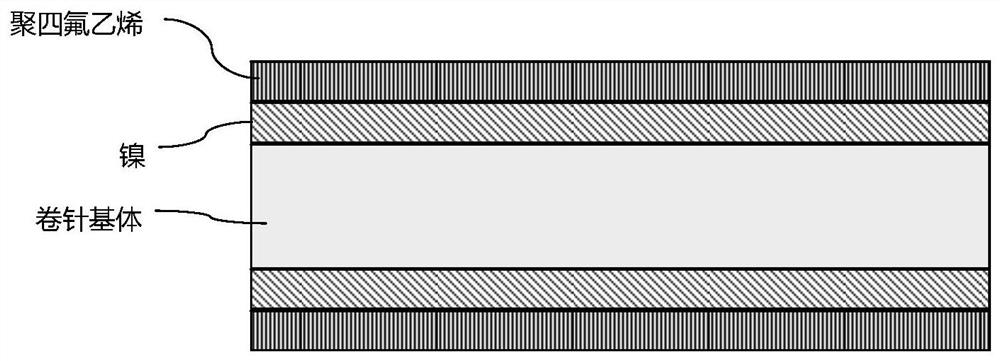

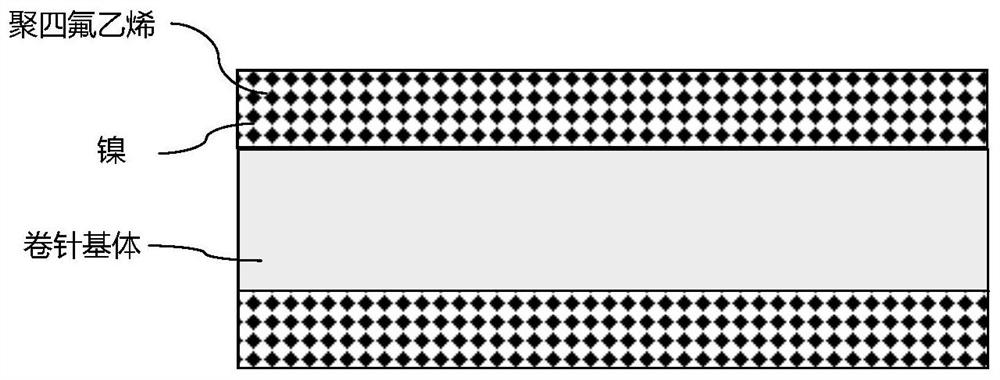

Nickel-polytetrafluoroethylene plating and wear-resistant anti-static rolling needle comprising plating

A polytetrafluoroethylene and coating technology, which is applied in the field of wear-resistant and anti-static rolling needles, can solve the problems of complicated preparation method of Teflon coating, inability to eliminate static electricity, and high frequency of rolling needle replacement, so as to reduce the carry-out or puncture The risk of separators and pole pieces, the effect of improving yield and performance stability, and reducing the defect rate of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052]

[0053] The present invention also provides a method for preparing the above-mentioned coating, the method comprising: preparing the coating by using the above-mentioned nickel-polytetrafluoroethylene mixed plating solution.

[0054] In a preferred solution of the present invention, the method includes: preparing the plating layer by electroplating the above-mentioned nickel-polytetrafluoroethylene mixed plating solution.

[0055] In a preferred version of the present invention, the method comprises the steps of:

[0056] 1) preparing nickel-polytetrafluoroethylene mixed plating solution;

[0057] 2) The element to be plated is used as a cathode plate, and the pure nickel plate is used as an anode plate for electroplating.

[0058] In a preferred solution of the present invention, the temperature of the electroplating is 35-65° C.; the time of the electroplating is 15-90 min.

[0059] In a preferred solution of the present invention, the electroplating is DC electr...

Embodiment 1

[0103] Preparation of nickel-polytetrafluoroethylene mixed plating solution:

[0104] Mix ammoniacal liquor, nickel chloride, polytetrafluoroethylene particles, brightener (tetrabutylammonium bromide) and dispersant (sodium dodecylsulfonate) to obtain the mixed plating solution; wherein the concentration of ammoniacal liquor is 2.5 mol / L, the concentration of nickel chloride is 120g / L, the concentration of polytetrafluoroethylene particles with a particle size of 0.1μm is 9g / L, the concentration of brightener is 0.5g / L, and the concentration of dispersant is 5g / L. The pH of the plating solution was 12.

[0105] Coating preparation:

[0106] Use 250mm long * 10mm wide * 8mm thick nickel plate with a purity ≥ 99.95% as the anode, use surface pretreated 245mm long * 8.5mm wide * 8mm thick high-carbon high-chromium alloy tool steel as the cathode, and the distance between the two electrodes is 3.5cm. The current density of DC constant current plating is 350A / m 2 , the electropl...

Embodiment 2

[0108] Preparation of nickel-polytetrafluoroethylene mixed plating solution:

[0109] Mix ammoniacal liquor, nickel chloride, polytetrafluoroethylene particles, brightener (tetrabutylammonium bromide) and dispersant (sodium dodecylsulfonate) to obtain the mixed plating solution; wherein the concentration of ammoniacal liquor is 2.5 mol / L, the concentration of nickel chloride is 350g / L, the concentration of polytetrafluoroethylene particles with a particle size of 0.1μm is 9g / L, the concentration of brightener is 0.5g / L, and the concentration of dispersant is 5g / L. The pH of the plating solution was 12.

[0110] Coating preparation:

[0111] Use 250mm long * 10mm wide * 8mm thick nickel plate with a purity ≥ 99.95% as the anode, use surface pretreated 245mm long * 8.5mm wide * 8mm thick high-carbon high-chromium alloy tool steel as the cathode, and the distance between the two electrodes is 3.5cm. The current density of DC constant current plating is 350A / m 2 , the electropl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com