Vane structure for weakening axial flow pump vane top leakage flow and leakage vortex

A technology of blade tip leakage and blade structure, which is applied to the components, pumps, and pump elements of pumping devices for elastic fluids, can solve problems such as increased workload, complex blade shapes, and difficult processing, and achieves improved lift and Effects of hydraulic efficiency, improved hydraulic stability, and mature processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

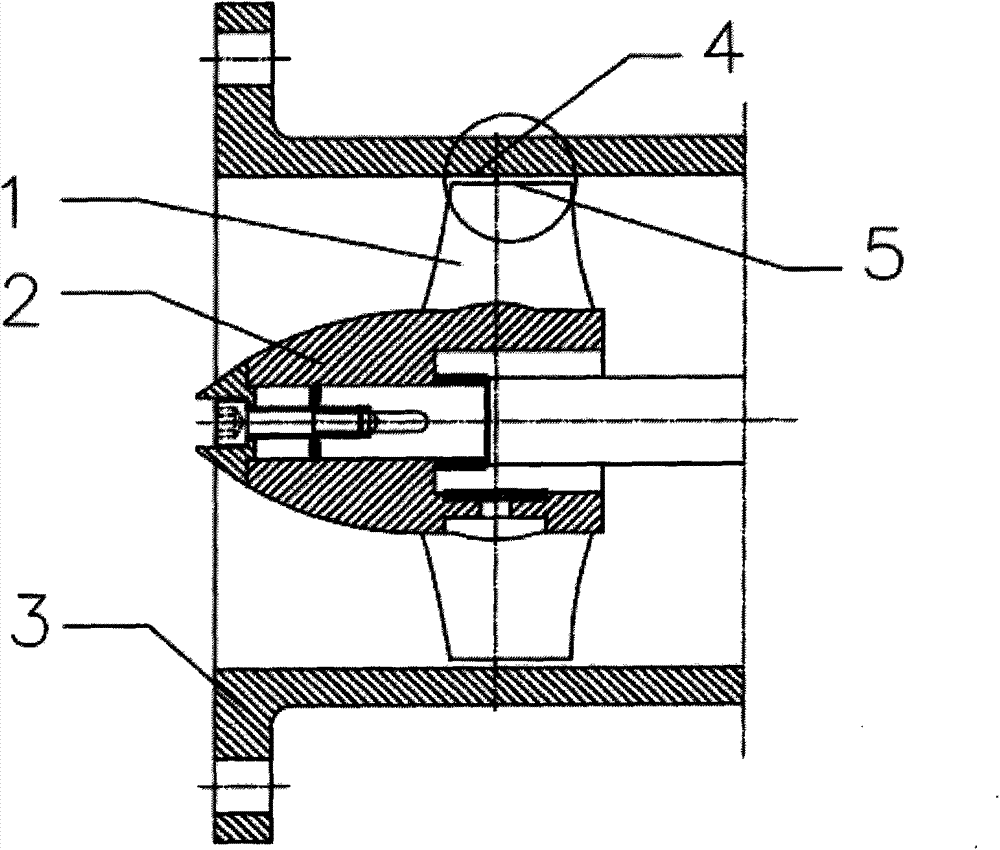

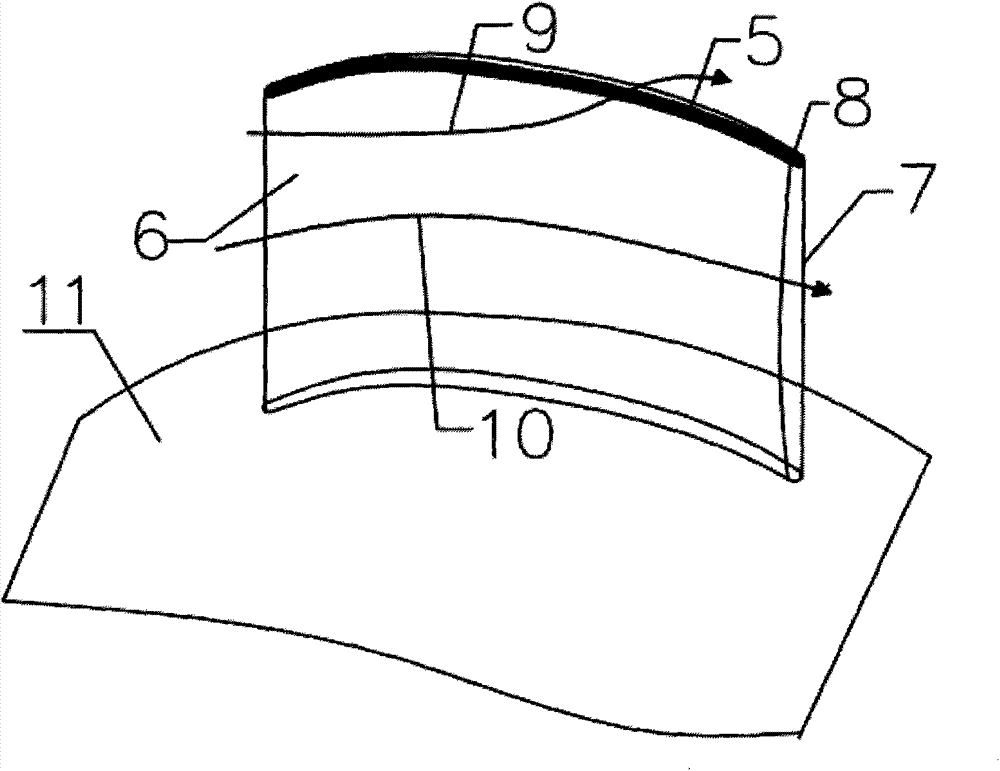

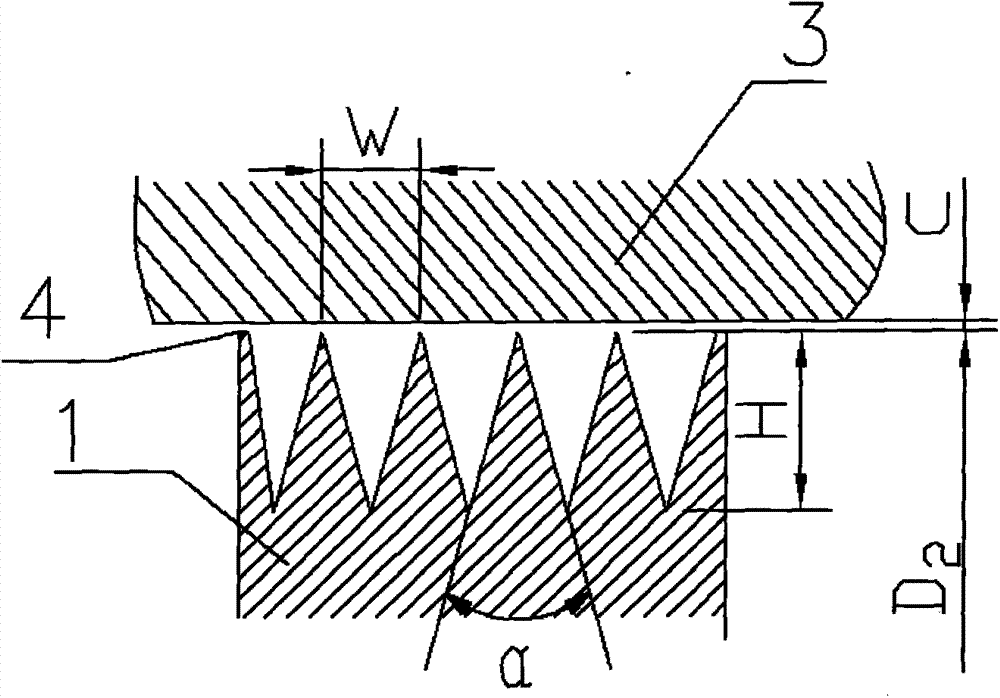

[0014] A partial schematic of an axial flow pump figure 1 , including the impeller blade (1) of the axial flow pump, the impeller hub (2), the runner chamber (3), the impeller gap (4) and the blade top (5). The zigzag labyrinth structure of the present invention is designed on the blade top (5), and the distance between the impeller blade (1) and the wall surface of the runner chamber (3) is the impeller gap (4). The impeller blades are fixed on the impeller hub (2) by a fixing piece. Due to the pressure difference between the blade pressure surface (7) and the suction surface (6), the liquid (10) between the vane passages of the axial flow pump leaks from the blade pressure surface (7) to the The suction surface (6) passes through the zigzag labyrinth structure (8) of the blade top, which increases the fluid flow resistance and consumes part of the kinetic energy of the fluid flowing through the blade tip gap, thereby reducing the leakage of the blade tip gap and inhibiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com