Press fitting mechanism

A press-fitting and clamping technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of multi-manpower, easy wrong installation, and reduced press-fitting efficiency of magnetic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

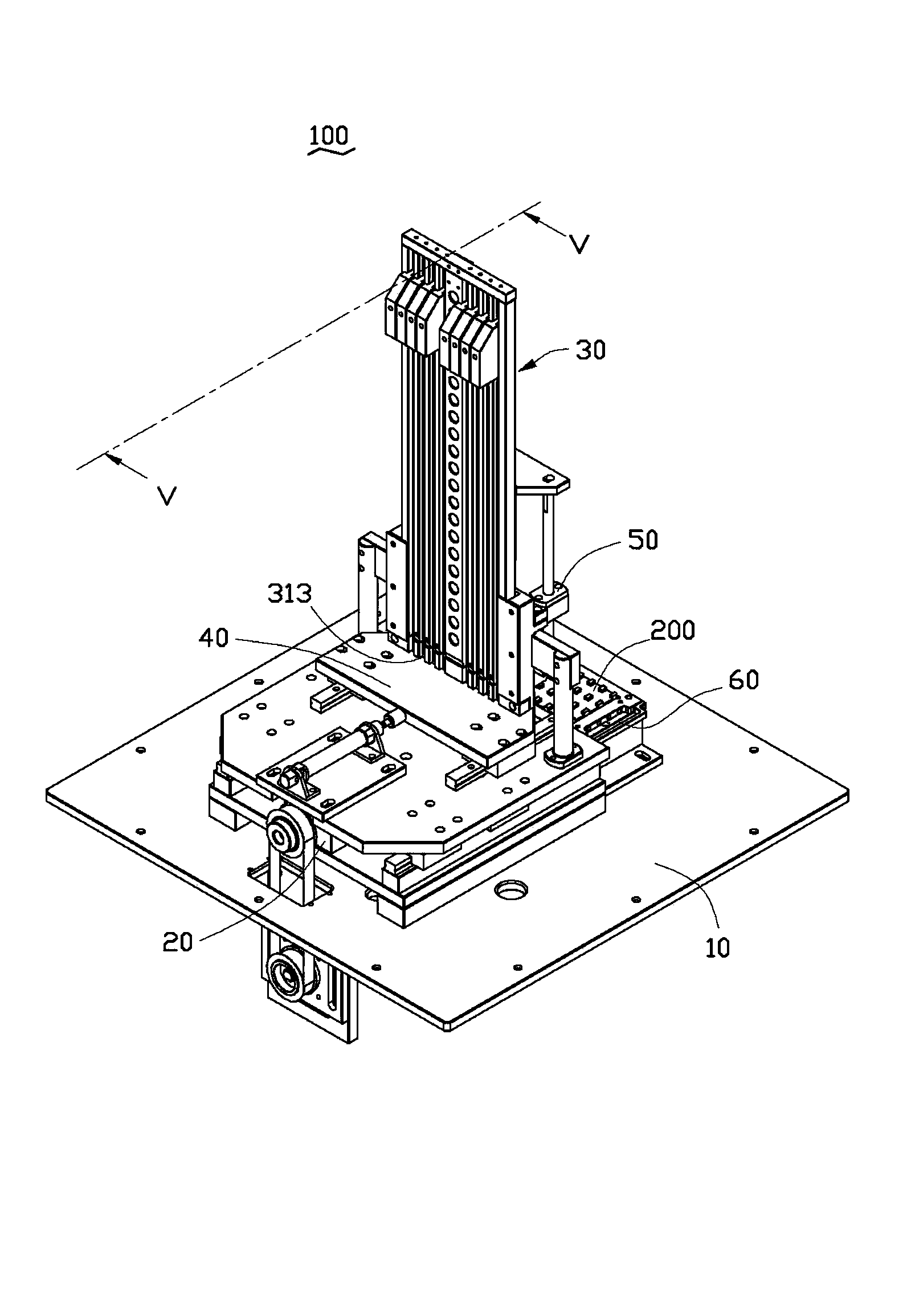

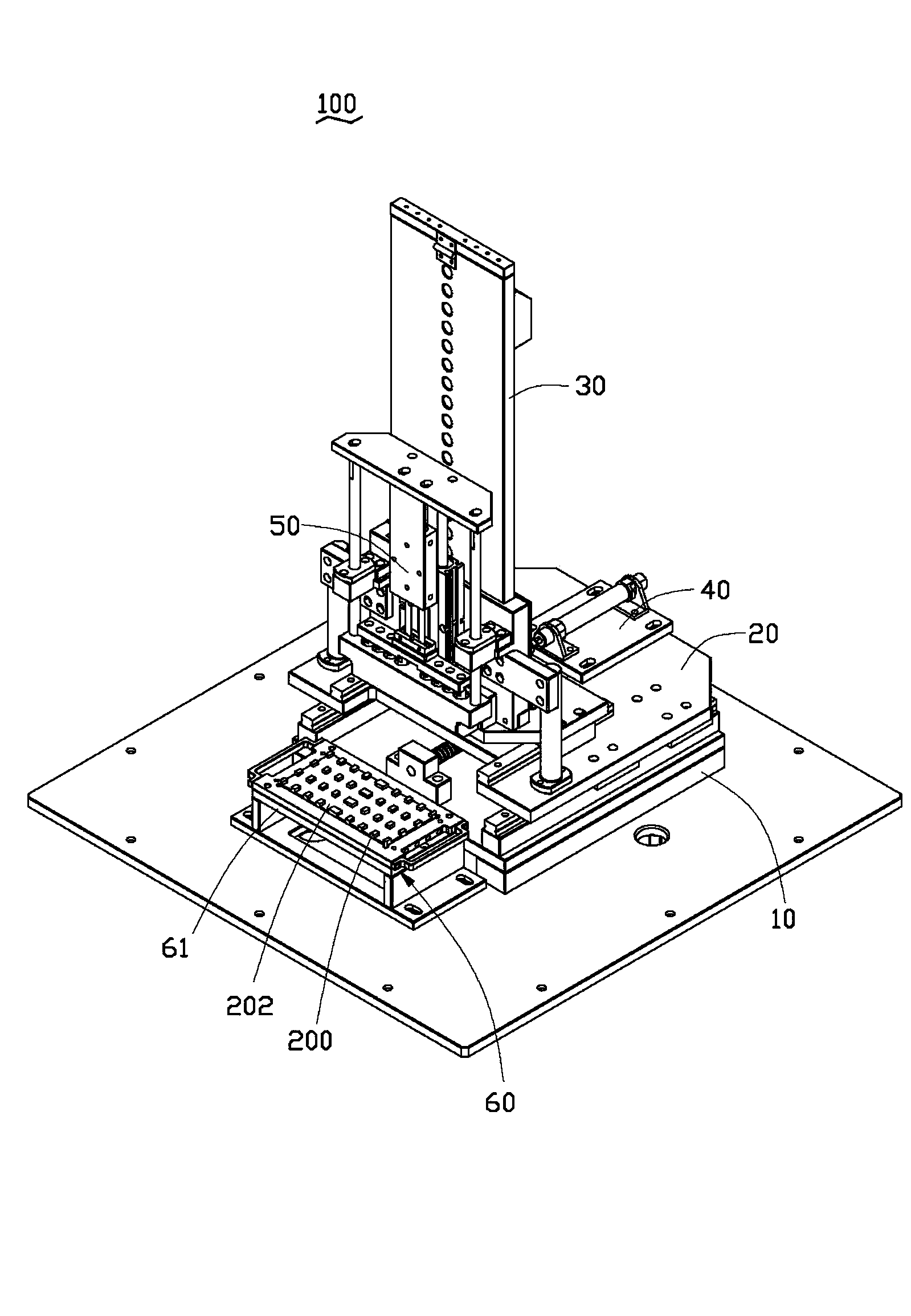

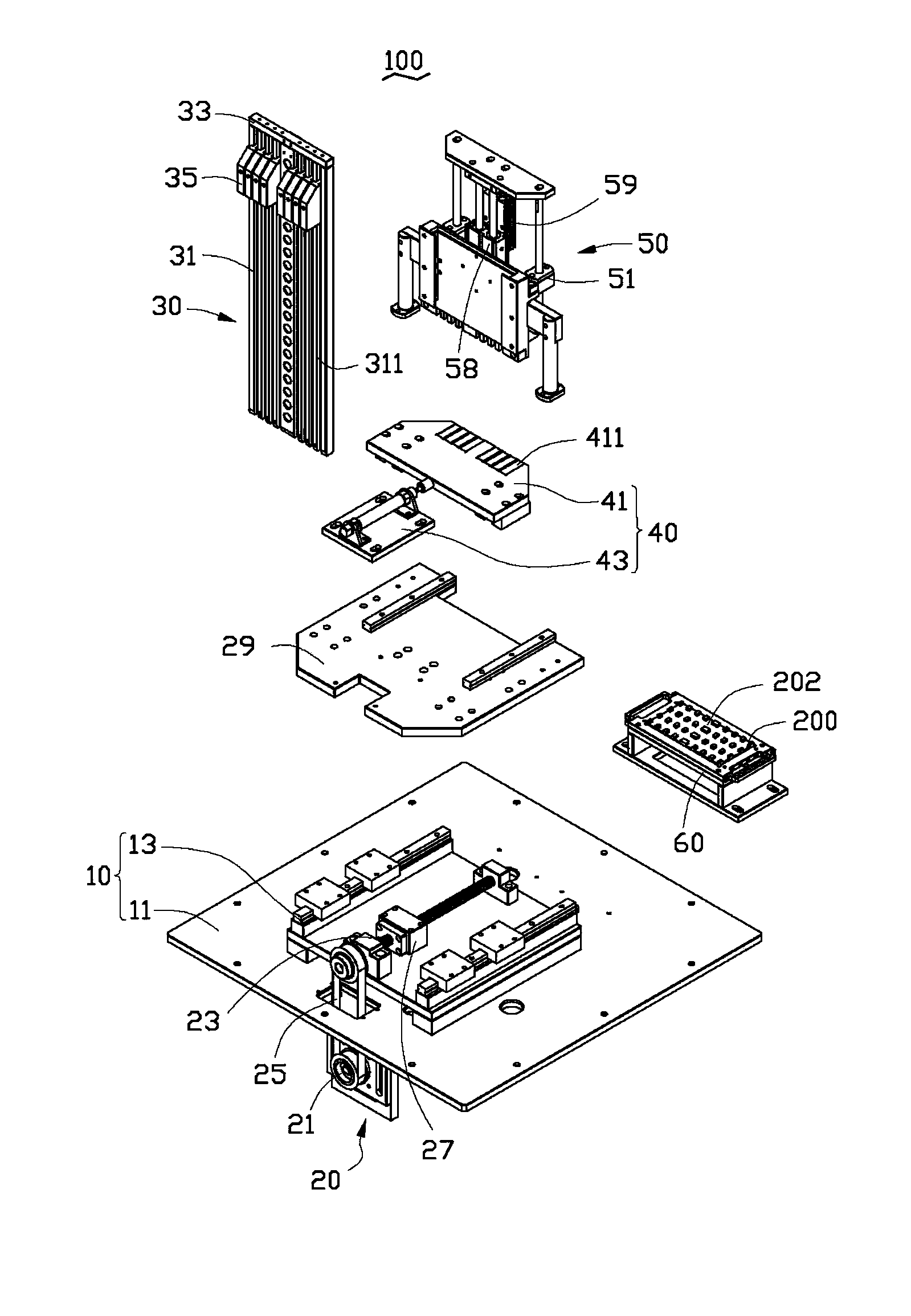

[0015] see figure 1 and figure 2 , the press-fit mechanism 100 of the present invention is used to press-fit magnets (not shown) arranged in a row with one positive and one negative in the receiving portion 202 of the workpiece 200 . The pressing mechanism 100 includes a base 10 , a conveying component 20 , a clamping component 30 , a pushing component 40 , a pressing component 50 and an absorbing component 60 . The transmission assembly 20 is installed on the base 10, the clamping assembly 30 is adjacent to the pushing assembly 40 and is installed on the transmission assembly 20, the pressing assembly 50 is installed on the transmission assembly 20 and faces away from the clamping assembly 30, and is in The side opposite to the pushing assembly 40 . The adsorption component 60 is installed on the base 10 and located below the press-fit component 50 . The clamping assembly 30 is used to move the magnet to the transmission assembly 20 and pull the magnet away from the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com