Design method of impeller and pressurized water chamber of a high-lift vortex pump

A pressurized water chamber and vortex pump technology, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, can solve the difficulty of manufacturing and processing vortex pump units, and does not propose the design of impellers and pressurized water chambers method, unable to adapt to changes in head working conditions, etc., to achieve the effects of improving internal flow conditions, increasing design head and design flow values, and stabilizing performance curve characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

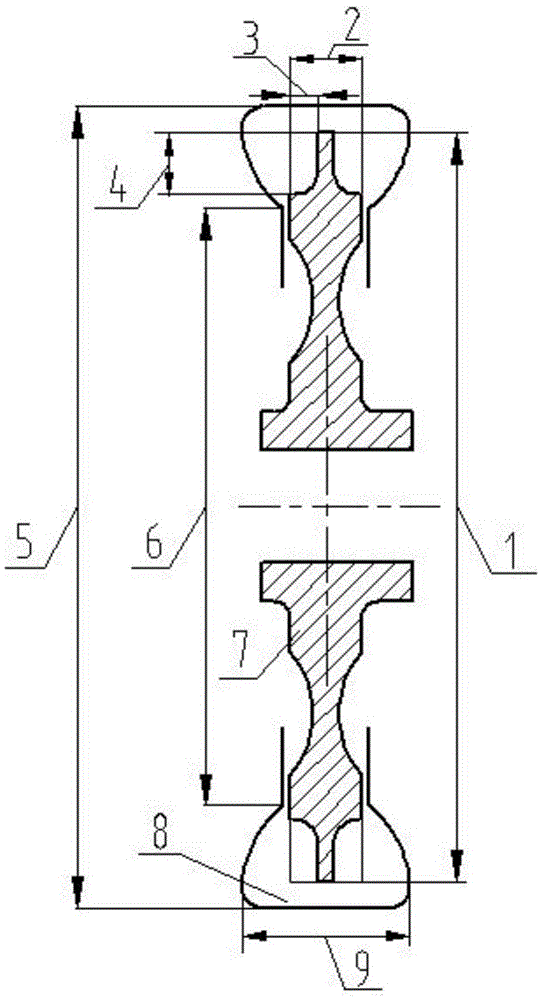

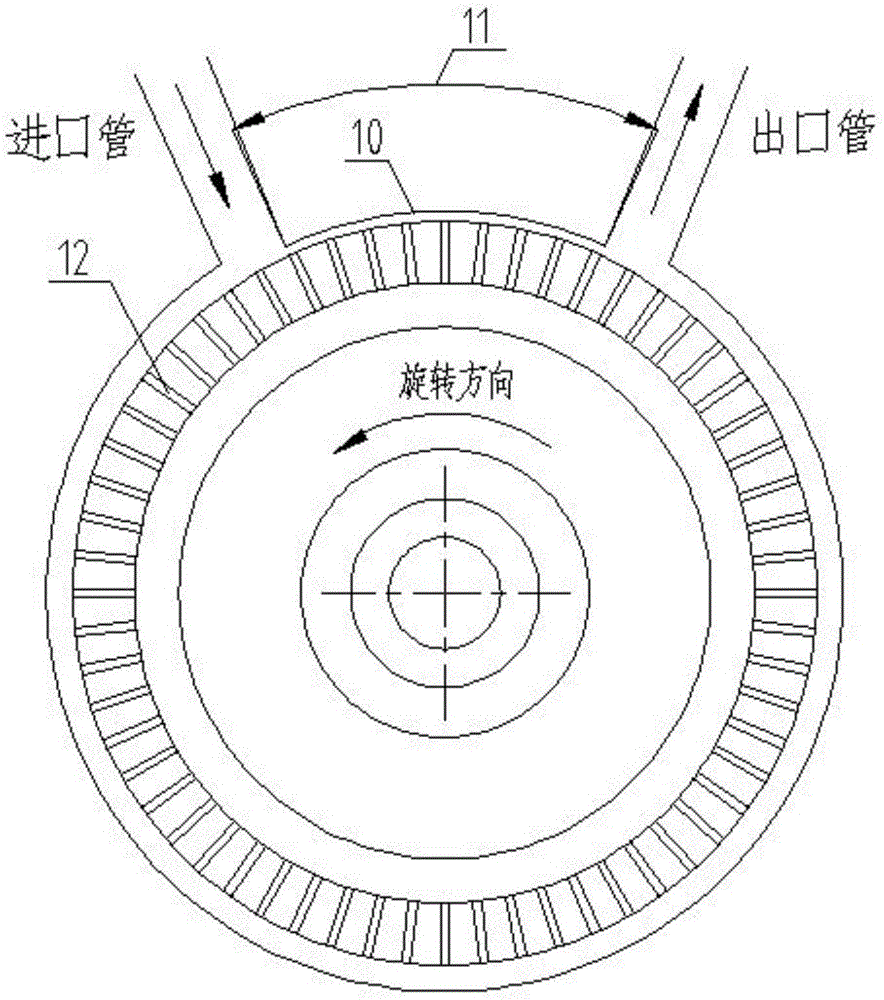

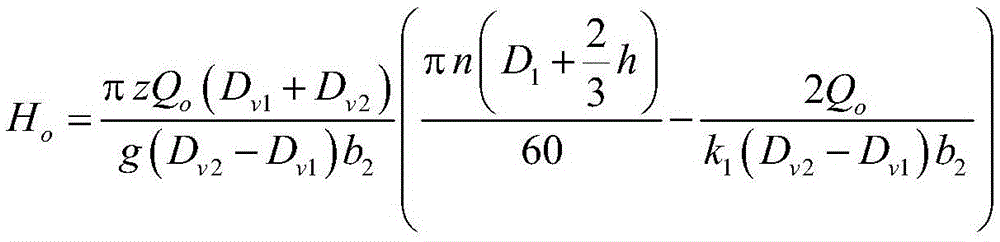

[0072] figure 1 and figure 2 Together, the geometrical and dimensional parameters of this high head scroll pump embodiment were determined. This is a vortex pump with closed impeller double-side open flow channel. The impeller blades (12) and the pressurized water chamber (8) are symmetrically arranged on both sides. The impeller blades (12) adopt a straight blade structure. ) is axisymmetrically distributed on the outer edge. The pressure water chamber (8) has a trapezoidal structure, and its flow area is larger than the design value of the conventional vortex pump, which is beneficial to reduce the hydraulic loss of the liquid in the pressure water chamber and improve the momentum exchange level of the liquid in the impeller blade (12). Water outer diameter D v2 (5) slightly larger than the outer diameter of the impeller D 1 (1), the width of the pressurized water chamber b 2 Greater than the impeller outlet width b 1 . The inlet pipe and outlet pipe of the vortex pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com