Patents

Literature

492 results about "Servo press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

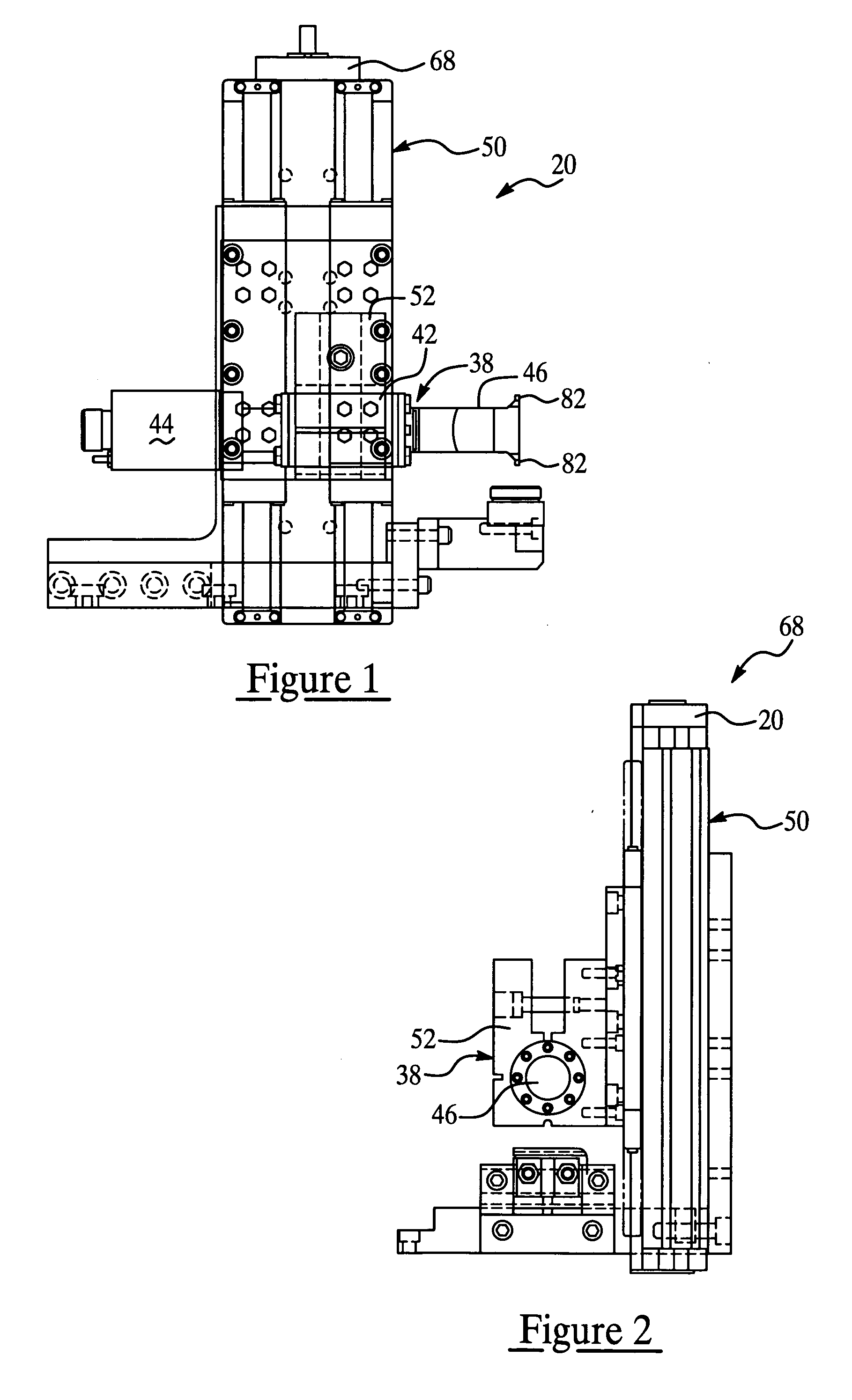

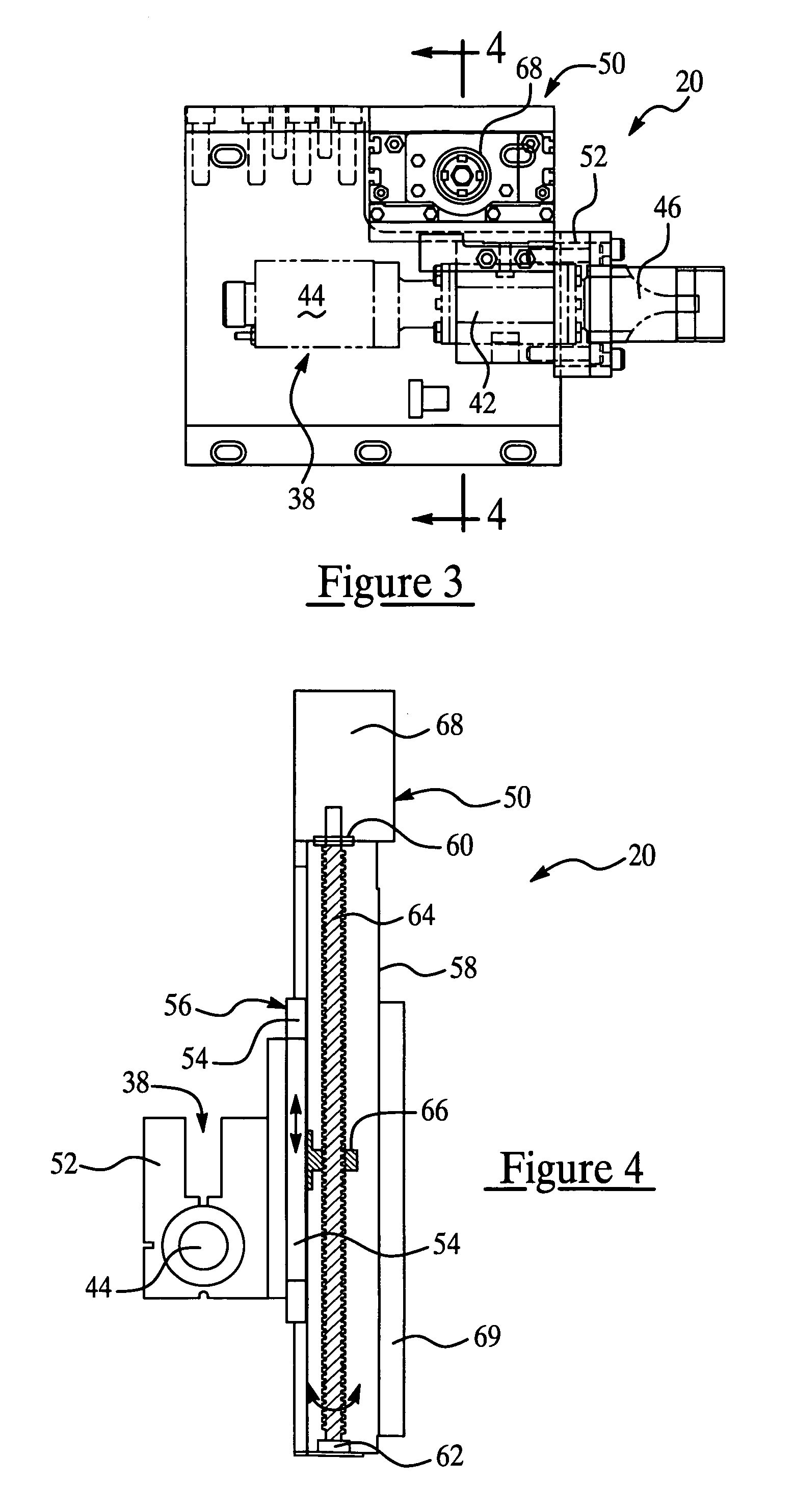

The Promess Servo Press is a programmable motion controlled ball screw press with integrated motion control and monitoring. The Work Station provides a fully mobile and readily accessible, customized foundation for assembly, test, and lab applications.

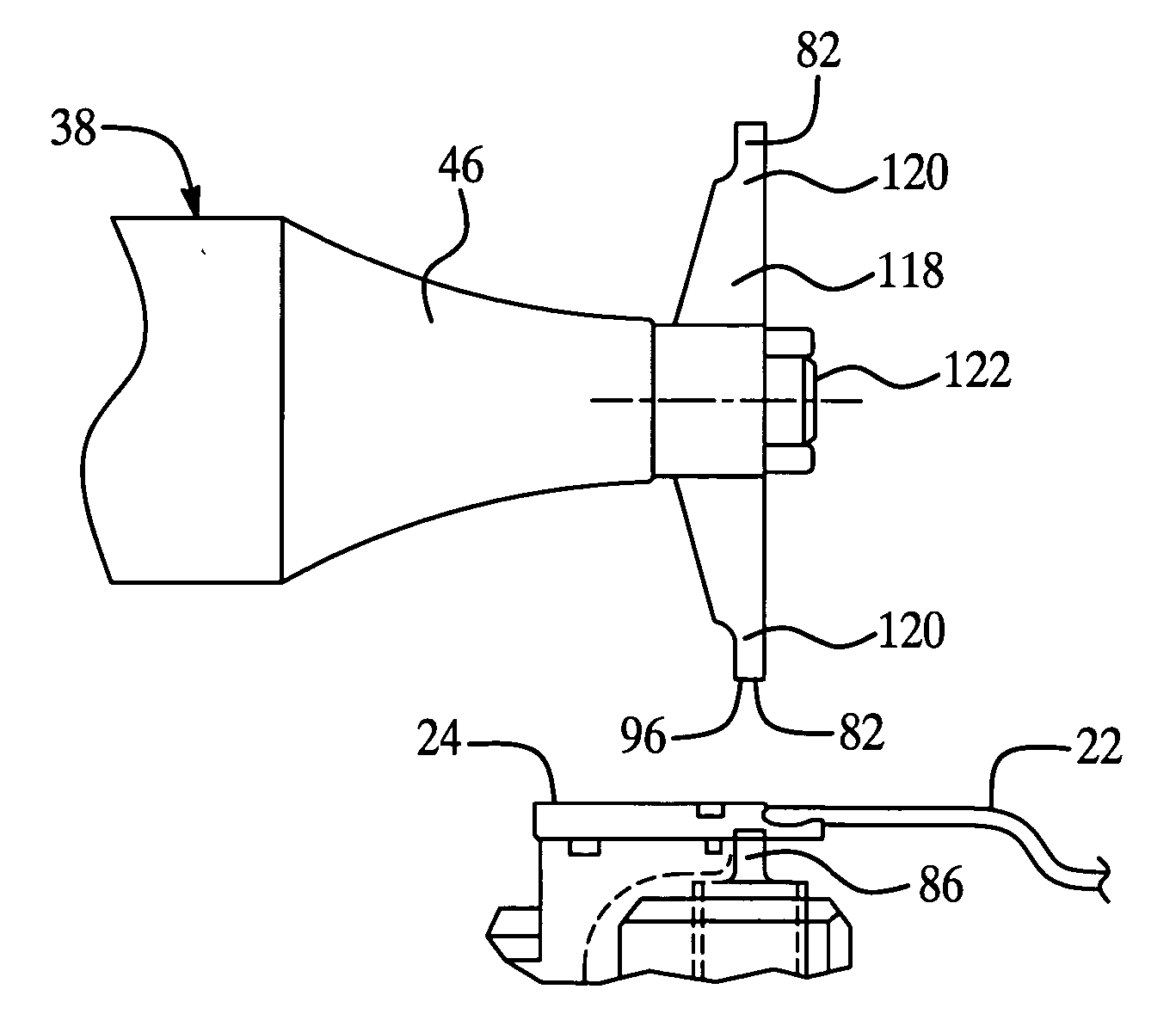

Ultrasonic welding system

InactiveUS20070068991A1Highly versatileRobust systemElectrically conductive connectionsWelding/cutting auxillary devicesUltrasonic weldingTransducer

The present invention is an ultrasonic welding system having an ultrasonic welder integrated with a servo press for galling and ultrasonic welding of a first workpiece to a second workpiece. The first and second workpieces are substantially disposed between a confronting tip and stationary anvil of the ultrasonic welder. Prior to welding, the servo press preferably quickly moves the tip toward and generally against the first workpiece. During welding, a variable speed motor of the servo press preferably slowly moves the tip toward the anvil compressing the workpieces together while a transducer of the ultrasonic welder transmits mechanical vibration to the tip for welding the workpieces together.

Owner:DELPHI TECH INC

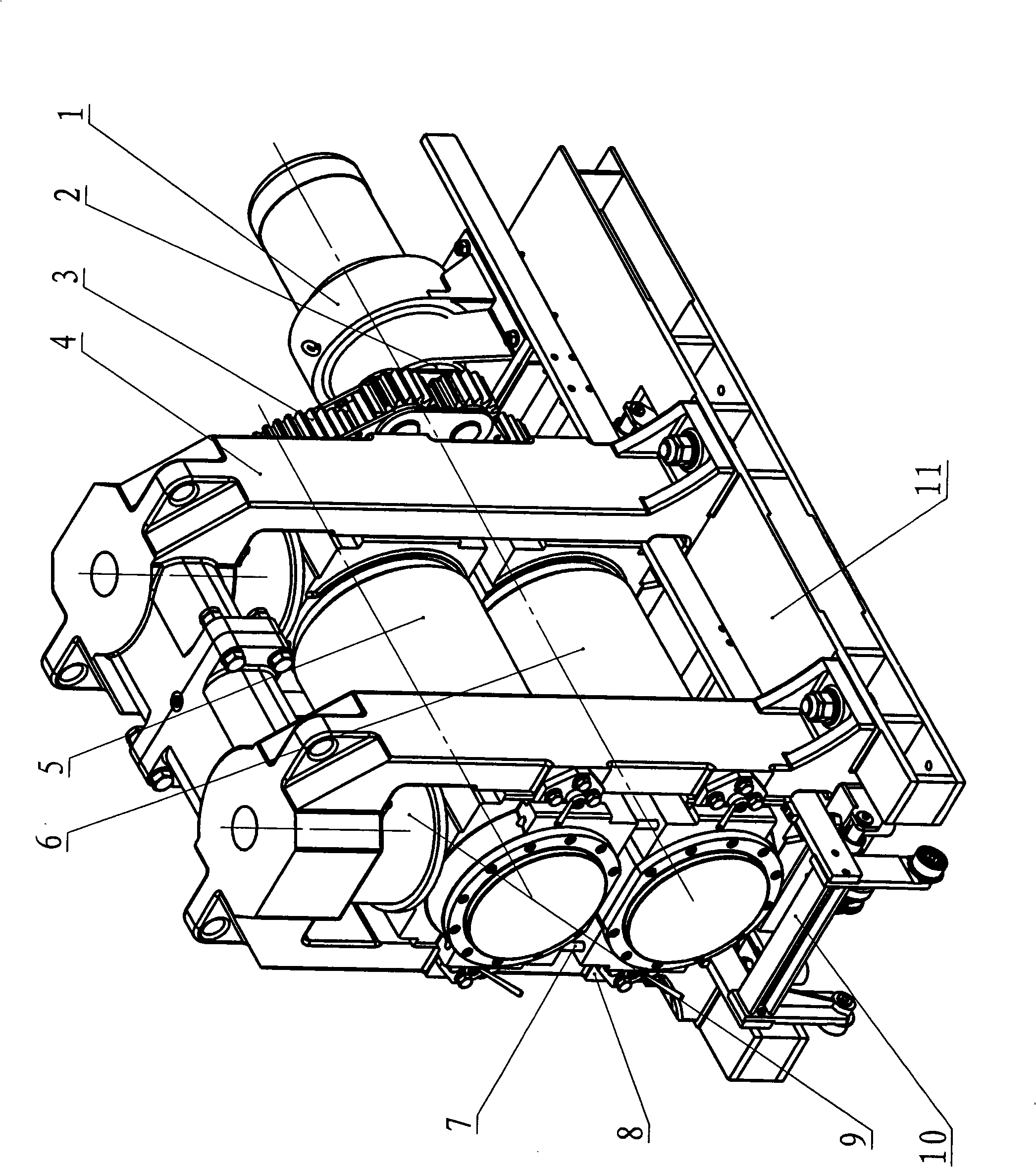

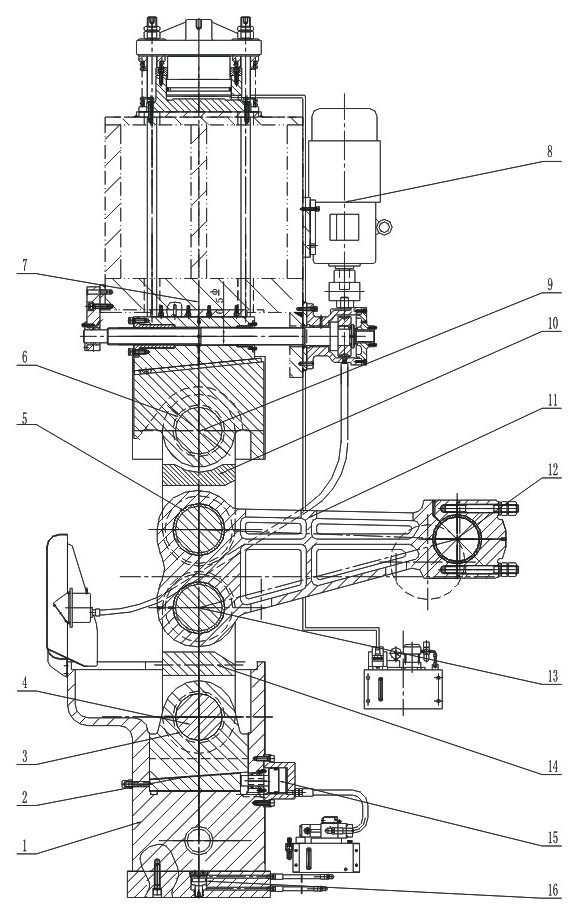

Strip mill of thin film

InactiveCN101347791AEfficient and stable productionEasy to change rollsMetal rolling stand detailsRolling mill drivesAutomatic controlEngineering

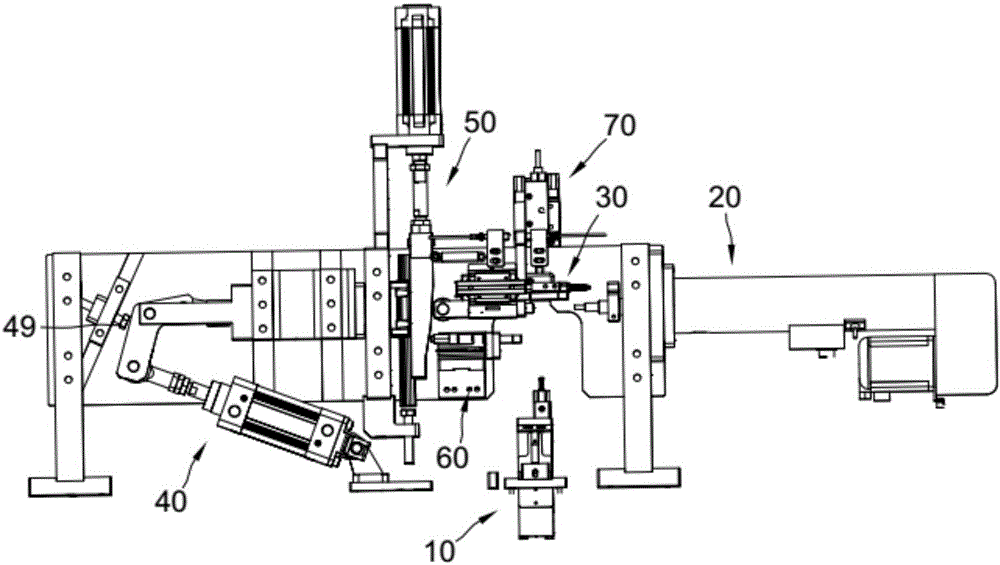

The invention provides a film band and strip rolling mill, consisting of a motor-reducer device, an elastic pin coupling device, a balance symmetric gear transmission device, a front stander device and a rear stander device, a lower roller system device, an upper roller system device, a roller system bearing radial windage eliminating device, a left baffle device of a roller, a right baffle device of the roller, an electro-hydraulic servo press-down device, a roller changing device and a base; the film band and strip rolling mill is characterized in that the size of the roller seam can be automatically controlled by adopting an electro-hydraulic servo control technology, thus stably producing battery electrodes which meet the quality standard without compressing air source from external part; meanwhile, the developed balance symmetric transmission device, the roller system bearing radial windage eliminating device, the roller left baffle device, the roller right baffle device and the roller changing device lead the adjustment and maintenance of the rolling mill to be simple and convenient, The invention is an ideal film band and strip rolling mill which has the advantages of improving the precision of battery electrodes, improving the productivity of the rolling mill and overcoming the shortages of the prior art.

Owner:张清

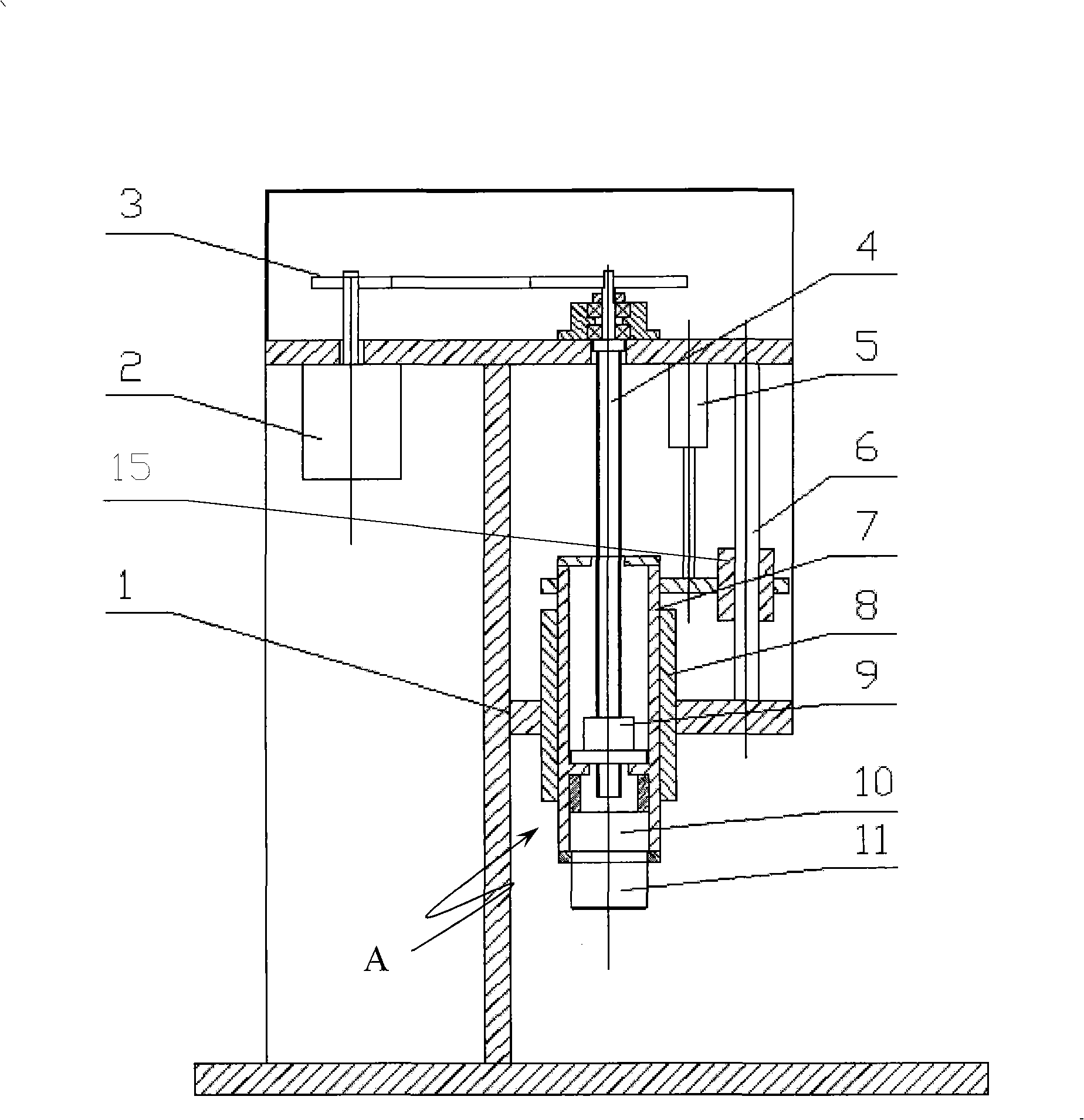

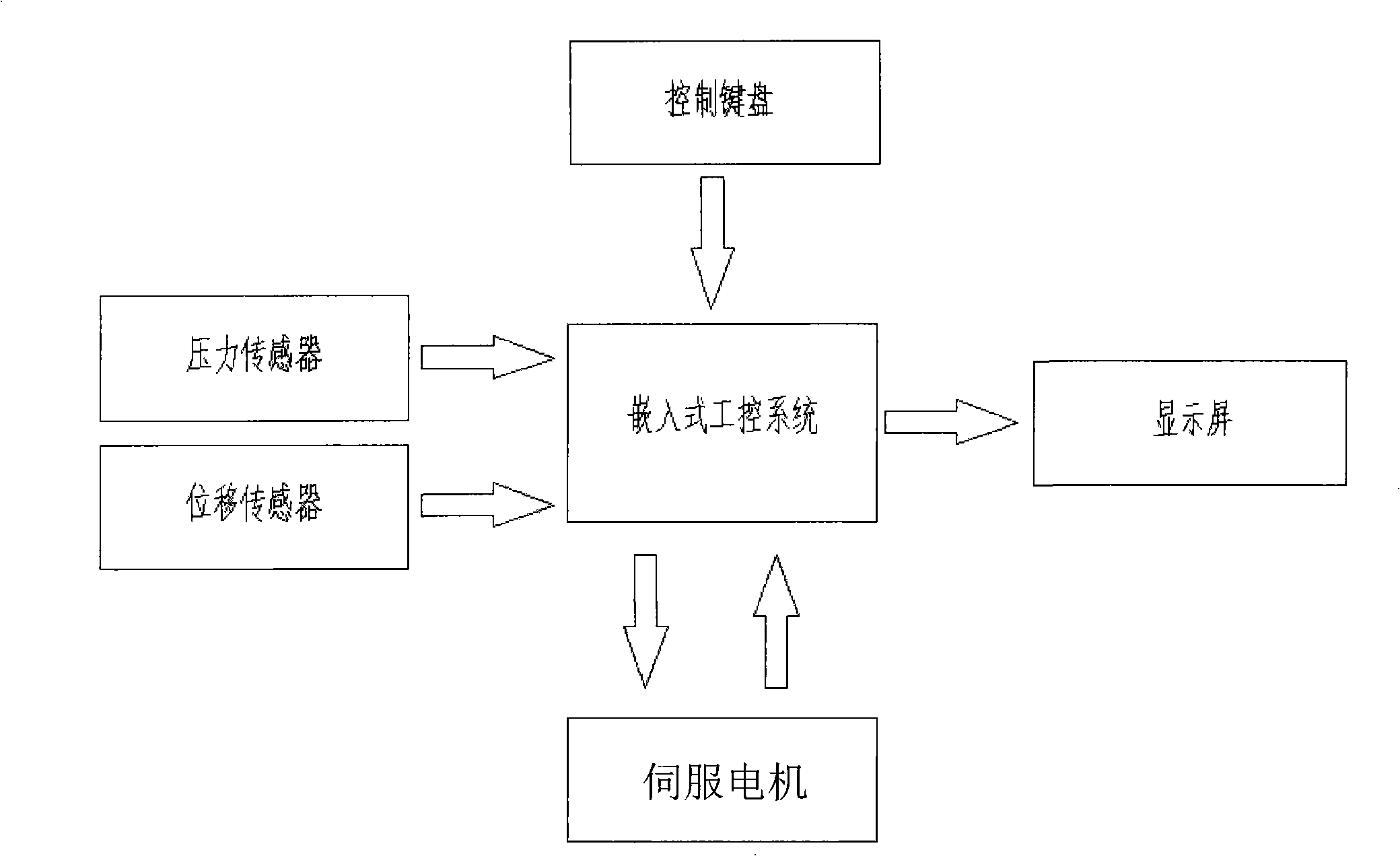

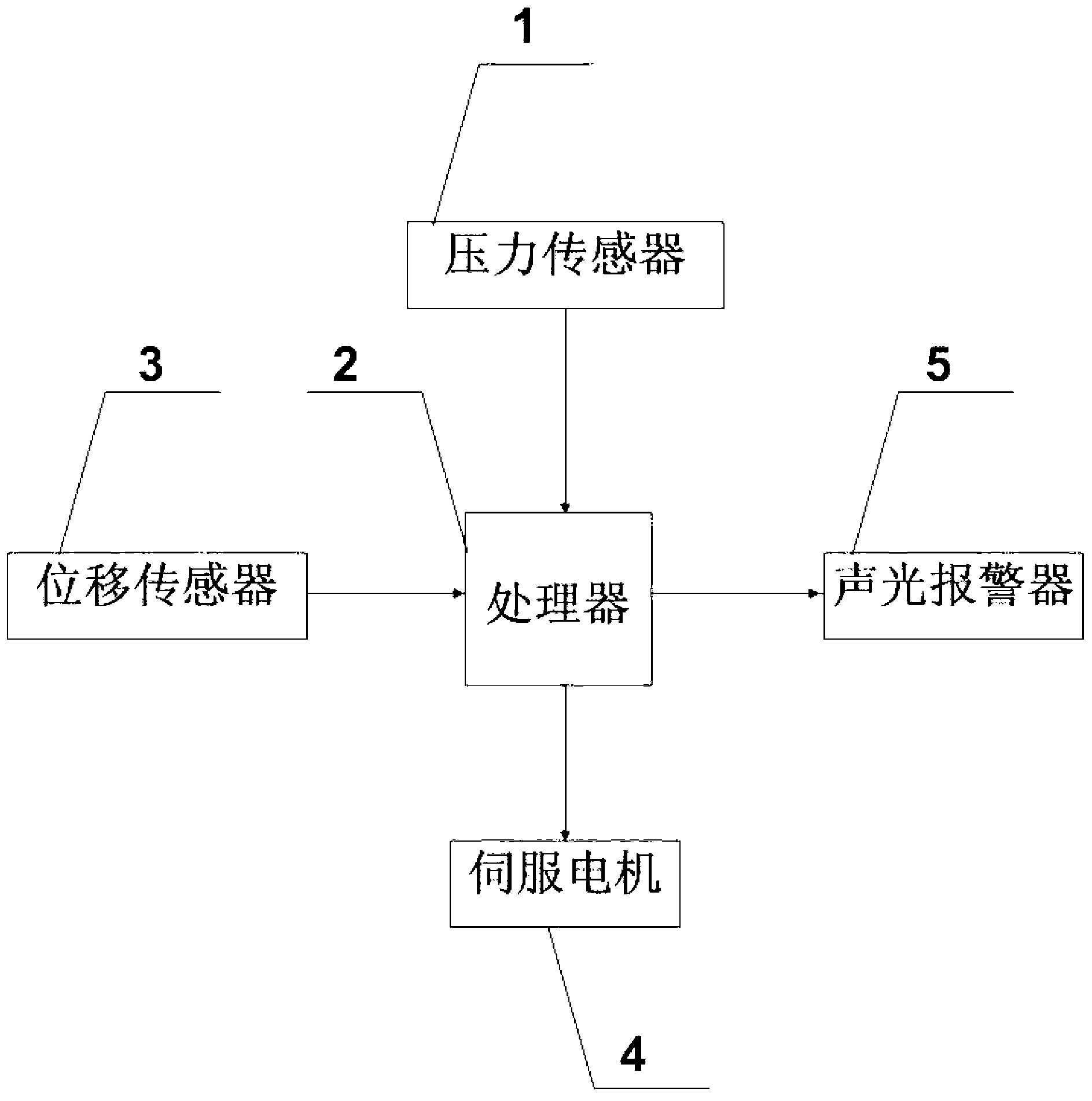

Servo press mounting device for monitoring press mounting force and displacement

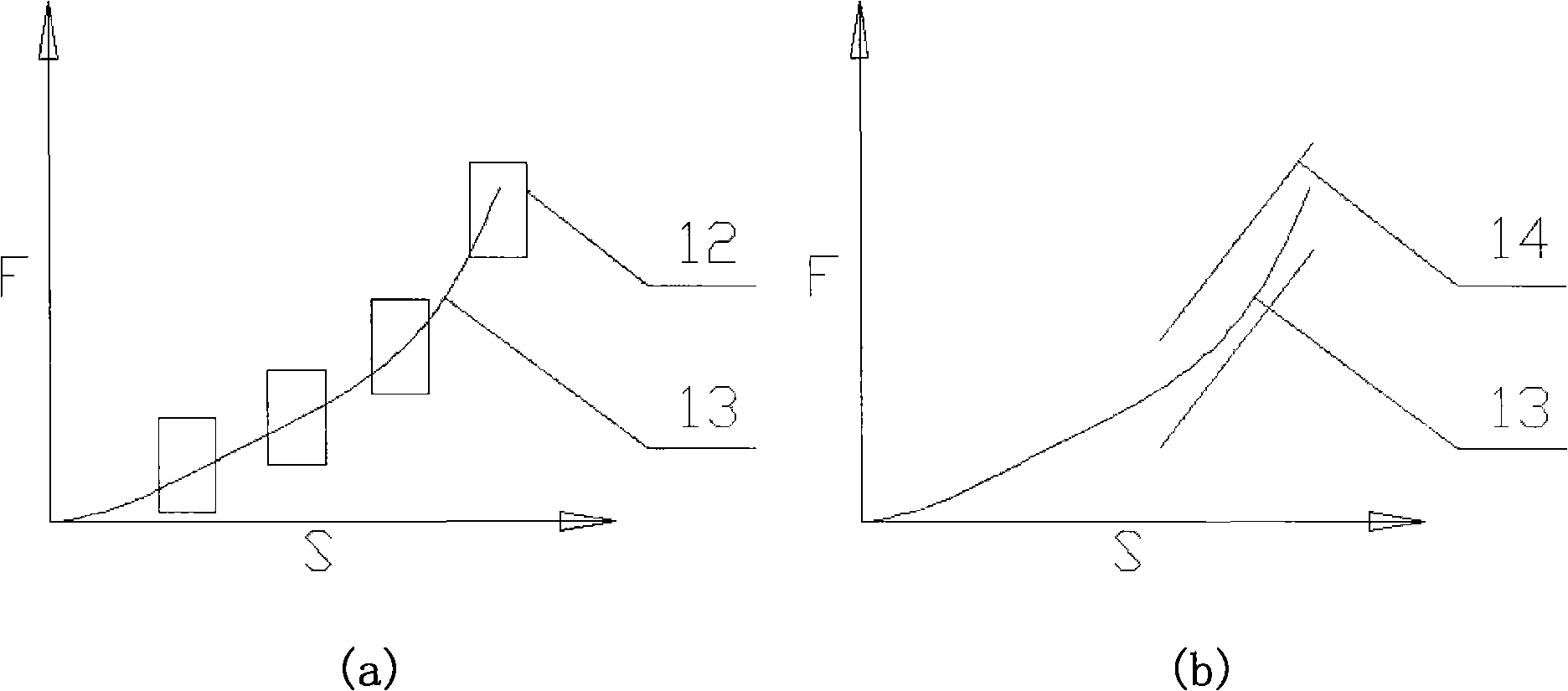

ActiveCN101288934APress-in (return) speed is stable and adjustableReal-time display of pressing force-displacement curveMeasurement/indication equipmentsMetal working apparatusDisplay deviceDisplacement control

A servo press-mounting machine for monitoring press-mounting force and displacement pertains to a mechanical assembling device. The prior art has the defect that the press-mounting result needs additional detection equipment for detection. A power device provided by the present invention consists of a servo motor controlled by an embedded industrial control system and a drive piece matched with the servo motor in a transmission way; the drive piece is matched with a press-mounting head by screw thread; the press-mounting head is provided with a pressure sensor for sending signals to the embedded industrial control system and connected with a displacement sensor; the embedded industrial control system is connected with a display and a control keyboard. The present invention takes the servo motor as the source power, is equipped with the pressure sensor and the displacement sensor and takes the embedded industrial control system as the core of the control system. The machine provided by the present invention has the advantages of stable and adjustable pressining speed, accurate and convenient press-mounting force control and press displacement control, the real-time display of press-mounting force-displacement curve, qualification determination when in press mounting, scientific and diversified qualification determination ways, etc.

Owner:HANGZHOU SANHUA RES INST CO LTD

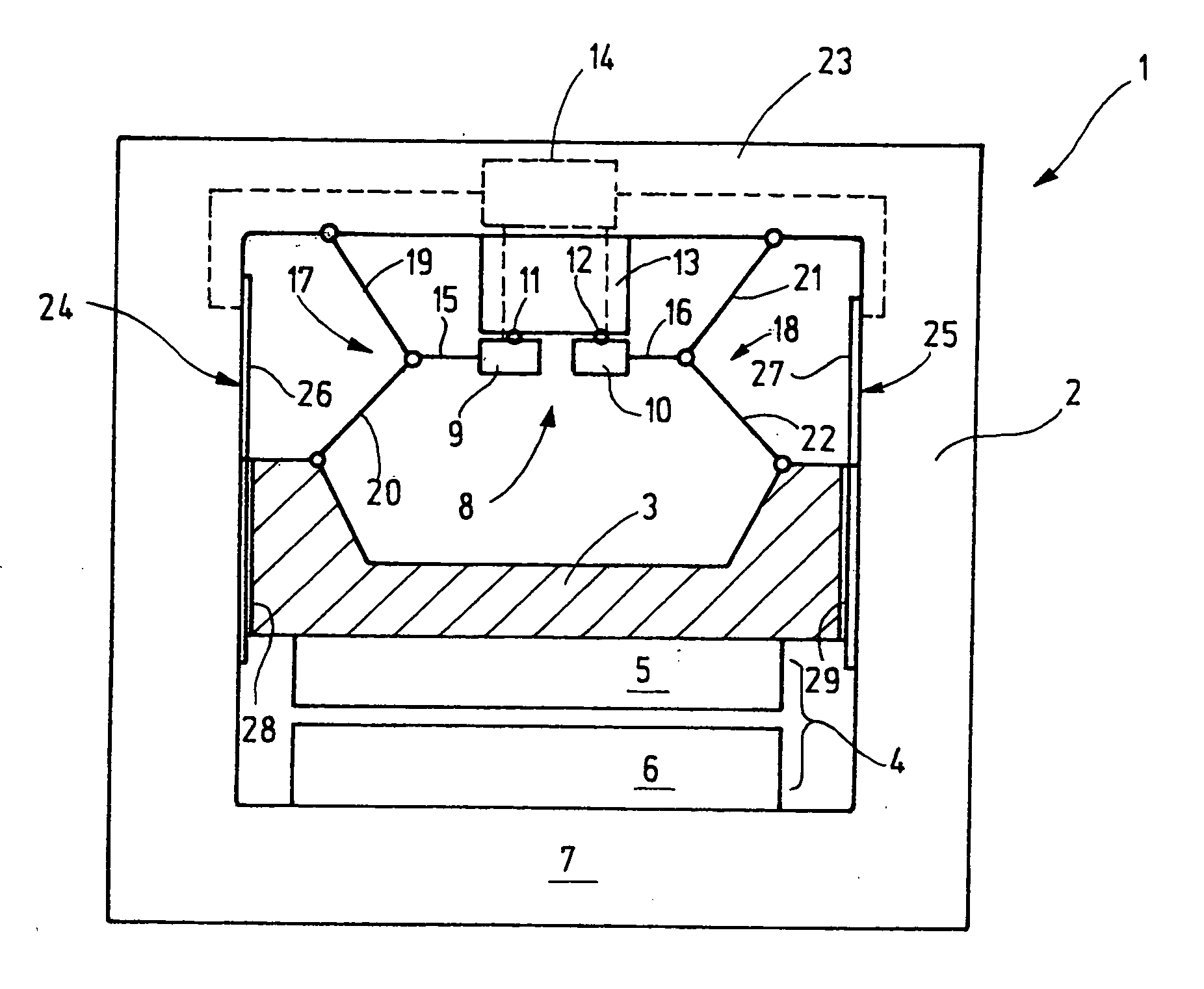

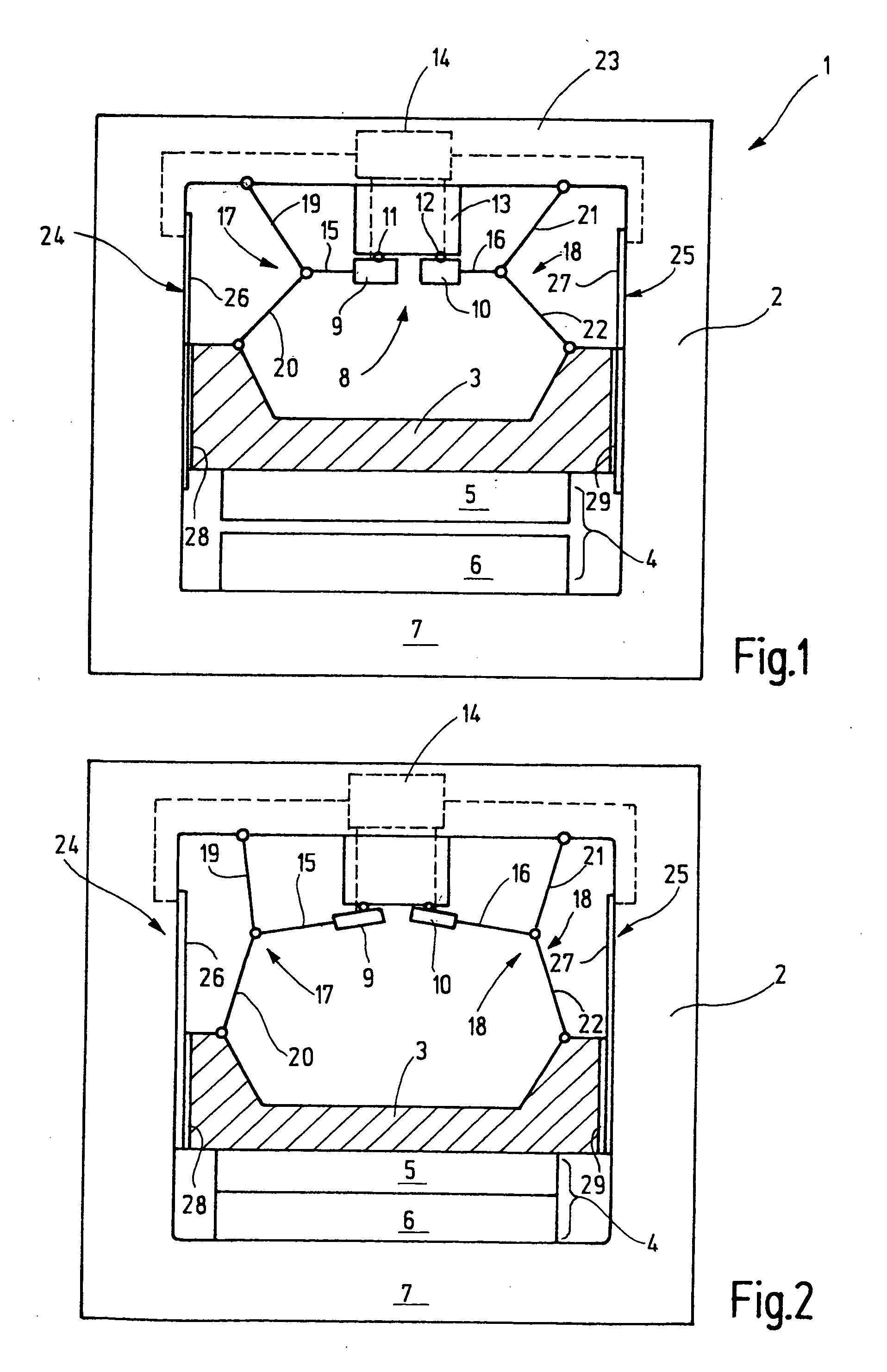

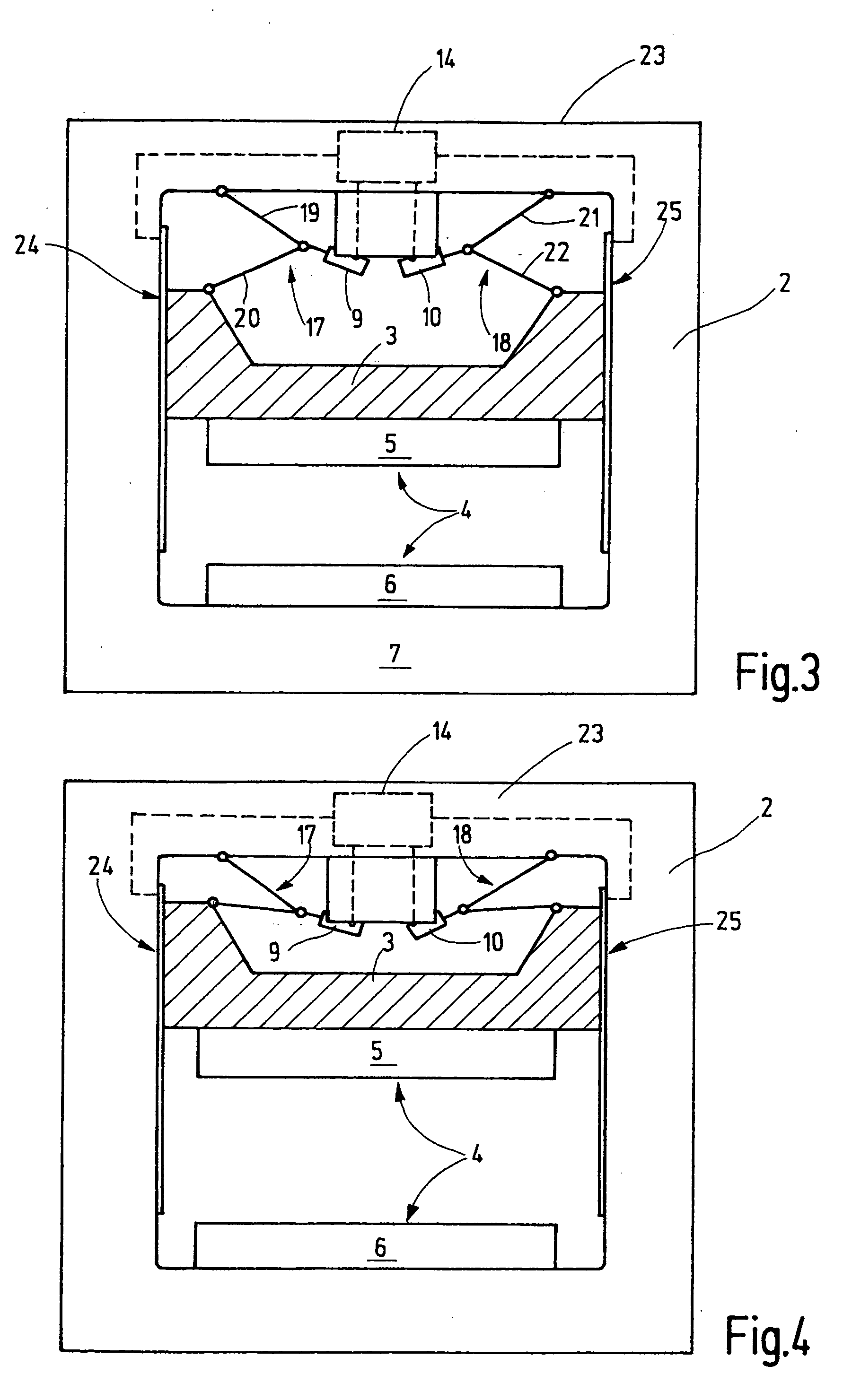

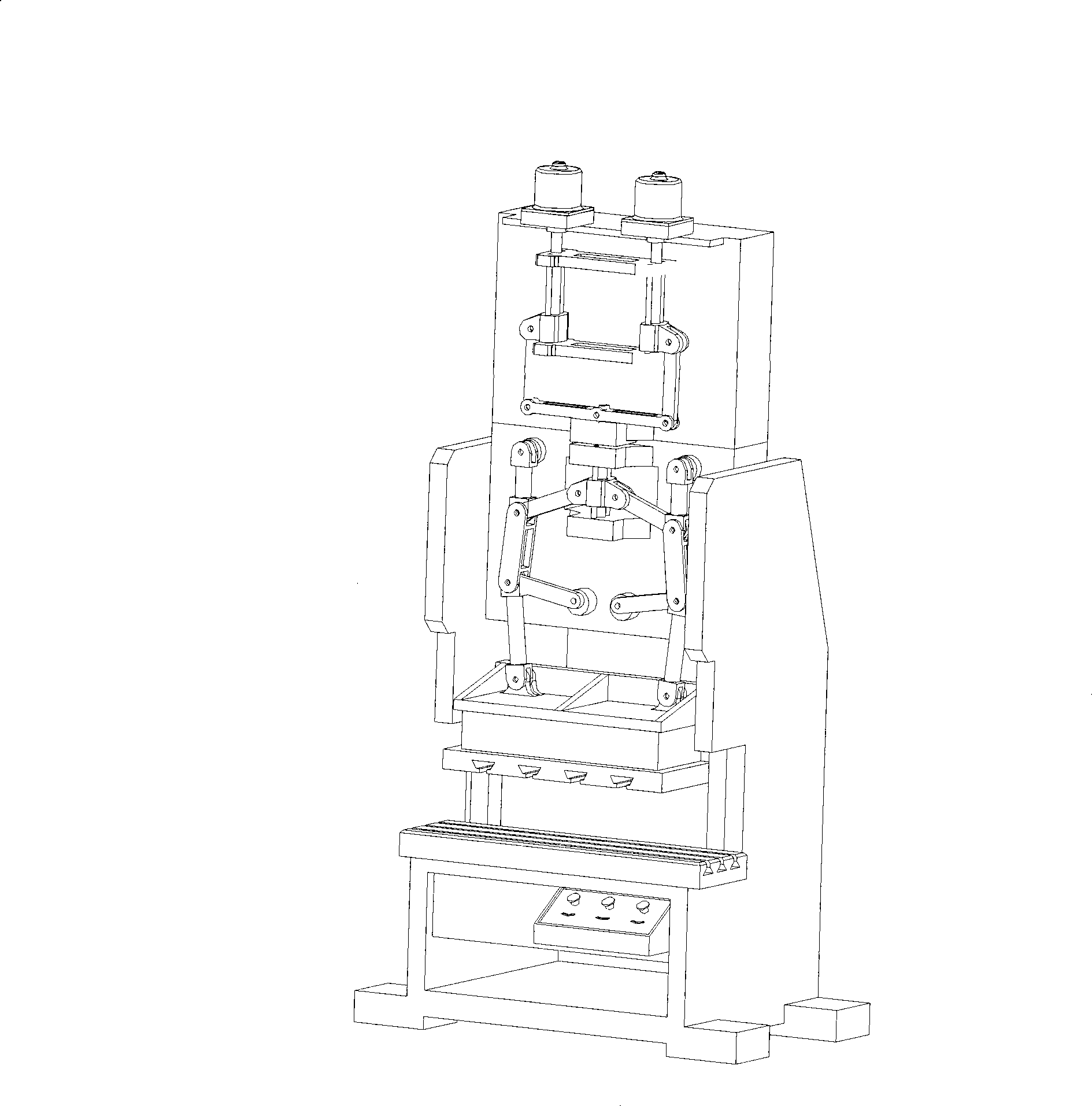

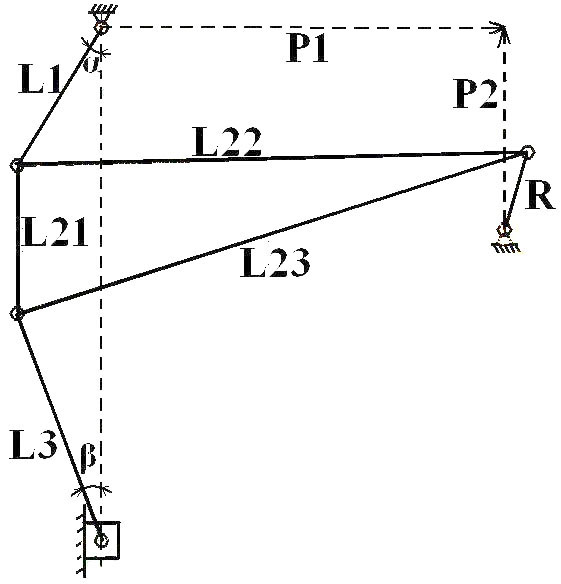

Servo press with elbow lever drive

In a press comprising a frame structure, a plunger movably supported by the frame structure, at least one servomotor for driving the plunger and an elbow lever drive connected to the servomotor and the plunger for actuating the plunger, at least one auxiliary drive is connected to the plunger for operating the plunger in stroke ranges where the elbow lever drive is ineffective for controllably moving the plunger.

Owner:SCHULER PRESSEN GMBH & CO KG

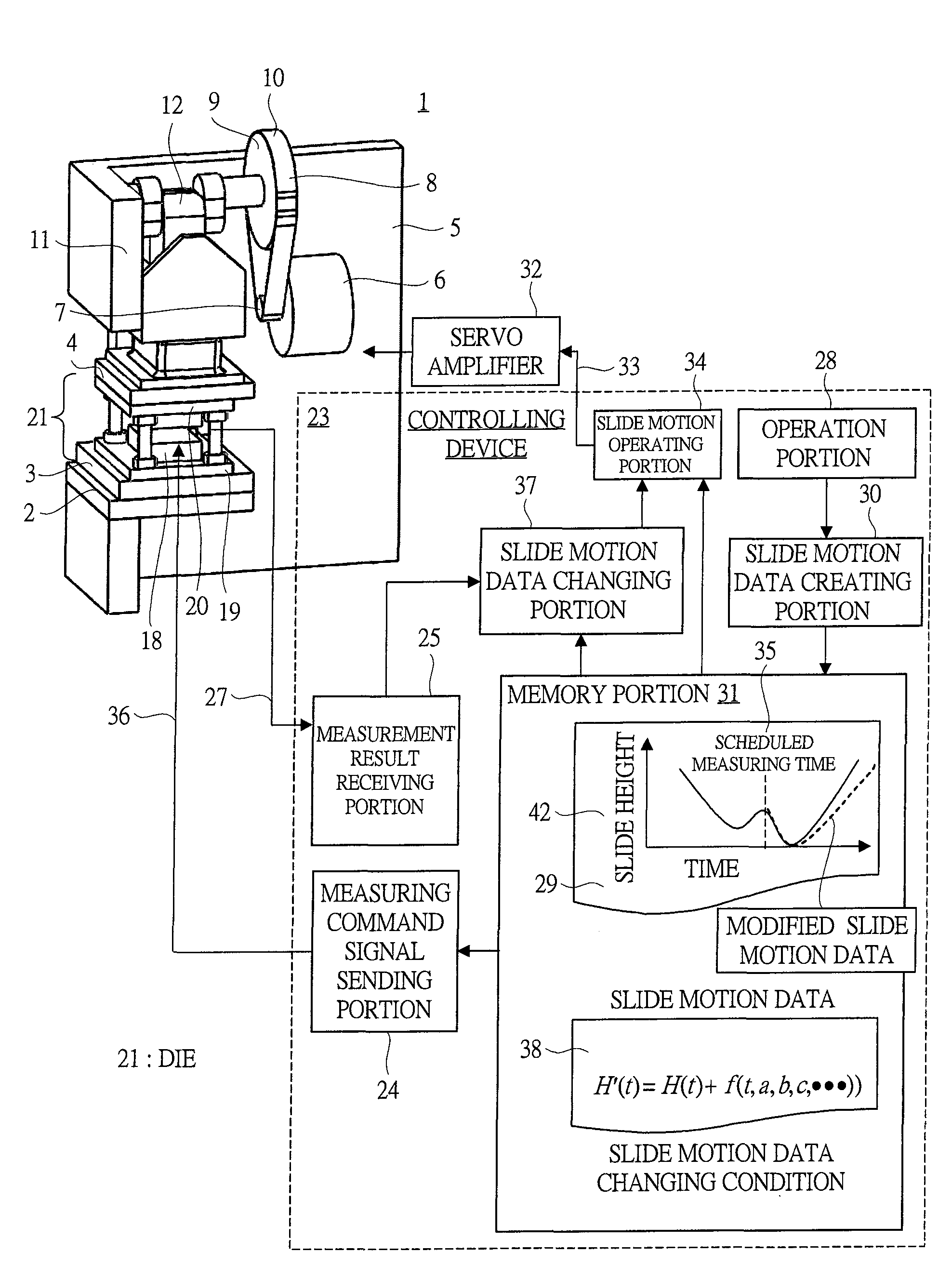

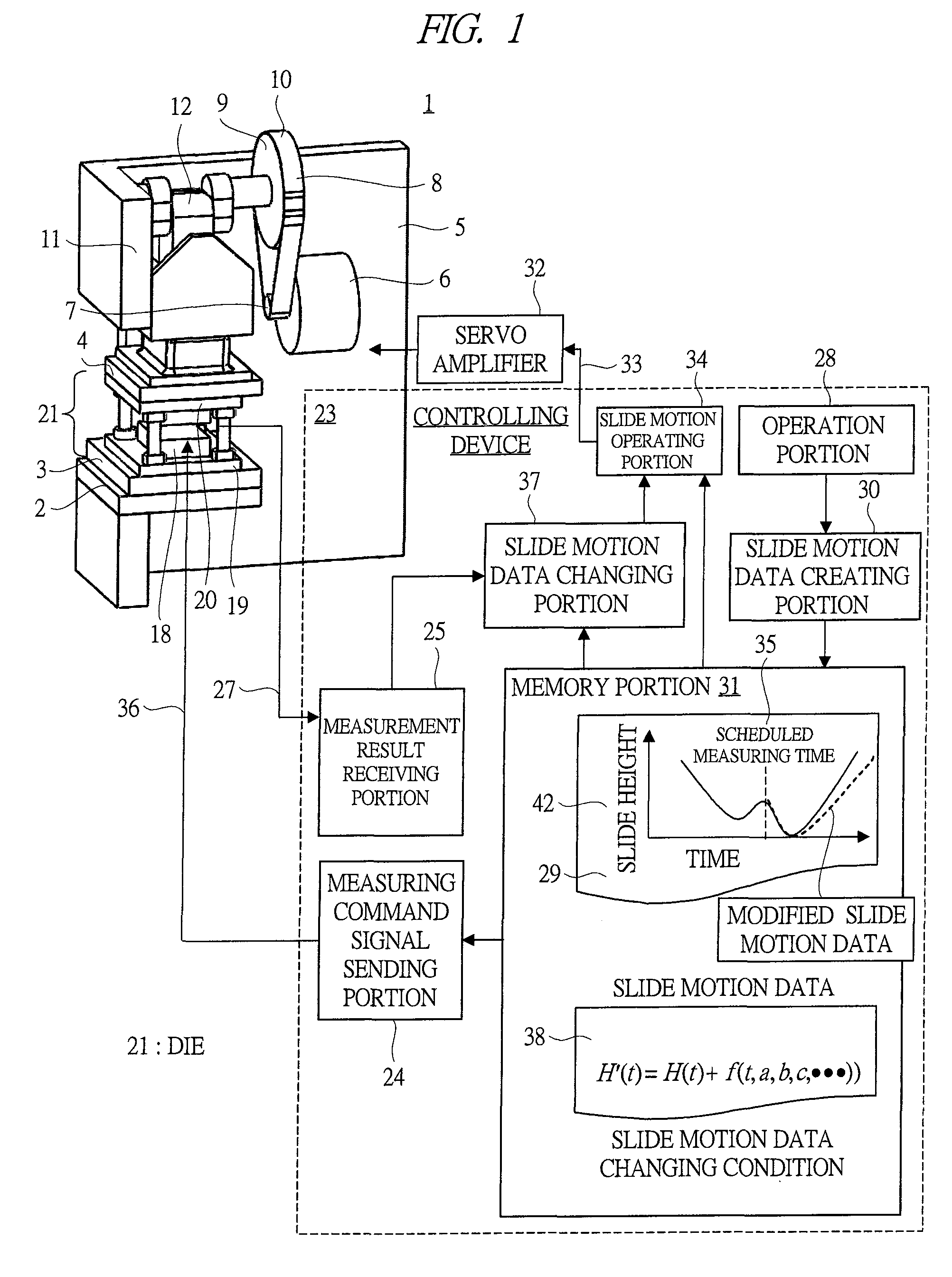

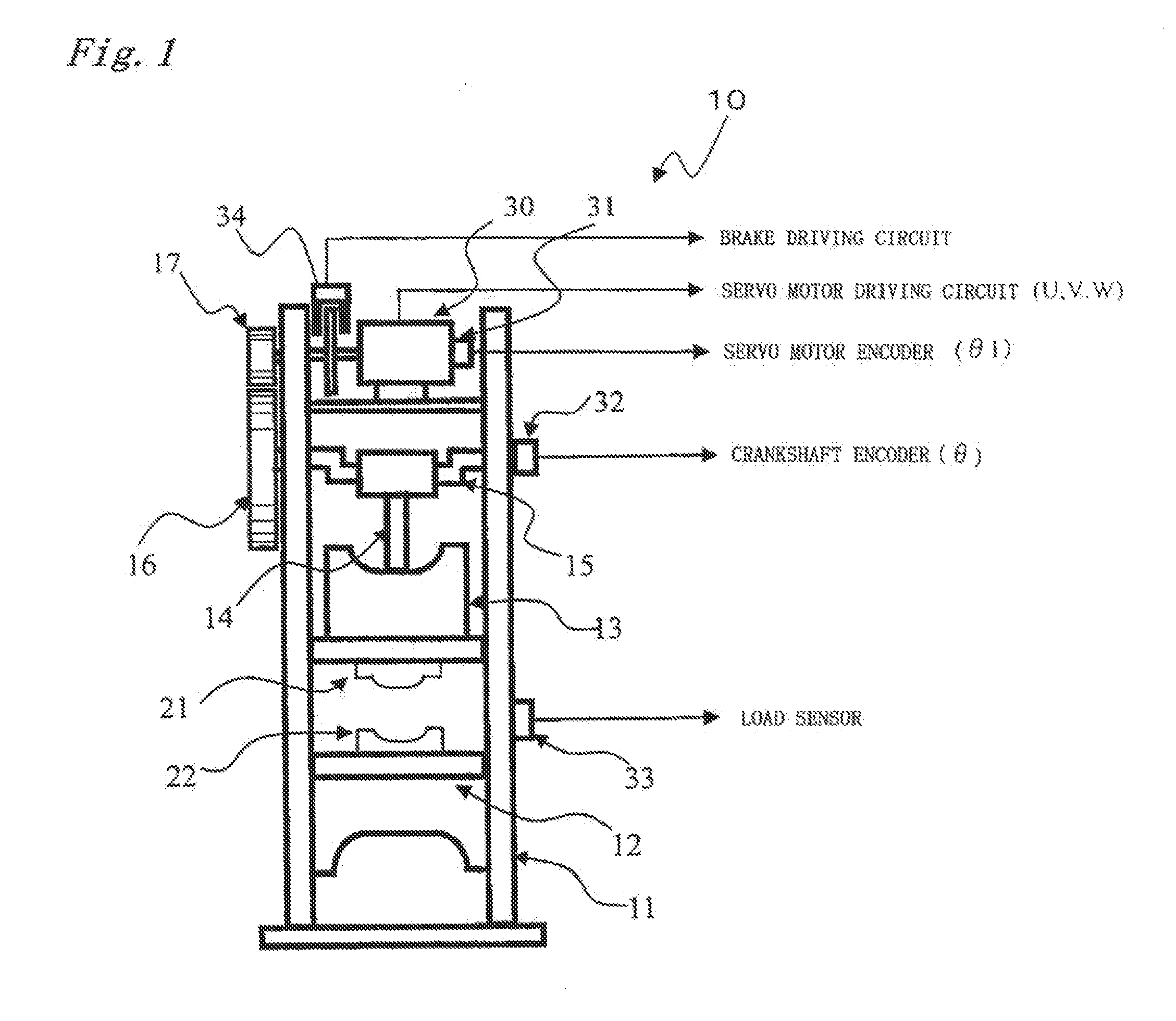

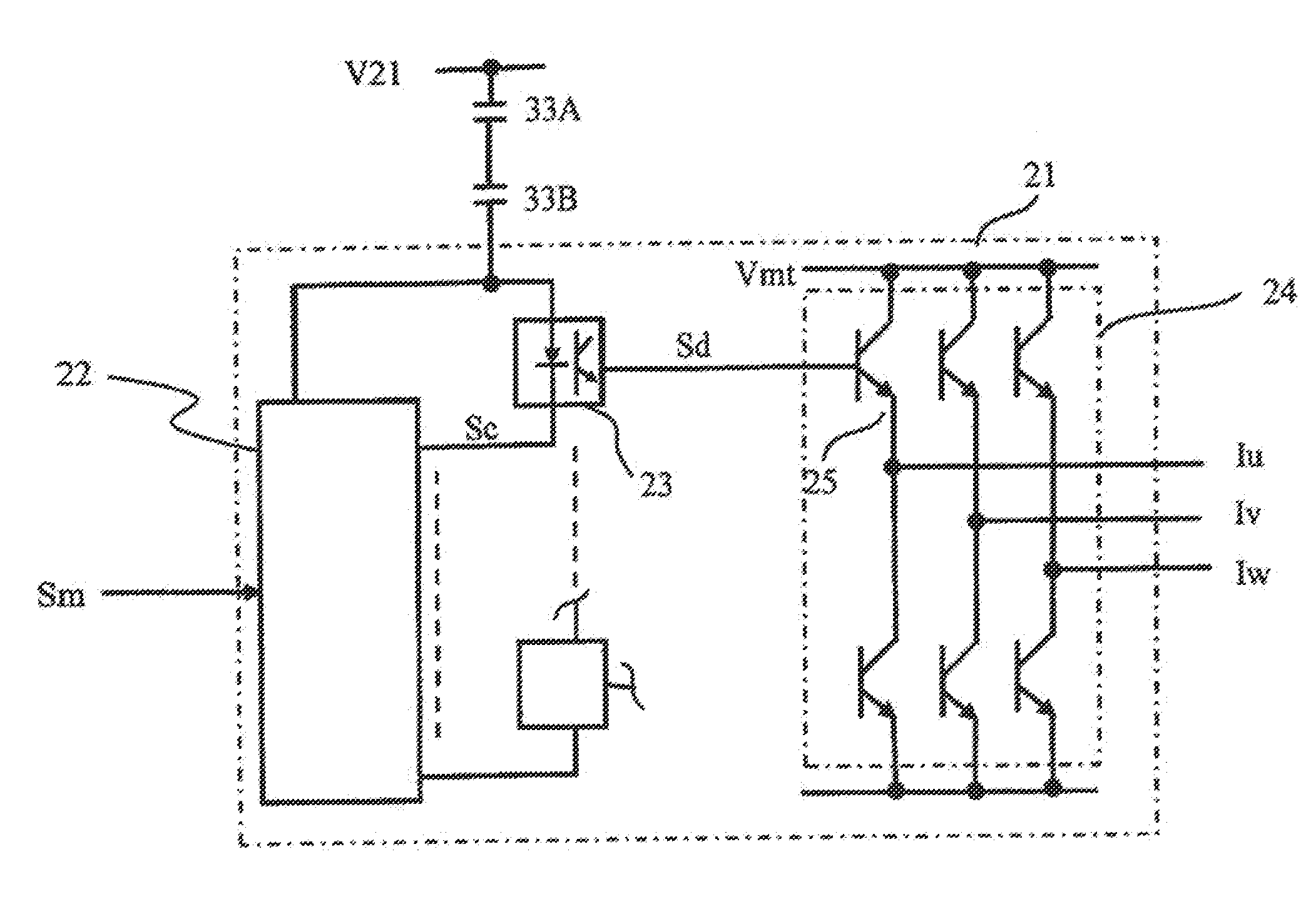

Controlling Device for Servo Press, Controlling Method for the Same and Servo Press Equipped with the Controlling Device

There is provided a controlling technique for a servo press capable of optimal forming for handling variability in a sheet thickness and material property of a workpiece and for handling each workpiece. A controlling device for controlling a servo press in accordance with a slide motion data includes: measurement equipment for measuring a forming state of a workpiece, attached to a die for forming the workpiece; a measurement result receiving portion for receiving a measurement result sent from the measurement equipment; and a slide motion data changing portion for changing a slide motion data for forming the same workpiece at scheduled measuring time in accordance with the measurement result received by the measurement result receiving portion.

Owner:HITACHI LTD

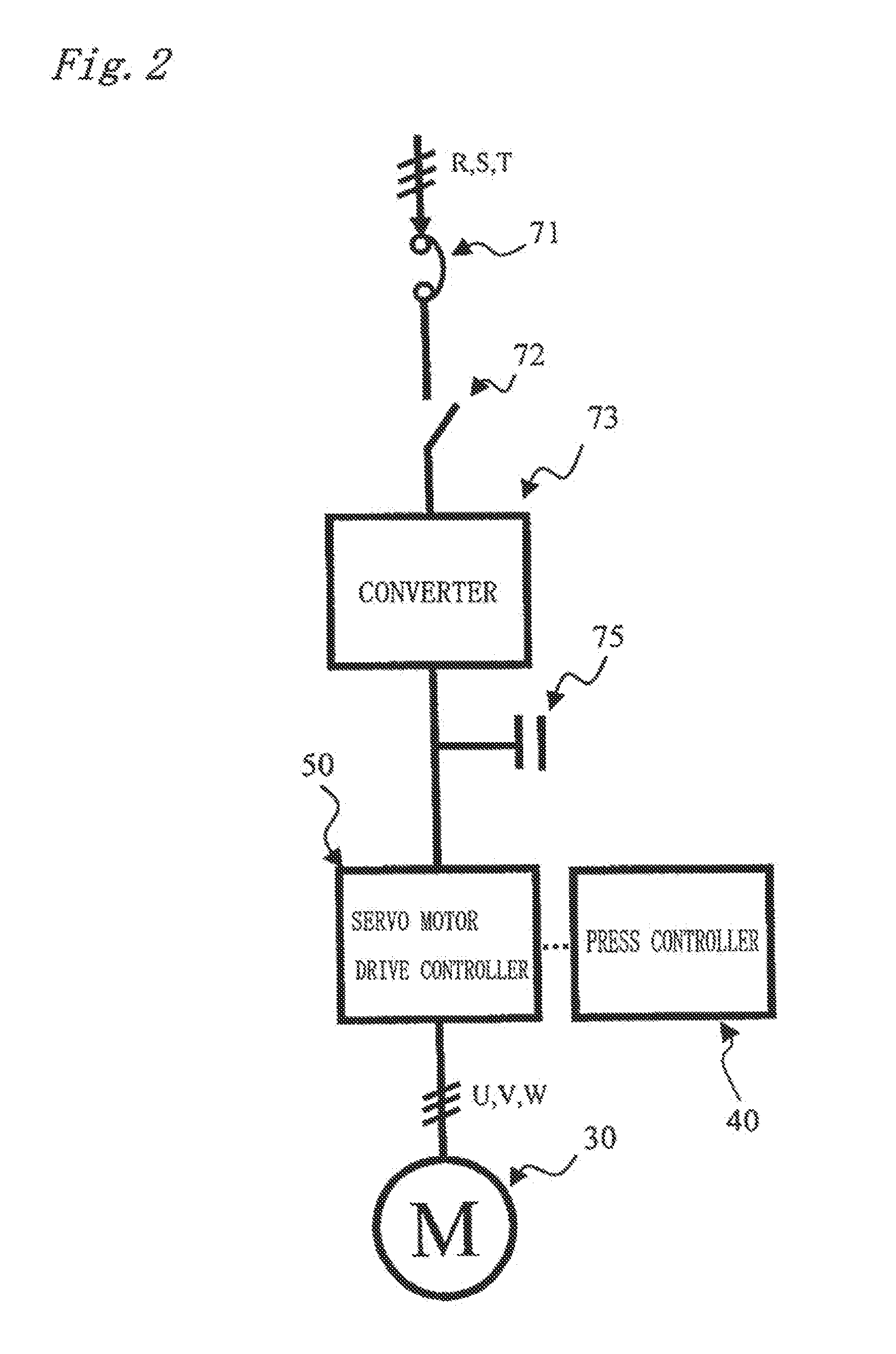

Method and apparatus for controlling electric servo press

InactiveUS20110132209A1High pressureSimple and low-cost configurationAutomatic control devicesPress ramLinear motionElectric machine

Provided is a controller for an electric servo press for linearly driving a slide through an intermediation of a rotary-to-linear motion converting mechanism for rotating a decentering shaft by a rotational output of a servo motor to convert rotation of the decentering shaft into linear motion, to perform press working, including : a press load sensor for detecting a pressure force of the slide; a pressure-force determination device for determining whether the pressure force of the slide reaches one or a plurality of different pressure-force setting values based on the one or the plurality of different pressure-force setting values and an output signal of the press load sensor, and for generating a pressure-force achievement signal each time the pressure force of the slide reaches each of the one or the plurality of different pressure-force setting values; a servo motor drive controller for controlling driving of the servo motor; and a motion command device, in which: in respond to generation of the pressure-force achievement signal, at least one of switching of a drive control mode by the servo motor drive controller and switching of a motion to be commanded by the motion command device is performed.

Owner:AIDA ENG LTD

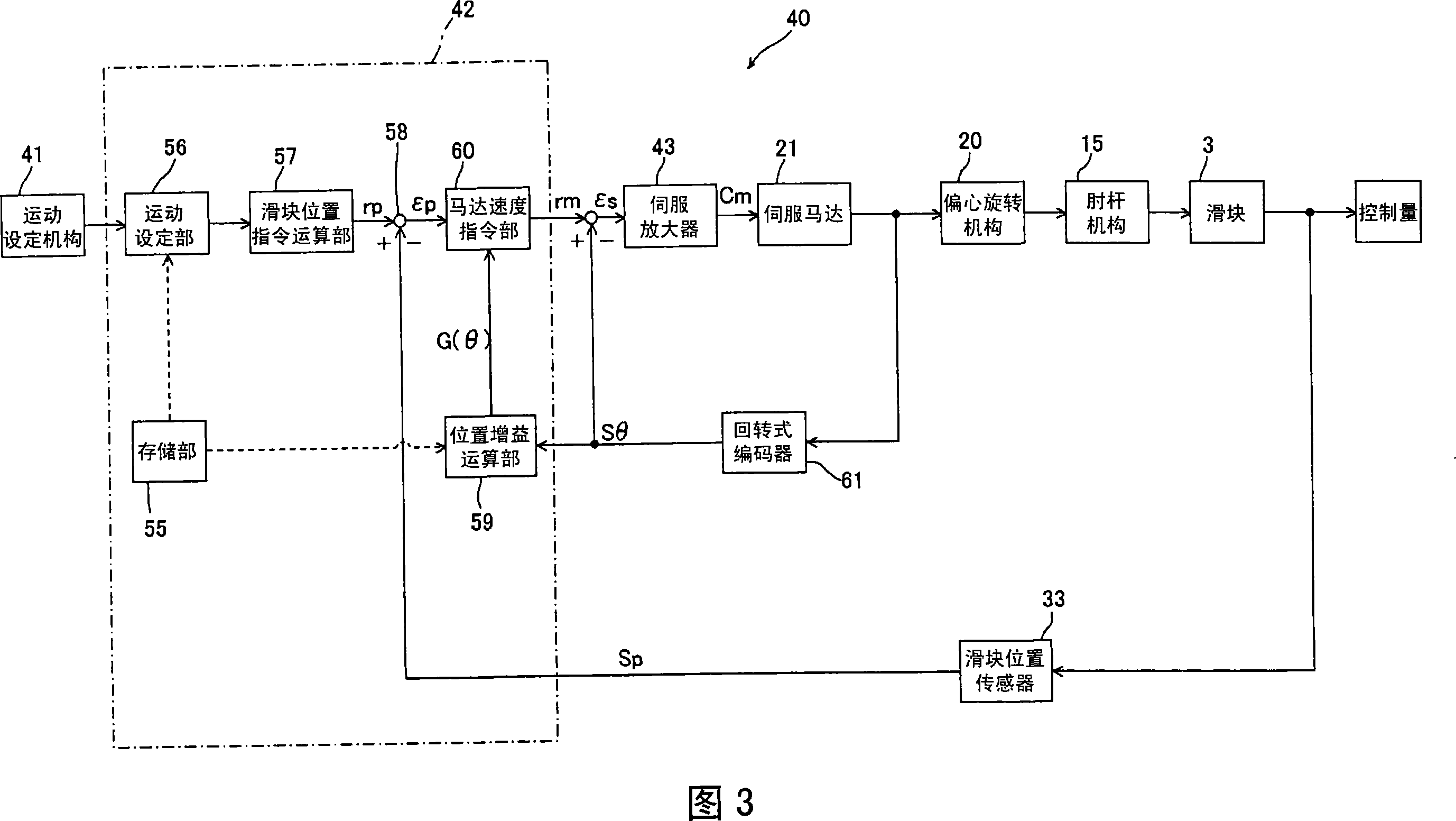

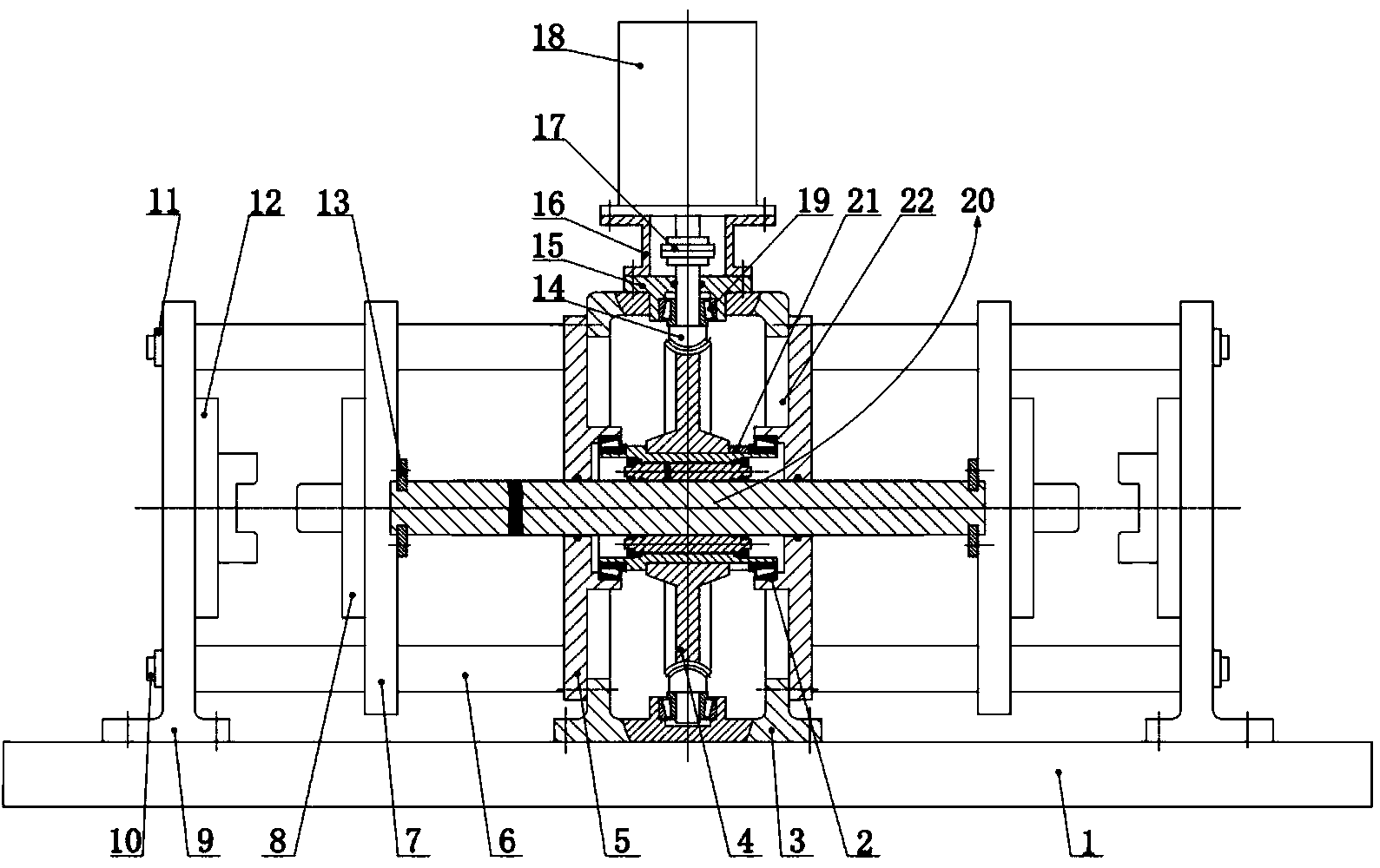

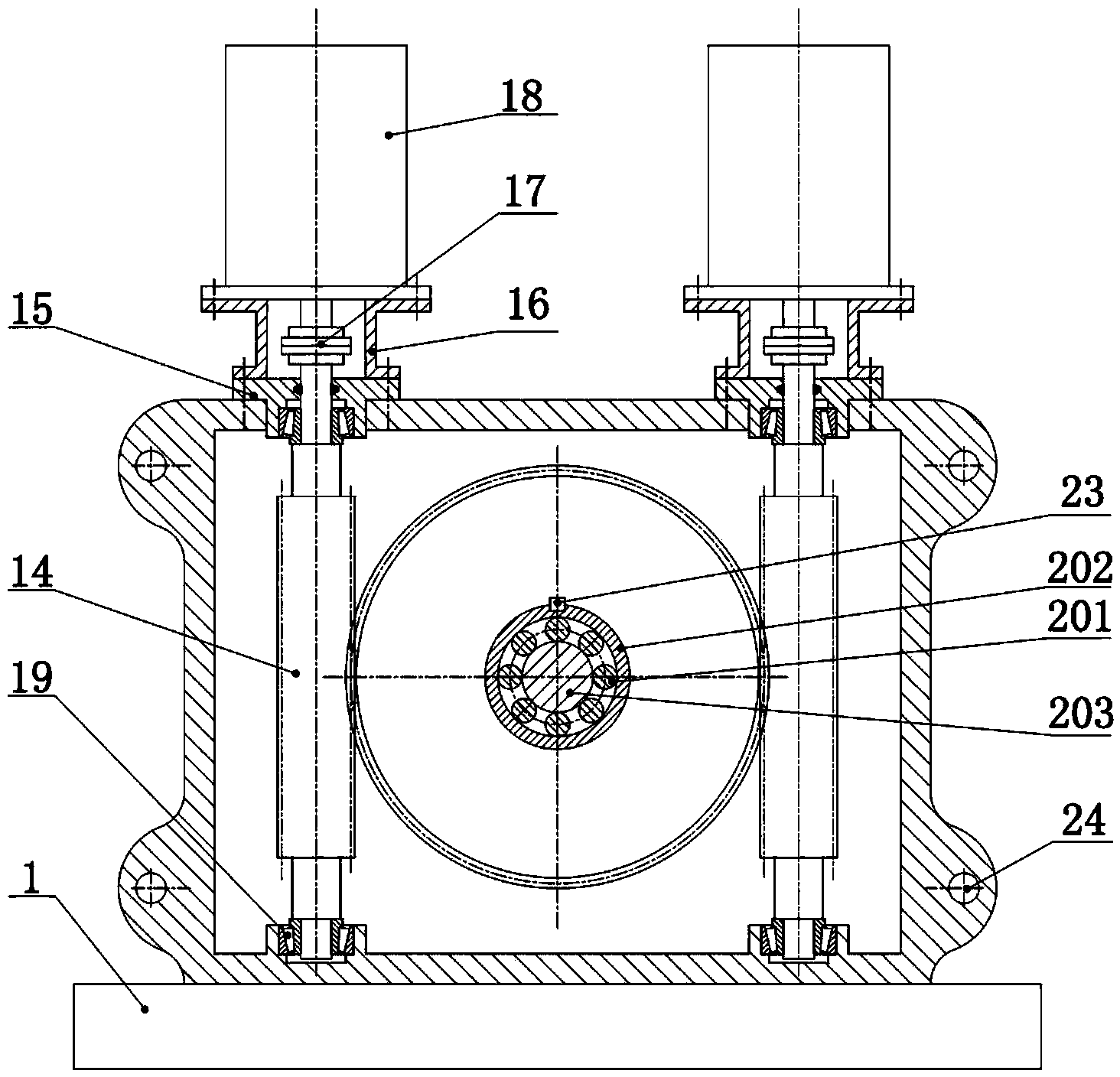

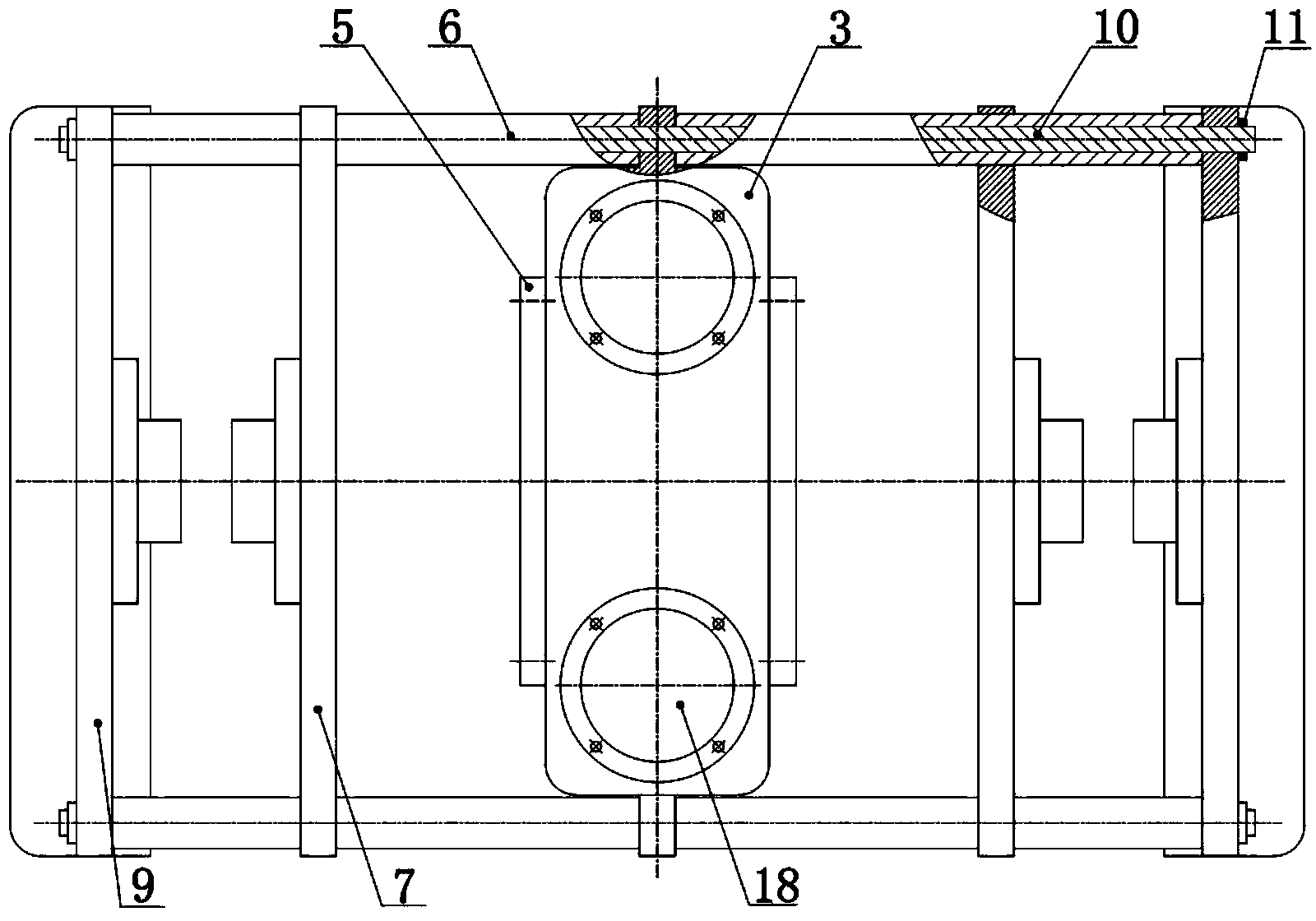

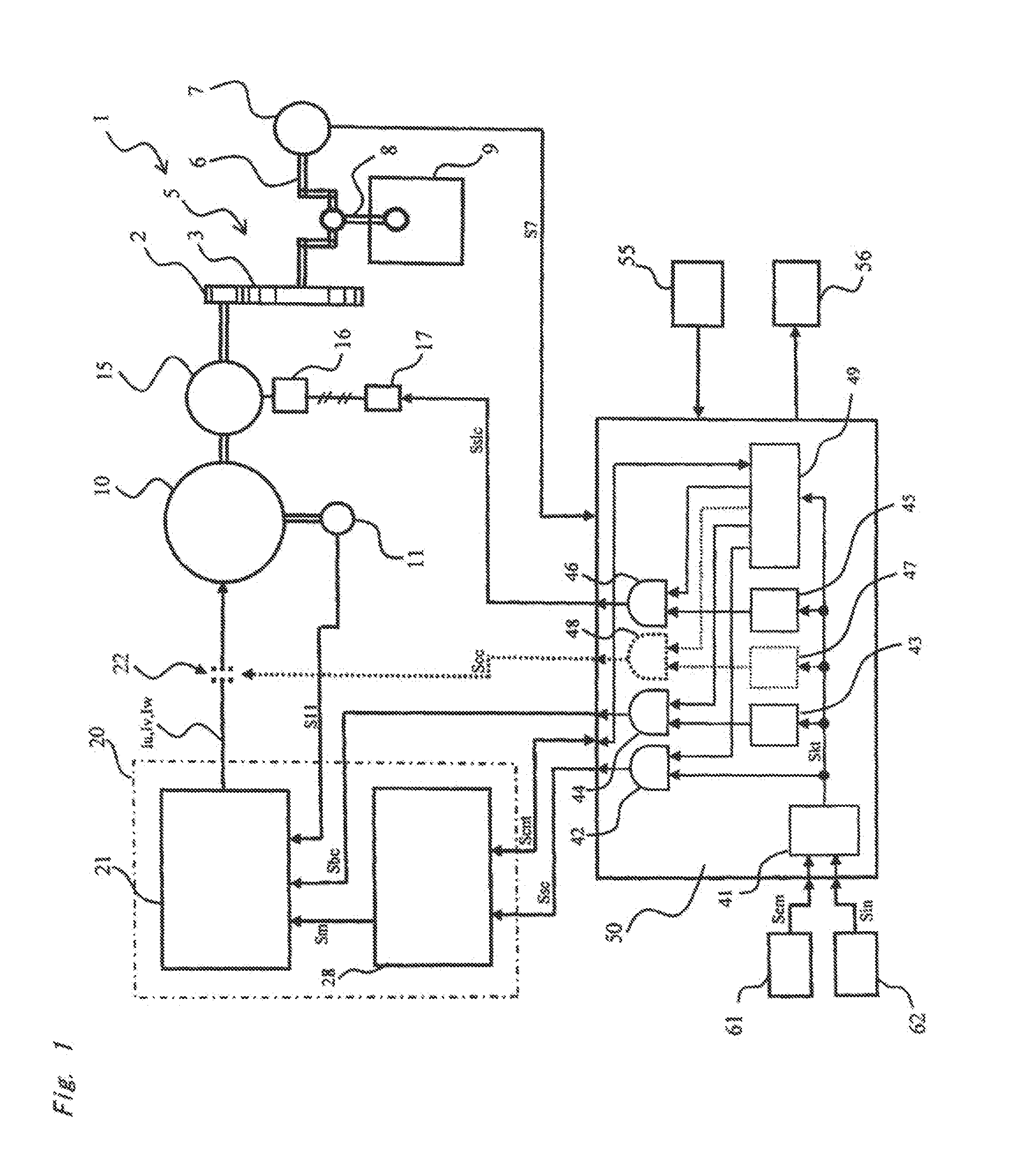

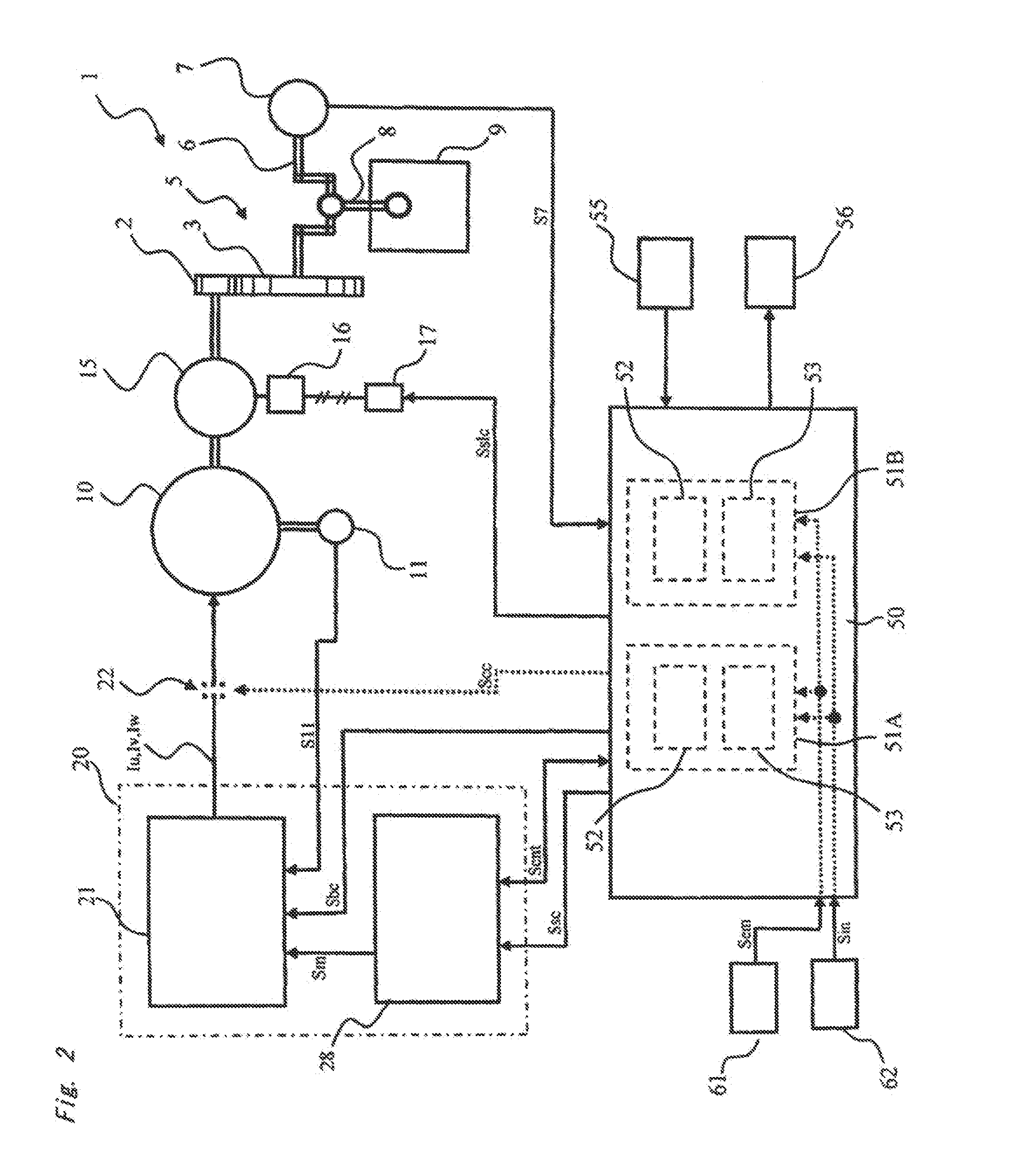

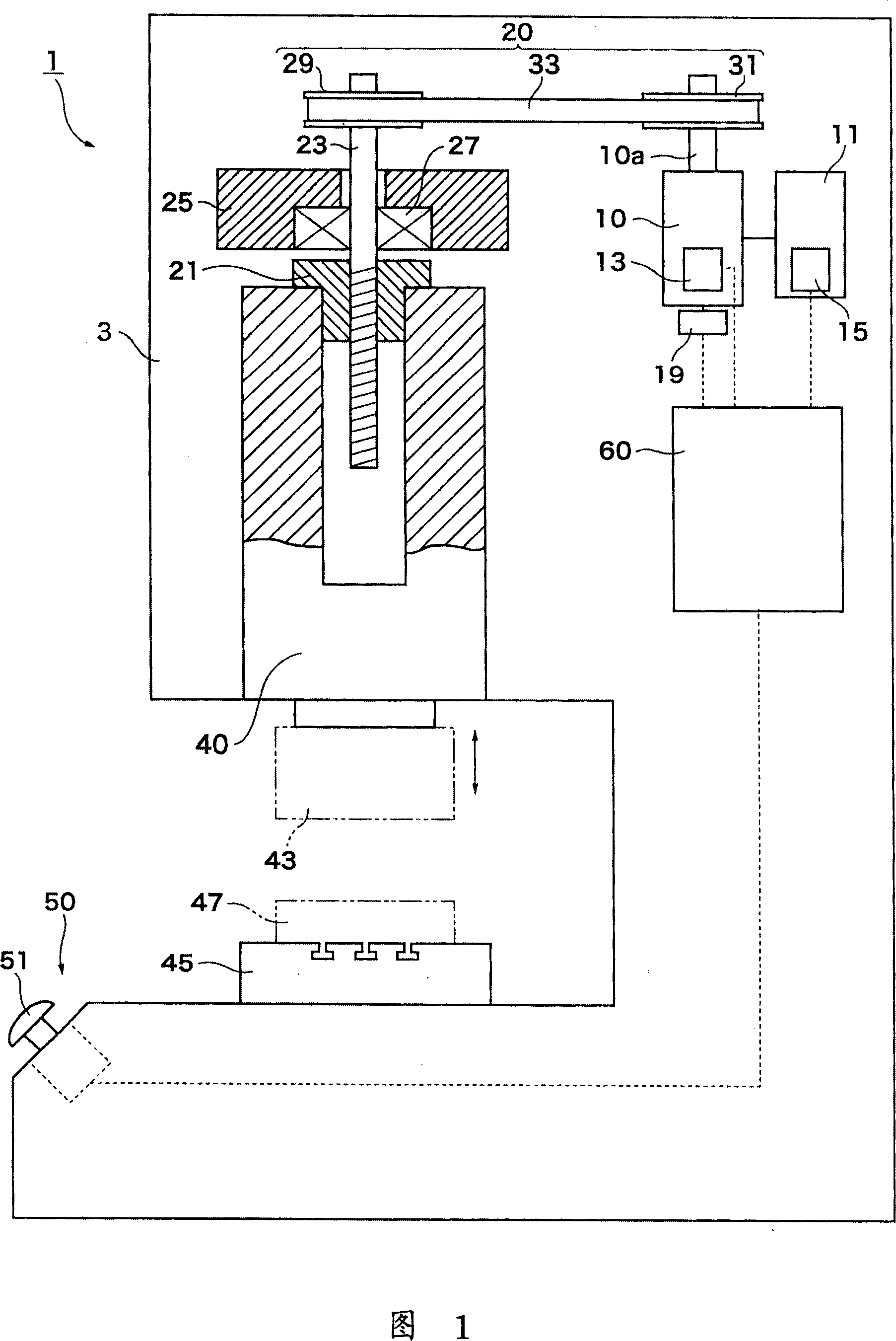

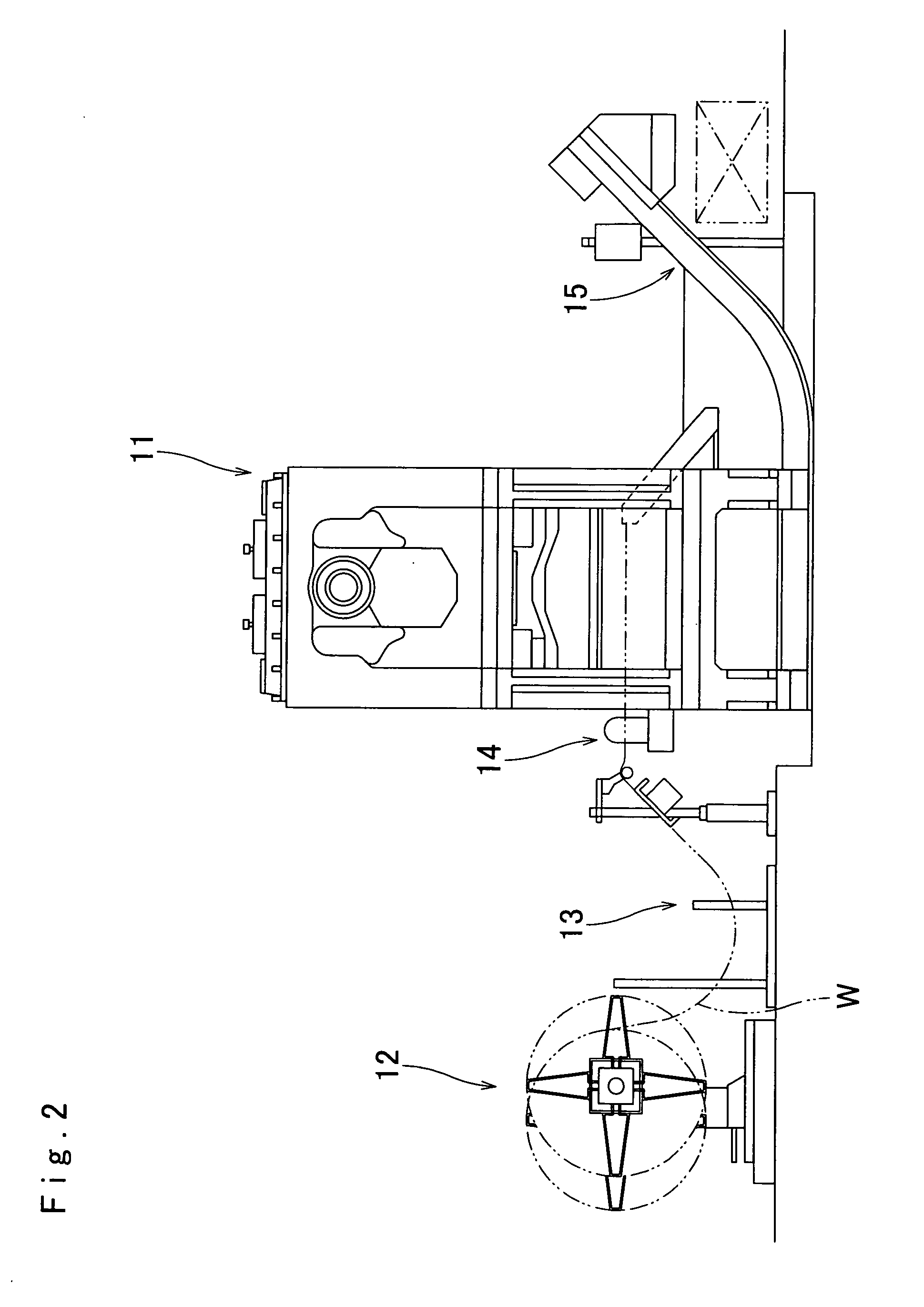

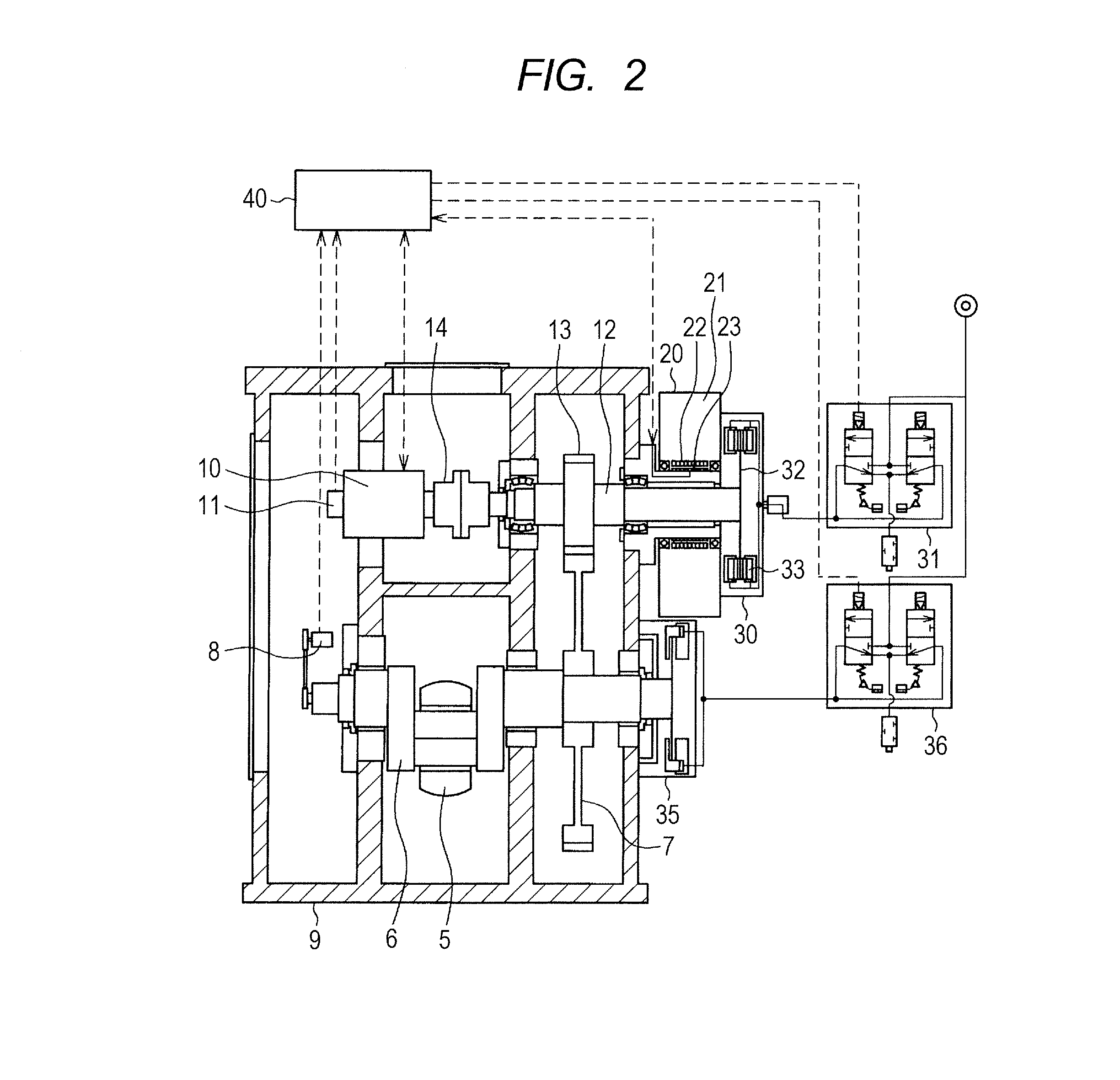

Apparatus for controlling servopress and method for controlling the same

A control device and a control method for a servo-press capable of selectively performing high-production working and high-accuracy working by one pressing machine. The servo-press (1) is so formed that an eccentric rotary mechanism (20) is driven by a servo-motor (21), and the rotating power of the eccentric rotary mechanism (20) is transmitted to a slide (3) through a toggle link mechanism (15) to vertically drive the slide (3). The rotation of the servo-motor (21) is controlled by a motor speed instruction (rm) calculated based on a position gain (G (theta)) pre-set according to the position deviation (epsilon p) of the slide (3) and the speed ratio of the slide (3).

Owner:KOMATSU LTD +1

Two-way horizontal servo pressure machine for transmission of planet roller lead screw

ActiveCN103802343AReduced commutation frequencyExtend your lifeGearingPortable liftingLinear motionGear drive

The invention discloses a two-way horizontal servo pressure machine for transmission of a planet roller lead screw. Two servo motors simultaneously drive one worm gear through two worms, a planet roller lead screw device is embedded into the worm gear, the worm gear drives a planet roller lead screw nut to rotate, the nut converts rotation into linear motion of the lead screw through a roller, dies at the two ends are driven to perform two-way stamping, the horizontal type arrangement form is adopted, a driving device is installed in a machine body, the machine body is installed in the middle of the pressure machine, the dies are symmetrically arranged on the two sides of the machine body, the structure is greatly simplified, and the structure of the whole machine is compact; the stamping efficiency is improved, energy consumption is reduced, and the service life of the motors is prolonged; loads of each worm are reduced, power of each motor is reduced, and cost is reduced.

Owner:XI AN JIAOTONG UNIV

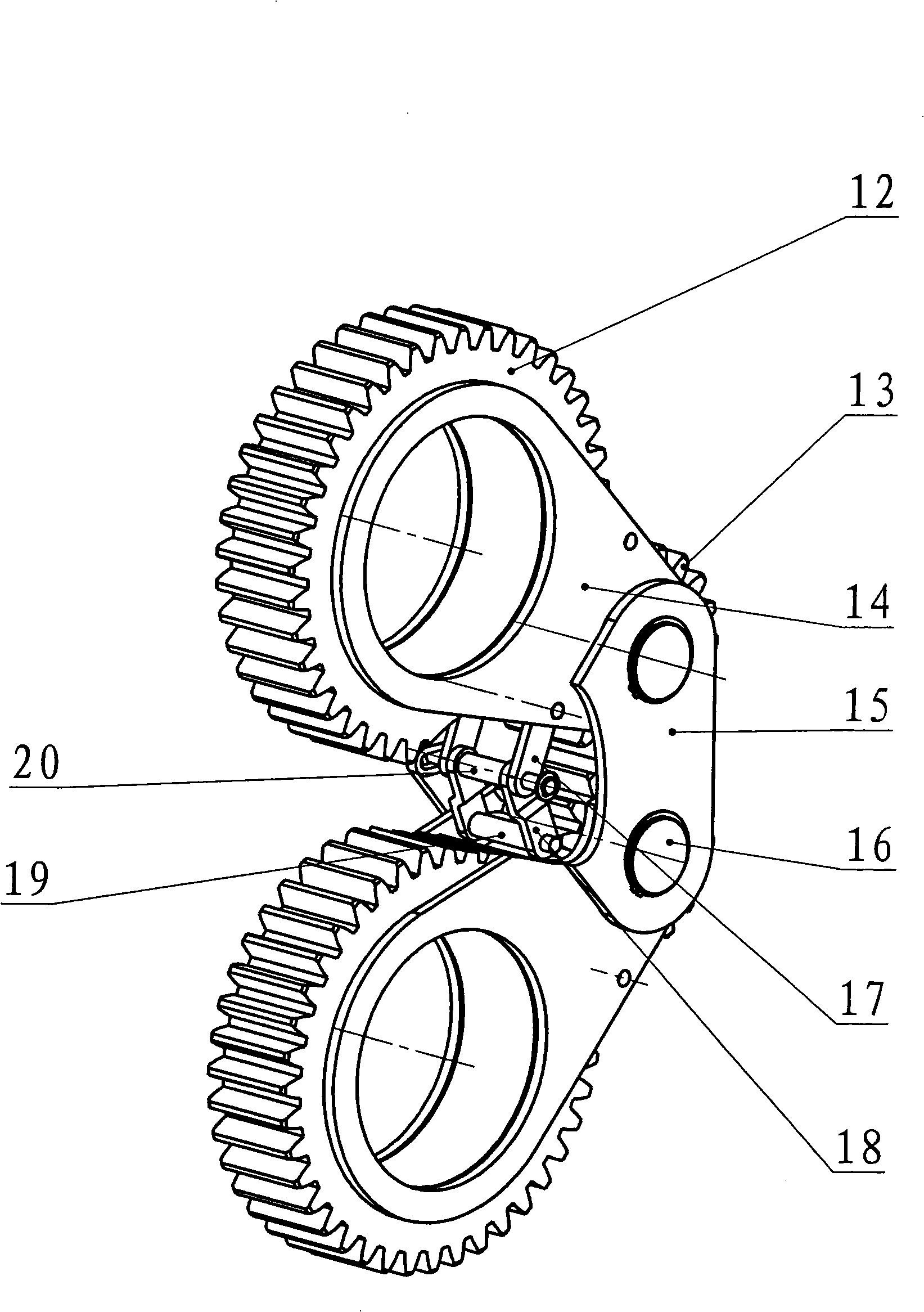

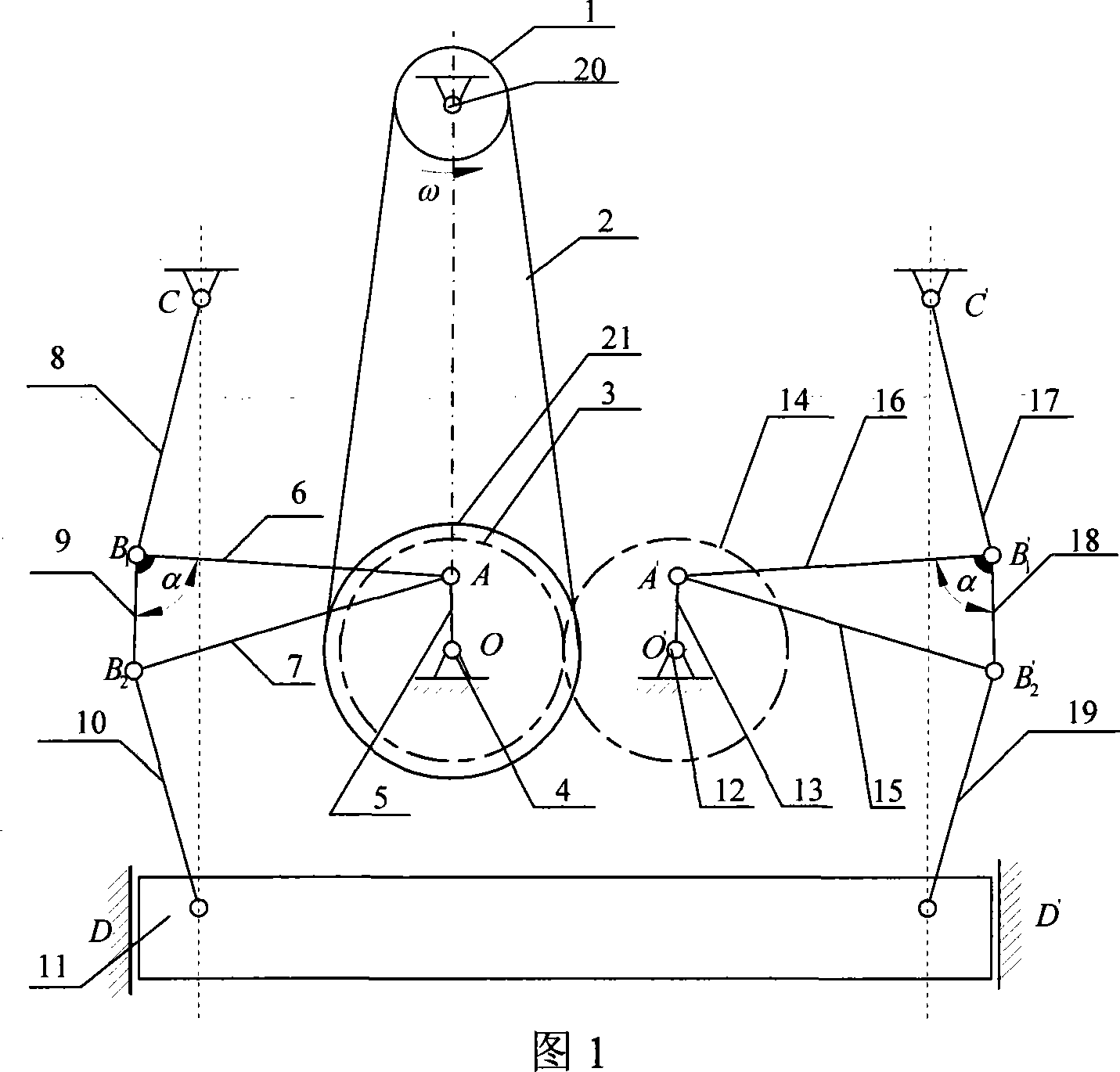

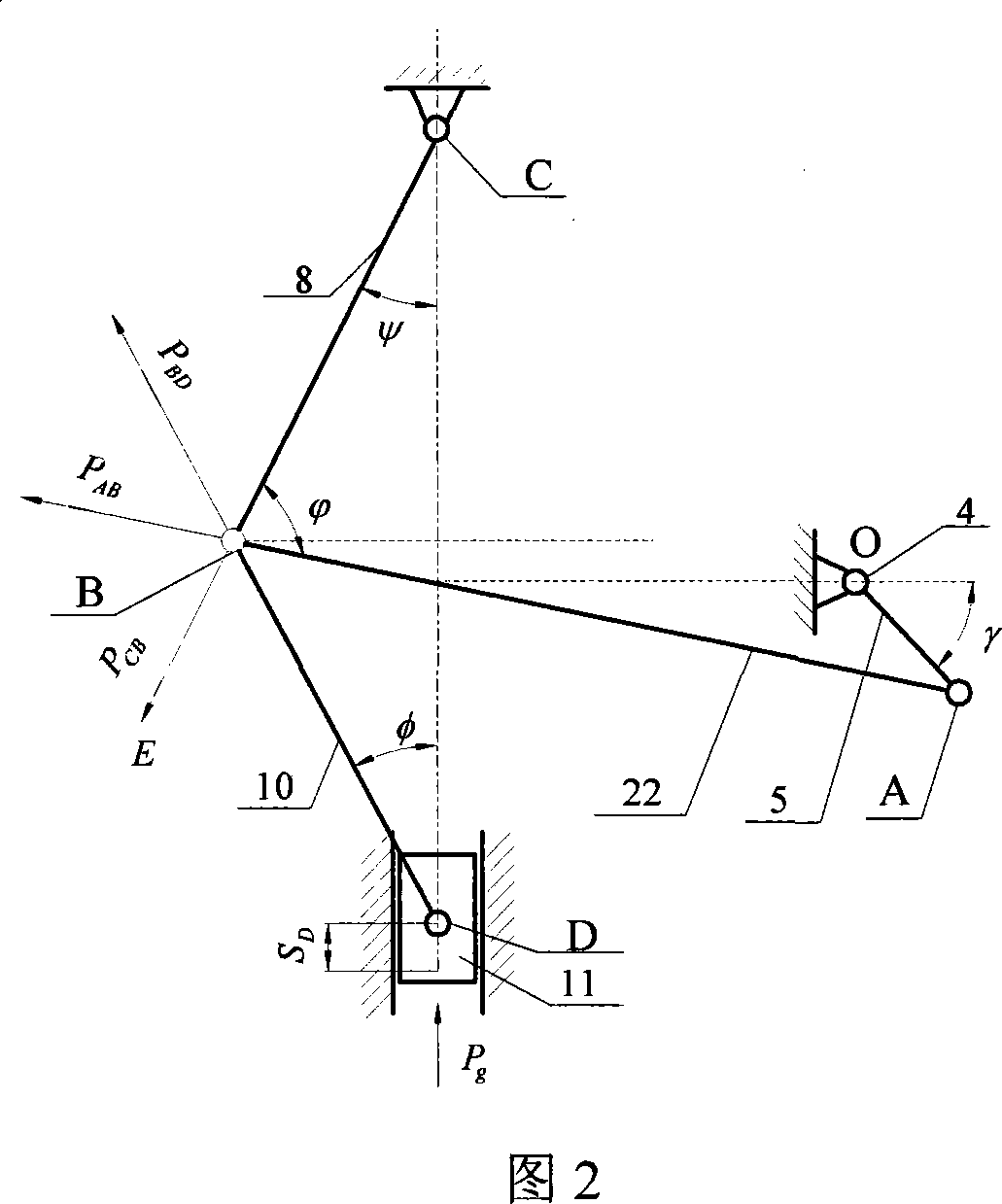

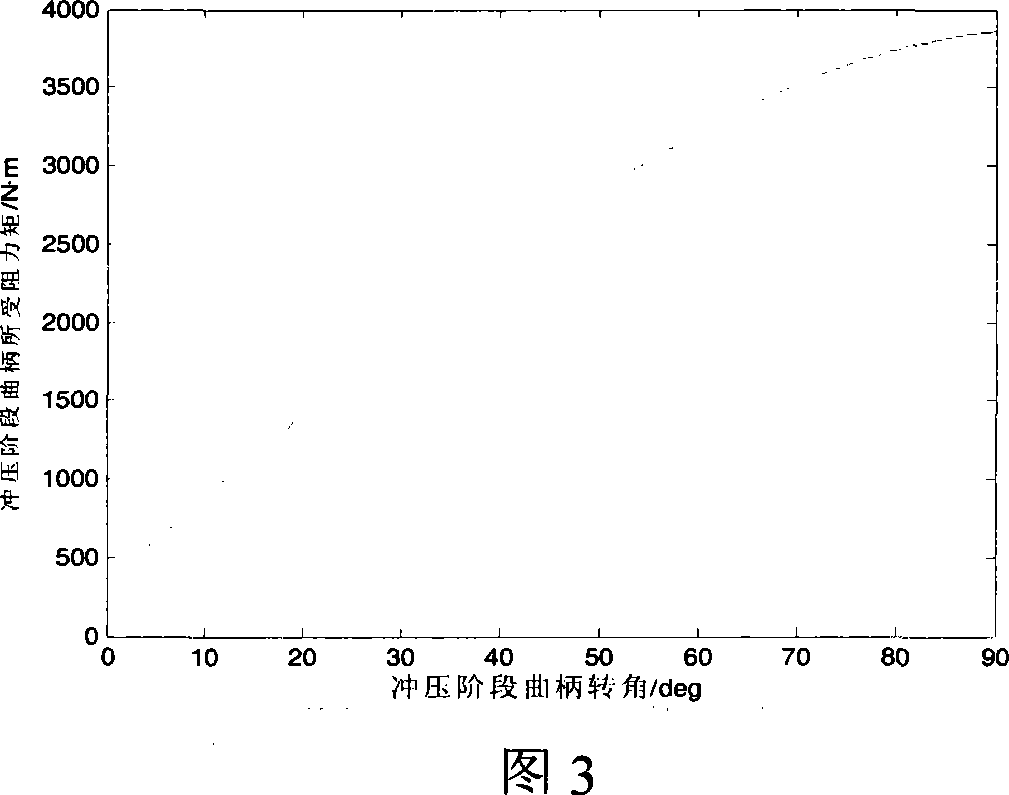

Transmission system of servo-driven double-angle lever mechanical press of switch magnetic reluctant motor

InactiveCN101073924ASimple structureFlexible and adjustable working characteristicsPress ramFreewheelLow speed

The invention is concerned with the driving system that the switched reluctance motor servos the driving double toggle links mechanical press, it is: the switched reluctance motor is speed-down by the first-level strap in order to send the power to the synchronizer gear structure, the synchronizer gear structure drives the slipper to move by the same-axle concretion crank toggle mechanism, maintains the flywheel with the proper moment of inertia. The invention is with the low speed features during the punching moment and the high speed features during the return and feeding moment, which can achieve the flexibility control of the slider movement, simplify the structure of the pressing machine, and reduce the cost.

Owner:XI AN JIAOTONG UNIV

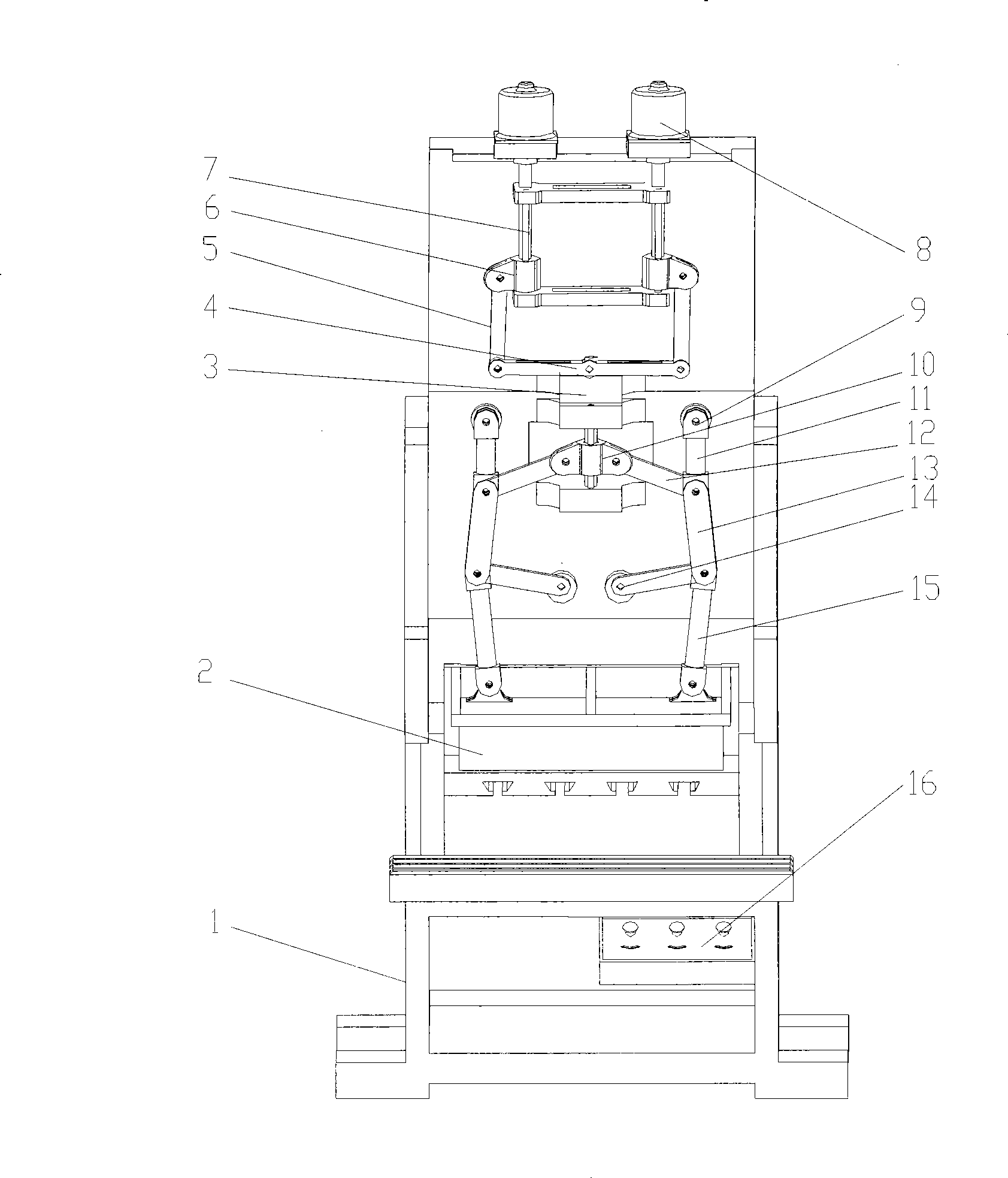

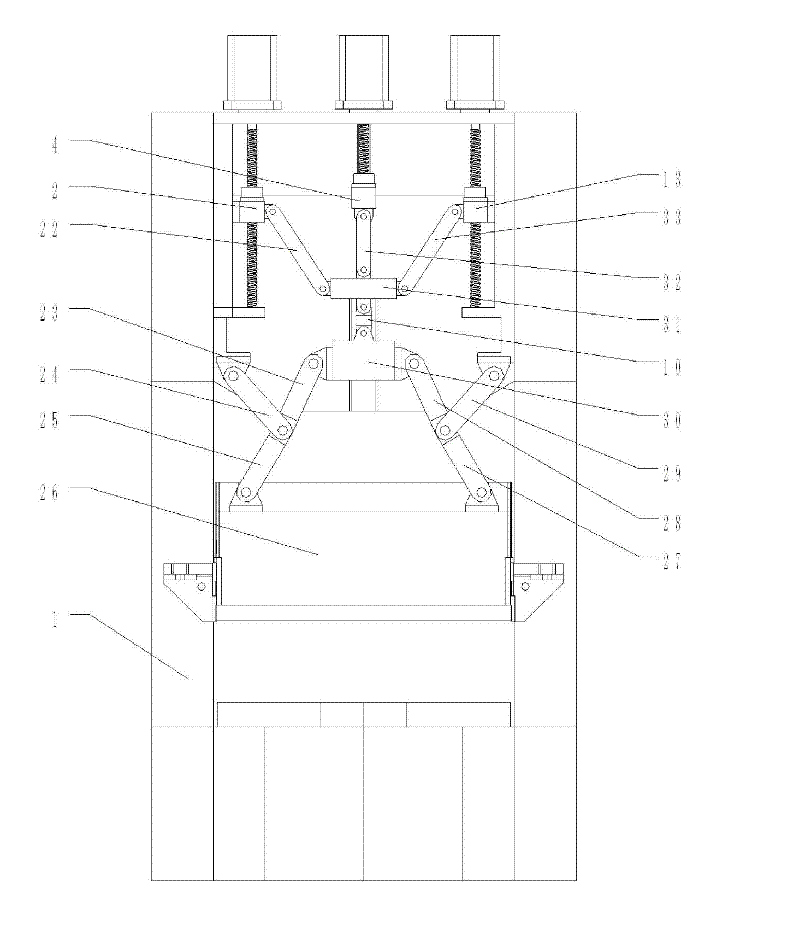

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876AGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, a horizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAO TONG UNIV

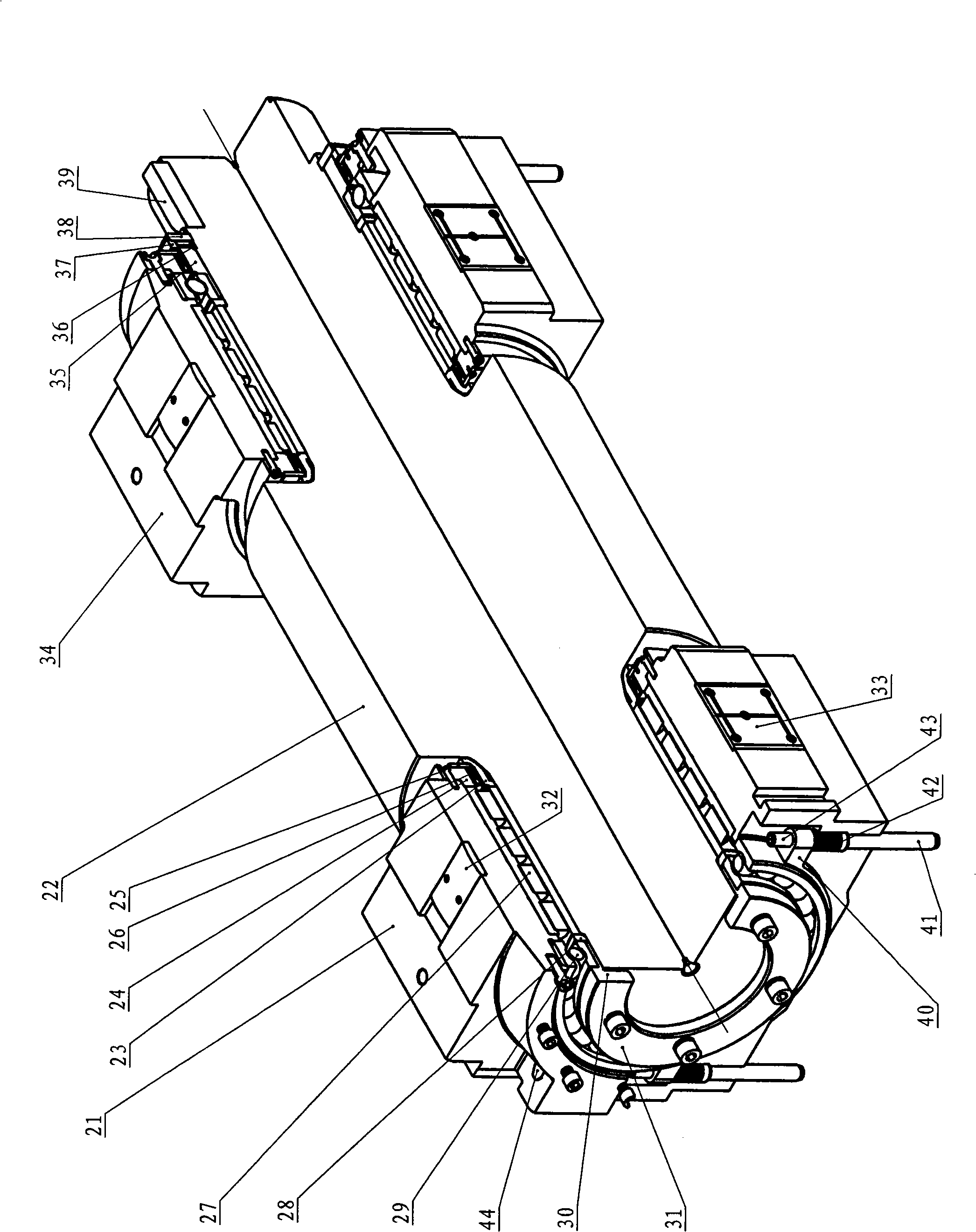

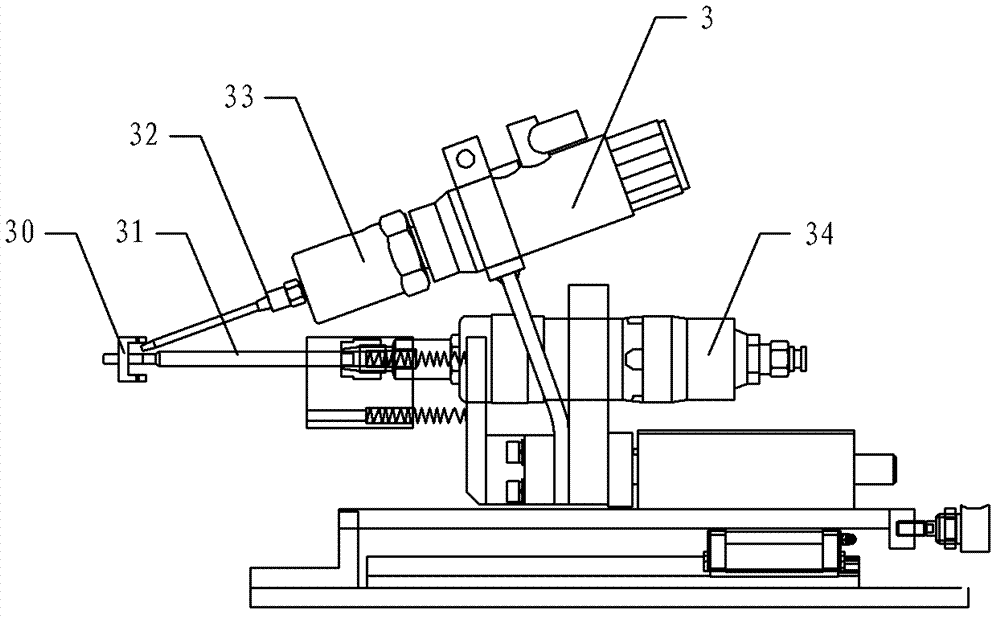

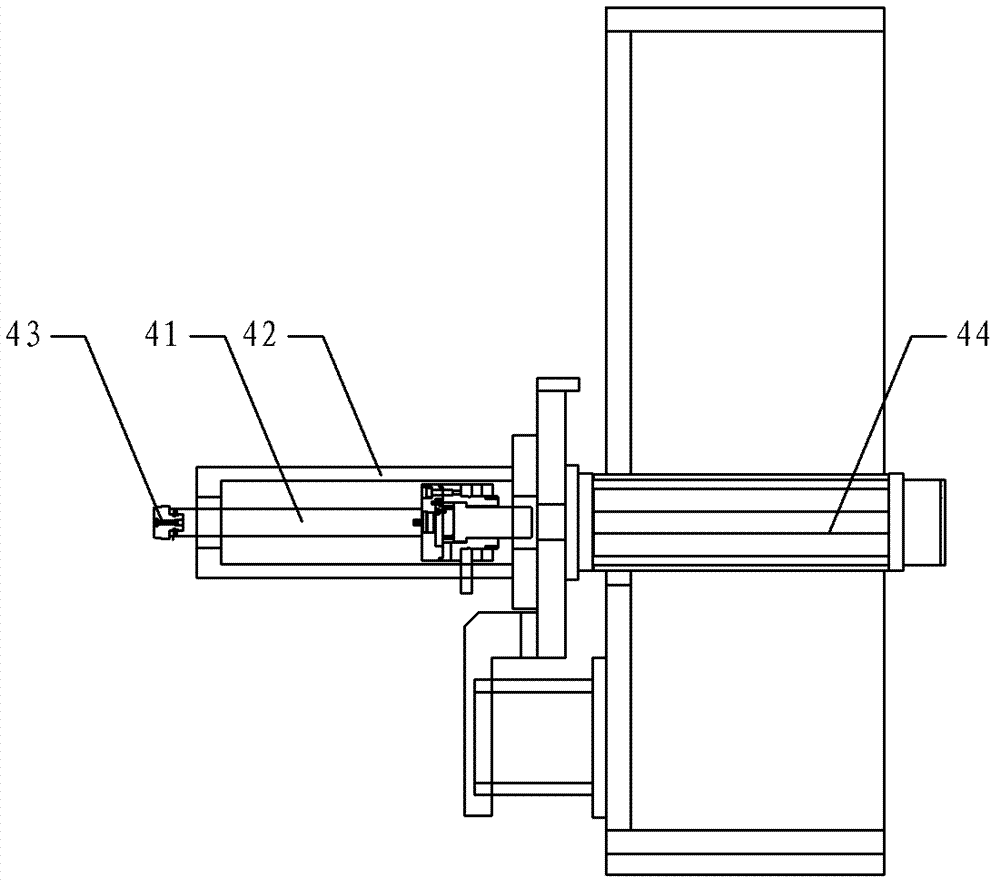

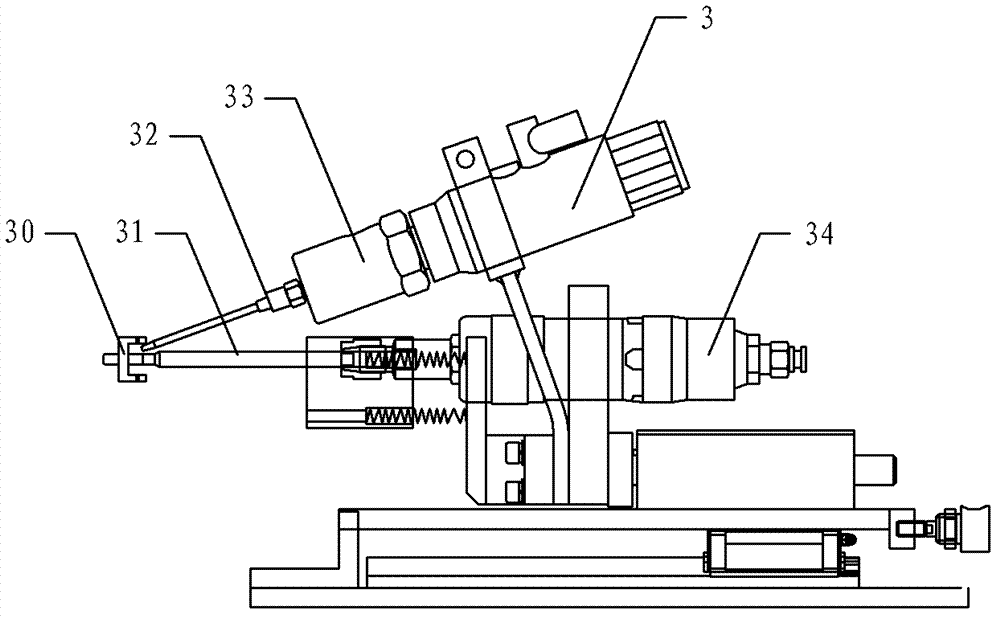

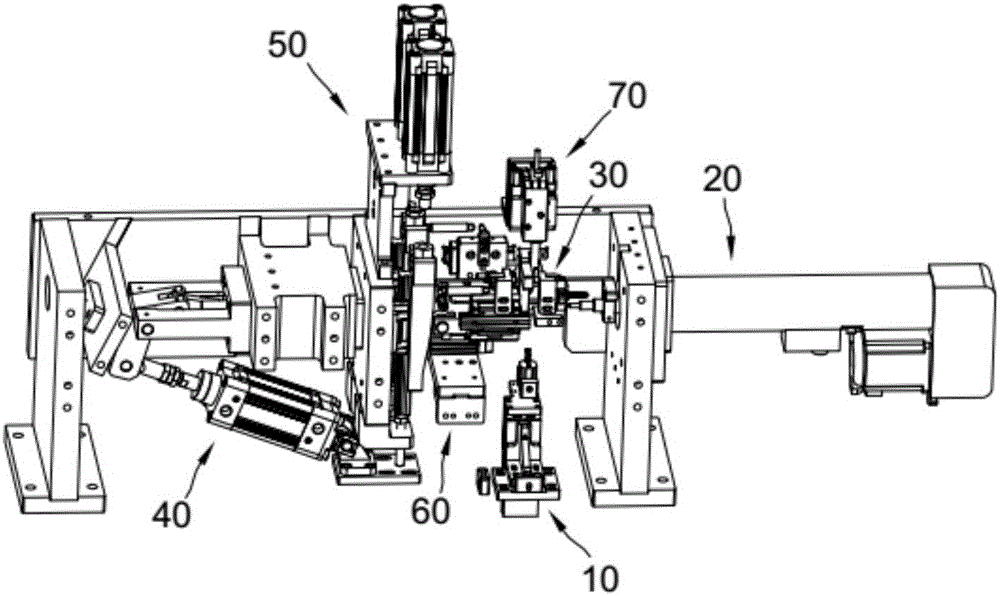

Gluing and servo pressing device for engine blocks and seals

The invention discloses a gluing and servo pressing device for engine blocks and seals. The gluing and servo pressing device comprises a flexible roller bed, a gluing device and a servo pressing device. The flexible roller bed is used for delivering and positioning the cylinder blocks; the gluing device is arranged on the lateral portion of the flexible roller bed delivering route; A glue dispenser is connected with a glue dispensing rod, the output end of the glue dispensing rod is connected with a glue dispensing plate, the glue dispensing plate is provided with small holes communicated with the outside environment, and one end of a glue-infusing needle is communicated with a glue-storing pot and the other end of the glue-infusing needle is communicated with small holes of the glue dispensing plate; the servo pressing device is arranged on the lateral portion of the flexible roller bed delivering route and a compression bar is in a guide sleeve; one end of the compression bar is fixedly connected with a pressure head and the other end of the pressure head is in transmission connection with a servo electric cylinder. By the gluing and servo pressing device for engine blocks and seals, the to-be-processed cylinders are automatically delivered to the fixed position by the flexible roller bed, the seals are automatically fed by a feeding device, the inner sides of the seal holes of the cylinder blocks are glued through the gluing device, and press fit of the blocks and the seals can be completed through the servo pressing device.

Owner:KETENG IND PANYU CITY

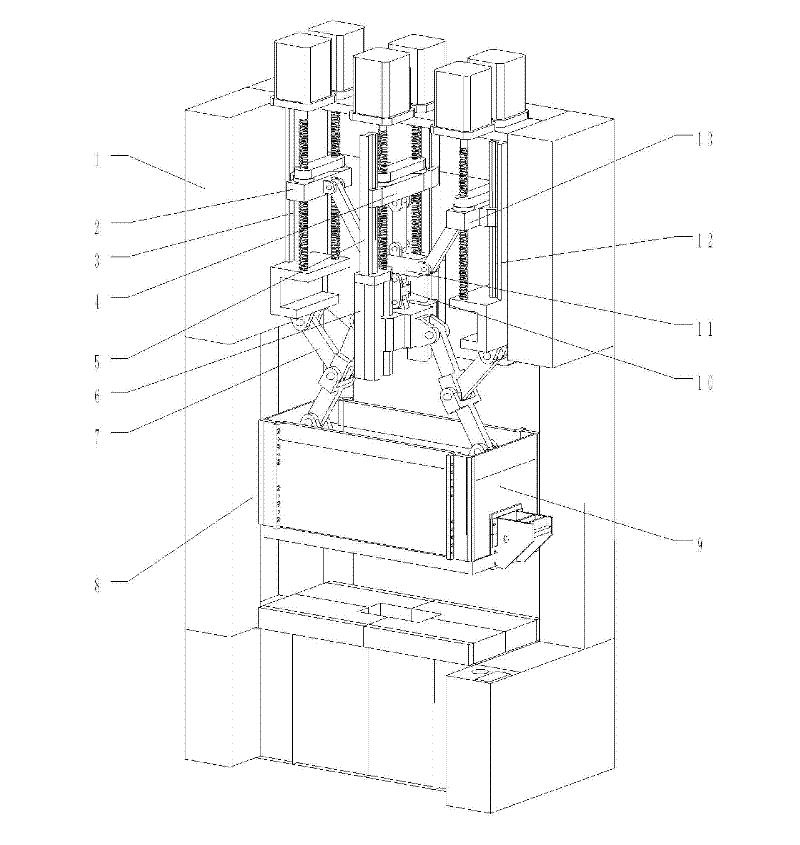

Mechanical multi-link servo press driven by six parallelly-connected motors

InactiveCN102172759AReduce loadReduce wearForging press drivesPress ramBall screwThree degrees of freedom

The invention discloses a mechanical multi-link servo press driven by six parallelly-connected motors, which belongs to the technical field of forging machines. The mechanical multi-link servo press comprises a rack, three sets of same linear drive mechanisms, a TDOF (three degree of freedom) parallel mechanism, a toggle link mechanism and a stamping slide block, wherein the three sets of linear drive mechanisms are connected with the parallel mechanism, the toggle link mechanism is respectively connected with the TDOF parallel mechanism and the stamping slide block, and the rack is connectedand sleeved on the outer sides of the drive mechanisms and the stamping slide block. The mechanical multi-link servo press disclosed by the invention has the advantages of simple structure and low manufacturing cost, is easy to control, and can solve the problem that that a large tonnage servo press cannot be structured because the traditional servo press is limited by the small carrying capacityof a ball screw and the small power and output torque of a servo motor.

Owner:SHANGHAI JIAO TONG UNIV

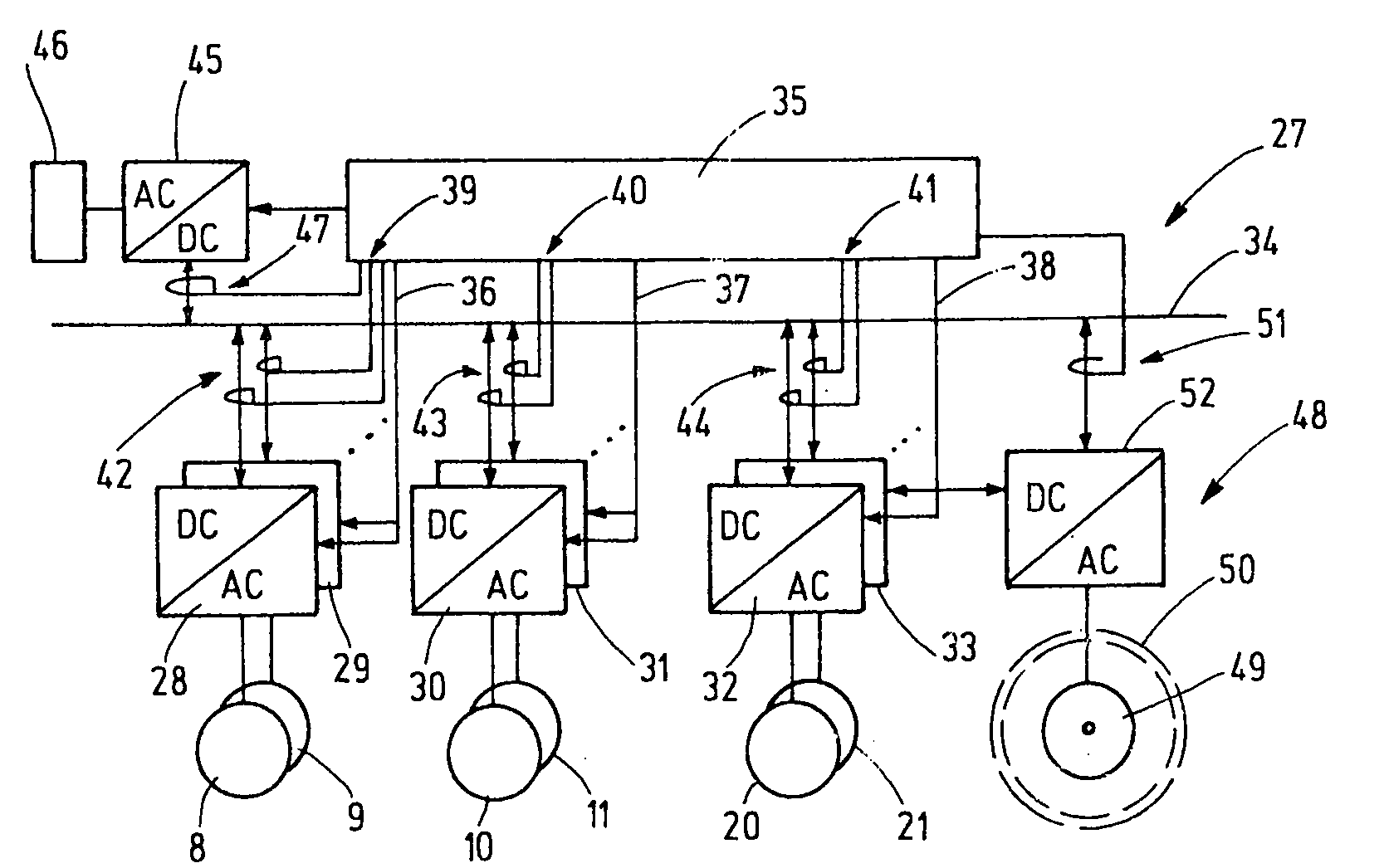

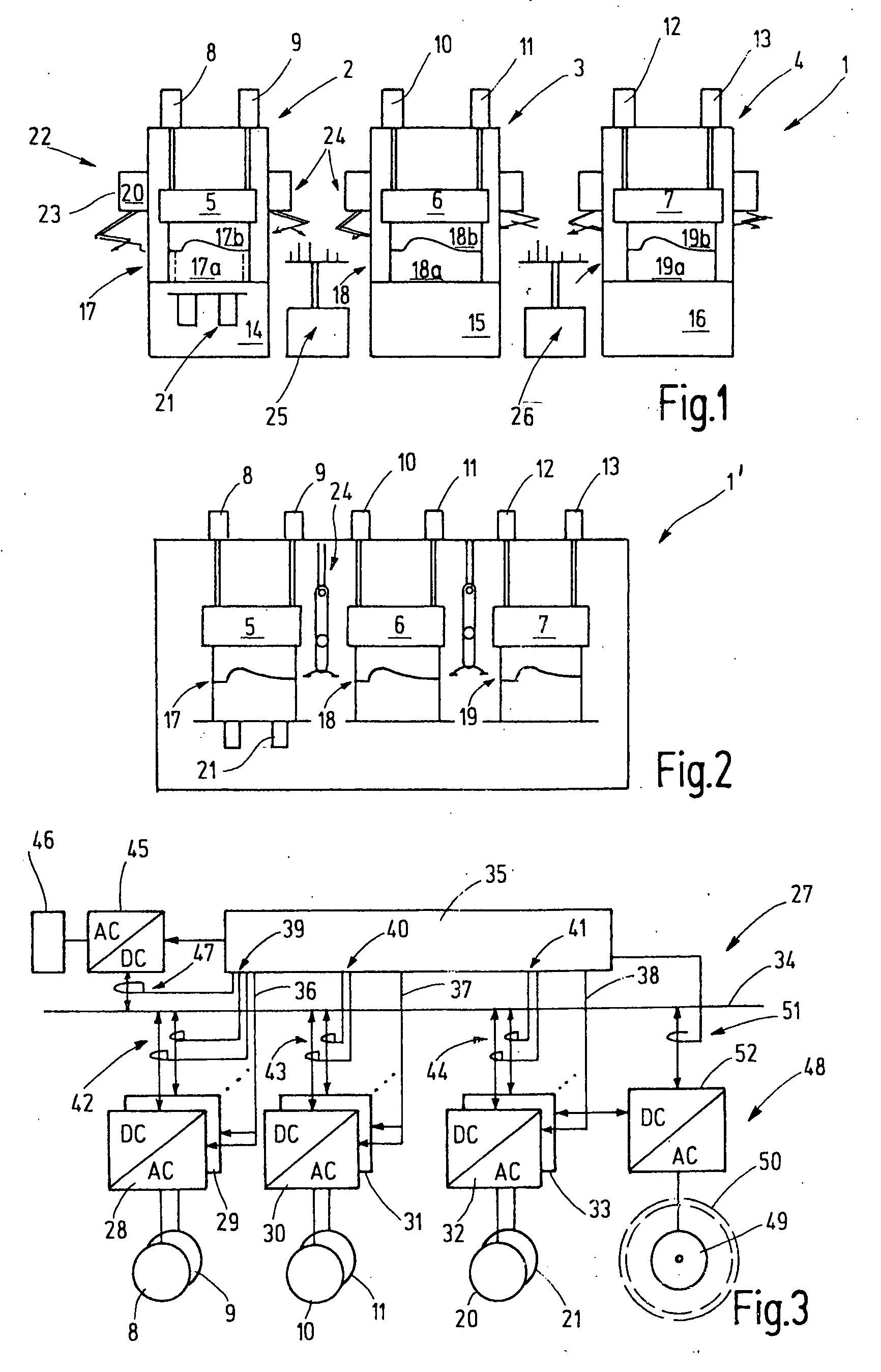

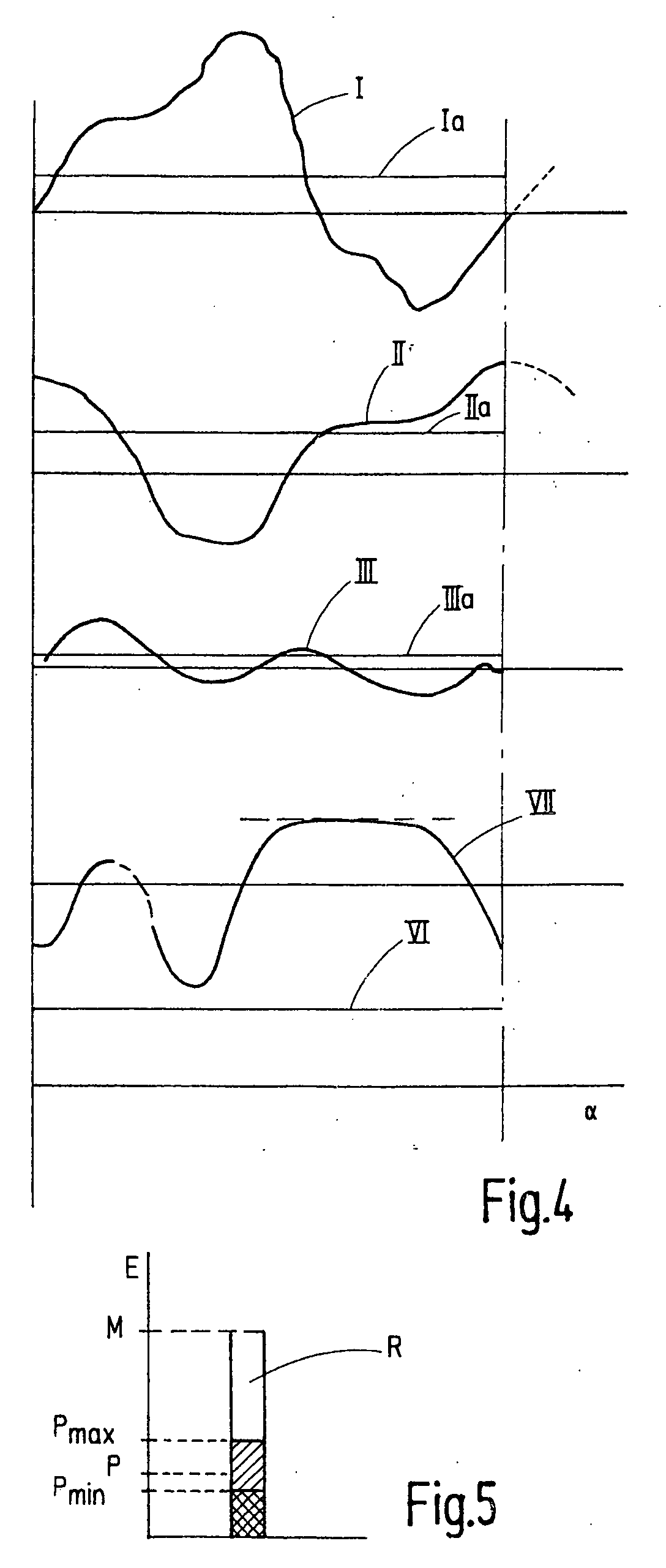

Servo-press with energy management

InactiveUS20080016940A1Arrangement be smallLow costDrop hammersMetal-working feeding devicesServo pressEnergy management system

In a press installation including a number of presses with servo-drives for operating the presses and auxiliary equipment such as workpiece handling devices wherein an energy management system is provided including a DC voltage intermediate circuit connected to a power supply grid via an AC / DC converter and to the servo-drives via servo-converters, a fly-wheel storage device is connected to the intermediate circuit for supplying energy thereto and recapturing energy therefrom under the control of a control arrangement which controls the flow of power between the intermediate circuit, the servo-drives, the fly-wheel storage device and the power supply grid.

Owner:SCHULER PRESSEN GMBH & CO KG

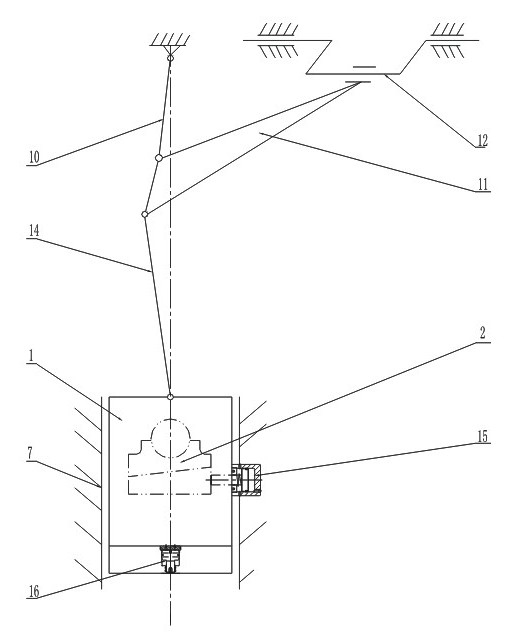

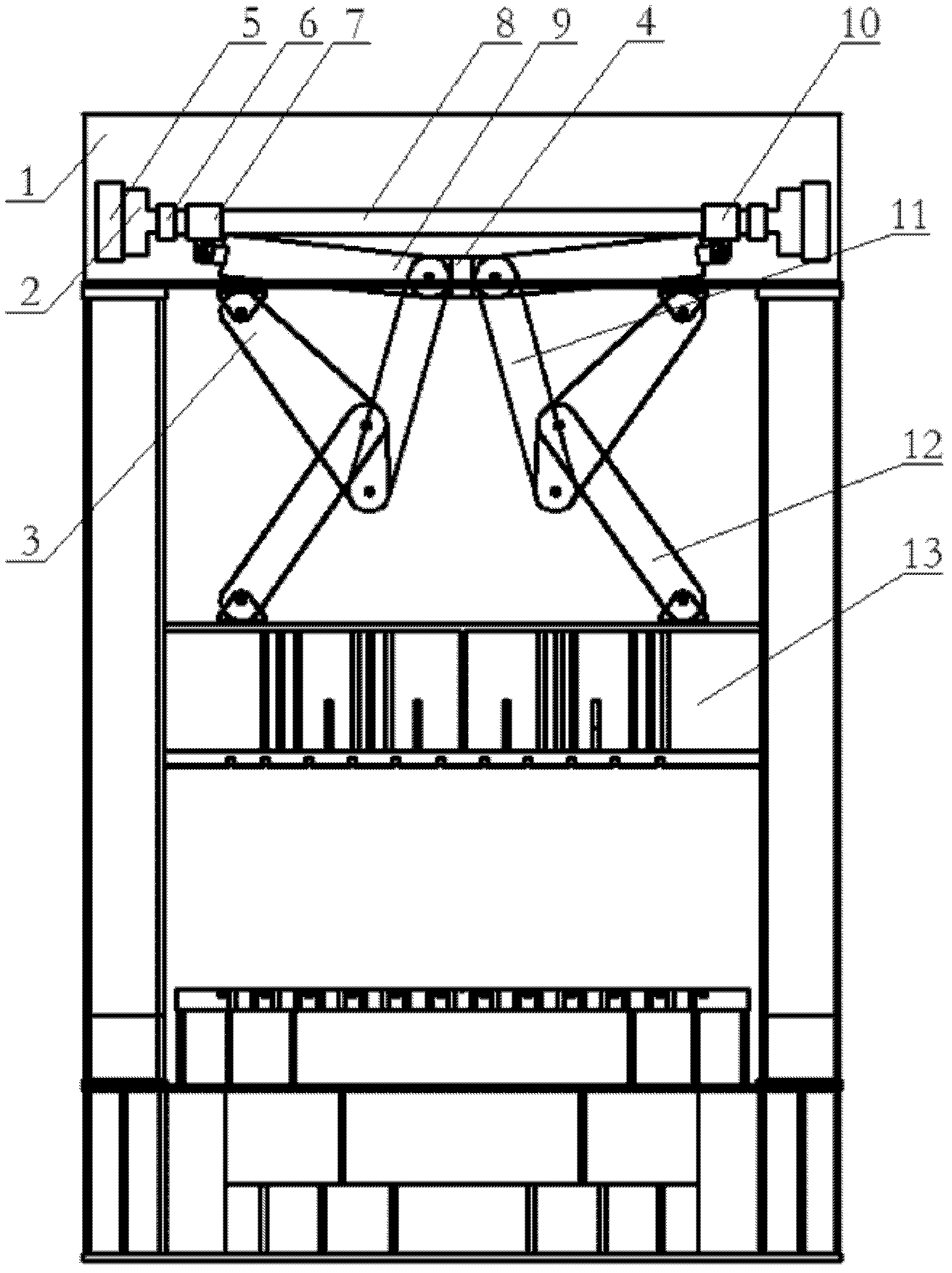

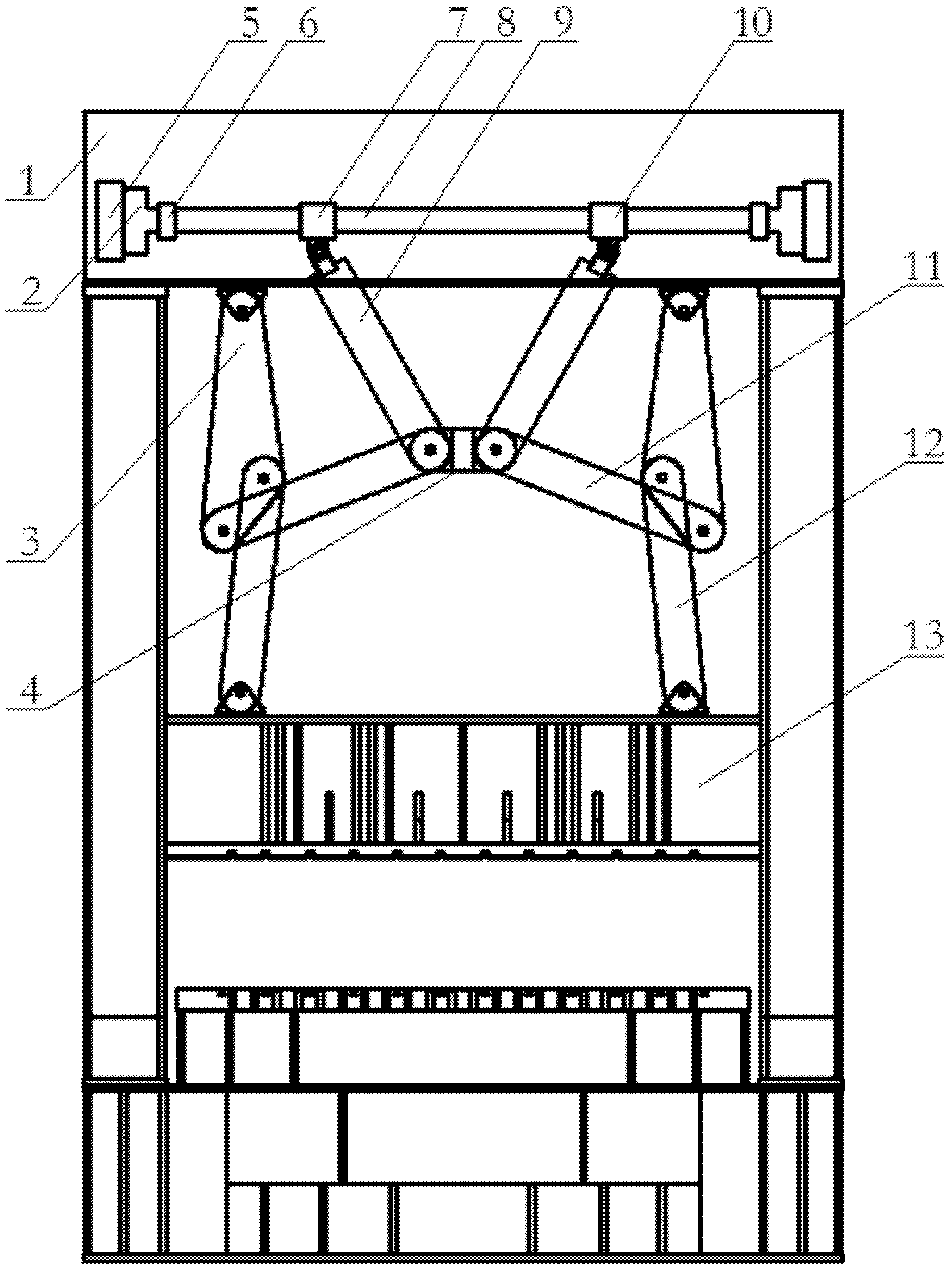

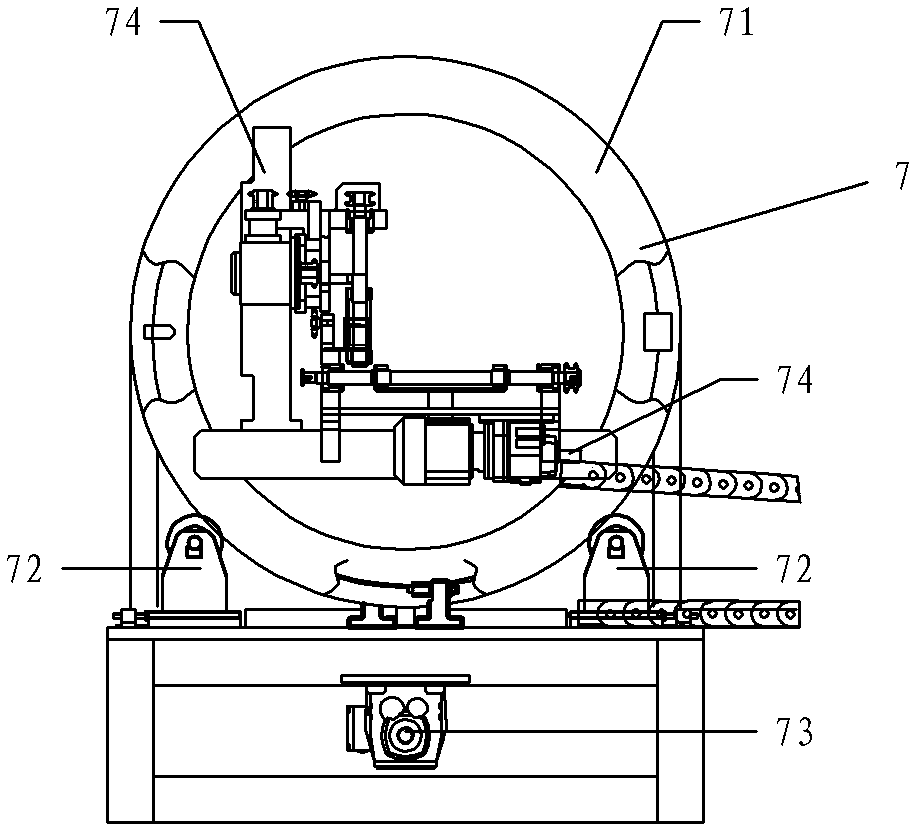

Triangular connecting rod-toggle rod transmission mechanism with large force magnification ratio for servo press

The invention discloses a triangular connecting rod-toggle rod transmission mechanism with a large force magnification ratio for a servo press. The mechanism comprises a servo motor, an upper pin shaft, an upper toggle rod, a triangular connecting rod, a crank, a middle pin shaft, a lower toggle rod, an unloading oil cylinder and an ejecting oil cylinder, wherein the output shaft of the servo motor is connected with the crank through a transmission mechanism; the crank is connected with the connecting rod; the connecting rod is connected with the upper toggle rod and the lower toggle rod respectively; the upper toggle rod is hinged and fixed on the machine body; the lower toggle rod is connected with a slider capable of linearly reciprocating up and down along a guide rail of the machine body through a wedged overload protection block and the unloading oil cylinder; the upper toggle rod and the lower toggle rod have different lengths and are asymmetric; and the connecting rod is triangular. As symmetric toggle rods are changed into asymmetric toggle rods, and a linear connecting rod is changed into the triangular connecting rod, a relatively large force magnification ratio is obtained, the drive torque required by the crank is remarkably reduced, and the capacity and cost of the servo motor are reduced under the condition of guaranteeing compact structure of the machine body, enough stroke of the slider and monotonous descending of the slider.

Owner:GUANGDONG METAL FORMING MACHINE WORKS +1

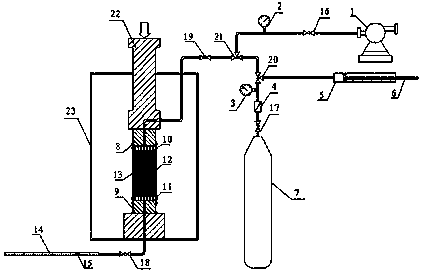

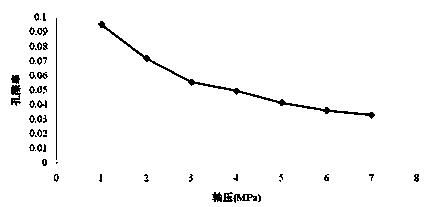

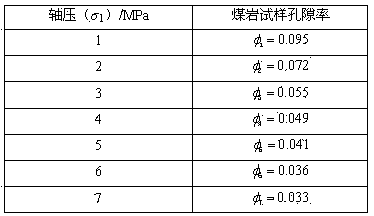

System and method for accurately measuring dynamic change of porosity of loaded coal rock

ActiveCN104266951AAccurate measurement of porosityAccurately measure dynamic changesPermeability/surface area analysisPorosityRock sample

The invention discloses a system and a method for accurately measuring the dynamic change of the porosity of loaded coal rock. The system comprises a vacuum-pumping device, a helium supply device, a porosity measurement device, a porosity variation measurement device and a three-axis servo press used for applying load. The system is capable of accurately measuring the dynamic change of the porosity of the coal rock under the loading condition, and can be used for accurately measuring the porosity of the coal rock sample under the specific load and accurately measuring the dynamic change of the porosity of the coal rock sample in the loading process.

Owner:HENAN POLYTECHNIC UNIV

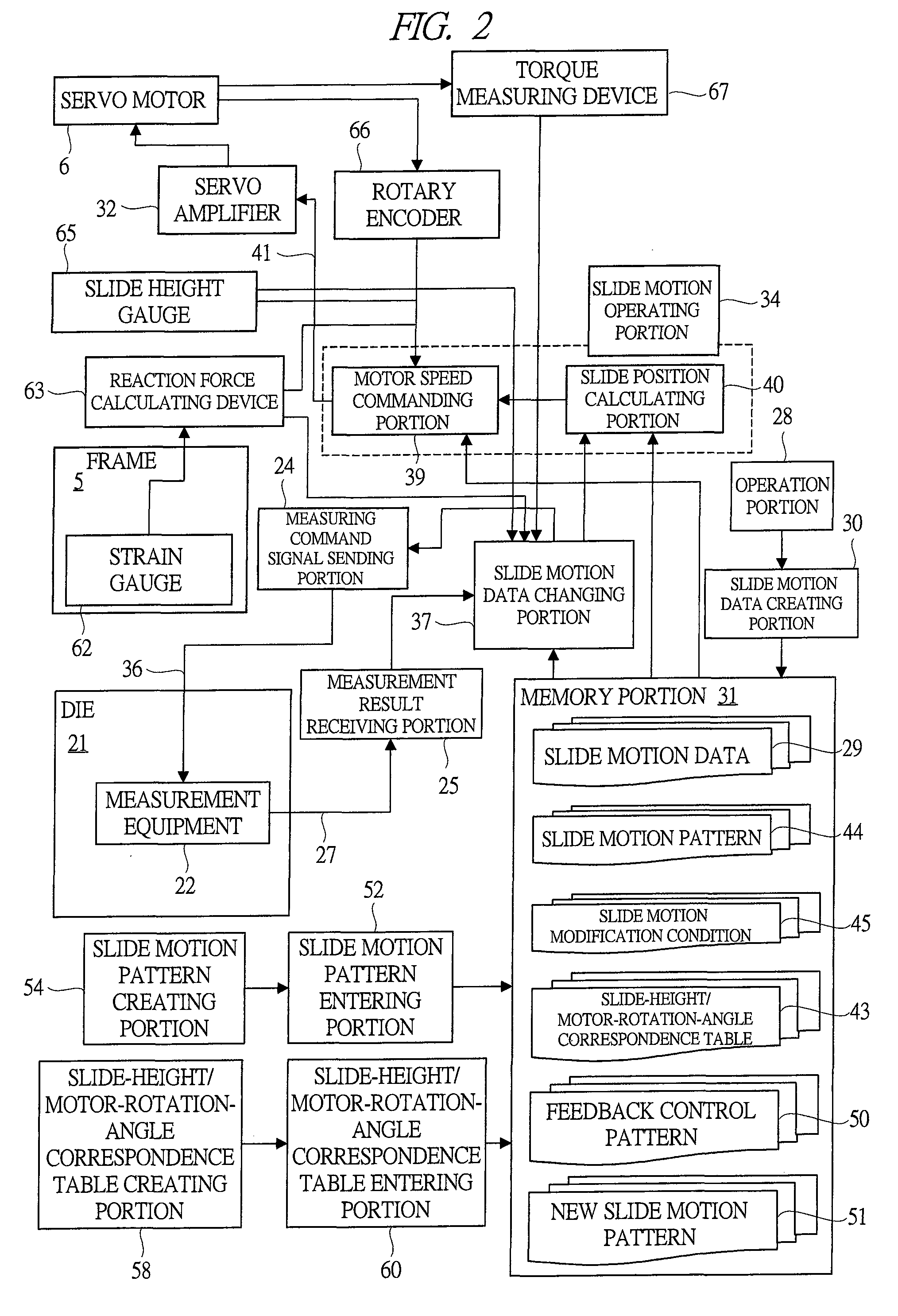

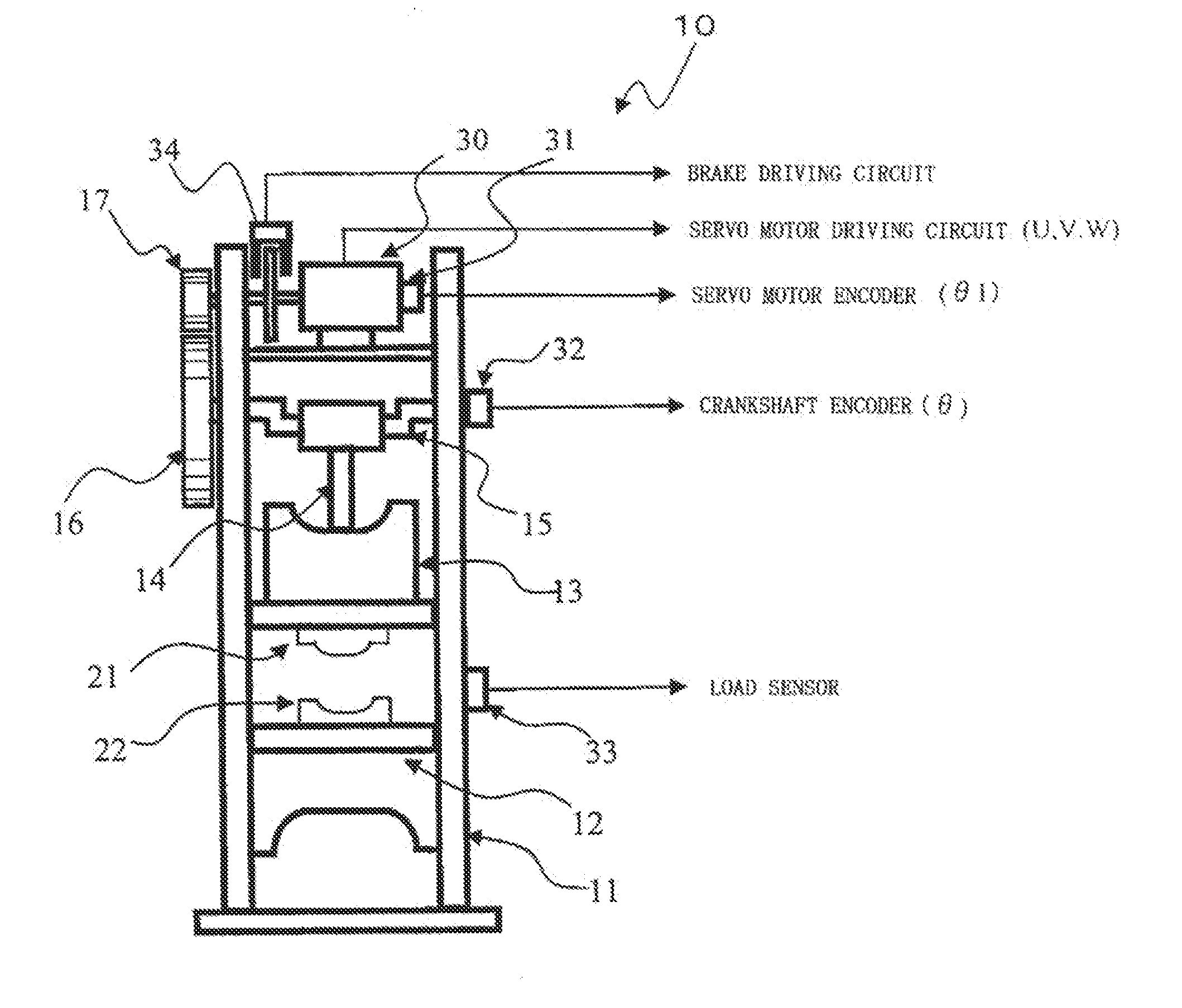

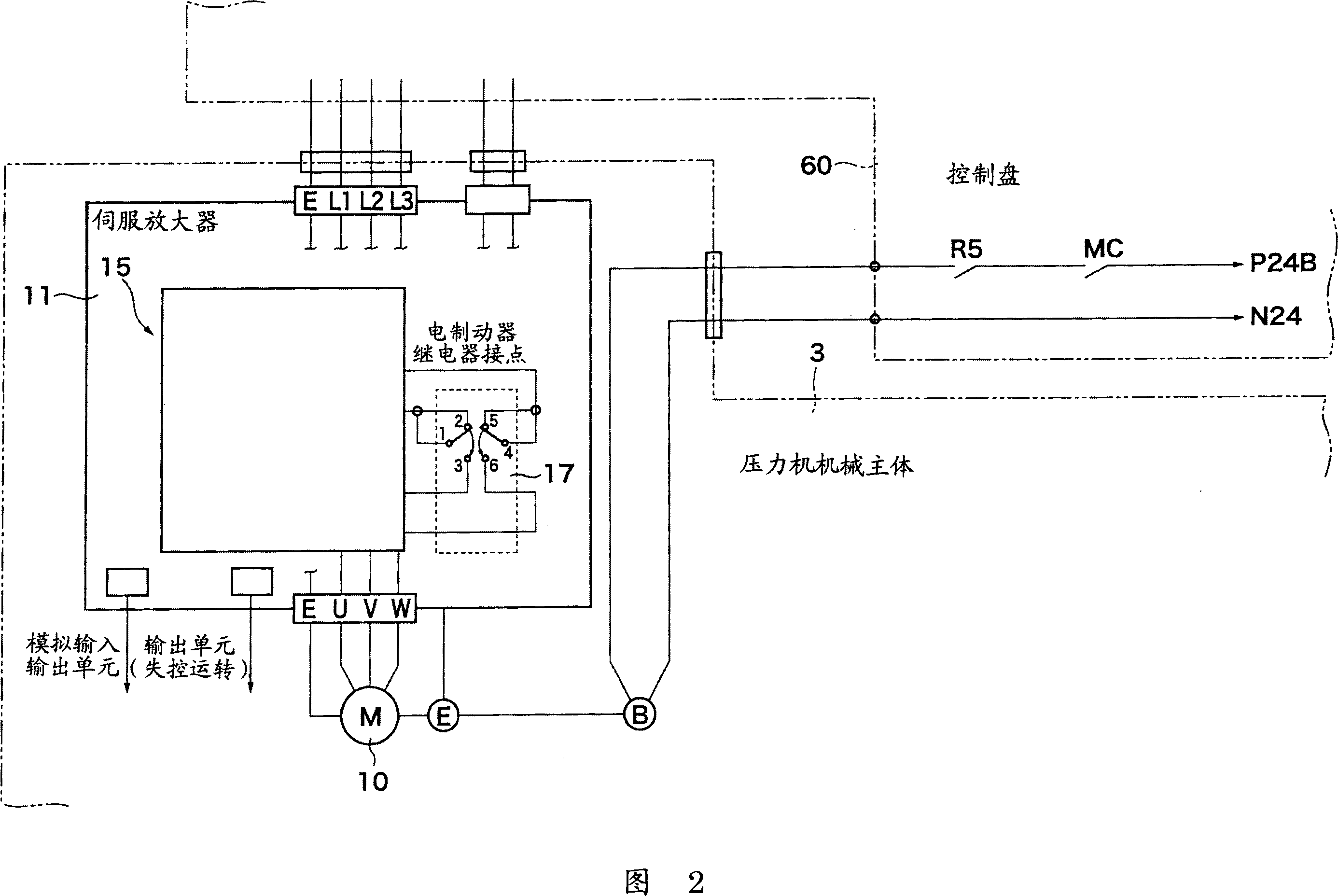

Electric servo-press, and control device and control method for electric servo press

ActiveUS20110109257A1Simple and inexpensive structureSafe and reliable stopLimiting/preventing/returning movement of partsPressesElectric machineControl system

Provided is a low-cost control device for an electric servo press, which is excellent in operability and operation efficiency, capable of abruptly stopping a servomotor in a safe and reliable manner within a short time period in response to an abrupt stop command while avoiding hard actuation of a mechanical brake, reliably and quickly stopping the servomotor even in the case where runaway of the servomotor or the like occurs. An electric servo press performs switching to rotation stop control for a servomotor according to an abrupt stop motion based on an abrupt stop command signal to perform brake actuation so as to cause a mechanical brake to actually start braking and to forcibly interrupt rotational drive power to the servomotor at a scheduled stop time at which the servomotor is stopped according to the abrupt stop motion. As a result, even if an abrupt stop request is issued in the case where runaway or the like occurs due to abnormality of the servomotor, a control system therefor, or the like, the rotation of the servomotor may be reliably and quickly stopped.

Owner:AIDA ENG LTD

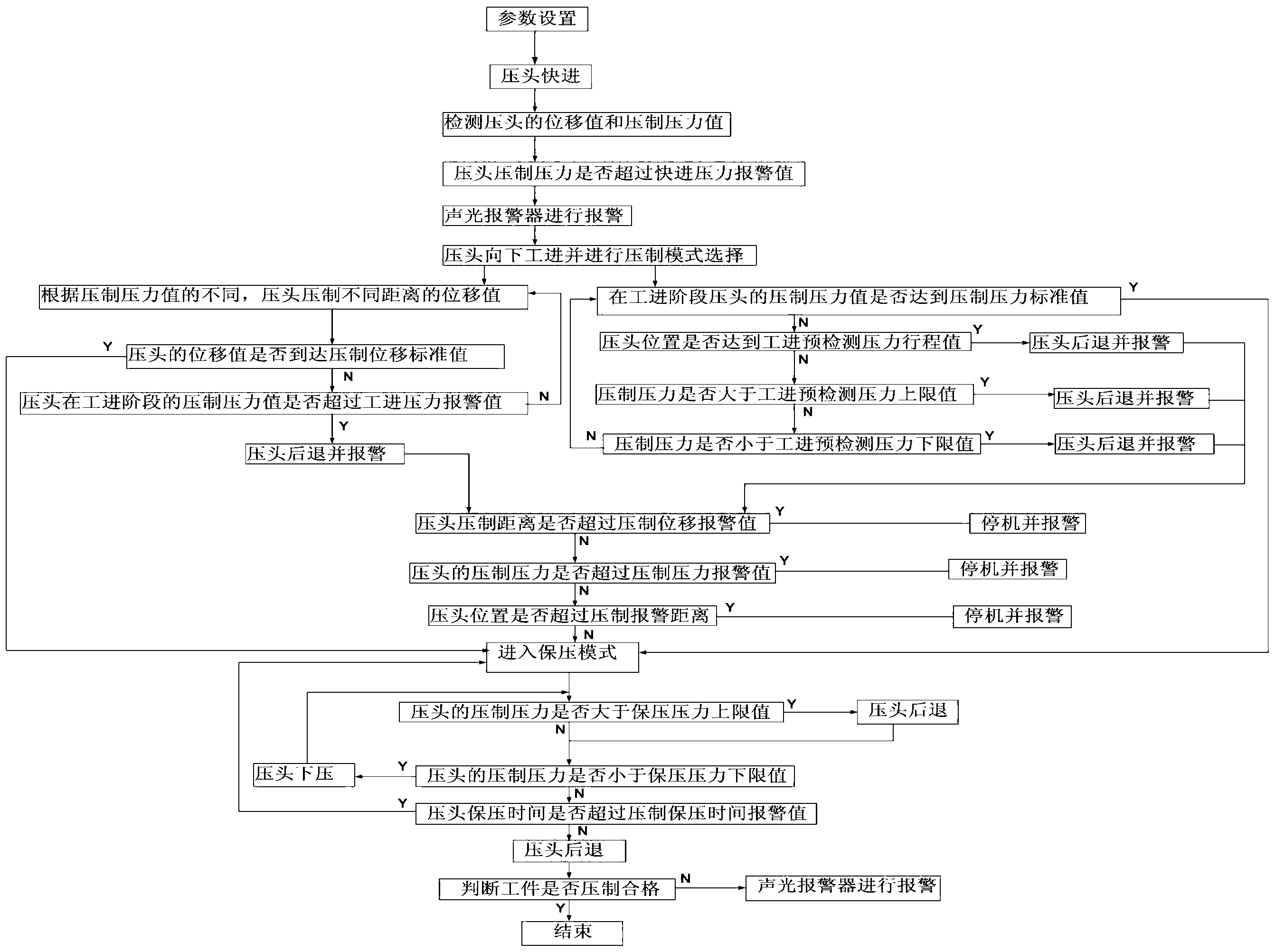

Full-route high-accuracy servo press mounting method

The invention discloses a full-route high-accuracy servo press mounting method and belongs to the technical field of numerical control machine tools. The full-route high-accuracy servo press mounting method integrates advanced technologies of servo control technology, sensing technology, industrial computer control technology and the like and solves the problem of inaccurate position and bounce of press-in workpieces of the previous production process. By means of the full-route high-accuracy servo press mounting method, pressure, speed and interference magnitude can be automatically adjusted according to different gaps, different roughness and different hardness, and stable and accurate positioning accuracy can be ensured. By monitoring the pressure and displacement during the whole pressing process, workpieces deformed elastically can be pressed accurately, errors caused by manual observation can be reduced, and qualified pressing on the workpeices deformed elastically can be ensured.

Owner:CHONGQING INST OF MECHANICAL & ELECTRICAL ENG

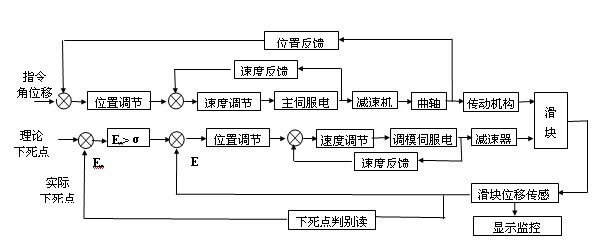

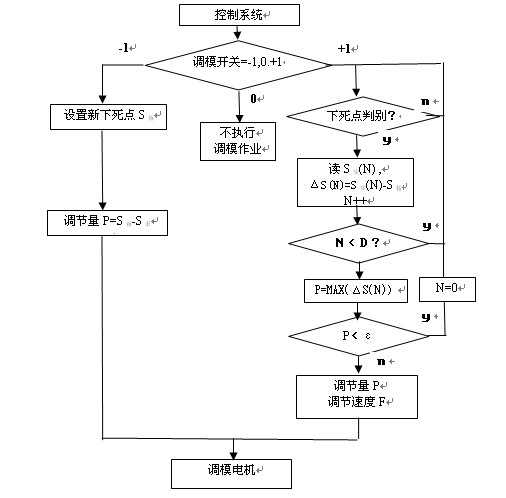

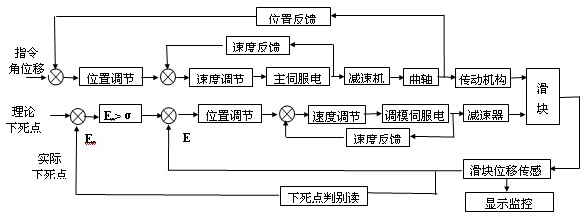

Control method of servo press

The invention relates to a control method of a servo press, and in particular to a bottom dead centre control method of the servo machine. The control method comprises a bottom dead centre reading and identification module, a comparison module and a threshold value module, wherein the bottom dead centre reading and identification module is used for identifying continuous signals in each work cycle period which are detected by a sliding block displacement sensor, and reading a bottom dead centre position value in the current cycle period; the comparison module is used for comparing a current bottom dead centre position value with a system setting value, and calculating an offset of the bottom dead centre; the threshold value module is used for comparing the current bottom dead centre offset of a sliding block with a given threshold value, if the bottom dead centre offset is greater than the given threshold value, the system starts a mould adjusting system to adjust the sliding block to a commanded bottom dead centre. The invention provides the control method of the servo press which can automatically adjust the bottom dead centre of the sliding block, and can satisfy work requirements for precision punching of the press.

Owner:扬州智科光机电技术开发中心有限公司

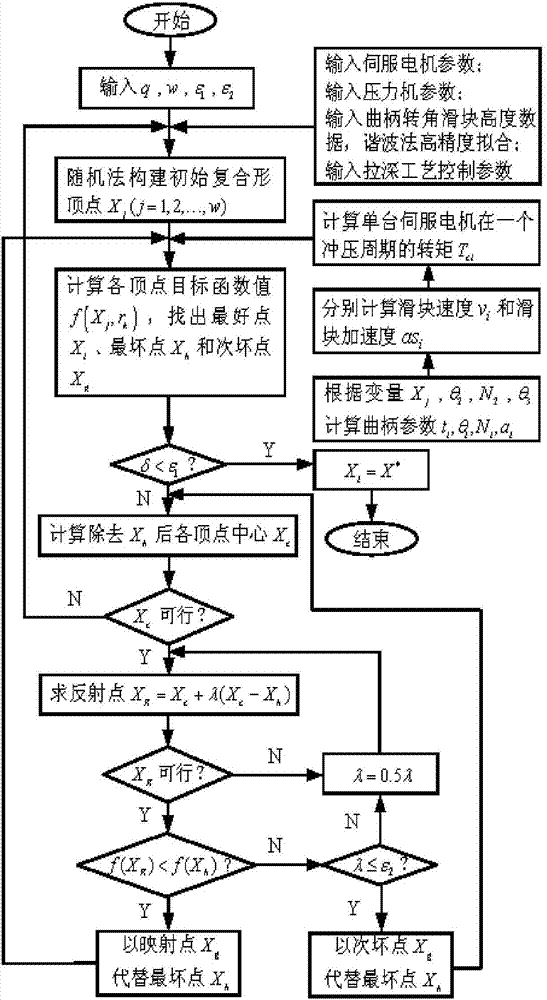

Optimum design method of drawing processing technology locus of servo press

InactiveCN103678829AImprove general performanceMeet real-time requirementsSpecial data processing applicationsMathematical modelElectric machinery

The invention discloses an optimum design method of a drawing processing technology locus of a servo press. The optimum design method comprises the following steps of establishing a general mathematical model used for describing a movement locus of a slider block of the servo press by utilizing a Fourier series theory; establishing a drawing processing technology mode of the servo press by utilizing the acceleration and deceleration characteristic of a servo motor; establishing a crank acceleration and deceleration mathematical model based on a quintic polynomial; selecting an optimum design variable and establishing all kinds of constraint conditions which need to be met during operation of a press, the servo motor and a transmission manipulator; establishing an optimum target function; obtaining the drawing processing technology locus with a minimum stamping period of the servo press. The optimum design method adopts the Fourier series theory to construct the general mathematical model of a transmission mechanism of the servo press at high precision, and is suitable for any transmission mechanism configuration and different mechanism sizes, and is strong in universality. The optimum design method adopts a compound optimization algorithm and a computing method of classifying the constraint conditions, so that the optimal computation efficiency is high to meet the engineering instantaneity requirement.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

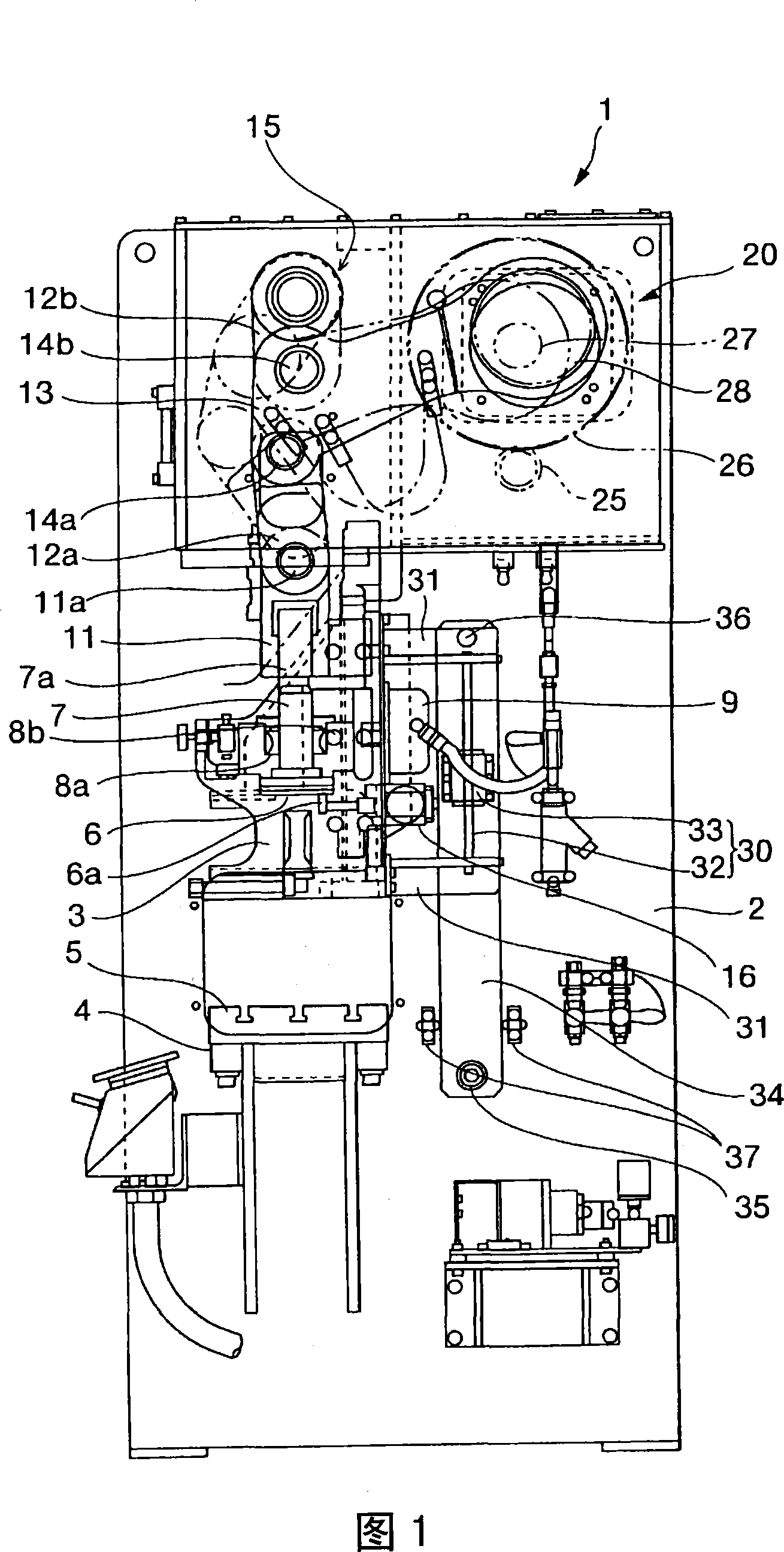

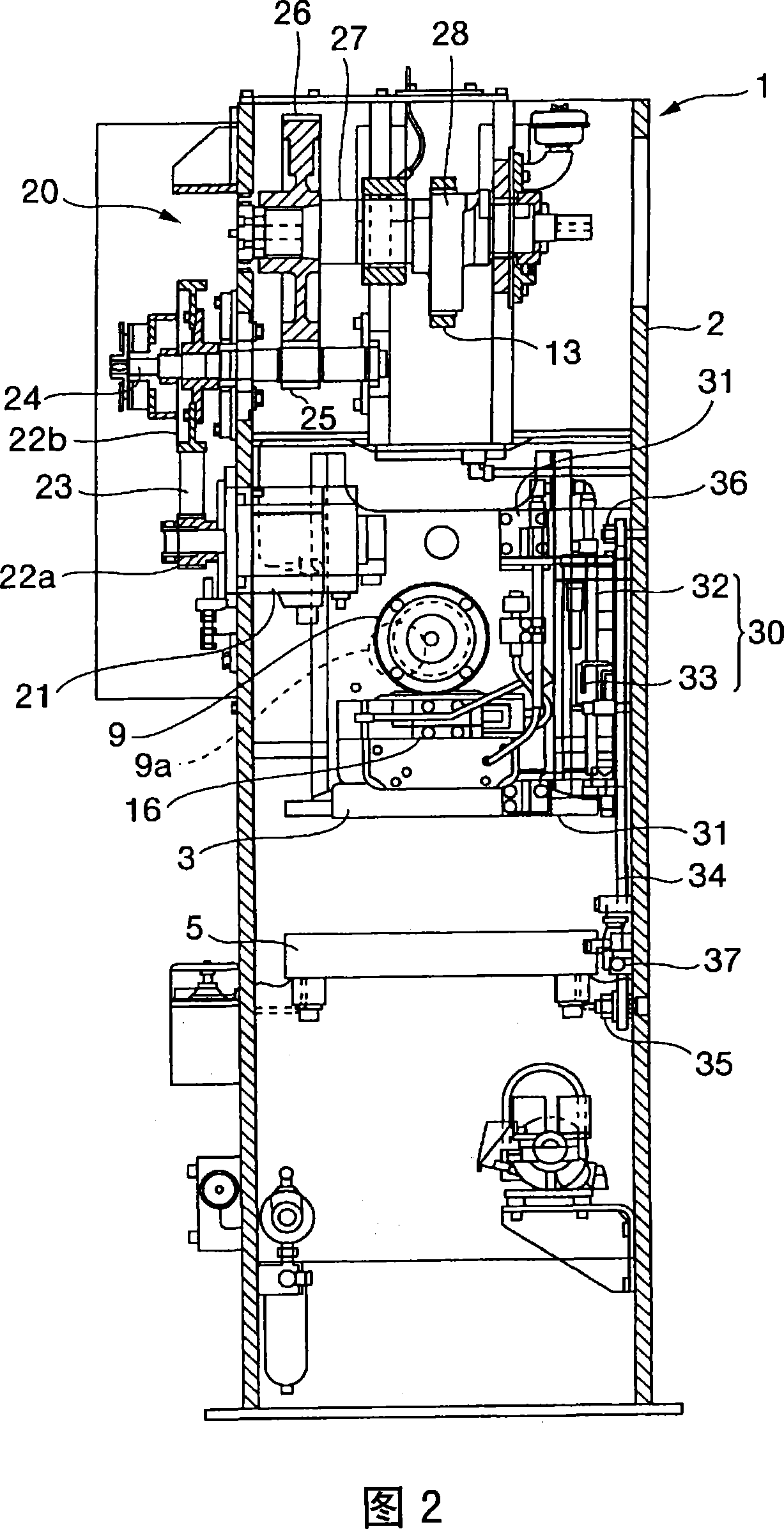

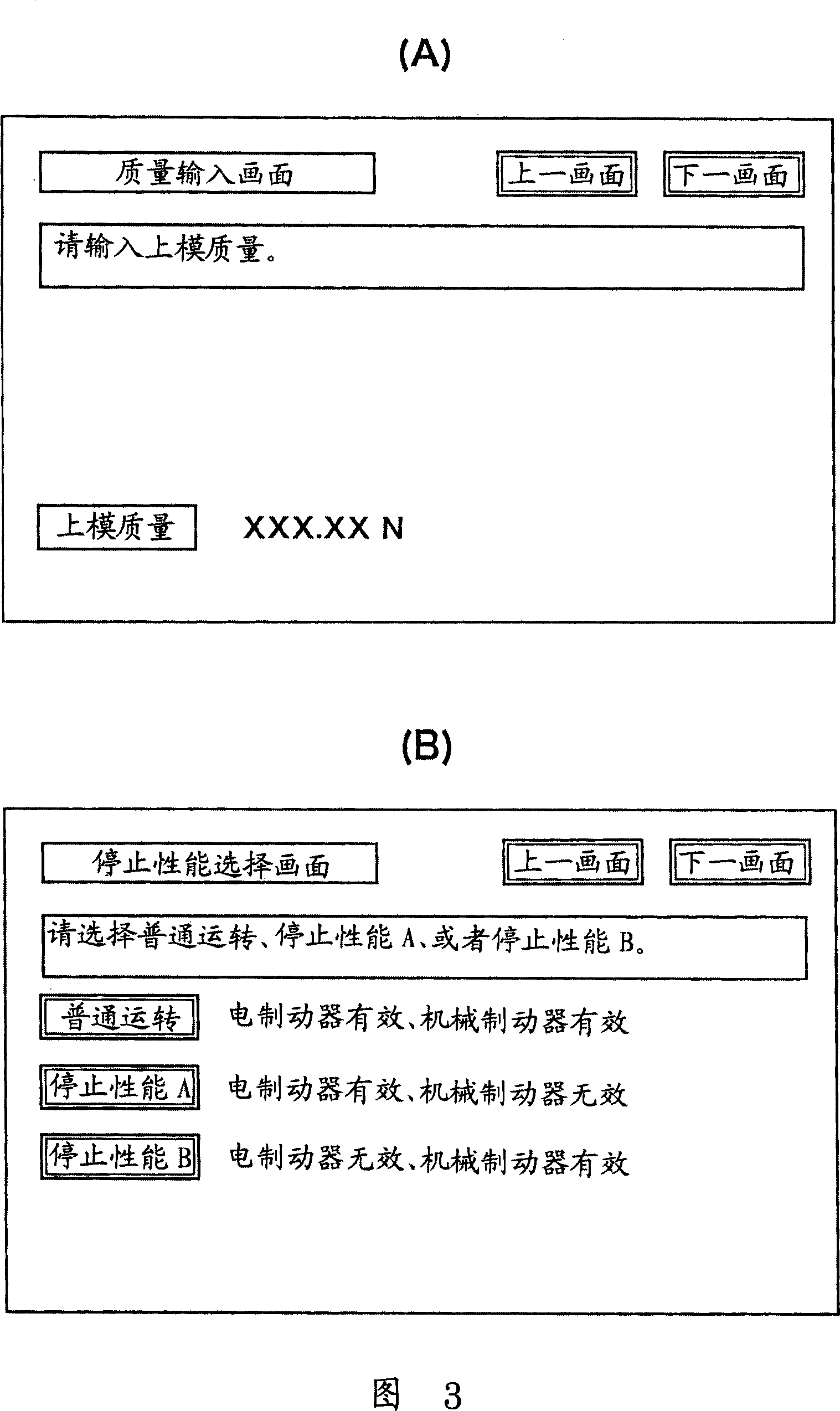

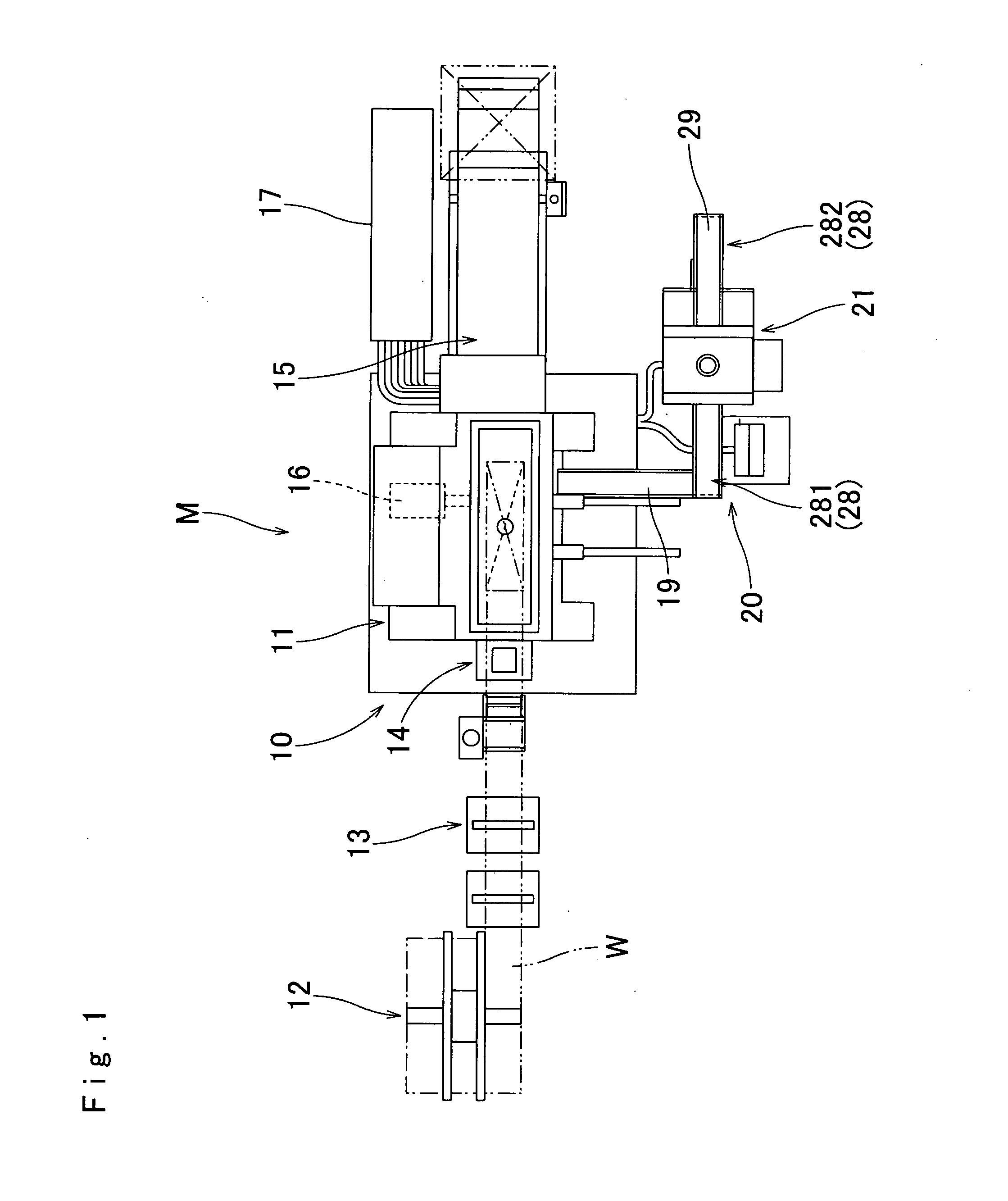

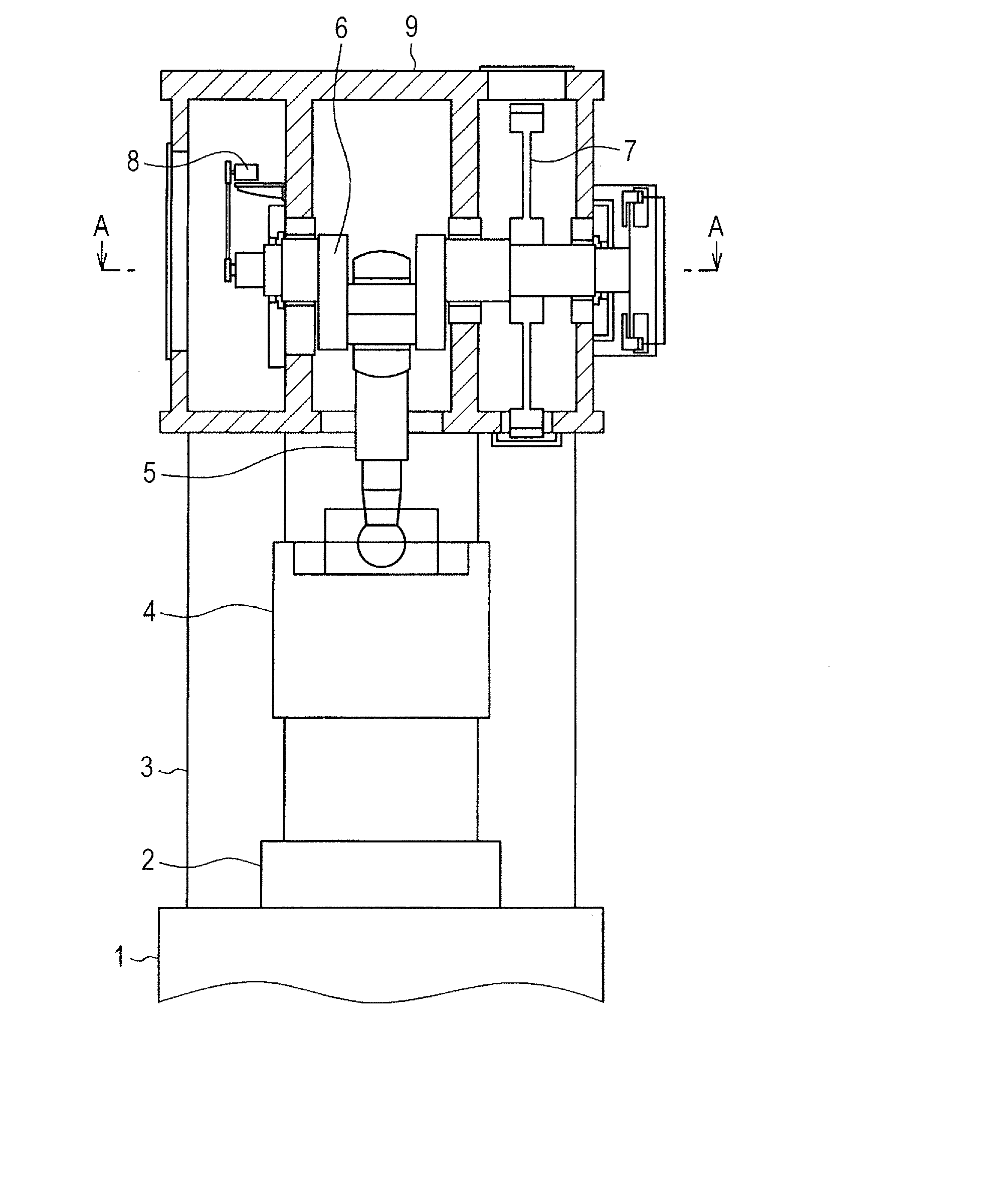

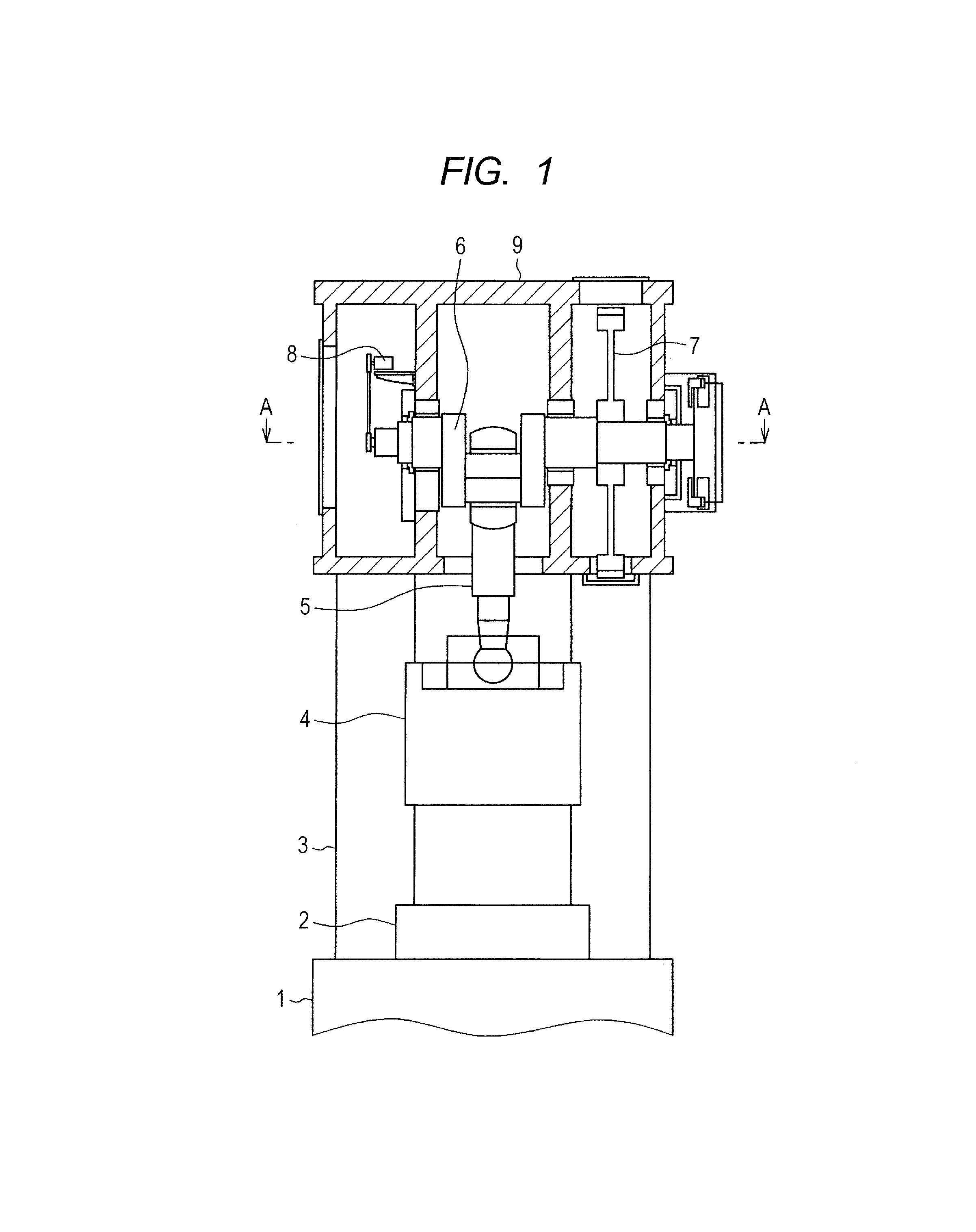

Servo pressing machine

Provided is a servo- pressing machine having experiment functions to judge more accurately brake performances during emergency stop. The servo- pressing machine (1) executes as a series of actions, e following brake performance experiments: a) beginning an experiment; b) dropping down a link slide block at a fixing speed; c) emergency stop signals instructions; d) working of the electrical brake and the mechanical brake; e) measuring the time (stop time) from c) to stopping of the link slide block, and / or calculating the moving distance from c) to stopping of the link slide block; f) judging whether the stop time and / or the moving distance is qualified; g) making only the electrical brake of the mechanical brake to run and implementing b)-e), if f) judges that is not qualified; h) judging respectively whether the stop time and / or moving distance for each brake is qualified; i) displaying the judging results. Since the servo- pressing machine body has an instruction sequence for executing brake performance tests, one can executing examination procedures proportioning task instances without consigning an inspecting authority to execute emergency stops for examination procedures affirmation and the like.

Owner:JAPAN AUTOMATIC MACHINE

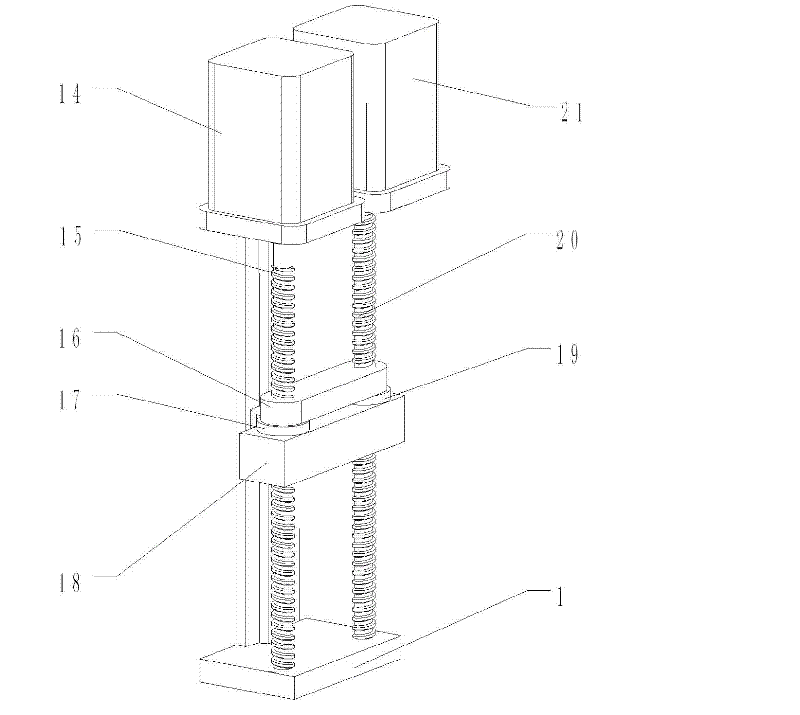

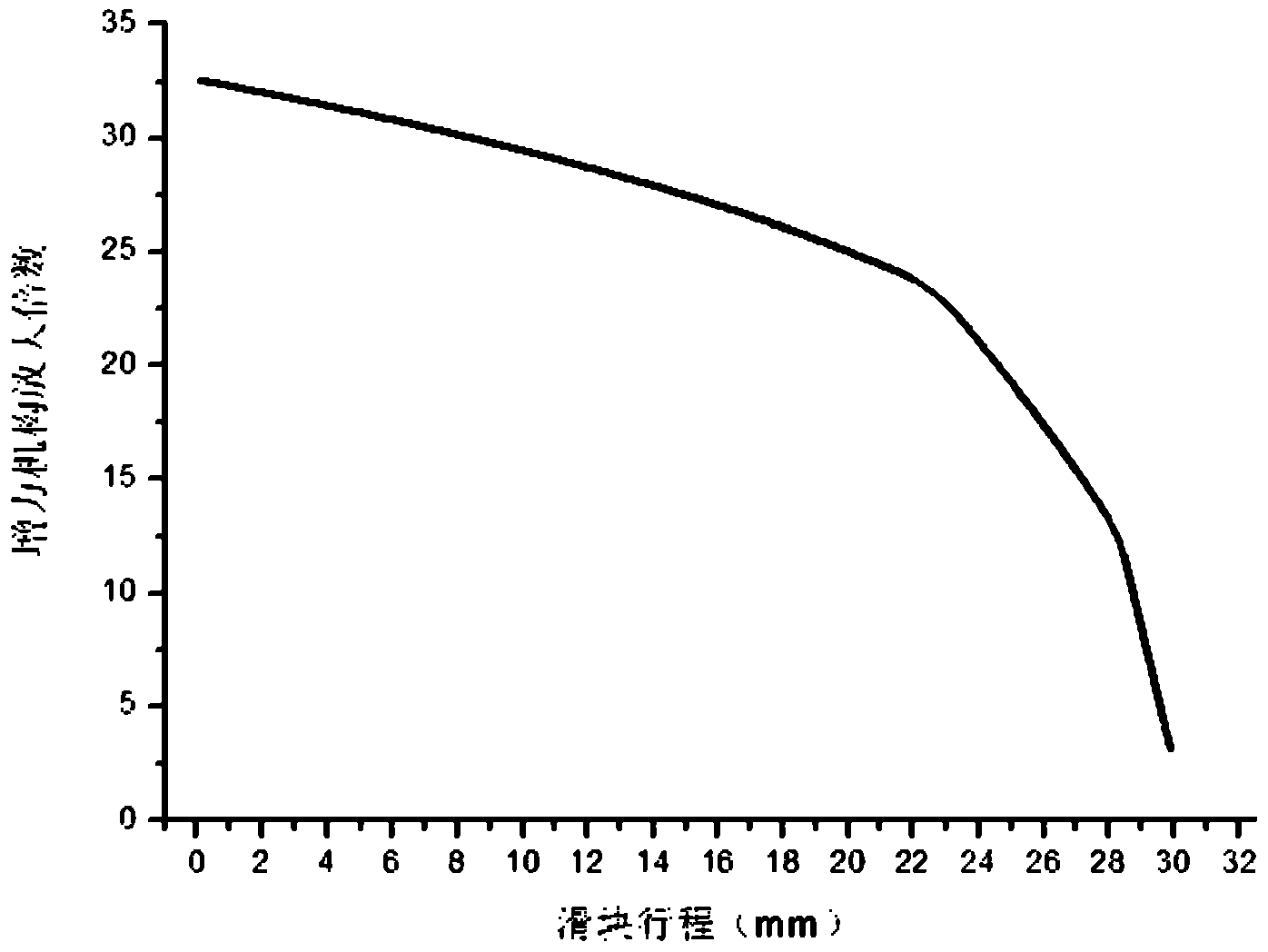

Transmission system suitable for large-tonnage alternating current servo press

ActiveCN102320153AOvercome the disadvantage of small magnificationLow powerGearingPressesThree levelBall screw

The invention discloses a transmission system suitable for a large-tonnage alternating current servo press. The output shaft of a disk-type permanent magnet synchronous servo motor and a planet gear speed reducer are made into integral structure; the screw of a driving mechanism and two nuts arranged on the nut form a ball screw structure; the screw is connected with the planet gear speed reducer; the left and the right of a top bar as well as the front and the back of the top bar are symmetrically provided with double toggle rod boosting mechanisms; a symmetrical oscillating rod input type boosting mechanism is arrange between the top bar and the double toggle rod boosting mechanisms; a three-level boosting mechanism causes the amplification multiple of the boosting mechanisms in the beginning stage to be above 15 times; and the amplification multiple is bigger and bigger along with the shaping process to lower the power of the disk-type permanent magnet synchronous servo motor. The transmission system can provide large amplification multiple and has the advantages of obvious boosting effect, large effective boosting travel, small integral structural size, big sliding block travel, quick virtual travel, high working efficiency, quick feeding, low shaping speed and the like, and unbalance loading is simultaneously eliminated.

Owner:XI AN JIAOTONG UNIV

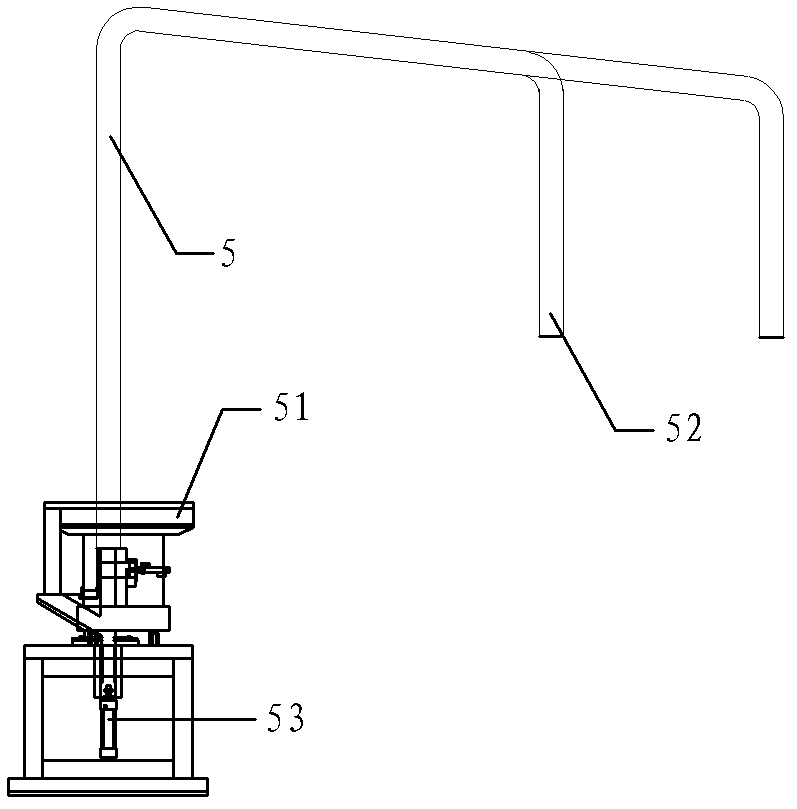

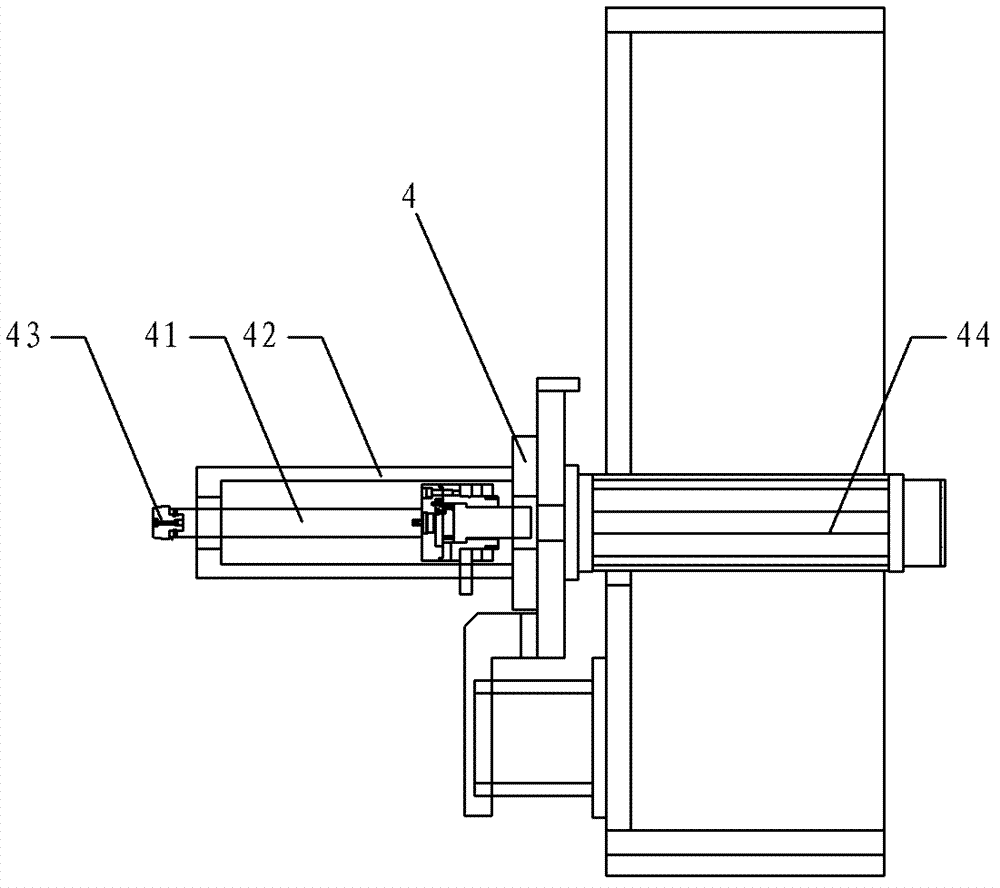

Gluing and servo pressing machine tool for engine blocks and seals

The invention discloses a gluing and servo pressing machine tool for engine blocks and seals. The gluing and servo pressing machine tool comprises a flexible roller bed, a turnover mechanism, and gluing and servo pressing devices for the engine block and the seal. The gluing and servo pressing devices are respectively arranged at the upper end and the lower end of the flexible roller bed delivering route; the turnover mechanism is arranged on the middle portion of the flexible roller bed delivering route. Each gluing and servo pressing device includes a gluing device and a servo pressing device. By the gluing and servo pressing machine tool for the engine blocks and the seals, the cylinder blocks are delivered to a fixed position by the flexible roller bed, and then the seals are fed, the gluing devices and the servo pressing devices implement gluing of the inner sides of seal holes of the cylinder blocks, and press fitting of the cylinder blocks and the seals; after one side or two opposite sides of the cylinder blocks are glued and pressed, the turnover mechanism vertically turnovers the cylinder blocks and the cylinder blocks are delivered to the gluing and pressing working position of the lower end of the flexible roller bed by the flexible roller bed, so that the bottom surfaces and the top surfaces of the cylinder blocks can be glued and pressed.

Owner:KETENG IND PANYU CITY

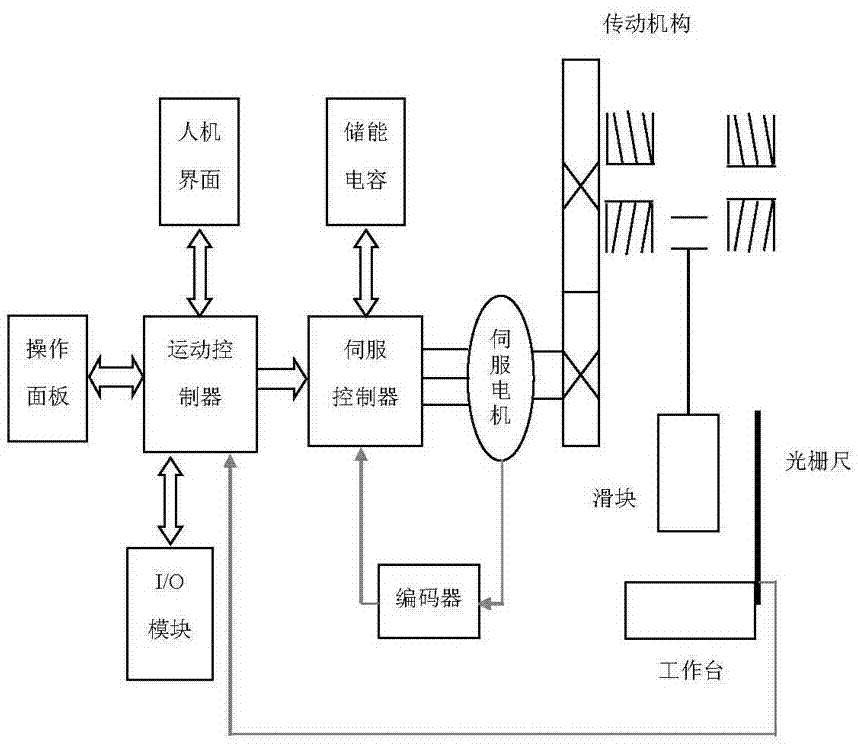

Servo press control system

InactiveCN106881903AShow location in real timeDisplay pressure in real timePressesProduction rateGrating

A servo press control system comprises a servo press. The servo press comprises a servo motor, a servo controller, a transmission mechanism, a sliding block, a workbench and a grating ruler, wherein the servo controller is in communication connection with a movement controller through a network, and an I / O interface module, an operation panel and a human-machine interface are connected to the movement controller; the input end of the servo controller is connected with a capacitive energy storage device, and the output end of the servo controller is connected with the servo motor; the servo motor is connected with the transmission mechanism; the sliding block is connected with the transmission mechanism; and the human-machine interface is in communication connection with the movement controller. According to the servo press control system, requirements for different technological curves for movement of the sliding block can be met according to different working conditions, and the torque requirement of the sliding block in a certain position is met; and the stroke of the sliding block can be adjusted according to different workpieces, and the sliding block does not need to move to the top dead center every time in all cycles, so that the cycle time is shortened, meaningless stroke is minimized, and productivity is greatly improved.

Owner:GUANGDONG HUST IND TECH RES INST +1

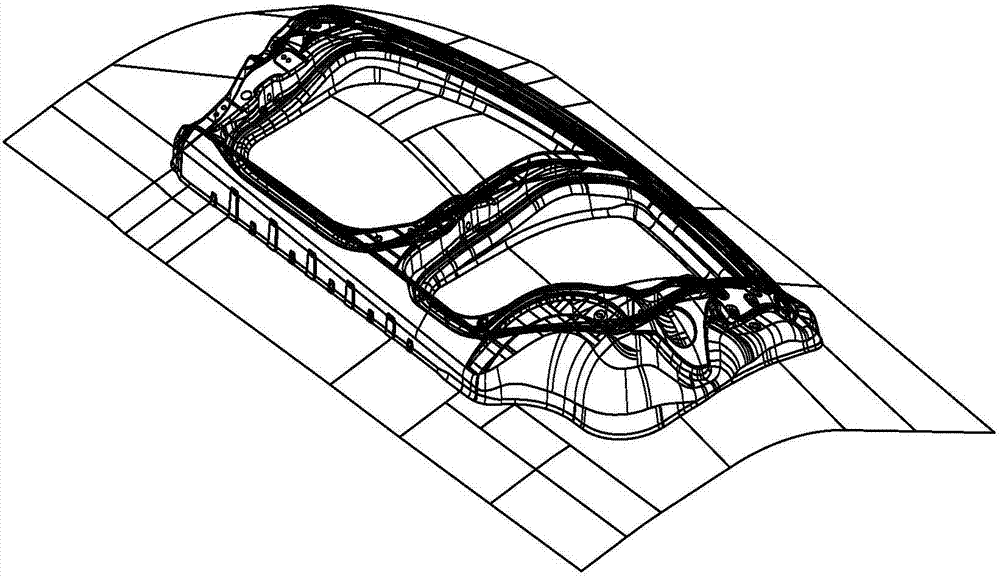

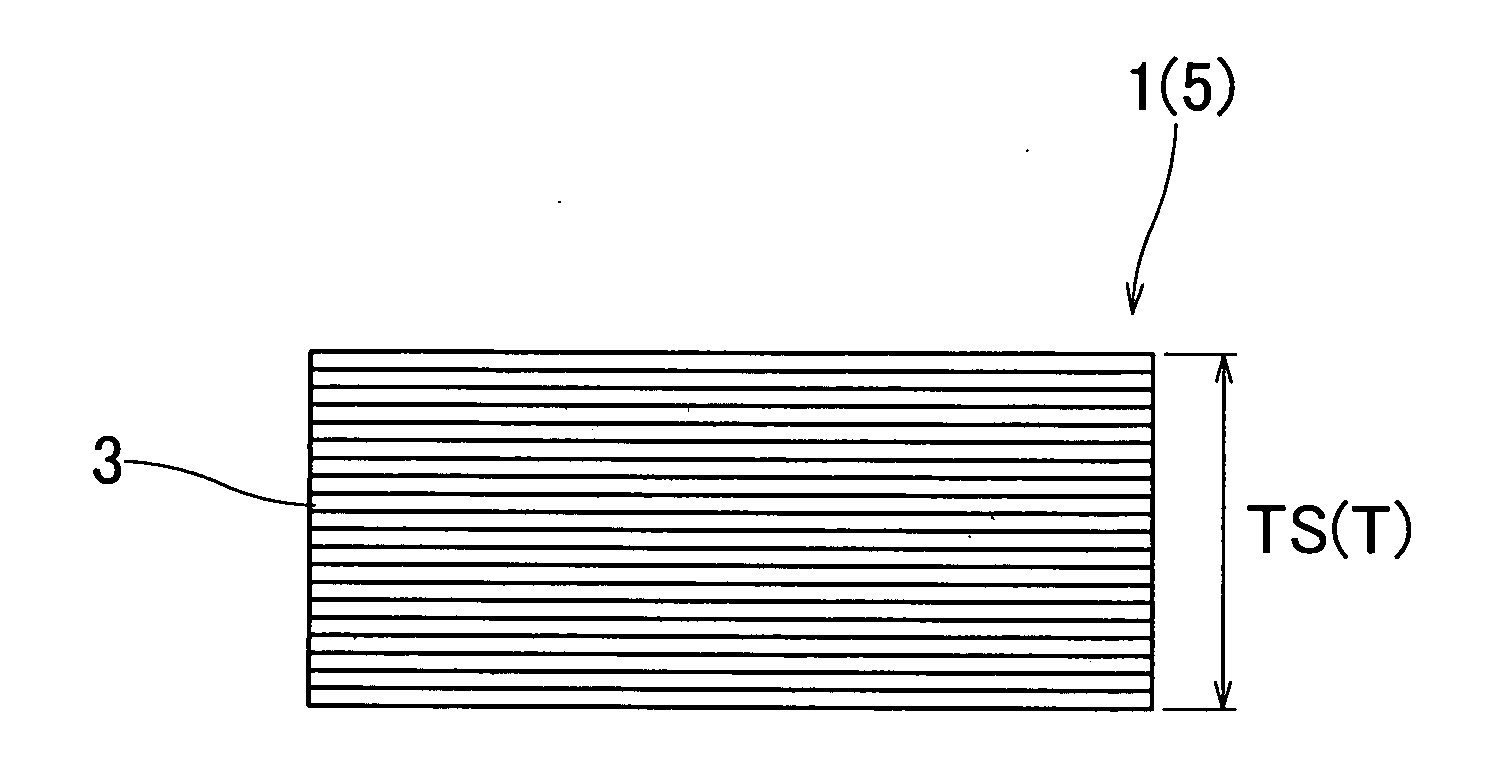

Method and production line for laminate assembly

ActiveUS20100154968A1Increase productionImprove accuracy in lamination height of laminateLamination ancillary operationsElectronic circuit testingProduction lineEngineering

The production line according to the present invention is provided with a pressurization measurement apparatus adjacent to a press-working apparatus, a temporary laminate assembly worked and laminated by a press in the press-working apparatus is sent to the pressurization measurement apparatus, and a laminate assembly is produced by being pressurized and being subjected to regular caulking by a hydraulic servo press of the pressurization measurement apparatus. At this time, the lamination height of a regularly caulked laminate assembly is measured by a linear scale secured at the pressurization measurement apparatus. The main controller of a control apparatus inputs data of the measured lamination height, and adds and subtracts the set number of thin plates to be laminated of a laminate assembly by controlling the laminating means of the press-working apparatus so that the measurement lamination height is matched to the set lamination height using the measured lamination height, the preset lamination height, the height dimension tolerance, and the tolerance for judging the number of thin plates.

Owner:YAMADA DOBBY

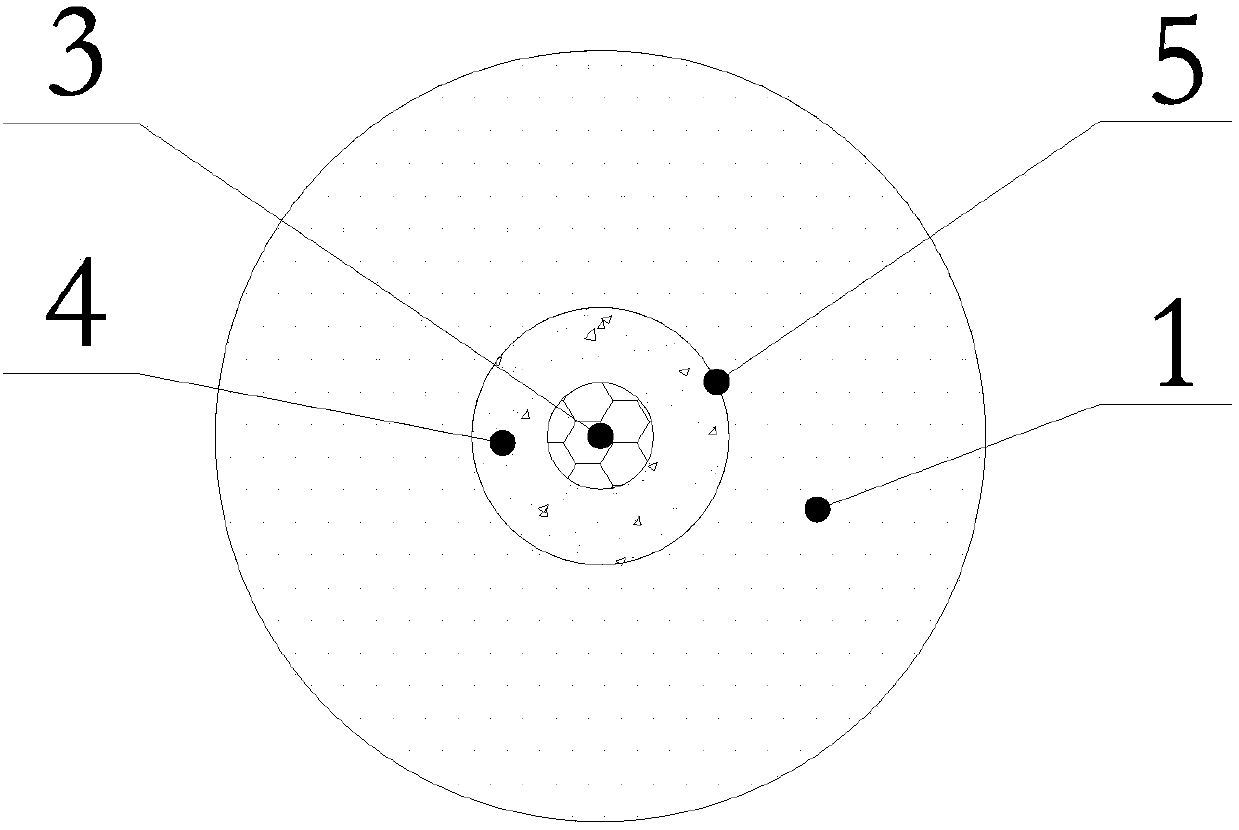

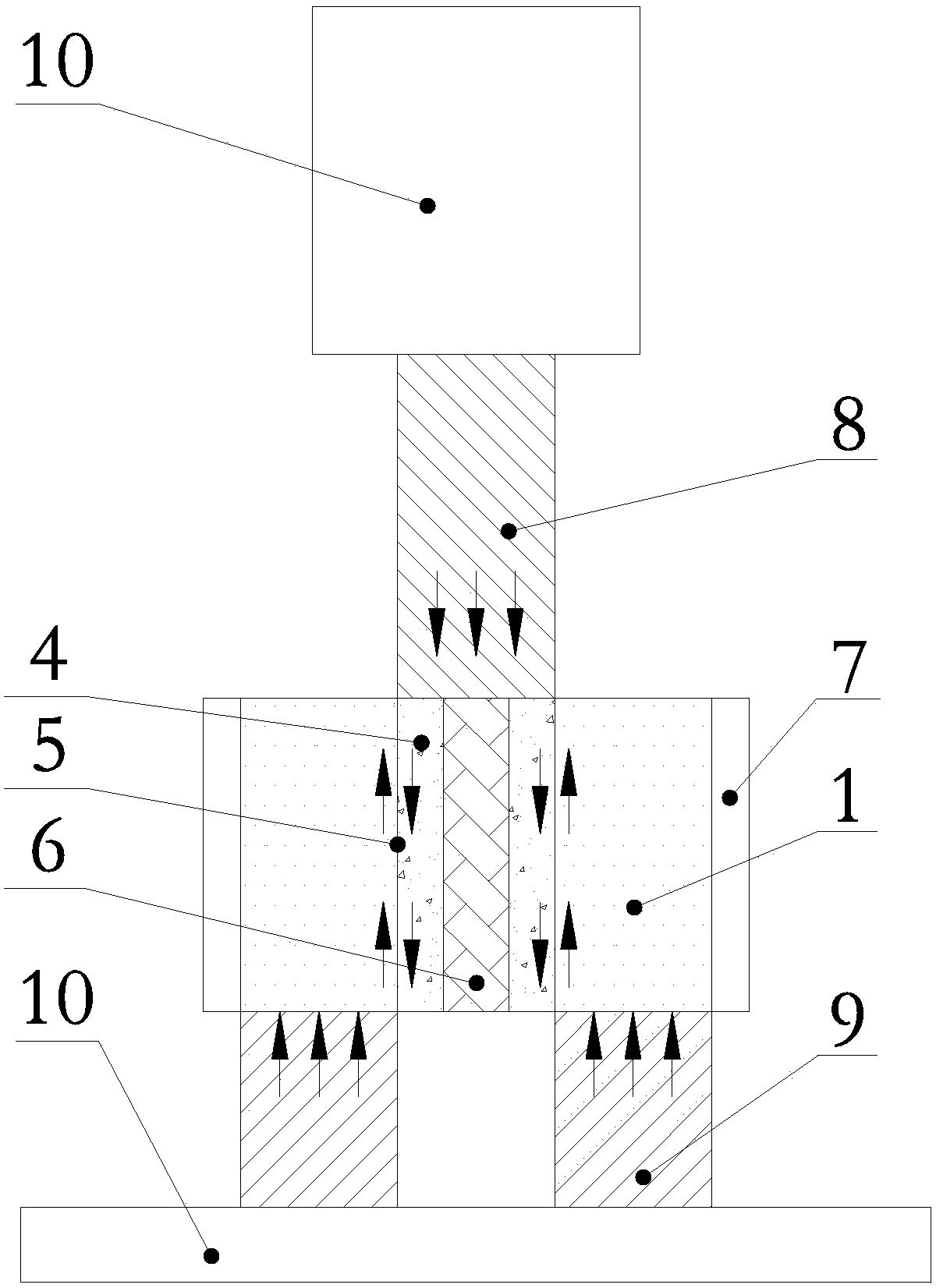

Coal body and anchoring agent interface bonding strength testing method

ActiveCN107843553AEfficient simulation of squeeze situationsAvoid situations that are difficult to process into specimensUsing mechanical meansMaterial analysisCoal matrixAtmospheric pressure

The invention discloses a coal body and anchoring agent interface bonding strength testing method. The method is characterized in that according to coal body existing conditions, a coal matrix (1) iscompacted, a through hole (2) is formed at middle of the coal matrix (1), an elastic circular column (3) is placed at the middle of the through hole (2), an anchoring agent cylinder (4) is formed by injecting an anchoring agent in the through hole (2), the elastic circular column (3) is subjected to pneumatic compression, after the anchoring agent is completely acted while a certain air pressure is kept, the elastic circular column (3) is changed to a rigid cylinder (6), two ends of the through hole (2) are plugged to form a test piece, then the test piece is placed on a servo press (10), an aperture same with the through hole (2) is placed at a lower part of the test piece, the aperture is aligned with the through hole (2), a pressure head (8) is a cylinder having a same diameter with theanchoring agent cylinder (4), the pressure head (8) is lowered for testing the bonding strength, and finally data is collected for analysis. The real coal body is taken as an anchoring matrix, and the testing result is more close to on-site condition.

Owner:CHINA UNIV OF MINING & TECH

Servo press and servo press controlling method

Provided is a low-cost servo press promoting energy saving by driving a press machine by a driving system suited for the magnitude of a load on a worked object. It includes a first motor coupled to a slide drive shaft to ascend / descend a slide, a second servo motor driving a flywheel, a clutch coupling / decoupling the second servo motor to / from the slide drive shaft, and a press controller controlling rotation of the first and second servo motors and coupling / decoupling of the clutch. The press controller controls to decouple the clutch when the press is small-loaded, thereby ascending / descending the slider by driving the first servo motor, and to couple the clutch when the press is large-loaded, thereby ascending / descending the slider by driving the first and second servo motors.

Owner:AIDA ENG LTD

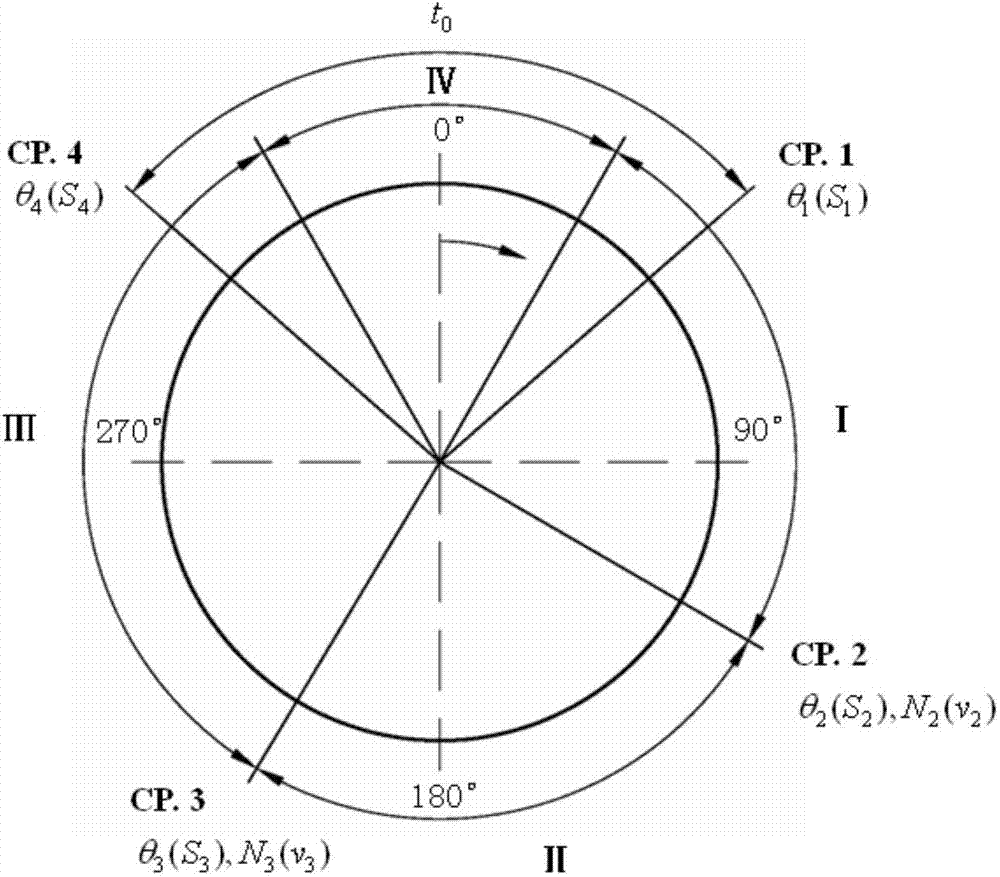

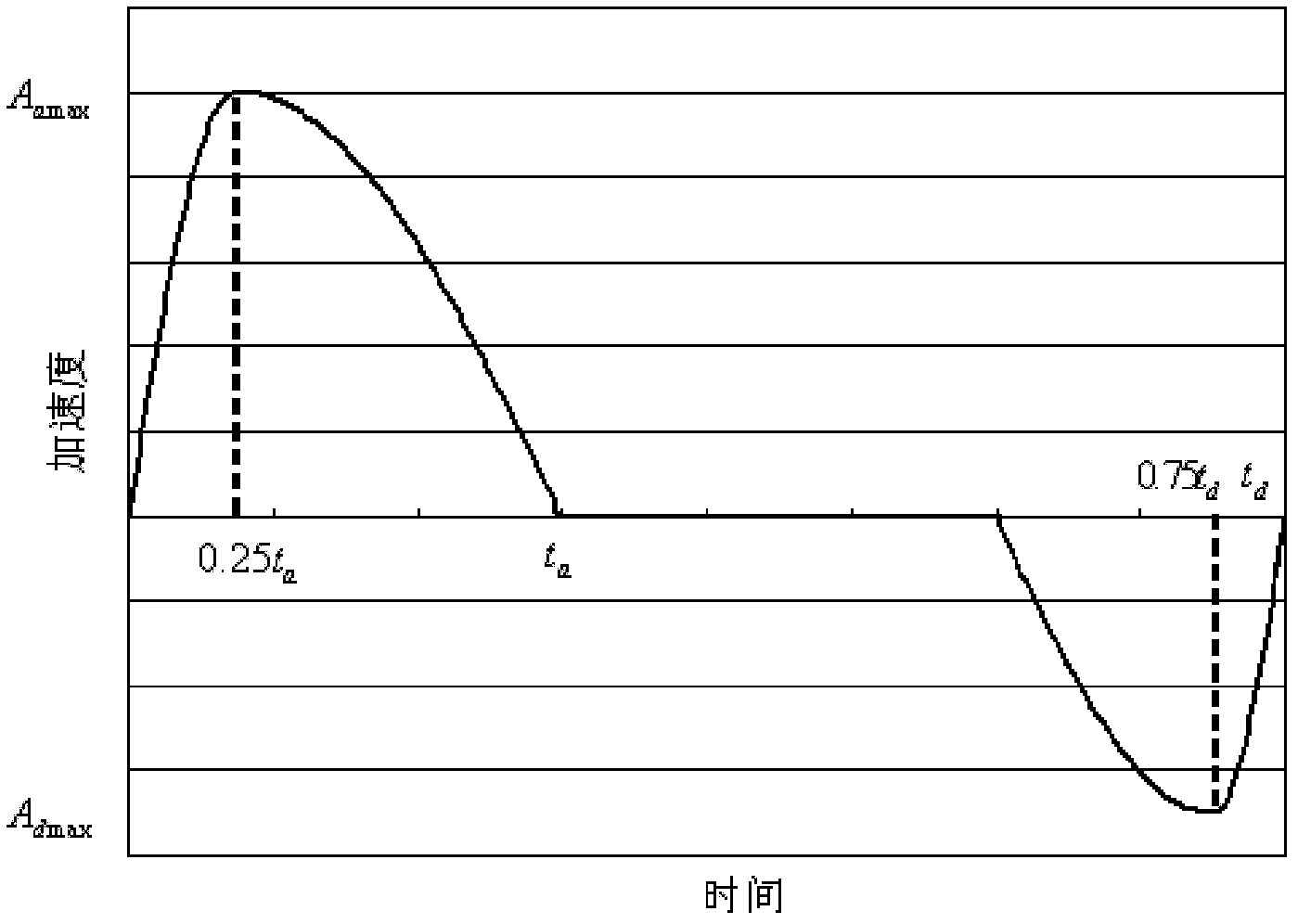

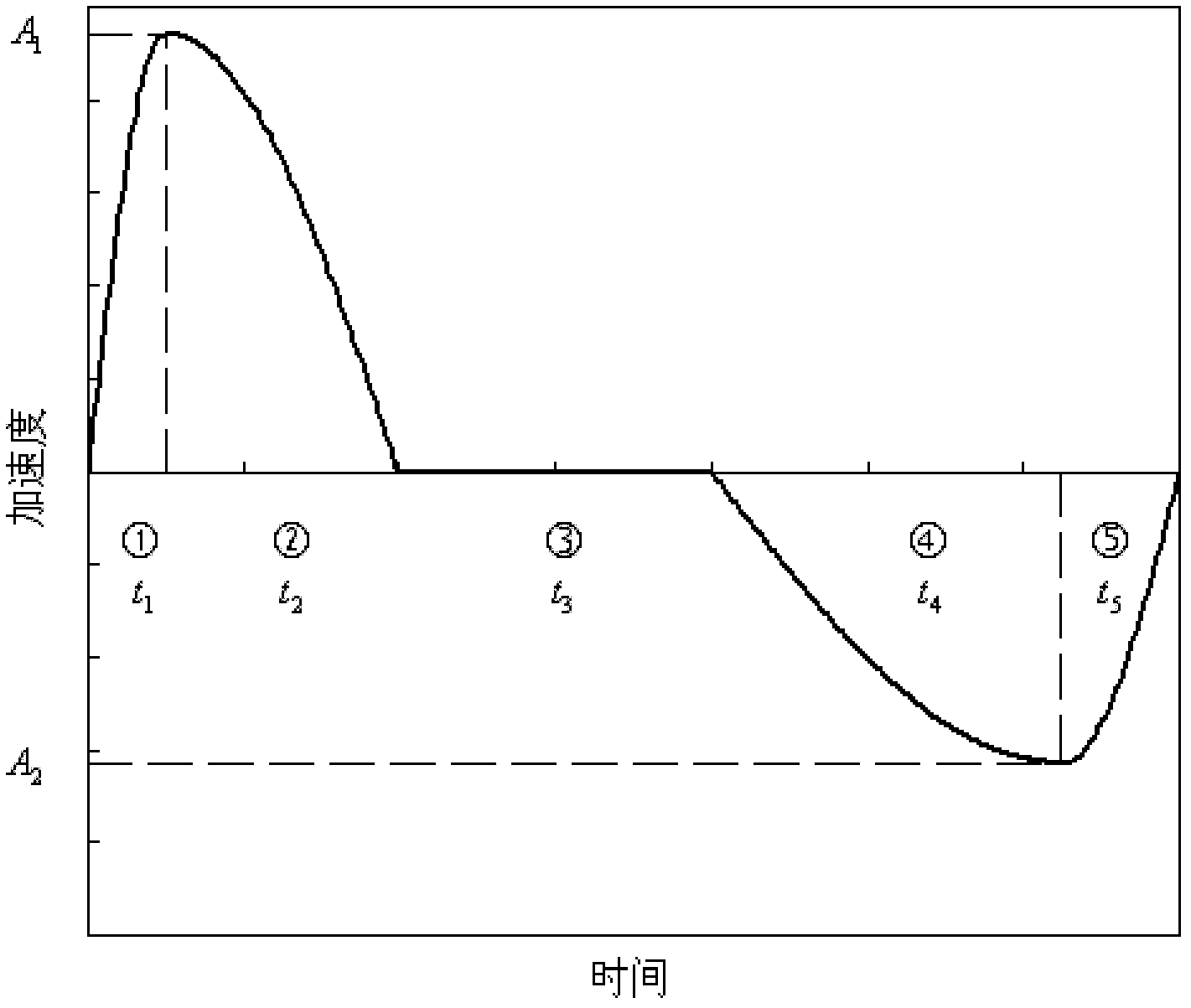

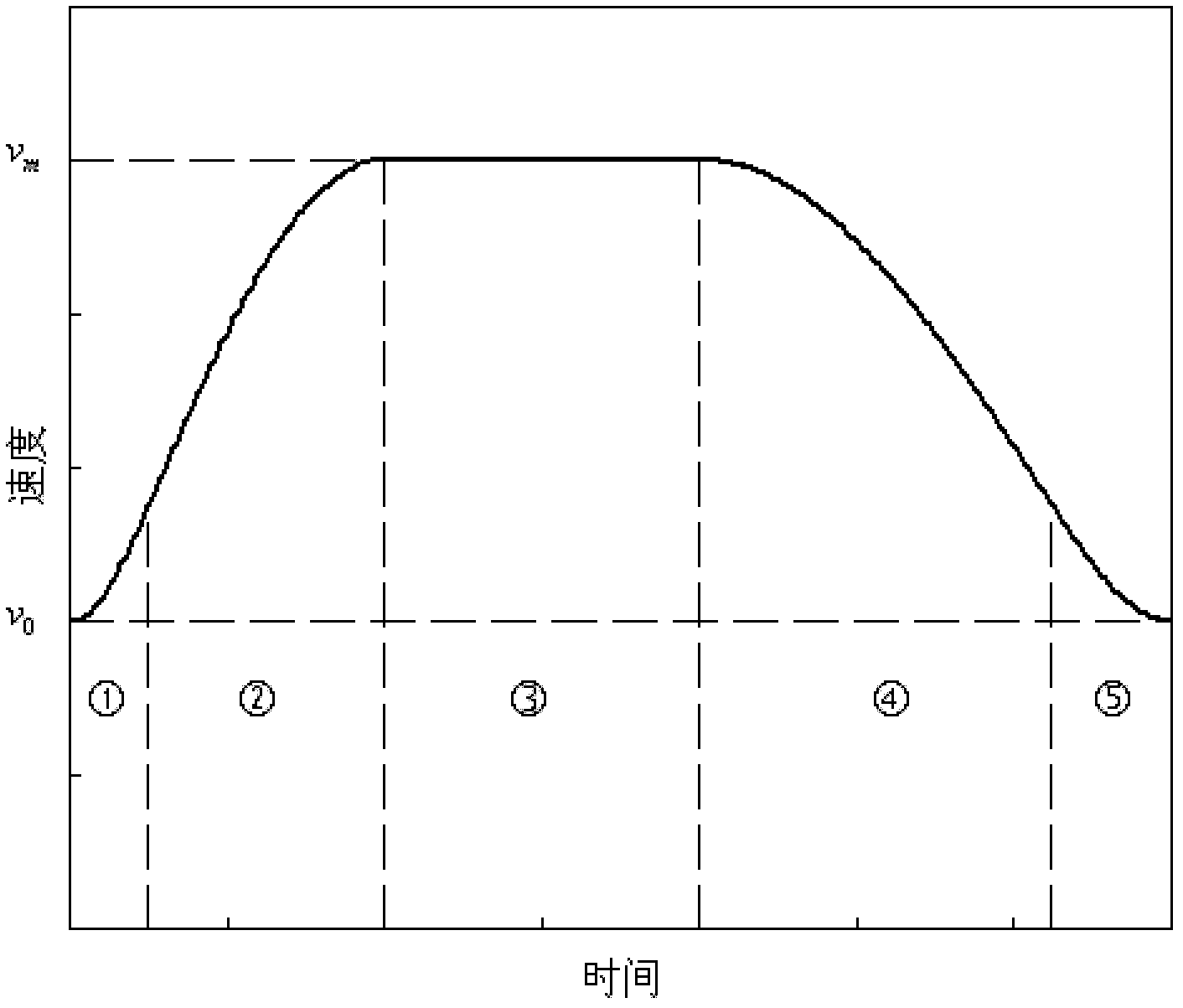

Servo-motor acceleration-deceleration control method for servo pressure machine

ActiveCN102522944AContinuous changeAvoid Flex ShockElectronic commutation motor controlElectric motor controlTriangular functionAcceleration deceleration

The invention discloses a servo-motor acceleration-deceleration control method for a servo pressure machine, comprising the following steps of: constructing an acceleration function of a servo motor at an acceleration stage; establishing a speed expression of the servo motor at the acceleration stage; establishing a rotary displacement expression of the servo motor at the acceleration stage; constructing an acceleration function of the servo motor at a deceleration stage; establishing a speed expression of the servo motor at the deceleration stage; establishing a rotary displacement expression of the servo motor at the deceleration stage; and determining total acceleration time and total deceleration time. According to the servo-motor acceleration-deceleration control method, two triangular functions with different periods are adopted as acceleration-deceleration constructed functions of the servo motor, so that the change of the speed, the acceleration and the accelerated acceleration is continuous, the soft shock of the acceleration-deceleration process on the machine body is avoided, the operation stability of the pressure machine is improved and the softness of acceleration-deceleration control of the pressure machine is higher; and by full utilization of the constant and maximum output torque of the server motor under the rated rotating speed, the operation period of the servo pressure machine can be shortened and the takt time of stamping production is improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

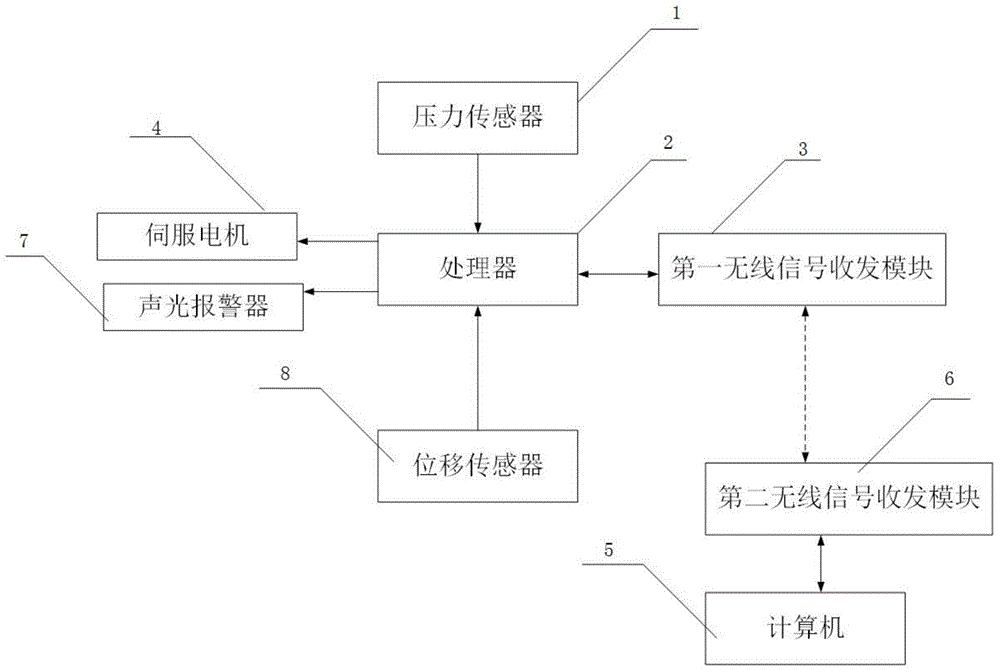

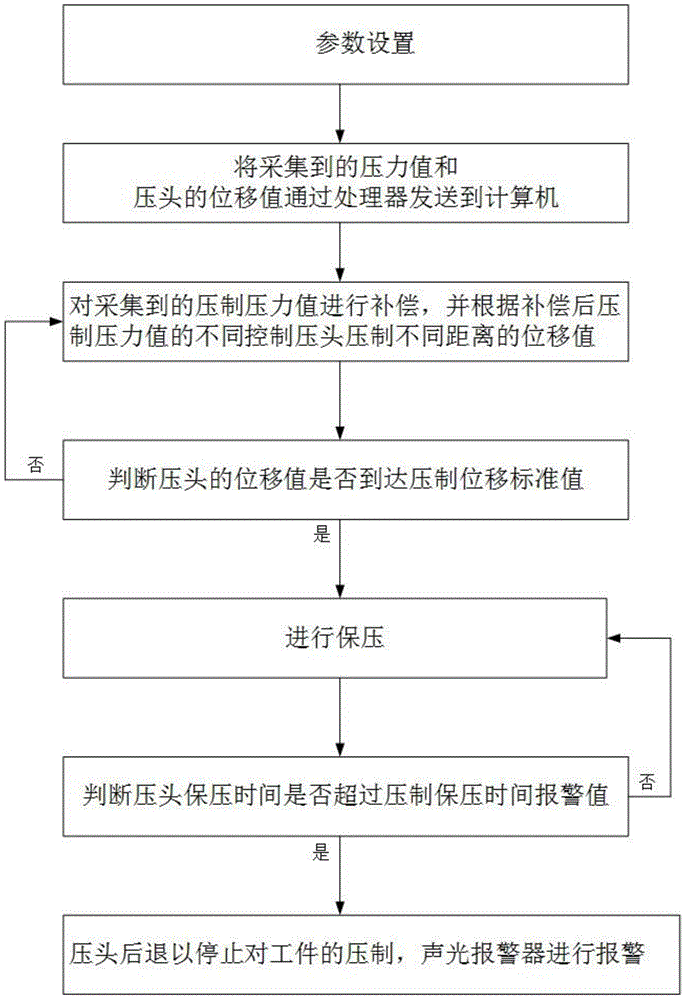

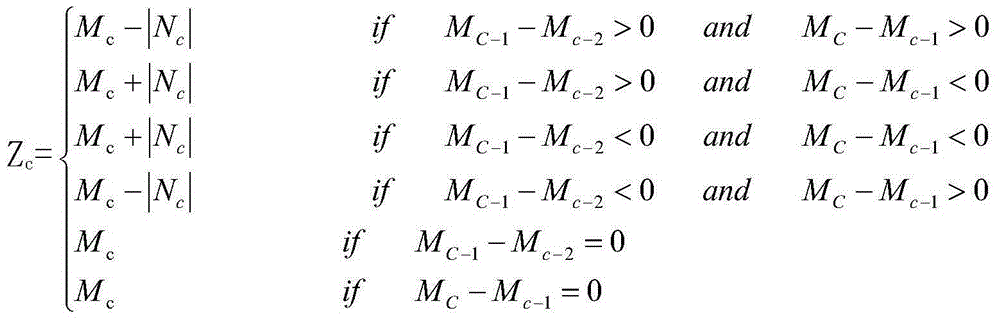

High-precision servo press fitting method based on computer

InactiveCN105109094AQuality improvementQuality assurancePressesEngineeringPressure controlled method

The invention discloses a high-precision servo press fitting method based on a computer, and relates to the field of automation control. The collecting pressure is dynamically compensated according to collected pressure values and a pressure change trend, adaptive control is performed on an elastic workpiece by combining with a displacement sensor and a pressure sensor, therefore, the pressing accuracy and pressure control stability for the elastic workpiece are improved, the phenomenon that elastic workpiece pressing is unqualified due to the fact that in a traditional technology, the pressure is too large or the actual pressing pressure is slightly smaller cannot occur, and the workpiece quality is guaranteed; meanwhile, due to the fact that the influence of interfering data is greatly eliminated, the adaptability of the pressure control method in different processing environments can be guaranteed.

Owner:CHONGQING TECH & BUSINESS INST

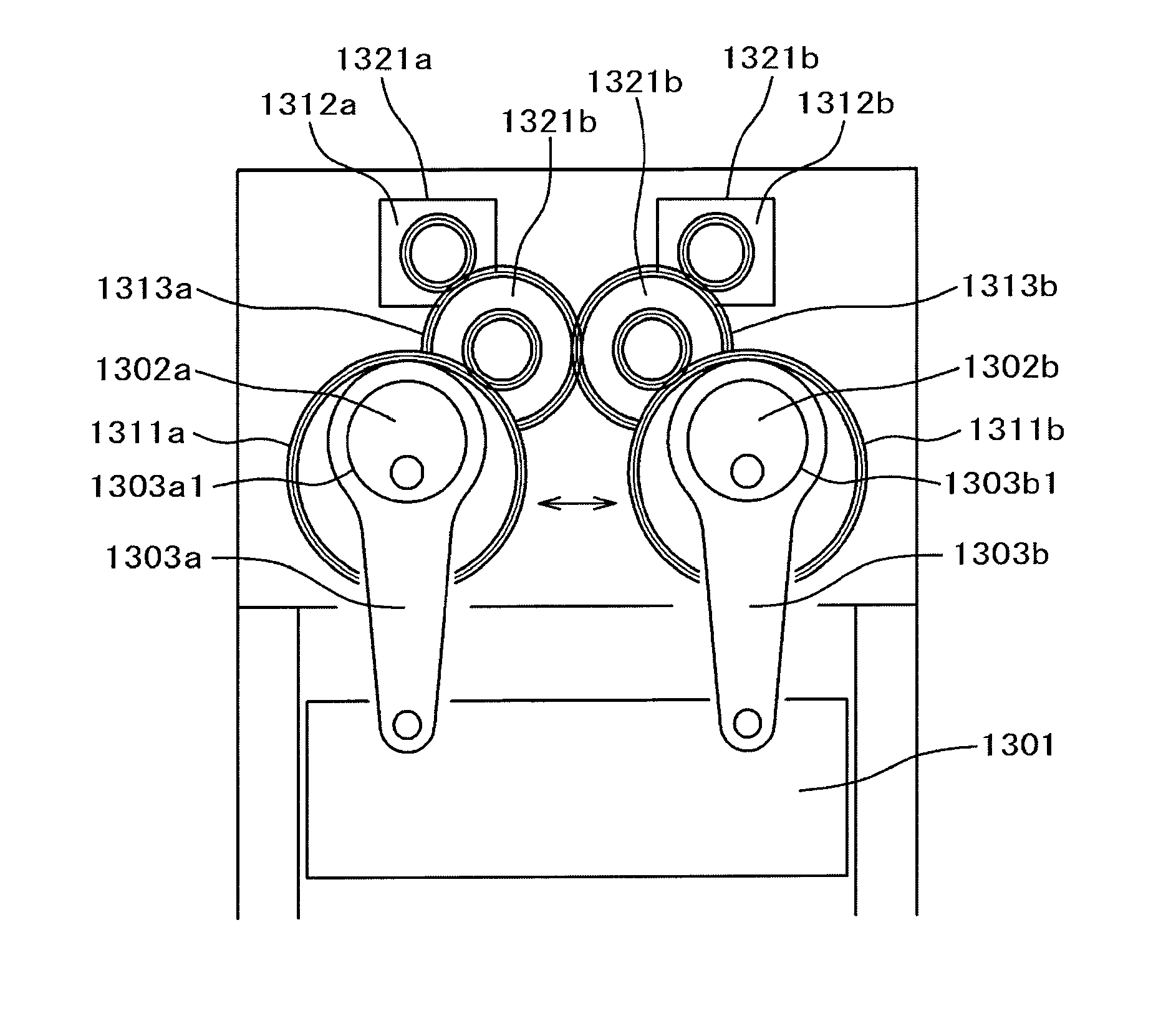

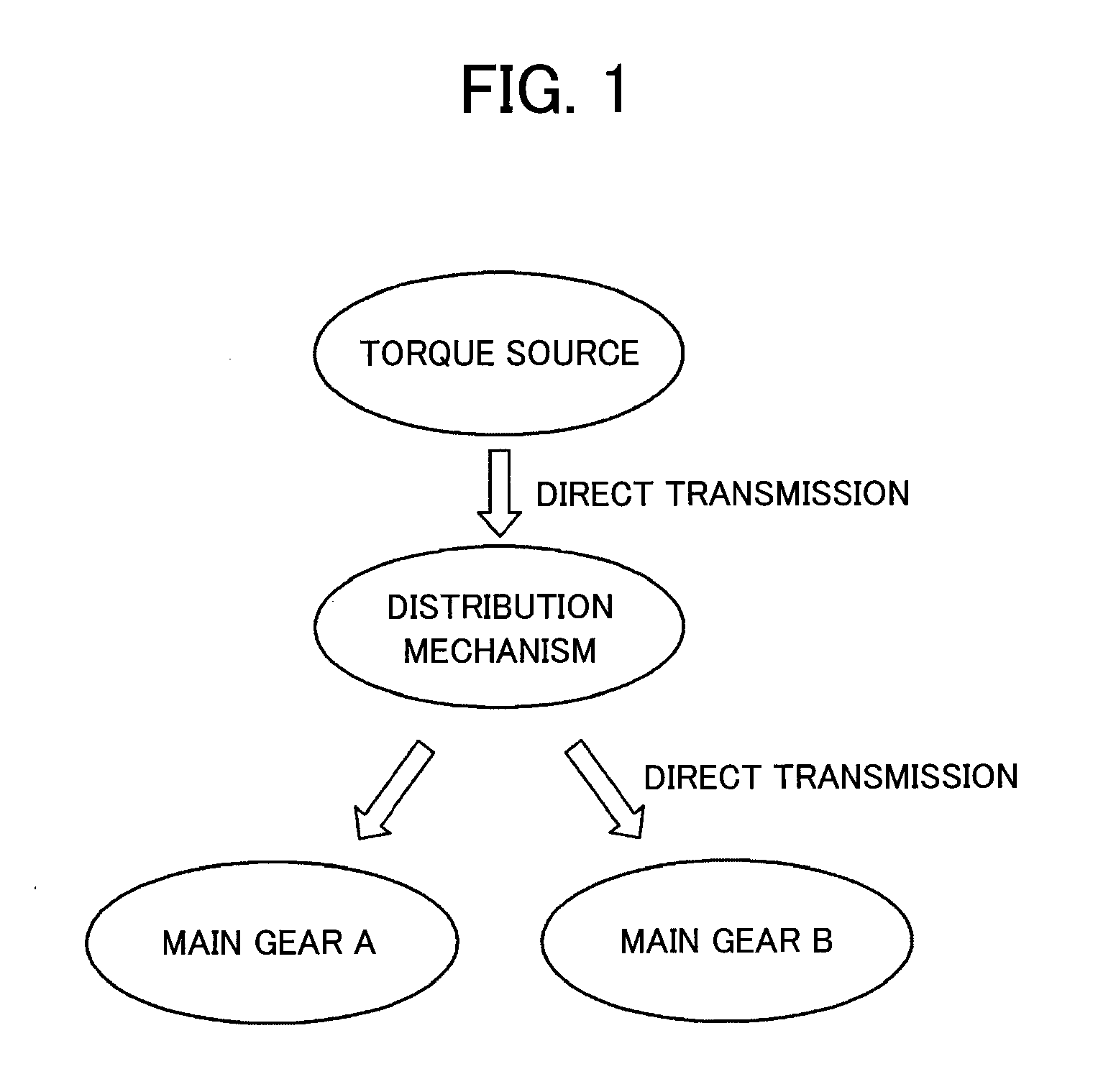

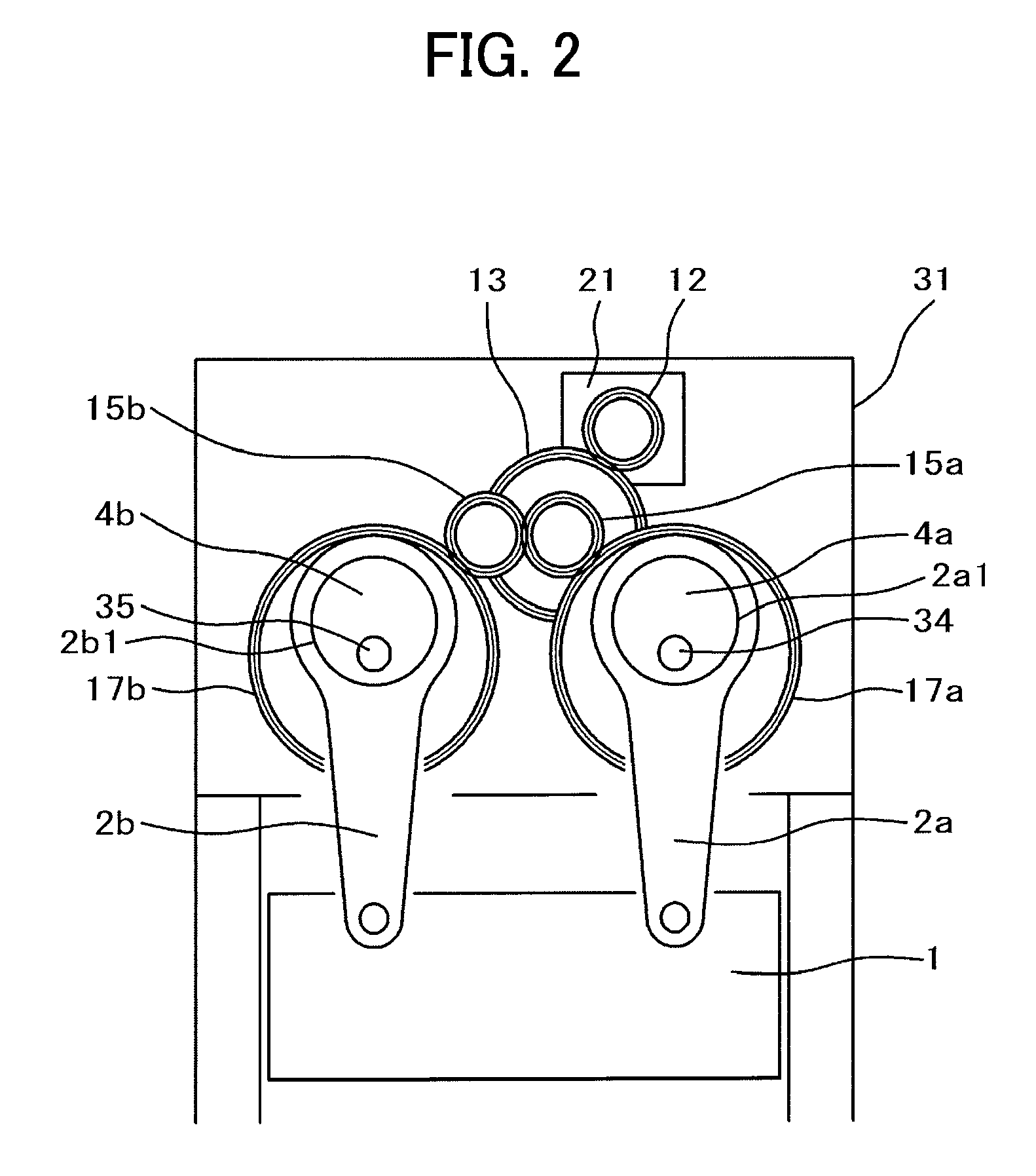

Multipoint servo press machine

InactiveUS20110290126A1Reduce gear backlashLess-decrease in positional precisionPress ramGear driveElectric machine

The invention provides a servo press machine including a slide moved up and down by multiple crank structures, the machine which provides perfect synchronism between main gears driving the respective crank structures and in which a compact, efficient power transmission structure can be implemented in a simple construction. In the servo press machine including the slide moved up and down by the multiple crank structures, synchronous distribution gears are driven by servo motors; the multiple main gears are driven in synchronism by the synchronous distribution gears; and each of the crank structures is driven by each of the main gears.

Owner:AIDA ENG LTD

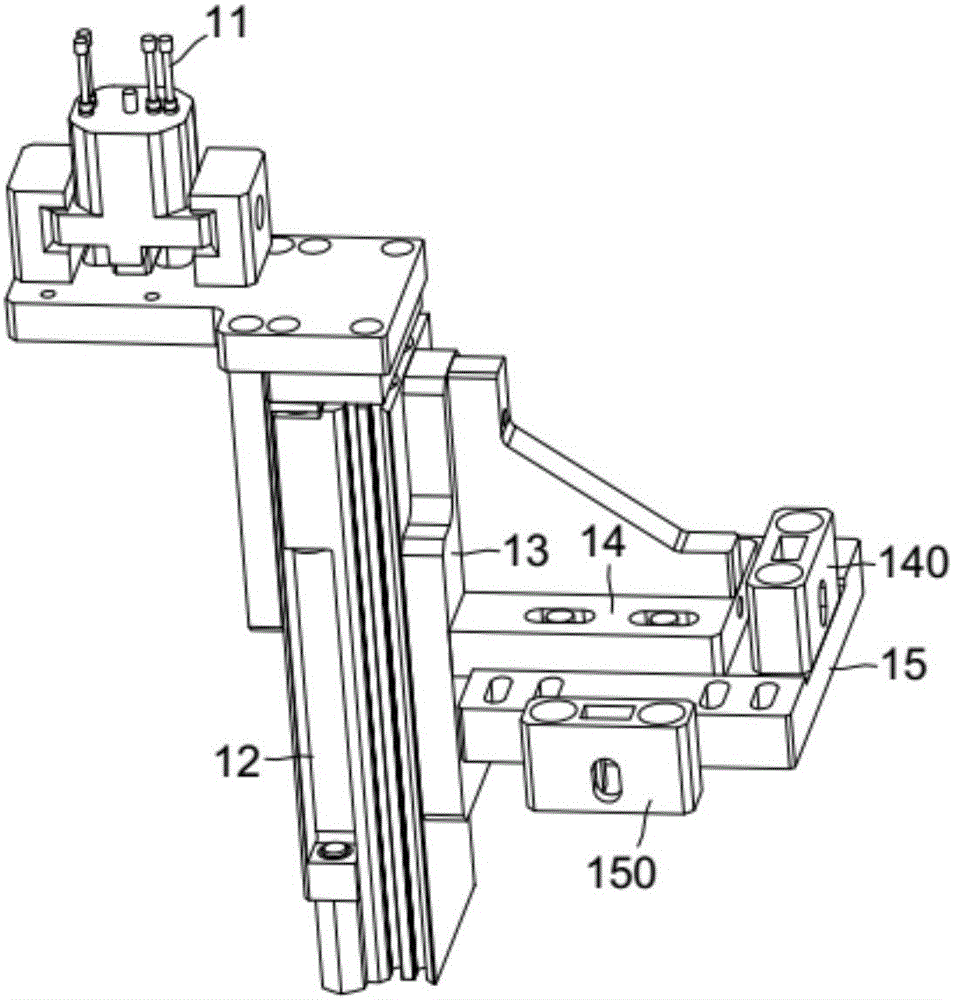

Over-travel parameter setting apparatus of relay

The invention relates to an over-travel parameter setting apparatus of a relay. The apparatus comprises a positioning assembly for relay positioning, an electrification assembly with a probe group in contact with a relay pin, a servo pressing machine assembly pushing a relay reed and the relay pin to be in contact, a displacement detection assembly connected with the electrification assembly and the servo pressing machine assembly electrically, and a riveting assembly for carrying out riveting on a relay iron core. During operation, the servo pressing machine assembly pushes the relay reed to be in contact with the relay pin; the probe group in contact with the relay pin obtains an electrification signal; the displacement detection assembly records a displacement position; the servo pressing machine assembly moves forwardly with a set feeding value, wherein the data is an over-travel parameter of the relay; and the riveting assembly carries out riveting on a relay iron core and carries out solidification on the over-travel data set by the relay. According to the invention, with cooperation of the electronic servo pressing machine and the displacement sensor as well as multiple motions like electrification and riveting, the over-travel numerical value of the relay is set in a data quantification mode.

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com