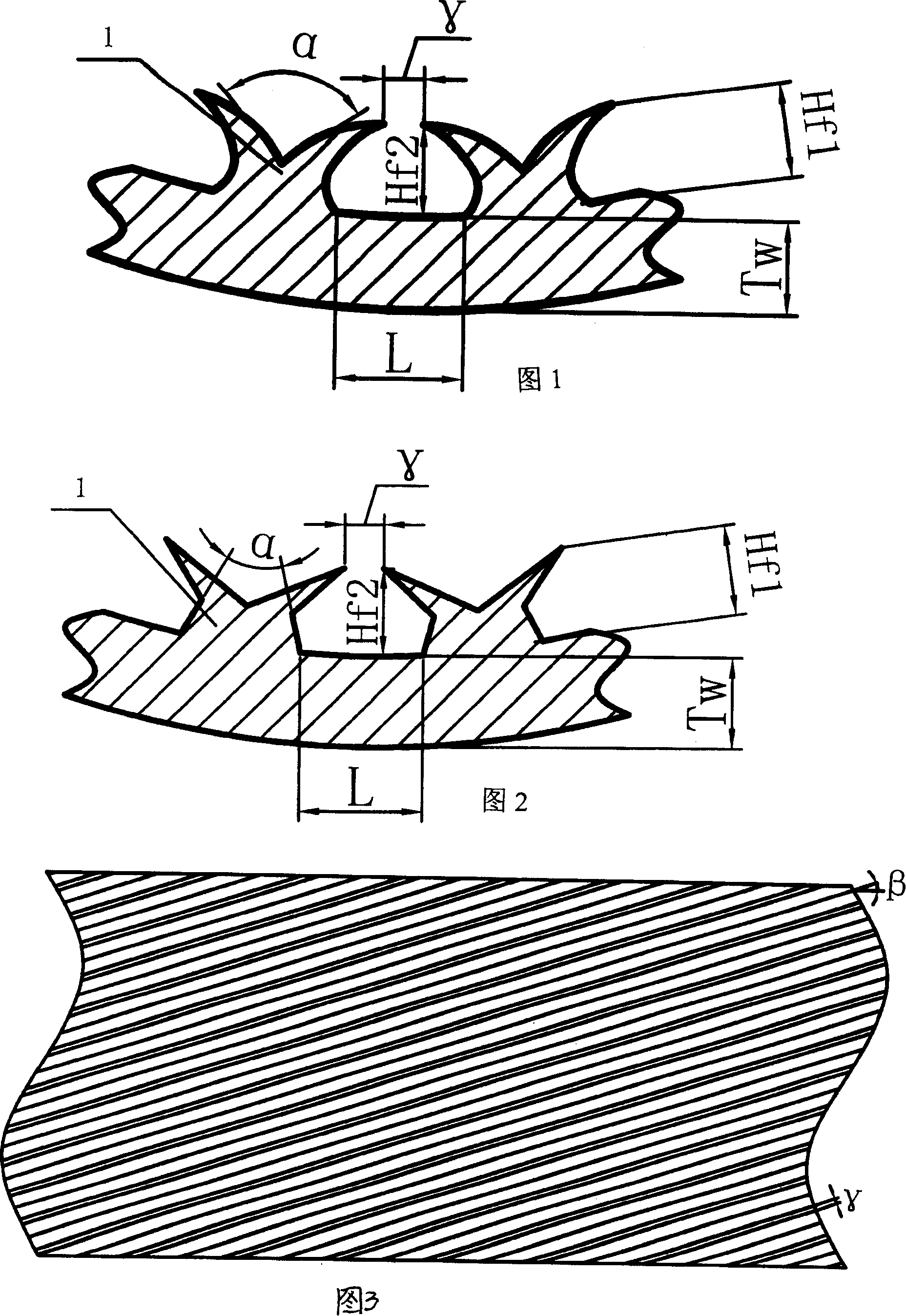

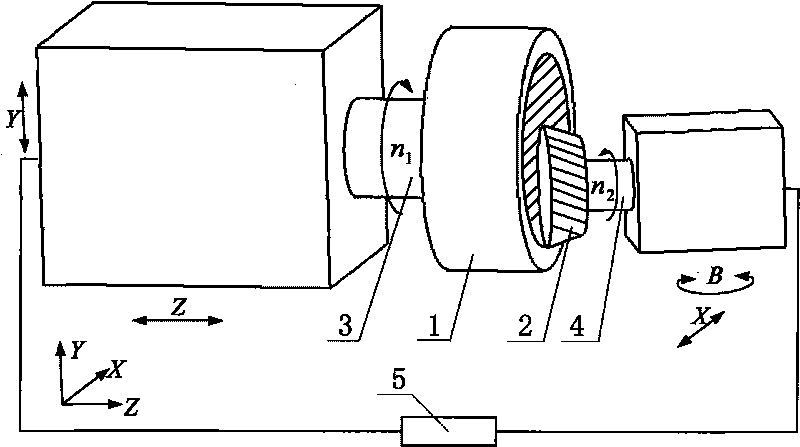

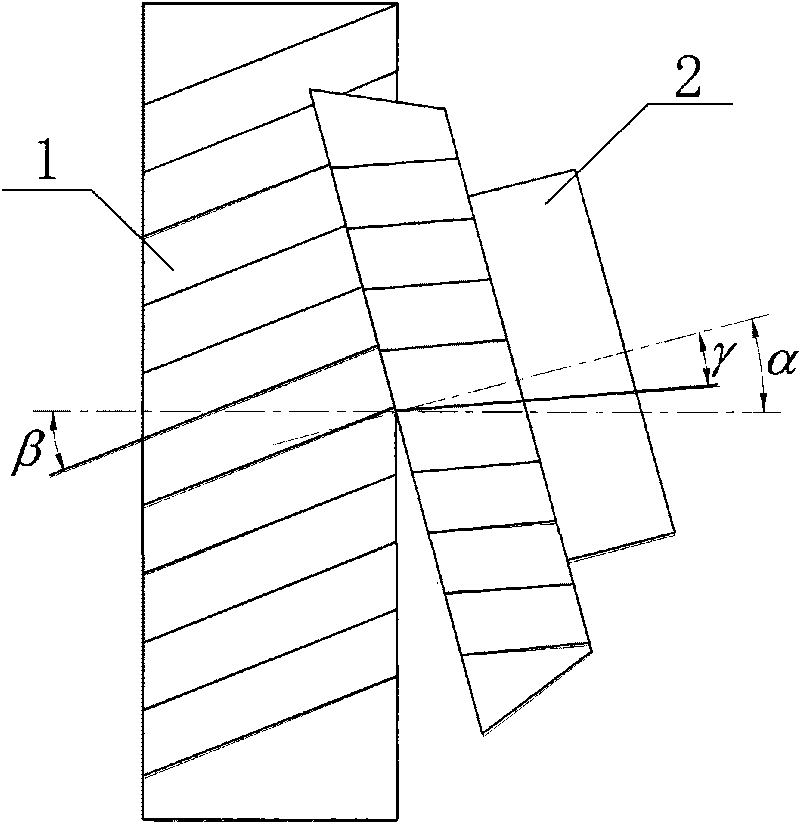

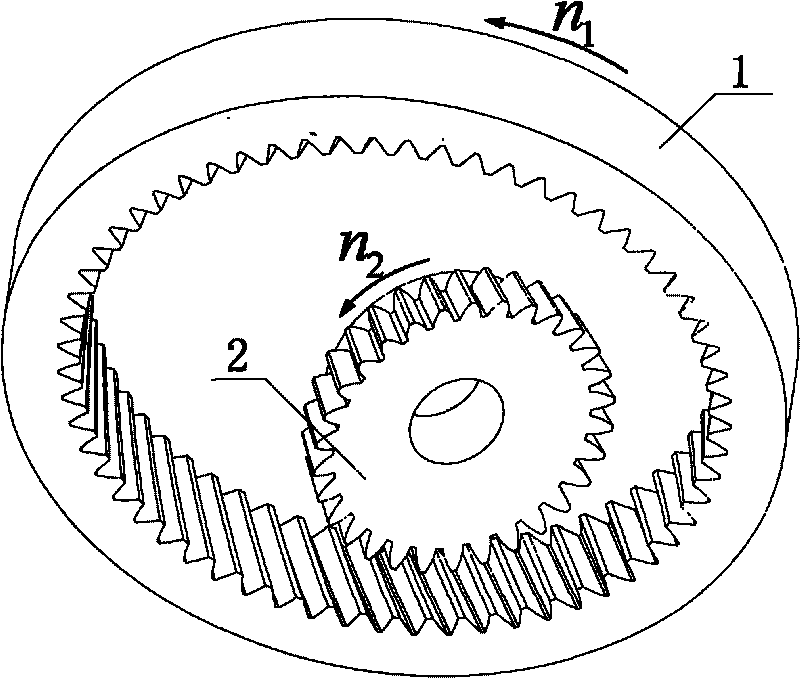

Method for machining cylindrical gear cutting teeth

InactiveCN101733486ASolve processing problemsImprove efficiencyGear teethManufacturing cost reductionGear wheel

The invention discloses a method for machining cylindrical gear cutting teeth. The rotation speeds of a workpiece and a cutter are n1 and n2 respectively, the ratio of the n1 to the n2 is equal to the ratio of the tooth number of the cutter and the workpiece, and the cutter is equivalent to a gear engaged with the workpiece. During machining, the axes of two main shafts of the workpiece and the cuter form a crossed axis angle alpha, and the angle alpha is the algebraic sum of a tooth directional spiral angle beta of the workpiece and a tooth directional spiral angle gamma of the cutter. The blade shape of the cutter is designed to be conjugate with the tooth shape of the workpiece; the rotations of the workpiece and the cutter are controlled by a multi-axis movement controller; and the cutter has axial feed and radial feed. At a cutting point, the cutting speed V is changed along with the change of the cutting point on the blade to form a cutting action so as to finish cutting and shaping of a gear tooth surface of the workpiece. The machining for a non-penetrating involute inner tooth can be finished without a tool withdrawal groove and cannot be finished by the existing gear machining technology. An inserting tooth and a pull tooth can be replaced, the machining precision and efficiency can be improved, and the manufacturing cost can be greatly reduced.

Owner:TIANJIN UNIV +1

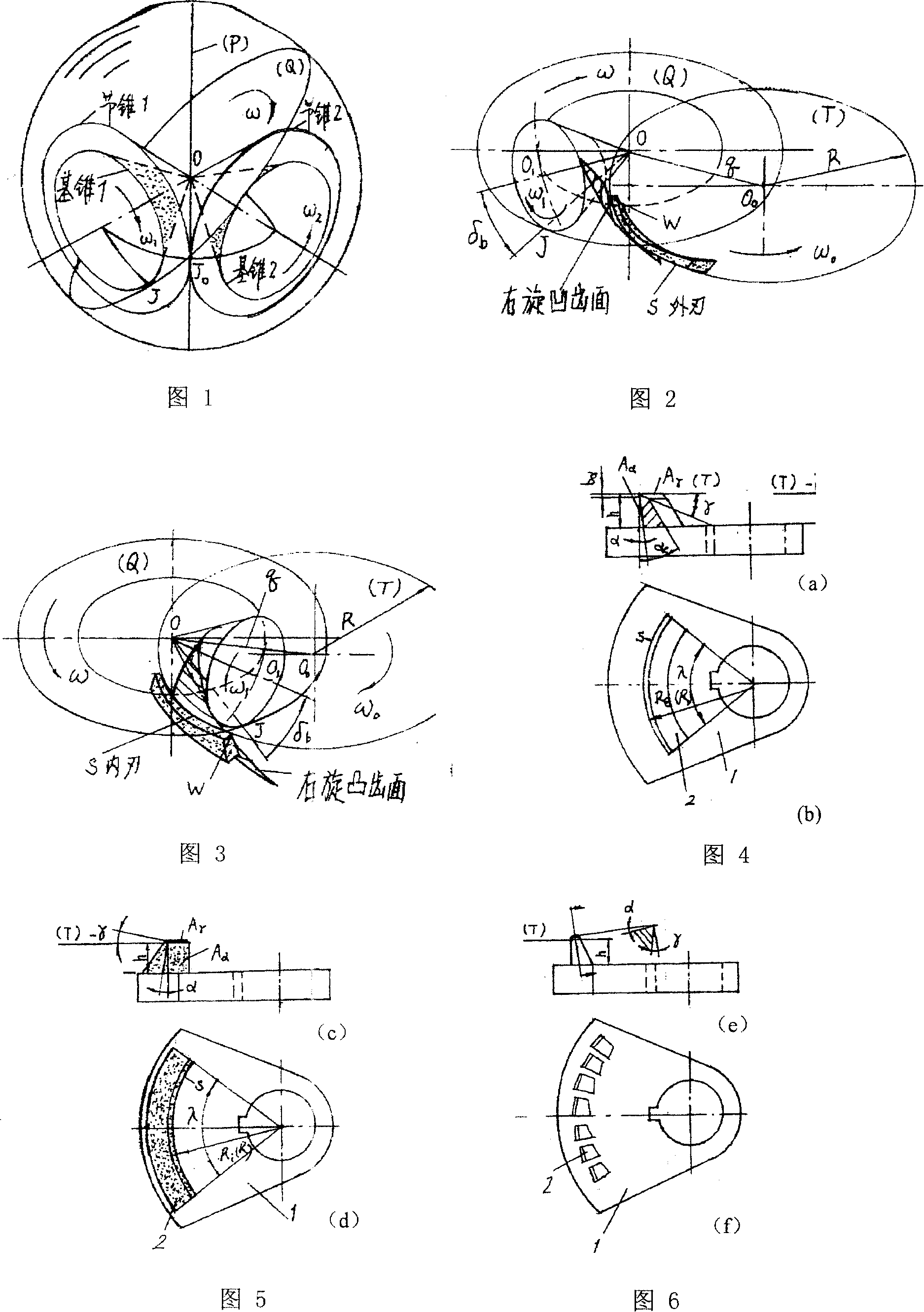

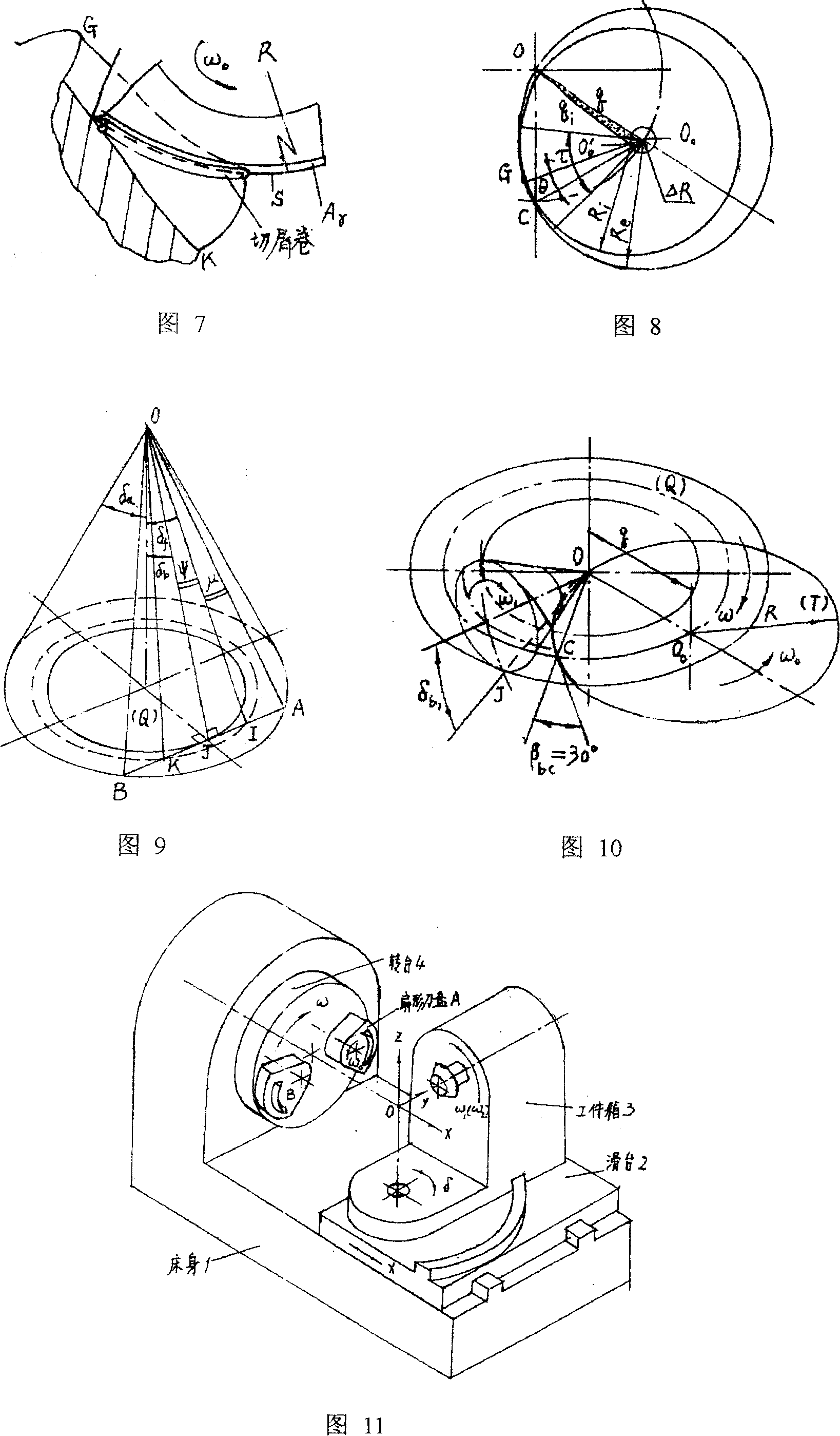

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

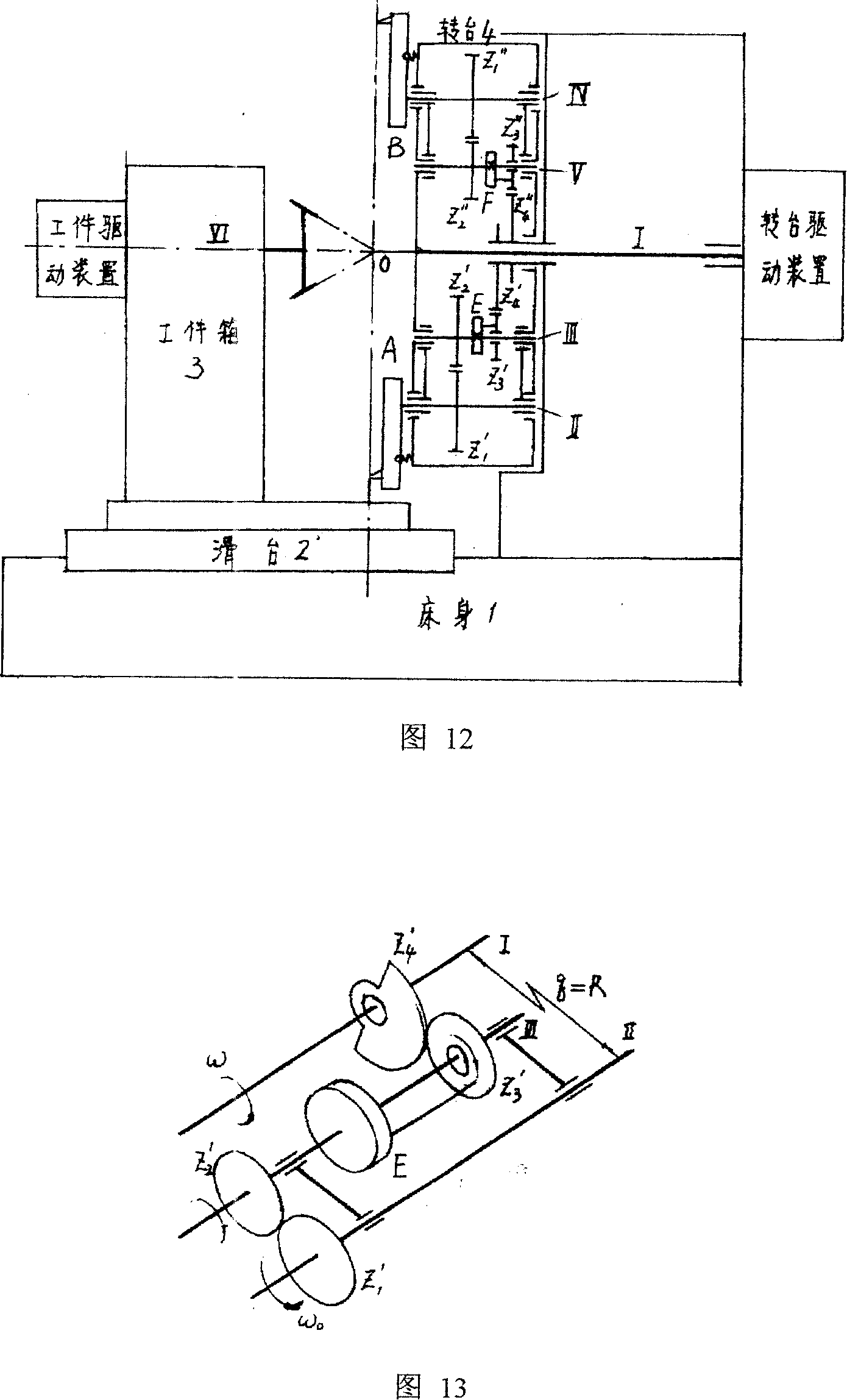

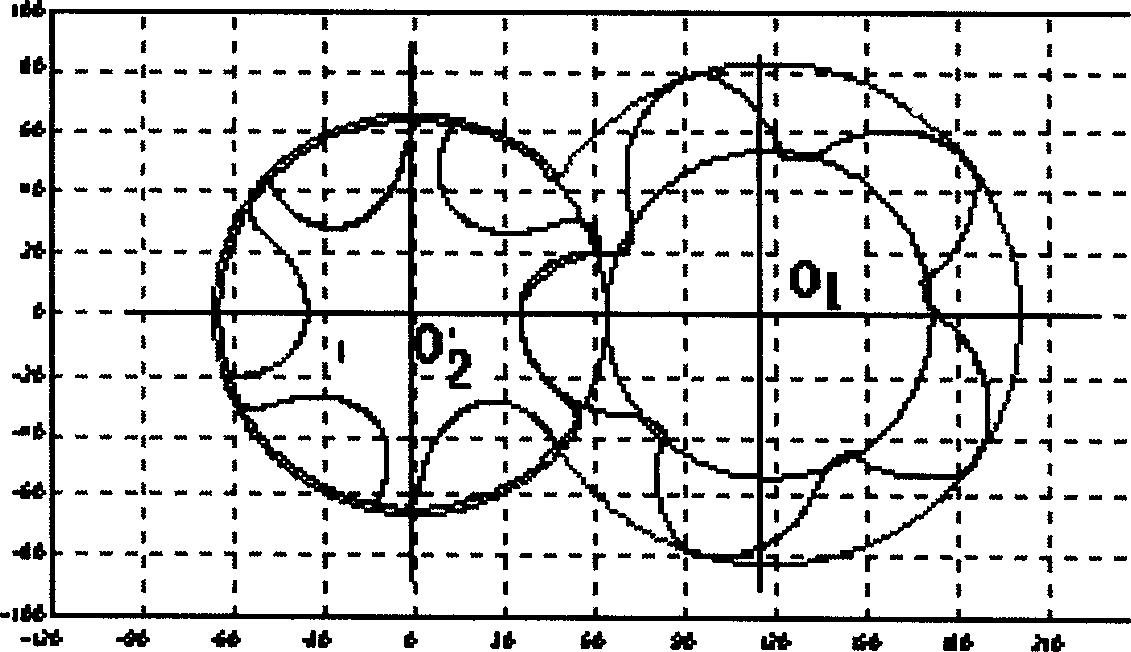

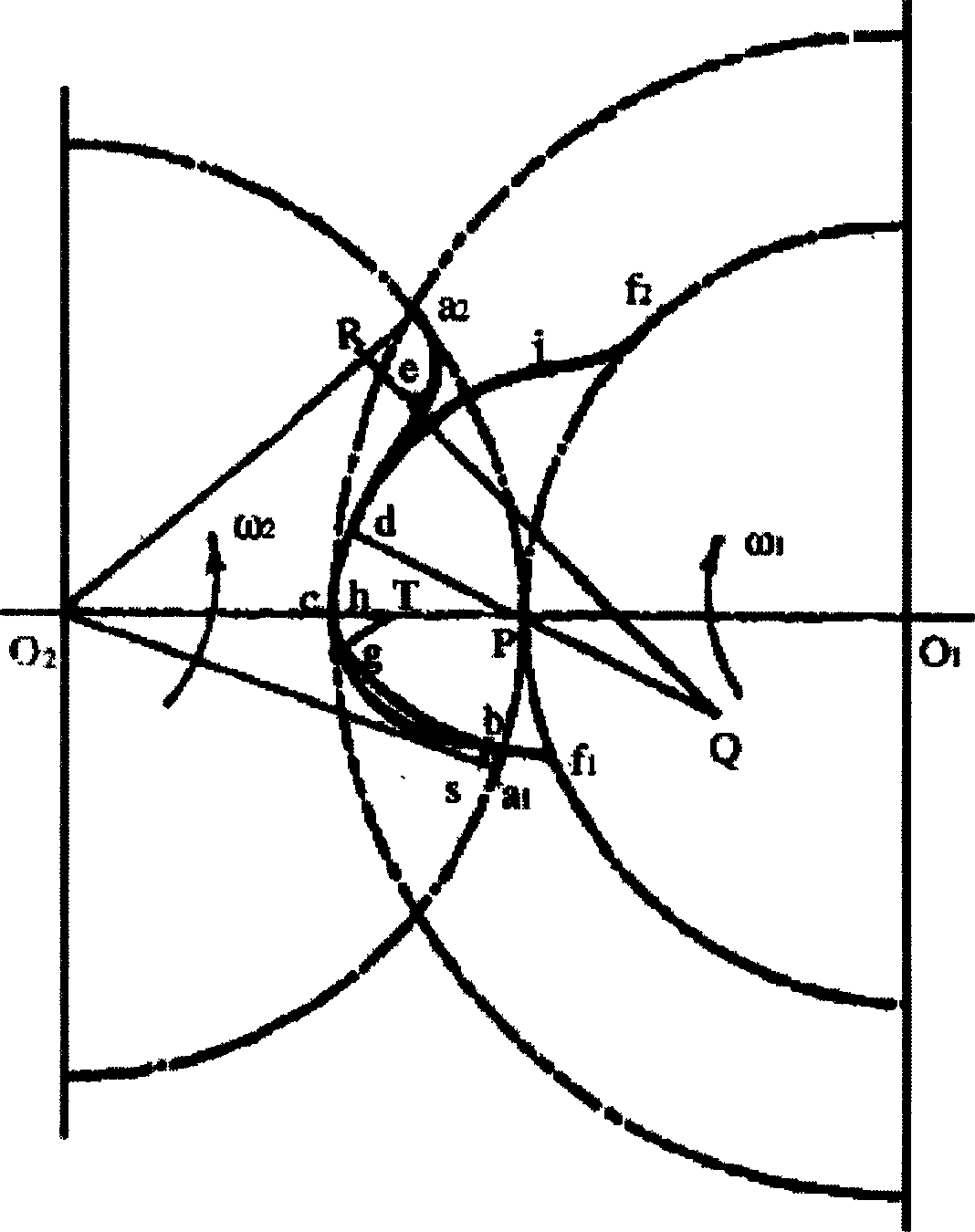

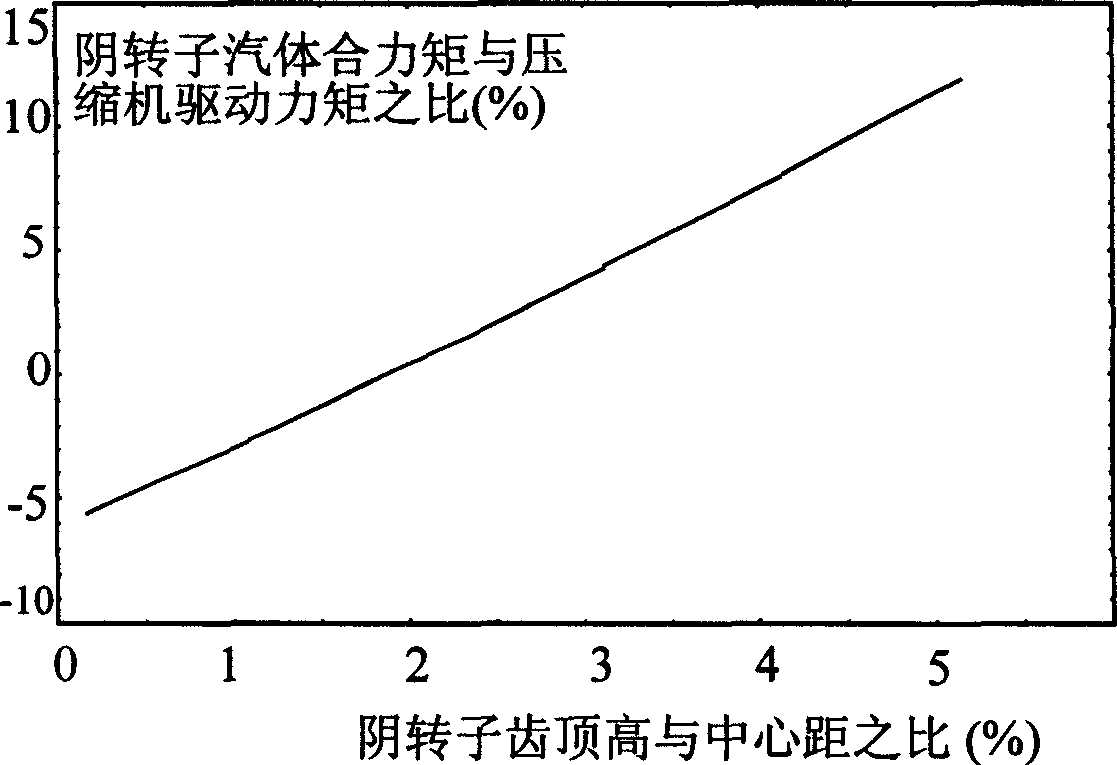

Method for designing molded lines of rotor of helical lobe compressor

ActiveCN1760552AImprove performanceReduce noiseRotary piston pumpsRotary piston liquid enginesNODALEllipse

A method for designing modeled lines of rotor on screw compressor includes selecting one or a numbers of quadric curves to form tooth curve , using quantitative calculation to calculate out geometric character value of tooth curve and predicting integral performance of said compressor, adjusting and optimizing tooth number combination and modeled lines parameter to make steam resultant torque of negative rotor with designed modeled lines be near to zero , using finite element method to analyze and calculate deformation of each element of modeled lines for confirming engagement gap and setting driving zone at driving and no driving side near to nodal circle in order to use pure roll mode to contact and transmit torque near nodal circle .

Owner:NINGBO BAOSI ENERGY EQUIP

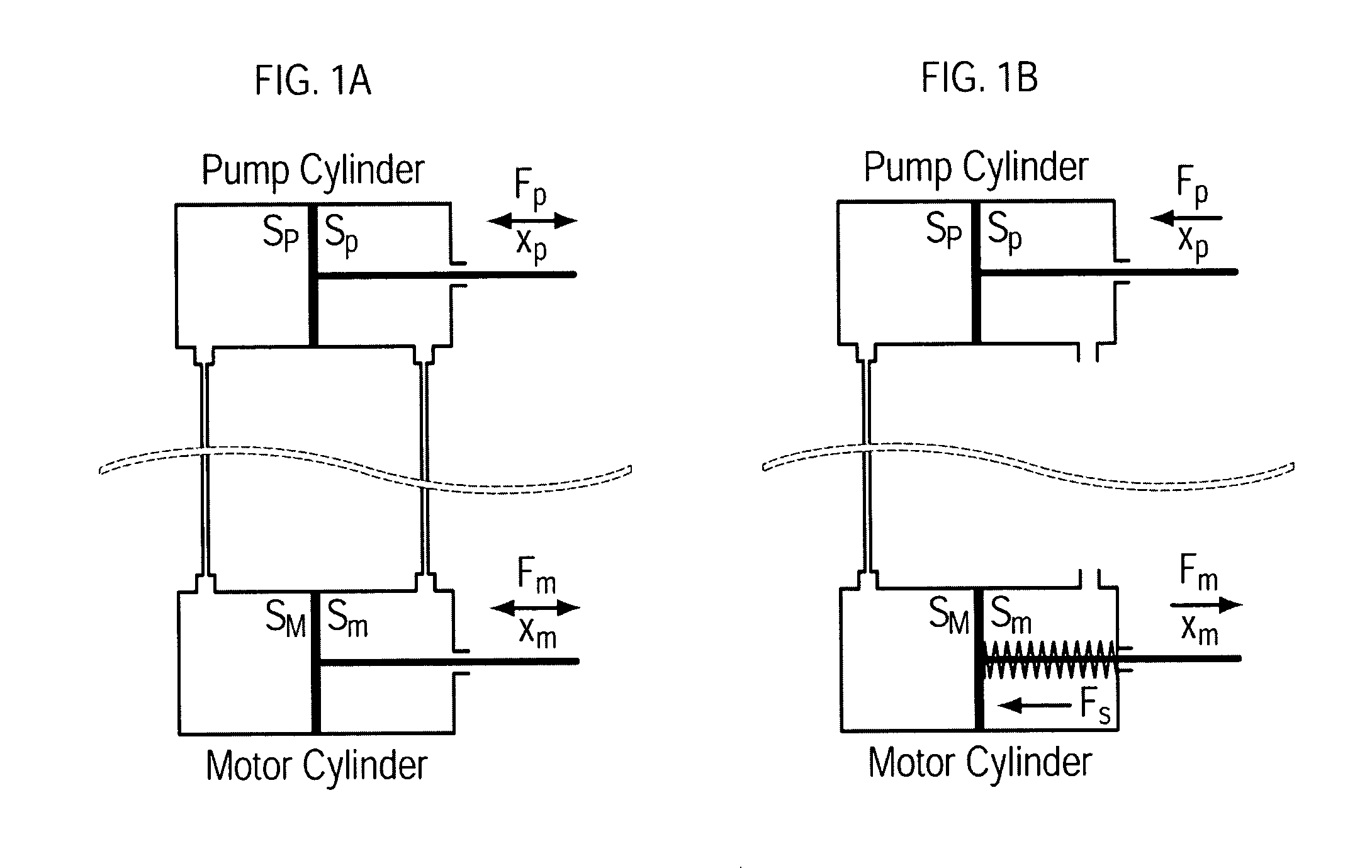

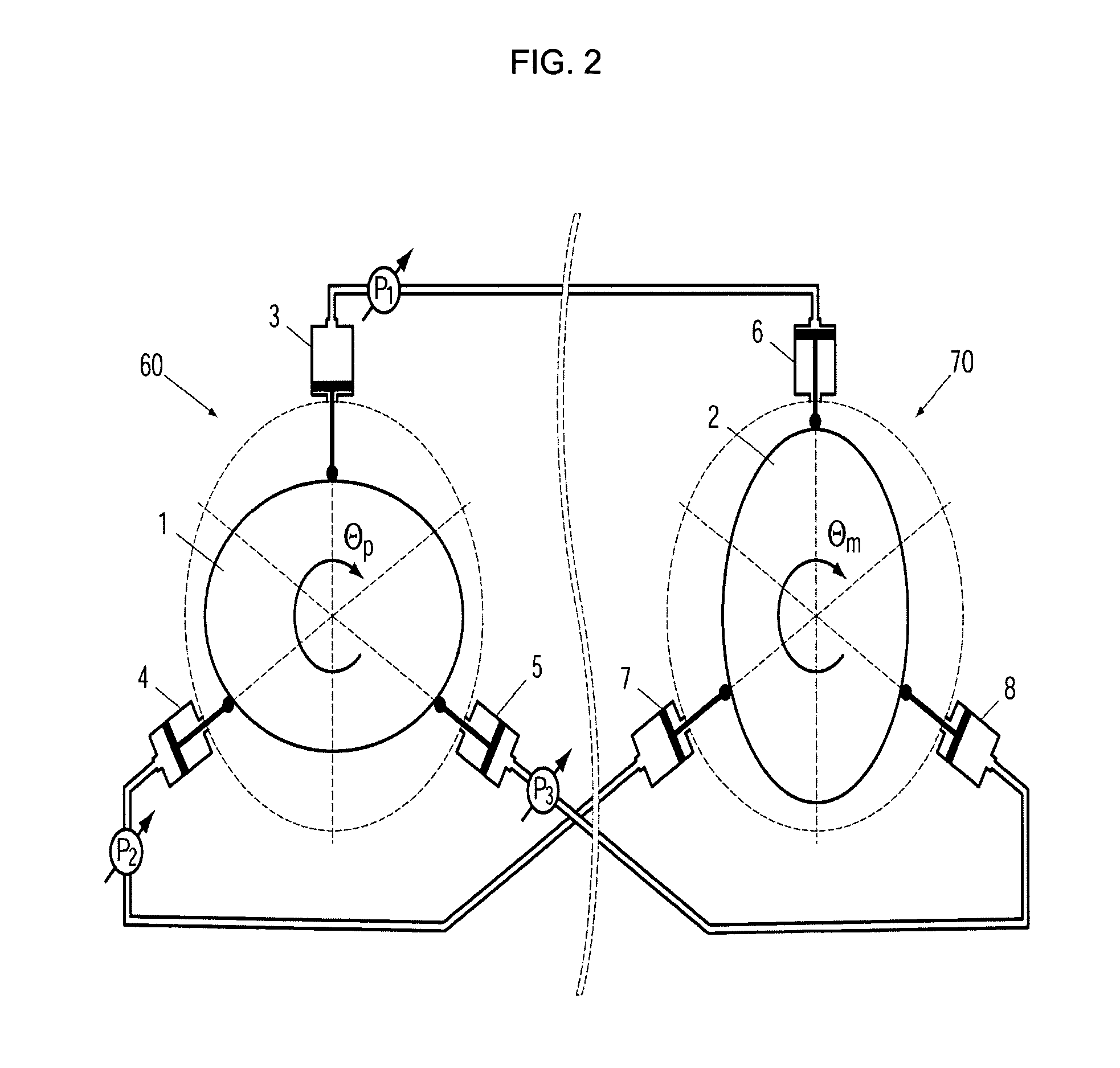

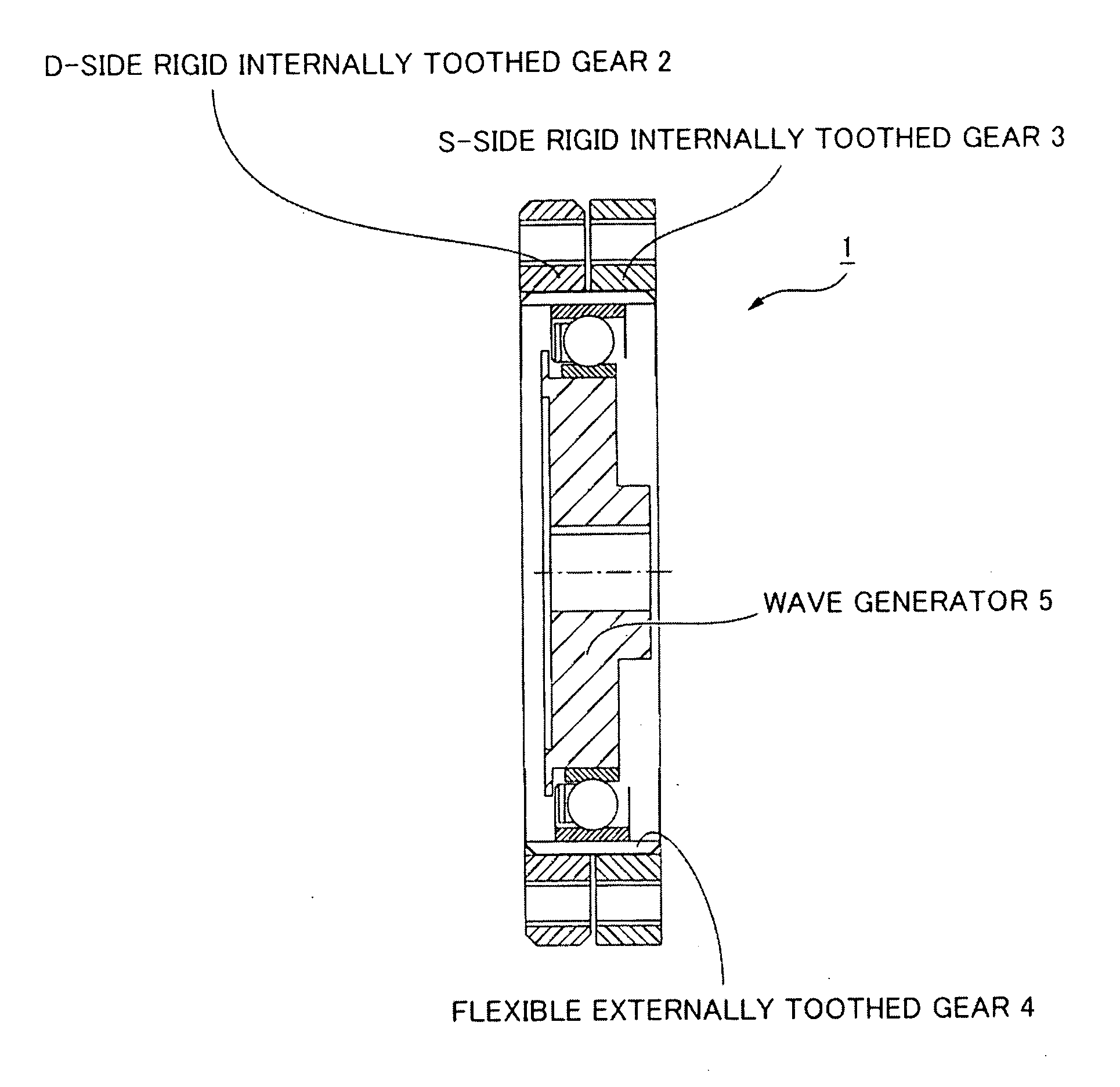

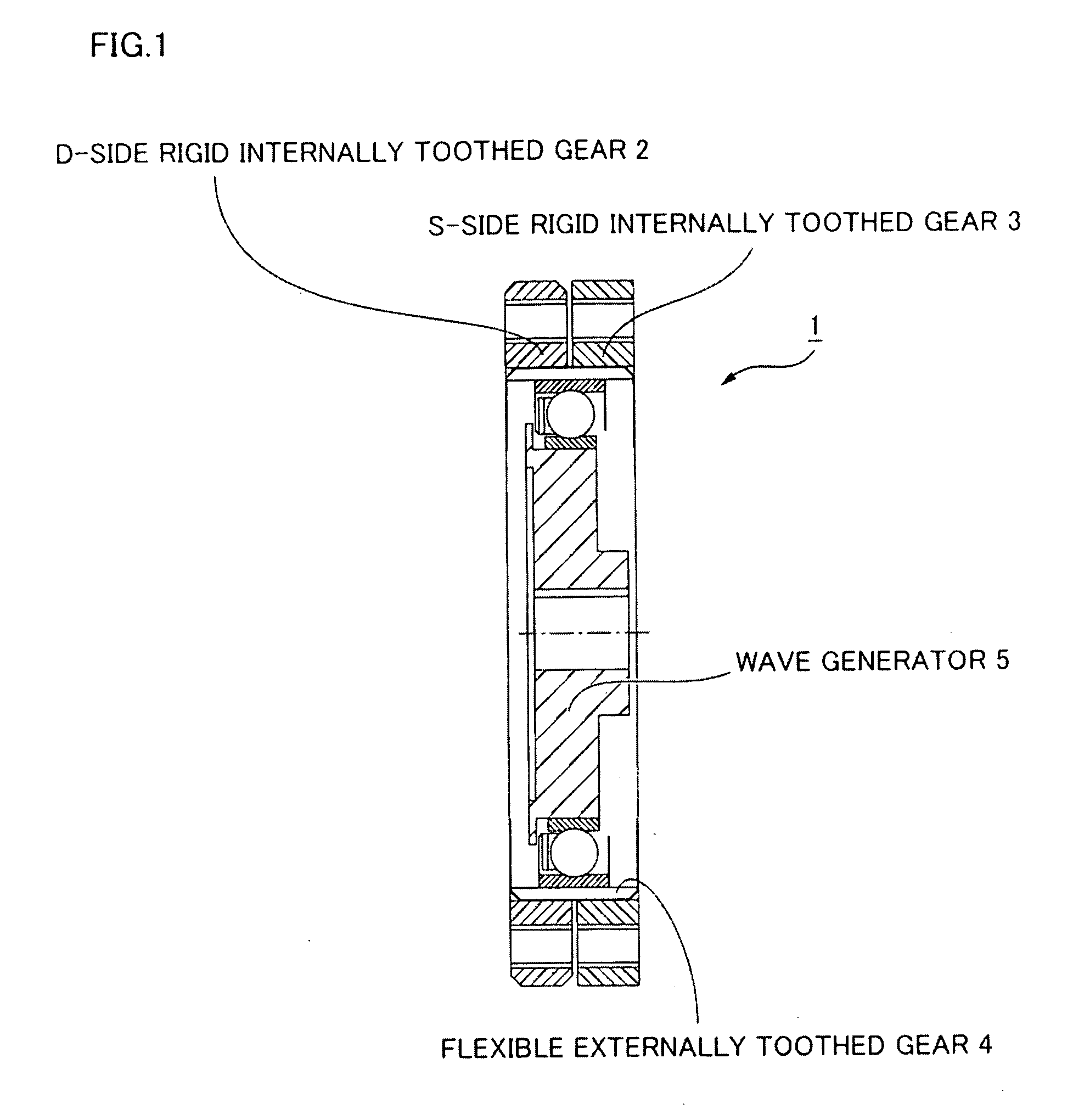

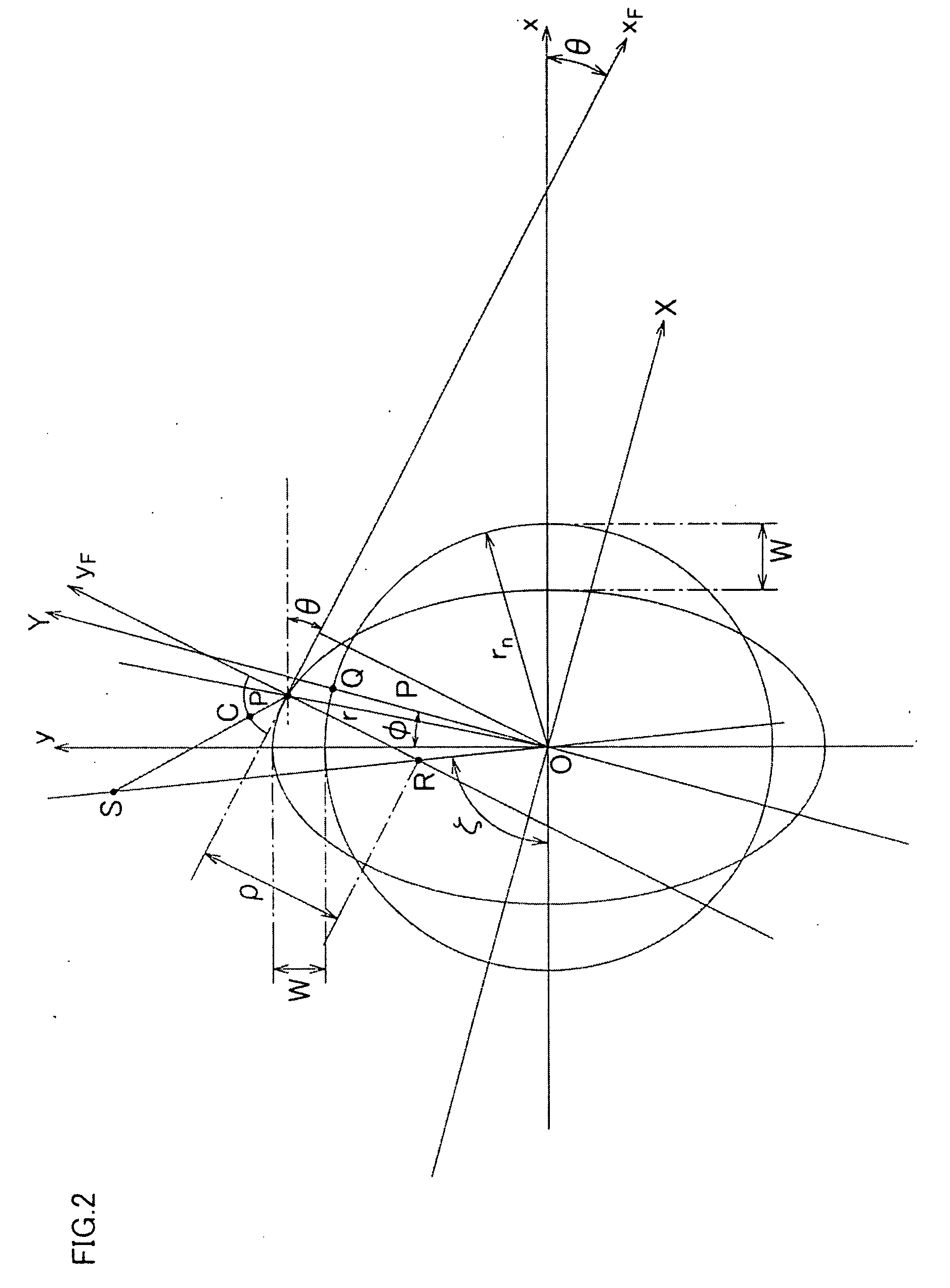

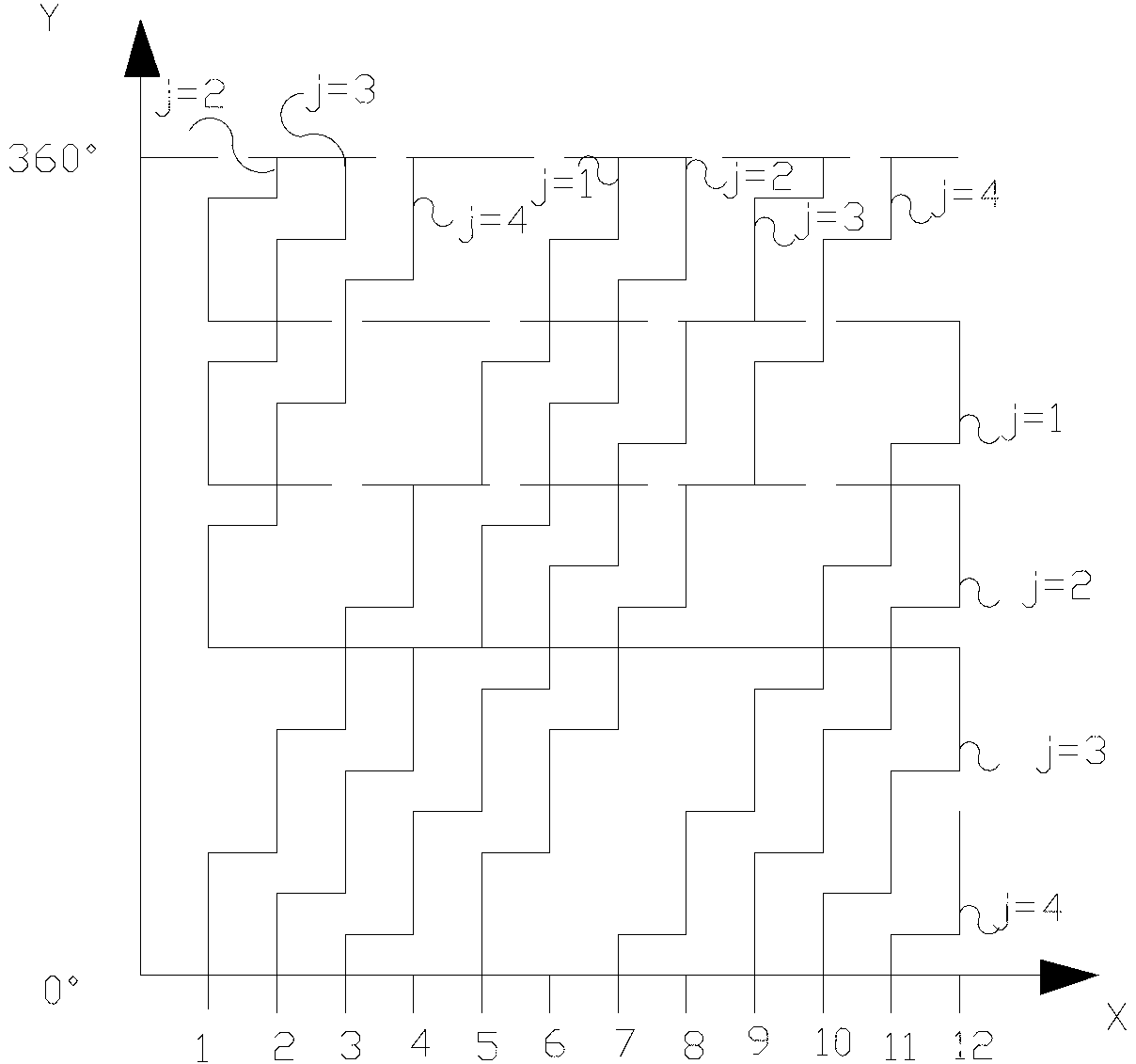

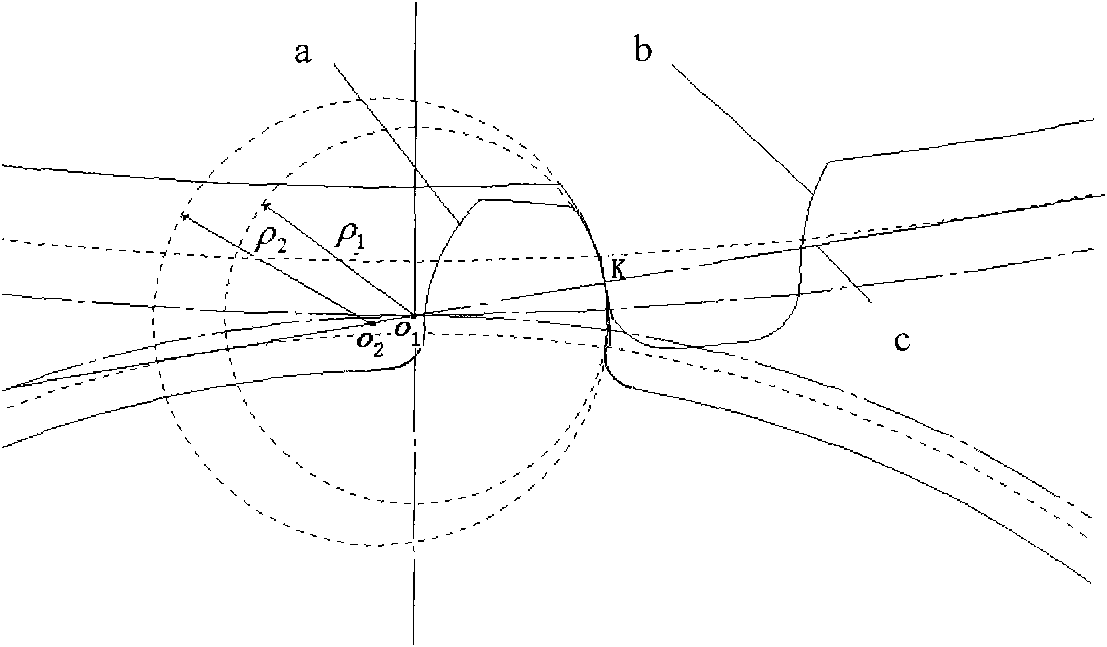

Method For Setting Gear Tooth Profile In Flat Wave Gear Device On Side Where Gears Have Same Number Of teeth

ActiveUS20090139358A1Precise designZero backlashToothed gearingsPortable liftingGear wheelTooth number

Owner:HARMONIC DRIVE SYST IND CO LTD

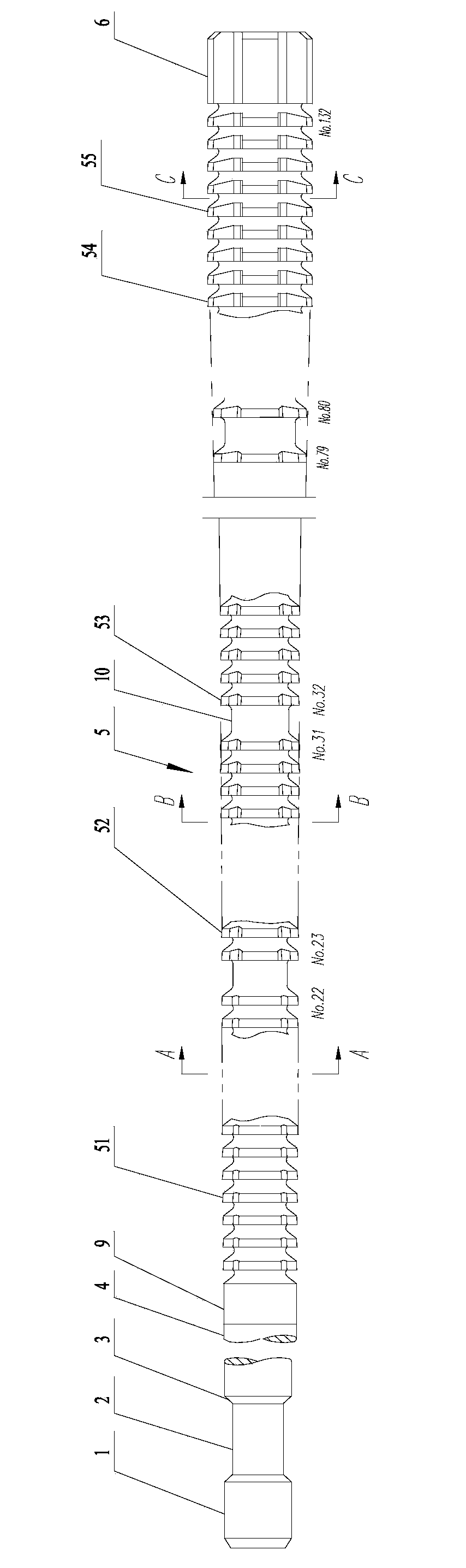

Special-shaped hole broach and machining process method thereof

InactiveCN104191036AGood technical effectAvoid stress deformationBroaching toolsNeck partsEngineering

The invention relates to a broach and discloses a special-shaped hole broach which comprises a handle part, a neck part, a transition conical part, a front guide part, cutting parts and a tail part. The handle part, the neck part, the transition conical part, the front guide part, the cutting parts and the tail part are sequentially connected into a whole from the cutting-in end to the cutting-out end. A scrap containing groove is formed between every two adjacent cutting teeth. The total length from the front end of the handle part to the tail end of the tail part is not smaller than 1200 mm, and the outer diameters from the front guide part to the tail part in sequence are sequentially increased; the cutting parts comprise round hole teeth, circular arc teeth, cutting teeth, transition teeth and calibration teeth, wherein the round hole teeth, the circular arc teeth, the cutting teeth, the transition teeth and the calibration teeth are sequentially arranged from front to back and connected into a whole. The number of the teeth of the cutting parts is from 130 to 150. The invention further discloses a machining process method for the special-shaped hole broach. The broach is large in total length and high in slenderness ratio; the multiple cutting parts different in tooth shape are used for broaching a special-shaped hole, based on the high-precision ultra-slenderness machining and thermal treating process, a method for carrying out segmentation gradual grinding through a locating sleeve and a supporting point is adopted, it is ensured that jump of the solid broach is from 0.01 mm to 0.02 mm, stress deformation caused by cutter relieving and drooping can be effectively avoided, and therefore the stability of machining and forming is good.

Owner:金华市红太阳工具厂

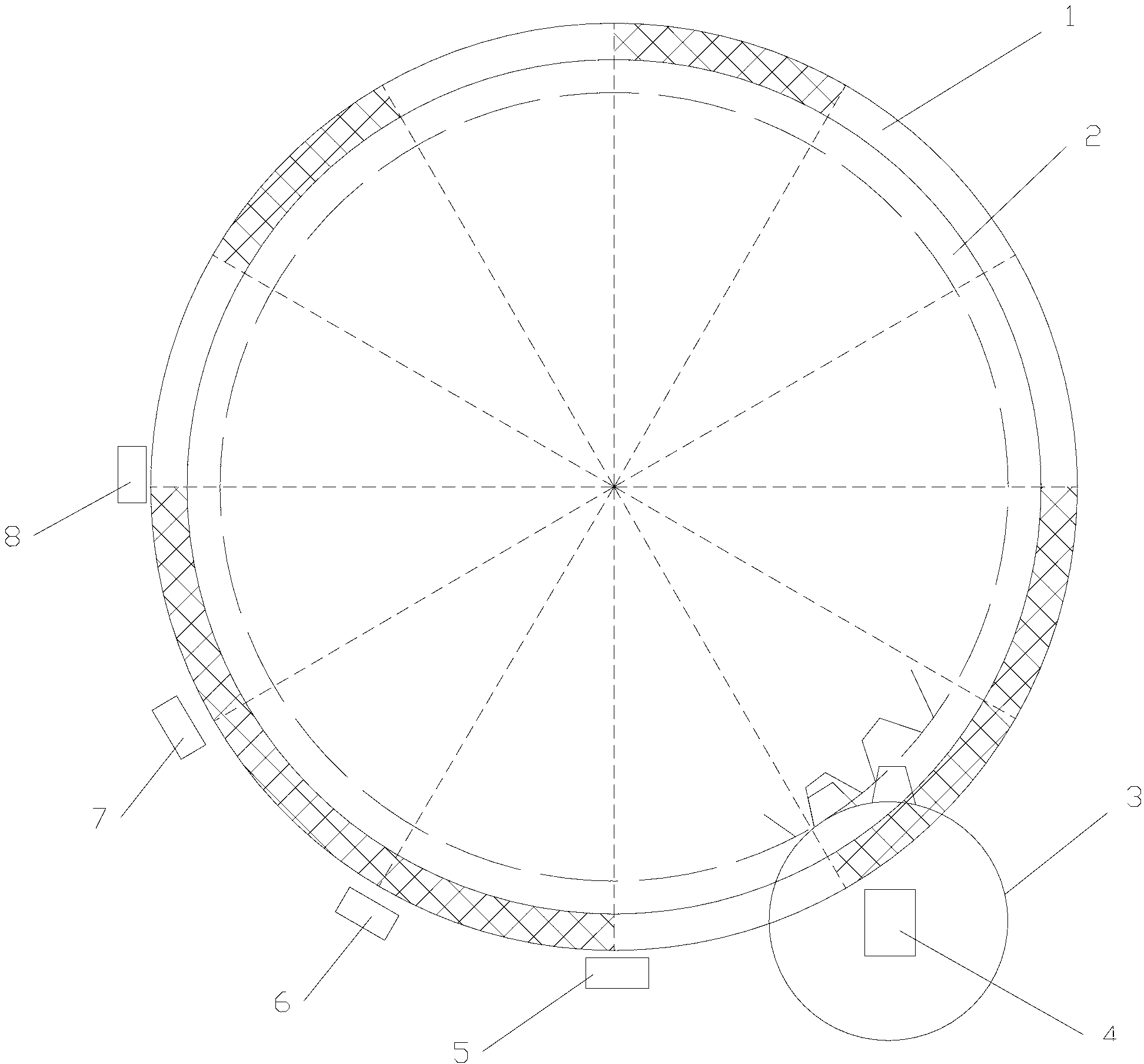

Coding magnetic resistance combination type electronic stability program (ESP) absolute type multi-loop angle sensor

ActiveCN103063127AReduce usageReduce precisionUsing electrical meansConverting sensor output electrically/magneticallySteering wheelTooth number

The invention relates to a sensor, and aims at providing a coding magnetic resistance combination type electronic stability program (ESP) absolute type multi-loop angle sensor which is developed special for an automobile ESP. The angle sensor comprises a gear which rotates along with a steering wheel tubular column, a coding disc with a concentric circle is arranged on the gear, notches of arc section shapes are distributed on the coding disc, a small gear is further meshed with the gear, the small gear further comprises magnets which are distributed in a radial mode, rotation of the small gear can be detected by a magnetic induction angle sensor, and the output range of the small gear is from 0-360 degrees; the small gear is k times as small as the gear in tooth number, four Hall-effect switch chips with magnets are arranged on the circumference of the coding disc at intervals of 30 degrees, when the coding disc rotates 30 degrees, output of the four Hall-effect switch chips changes once, and the four Hall-effect switch chips can be combined with the coding disc to achieve four-digit binary digits formed by 0 and 1 in a single loop to indicate every 30 degrees. According to the coding magnetic resistance combination type ESP absolute type multi-loop angle sensor, a vernier principle is designed in a step-by-step mode, the tolerance range of a product is enlarged, the number of used angle sensing chips is reduced, accuracy of the angle sensors is not reduced, and design cost is reduced at the same time.

Owner:WANXIANG QIANCHAO SHANGHAI AUTOMOTIVE SYST +1

Dental implant and method for making and installing same

InactiveUS20080020343A1Easy to disassemblePromote bone growthDental implantsMechanical/radiation/invasive therapiesCementoenamel junctionReplacement implant

A method for making a dental implant by obtaining images of the tooth pre-atraumatic tooth extraction and post extraction and using those images to computer generate and mill a titanium replacement implant employing CAD / CAM equipment. The implant includes a scalloped neck interface similar to the replaced tooth's scalloped cementoenamel junction, a polished neck area between a root portion and a crown portion, and the numeral for the tooth number imprinted on the implant's facial surface. Chevron retention fins are provided on the root portion for engaging the bone of the tooth socket or osteotomy when the implant is tapped into position. Retention grooves are provided on the crown portion to which a provisional crown is cemented slightly out of occlusion at the time the implant is placed. The provisional crown will be replaced with a permanent crown after osteointegration of the implant has occurred.

Owner:MOUNT K TIM

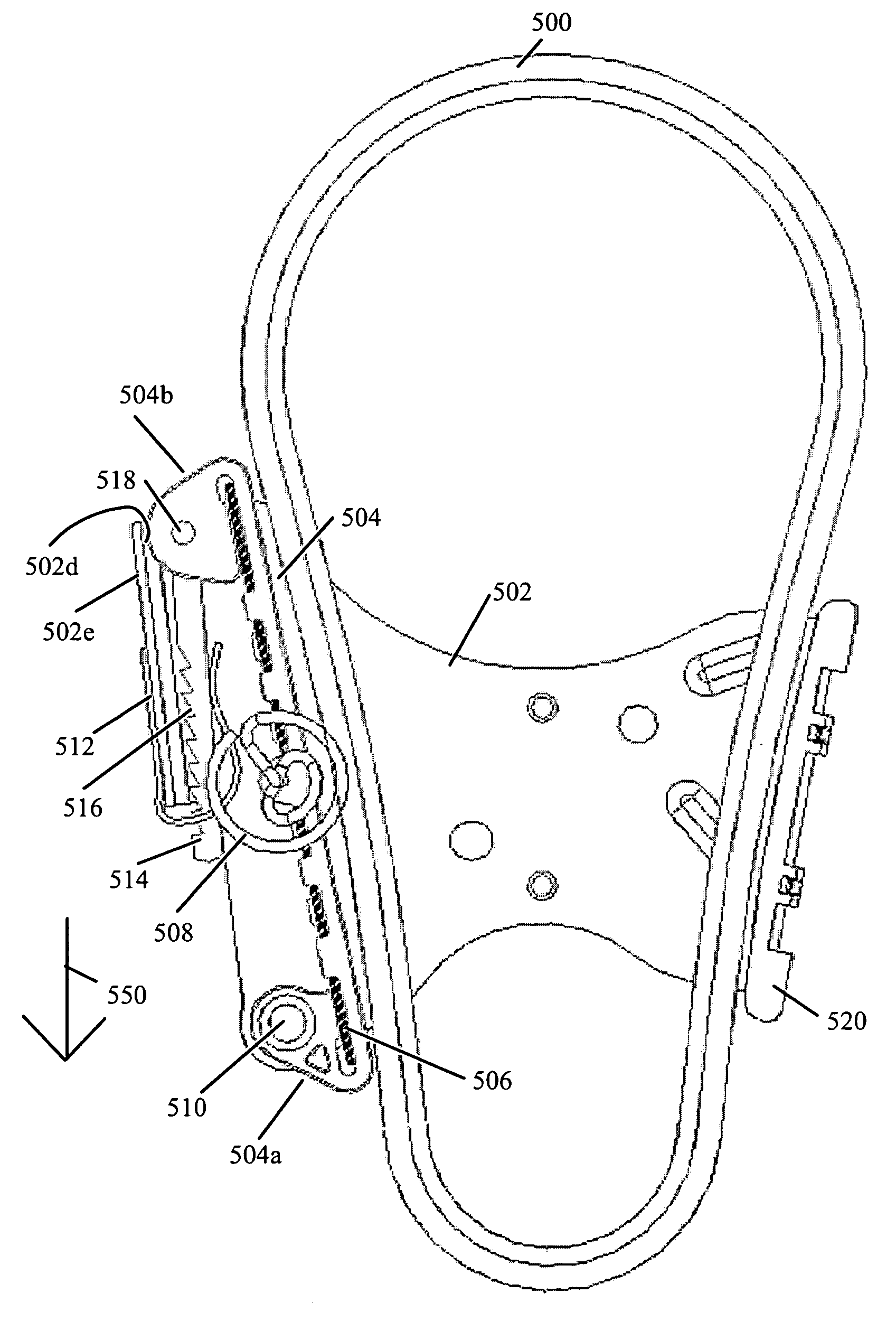

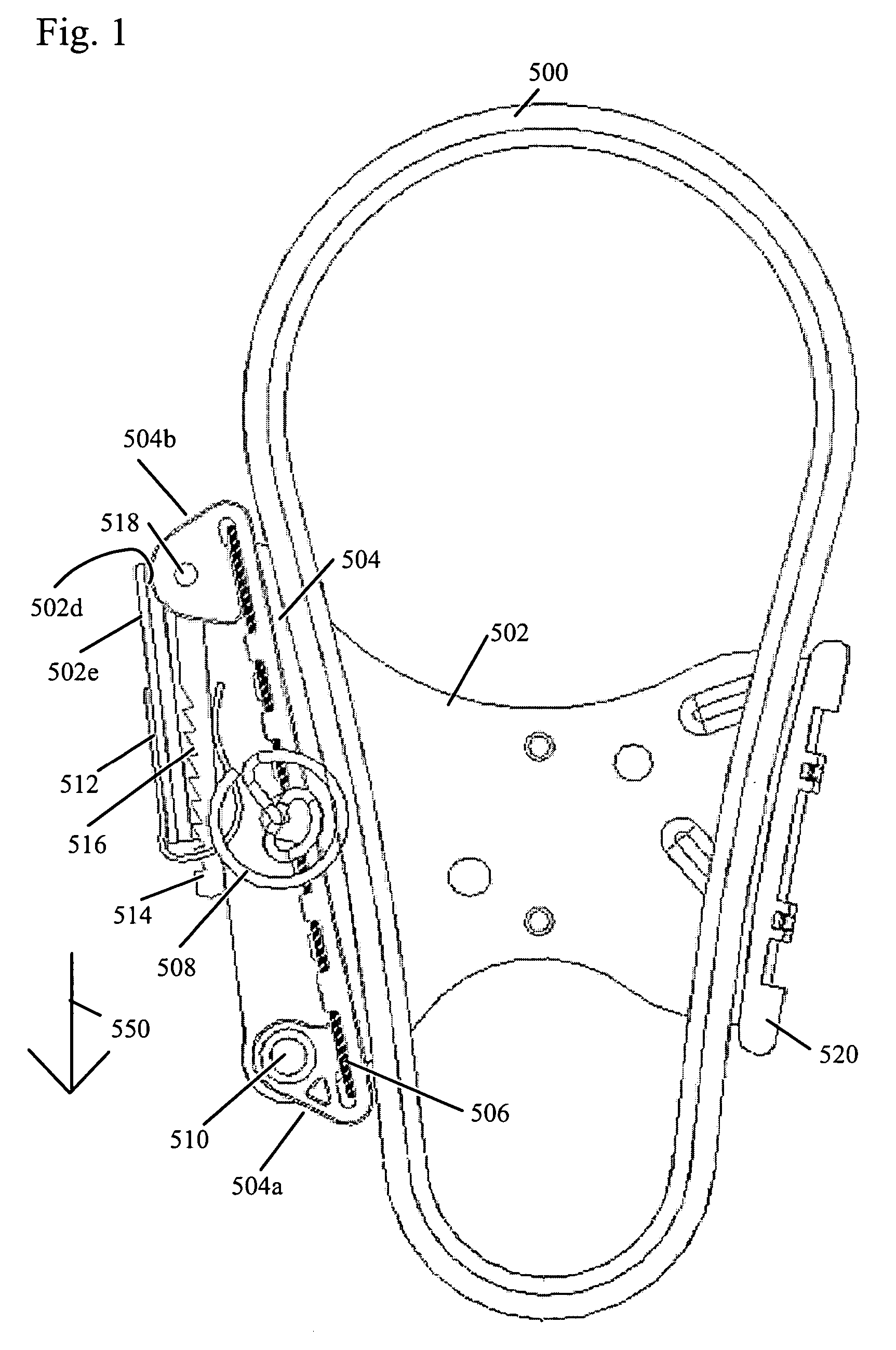

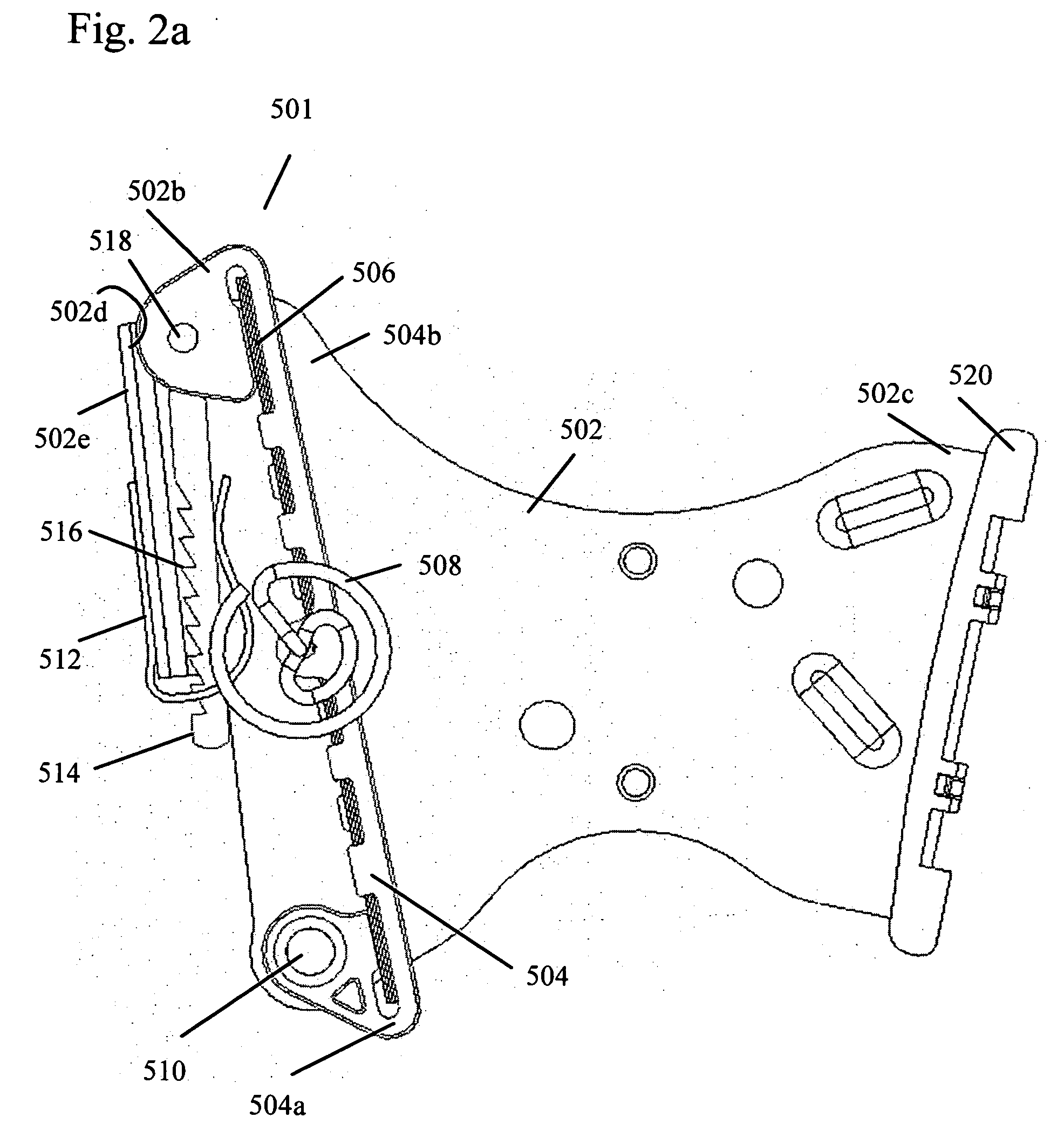

Mechanical chain tensioner with ratcheting device

A blade tensioner comprising a blade shoe, a sliding surface with a first and a second side, a ratchet rod attached to the distal end of the blade shoe having a length of teeth, and a spring clip for receiving the ratchet rod and being slidable along the second side of the sliding surface. The spring clip also has an edge for abutting the plurality of teeth of the ratchet rod. When the slack on the chain increases, a distal end of the blade shoe pivots and slides on the first side of the sliding surface, and the spring clip slides on the second side of the sliding surface a distance limited by the engagement of the tab of the spring clip with the corresponding indentation on the second side of the sliding surface and the edge of the spring clip abuts the teeth of the ratchet rod.

Owner:BORGWARNER INC

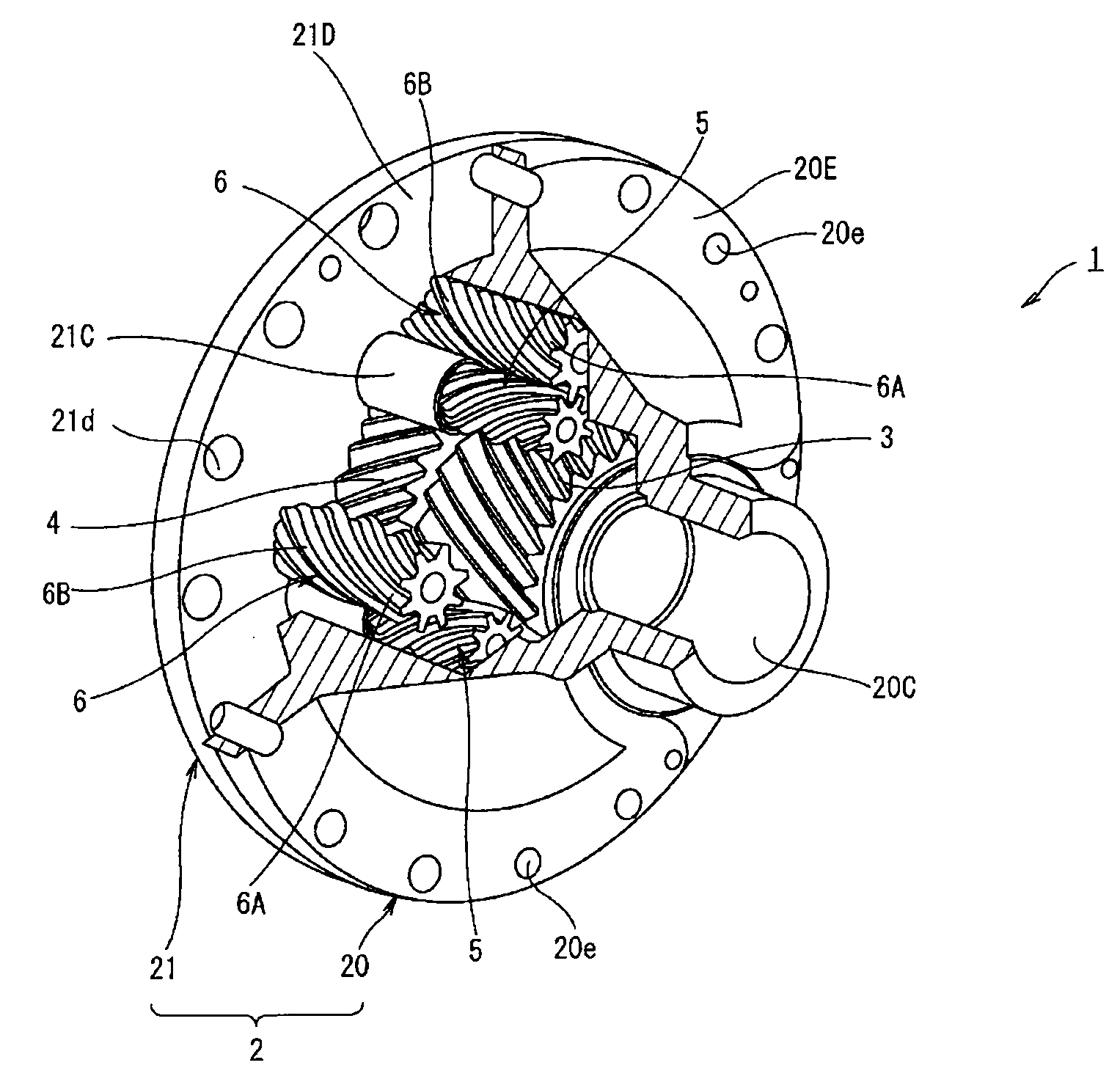

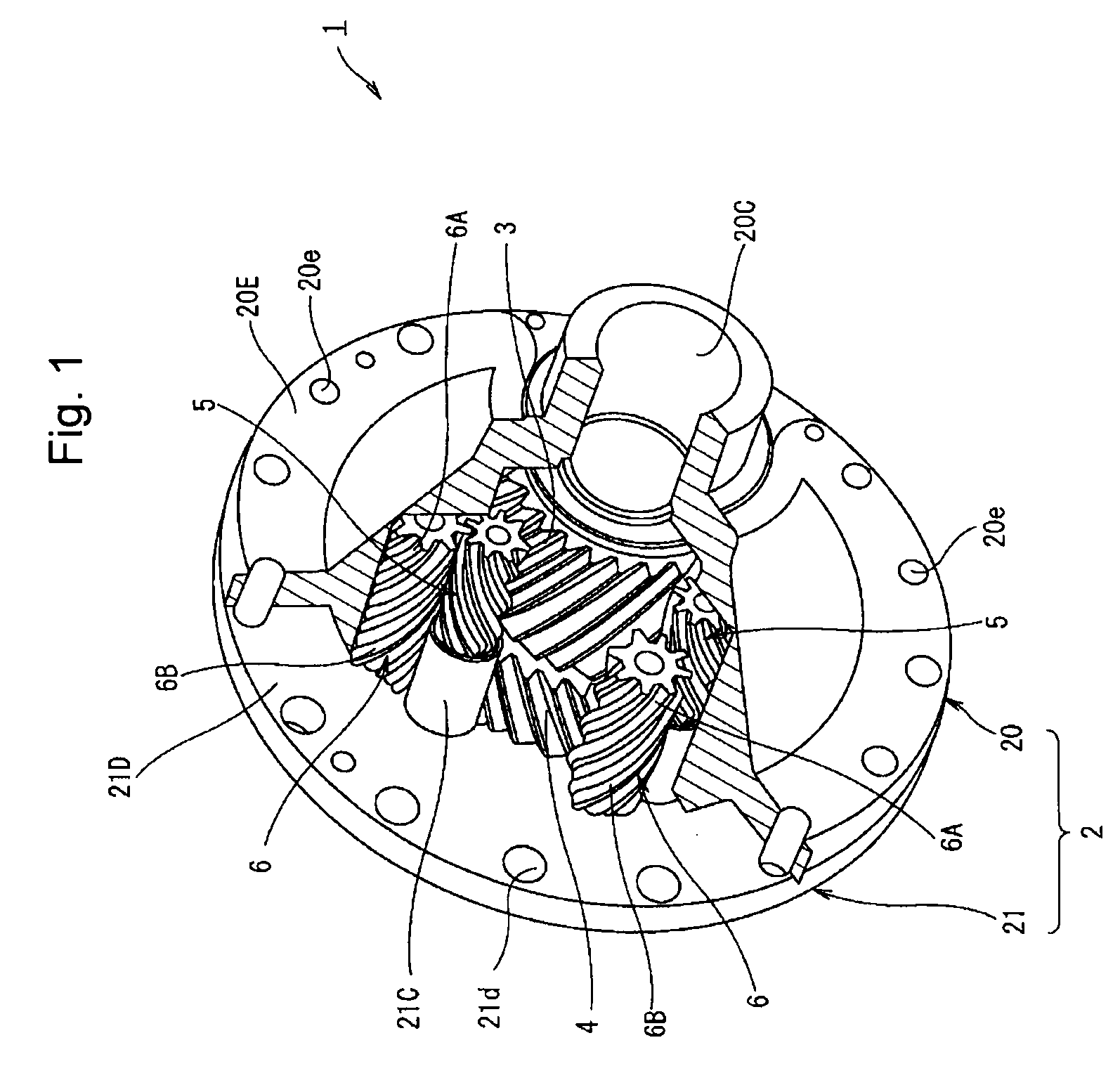

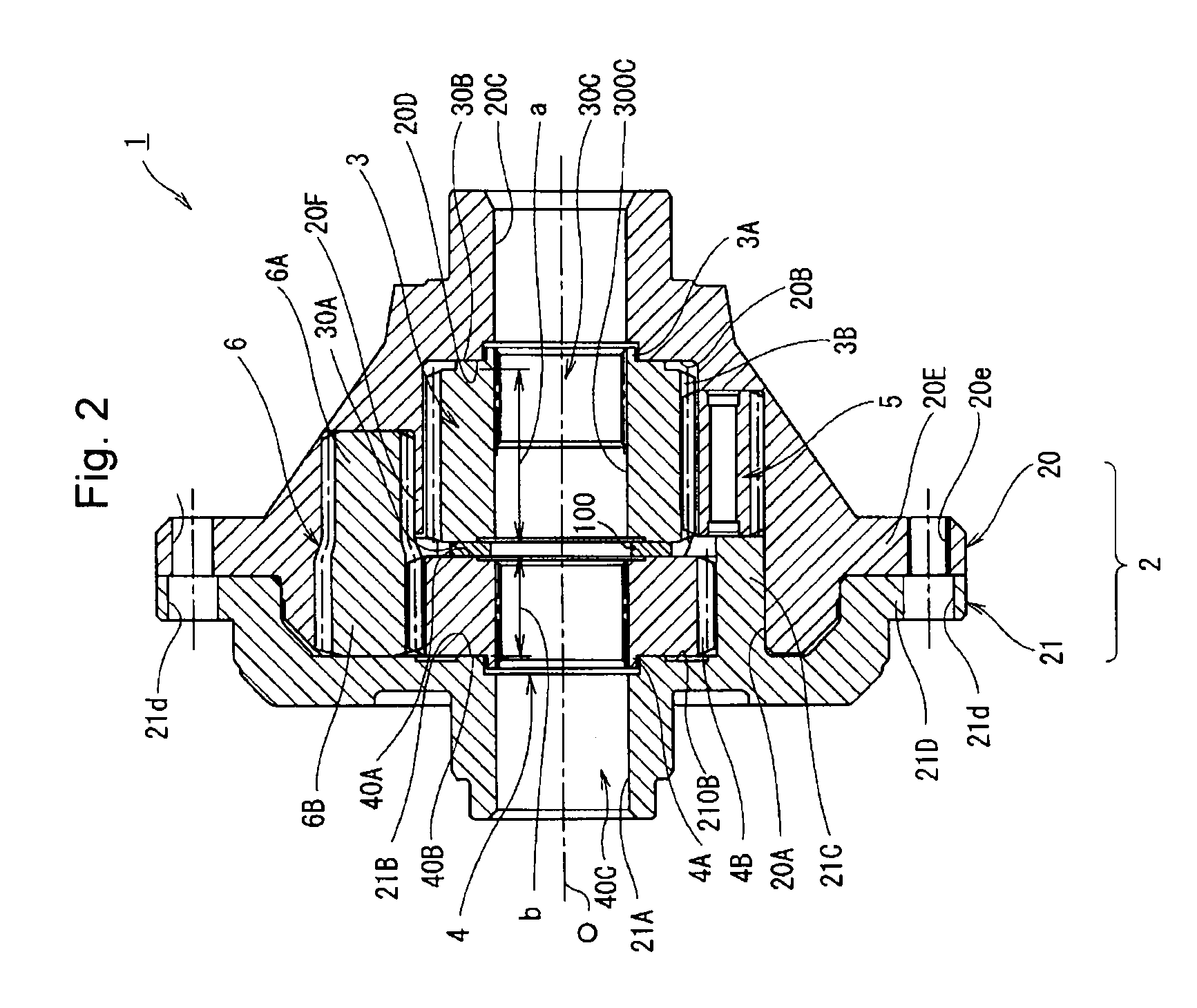

Gear and differential apparatus provided therewith for vehicle

ActiveUS20090215576A1High mechanical strengthWider widthPortable liftingToothed gearingsTooth numberPinion

It is an object of the present invention to provide a differential apparatus for a vehicle with a gear obtaining a sufficient mechanical strength against any torsion torque and preventing from being large and heavy as a whole and preventing from making a high manufacturing cost.The differential apparatus for the vehicle with the gear comprises a pair of output gears 3, 4, a first pinion gear 5 intermeshing with one of output pinion gears 3, 4 with a parallel gear axis to the first pinion gear 5, a second pinion gear 6 intermeshing with both of the other of output pinion gears 3, 4 and the first pinion gear 5 with parallel gear axes to the second pinion gear 6 respectively, and a differential case 2 accommodating the pair of output gears 3, 4, the first pinion gear 5 and the second pinion gear 6. The second pinion gear 6 has a large and a small gear portions 6A, 6B each of which pitch diameter is different respectively and each of which tooth number is same respectively, and a tooth lead 60 and a tooth space 61 formed to be shared by the large and the small gear portions 6A, 6B continuously from the large gear portion 6B to the small gear portion 6A.

Owner:JTEKT CORP

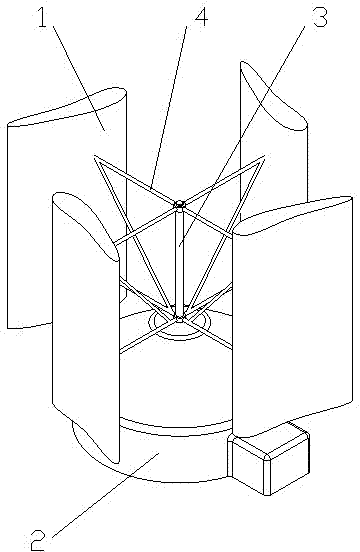

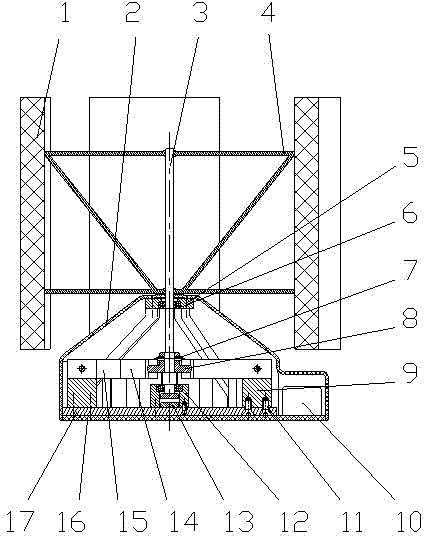

Breeze power generation device based on piezoelectric effects

InactiveCN102777327AReduce utilizationReduce lossPiezoelectric/electrostriction/magnetostriction machinesWind motor combinationsPiezoelectric actuatorsEngineering

The invention discloses a breeze power generation device based on piezoelectric effects. The breeze power generation device comprises a base plate, piezoelectric vibrators and a lifting fan, wherein the piezoelectric vibrators and the lifting fan are arranged on the base plate, a cam with teeth is connected onto a rotation shaft of the lifting fan, the piezoelectric vibrators are evenly distributed on the outside of the cam, a tooth crest of the cam is pinnacle, and teeth number of the cam is N, the number of the piezoelectric vibrators is M, the M and the N are relatively prime, and 2<=M<=18, and 4<=N<=19. The teeth number of the cam and the number of the piezoelectric vibrators are relatively prime, the cam can be guaranteed to be contacted with one piezoelectric vibrator at the same time to reduce a peak value of transient drag and enable the lifting fan to be stable in a rotation process, the tooth crest of the cam is polished to be tip, and when the piezoelectric vibrators are stirred, no contact exists. After that, the piezoelectric vibrators begin to freely vibrate, and energy caused by stirring and wiping each time is effectively used. The breeze power generation device effectively reduces rotation resistance, improves energy utilization efficiency and enables start-up wind speed and work speed to be lowered compared with the prior art.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

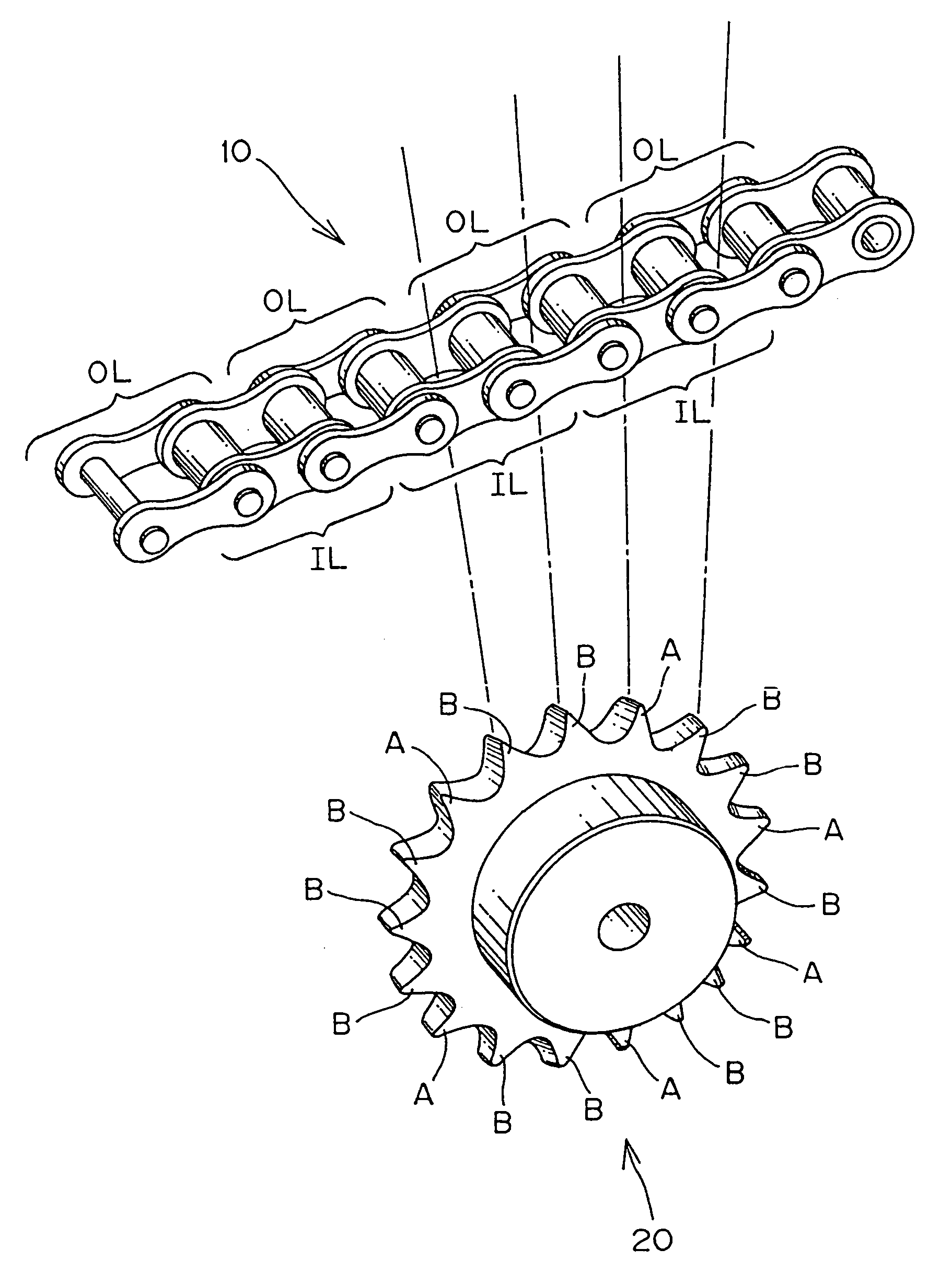

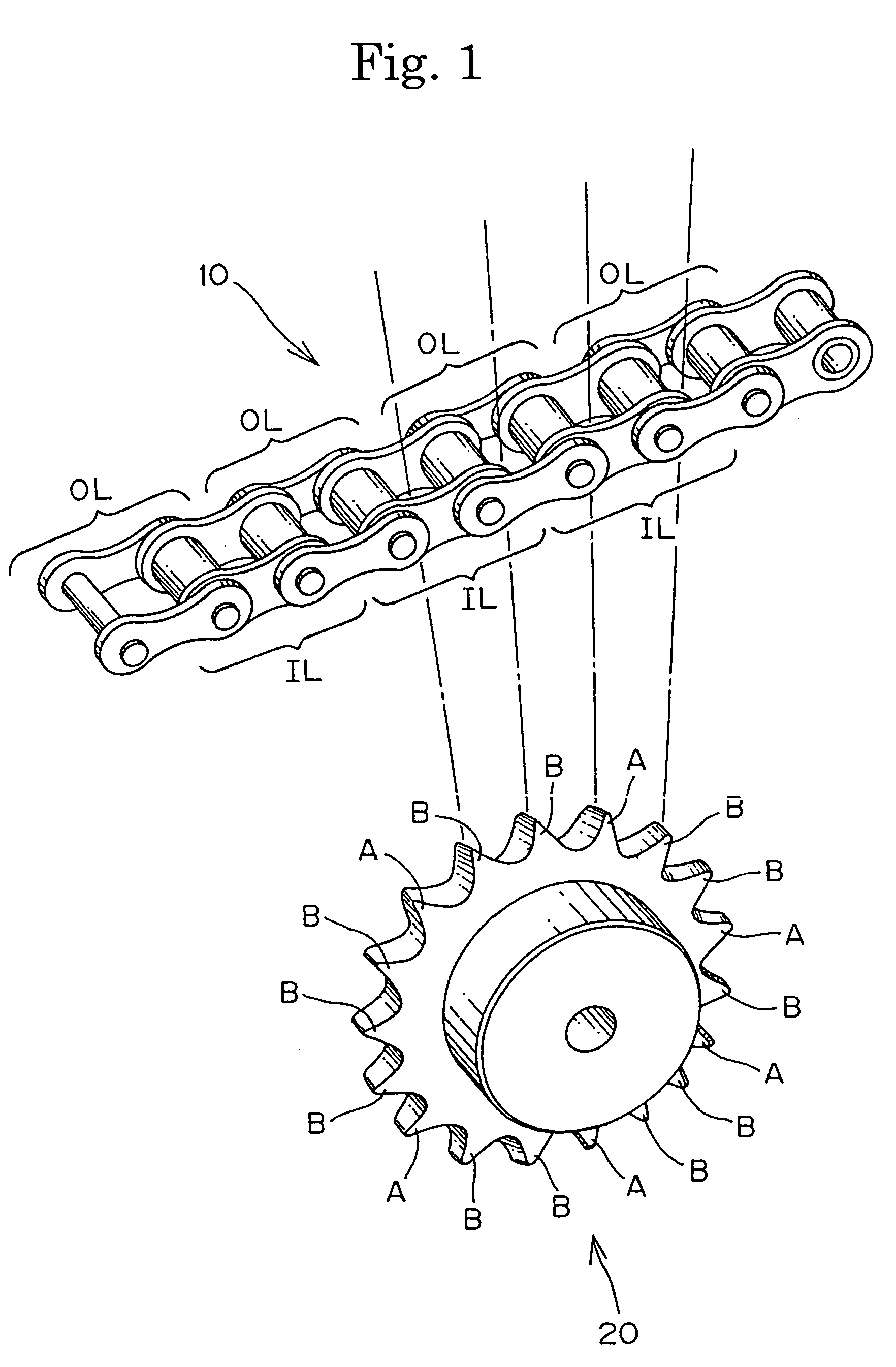

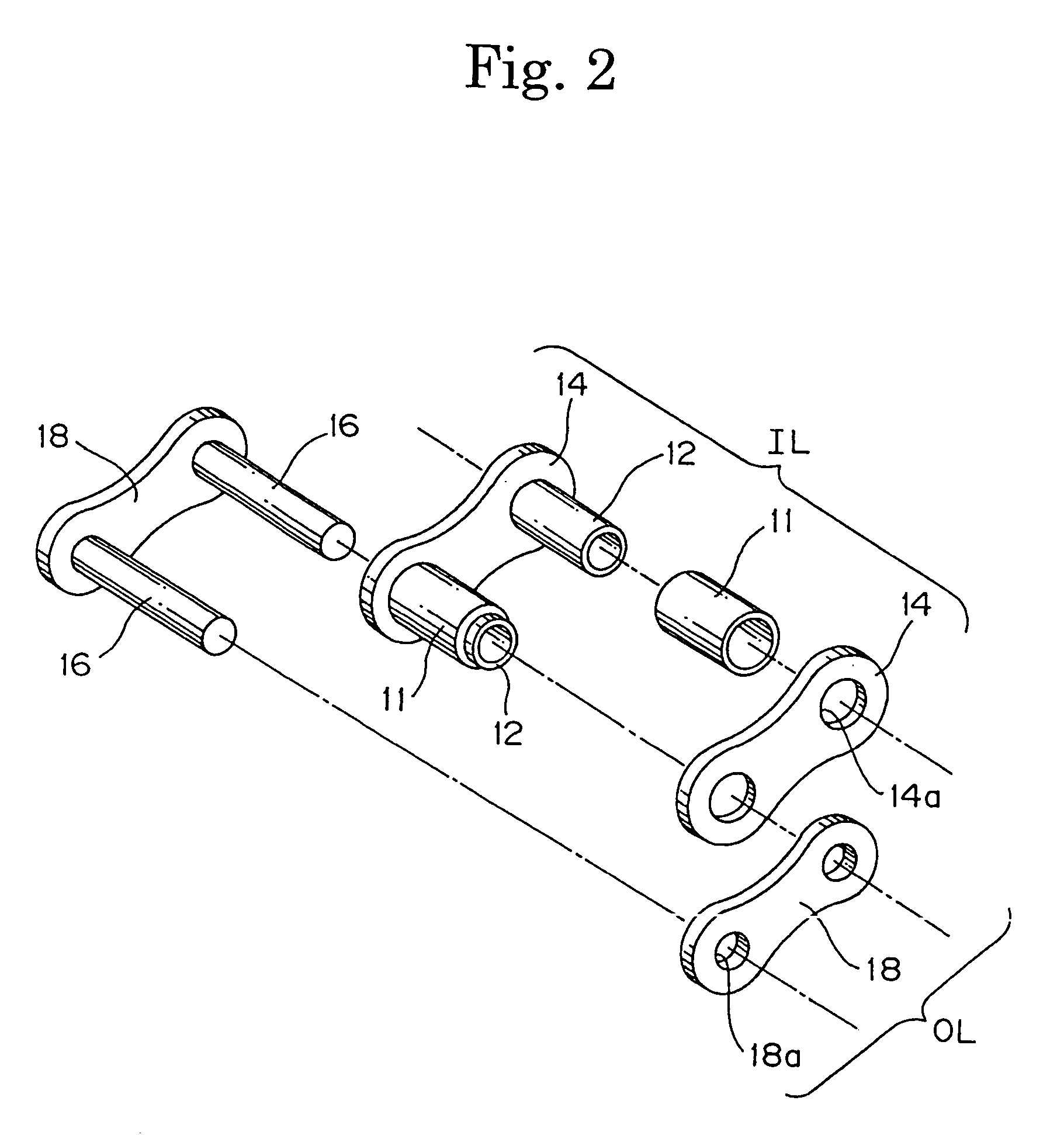

Roller chain transmission device

A roller chain transmission comprises a sprocket having at least first teeth and second teeth having different tooth forms, the first teeth and second teeth being randomly arranged, and the number of the second teeth not exceeding four times of the number of the first teeth. The roller chain may also have pins of slightly differing diameters, randomly arranged along the length of the chain.

Owner:TSUBAKIMOTO CHAIN CO

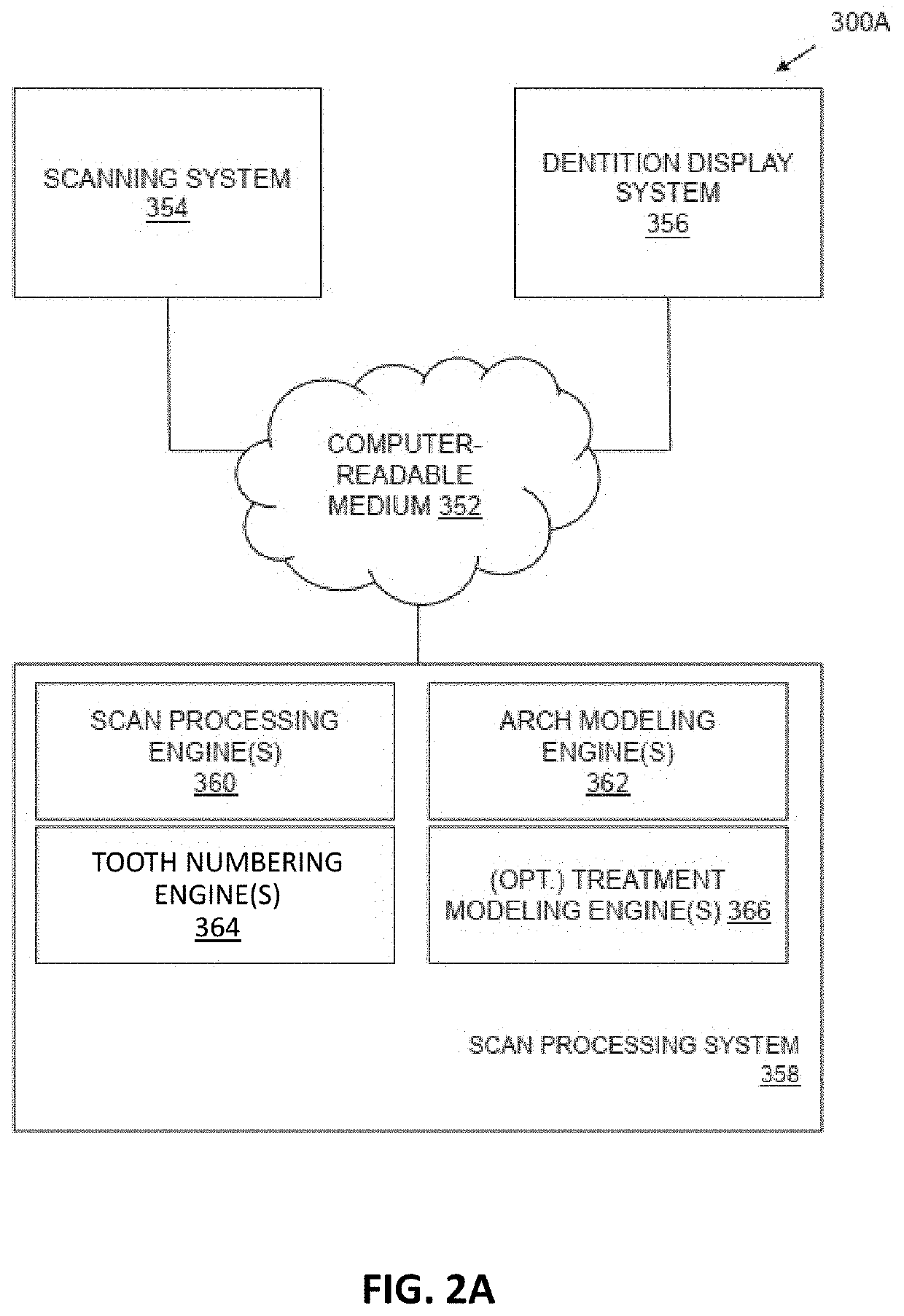

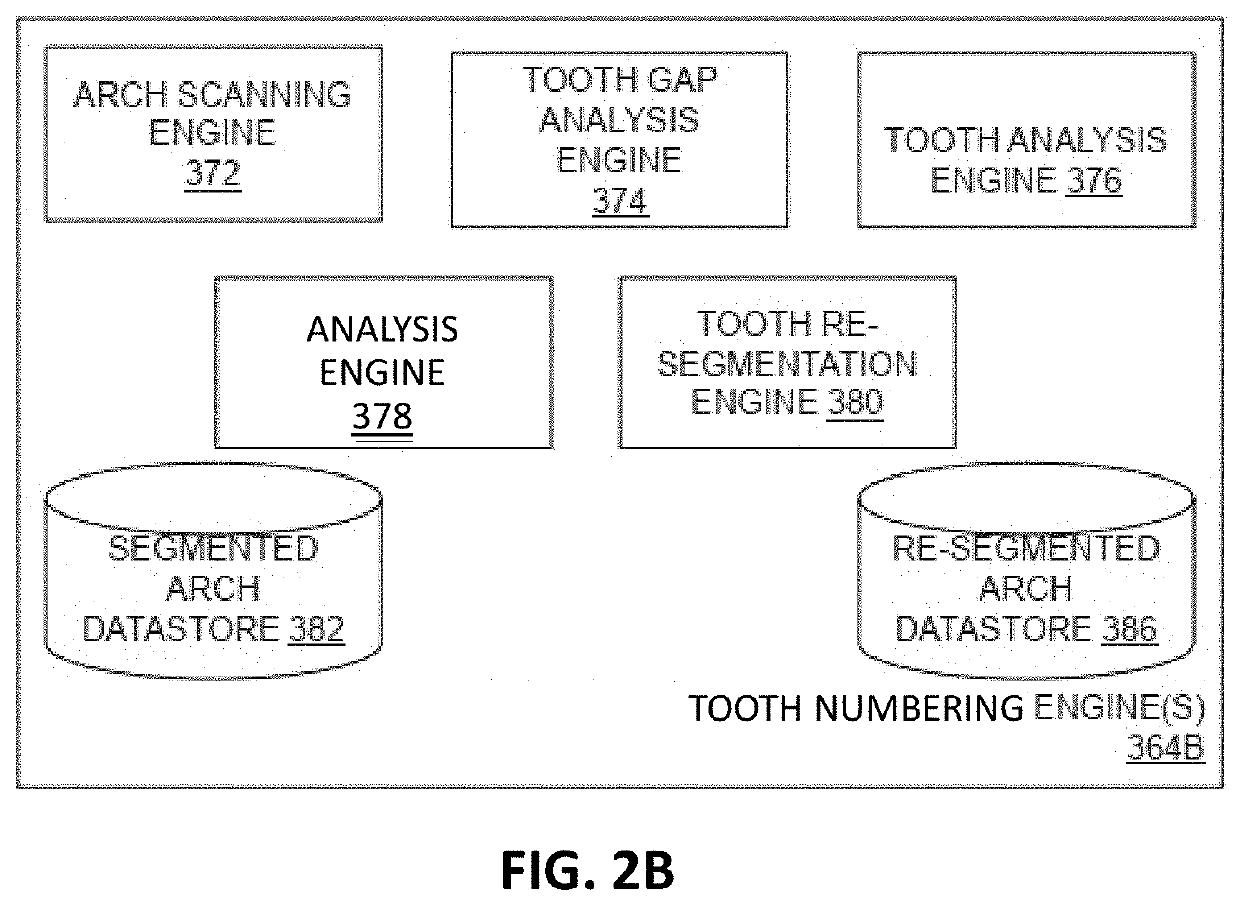

Dental arch analysis and tooth numbering

ActiveUS20200315744A1Accurate identificationExact numberMedical simulationImpression capsTooth numberDentition

Provided herein are methods and apparatuses for analyzing a patient's dental arches in order to generate a treatment plan for the dentition. In particular described herein are methods and apparatuses for determining accurate standardized tooth numbering even when there are missing and / or supernumerary teeth.

Owner:ALIGN TECH

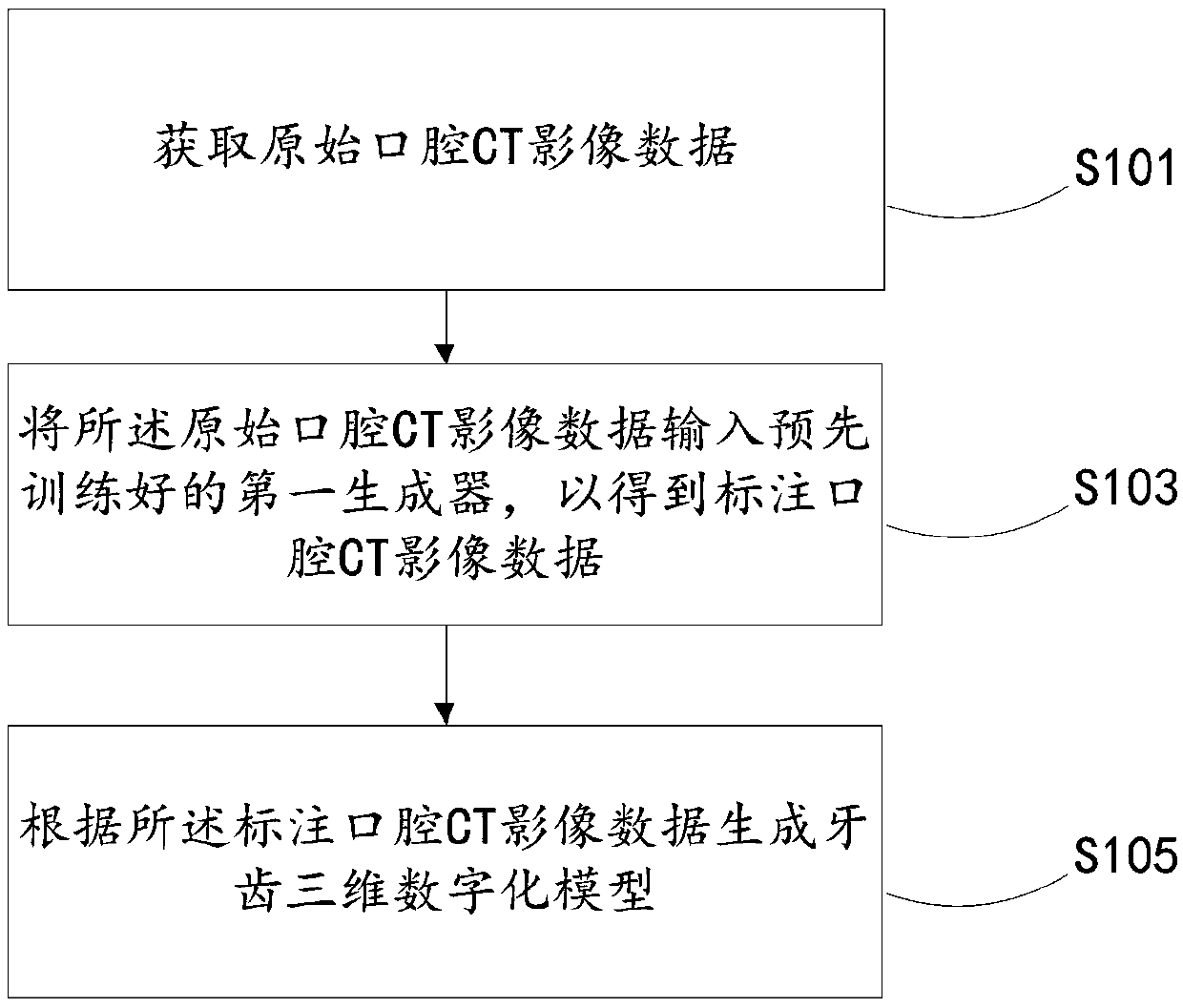

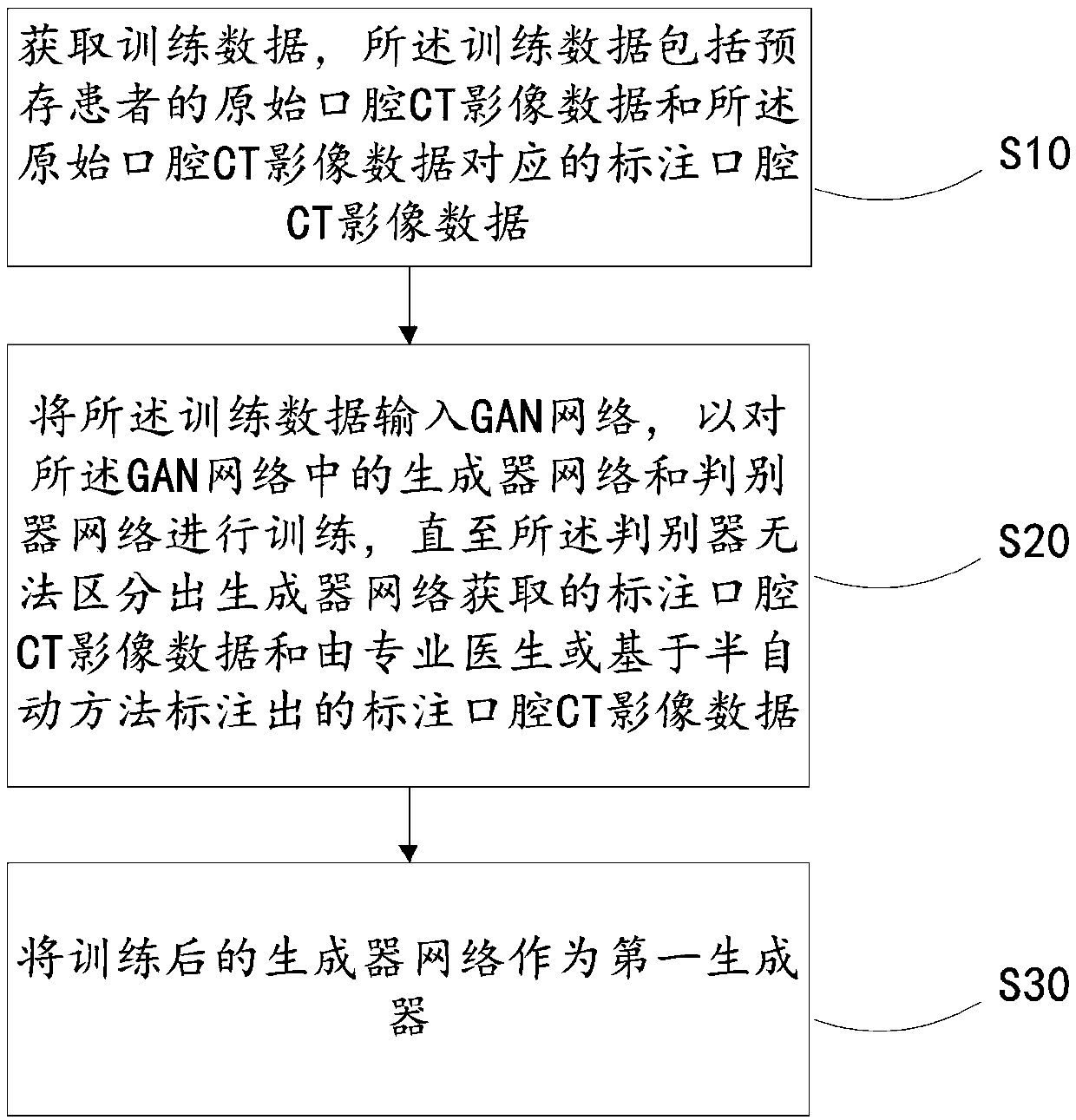

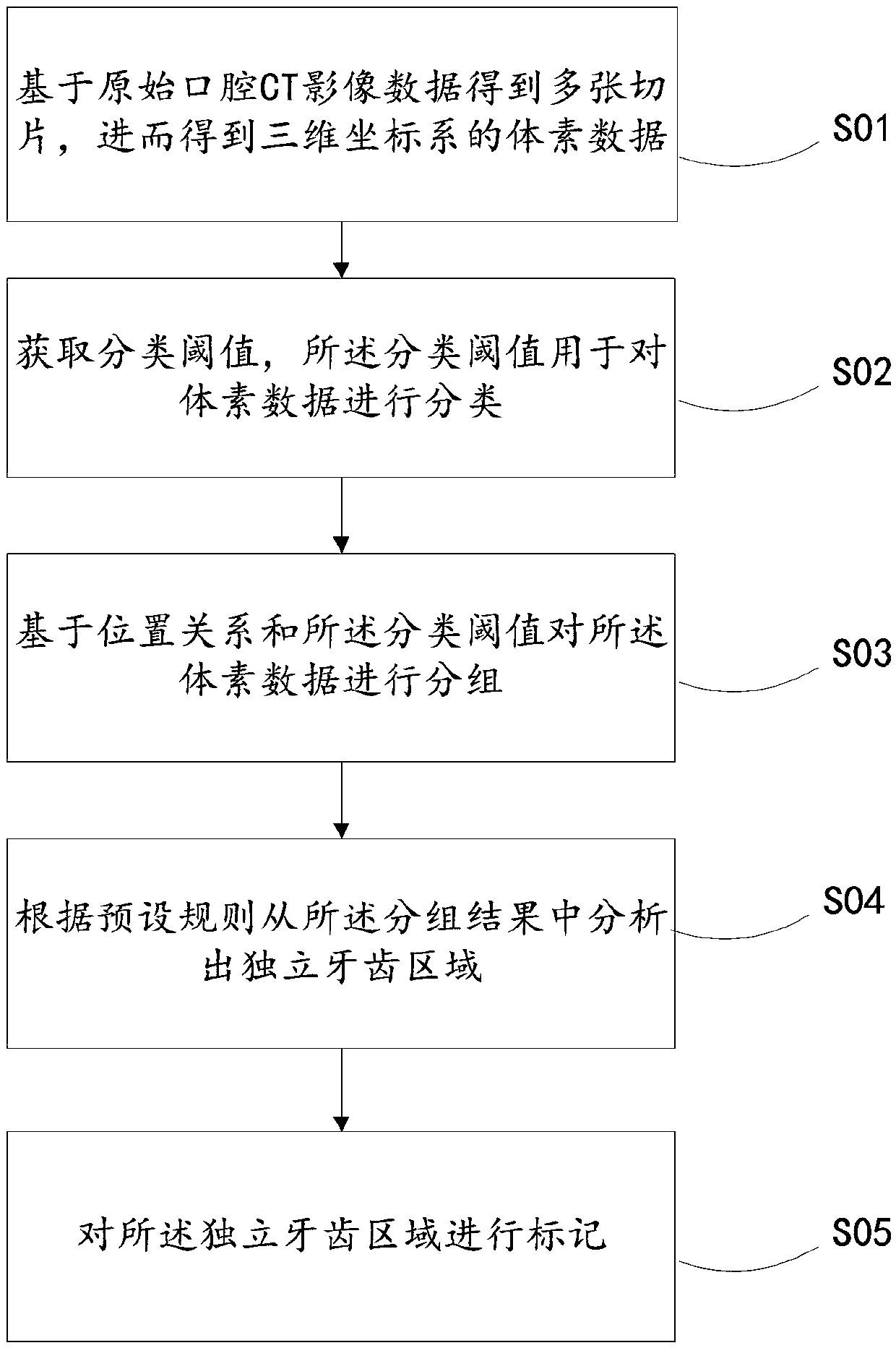

Orthodontic method and device based on artificial intelligence

ActiveCN109528323ALess susceptible to subjective influenceFully automatedImage enhancementImage analysisTooth numberArtificial Intelligence System

The invention provides an orthodontic method and device based on artificial intelligence. The method comprises obtaining tagged oral CT image data, wherein the tagged oral CT image data circle the tooth area on each frame of the image in the form of an annotation; the circled area is marked with the corresponding tooth number, and the non-dental area is set to 0; the tagged oral CT image data is inputted into a second generator to obtain an orthodontic scheme represented in a coded form; according to the orthodontic scheme, a printable dentition model is obtained by combining the three-dimensional digital model of teeth obtained from the marked oral CT image data; an appliance can be made in basis of the model of the teeth. The device relates to multiply machine learning models and realizes automation of the whole process from 3D digitization of teeth to Model Manufacturing, which is not easily subject to the subjective influence of a doctor and capable of improving the efficiency of diagnosis and treatment.

Owner:YADIAN SOFTWARE TECH SHANGHAI CO LTD

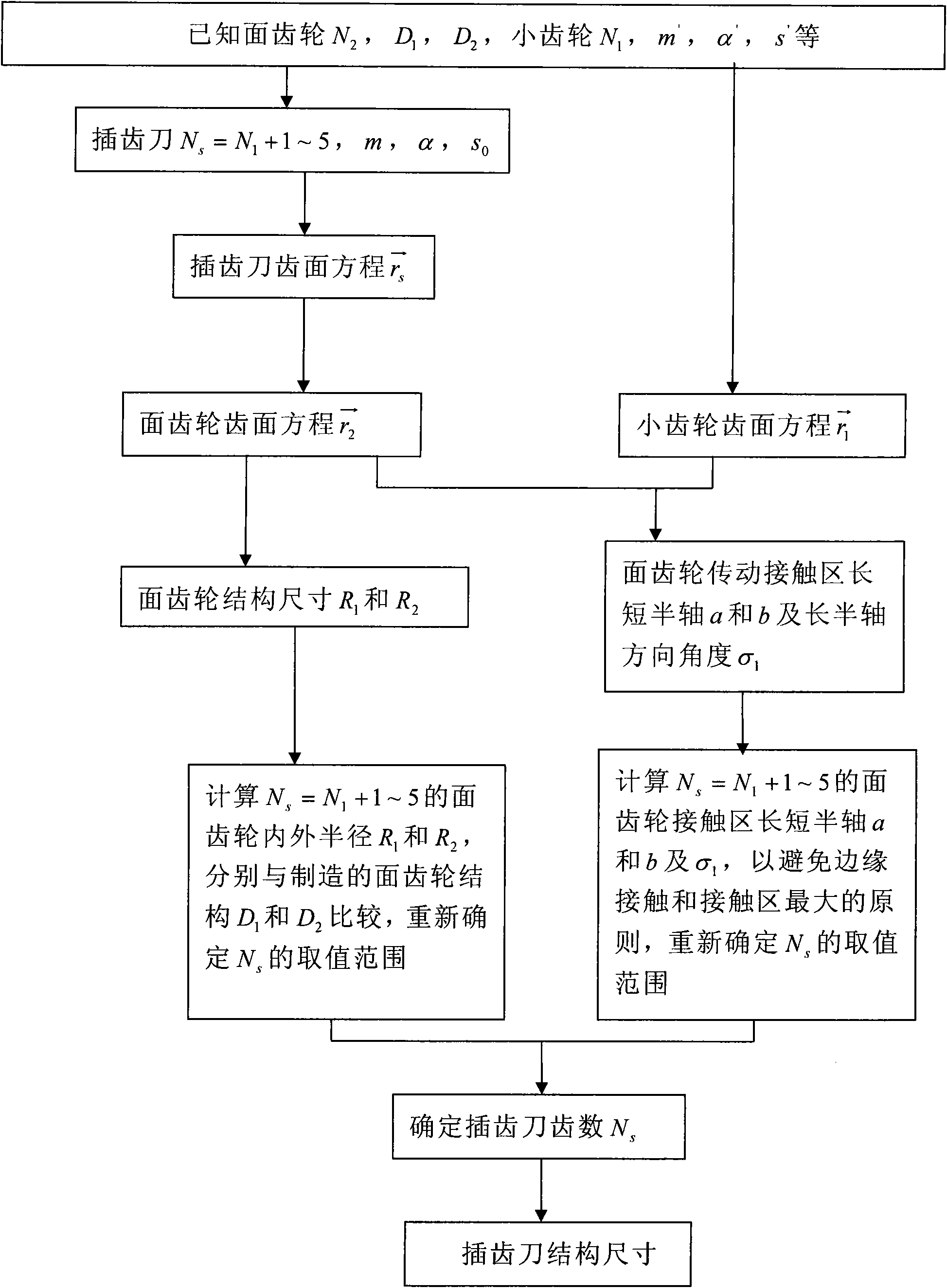

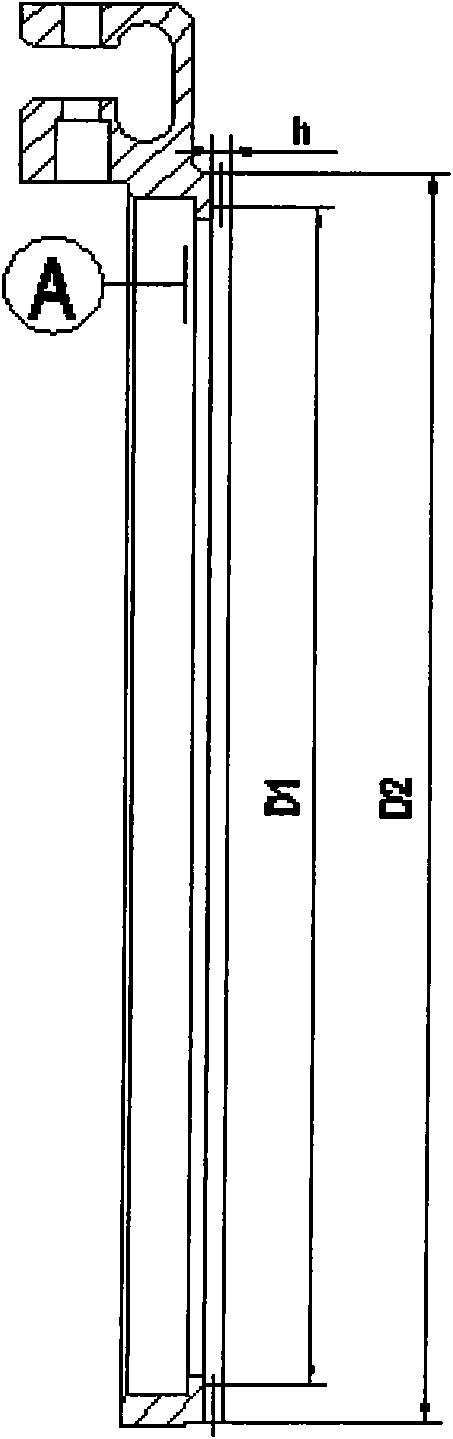

Design method for face gear slotting cutter tooth form

InactiveCN101937482AFacilitate transmissionImprove processing efficiencySpecial data processing applicationsTooth numberEngineering

The invention relates to a method for determining a face gear slotting cutter tooth form structure, which can determine a reasonable tooth number of a face gear slotting processing cutter based on the basic principles of face gear slotting gear processing and face gear meshing drive in comprehensive consideration of affects of different slotting cutter tooth number to the processing dimensions of a face gear and the drive meshing performance of a processed face gear, and further determines a face gear slotting cutter structure to be processed according to the tooth number of a pinion that is matched with the face gear. The face gear processed by the determined face gear slotting cutter tooth structure has good drive performance, the follow-up cost to reshape the face gear in order to improve the meshing performance of the face gear is saved, and meanwhile, the processing efficiency of the face gear is improved.

Owner:BEIHANG UNIV

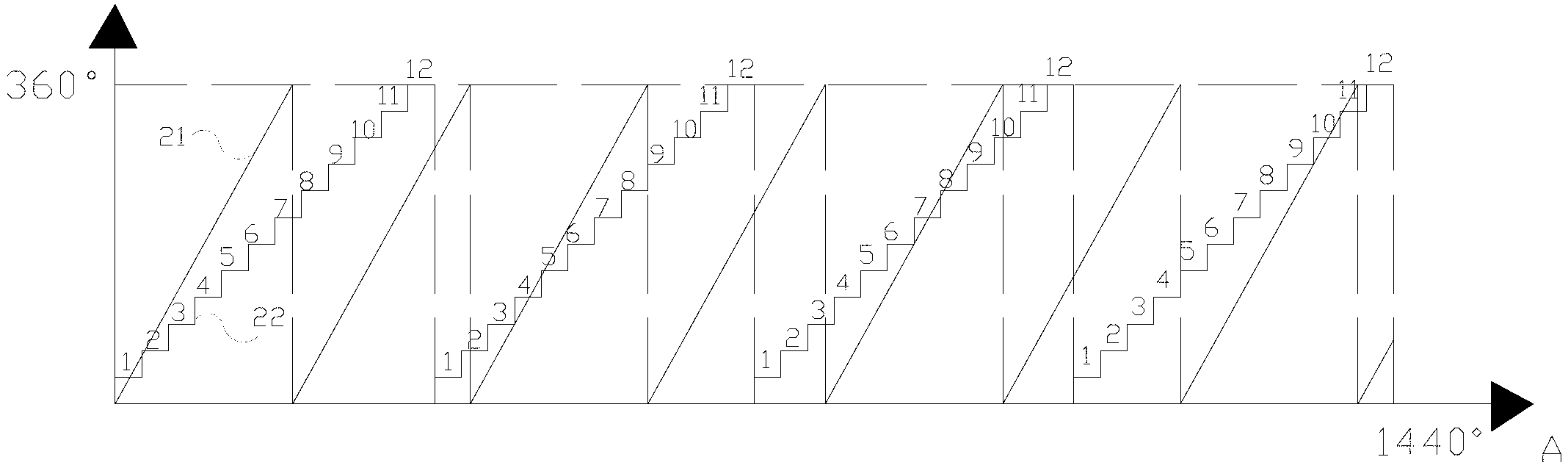

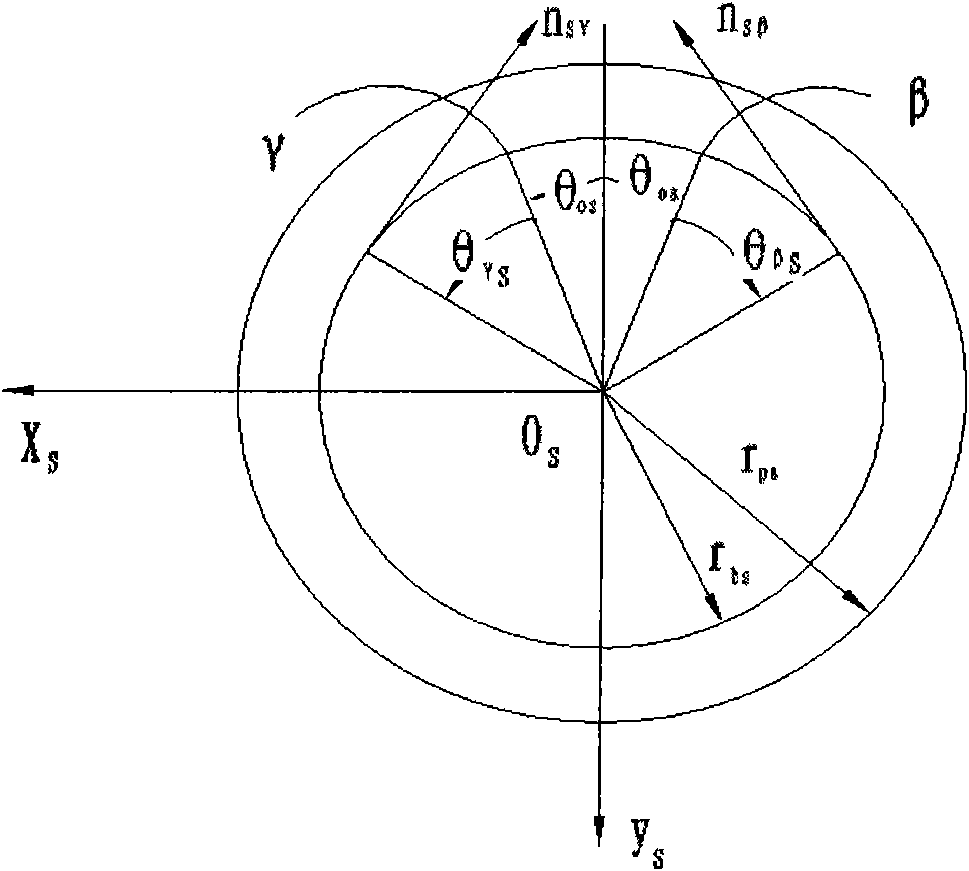

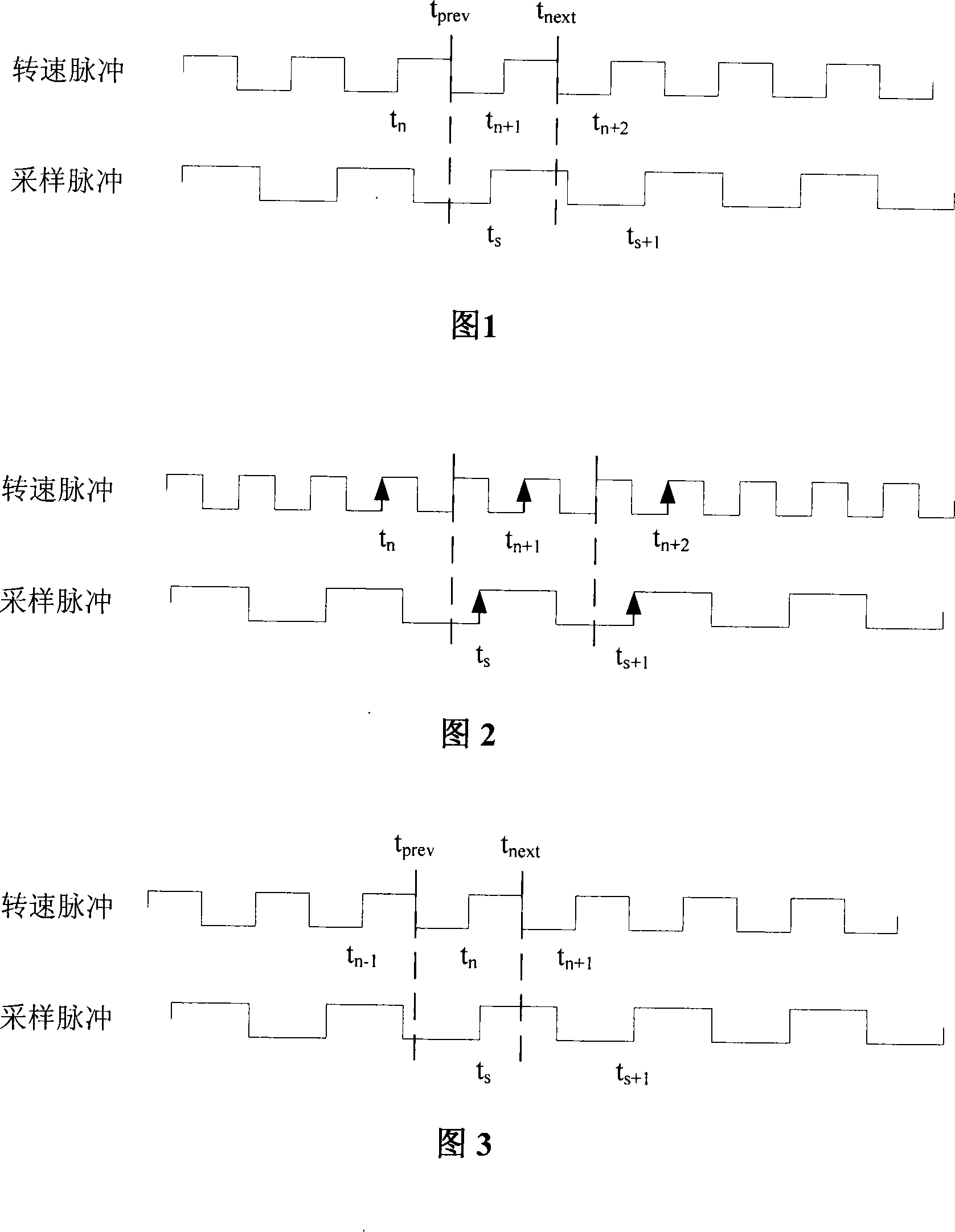

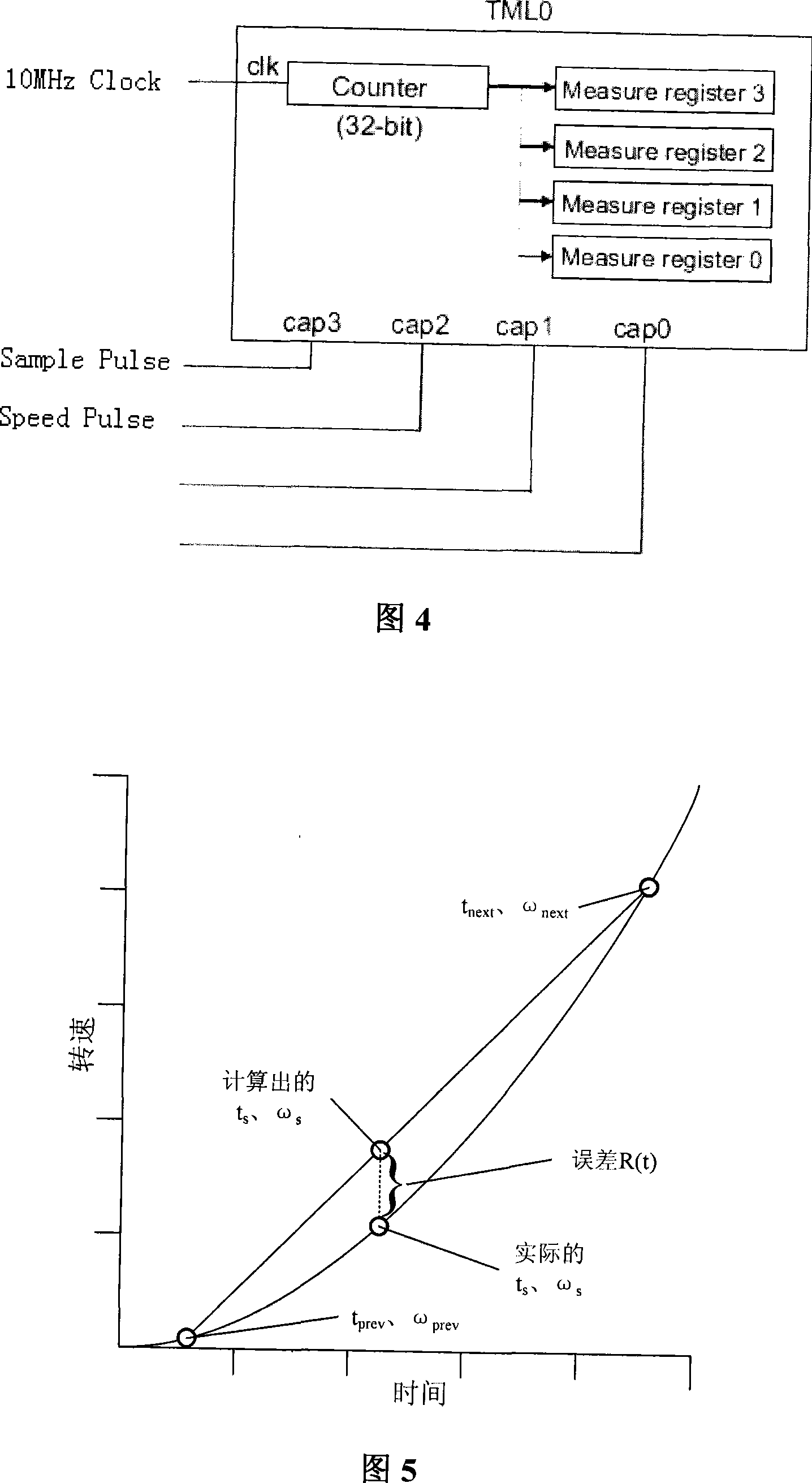

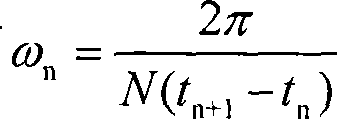

Secondary sampling method for speed-measuring fluted disc teeth number of self-adapting large steam turbine generator

ActiveCN101241045AEasy to calculateSubsynchronous Oscillation ResolutionVibration measurement in solidsEngine testingTooth numberTorsional vibration

The invention relates to a measuring method of shaft torsional vibrations of 300MW, 600MW, 1000MW large turbogenerator unit of heat power generation, disclosing a method of self-adapting velocity-measuring tooth disc tooth number. The method firstly measures transient speed of the generator by perimeter measuring method, then processing secondary sampling with uniformly-face and fixed sampling frequency for the speed data via linear interpolation, further obtaining real-time speed data with equal space and fixed frequency sampling frequency irrelevant to tooth number of the generator, which reduces influence on trailing torsion calculation caused by inconsistency of tooth number of the velocity-measuring tooth disc. For the velocity tooth disc with different tooth numbers, sampling data with same sampling frequency and equal sampling space can be obtained measured by the method. The method unifies sampling rate of output data, reduces complexity level of processing link of trailing data, at the same time, guarantees reliability and precision of the data. The method is a basis for accomplishing measurement of shaft torsional vibrations, which is an important link for safe and stable operation of the generator unit.

Owner:BEIJING SIFANG JIBAO AUTOMATION

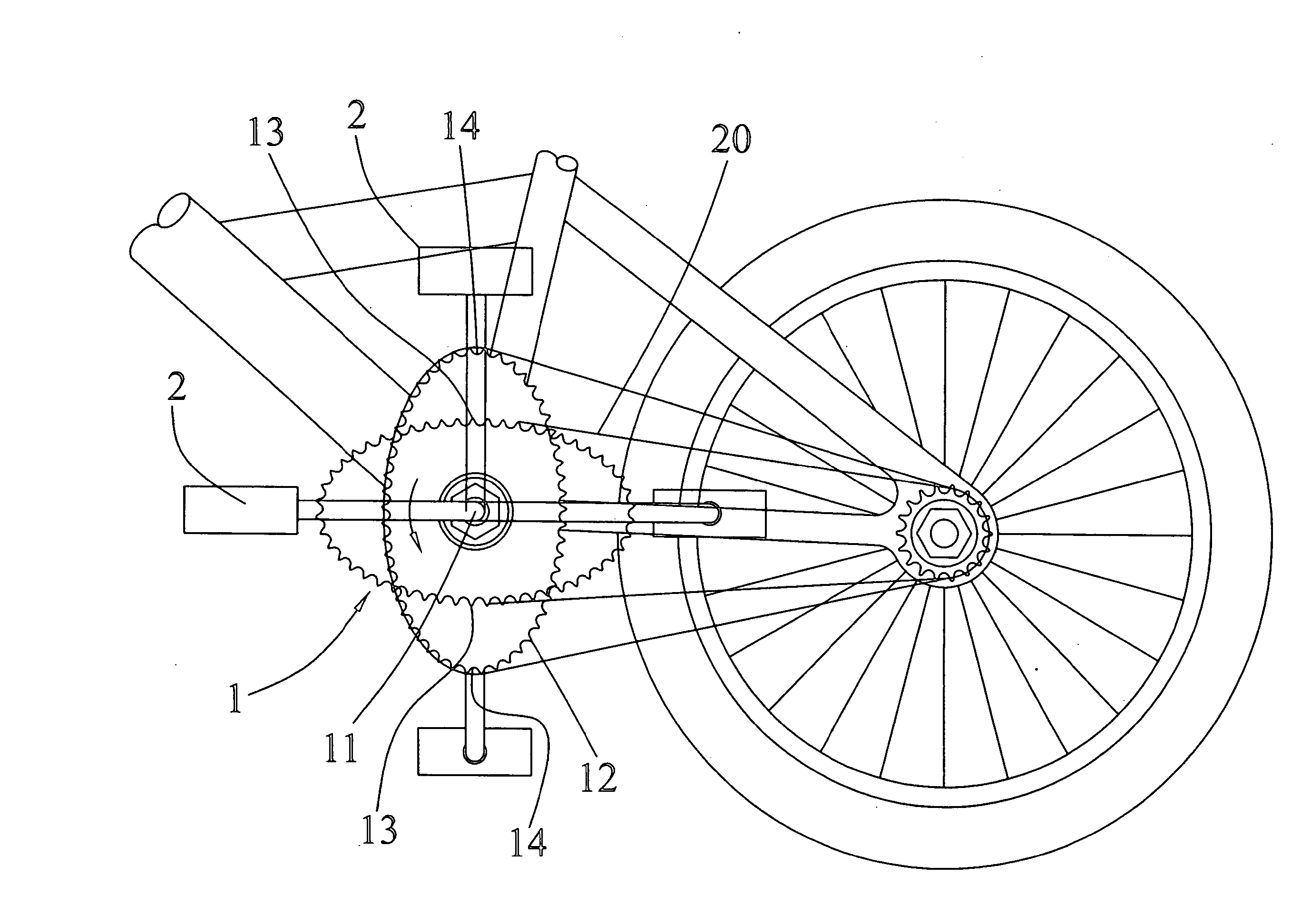

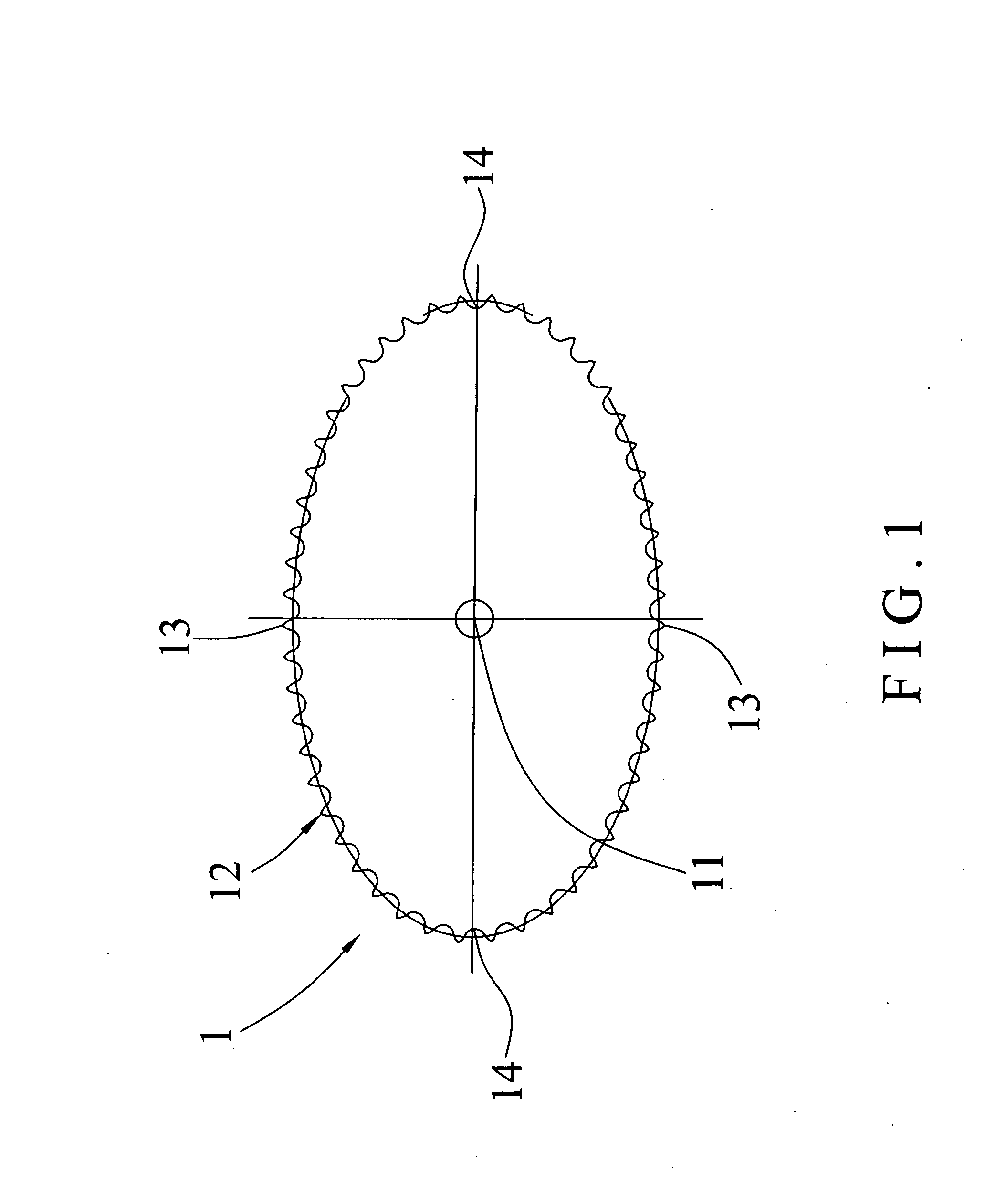

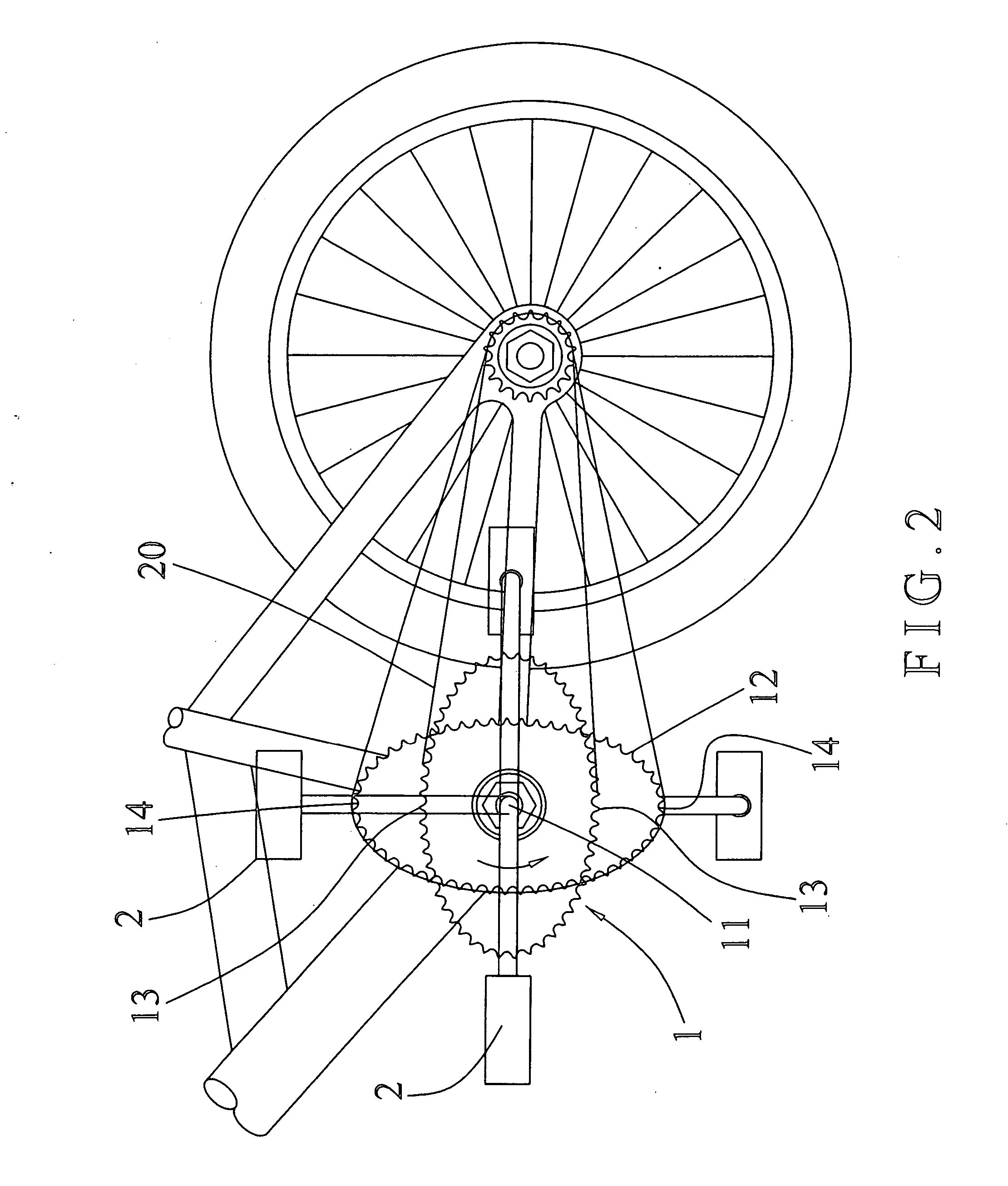

Chain wheel for bicycle

InactiveUS20070246908A1Uniform forceDrive stabilityChain/belt transmissionRider propulsionGear wheelEngineering

A chain wheel for a bicycle includes an oblong gear having a flat shape. The oblong gear has a central point and has a periphery having two opposite relatively shortest points and two opposite relatively longest points. The periphery of the oblong gear has a tooth number equal to that of a circular gear. The oblong gear is driven by two pedals to drive and rotate a chain. Thus, the moment produced by the oblong gear has different values to compensate the different positions of the two pedals, so that the rider's legs can apply a pedaling force on the two pedals evenly and smoothly, thereby facilitating the rider pedaling the two pedals.

Owner:SHU MING TSAN

Involute arc tooth profile bevel gear and meshing pair thereof

ActiveCN101975264AImprove carrying capacityReduce contact stressToothed gearingsPortable liftingInvolute gearTooth number

The invention discloses an involute arc tooth profile bevel gear and a meshing pair thereof. The tooth profile curve of bevel gear is formed by the way that an arc does helical motion along the tooth surface contact line on involute helicoids, thus having the advantages that involute gear center distance has separability and is convenient to measure, involute gear is convenient to manufacture and an arc gear has high contact strength and good running-in property, tooth surface contact stress is reduced, tooth surface carrying capacity is greatly improved, and processing is convenient; and the tooth curve of the arc and the radial length of involute participating in meshing are short, thus avoiding undercutting phenomenon of standard gear, so that minimum tooth number of the gear can reach 1. Compared with the gear in the prior art, weight and size are greatly reduced; and the meshing pair adopts the way that a convex gear is meshed with a concave gear, and carrying capacity is high.

Owner:CHONGQING UNIV

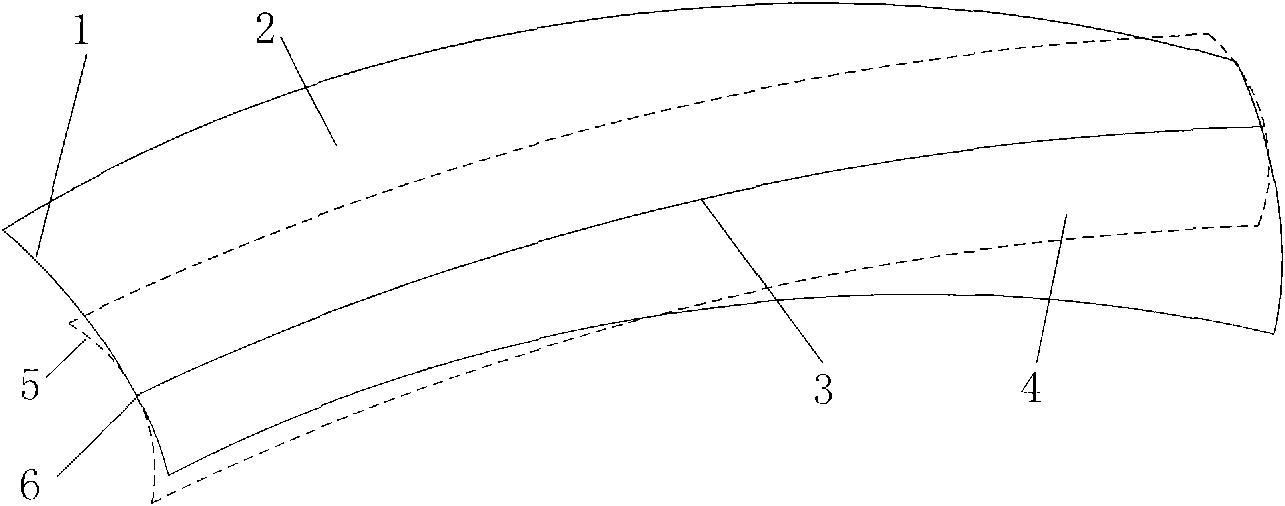

Vane structure for weakening axial flow pump vane top leakage flow and leakage vortex

InactiveCN103671254AHigh liftImprove hydraulic efficiencyPump componentsPumpsAxial-flow pumpEngineering

The invention relates to a vane structure for weakening axial flow pump vane top leakage flow and leakage vortex. The vane structure is characterized in that an axial flow pump vane top is machined to be of a mazy structure which is in a sawtooth shape and has a certain gap, height, width, tooth numbers, tooth top angles and the like. The vane structure has the advantages that proper sawtooth size is selected, through the vane tip mazy structure of an axial flow pump, energy loss is increased when fluid passes through the vane top gap, leakage amount is lowered, accordingly, vane top leakage flow and leakage vortex are weakened, and the hydraulic efficiency and the operation stability of the axial flow pump are improved.

Owner:JIANGSU UNIV

Integrated cutting and conveying device of sugarcane harvester

The invention discloses an integrated cutting and conveying device of a sugarcane harvester. The integrated cutting and conveying device comprises a cutting mechanism and a conveying mechanism fixed to each other. The conveying mechanism comprises a feeding fixed plate and a rubber plate. The feeding fixed plate is fixed on a roller. The rubber plate penetrates through the feeding fixed plate and is then fixedly connected to the outside of the roller. Cut canes are effectively conveyed back by the feeding fixed plate and the rubber plate disposed on the roller. Gears in a gear bank have different tooth numbers, so that rotation speed of the rubber plate is smaller than that of a disc cutter, the cut canes can be timely, stably and orderly conveyed to subsequent procedures through the feeding fixed plate and the rubber plate, multi-breakage of the canes is avoided, cane harvesting quality is improved, and damage of sugar content of the canes is avoided.

Owner:LINHAI HENGFENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com