Method of preparing compound osseous tissue renovating material interconsistency agent of polylactic acid/hydroxyapatite

A technology of hydroxyapatite and repair materials, applied in medical science, prosthesis, etc., can solve the problems of poor compatibility between natural polymer materials and hydroxyapatite, and low mechanical properties of composite materials, so as to facilitate industrial production and improve mechanical properties. Effect of improving mechanical properties and bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Using vinyltrimethoxysilane as a coupling agent to treat hydroxyapatite.

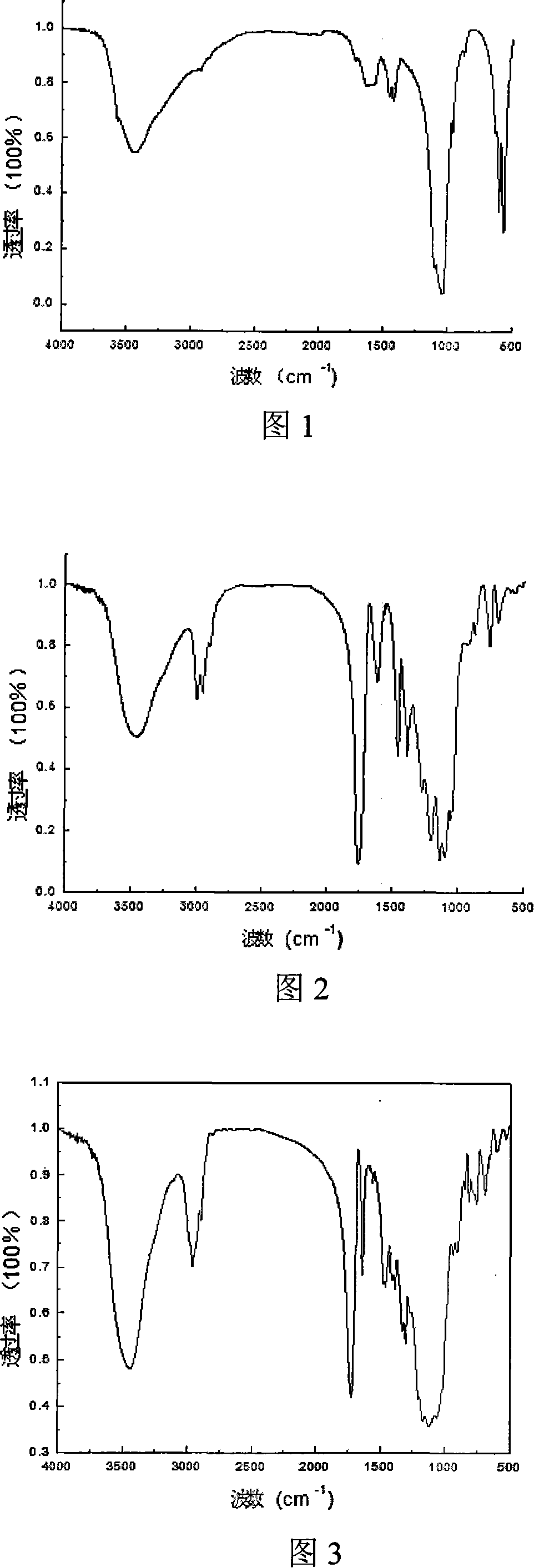

[0021] Reflux 10g of micron-sized hydroxyapatite in 0.1g of vinyltrimethoxysilane in 10ml of 80% ethanol solution for 40 hours, and use Fourier transform infrared spectroscopy to detect the treated hydroxyapatite surface. The Fourier transform infrared spectrum is shown in Figure 1 As shown, 3000cm -1 The stretching vibration peaks of C-H appear on the left and right, and it is confirmed by Fourier transform infrared spectroscopy that vinyltrimethoxysilane containing ethylene double bonds that can react with free radicals has been introduced on the surface of hydroxyapatite.

Embodiment 2

[0022] Example 2: Treating hydroxyapatite with γ-methacryloxypropyltriethoxysilane and vinyltrimethoxysilane as coupling agents.

[0023] Reflux 10g micron-sized hydroxyapatite in 10ml 50% ethanol solution of 0.5g γ-methacryloxypropyltriethoxysilane and 0.5g vinyltrimethoxysilane for 12 hours, and use Fourier transform infrared spectroscopy Detect the treated hydroxyapatite surface, the Fourier transform infrared spectrum is shown in Figure 1, 3000cm -1 The stretching vibration peaks of C-H appear on the left and right, and it is confirmed by Fourier transform infrared spectroscopy that γ-methacryloxypropyltriethoxysilane containing ethylene double bonds that can react with free radicals has been introduced on the surface of hydroxyapatite.

Embodiment 3

[0024] Example 3: Treatment of hydroxyapatite with isopropyl bis(diethylene glycol oleate)aluminate.

[0025] 10g of nano-sized hydroxyapatite was refluxed in 10ml of 10% ethanol solution of 0.3g bis(diethylene glycol oleate)aluminate in 10% ethanol solution for 24 hours, and the processed hydroxyapatite was detected by Fourier transform infrared spectroscopy Surface, Fourier Transform Infrared Spectrum is similar to Figure 1, at 3000cm -1 The stretching vibration peak of carbon and hydrogen appeared around the wave number, and it was confirmed by Fourier transform infrared spectroscopy that the free radical-reactable bis(diethylene glycol oleate)aluminate isopropyl aluminate containing ethylene double bonds has been introduced on the surface of hydroxyapatite. ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com