Laser ultrasonic detection device and detection method applicable to large component nondestructive detection

A non-destructive testing and laser ultrasonic technology, which is applied to the analysis of solids, instruments, and analysis materials using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as small active area, fast attenuation, and short ultrasonic propagation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

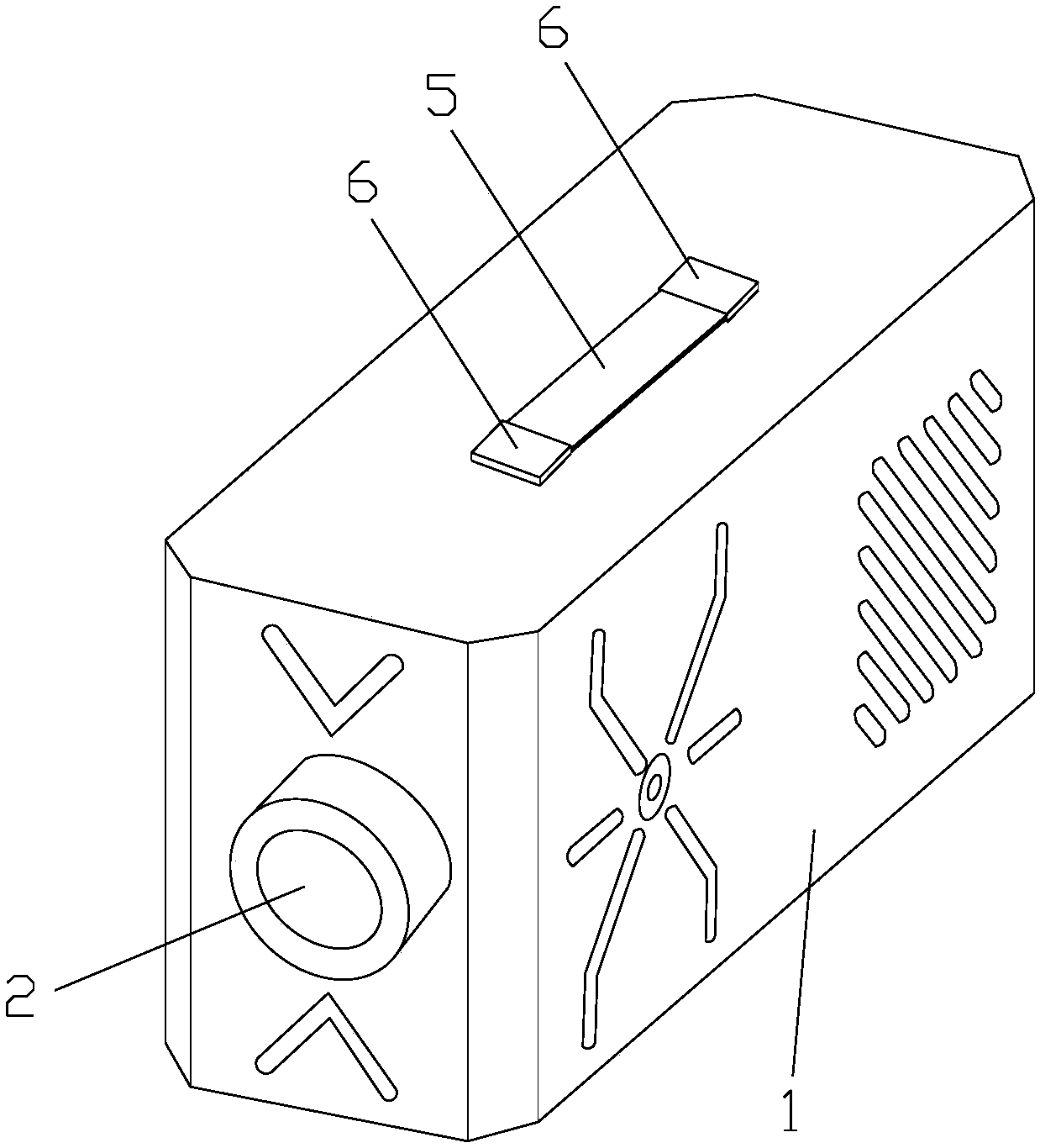

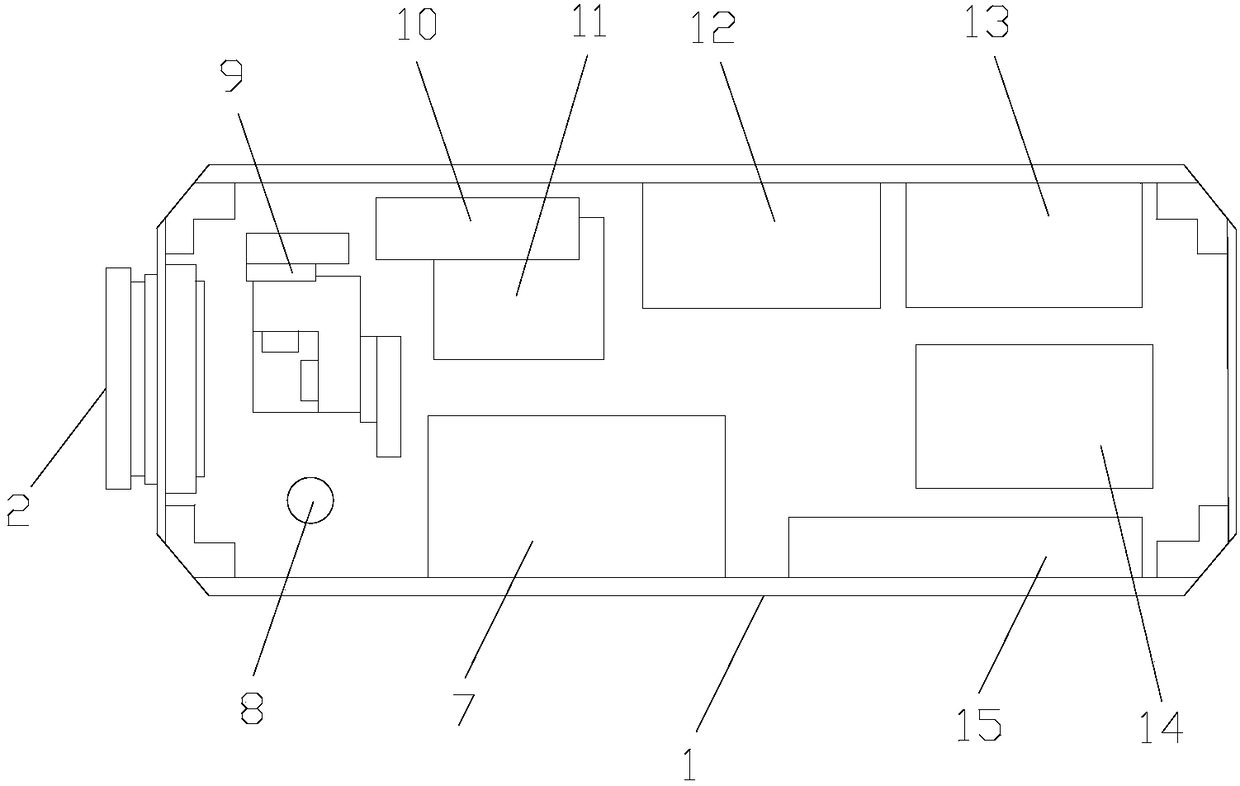

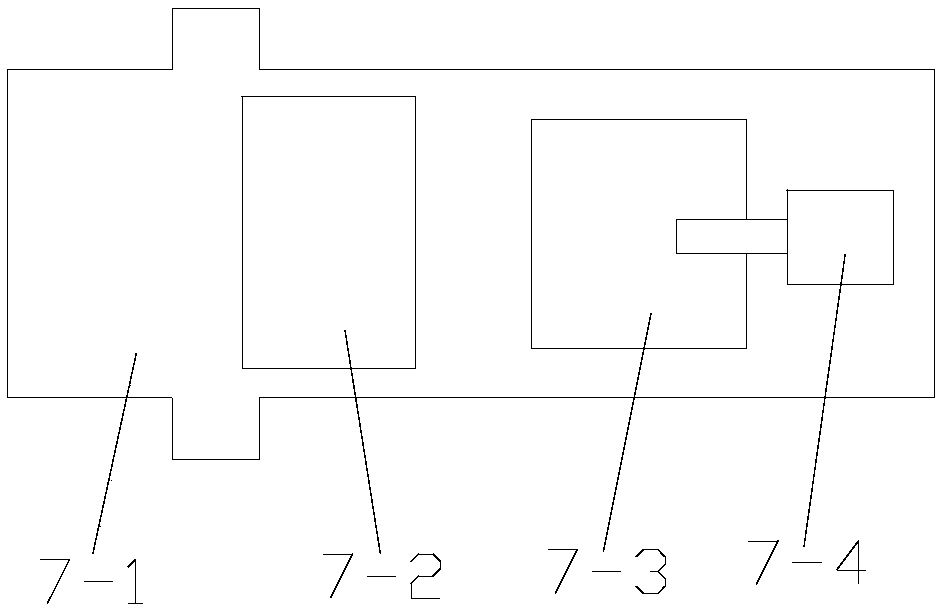

[0073] Such as figure 1 and figure 2 As shown, the laser ultrasonic testing device suitable for non-destructive testing of large components of the present invention includes a power supply 15, a housing 1, an optical system and a control system, and the power supply 15, the optical system and the control system are all arranged in the housing 1, The front end of the housing 1 is a laser light outlet 2, and the upper panel of the housing 1 is provided with a handle 5 and two handle seats 6 for fixedly connecting the handle 5, and the optical system includes Laser and lens group module 7, total reflection mirror 8 and two-dimensional galvanometer 9, described laser device and lens group module 7 are arranged at the position in the middle of the lower part of housing 1, and described total reflection mirror 8 is arranged at laser and lens In front of the group module 7, the two-dimensional vibrating mirror 9 is arranged above the total reflection mirror 8; as image 3 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com