Propeller pumps for pumping liquids

A propeller, liquid technology, applied to the components of pumping devices for elastic fluids, liquid fuel engines, pumps, etc., can solve problems such as large losses, increased risk of reverse flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

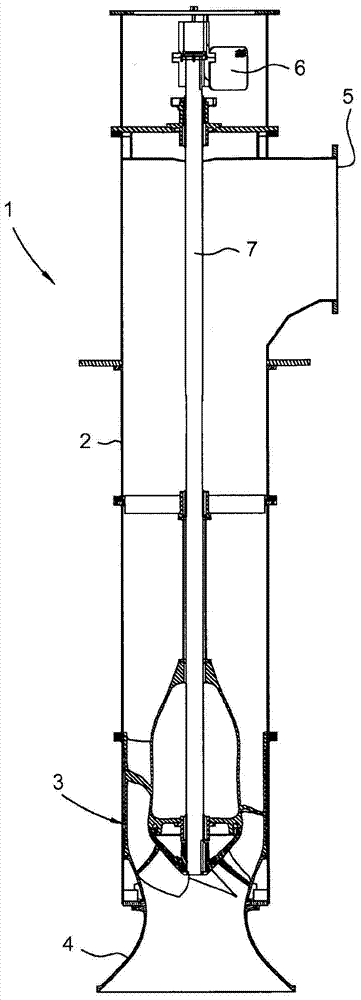

[0024] Referenced by way of the foreword figure 1 , which shows a propeller pump arrangement generally indicated by reference number 1 . The propeller pump arrangement 1 comprises: a housing pipe 2 having one or more segments; a propeller pump according to the invention generally designated with reference numeral 3 arranged in said housing In the lower end of the tube 2 ; an inlet funnel 4 connected to the lower end of the housing tube 2 ; an outlet 5 arranged in the upper end of the housing tube 2 ; and a drive unit 6 . In the illustrated embodiment, the drive unit 6 is located at a distance from the propeller pump 3 and outside the housing tube 2 and is connected to the propeller pump 3 by an axially extending drive shaft 7, however, it should be mentioned that the drive The unit 6 can be arranged in a suitable propeller pump 3 .

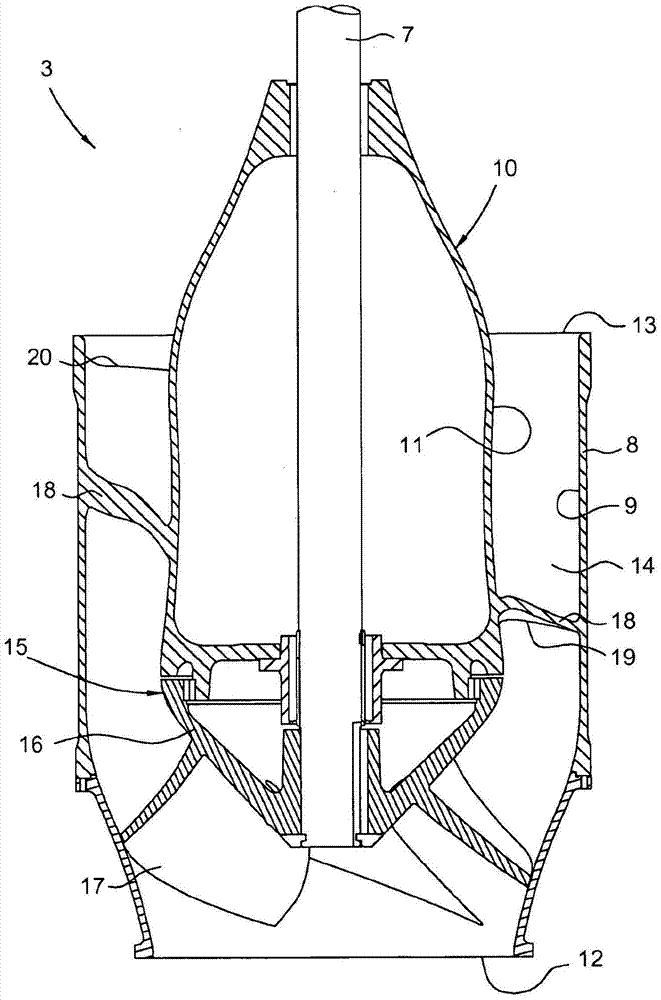

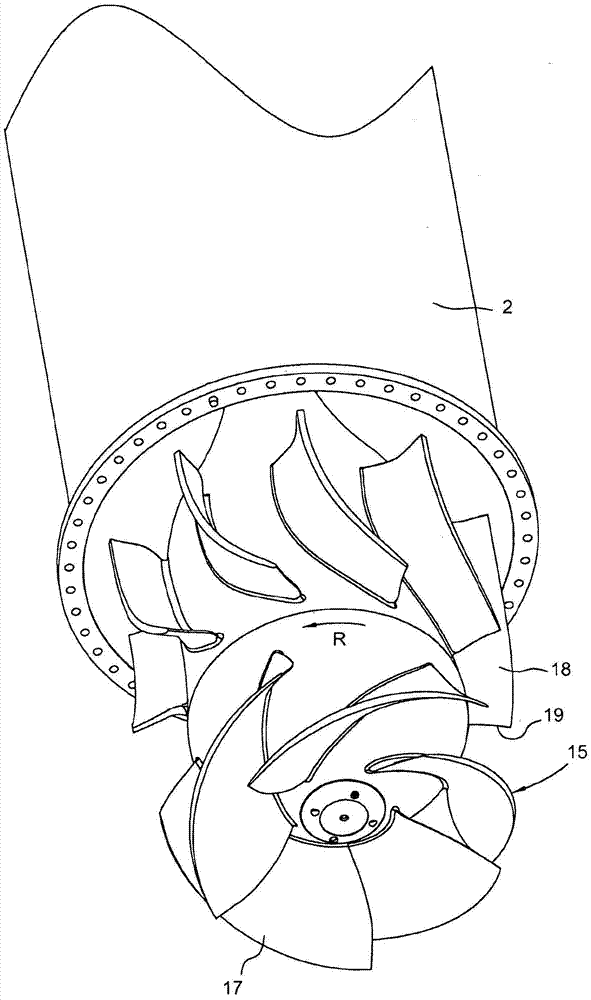

[0025] now also refer to Figure 2-Figure 4 , which shows a propeller pump 3 according to the invention. The propeller pump 3 is also known a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com