High-precision servo press fitting method based on computer

A computer, high-precision technology, used in presses, manufacturing tools, etc., can solve problems such as low stability, weakening of servo press machining accuracy and quality control, and inaccurate pressure acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

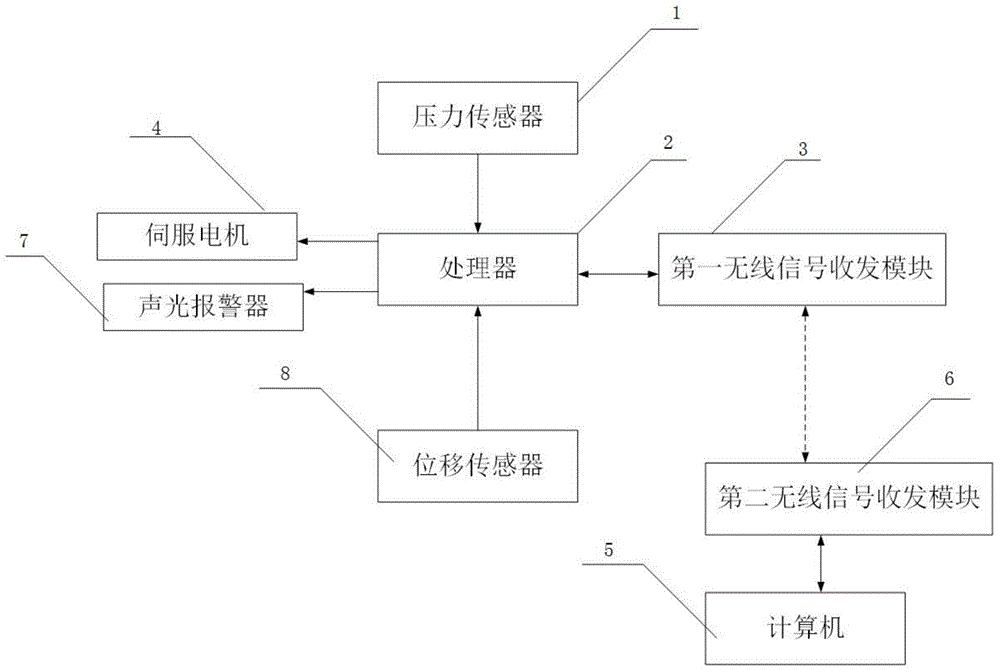

[0031] Such as figure 1 As shown, a computer-based press elastically deformable workpiece pressing system includes a pressure sensor 1 arranged under the pressure bar of the numerical control press, and the output end of the pressure sensor 1 is connected to the first signal input end of the processor 2; The second input end of the processor 2 is connected with the output end of the displacement sensor 8; the processor 2 is bidirectionally connected to the first wireless signal transceiver module 3; the first wireless signal transceiver module 3 is connected to the second wireless signal transceiver module 6 Carry out data transmission by wireless signal, described second wireless signal transceiving module 6 two-way connection computer 5; The first signal output end of described processor 2 is connected the control signal input end of servo motor 4; The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com