Biodiesel fuel and preparation method thereof

A biodiesel and material technology, applied in the petrochemical field, can solve the problems of hidden danger of production safety, high energy consumption, low conversion rate, etc., and achieve the effects of good starting performance, good economic benefits, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

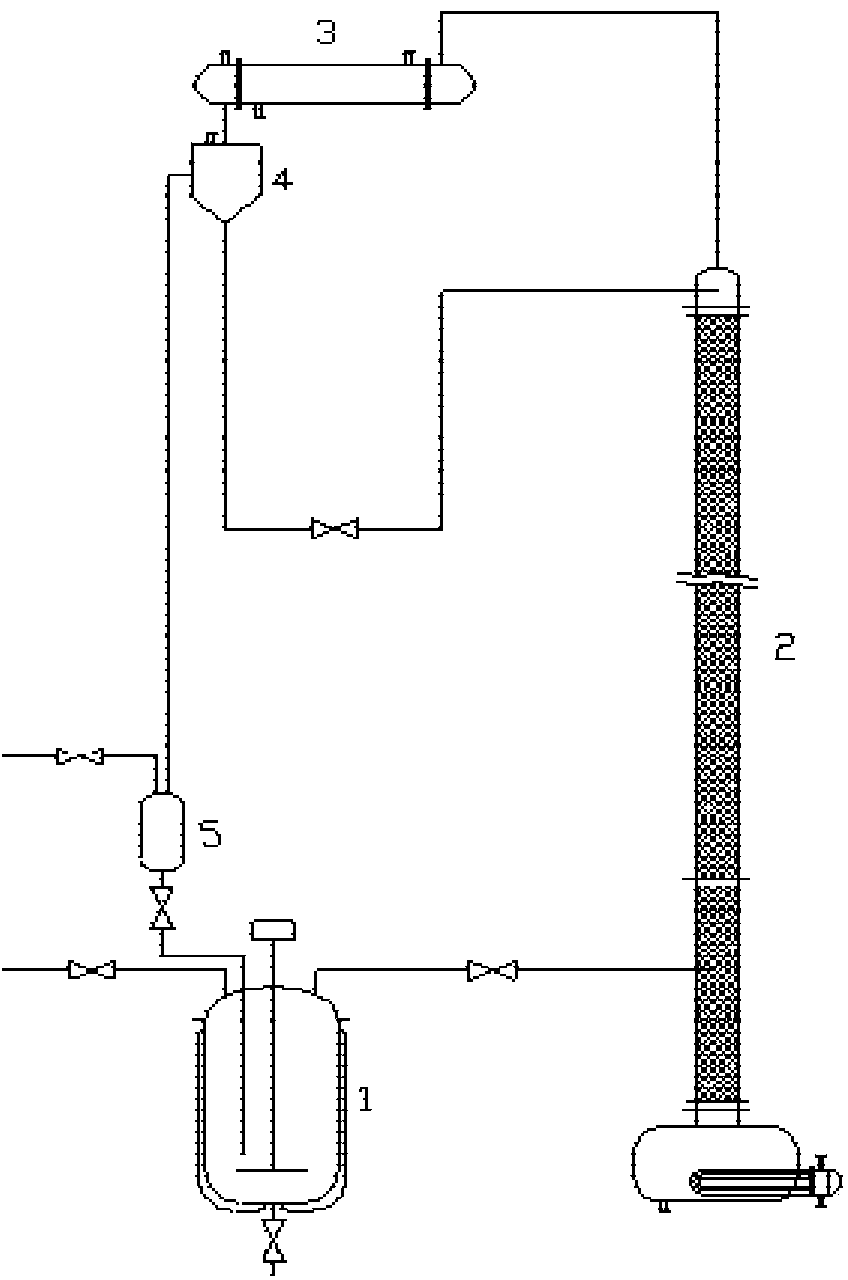

Image

Examples

Embodiment 1

[0025] A method for preparing biodiesel is provided, comprising the steps of:

[0026] Step 1: with CO 2 Replace the air in the esterification reactor 1, put monomeric acid into the esterification reactor heated by heat transfer oil, and add high-temperature-resistant macroporous styrene-based strongly acidic cation exchange resin at the same time;

[0027] Step 2: Warm up the material in the esterification reactor to 130-160°C within 30 minutes, then continuously add DMM through the methanol feeding tank 5 within 30 minutes, and pay attention to the pH of the material in the reactor during the injection process;

[0028] Step 3: When the acid value of the material is less than (GB264-1983) mgKOH / g0.09, stop adding DMM, fully stir and react for 2 hours, then extract and leave in the methanol condenser 3 through the methanol rectification tower and mix with the previous material After reacting for 2 hours, the material is cooled to below 70-80°C and discharged to the semi-fini...

Embodiment 2

[0031] A method for preparing biodiesel, comprising the following steps: replacing the air in a reactor with CO2 before feeding materials, putting monomeric acid into an esterification reactor 1 heated with heat-conducting oil, and simultaneously adding D008 high-temperature-resistant perforated benzene Ethylene-based strongly acidic cation exchange resin. When the temperature of the material was raised to 130-160° C. within 30 minutes, DMM was continuously added from the methanol feeding tank 5 . During the reaction process, the acid value of the material was sampled at regular intervals until the acid value of the material was less than 1mgKOH / g, the addition of DMM was stopped, the temperature of the material was lowered to below 80°C and the material was discharged to obtain vegetable oil methyl ester (new biodiesel semi-finished product). When the vegetable oil methyl ester is cooled to 30°C, it is poured into the tank 6, and the finished product is obtained after slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com