Production specific vibration device for preventing plastic silver powder paint from being solidified

A vibrating device, a technology of silver powder paint, applied in the directions of shaking/oscillating/vibrating mixer, transportation and packaging, dissolving, etc., can solve the problems of prone to solidification, lack of vibration device, speeding up solidification, etc., to prolong the solidification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

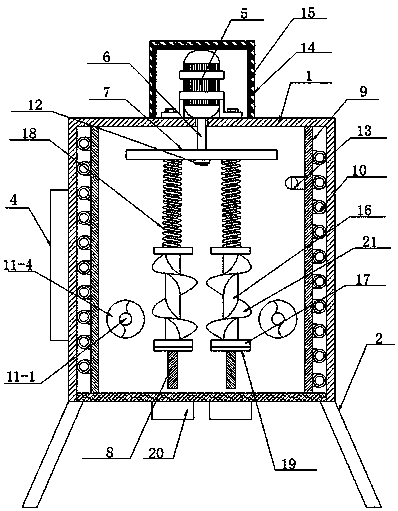

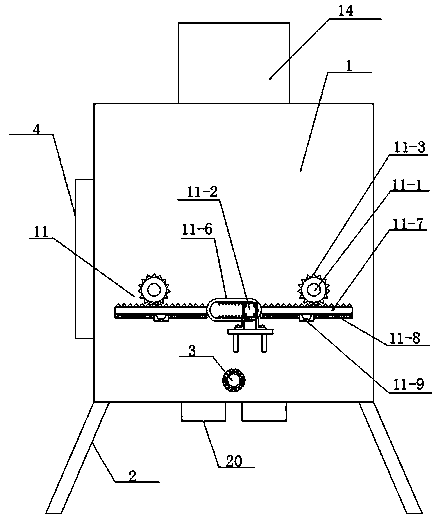

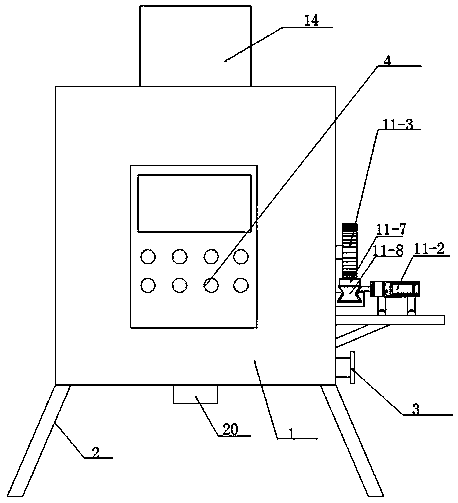

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as Figure 1-Figure 5As shown, the technical solution adopted in this specific embodiment is: it comprises a box body 1, legs 2, inlet and outlet 3, electric control box 4; the four corners of the bottom of the box body 1 are fixedly welded with legs 2, and the box The surrounding wall and top surface of the body 1 are made of nickel-based alloy metal material, which has weak magnetic permeability. The bottom surface of the box body 1 is made of iron metal material, which has strong magnetic permeability. The bottom of the wall is fixedly welded with an inlet and outlet 3, which is connected to the external feeding and unloading device; the left side wall of the box 1 is fixed with an electric control box 4 by bolts, and the inside of the electric control box 4 is set There is a power supply and a KS02Y controller, which is convenient for controlling the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com