Glue brushing device for shoemaking

A technology for brushing glue and shoes, which is applied to the device for coating liquid on the surface, coating, etc., which can solve the problems of lack of automatic glue brushing device, etc., and achieve the effect of automatic production, convenient installation and disassembly, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

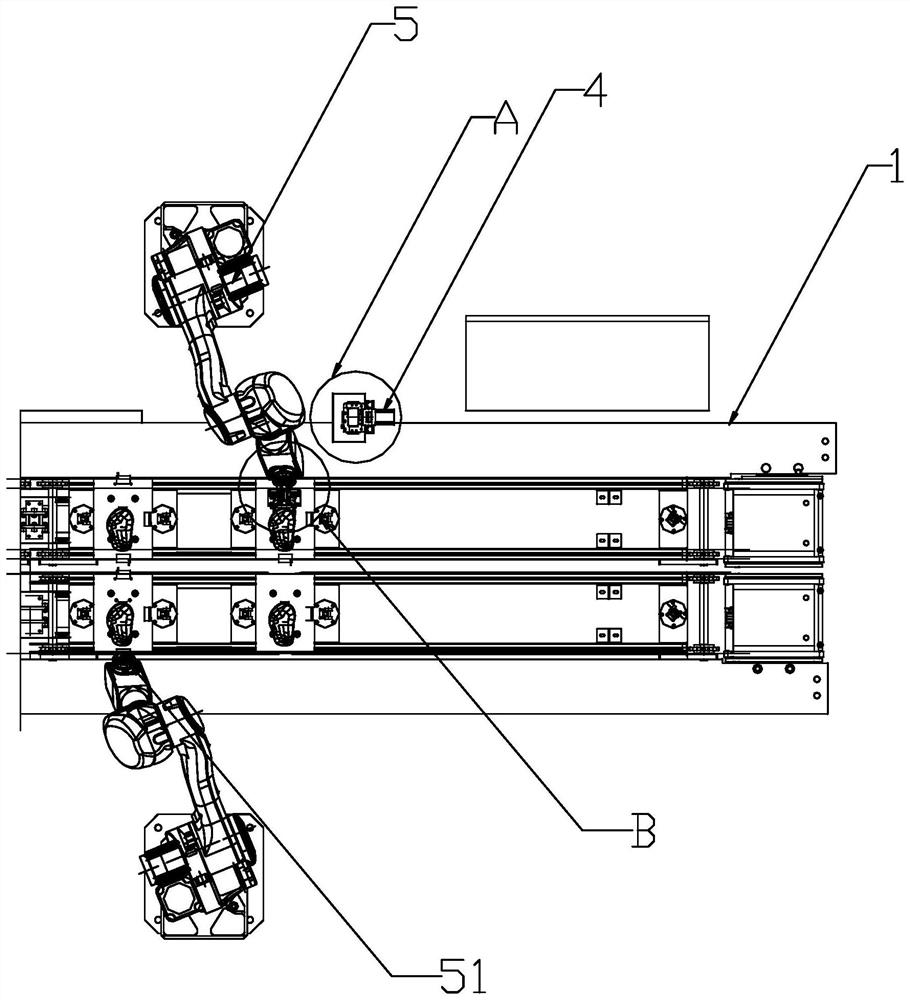

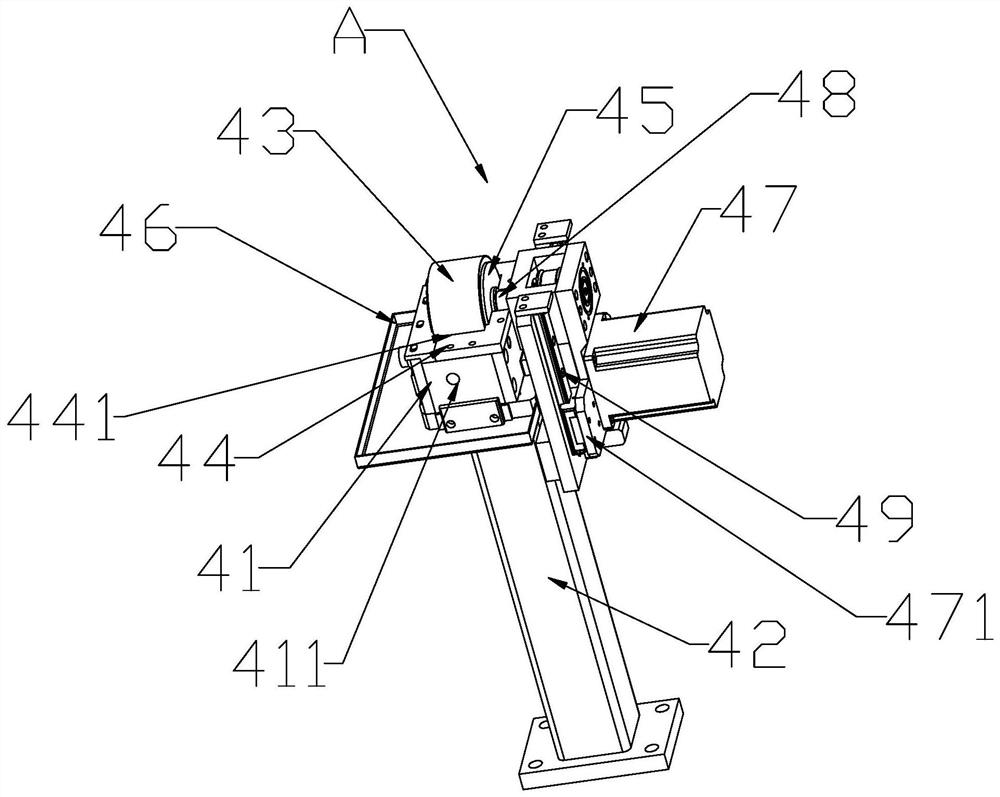

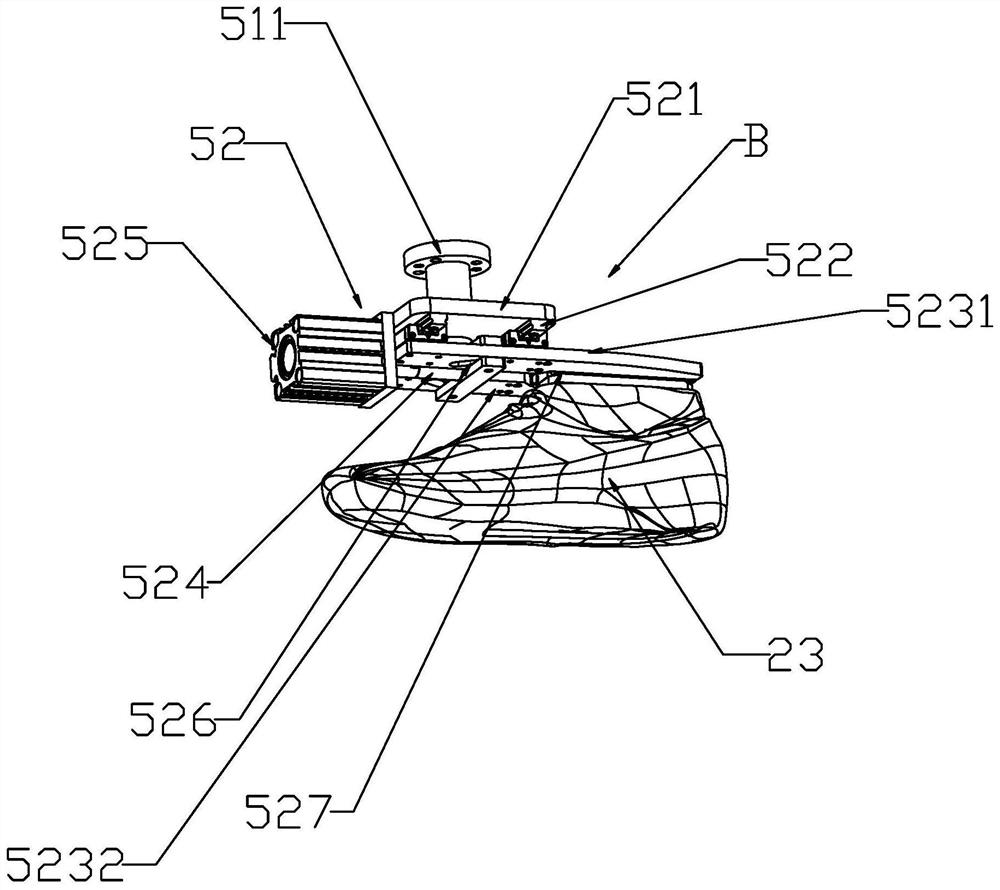

[0060] A kind of glue brushing device for shoemaking, such as figure 1 As shown, it includes: a frame 1, and the glue brushing device 4 is arranged on the frame 1, as figure 2 As shown, the glue brushing device 4 includes: a column 42, a glue brush box 41, a rubber brush wheel 43, a scraper 44, and a drive mechanism 47; the column 42 is placed on one side of the frame 1; the brush The rubber box 41 is fixed on the upper end of the column 42, and the rubber brushing box 41 is provided with a glue inlet 411; part of the cylindrical surface of the rubber brushing wheel 43 is placed in the rubber brushing box 41, as described in this embodiment At least one-third of the cylindrical surface of the rubber brushing wheel 43 is placed in the rubber brushing box 41, and the remaining cylindrical surfaces of the rubber brushing wheel 43 are placed above the rubber brushing box 41. The busbar of the rubber brushing wheel 43 is connected to the The bottom surface of the rubber brushing ...

Embodiment 2

[0083] This embodiment only describes the differences from the above-mentioned embodiments, and the similarities between this embodiment and the above-mentioned embodiments will not be repeated. In this embodiment, the drive mechanism 47 is a motor, and the main shaft of the motor is a drive shaft 48. The drive shaft 48 is directly connected to the rubber brushing wheel 43 .

Embodiment 3

[0085] This embodiment only describes the differences from the above embodiments, and the similarities between this embodiment and the above embodiments will not be repeated. In this embodiment, the scraper 44 can be integrally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com