High-polymer water reducing agent for ceramic concentrated suspension as well as preparation method and application of high-polymer water reducing agent

A suspension and polymer technology, applied in the field of ceramic additives, can solve the problems of slurry stability decline, narrow decondensation range, easy coagulation and sedimentation, etc., and achieve the effect of low equipment requirements, wide decondensation range, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

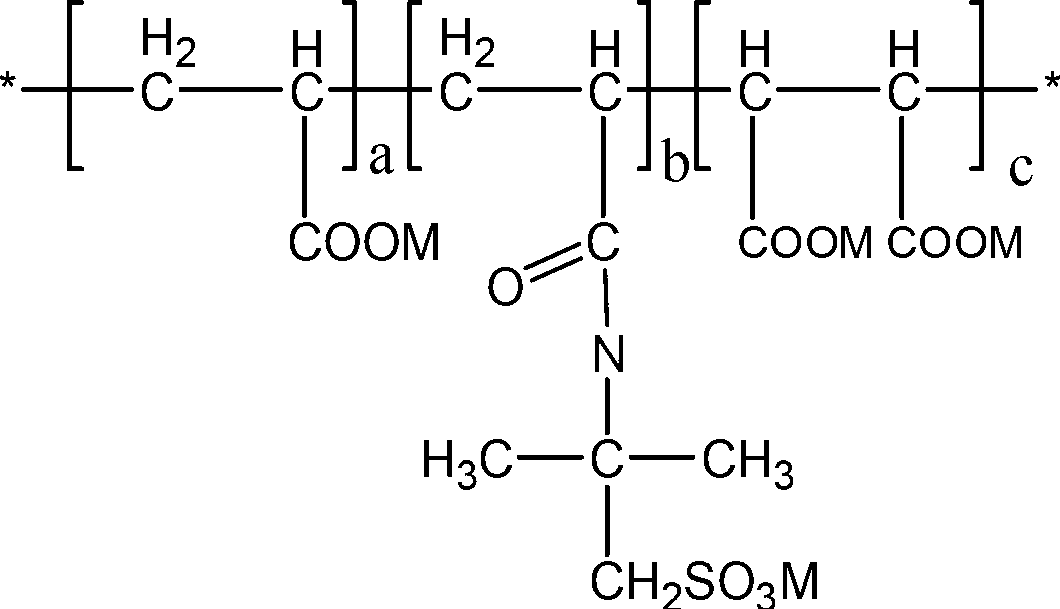

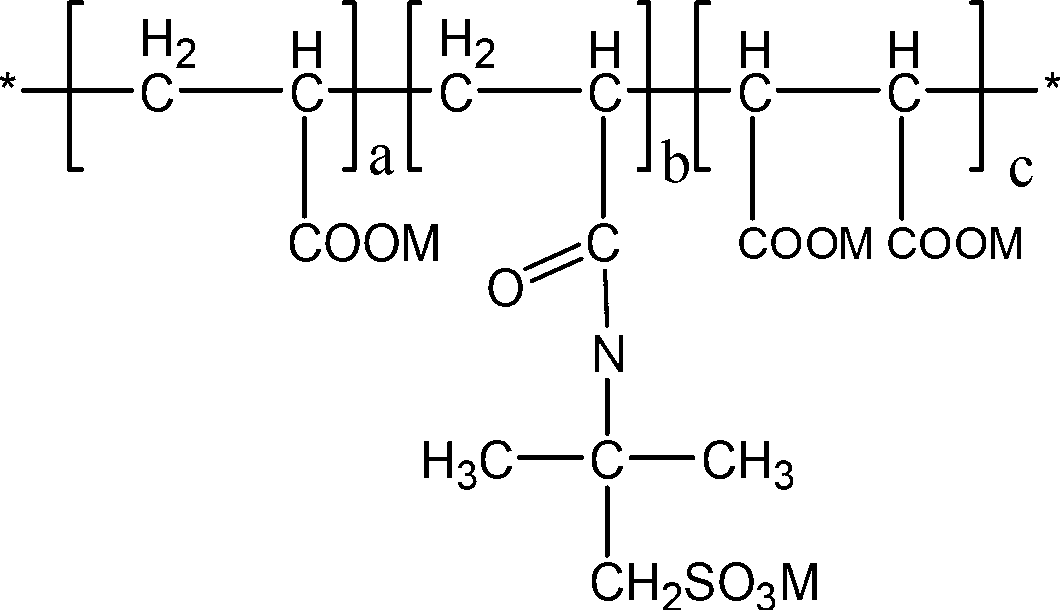

Method used

Image

Examples

Embodiment 1

[0030] A polymer water reducer for ceramic concentrated suspension, prepared by the following method:

[0031] Weigh 158g of acrylic acid, 52g of 2-acrylamide-2-methylpropanesulfonic acid and 19.5g of maleic anhydride into a three-necked flask, dissolve with 300g of distilled water, and then add dropwise a 50% sodium hydroxide solution to mix The pH value of the solution is 7, add 36.7g of chain transfer agent sodium bisulfite, and keep stirring to raise the temperature. When the temperature rises to 80°C, dissolve 2.98g of ammonium persulfate with distilled water and pour it into a constant pressure dropping funnel and slowly add Put it into a three-necked flask and react at constant temperature for 3 hours to obtain a polymer water reducer.

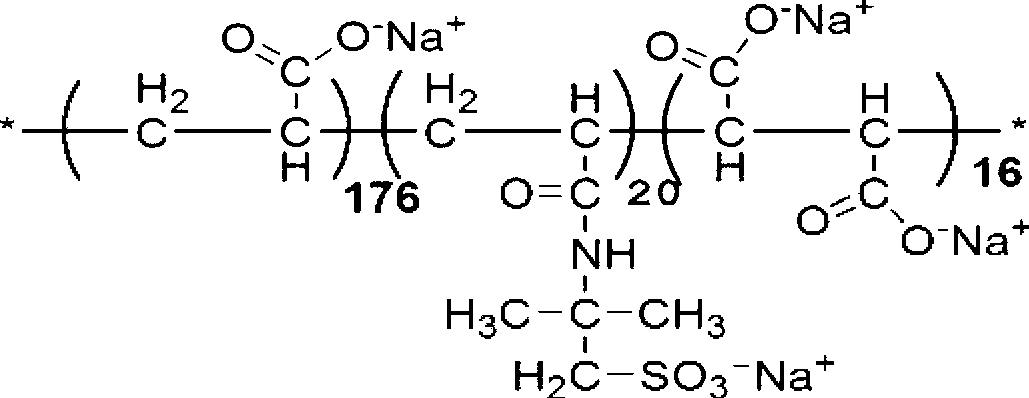

[0032] After the obtained polymer water reducer is separated and purified, its infrared spectrum is measured by the method of KBr pressing, IR (KBr) (wavenumber, cm -1 ):3436(-OH),

[0033] 2946(-CH 2 ), 1660(C=O), 1568, 1458(-COO -...

Embodiment 2

[0039] A polymer water reducer for ceramic concentrated suspension, prepared by the following method:

[0040] Weigh 168g of acrylic acid, 28g of 2-acrylamide-2-methylpropanesulfonic acid and 14g of maleic anhydride into a three-necked flask, dissolve with 300g of distilled water, and dropwise add a 40% sodium hydroxide solution to make the mixture The pH value of the solution is 8, add 25.2g of chain transfer agent sodium bisulfite, and keep stirring to raise the temperature. When the temperature rises to 100°C, dissolve 2.98g of ammonium persulfate with distilled water and pour it into a constant pressure dropping funnel and slowly add it to In the three-necked flask, after constant temperature reaction for 4 hours, the polymer water reducer was obtained.

[0041] After the obtained polymer water reducer is separated and purified, its infrared spectrum is measured by the method of KBr pressing, IR (KBr) (wavenumber, cm -1 ):3439(-OH),

[0042] 2944(-CH 2 ),1660(C=O),1565,...

Embodiment 3

[0047] A polymer water reducer for ceramic concentrated suspension, prepared by the following method:

[0048] Weigh 160g of acrylic acid, 40g of 2-acrylamide-2-methylpropanesulfonic acid and 20g of maleic anhydride into a three-neck flask, dissolve with 400g of distilled water, and dropwise add a 40% mass fraction of sodium hydroxide solution to make the mixture The pH value of the solution is 8, add 22g of chain transfer agent sodium bisulfite, and keep stirring to raise the temperature. When the temperature rises to 80°C, dissolve 1.98g of ammonium persulfate with distilled water and pour it into a constant pressure dropping funnel and slowly drop it into the three In the flask, after constant temperature reaction for 5 hours, the polymer water reducer was obtained.

[0049] After the obtained polymer water reducer is separated and purified, its infrared spectrum is measured by the method of KBr pressing, IR (KBr) (wavenumber, cm -1 ):3437(-OH),

[0050] 2946(-CH 2 ), 1660...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com