Softener filling equipment capable of preventing liquid leakage

A technology of filling equipment and softener, which is applied in the field of softener filling equipment to prevent leakage, which can solve problems such as poor bonding effect, easy leakage, product waste, etc., and achieves good material guiding effect and smooth feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In order to make the techniques, creative features, the purpose and efficacy of the present invention, and the embodiments are further illustrated below, but the invention is further illustrated, but the following examples are merely preferred embodiments of the invention, not all. Based on the embodiments in the embodiment, those skilled in the art will belong to the scope of the invention without making creative labor. The experimental method in the following examples, as not particularly illustrative, all of which are conventional methods, materials, reagents, etc. used in the following examples, such as non-special descriptions, can be obtained from the business pathway.

[0025]Embodiment:

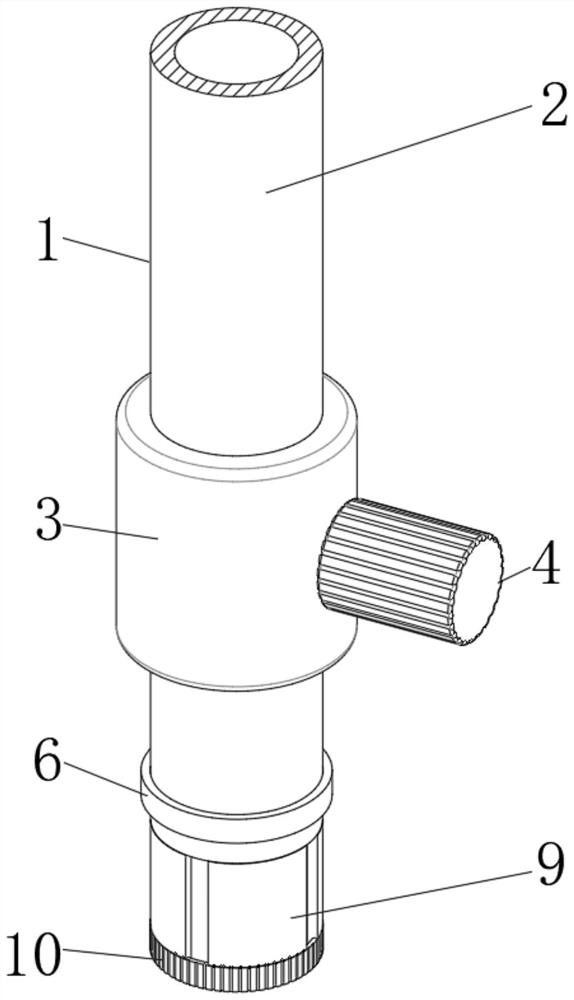

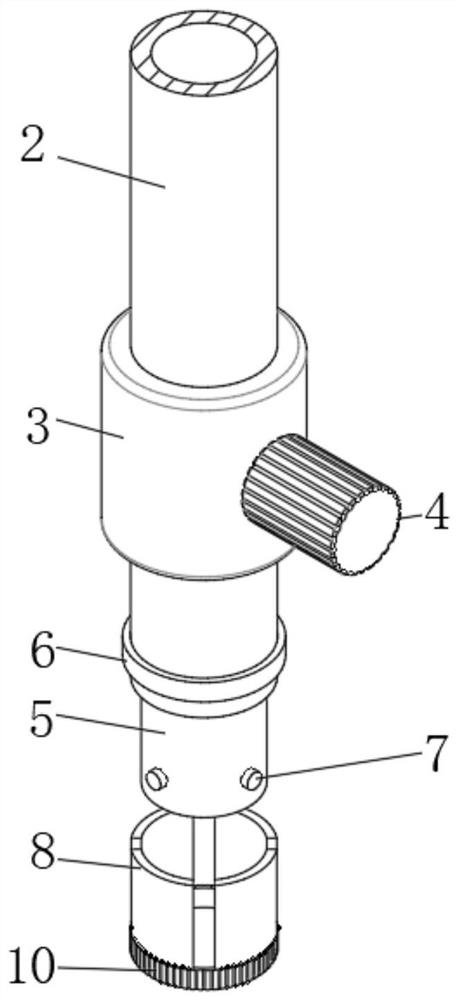

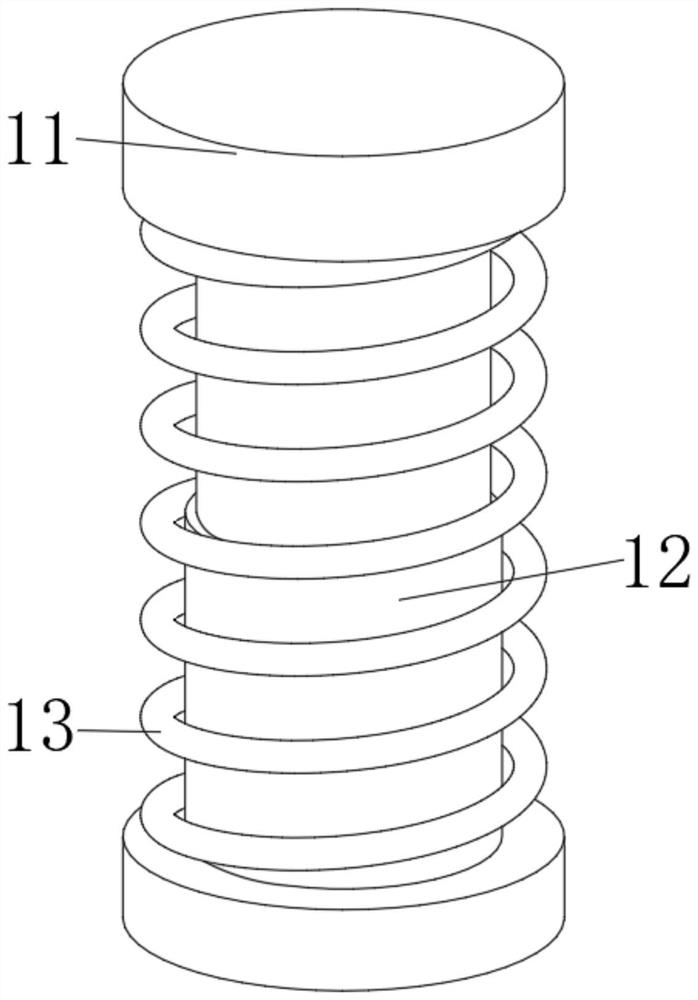

[0026]Such asfigure 1 ,figure 2 ,image 3 as well asFigure 5As shown, the present invention provides, a stuffer filling apparatus that prevents the leakage, including the filling assembly 1, the filling assembly 1 contains the tube 2, and the lower tube 2 is fixed to the bottom end to fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com