Gluing and servo pressing machine tool for engine blocks and seals

A technology of engine cylinder block and glue press-fitting, which is applied to the surface coating liquid device, coating, metal processing, etc., which can solve the problems of polluting the environment, affecting the sealing performance of the bristles, and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

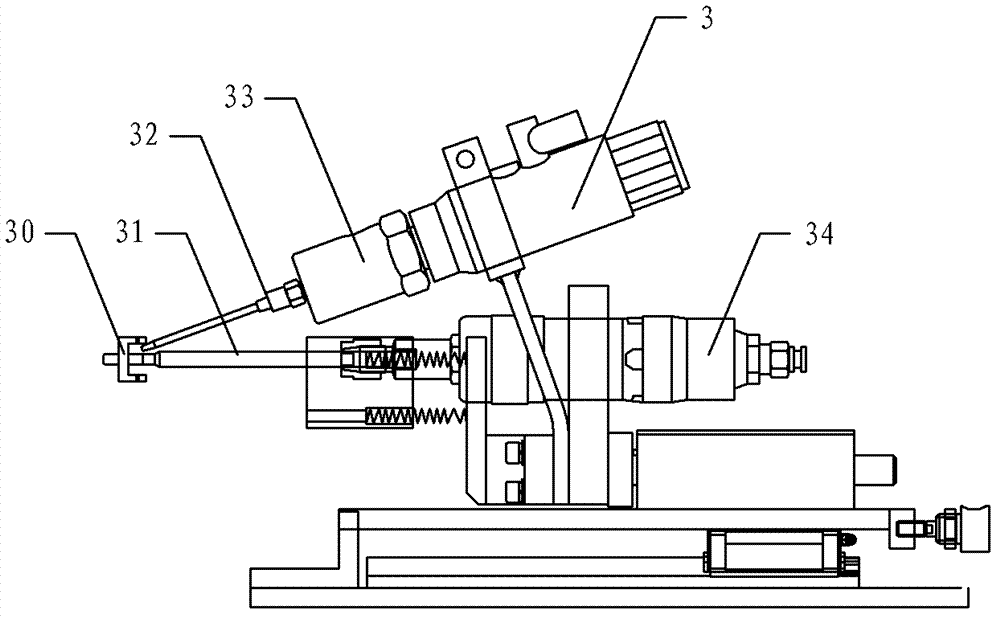

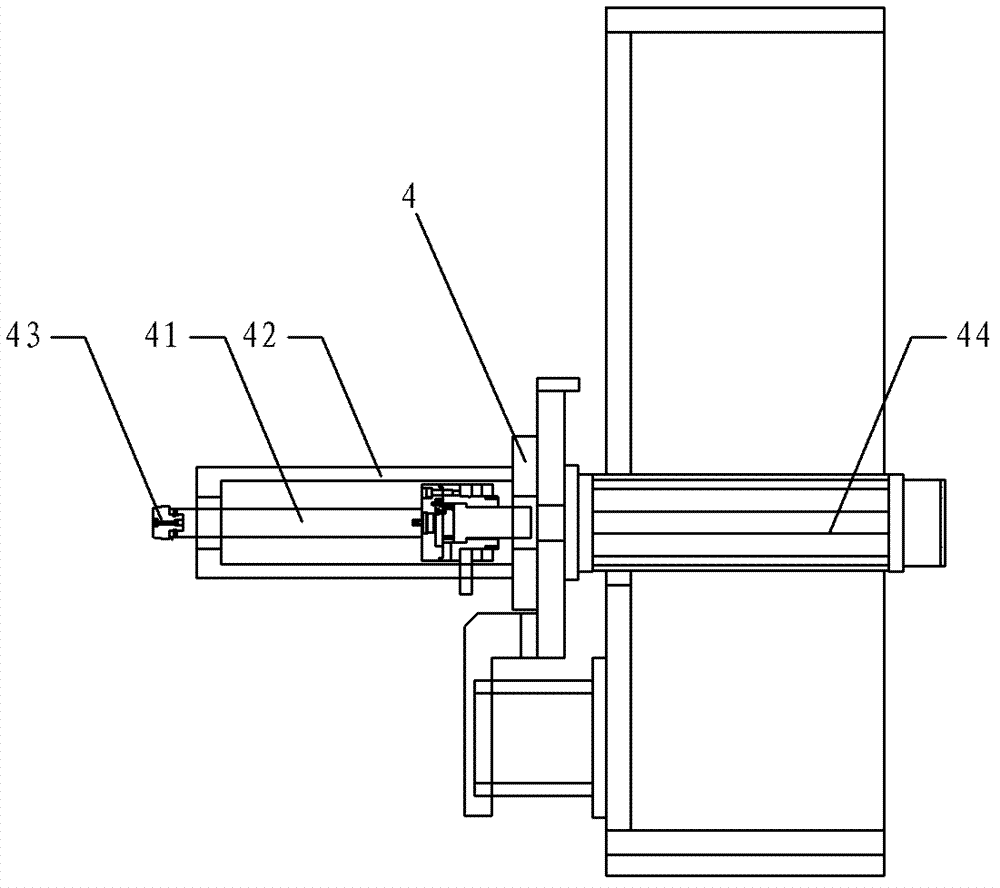

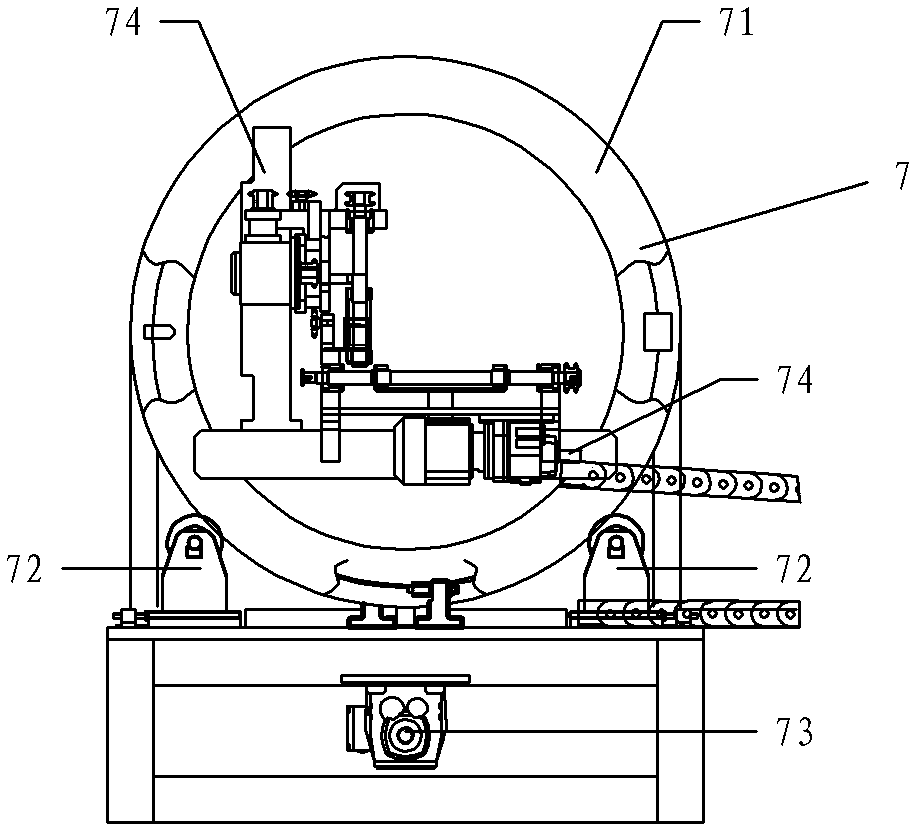

[0021] like Figure 1 to Figure 6 As shown, the engine cylinder bowl plug servo glue pressing machine includes

[0022] The motorized roller table 1 is used for the conveying and positioning of the cylinder body. The workpiece is connected to the roller table from the front to this station. The motorized roller table 1 is equipped with a material blocking device and a material separation device to ensure that only one workpiece is conveyed to the downward station at a time. , The part of the motorized roller table 1 that is in contact with the workpiece is made of special rollers that are plated with hard chrome and polished to ensure that the workpiece will not be damaged during the conveying process. There are guide strips on both sides of the motorized roller table 1, which have been adjusted and fixed before leaving the factory. Good, do not adjust at will, the workpiece is mainly guided and positioned by the guide bar on the side near the person;

[0023] Body 2, the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com