Patents

Literature

43 results about "Ram pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, ram pressure is a pressure exerted on a body moving through a fluid medium, caused by relative bulk motion of the fluid rather than random thermal motion. It causes a drag force to be exerted on the body. Ram pressure is given in tensor form as Pᵣₐₘ=ρuᵢuⱼ, where ρ is the density of the fluid; this is the momentum flux per second in the i direction through a surface with normal in the j direction.

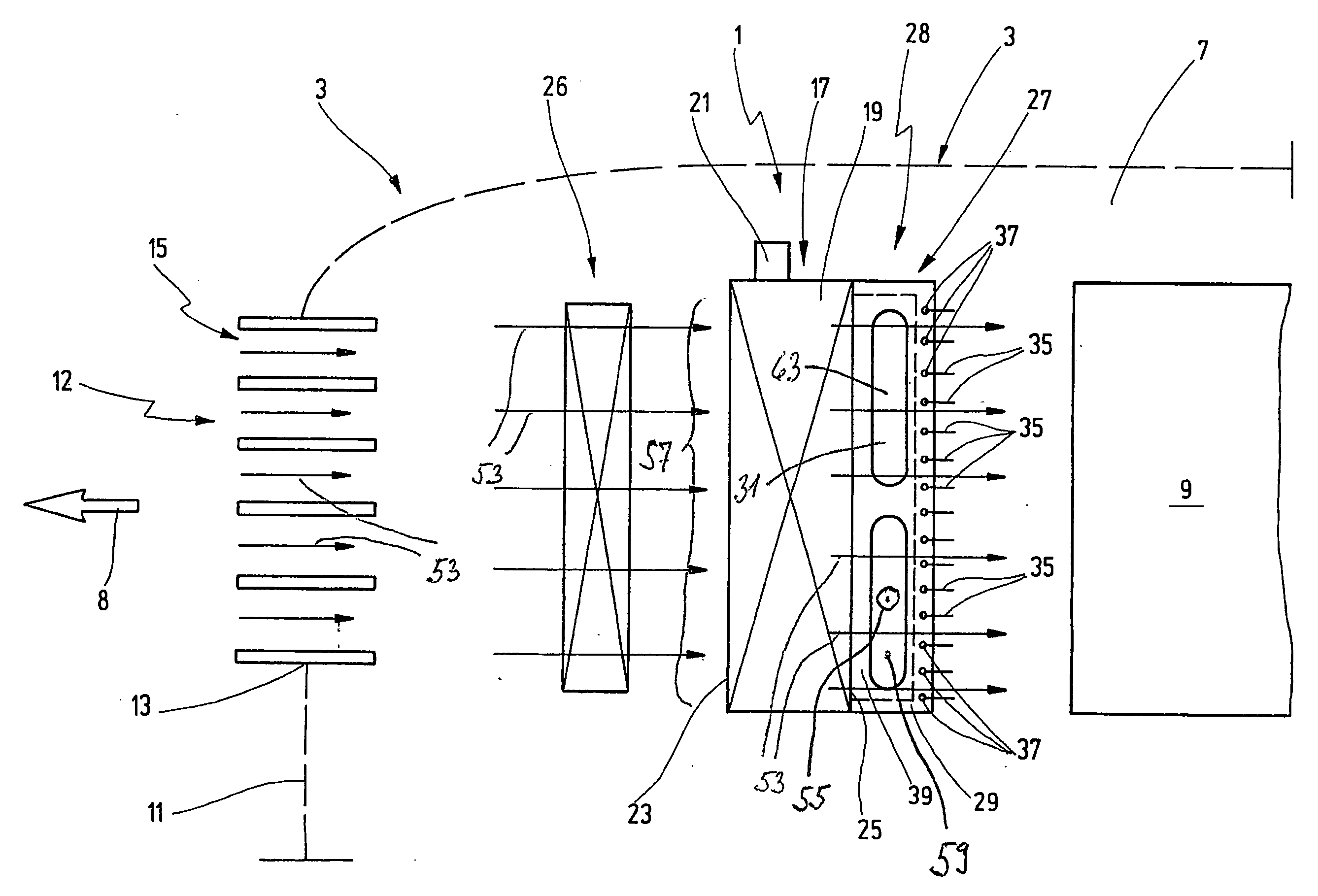

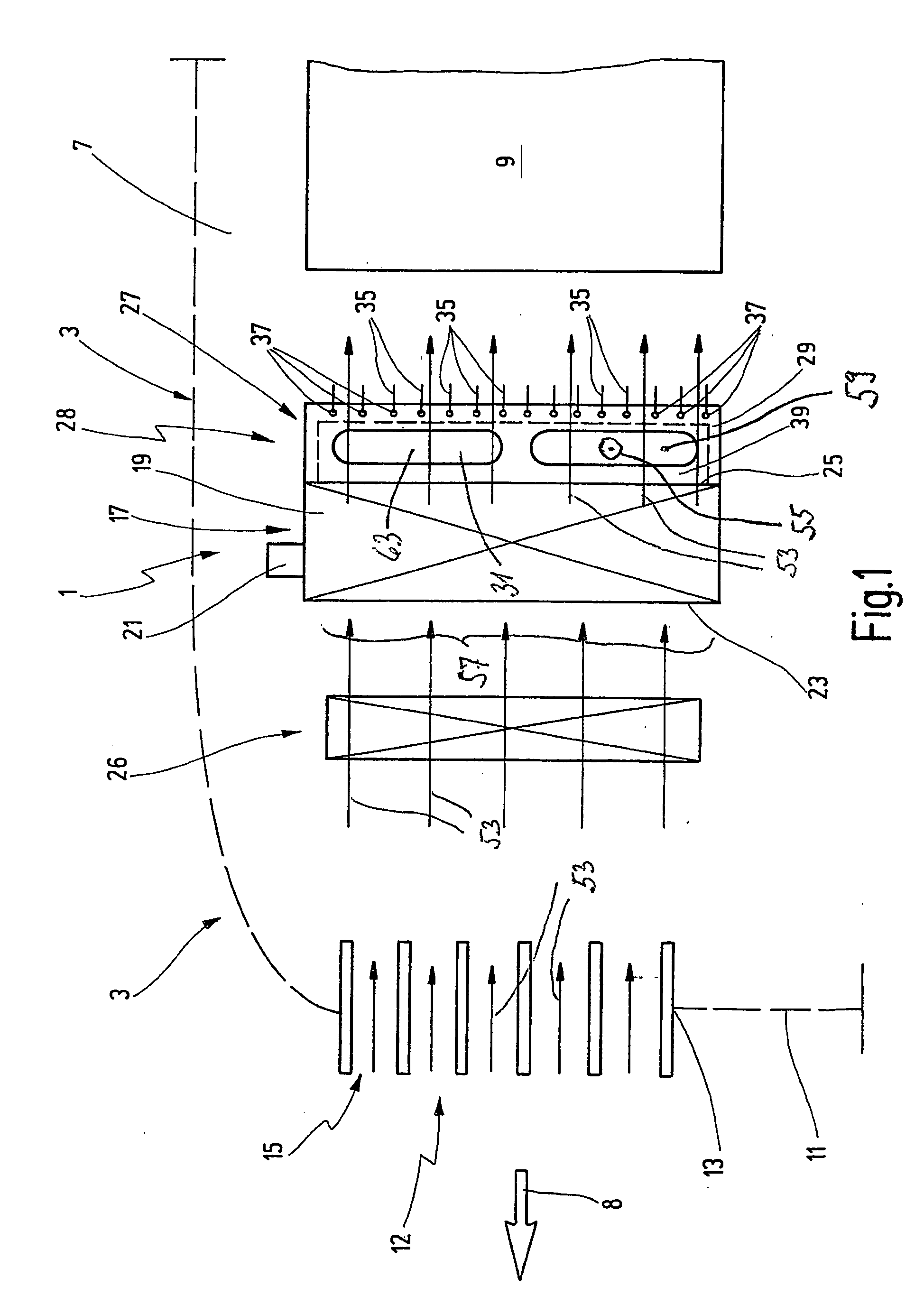

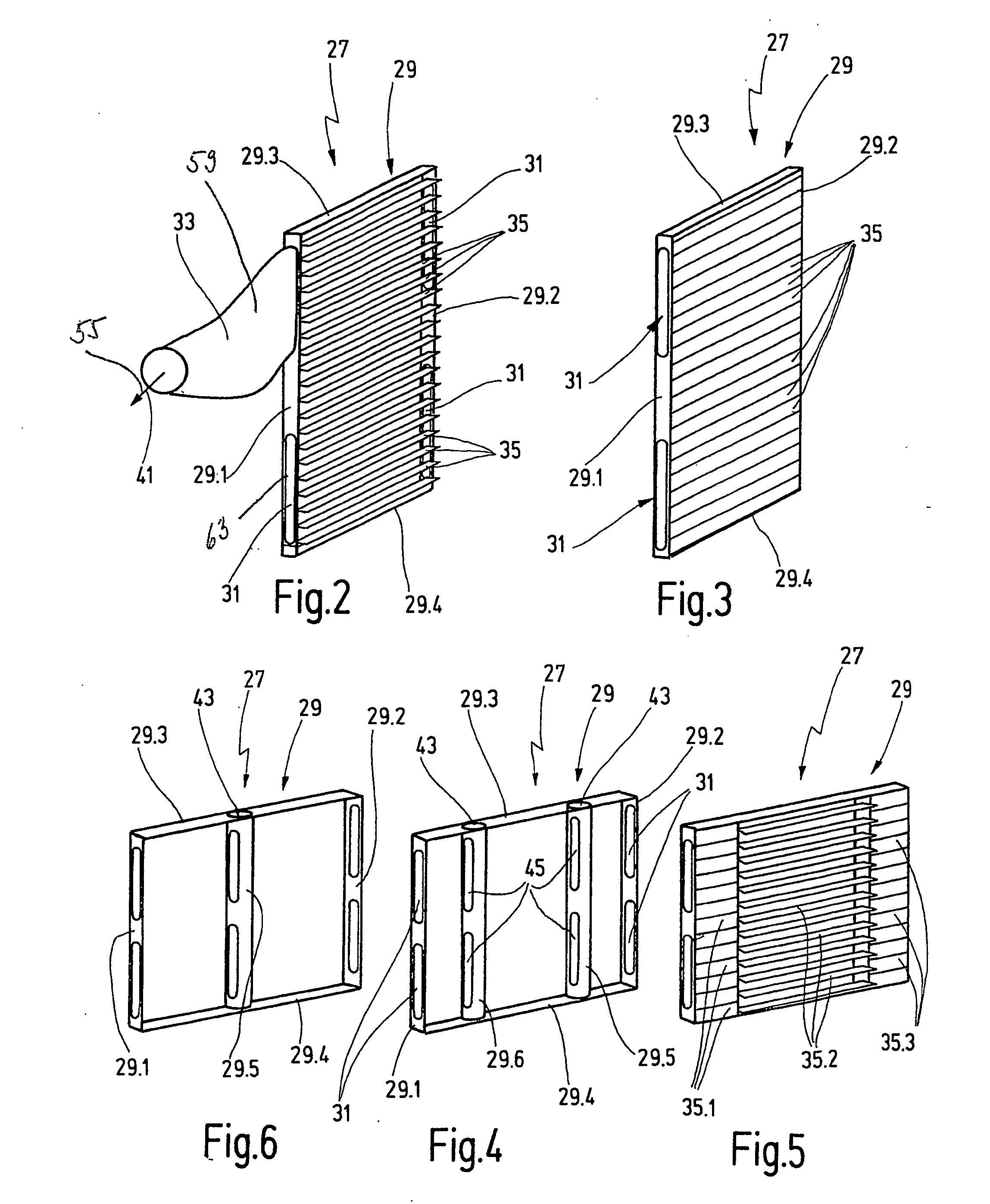

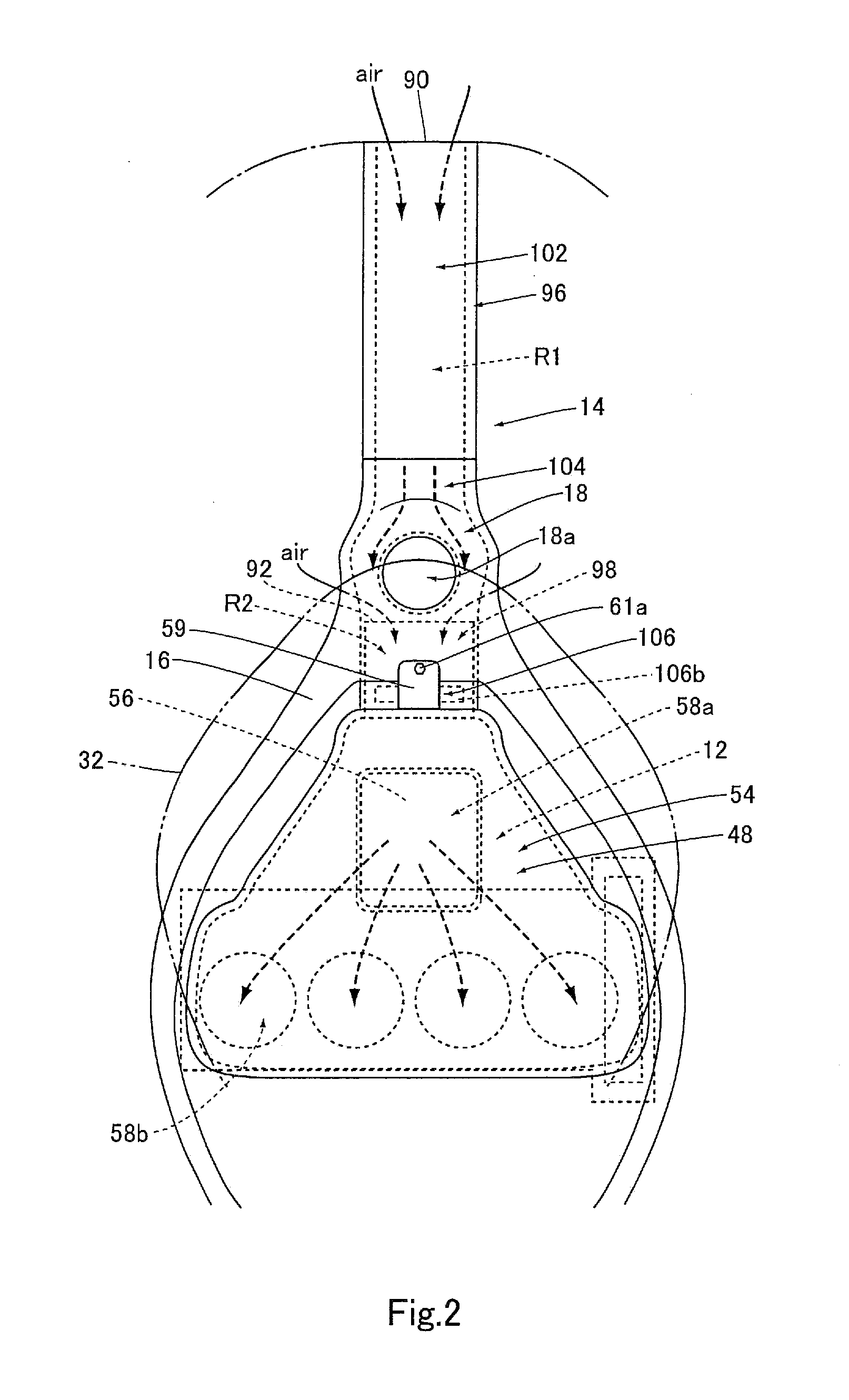

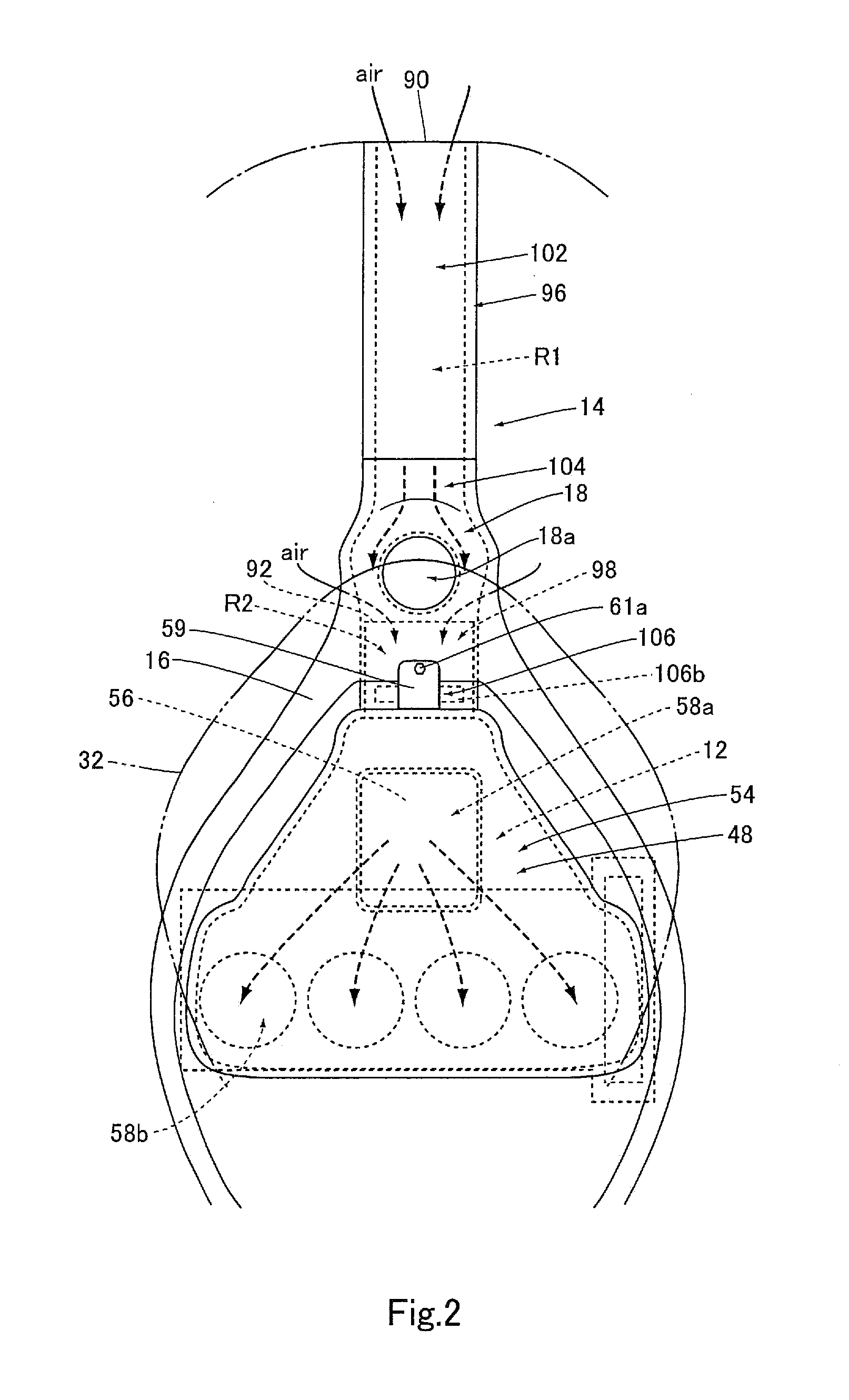

Cooling system for motor vehicles and method for controlling at least one air mass flow through a radiator

InactiveUS20060211364A1Easy to controlHeating up fastDucting arrangementsCoolant flow controlMobile vehicleEngineering

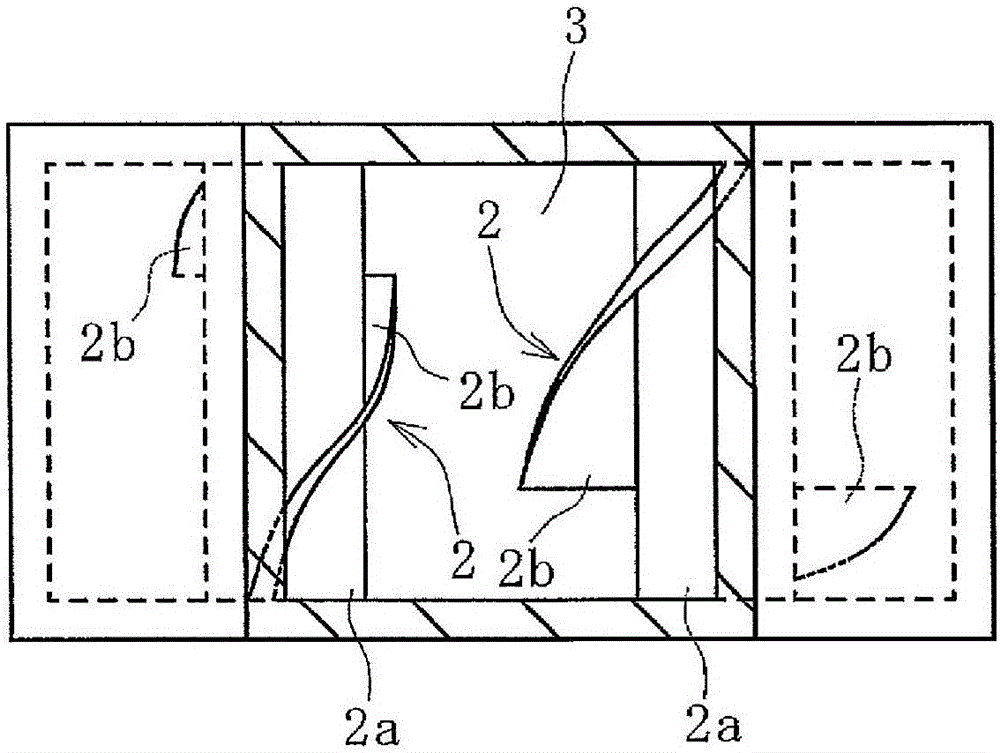

Cooling system for motor vehicles with at least one radiator to which in a first operating phase, particularly in the ram pressure phase, a first air stream can be supplied via a first air flow path and which in an alternative or simultaneous second operating phase, particularly during fan operation, can be supplied by means of at least one air-conveying device, with a second air stream flowing along a second air flow path. Among other things, it is also provided that at least in some regions the two air flow paths are oriented at an angle to each other so that the air-conveying device is disposed outside or essentially outside the first air flow path. The invention also related to a corresponding method.

Owner:ILLINOIS TOOL WORKS INC +1

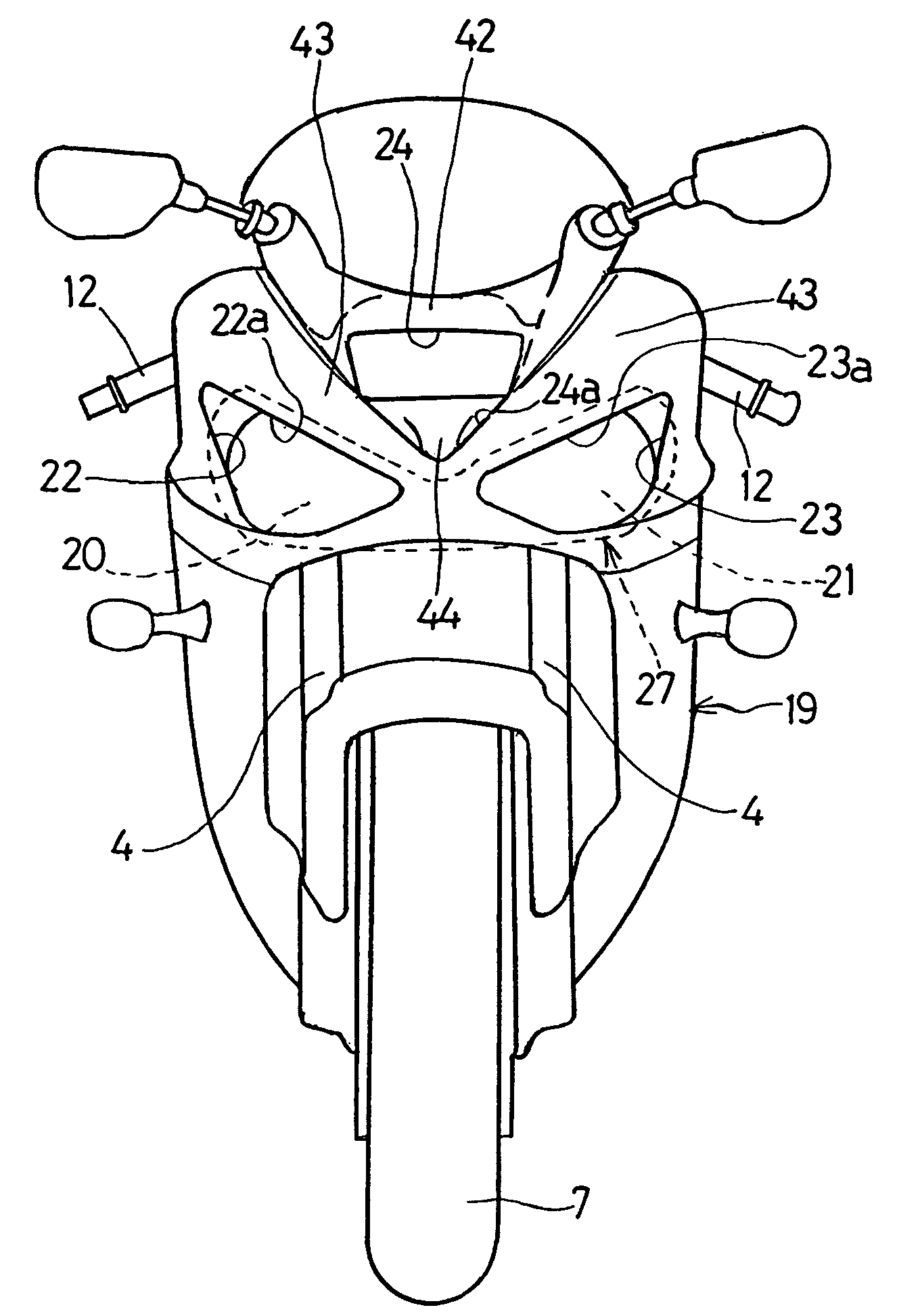

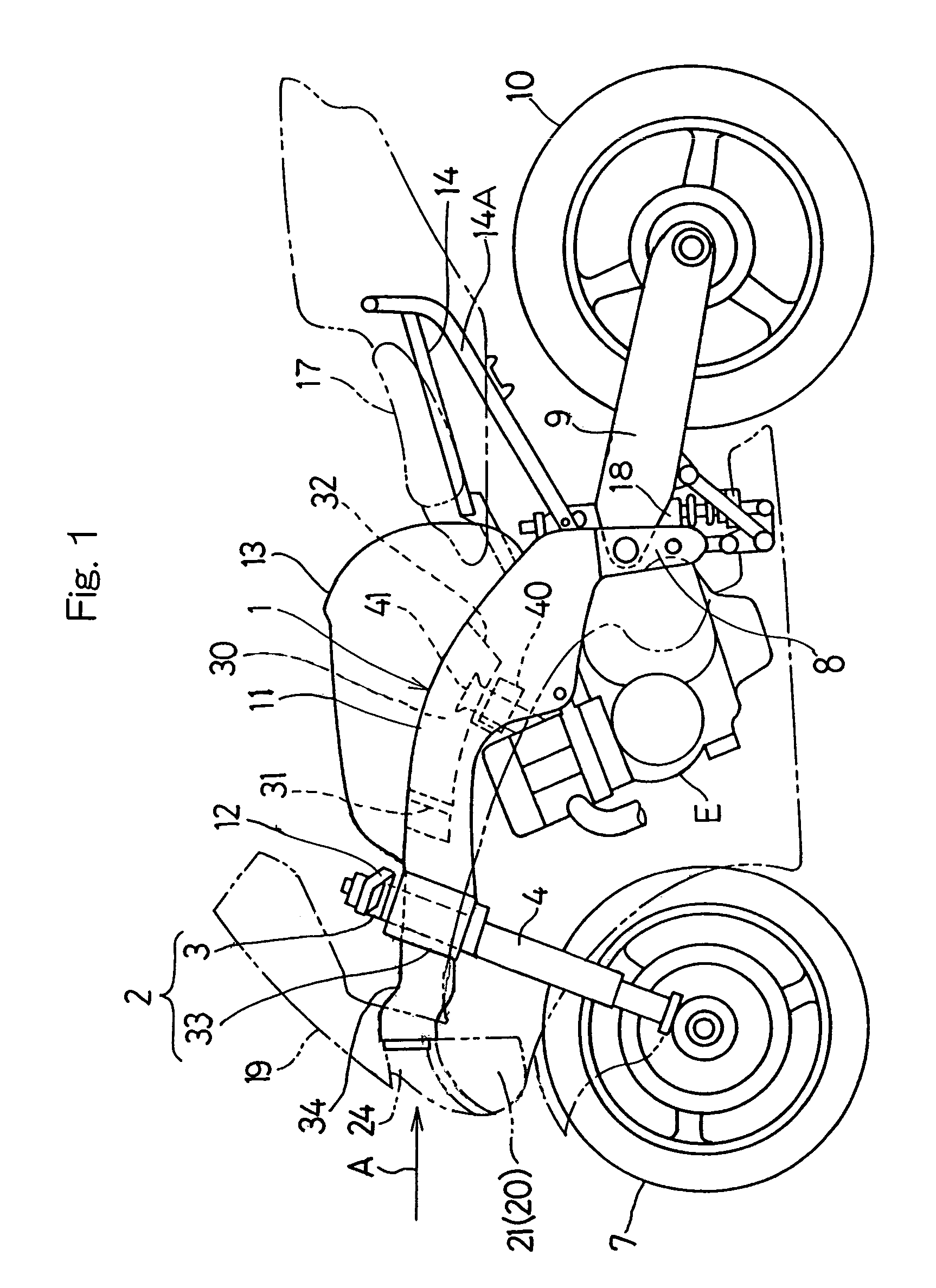

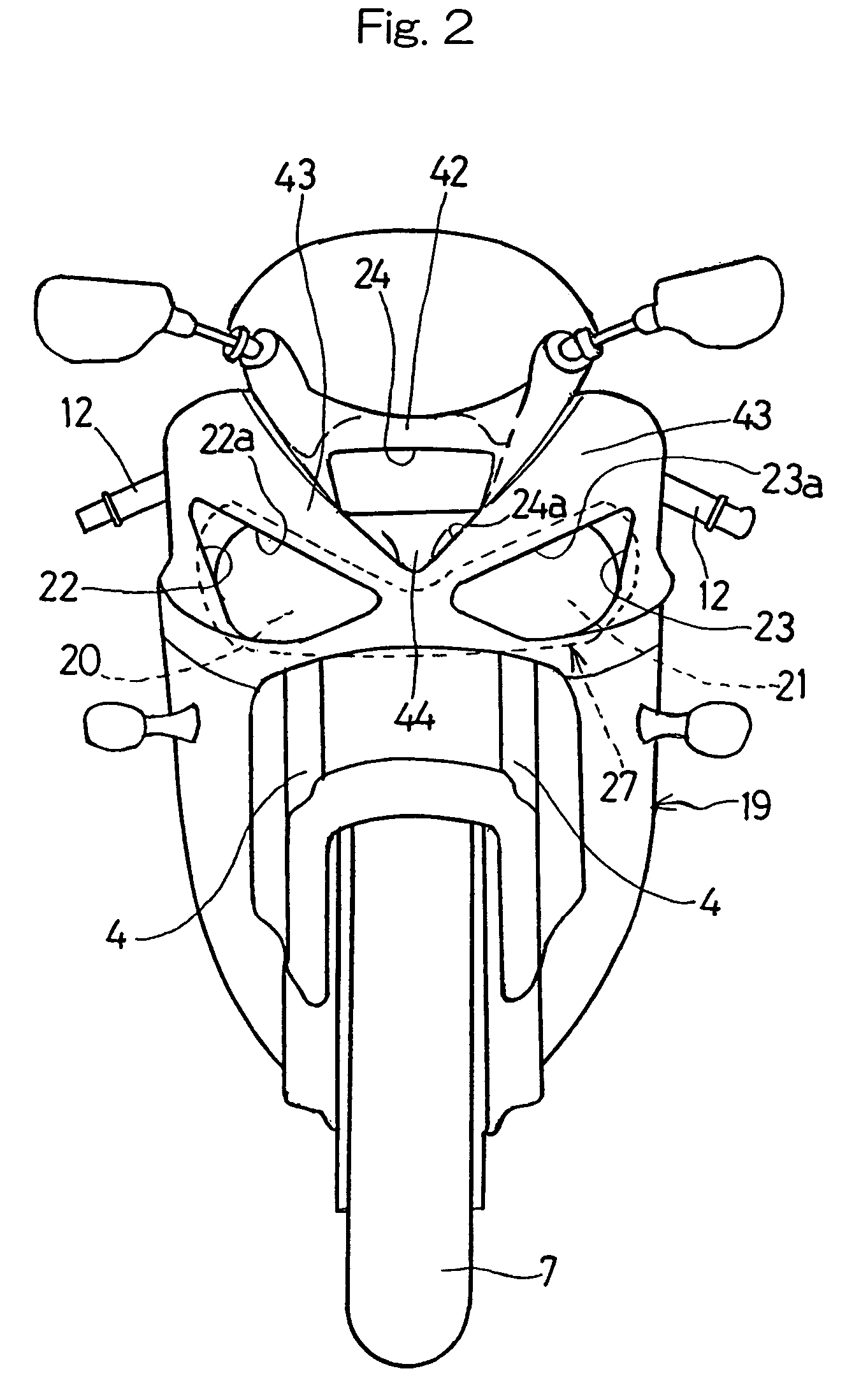

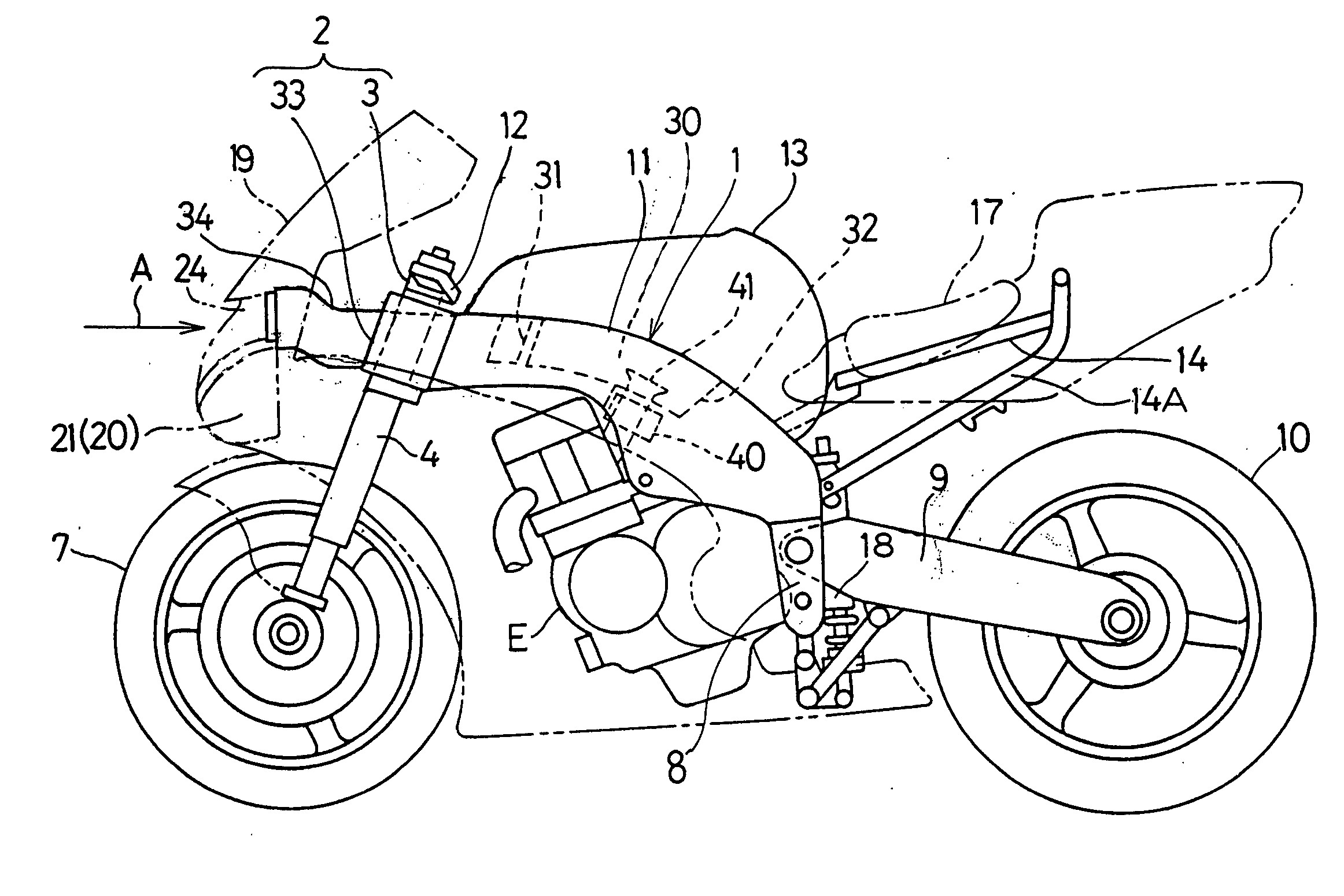

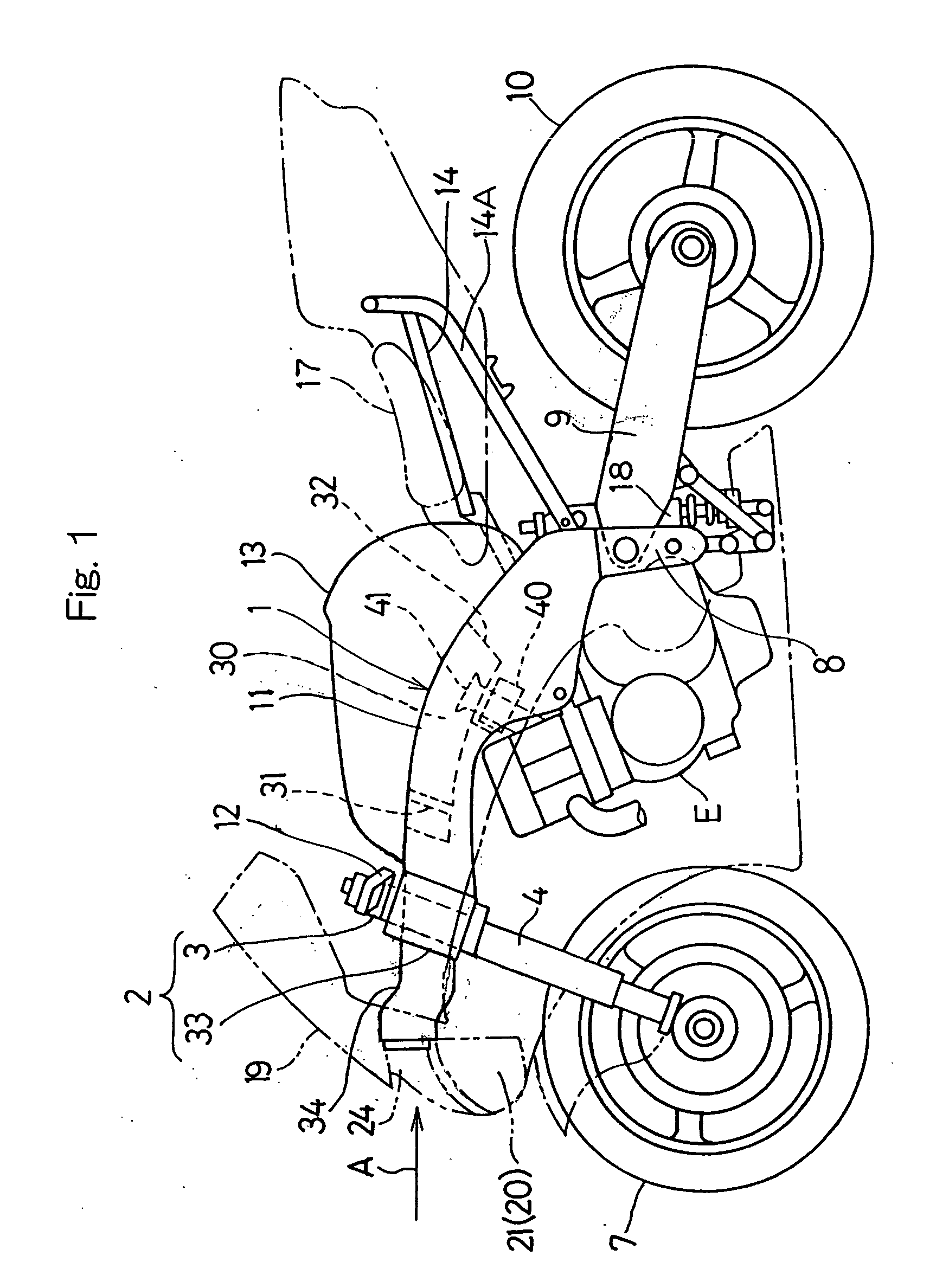

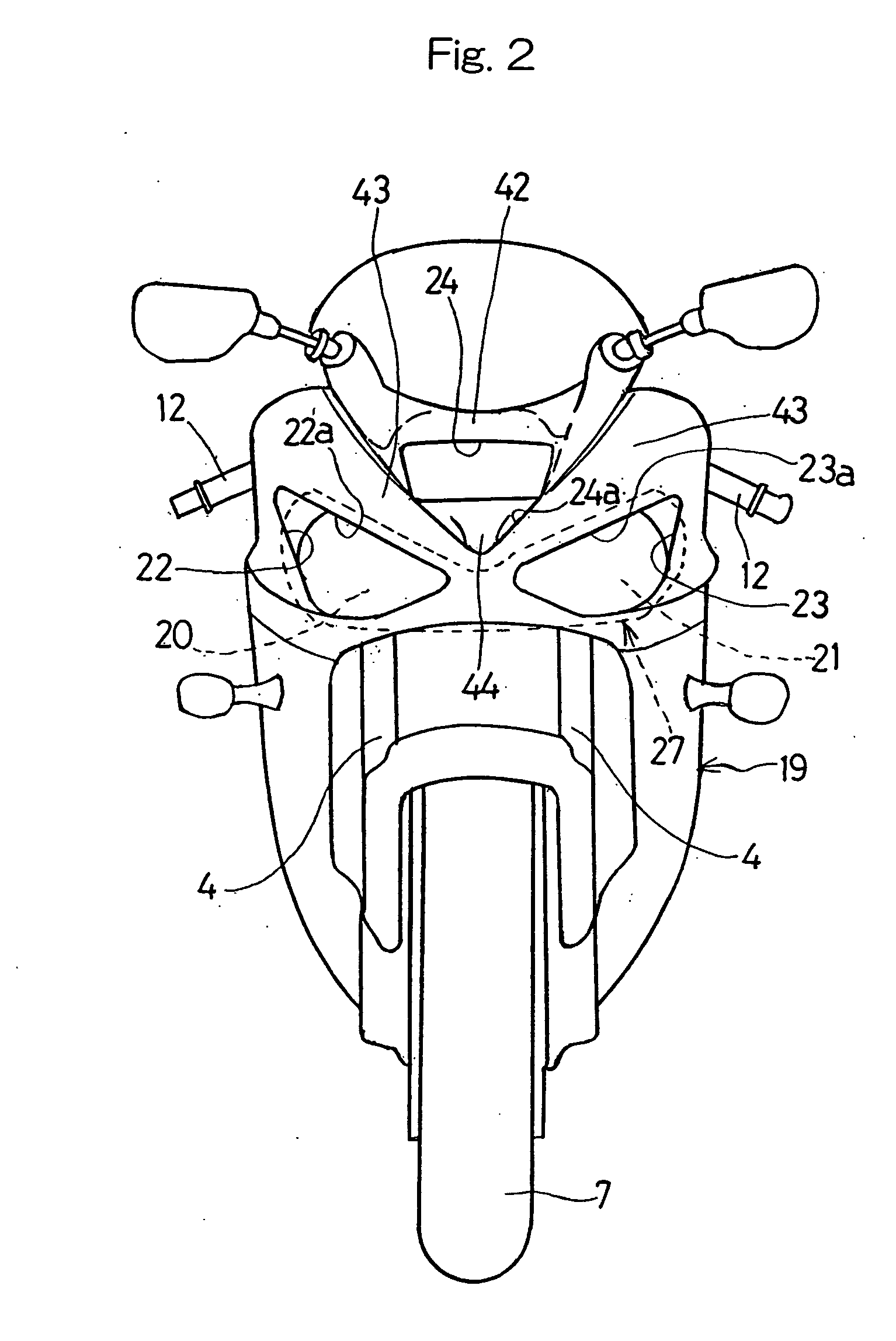

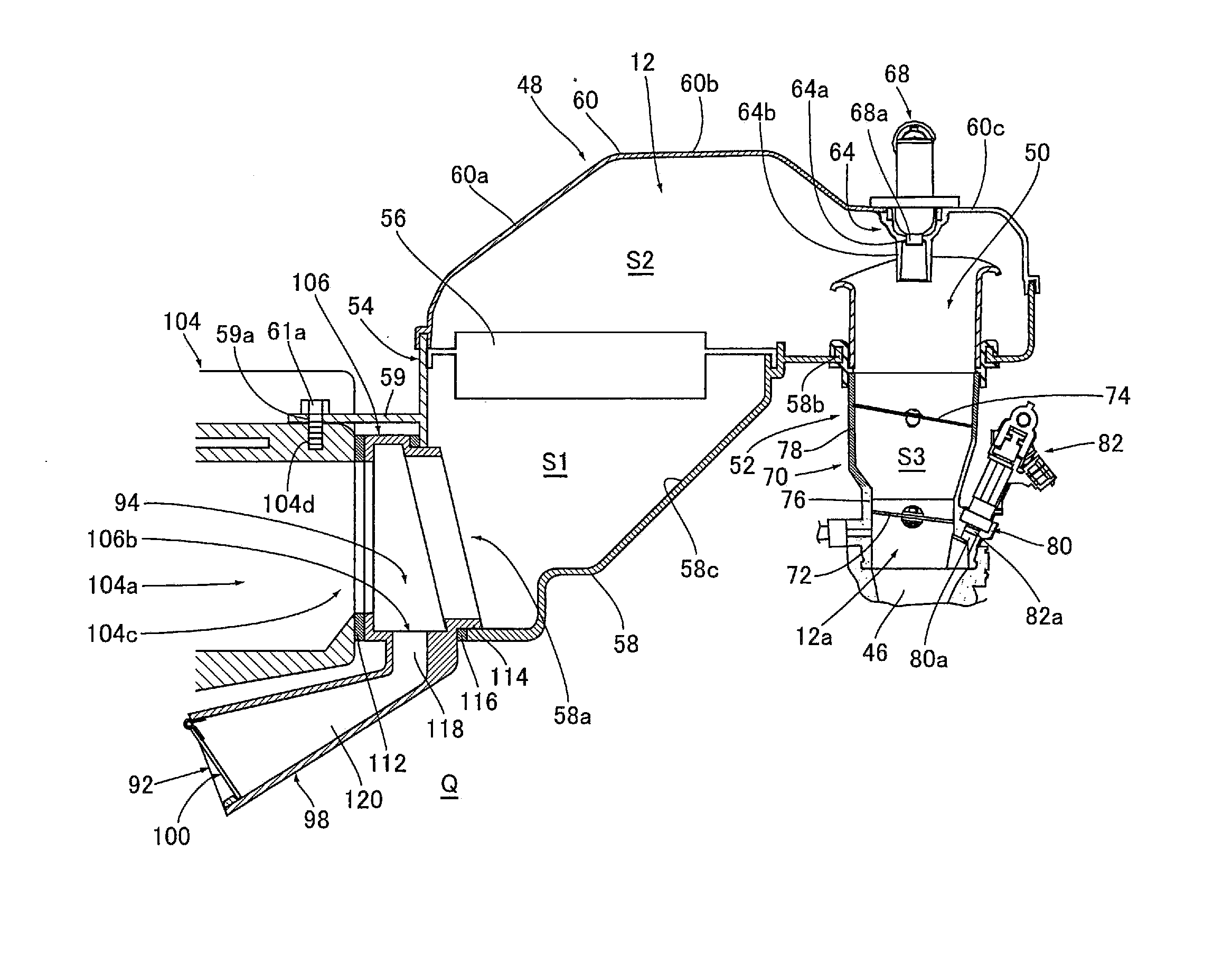

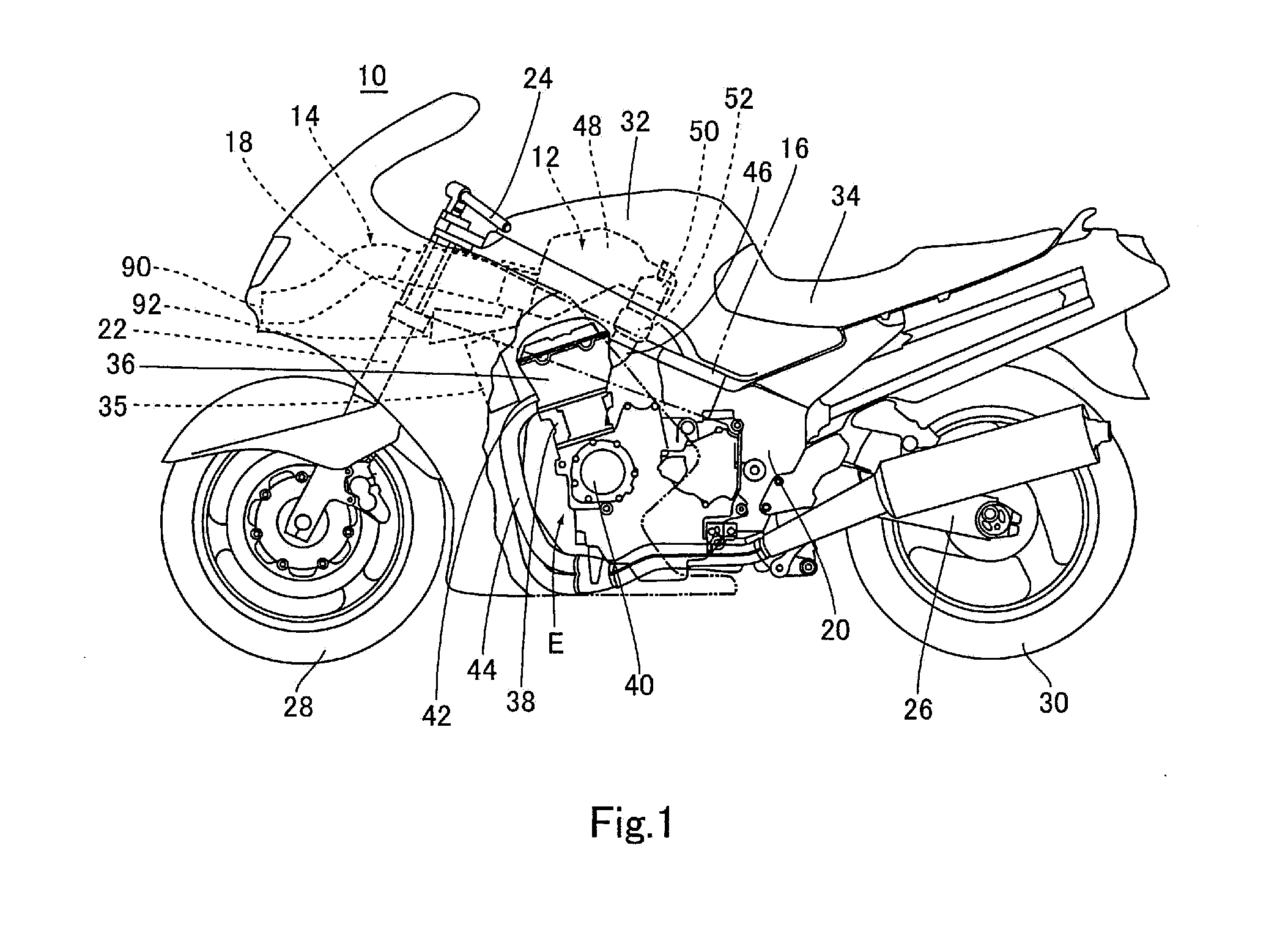

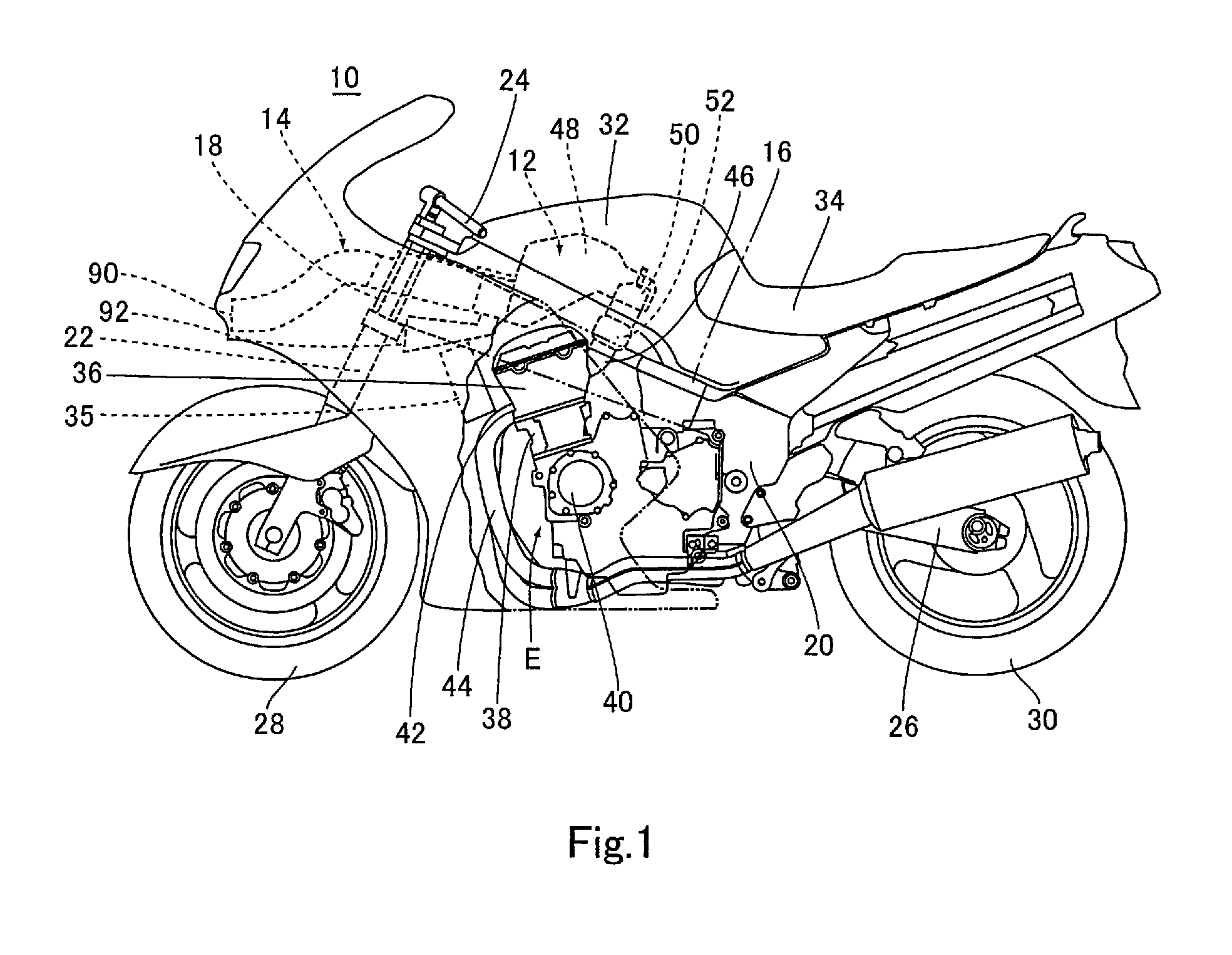

Air intake system for vehicle combustion engine

ActiveUS7270207B2Simple structureReduce manufacturing costInternal combustion piston enginesWeather guardsCombustionEngineering

To provide an air intake system for a vehicle, so simple in structure as to reduce the cost and effective to increase the ram pressure, a front cowling (19) is mounted on a front portion of a vehicle body structure (1). This front cowling (19) has left and right headlight windows (20 and 21) aligned with left and right headlights (22 and 23), respectively, and also has an air intake opening (24) defined therein at a location above the headlight windows (20 and 21) for introducing an external combustion air (A) towards the vehicle engine (E). An intake air passage (35) is provided for introducing the combustion air (A), then entering the air intake opening (24), towards an air cleaner (30) by way of opposite lateral portions of a head tube (3).

Owner:KAWASAKI MOTORS LTD

Air intake system for vehicle combustion engine

ActiveUS20040050357A1Internal combustion piston enginesNon-fuel substance addition to fuelCombustionInternal combustion engine

To provide an air intake system for a vehicle, so simple in structure as to reduce the cost and effective to increase the ram pressure, a front cowling (19) is mounted on a front portion of a vehicle body structure (1). This front cowling (19) has left and right headlight windows (20 and 21) aligned with left and right headlights (22 and 23), respectively, and also has an air intake opening (24) defined therein at a location above the headlight windows (20 and 21) for introducing an external combustion air (A) towards the vehicle engine (E). An intake air passage (35) is provided for introducing the combustion air (A), then entering the air intake opening (24), towards an air cleaner (30) by way of opposite lateral portions of a head tube (3).

Owner:KAWASAKI MOTORS LTD

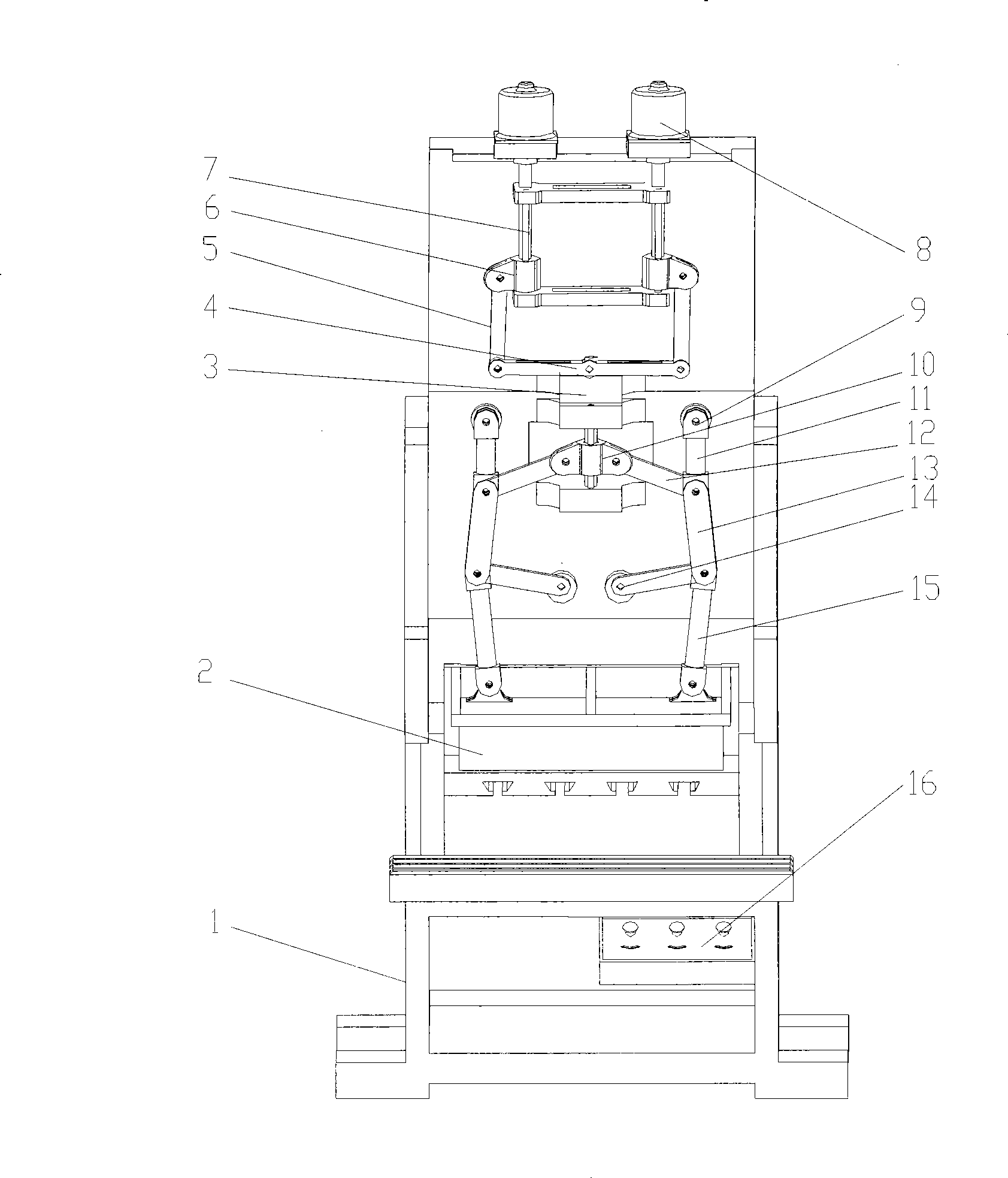

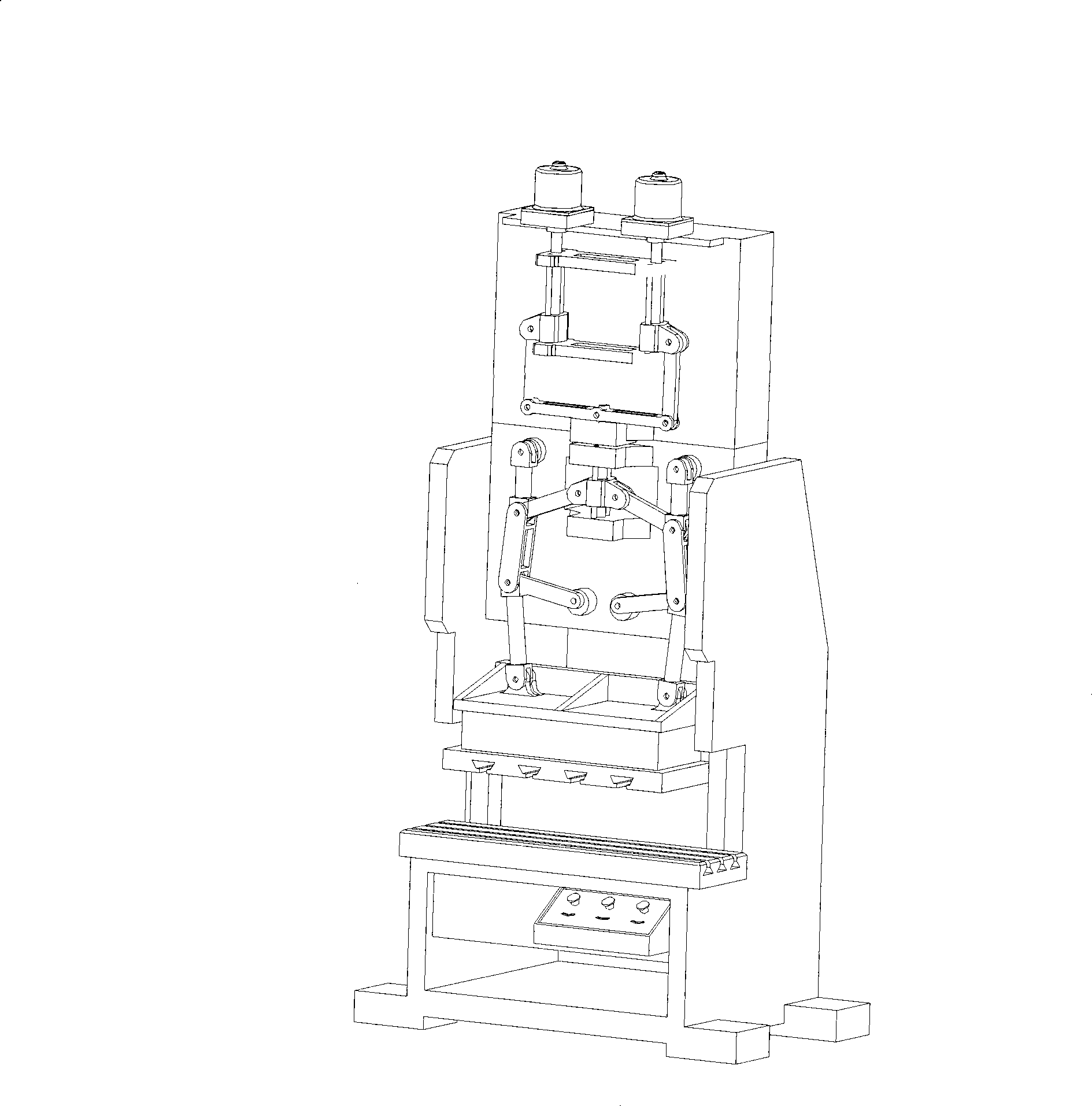

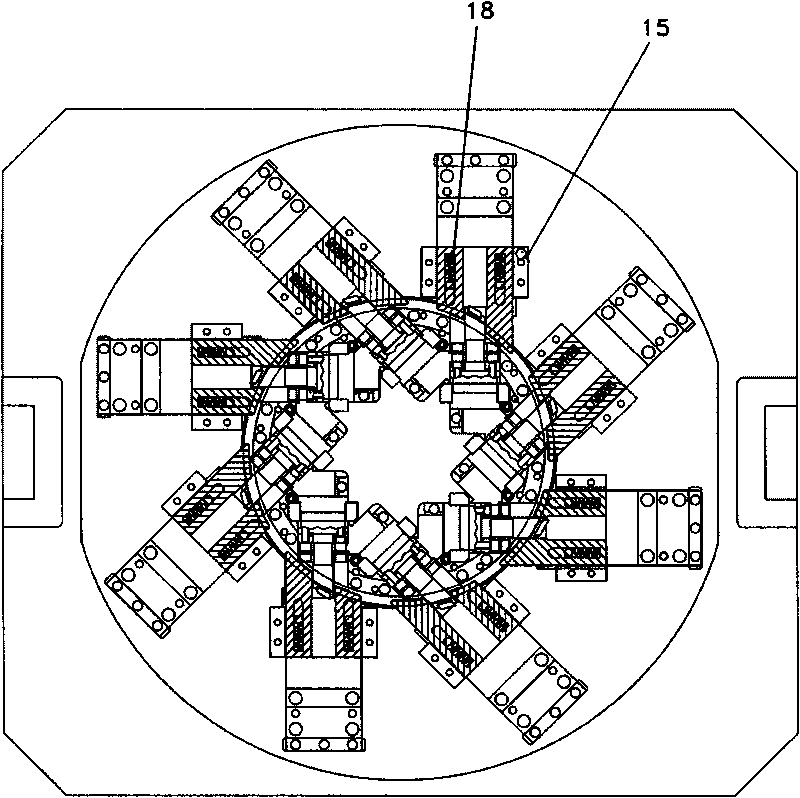

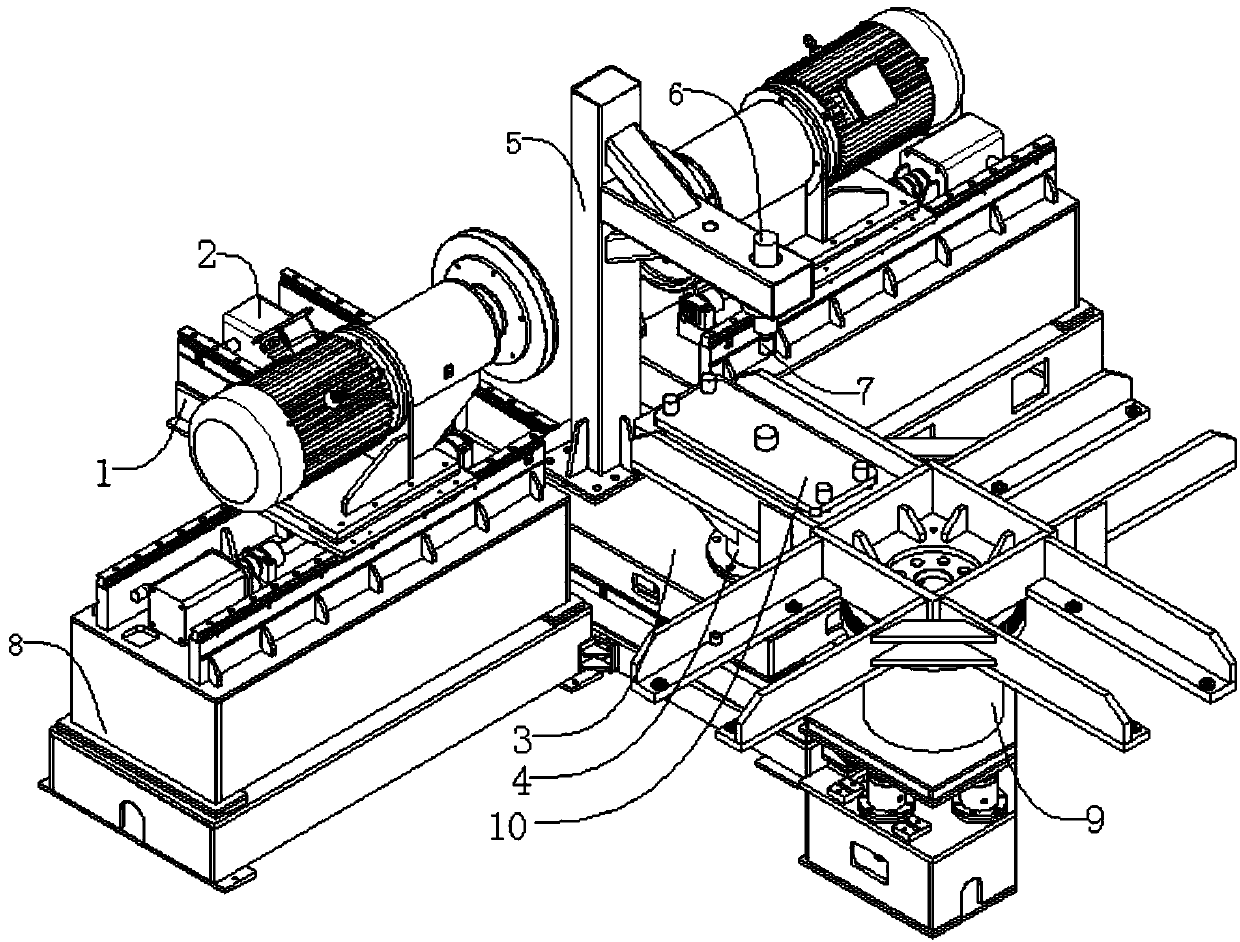

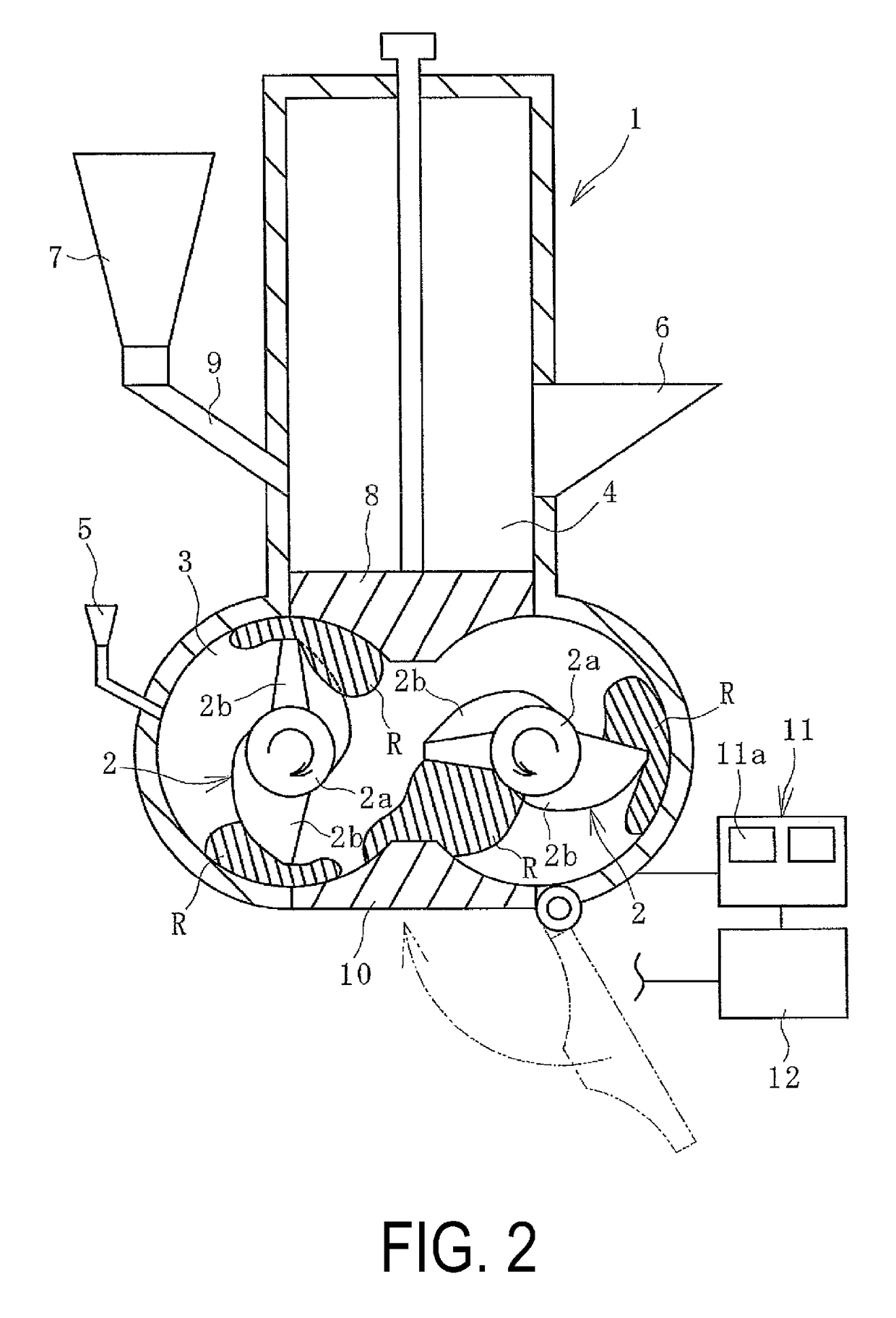

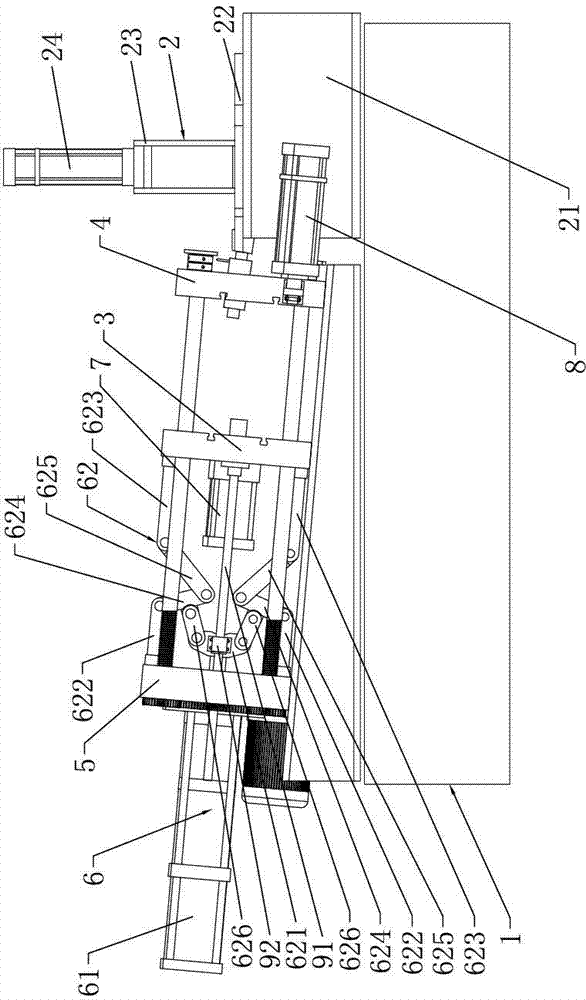

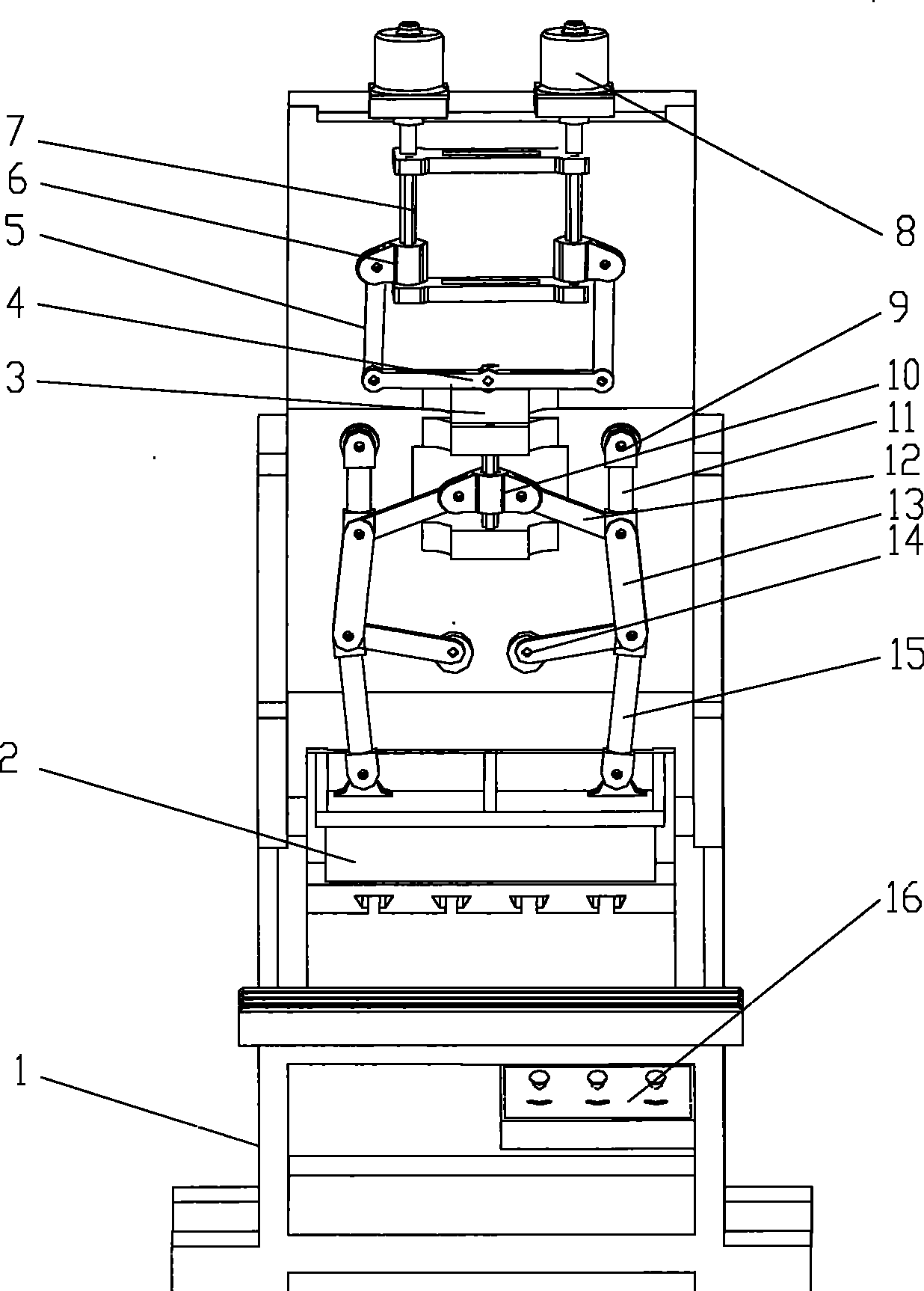

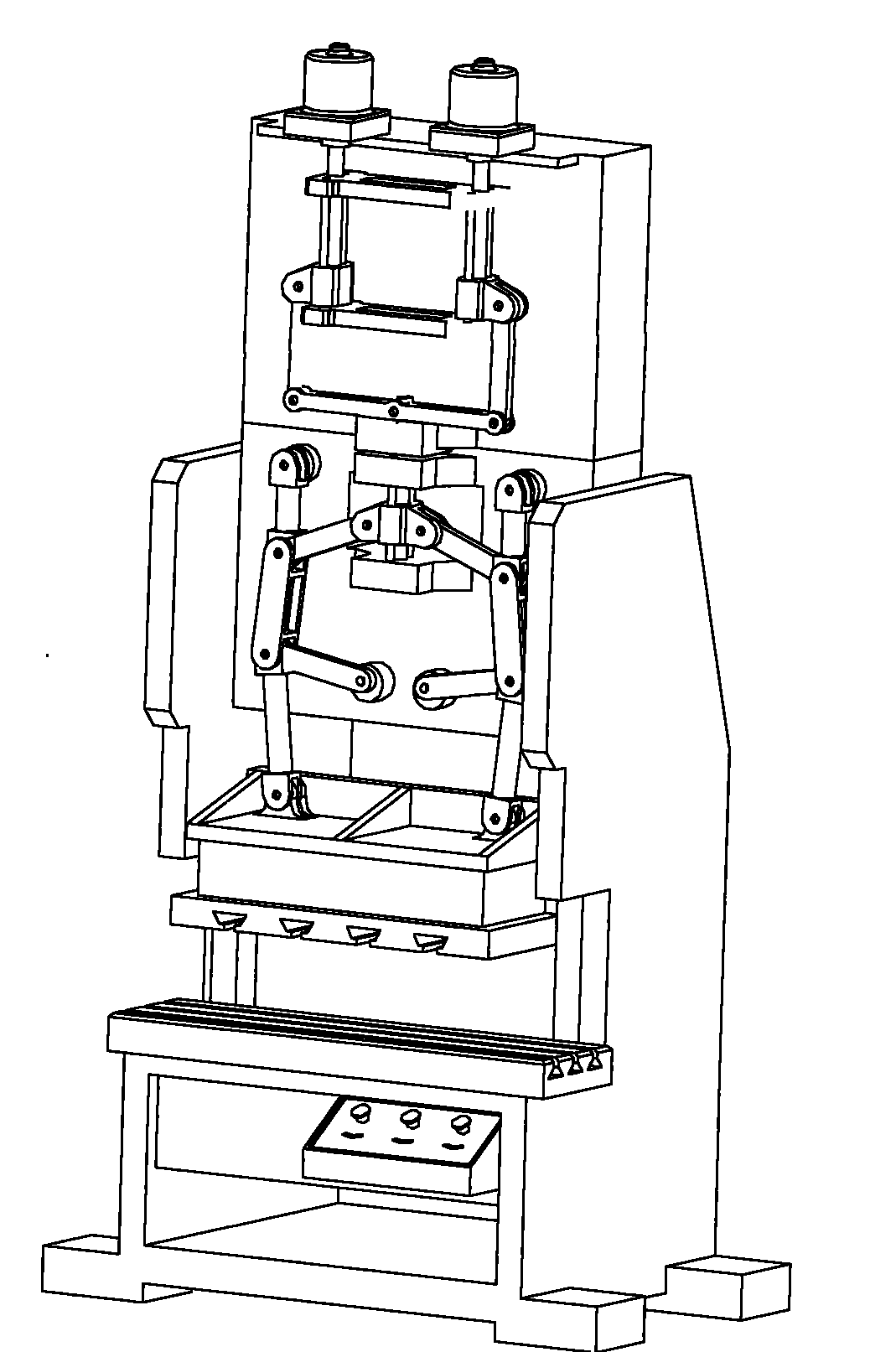

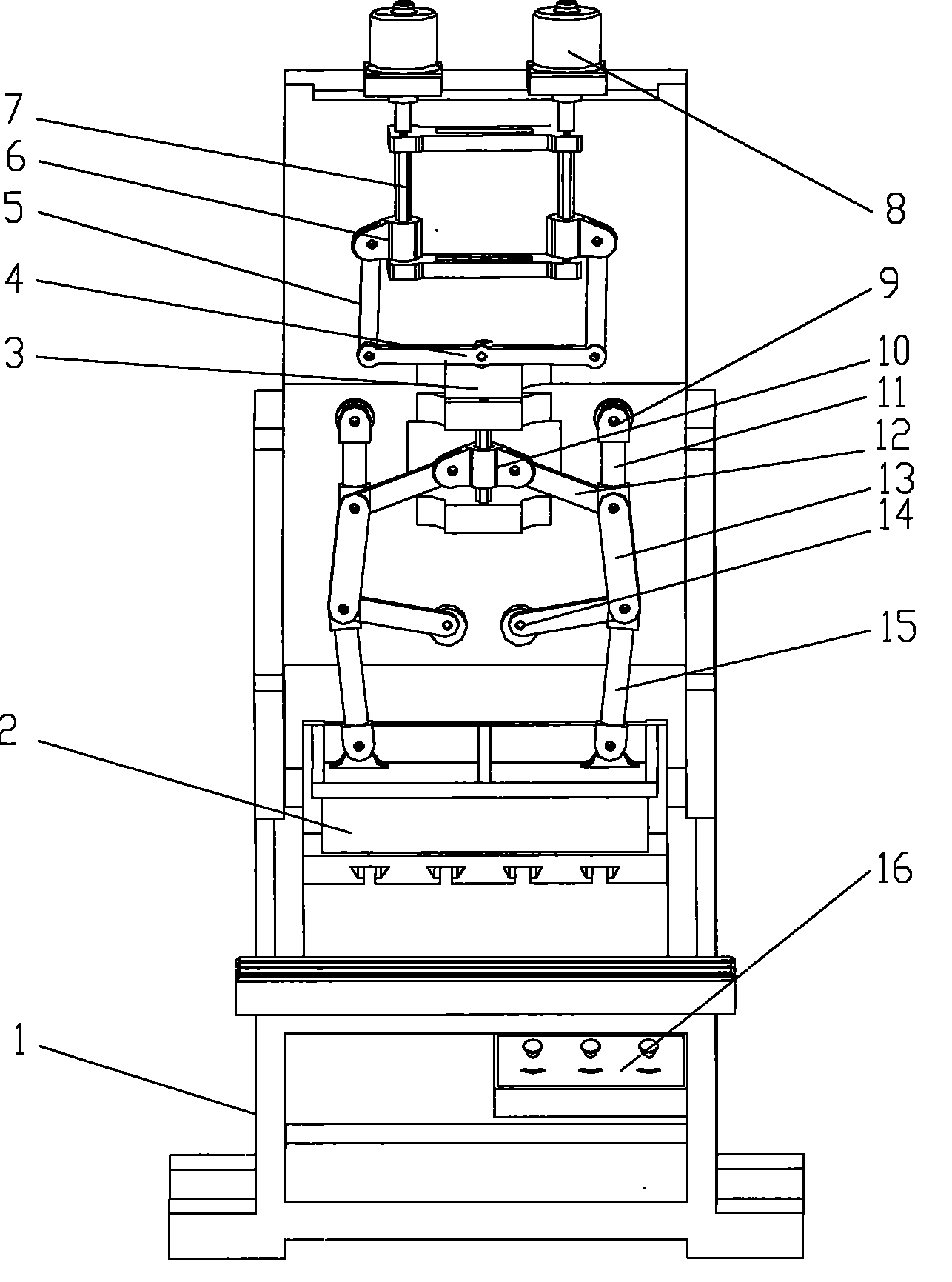

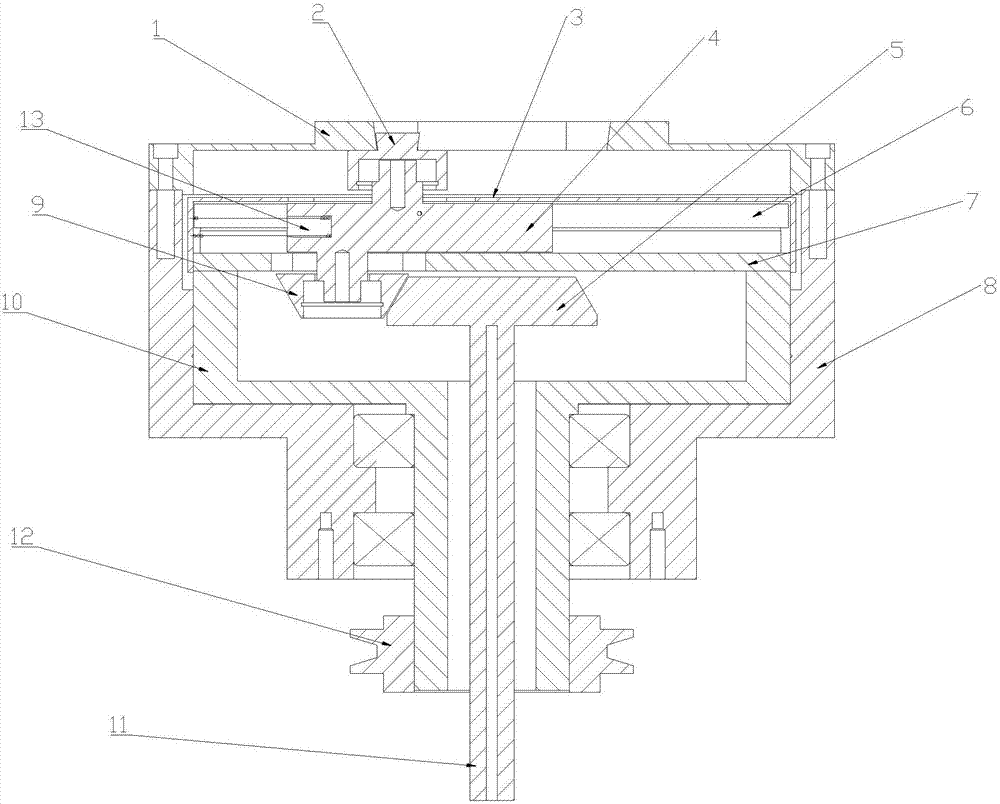

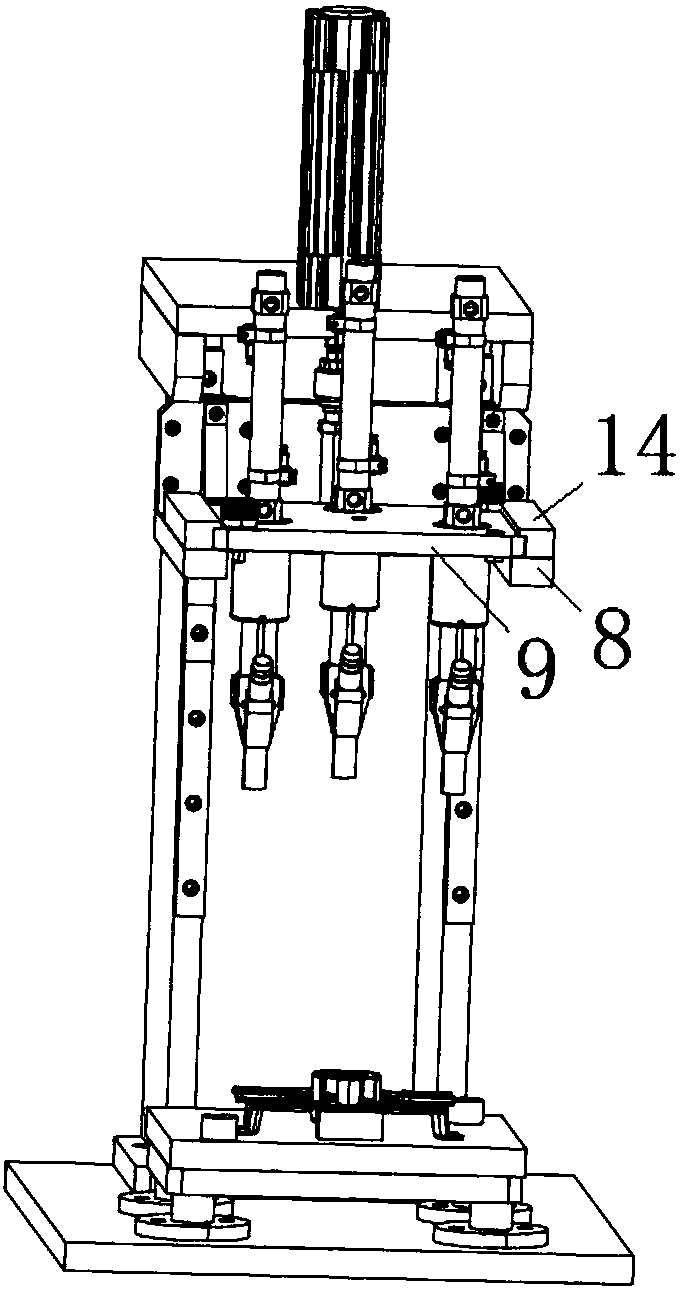

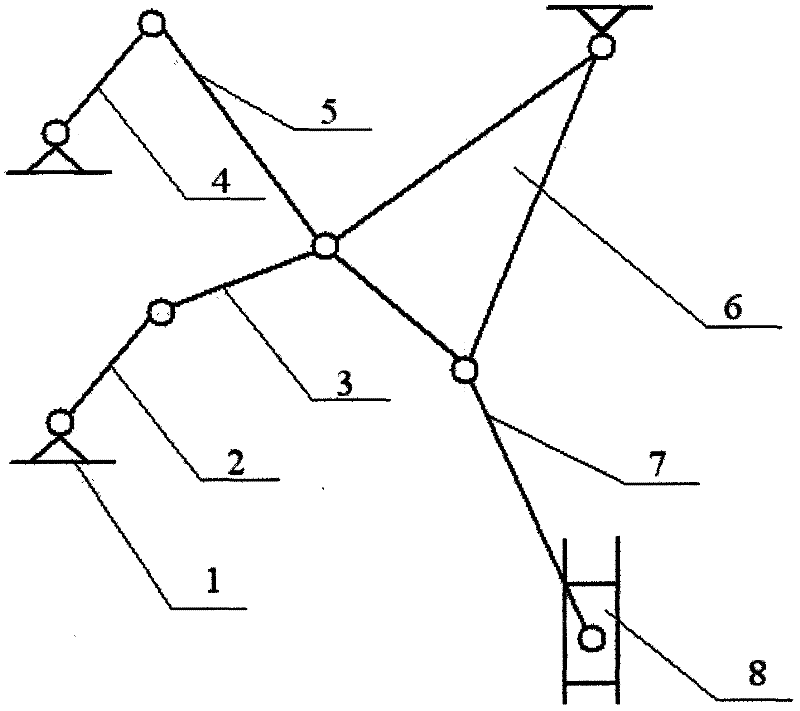

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876AGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, a horizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAO TONG UNIV

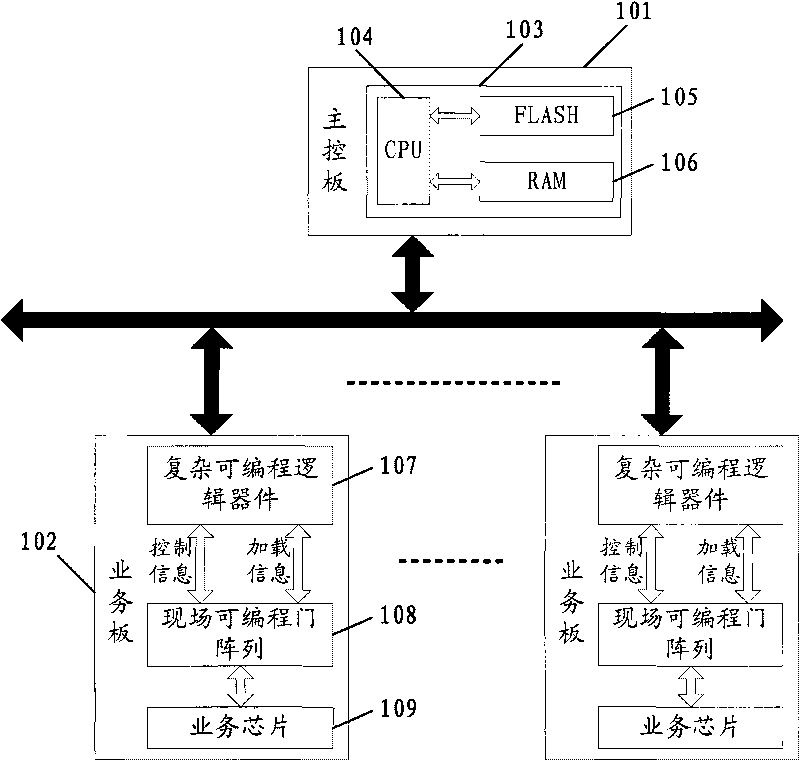

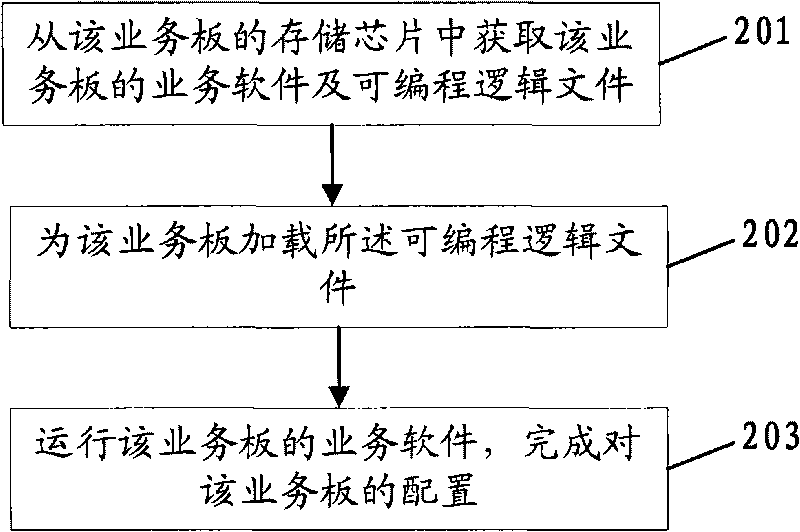

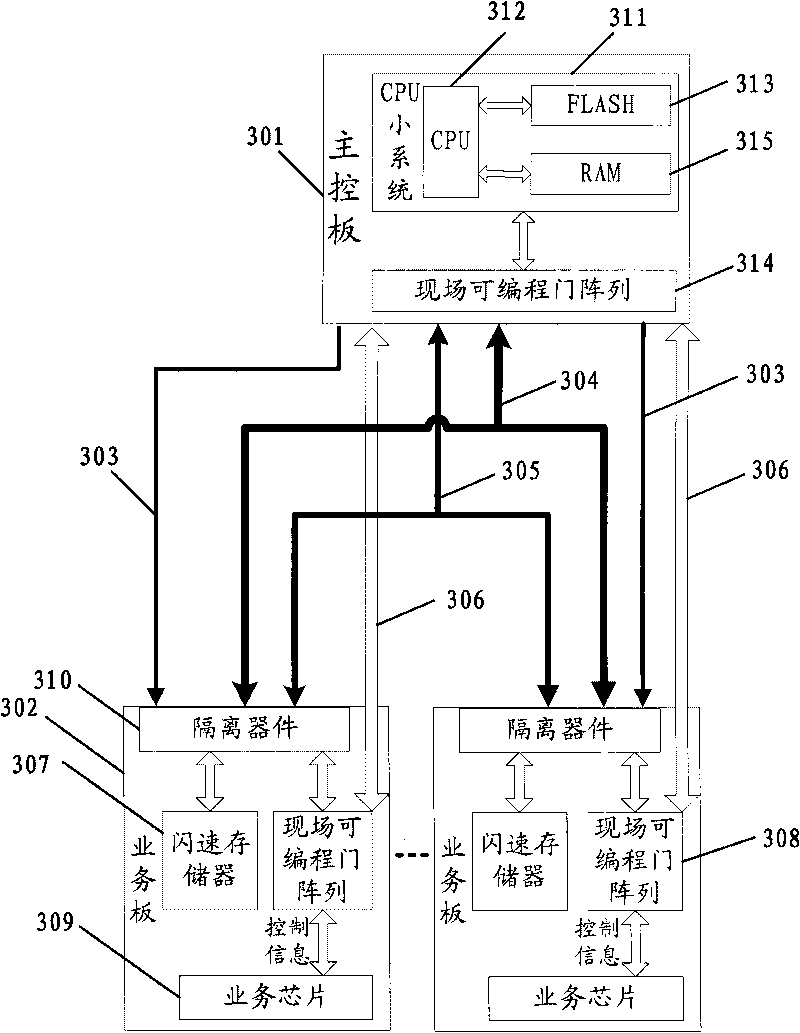

Method for dynamically loading service boards and dynamic loading system

InactiveCN101741593AReduce storage pressureSave RAMProgram loading/initiatingData switching networksRam pressureSoftware

The embodiment of the invention discloses a method for dynamically loading service boards and a dynamic loading system, relates to the communication field and solves the problems of storage capacity waste of a main control board and great RAM pressure, and influence on operating services caused by reloading service board software and FPGA files in communication equipment adopting a centralized control scheme. The method comprises the following steps: when detecting that the service board is on-line, acquiring service software and a programmable logic file of the service board from a storage chip of the service board; loading the programmable logic file for the service board; and running the service software of the service board to complete the configuration of the service board. The method for dynamically loading the service boards and the dynamic loading system can be applied to constructing a centralized control scheme of communication equipment.

Owner:HUAWEI TECH CO LTD

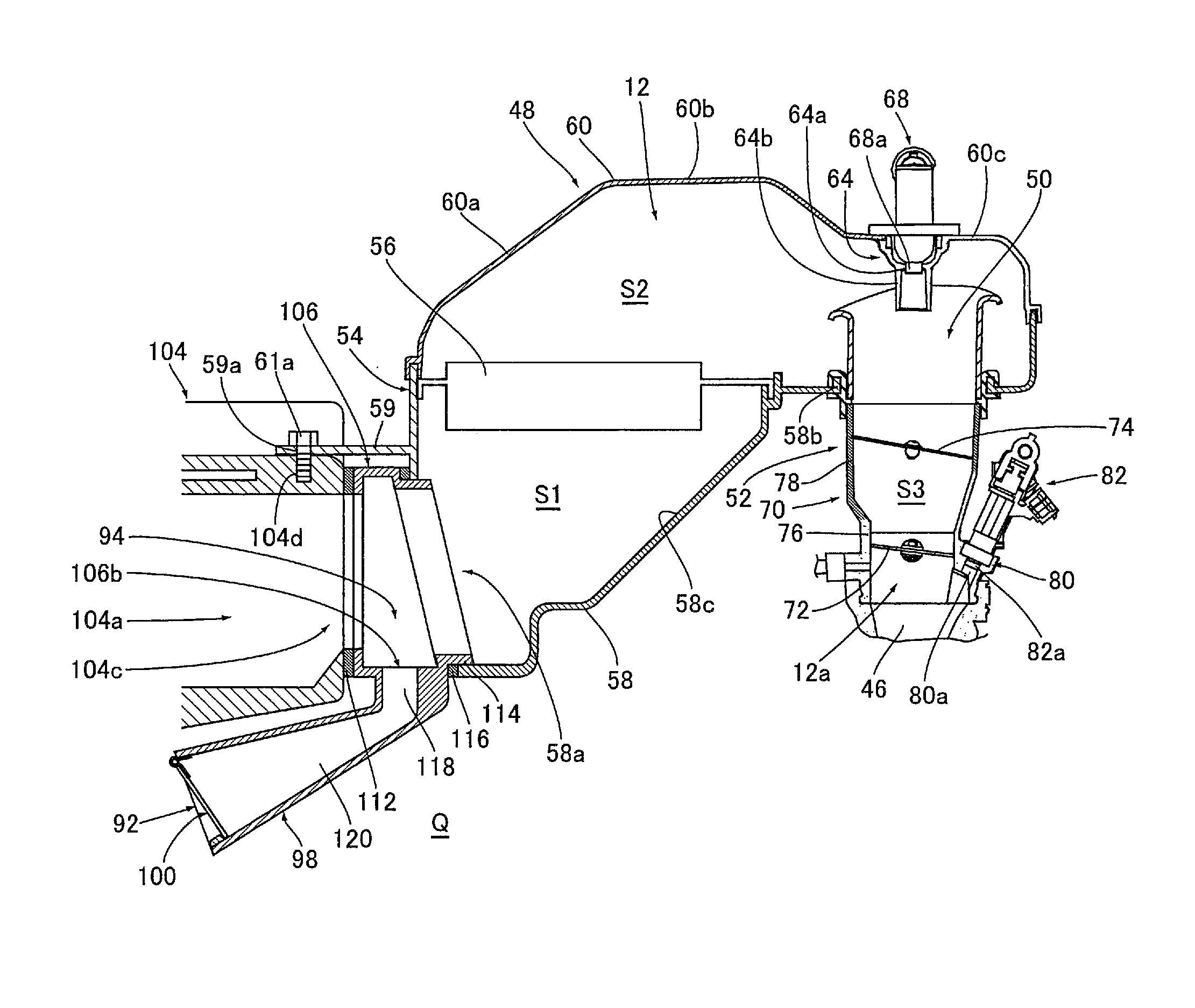

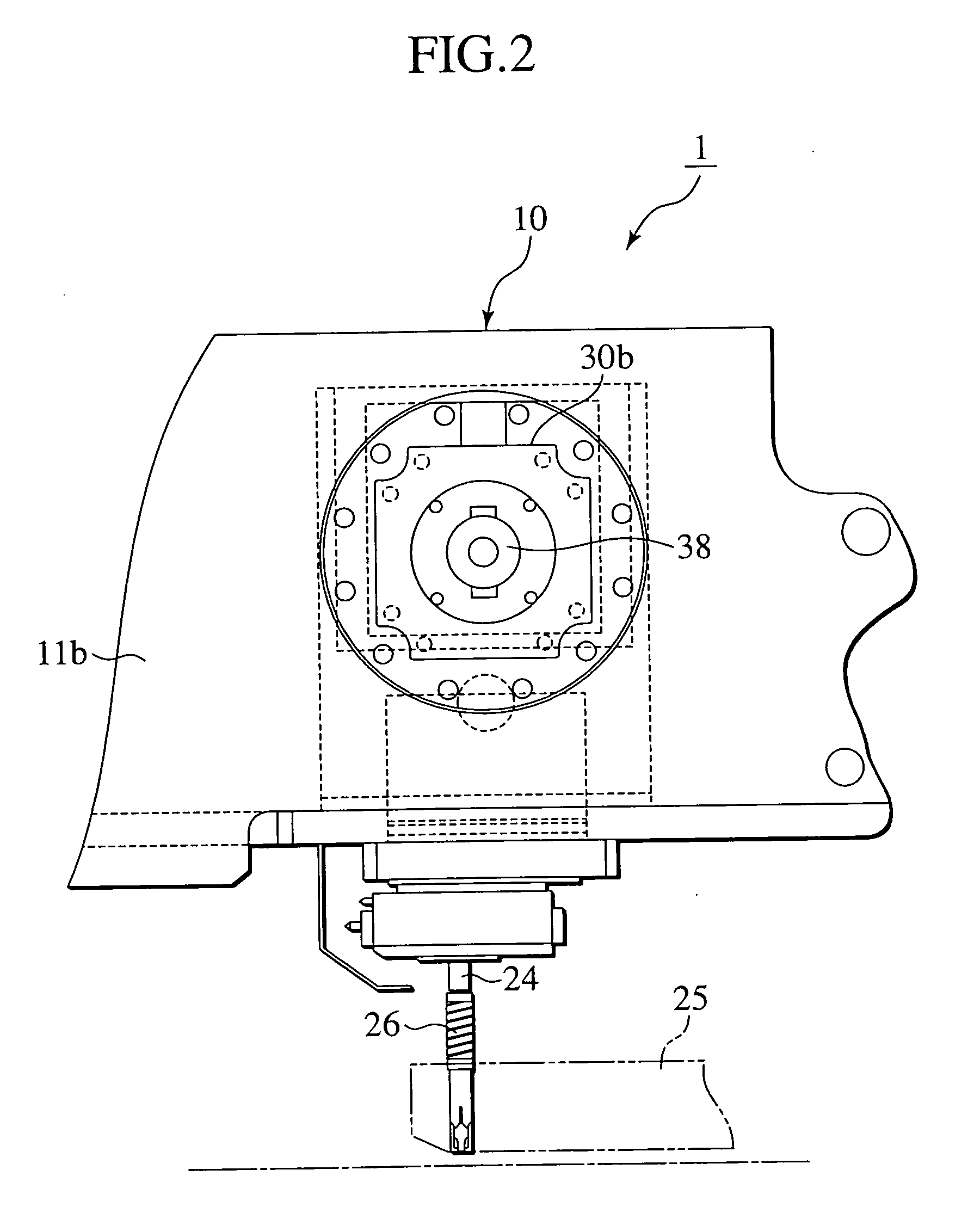

Vehicle

A vehicle includes a duct structure configured to take in air from outside; an air cleaner including an air filter configured to clean the air guided to the air cleaner through the duct structure; a throttle device including a throttle valve for controlling a flow rate of the air guided to the throttle device through the air cleaner; and an engine including an intake port configured to suction the air guided to the engine through the throttle device; the duct structure including: a main inlet configured to take in air therethrough from outside by utilizing a ram pressure; a main passage extending from the main inlet to the air filter; a sub-inlet configured to take in air therethrough from outside; and a joint section located upstream of the air filter, the air flowing from the sub-inlet being joined to the air in the main passage, at the joint section.

Owner:KAWASAKI MOTORS LTD

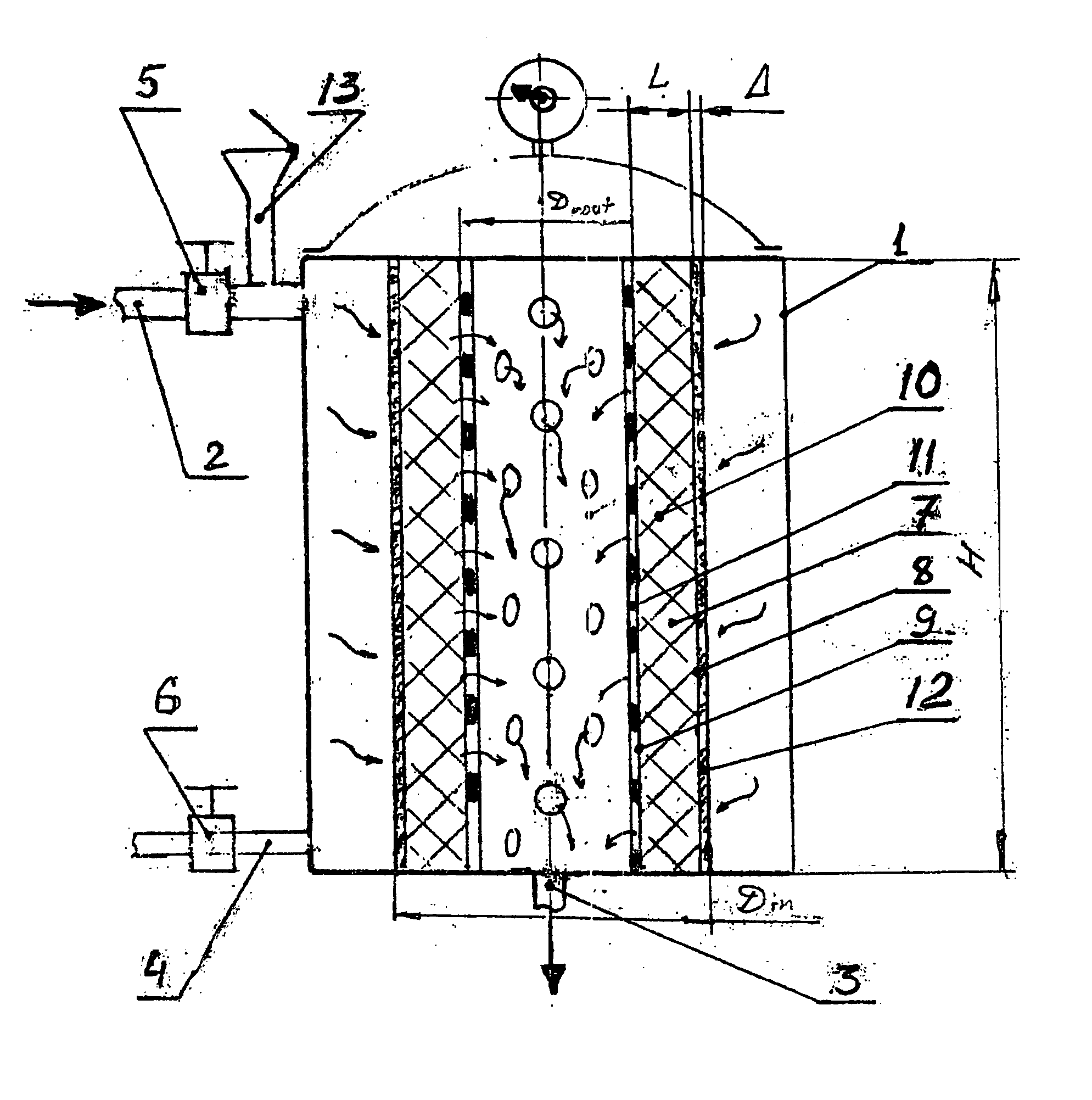

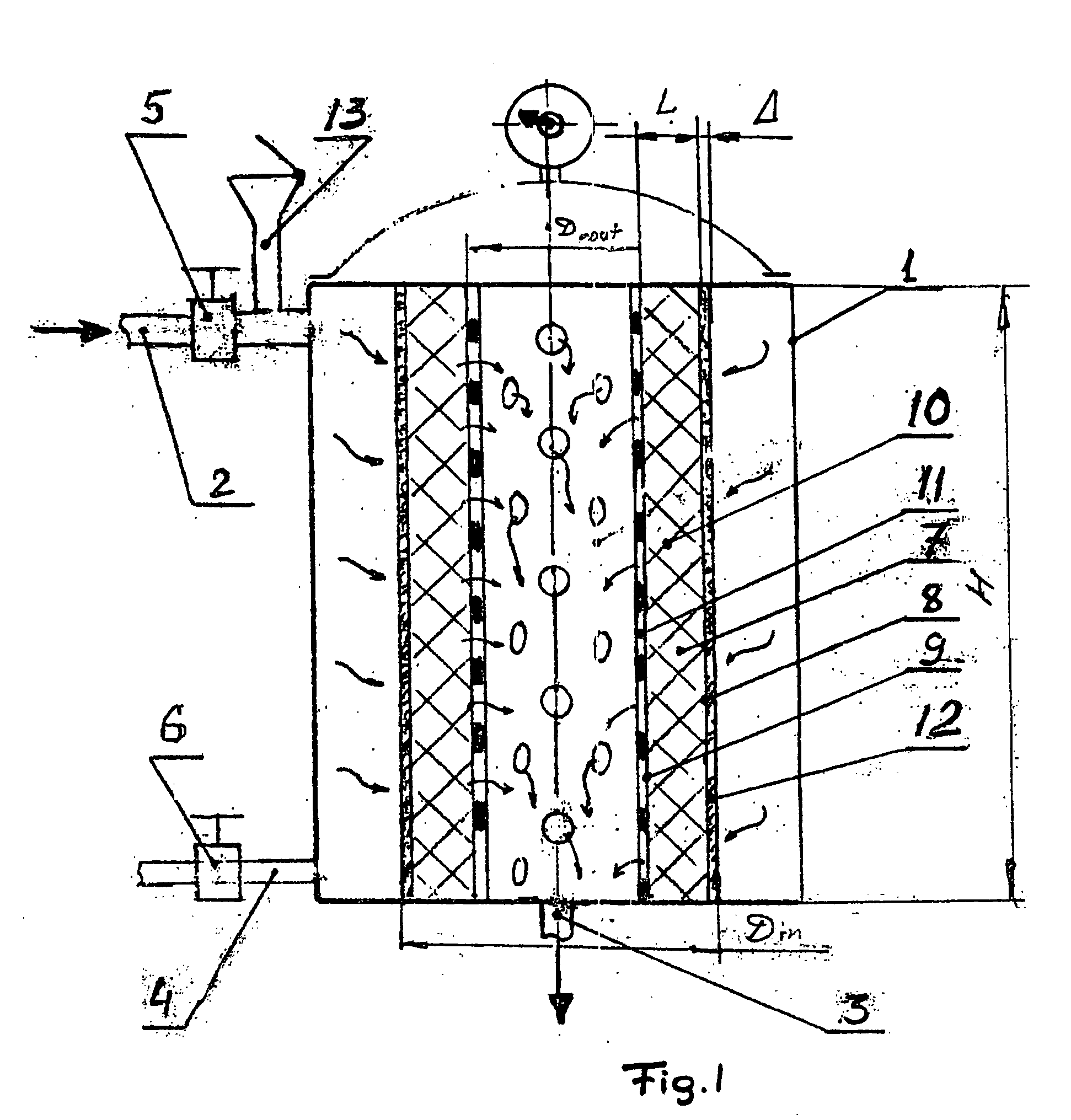

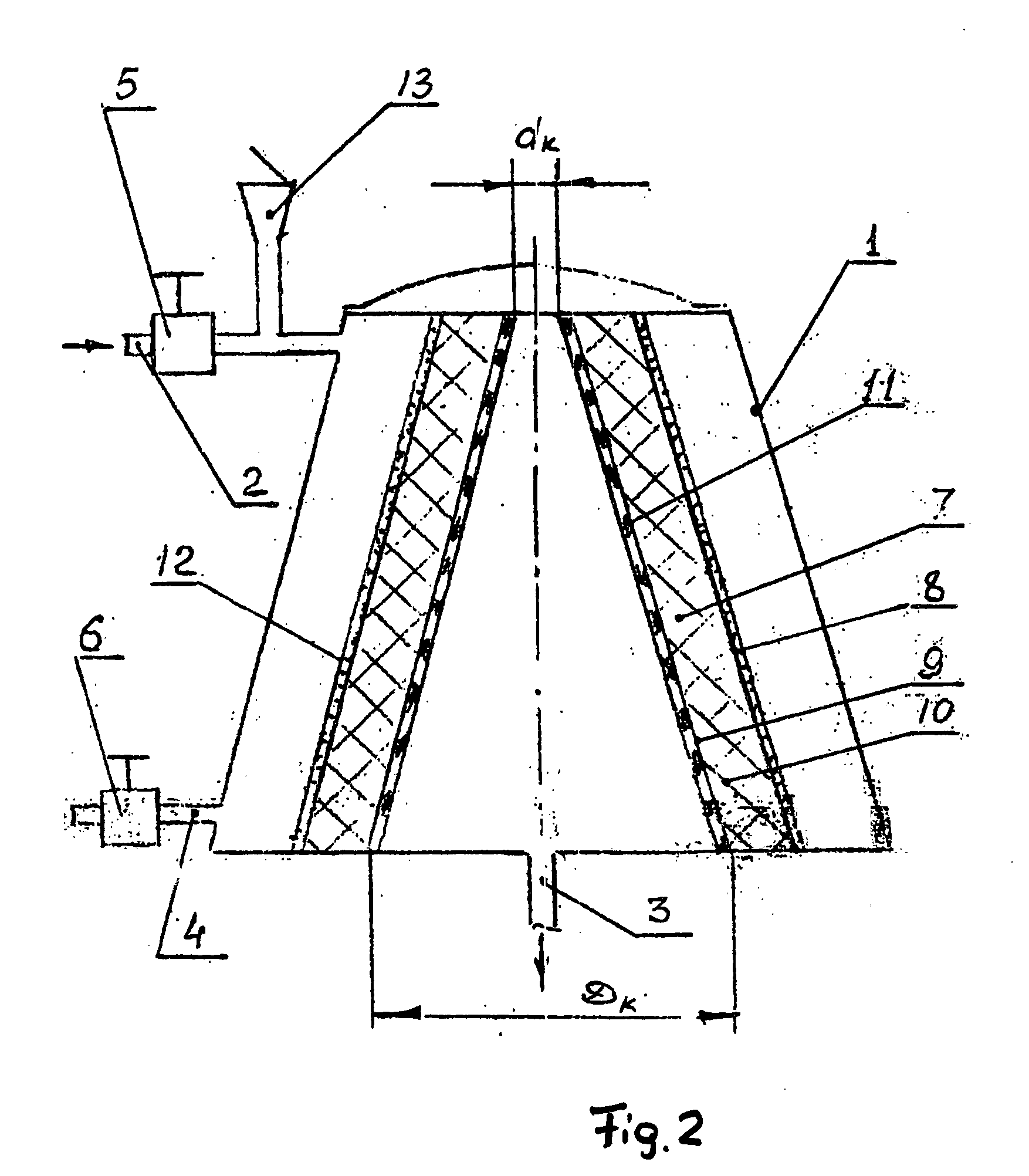

Water filter and the production method therefor

InactiveUS20050115879A1High strengthProtection from poisonIon-exchange column/bed processesIon-exchanger regenerationWater filterIon exchange

A water filter has a body provided with an inlet, an outlet and a drain pipe provided with lock valves and a main filtering element composed of an ion-exchange material and having input and output surfaces for filtrated liquid, wherein the ion-exchange material is embodied in such a way that it is voluminous, has a required shape, is reinforced with a rigid reinforcement which is fixed to a perforated support, and forms a continuous porous frame from sphero colloids having required pore sizes which are defined by required cleaning parameters, the volume of the filtering mass of the element material being calculated according to mathematical expressions, and the input surface of the main filtering element is coated with an additional filtering and correcting layer of a fine substance introduced in the form of a powder through a loading valve in the cavity of the body in a filtered liquid flow deposited on the input surface of the main filtering element and dynamically retained by ram pressure of liquid, with the powder granule sizes being higher than the pores of the pores of the ion-exchange material, and the volume thereof corresponding to the shape of the main filtering element and defined according to mathematical expressions.

Owner:KOCHERGIN STANISLAV MIKHAYLOVICH +2

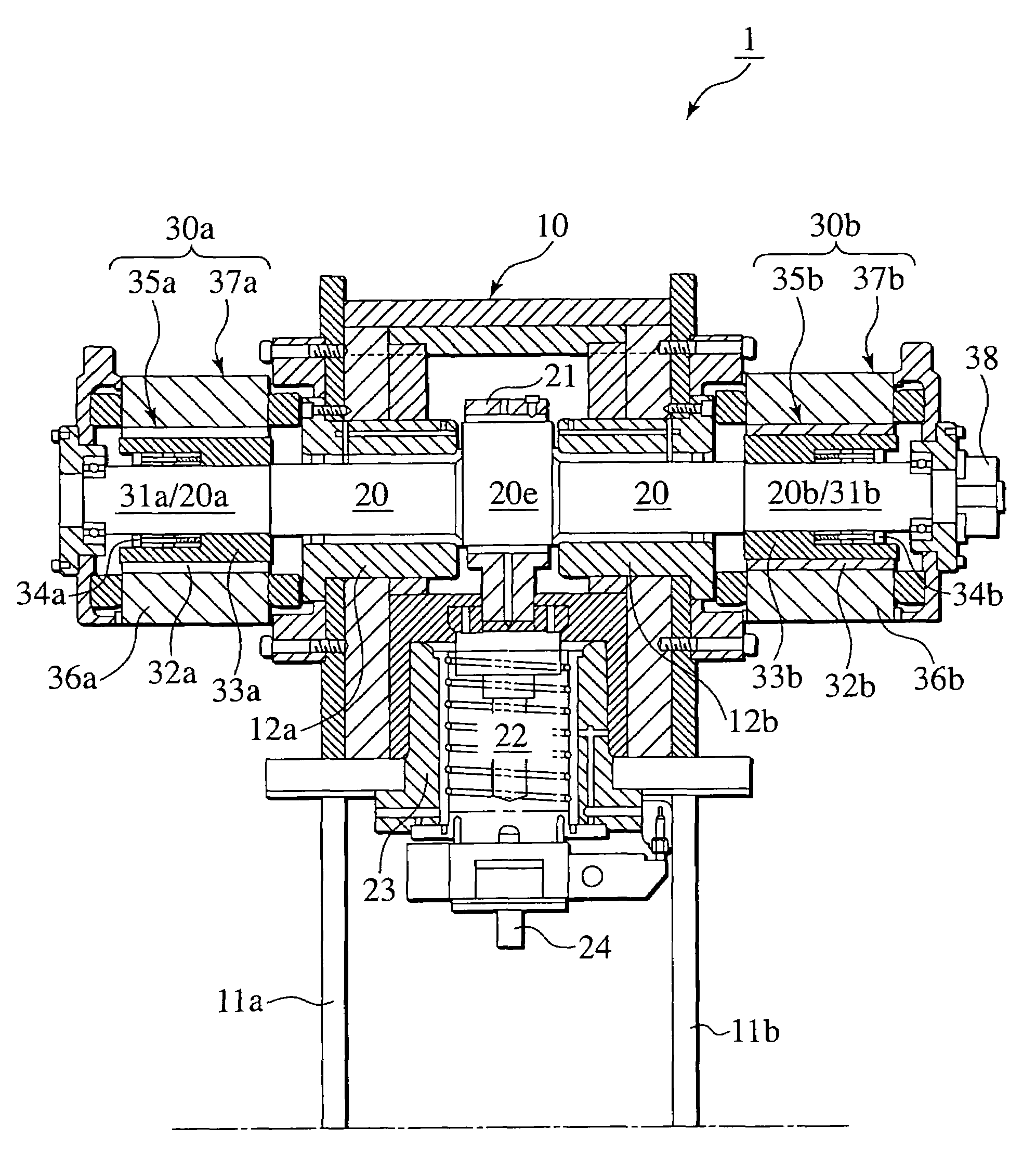

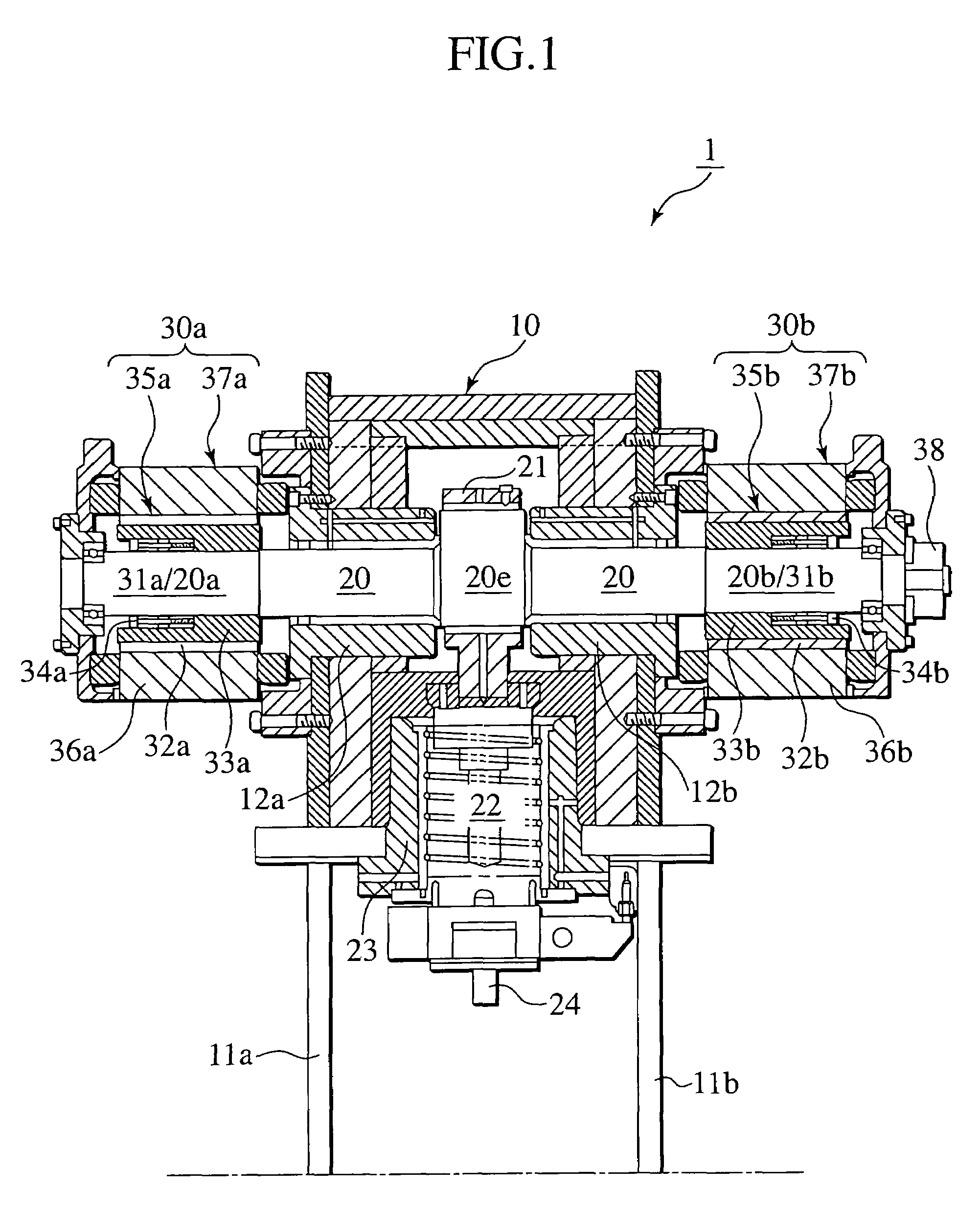

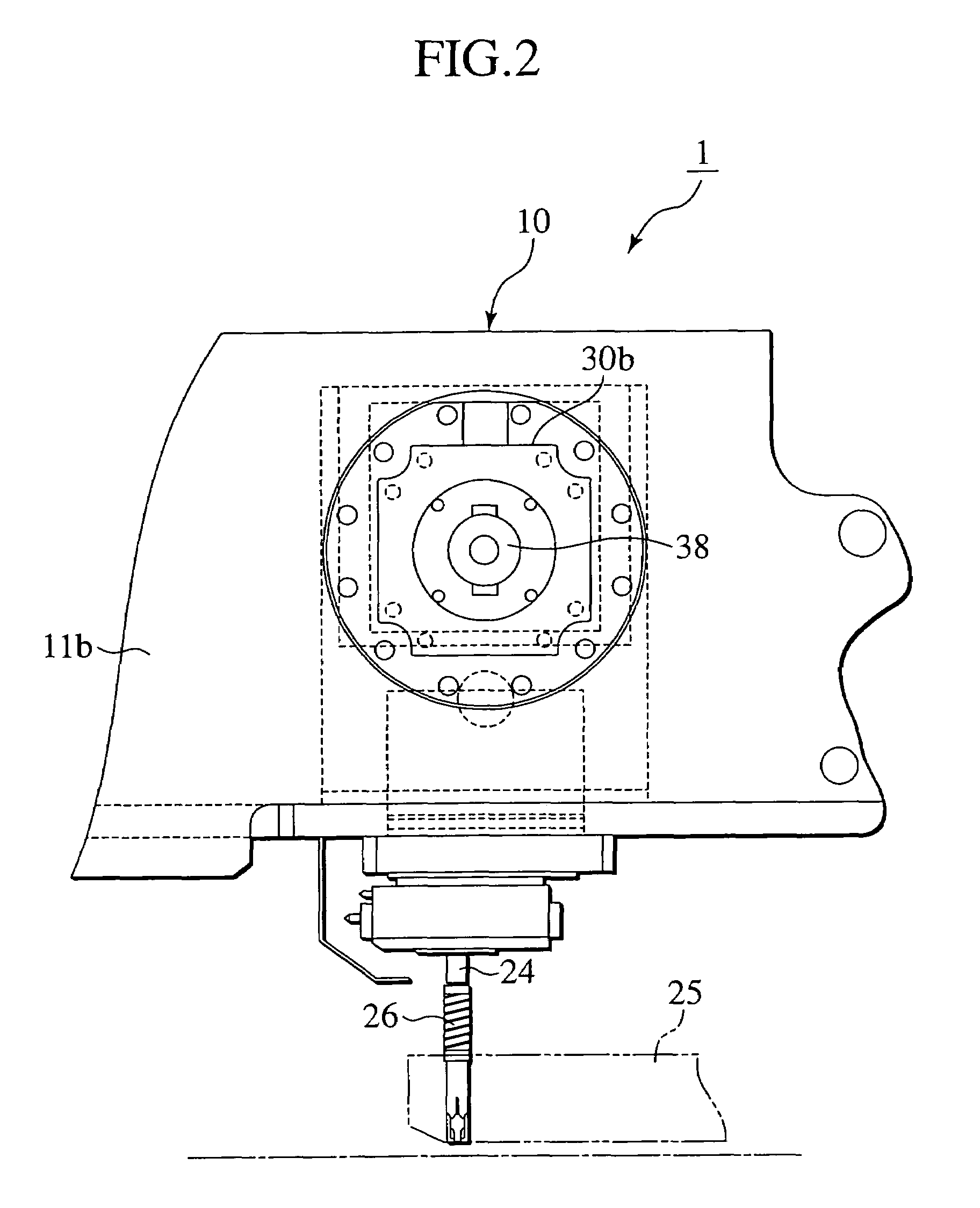

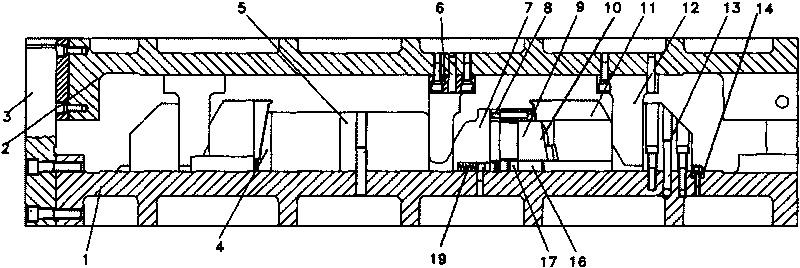

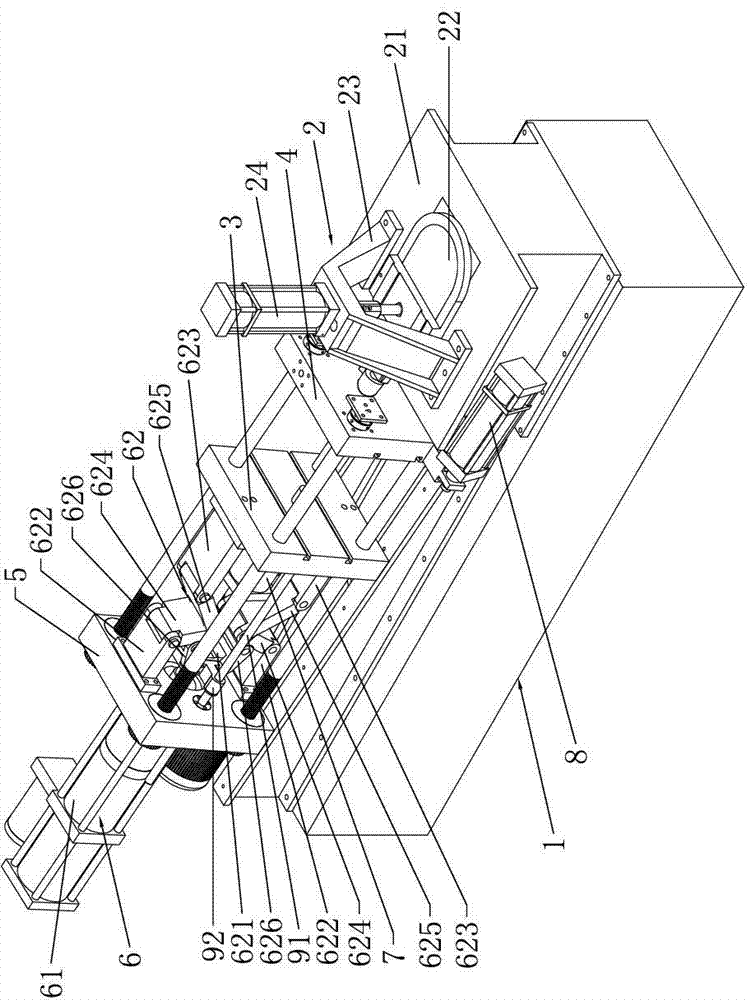

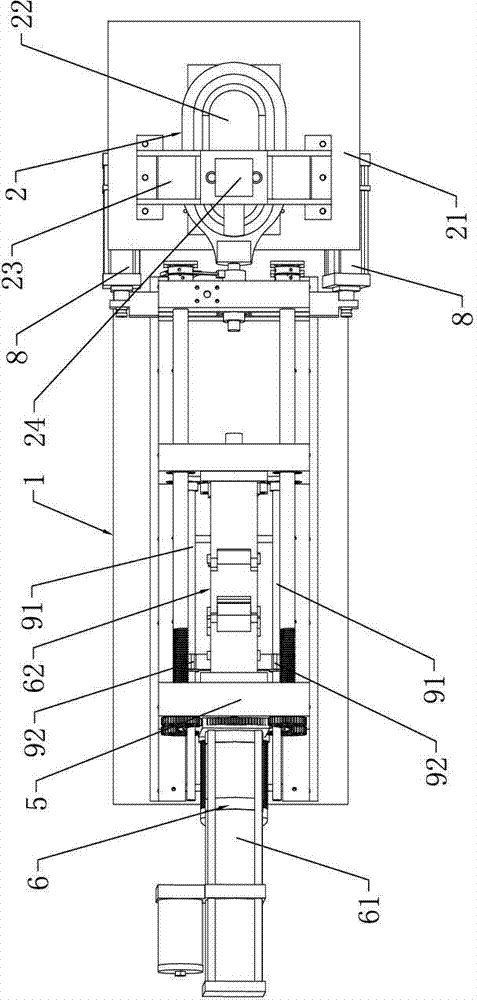

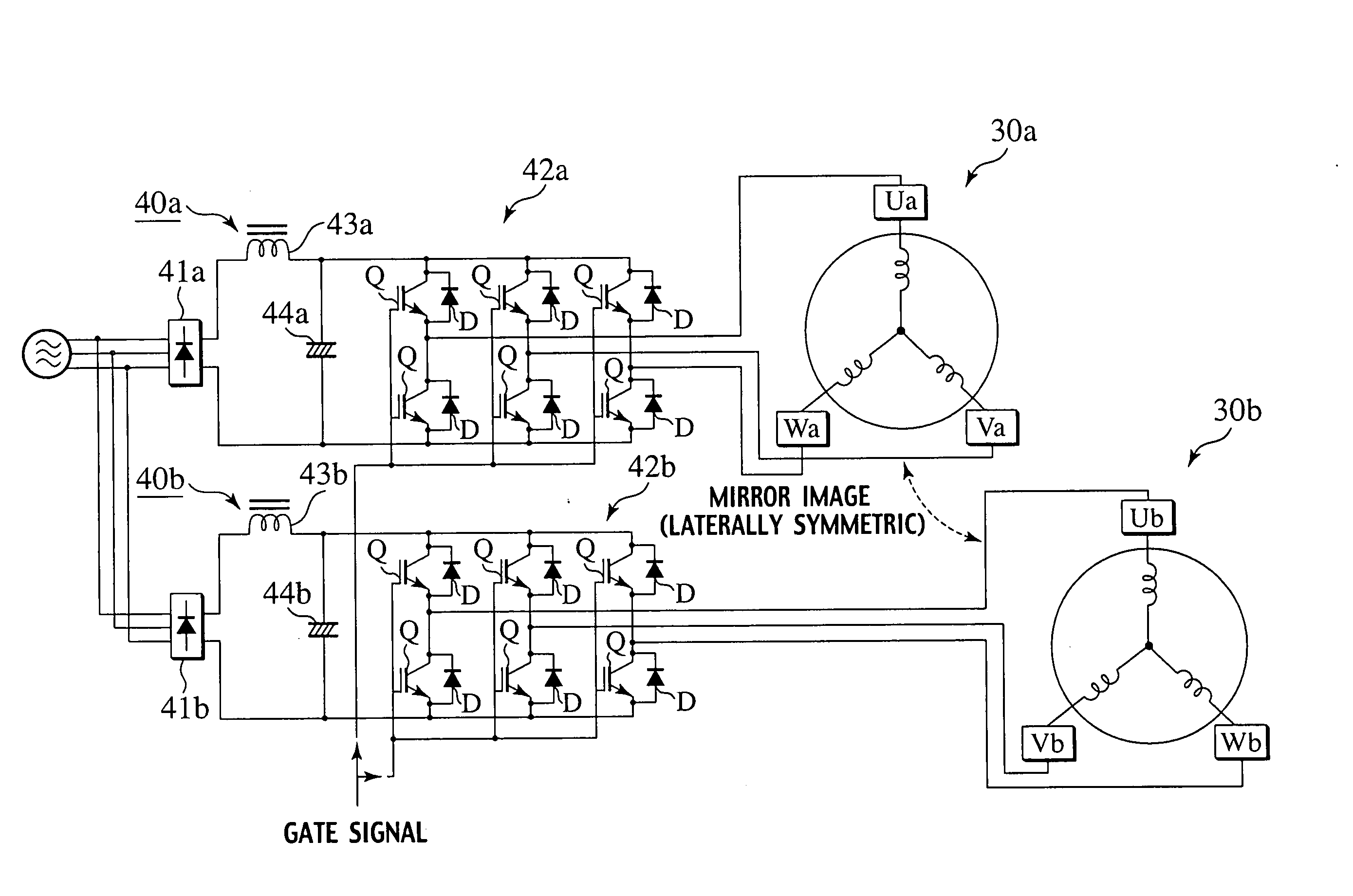

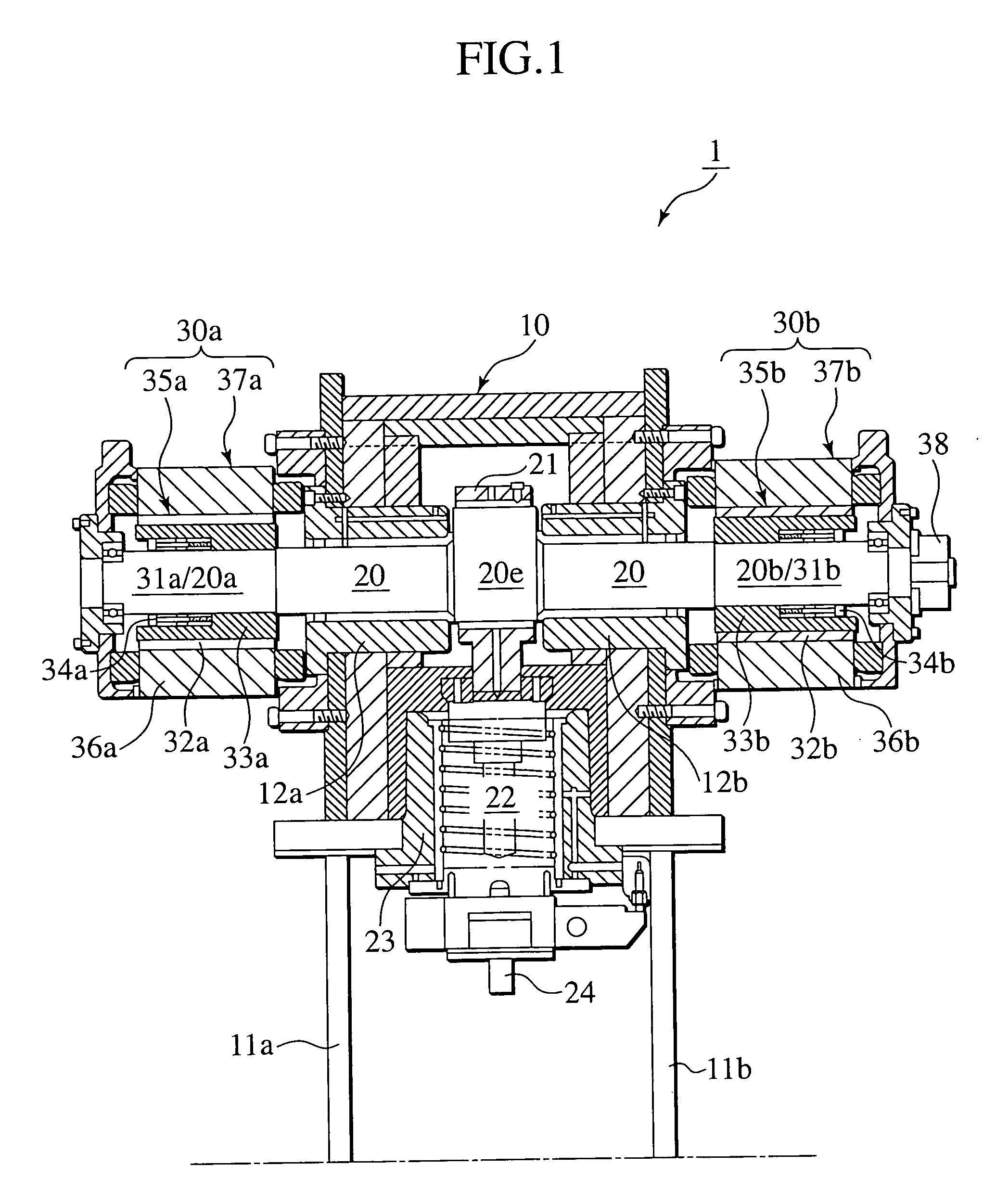

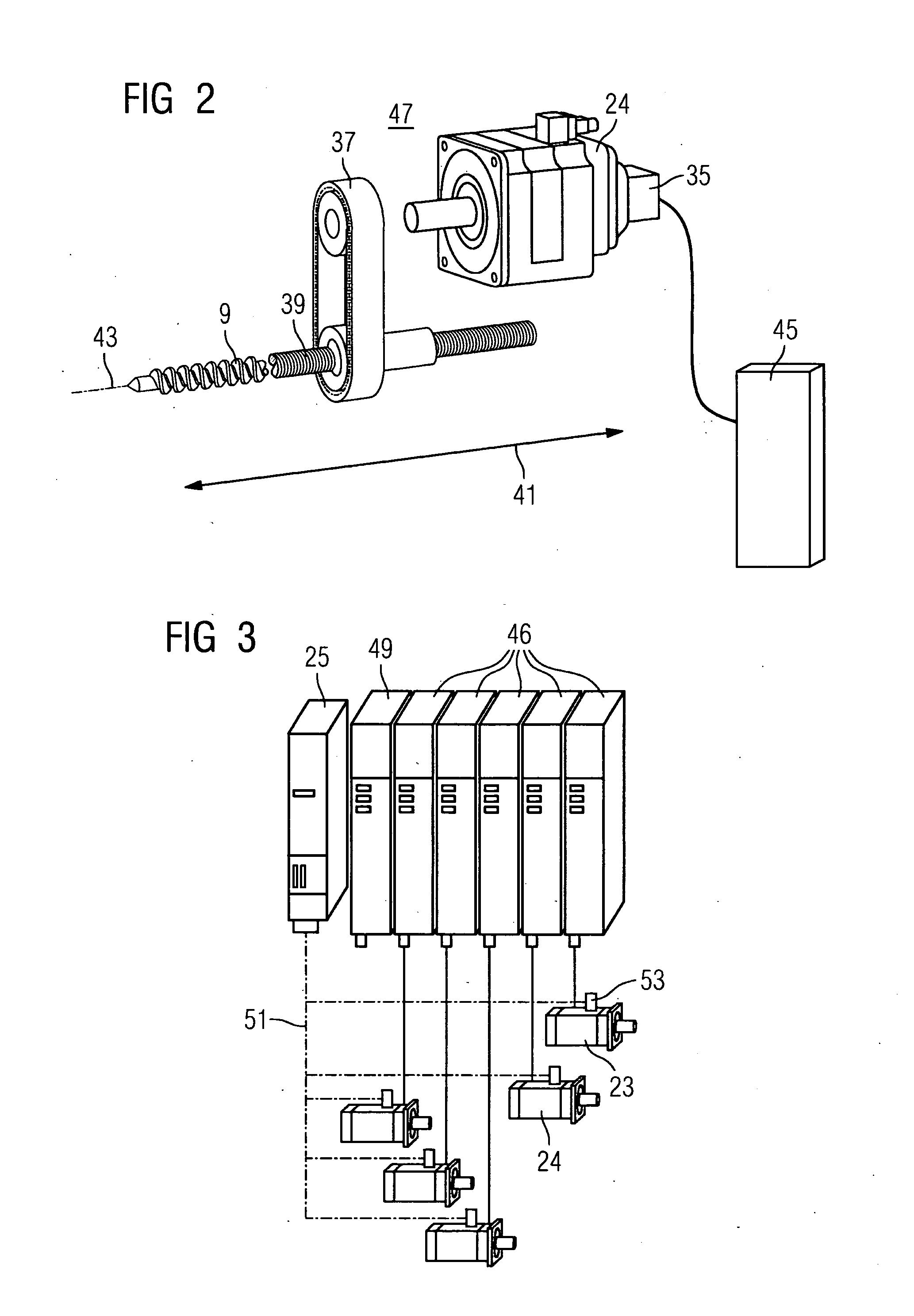

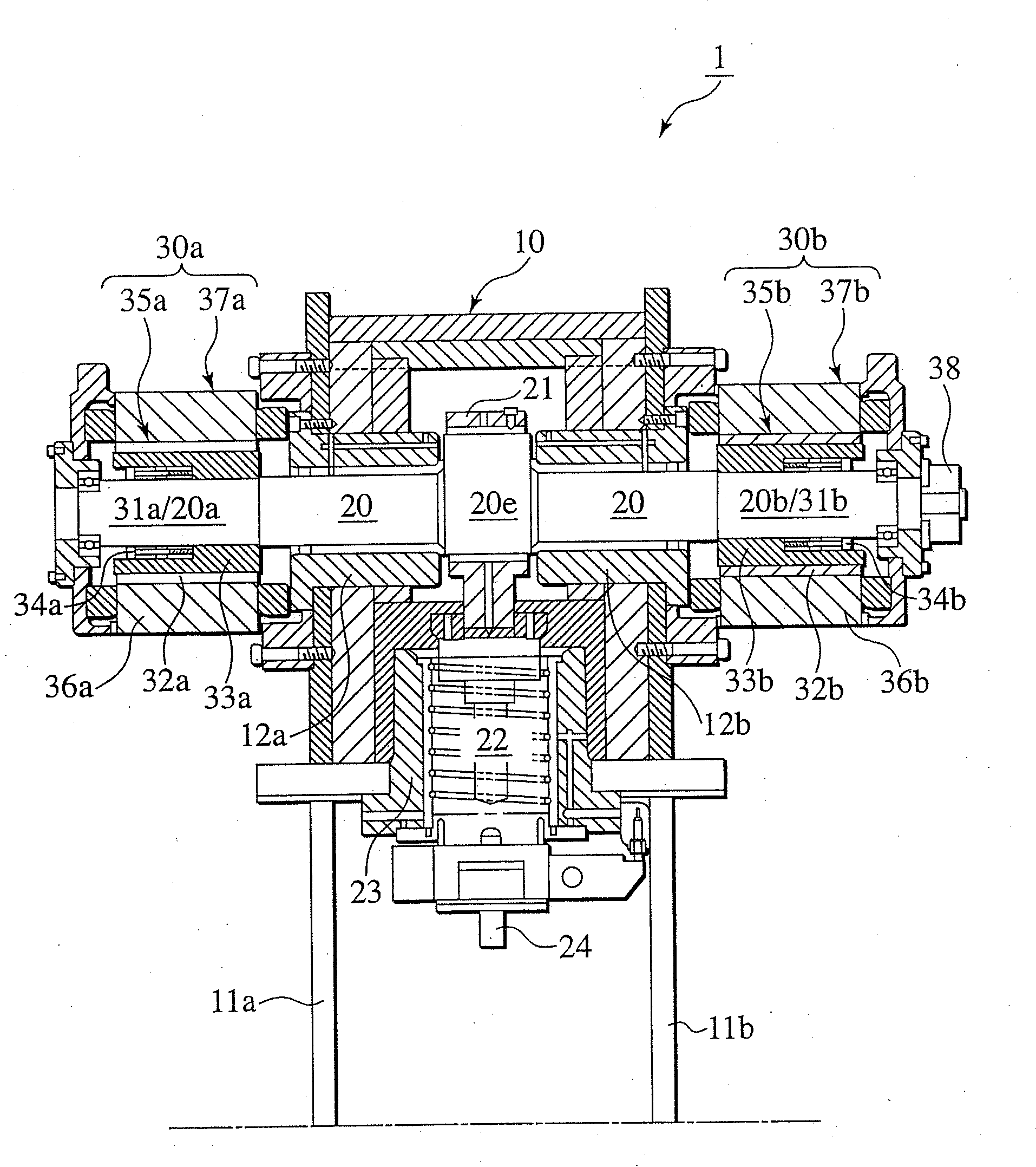

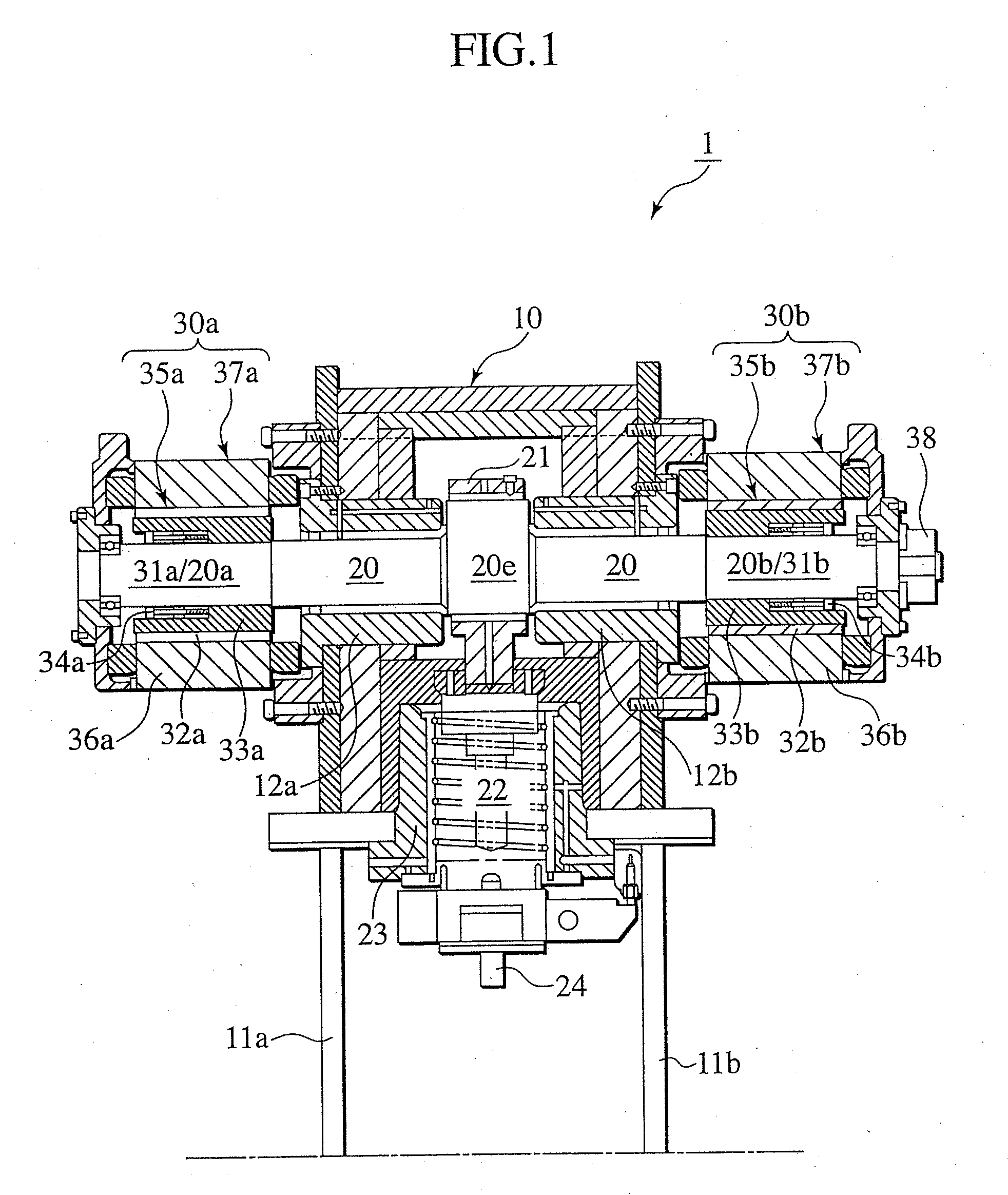

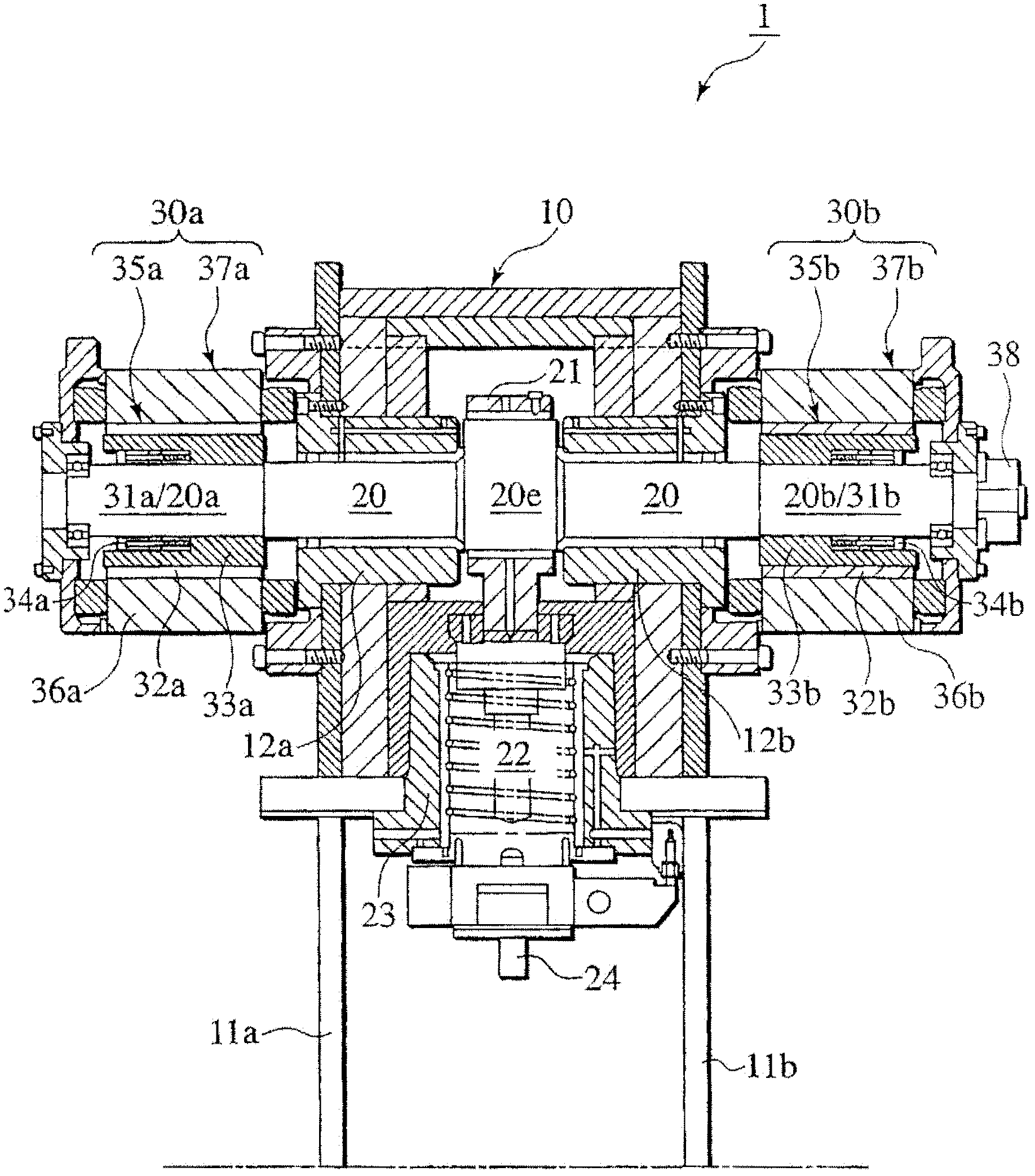

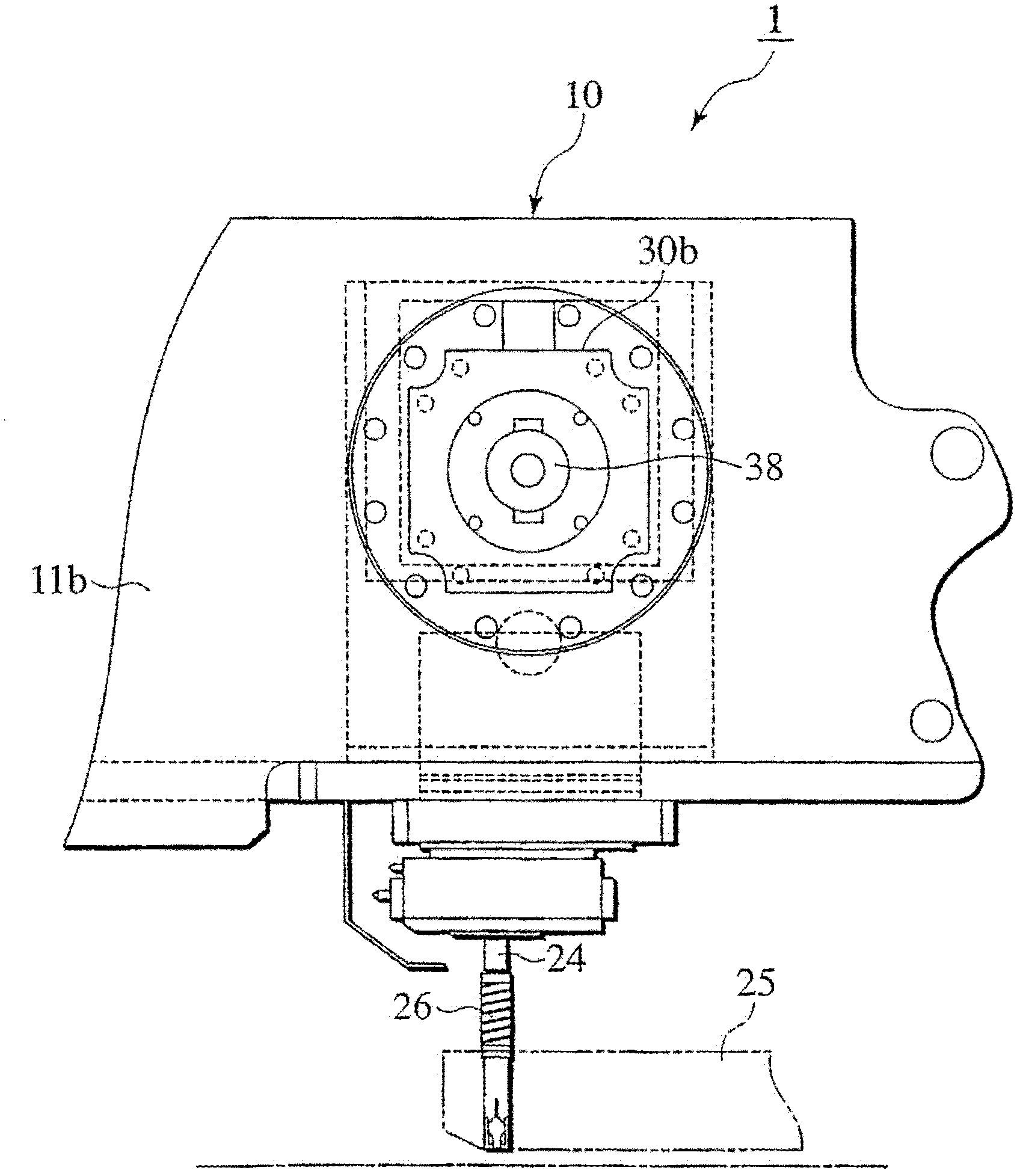

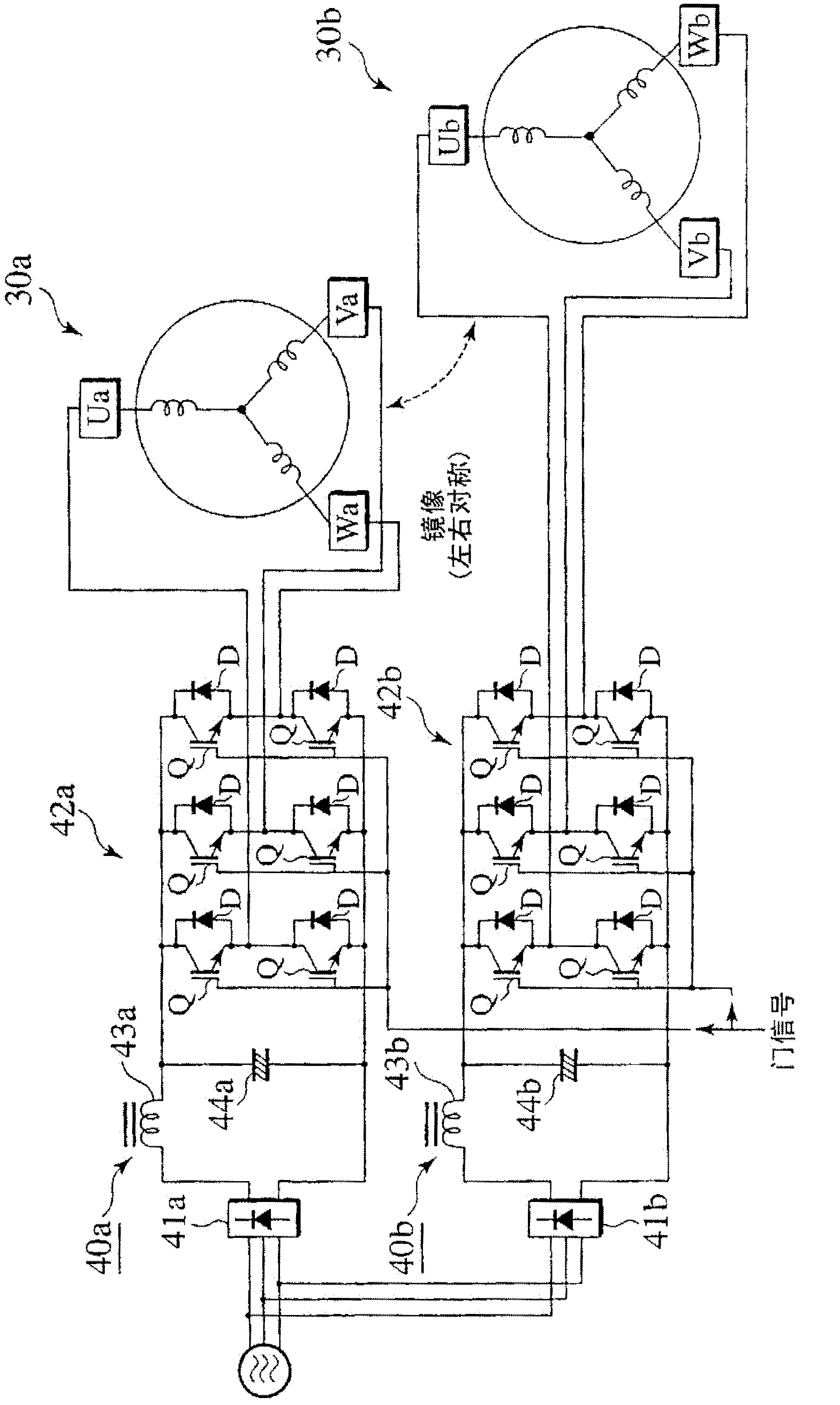

Servo-drive system and continuous finishing system of press

ActiveUS7475584B2Shorten speedReduce peak electricity usageSingle motor speed/torque controlHammer drivesMachining systemMirror image

A servo drive system of a press machine has a pair of servo motors which can generate necessary ram pressure by compositing and using a torque based on the same speed-torque characteristics. The servo motors are symmetric with each other in a mirror image manner. The servo motors are opposed to each other at opposite ends of an operation shaft which vertically moves a ram. The servo motors are integrally operated, thereby directly driving the operation shaft.

Owner:AMADA CO LTD

Method for flanging slant notch of cylindrical shell

The invention relates to a method for flanging a slant notch of a cylindrical shell, comprising the following steps: moulding and punching are carried out on 8 parts along the periphery of the cylindrical shell parts, 8 slant flanging notches are correspondingly arranged along the periphery of the cylindrical shell; first, sheet metal is produced into a sector and then rolled into a cone and then welded and corrected; afterwards, laser is adopted to cut the cone into kerves of the notches, the method of mould stamping is adopted to stamp all 8 notches in a stroke; a wedge block is adopted to transform vertical ram pressure of a punching machine into horizontal ram pressure which is exerted on 8 slotting parts, so that both internal mould and external mould can move; an active structure can be adopted to a female groove, when stamping is carried out, the outside female groove is first put in place, and then the inside male groove moves and is flanged.The invention has the advantages that high-accuracy part stamping is realized by using an ordinary pressure machine.The mechanism features good implementation effect, satisfies high-accuracy engine part processing requirements and enjoys good TOP.In addition, the processing efficiency is high; when specialized equipment is not used, the method of the invention is a reliable and economical method for processing similar parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Air-intake structure of an engine

A vehicle includes a duct structure configured to take in air from outside; an air cleaner including an air filter configured to clean the air guided to the air cleaner through the duct structure; a throttle device including a throttle valve for controlling a flow rate of the air guided to the throttle device through the air cleaner; and an engine including an intake port configured to suction the air guided to the engine through the throttle device; the duct structure including: a main inlet configured to take in air therethrough from outside by utilizing a ram pressure; a main passage extending from the main inlet to the air filter; a sub-inlet configured to take in air therethrough from outside; and a joint section located upstream of the air filter, the air flowing from the sub-inlet being joined to the air in the main passage, at the joint section.

Owner:KAWASAKI MOTORS LTD

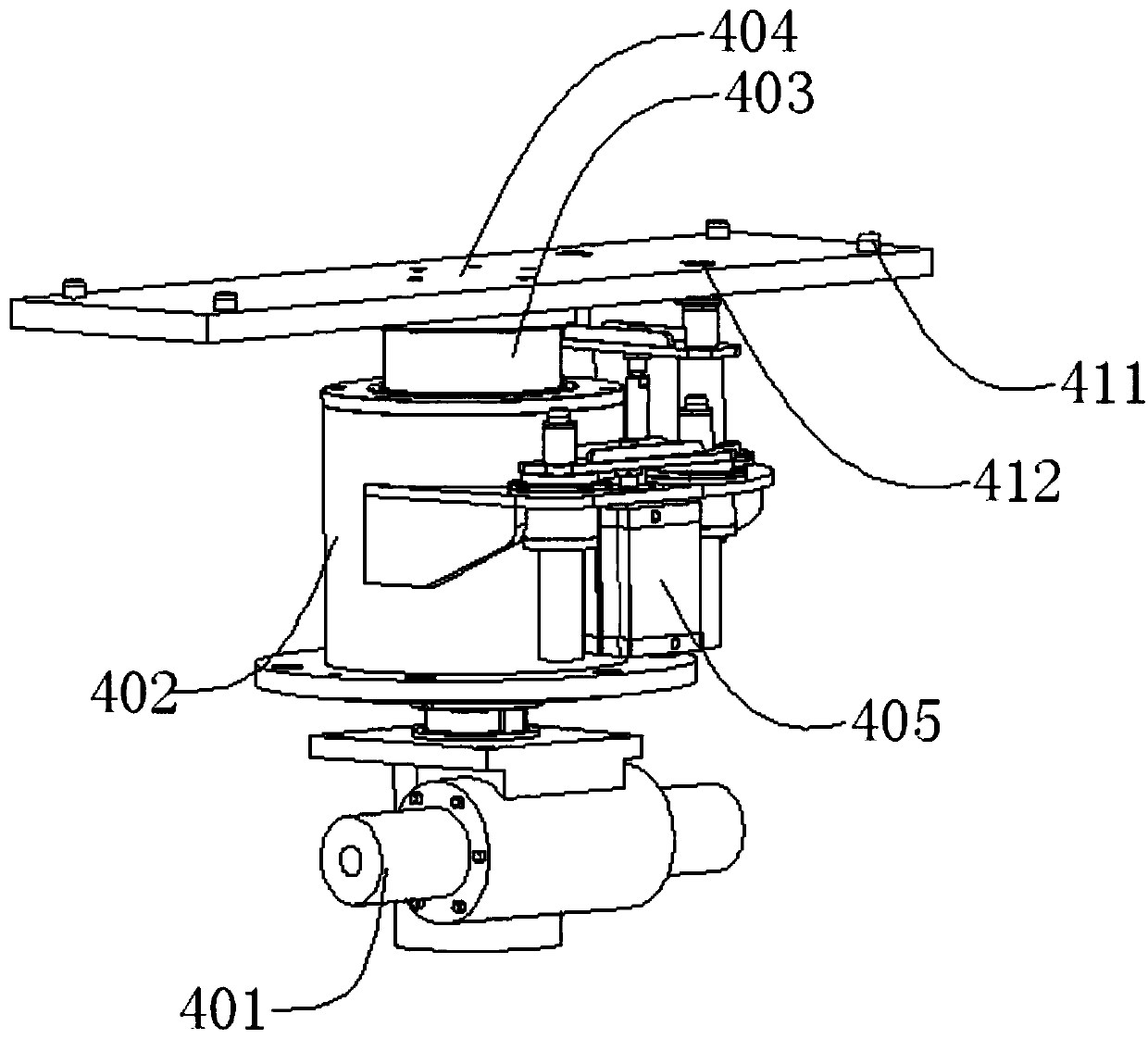

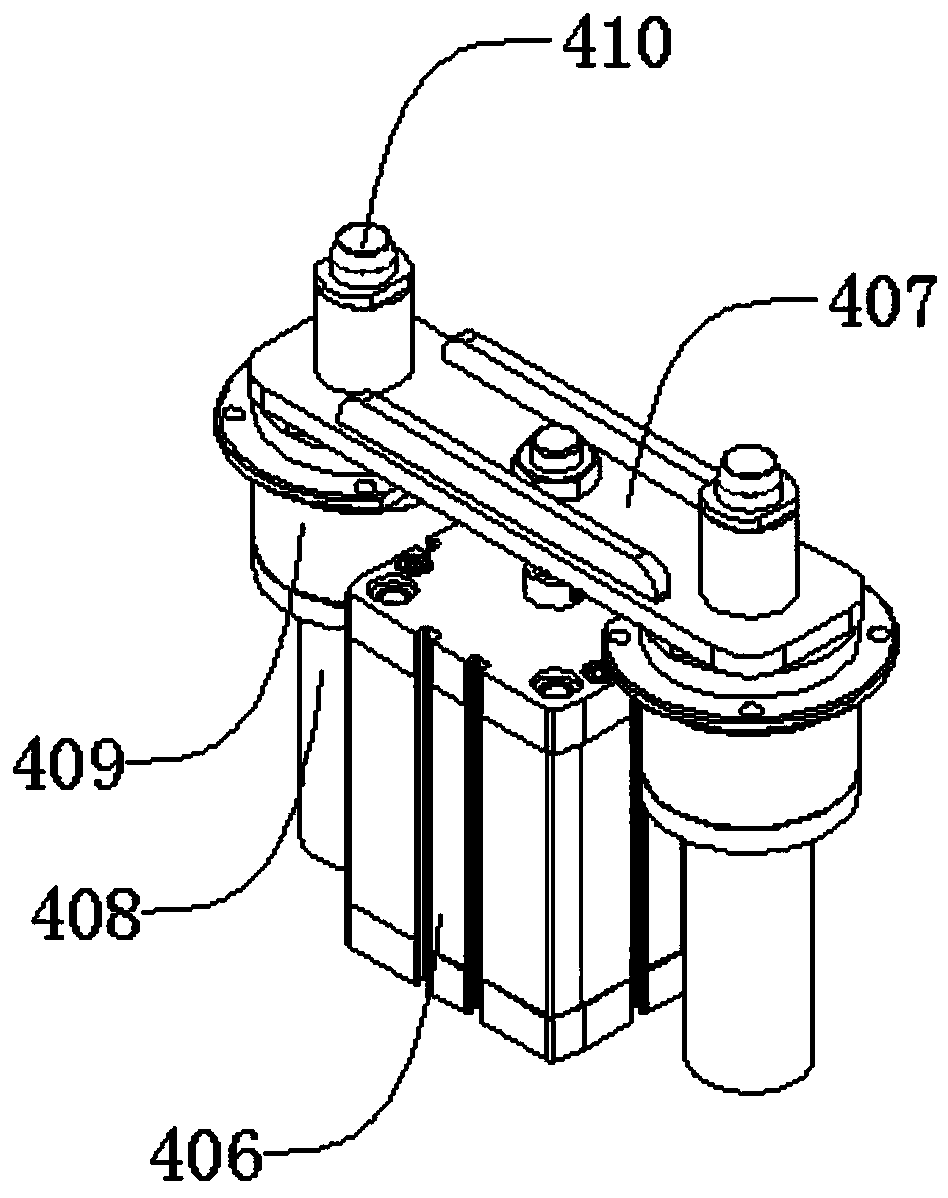

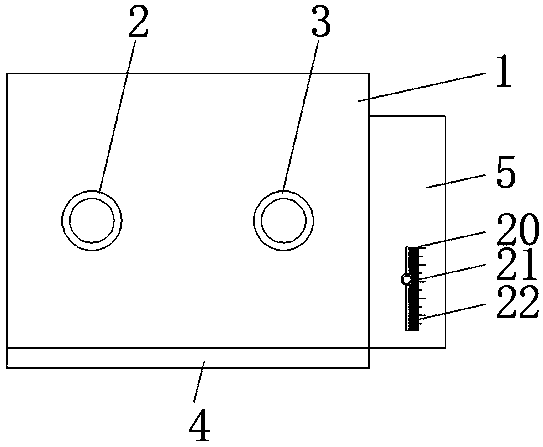

Automatic lateral surface grinding device

PendingCN107855852AAvoid deflectionAvoid vibration up and downPlane surface grinding machinesEngineeringSurface grinding

The invention discloses an automatic lateral surface grinding device. The automatic lateral surface grinding device comprises a first base, a first linear module, a moving seat, a rotary positioning mechanism, a portal, a downward pressing oil cylinder, a pressing head, a grinding mechanism, a rotary feeding mechanism and a combined supporting plate. The combined supporting plate is put at the upper ends of two adjacent track frames. A casting is put on the combined supporting plate. When the rotary feeding mechanism rotates by a set angle, the first linear module drives the moving seat to drive the rotary positioning mechanism to move to the position under the combined supporting plate. A lifting oil cylinder returns, the combined supporting plate is made to completely fall at the upper end of the rotary positioning mechanism, the first linear module drives the moving seat to reset, the positioning mechanism works to fix the combined supporting plate, and the downward pressing oil cylinder pushes the pressing head to press the casting, so that the casting is ground. The automatic lateral surface grinding device is simple in structure, and automatic and continuous feeding can be conducted only by putting the casting on the combined supporting plate. The rotary positioning mechanism is designed and can rotate the casting by 90 degrees. Therefore, four faces of the casting can beground automatically, and production efficiency is effectively improved.

Owner:SUZHOU SUZHU HEAVY IND

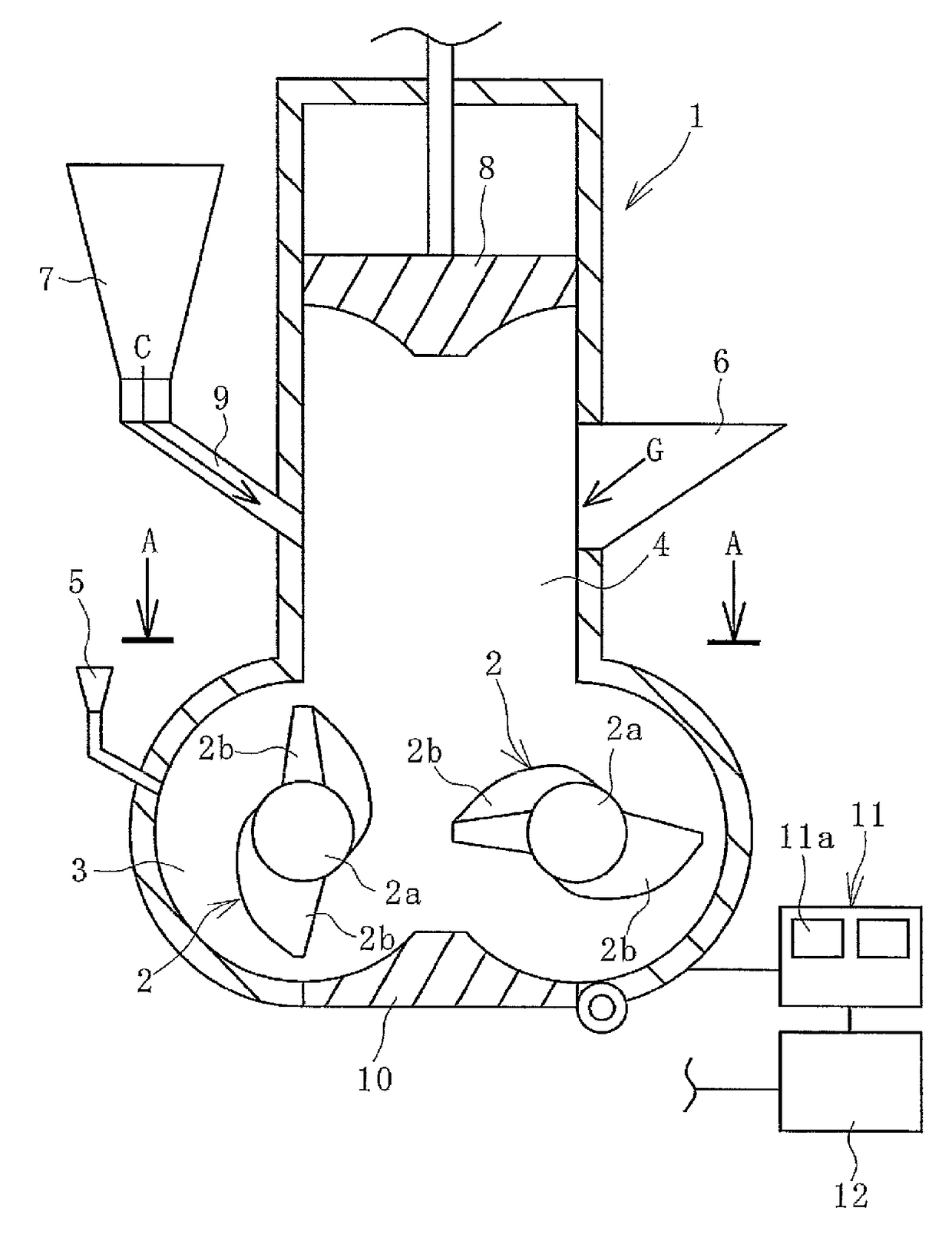

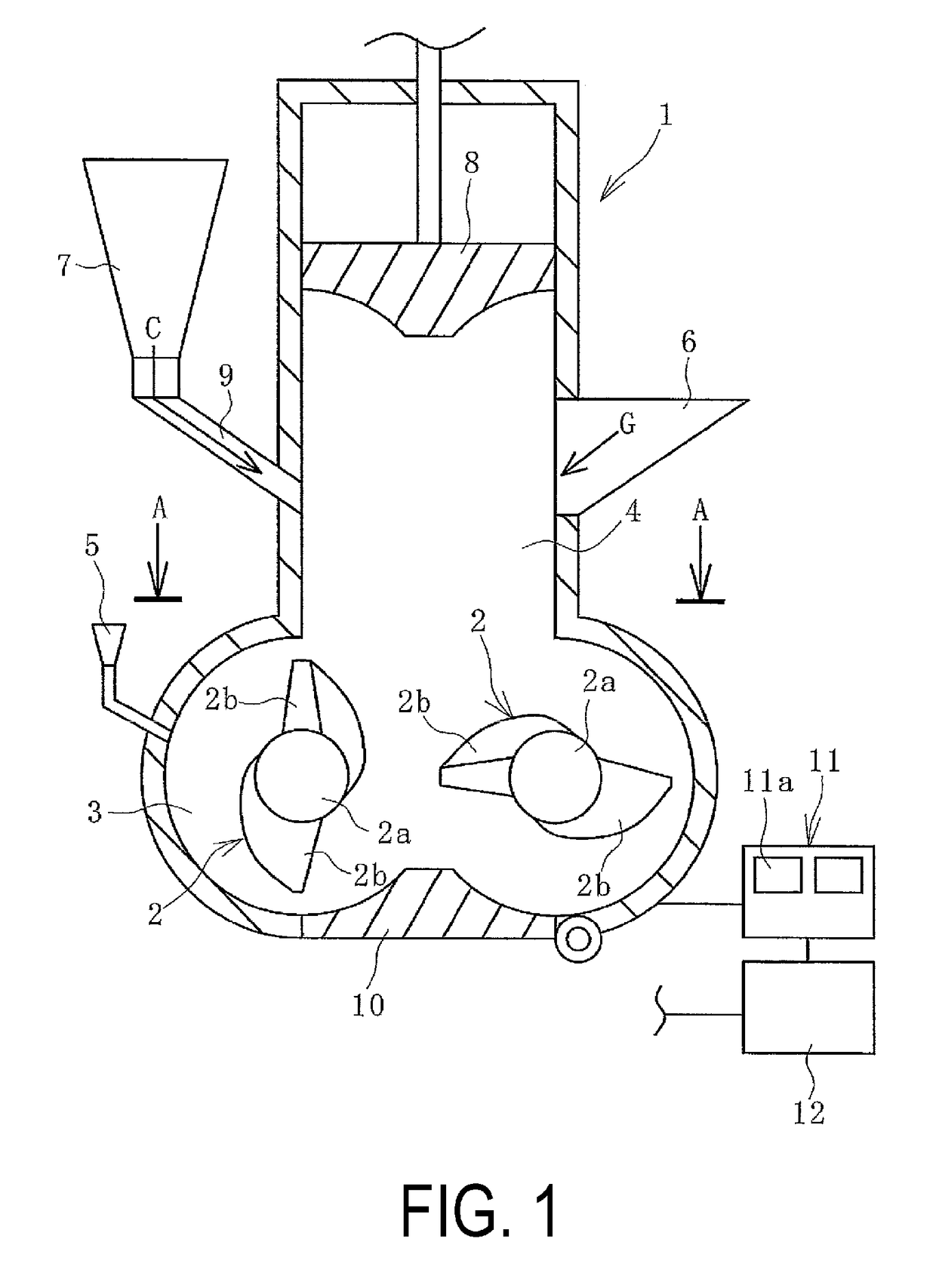

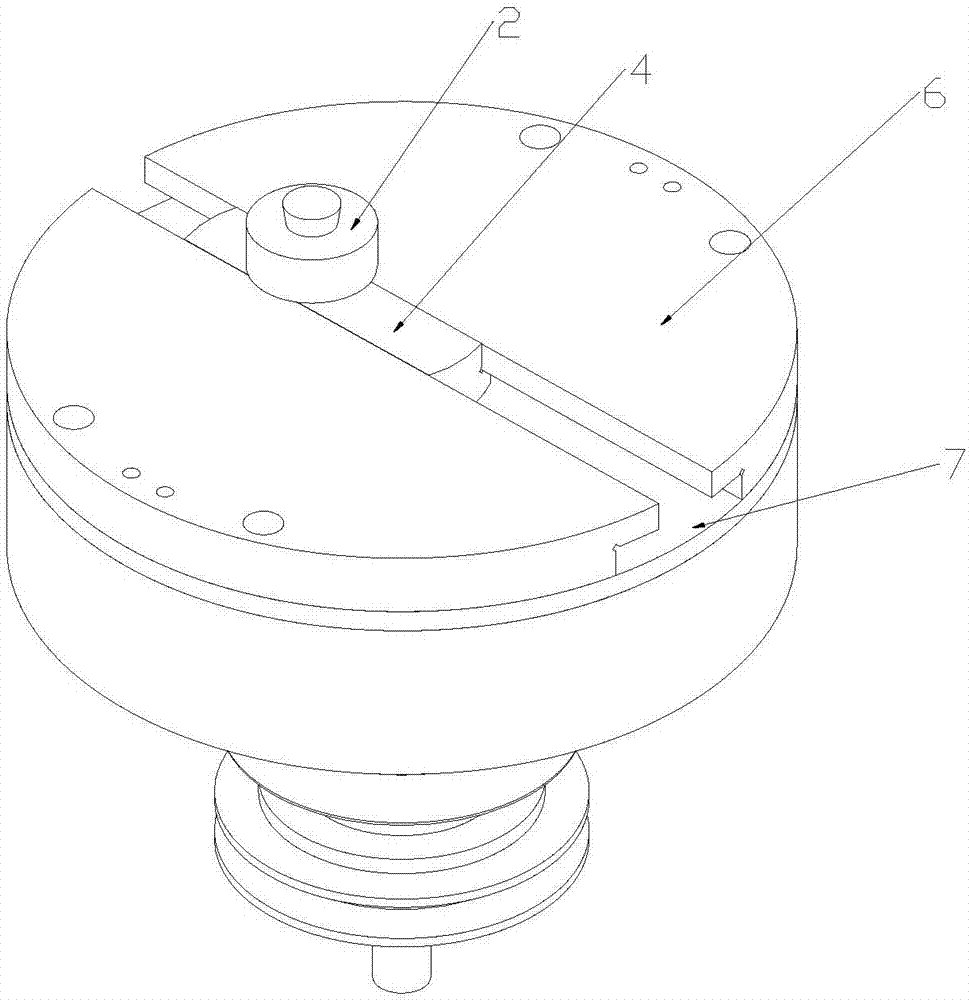

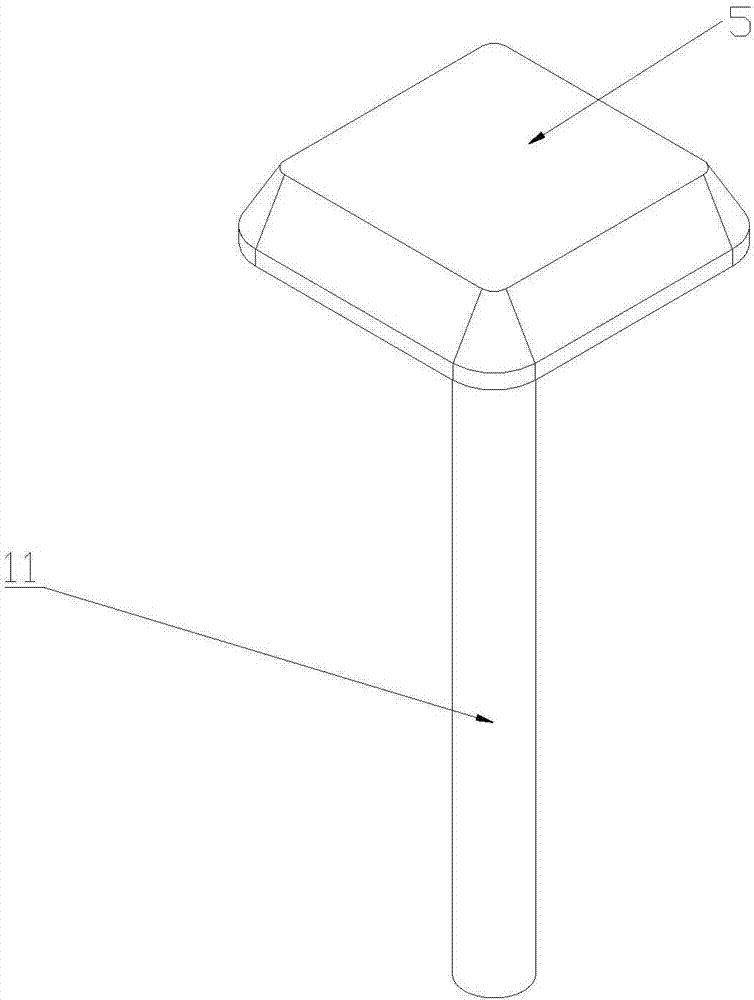

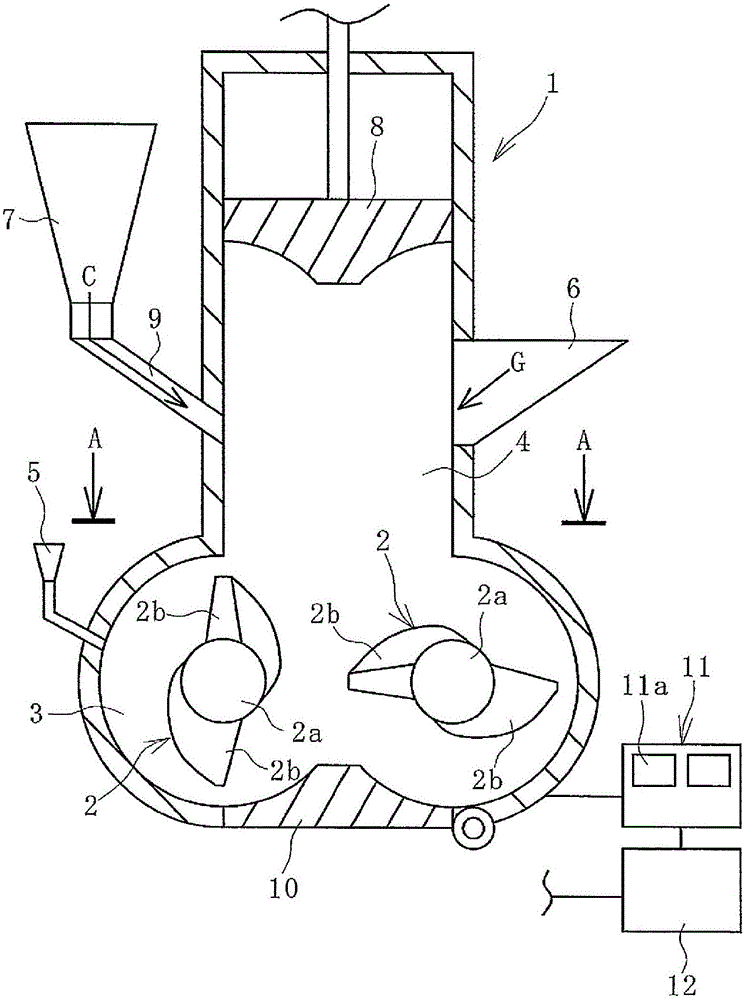

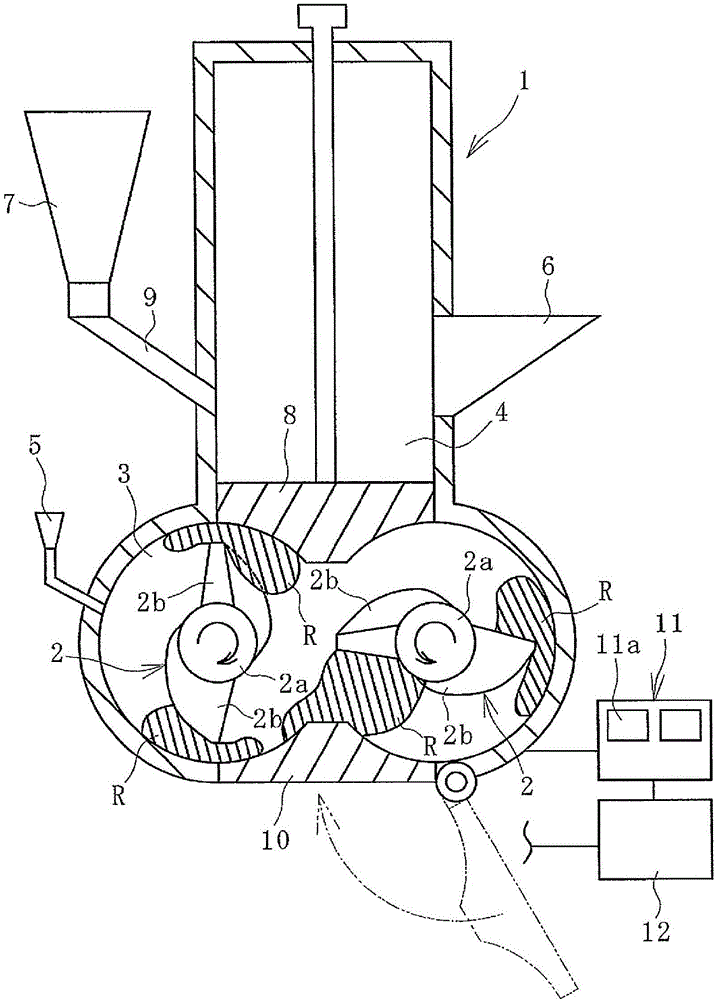

Method of Mixing Rubber Composition and System for Mixing Rubber Composition

ActiveUS20170225132A1Rate of temperature increaseReduce variationTransportation and packagingMixer accessoriesPolymer scienceRam pressure

A method of mixing a rubber composition includes a carbon introduction step and a uniform dispersion step. In the carbon introduction step, on the basis of a deviation between a rate of temperature increase of the rubber mixture (R) and a target value, at least one of a ram pressure (Pr) and a rotational speed (N) of the mixing rotor (2) is PID controlled so that the ultimate temperature of the rubber mixture (R) at the conclusion of the step is within a tolerance range. In the uniform dispersion step, the ram pressure (Pr) or the rotational speed (N) of the mixing rotor (2) is adjusted to reduce a deviation between a value based on successively detected data associated with a predetermined control target and a target value.

Owner:THE YOKOHAMA RUBBER CO LTD

Novel horizontal pressure casting machine

InactiveCN103752791AGood energy saving and environmental protection effectSimple structurePressure castingWorking environment

The invention discloses a novel horizontal pressure casting machine. A ramming component, a front base plate, a moving base plate, a rear base plate and two nozzle fitting pressure cylinders are mounted on a rack. The ramming component comprises a melting pot, a melting pot sleeve, a pressure cylinder supporting frame and a ramming pressure cylinder. A die locking component is mounted between the rear base plate and the moving base plate and comprises a die locking pressure cylinder and a die locking arm. An ejection pressure cylinder is arranged at the center of the left surface of the moving base plate. Extension end portions of piston rods of the two nozzle fitting pressure cylinders are connected with the front base plate. Each of the ramming pressure cylinder, the die locking pressure cylinder, the ejection pressure cylinder and the nozzle fitting pressure cylinders is of a gas-liquid pressure cylinder structure, in other words, an oil cylinder and a pressurizer are integrally combined and pure gas is used as a power source. During working, each action part is driven through the corresponding gas-liquid pressure cylinder, accordingly only a gas source needs to be adopted as power, and energy-saving and environment-friendly effect is better. Therefore, the novel horizontal pressure casting machine has the advantages of simple structure, energy saving and environment friendliness, and benefit of improving working environment.

Owner:江西意哥尔科技有限公司

Servo-drive system and continuous finishing system of press

ActiveUS20060055269A1Reduce noiseOperation efficiency can be improvedSingle motor speed/torque controlToothed gearingsControl theoryMirror image

A servo drive system of a press machine has a pair of servo motors which can generate necessary ram pressure by compositing and using a torque based on the same speed-torque characteristics. The servo motors are symmetric with each other in a mirror image manner. The servo motors are opposed to each other at opposite ends of an operation shaft which vertically moves a ram. The servo motors are integrally operated, thereby directly driving the operation shaft.

Owner:AMADA CO LTD

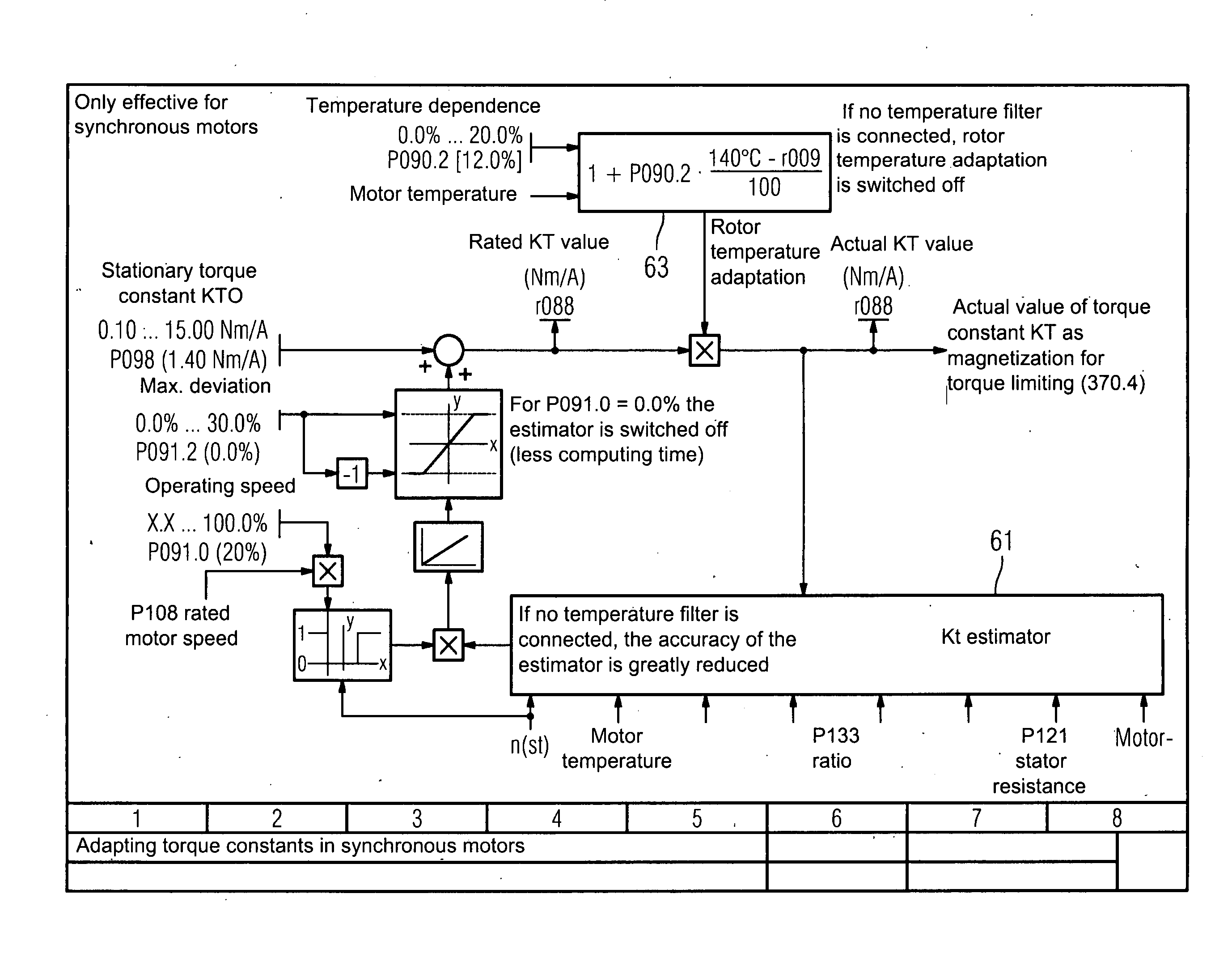

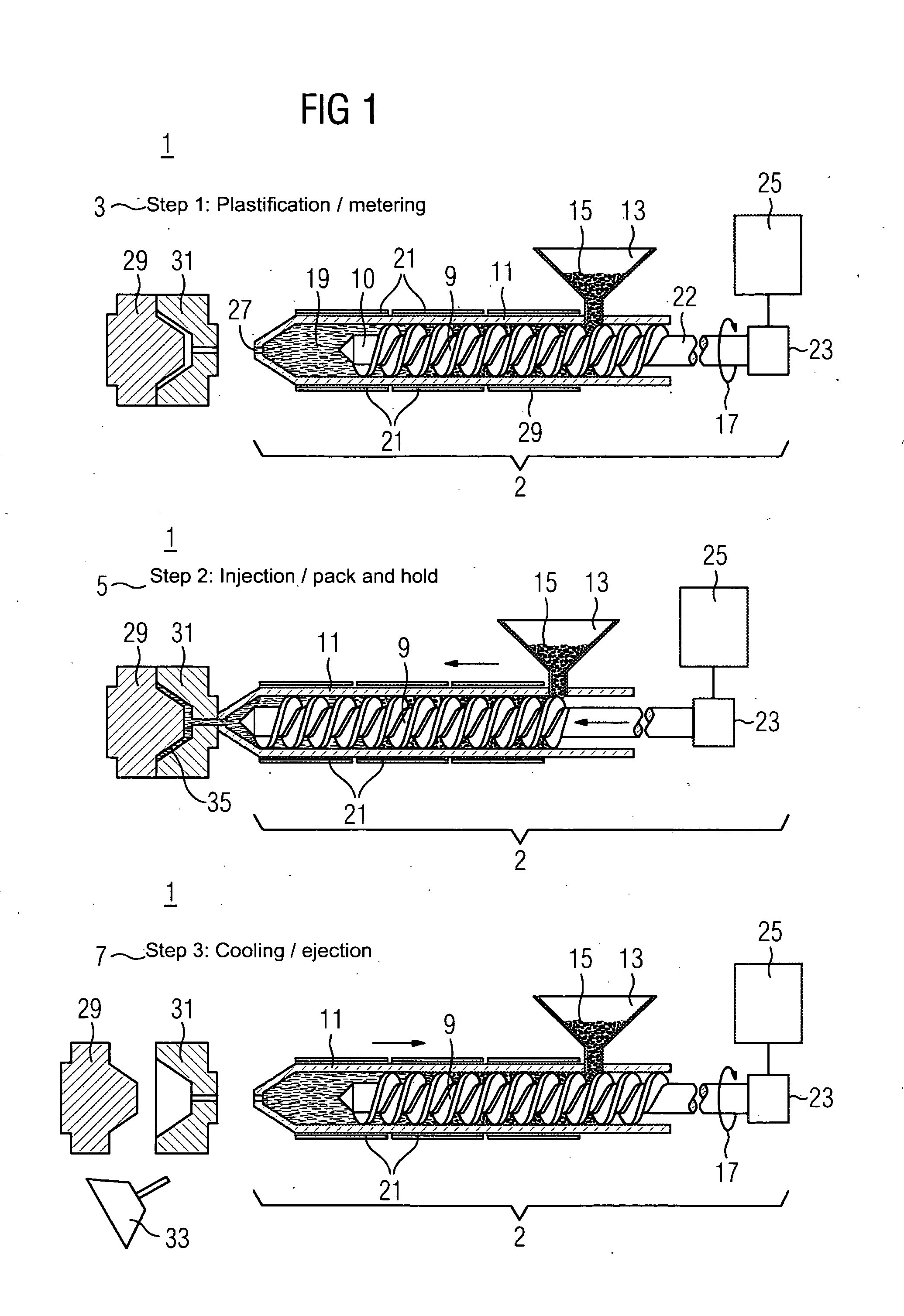

Injection Device of an Injection Molding Machine and Method for the Operation Thereof

InactiveUS20090065962A1Low costHigh pressure accuracyAuxillary shaping apparatusInjection pressureOperating point

There is described a device and a method for operating an injection device for an injection molding machine which is provided with an extruder screw that is driven by an electric machine. Acceleration values and / or values depending on an operating point of the electric machine are used for calculating an injection pressure and / or a ram pressure, thus dispensing with the need for a pressure sensor.

Owner:SIEMENS AG

Servo drive system and continuous working system of press machine

InactiveUS20090064839A1Shorten speedReduce peak electricity usageMechanical apparatusSingle motor speed/torque controlPunchingElectric machine

Owner:AMADA CO LTD

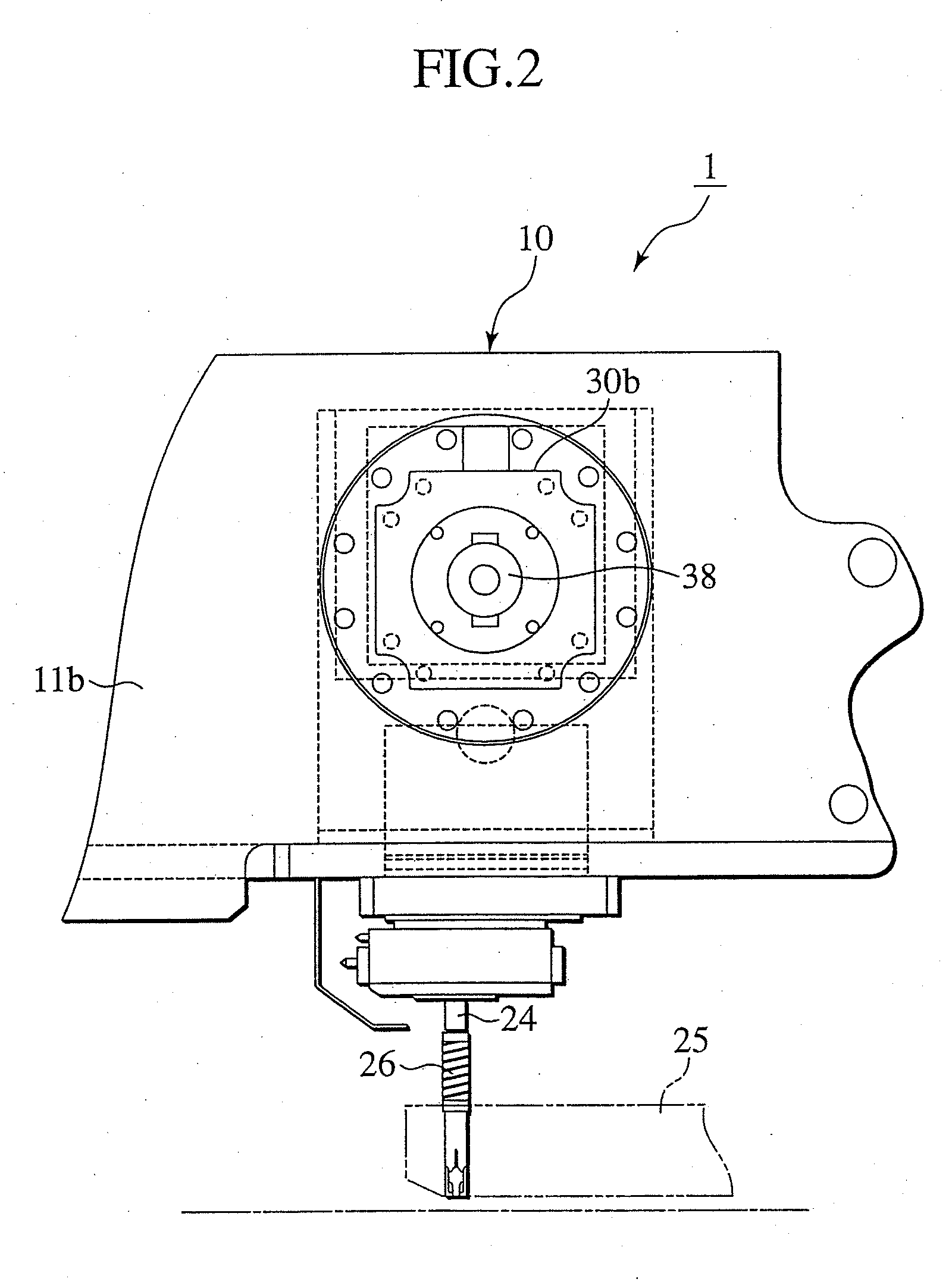

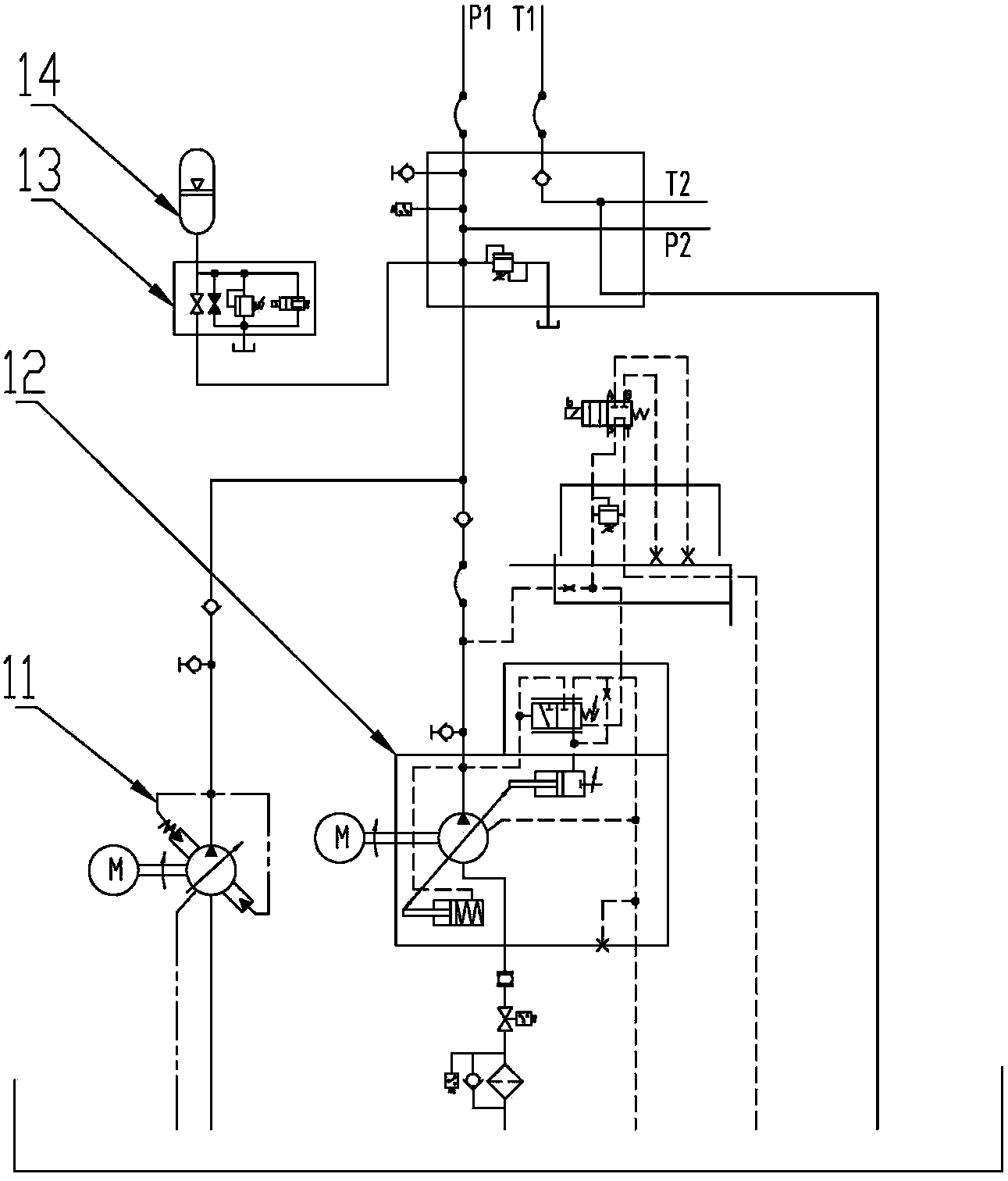

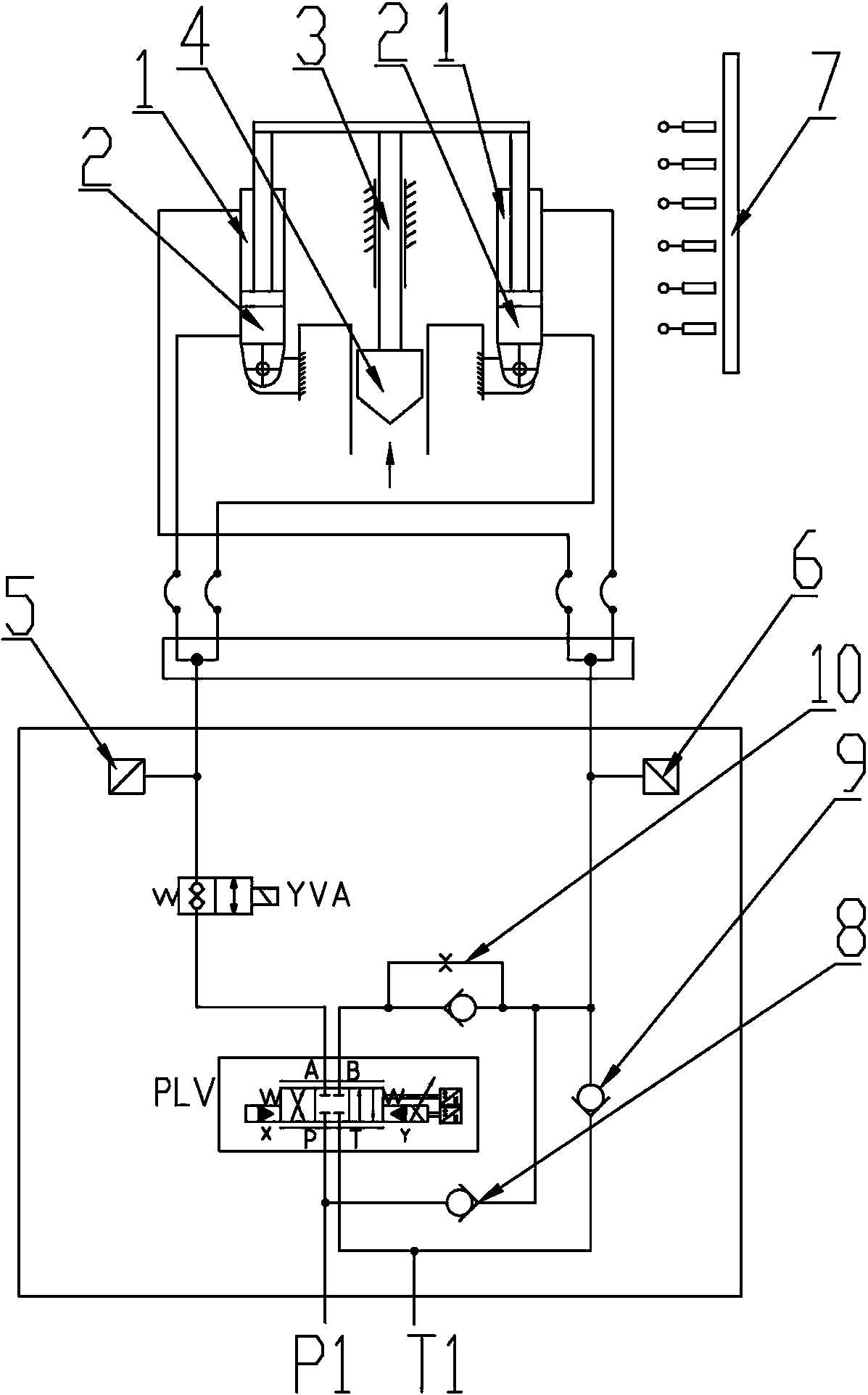

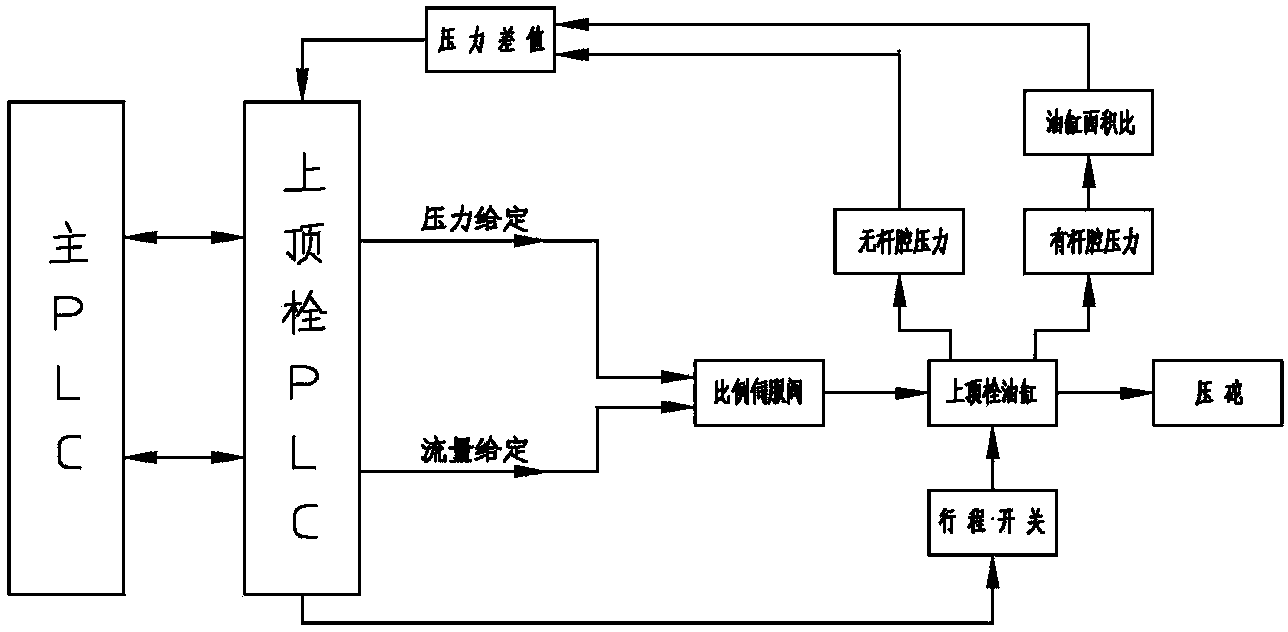

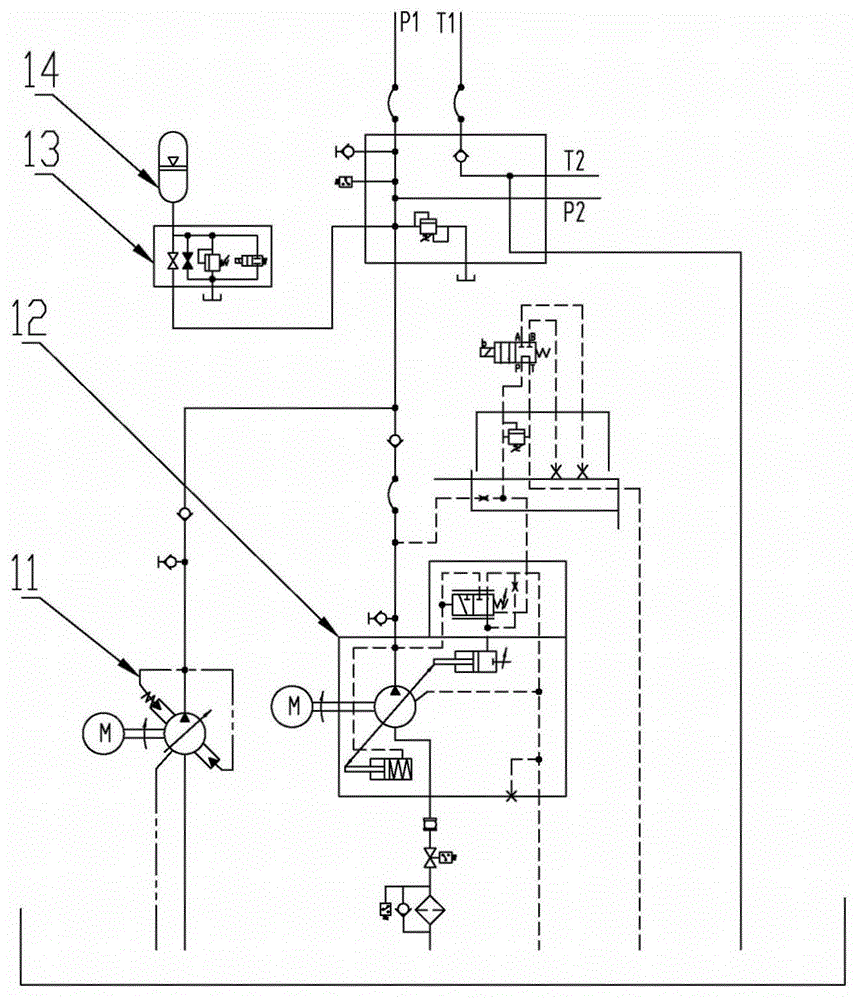

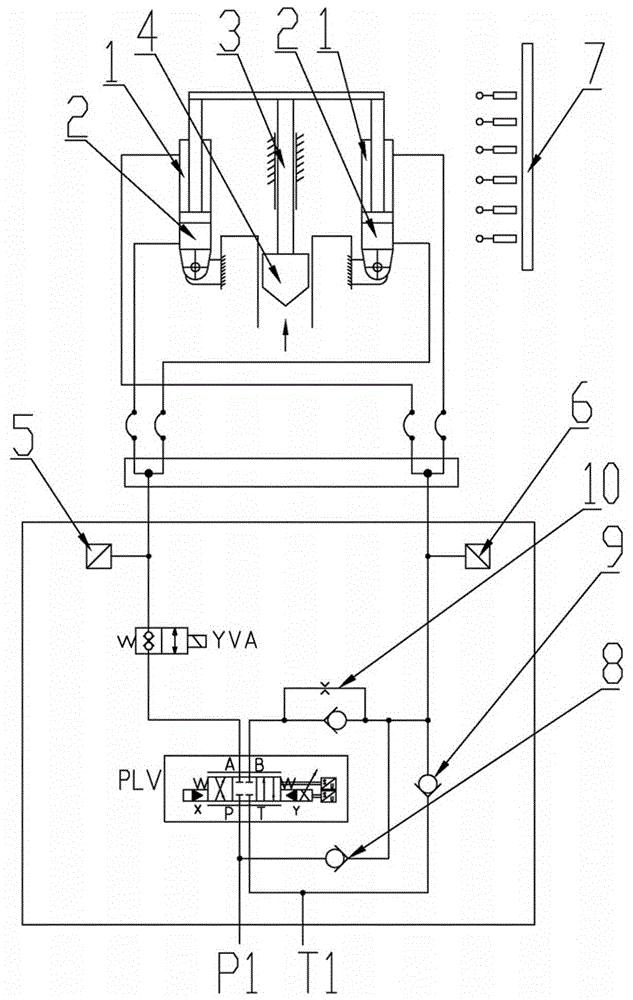

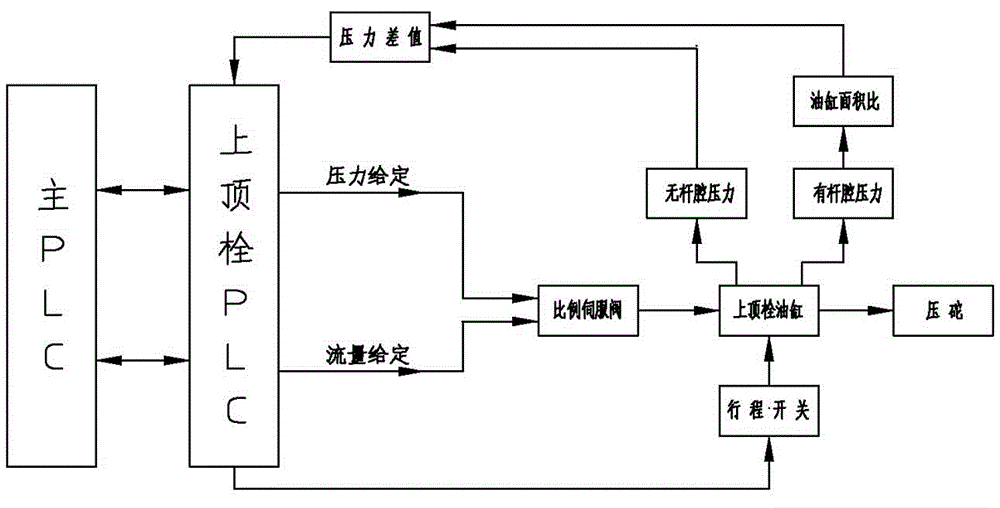

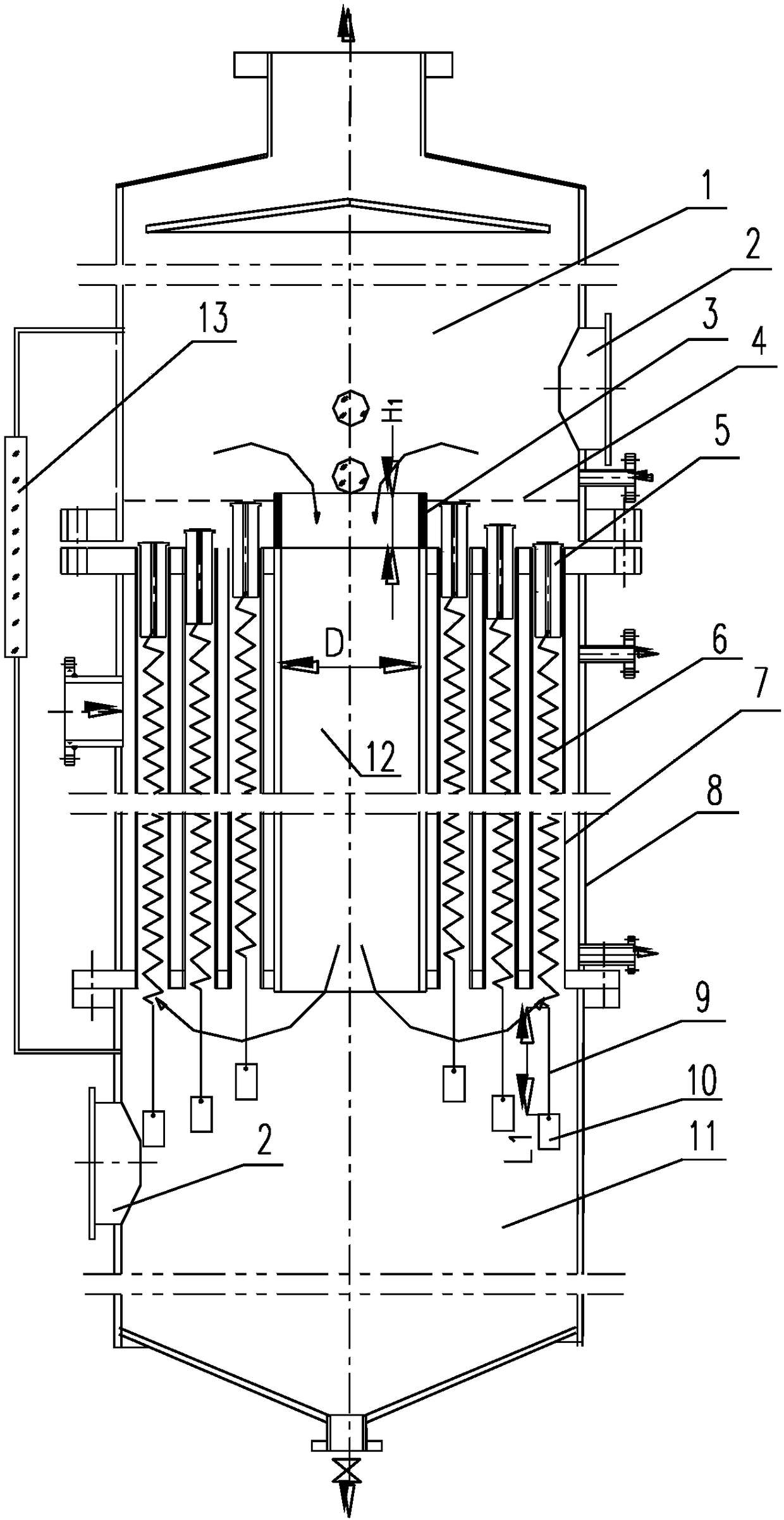

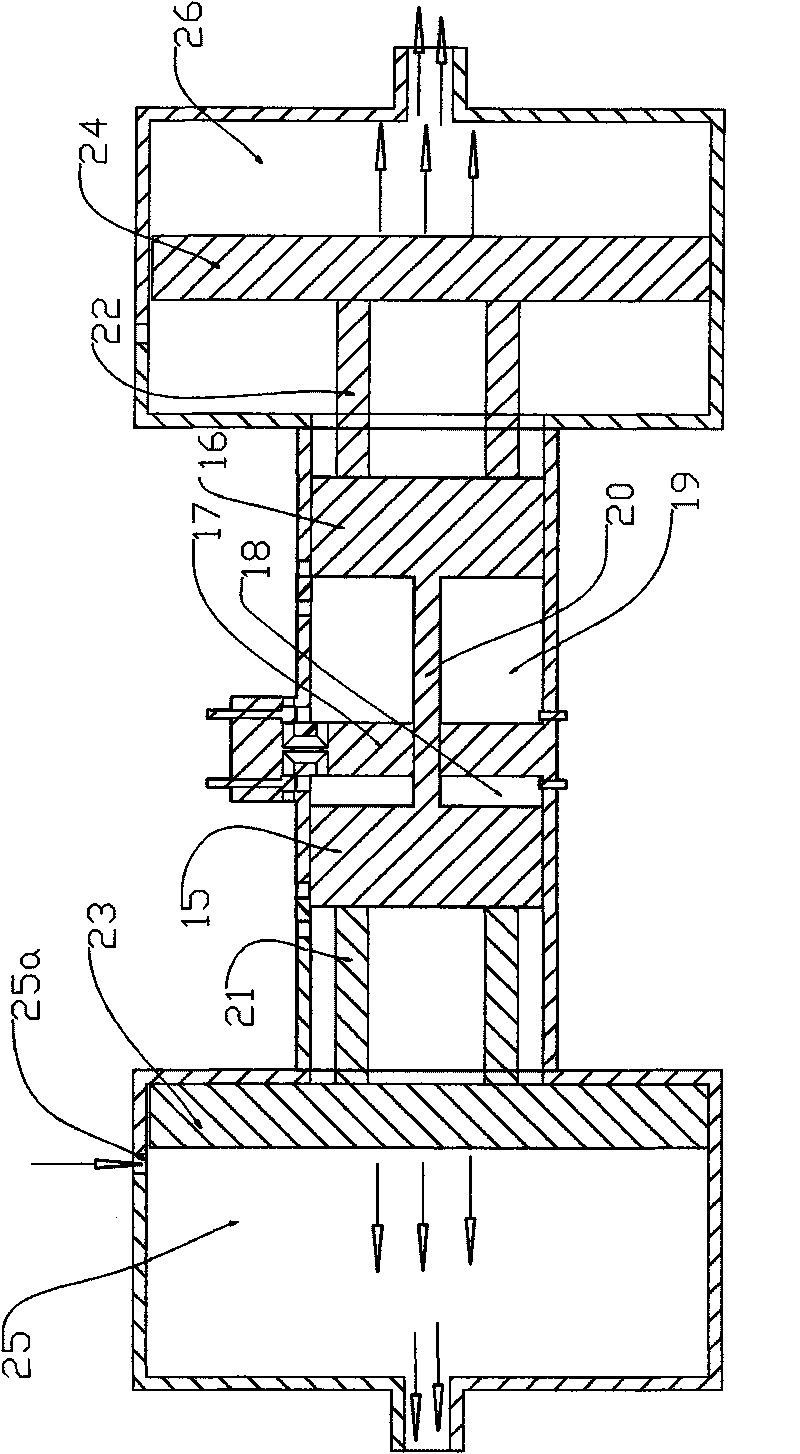

Hydraulic control apparatus for internal mixer

ActiveCN103660061AStable controlHigh precisionServomotorsServometer circuitsFailure rateHydraulic pump

The invention discloses a hydraulic control method and a hydraulic control apparatus for an internal mixer. The hydraulic control method comprises a step of using a hydraulic pump station composed of a hydraulic pump and an energy accumulator for hydraulic control of an upper ram, a discharging door and a charging door. The hydraulic control apparatus is characterized in that the hydraulic pump comprises a high pressure variable displacement piston pump supplying oil to the upper ram and a duplex vane pump supplying oil to the discharging door and the charging door, the duplex vane pump is connected with an auxiliary energy accumulator through an energy accumulator safety valve block, the pressure and the speed of the upper ram are controlled by a main PLC of the internal mixer, upper ram pressure control refers to pressure control of a rod-existing chamber of an upper ram oil cylinder, and the main PLC of the internal mixer realizes smooth control of opening and closing of the discharging door and opening and closing speeds through a proportional directional valve and a rotary oil cylinder. According to the invention, the hydraulic control apparatus for the internal mixer is simplified, the problems of a high failure rate of a hydraulic station and a short service life of a high pressure pump in the prior art are overcome, closed-loop control of upper ram pressure is realized through controlling of the main PLC of the internal mixer, upper ram pressure control is stable and highly precise, rubber fining quality is improved, and smooth control of the opening and closing speeds of the discharging door is realized.

Owner:YIYANG RUBBER PLASTICS MACHINERY GROUP

Internal mixer hydraulic control device

The invention discloses a hydraulic control method and a hydraulic control apparatus for an internal mixer. The hydraulic control method comprises a step of using a hydraulic pump station composed of a hydraulic pump and an energy accumulator for hydraulic control of an upper ram, a discharging door and a charging door. The hydraulic control apparatus is characterized in that the hydraulic pump comprises a high pressure variable displacement piston pump supplying oil to the upper ram and a duplex vane pump supplying oil to the discharging door and the charging door, the duplex vane pump is connected with an auxiliary energy accumulator through an energy accumulator safety valve block, the pressure and the speed of the upper ram are controlled by a main PLC of the internal mixer, upper ram pressure control refers to pressure control of a rod-existing chamber of an upper ram oil cylinder, and the main PLC of the internal mixer realizes smooth control of opening and closing of the discharging door and opening and closing speeds through a proportional directional valve and a rotary oil cylinder. According to the invention, the hydraulic control apparatus for the internal mixer is simplified, the problems of a high failure rate of a hydraulic station and a short service life of a high pressure pump in the prior art are overcome, closed-loop control of upper ram pressure is realized through controlling of the main PLC of the internal mixer, upper ram pressure control is stable and highly precise, rubber fining quality is improved, and smooth control of the opening and closing speeds of the discharging door is realized.

Owner:YIYANG RUBBER PLASTICS MACHINERY GROUP

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876BGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, ahorizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAOTONG UNIV

Press machine with a servo-drive system and a continuous process system

InactiveCN102555272AAvoid deformationGuaranteed uptimeMechanical apparatusSingle motor speed/torque controlProcess systemsMachining system

A servo drive system of a press machine has a pair of servo motors 30a and 30b which can generate necessary ram pressure by compositing and using a torque based on the same speed-torque characteristics. The servo motors 30a and 30b are symmetric with each other in a mirror image manner. The servo motors 30a and 30b are opposed to each other at opposite ends of an operation shaft 20 which vertically moves a ram 22. The servo motors 30a and 30b are integrally operated, thereby directly driving the operation shaft 20.

Owner:AMADA CO LTD

Ejector rod bottom rolling type bottom press device

PendingCN107263920AOvercome the lack of sealingBox making operationsPaper-makingKnurlingBottom pressure

The invention discloses an ejector rod bottom rolling type bottom press device comprising a knurling outer die, a knurling wheel, a lifting mechanism, a rotating mechanism, a bottom rolling outer die seat, a sliding block seat and an ejector rod. The bottom rolling outer die seat is arranged outside the sliding block seat. The knurling outer die is arranged on the bottom rolling outer die seat. An inner sliding block is arranged on the sliding block seat. A spring is arranged between the inner sliding block and the sliding block seat. The upper side of the inner sliding block is provided with the knurling wheel, and the lower side of the inner sliding block is provided with an ejector pin wheel. The knurling wheel corresponds to the knurling outer die in position. An ejector head is arranged at the upper end of the ejector rod, and the lower end of the ejector rod is connected with the lifting mechanism. The ejector head corresponds to the ejector pin wheel in position. A belt wheel is arranged on the sliding block seat. The belt wheel is connected with the rotating mechanism through a belt. The ejector rod bottom rolling type bottom press device overcomes the defect that an existing planetary type bottom press device can be only used for bottom seal of cylindrical paper containers, and the ejector rod bottom rolling type bottom press device can be used for bottom seal of a square paper container with a bottom rolling outer die provided with a square inner cavity.

Owner:ZHEJAING DISCOVER MACHINERY MFG CO LTD

Mixing method and mixing system for rubber composition

ActiveCN106573396AStable physical propertiesRotary stirring mixersTransportation and packagingHybrid systemProcess engineering

A mixing method and a mixing system for a rubber composition are provided with which unevenness in the temperature of a rubber mixture that is reached at the point of time when a carbon incorporation process is completed is reduced, thereby stabilizing the rubber properties. In each of steps of a carbon incorporation process and steps of a homogeneously dispersing process, at the point of time when the integrated quantity (S) of electric power required for rotating the mixing rotor(s) (2) has reached a predetermined integrated quantity of electric power, this step shifts to a next one. In the carbon incorporation process, the ram pressure (Pr) and / or the number of revolutions (N) of the mixing rotor(s) (2) is subjected to PID control on the basis of the difference between the temperature-rising rate of the rubber mixture (R) and a predetermined value thereof, thereby regulating the temperature of the rubber mixture (R) that is reached at the time of process completion to a value within an acceptable range. In each step of the homogeneously dispersing process, the ram pressure (Pr) or the number of revolutions (N) of the mixing rotor(s) (2) is controlled so as to reduce the difference between a value based on successively detected data on a given subject to be controlled and a predetermined value thereof.

Owner:THE YOKOHAMA RUBBER CO LTD

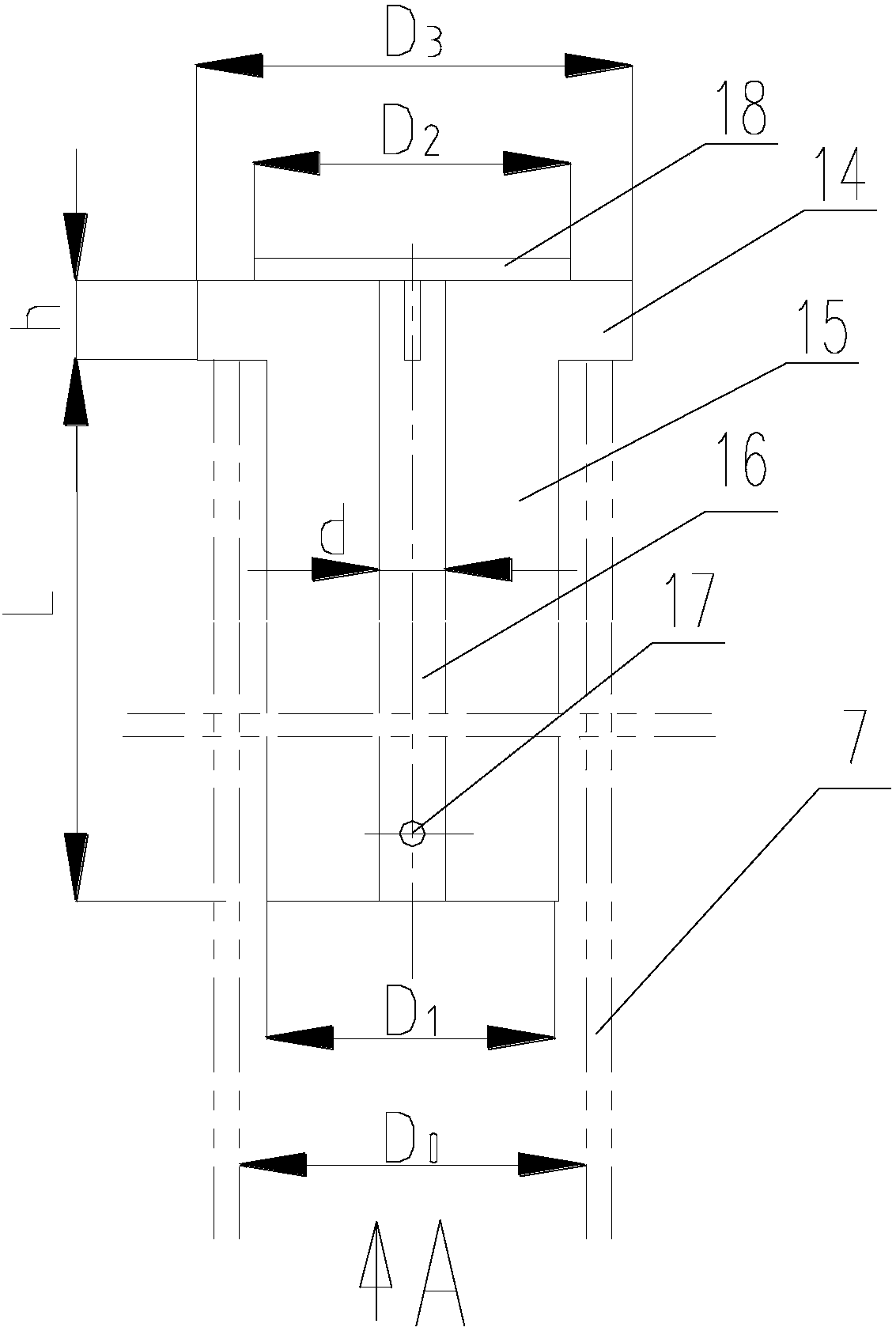

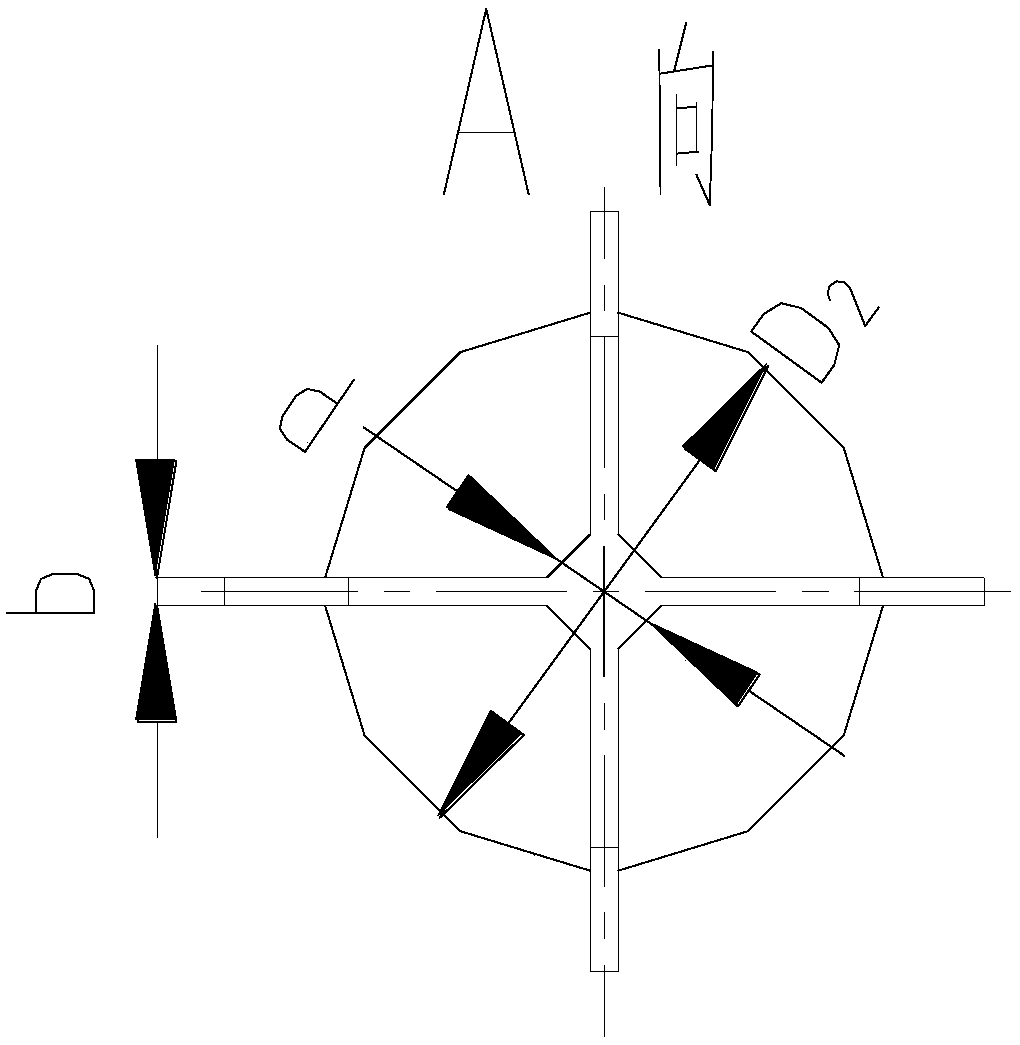

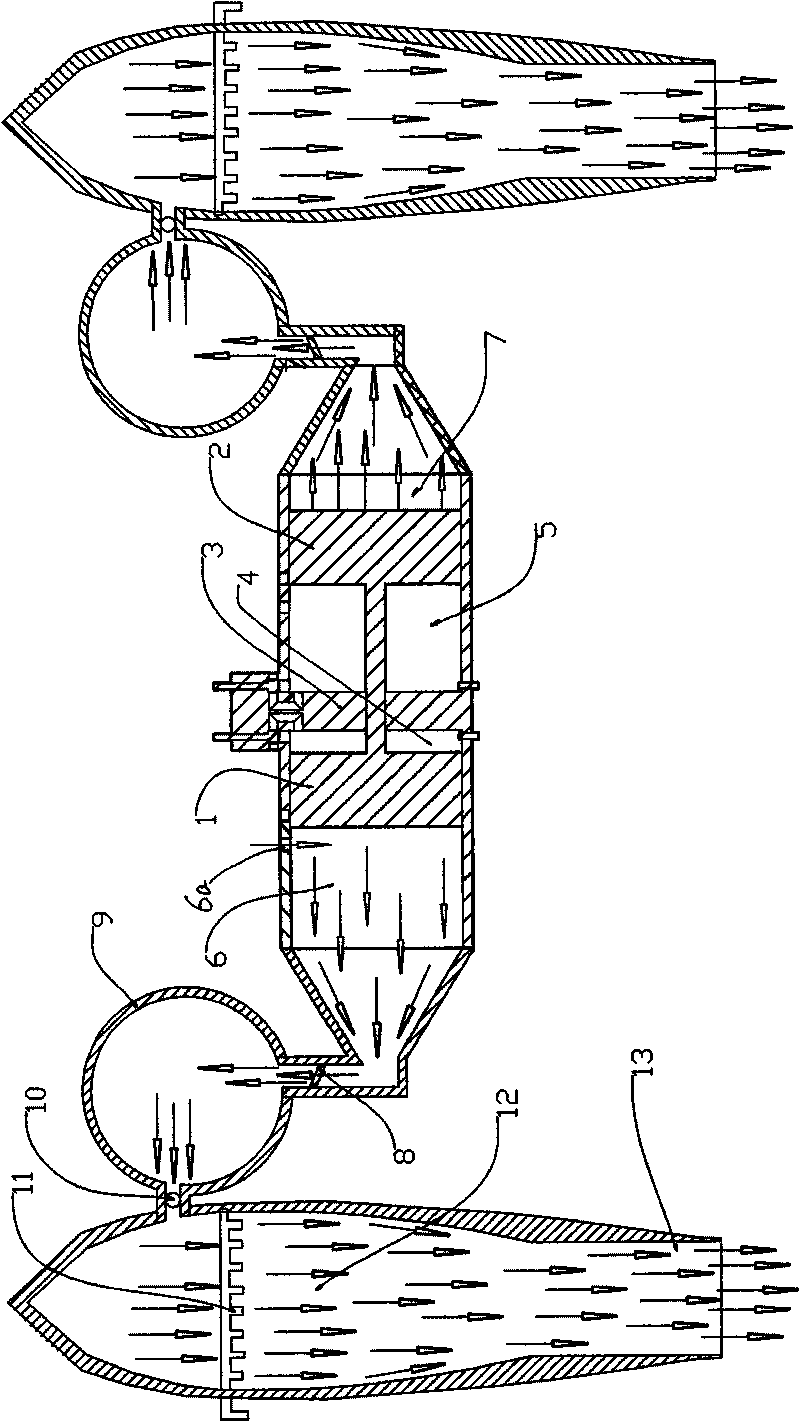

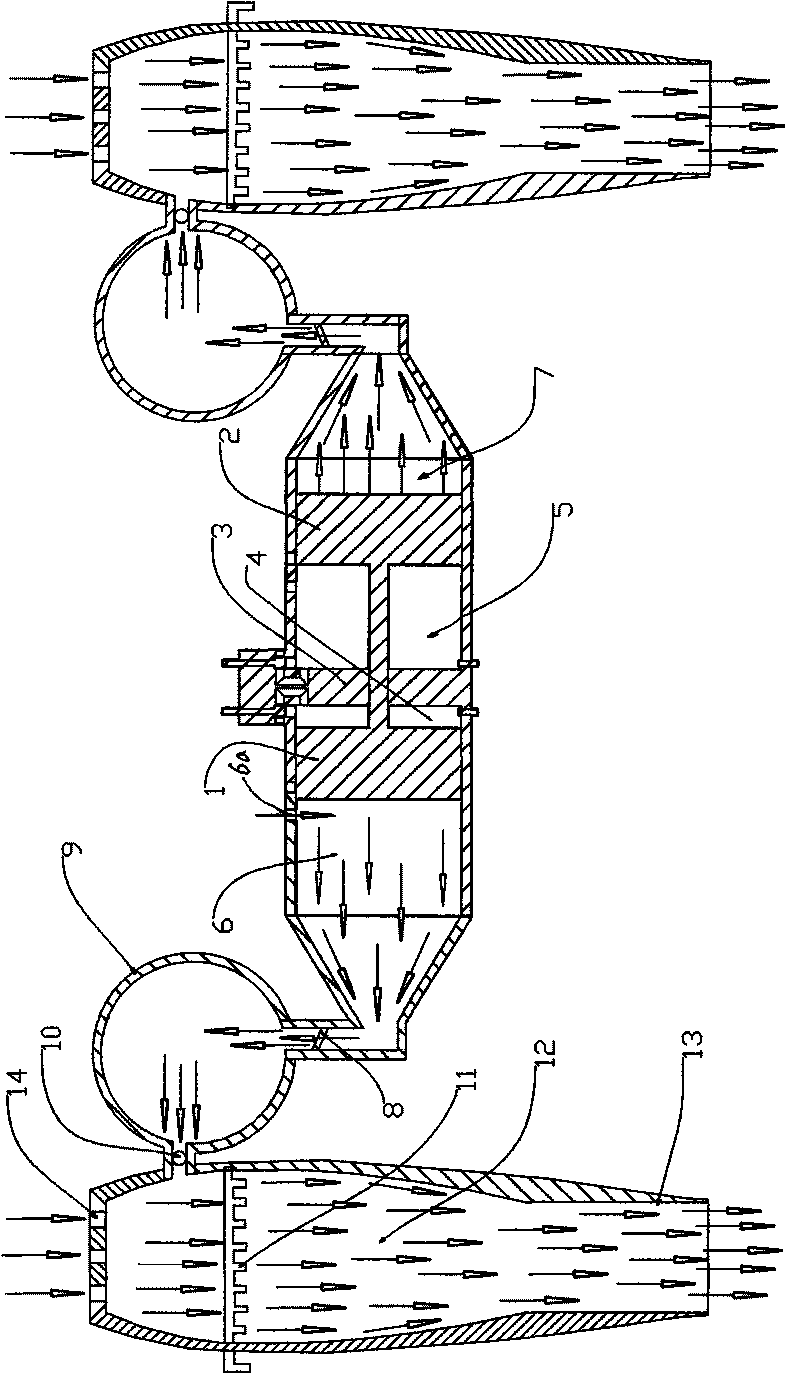

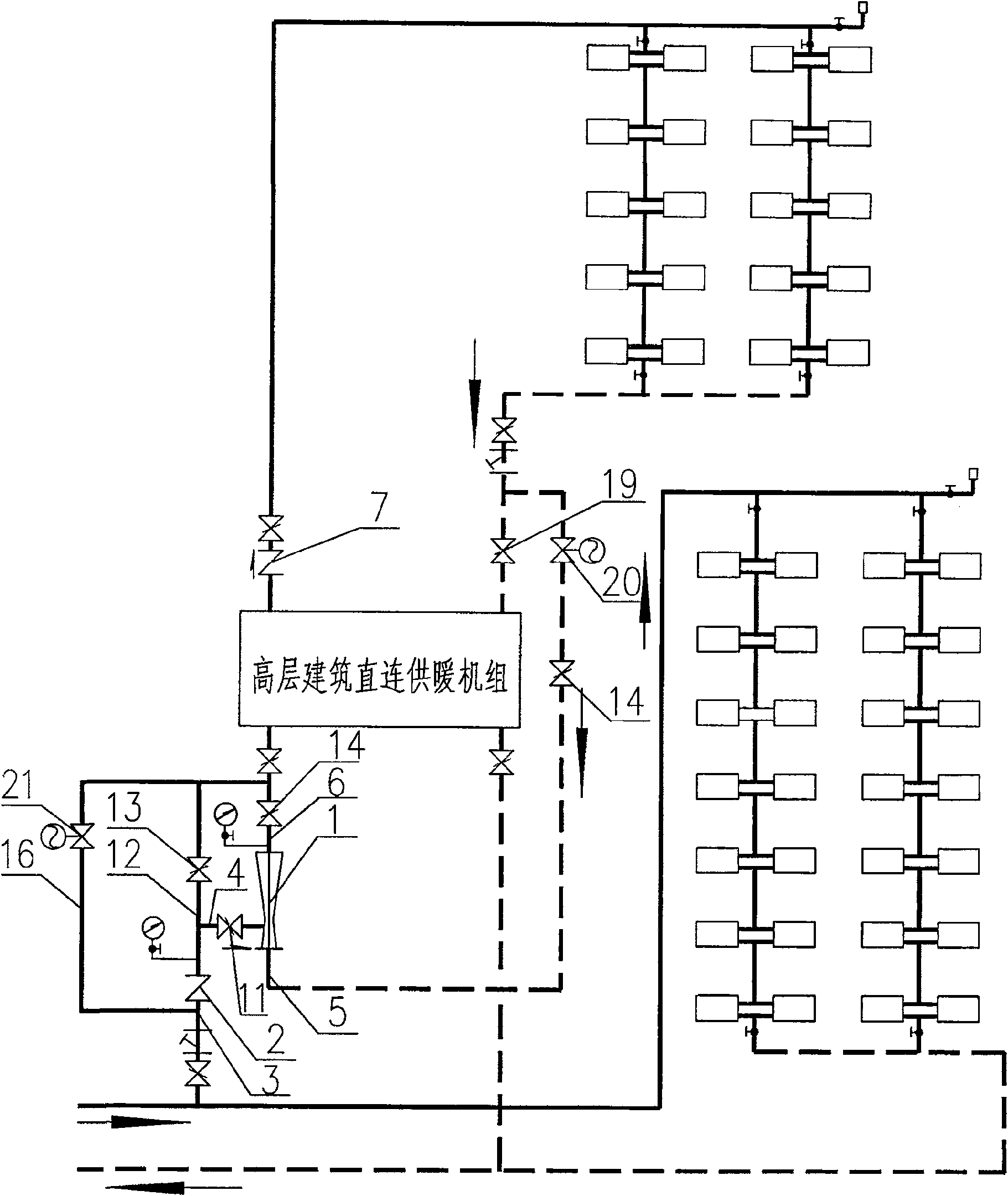

Heat transfer intensification and automatic cleaning mechanism of natural circulation evaporator

InactiveCN108317890ARealize automatic cleaningStrong radial vibrationFlush cleaningVapor liquidReboiler

The invention discloses a heat transfer intensification and automatic cleaning mechanism of a natural circulation evaporator. The automatic cleaning mechanism at least comprising straight leaf discs,heat transfer intensification and automatic cleaning function screws and hanging weights is mounted on heating pipes of the center circulating pipe natural circulation evaporator. When the mechanism operates, the straight leaf discs utilize rise of ram pressure of undulatory flows of vapor-liquid two-phase flows at orifice sections of the heating pipes; the hanging weights provide downward movement power; and the function screws make up and down reciprocating motion with a stroke of 20-100mm, autorotate slowly or radially vibrate quickly for automatic cleaning and convective heat transfer intensification of inner walls of the pipes. The automatic cleaning mechanism is reliable and simple in structure, is applicable to the heat transfer intensification and automatic cleaning of the heatingpipes of the vertical shell and tube natural circulation evaporator, an evaporating crystallizer, and a reboiler.

Owner:HUNAN UNIV OF TECH

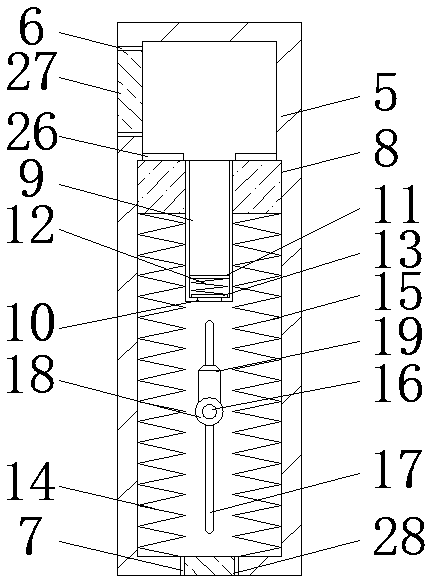

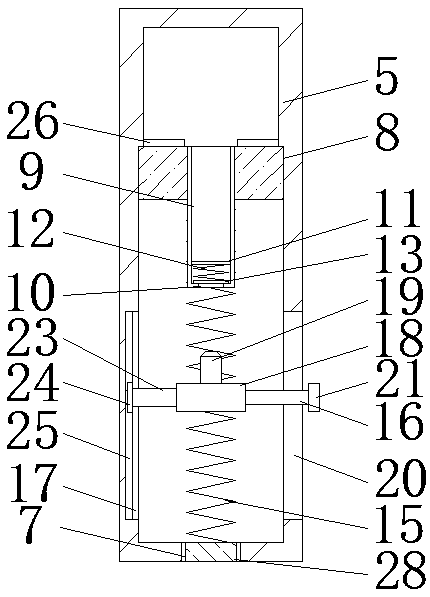

Speed reducer ventilation device

The invention discloses a speed reducer ventilation device. The speed reducer ventilation device comprises a speed reducer. A high-speed shaft is rotatably connected to the left side of the front surface of the speed reducer. A low-speed shaft is rotatably connected to the front surface of the speed reducer and located on the right side of the high-speed shaft. A base is welded to the bottom of the speed reducer. A ventilation device body is connected to the bottom of the right side of the speed reducer through bolts. A First air hole is formed in the position, corresponding to the speed reducer, of the top of the left side of the ventilation device body. A sealing pad is arranged on the surface of the inner wall of the ventilation device body and slidably connected to the bottom of the first air hole. The bottom of the sealing pad communicates with a vent pipe. According to the speed reducer ventilation device, through cooperation of the ventilation device body, the sealing pad, the vent pipe, an air hole, a fixed rod, a first spring, a second spring, a third spring, a first sliding groove, a push rod and air pressure scale marks, the problems that part damage or oil leakage is caused due to the fact that the air pressure value cannot be set and the air pressure value of a speed reducer cannot be adjusted during ventilation when an existing speed reducer ventilation device isin use are solved.

Owner:吕丽娅

Air jet engine using piston engine as air compressor and application thereof

InactiveCN101709680AIncrease rotational powerHigh speedPower plants being motor-drivenContinuous jet plantsFree-piston engineCombustion chamber

The invention provides an air jet engine using a piston engine as an air compressor and application thereof. The air jet engine is characterized in that: by the motion of a piston in the piston engine, air entering an air cylinder is directly or indirectly compressed, and the compressed air and fuel are mixed and combusted in a combustion chamber and then jetted out from a jet pipe so as to generate a required propelling power. The piston engine and a ram jet are combined to form a ram pressure / piston jet engine. The gas jet pipes are arranged in all directions of an aircraft, so that the aircraft can obtain the abilities of vertical takeoff and landing, hovering and flexible turning. The gas is tangentially jetted by nozzles at the tail ends of aerovanes of the aircraft, so that the aerovanes can obtain higher rotary power and speed.

Owner:徐林波

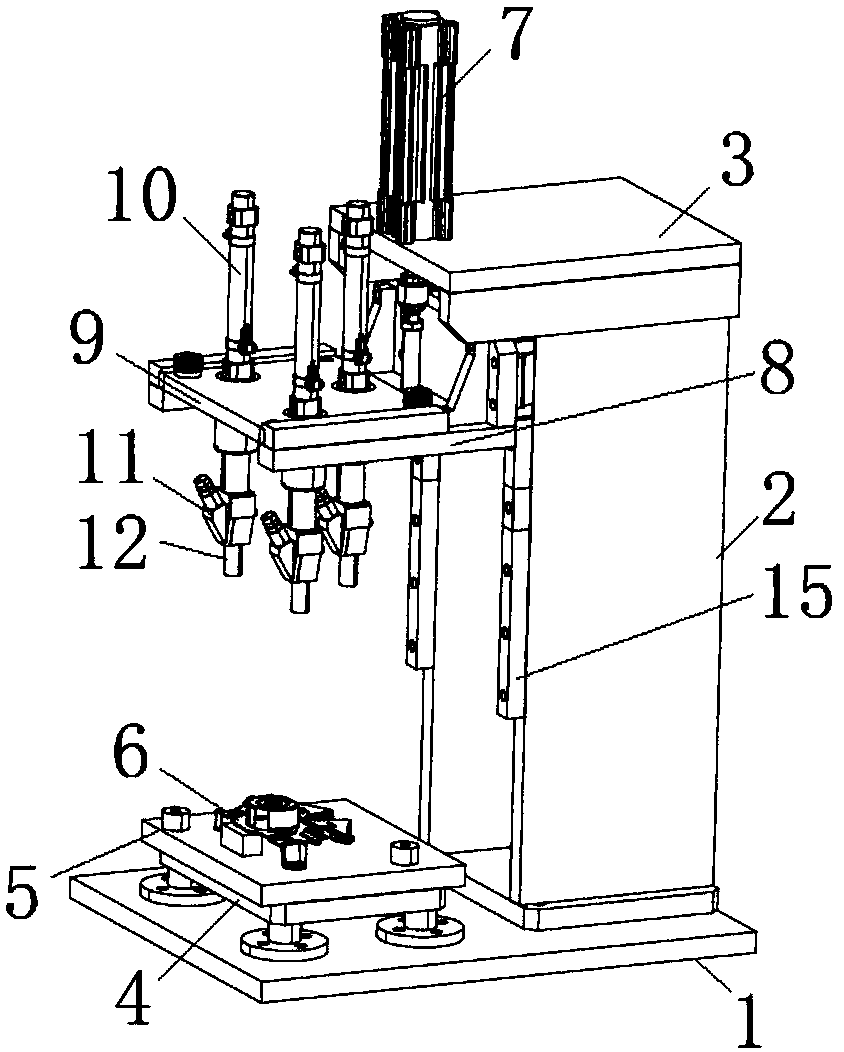

Press-riveting process for automobile glass lifter motor support

InactiveCN107552711AIncrease productivityAvoid manual rivet placement safety risksEngineeringRam pressure

The invention discloses a press riveting process for a motor bracket of an automobile glass lifter, which comprises the following steps: (1) setting the motor bracket on a positioning structure of a tooling platform; (2) driving a stamping cylinder by a lifting cylinder arranged above the tooling platform And the pressure head on the stamping cylinder moves downward until it moves down until the end of the pressure head contacts the outer edge of the riveting hole of the motor bracket; (3) The automatic rivet feeder sends the rivets to the pressure head through the rivet feeding port on the pressure head. (4) The stamping cylinder drives the stamping rod in the stamping head to press the rivets in the stamping head; (5) After the pressing is completed, the lifting cylinder drives the stamping cylinder to reset, and removes the processed motor bracket. Automatic rivet feeding and automatic rivet pressing are realized through the lifting cylinder and punching cylinder, without manual control operation, and the riveting and pressing are completed automatically, which greatly improves production efficiency, avoids the safety risk of manually placing rivets, and reduces costs.

Owner:WUHU MOTIONTEC AUTOMOTIVE

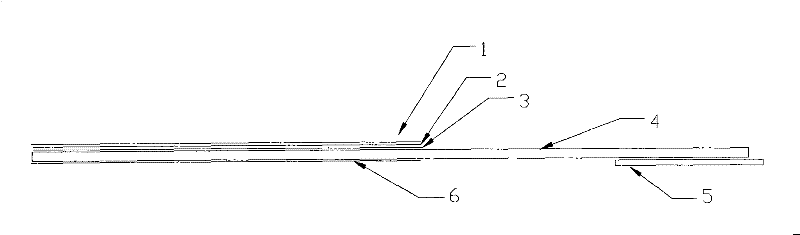

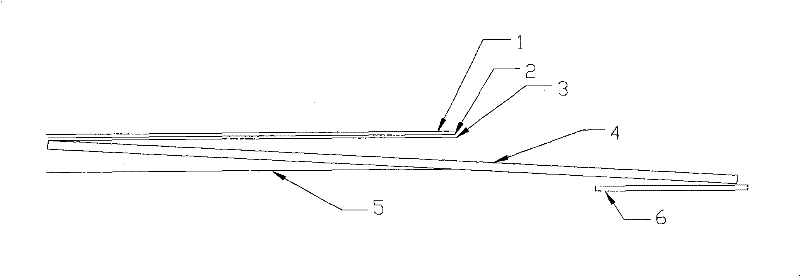

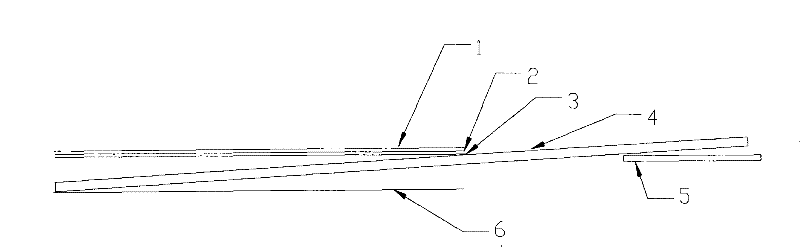

The adjustment method of the thermal pressure equipment

InactiveCN101728142BNo cracked screenAvoid broken screenControlling laminationLaminationEngineeringMechanical engineering

Owner:深圳市聚美通用科技有限公司

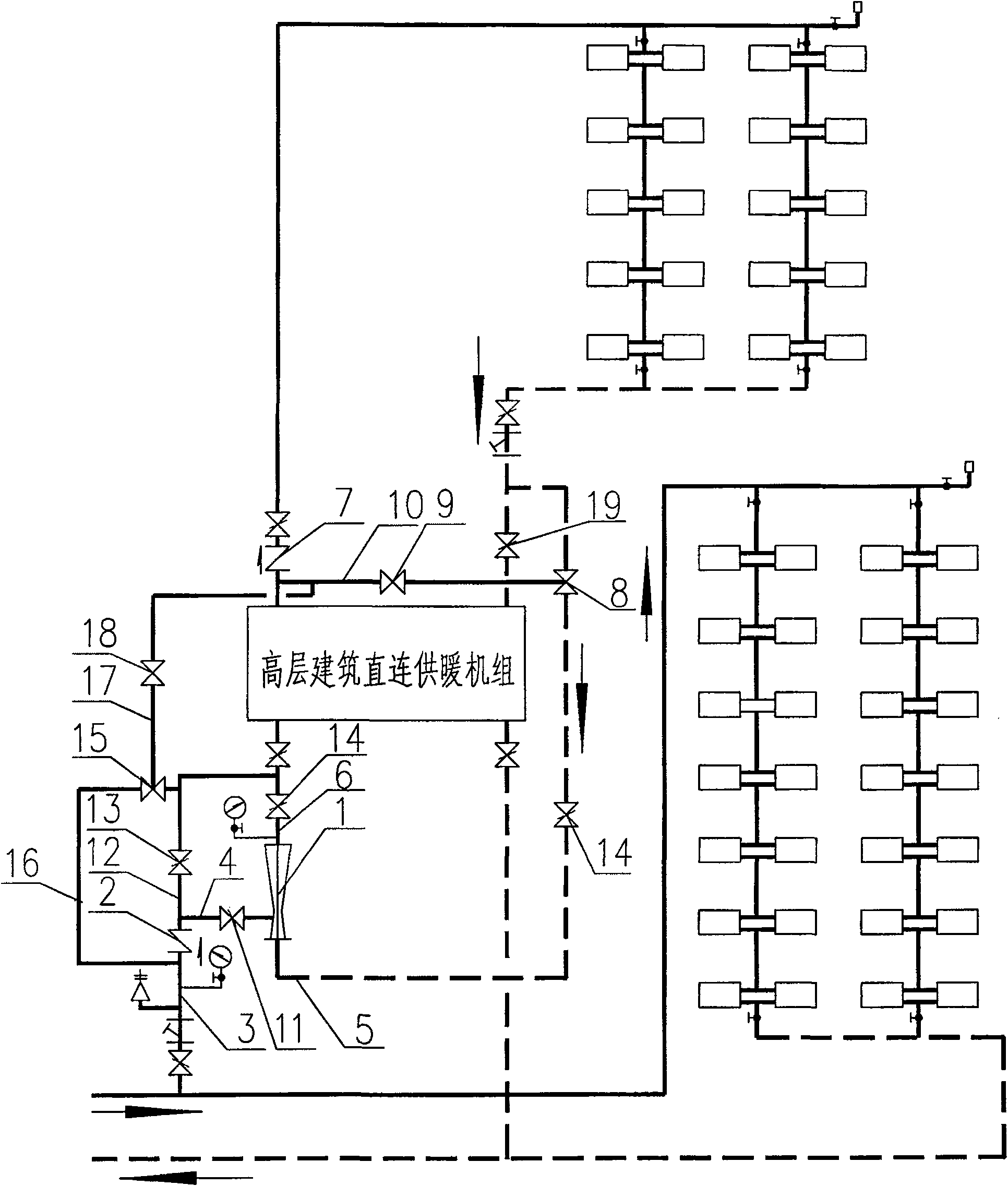

Direct connection heating self-compressing unit for high-rise building

InactiveCN100572931CSave electricityEasy maintenanceLighting and heating apparatusHot-water central heatingEngineeringDirect heating

This high-rise building is directly connected to the heating self-pressurization unit, which is composed of a water injector 1, a check valve 2 and a piping system; there is a water suction pipe section 3 in front of the check valve 2, which can be connected with the water supply pipe of the municipal heating pipe network, and the water supply pipe can be stopped. The water outlet pipe section 4 behind the return valve 2 can be connected with the water suction pipe of the high-rise building directly connected to the heating unit through the water ejector 1; it is characterized in that: the water inlet pipe section 5 of the water ejector 1 can be connected with the main return pipe of the heating system in the high area, The outlet pipe section 6 can be connected with the water suction pipe of the direct-connected heating unit of the high-rise building, and the water injector 1 ejects the heating water supply in the low area of the pipe section 4, so as to improve the dynamic pressure head of the direct-connected heating unit of the high-rise building to absorb water, and reduce the power consumption of the high-rise heating unit. At the same time, the hot water required for heating conditions is prepared. It has the following advantages. It can be debugged and operated only by connecting the relevant pipelines. It is safe and reliable, easy to maintain, low in cost, easy to popularize, and saves electric energy. It brings great convenience for high-rise buildings and buildings with large terrain height difference to use urban external network heating, and provides reliable and energy-saving equipment for heating systems to prepare hot water under different working conditions.

Owner:徐立华

An antifreeze differential pressure flowmeter

ActiveCN104792374BNo coagulationVolume/mass flow by differential pressureDifferential pressureHydrostatic pressure

The invention discloses an antifreeze differential pressure flowmeter, which has a flow totalizer and a Bitoba flow sensor to take a pressure head, the upper part of the cylindrical joint of the pressure head has a cylindrical chamber, and the lower part is provided with a differential pressure switch device; the differential pressure switch device includes a radial cylindrical hole that runs through the lower part of the cylindrical joint. The axes of the pressure channels are perpendicular to each other, and the inner diameters of the cylindrical holes are respectively larger than the inner diameters of the total pressure channel and the static pressure channel. They are located approximately in the middle of the axis of the cylindrical hole and are sealed with a differential pressure sensitive diaphragm. The total pressure channel and the static pressure channel The upper ports of the differential pressure sensitive diaphragm are respectively located on both sides of the differential pressure sensitive diaphragm, and the two ends of the cylindrical hole are sealed with side end covers. The signal output end of the differential pressure sensitive diaphragm is connected with a signal cable, and the signal cable passes through the The cylindrical chamber is connected with the signal input end of the flow totalizer. When the invention measures the fluid flow in the pipeline, it is not affected by the ambient temperature outside the pipeline.

Owner:LIAONING BITOBAR TECH CO LTD

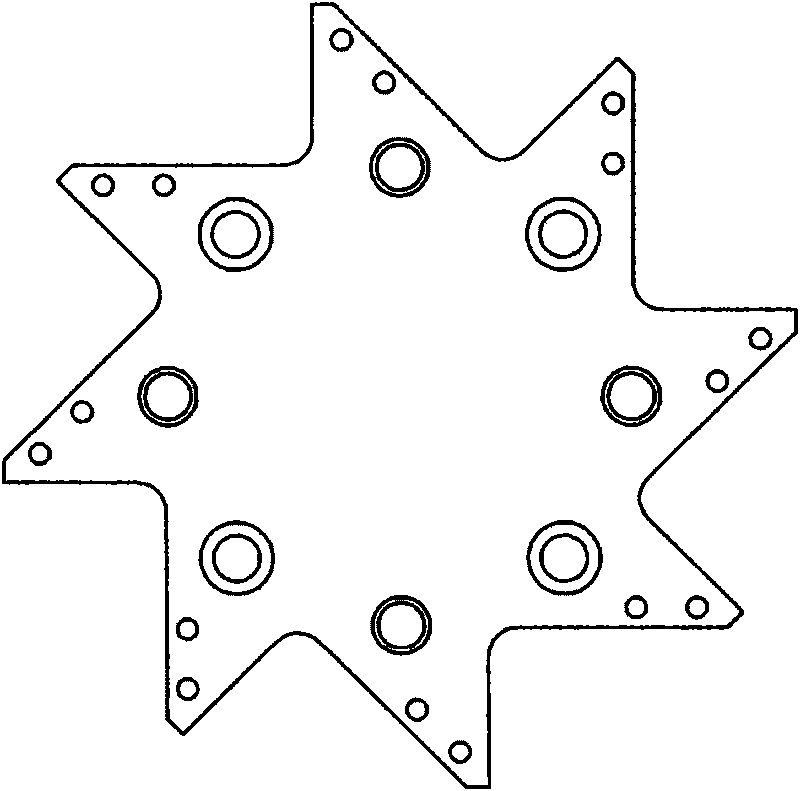

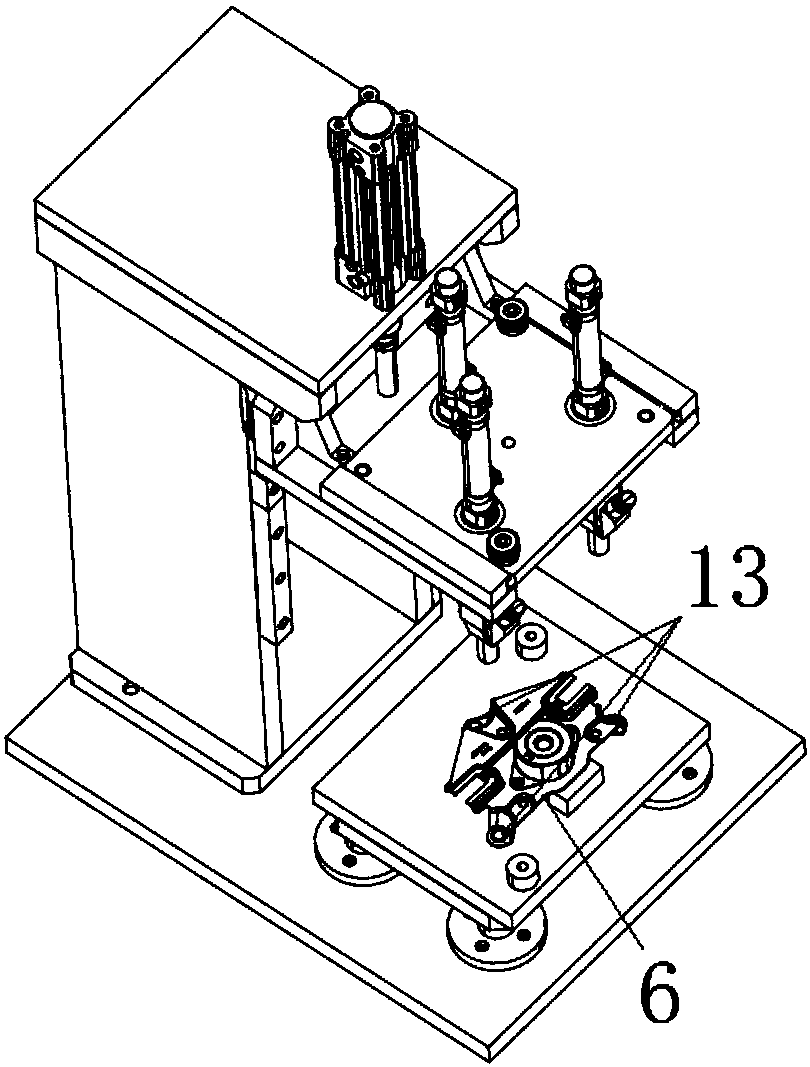

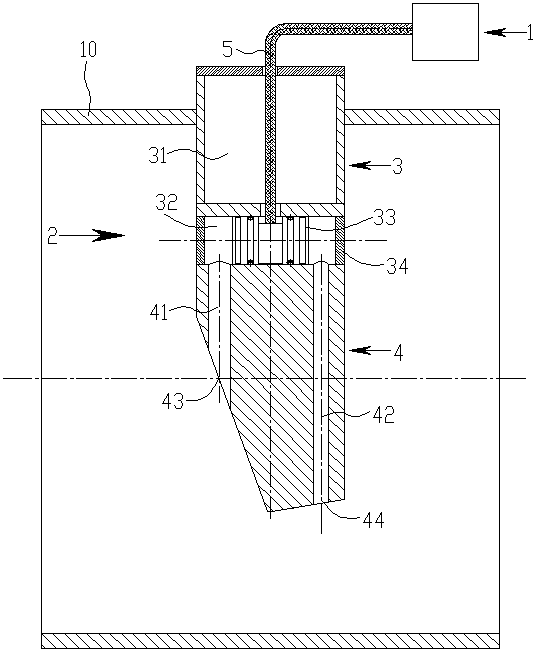

Eight-bar servo press with triangular pendulum

InactiveCN102285133ADiversified pressure working curveGood force transmission characteristicsPress ramMotor driveElectric machinery

The invention relates to an eight-bar servo press with a triangular pendulum. The press includes a frame, a first crank, a second crank, a first connecting rod, a second connecting rod, a triangular pendulum, and a hammer connection. Rod and hammer, the first crank and the second crank are respectively connected with the frame through the rotating pair; the first crank is connected with the servo motor, and the servo motor drives the first crank to rotate; the first connecting rod and the first crank are rotated The pair is connected, the second connecting rod is connected with the second crank through the rotating pair, the first connecting rod, the second connecting rod and the triangular pendulum are connected at the same point through the revolving joint; It is connected with the hammer connecting rod, and the end of the hammer connecting rod is connected with the hammer through a rotating pair, and the hammer is in the fixed guide rail. The present invention can obtain diversified pressure working curves of the punching hammer, which solves the problems of poor "flexibility" and low quality of stamping forming of the traditional mechanical press; the addition of the triangular pendulum can make the working pressure curve of the punching hammer more diversified; At the same time, the press has good force transmission characteristics.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com