Super capacitor and preparation method thereof

A Farad capacitor and electrolyte technology, applied in the field of capacitors, can solve problems such as Farad capacitors not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

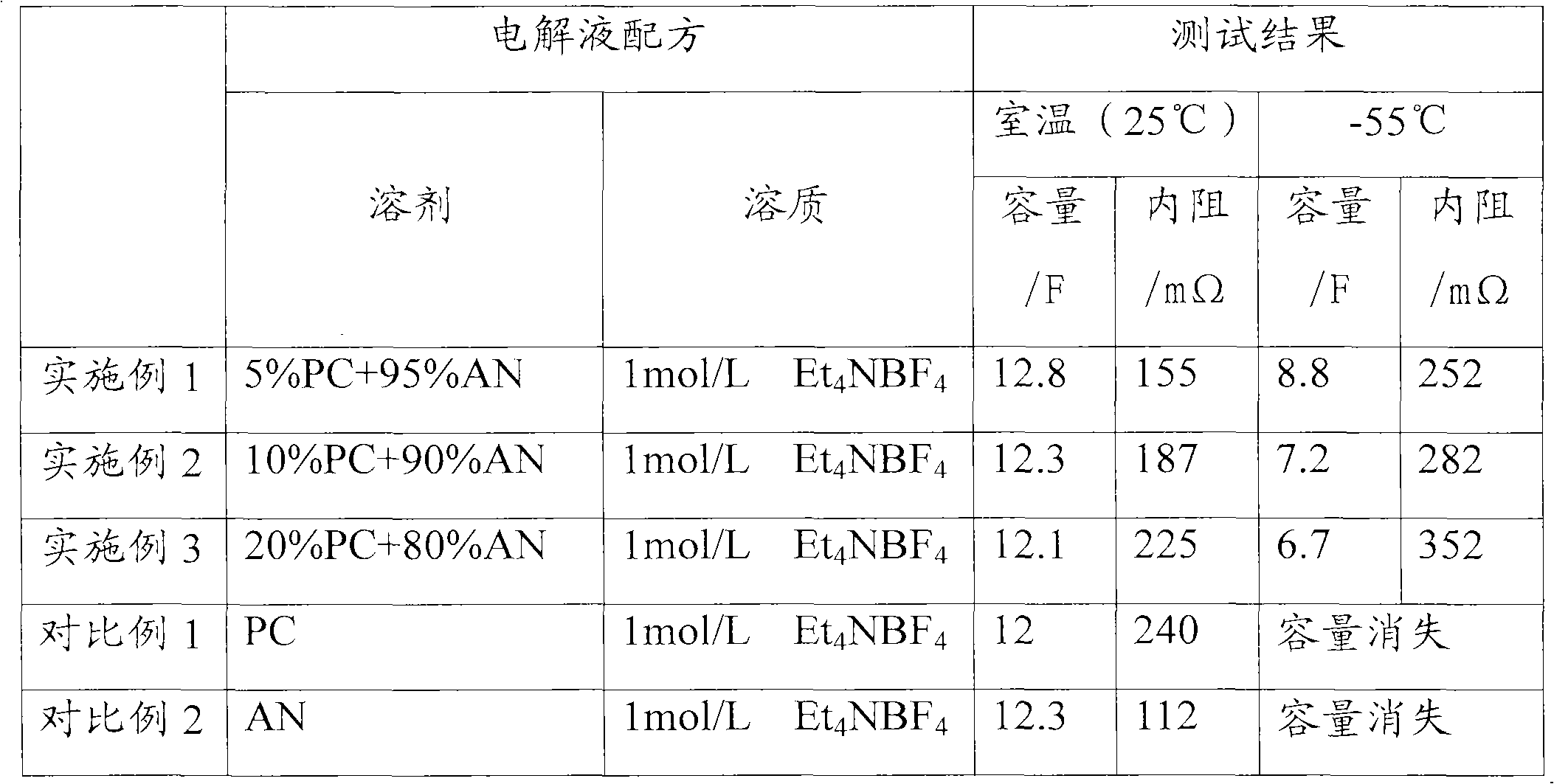

Embodiment 1

[0028] a) Take 90g of activated carbon, 10g of carbon black and 10g of polyvinylidene fluoride and mix them with N-methylpyrrolidone solvent to obtain a slurry;

[0029] b) Use a coater to coat the slurry on aluminum foil to make pole pieces, and then press and cut the pole pieces to obtain positive and negative electrodes;

[0030] c) Winding the positive and negative plates and the diaphragm to form a Faraday capacitor core package, and immersing the Faraday capacitor core package in an electrolyte after drying treatment; the solvent of the electrolyte is PC with a volume ratio of 5:95 And AN, the solute is Et with a concentration of 1mol / L 4 NBF 4 ; Finally, seal and make a farad capacitor.

[0031] The water content in the electrolyte of this embodiment is less than 20 ppm.

Embodiment 2

[0033] a) Take 90g of activated carbon, 10g of carbon black and 10g of polyvinylidene fluoride and mix them with N-methylpyrrolidone solvent to obtain a slurry;

[0034] b) Use a coater to coat the slurry on aluminum foil to make pole pieces, and then press and cut the pole pieces to obtain positive and negative electrodes; to obtain positive and negative electrodes;

[0035] c) Winding the positive and negative plates and the diaphragm to make a Faraday capacitor core package, and immersing the Faraday capacitor core package in electrolyte after drying treatment; the solvent of the electrolyte is PC with a volume ratio of 10:90 And AN, the solute is Et with a concentration of 1mol / L 4 NBF 4 ; Finally, seal and make a farad capacitor.

[0036] The water content in the electrolyte of this embodiment is less than 20 ppm.

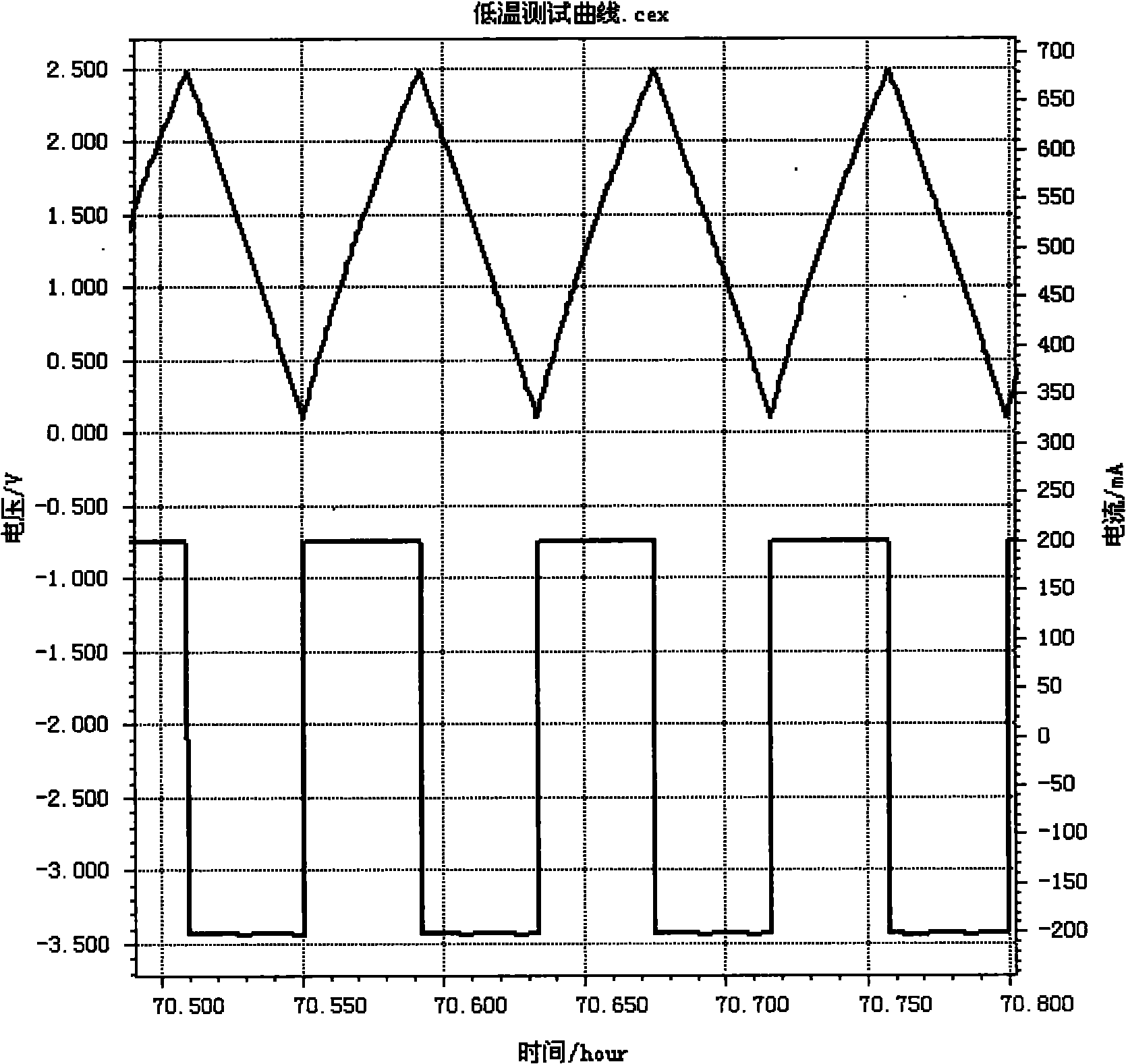

[0037] Take the farad capacitor prepared in this example and test the charge and discharge characteristics in a low temperature environment of -55°C to obtain figure ...

Embodiment 3

[0039] a) Take 90g of activated carbon, 10g of carbon black and 10g of polyvinylidene fluoride and mix them with N-methylpyrrolidone solvent to obtain a slurry;

[0040] b) Use a coater to coat the slurry on aluminum foil to make pole pieces, and then press and cut the pole pieces to obtain positive and negative electrodes;

[0041] c) Winding the positive and negative plates and the diaphragm to make a Faraday capacitor core package, and immersing the Faraday capacitor core package in an electrolyte after drying; the solvent of the electrolyte is PC with a volume ratio of 20:80 And AN, the solute is Et with a concentration of 1mol / L 4 NBF 4 ; Finally, seal and make a farad capacitor.

[0042] The water content in the electrolyte of this embodiment is less than 20 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com