Patents

Literature

42results about How to "No turning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

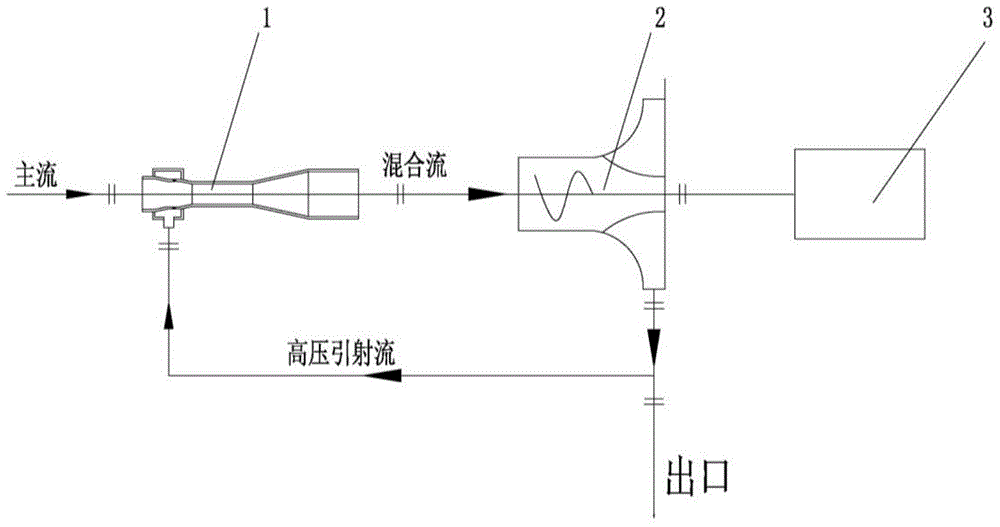

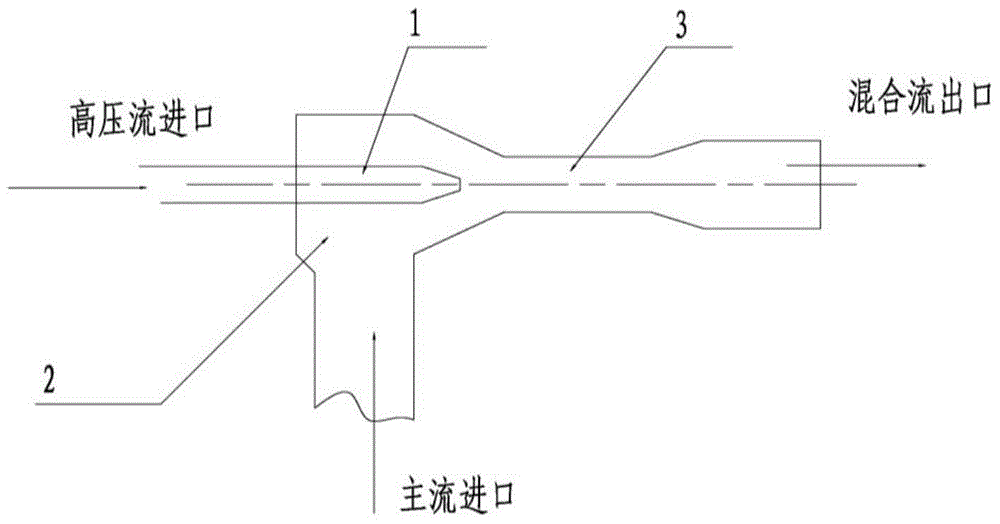

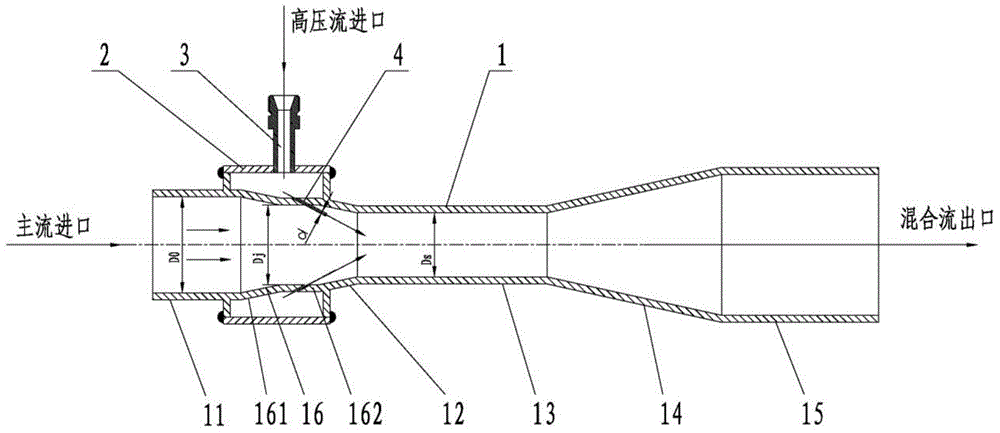

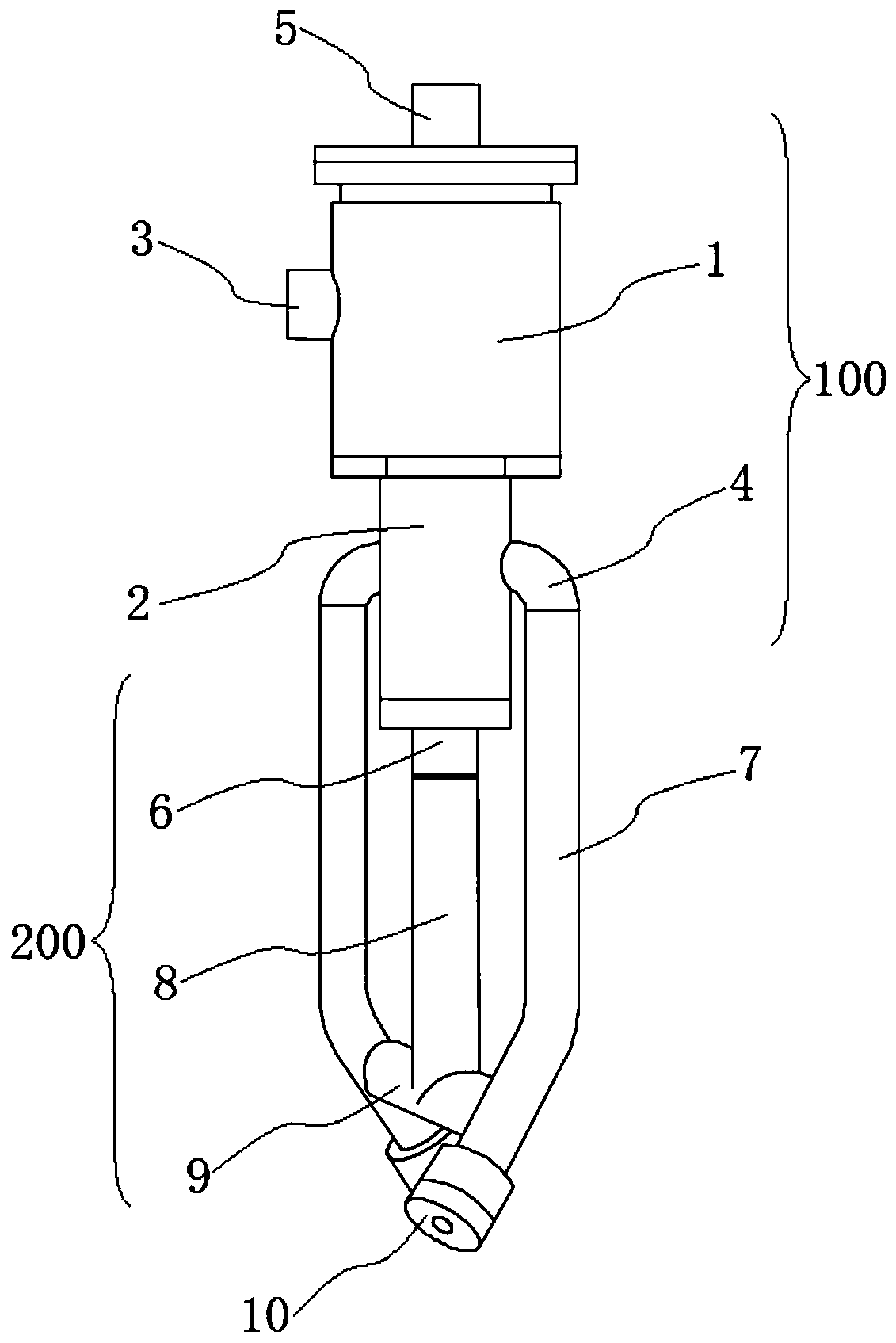

High pressure annular jet pump suitable for pumping pressure type supply system

The invention belongs to the technical field of aviation and space, and particularly relates to a high pressure annular jet pump suitable for a pumping pressure type supply system. The high pressure annular jet pump comprises an inlet section pipe, a mixing section pipe, a throat pipe, a diffusion section pipe and an outlet section pipe which are sequentially arranged in the flowing direction of main fluid. The high pressure annular jet pump is characterized by further comprising step section pipes which are sequentially arranged between the inlet section pipe and the mixing section pipe; each step section pipe comprises a convergence section pipe and a straight section pipe; each straight section pipe is provided with a spraying nozzle for providing high pressure fluid. The high pressure annular jet pump is compact in structure, light in weight, good in anti-cavitation performance and capable of meeting the requirement for normal work under the working conditions of high rotating speed and low inlet pressure.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

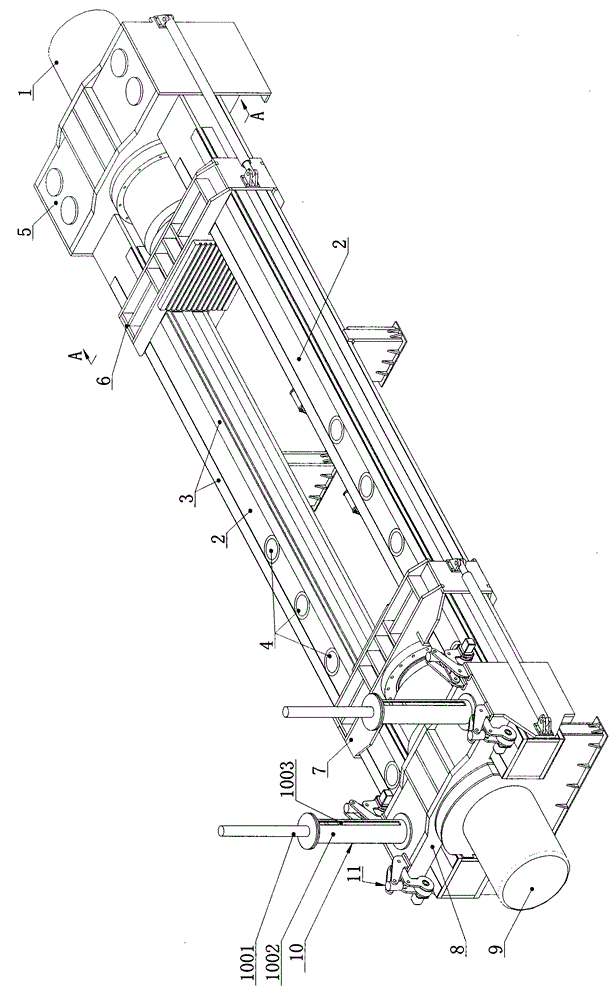

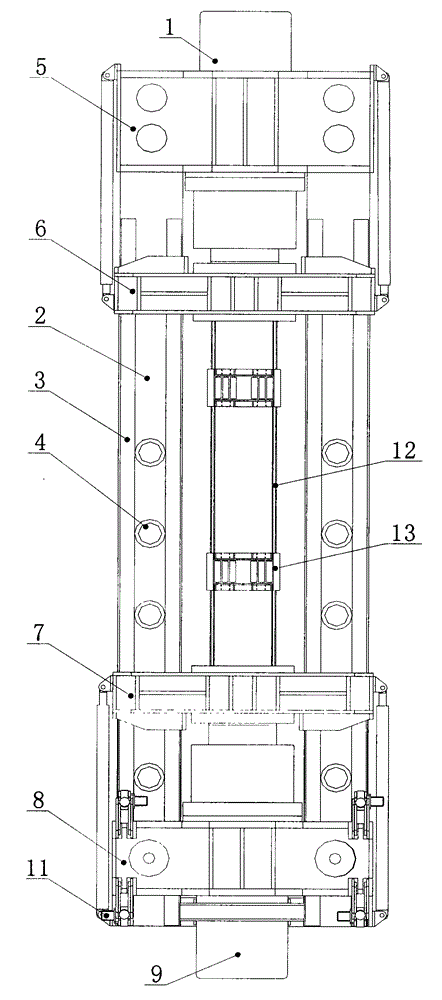

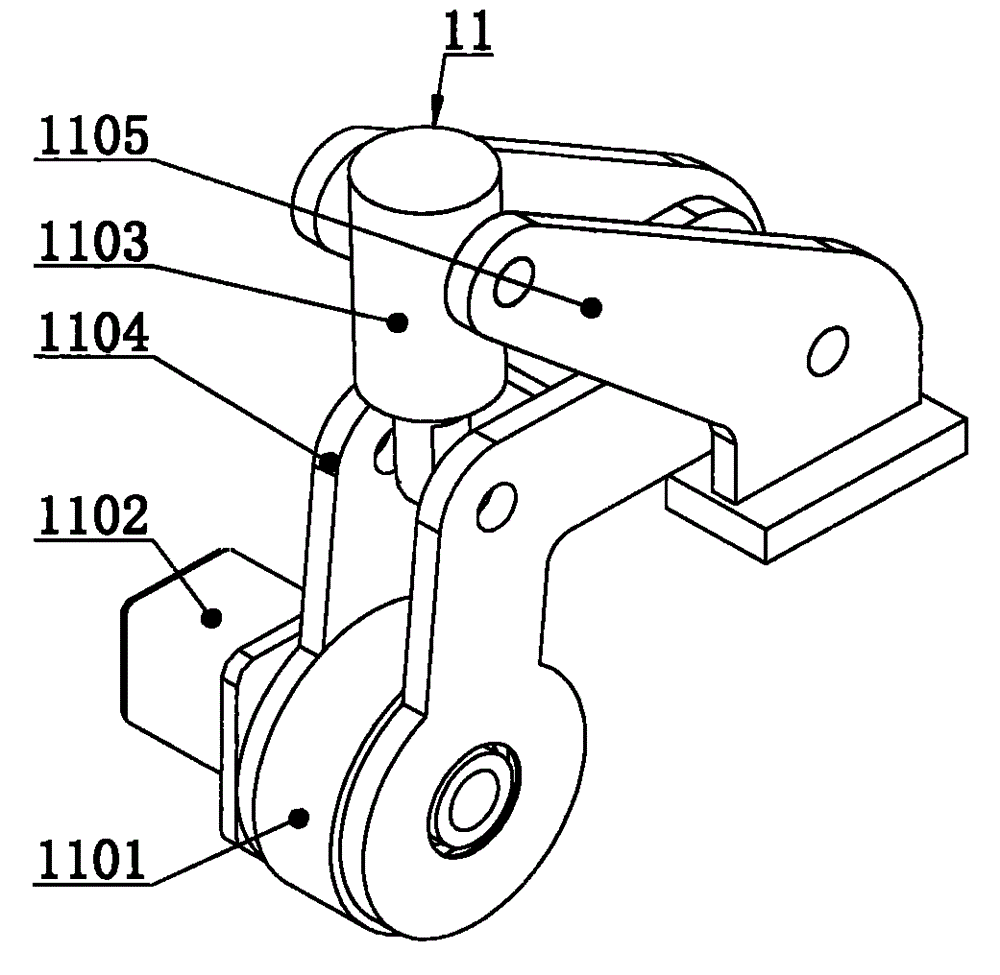

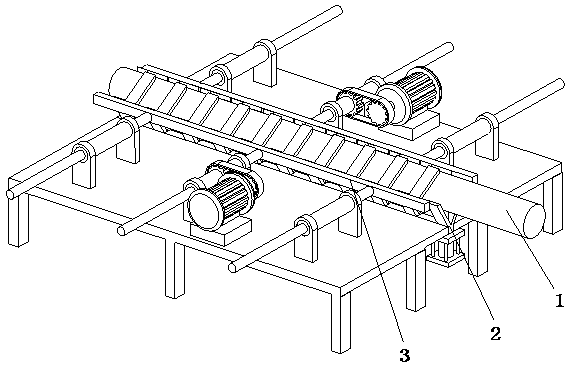

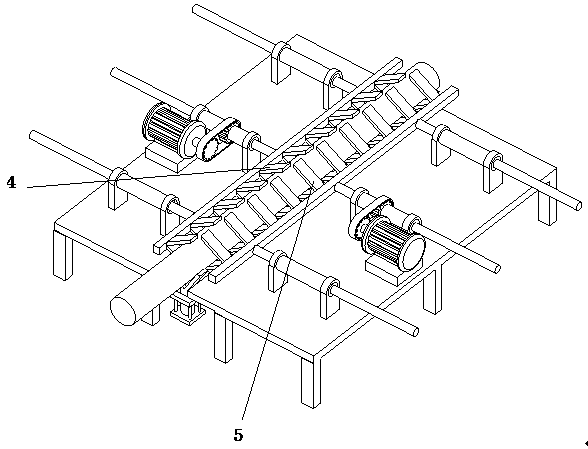

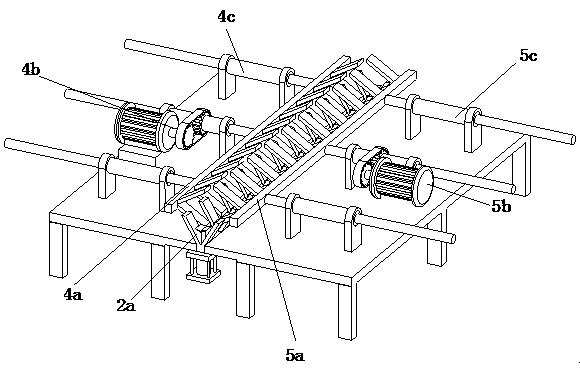

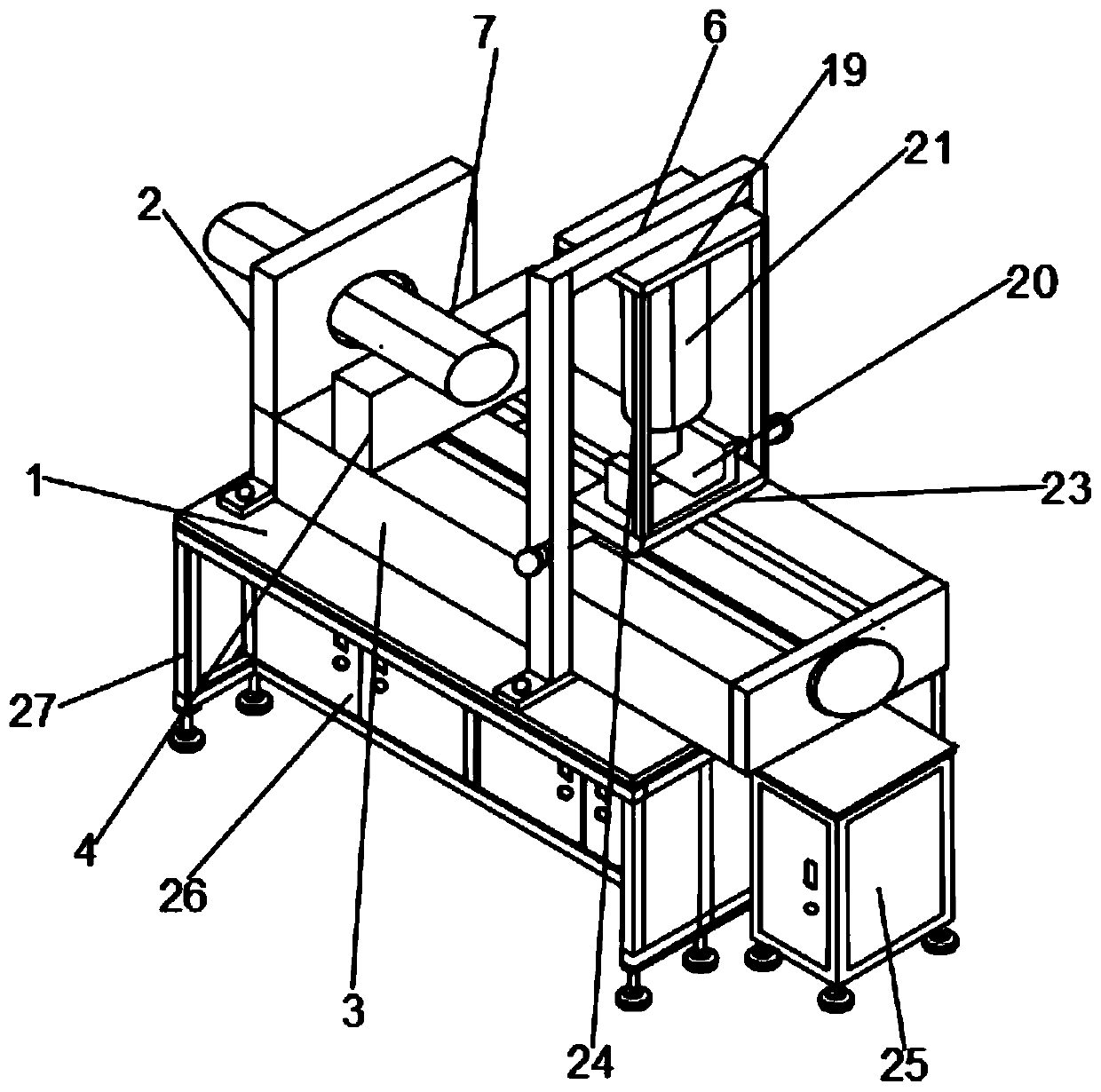

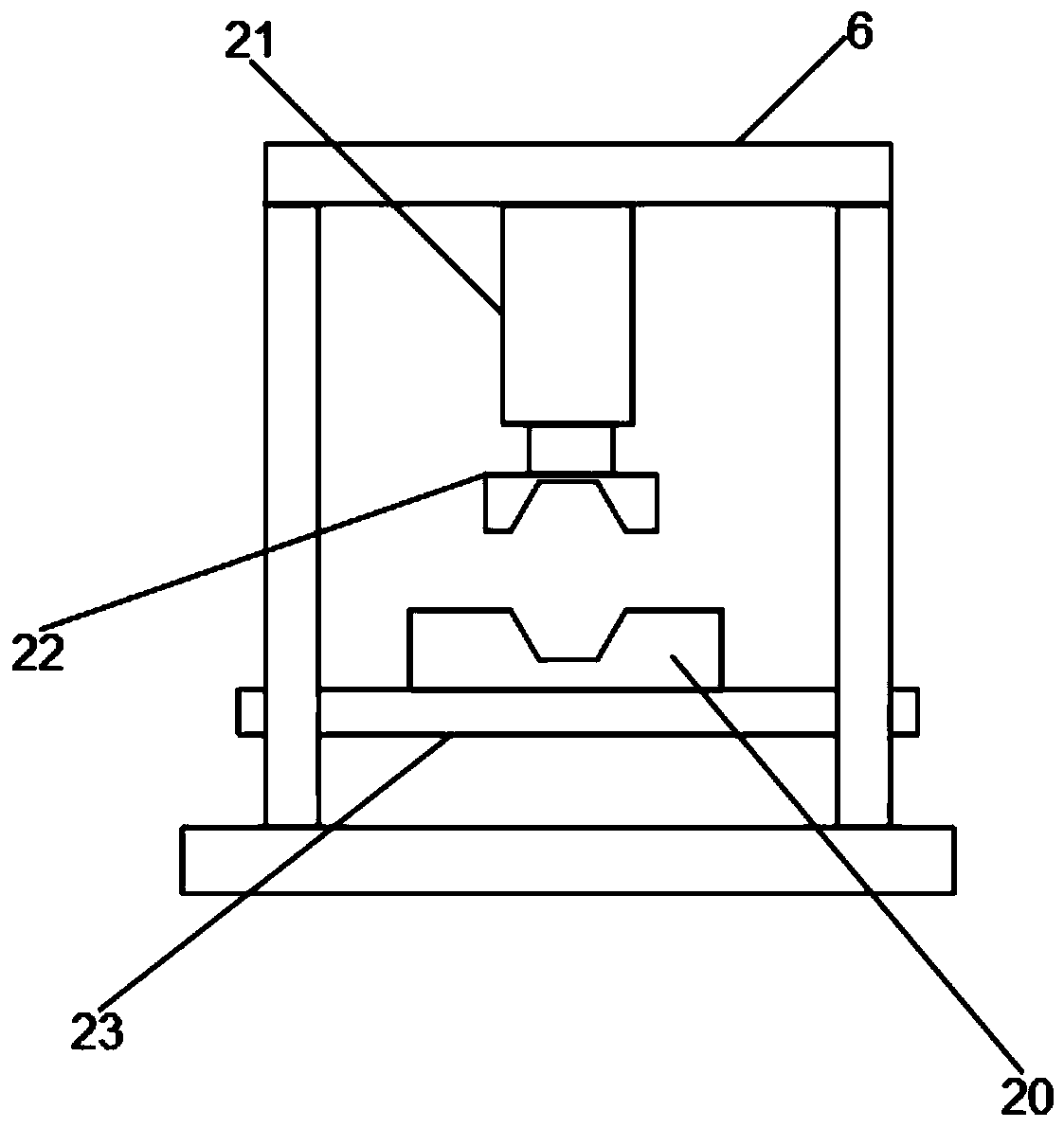

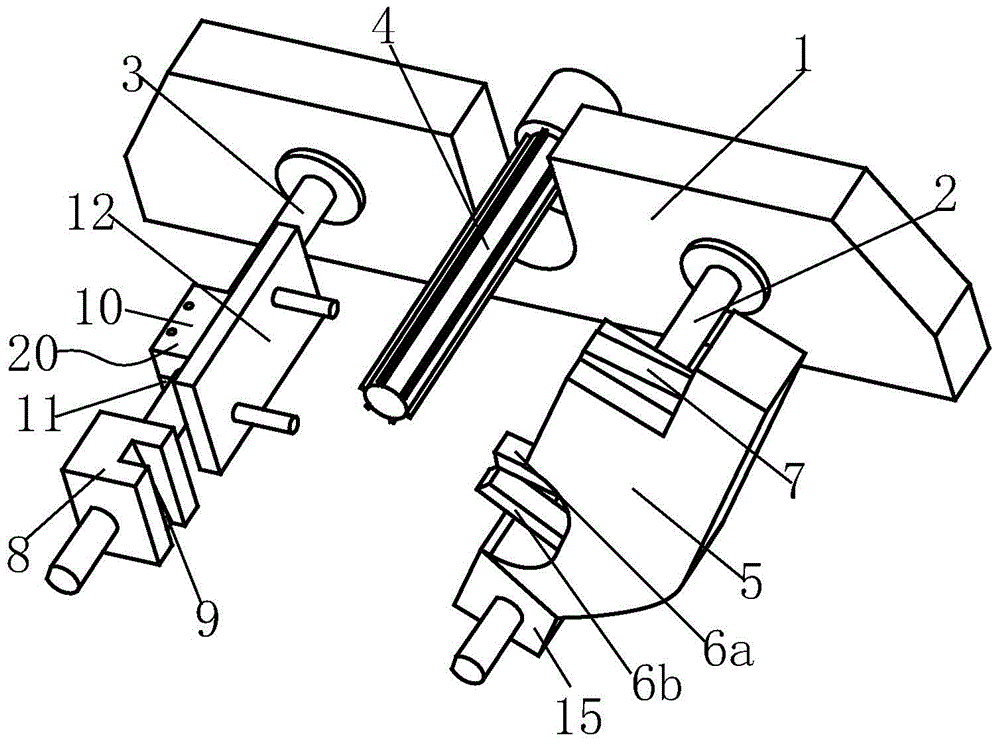

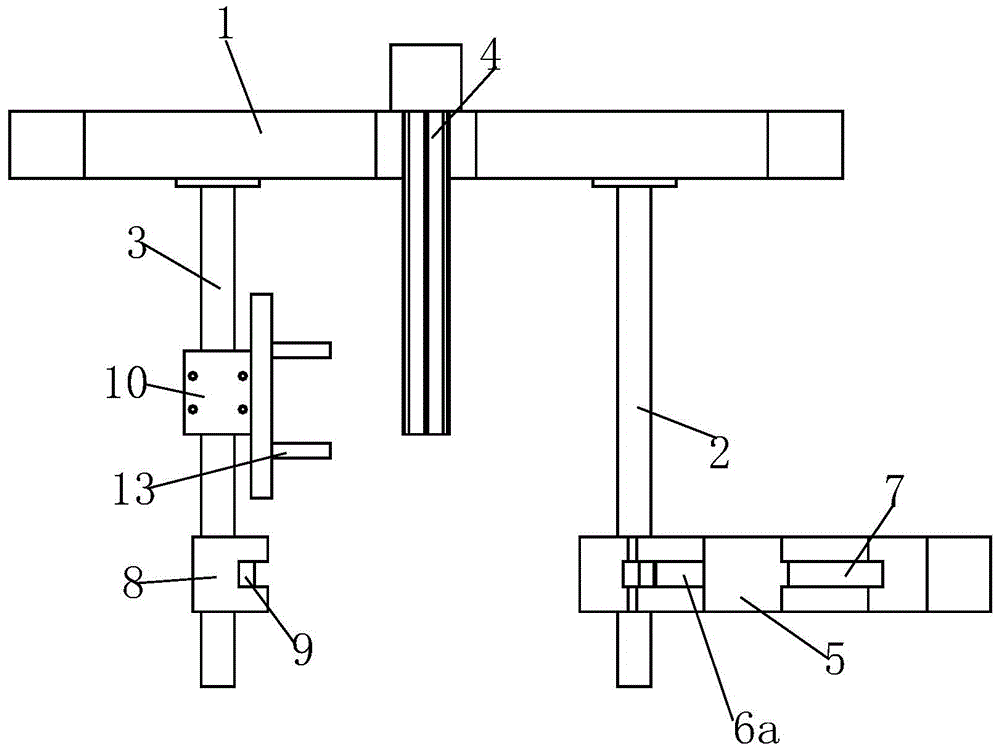

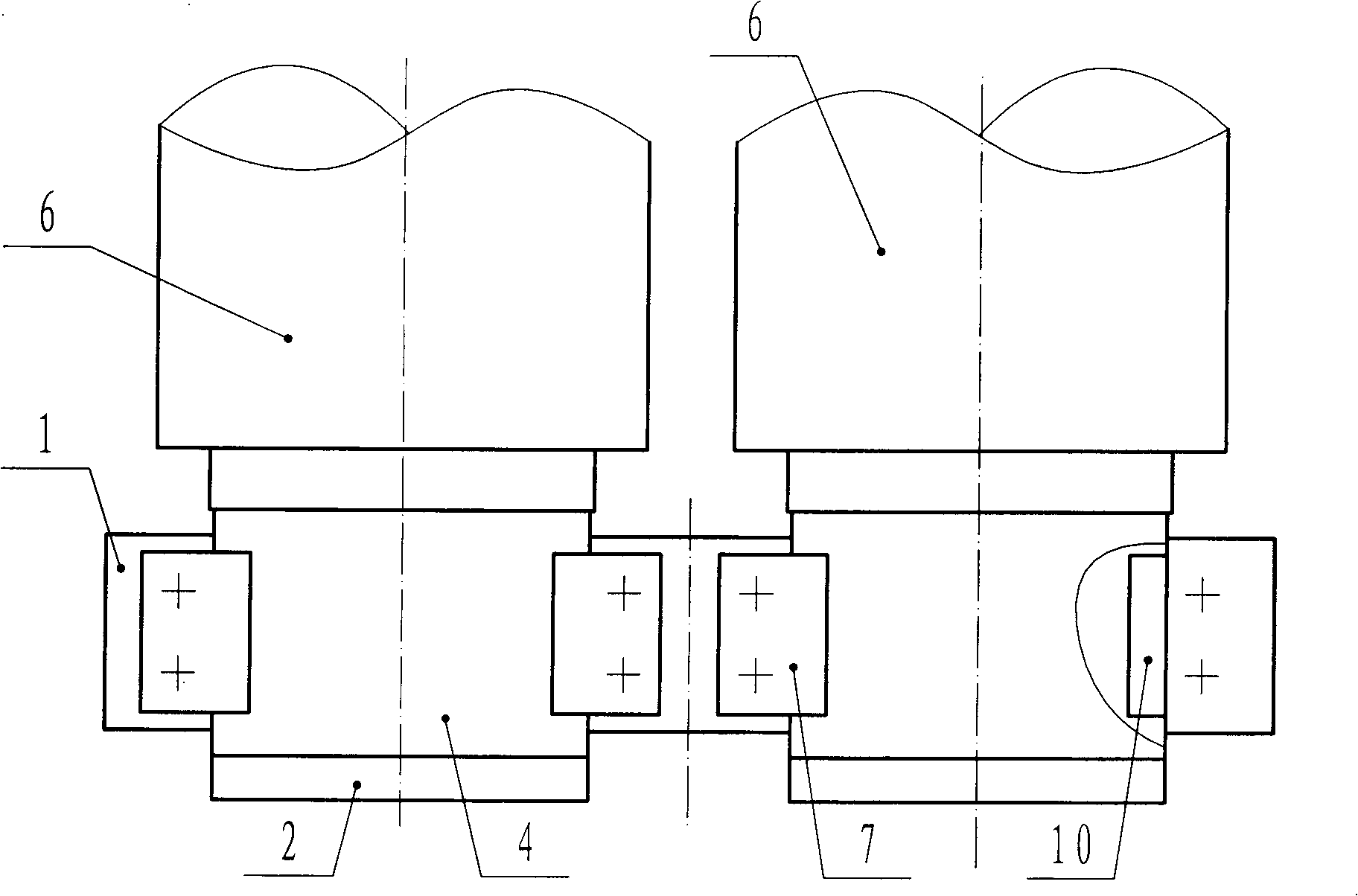

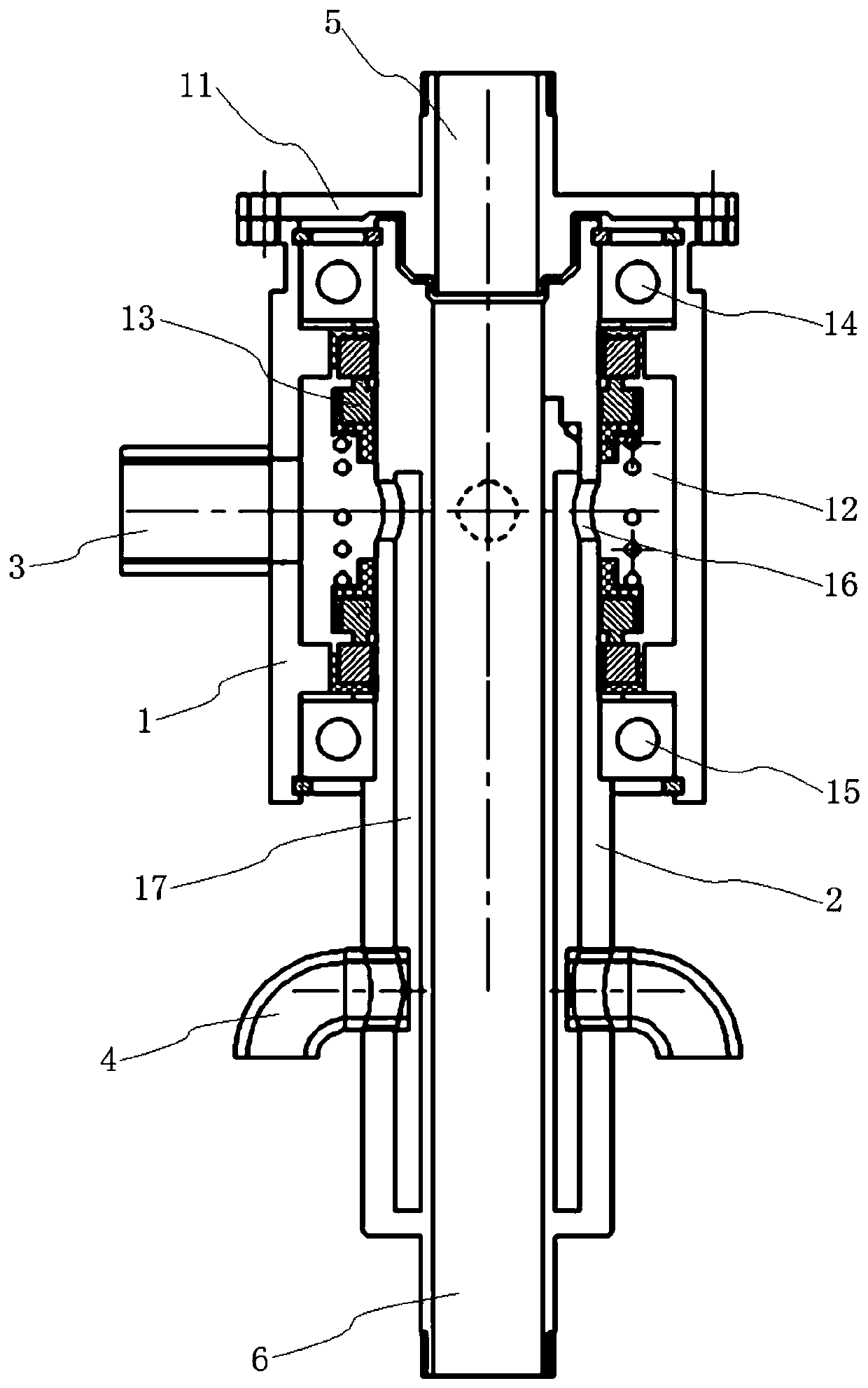

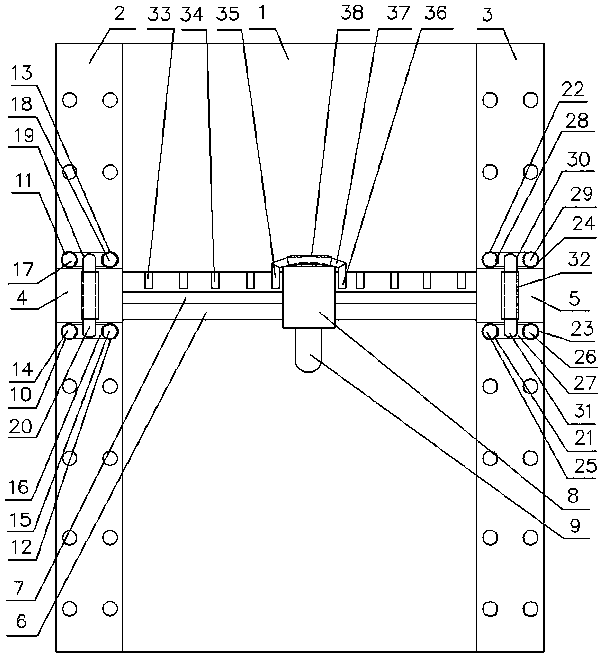

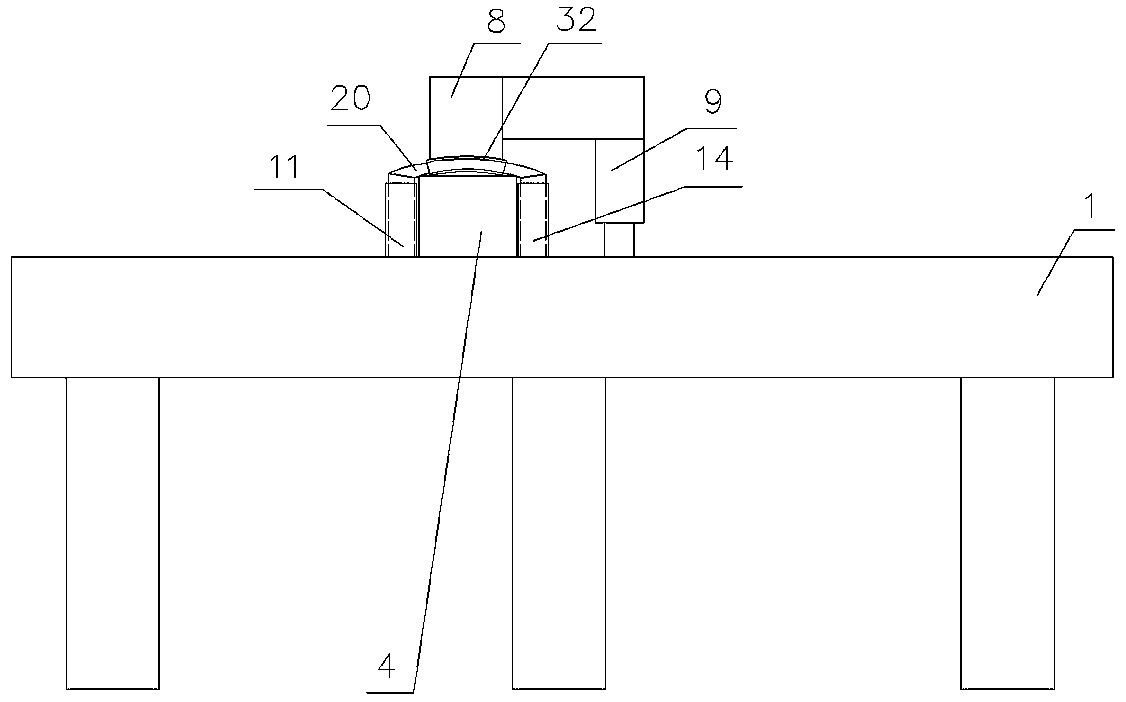

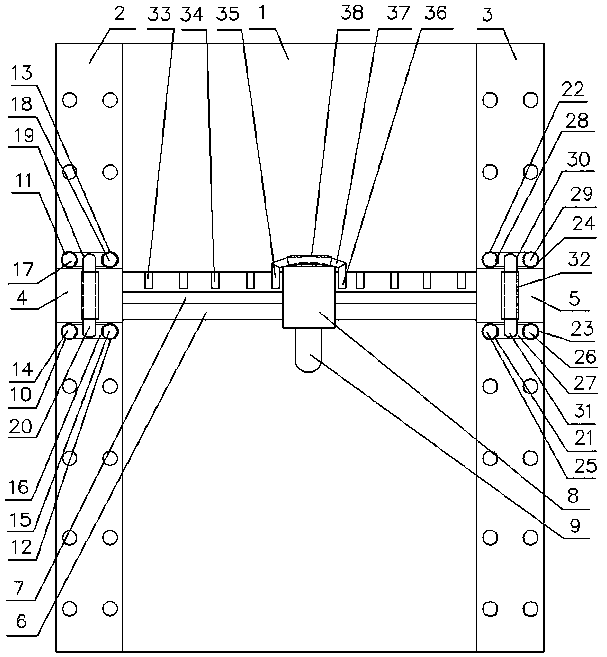

Test-bed of fully mechanized coal mining hydraulic support column

ActiveCN104697779AIncreased test load lengthNo turningMachine part testingAuto regulationCentral line placement

The invention discloses a fully mechanized coal mining hydraulic support column, relates to the technical field of the fully mechanized coal mining hydraulic support column, and is capable of solving the technical problems that an existing test-bed of a fully mechanized coal mining hydraulic support column is short in loading travel, difficult to adjust the position of the center line of a tested column, is incapable of adjusting the testing length of the test-bed and the like. The test-bed of the fully mechanized coal mining hydraulic support column comprises a first hydraulic oil cylinder, a cross beam, a front beam, a first guide holder, a second guide holder, a movable tail beam and a second hydraulic oil cylinder, wherein the movable tail beam is provided with a driving device, the test-board is further provided with a support trolley and a horizontal guiding device which moves along a ground guide rail, therefore the long-stroke loading of the test-bed of the fully mechanized coal mining hydraulic support column, and the automatic adjustment of the position of the center line of the tested column and the testing length can be comprehensively realized.

Owner:煤科(北京)检测技术有限公司

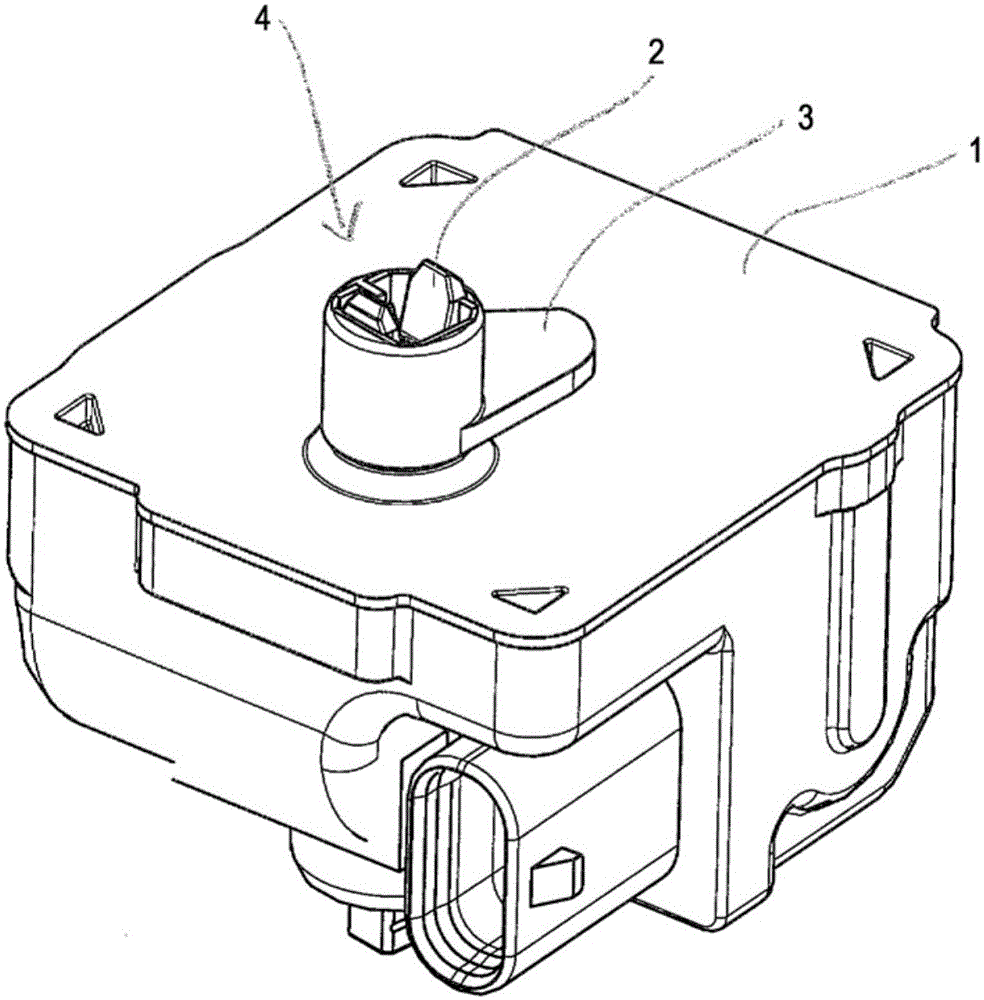

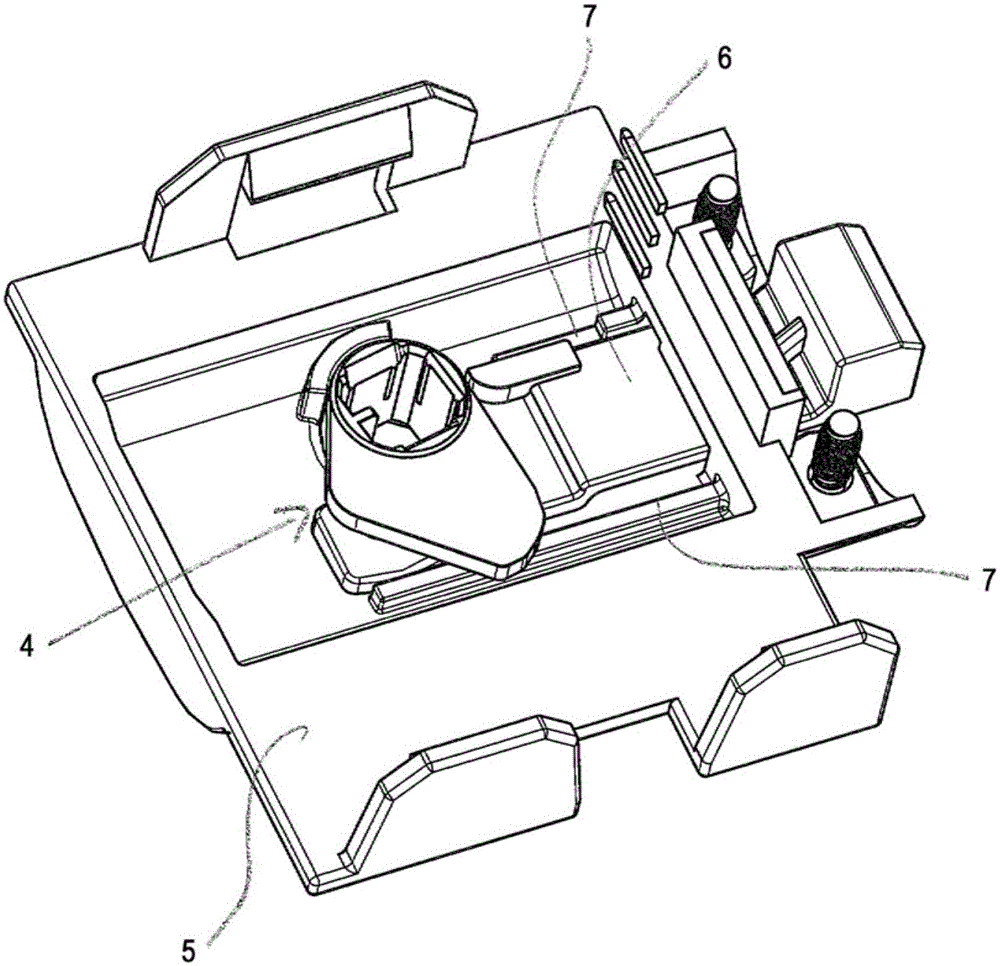

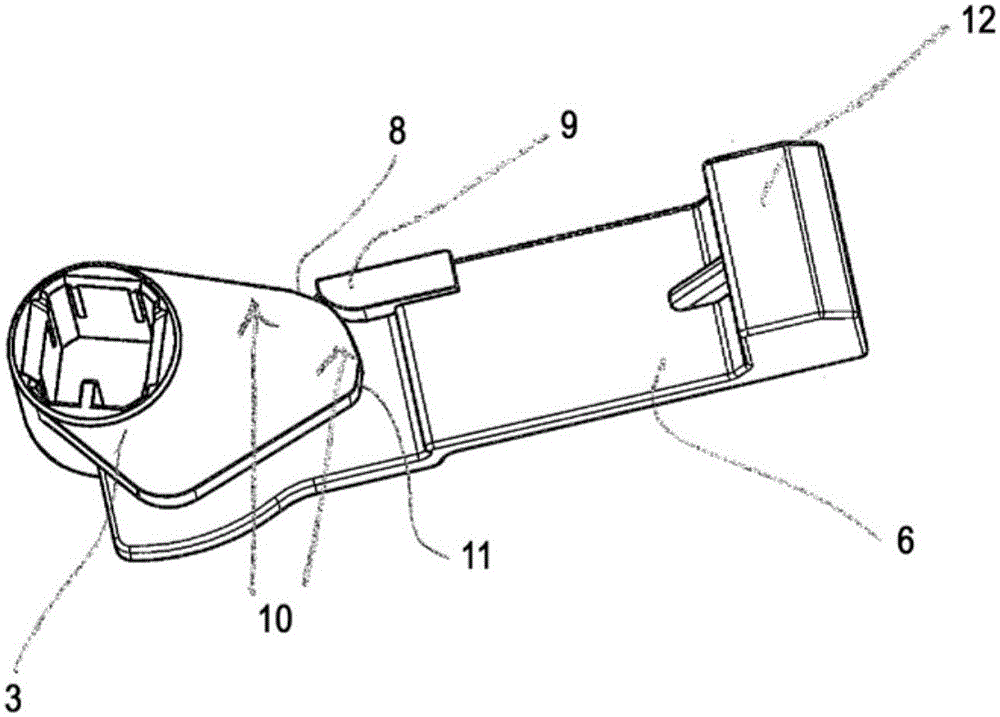

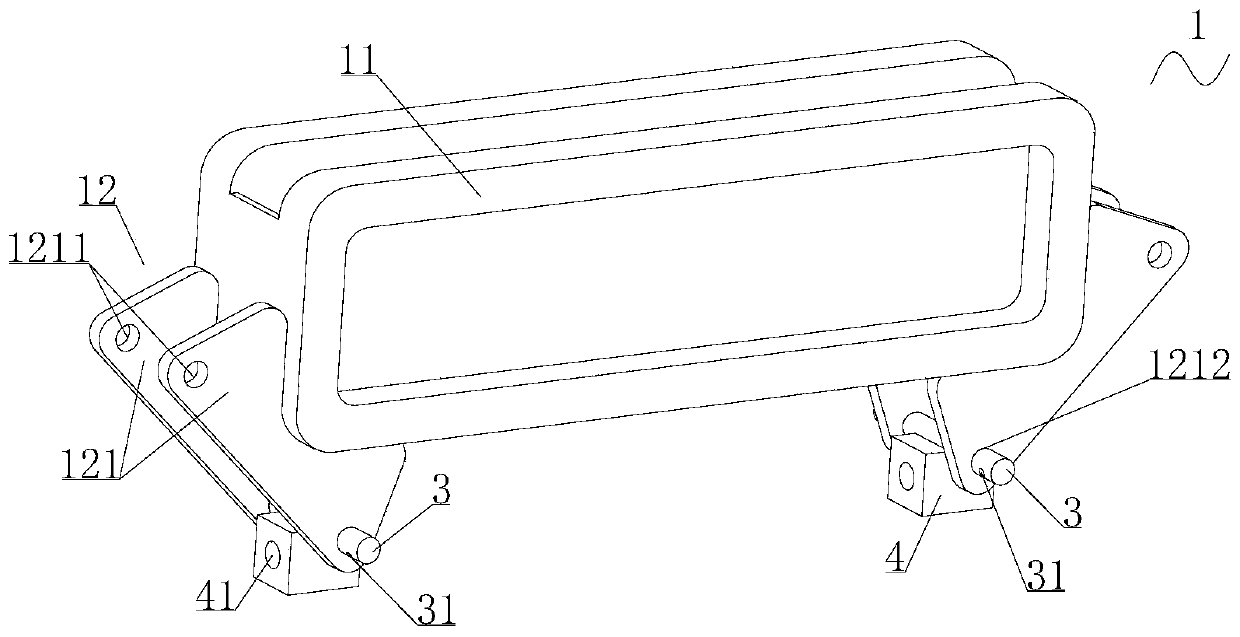

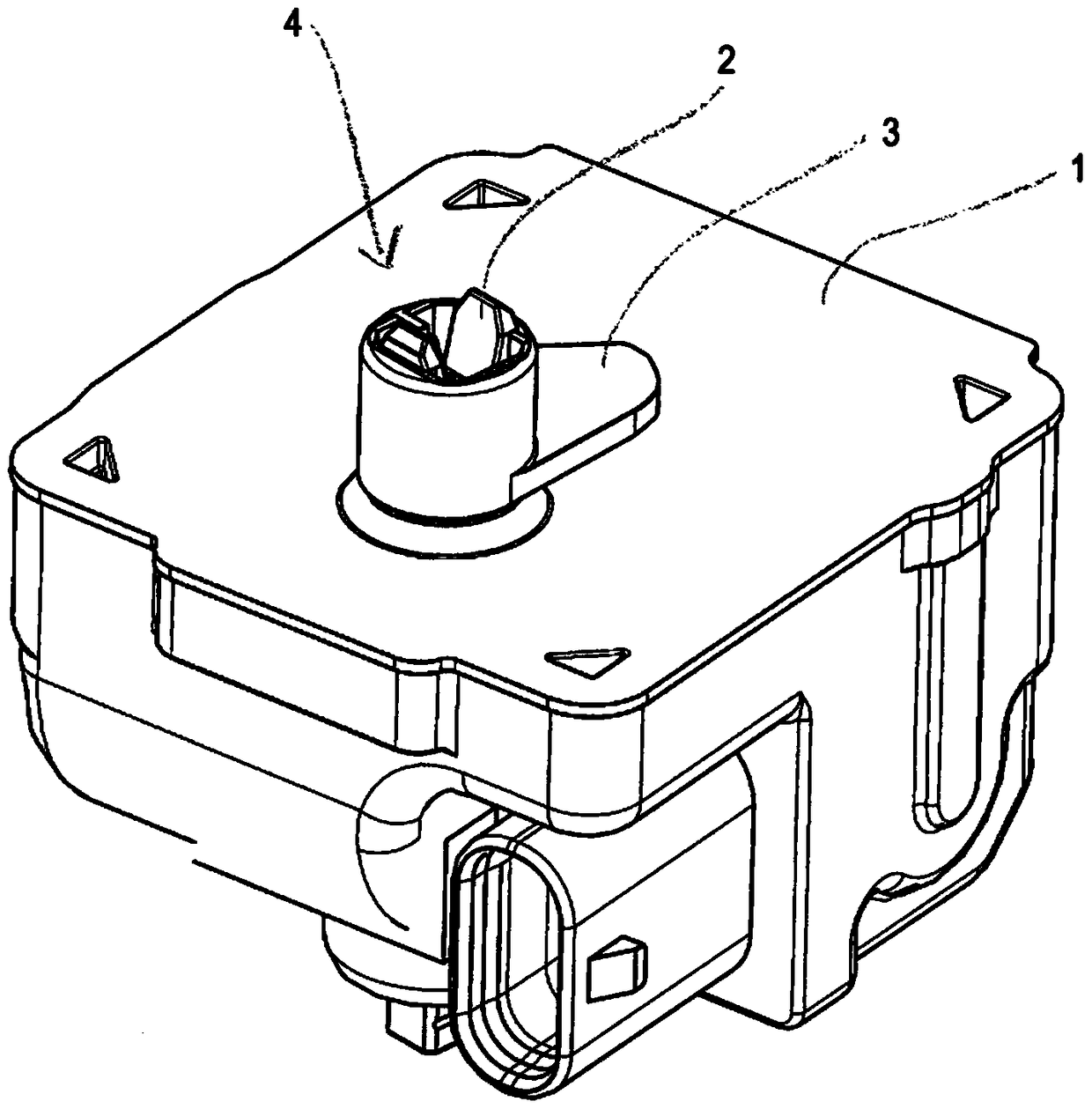

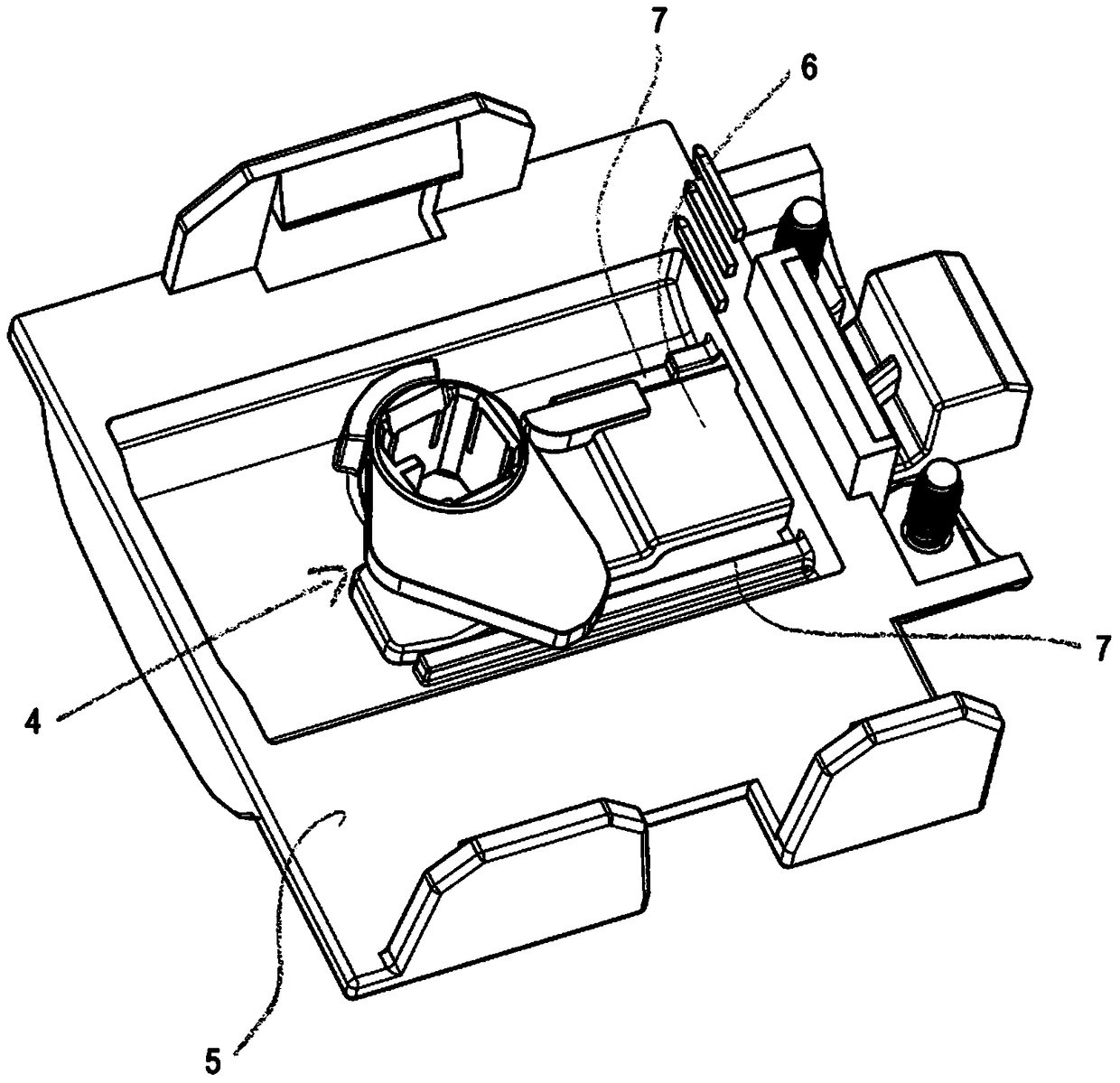

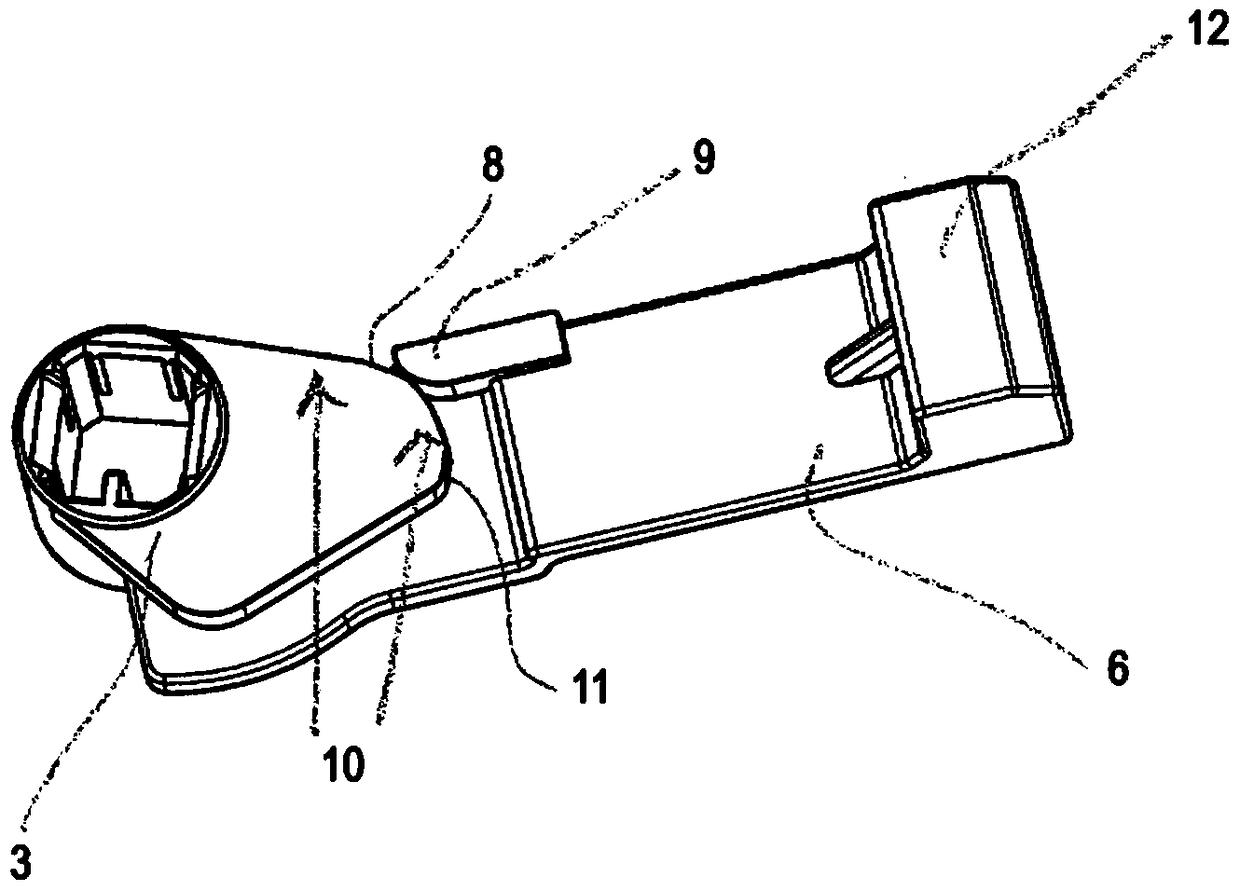

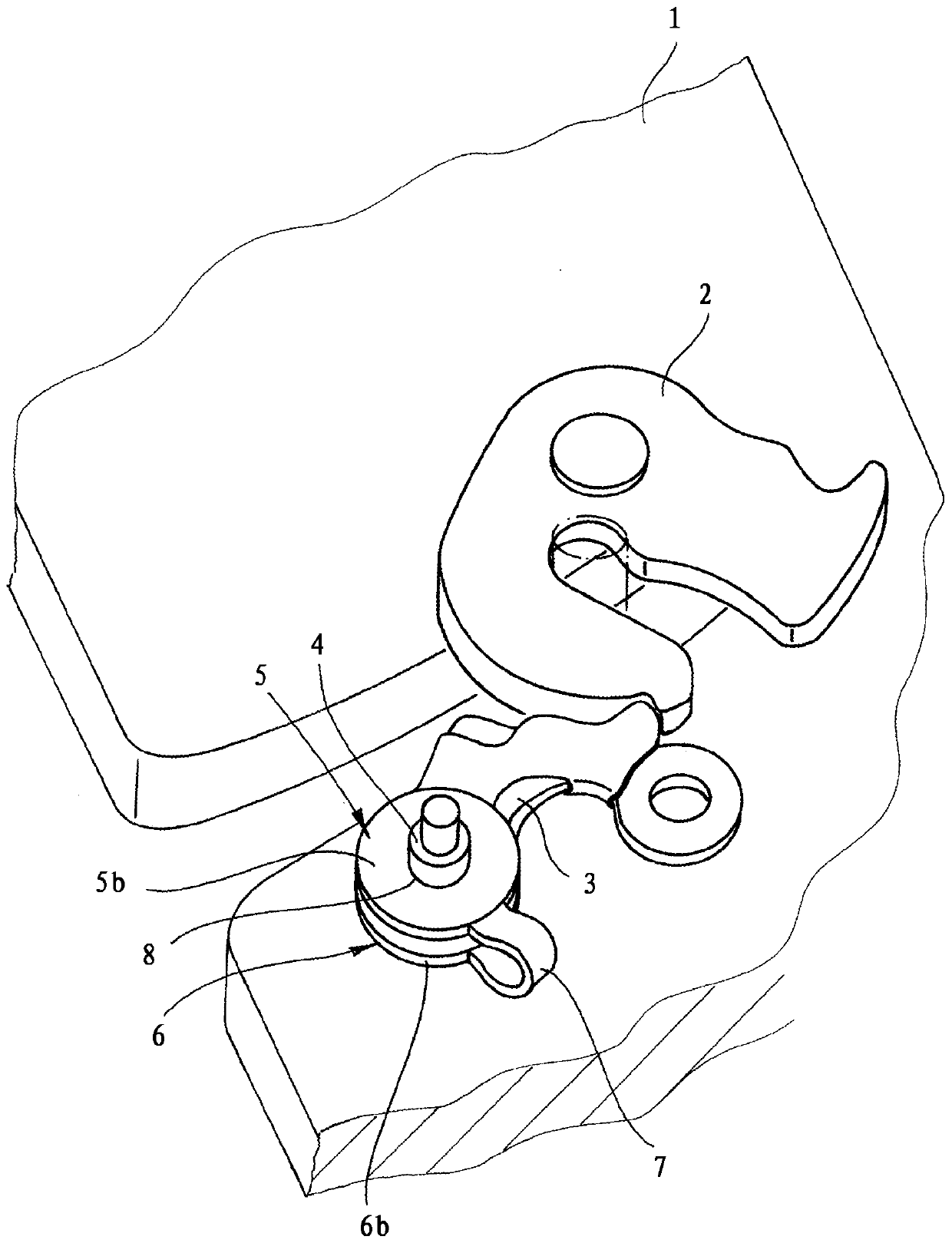

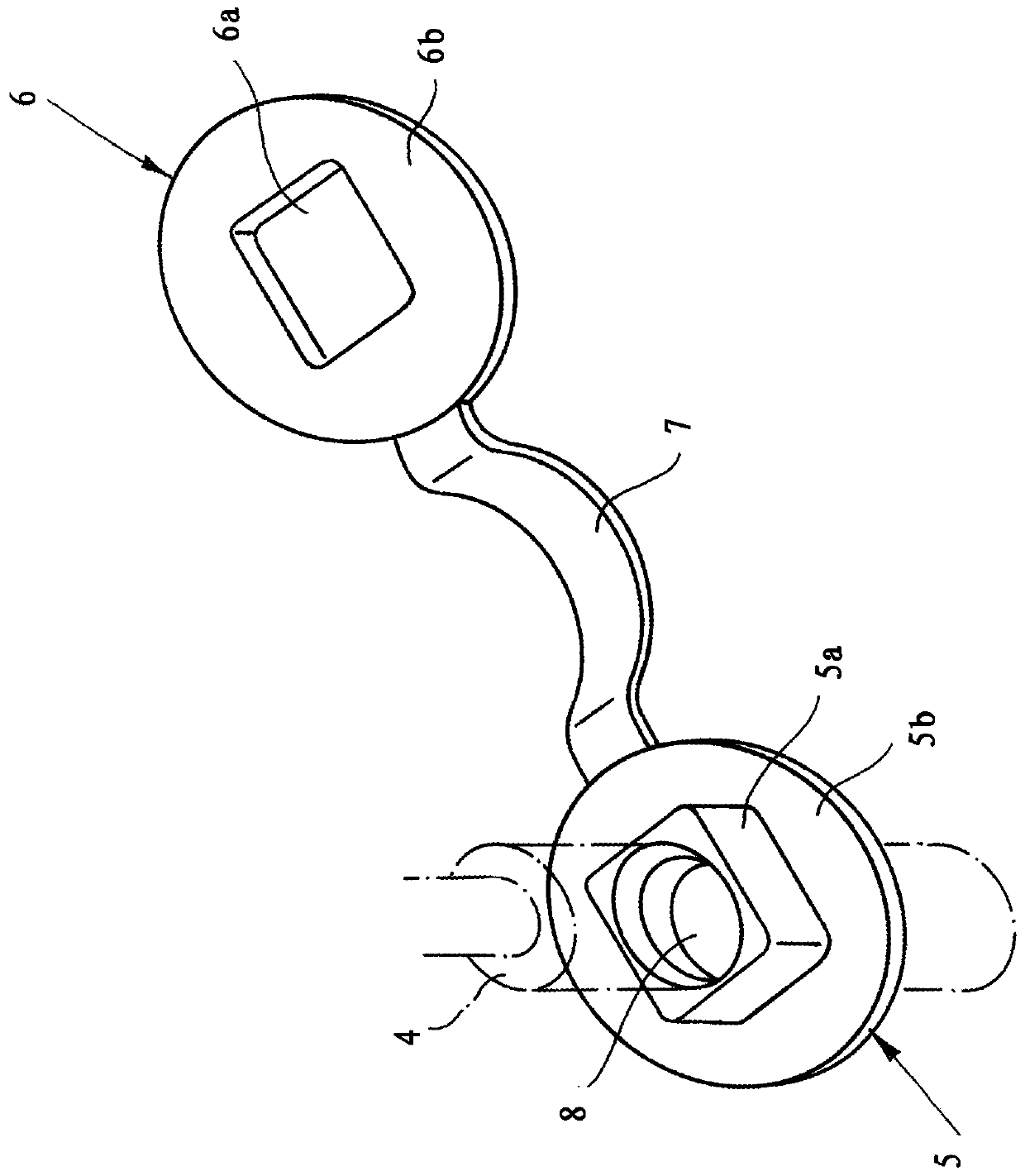

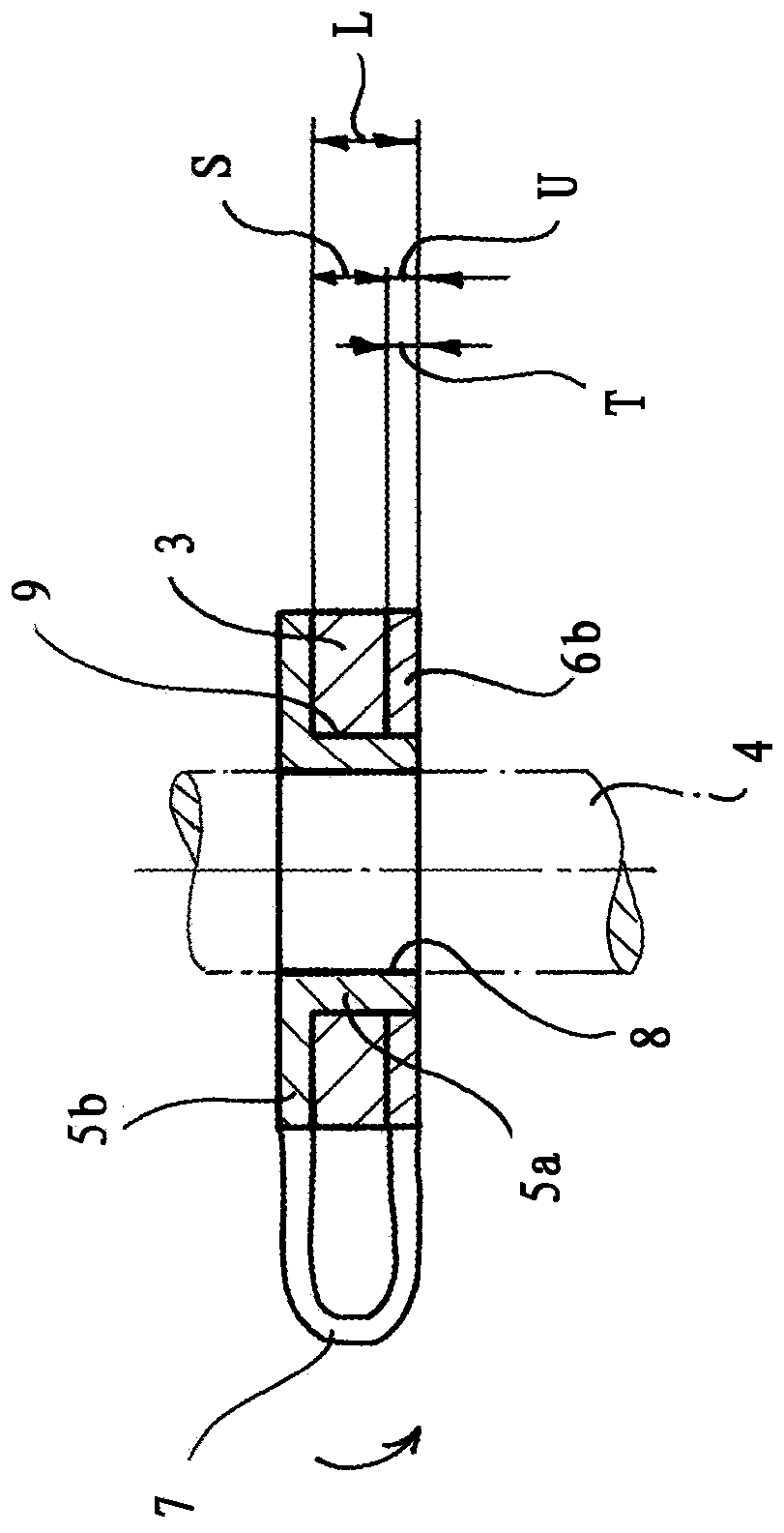

Locking device for a plug-in connection

InactiveCN105122558AEasy to moveAchieve interactionCoupling device detailsElectric propulsionEngineeringActuator

The invention relates to a locking device for a plug-in connection between a plug and a socket. According to the invention, an actuator (4) and a blocking slide (6) are provided, wherein the actuator (4) can be rotated about an axis of rotation, the blocking slide (6) can be moved between an unlocking position and a locking position in the longitudinal direction of the blocking slide, and the actuator (4) and the blocking slide (6) are designed in such a way and interact with each other in such a way that a rotation of the actuator (4) is always accompanied by a longitudinal movement of the blocking slide (6) and vice versa, wherein a longitudinal movement of the blocking slide (6) by means of a rotation of the actuator (4) is always possible, while conversely a rotation of the actuator (4) by means of a longitudinal movement of the blocking slide (6) is possible only outside of the locking position. Thus, simple and economical axial locking that cannot be manipulated is enabled.

Owner:菲尼克斯电子有限公司

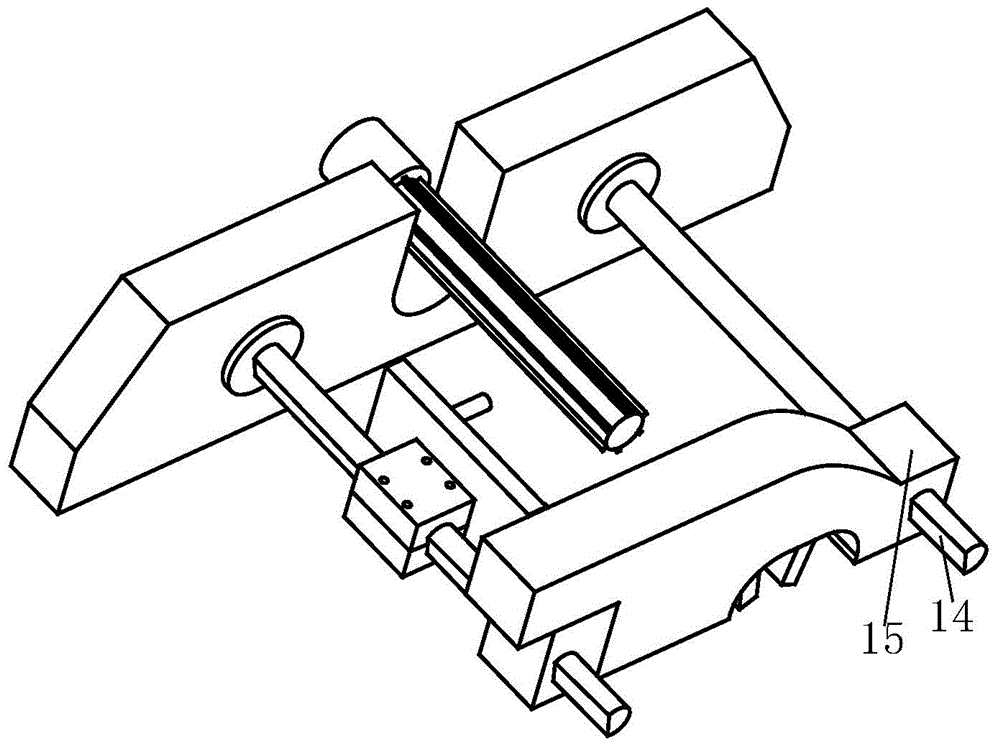

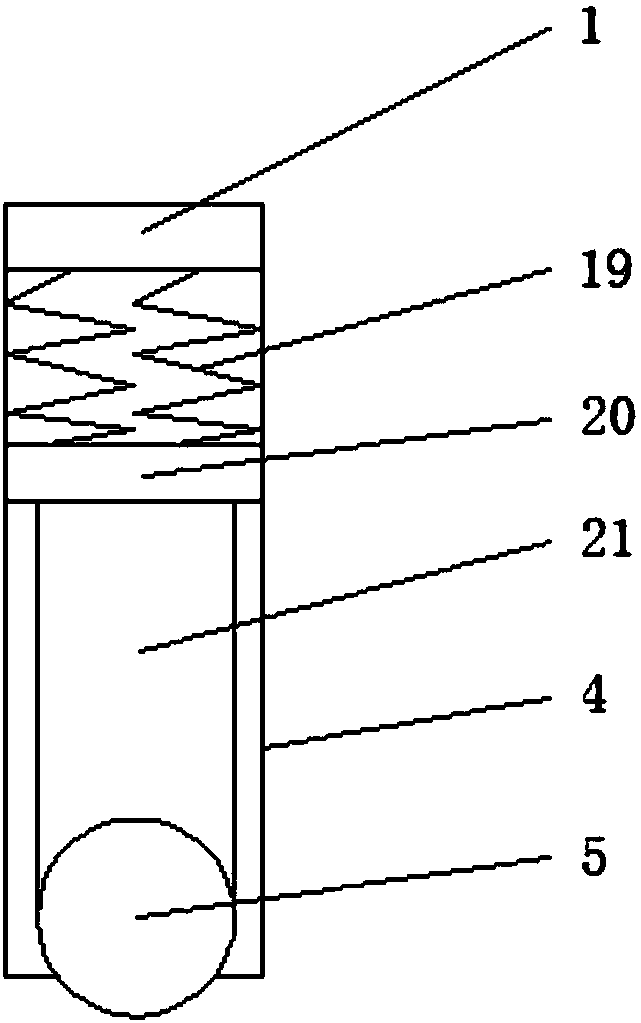

Positioning device of PA nylon stick

The invention relates to the field of production equipment, in particular to a positioning device for PA nylon rods, which includes a supporting mechanism and a clamping mechanism. Lifting and lifting assembly, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism that are symmetrically arranged, and the first clamping mechanism includes a V-shaped first clamping mechanism that interferes with the cylindrical side of the nylon rod. The clamping part and the first drive assembly that drives the first clamping part to travel in the direction perpendicular to the axis of the nylon rod, the second clamping mechanism includes a V-shaped second clamping mechanism that interferes with the cylindrical side of the nylon rod part and the second drive assembly that drives the second clamping part to travel in the direction perpendicular to the axis of the nylon rod. The present invention ensures that the nylon rod will not rotate during the cutting process, reducing unnecessary cost waste. Increase productivity.

Owner:盘海秀

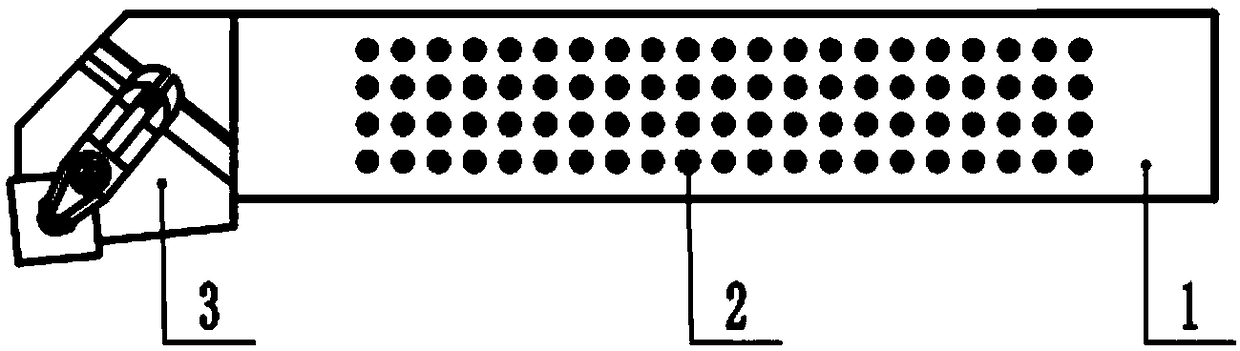

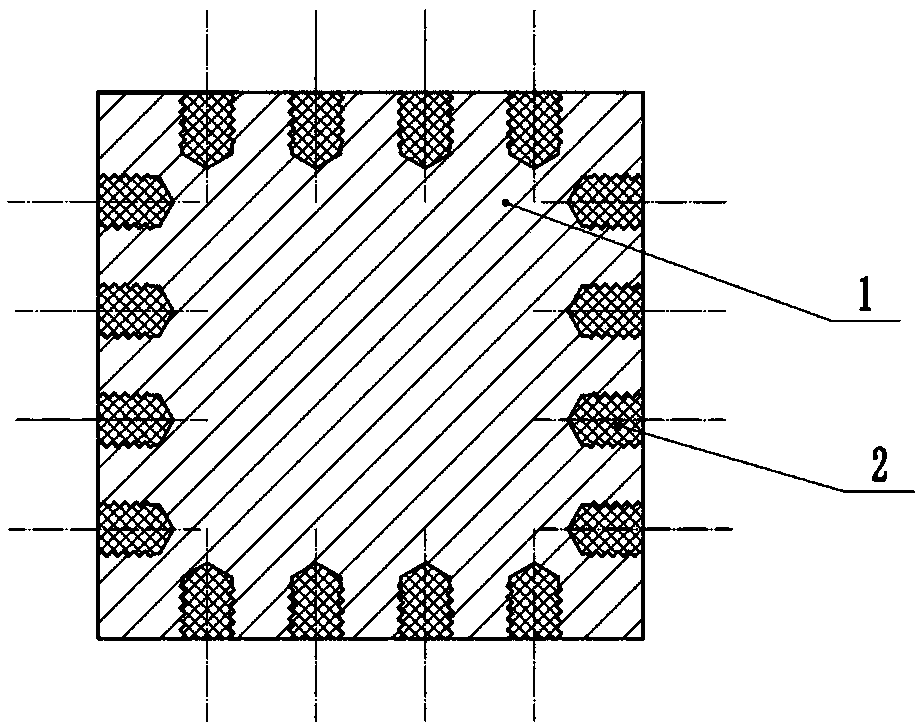

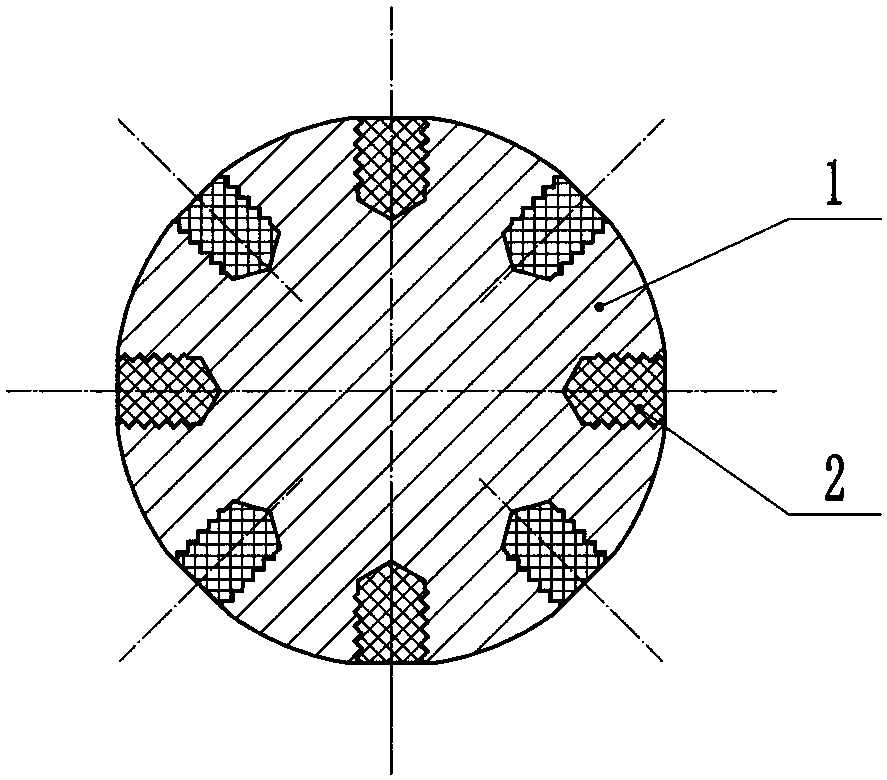

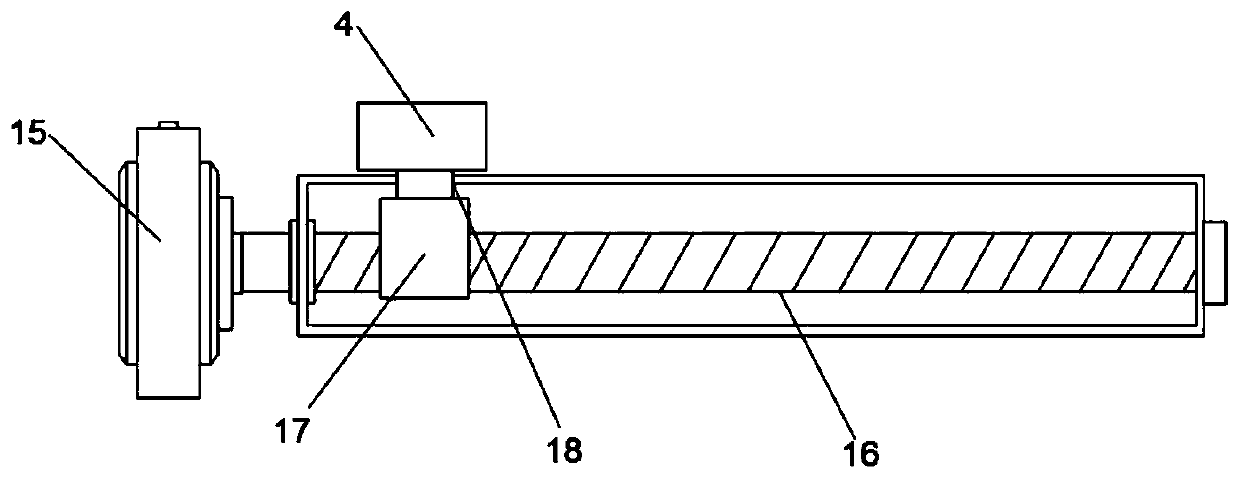

Scattering type periodic structure damping vibration reducing lathe cutter rod

The invention discloses a scattering type periodic structure damping vibration reducing lathe cutter rod. By means of the scattering type periodic structure damping vibration reducing lathe cutter rod, the problem of lathe cutter vibration in lathing is solved, vibration energy can be made to be attenuated in the lathing process, propagation of mechanical waves is inhibited, noise is reduced, themachining stability is improved, and the scattering type periodic structure damping vibration reducing lathe cutter rod is made to have vibration isolation performance within the forbidden band frequency range utilizing the frequency band gap characteristic of a periodic structure. The technical scheme of the scattering type periodic structure damping vibration reducing lathe cutter rod is that the scattering type periodic structure damping vibration reducing lathe cutter rod comprises a cutter rod base body and a cutter head which are connected into a whole, the peripheral surface of the cutter rod base body is evenly provided with multiple rows and columns of damping scattering bodies in a period distribution manner, the cutter rod base body and the damping scattering bodies form the scattering type periodic structure, in the lathing process, the vibration energy generated at the cutter head position is delivered to the damping scattering bodies, inhibiting effect is performed on elastic waves within the forbidden band range utilizing the damping scattering bodies, so that the vibration energy is converted into heat dissipation to realize inhibiting of lathing vibration.

Owner:SHANDONG UNIV

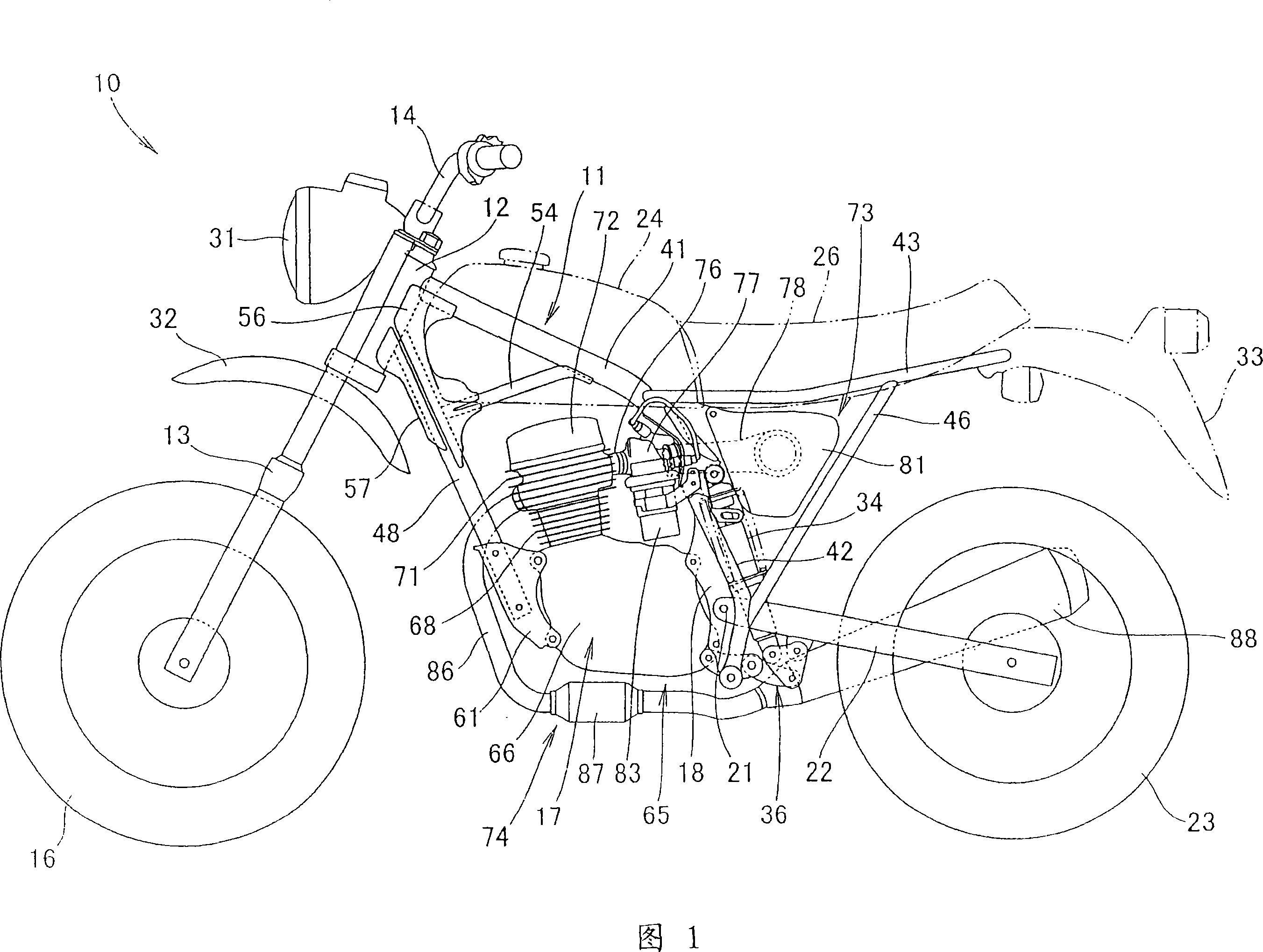

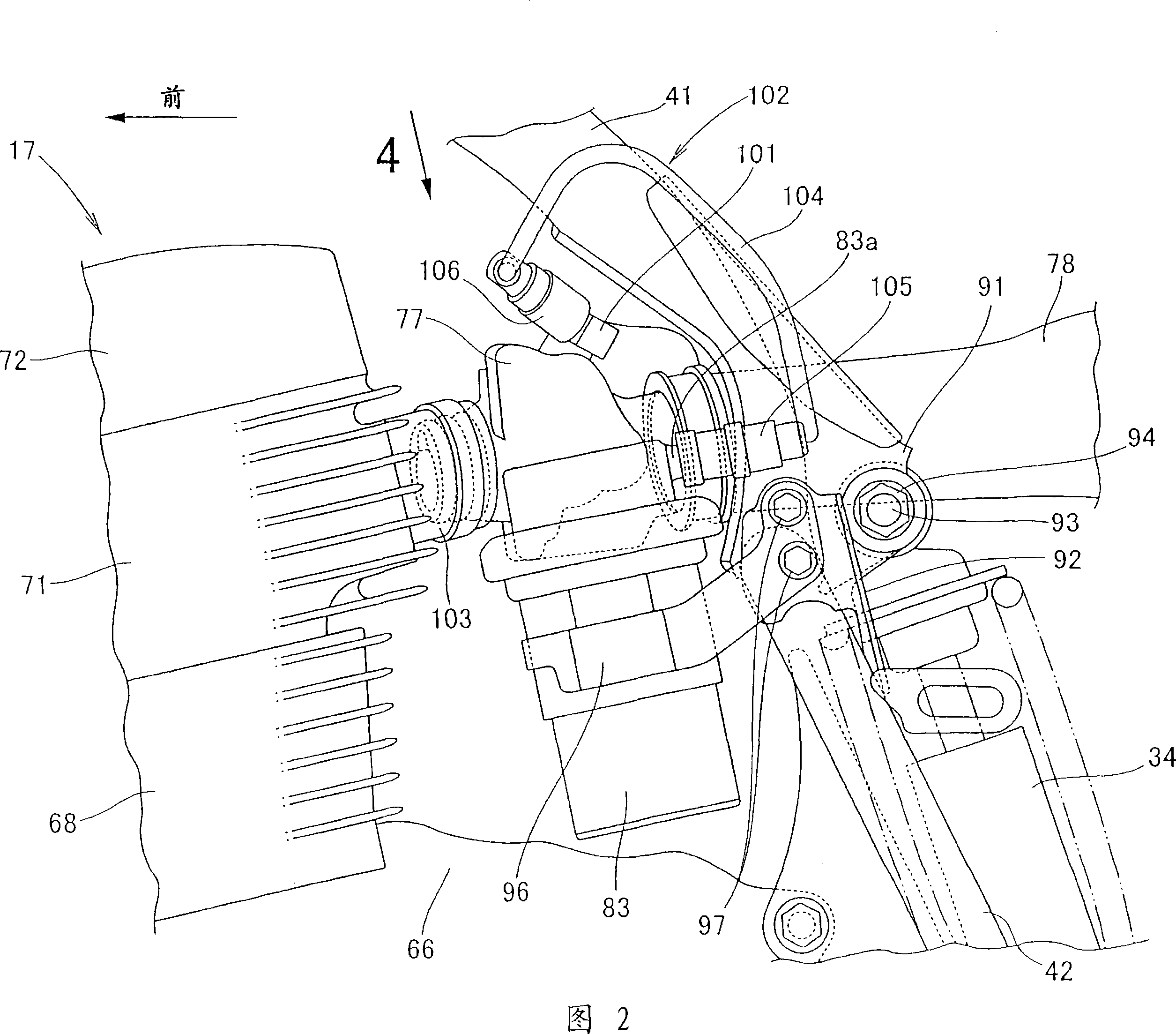

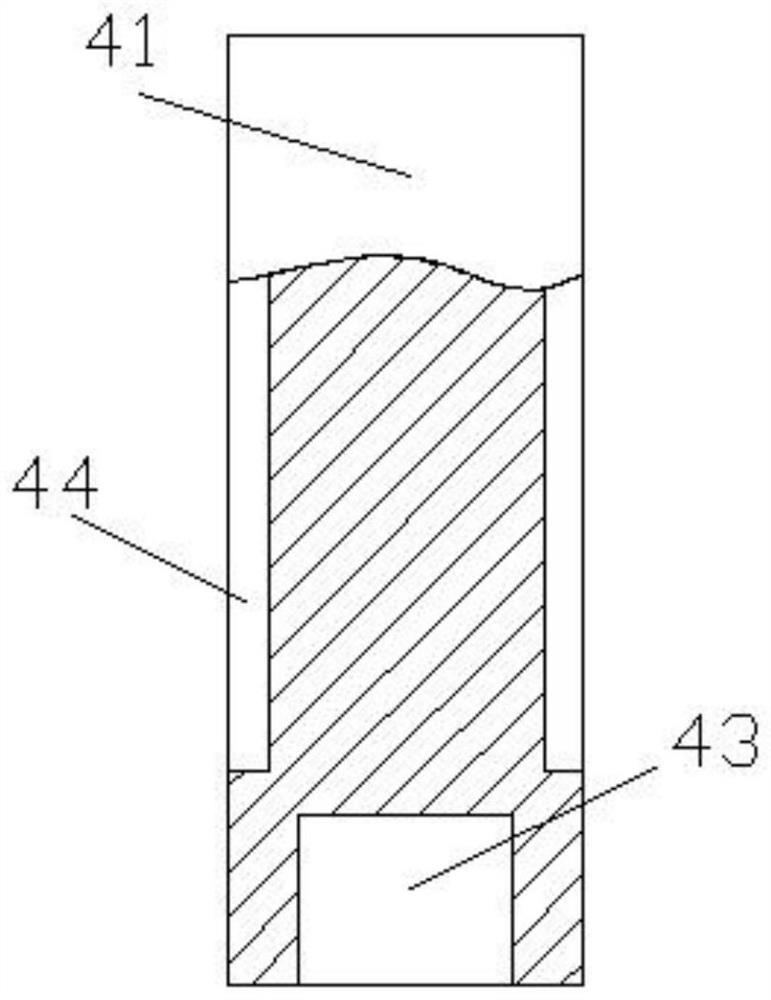

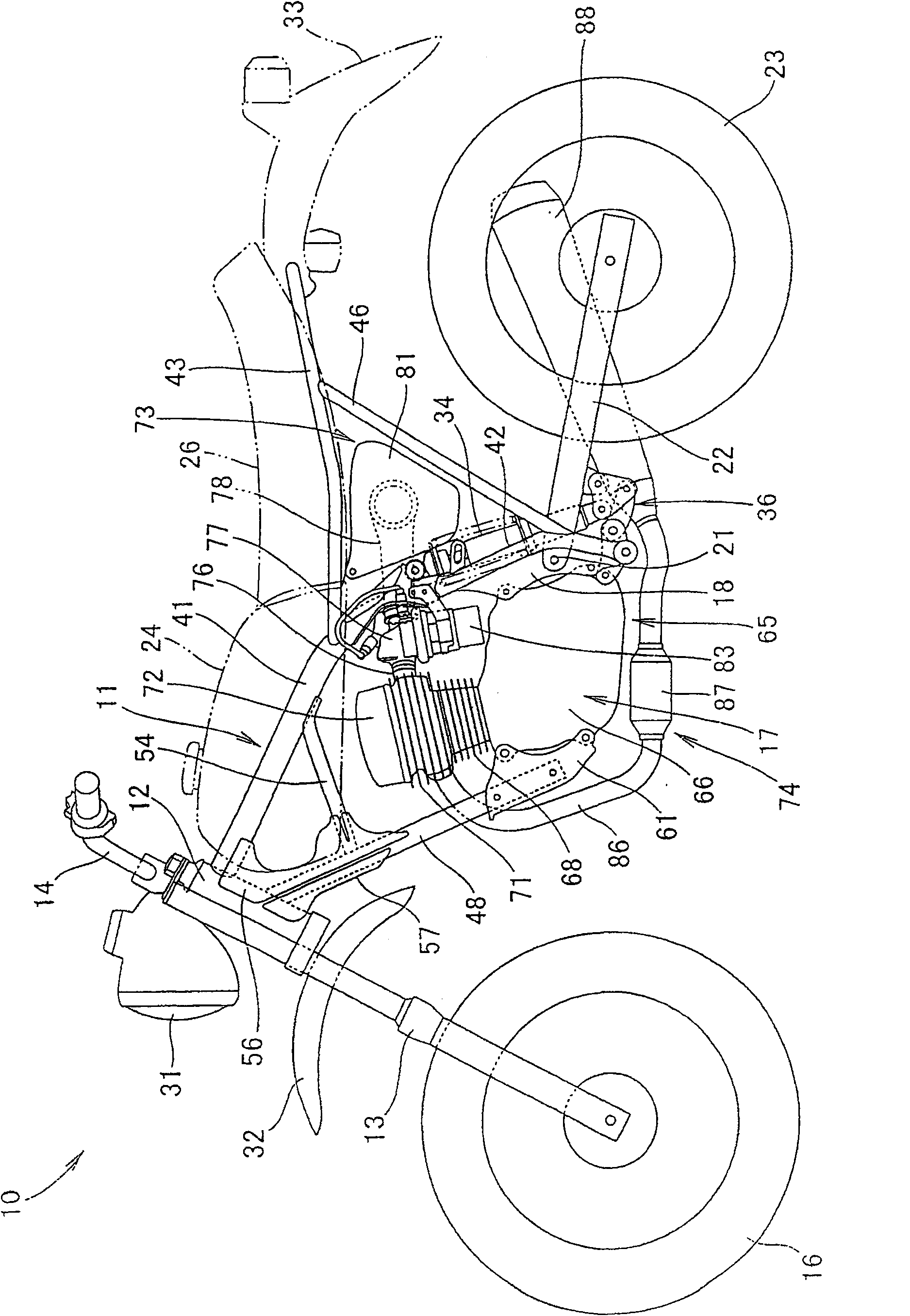

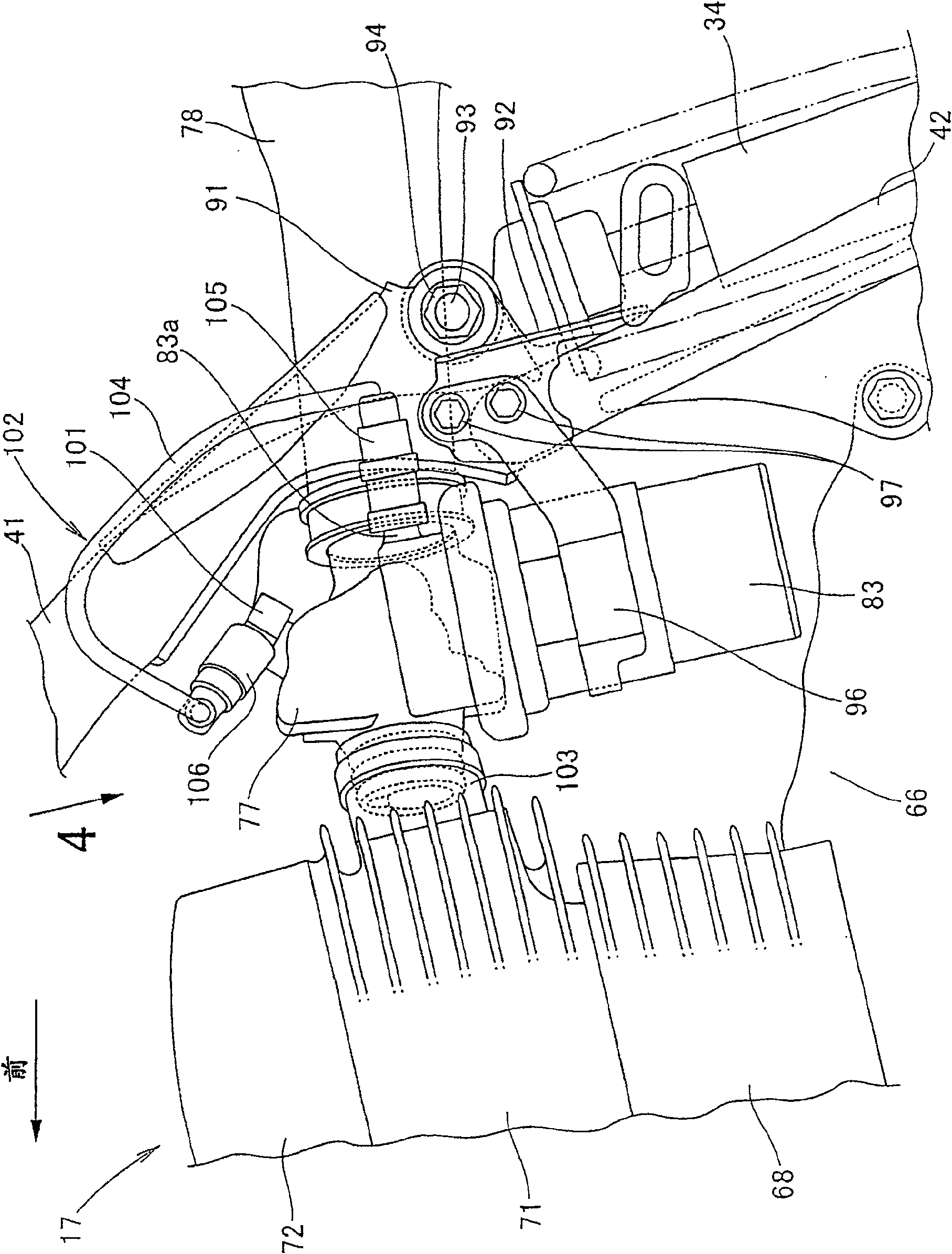

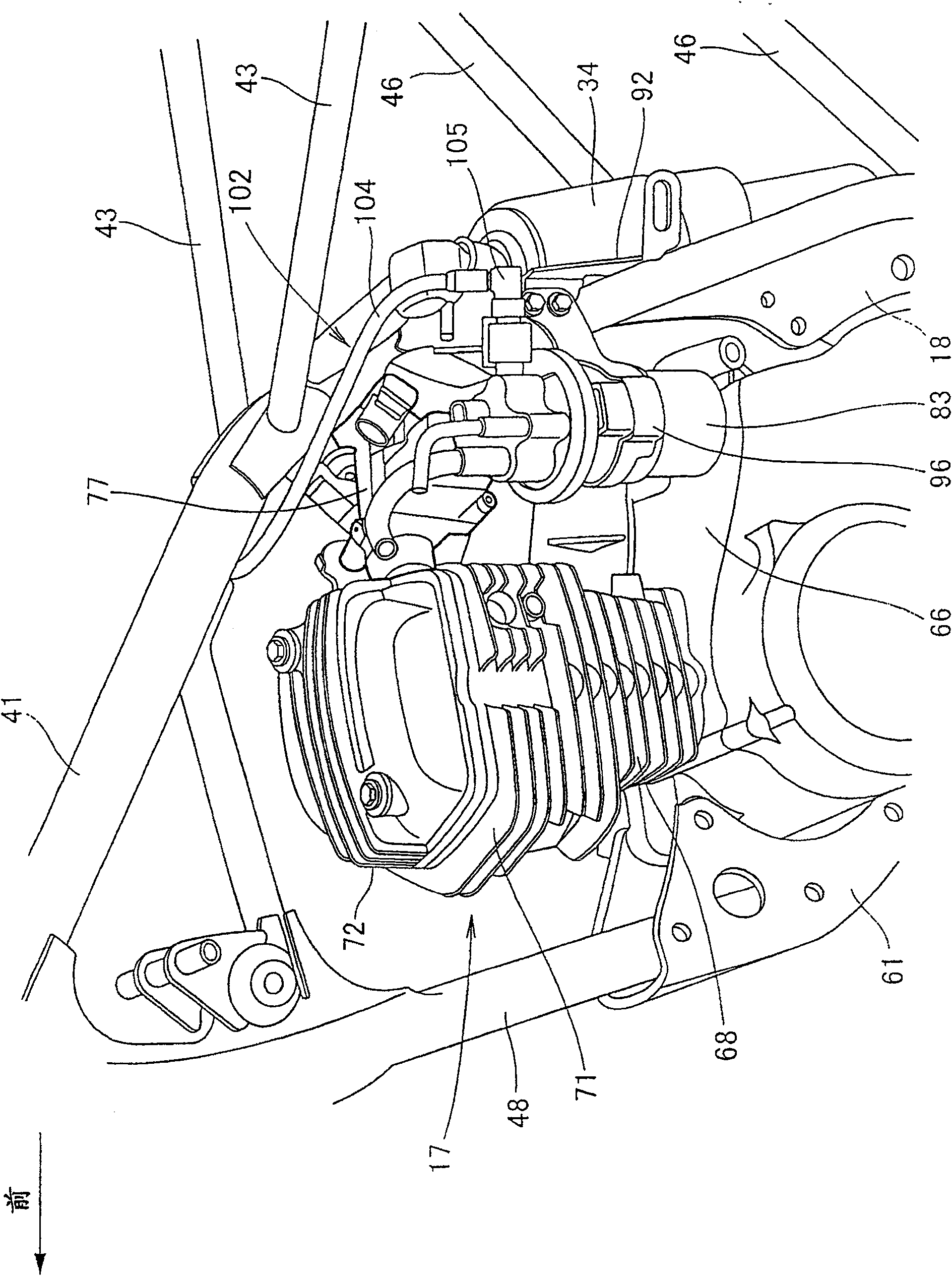

Fuel pump configuring structure of vehicle

ActiveCN101195397ANot easy to turnIncrease configuration freedomInternal combustion piston enginesFuel tanksVehicle frameFuel tank

The present invention relates to a fuel pump configuration structure for a vehicle, which can increase the configuration freedom and design freedom of the fuel pump. The fuel pump arrangement structure is such that in the vehicle, a main frame (41) is arranged along the body center line (110) extending front and rear from the center of the vehicle width direction, and a main frame (41) is installed on the upper part of the vehicle. The fuel tank (24) is integrated with the fuel pump (83), the engine (17) is arranged below the main frame (41), and the throttle body (77) is arranged behind the engine (17), wherein, When viewed in plan, the fuel pump (83) is disposed on the opposite side to the throttle body (77) across the main frame (41), and is disposed parallel to the throttle body (77) in the vehicle width direction.

Owner:HONDA MOTOR CO LTD

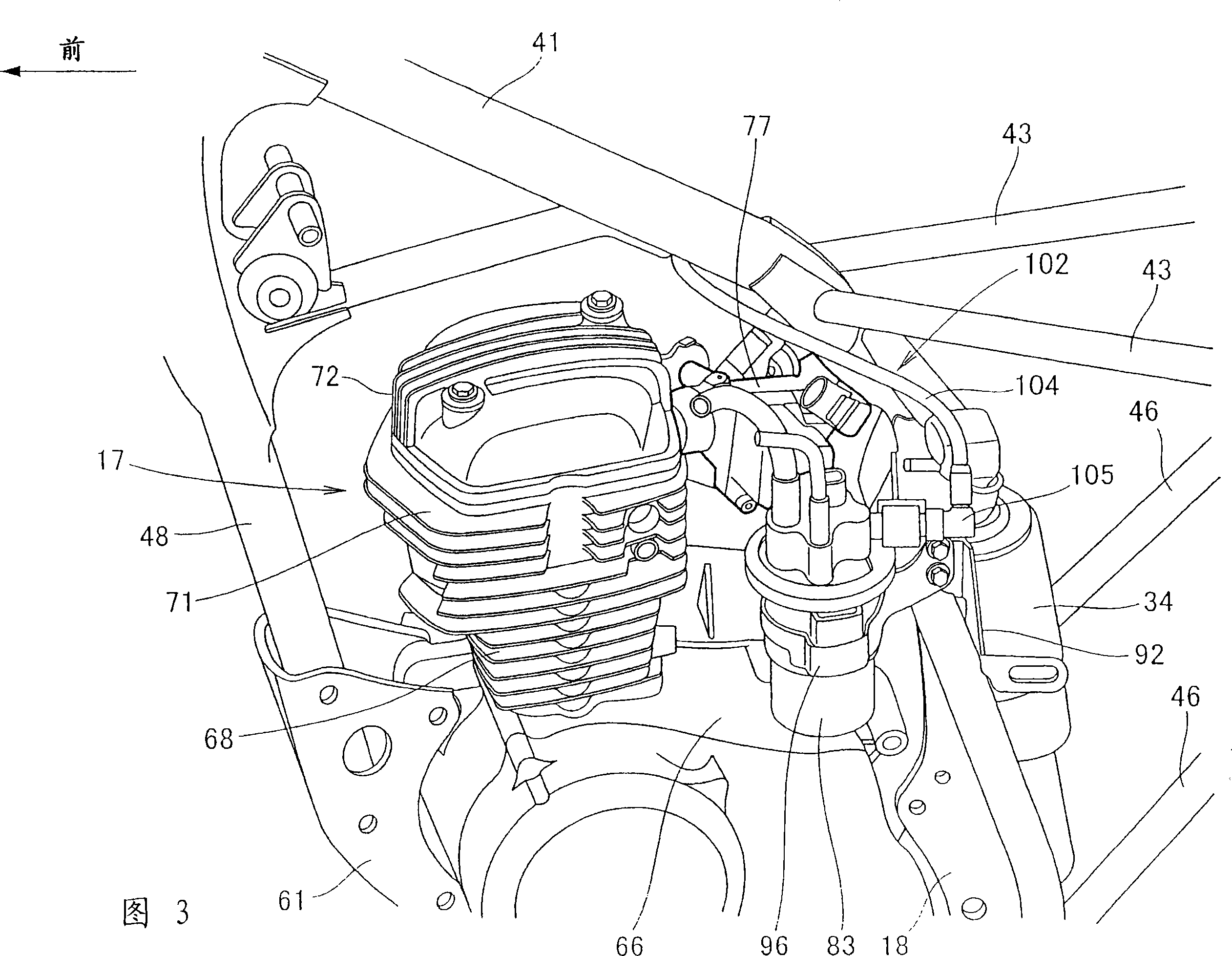

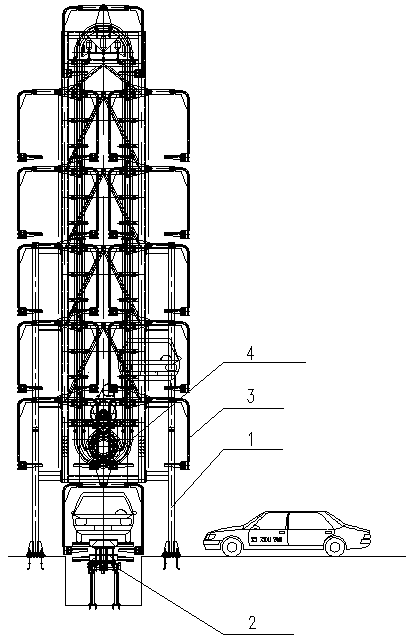

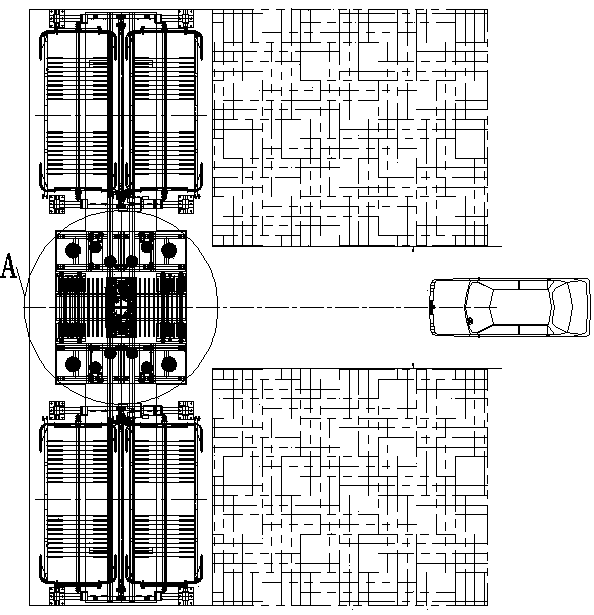

Conveying-type comb vertical circulation parking method

The invention discloses a conveying-type comb vertical circulation parking method. A vehicle is driven into an intelligent conveying mechanism, and a driver walks to the ground from moving pedals; themoving pedals move to the two ends, and a micro lifting mechanism raises the vehicle and a comb rotating table; the comb rotating table rotates by 90 degrees; a comb hanging basket is in position; acarrying mechanism drives the comb rotating table and the vehicle along a conveying track into a vertical circulation garage, after the carrying mechanism is in place, the micro lifting mechanism is lowered, the comb fork exchange of the comb rotating table and the comb hanging basket is realized, and the vehicle falls from the comb rotating table to the comb hanging basket; after the micro lifting mechanism is lowered, the carrying mechanism drives the comb rotating table to return to the position along the track and moves out of the comb vertical circulation garage; and after the carrying mechanism drives the comb rotating table to return in the position, the comb rotating table is slightly lifted again and rotated to return to the position, the moving pedals return to the positions along a transverse track, the conveying mechanism is slightly lowered to fill-in, and the vehicle parking is finished. The conveying-type comb vertical circulation parking method greatly saves the groundflow space required for the vehicle driving, and the number of parking spaces is doubled.

Owner:JIANGSU PARKTEC PARKING EQUIP

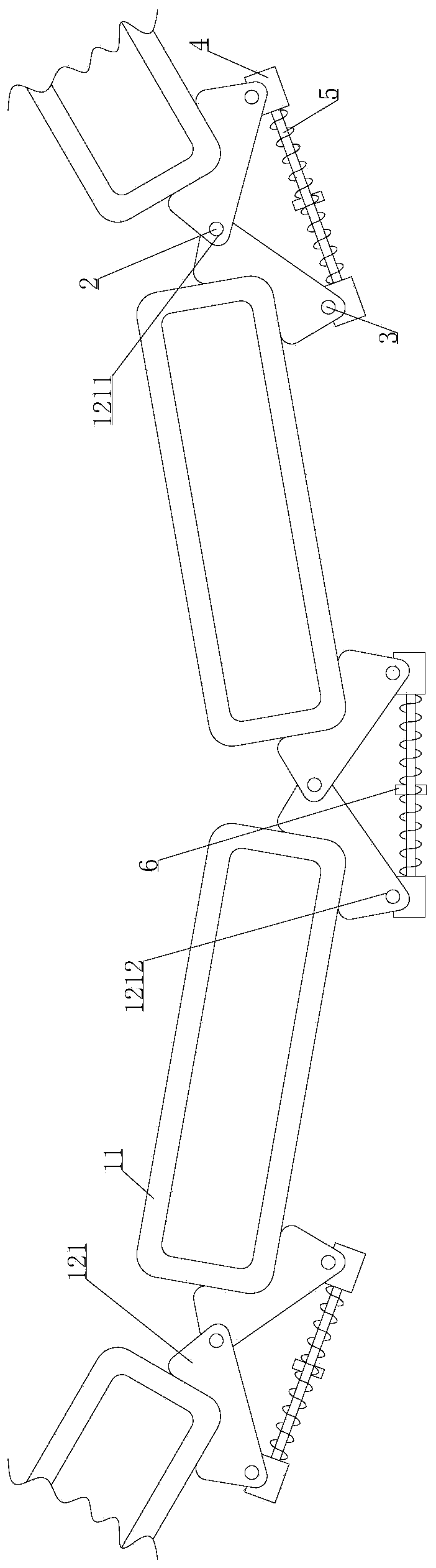

Adjustable arc building wood formwork

PendingCN110700565ASimple structureEasy to useAuxillary members of forms/shuttering/falseworksForming/stuttering elementsScrew threadCivil engineering

The invention relates to an adjustable arc building wood formwork. The adjustable arc building wood formwork comprises a plurality of adjusting supports and wood formwork bodies, wherein the adjustingsupports are sequentially connected end to end, and the wood formwork bodies are placed on the adjusting supports; each adjusting support comprises a back ridge and two adjusting pieces; the two adjusting pieces are fixedly arranged on the two sides of the back ridge correspondingly; each adjusting piece comprises two adjusting plates; the two adjusting plates are fixed to one side of the back ridge in parallel and provided with a first hinge hole and a second hinge hole correspondingly; the two adjusting plates in one adjusting support are clamped in the two adjusting plates in the other adjusting support, and the two adjusting supports are connected through a first hinge shaft inserted in the first hinge hole; second hinge shafts are arranged in the second hinge holes; each second hingeshaft is detachably provided with a fixing base; each fixing base is provided with a threaded hole; and a lead screw sleeved with a nut is connected between the threaded hole in one adjusting supportand the threaded hole in the other adjusting support. The purposes that the structure is simple, and the angle between every two connected formwork bodies can be adjusted in a stepless manner are achieved.

Owner:湖北旺科模板有限公司

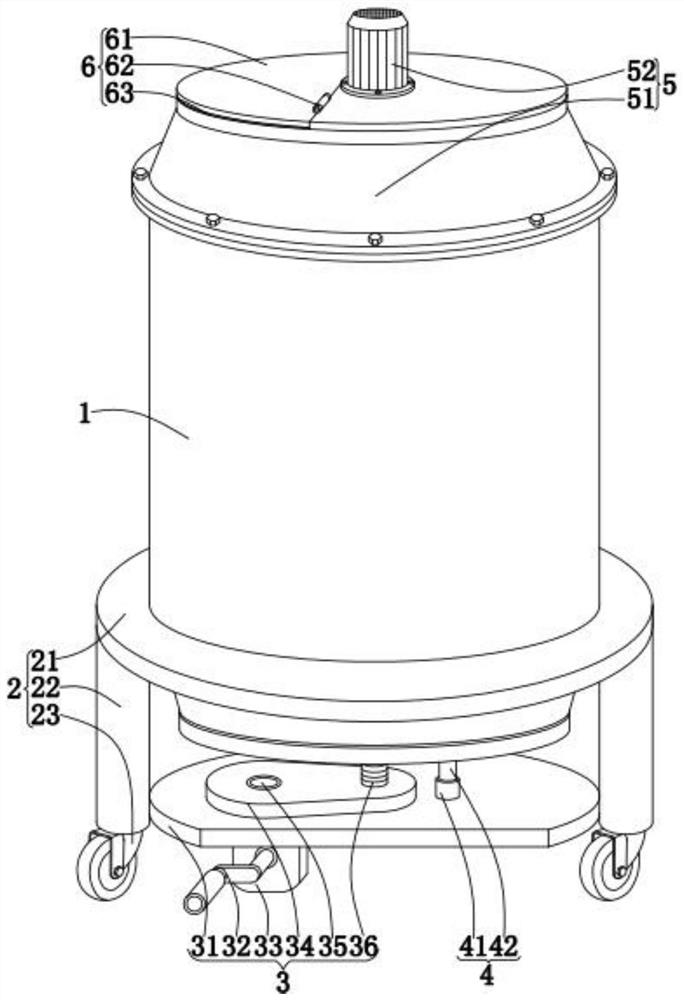

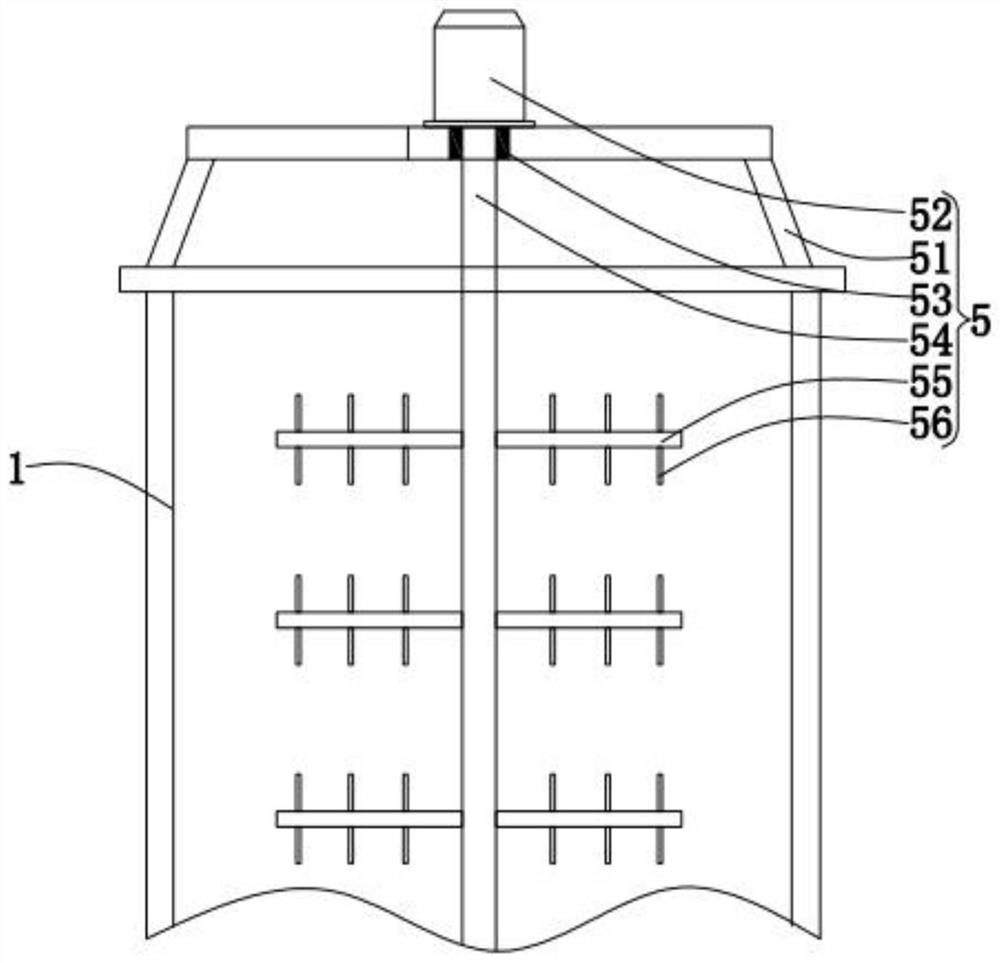

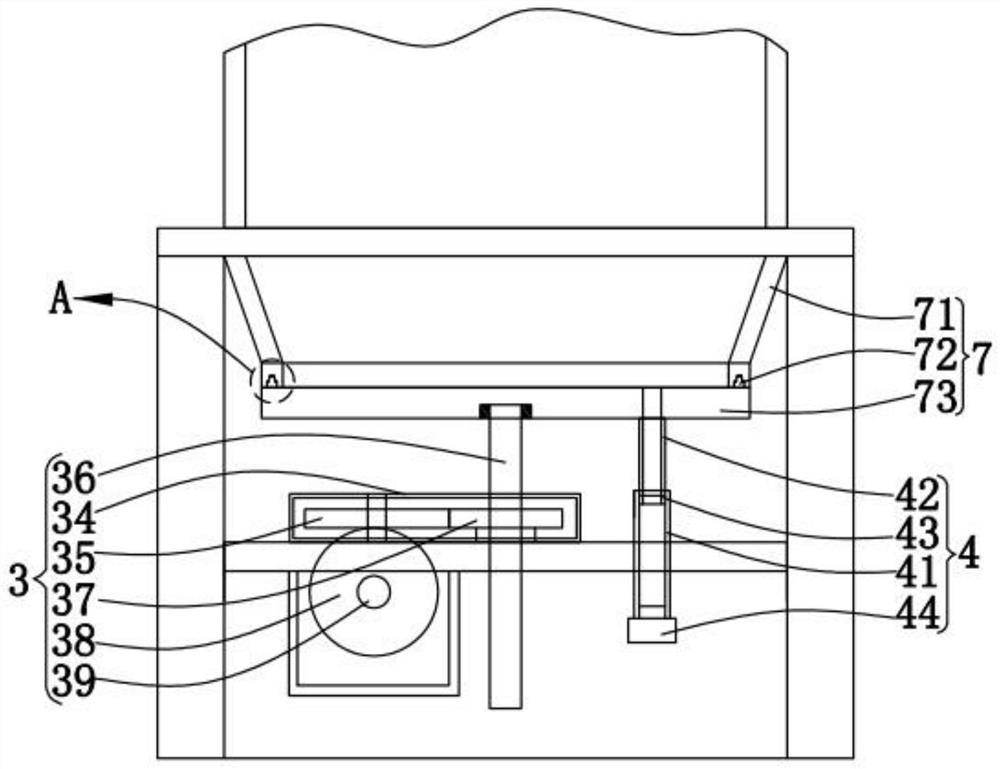

A pulp storage tank for papermaking

ActiveCN109178688BImprove sealingEasy to cleanRotary stirring mixersLarge containersAnnular arrayInternal rotation

The invention relates to the field of papermaking equipment, in particular to a pulp storage tank for papermaking, which includes a tank body, a moving structure, a lifting structure, a position limiting structure, a stirring structure, an opening and closing structure and a sealing structure; the bottom end of the tank body is provided with The sealing structure that can be separated from the tank body can open the bottom end of the tank body through the joint use of the sealing structure and the tank body, so as to facilitate the cleaning of pulp deposited at the bottom end inside the tank body, and through the setting of the sealing structure, it can To achieve a good seal between the tank body and the bottom end, and then through the lifting structure fixed between the moving structures, the opening and closing of the sealing structure can be realized by hand, which is convenient for the sealing of the sealing structure; the internal rotation of the tank body is connected with a rotating rod, and the rotating There are multiple stirring rods distributed in a circular array on the outside of the rods, and there are multiple fixed rods on the outside of each stirring rod. Through the combined use of the stirring rods and the fixed rods, the pulp stored in the tank can be fully stirred. , effectively prevent pulp deposition inside the tank.

Owner:泗县田原秸秆回收再利用有限责任公司

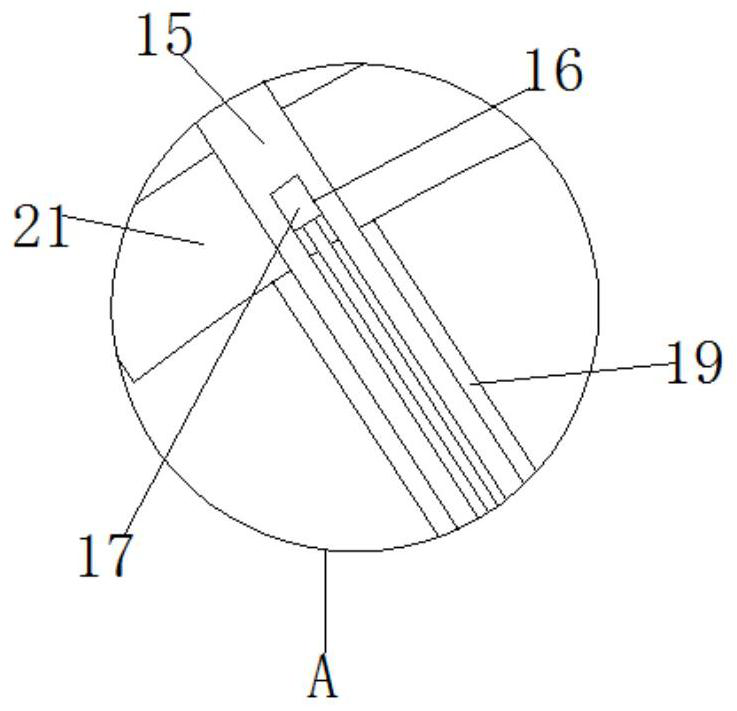

Device and method for stripping communication optical cable

PendingCN113219607ACut offReduce the situationFibre mechanical structuresBare fiberStructural engineering

The invention discloses a device and method for stripping a communication optical cable. The front end face of a cover body is provided with a transverse cutting assembly, the rear end face of the cover body is connected with a side supporting seat, and the side supporting seat is provided with a plurality of observation holes at intervals; the part, close to the bottom, in the cover body is provided with a rotating assembly, and the outer surface of the rotating assembly is uniformly provided with a plurality of cable grooves; an optical cable needing to be peeled extends into the cable groove through the positioning hole and extends out of the device through the observation hole. A vertical cutting assembly is fixedly connected to the portion, above the rotating assembly, of the cover body, and a vertical cutter is connected to the vertical cutting assembly in a sliding mode. According to the invention, after the skin of the optical fiber is stripped, a worker pulls the optical cable towards one side of the positioning seat, so that each stripped skin can be taken down from the rotating frame, a bare fiber protection sleeve is embedded into the bottom side of each cable groove, and each bare fiber protection sleeve can be embedded into the surface of each optical fiber by rotating a hand wheel; therefore, the device can not only open and pull the optical cable, but also protect the optical fiber, and is convenient to use.

Owner:HOHAI UNIV

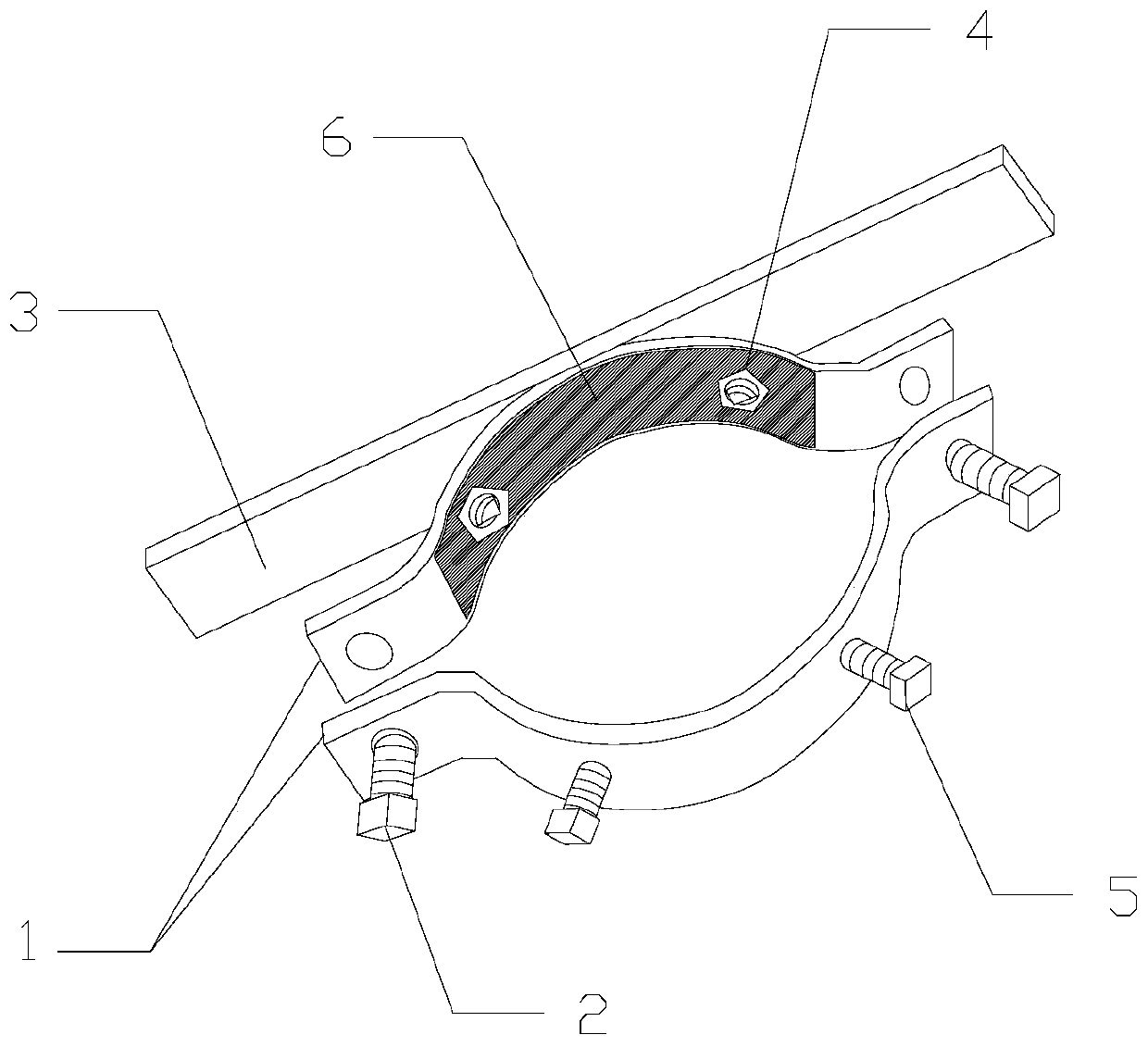

Wire pole hoop capable of achieving secondary fastening

InactiveCN110145515ANo sliding up and downNo turningFriction grip releasable fasteningsEngineeringFastener

Owner:山东厚俞实业有限公司

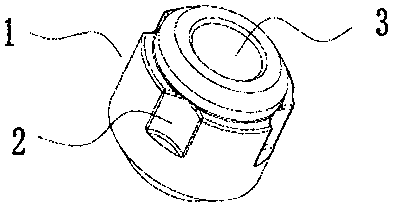

Shaft sleeve used for motor rotor

InactiveCN107659037ANo turningImprove connection reliabilitySupports/enclosures/casingsElectric machineBiochemical engineering

The invention relates to a shaft sleeve for a motor rotor, which comprises a shaft sleeve body, a through hole is arranged in the center of the shaft sleeve body; Positioning groove, the limiting groove is set in a depression toward the axis of the shaft sleeve body, the inner end surface of the limiting groove is an arc-shaped structure with the opening facing outward, the diameter of the limiting groove is 2.5mm, and the height of the limiting groove is 1cm‑ 1.5cm. The invention has the advantages of simple structure and ensuring the connection reliability between the shaft sleeve and the motor housing.

Owner:南通旭越光电科技有限公司

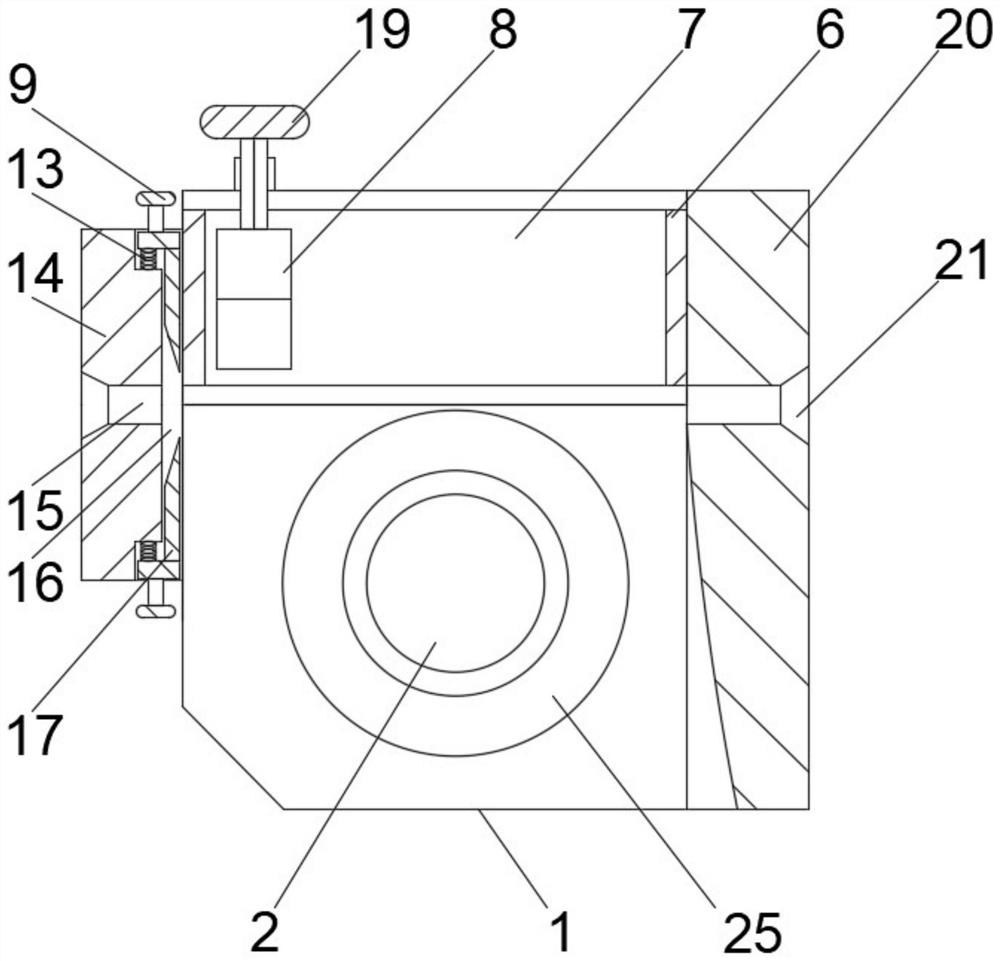

Cable press-fitting equipment

InactiveCN110718830AAvoid damageImprove pressing efficiencyLine/current collector detailsWorkbenchPortal frame

The invention discloses cable press-fitting equipment, and belongs to the technical field of press-fitting equipment. The equipment comprises a workbench, a first supporting plate and a shell, whereinthe first supporting plate is fixedly mounted above the workbench through a screw, and the shell is located at one side of the first supporting plate; the shell is welded to the upper surface of theworkbench, and a second supporting plate is arranged above the shell in a sliding mode; a fixed pipe is integrally formed above the second supporting plate, a portal frame is fixedly installed on theworkbench through a screw, a press-fitting mechanism is fixedly installed on the inner side of the portal frame through a screw, and a sliding mechanism is arranged in the shell. According to the invention, through the arrangement of a fixed rod and the sliding mechanism, a cable connector lug is conveyed to the position below the press-fitting mechanism, thereby improving the press-fitting quality of a cable, and improving the press-fitting efficiency of the cable.

Owner:安徽国信电缆科技股份有限公司

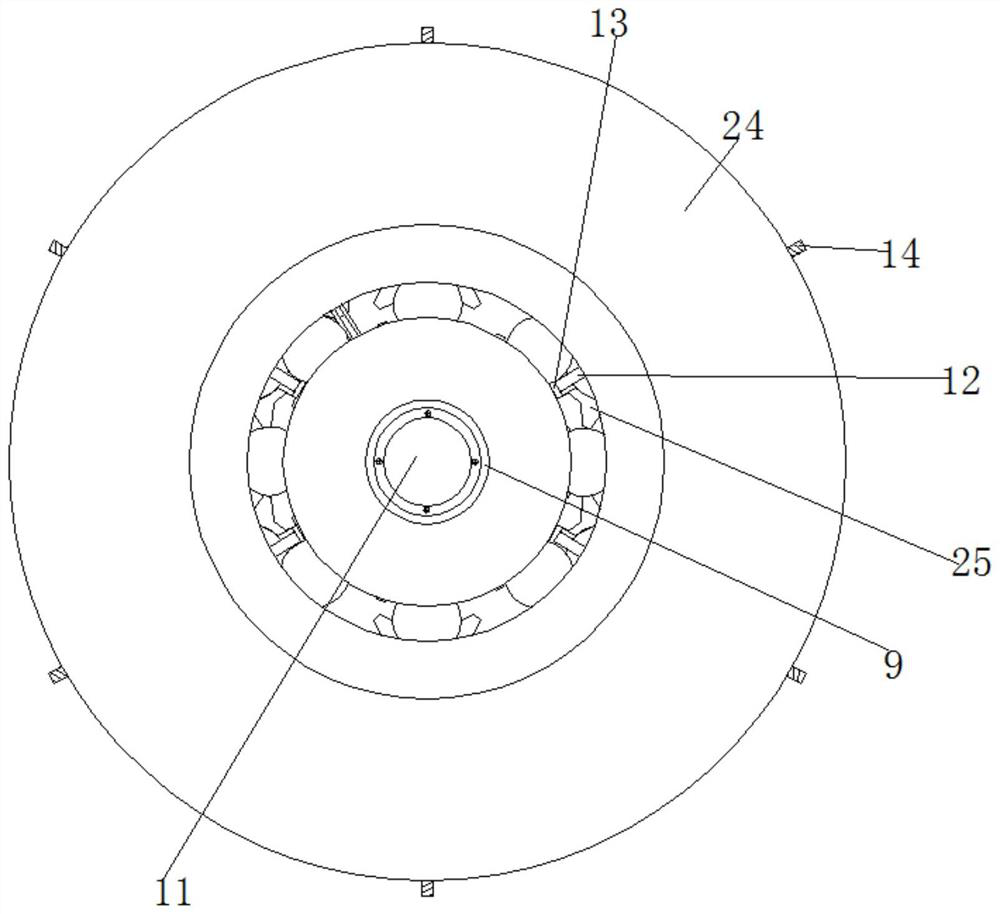

Connecting structure for machining driving motor shaft

ActiveCN114290089AAdjustable distanceImprove mass production efficiencyMetal working apparatusPositioning apparatusElectric machineryDrive motor

The invention relates to the technical field of motor shafts, and discloses a connecting structure for machining a driving motor shaft, which comprises an outer cylinder, and a plurality of clamping nuts meshed with the bottom tooth surface of a bottom tooth surface rotating cylinder are driven to rotate by rotating the bottom tooth surface rotating cylinder, so that the clamping nuts move along a threaded rod in the rotating process; the multiple movable heads can be adjusted in the same direction along the threaded rod, the effect that multiple machining shafts can be clamped or disassembled at the same time is achieved, the efficiency of batch production is improved, the multiple clamping nuts are moved to different positions by rotating the clamping nuts at different positions, and the machining efficiency is improved. Therefore, the effect that the multiple moving heads and the multiple fixed heads which are used in pairs clamp motor shafts of different specifications is achieved, the function of machining the multiple motor shafts by starting the motor at a time is achieved, the starting frequency of the motor is reduced under the condition that the same number of machining shafts are machined, and the service life of the motor is prolonged.

Owner:浙江迅达工业科技股份有限公司

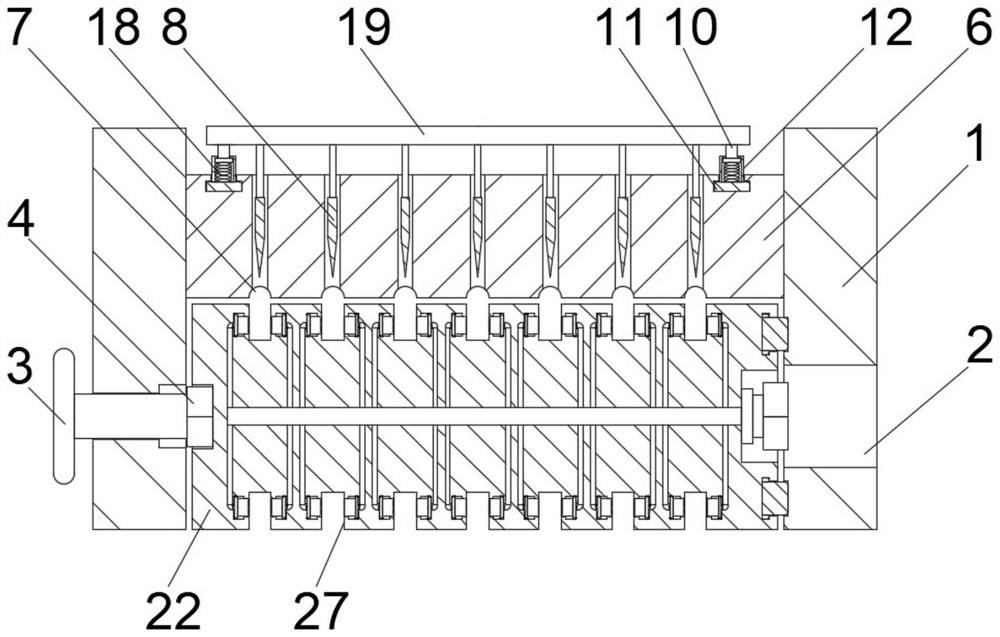

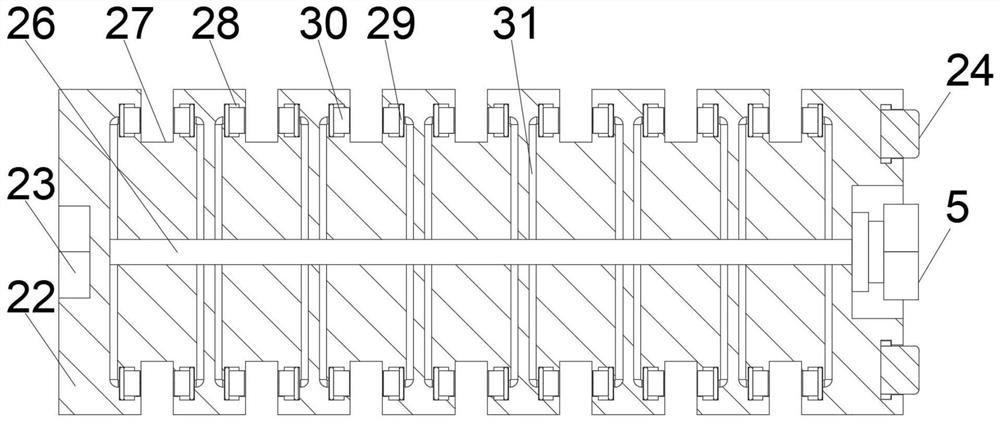

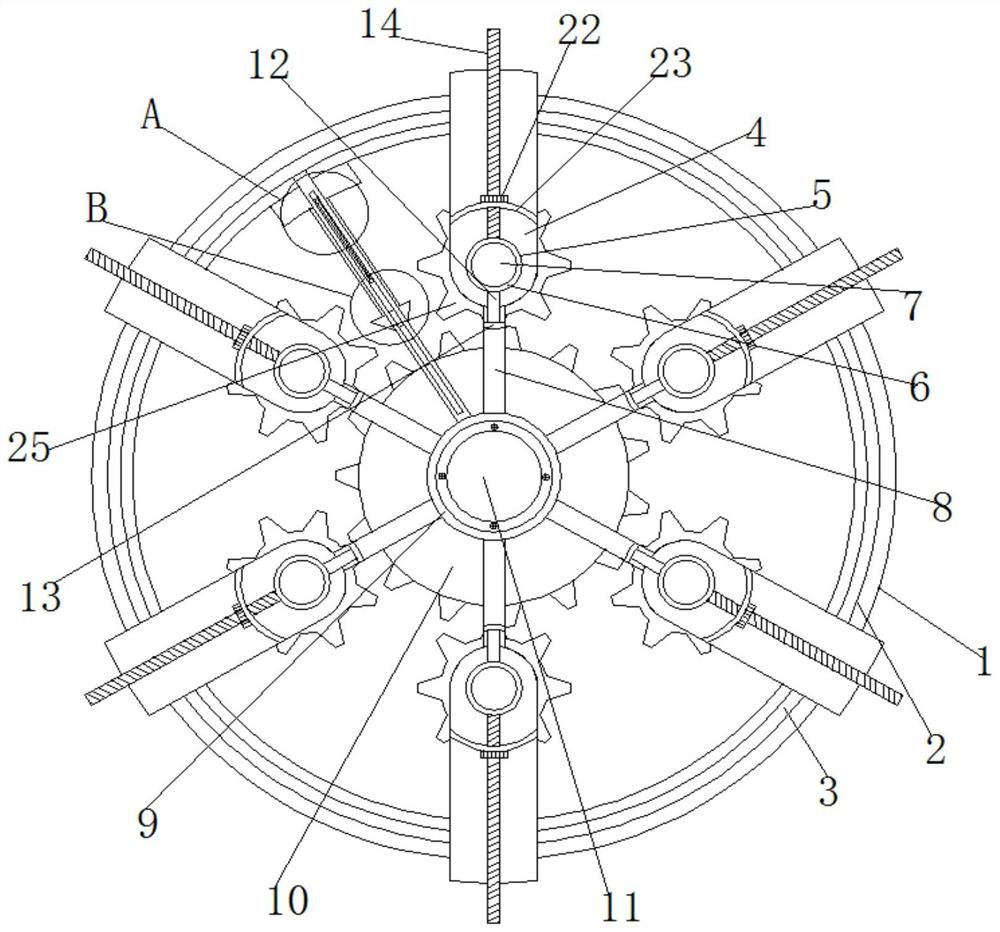

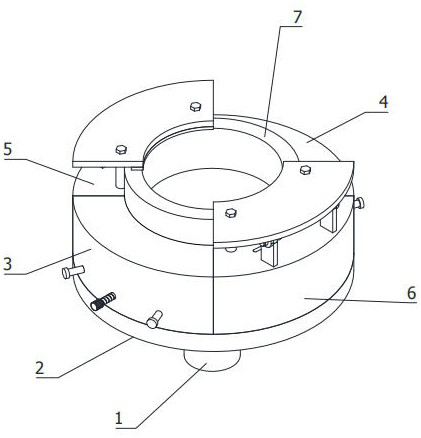

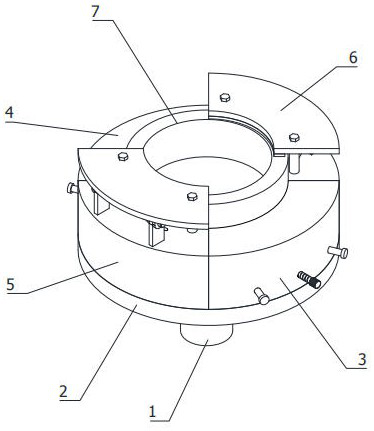

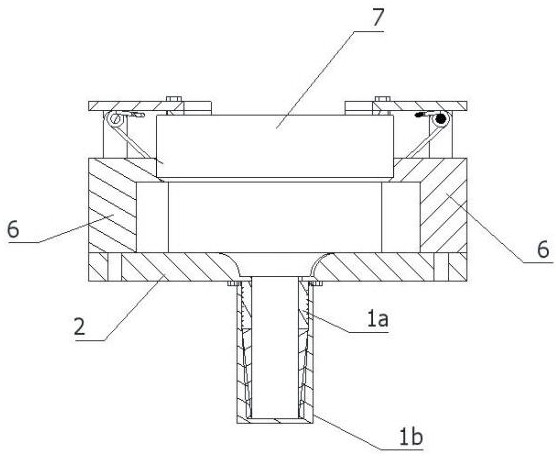

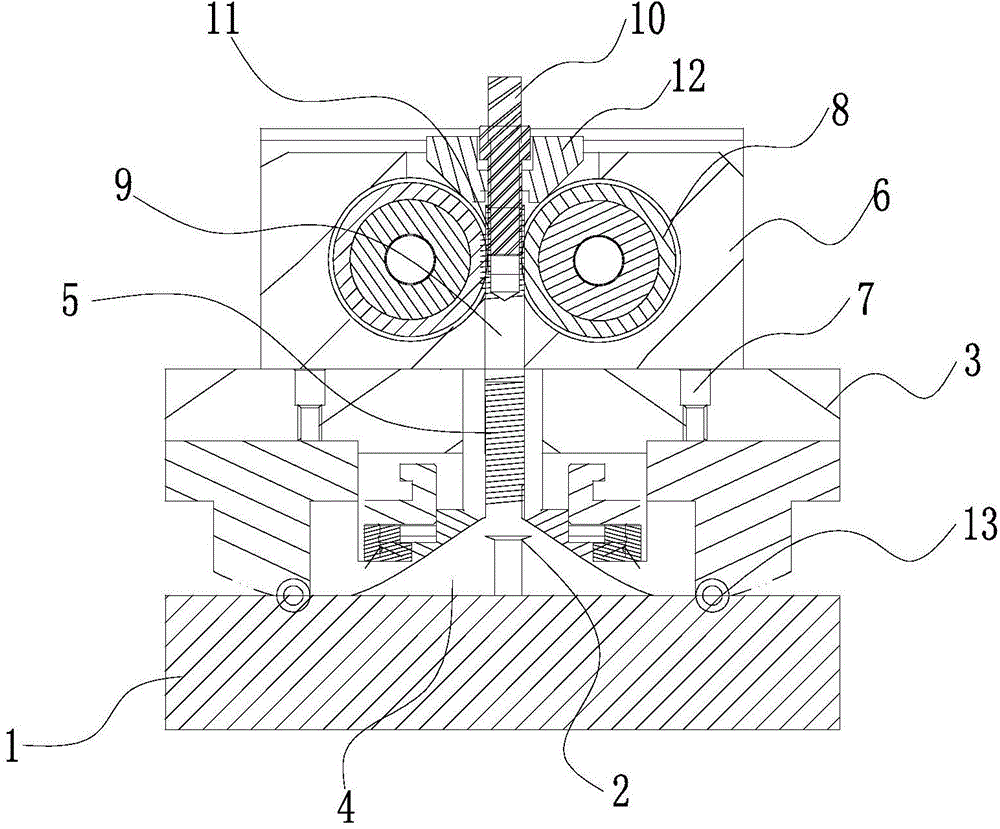

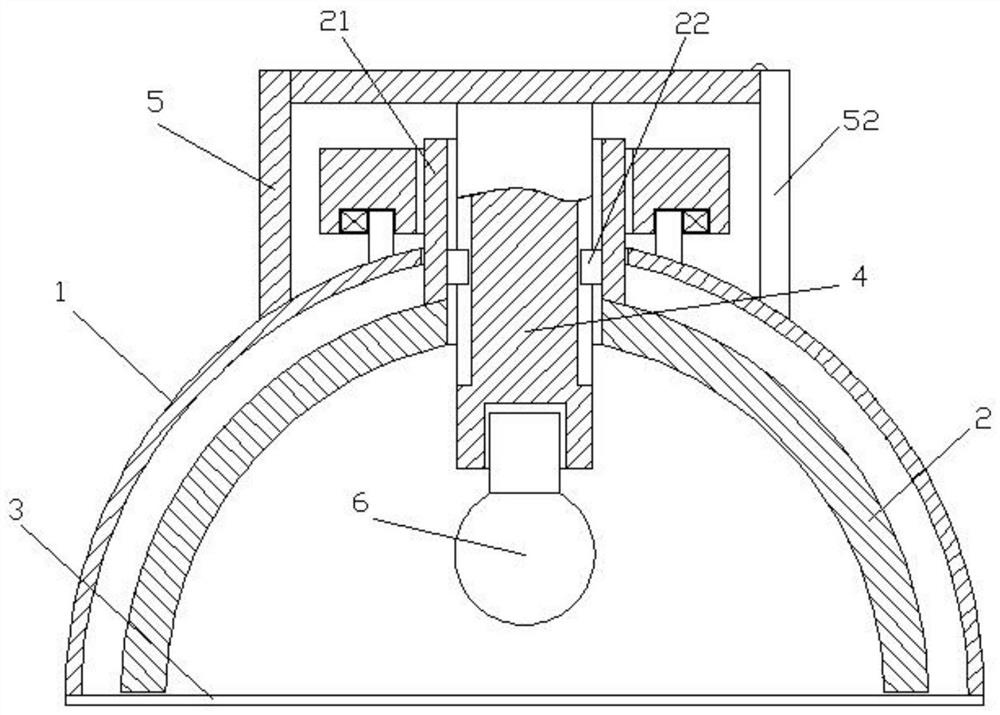

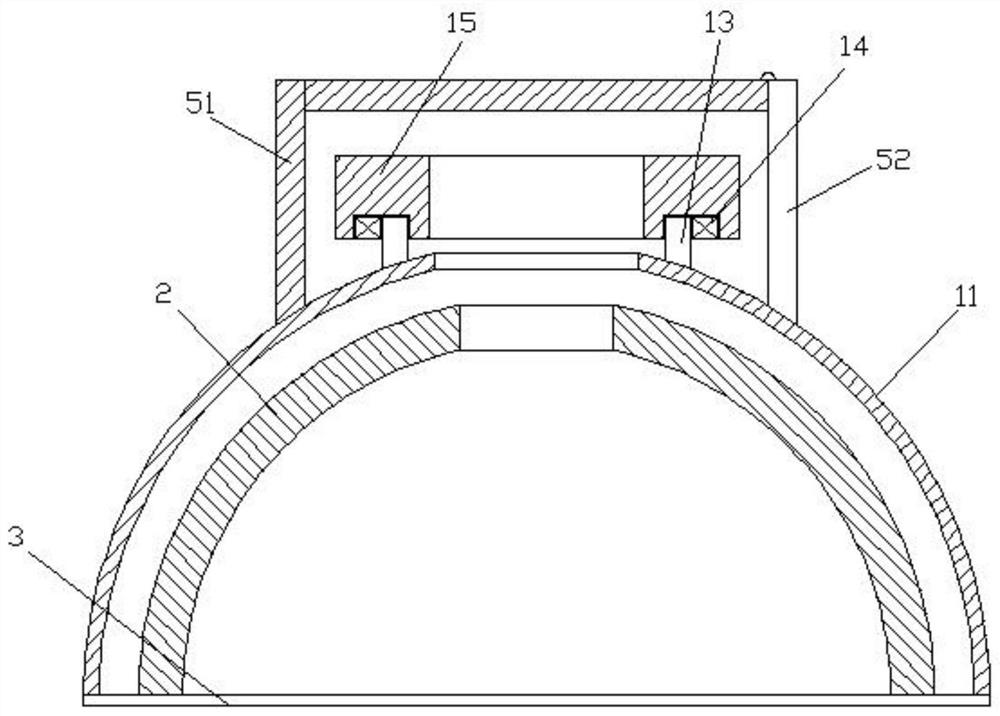

Tooling for rough turning of constant velocity universal joint bell shell

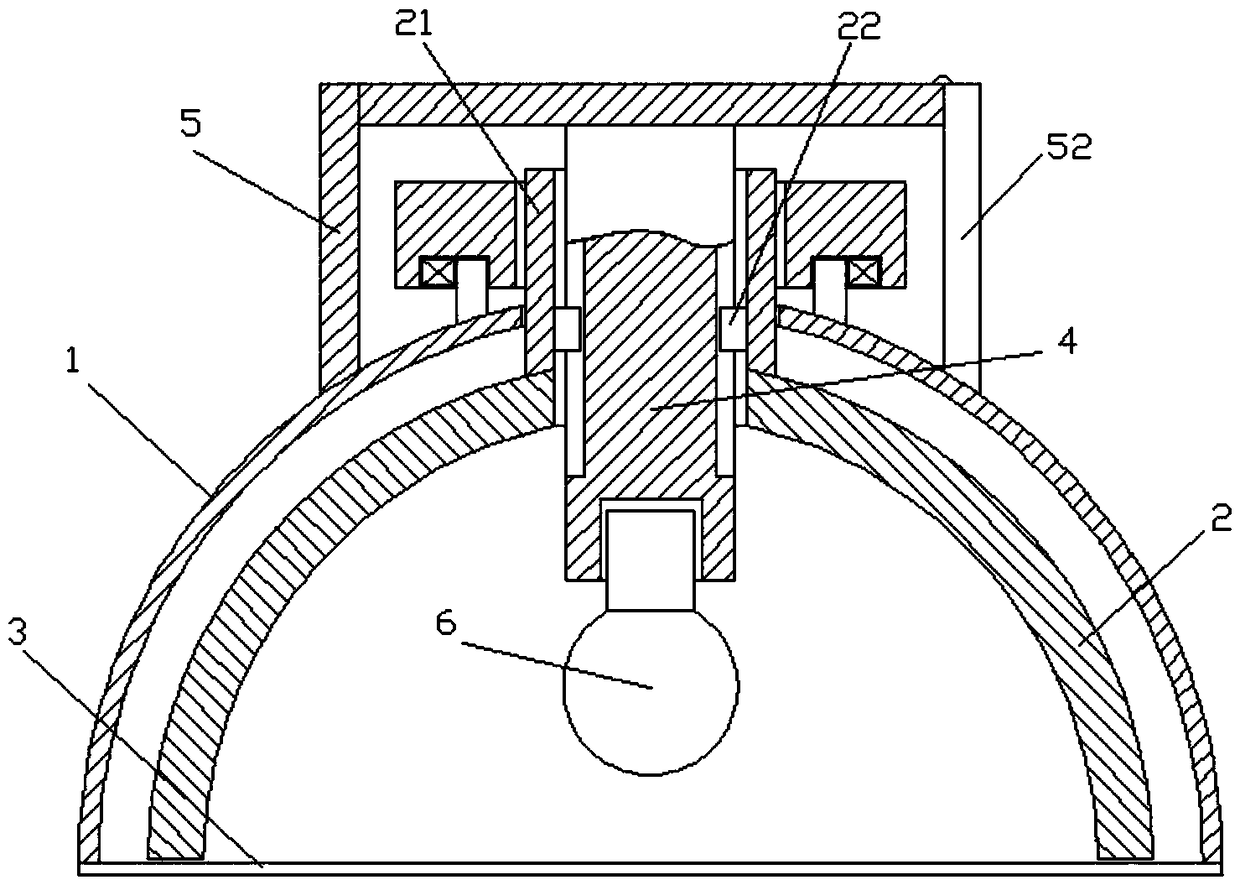

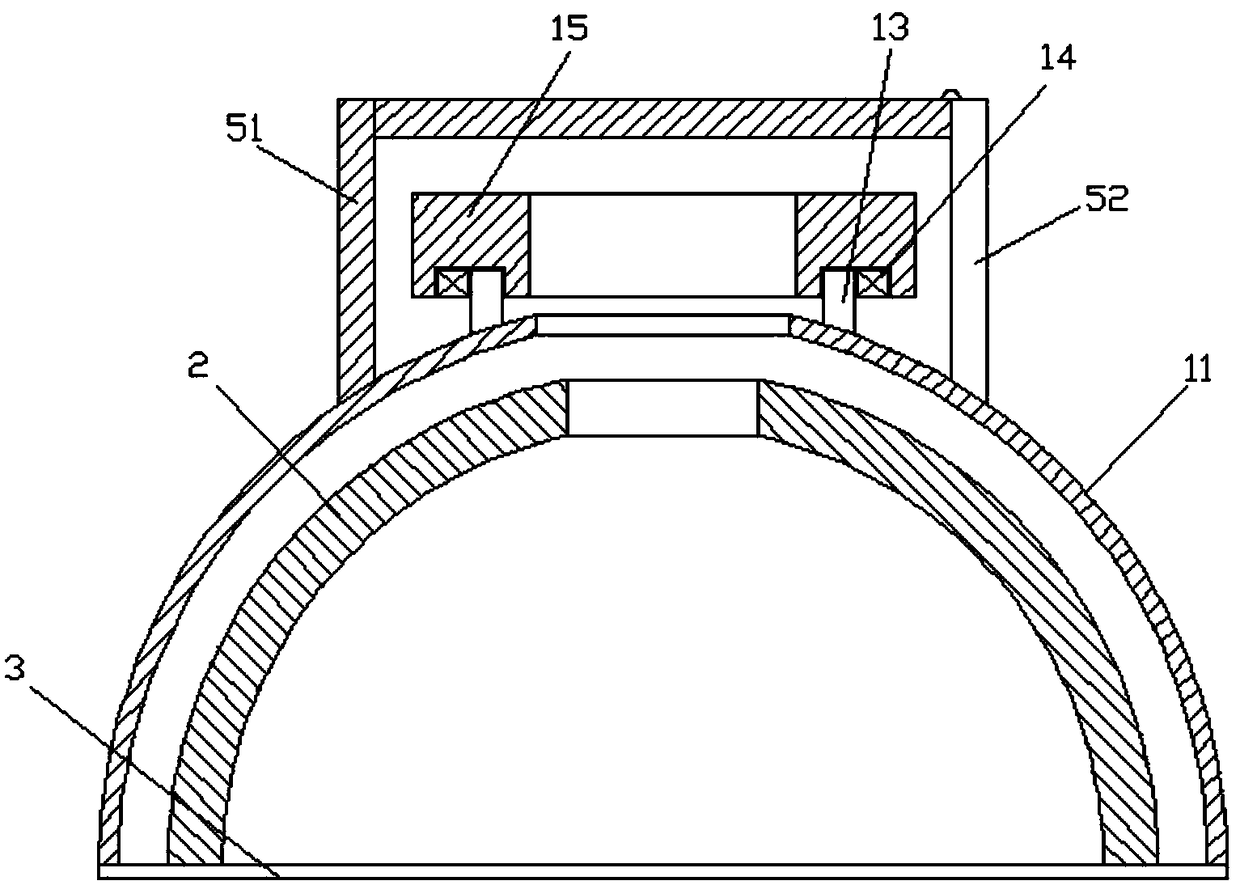

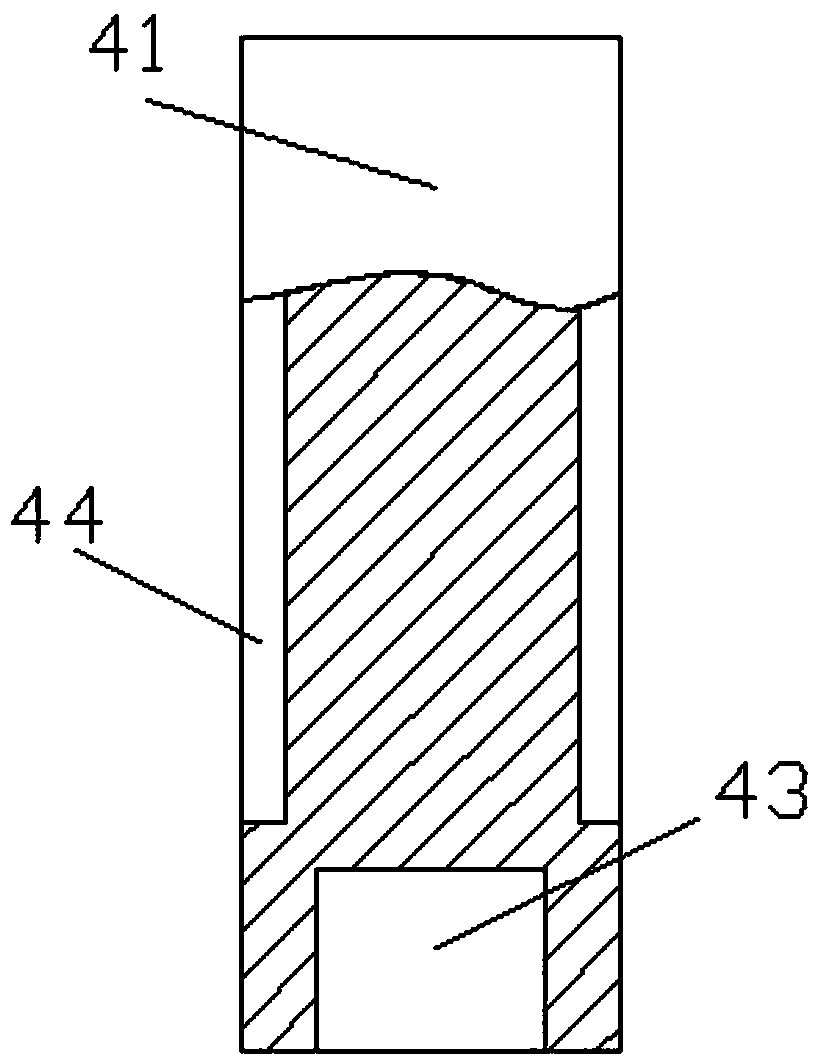

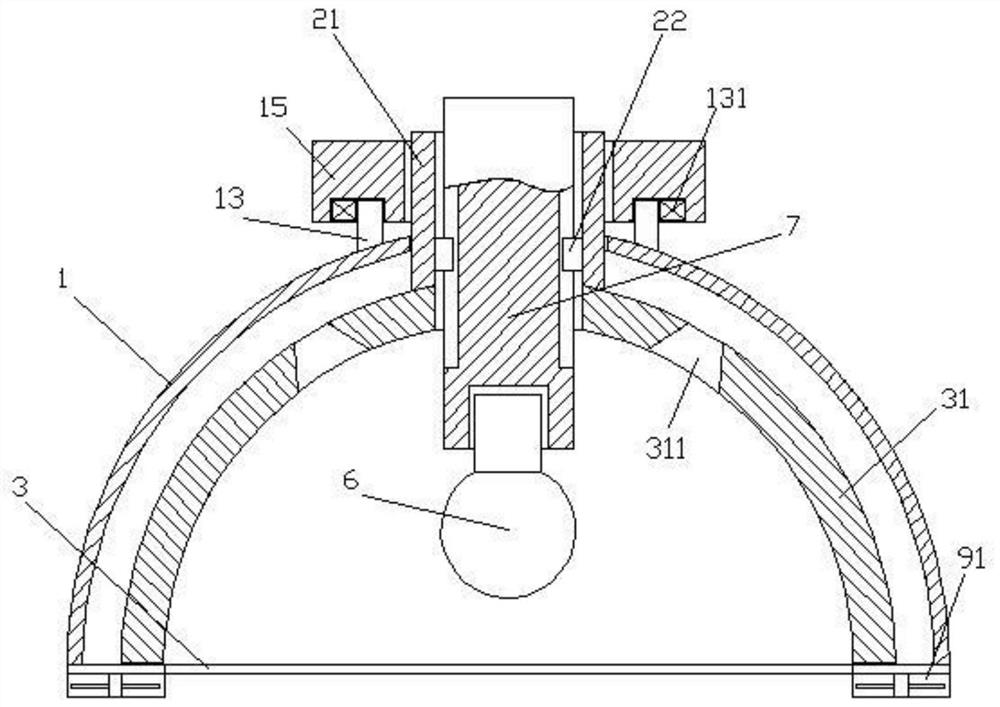

ActiveCN111185778BConvenient rough carStop shakingWork clamping meansPositioning apparatusMotor vehicle partUniversal joint

The invention relates to the field of automobile part manufacturing, in particular to a constant velocity universal joint bell housing rough turning tool. The constant velocity universal joint bell housing rough turning tool comprises a bottom anti-rotation assembly, a supporting bottom plate, a first annular face clamping assembly, a second annular face clamping assembly, a first end face pressing assembly and a second end face pressing assembly, the bottom anti-rotation assembly is located at the bottom of the supporting bottom plate, the first annular face clamping assembly and the second annular face clamping assembly are both located at the top of the supporting bottom plate, the first end face pressing assembly and the second end face pressing assembly are both located at the top ofthe supporting bottom plate, and the first end face pressing assembly and the second end face pressing assembly are both located at the top of the supporting bottom plate. According to the constant velocity universal joint bell housing rough turning tool, the lower ring column of the bell housing can be clamped and prevented from shaking, a layer of insurance can be provided for fixation of the bell housing, and the bell housing cannot rotate during machining.

Owner:石娟娟

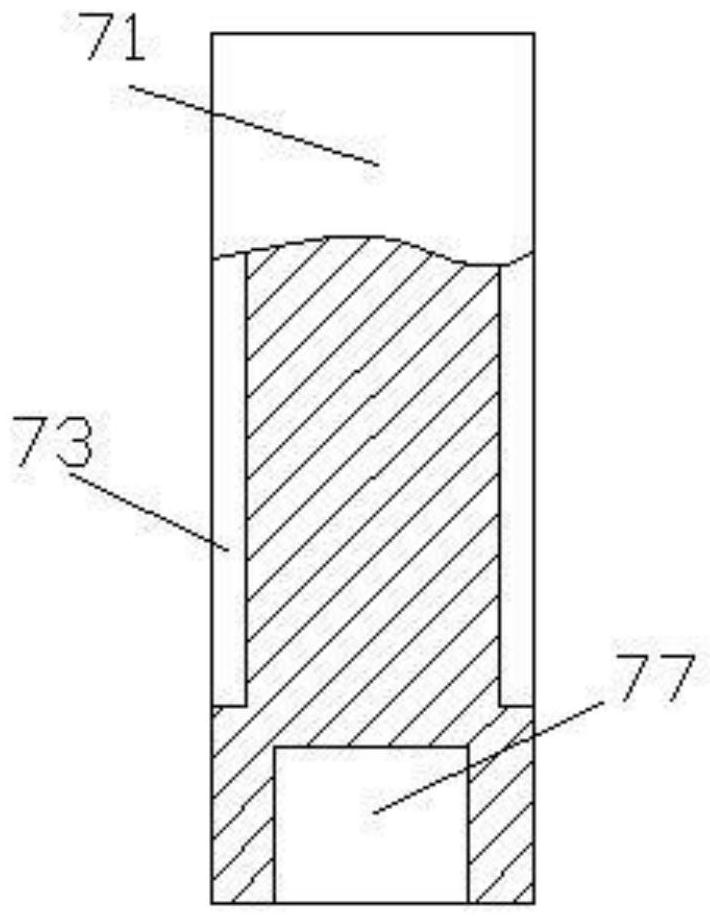

Spotlighting LED lamp

ActiveCN109058847AAvoid touchingSpotlight Effect AdjustmentProtective devices for lightingCoatingsGlass coverEngineering

The invention discloses a spotlighting LED lamp comprising a shell. A cover plate is arranged at the bottom of the shell and is a transparent glass cover plate. A cover lid is arranged at the top of the shell and is overall cylindrical. The lower end of the cover lid is fixedly connected with the outer surface of the shell. A lamp pole is arranged in the shell and is vertically arranged in the middle of the shell, and the stretching end of the lamp pole is fixedly connected with the lower surface of the top of the cover lid. An LED lamp body is connected to the lower end of the lamp pole. A rotary assembly is arranged in the cover lid and is in matched connection with the shell. A lampshade is arranged in the shell and is in matched connection with the rotary assembly. The inner wall of the lampshade is coated with reflection materials. The problems that when an LED lamp needs to be replaced, the position of a light source changes, the spotlighting effect becomes poor, and in the priorart, light rays are adjusted only by changing the luminance of the light rays for different work are solved.

Owner:安徽省富鑫雅光电科技有限公司

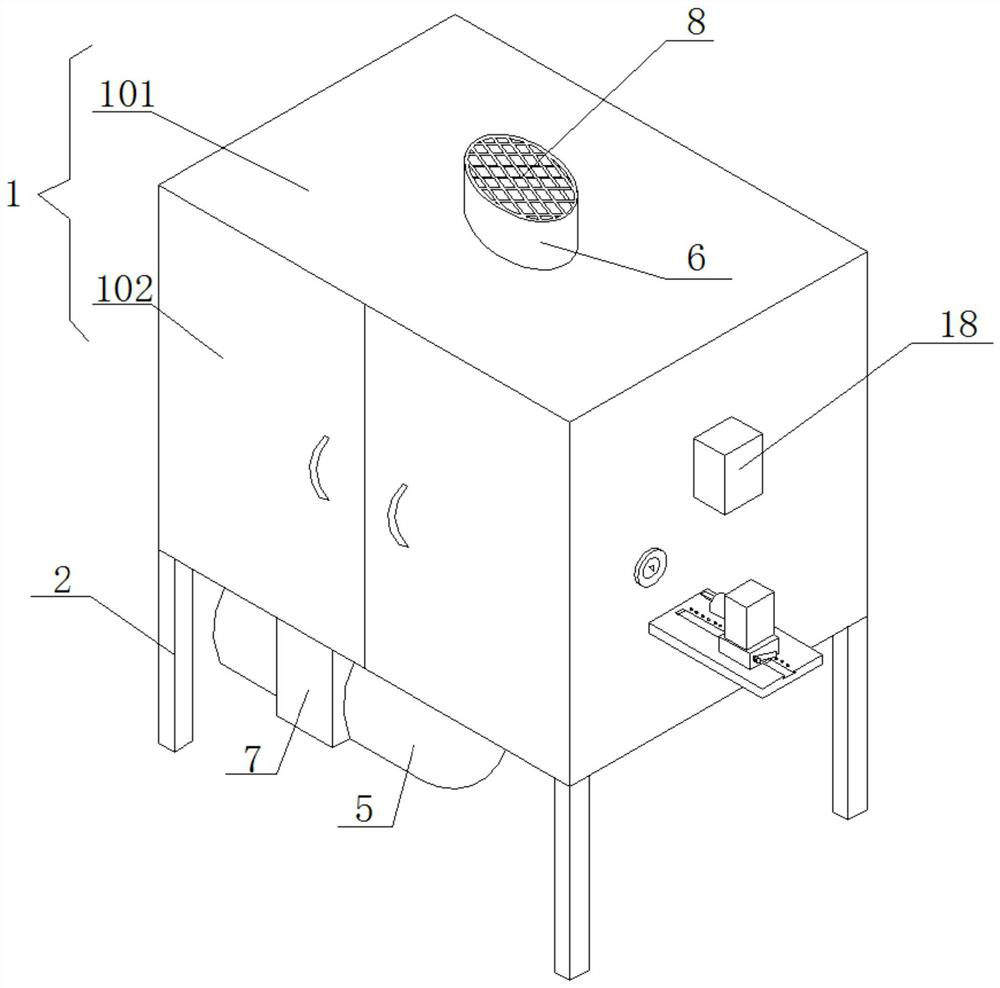

A storage device for peanut prevention and control of aflatoxin

ActiveCN109792895BImprove breathabilityImprove ventilationAgriculture tools and machinesHarvested fruit hanging devicesAnimal scienceMechanical engineering

The invention discloses a peanut storage device for preventing and controlling aflatoxin, and belongs to the technical field of peanut storage equipment. It includes a storage box, a turning device, a driving device and a ventilation device. The turning device is set in the storage box. The turning device includes a turning cylinder and a rotating shaft arranged at both ends of the turning barrel. It coincides with the axis of the rotating shaft, and the rotating shaft is connected to the turning cylinder through a clamp, and the end of the rotating shaft far away from the turning barrel is connected to the side wall of the storage box, and the rotating shaft is connected to the driving device. The ventilation device includes an air inlet pipe, an air outlet pipe and a fan , the air inlet pipe is arranged under the turning drum, the air outlet pipe is arranged above the turning drum, and the fan is arranged on the air inlet pipe. The invention can enhance the air permeability of the peanut heap, improve the ventilation effect among the peanuts in the peanut heap, and furthermore, can effectively change the temperature and humidity among the peanuts, and effectively prevent and control the generation of aflatoxin.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

Mounting rack for honing pump body

The invention relates to a mounting rack for honing a pump body. The mounting rack for honing the pump body comprises a base frame, wherein a left cantilever is fixed on the left side of a front end surface of the base frame; a right cantilever is fixed on the right side of the front end surface of the base frame; sections are respectively arranged on the left cantilever and the right cantilever; a mounting table is fixed in the middle of the left cantilever; a gripping opening is fixedly formed in the front end of the left cantilever and is provided with a chute; a connecting block is fixed at the front end of the right cantilever and is hinged to a front stopping rack; an oblique pressing block which is matched with the chute is arranged at the left end of the front stopping rack; and a left stopping block and a right stopping block are arranged in the middle of the front stopping rack. The mounting rack for honing the pump body is convenient to fix, simple in structure and low in manufacturing cost and is mounted firmly; side plates and supporting columns are fixed by upper clamping blocks and lower clamping blocks, so that the side plates and the pump body on the side plates can slide on the left cantilever; the mounting rack is convenient to adjust; and the left cantilever with the section and the right cantilever with the section are fixed firmly, and cannot rotate.

Owner:桐乡市恒达经编股份有限公司

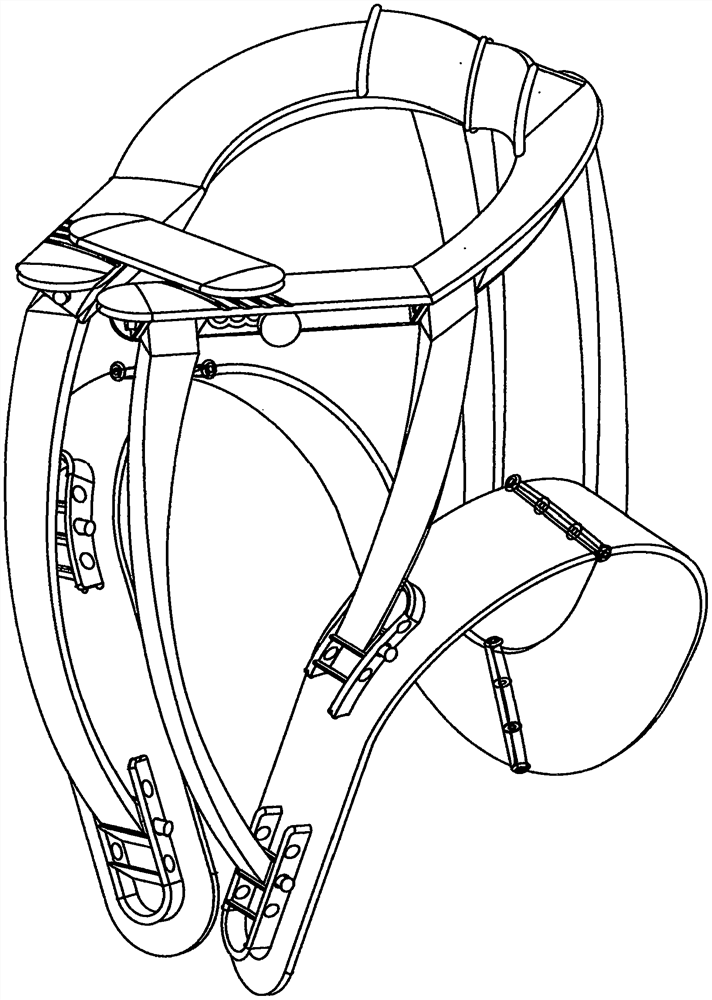

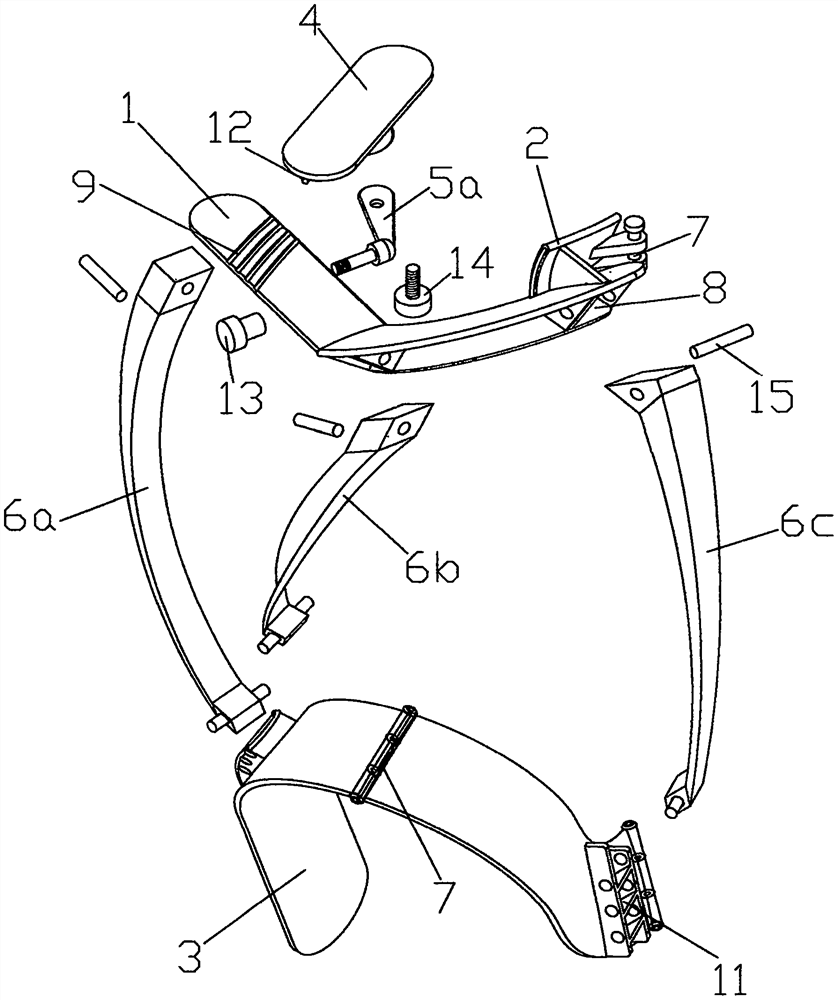

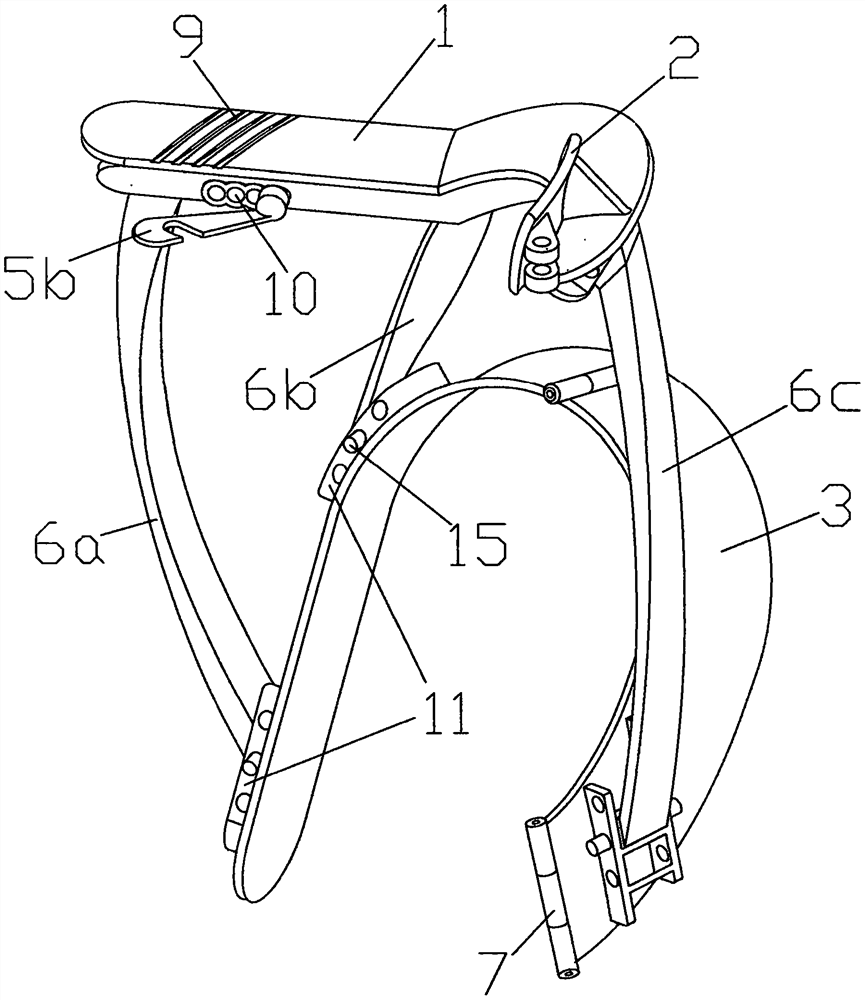

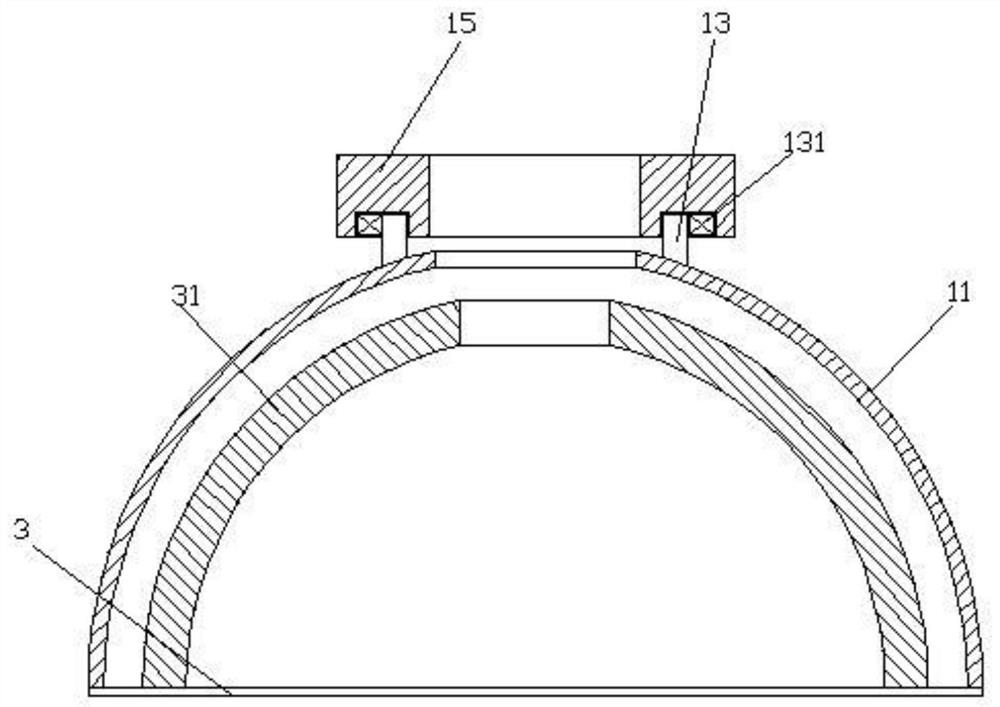

Omnidirectional neck exerciser

PendingCN114259699ARealize wearingEasy to adaptMuscle exercising devicesPhysical medicine and rehabilitationPhysical therapy

The invention discloses an omnidirectional neck exerciser capable of performing neck exercise on the premise of protecting the cervical vertebra. The whole instrument is worn under the head and can enclose the shoulder and neck, and the main parts are as follows: a left neck support and a right neck support are encircled into a heart shape through a connecting shaft and can be opened and closed, the front half part is linear, and the rear half part is arc-shaped and is connected with an arc-shaped pillow support; the shoulder enclosure adopts a structure for enclosing a shoulder and a neck, and each part can be opened and closed around a connecting shaft; the left piece of the positioning piece is provided with a round hole, and the right piece is hook-shaped and connected with the lower jaw abutting plate through connecting screws; the arc-shaped elastic columns are arranged on the front side and the rear side respectively. During assembly, the neck support and the lower jaw abutting plate are adjusted by inserting the positioning pieces into the corresponding positioning holes in the neck support, and the upper end and the lower end of each elastic column are fixed to the corresponding clamping openings of the neck support and the shoulder fence through the clamping pins respectively. When in use, the right positioning piece is unhooked from the connecting screw, the whole instrument is opened towards two sides around the connecting shaft, then the instrument is sleeved from the back of the neck from the opening, and finally the right positioning piece hooks the connecting screw, so that the whole instrument encloses the shoulder and the neck, and then the neck can be exercised.

Owner:张杨

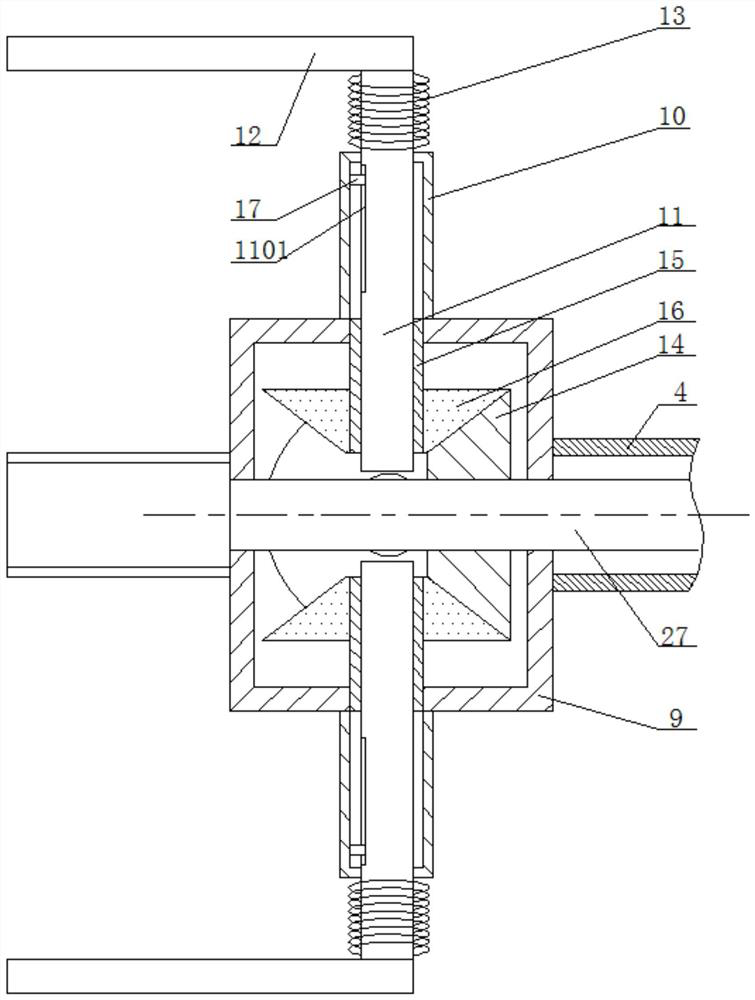

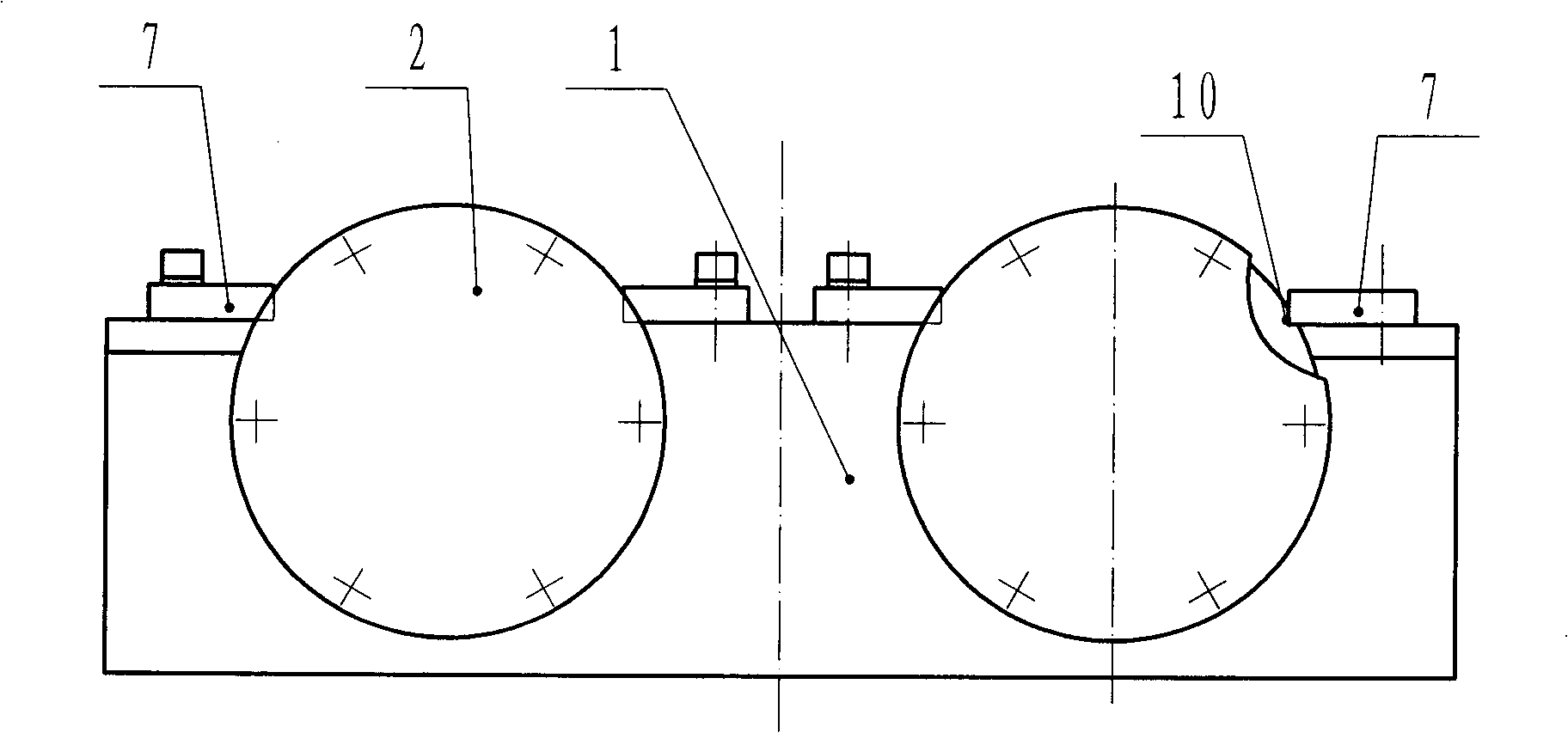

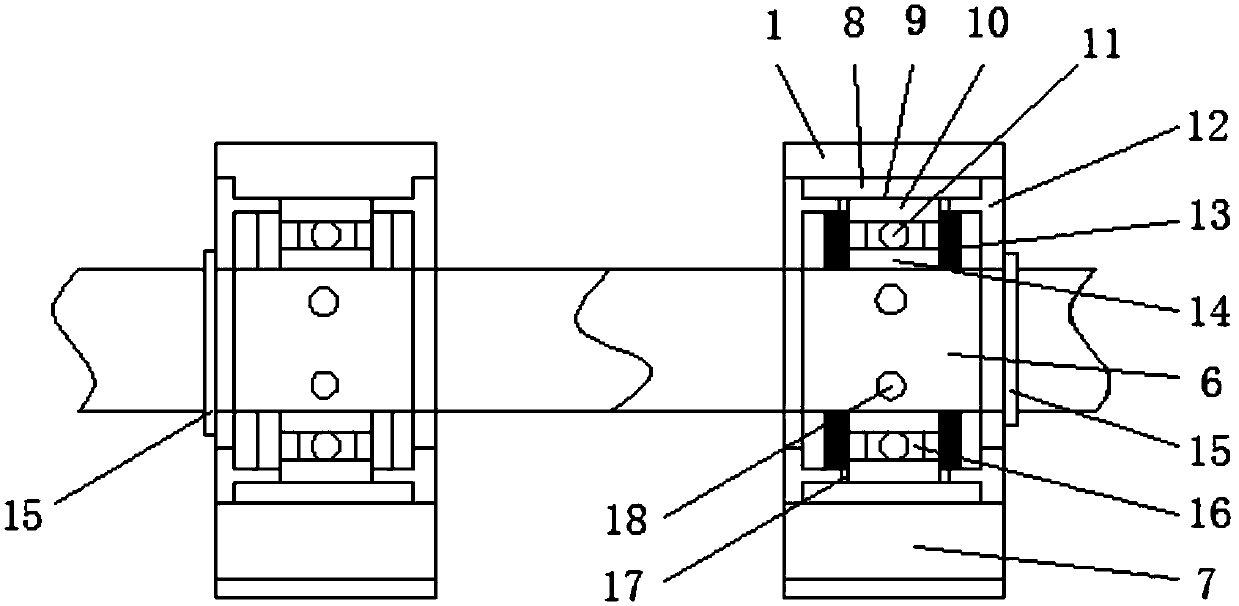

Quick fix mechanism of lower roller

InactiveCN101352736AGuaranteed axial positioningGuaranteed radial positioningEngineeringMechanical engineering

The invention provides a lower roll quick dispatch mechanism, which relates to a quick dispatch mechanism of the lower roll of a novel roll bending machine, and belongs to the technical field of roll bending machines. The invention aims at providing a quick dispatch mechanism which can realize lower roll quick dispatch of the roll bending machine and can solve the problem of positioning the lower roll; the technical proposal adopted is that: a quick dispatch bearing body with a U-shaped groove is fixed at the left end of the low roll, the bearing is sheathed on the left spindle head of the lower roll and is located in the U-shaped groove of the quick dispatch bearing body, an opening is arranged on the outer end face of the quick dispatch bearing body, and the quick dispatch bearing body is fixed in a groove corresponding to a frame by the opening. The lower roll quick dispatch mechanism can be widely applied to roll bending machines.

Owner:长治钢铁(集团)锻压机械制造有限公司

Shaft body machining tool

InactiveCN106270565ANo turningWill not happenWork clamping meansTurning machinesEngineeringMachine tool

The invention relates to a shaft body machining tool. The shaft body machining tool comprises a lathe base and a cutter arranged on the lathe base. A shaft body fixing plate is arranged on the lathe base. A shaft body mounting cavity is formed in the bottom of the shaft body fixing plate. A shaft body positioning plate is arranged on the shaft body fixing plate. Two rotating wheels are arranged inside the shaft body positioning plate. A vertical positioning channel is formed between the two rotating wheels. A positioning rod is arranged in the positioning channel. The positioning channel formed in the shaft body positioning plate and the shaft body mounting cavity formed in the shaft body fixing plate are located on the same straight line. The end of the positioning rod corresponds to the shaft body mounting cavity. When the cutter below the shaft body fixing plate is used for machining a shaft body, the two rotating wheels on the shaft body positioning plate drive the positioning rod engaged with the two rotating wheels to move downwards and stretch into the shaft body mounting cavity to abut against the end of the to-be-machined shaft body, so that the to-be-machined shaft body is positioned; and when the cutter on the lathe base is used for machining the shaft body, the shaft body cannot rotate or loose; and the tool is simple in structure and good in shaft body positioning effect.

Owner:天津世创机械制造有限公司

Locking device for plug-in connection

InactiveCN105122558BAchieve rotationAchieving protection against manipulationCoupling device detailsElectric propulsionMechanical engineering

Owner:菲尼克斯电子有限公司

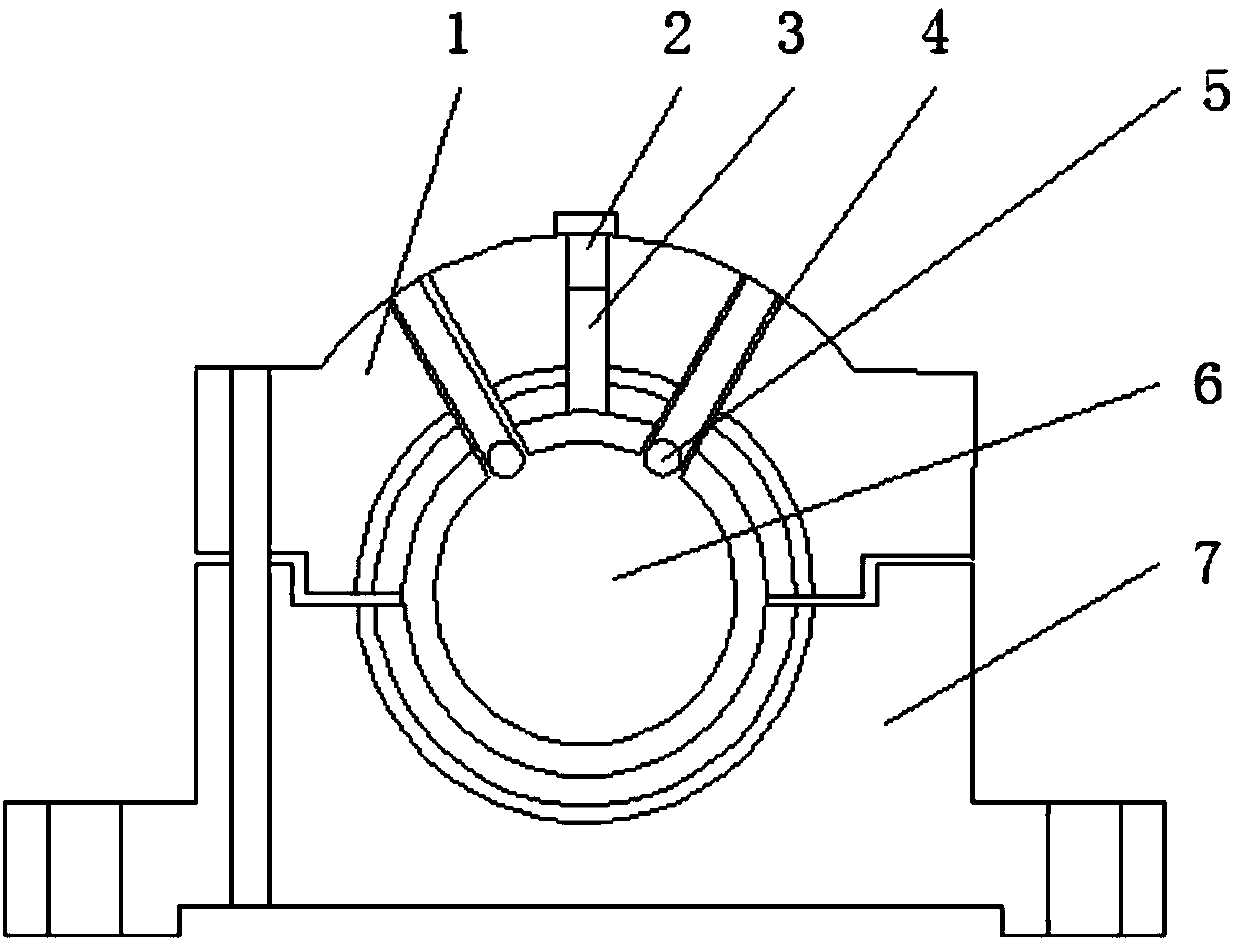

Switching device for bearing seats

InactiveCN107605961AWill not rotate togetherFirmly connectedBearing unit rigid supportAgricultural engineeringSteel ball

The invention discloses a switching device for bearing seats. The switching device comprises a bearing cap, wherein an oil hole is formed in the top end of the bearing cap; a sealing cover is connected to the top end of the oil hole in a sleeving manner; two plunger holes are formed in the inner part of the bearing cap; a spring is fixedly connected to the interior of each of the plunger holes; afixing plate is fixedly connected to the upper part of each of the springs; a plunger is fixedly connected to one end of each of the fixing plates; a steel ball is arranged at the tail end of each ofthe plungers; a bearing seat is in bolted connection with the bottom of the bearing cap; a shaft is fixedly connected to the middle of the bearing cap and the bearing seat; an upper cover is arrangedin bearing cover; a bearing is rotatably connected with the interior of the upper cover; a bearing outer ring is arranged in the bearing; a bearing inner ring is arranged below the bearing outer ring;and a rolling body is clamped and connected between the bearing outer ring and the bearing inner ring. According to the switching device for bearing seats, the structure is simple, the operation is convenient, the service life is long, and the switching device is used for realizing the switching among bearing seats and quite suitable for long-time machining occasions.

Owner:响水县弘博重型轴承座制造有限公司

a spotlight led light

ActiveCN109058847BAvoid touchingSpotlight Effect AdjustmentProtective devices for lightingCoatingsGlass coverEngineering

The invention discloses a spotlighting LED lamp comprising a shell. A cover plate is arranged at the bottom of the shell and is a transparent glass cover plate. A cover lid is arranged at the top of the shell and is overall cylindrical. The lower end of the cover lid is fixedly connected with the outer surface of the shell. A lamp pole is arranged in the shell and is vertically arranged in the middle of the shell, and the stretching end of the lamp pole is fixedly connected with the lower surface of the top of the cover lid. An LED lamp body is connected to the lower end of the lamp pole. A rotary assembly is arranged in the cover lid and is in matched connection with the shell. A lampshade is arranged in the shell and is in matched connection with the rotary assembly. The inner wall of the lampshade is coated with reflection materials. The problems that when an LED lamp needs to be replaced, the position of a light source changes, the spotlighting effect becomes poor, and in the priorart, light rays are adjusted only by changing the luminance of the light rays for different work are solved.

Owner:安徽省富鑫雅光电科技有限公司

Heat dissipation LED lamp

PendingCN112432068AGood spotlightChange spotlight effectNon-electric lightingPoint-like light sourcePhysicsEngineering

The invention discloses a heat dissipation LED lamp, and relates to the field of LED lamps, the heat dissipation LED lamp comprises a shell, wherein the whole shell is hemispherical; a cover plate arranged at the bottom of the shell; a lamp post vertically arranged in the shell, wherein the lamp post is slidably connected with the shell, and the lower end of the lamp post is connected with the LEDlamp; a lampshade cover arranged in the shell, wherein the inner wall of the lampshade cover is coated with a reflective material, and the lampshade cover is provided with a plurality of heat dissipation openings; and cooling fans arranged on the outer surface of the cover plate in a central symmetry mode and arranged between the shell and the lampshade cover; wherein a temperature sensor is arranged in the lampshade cover and connected with a central control module, and the cooling fan is electrically connected with the central control module. The problems that a conventional LED does not have a heat dissipation function, the internal temperature rises after the LED is used for a period of time, normal use is affected, and maintenance is not facilitated are solved.

Owner:安徽省富鑫雅光电科技有限公司

Fuel pump configuring structure of vehicle

ActiveCN100577504CIncrease configuration freedomIncreased Design FreedomInternal combustion piston enginesFuel tanksVehicle frameFuel tank

The present invention relates to a fuel pump configuring structure of a vehicle which can increase the configuration freedom and designing freedom of the fuel pump. The fuel pump configuration structure is that in the vehicle a main bicycle frame (41) is arranged along the vehicle body center line (110) which extends from the center of the vehicle width direction to front and back, and the upper part of the main vehicle frame (41) is arranged with a fuel tank (24) which is additionally integrated with the fuel pump (83), the engine (17) is arranged at the lower part of the main vehicle frame (41) and the throttle valve body (77) is arranged at the back of the engine (17), wherein, seeing from the plane the fuel pump (83) and is arranged at the side opposite to the throttle valve body (77) clamping the main vehicle frame (41) and is parallel arranged with the throttle valve body (70) in the vehicle width direction.

Owner:HONDA MOTOR CO LTD

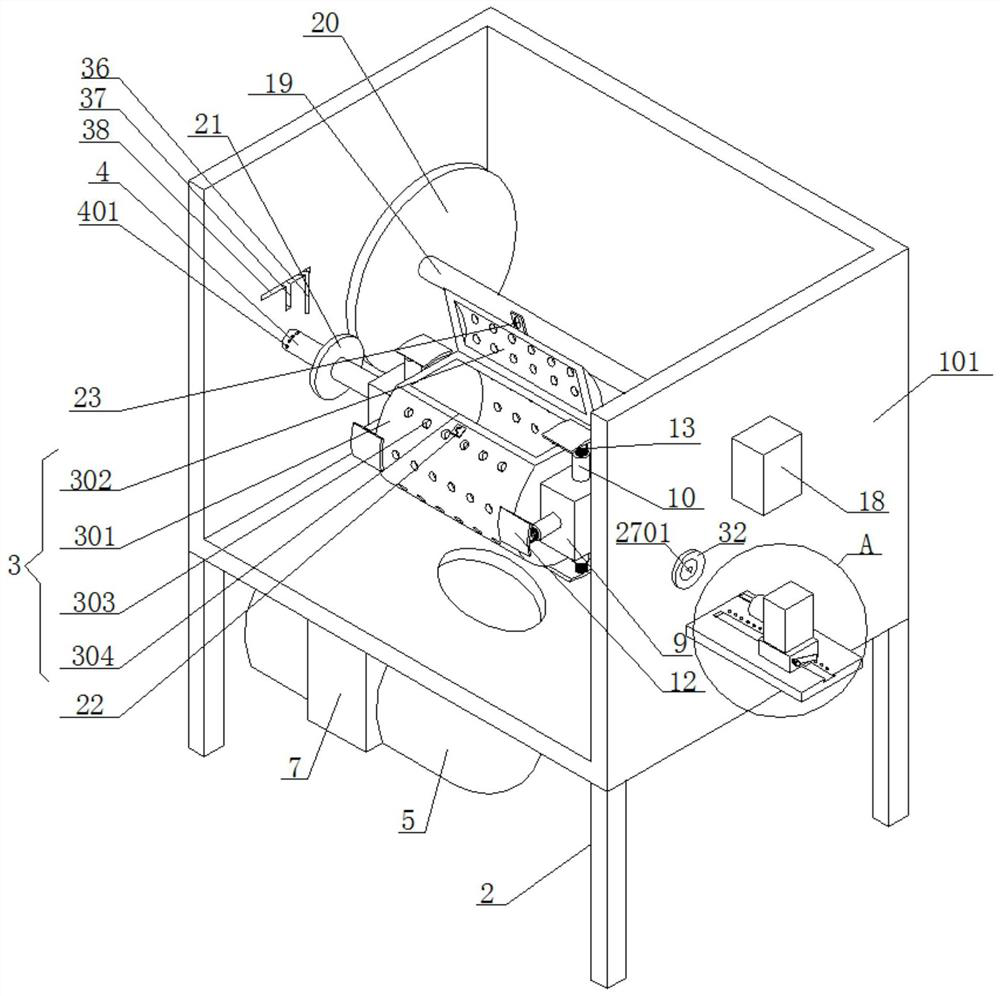

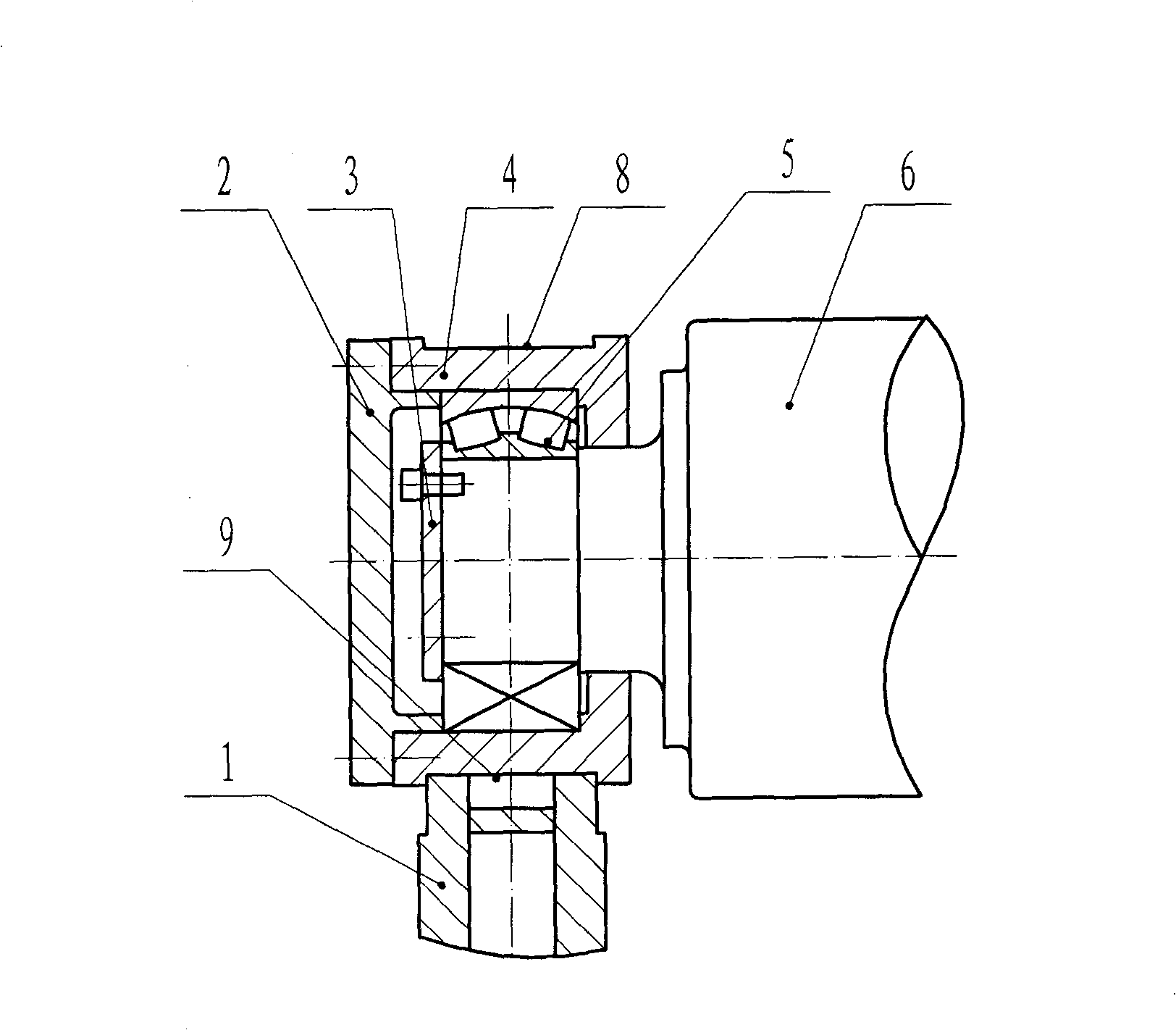

Suction-type rotary sand-blasting and powder-spraying device

PendingCN110216595AMeet the structural wear resistance requirements of high-speed flowMeet structural wear resistance requirementsBlast gunsAbrasive feedersSand blastingSolid particle

The invention discloses a suction-type rotary sand-blasting and powder-spraying device, and belongs to the field of rotary sand-blasting devices. The suction-type rotary sand-blasting and powder-spraying device comprises a rotary sealing base and a suction-type sand-blasting gun. The rotary sealing base is provided with two independent fluid pipelines, wherein one pipeline is designed on the coreof a central tube, so that when a powder-containing and sand-containing two-phase medium flows passes through the rotary central tube, abrasion is minimized, the abrasion-resistant requirement of a structure allowing powder-containing and sand-containing fluid containing solid particles to pass through at a high speed is met, and suction-type rotary sand-blasting and powder spraying is made possible. High-pressure gas rapidly flows through the suction-type sand-blasting gun to form a negative pressure in a sand suction passageway to enable the solid particles to be sucked into the sand-blasting and powder spraying device, and rotary sand-blasting and powder-spraying are achieved by means of reactive force of a jet flow. Compared with an existing sand-blasting machine, the suction-type rotary sand-blasting and powder-spraying device has the advantages that the material spraying range is wide, materials can be dispersed more uniformly, metering is more accurate, the size is small, and operation is more flexible and convenient.

Owner:江苏龙冶节能科技有限公司

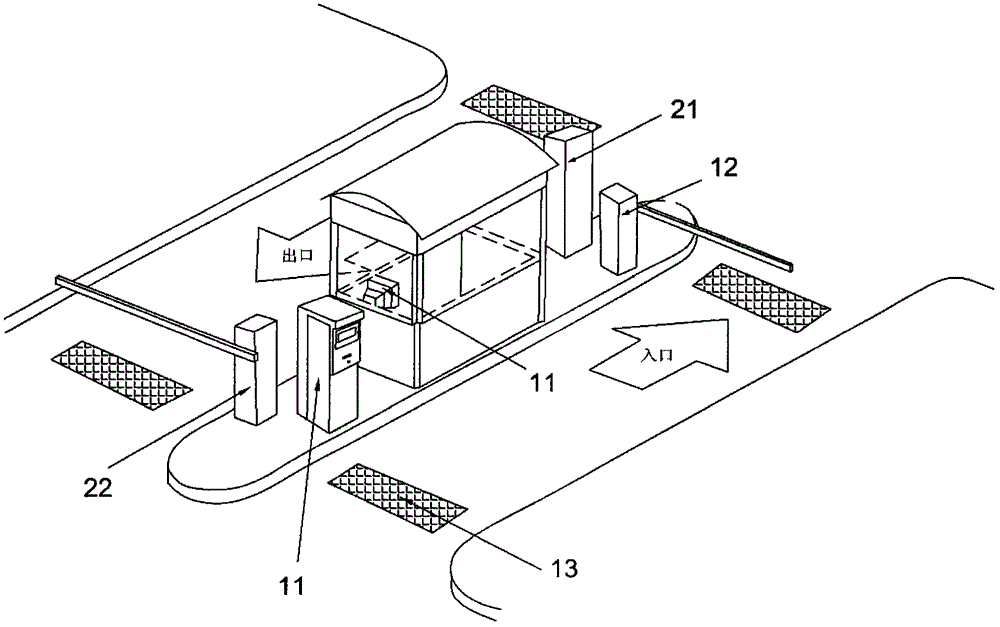

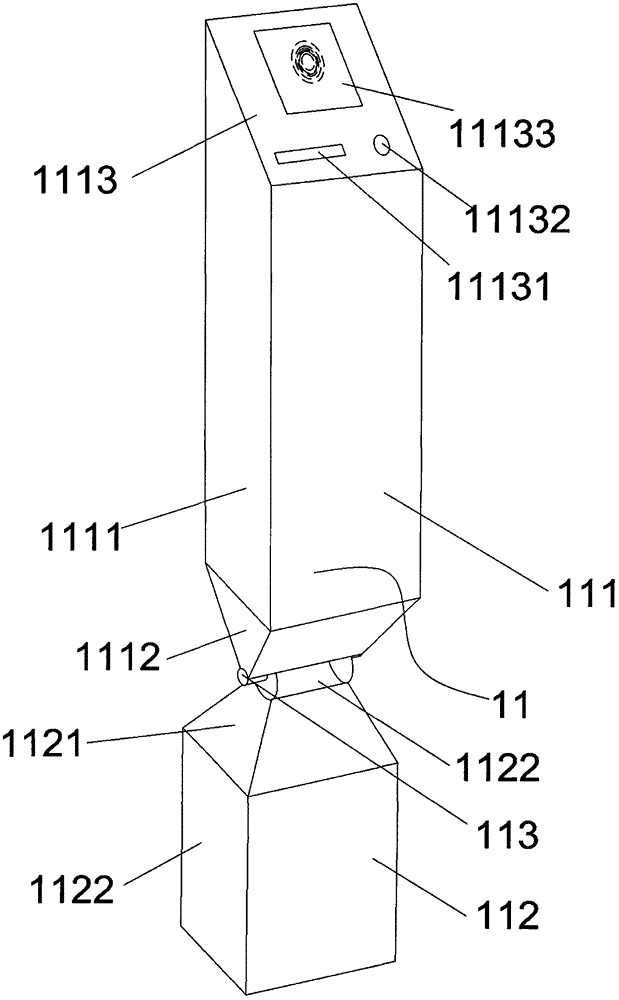

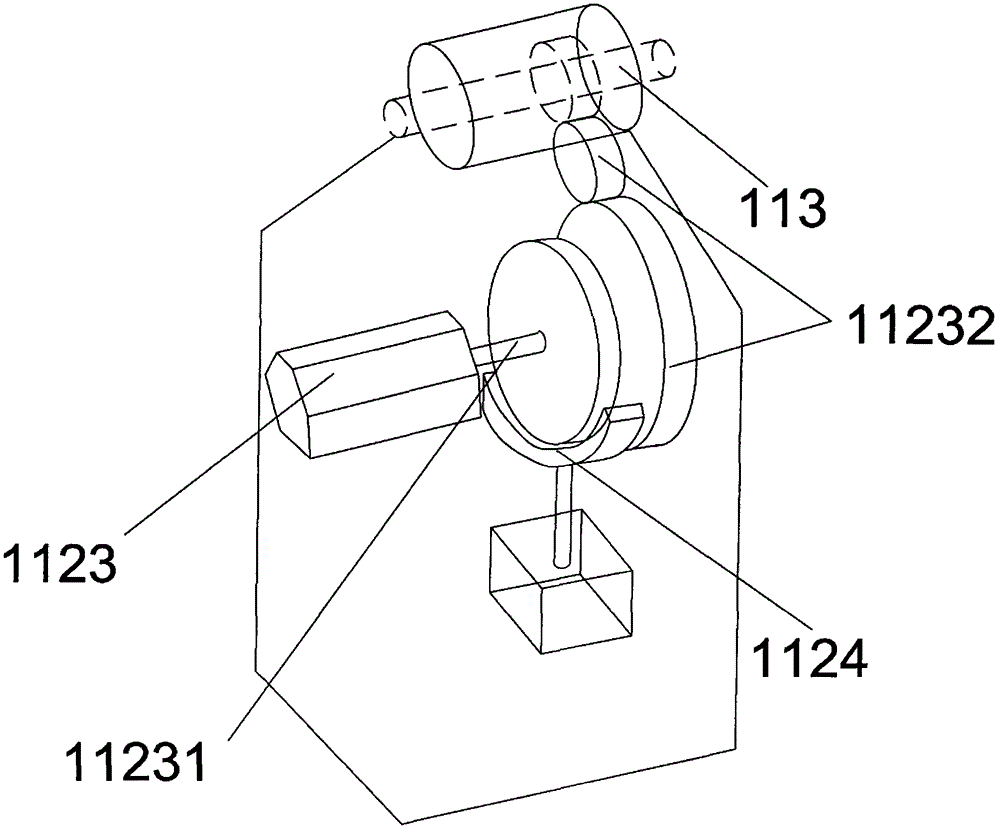

A card machine and parking lot charging system

A card machine (11) for a parking lot charging system and a parking lot charging system with the card machine (11). The card machine (11) comprises a body (111) provided with a card dispenser and / or a card reader inside. The card machine (11) further comprises a base (112) fixed on the ground. The body (111) rotates around a rotating shaft (113) arranged between the base (112) and the body (111). Accordingly, the distance between the body (111) and a side of a vehicle is shortened; people can pick cards dispensed from a card slot of the body (111) conveniently.

Owner:邳州市铁富九龙公共服务有限公司

STM32-based numerical control laser cutting machine device

PendingCN109967868ANo automatic actionNo side scrollingLaser beam welding apparatusNumerical controlShaped beam

The invention provides an STM32-based numerical control laser cutting machine device, which comprises a numerical control laser cutting machine body. The numerical control laser cutting machine body is provided with a left slideway and a right slideway; a set of vertically-arrayed holes of a front left square fixing hole, a rear left square fixing hole, a front right square fixing hole and a rearright square fixing hole is formed in the left slideway; a front left square rod is inserted in the front left square fixing hole in a tight fit mode, a front right square rod is inserted in the frontright square fixing hole in a tight fit mode, and the front left square rod and the front right square rod are connected through a front left arc-shaped rod; a rear left square rod is inserted in therear left square fixing hole in a tight fit mode, a rear right square rod is inserted in the rear right square fixing hole in a tight fit mode, and the rear left square rod and the rear right squarerod are connected through a rear left arc-shaped rod; and the front left arc-shaped rod and the rear left arc-shaped rod are connected through a left arc-shaped beam rod. The STM32-based numerical control laser cutting machine device is used for an STM32-based numerical control laser cutting machine.

Owner:诺克(天津)机械设备有限公司

Motor vehicle door lock

ActiveCN108368712BAvoid deformationShape stableNoise-prevention/anti-rattling lockingEngineeringCar door

Owner:KIEKERT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com