An antifreeze differential pressure flowmeter

A technology of differential pressure flowmeter and flow totalizer, which is applied in the field of flowmeters, and can solve problems such as the failure of fluid medium to conduct pressure, fluid solidification, and inability to measure fluid flow in pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

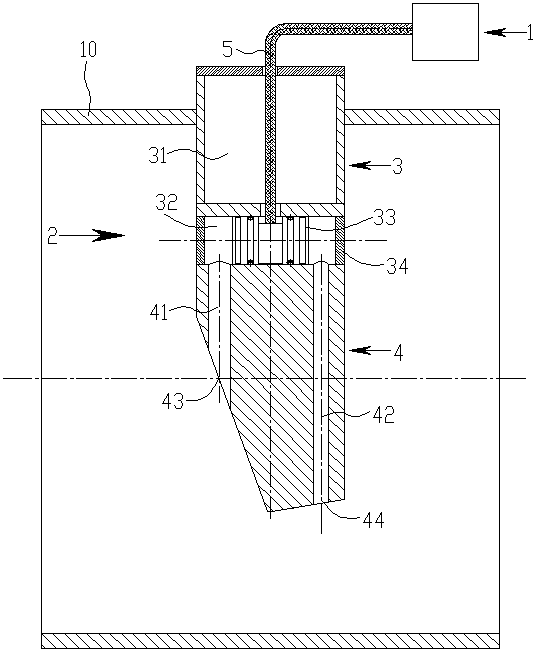

[0009] see figure 1 , figure 1 It shows a schematic cross-sectional structural view of an antifreeze differential pressure flowmeter of the present invention installed on the pipeline 10 . The antifreeze differential pressure flowmeter of the present invention has a flow totalizer 1 and a pressure taking head 2 of a Bitobar flow sensor, and the pressure taking head 2 of the Bitobar flow sensor includes a cylindrical joint 3 in the upper section and a pressure taking head in the lower section Body 4, pressure taking head body 4 is provided with a total pressure channel 41 and a static pressure channel 42 whose axis is parallel to the axis of the pressure taking head and located in the same plane. The bottom of the total pressure channel 41 has a total pressure hole 43 and a static pressure channel 42 The bottom of the bottom has a static pressure hole 44, the upper part of the cylindrical joint 3 has an axial cylindrical chamber 31, and its lower part is provided with a differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com