Method for designing hydraulic model of blade front bent type circulating booster pump

A technology of cyclic pressurization and design method, applied in the direction of non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

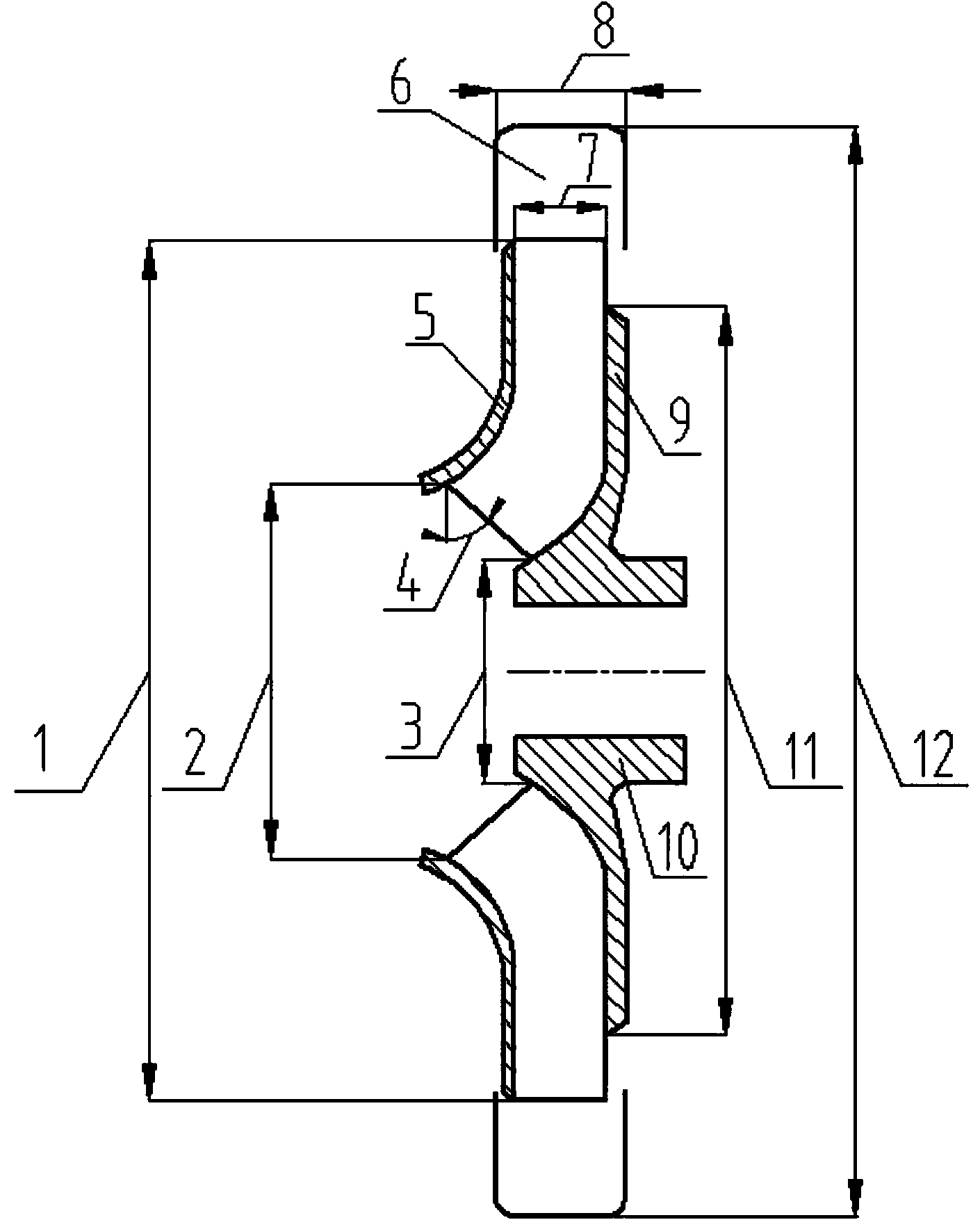

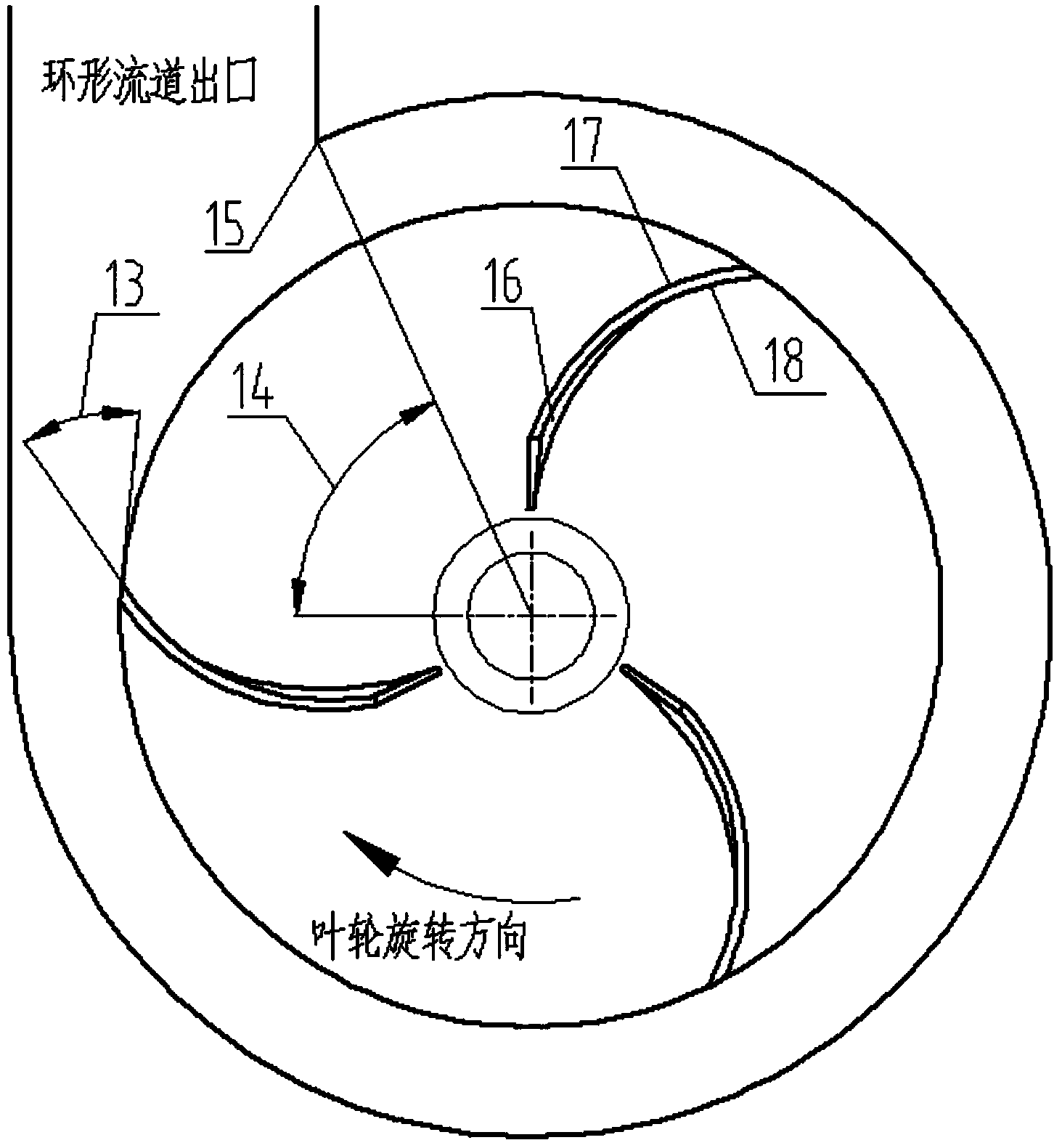

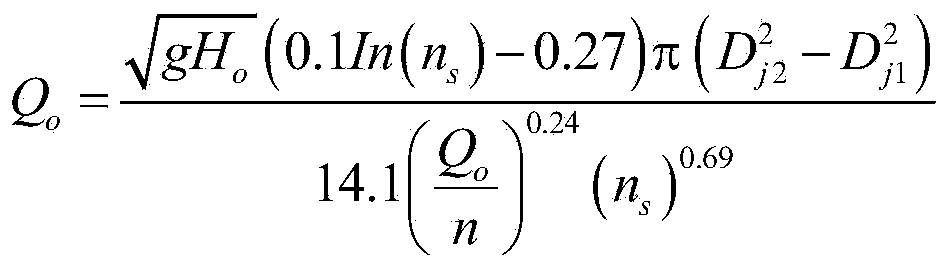

[0058] figure 1 and figure 2The geometrical and dimensional parameters of this hydraulic model embodiment of a forward-curved-vane circulating booster pump were jointly determined. The pump adopts a closed impeller structure, and the impeller blades (16) are backward curved, so that the flow and head performance parameters of the design working point of the circulating booster pump are larger, and the outer diameter of the impeller rear cover plate is D 4 (11) slightly smaller than the outer diameter of the front cover plate (5) of the impeller, which is conducive to reducing the axial load of the impeller and improving the reliability of the rotor components of the circulating booster pump. The pressure water chamber of the circulating booster pump adopts the type of annular flow channel (6), which is beneficial to reduce the radial dynamic load of the impeller, makes the impeller run more smoothly, and the vibration level of the pump unit is lower. Annular channel width b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com