Patents

Literature

645results about How to "Improve pressing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

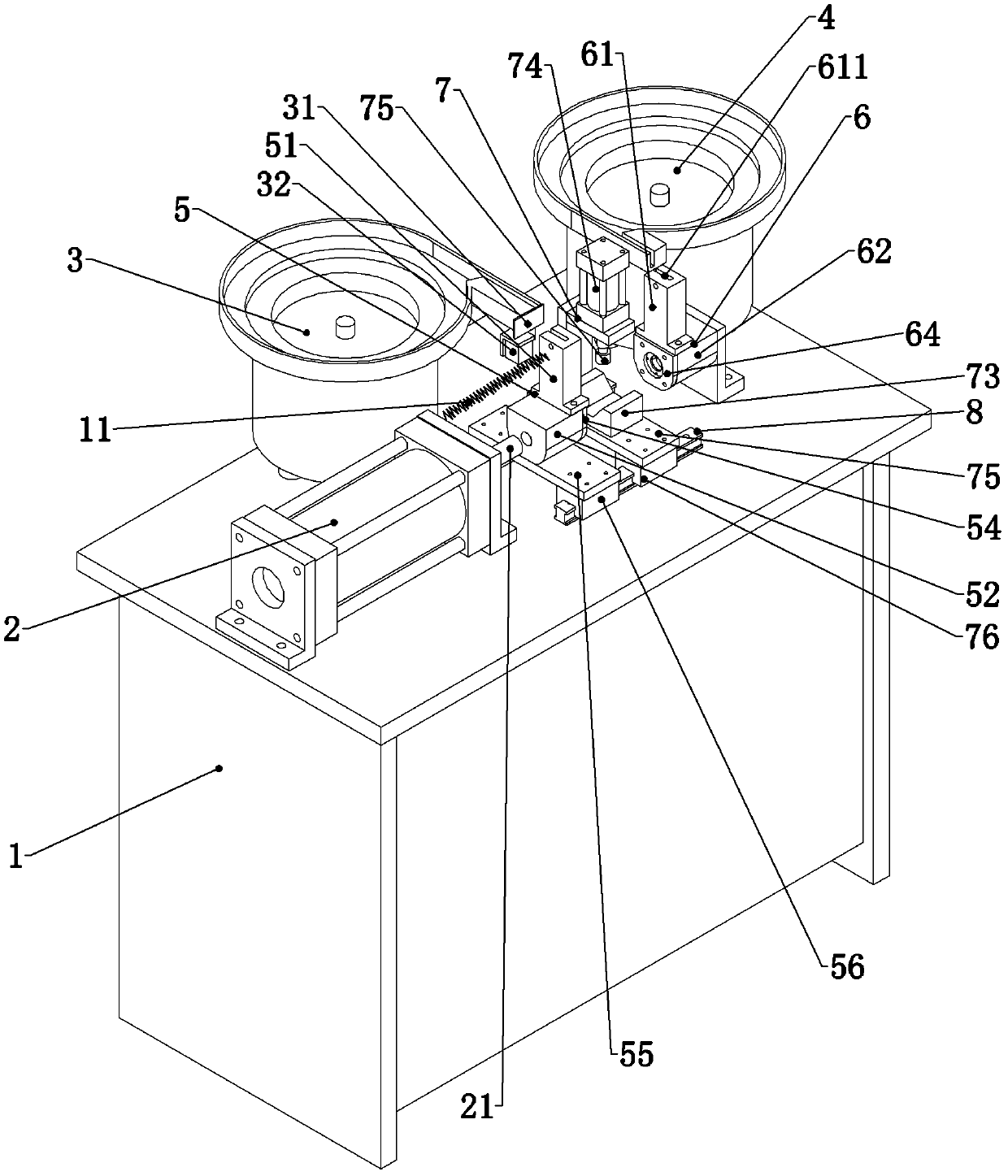

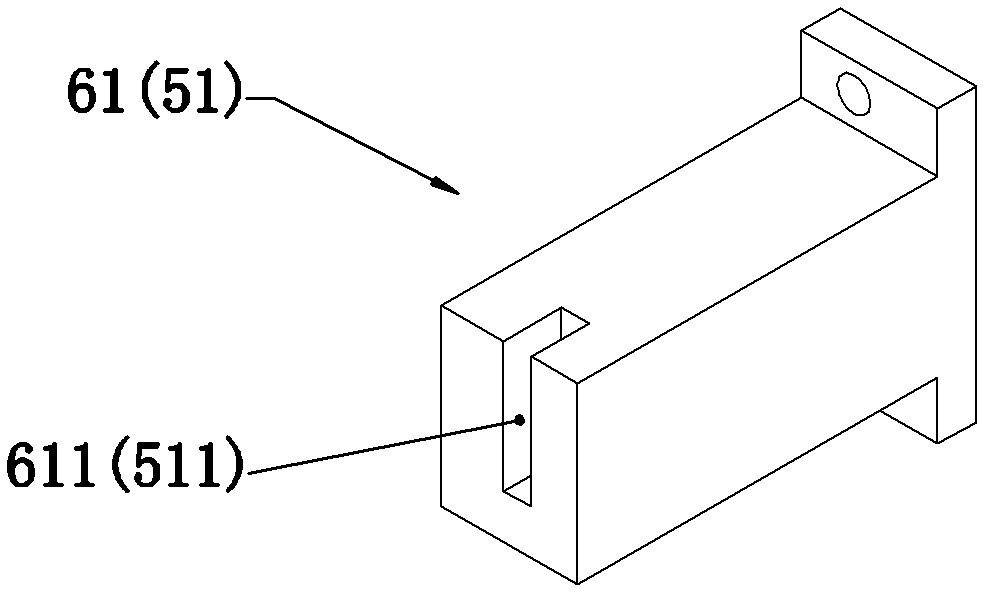

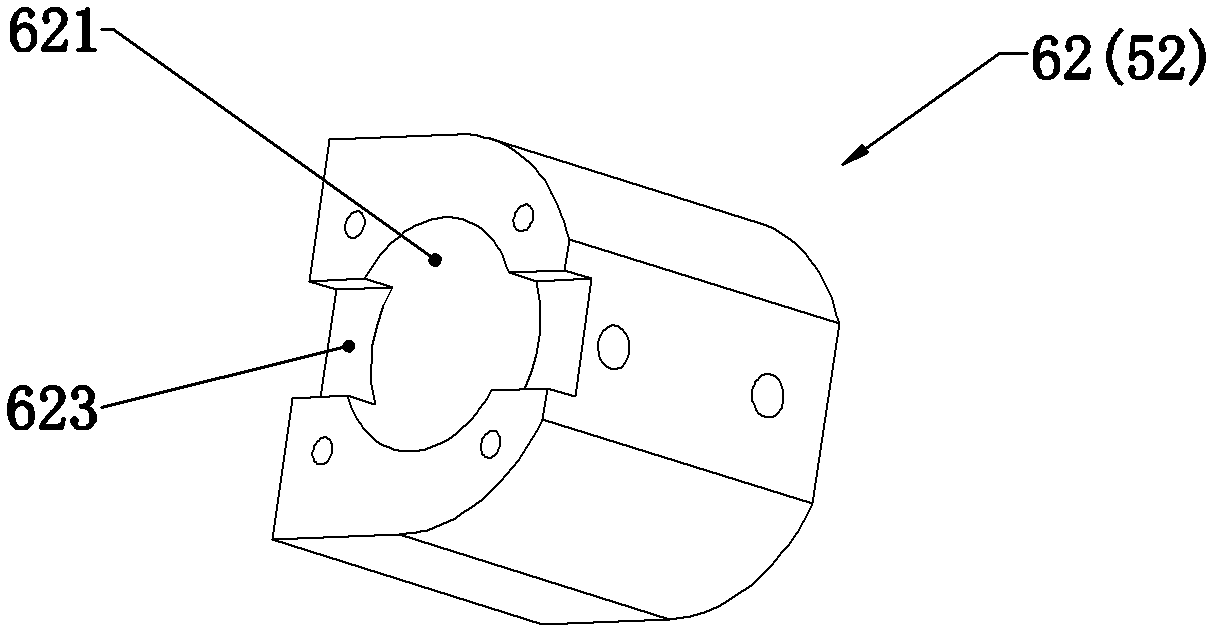

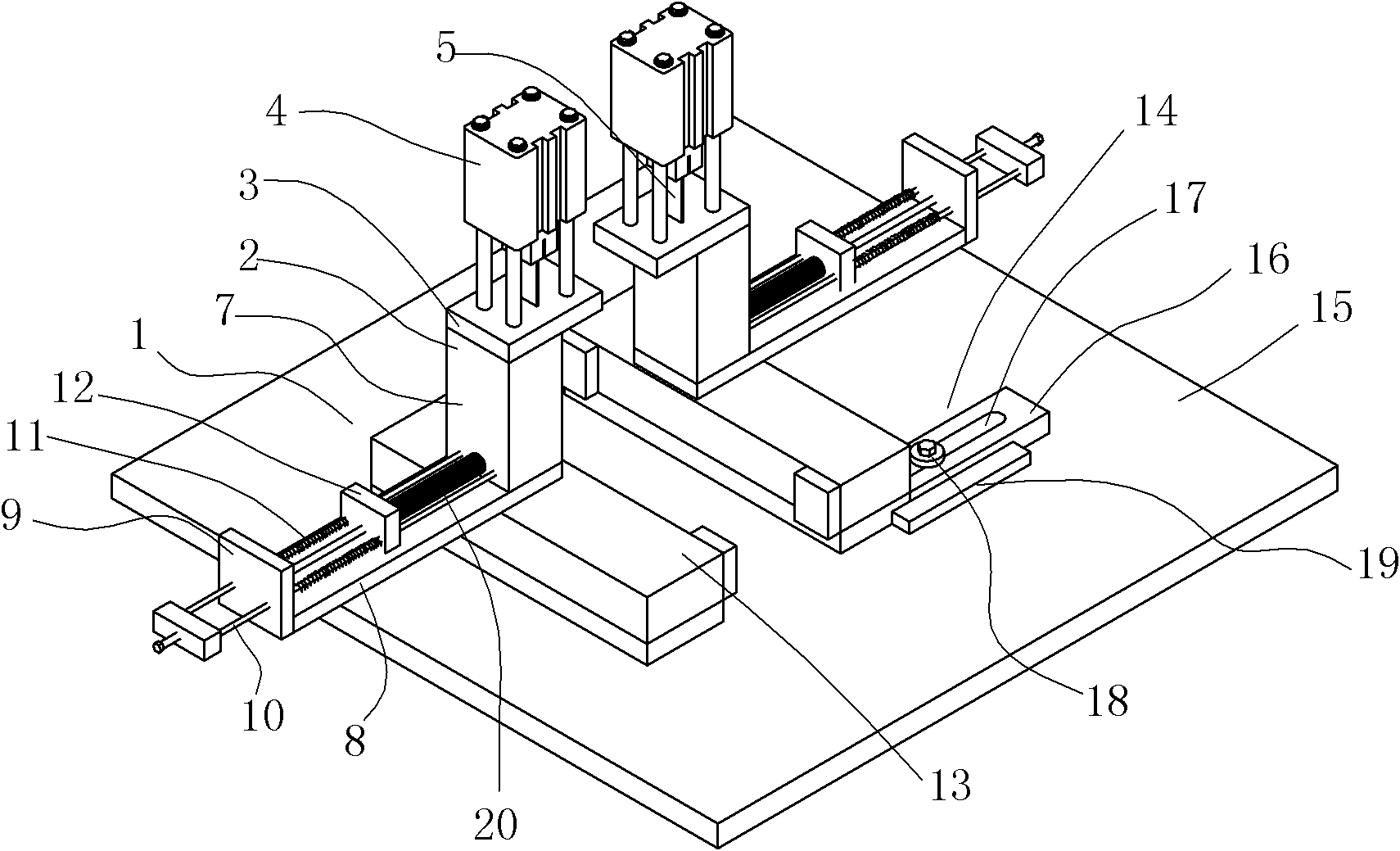

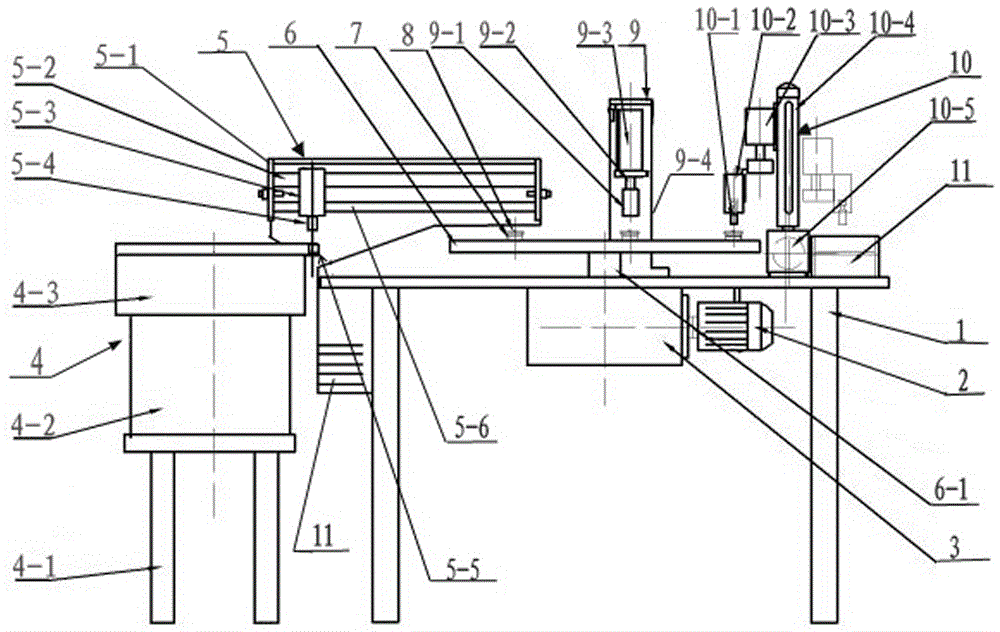

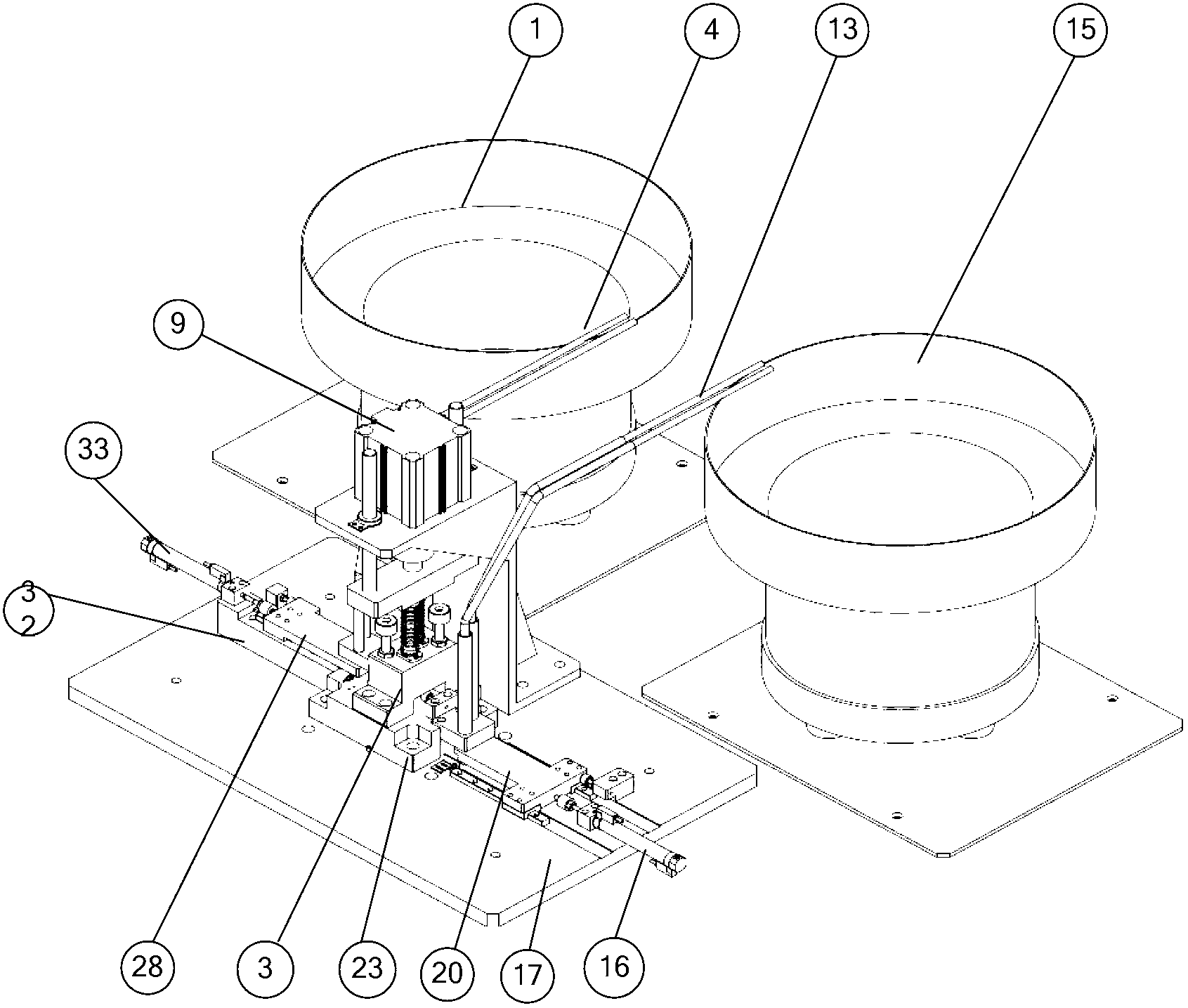

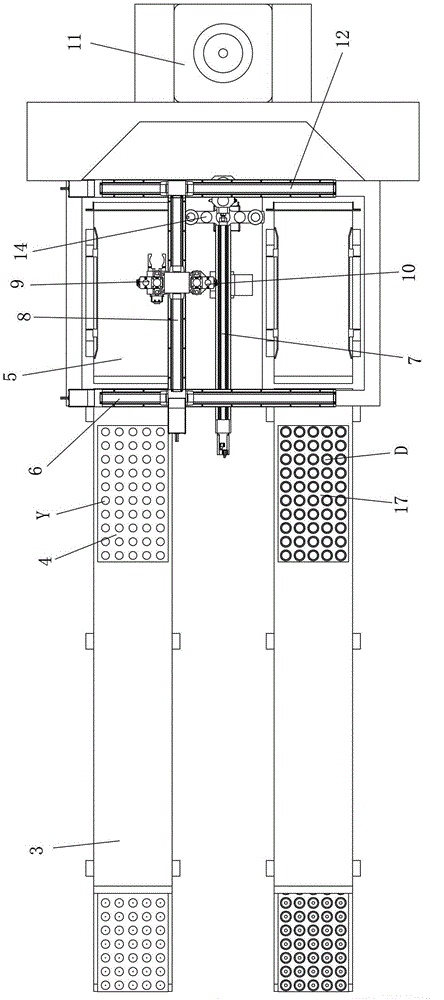

Automatic bearing press-fitting machine

ActiveCN102601607ARealization costLow costMetal working apparatusProgrammable logic controllerEngineering

The invention relates to a bearing press-fitting device, in particular to an automatic bearing press-fitting machine for motor rotors. The invention aims at providing the automatic bearing press-fitting machine which is capable of pressing and fitting rotors at the two ends at one time, is simple to operate, safe and reliable, high in press-fitting efficiency and good in press-fitting quality. The automatic bearing press-fitting machine comprises a base, press-fitting cylinders, a left bearing supply mechanism, a right bearing supply mechanism, a left bearing locating mechanism, a right bearing locating mechanism and a rotor locating mechanism; the left and the right bearing supply mechanisms supply bearings to the left and the right bearing locating mechanisms; the bearings are located by the left and the right bearing locating mechanisms; the left bearing locating mechanism and the rotor locating mechanism are pushed by a piston rod of the press-fitting cylinders to slide to the position of the right bearing locating mechanism to press and fit the bearings at the two ends at one time. In addition, the cylinders in the whole device are all provided with magnetic switches. A PLC (programmable logic controller) can automatically control the operation of the whole device by the signals from the magnetic switches to the PLC so as to press and fit the bearings at the two ends automatically.

Owner:SHANDONG BETTER MOTOR

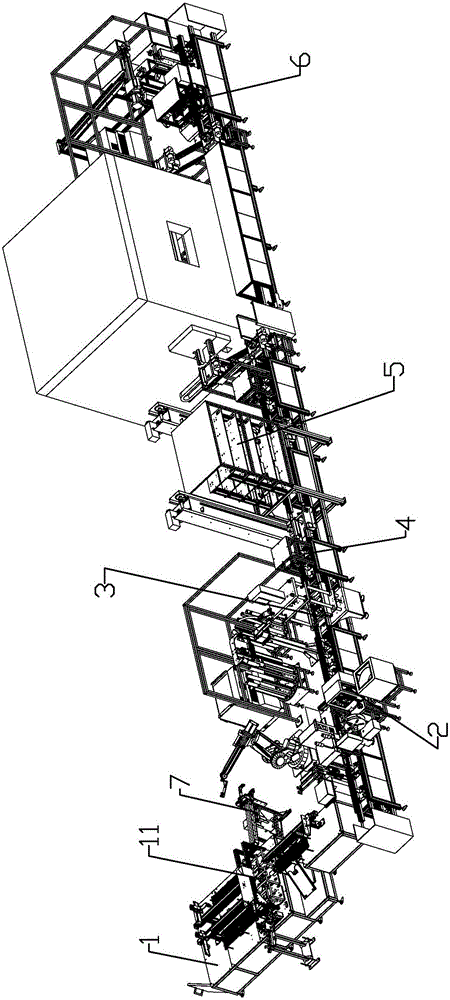

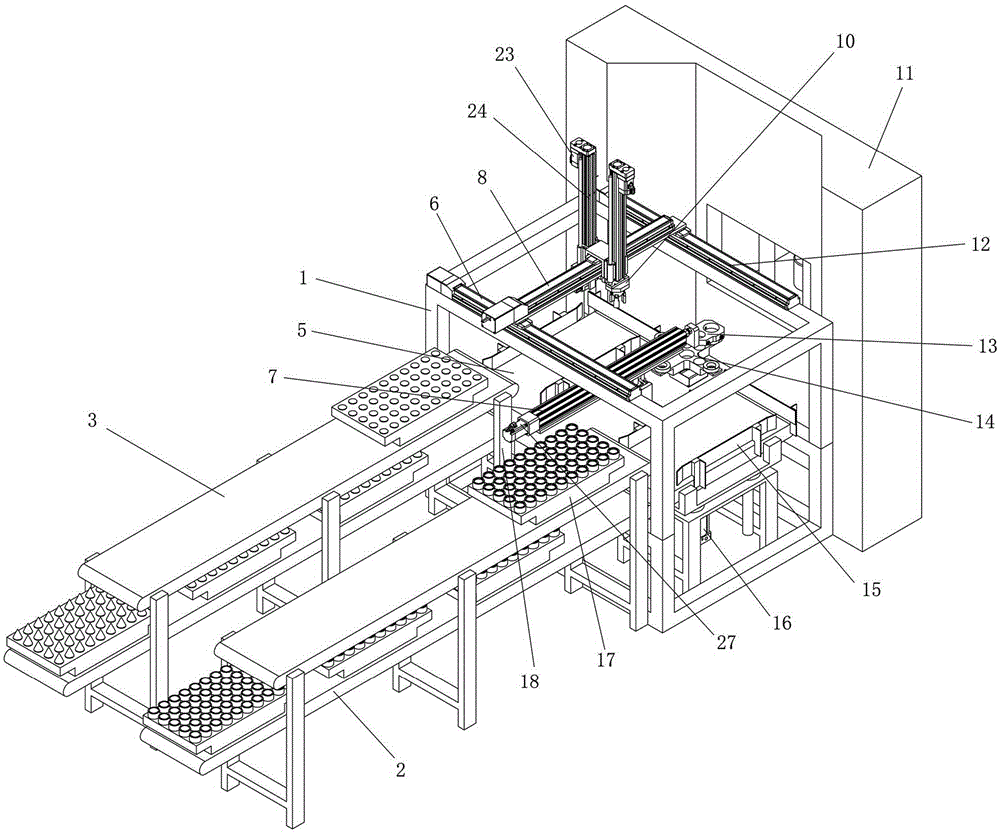

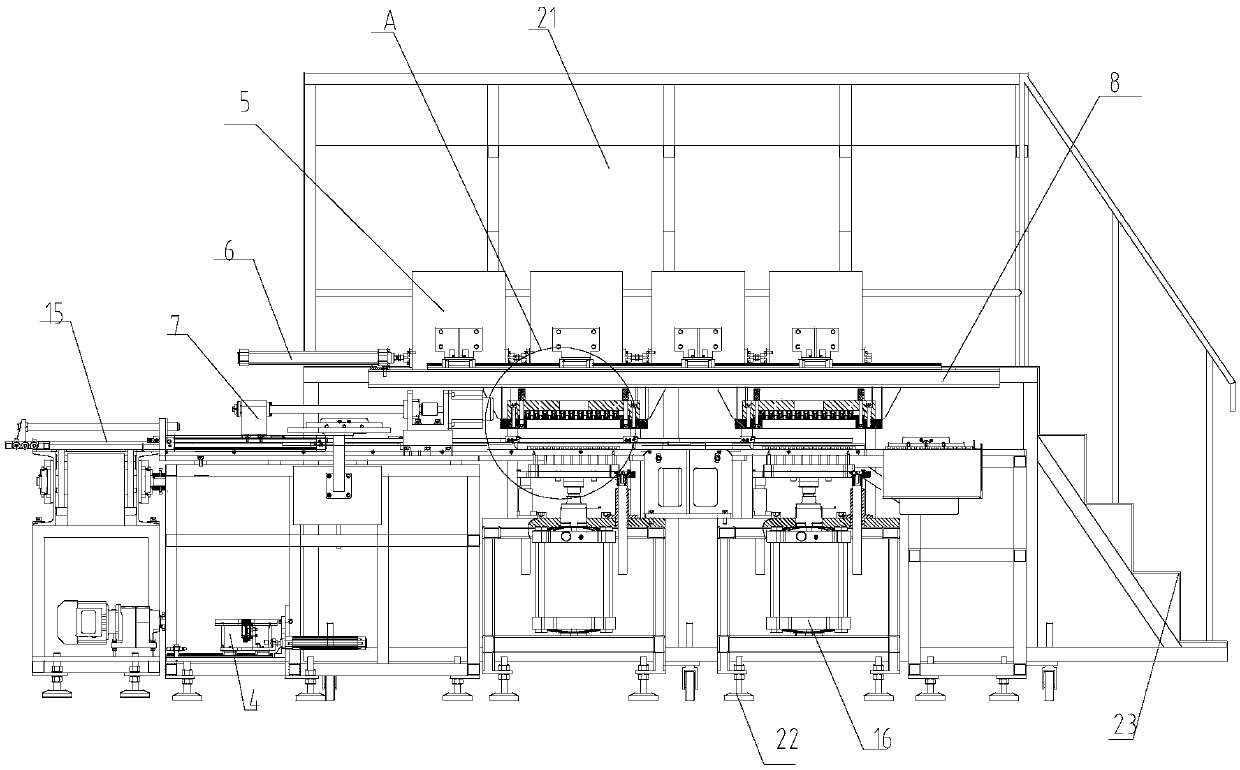

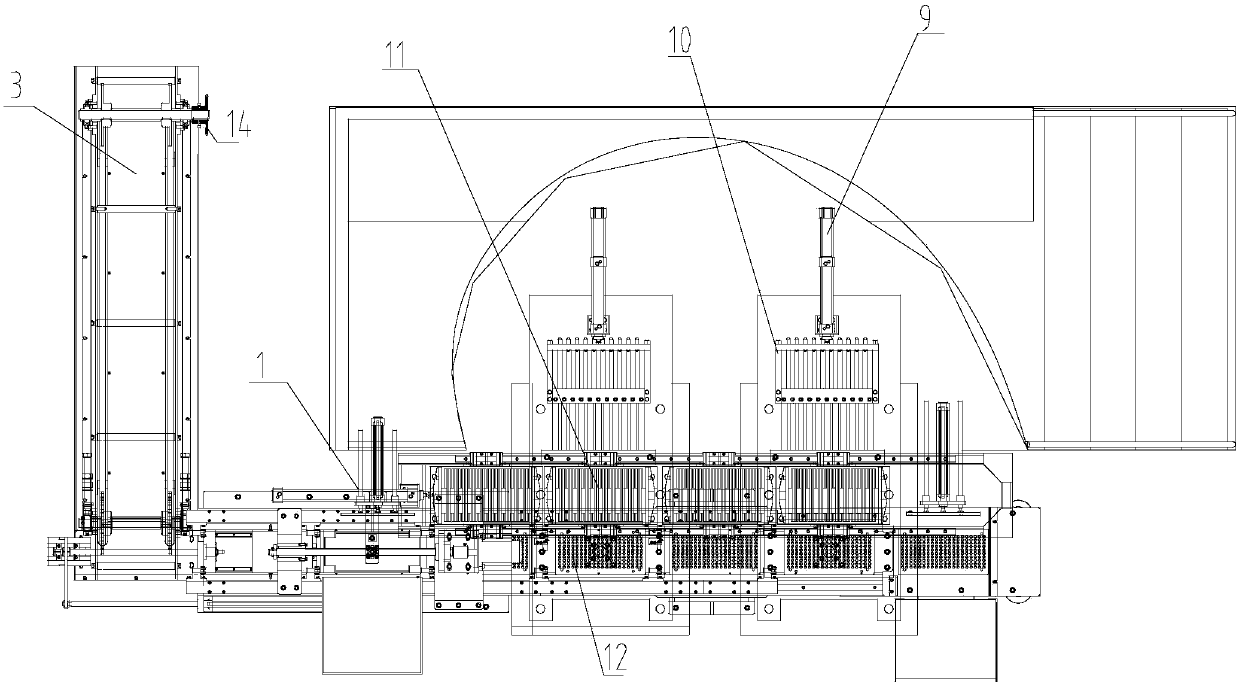

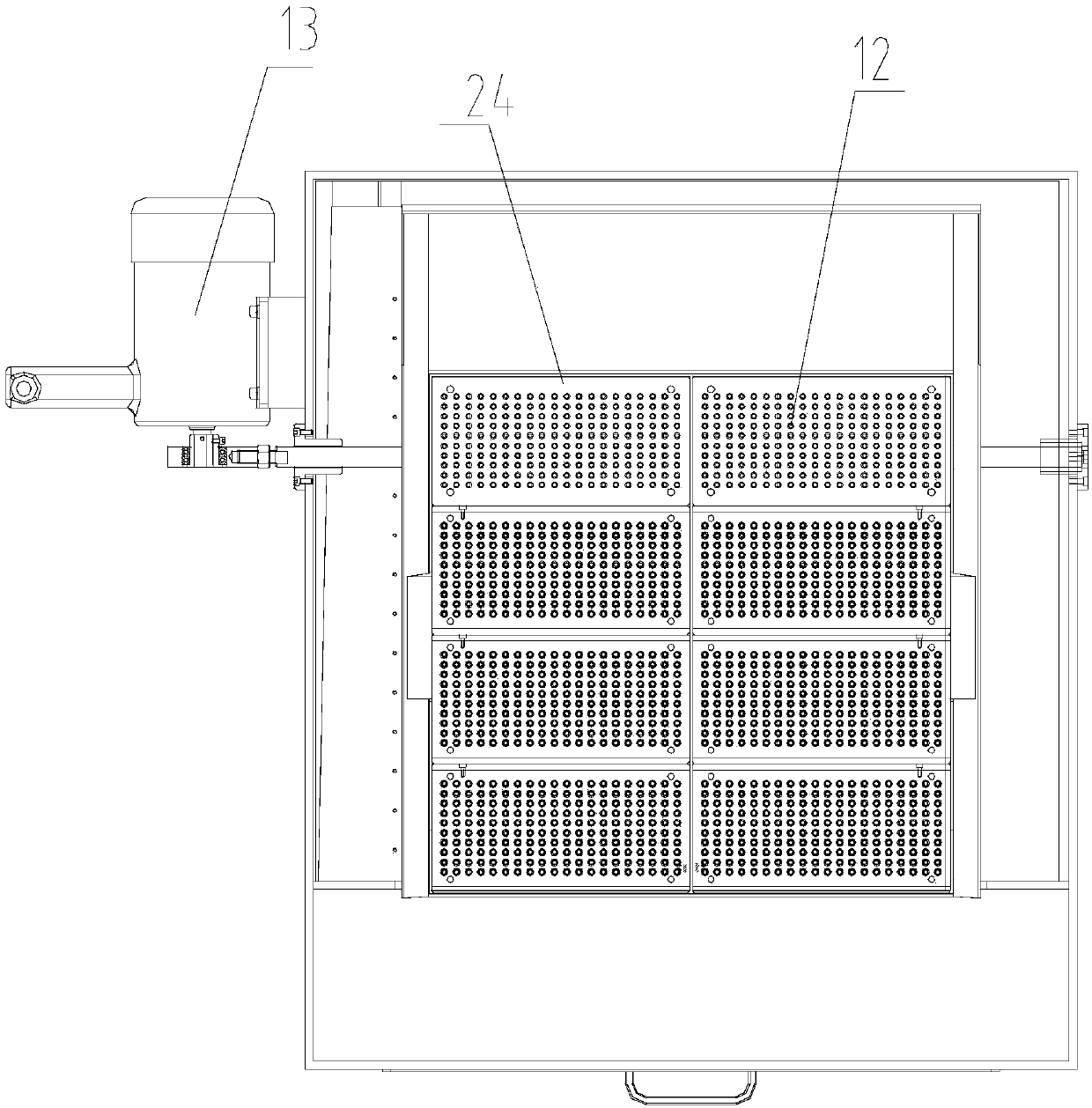

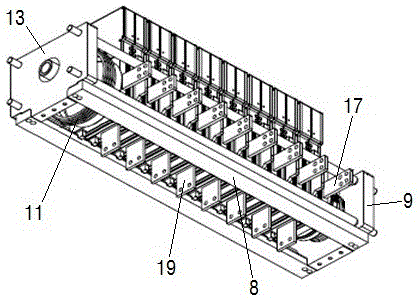

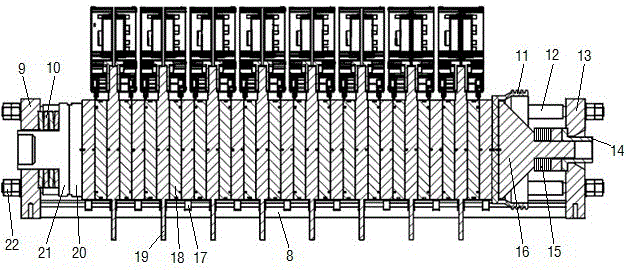

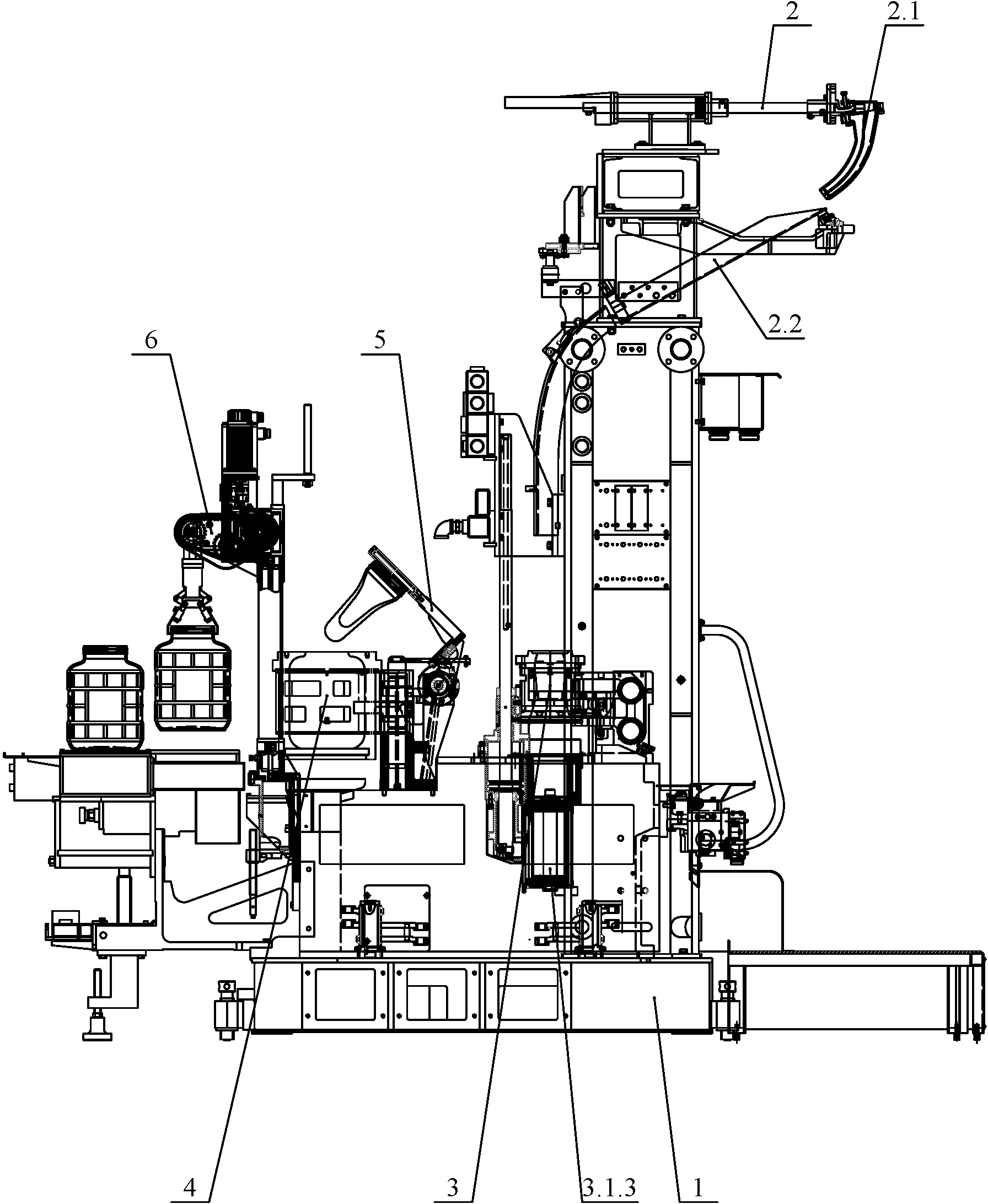

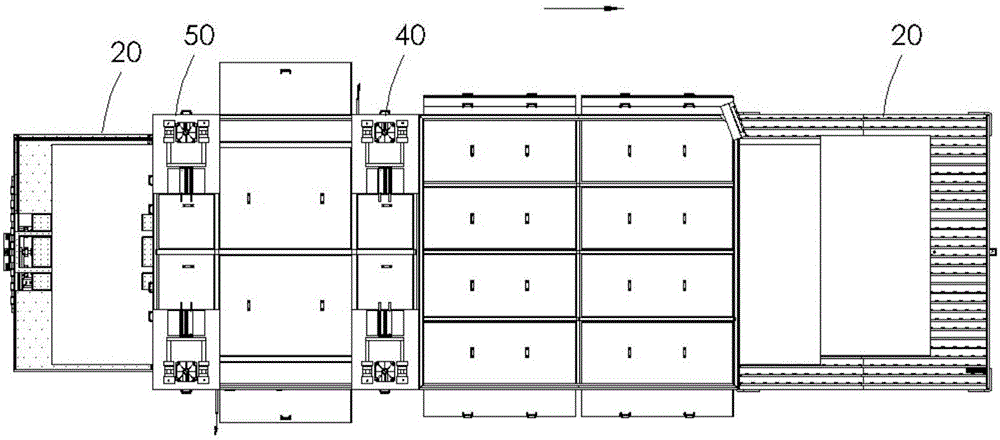

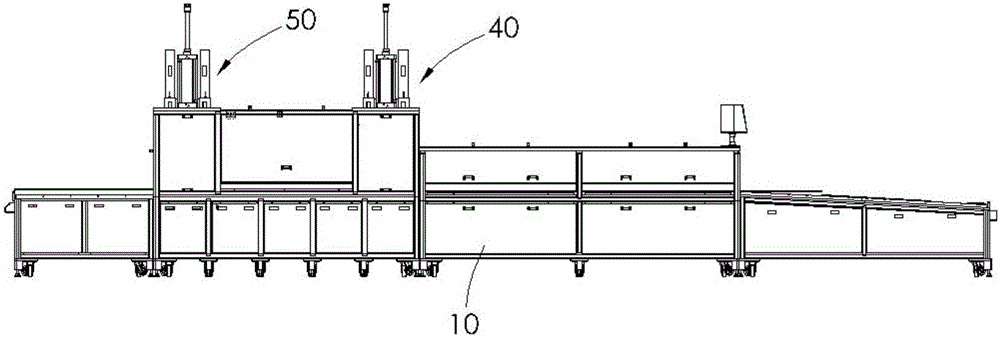

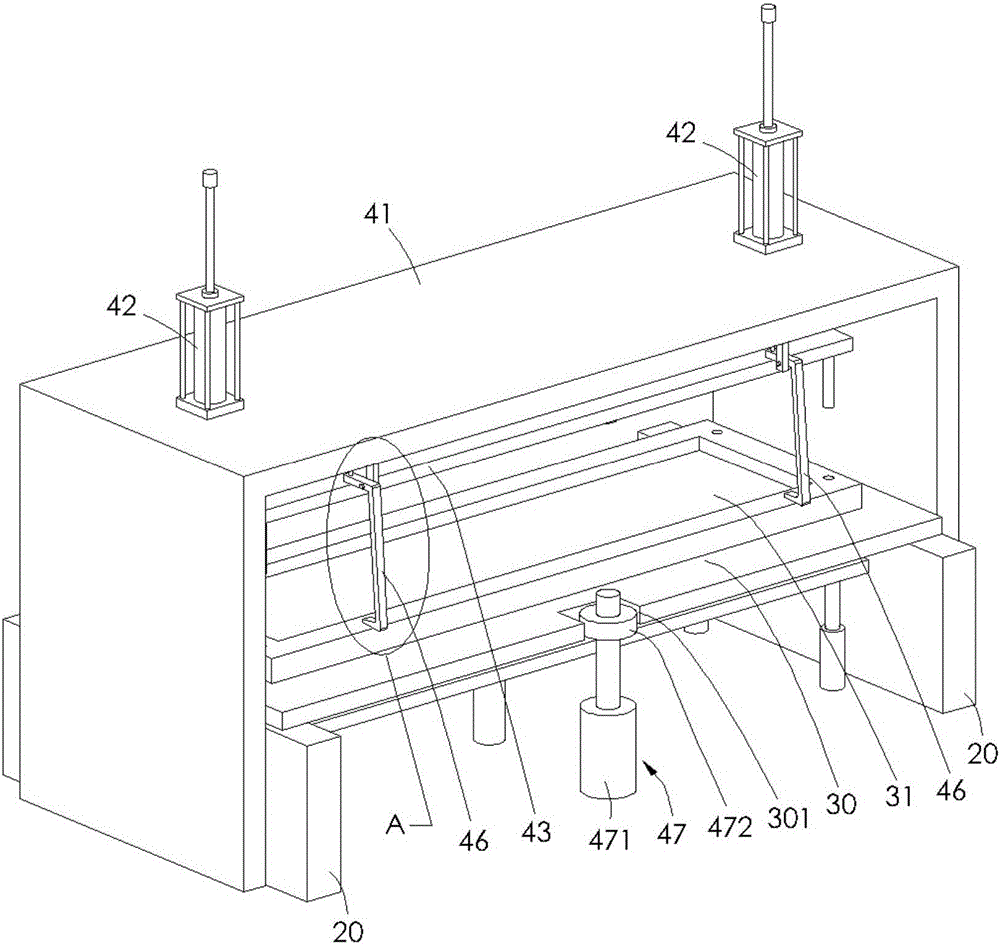

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

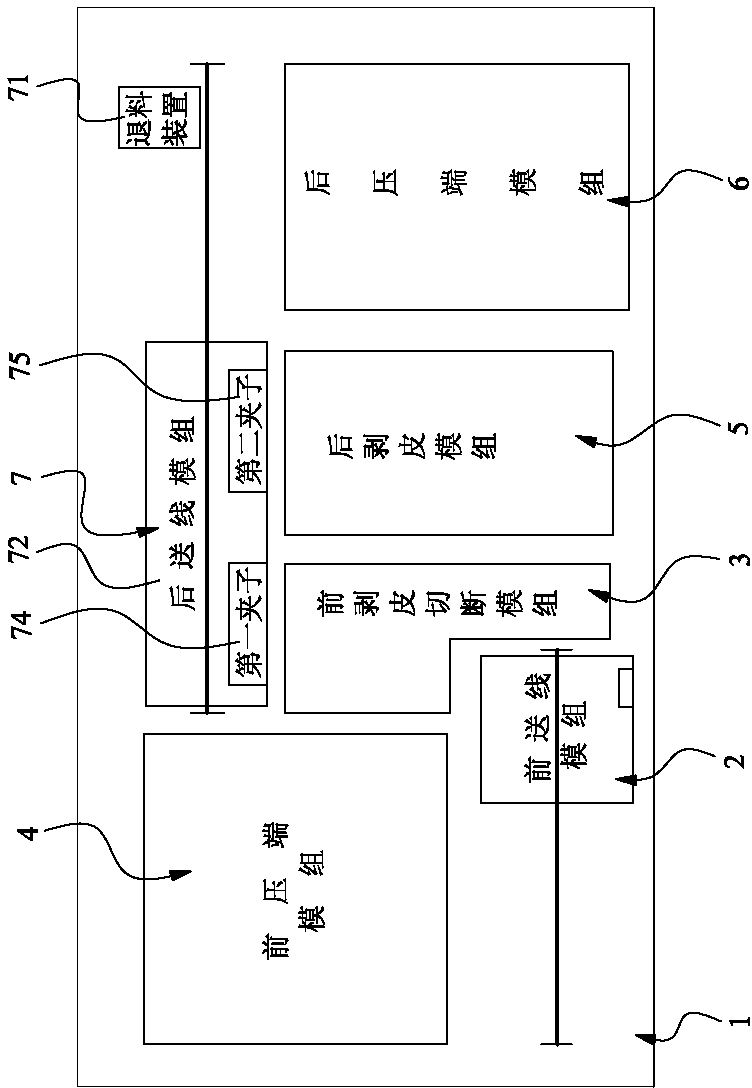

Multifunctional full automatic wire ranging terminal pressing machine

ActiveCN102709782AHigh degree of automationReduce the burden onConnection formation by deformationEngineeringProduction quality

The invention discloses a multifunctional full automatic wire ranging terminal pressing machine, which comprises an organic frame, as well as a front wire feeding module, a rear wire feeding module, a front peeling and cutting module, a rear peeling and cutting module, and a rear pressing end module which are arranged on the organic frame, therefore, the front wire feeding module is utilized to feed the wire ranging, two wires adhered together on the wire ranging are divided and moved horizontally; the front peeling and cutting module is utilized to complete cutting and front end peeling; the rear peeling module is used for peeling the rear end of the wire ranging; the front pressing end module and the rear pressing end module are respectively applied for pressing the front and the rear terminals of the wire ranging; and the rear wire feeding module is utilized to moving the wire ranging and complete the wire ranging output of the terminal pressing, the whole operation can be completed without operators, so that the automation degree of the production is improved, the structure of the whole device is simple, the control is convenient, the production efficiency is effectively improved, the production quality of the product is ensured, the production cost is lowered, and load of enterprises is lowered.

Owner:东莞市超日自动化设备科技有限公司

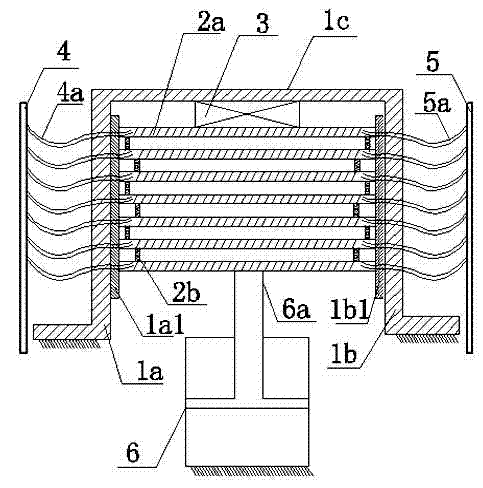

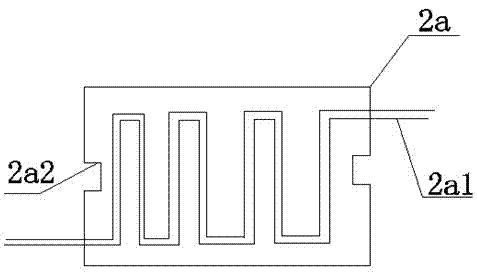

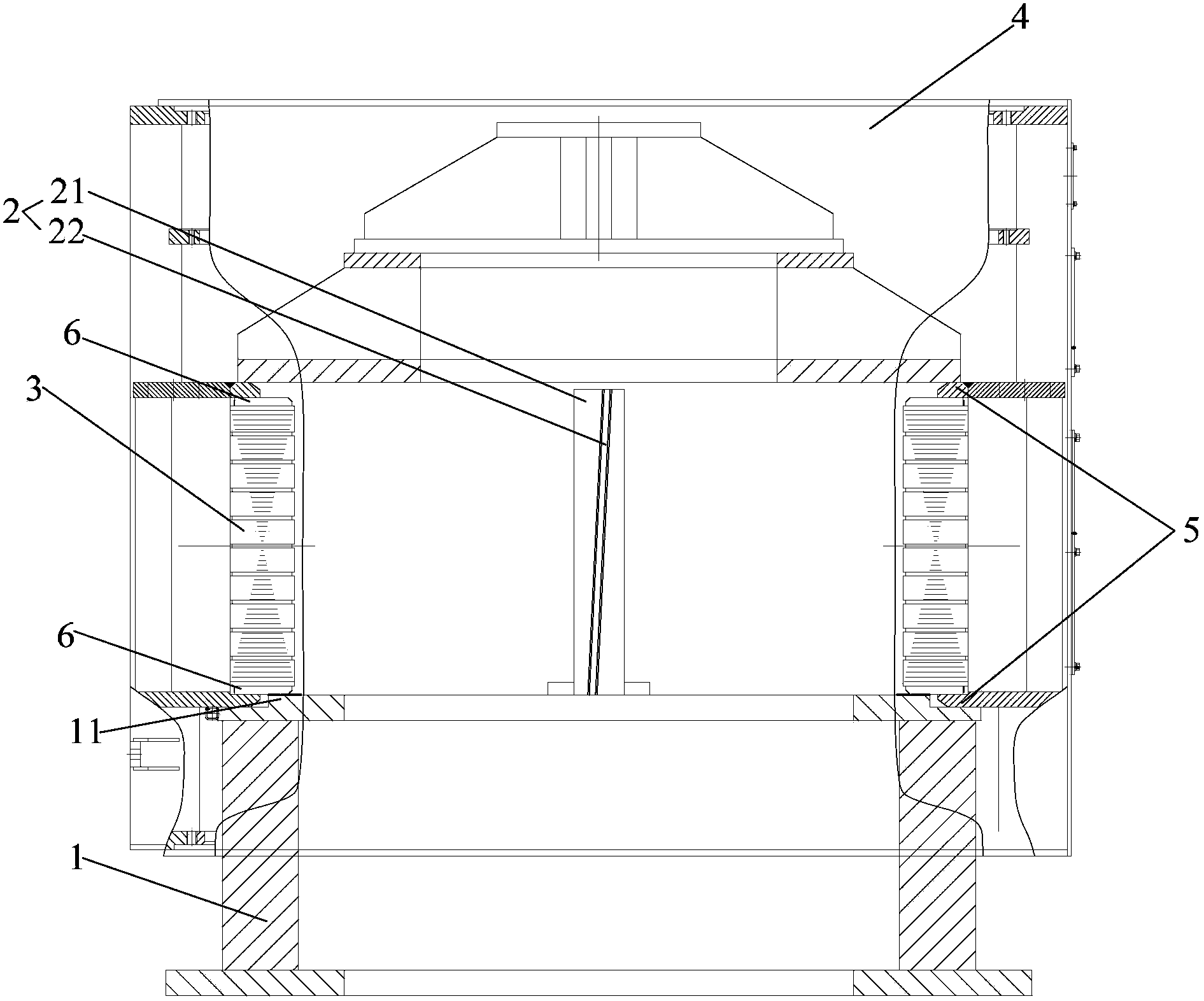

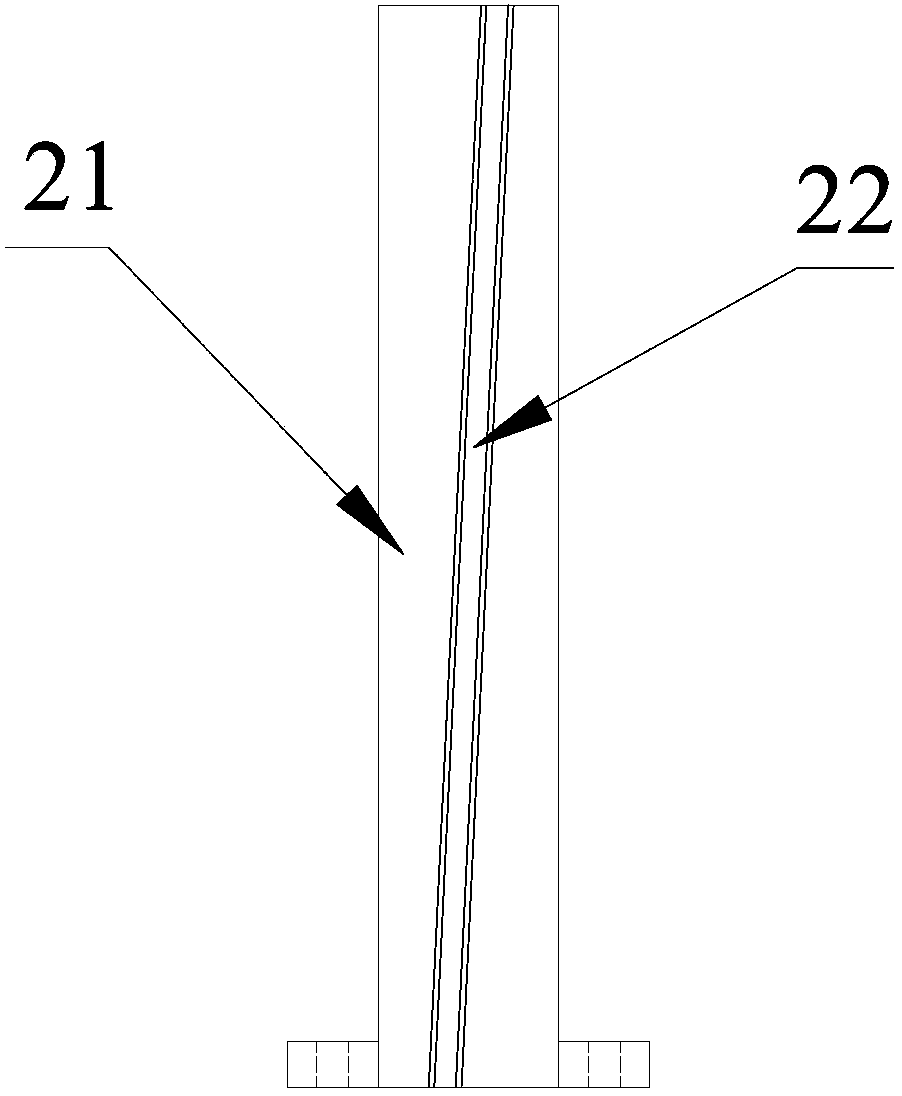

Platen machine

InactiveCN102922570AImprove pressing efficiencyHeating up fastPlywood pressesVeneer pressesEngineeringHeat exchanger

The invention discloses a platen machine which comprises a gantry frame and a compacting mould. The compacting mould is composed of multiply heating platens (2a), and an elastic connecting element (2b) is arranged between two adjacent heating platens. Each heating platen (2a) is hollow inside. A heat-exchanger tube (2a1) is arranged inside the platen machine, and the heat-exchanger tube (2a1) is connected with a heat transfer oil circulating system. Guide pillars (1a1, 1ab) used for guiding the multiply heating platens (2a) are arranged on the gantry frame. The platen machine also comprises a buffer device (3) which is fixedly connected on the bottom portion of the beam (1c) of the gantry frame, and is connected with the top layer heating platen of the multiply heating platens of the mould. The compacting mould is driven by a hydraulic cylinder (6) on the bottom portion of the compacting mould. A piston rod (6a) of the hydraulic cylinder is connected with the bottom layer heating platen. The platen machine can be used for compacting multiply wood plates each time, and compacting efficiency is high. Due to the fact heat transfer oil is adopted to transfer heat to the wood plates, the wood plates are heated up quickly, heat is distributed evenly, glue cement among the wood plates is enabled to solidify rapidly, compacting quality is high, and compacting speed is fast.

Owner:江苏福通木业有限公司

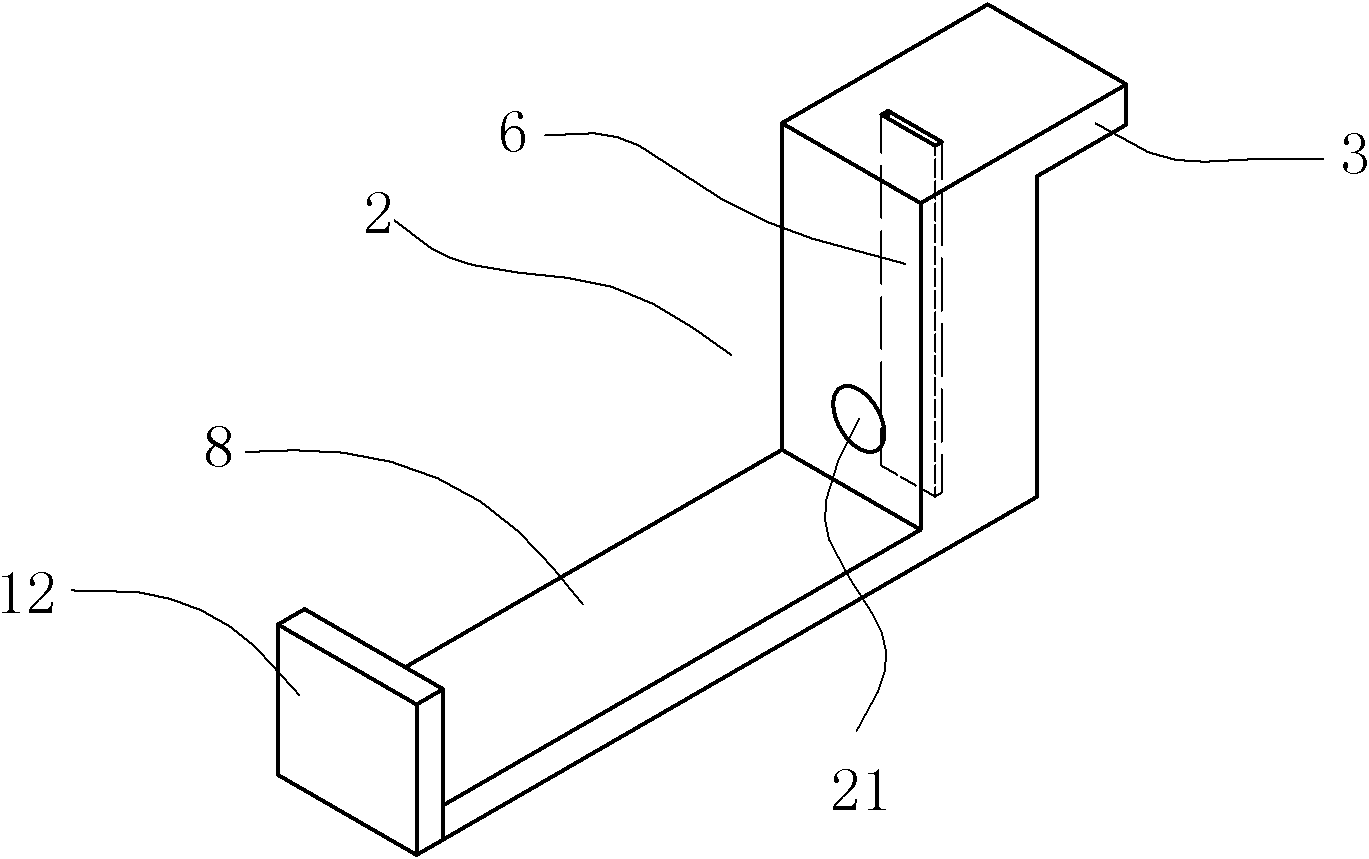

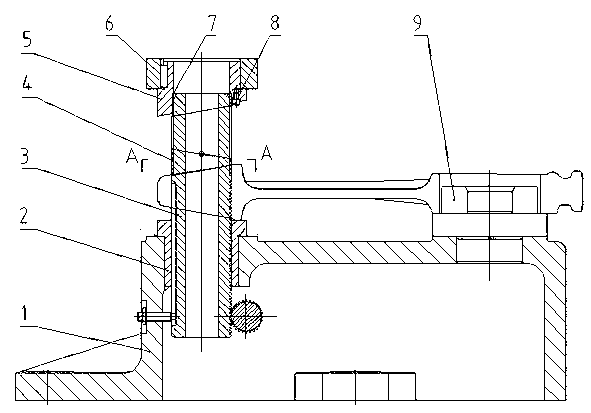

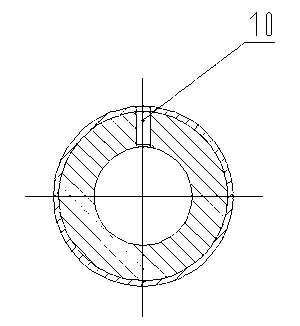

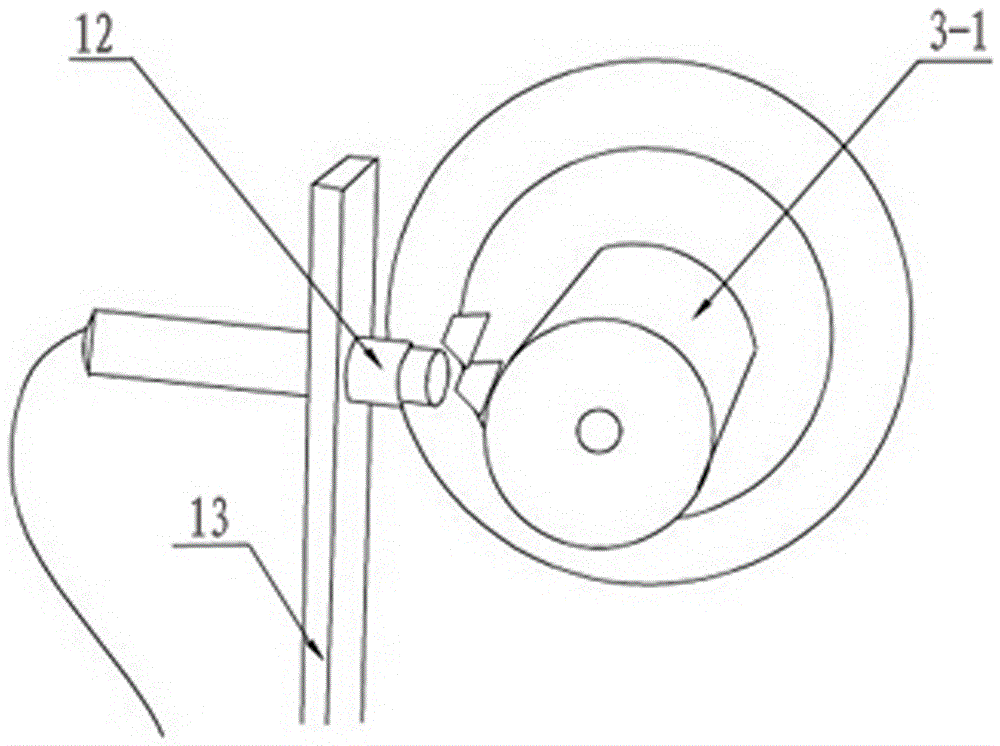

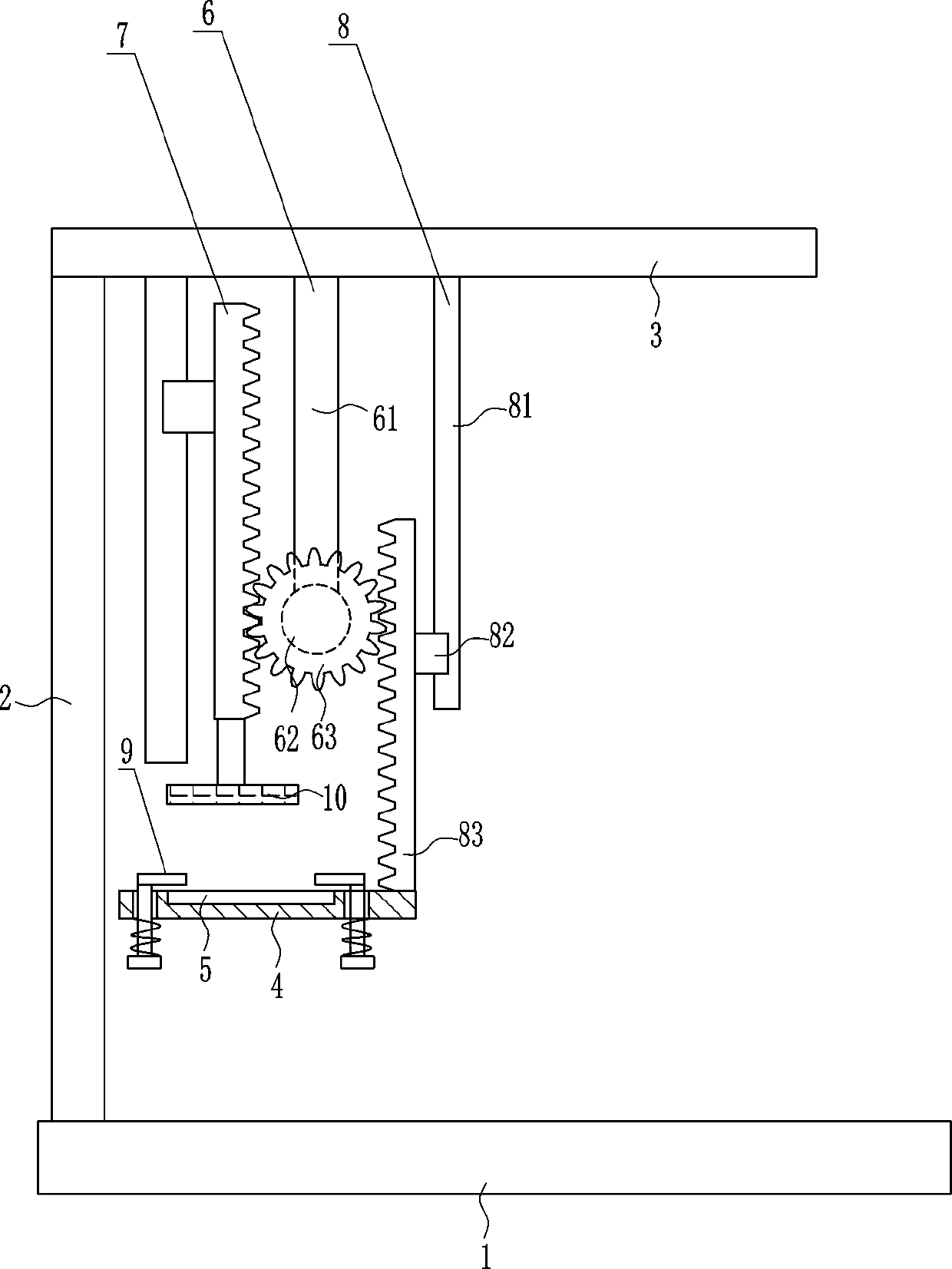

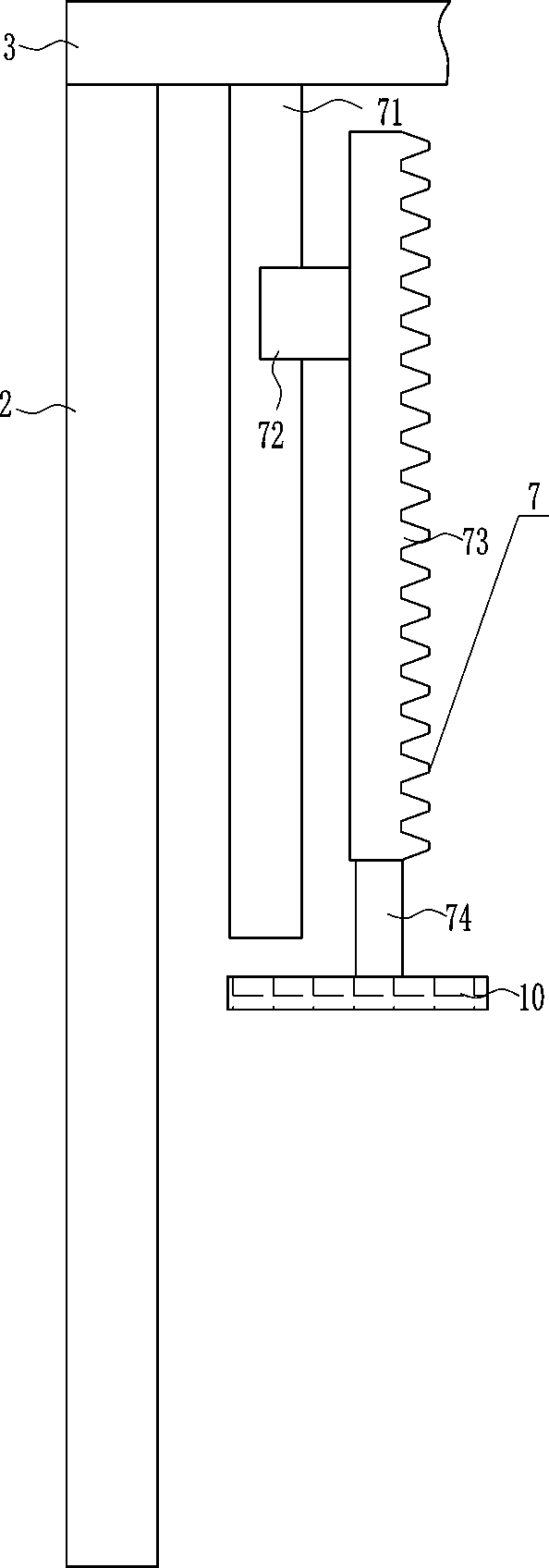

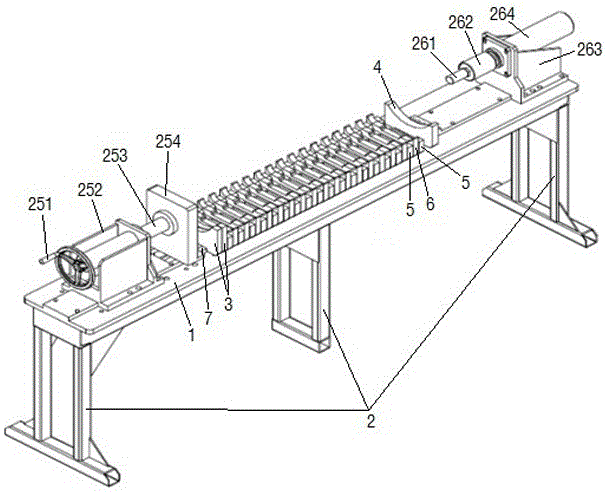

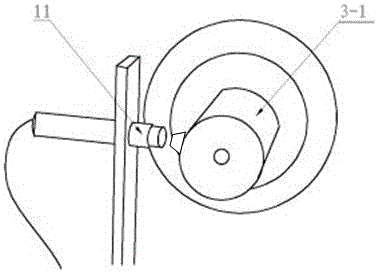

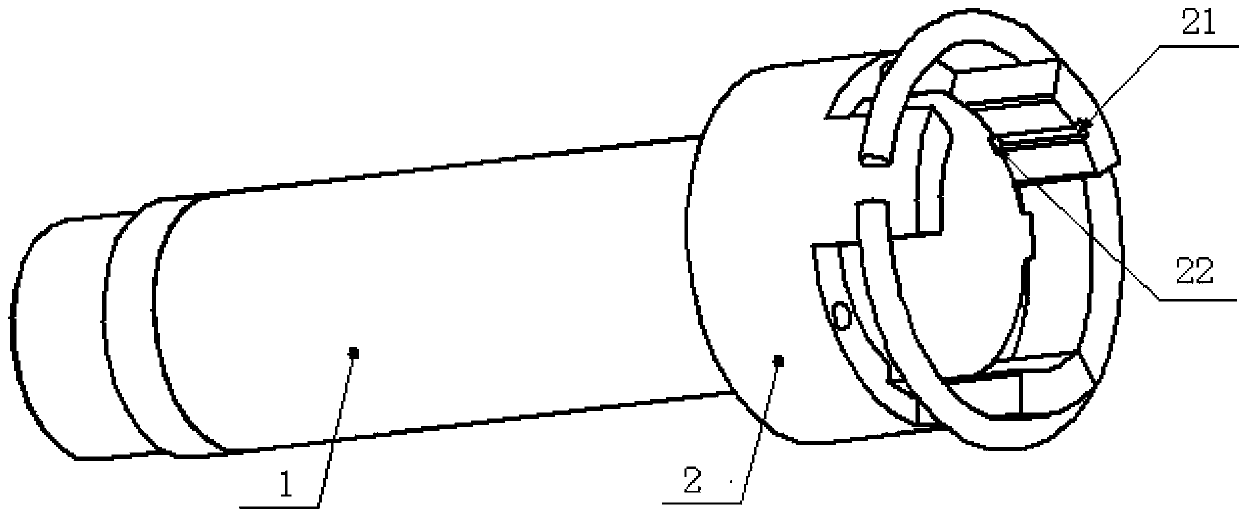

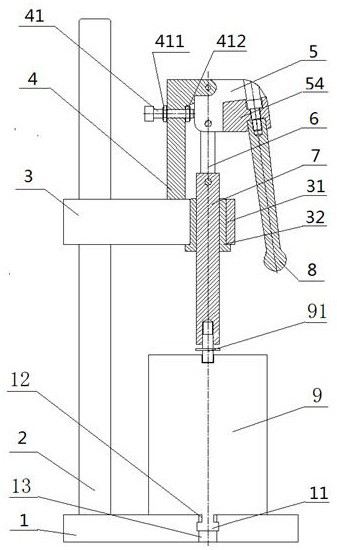

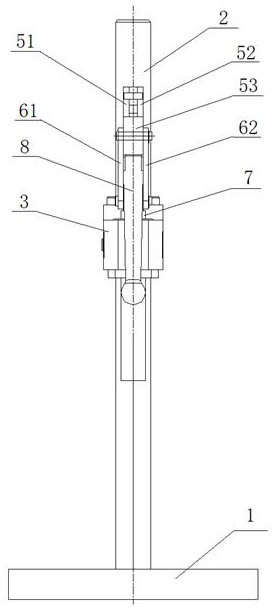

Circlip automatic pressing device and pressing method thereof

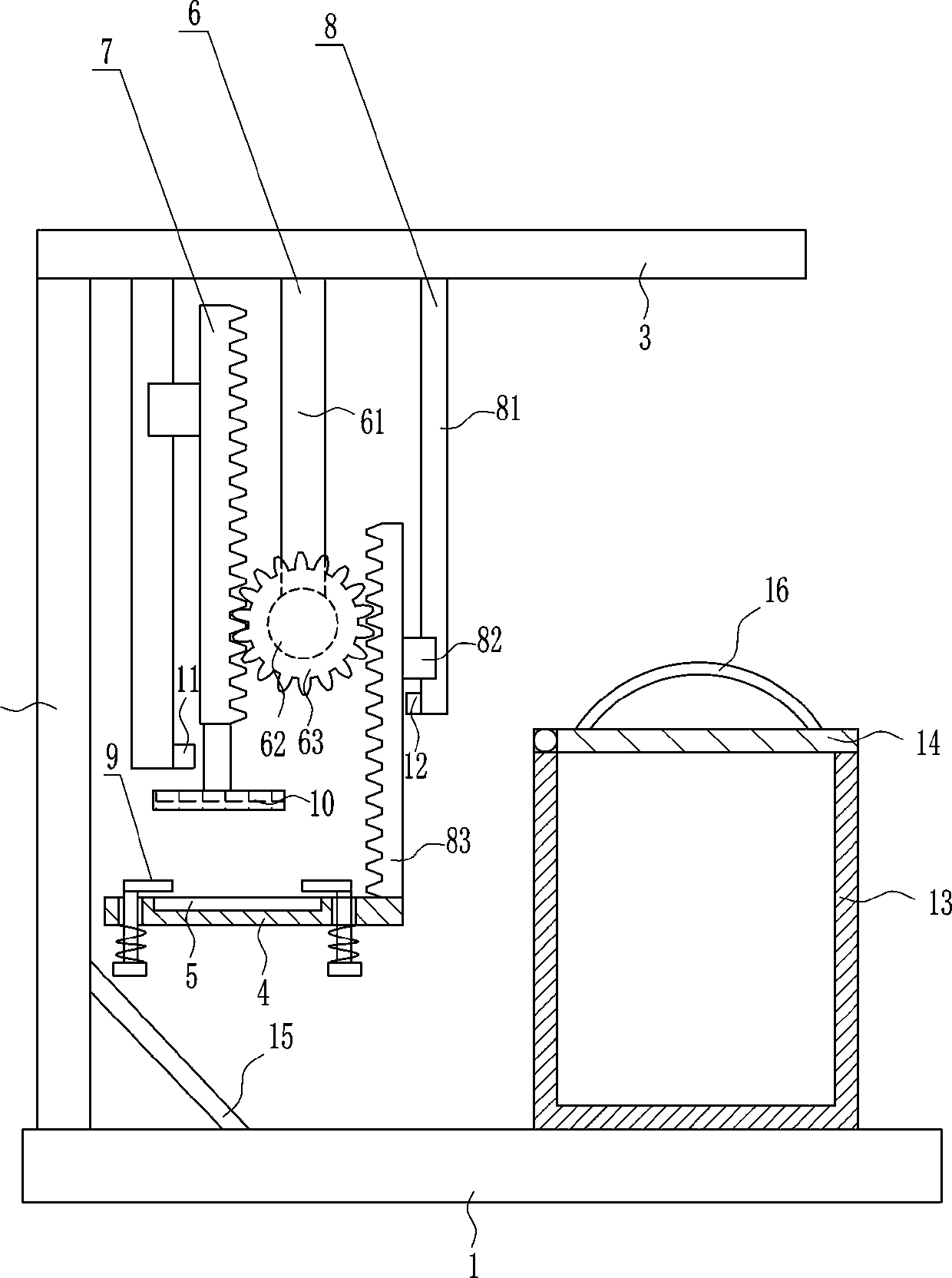

InactiveCN101982928AImprove assembly accuracyImprove pressing efficiencyManufacturing stator/rotor bodiesEngineeringCirclip

The invention discloses a circlip automatic pressing device and a pressing method thereof. The device of the invention comprises a pressing main body (1), wherein the pressing main body (1) comprises a Z-shaped base (2); a cylinder (4) is arranged above an upper transverse plate (3) of the base (2); a pressing piece (5) is fixed on a pushing head of the cylinder (4); a pressing piece groove (6) is arranged on the upper transverse plate (3) of the base (2); the pressing piece groove (6) vertically passes through a vertical plate (7) of the base (2); a fixing plate (9) is arranged at the tail end of a lower transverse plate (8) of the base (2); a guide rod (10) passes through the fixing plate (9); a spring (11) is sleeved on the guide rod (10); a pushing plate (12) is fixed at the end part of the guide rod (10); and the pushing plate (12) pushes a circlip to be strung on the pressing piece groove (6). The invention can greatly improve the pressing efficiency of the circlip on a rotor shaft, is suitable for industrialized mass production, improves the assembly accuracy of the circlip, and ensures the quality of finished products of rotors.

Owner:HUZHOU YONGCHANG BEISHITUO ELECTRIC APPLIANCE INDAL

Pop can flatting machine

The invention provides a pop can flatting machine which comprises a rack, a hopper, a pressing mechanism and a driving mechanism, wherein the rack is used for supporting and mounting other components; the hopper is fixedly arranged on the rack and used for accommodating pop cans; the bottom of the hopper is provided with a discharge hole, and the pop cans are discharged through the discharge hole; a pressing cavity is formed in the pressing mechanism and is positioned under the discharge hole of the hopper; the pressing mechanism is internally provided with a pressure lever capable of changing the volume of the pressing cavity; the bottom of the pressing cavity is provided with a discharge opening, and the flatted pop cans are discharged through the discharge opening; the driving mechanism is connected with the pressure lever and used for driving the pressure lever to reciprocate. The pop can flatting machine is simple in structure, convenient to operate, high in pressing efficiency, good in pressing effect and stable in operation.

Owner:WENZHOU POLYTECHNIC

Tool for pressing small copper sleeve of engine connecting rod

The invention discloses a tool for pressing a small copper sleeve of an engine connecting rod. The tool comprises a liner plate, a pressing sleeve, and a base fixed on a press, wherein a guide post is arranged inside an unthreaded hole at one end of the base corresponding to the pressing sleeve; the guide post is a stepped shaft which is thick in lower part and thin in upper part; a rack is arranged at the lower end of the guide post; a gear shaft meshed with the rack is arranged at one side of the rack; a locating sleeve of which the upper end face is matched with an inclined plane of the copper sleeve and the diameter corresponds to the copper sleeve is arranged on the step of the guide post; a bush for pressing the copper sleeve is sleeved on the upper end of the guide post, wherein the lower end surface of the bush is matched with the inclined plane of the copper sleeve; a diamond locating pin matched with the aperture of a large end of the connecting rod is arranged at the other end of the base; an inner hole of the pressing sleeve is a step hole which is large in lower part and small in upper part; the aperture of the small end of the step hole is smaller than the guide post; and the lower end face of the pressing sleeve is the inclined plane matched with that of the small head of the connecting rod, and a locating pin is arranged at the position of the inclined plane on the lower end of the pressing sleeve, corresponding to the plane end of the small end of the connecting rod. The tool disclosed by the invention is accurate in positioning and convenient to operate, and the pressing efficiency is improved.

Owner:HEBEI HUABEI DIESEL ENGINE

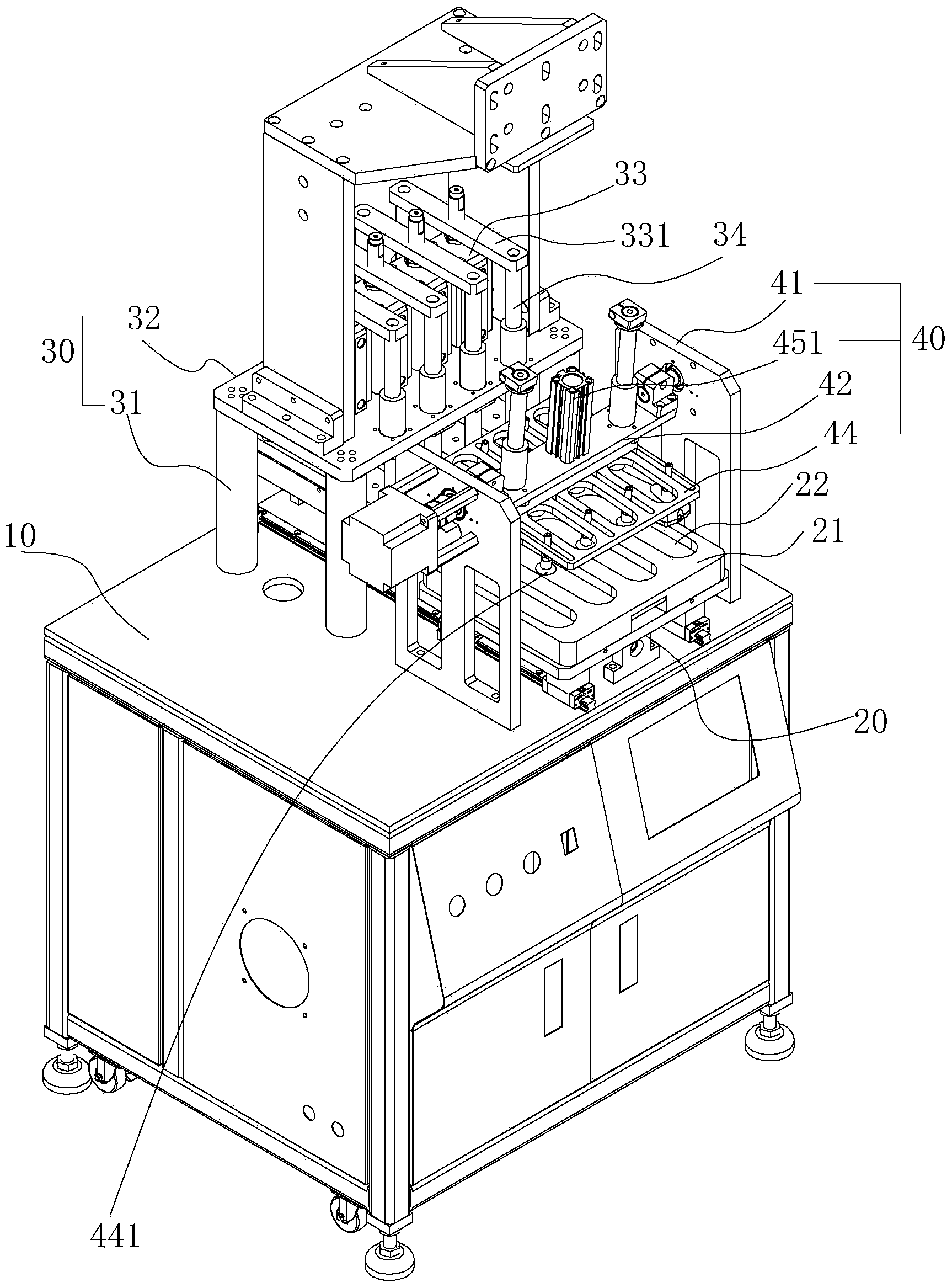

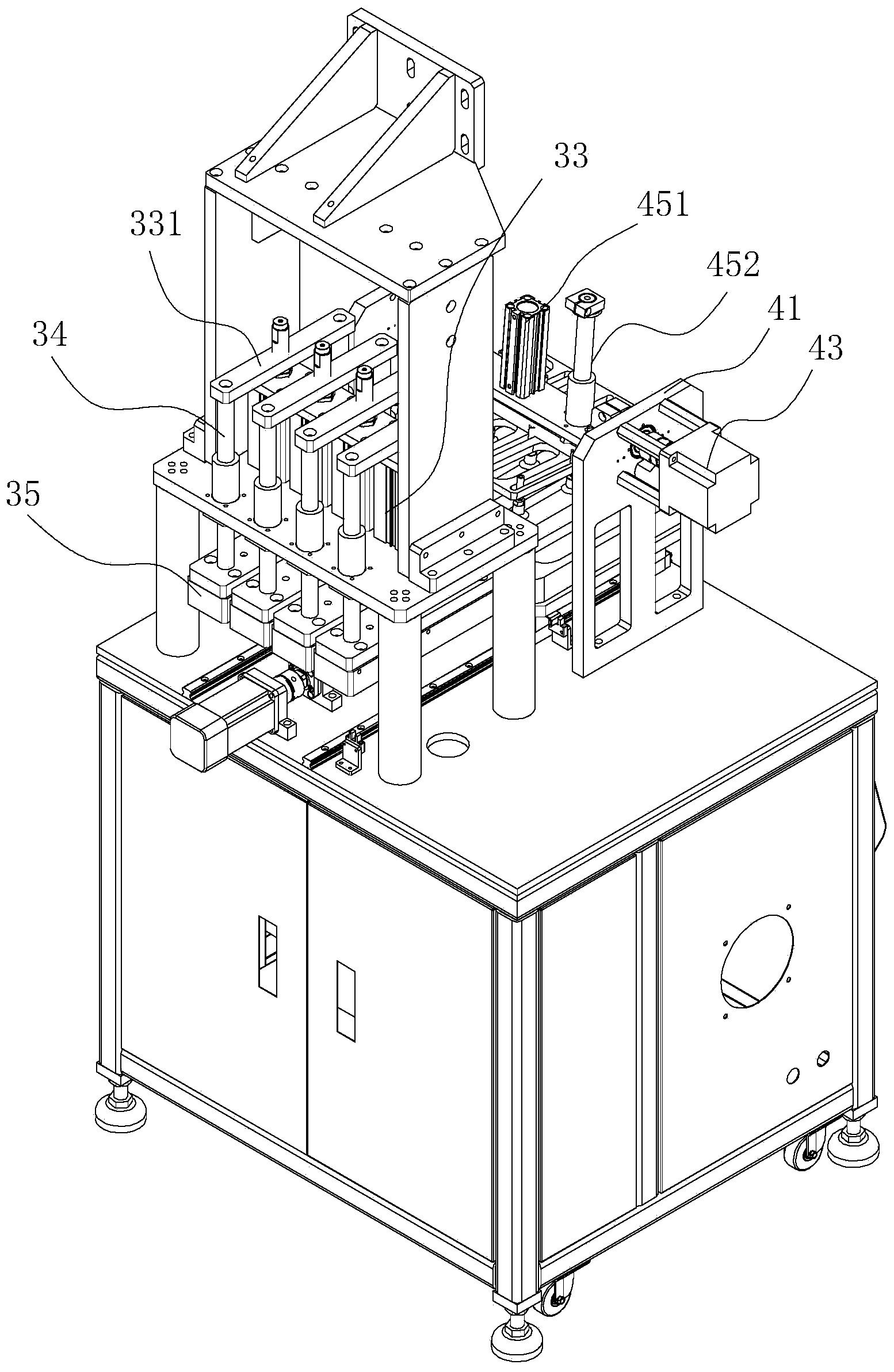

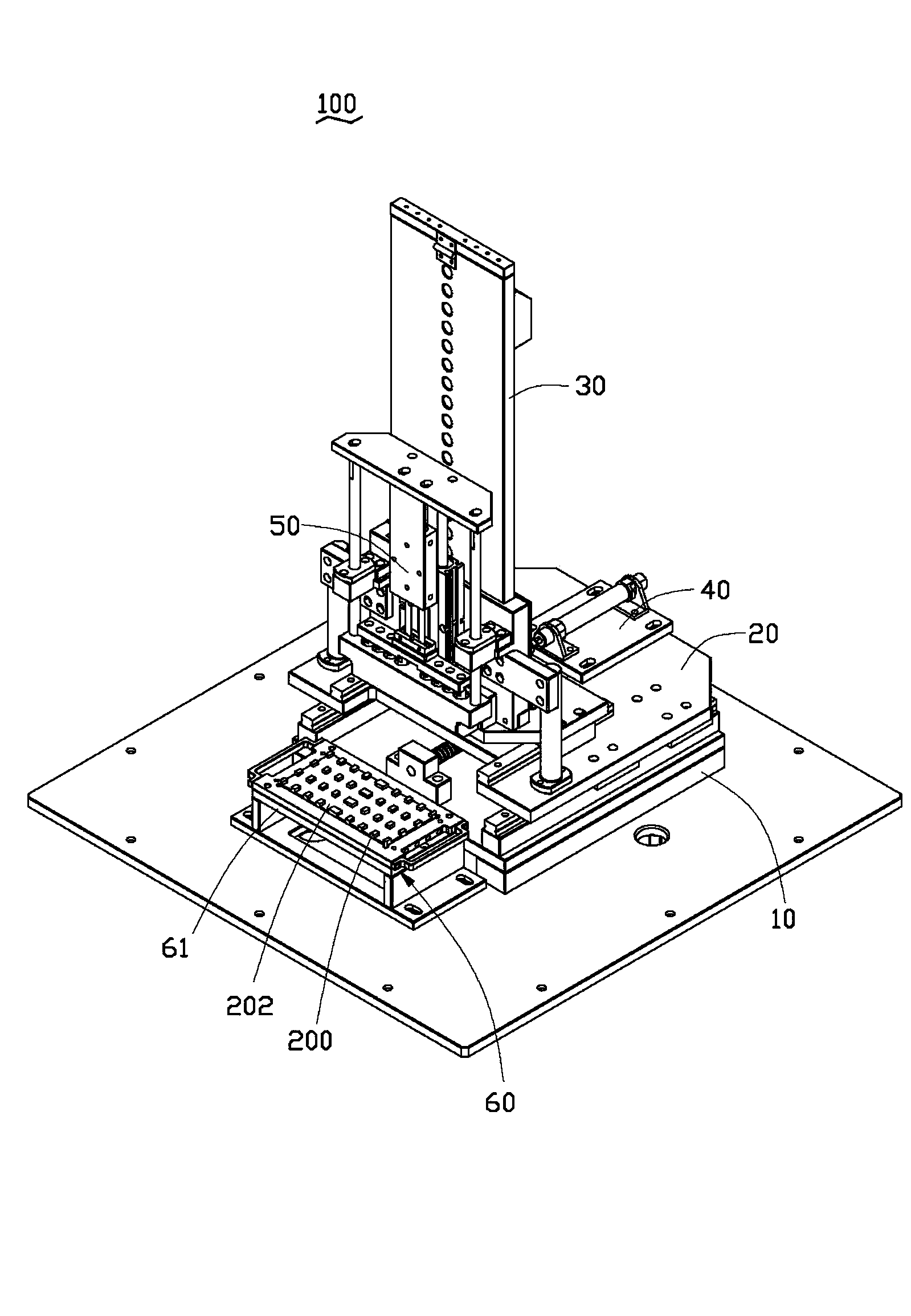

Press-fit device

InactiveCN103722375AAutomate operationRealize integrated layoutAssembly machinesTest efficiencyEngineering

The invention discloses a press-fit device which comprises a machine base. A longitudinal sliding table mechanism and a frame-shaped support are arranged on the machine base. The frame-shaped support comprises uprights located at the two sides of the longitudinal sliding table mechanism and an upper fixing board connected with the upper ends of the uprights at the two sides. The longitudinal sliding table mechanism is provided with a jig and a workpiece lower cavity is formed in the jig. A press-fit power piece and a press-fit guide mechanism for guiding the press-fit power piece are fixed to the portion above the upper fixing board. The movable end of the press-fit power piece is connected with an upper press-fit board. The press-fit power piece moves downwards, so that a workpiece in the jig is assembled in a press-fit mode. According to the press-fit device, the workpiece which needs to be pressed in the fit mode is fixed through the jig, press-fit assembly is completed through the press-fit power piece driven by an air cylinder or a motor, mechanical operation is achieved, the press-fit efficiency is improved, the labor cost is saved, the workpiece is automatically pressed in the fit mode, obtained and tested, the labor cost is saved, the assembly and test efficiency is improved, integrated arrangement of a production device is achieved, and the space of a production field is saved.

Owner:SHENZHEN RAPOO TECH

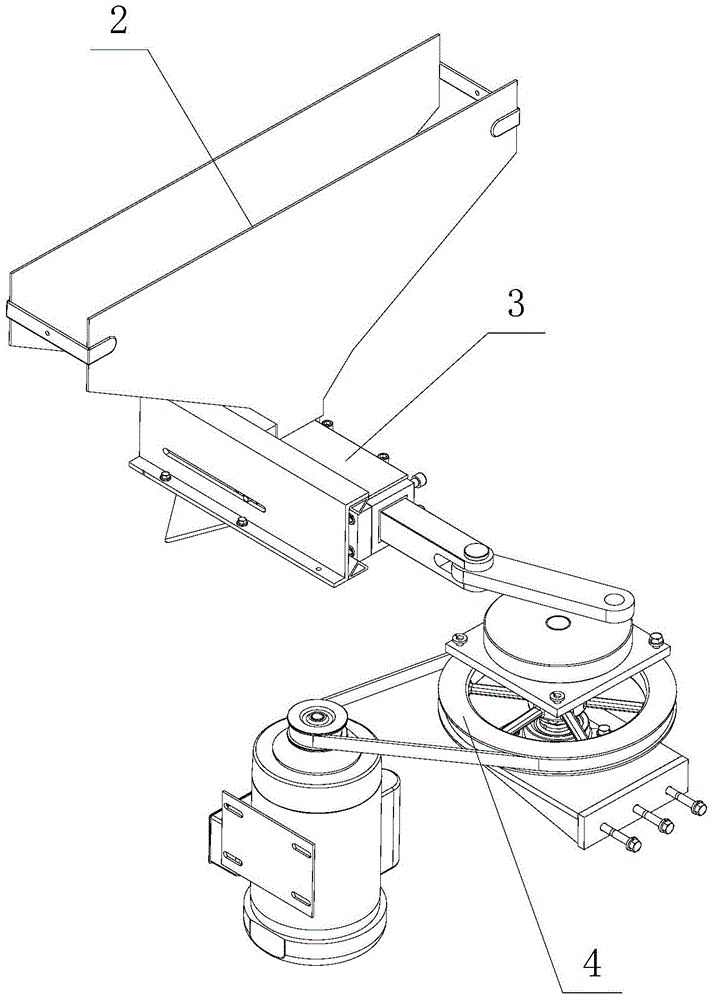

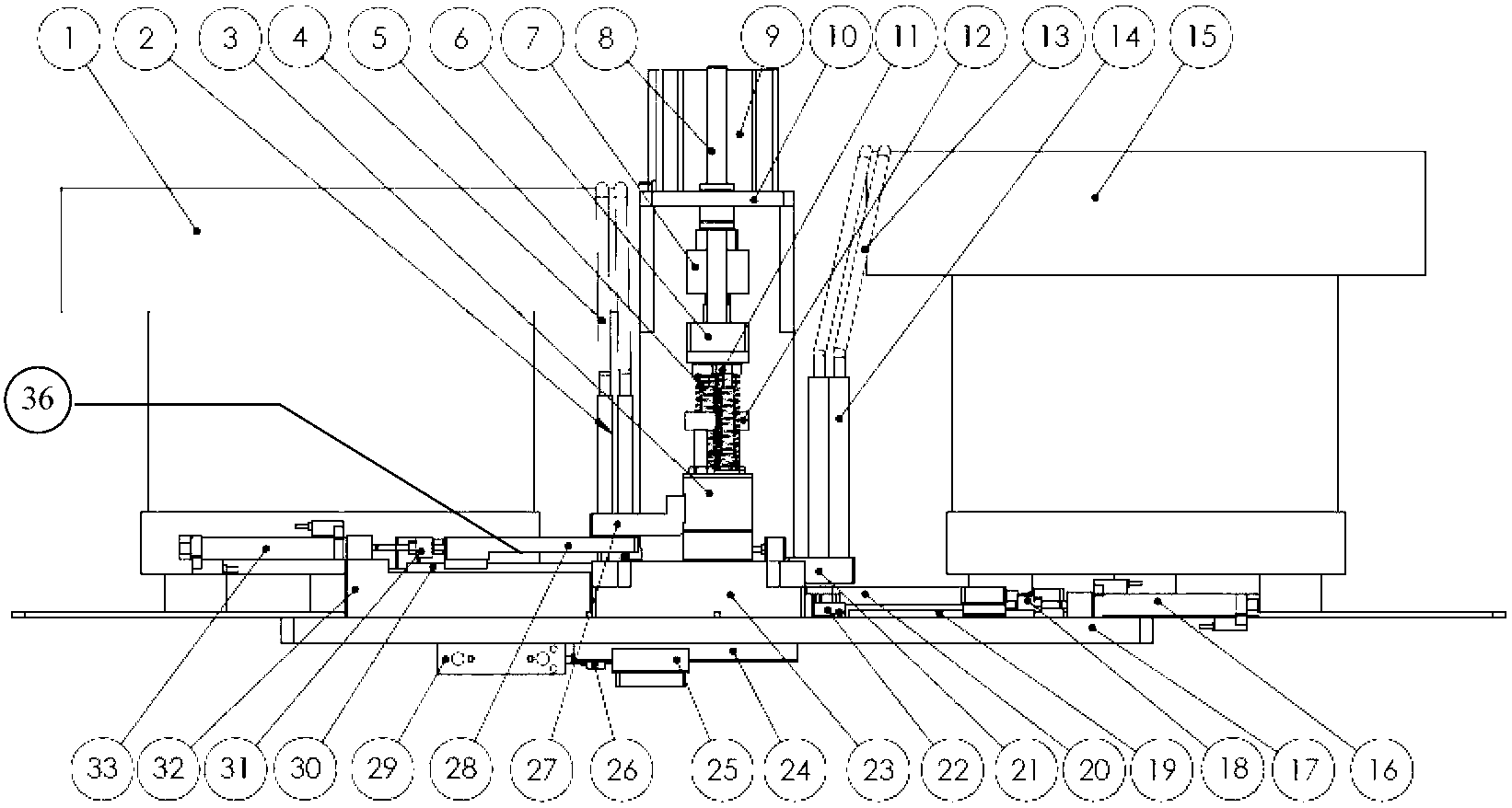

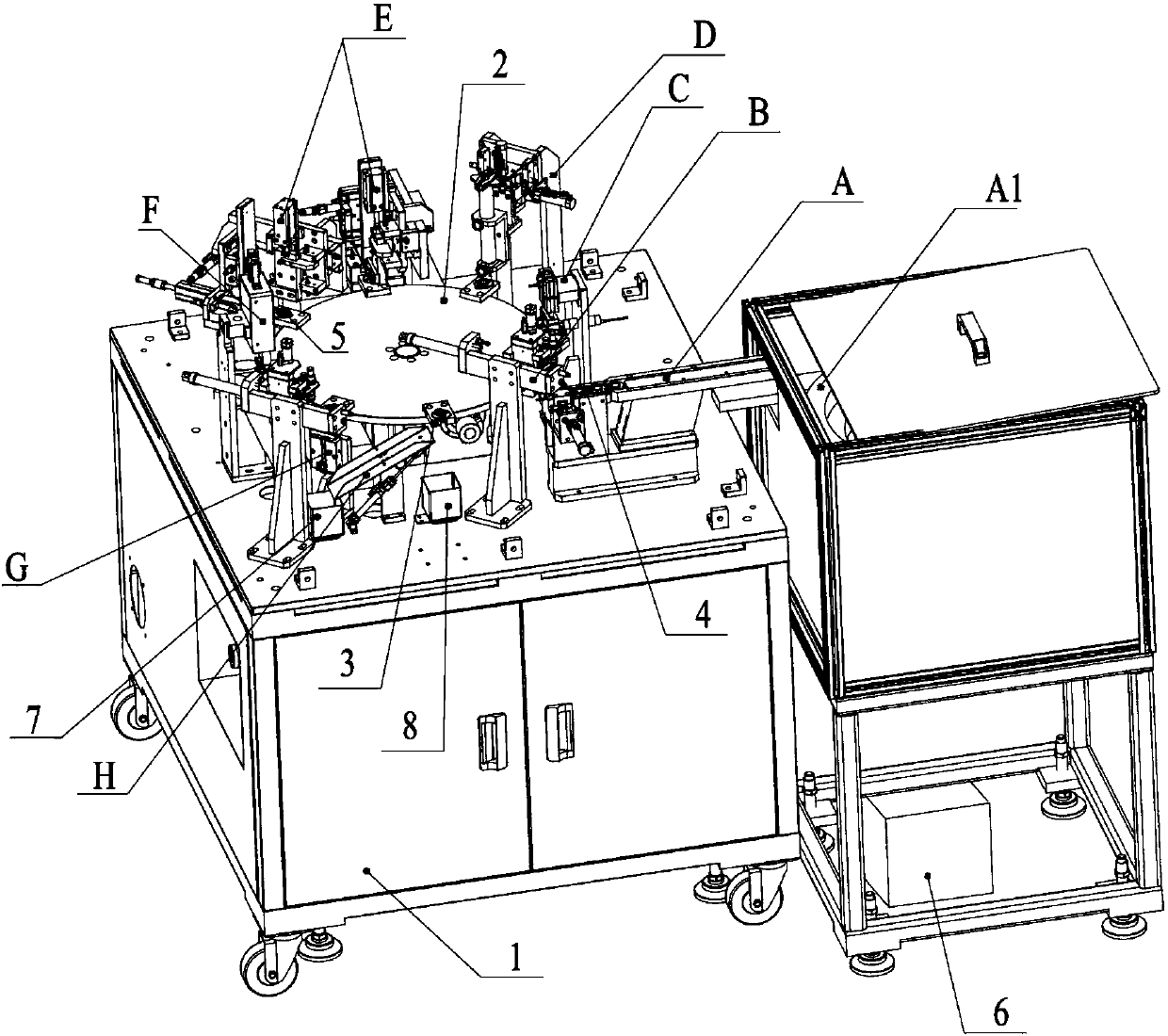

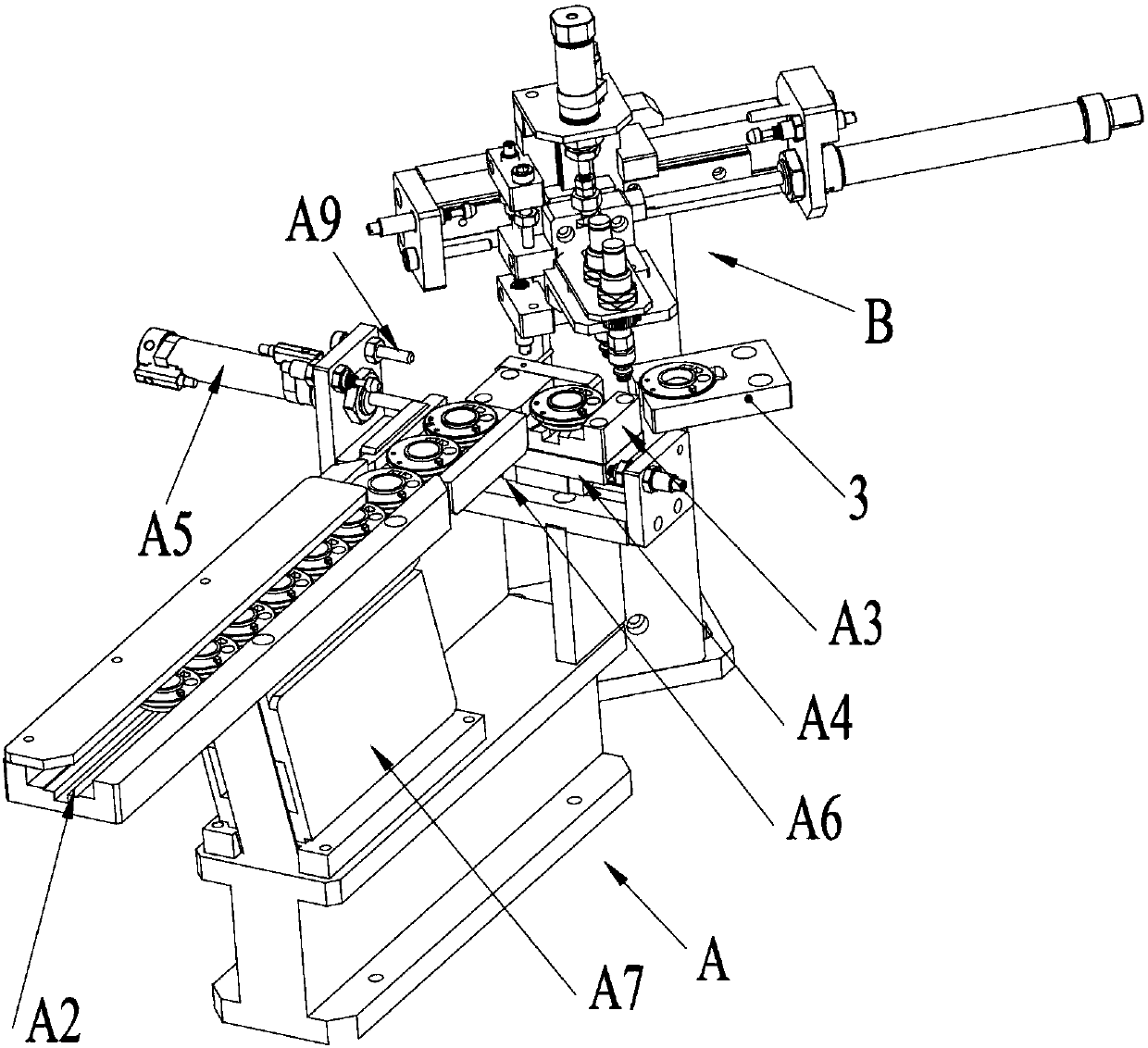

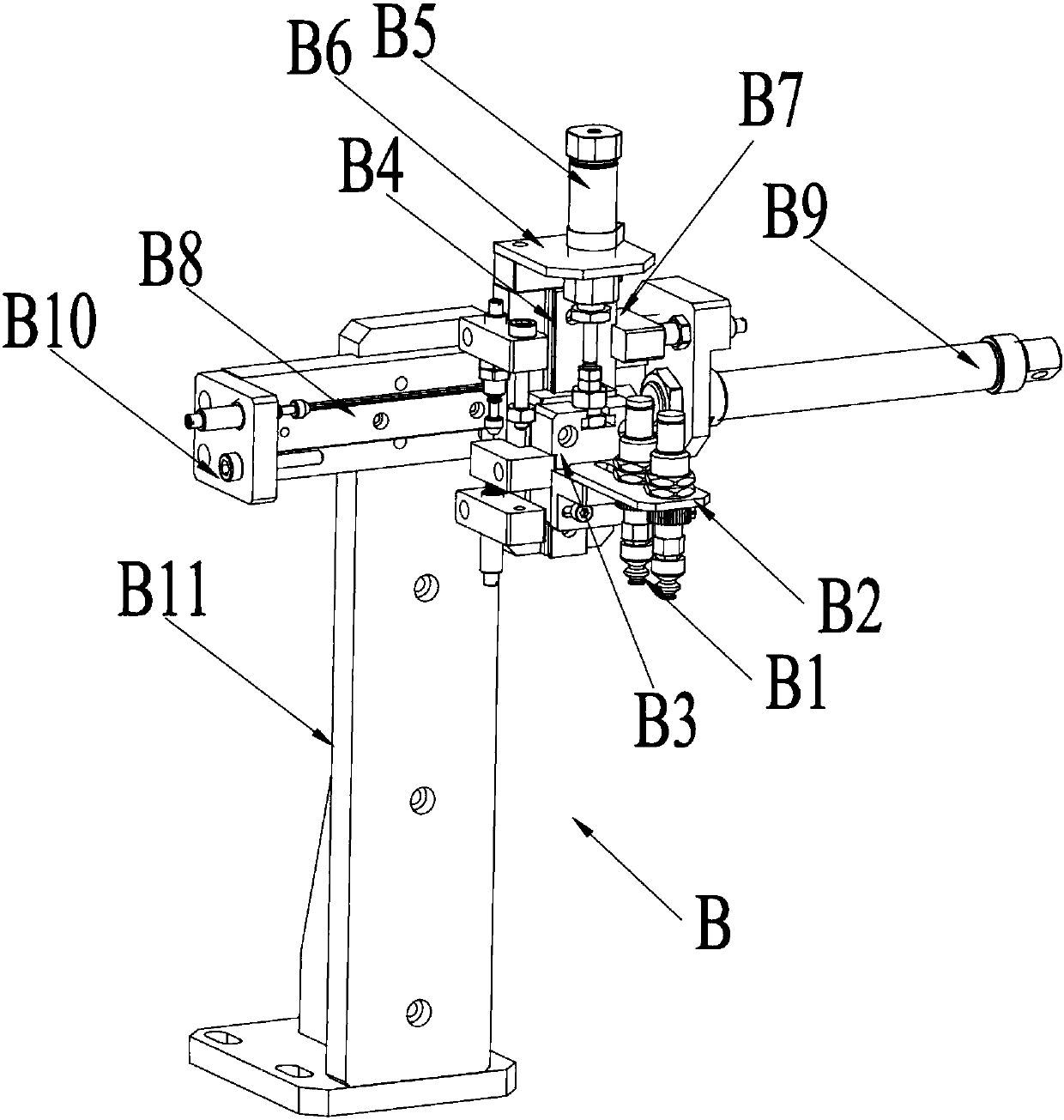

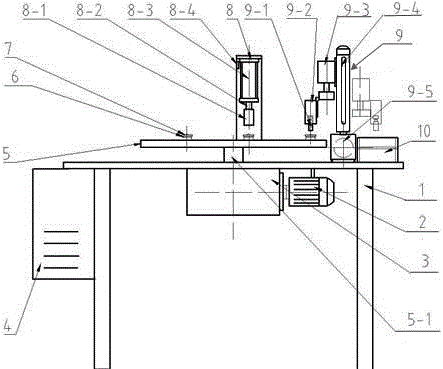

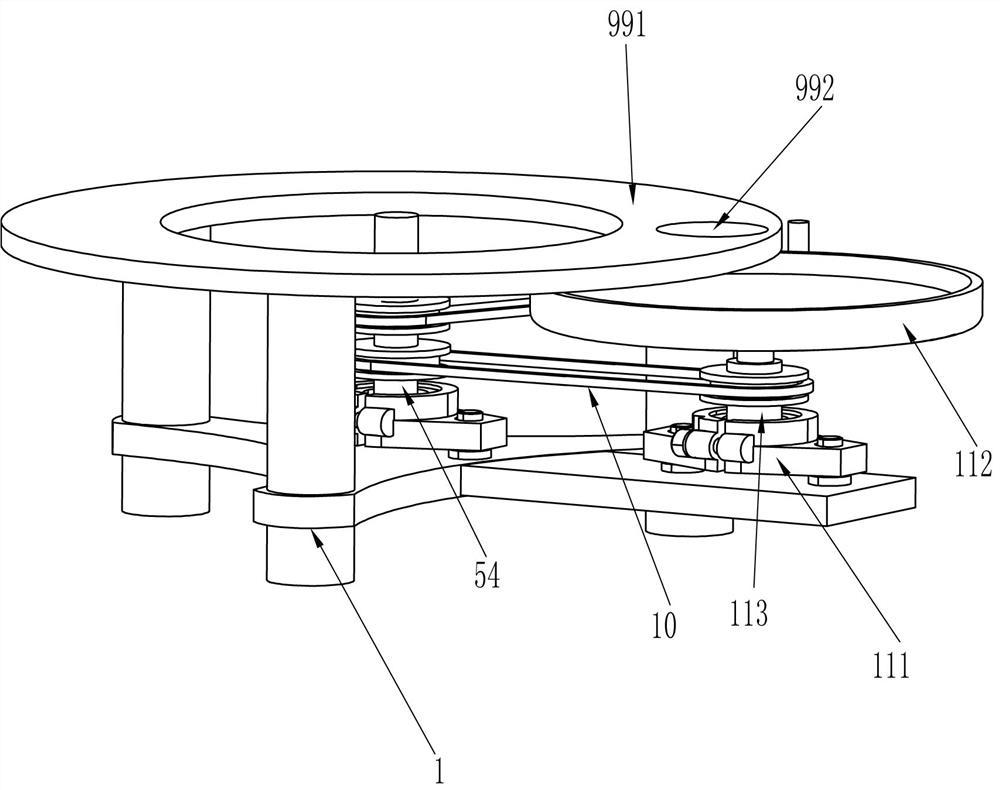

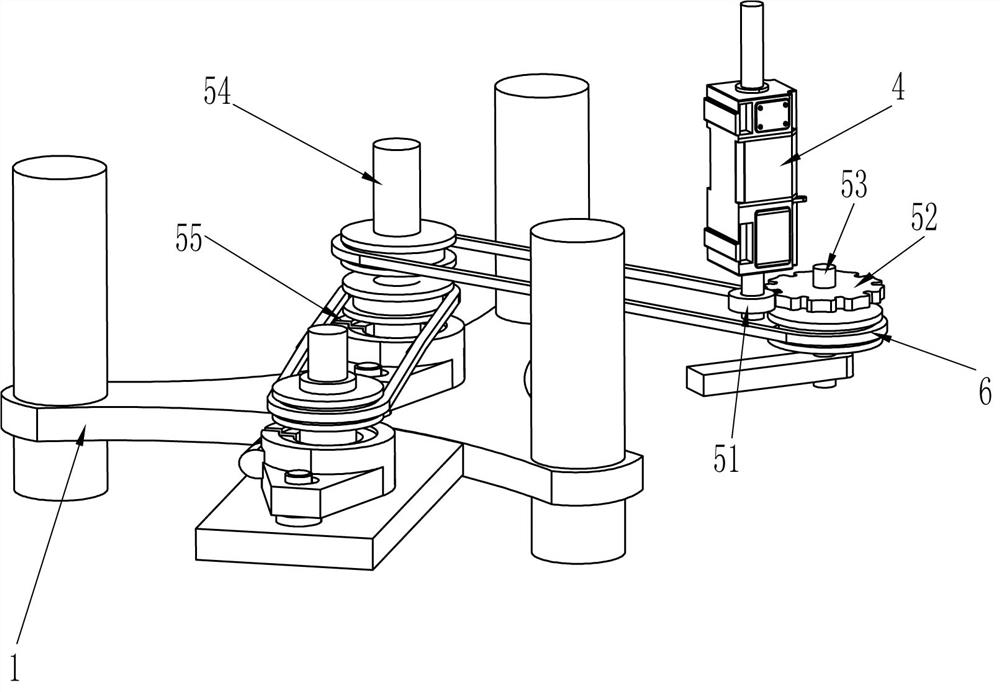

Automatic feeding and press fit machine of self-cleaning automobile shock absorber triple-linked part and control method thereof

The invention relates to an automatic feeding and press fit machine of a self-cleaning automobile shock absorber triple-linked part. The automatic feeding and press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a station rotary disc, a vibration feeding mechanism, a feeding mechanical hand, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with a variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the vibration feeding mechanism, the feeding mechanical hand, the pneumatic press fit mechanism and the collection box are arranged on one side of the workbench. The automatic feeding and press fit machine cooperates with an automatic control method to achieve automatic feeding and press fit of the self-cleaning shock absorber triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation time is shortened, the press fit accuracy is high, the action is reliable, the consistency is high, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

Full automatic pressing machine for plastic inserts

ActiveCN103009051AImprove securityReduce labor intensityMetal working apparatusEngineeringMechanical engineering

The invention discloses a full automatic pressing machine for plastic inserts and belongs to a mechanical-electrical integration device. The full automatic pressing machine comprises a pressing device, a plastic piece feeding device, a metal piece feeding device, as well as a blanking device, wherein the plastic piece feeding device and the metal piece feeding device are mounted on the two sides of the pressing device; and the blanking device is mounted at the bottom of the pressing device. After an optical fiber sensor senses that a plastic piece and a metal piece are both placed in place, the plastic piece feeding device and the metal piece feeding device are used for feeding the plastic piece and the metal piece into the pressing device in sequence; the metal piece is pressed into the plastic piece by using a cylinder; and then a stopping slide block in the blanking device is moved away, so that a plastic insert finished product falls into a finished product box. The full automatic pressing machine has the advantages of high automatic degree, no need of manual intervention, simple and convenient operation, high production efficiency, safety and so on.

Owner:杭州诺荣测控技术有限公司

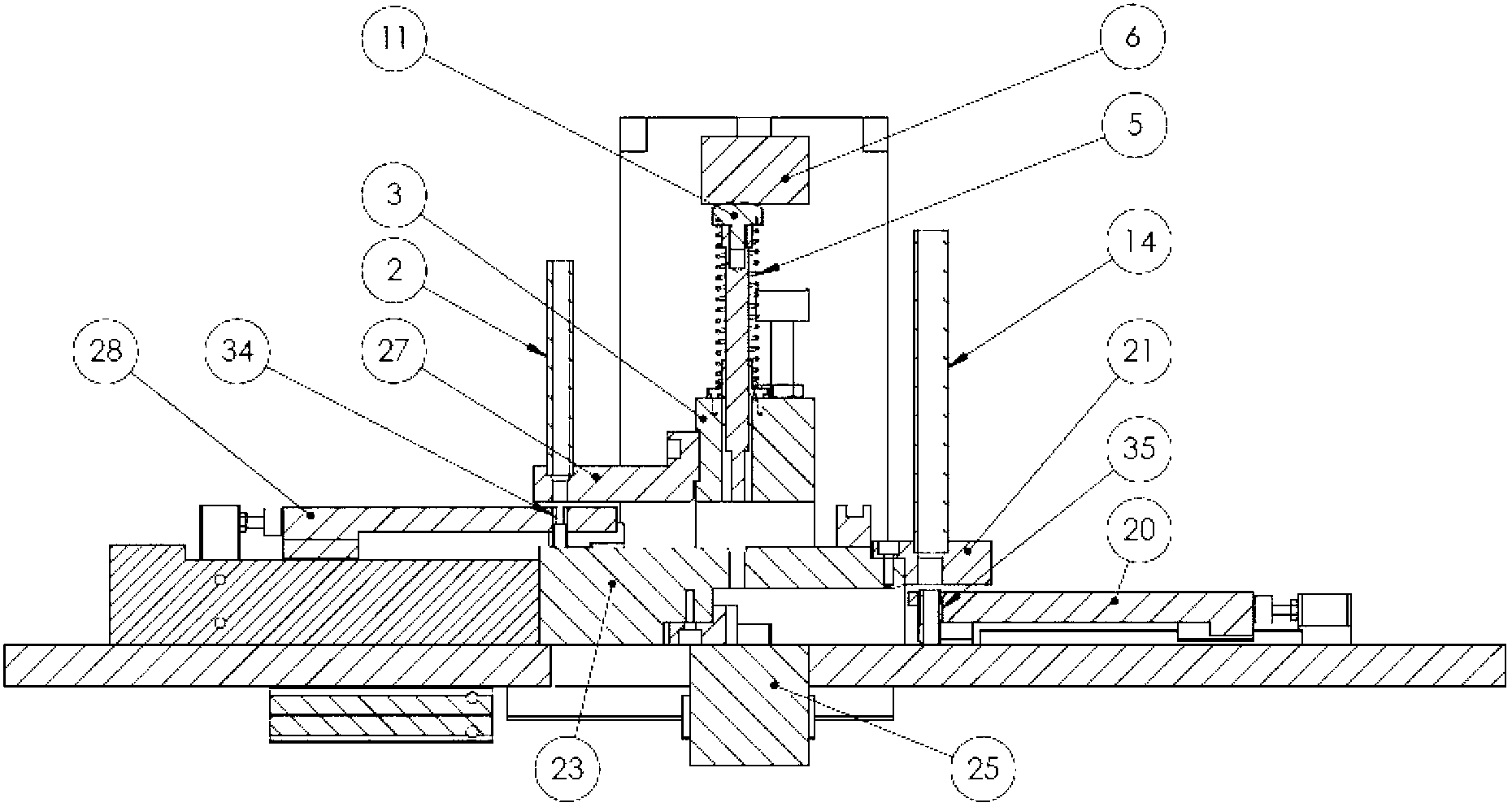

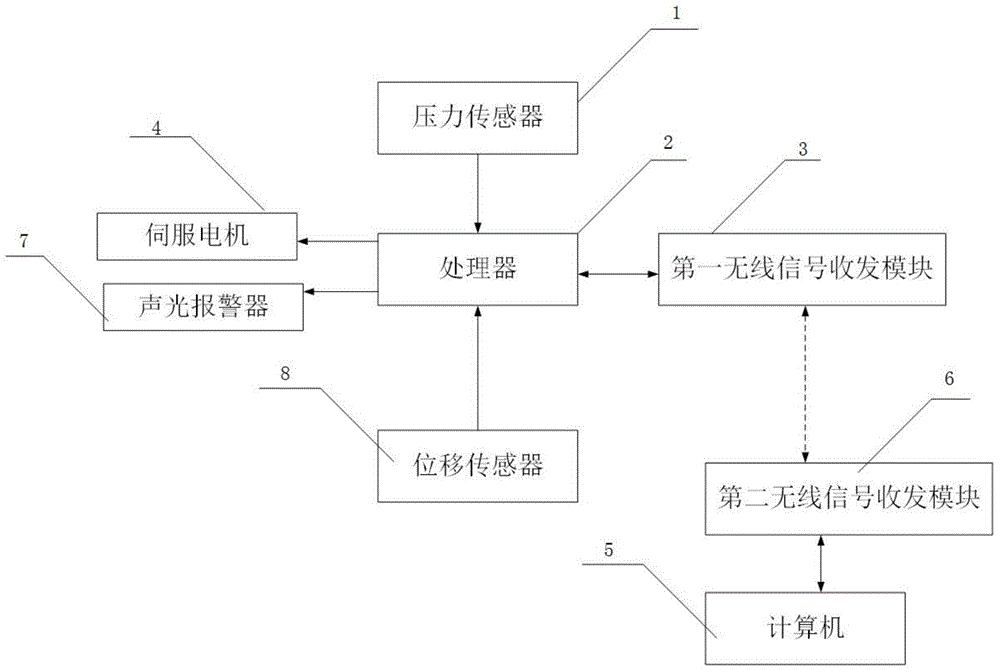

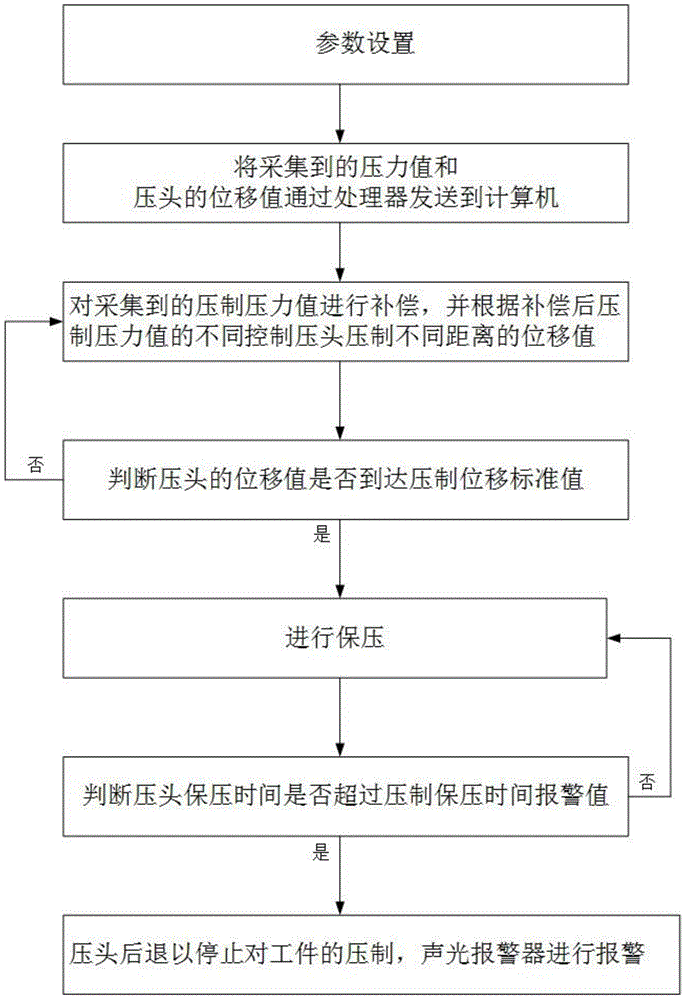

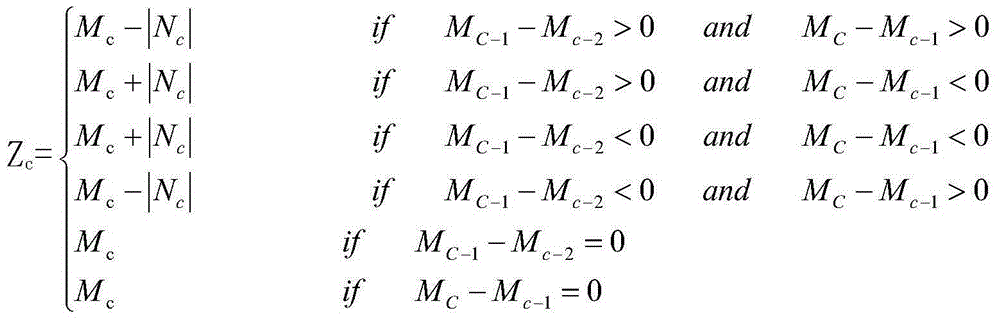

High-precision servo press fitting method based on computer

InactiveCN105109094AQuality improvementQuality assurancePressesEngineeringPressure controlled method

The invention discloses a high-precision servo press fitting method based on a computer, and relates to the field of automation control. The collecting pressure is dynamically compensated according to collected pressure values and a pressure change trend, adaptive control is performed on an elastic workpiece by combining with a displacement sensor and a pressure sensor, therefore, the pressing accuracy and pressure control stability for the elastic workpiece are improved, the phenomenon that elastic workpiece pressing is unqualified due to the fact that in a traditional technology, the pressure is too large or the actual pressing pressure is slightly smaller cannot occur, and the workpiece quality is guaranteed; meanwhile, due to the fact that the influence of interfering data is greatly eliminated, the adaptability of the pressure control method in different processing environments can be guaranteed.

Owner:CHONGQING TECH & BUSINESS INST

Press fitting machine for magnets

The invention discloses a press fitting machine for magnets. The press fitting machine comprises a rotary disc installed on a machine frame; a plurality of jigs are arranged on the edge of the upper surface of the rotary disc; the edge of the rotary disc is sequentially provided with a feeding mechanism for conveying workpieces to the positions of the jigs, a picking mechanism for transferring theworkpieces conveyed by the feeding mechanism onto the jigs, a workpiece squeezing mechanism for squeezing the workpieces into the jigs, an adhesive dispensing mechanism applied to pour an adhesive toset positions of the workpieces, a magnet press-in mechanism for pressing the magnets in adhesive dispensing positions on the workpieces, a detecting and marking mechanism for detecting and marking the magnet press-in states, a workpiece ejection mechanism for ejecting the workpieces bonded with the magnets out from the jigs, and a classification collection mechanism for conducting classificationcollection on the ejected workpieces; and the rotary disc and all the mechanisms are controlled by a controller to complete operation of automatically pressing the magnets in the workpieces. The press fitting machine for the magnets can achieve continuous automatic production on a large scale.

Owner:深圳市优迪泰自动化科技有限公司

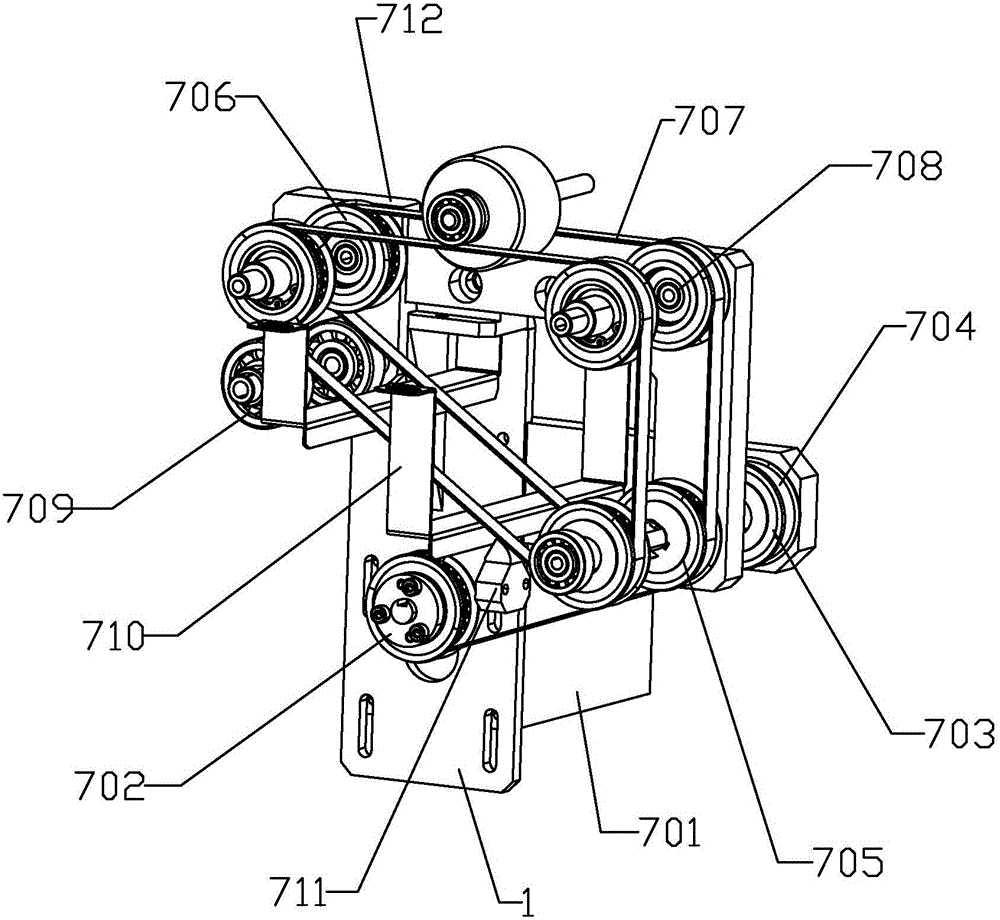

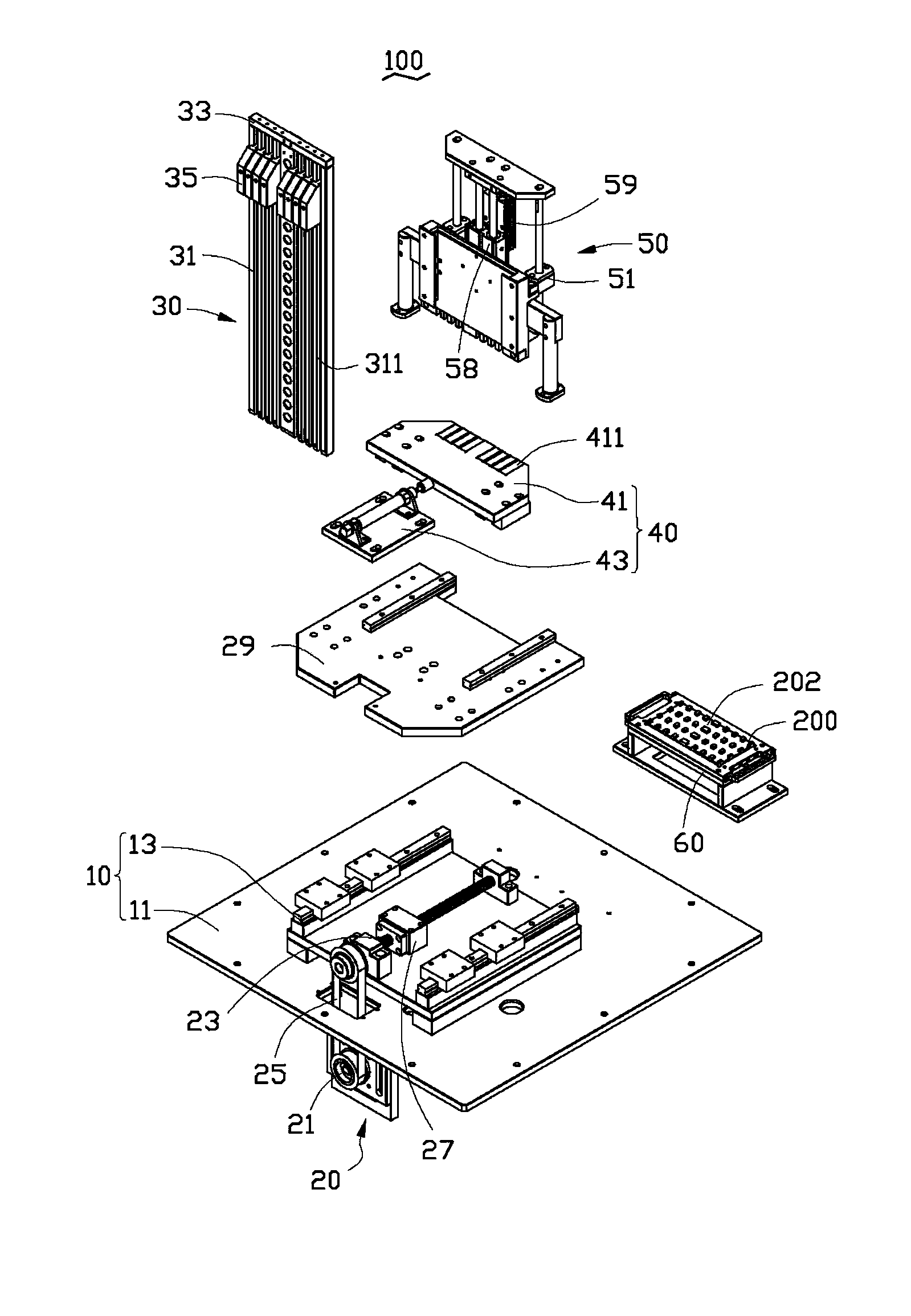

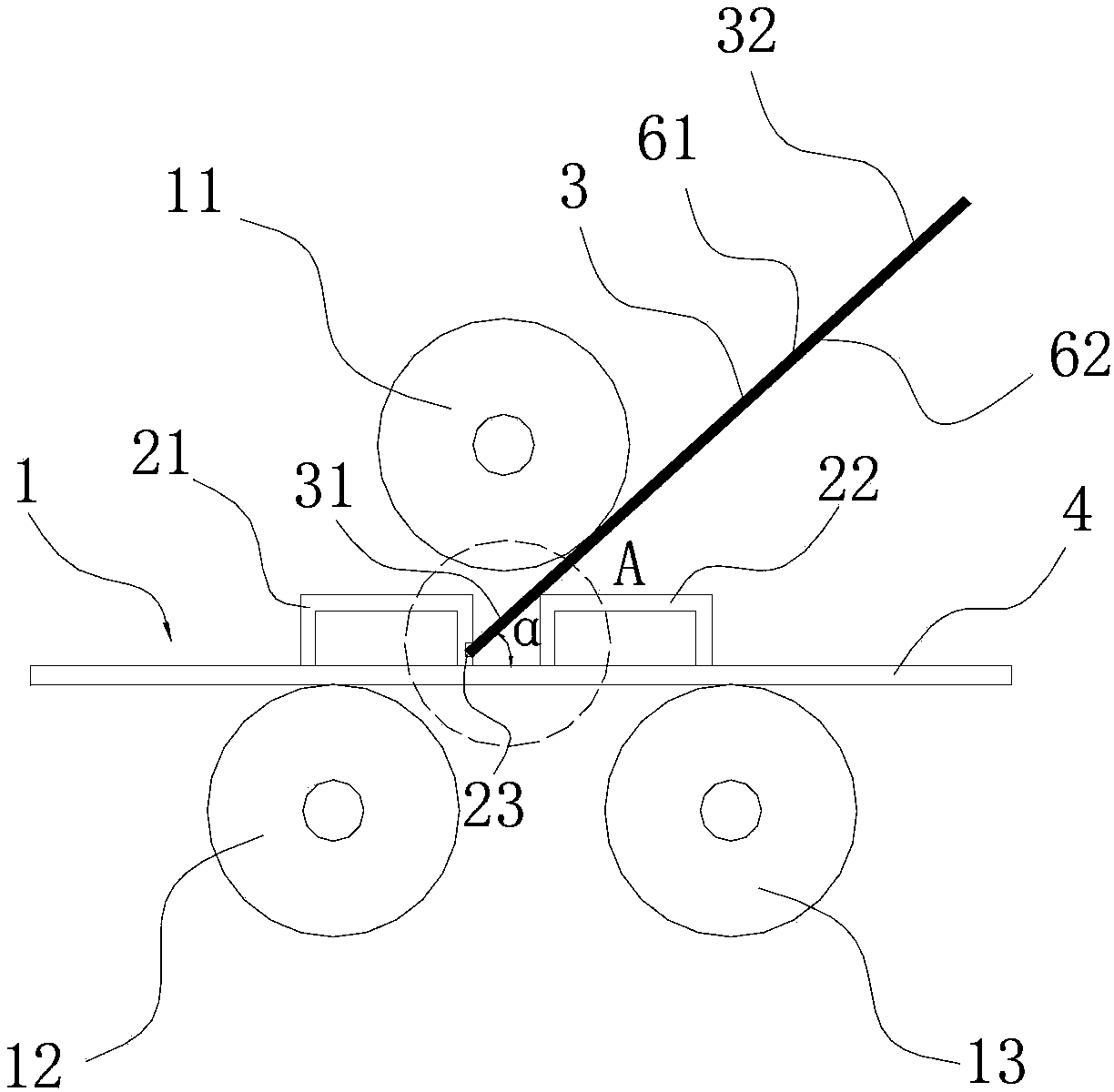

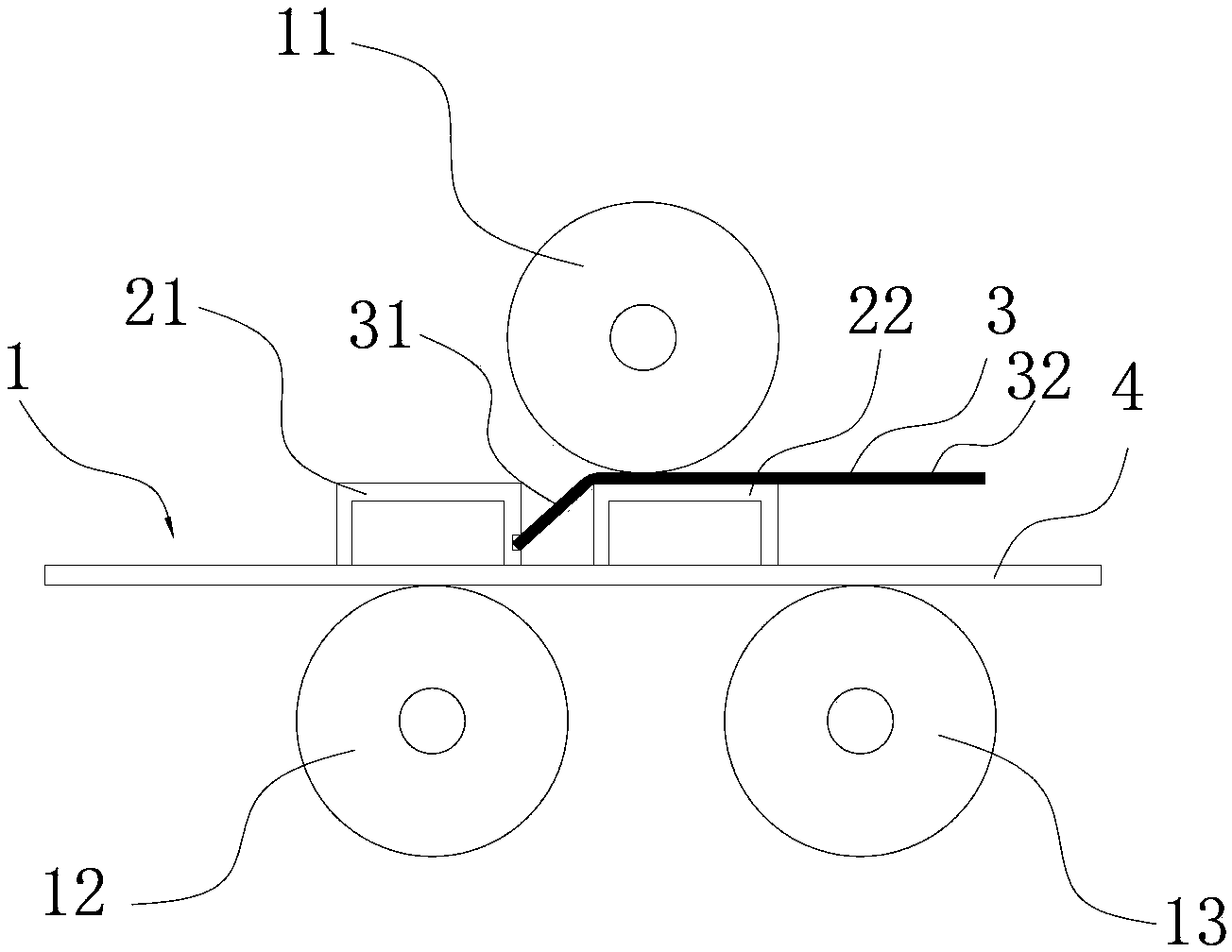

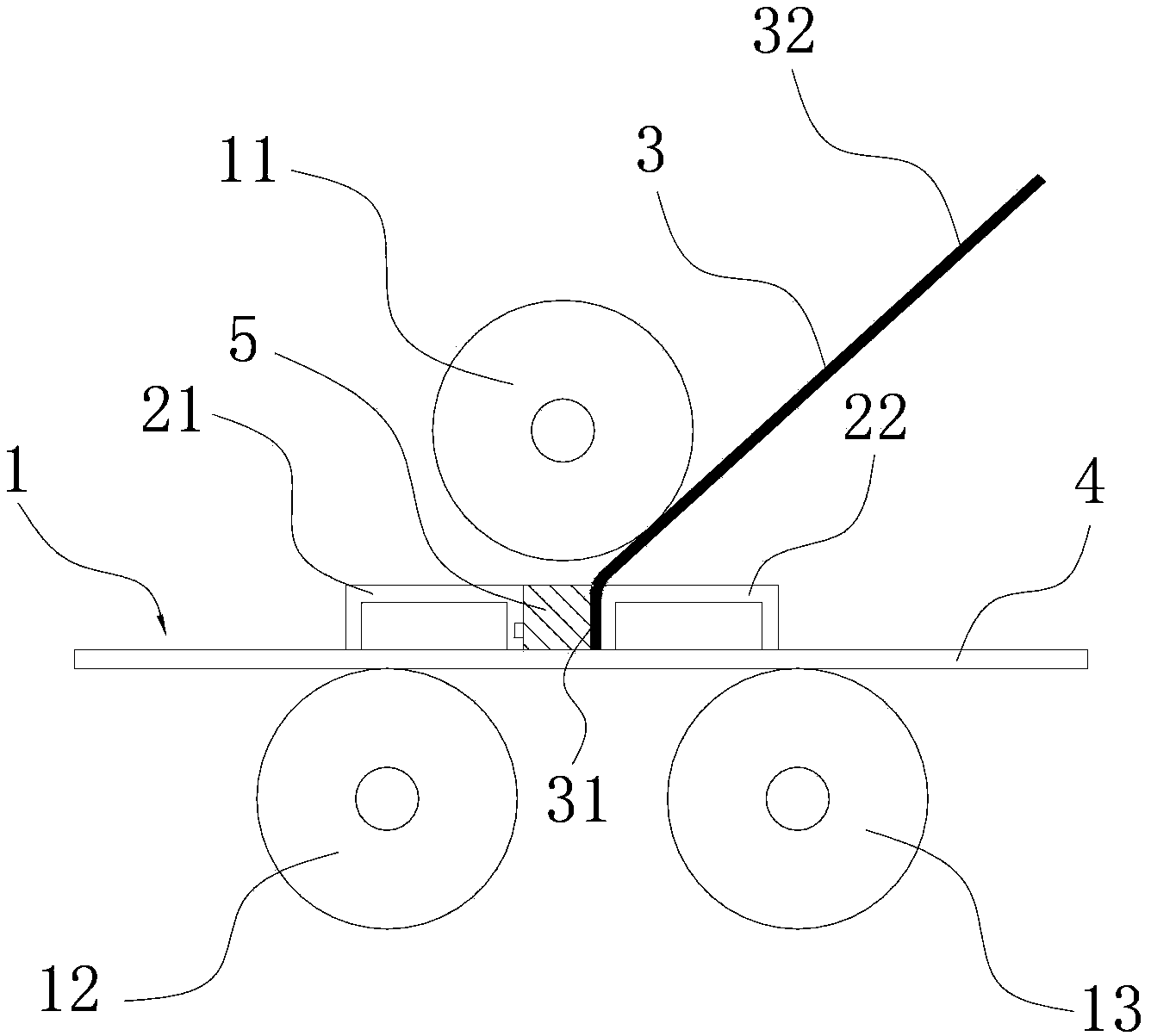

Press fitting mechanism

ActiveCN103537886AAchieve positioningImprove pressing efficiencyMetal working apparatusMechanical engineeringEngineering

A press-fit mechanism capable of mounting magnetic materials on a workpiece, includes a base plate, a transmission assembly, a resisting assembly, a loading assembly, a transferring assembly and a sucking assembly. The transmission assembly is slidably mounted on the base plate. The resisting assembly and the loading assembly are mounted on the transmission assembly. the resisting assembly includes a driving member and a resisting plate connected to the driving member. The transferring assembly is located between the resisting assembly and the loading assembly. The sucking assembly is mounted on the base plate. The driving member drives the resisting plate to resist the magnetic materials from the transferring assembly toward the loading assembly, the loading assembly is driven by the transmission assembly toward the sucking assembly, then the loading assembly releases the magnetic materials, the sucking assembly sucks the magnetic materials and places the magnetic materials on the workpiece.

Owner:泰州市海通资产管理有限公司

Quick lamination device for shoe production

InactiveCN107660844AImprove pressing efficiencyEven by forceInsolesUpperEngineeringUltimate tensile strength

Owner:晋江诺研机械设计有限公司

Refuse compressor

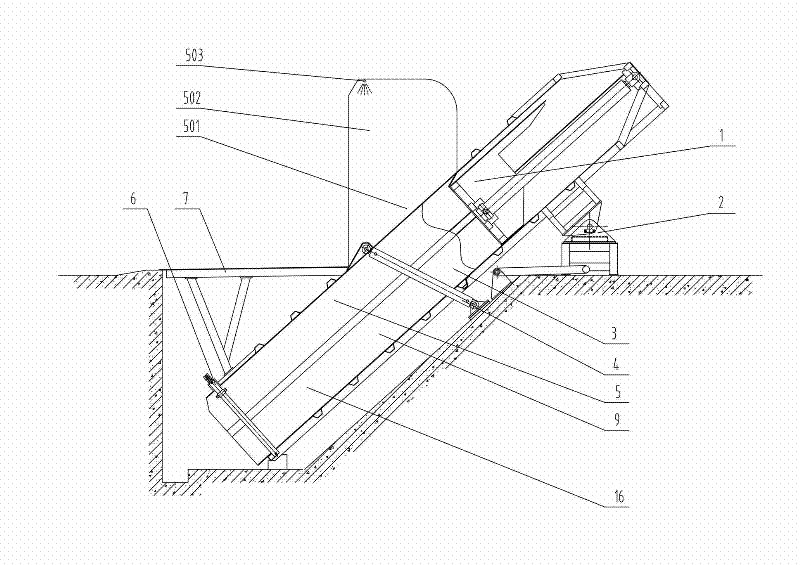

ActiveCN102173331AImprove pressing efficiencyImprove liquidityRefuse receptaclesRefuse transferringEngineering

The invention discloses a refuse compressor, which comprises a box body, a compression pusher component and a gate component, wherein the compression pusher component and the gate component are arranged in the box body; a box body cavity between the compression pusher component and the gate component forms a compression cavity; one end, adjacent to the gate component, of the box body extends intoa working pit which is positioned under the ground; and the other end of the box body is connected to or pressed against the ground. The refuse compressor has the advantages of high compression efficiency, good compression effect and the like.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

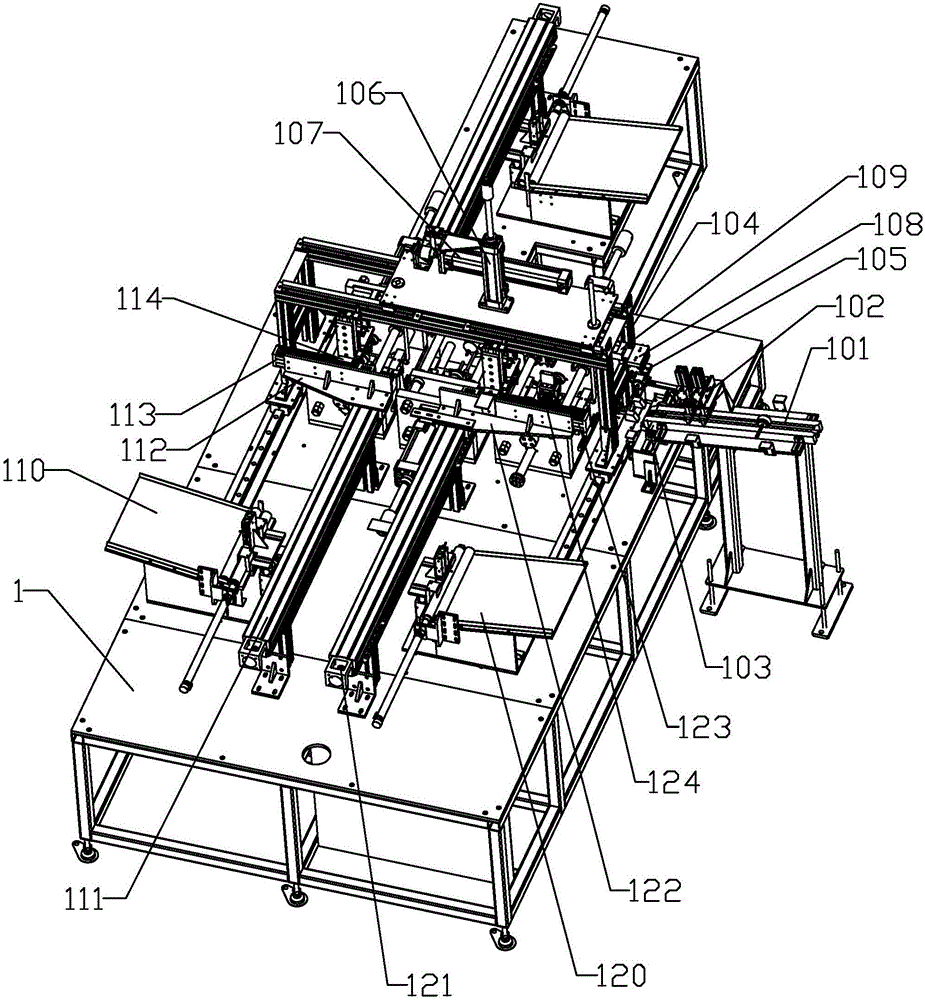

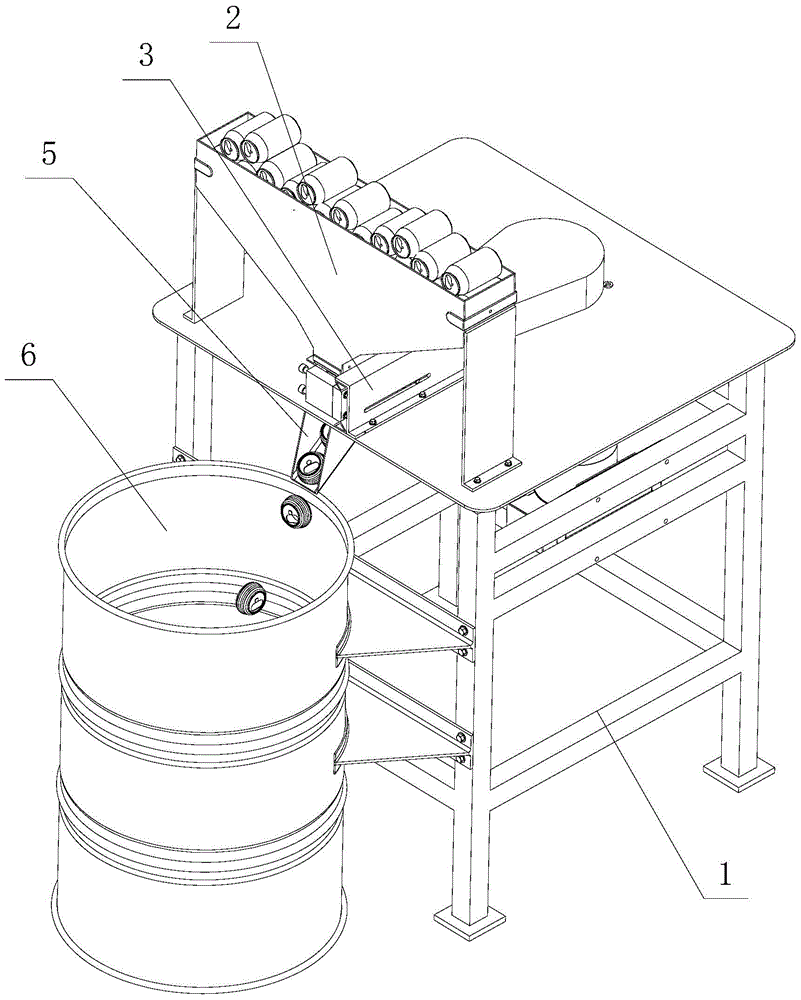

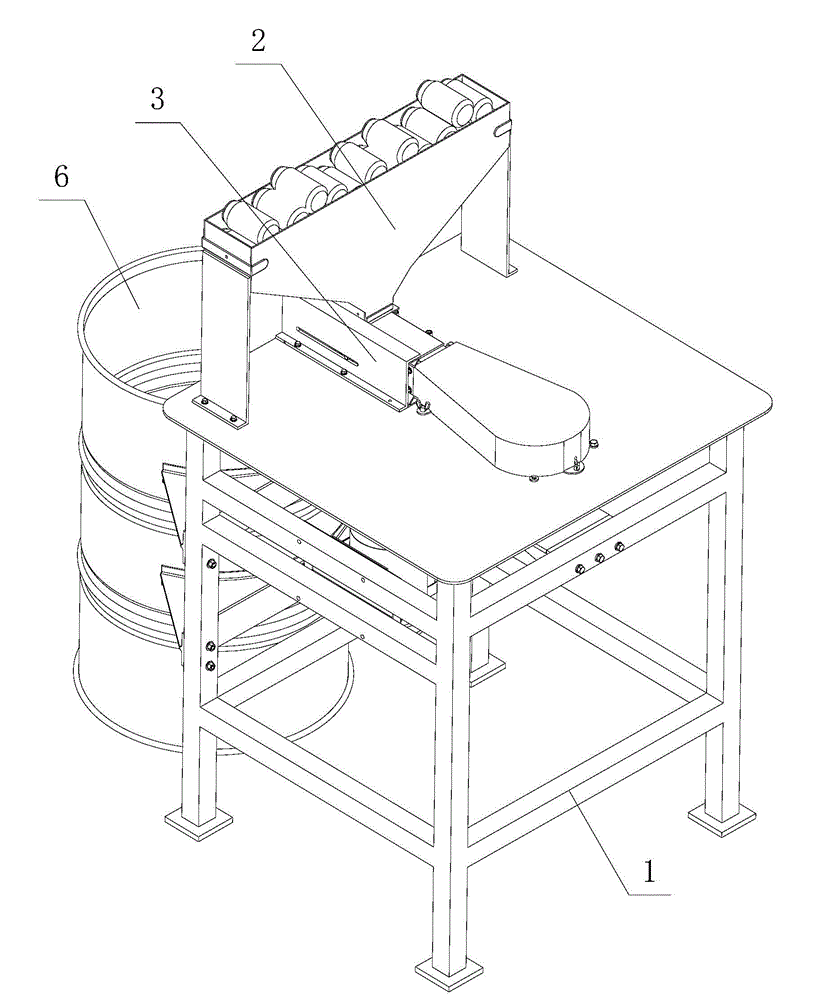

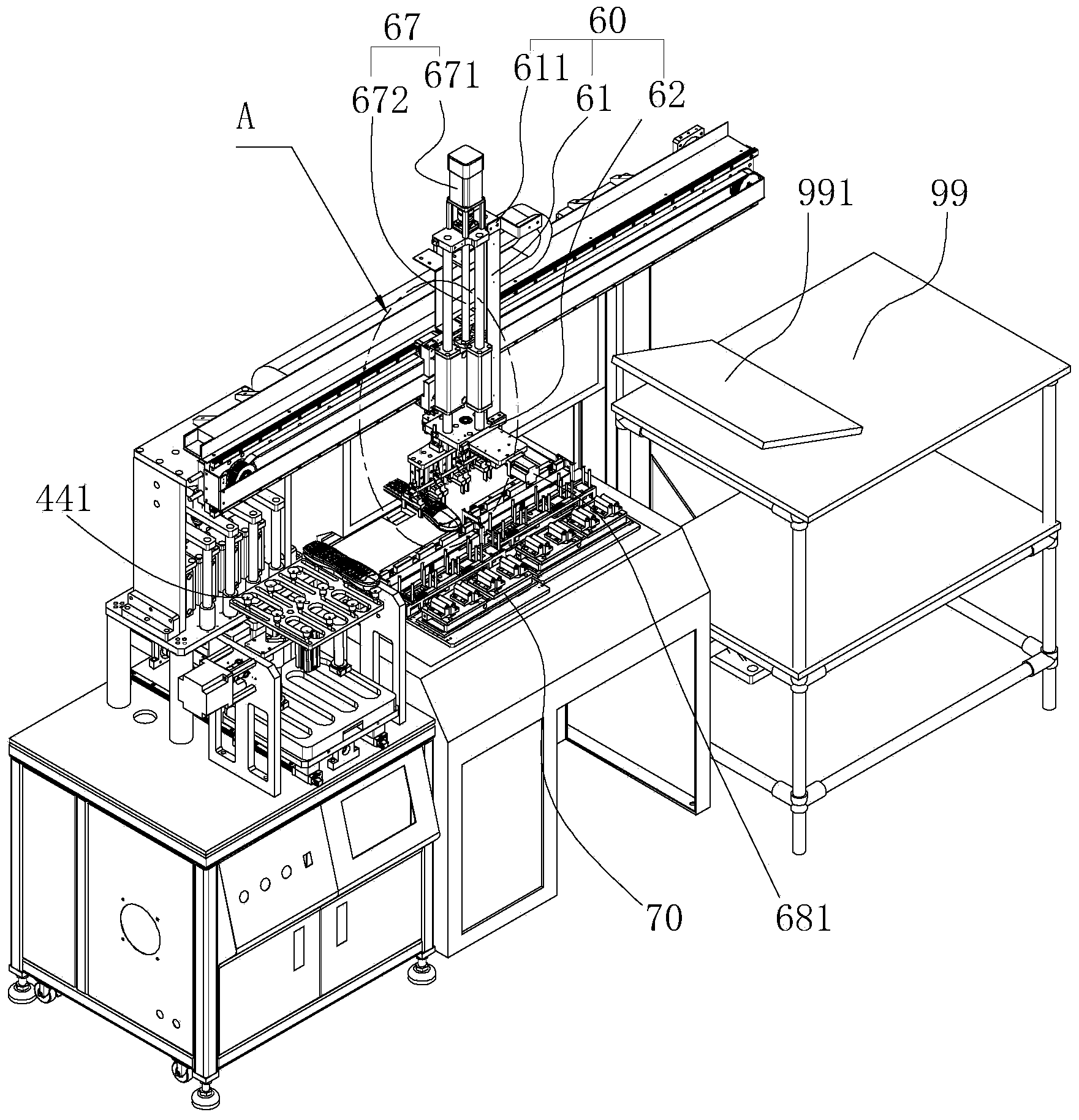

Full-automatic pressing device for perforating bullets

ActiveCN105252250AImprove pressing efficiency and product quality stabilityAvoid investmentFluid removalMetal working apparatusManipulatorEngineering

The invention discloses a full-automatic pressing device for perforating bullets. The full-automatic pressing device comprises a rack, at least two sets of conveying belts installed on the rack and used for conveying shaped charge covers and bullets bodies used for the perforating bullets and the perforating bullets which are formed in a pressed manner, a picking device installed on the rack and used for picking the shaped charge covers and the bullet bodies on at least two sets of conveying belts, conveying the picked shaped charge covers and the picked bullet bodies into a press to be pressed and putting the perforating bullets which are formed in the pressed manner onto one set of conveying belts in at least two sets of conveying belts, and a control system used for controlling conveying of the conveying belts and actions of mechanical arm devices. By means of the full-automatic pressing device, full-automatic pressing of the perforating bullets is achieved, and production efficiency, safety of pressing operation and stability of product quality are improved.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP +2

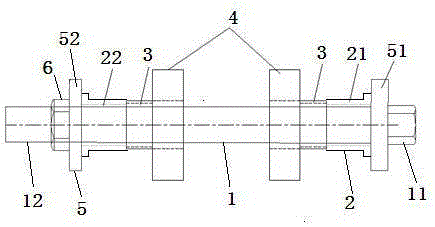

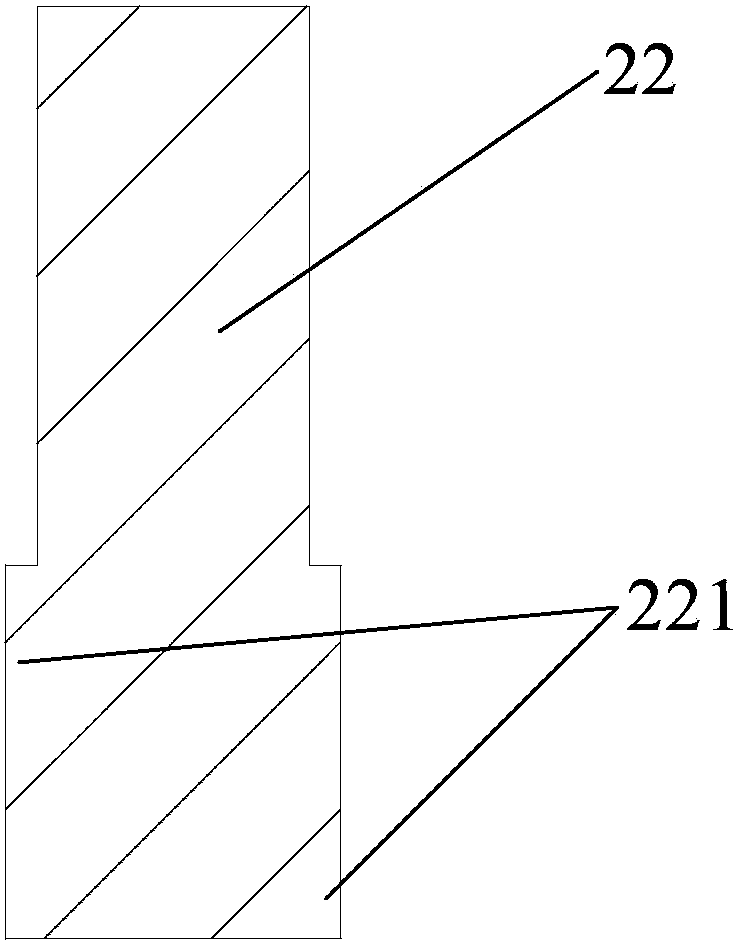

Bushing press-fit bolt and press-fit method thereof

InactiveCN105196241AImprove wear resistanceNot easy to damageMetal-working hand toolsEngineeringScrew thread

The invention discloses a bushing press-fit bolt and a press-fit method thereof. The bushing press-fit bolt is used for press fitting bushings into pressing sleeve holes of workpieces to be pressed and sleeved, and the center of each bushing is provided with a bushing hole. The bushing press-fit bolt comprises a pressing sleeve screw, a nut, two pressing sleeves and two flange discs; the pressing sleeve screw comprises a screw head and a screw rod, the two pressing sleeves comprise a first pressing sleeve and a second pressing sleeve, and the two flange discs comprise a head flange and a tail flange; the head flange, the first pressing sleeve, the second pressing sleeve, the tail flange and the nut are sequentially and coaxially installed on the screw rod from the screw head in a sleeving mode, and the outer diameter of each flange disc is larger than that of each pressing sleeve. By means of the structure and method, two bushings can be simultaneously press fit through one-time press-fit, the abrasive resistance of the press-fit bolt is good, the pressing sleeves and threads are all not prone to damage, the service life is long, the press-fit yield is high, the press-fit uniformity and centering performance are good, and the manufacturing cost is low.

Owner:CRRC NANJING PUZHEN CO LTD

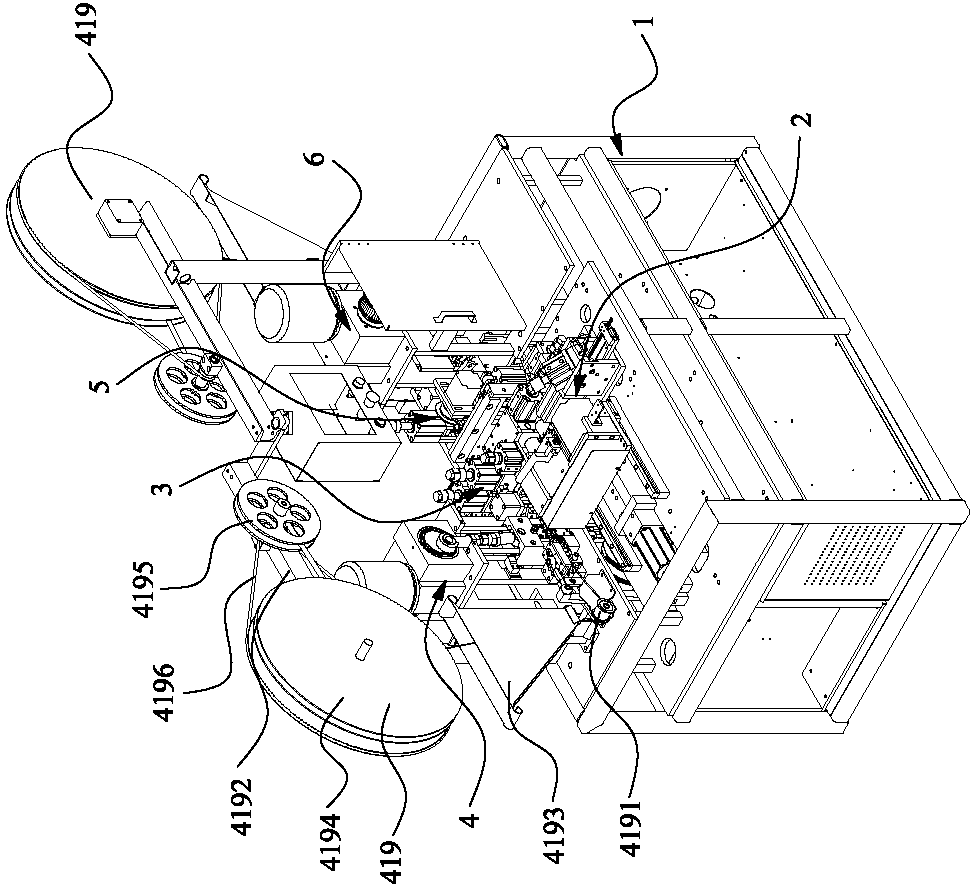

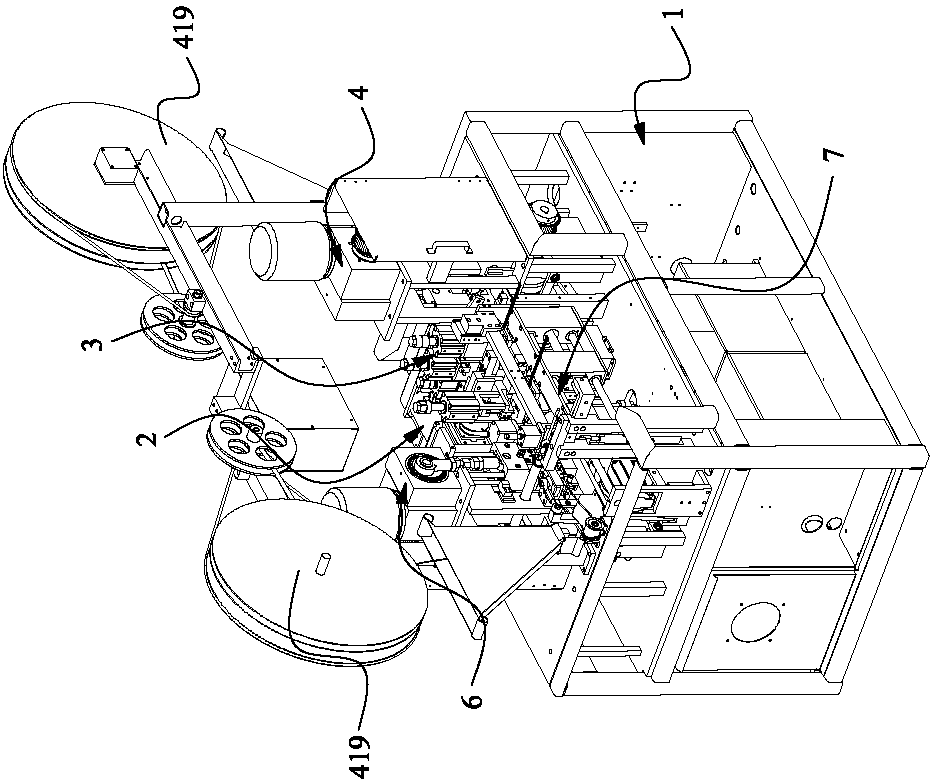

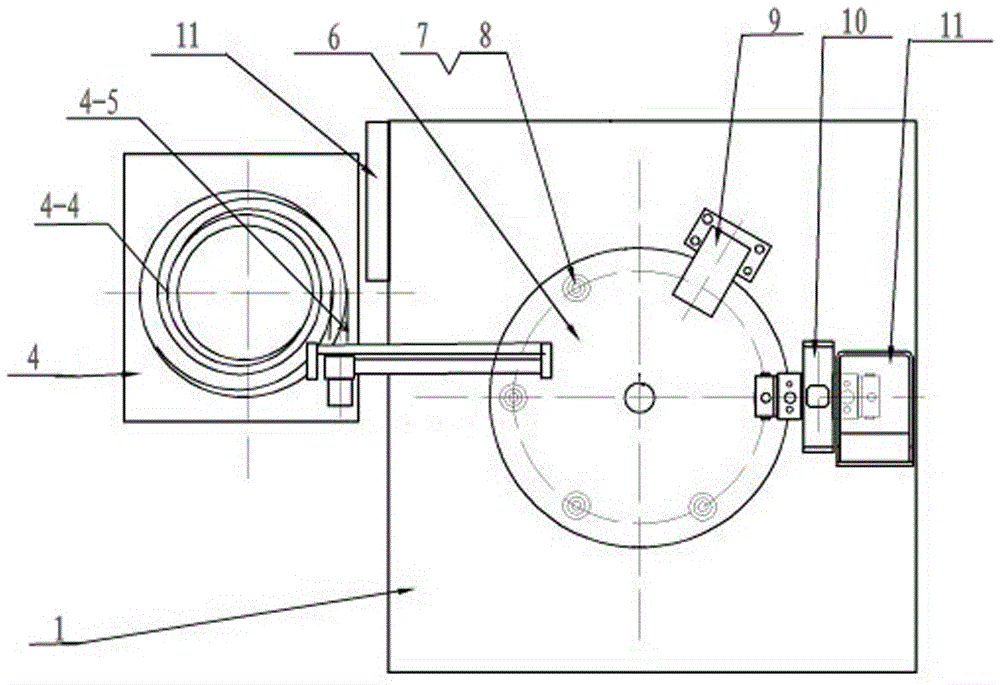

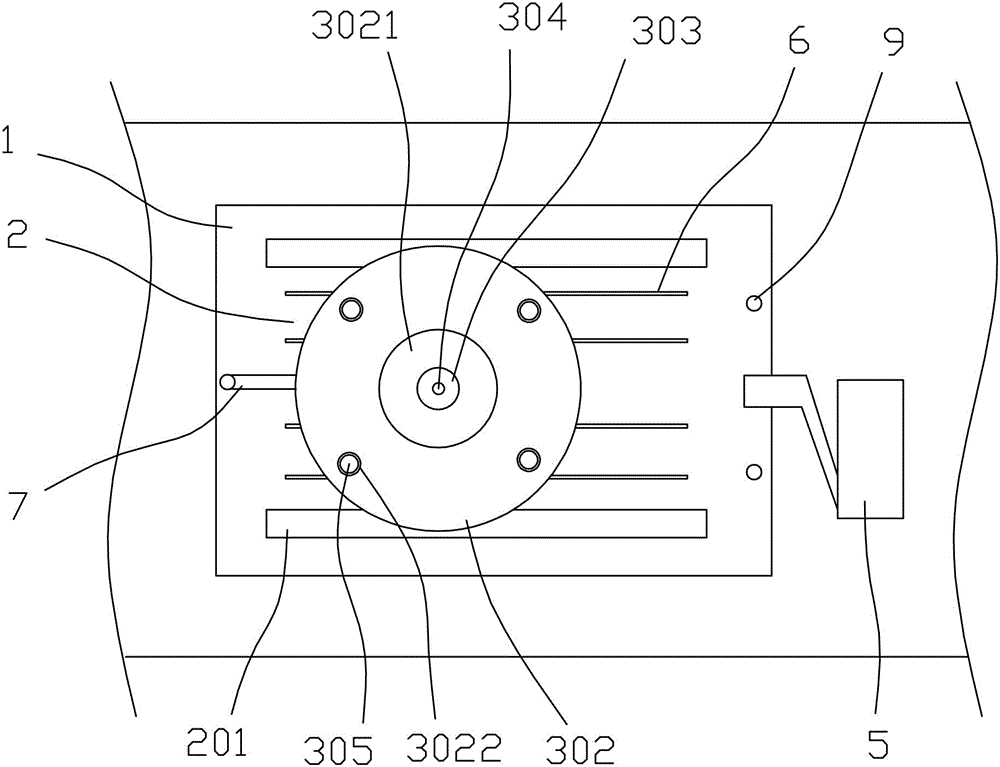

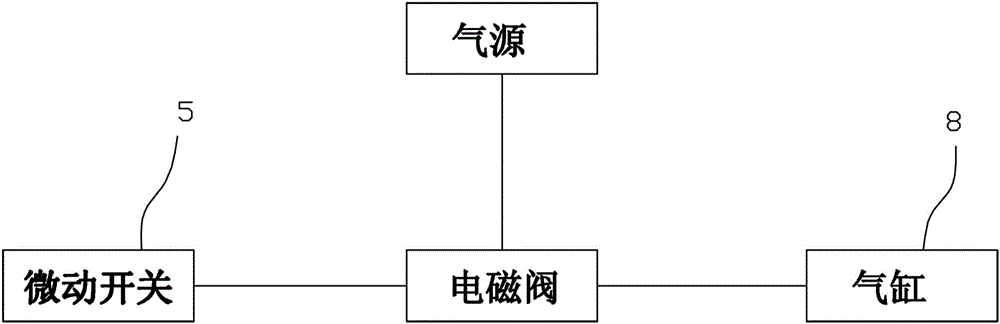

Automatic press-fitting system for nail-shooting pill clip

PendingCN107838663AImprove pressing efficiencyReduce labor costsSortingMetal working apparatusPhysical medicine and rehabilitationGas cylinder

The invention improves an automatic press-fitting system for a nail-shooting pill clip. The automatic press-fitting system comprises a pedestal as well as a rocking plate device, a feeding system, a clip filling device, a fixed frame, a first gas cylinder, a pushing plate, a nail-shooting pill turnover plate and a second gas cylinder which are mounted on the pedestal, wherein the rocking plate device is matched with the nail-shooting pill turnover plate for filling a nail-shooting pill into the nail-shooting pill turnover plate; the rocking plate device is connected with the feeding system; the first air cylinder is connected with the pushing plate for pushing the clip on the clip filling device onto the fixed plate; the fixed plate is matched with the nail-shooting pill turnover plate; and the second air cylinder is connected with a punch, so that a nail on the nail-shooting pill turnover plate is ejected out and ejected into the clip, and therefore, press-fitting efficiency is improved, and labor cost is reduced.

Owner:重庆重科智能装备研究院有限公司

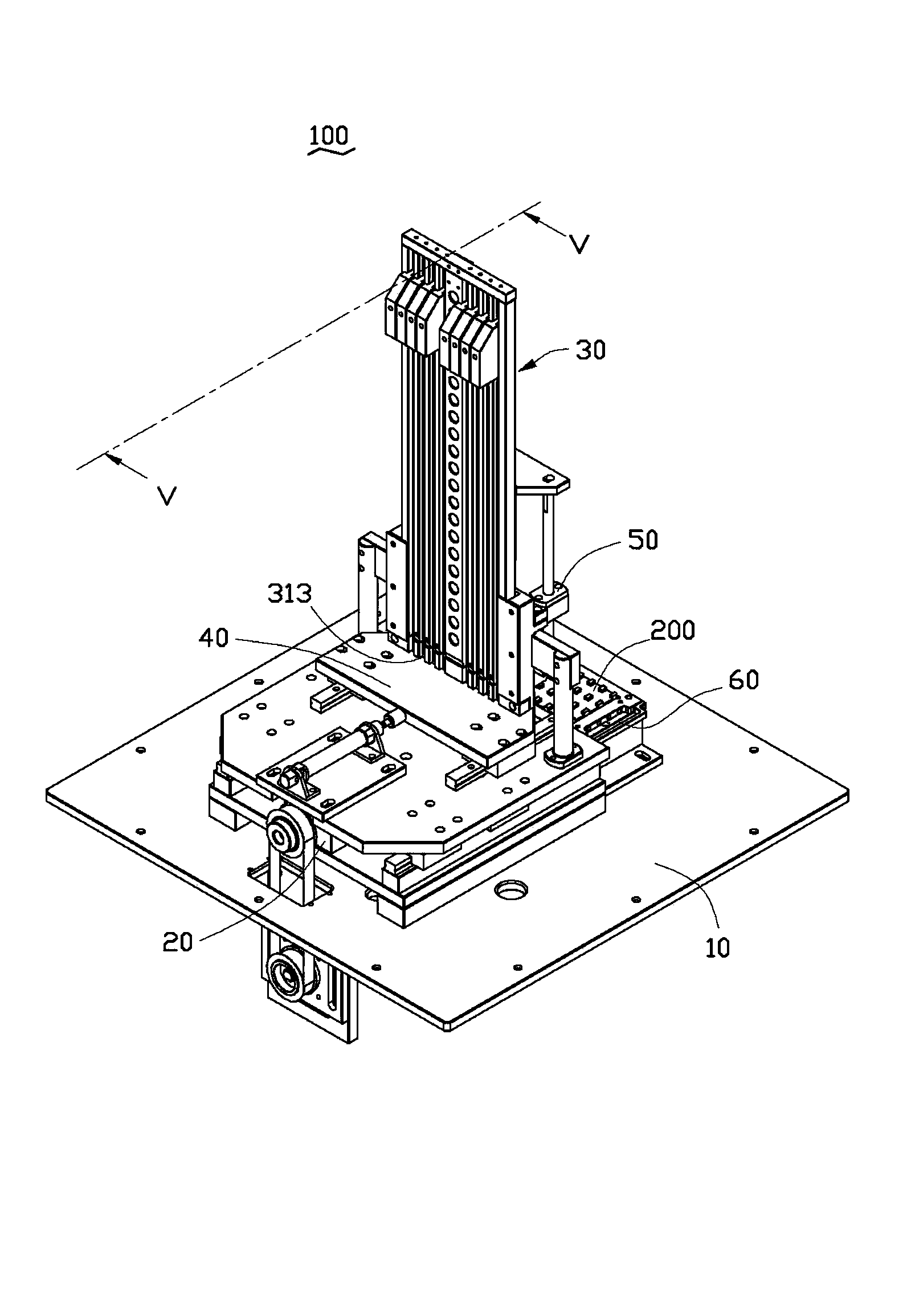

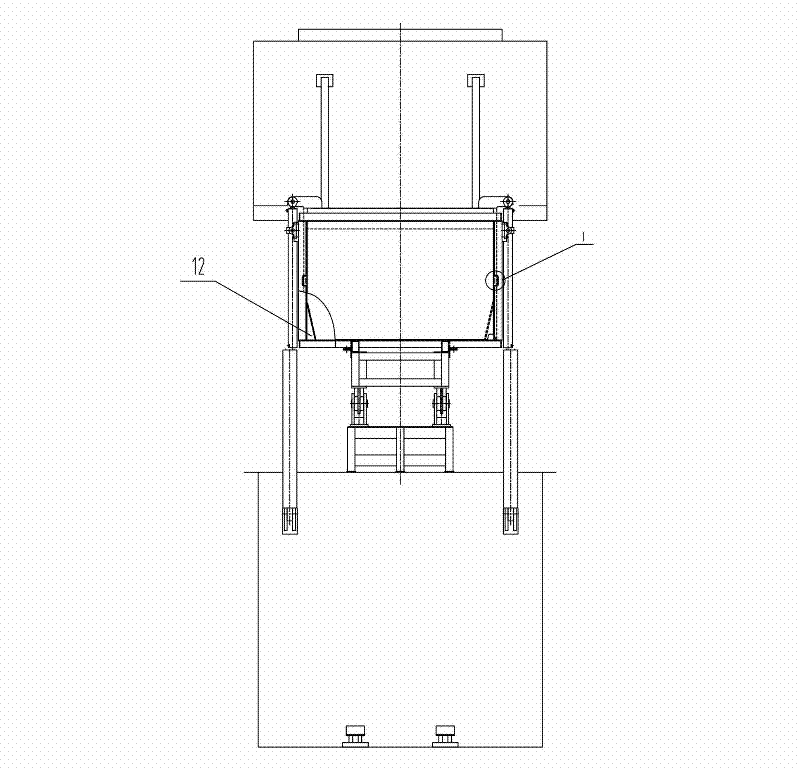

Press mounting apparatus and press mounting method of semiconductor valve string

ActiveCN106298594AImprove press stabilityGuaranteed assembly accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringPlacement method

The invention provides a press mounting apparatus and press mounting method of a semiconductor valve string. The press mounting apparatus comprises a horizontal workbench arranged on a frame, the horizontal workbench is provided with a guiding support mechanism used for guiding and supporting each device in a semiconductor valve string to be press-mounted, a force application mechanism is arranged at the end of a guiding direction on the frame, and the force application direction of the force application mechanism is the same as the guiding direction. The advantages are as follows: each device in the semiconductor valve string is horizontally placed on the guiding support mechanism for assembling, compared to a conventional vertical accumulation placement method, the method reduces transport paths, and therefore, the labor intensity is low and the assembling efficiency is high. Besides, the semiconductor valve string does not have to be hoisted and moved after being assembled, pressure loading can be carried out directly by use of the force application mechanism, the press-mounting efficiency and the automation degree of the whole press-mounting operation are improved, and the press-mounting precision is effectively guaranteed. At the same time, the height of the horizontally arranged semiconductor valve string is greatly reduced, and the press-mounting stability of the semiconductor valve string is improved.

Owner:PINGGAO GRP +3

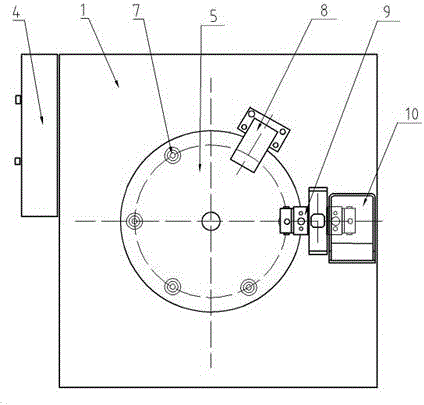

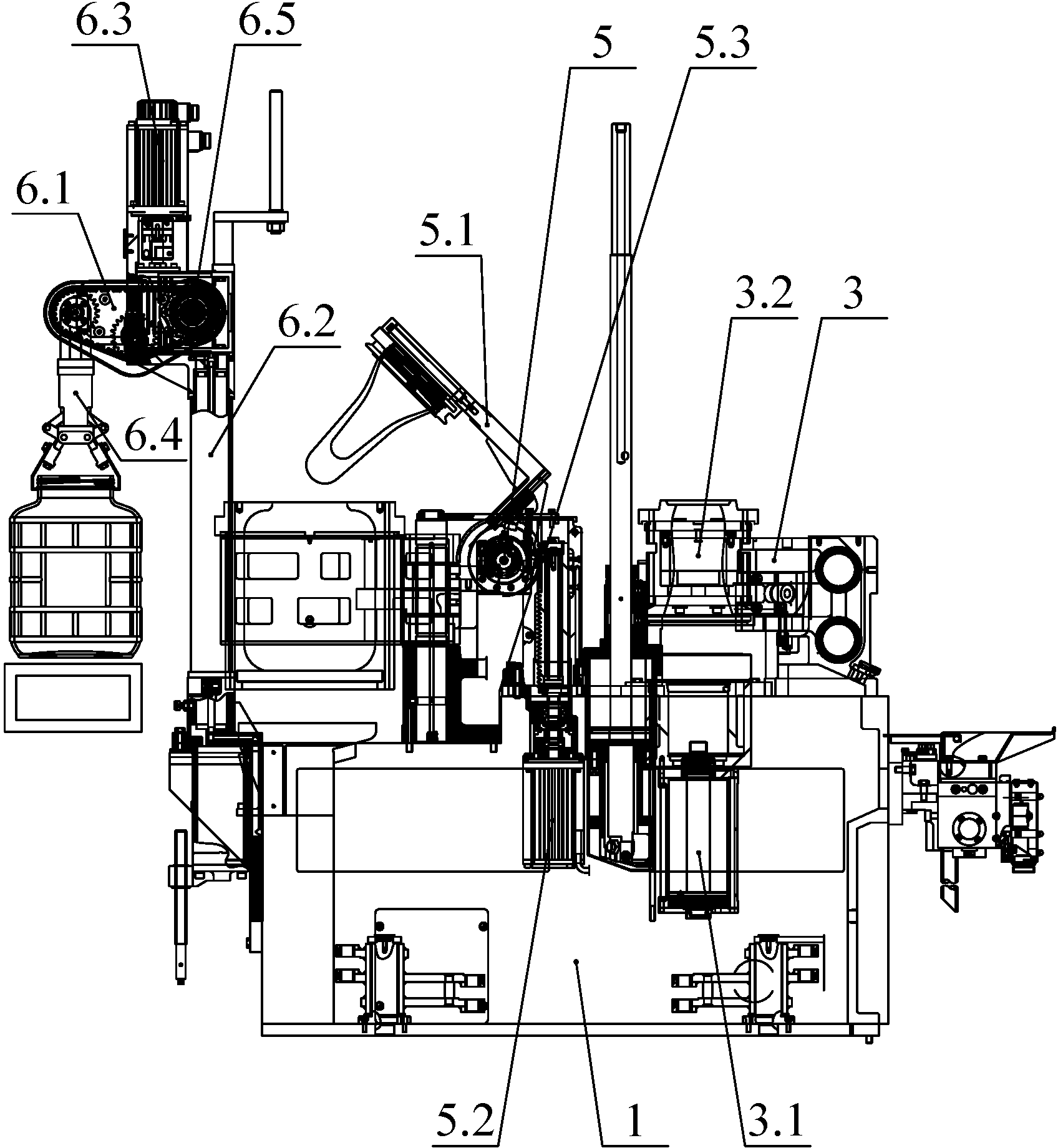

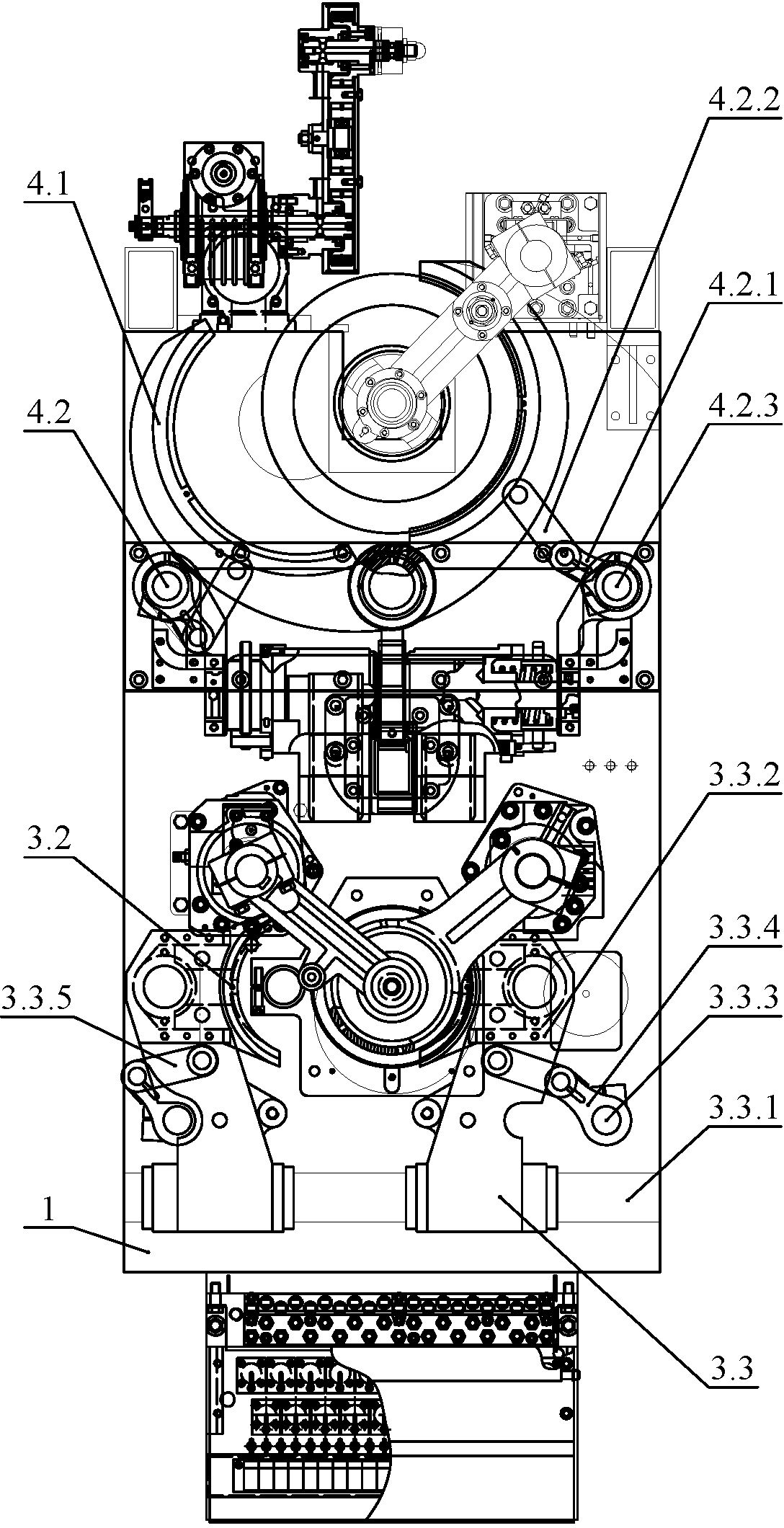

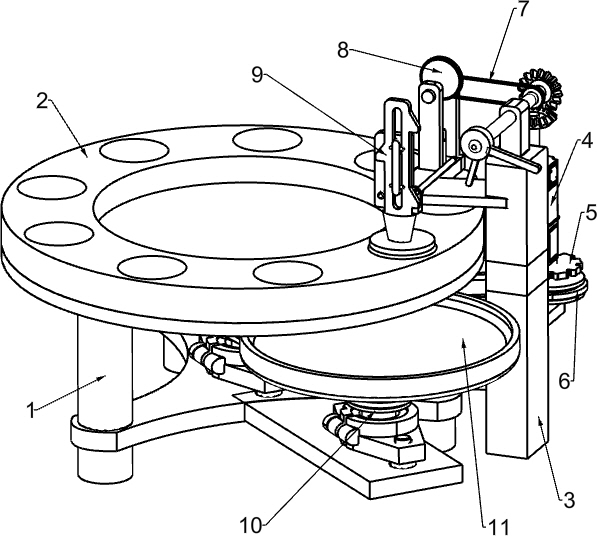

Automatic press fit machine of automobile shock absorber triple-linked part and automatic control method thereof

ActiveCN106112521ARealize continuous automatic pressingHigh speedAssembly machinesVehicle componentsAutomatic controlCoupling

The invention relates to an automatic press fit machine of an automobile shock absorber triple-linked part. The automatic press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a variable-frequency and variable-speed motor, a station rotary disc, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies embedded on the stations are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with the variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the pneumatic press fit mechanism, the pneumatic mechanical hand and the collection box are fixedly mounted on the working surface, corresponding to the stations, on the station rotary disc. The automatic press fit machine cooperates with an automatic control method to achieve continuous automatic press fit of the triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation is easy and convenient, the operation time is shortened, the press fit accuracy is high, the action is reliable, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

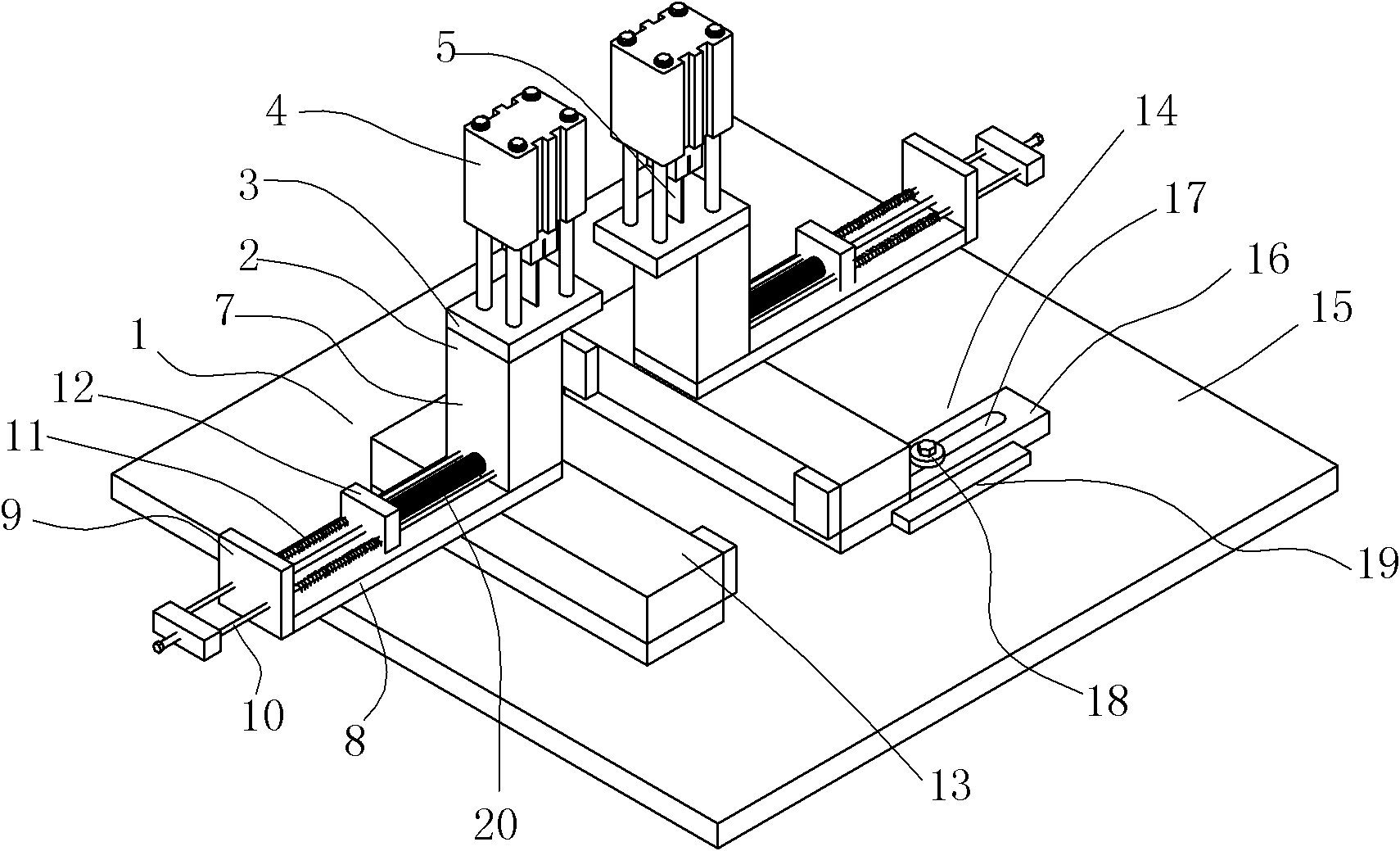

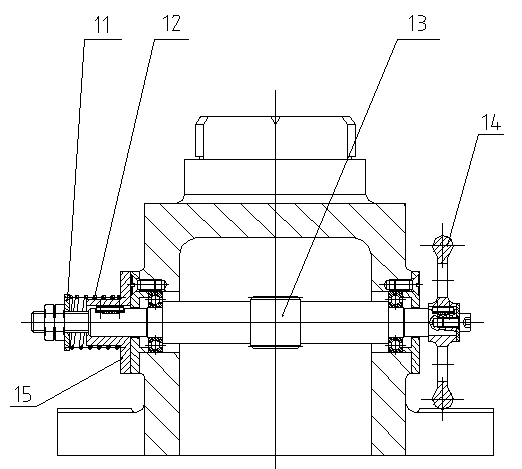

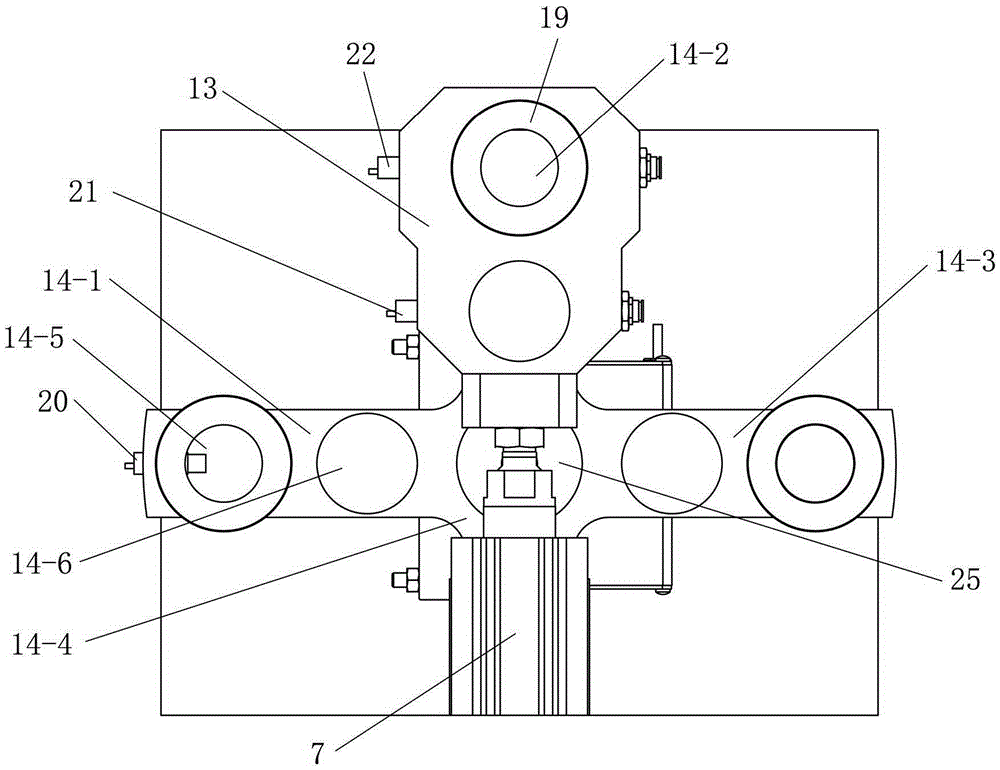

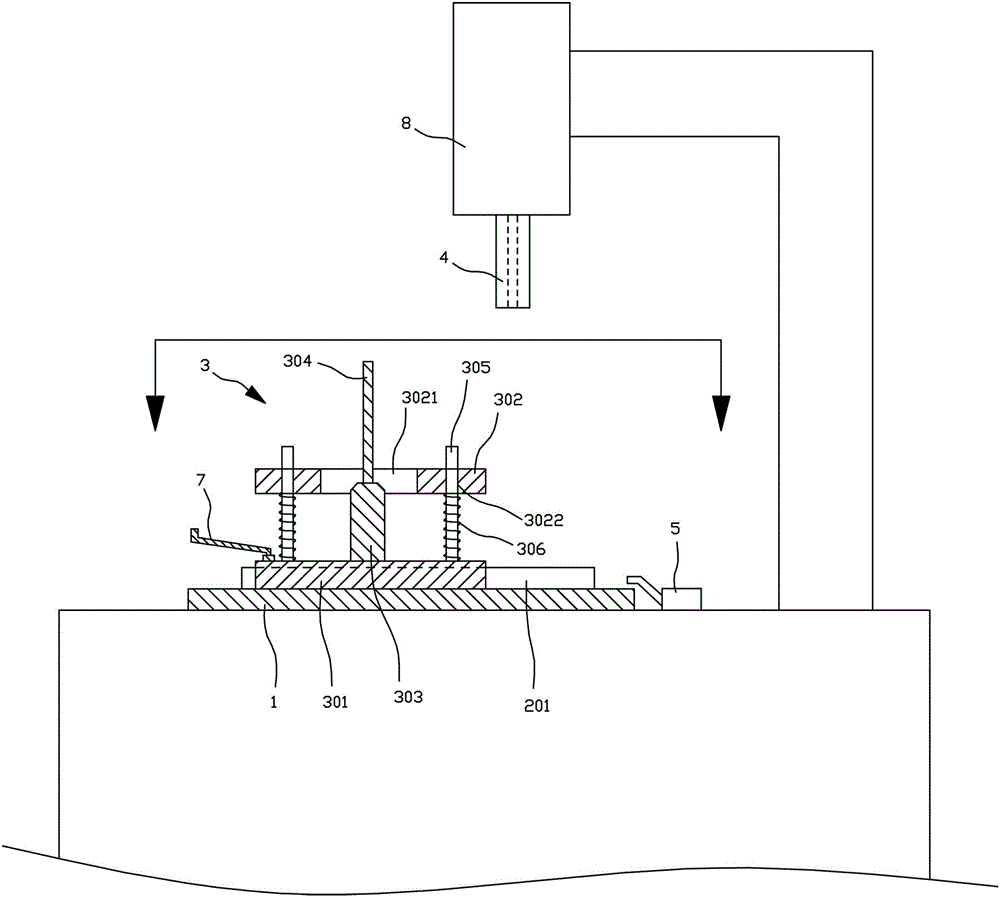

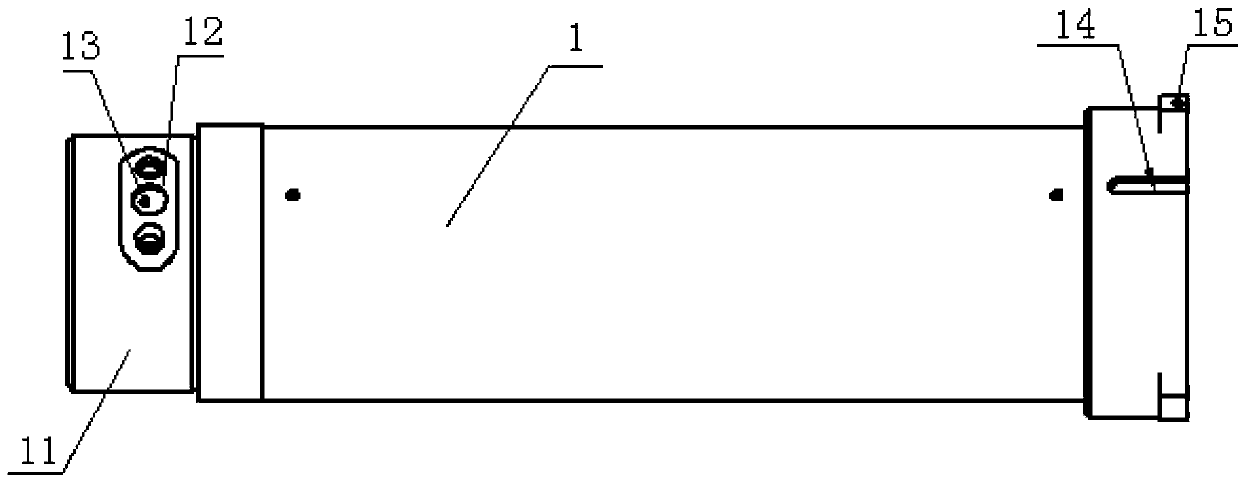

Bearing press-fitting device

InactiveCN103949872AImprove pressing efficiencyStable press fitMetal working apparatusMetal-working hand toolsPunchingEngineering

The invention discloses a bearing press-fitting device, comprising a workbench (1), wherein a slideway (2) is arranged on the workbench (1) and is internally provided with a base (3) capable of sliding along the slideway (2), a punching head (4) and a power device for driving the punching head (4) to act are arranged above the slideway (2), the rear end of the slideway (2) is provided with a limiting block (9) for limiting the position of the base (3) and a micro switch (5) for controlling the power device to be started, the base (3) comprises a lower supporting plate (301) and an upper supporting plate (302), and a balance buffer mechanism is arranged between the upper supporting plate (302) and the lower supporting plate (301). The press-fitting efficiency is relatively high, and the position of an enclosure can be automatically adjusted for enabling the enclosure to be horizontally placed in a bearing press-fitting process.

Owner:NINGBO LIONBALL VENTILATOR

Press fitting device of cam shaft bush of diesel engine

The invention discloses a press fitting device of a cam shaft bush of a diesel engine. The press fitting device comprises a compression bar and a limiting stick. A bush inserting head is arranged at one end of the compression bar, pressing blocks are arranged on the side face of the bush inserting head, a bush pre-positioning spring steel ball mechanism is arranged inside each pressing block, and backstop protrusions which protrude in the radial direction are arranged at the other end of the compression bar. A guiding groove is formed in the axial direction of the side face of the compression bar, and the guiding groove and steel balls of the bush pre-positioning spring steel ball mechanisms are placed in the same circumferential generatrix position of the compression bar. The limiting stick penetrates into an oblique oil hole from the position above a first gear of a cam shaft hole and falls into the guiding groove of the compression bar, and the circumferential position of the compression bar in the cam shaft hole is positioned so that the oblique oil hole can right face towards the guiding groove. When the press fitting device of the cam shaft bush of the diesel engine is used for press fitting of the cam shaft bush, the compression bar is made to directly penetrate into the cam shaft hole, meanwhile, the limiting stick penetrates into the oblique oil hole which communicates a spindle hole and the cam shaft hole from the position above the spindle hole, and the limiting stick is inserted into the guiding groove of the compression bar so that the compression bar can be positioned in the circumferential direction. Positioning operation is simple, precision is high, and press fitting efficiency is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

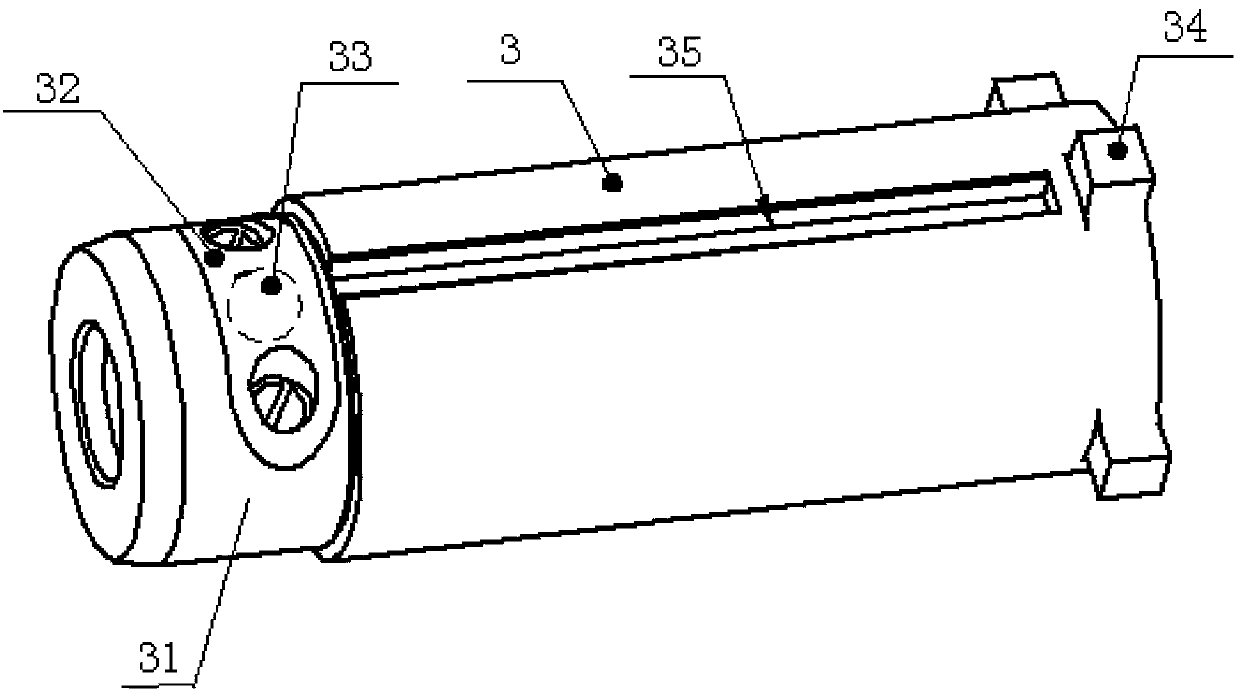

Press-fitting tool and press-fitting method

ActiveCN103475168AAchieve positioningAvoid misalignmentManufacturing stator/rotor bodiesPunchingEngineering

The invention provides a press-fitting tool which is used for press-fitting fan-shaped punching sheets of a skewed slot stator core and comprises a stator bracket and at least one skewed slot positioning device, wherein the skewed slot positioning devices are installed on the stator bracket and are matched with a skewed slot of a stator core to be press-fitted. When the fan-shaped punching sheets are press-fitted, the skewed slot positioning devices are used for positioning the fan-shaped punching sheets. Accordingly, the invention further provides a press-fitting method. With the press-fitting tool and the press-fitting method, the laminating precision of the skewed slot fan-shaped punching sheets and the press-fitting efficiency can be improved.

Owner:北京三一智能电机有限公司

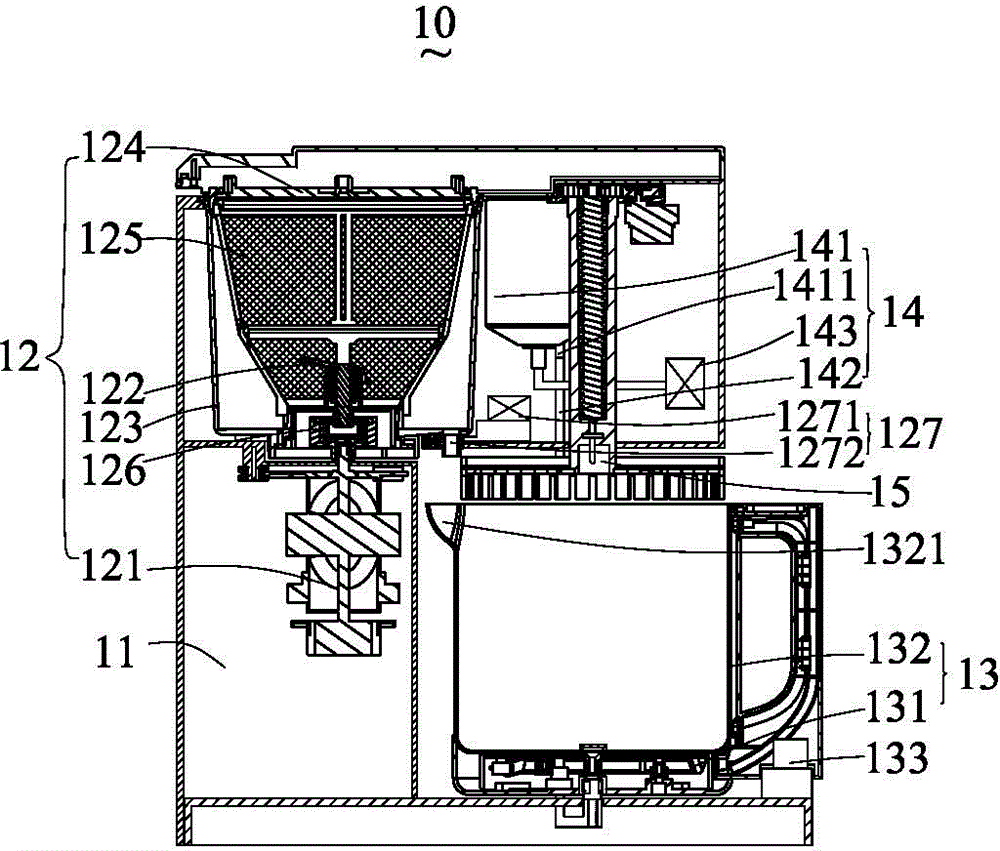

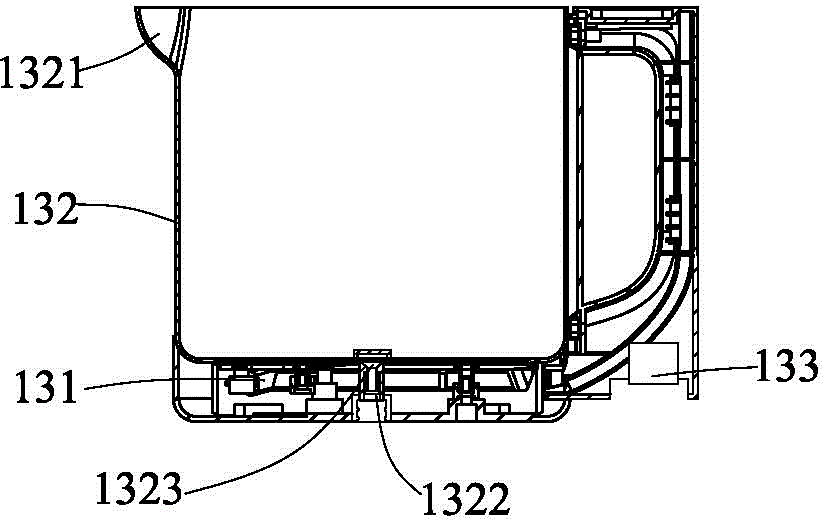

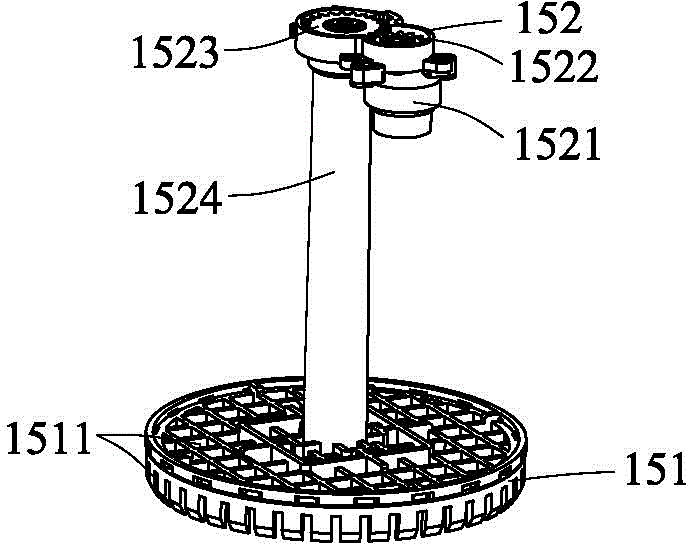

Technology for preparing bean curd/uncongealed bean curd by virtue of household bean curd machine

ActiveCN104642558ALong storage timeSimple structureCheese manufactureFood scienceElectric machinerySlurry

The invention relates to a technology for preparing bean curd / uncongealed bean curd by virtue of a household bean curd machine. The technology comprises the following steps: (a) in a crushing stage, adding water and materials to a crushing cup, wherein the motor drives a crushing tool to rotate and crush the materials into slurry, and the crushed slurry is filtered through a filter and then is discharged into a slurry boiling cup; (2) in a slurry boiling stage, heating the slurry in the slurry boiling cup by virtue of a heating element until the slurry is cooked, and cooling the slurry to a certain temperature; (c) in a marinating and solidifying stage, discharging the a marinating agent in a marinating box into the slurry boiling cup, marinating and then standing for a certain period of time; and (d) in a pressing stage, driving a pressure plate to advance along the inner wall of the slurry boiling cup by a drive mechanism, infiltrating yellow serofluid into the position above the pressure plate through a drainage groove and / hole in the pressure plate, and forming the bean curd below the pressure plate. Therefore, water sealing is achieved above the bean curd to be isolated from air; the bean curd is prevented from being polluted by bacteria; the storage time of the bean curd is relatively long; and meanwhile, the yellow serofluid can also play a role in natural heat preservation.

Owner:JOYOUNG CO LTD

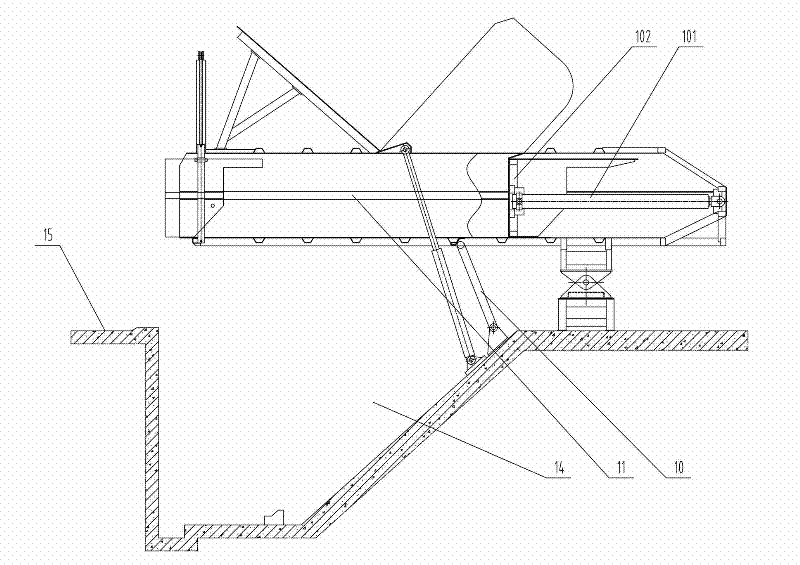

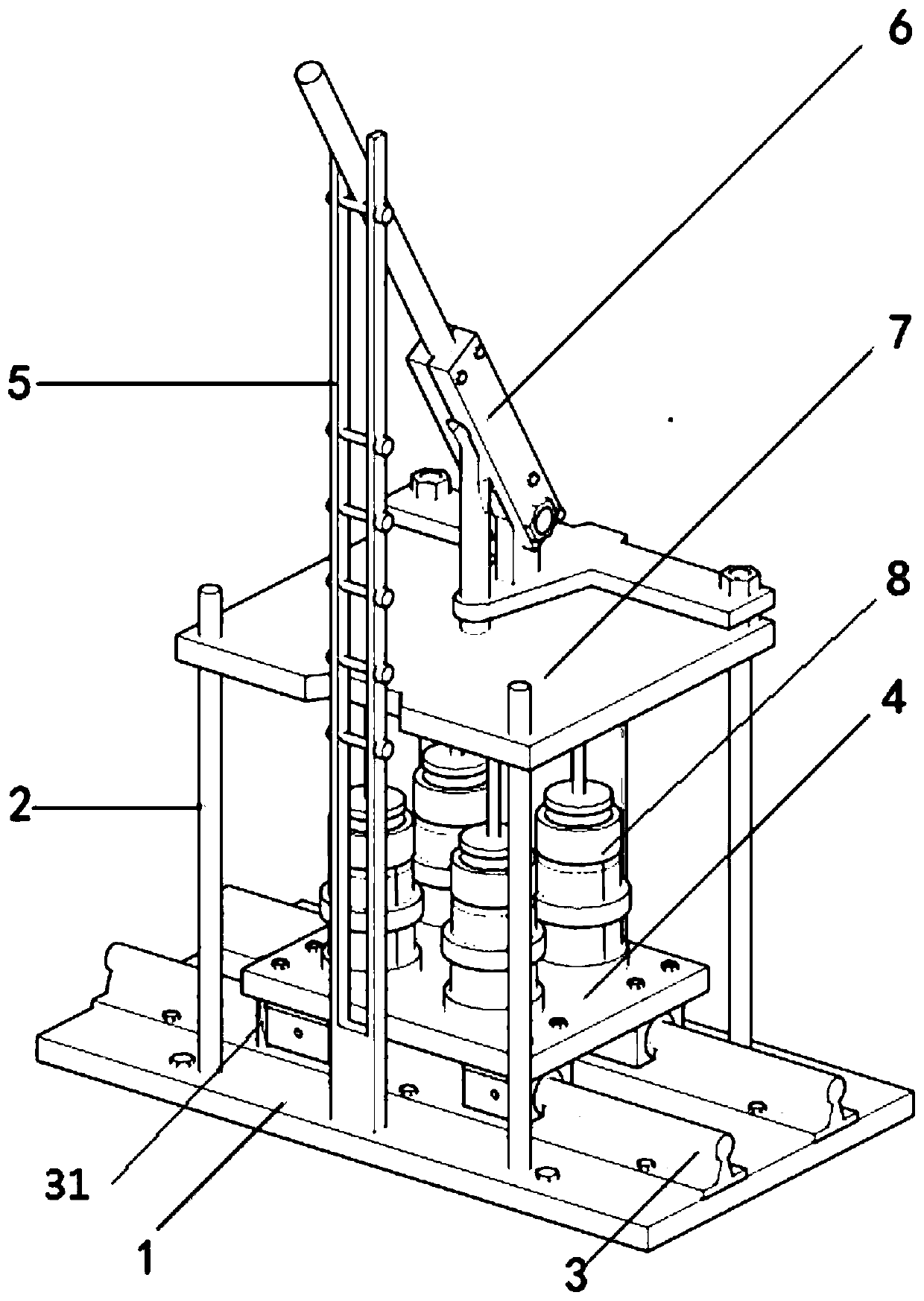

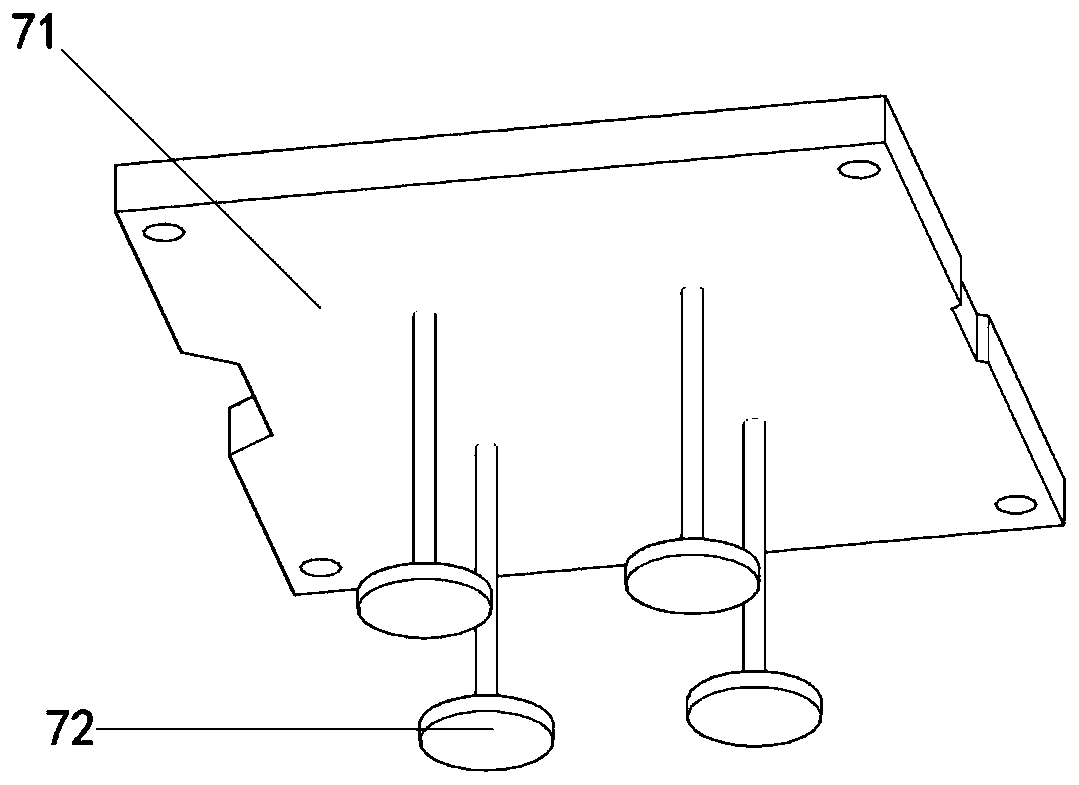

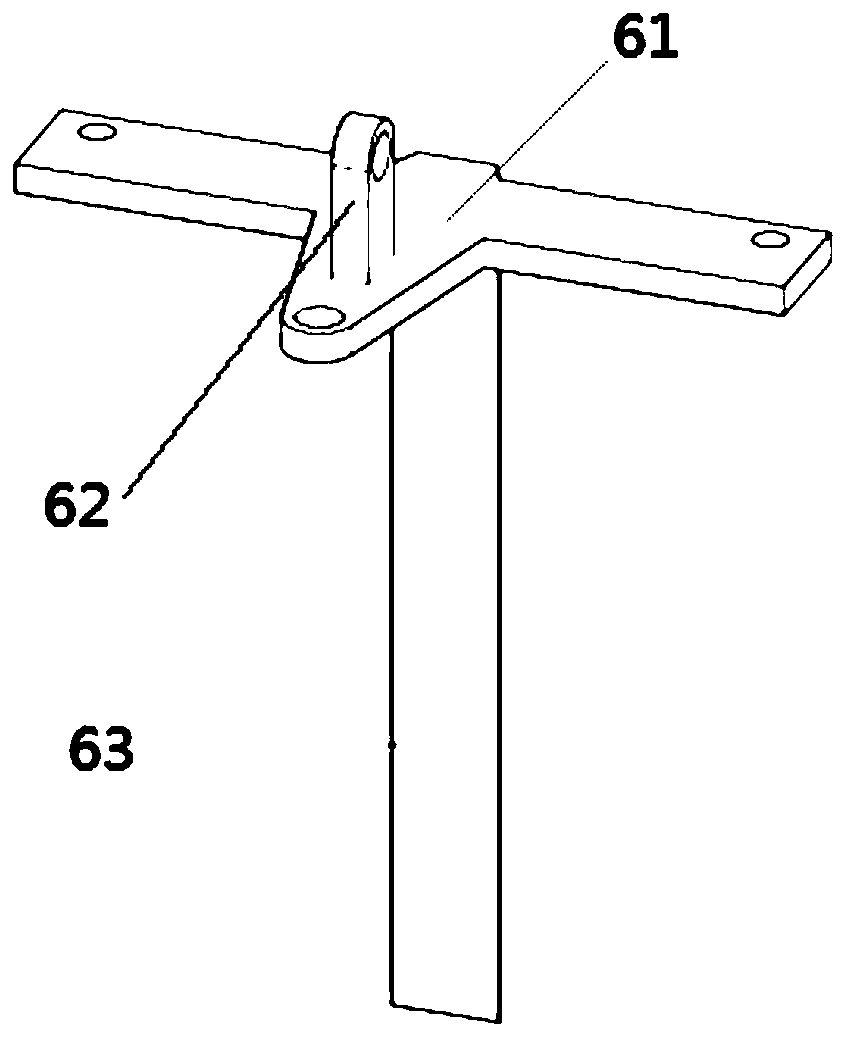

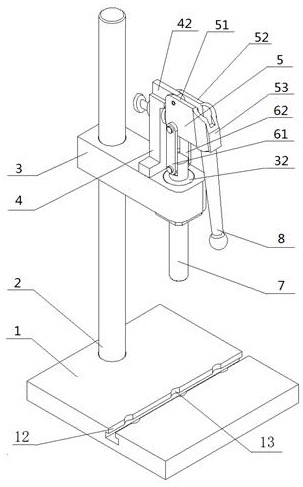

Lever-type sample preparation machine for disturbed soil triaxial compression test and sample preparation method thereof

PendingCN109916688AGuaranteed flatnessEasy to operatePreparing sample for investigationPunchingEngineering

The invention discloses a lever-type sample preparation machine for a disturbed soil triaxial compression test and a sample preparation method thereof. A sample preparation mold is fixed to a mold support plate. The mold support plate is fixed to the slider of a linear guide rail. The slider, the mold support plate and the sample preparation mold can be integrally detached from the guide rail multiple times in order to separately load various soil sample layers into the sample preparation mold. A lifting plate is connected with the push rod of a lever assembly. The force applying arm of the lever assembly rotates to lift or lower of a punch pin so that the punch pin compacts each soil sample layer in the sample preparation mold to a set thickness. The operation only requires to press downthe force applying arm manually. Multiple samples can be pressed at one time. The punching depth of the punch pin is controlled by a positioning frame to control the different heights of the force applying arm. The limit of the different heights of the positioning frame can be calculated in combination the size of the force applying arm and a motion track during sample preparation. The lifting plate is guided by a vertical pole when moving. The lever-type sample preparation machine can precisely control the thickness and flatness of the sample layers, has high sample preparation efficiency, and is simple in molding and demolding operation.

Owner:CENT SOUTH UNIV

Tengxian rice cake pressing device

The invention relates to a pressing device, in particular to a Tengxian rice cake pressing device. The technical problem is to provide a Tengxian rice cake pressing device which can automatically press rice cakes, collects prepared rice cakes, and reduces manual operations. According to the technical scheme the Tengxian rice cake pressing device comprises a base and a support frame, wherein the top part of the base is rotationally provided with a worktable; the top part of the worktable is evenly provided with a plurality of circular grooves for holding the rice cakes; the support frame is arranged on one side of the base; and the upper part of the side part of the support frame is provided with a dual-axis motor. According to the Tengxian rice cake pressing device, through an intermittentrotating mechanism, the worktable automatically rotates intermittently; without manually replacing and taking the rice cakes repeatedly during pressing, through a pressing mechanism, automation of rice cake pressing is realized, manual operation steps are reduced, and the efficiency of rice cake pressing is increased; and through a poking mechanism, after being pressed, the rice cakes on the worktable can automatically separate from the worktable without manually taking out the rice cakes.

Owner:董永辉

Height-adjustable air dryer bushing press-fitting device

ActiveCN112109038AImprove assembly efficiencySimple structureMetal-working hand toolsClassical mechanicsStructural engineering

A height-adjustable air dryer bushing press-fitting device comprises a bottom plate base, a height support, a guide connecting plate, a supporting support, a turnover pressing plate, a press-down connecting rod, a movable pressing rod and a handle, wherein one end of the guide connecting plate is perpendicularly connected with the middle of the height support, the other end of the guide connectingplate is in sliding fit with the movable pressing rod, the supporting support is arranged at the top of the guide connecting plate, the turnover pressing plate is arranged at one side of the supporting support, one end of the turnover pressing plate is in rotating fit with the top of the supporting support, the other end of the turnover pressing plate is in rotating fit with the top of the press-down connecting rod, the bottom of the press-down connecting rod is in rotating fit with the top of the movable pressing rod, a limiting bolt in limiting fit with the turnover pressing plate is arranged on the supporting base, and the handle is further fixed to the turnover pressing plate. According to the design, the device is simple in structure and convenient to operate, the press-fitting depthcan be adjusted through the limiting bolt, and the consistency of press-fitting products can be guaranteed.

Owner:DONGFENG AUTOMOBILE COMPANY

Pressing equipment

ActiveCN104999767AImprove pressing efficiencySame structureLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses pressing equipment which comprises a frame, a roller conveying rail, a carrier and a front end pressing station, wherein the front end pressing station comprises pressing plates driven by pressing air cylinders, lifting plates driven by lifting air cylinders and drag hook devices. After the carrier is supported by the lifting plates, the drag hook devices positions the carrier and panels on the carrier is pressed by virtue of the pressing plates. By adopting the technical scheme, the lifting air cylinders matched with the lifting plates are just tools for lifting the carrier and the tools for supporting the carrier are the drag hook devices. According to the design, in a pressing process, a first lifting air cylinder can be prevented from being impacted by a huge pressing force. According to the technical scheme, when the panels are pressed, the pressing plates press the panels on the carrier together at a stroke, so that the panels are prevented from being warped in the pressing process and the purpose of pressing the panels smoothly is realized.

Owner:JIANGSU GOLD IRON MAN AUTOMATION TECH

Method for veneer reeling machine pressed-steel ladder rung

InactiveCN103350131AImprove the quality of pressing processReduce stepping anglesEngineeringAngle alpha

The invention discloses a method for a veneer reeling machine pressed-steel ladder rung. The method can improve the quality of the pressed-steel ladder rung and reduce corner angles of the pressed-steel ladder rung. The method includes the following steps that a first fixing plate and a second fixing plate are manufactured and installed on a base plate, a material plate is installed between the first fixing plate and the second fixing plate on the base plate, the position of the material plate is adjusted, an angle alpha is formed between the material plate and the base plate, then the material plate is sent into a veneer reeling machine, a bent edge of the material plate is bent for the angle alpha, the material plate is taken out, the bent edge is vertically installed between the first fixing plate and the second fixing plate, a blocking plate is added between the first fixing plate and the second fixing plate so as to enable the bent edge to be clamped through the first fixing plate and the second fixing plate, the material plate is sent into the veneer reeling machine once again to be bent for the second time to enable the bent edge to be vertical to the material plate, the material plate is taken out and serves as one end to be installed on the base plate, the steps are repeated, and thus an N-shaped pressed-steel ladder rung or a Z-shaped pressed-steel ladder rung is obtained. By the adoption of the method, labor investment can be reduced, work efficiency is improved, and production cost is saved.

Owner:SICHUAN NO 3 ELECTRIC POWER CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com