Patents

Literature

55results about How to "No coagulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer-coated perovskite quantum dots and preparation method thereof

InactiveCN109306265AGood dispersionNo coagulationLuminescent compositionsThiocarboxylic acidWater vapor

The invention provides a preparation method of polymer-coated perovskite quantum dots. The preparation method comprises the following steps: supplying perovskite quantum dots, and dispersing the perovskite quantum dots in a solvent to form a perovskite quantum dot solution, wherein ligands on the surfaces of the perovskite quantum dots comprise thiocarboxylic acid ligands; adding a polymer monomerand a photoinitiator into the perovskite quantum dot solution for reacting under an ultraviolet radiation condition in which the water vapor content is less than 30 percent to generate the polymer-coated perovskite quantum dots, wherein the polymer monomer is an unsaturated polymer monomer containing amidogen.

Owner:TCL CORPORATION

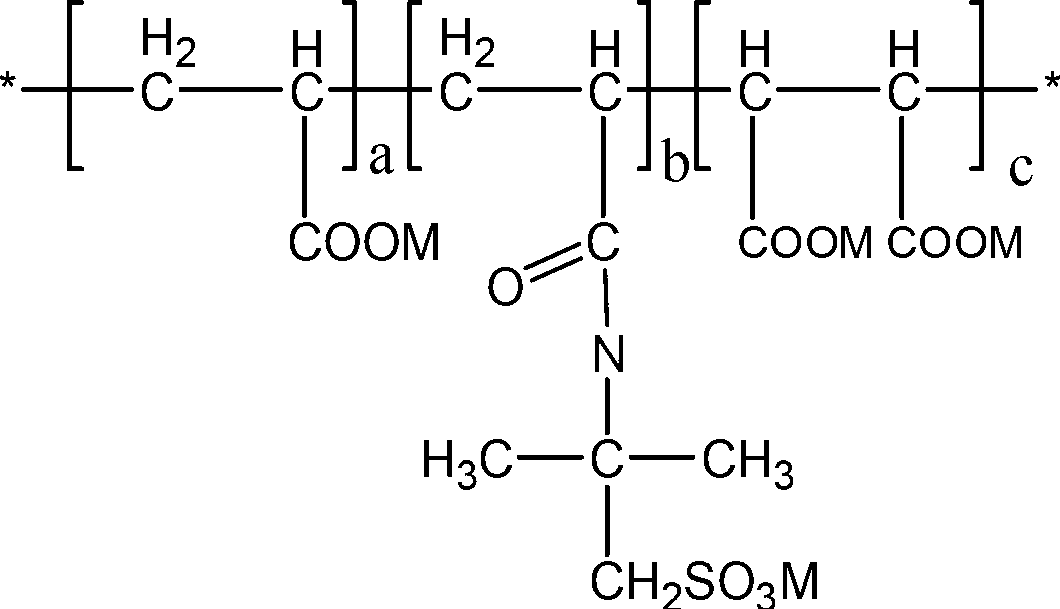

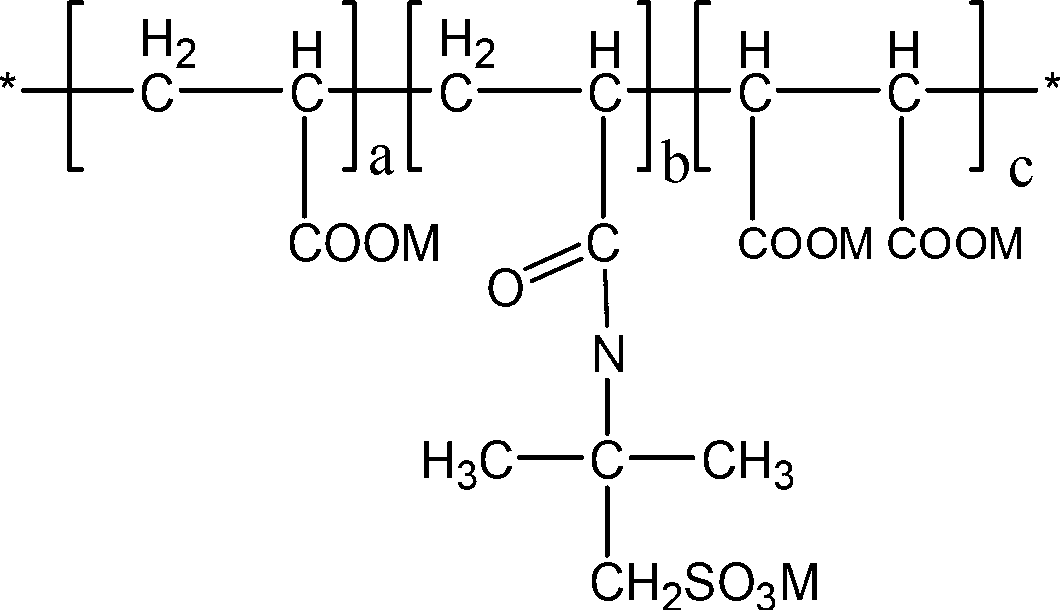

High-polymer water reducing agent for ceramic concentrated suspension as well as preparation method and application of high-polymer water reducing agent

The invention discloses a high-polymer water reducing agent for a ceramic concentrated suspension as well as a preparation method and application of the high-polymer water reducing agent. The structure of the water reducing agent is as shown in a formula. The water reducing agent is prepared through the following steps of: dissolving acrylic acid, maleic anhydride and 2-acrylamide-2-methylpropane sulfonic acid in distilled water to form a mixed solution; adjusting the pH value of the mixed solution to be 7-8; adding an inorganic chain transfer agent and then heating to 80-100 DEG C; dropwise adding an initiating agent; reacting for 3-5 hours to obtain the high-polymer water reducing agent for the ceramic concentrated suspension. By adopting the high-polymer water reducing agent, under the condition that the added amount is low and the fluidity of ceramic slurry is good, so that the water reducing agent can meet requirements for ceramic production and processing. The high-polymer water reducing agent prepared by the method has the advantage of high water reducing rate, and not only ensures that the water content of the slurry is less than 30%, but also can keep good fluidity of the slurry.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Bio-based hemodialysis membrane and preparation method thereof

InactiveCN106076126AImprove transmittanceHigh retention rateSemi-permeable membranesMembranesBiocompatibility TestingClelands Reagent

The invention discloses a bio-based hemodialysis membrane and a preparation method thereof. The hemodialysis membrane is prepared from polylactic acid, laminarin, thiolated chitosan, silk fibroin, sodium ascorbyl phosphate, cellulose acetate, dithiothreitol, stachyose, betulin caffeate, ammonium persulfate, ferulic acid, hydroxyethyl starch, N-benzyl glycine hydrochloride, deoxycholic acid, polyhydroxyalkanoate, hexamethylenediamine, hyaluronic acid, benzoperoxide and dimethyl sulfoxide. According to the prepared hemodialysis membrane, the tensile strength is not lower than 7.0 MPa, the transmittance of urea is higher than 86%, the transmittance of beta2 microglobulin is higher than 66%, the rejection rate of macromolecular protein is higher than 95%, the biocompatibility is good, coagulation, thrombus, inflammation, poisoning and other adverse reactions do not exist, and an application prospect is wide.

Owner:林春梅

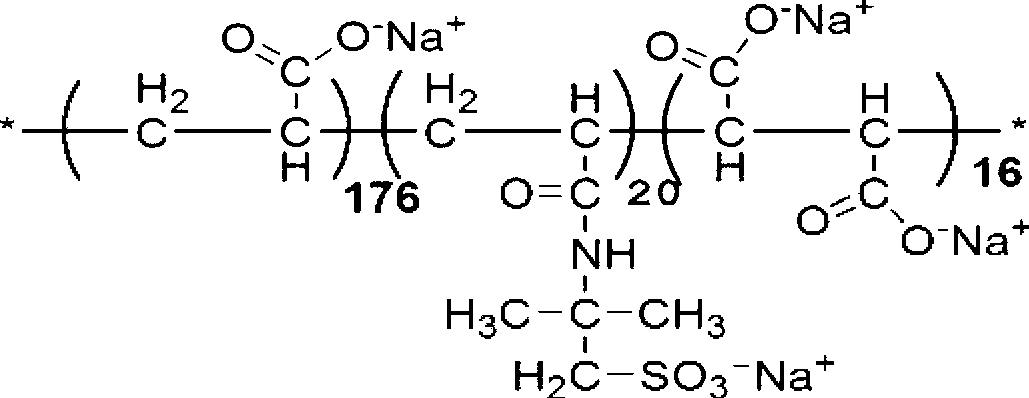

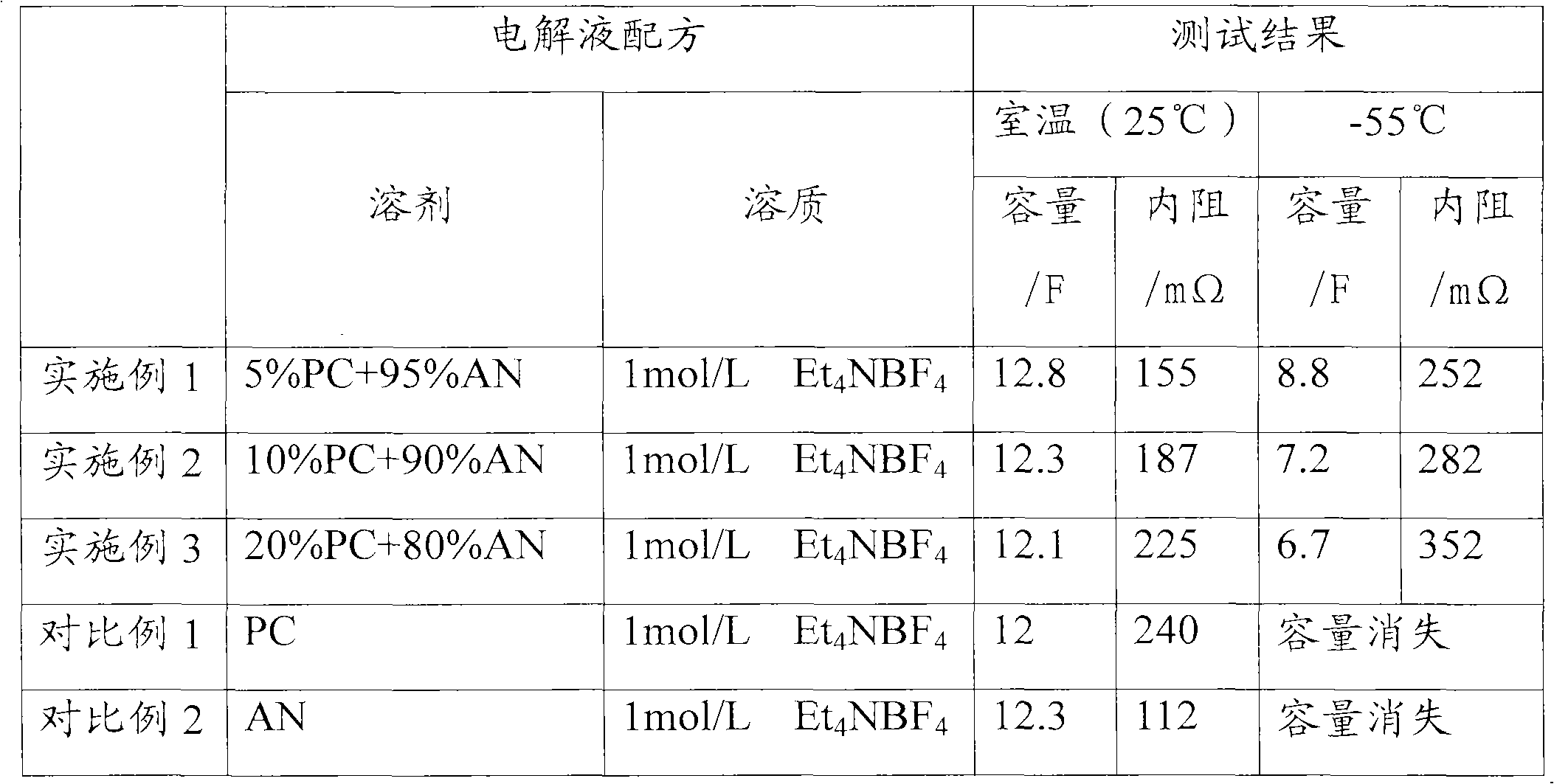

Super capacitor and preparation method thereof

InactiveCN101840793ATo achieve the purpose of normal workNo coagulationHybrid capacitor electrolytesElectrolytic capacitorsTetrafluoroborateAcetonitrile

The embodiment of the invention provides a super capacitor and a preparation method thereof. Electrolyte of the super capacitor provided by the invention adopts the mixture of propylene carbonate and acetonitrile the volume ratio of which is 5-20:80-95 as a mixed solvent of the electrolyte. The super capacitor adopts tetraethylammonium tetrafluoroborate as a solute. The electrolyte has low melting point, thus, the super capacitor cannot have phenomenon of electrolyte solidification at low temperature, has high electric conductivity and fulfills the aim of normally working at low temperature.

Owner:ZHUZHOU RIWANG ELECTRONICS TECH

Preparation method of liquid lard oil

InactiveCN106635380ALow viscosityImprove cold storage performanceFatty-oils/fats refiningFatty-oils/fats productionNutrientLong chain fatty acid

The invention relates to edible oil, in particular to a preparation method of liquid lard oil. The preparation method specifically comprises the following steps of smelting of edible lard oil fat, filtering to remove impurities, removing residues, decolorizing by vacuum, deacidifying, deodorizing, performing antioxidation treatment, chilling, enriching nutrients, and boiling, so as to form a finished product. The preparation method of the liquid lard oil has the advantages that long chain fatty acid in the lard oil can be removed, the viscosity of the lard oil is decreased, the low-temperature storage property of the lard oil is improved, the contact interface tension between the lard oil and air is effectively improved, the heat-resistant and antioxidation properties of the lard oil are improved, the final lard oil is rich in short chain fatty acid, the mouth feel is fragrant and tasty, and the fragrance is heavy; the lard oil can be stored for 8 months at normal temperature, and can be stored for 3 months at the temperature higher than 35 DEG C, and the condensing is avoided at the temperature of 0 DEG C or above.

Owner:ANHUI TIANXIANG GRAIN & OIL FOOD

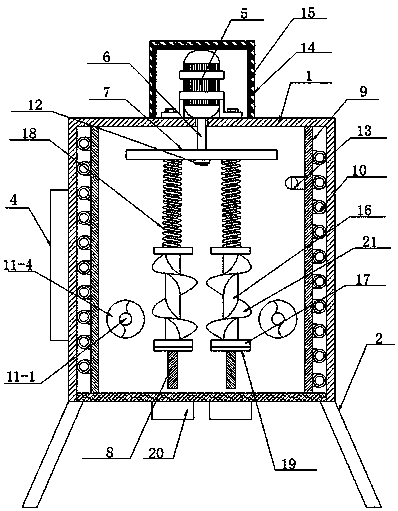

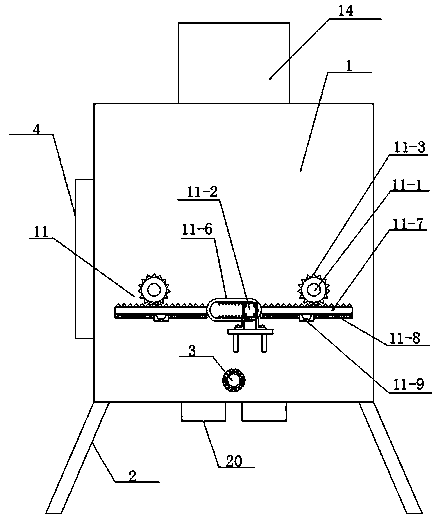

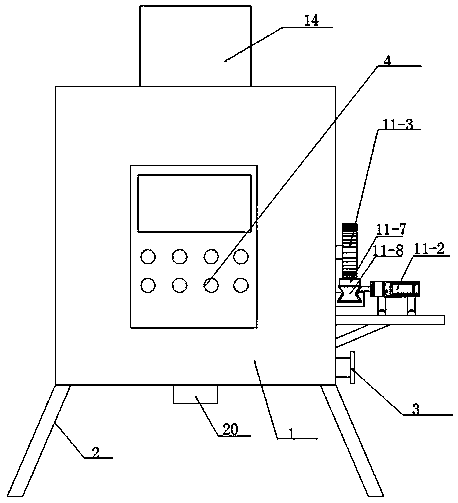

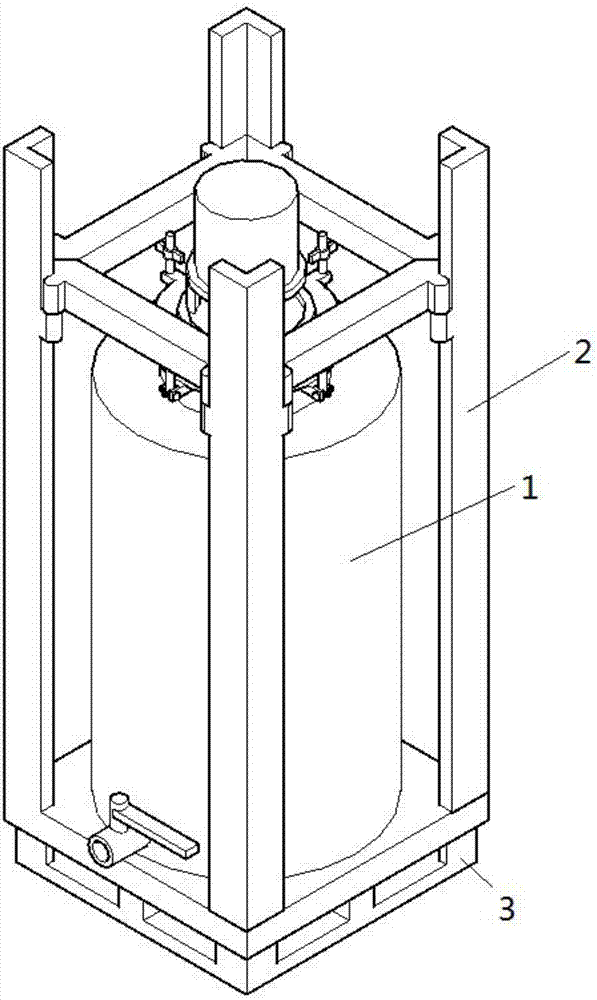

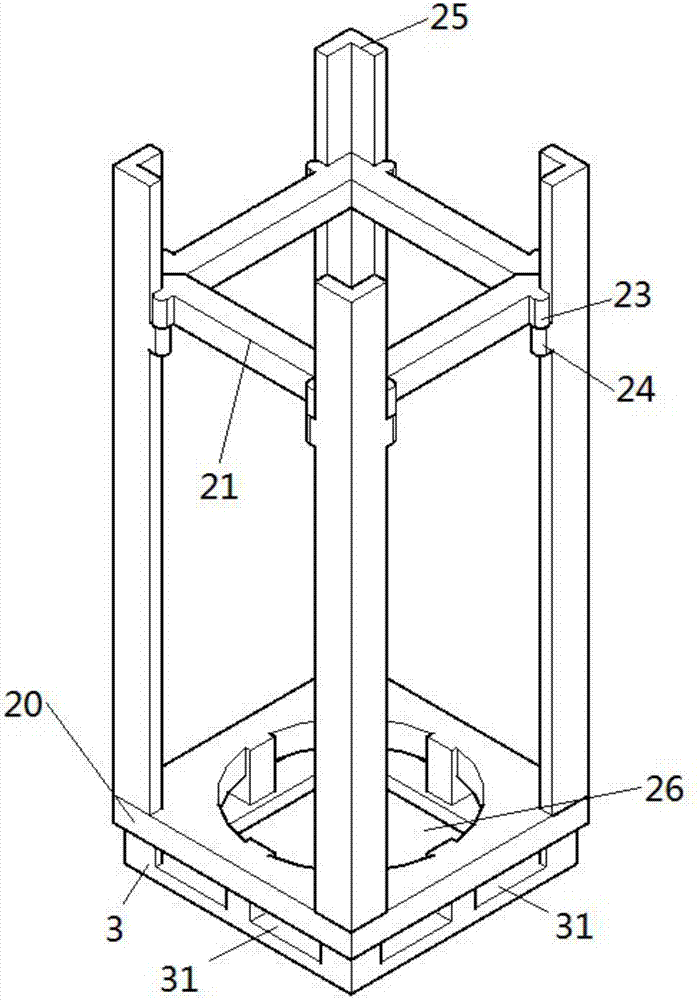

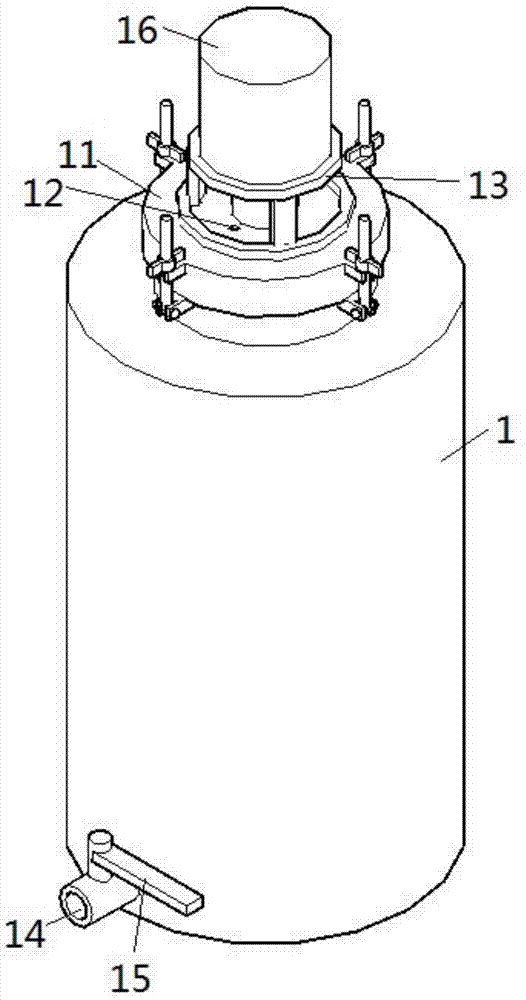

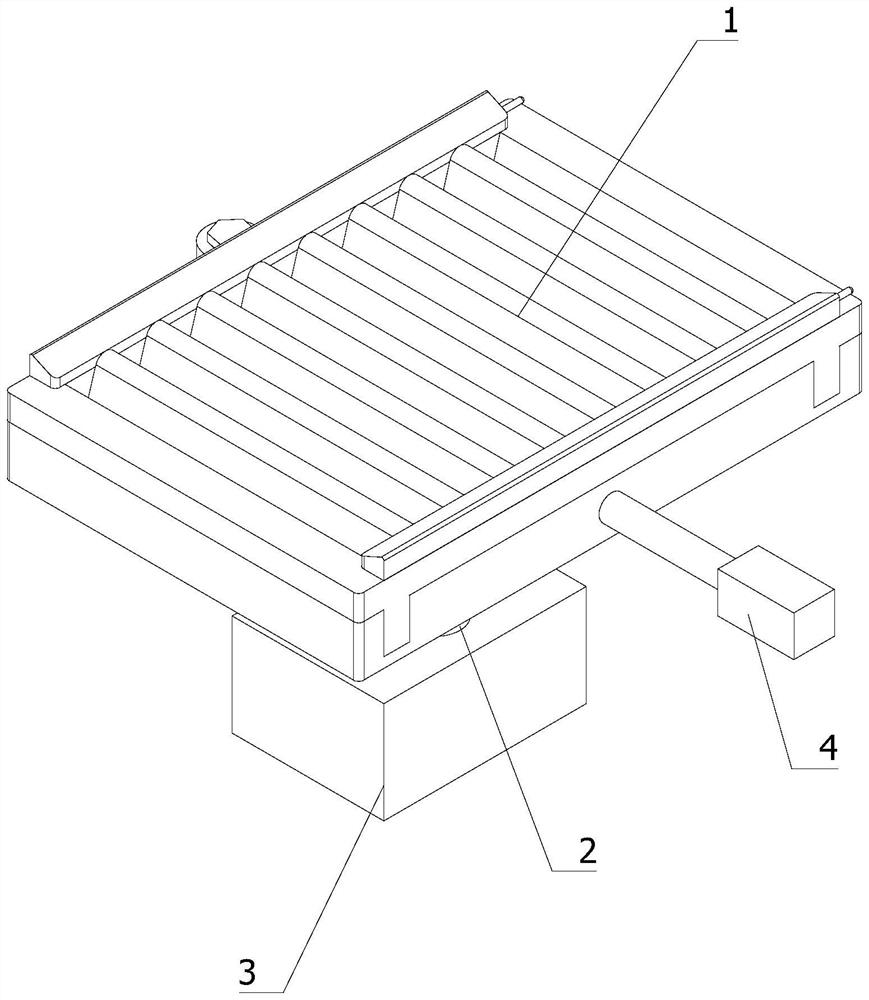

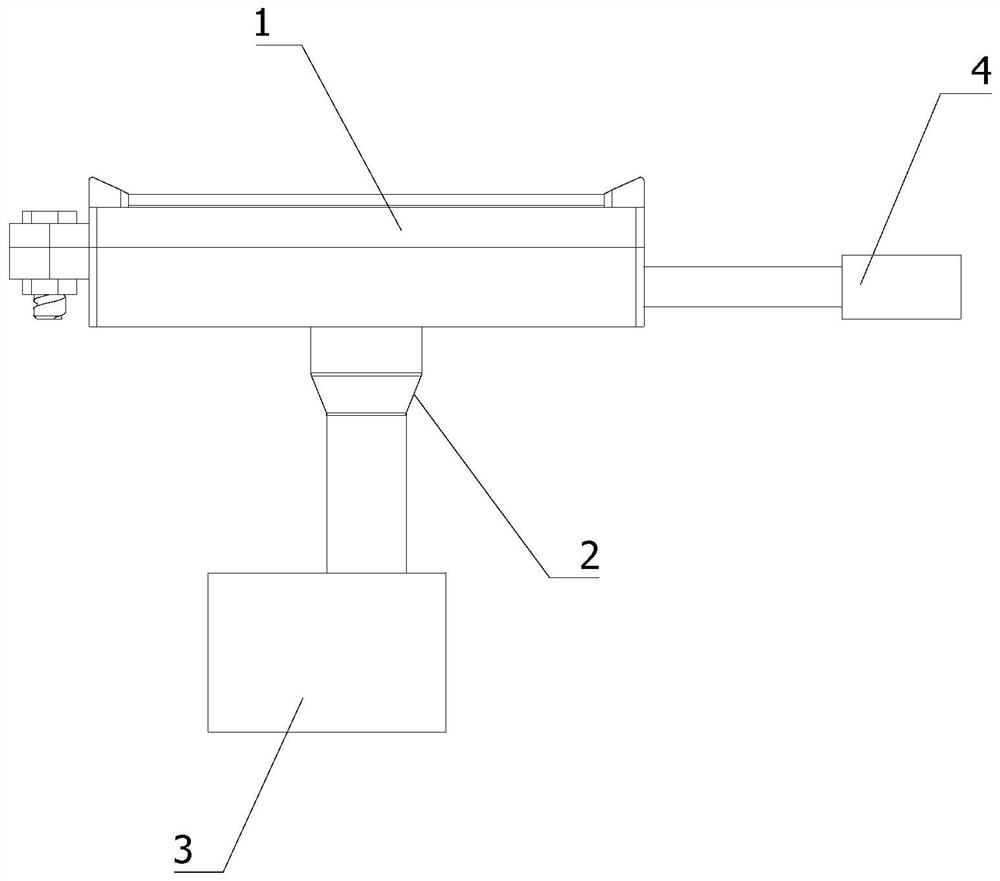

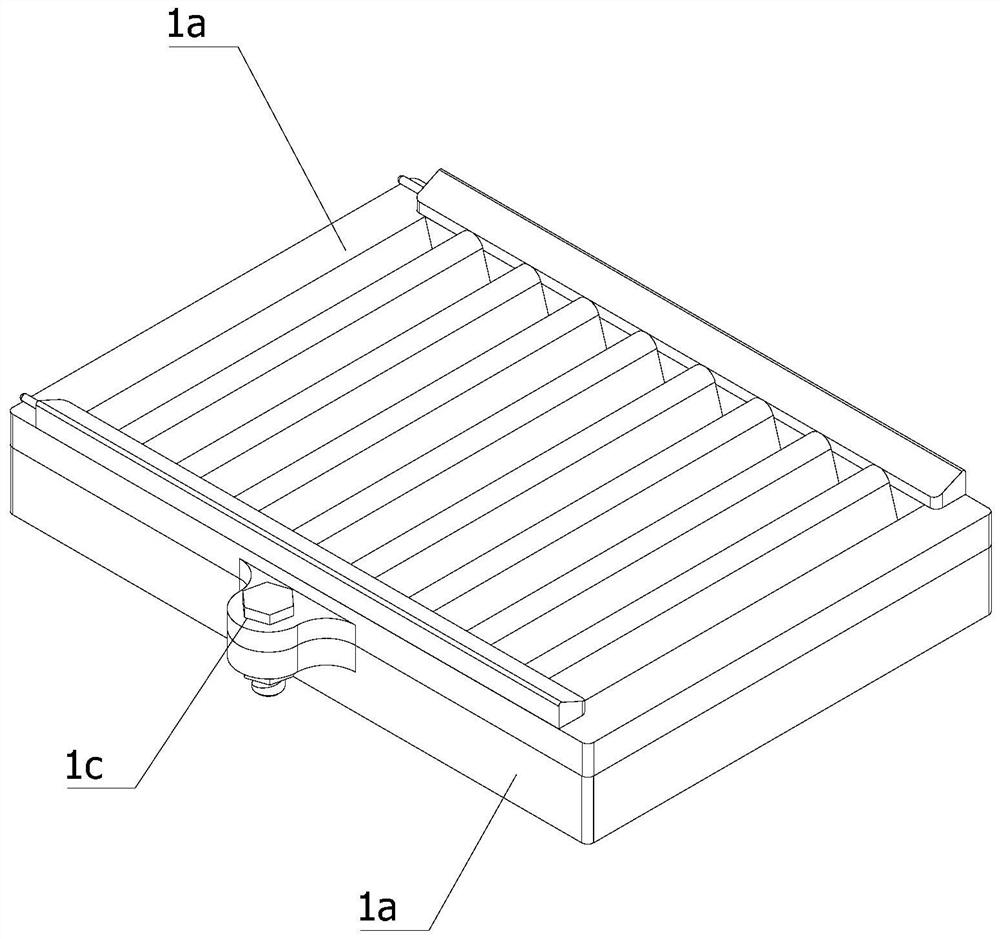

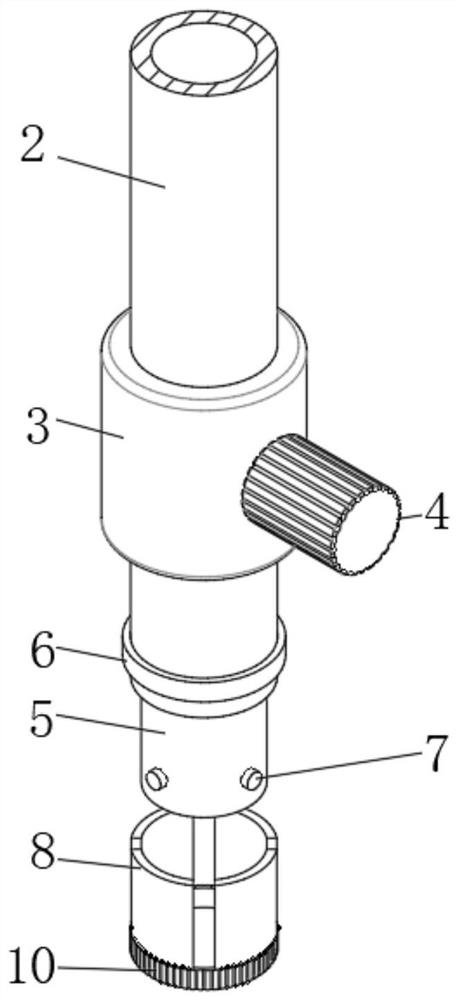

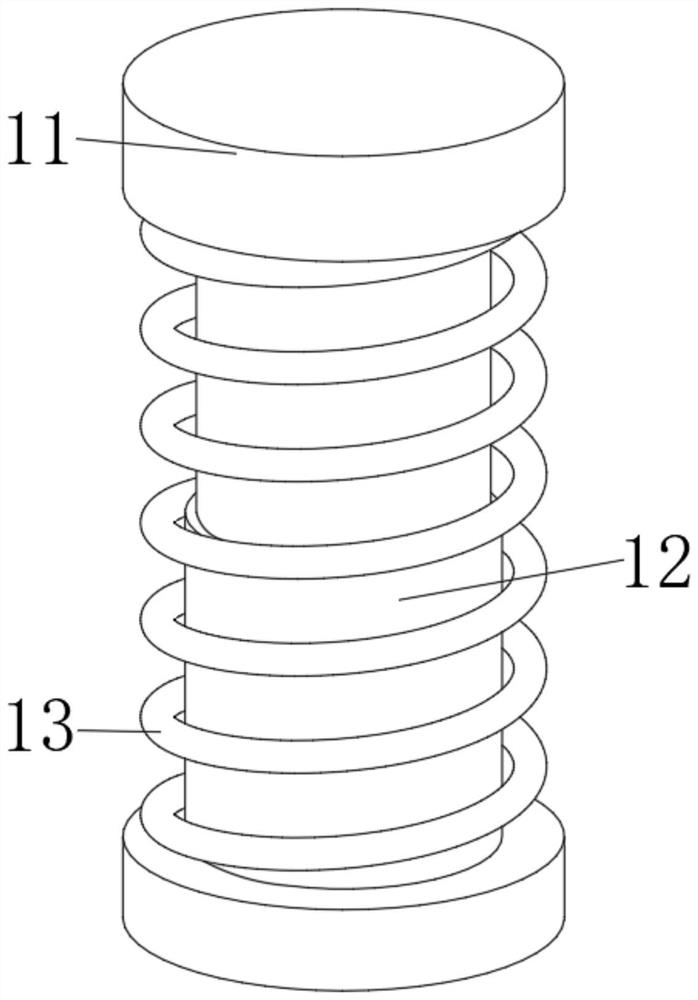

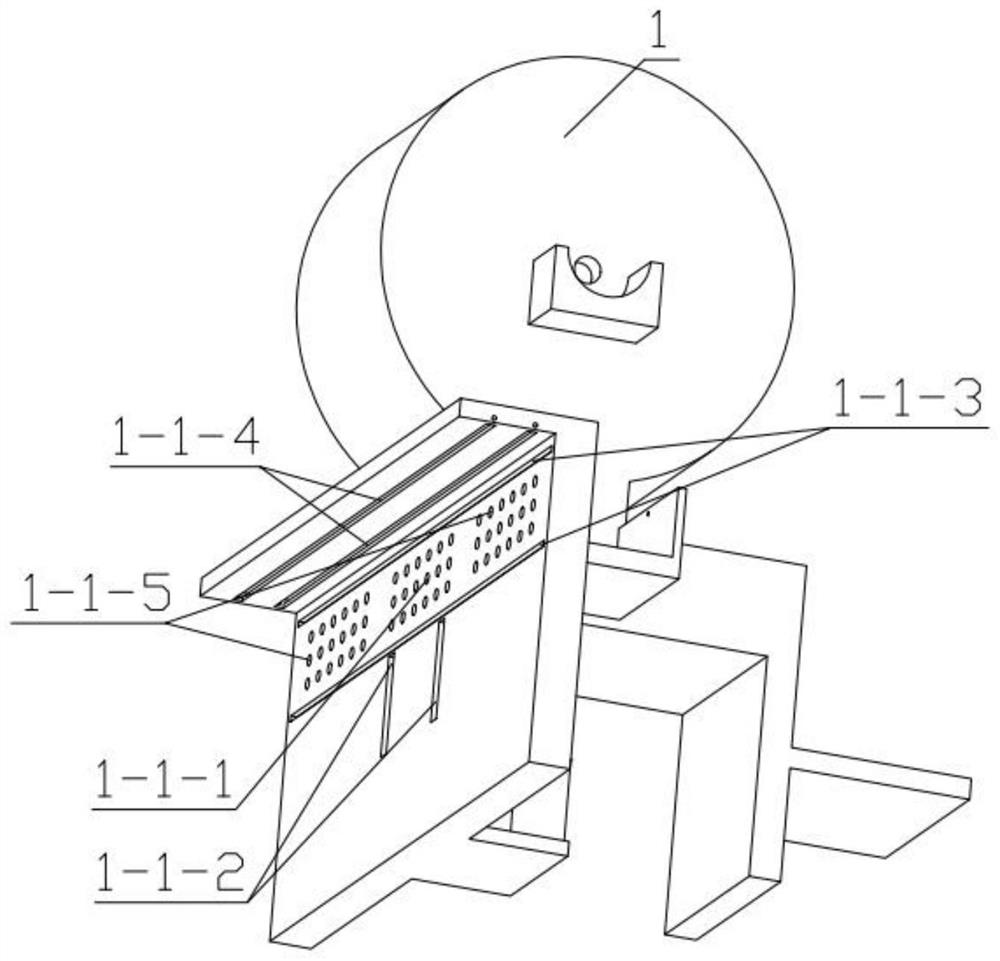

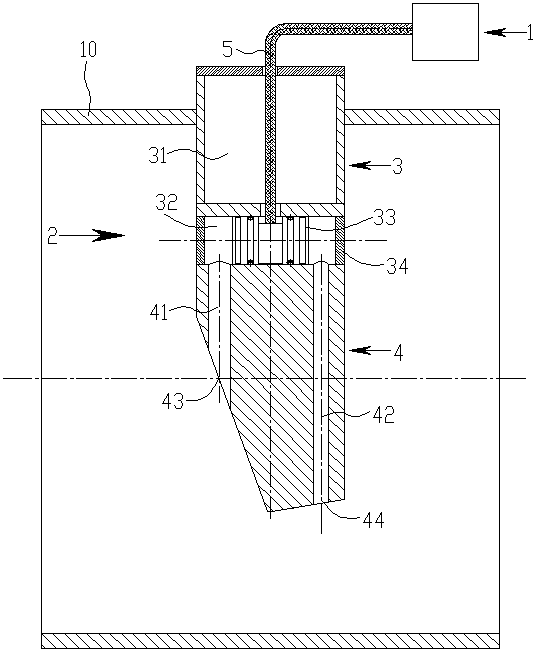

Production specific vibration device for preventing plastic silver powder paint from being solidified

InactiveCN110787704ANo coagulationProlong clotting timeShaking/oscillating/vibrating mixersTransportation and packagingElectric machineDrive shaft

The invention provides a production specific vibration device for preventing plastic silver powder paint from being solidified, and relates to the technical field of paint production equipment. A transmission shaft is fixedly connected to the output end of a vibration motor, and the lower end of the transmission shaft passes through the top surface of a box body to be fixedly connected with the middle part of a connecting plate suspended in the box body; the left and right sides of the bottom surface of the connecting plate are symmetrically and vertically and fixedly provided with transmission rods; the front and rear side walls of a partition plate are fixedly connected with the front and back side walls of the interior of the box body respectively, and the upper and lower side walls ofthe partition plate are fixedly connected with the upper and lower side walls of the interior of the box body respectively; and a gap is arranged between the partition plate and the left and right side walls of the interior of the box body, and a plurality of heating pipes are fixedly arranged at equal intervals from the top to the bottom in the gap. Vibration of a rotor of the vibration motor istransmitted to the interior of the box body, stirring is performed by using a stirring mechanism, so that the plastic silver powder paint in the box body is prevented from being solidified in a shorttime, at the same time, the temperature in the box body can be adjusted, and the solidification time of the plastic silver powder paint can be prolonged.

Owner:江苏新东周新材料有限公司

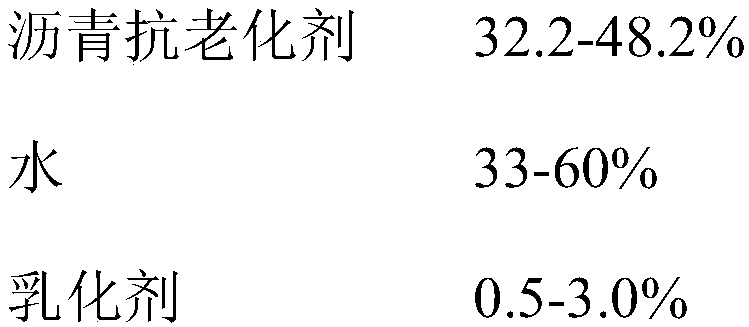

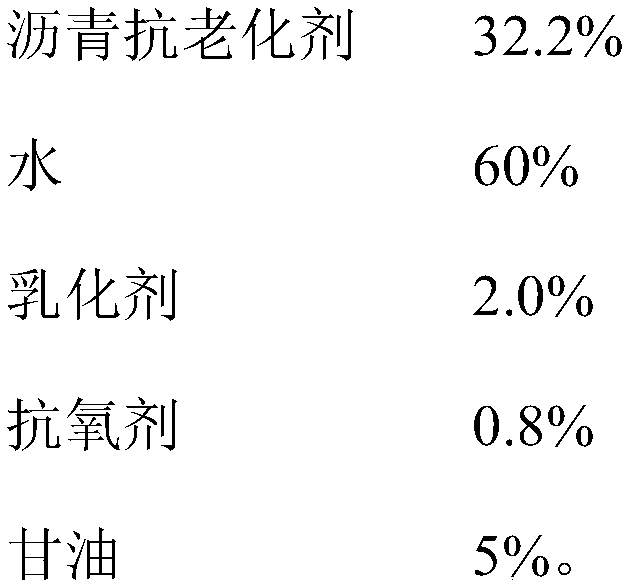

Asphalt pavement roller isolating agent as well as preparation method and test method thereof

The invention relates to an asphalt pavement roller isolating agent as well as a preparation method and a test method thereof. The asphalt pavement roller isolating agent comprises the following components in percentage by weight: 32.2-48.2% of an asphalt anti-aging agent, 33-60% of water, 0.5-3.0% of an emulsifier, 0.3-0.8% of an antioxidant and 5-15% of glycerin. The preparation method of the asphalt pavement roller isolating agent is used for preparing the asphalt pavement roller isolating agent, and comprises the following steps: S1, heating water, and mixing with the emulsifier, the antioxidant and glycerin according to a ratio so as to obtain emulsified liquid A for later use; S2, heating the asphalt anti-aging agent, conveying the emulsified liquid A and the heated asphalt anti-aging agent into a colloid mill emulsifying machine, fully shearing and blending until clustering is avoided or no flocculent mass exists so as to obtain a blend B; S3, pouring out the blend B, and cooling to obtain the asphalt pavement roller isolating agent, and storing or filling the prepared asphalt pavement roller isolating agent. The invention further provides a test method of the asphalt pavement roller isolating agent.

Owner:GUANGZHOU HONGJIN SYNTHETIC MATERIAL CO LTD

Water base ink set for ink-jet recording

ActiveUS20050235868A1No coagulationHigh densityMeasurement apparatus componentsDuplicating/marking methodsIonWater soluble

A water base ink set for ink-jet recording includes a black ink containing a negatively charged self-dispersing black pigment and a water-soluble polyvalent alcohol alkyl ether; and a yellow ink containing a water-soluble anionic yellow dye in which a number of counter ion or ions per one molecule is not more than 3, a surfactant based on amine represented by the following general formula (1), and a water-soluble polyvalent alcohol alkyl ether; R—N—(CH2CH2O)xH(CH2CH2O)yH (1) wherein R represents an alkyl group or an alkenyl group having a number of carbons of 8 to 18, and x+y is 5 to 15. Accordingly, the water ink set in which no bleeding or no coagulation of the pigment occur is provided.

Owner:BROTHER KOGYO KK

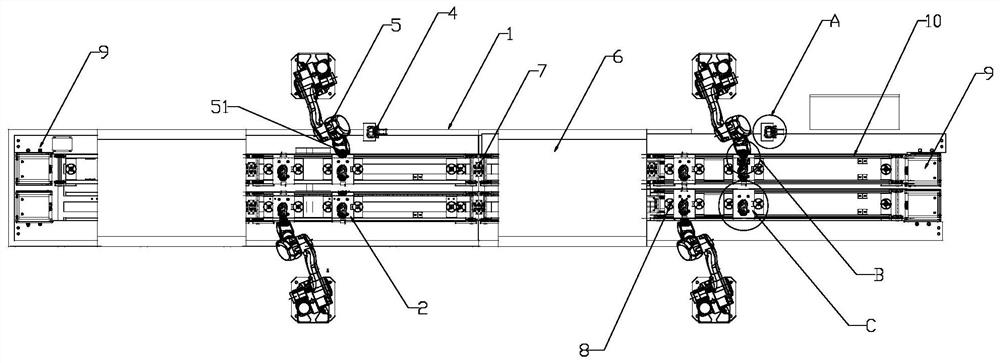

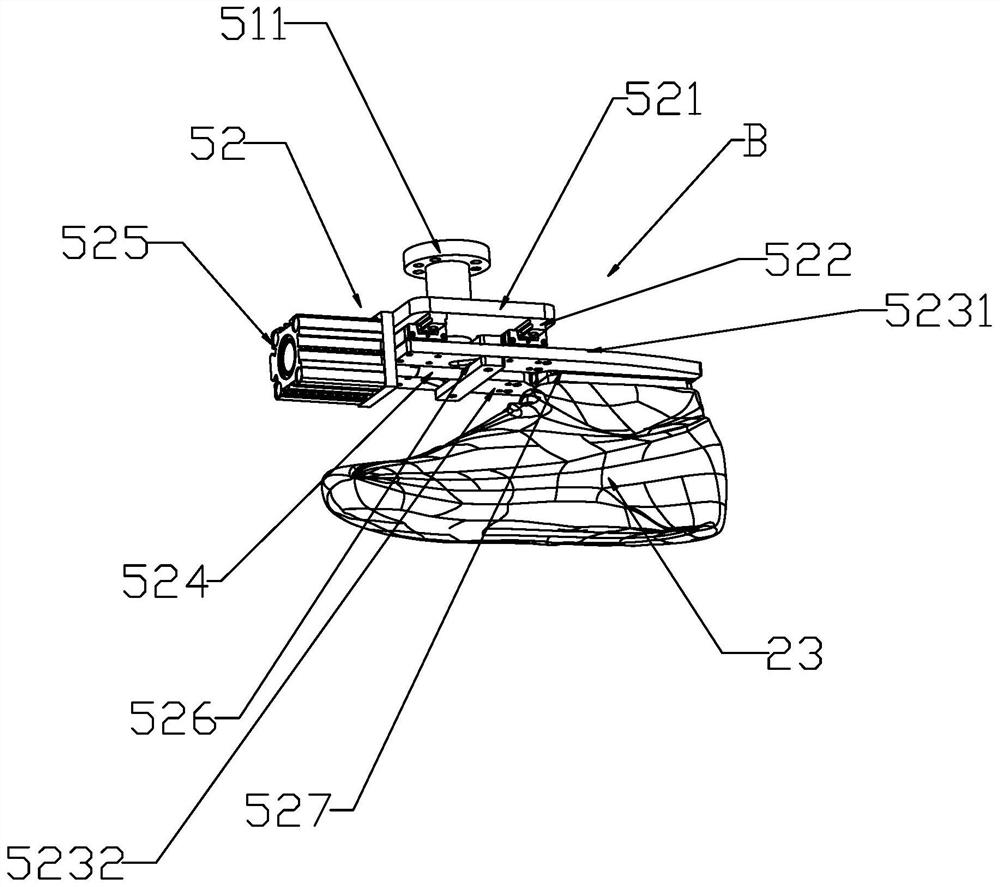

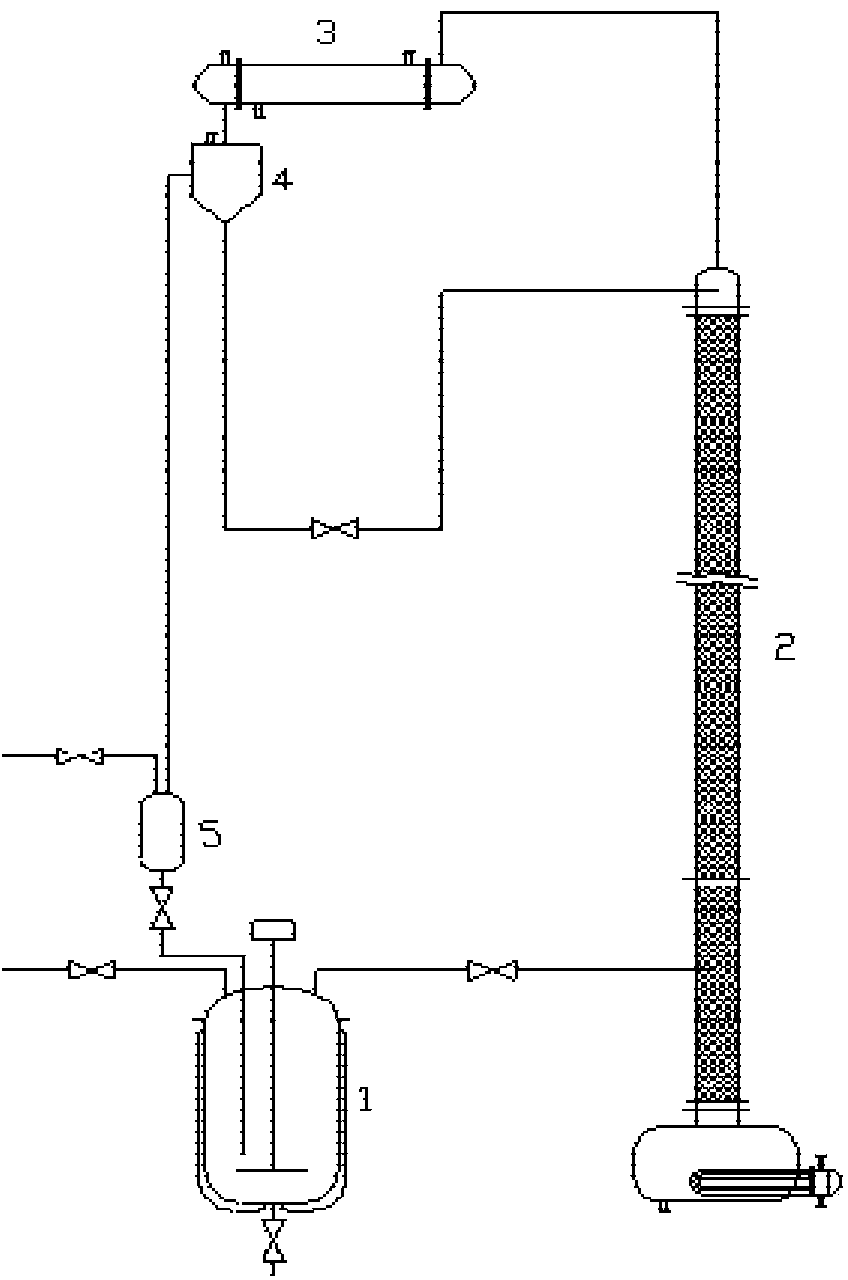

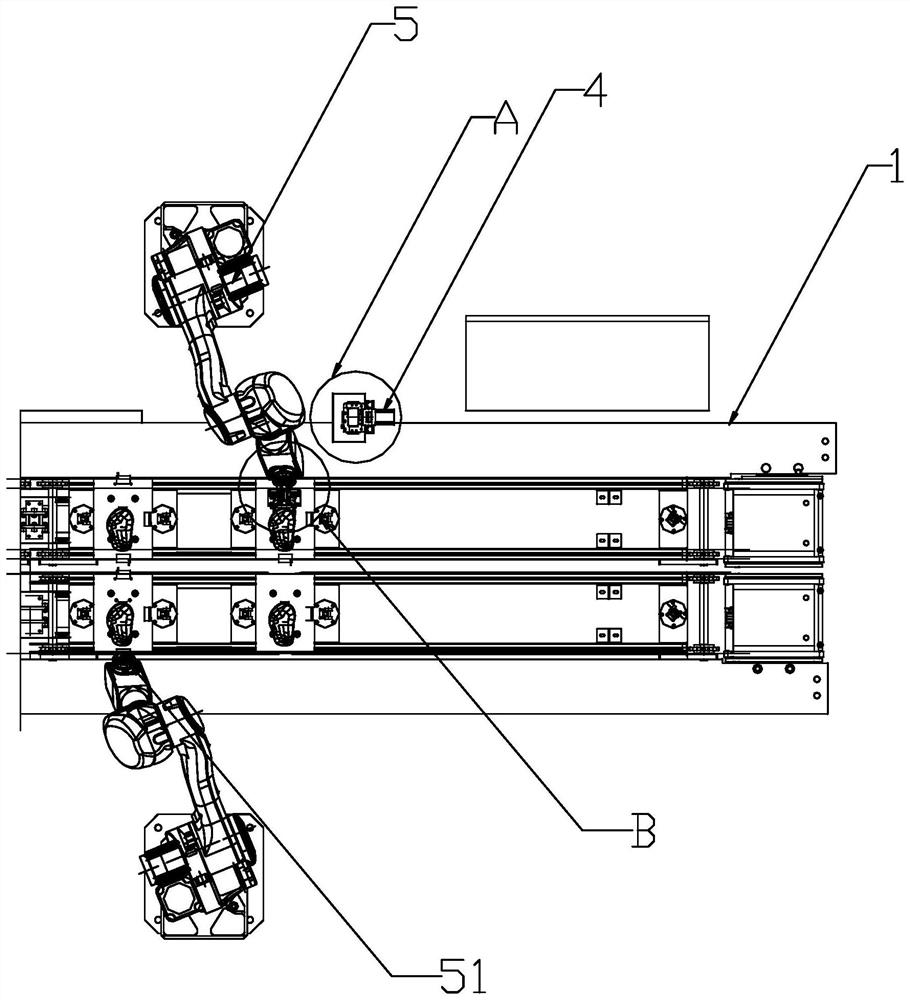

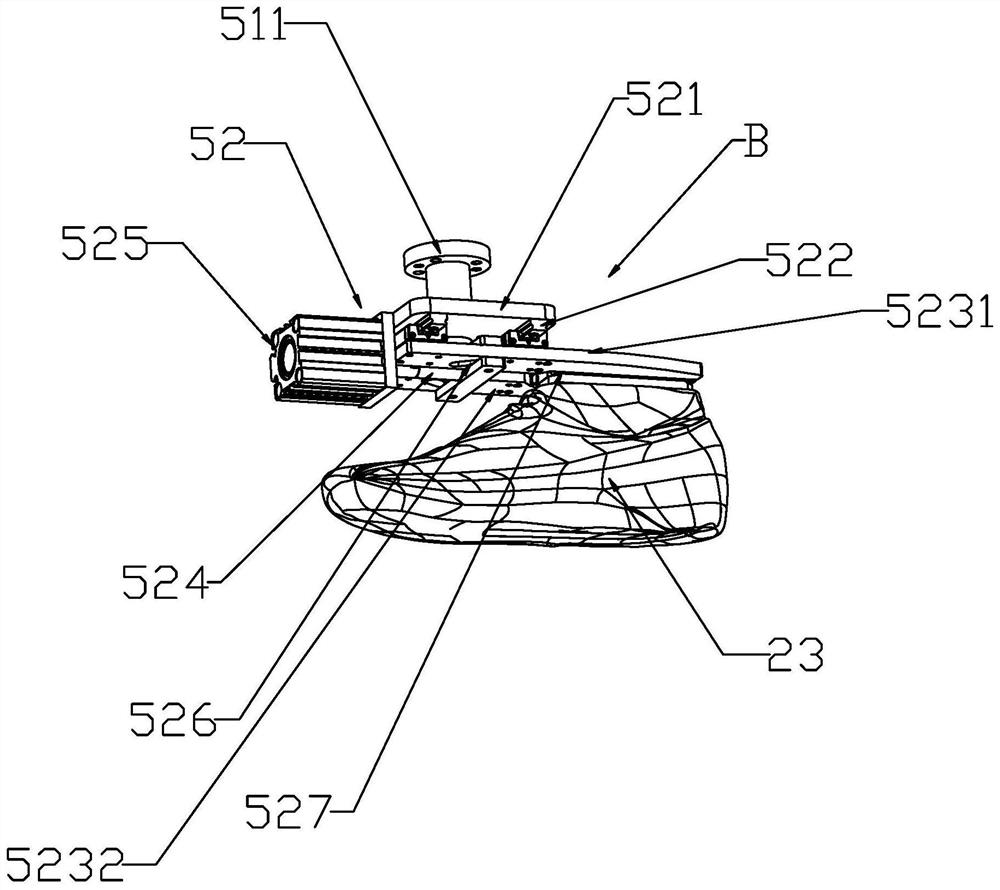

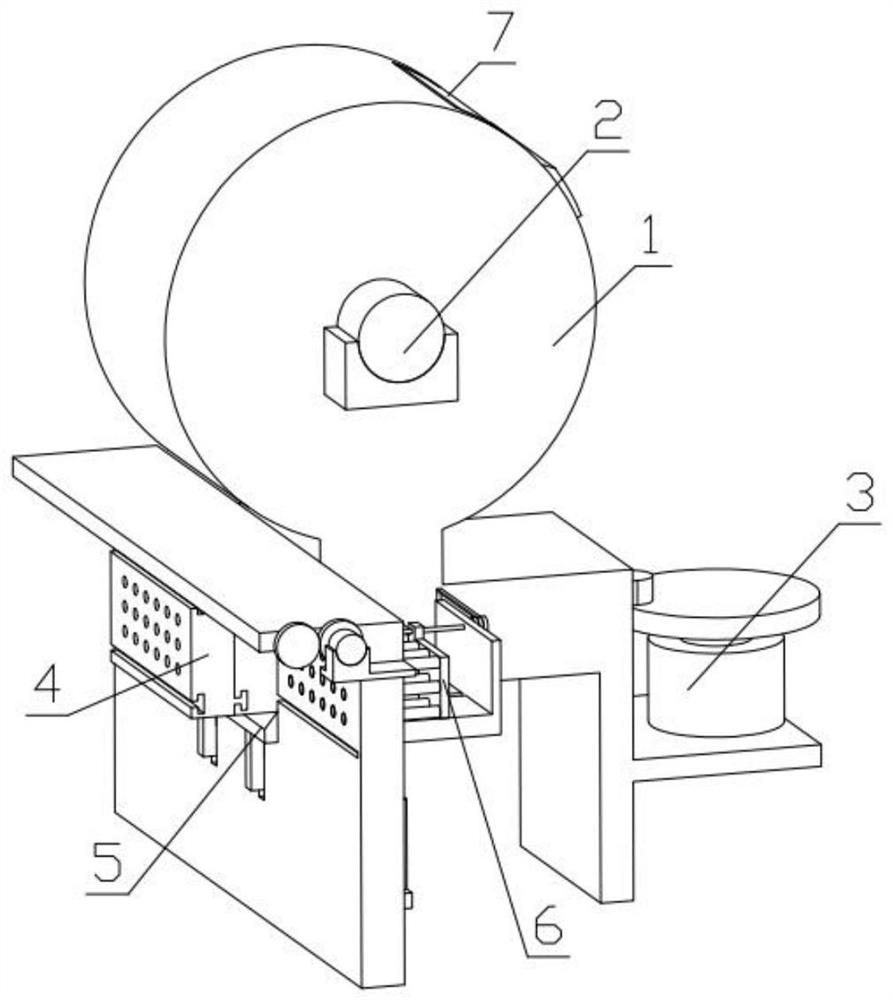

Full-automatic glue brushing line for shoemaking

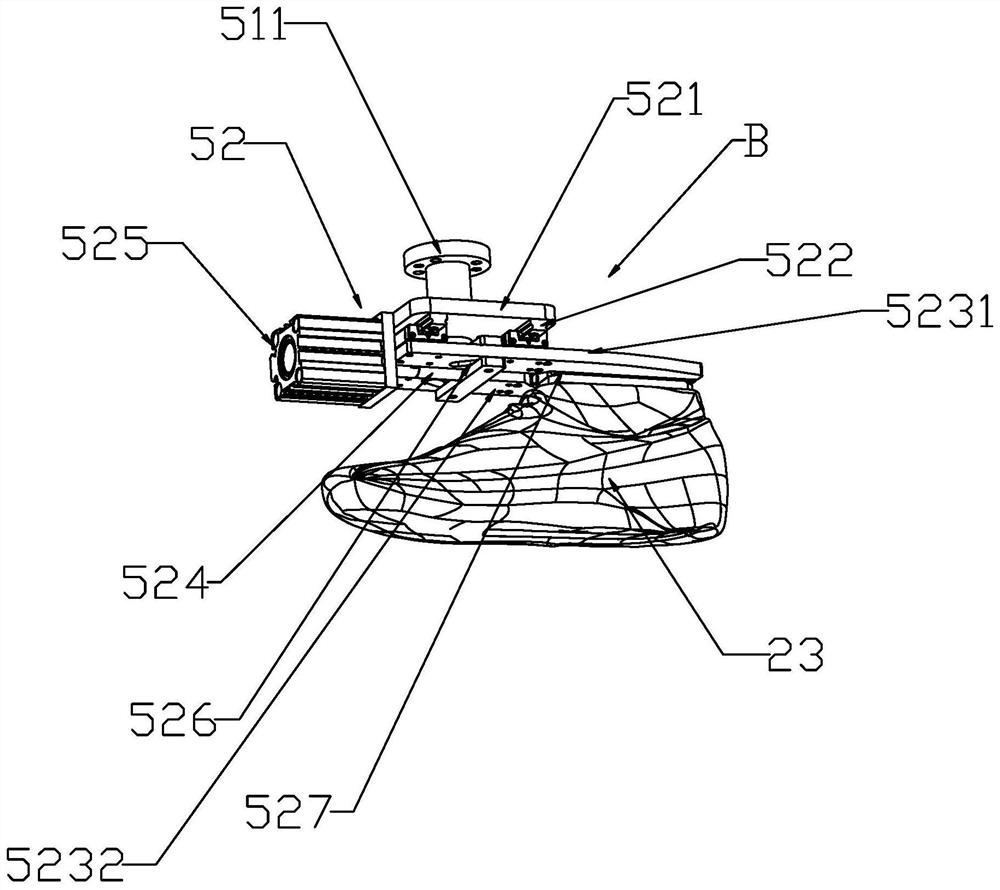

ActiveCN111921798ASimple structureEasy to replacePretreated surfacesCoatingsEngineeringAssembly line

The invention discloses a full-automatic glue brushing line for shoemaking. The full-automatic glue brushing line for shoemaking comprises a rack, a shoe tree positioning plate, a positioning mechanism, a robot assembly and a glue brushing system; the rack is provided with a conveying device used for conveying the shoe tree positioning plate; the shoe tree positioning plate is used for positioninga shoe tree; the positioning mechanism is used for positioning the shoe tree positioning plate, and the conveying device conveys the shoe tree positioning plate to the upper part of the positioning mechanism; the robot assembly comprises a robot body and a gripper mechanism, the gripper mechanism is fixed at the end part of the robot body, and the gripper mechanism is used for gripping the shoe tree on the shoe tree positioning plate; and the glue brushing system is used for gluing the shoe tree. According to the full-automatic glue brushing line for shoemaking, the positioning mechanism, therobot assembly, the glue brushing system and an oven are arranged on the rack, automatic shoe tree positioning, automatic gripping and automatic glue brushing are completed, an assembly line production mode combining automatic glue brushing and baking is formed, the traditional method of manual glue brushing is replaced, and automatic production is realized.

Owner:XR AUTOMATION EQUIPGZ CO LTD

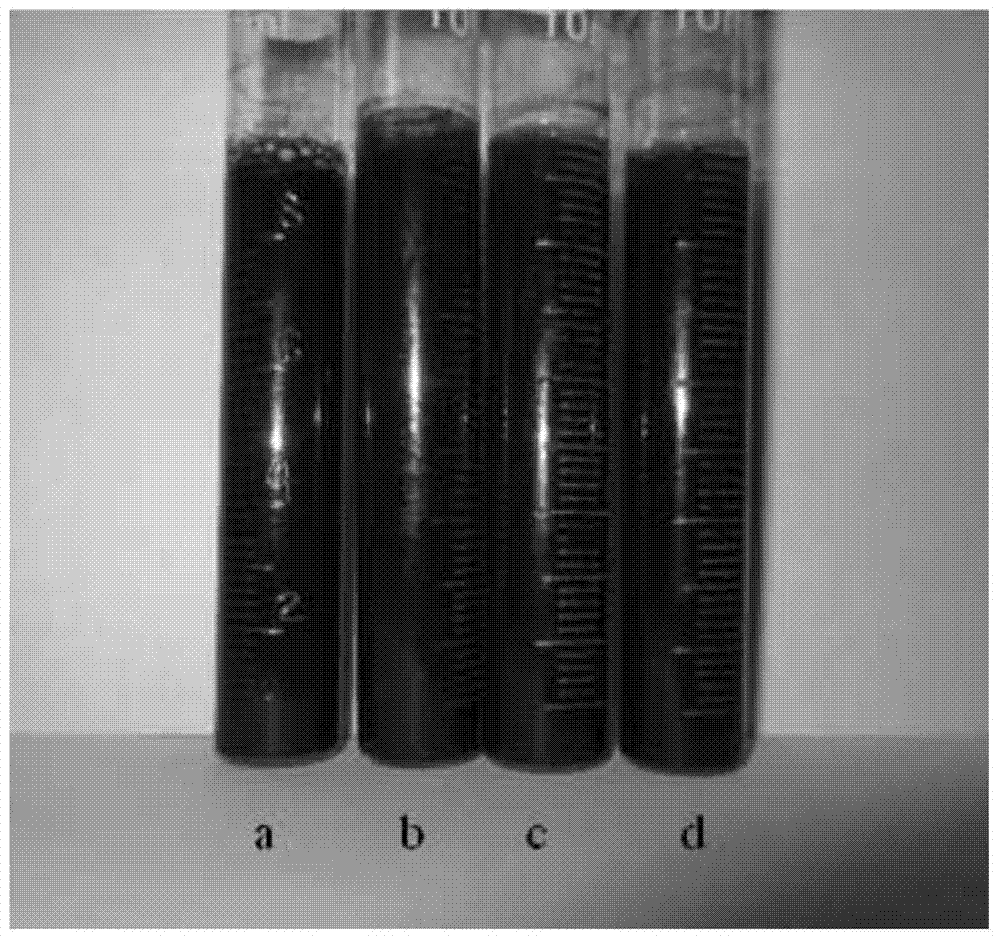

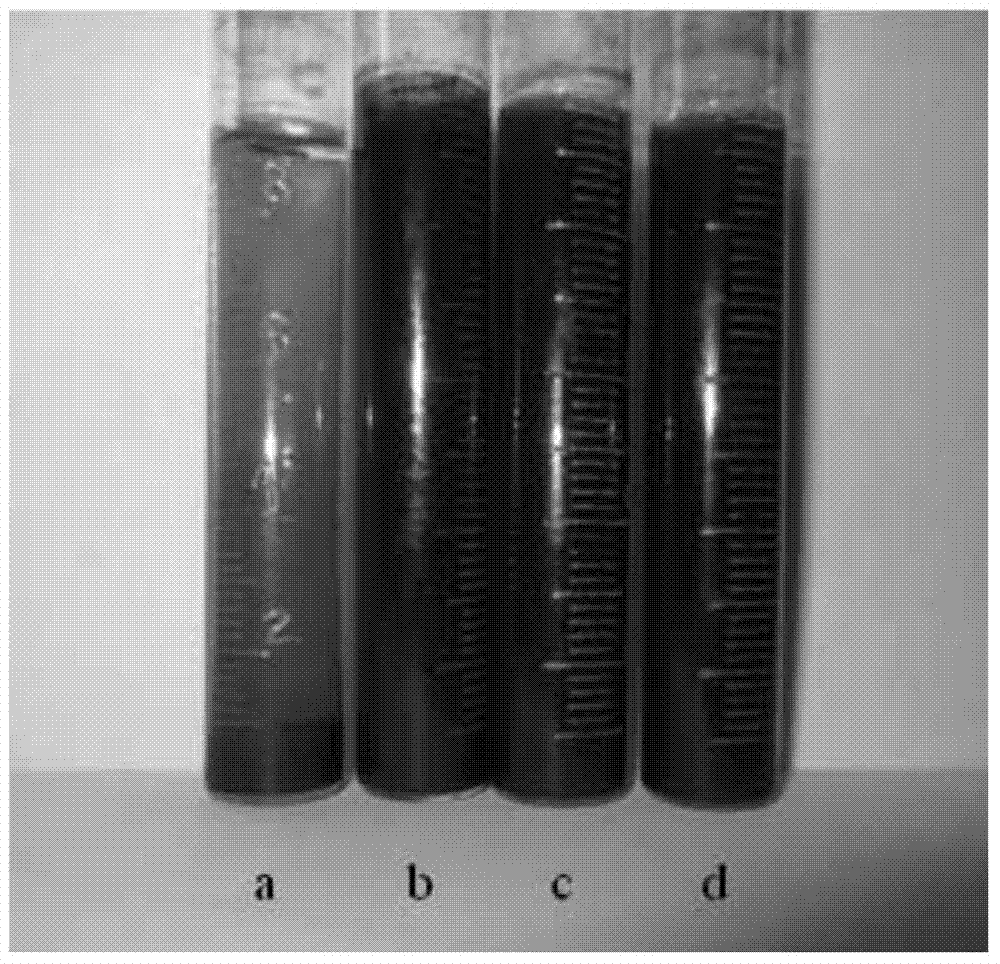

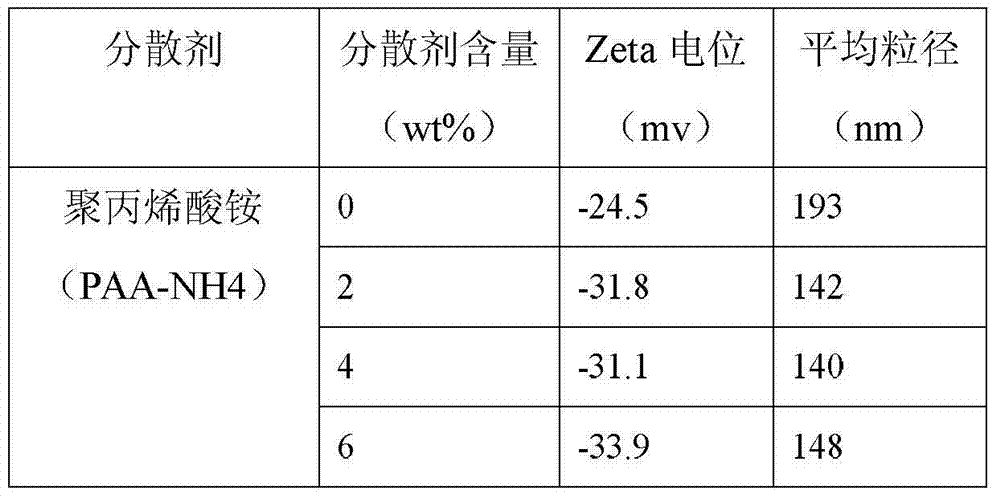

Method for dispersing nanometer ZrB2-SiC composite powder

The invention relates to a method for dispersing nanometer composite powder, and concretely relates to a method for dispersing nanometer ZrB2-SiC composite powder. A problem of easy agglomeration of present nanometer ZrB2-SiC composite powders in water is solved. The method comprises the following steps: 1, titrating deionized water by using an alkali to obtain a solvent with the pH value of 11; and 2, weighing ZrB2-SiC composite powder and a dispersant, adding the ZrB2-SiC composite powder and the dispersant into the solvent, and carrying out ultrasonic treatment for 14-16min to obtain a uniformly dispersed slurry in order to complete dispersion of the nanometer ZrB2-SiC composite powder. The method has the advantages of good dispersion effect, uniform dispersion, and no obvious coagulation within 24h, and can be used for dispersing the nanometer ZrB2-SiC composite powder.

Owner:HARBIN INST OF TECH

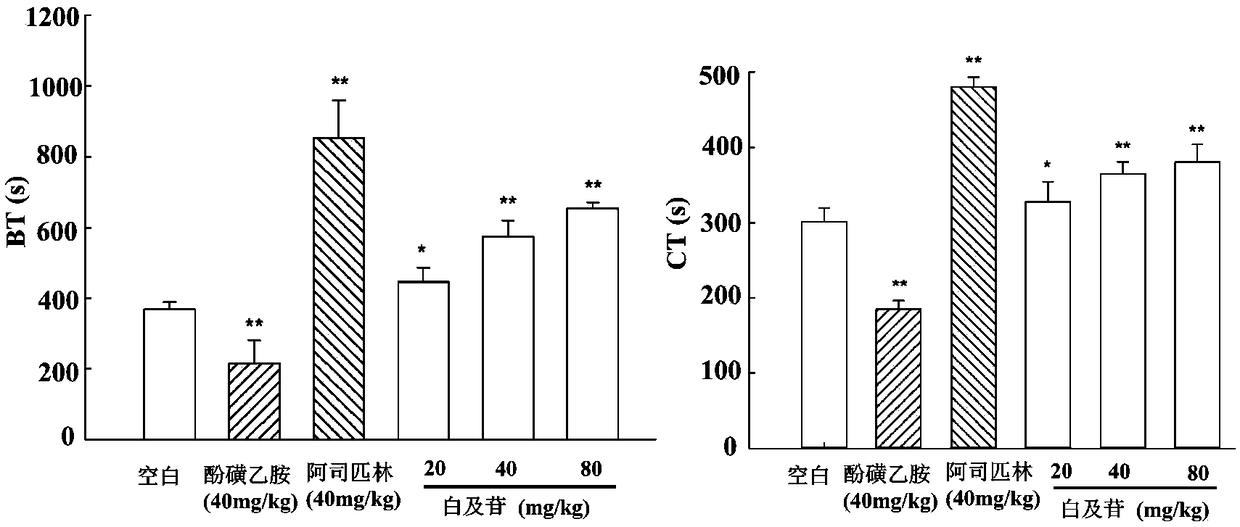

Method for preparing liquid fuel oil by catalyzing and cracking triglyceride

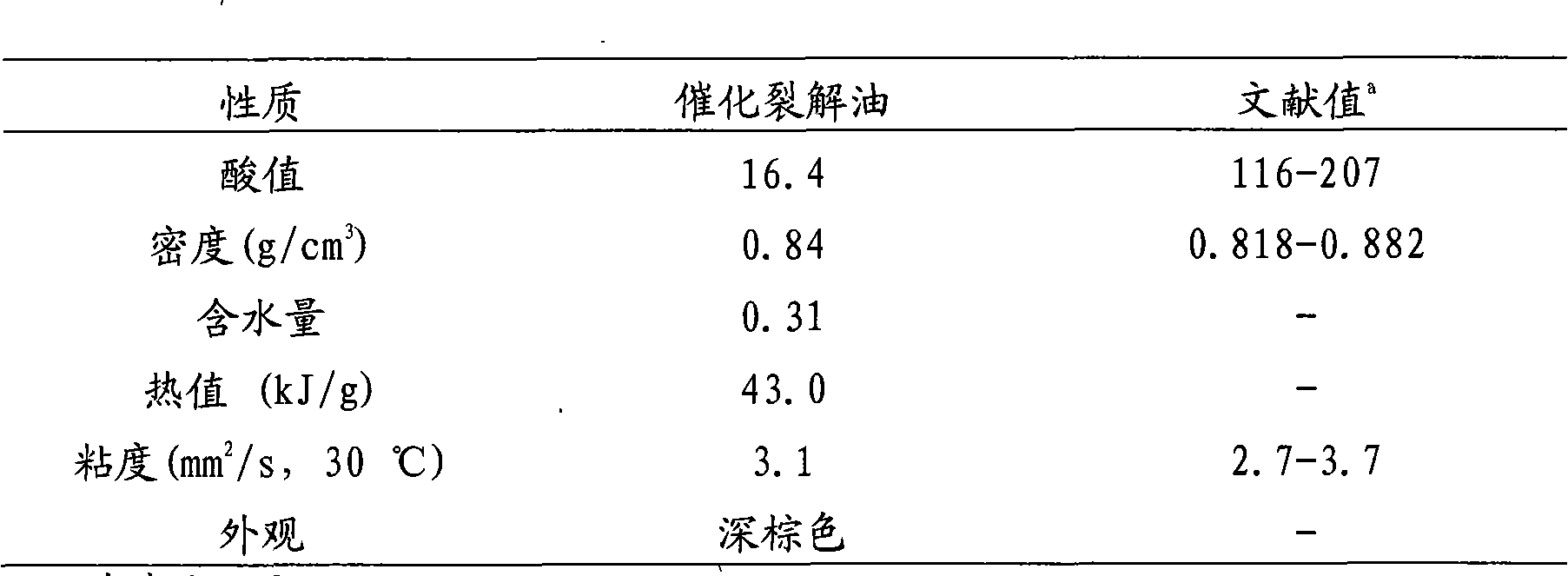

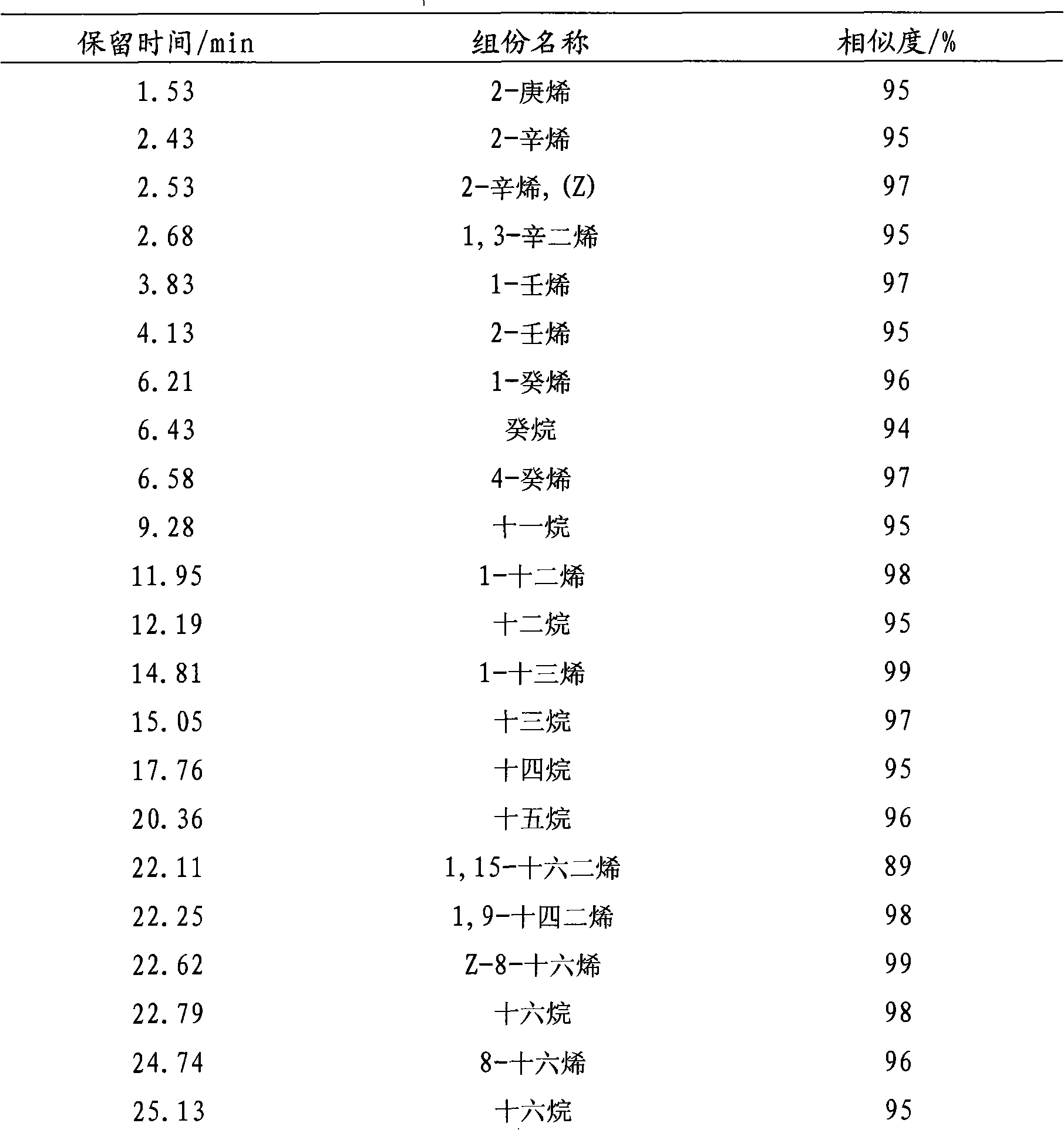

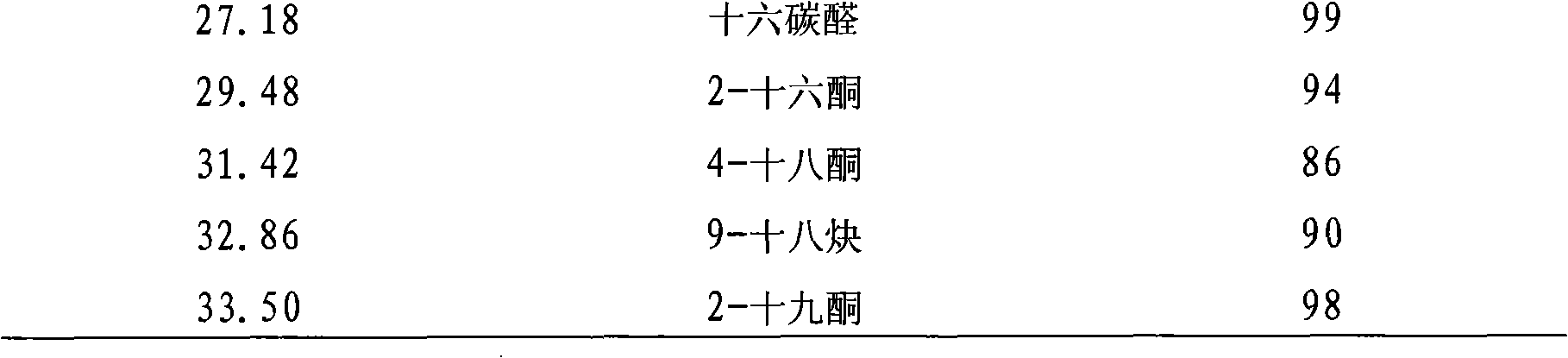

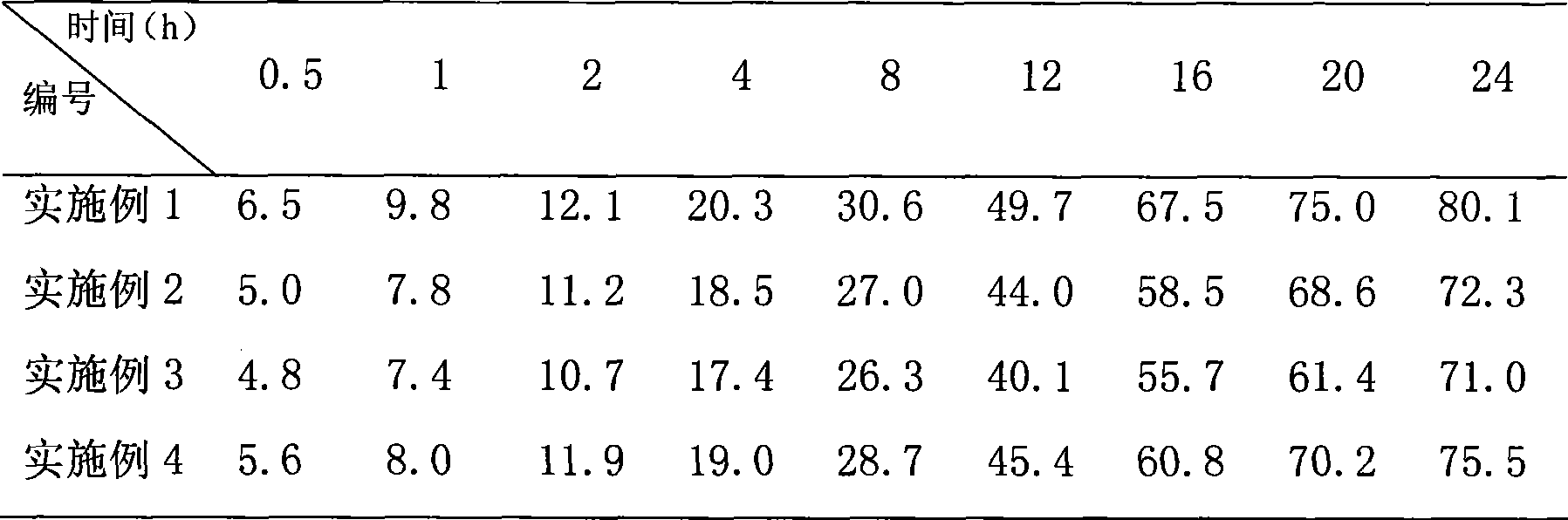

InactiveCN101531920BLess carboxyl contentLow acid valueCatalytic crackingLiquid hydrocarbon mixture productionGramAcid value

The invention discloses a method for preparing liquid fuel oil by catalyzing and cracking triglyceride, which comprises: a first step, according to a proportion of the triglyceride to a catalyst by mass being 100:1-10, weighing the triglyceride and the catalyst, and adding 5 to 30 percent of the triglyceride and the catalyst into a reaction kettle simultaneously; and a second step, heating the reaction kettle to between 350 and 500 DEG C, dropwise adding the rest 70 to 95 percent of the triglyceride into the reaction kettle, and condensing the generated vapor to obtain dark brown liquid, wherein the acid value is 16.4 mg KOH / g, the density is 0.84 g / cm3, the water content is 0.31 percent, the thermal value is 43.0 kilojoules per gram, and the viscosity is 3.1 mm2 / s.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

2-methoxyestradiol lipidosome freeze-dried injection and preparation method thereof

InactiveCN101411690BHigh encapsulation efficiencyStable drug loadingOrganic active ingredientsPowder deliveryCholesterolActive agent

The invention relates to 2-methoxyl estradiol lipidosome freeze-dried powder injection and a preparation method thereof. The invention can effectively solve the problems of poor water solubility of 2-methoxyl estradiol, short half-life and low oral administration bioavailability, and adopts the technical proposal that the 2-methoxyl estradiol lipidosome freeze-dried powder injection comprises the following raw materials in weight portion: 1 portion of the 2-methoxyl estradiol, 3 to 100 portions of phospholipid, 1 to 30 portions of cholesterol, surfactant and freeze-dried preservative, wherein according to the weight ratio of the phospholipid, 0.1 to 10 portions of the freeze-dried preservative is added into 1 portion of the phospholipid, and the adding quantity of the surfactant is 0.2 to 3 percent of the total amount of the freeze-dried powder injection. The freeze-dried powder injection using the components as raw materials can be realized by three preparation methods, namely, a film dispersion method, a reverse phase evaporation method and an injection method, has high medicament content, is suitable for intravenous administration, has the advantages of slow release capability, in vivo targeting property and the like, can overcome the defects of oral preparations, is safe and reliable, and has large economic benefit and social benefit.

Owner:ZHENGZHOU UNIV

Filling paint transportation device

InactiveCN107352128AEasy loading and unloadingEasy to passPackaging under vacuum/special atmosphereShock-sensitive articlesEngineeringPallet fork

The invention discloses a filling paint transportation device which comprises a loading and unloading frame and a paint bucket, wherein the paint bucket is arranged in the loading and unloading frame; the loading and unloading frame comprises a square base and a bucket body protection frame arranged on the base. A forklift fixing seat is arranged at the bottom of the base, the inner part of the forklift fixing seat is hollow, and socket parts matched with pallet forks of a forklift are respectively arranged at the periphery of the forklift fixing seat. The bucket body protection frame comprises four rectangular pillars which are vertical to the base and extend upwards, and the four rectangular pillars are respectively arranged at the four corners of the base. The bottom of each rectangular pillar is screwed on the base through a screw rod structure. The filling paint transportation device has the advantages of simple of integral structure and convenience in assembly and disassembly and is beneficial to loading, unloading and transporting paint. The forklift fixing seat is arranged at the bottom of a bucket body, so that the pallet forks of the forklift can be inserted into the socket parts of the base, and the paint bucket and the whole loading and unloading frame are conveniently loaded and unloaded together. The manpower is reduced, and the loading and unloading and carrying efficiency is improved.

Owner:宜兴市华瑞铸造材料有限公司

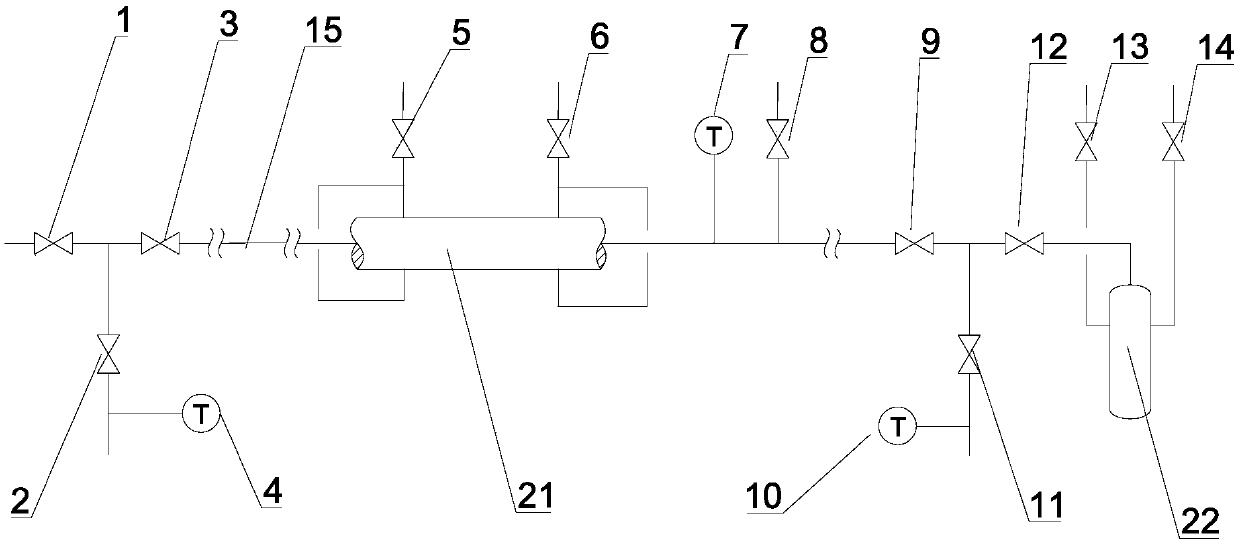

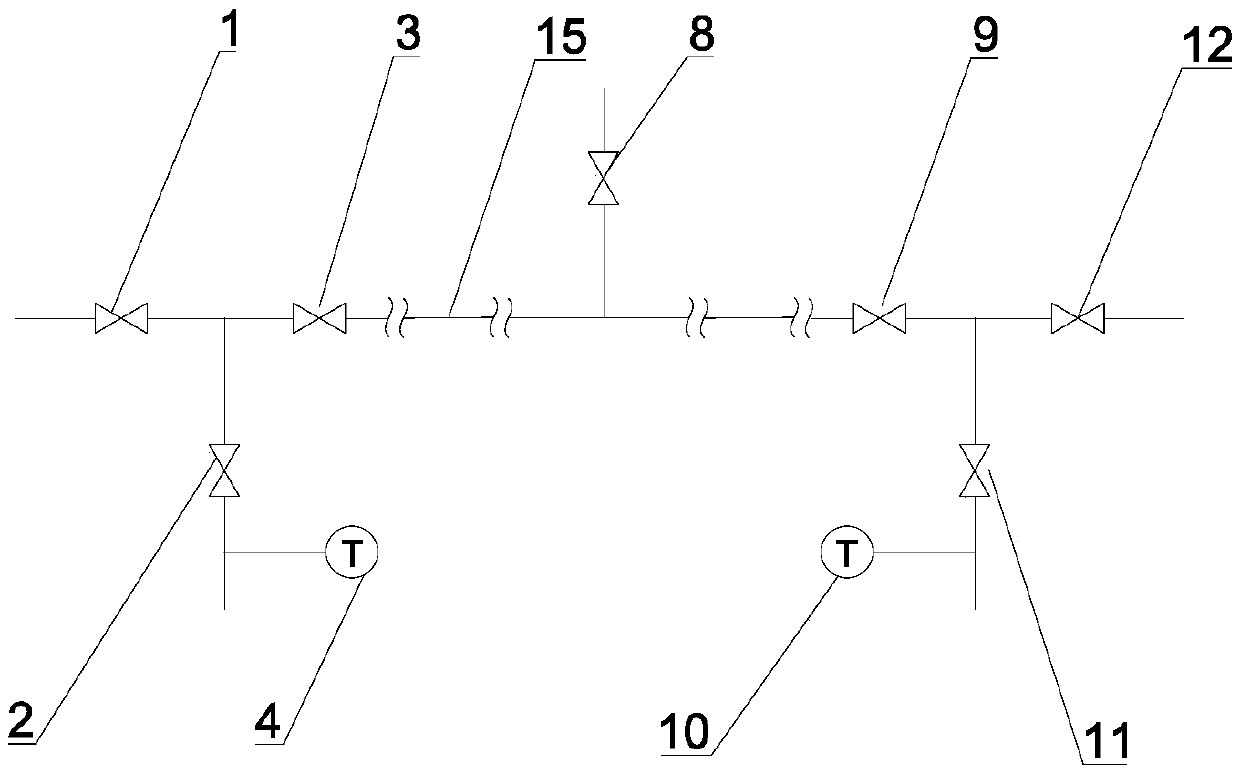

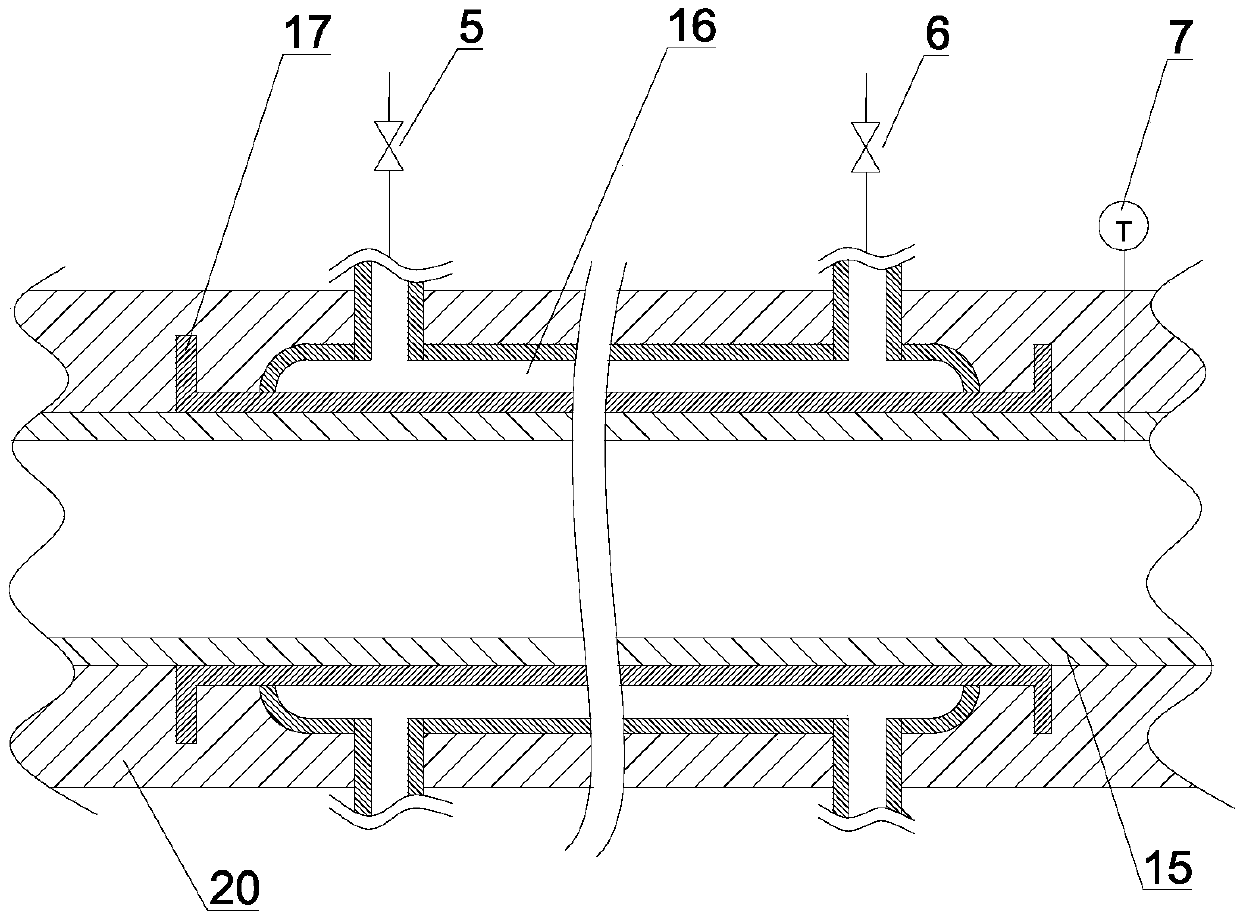

Saturated fatty acid sterile pipeline transportation device

ActiveCN111350942AEasy to operateReliable sterilization effectPipeline systemsProcess engineeringElectrical and Electronics engineering

The invention relates to a saturated fatty acid sterile pipeline transportation device which solves the technical problems that it is hard to transform and mount an existing transportation pipeline, it is needed to stop pipeline transportation during maintenance, a pipeline heating function and a sterilizing function at the connection of the transportation pipeline and a reaction kettle are not available, the heating efficiency is low and the like. The saturated fatty acid sterile pipeline transportation device is provided with the transportation pipeline, wherein a supplementary port heater is arranged at the tail end of the transportation pipeline, the supplementary port heater is provided with a sleeve, a water return valve of the supplementary port heater and a water inlet valve of thesupplementary port heater, the sleeve separately communicates to the water return valve of the supplementary port heater and the water inlet valve of the supplementary port heater, separately, and the upstream end of the sleeve communicates to the transportation pipeline. The transportation pipeline is further provided with a pipeline heater and a sterilizing device. The invention can be widely applied to the saturated fatty acid sterile pipeline transportation device.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

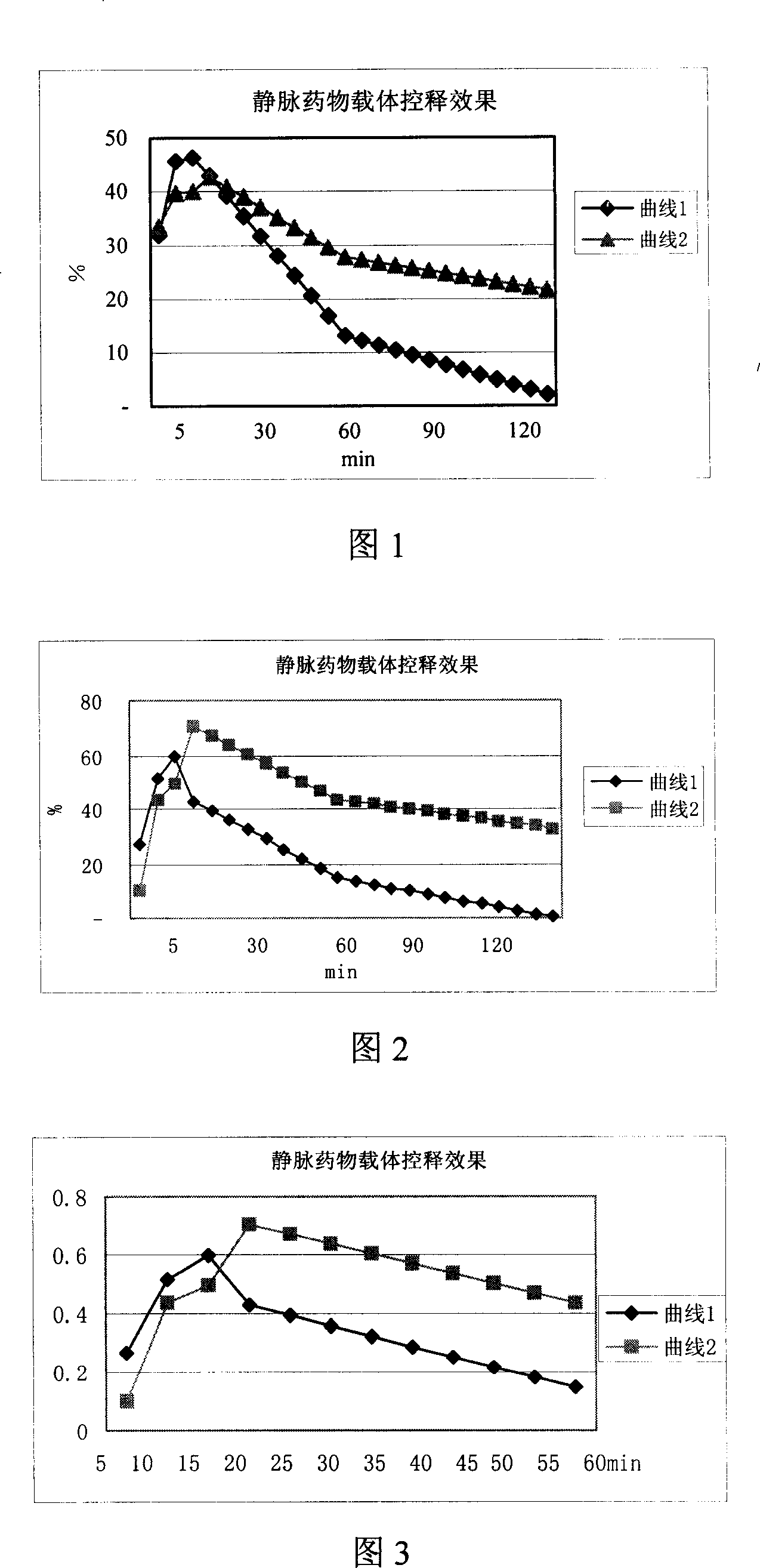

Intravenous medicine carrier material and its prepn process

InactiveCN101088564AWith controlled drug releaseNo hemolysisMacromolecular non-active ingredientsCross-linkDrug carrier

The present invention relates to intravenous medicine carrier material and its preparation process. The intravenous medicine carrier material is medicine release controlling material to avoid the fast removing of medicine from blood, and has itself no pharmacological effect. It is prepared with gelatin as base material, and through degrading gelatin in enzyme solution, cross-linking with cross-linking agent, purifying and drying. It has intravenous medicine release controlling effect, no toxicity, and other advantages.

Owner:李潮

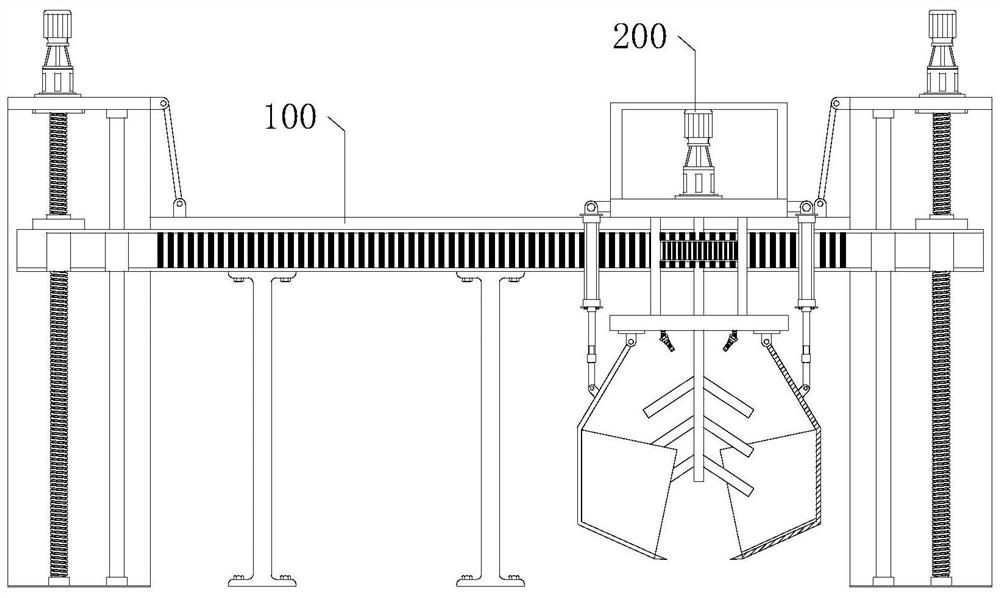

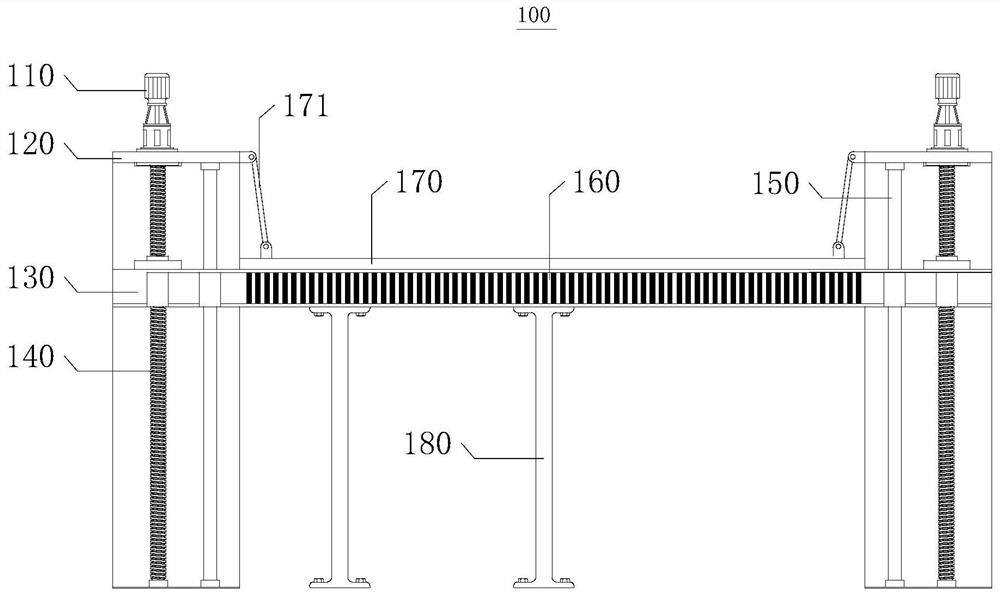

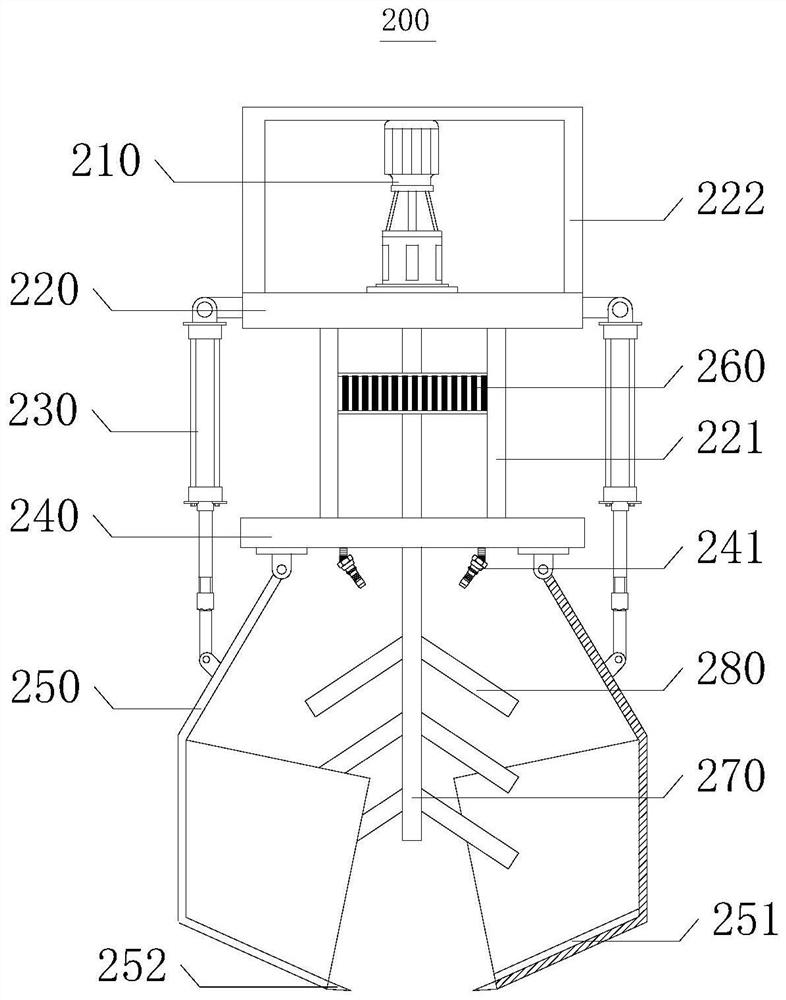

Long-distance building concrete taking device

InactiveCN112707161AAchieve lateral transportPrevent solidificationHollow article cleaningSupporting framesGear wheelArchitectural engineering

The invention provides a long-distance building concrete taking device, and belongs to the technical field of building construction machineries. The long-distance building concrete taking device comprises a lifting mechanism and a taking conveying mechanism, a first mounting plate is slidably connected with the side wall of a mounting frame, a screw rod penetrates through the first mounting plate in a threaded mode and is in key connection with an output shaft of a first motor, a air cylinder is hinged to the side face of a second mounting plate, a telescopic rod of the air cylinder is hinged to the outer wall of a rotating bucket, a grab bucket is hinged to the bottom of a third mounting plate, a gear is meshed with a rack, and a stirring rod is fixedly installed on a rotating shaft. According to the long-distance building concrete taking device, through automatic conveying and continuous stirring of concrete in the conveying process, it is guaranteed that the solidification phenomenon does not occur even if the concrete is conveyed for a long distance, meanwhile, a large amount of labor force is reduced, and the construction efficiency is improved.

Owner:谢远纪

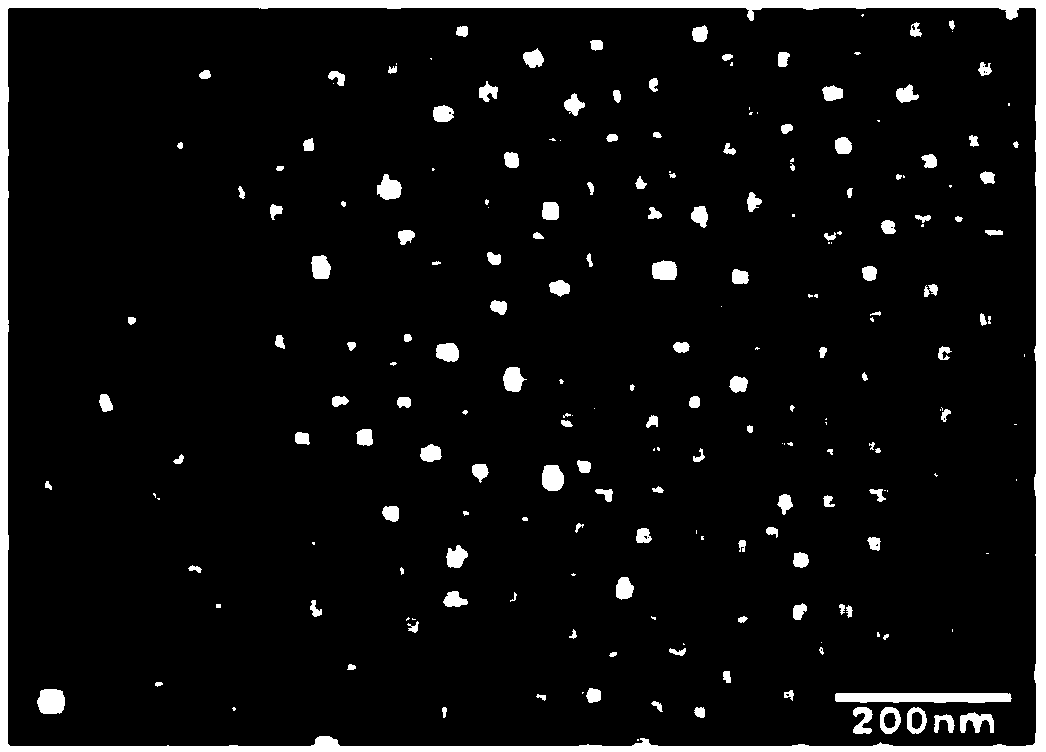

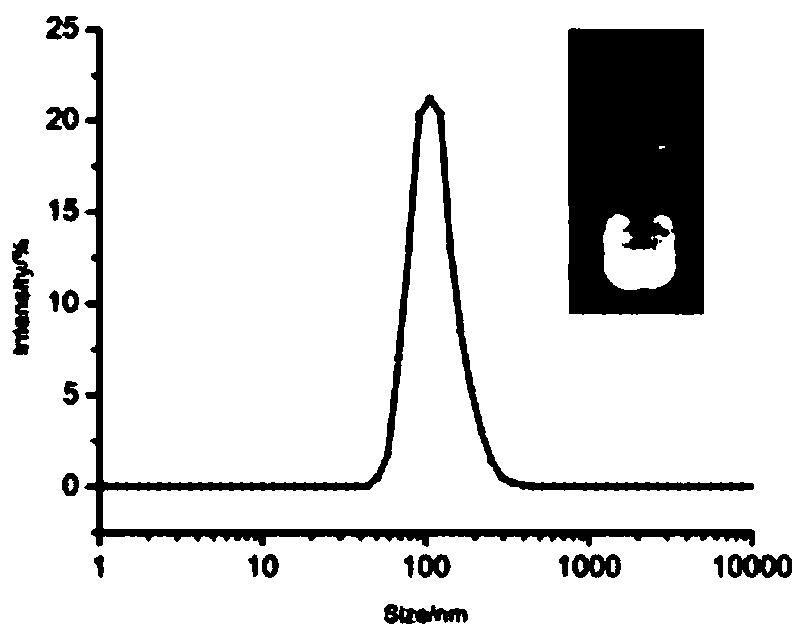

Nanoparticle with effect-enhancing and toxicity-reducing effect on synergistic and attenuating effects on annonaceous acetogenins drugs, and preparation method and application thereof

ActiveCN109223769AImprove the anti-tumor effect in vivoBreak through narrow bottleneck problemsOrganic active ingredientsPharmaceutical non-active ingredientsAdjuvantNanoparticle

The invention provides a nanoparticle with effect-enhancing and toxicity-reducing effect on synergistic and attenuating effects on annonaceous acetogenins drugs, and belongs to the field of pharmaceutical preparations. The present invention uses poloxamer P188, Poloxamer P407, Poloxamer P124, one or more of poloxamer P237 and poloxamer P338 are adjuvants, By limiting the kinds and dosage of excipients, the problems of insoluble and difficult administration of annonolactone are solved, and more importantly, the anti-tumor effect in vivo is improved, at the same time, it has better safety, breaks through the bottleneck problem of narrow window of treatment of annonolactone, and provides a feasible solution for clinical application.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

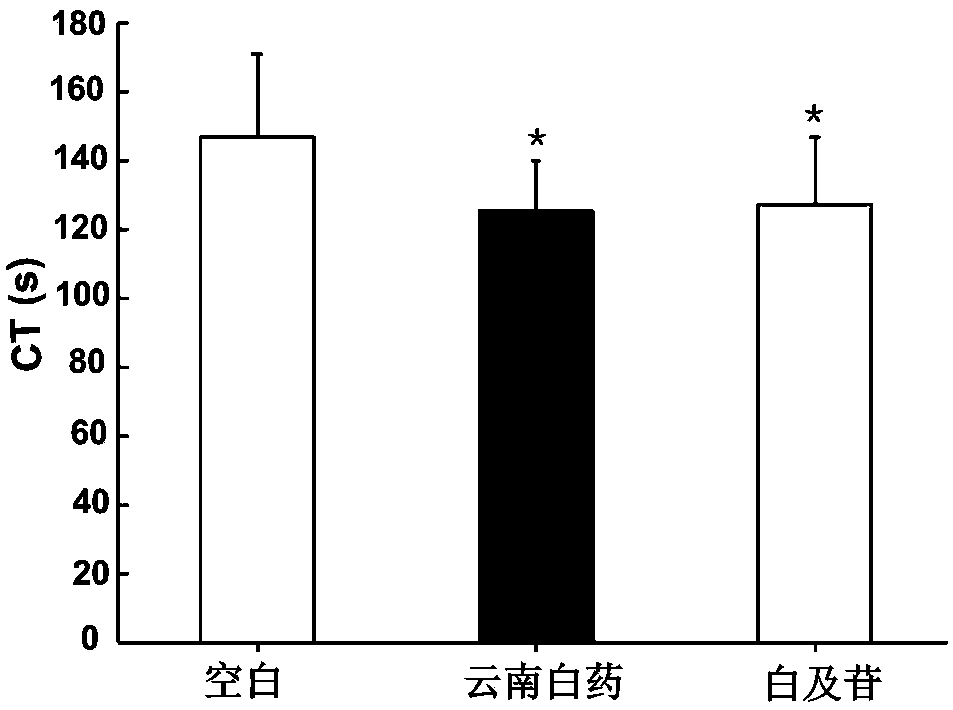

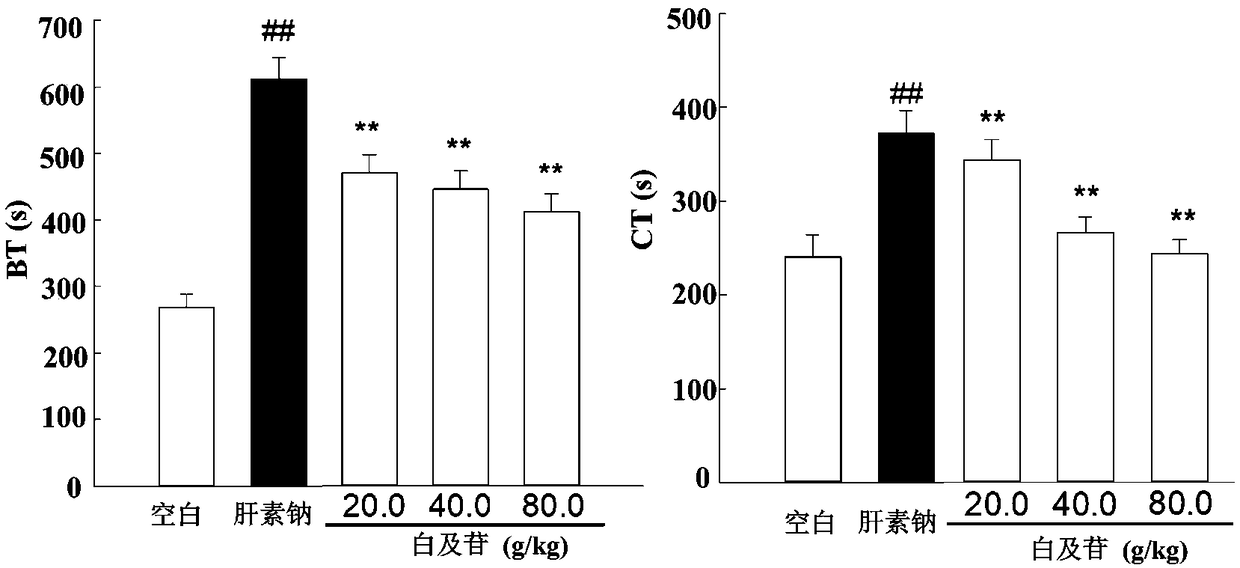

Militarine and application thereof in preparation of hemostasis medicines

InactiveCN108606971ADoes not cause allergiesGood hemostasisOrganic active ingredientsPill deliveryMedicineAllergy

The invention discloses militarine and an application thereof in preparation of hemostasis medicines, wherein the militarine has significant hemostatic effect under bleeding status, and can achieve the equivalent hemostatic effect as Yunnan Baiyao just at the usage amount of 10% of the Yunnan Baiyao. What is more, under normal status, the militarine does not show the hemostatic effect but shows certain blood activation effect, which has important significance on possibility of improper usage of hemostasis medicines. The militarine belongs to natural active compounds and will not cause adversereaction, such as allergy, to human body, so that the militarine is safe and toxic-free, can be produced industrially and has great application prospect.

Owner:GUIZHOU MEDICAL UNIV

6S high oleic acid peanut oil making process

InactiveCN109749845AImprove qualityHigh in oleic acidFatty-oils/fats refiningFatty-oils/fats productionHazardous substanceFiltration

The invention discloses a 6S high oleic acid peanut oil making process which comprises the following steps: S1) baking and frying peanuts to enhance fragrance; S2) carrying out physical squeezing; S3)carrying out low-pressure filtration; S4) carrying out mold removal and sterilization; S5) carrying out fresh keeping and oxidation prevention; S6) freezing, and refining. The process is particularlyapplied to high oleic acid peanuts to make high oleic acid peanut oil, advantages and high quality of the high oleic acid peanut oil can be well highlighted, and chemical pollution can be avoided inthe making process because of physical squeezing, all impurities can be eliminated through low-pressure filtration, harmful substances such as aflatoxin can be degraded, oxidation prevention in production, storage and transportation can be enhanced, through freezing and physical refining, high oleic acid peanut oil which is clear and transparent and thick in peanut fragrance, can be eaten with cold vegetables with sauces and has high-end quality can be made, and the high oleic acid peanut oil is high in high oleic acid content, high in quality, free of floccules at 0-10 DEG C, is free of solidification phenomenon and has great practical significances and commercial values.

Owner:贺群岭

Biodiesel fuel and preparation method thereof

InactiveCN104312733AImprove water resistanceReduce usage requirementsFatty acid esterificationBiofuelsBiodieselEconomic benefits

The invention relates to the field of petrochemical complex and particularly relates to a biodiesel fuel and a preparation method thereof. The preparation method of the biodiesel fuel comprises the following steps: step 1, using carbon dioxide to replace air inside an esterification reaction kettle, putting monomer acid into the esterification reaction kettle heated by conduction oil, and meanwhile adding high-temperature resisting big-hole phenethylene highly acidic cation exchange resin; step 2, heating a material inside the esterification reaction kettle to reach a temperature of 130 to 160 DEG C within 30 minutes, and continuously adding DMM; step 3, stopping DMM adding when the acid value of the material is smaller than 1mg KOH / g, and emptying when the temperature of the material is reduced to be lower than 80 DEG C, so as to obtain a biodiesel semi-finished product; step 4, adding a composite catalyst and stirring sufficiently when the biodiesel semi-finished product is cooled to be a temperature of 30 DEG C, namely a finished product is obtained. The biodiesel prepared through the method provided by the invention is excellent in water resistance, insoluble in water, and excellent in starting performance in winter, can be matched and mixed with petroleum diesel according to any proportion and has excellent economic benefits.

Owner:FUJIAN ZHONGDE ENERGY

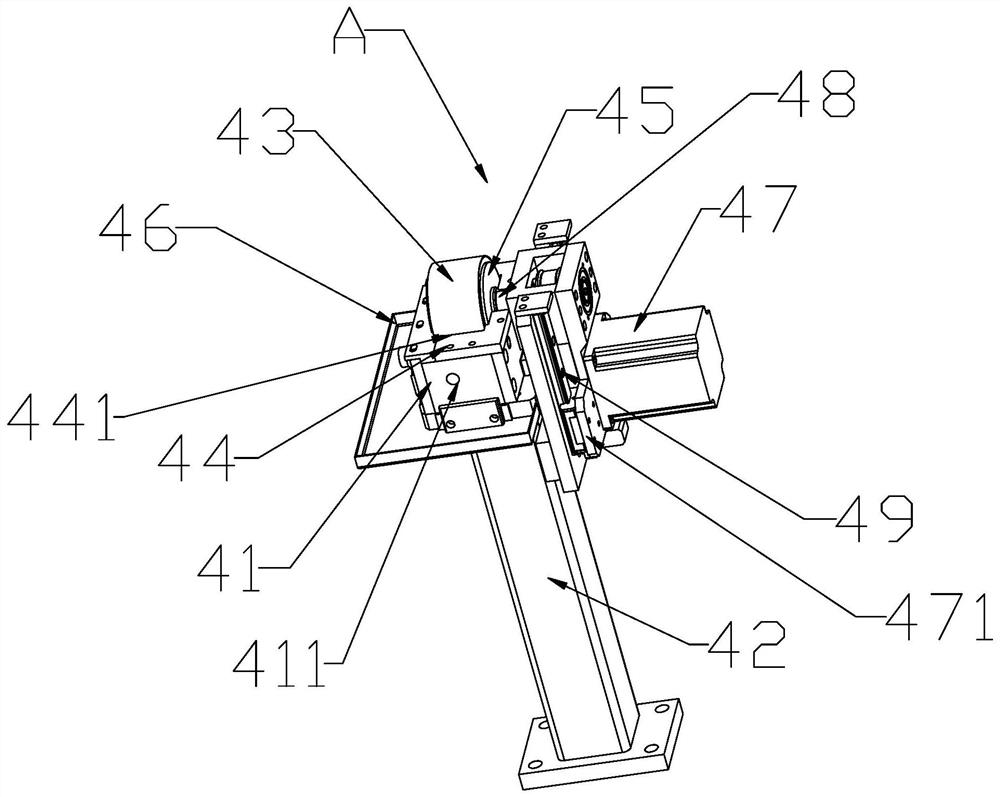

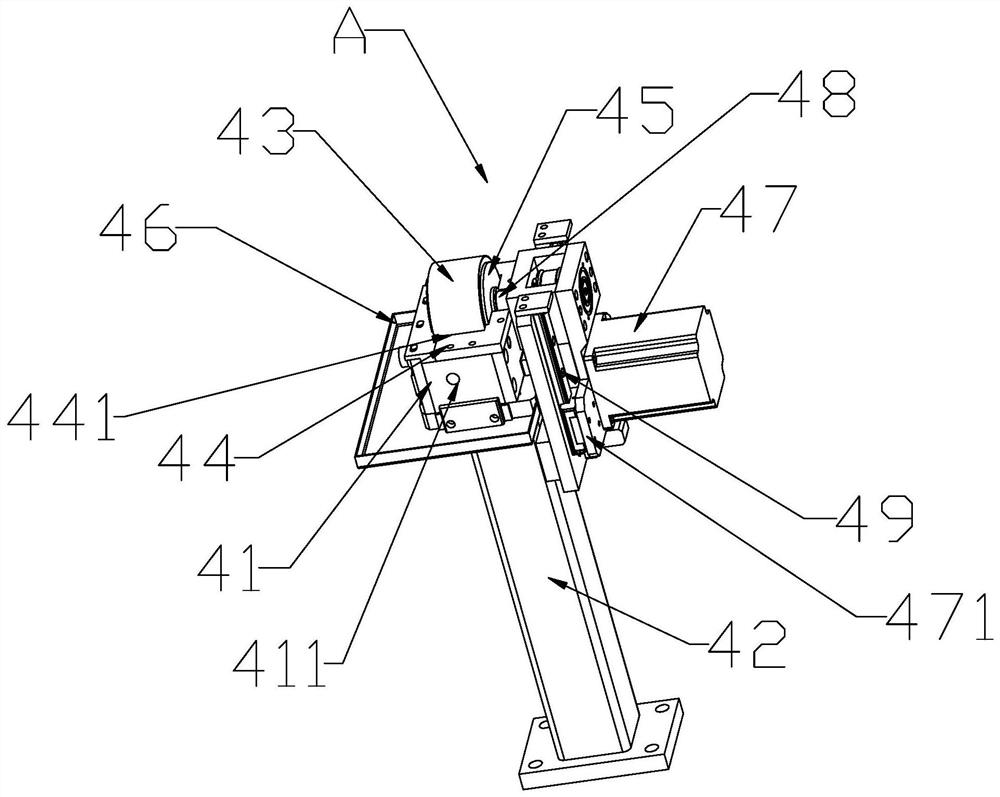

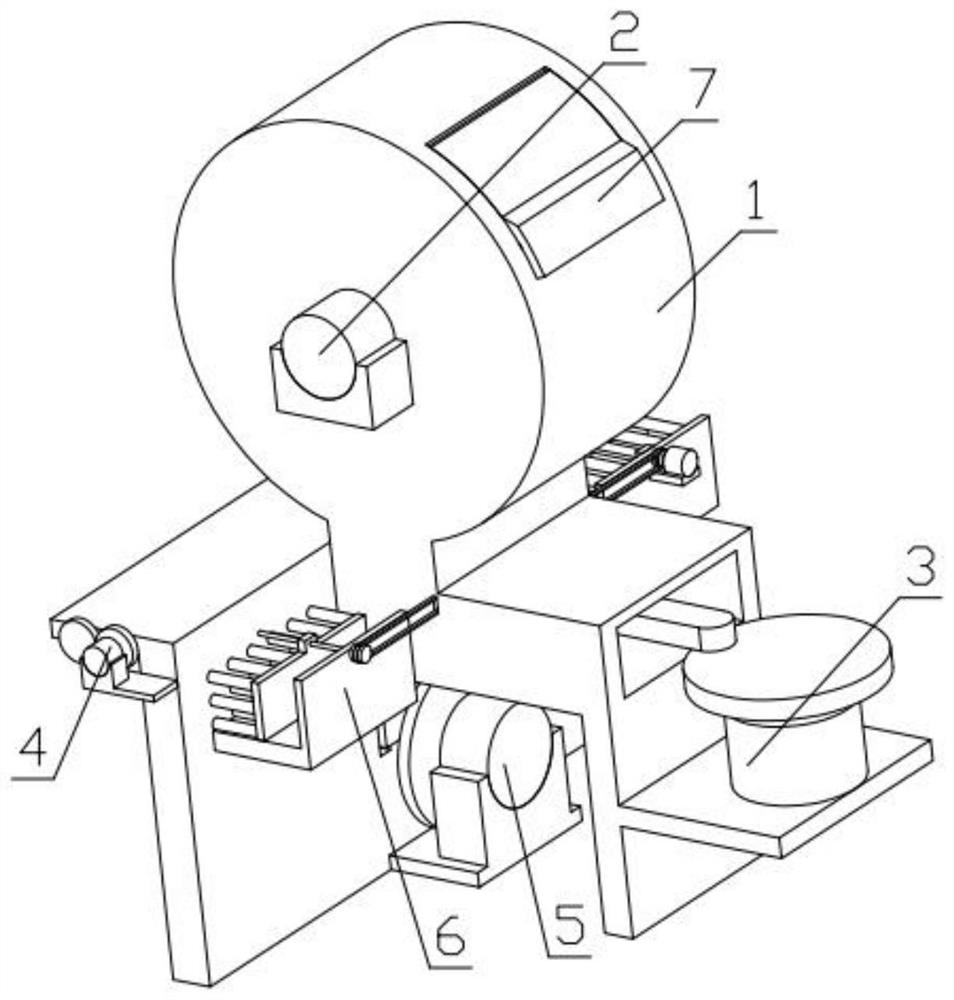

Glue brushing device for shoemaking

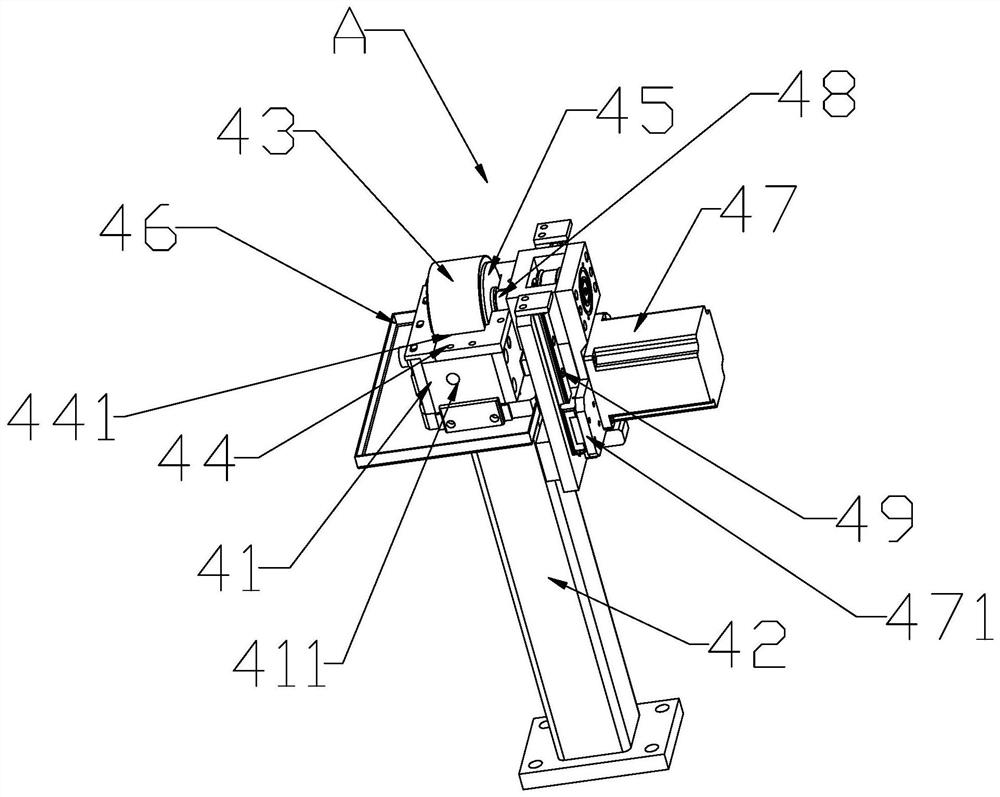

ActiveCN111940221AImprove qualitySimple structureLiquid surface applicatorsCoatingsDrive shaftAdhesive glue

The invention discloses a glue brushing device for shoemaking. The glue brushing device comprises a stand column, a glue brushing box, a glue brushing wheel, a scraping blade and a driving mechanism,wherein the stand column is arranged on one side of a rack, the glue brushing box is fixed to the upper end of the stand column, a glue inlet is formed in the glue brushing box, part of the cylindrical surface of the glue brushing wheel is arranged in the glue brushing box, the other cylindrical surface of the glue brushing wheel is arranged above the glue brushing box 41, the generatrix of the glue brushing wheel is parallel to the bottom surface of the glue brushing box, the axis of the glue brushing wheel is parallel to the bottom surface of the glue brushing box, the scraping blade is arranged at an opening in the upper end of the glue brushing box, a driving shaft of the driving mechanism is used for being connected with the glue brushing wheel, the driving shaft drives the glue brushing wheel to rotate, the driving shaft rotates to enable the glue brushing wheel to rotate, a layer of glue is evenly attached to the cylindrical face of the glue brushing wheel, then a robot assemblygrabs a shoe tree and places the shoe tree on the glue brushing wheel, and the glue brushing procedure on multiple faces of the shoe tree is completed through rotation of a sixth shaft of a robot body.

Owner:XR AUTOMATION EQUIPGZ CO LTD

Glue brushing device for shoemaking

ActiveCN111940221BImprove qualitySimple structureLiquid surface applicatorsCoatingsDrive shaftAdhesive glue

The invention discloses a rubber brushing device for shoemaking, which comprises a column, a rubber brushing box, a rubber brushing wheel, a scraper, and a driving mechanism; the column is placed on one side of the frame; the rubber brushing box is fixed At the upper end of the column, a glue inlet is set on the glue brushing box; part of the cylindrical surface of the rubber brushing wheel is placed in the glue brushing box, and the remaining cylindrical surface of the rubber brushing wheel is placed above the glue brushing box 41 , the busbar of the rubber brushing wheel is parallel to the bottom surface of the rubber brushing box, the axis of the rubber brushing wheel is parallel to the bottom surface of the rubber brushing box; the scraper is arranged at the upper opening of the rubber brushing box ; The drive shaft of the drive mechanism is used to connect the rubber brush wheel, and the drive shaft drives the rubber brush wheel to rotate. The driving shaft rotates so that the rubber brush wheel rotates, so that a layer of glue is evenly attached to the cylindrical surface of the rubber brush wheel, and then the robot component grabs the shoe last and places it on the rubber brush wheel, and completes the shoe tree by the rotation of the sixth axis of the robot body. The brushing process of multiple surfaces.

Owner:XR AUTOMATION EQUIPGZ CO LTD

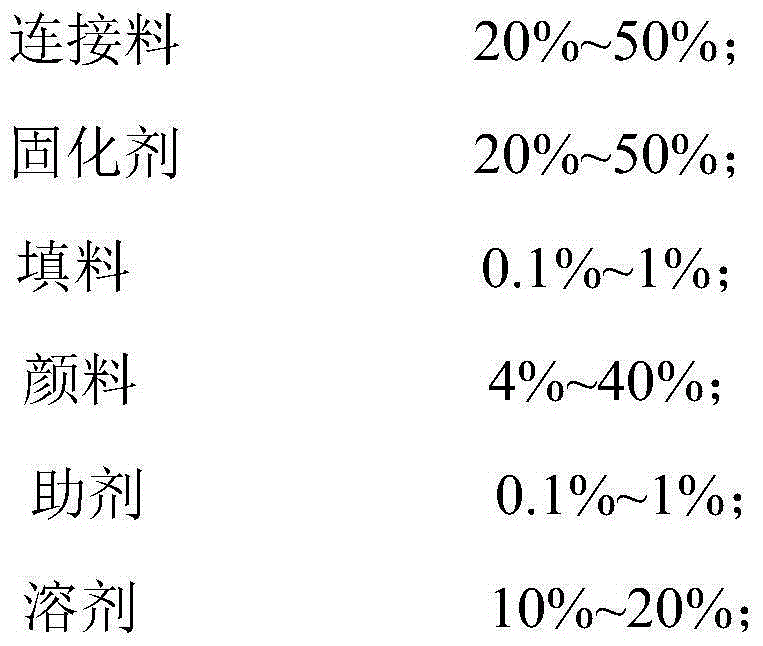

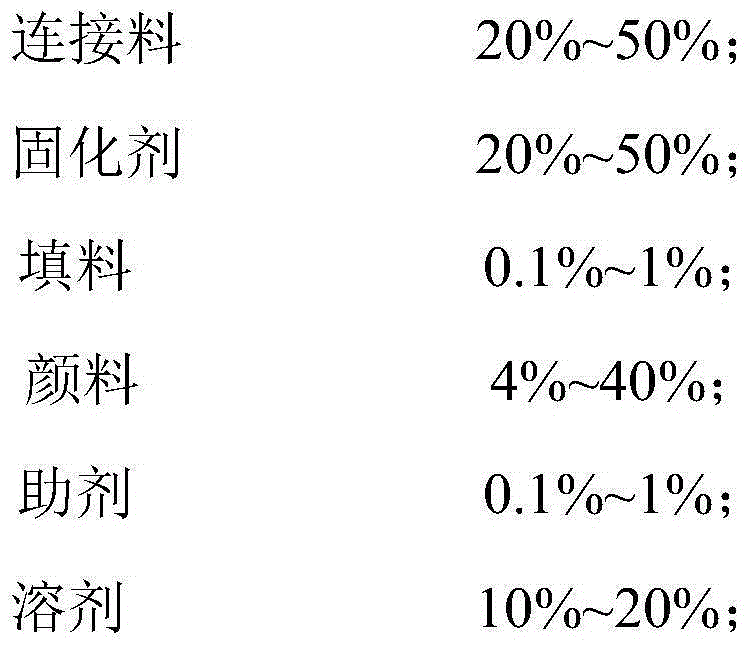

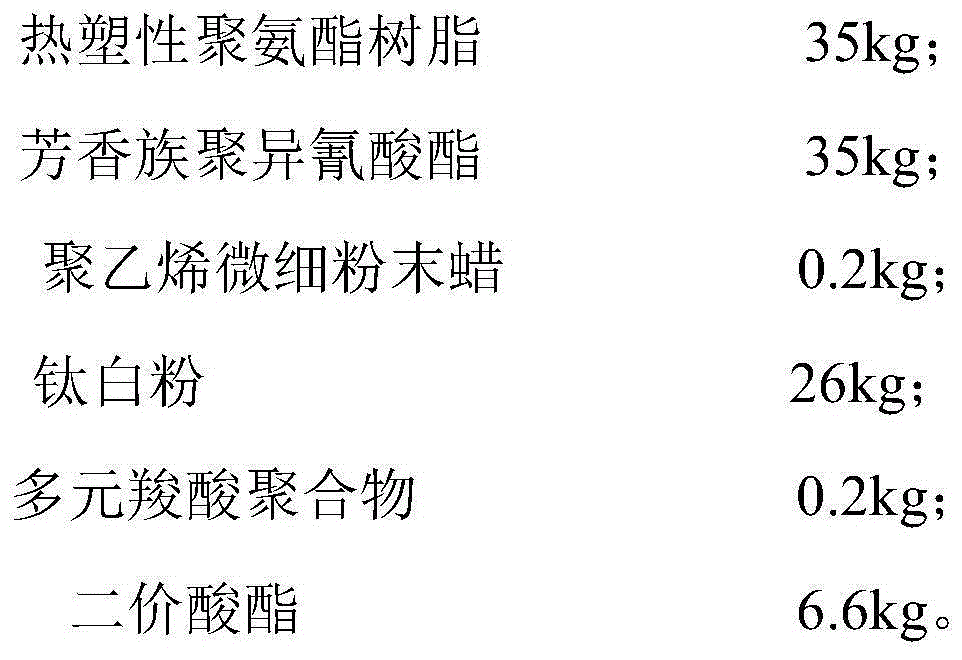

Environment-friendly transfer printing ink and preparing method and application thereof

InactiveCN105038394AHigh ink densityHigh color densityInksOther printing apparatusPolycyclic aromatic hydrocarbonThermoplastic polyurethane

The invention relates to the technical field of transfer printing ink and particularly discloses environment-friendly transfer printing ink and a preparing method and application thereof. The environment-friendly transfer printing ink comprises, by weight, 20-50% of a connecting material, 20-50% of a curing agent, 0.1-1% of filler, 4-40% of pigment, 0.1-1% of an auxiliary and 10-20% of solvent, wherein the connecting material is thermoplastic polyurethane resin and / or modified thermoplastic polyurethane resin, and the curing agent is aliphatic polyisocyanate and / or aromatic polyisocyanate. The environment-friendly transfer printing ink has the advantages of being fast to dry, stable, high in color concentration, stable in colloid property, large in adhesive force and the like, and has the advantages that printing performance and paint film solvent resistance are good, and colors of printed products are bright and full when used for the surfaces of the paint products with elastic hand-feel, the environmental protection performance is up to detection standards of EU2009 / 48 / EC, polycyclic aromatic hydrocarbon (PAHS), REACH SVHC and GB24613, the preparing method is simple, and the transfer printing ink is suitable for large-scale application and production.

Owner:CHINA PAINT MFG CO SHENZHEN

Blood counting equipment for natural delivery

InactiveCN114376535ASolve the defect of inaccurate collection amountImplement the collection functionOperating tablesCatheterBlood flowEngineering

The invention relates to the technical field of detection equipment, in particular to blood counting equipment during natural delivery, which comprises a collection main body, a collection pipe, a collection bag and a fan, the collection main body comprises a collection main plate and a collection top plate, and a plurality of uniformly distributed strip-shaped grooves are formed in the collection top plate; an inner cavity is formed in the face, close to the collecting top plate, of the collecting main plate, a water outlet hole is formed in the downward face of the inner cavity and connected with one end of a collecting pipe, an air inlet hole connected with a draught fan is formed in the side wall of the collecting main plate, and an air outlet hole communicated with the air inlet hole is formed in the upward face of the collecting main plate. And a heating assembly is fixedly arranged in the collecting main plate. According to the blood counting equipment for natural delivery, the function that blood cannot be accumulated and coagulated before entering the collection bag is achieved through the collection main plate and the collection top plate; the defect that the blood collection amount of blood counting equipment is inaccurate due to the phenomena of accumulation, solidification and the like before blood flows into a collection bag is overcome.

Owner:LISHUI PEOPLES HOSPITAL

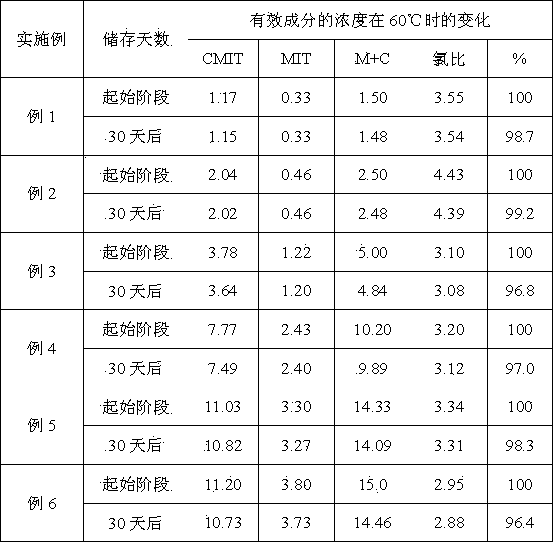

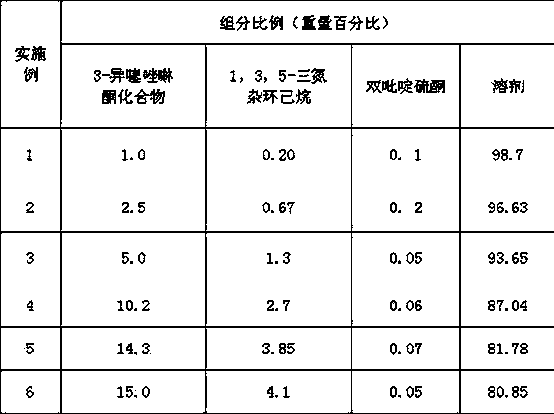

Isothiazolinone composition

The invention relates to an isothiazolinone composition. The isothiazolinone composition is characterized by comprising 1 to 15wt% of a 3-isothiazolinone compound, 0.05 to 0.2wt% of bispyrithione, 0.2 to 5wt% of 1,3,5-triazaphosphorine and the balance of one or more solvents. The isothiazolinone composition has excellent stability, does not contain inorganic salts and organic solvents, can be used in a dispersion solution or an emulsion or latex, has a wide application range and can effectively inhibit growth of harmful microorganisms.

Owner:DALIAN BIO CHEM

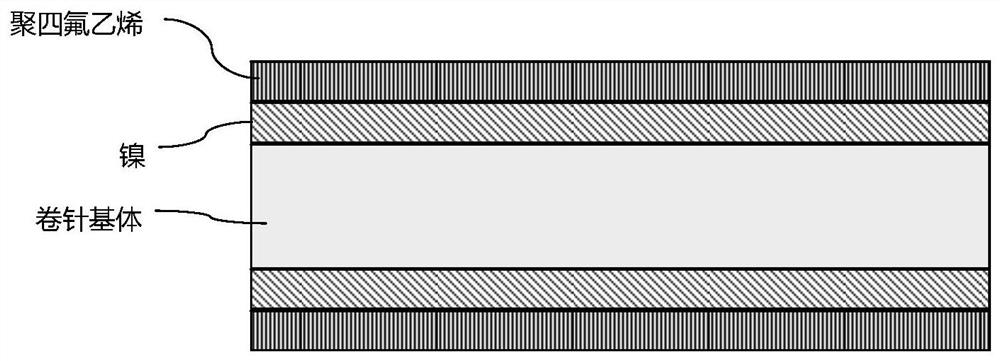

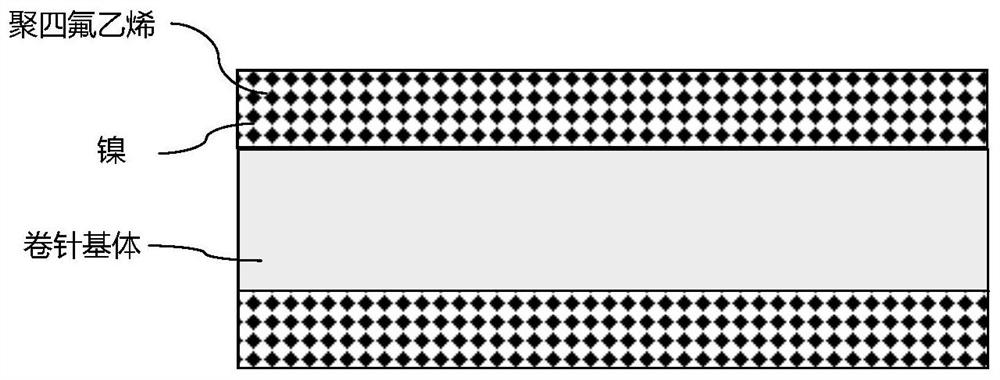

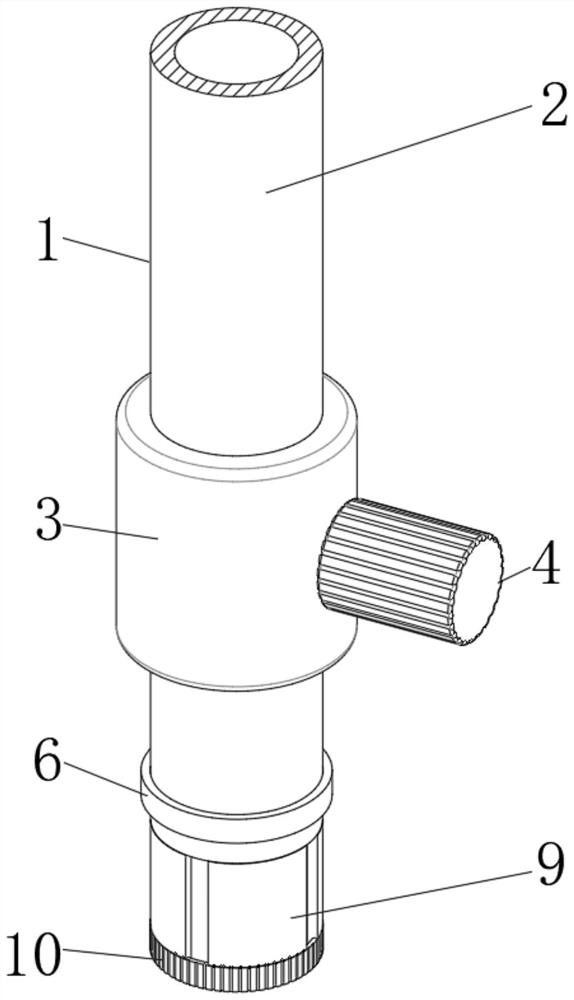

Nickel-polytetrafluoroethylene plating and wear-resistant anti-static rolling needle comprising plating

ActiveCN111636090AReduce frictional resistanceReduce defective rateElectrolytic coatingsFinal product manufactureTetrafluoroethyleneNickel salt

The invention provides a nickel-polytetrafluoroethylene plating and a wear-resistant anti-static rolling needle comprising the plating. The plating comprises nickel metal particles and polytetrafluoroethylene particles, wherein the nickel metal particles and the polytetrafluoroethylene particles are dispersed in the plating. The plating is obtained by electroplating of a mixed plating solution containing ammonia water, nickel salt and the polytetrafluoroethylene particles, wherein the mixed plating solution is stable in performance, and the polytetrafluoroethylene particles have high dispersity in the mixed plating solution and do not coagulate. In the electroplating process, when nickel ions of nickel-ammine complexing cations adsorbing the polytetrafluoroethylene particles are reduced and deposited on a cathode plate, the polytetrafluoroethylene particles can be released and uniformly co-deposited on the cathode plate along with the nickel ions, and therefore the nickel-polytetrafluoroethylene mixed plating with a smooth and dense surface is obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

Softener filling equipment capable of preventing liquid leakage

InactiveCN112794268ASmall expansion areaEasy to importLiquid bottlingStructural engineeringMechanical engineering

The invention discloses softener filling equipment capable of preventing liquid leakage. The softener filling equipment comprises a filling assembly, the filling assembly comprises a discharging pipe, a stirring pipe is fixedly installed in the position, close to the bottom end, of the discharging pipe, the discharging pipe and the stirring pipe communicate with each other, and a groove is formed in the position, attached to the lower end, of the interior of the discharging pipe. A plurality of elastic connecting pieces are fixedly installed at the bottom of the groove, the other ends of the elastic connecting pieces are fixedly connected with a sleeve plate assembly, the sleeve plate assembly comprises a plurality of extrusion plates, and a fixing clamping ring is movably connected into the discharging pipe in a sleeved mode. According to the softener filling equipment capable of preventing liquid leakage, after the discharging pipe is guided into a bottle opening, the fixing clamping ring is lifted up and does not make contact with the sleeve plate assembly, the sleeve plate assembly is not limited by the fixing clamping ring, meanwhile, the sleeve plate assembly is pushed by the elastic connecting pieces, the sleeve plate assembly expands outwards again, then the sleeve plate assembly is better attached to the inner wall of the bottle opening, and when materials are guided into a bottle, liquid leakage is avoided.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

Strip-shaped feed processing device

InactiveCN112674372AGuaranteed service lifeTake advantage ofFeeding-stuffGranulation by material expressionFeed processingAgricultural engineering

The invention relates to feed processing related machinery, and in particular relates to a strip-shaped feed processing device. The strip-shaped feed processing device comprises a main body frame, a stirring and wall cleaning mechanism, a pushing mechanism, a dislocation adjusting mechanism, a conventional cutting mechanism, a long grain bending preventing mechanism and a sealing door; the sealing door is installed on the main body frame; the stirring and wall cleaning mechanism is fixedly installed on the main body frame; the pushing mechanism is fixedly installed on the main body frame; the dislocation adjusting mechanism is fixedly installed on the main body frame; the conventional cutting mechanism is fixedly installed on the main body frame; and the long grain bending preventing mechanism is fixedly installed on the main body frame. According to the strip-shaped feed processing device, small-particle feed processing and long-strip-shaped feed processing can be carried out; it is guaranteed that the long-strip-shaped feed cannot be bent in the processing process; the device has the function of cleaning the inner wall while having a stirring function; and the cleaning degree of the device is guaranteed.

Owner:哈尔滨金玉钰科技开发有限公司

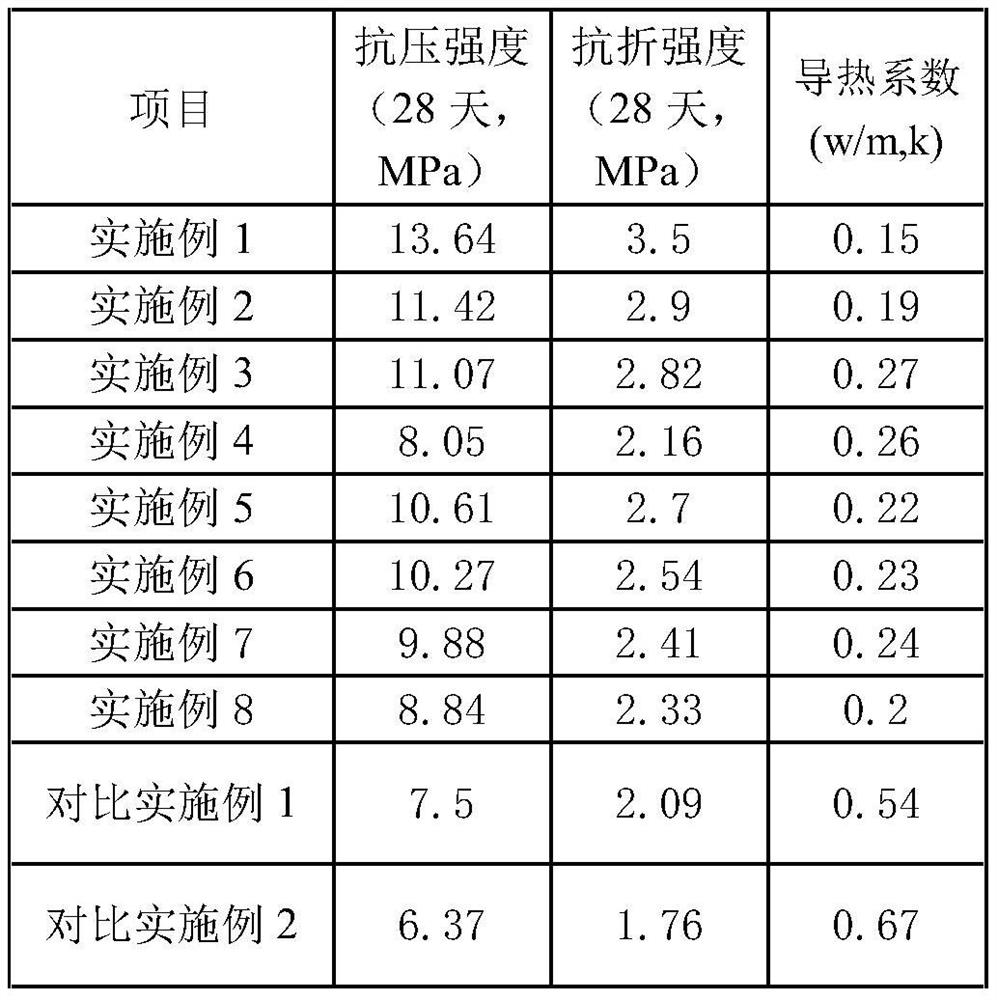

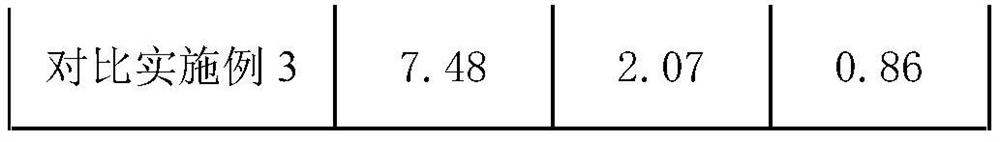

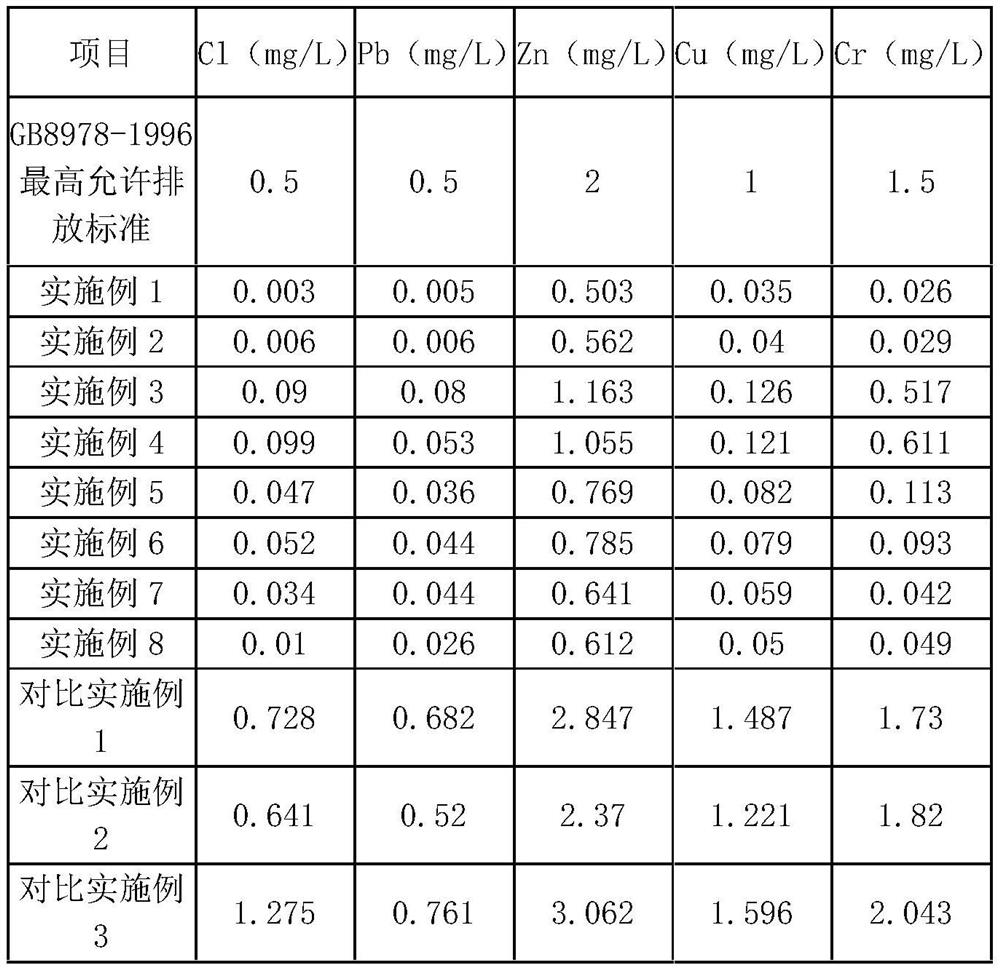

Wall thermal insulation material utilizing dangerous solid waste and preparation method thereof

The invention relates to a wall thermal insulation material utilizing dangerous solid waste and a preparation method thereof. The thermal insulation material comprises the following raw materials: modified dangerous solid waste, blast furnace slag, fly ash, cement and polypropylene, wherein the modified dangerous solid waste is dangerous solid waste which is modified by an organic polybasic phosphonic acid wet method and modified by an aminoalkyl silane coupling agent dry method. According to the invention, the organic polybasic phosphonic acid and the aminoalkyl silane coupling agent are usedfor modifying the dangerous solid waste so as to stabilize heavy metals in the dangerous solid waste, and it is accidentally found that the modified dangerous solid waste is used as a raw material ofthe wall thermal insulation material, so that the dosage of cement for curing can be reduced on the premise that the leaching toxicity of the heavy metals reaches the standard through detection, andthe mechanical property and the heat insulation effect are improved.

Owner:UNIV OF SCI & TECH BEIJING +1

An antifreeze differential pressure flowmeter

ActiveCN104792374BNo coagulationVolume/mass flow by differential pressureDifferential pressureHydrostatic pressure

The invention discloses an antifreeze differential pressure flowmeter, which has a flow totalizer and a Bitoba flow sensor to take a pressure head, the upper part of the cylindrical joint of the pressure head has a cylindrical chamber, and the lower part is provided with a differential pressure switch device; the differential pressure switch device includes a radial cylindrical hole that runs through the lower part of the cylindrical joint. The axes of the pressure channels are perpendicular to each other, and the inner diameters of the cylindrical holes are respectively larger than the inner diameters of the total pressure channel and the static pressure channel. They are located approximately in the middle of the axis of the cylindrical hole and are sealed with a differential pressure sensitive diaphragm. The total pressure channel and the static pressure channel The upper ports of the differential pressure sensitive diaphragm are respectively located on both sides of the differential pressure sensitive diaphragm, and the two ends of the cylindrical hole are sealed with side end covers. The signal output end of the differential pressure sensitive diaphragm is connected with a signal cable, and the signal cable passes through the The cylindrical chamber is connected with the signal input end of the flow totalizer. When the invention measures the fluid flow in the pipeline, it is not affected by the ambient temperature outside the pipeline.

Owner:LIAONING BITOBAR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com