Patents

Literature

128 results about "Thiocarboxylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiocarboxylic acids are organosulfur compounds related to carboxylic acids by replacement of one of the oxygen atoms with a sulfur atom. Two tautomers are possible: a thione form (RC(S)OH) and a thiol form (RC(O)SH). These are sometimes also referred to as "carbothioic O-acid" and "carbothioic S-acid" respectively. Of these the thiol form is most common (e.g. thioacetic acid).

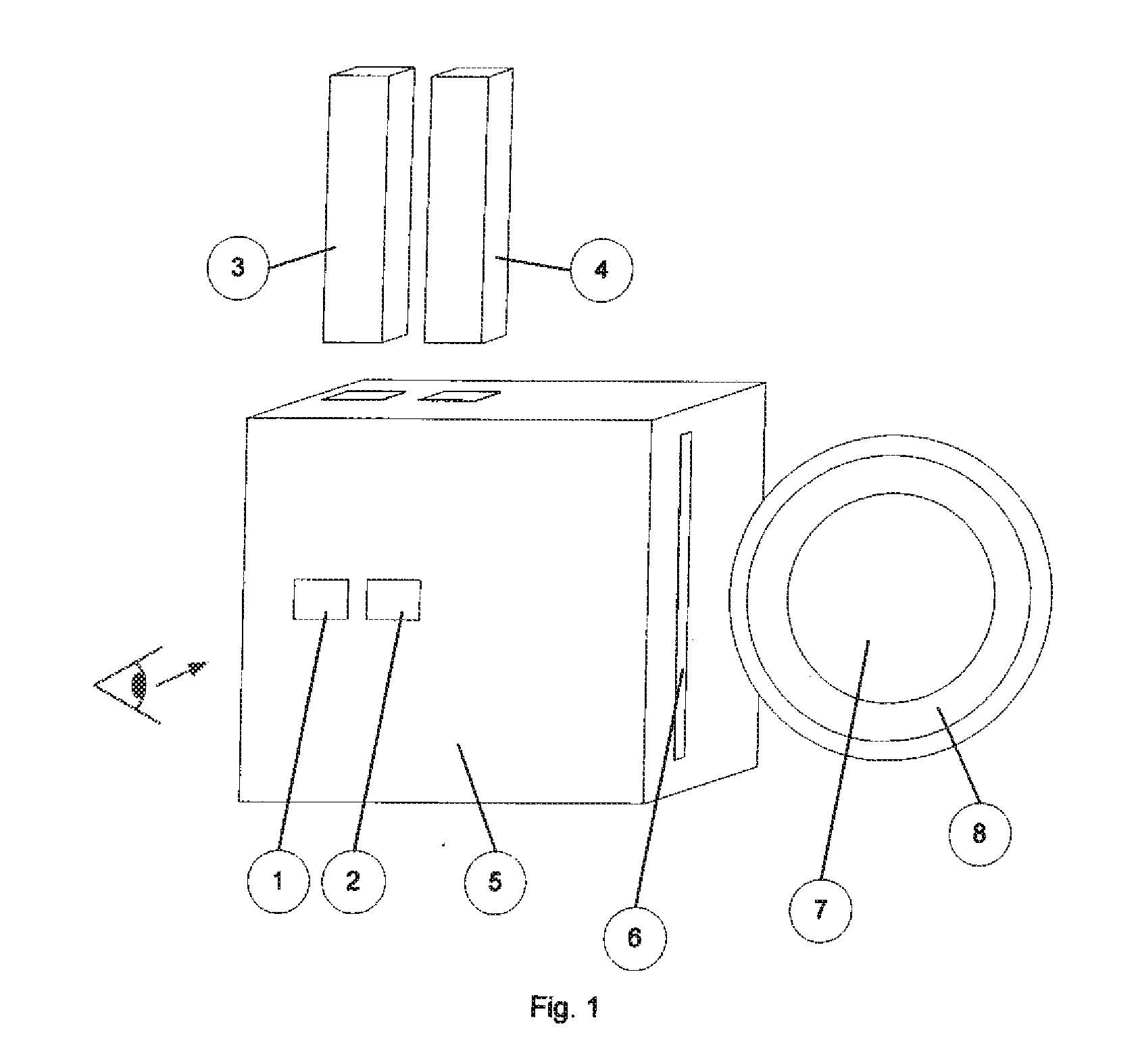

Functionalized polymers and methods for their manufacture

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a carboxylic or thiocarboxylic ester containing a silylated amino group.

Owner:BRIDGESTONE CORP

Method of polishing a multi-layer substrate

InactiveUS6852632B2Increase rate increaseOther chemical processesAbrasion apparatusThiocarboxylic acidNitroso

The invention provides a method for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (i) contacting the first metal layer with a polishing system comprising a liquid carrier, at least one oxidizing agent, at least one polishing additive that increases the rate at which the system polishes at least one layer of the substrate, wherein the polishing additive is selected from the group consisting of pyrophosphates, condensed phosphates, phosphonic acids and salts thereof, amines, amino alcohols, amides, imines, imino acids, nitriles, nitros, thiols thioesters, thioethers, carbothiolic acids, carbothionic acids, thiocarboxylic acids, thiosalicylic acids, and mixtures thereof, and a polishing pad and / or an abrasive, and (ii) polishing the first metal layer with the system until at least a portion of the first metal layer is removed from the substrate.

Owner:CABOT MICROELECTRONICS CORP

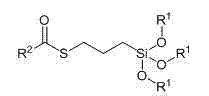

Aqueous catalytic process for the preparation of thiocarboxylate silane

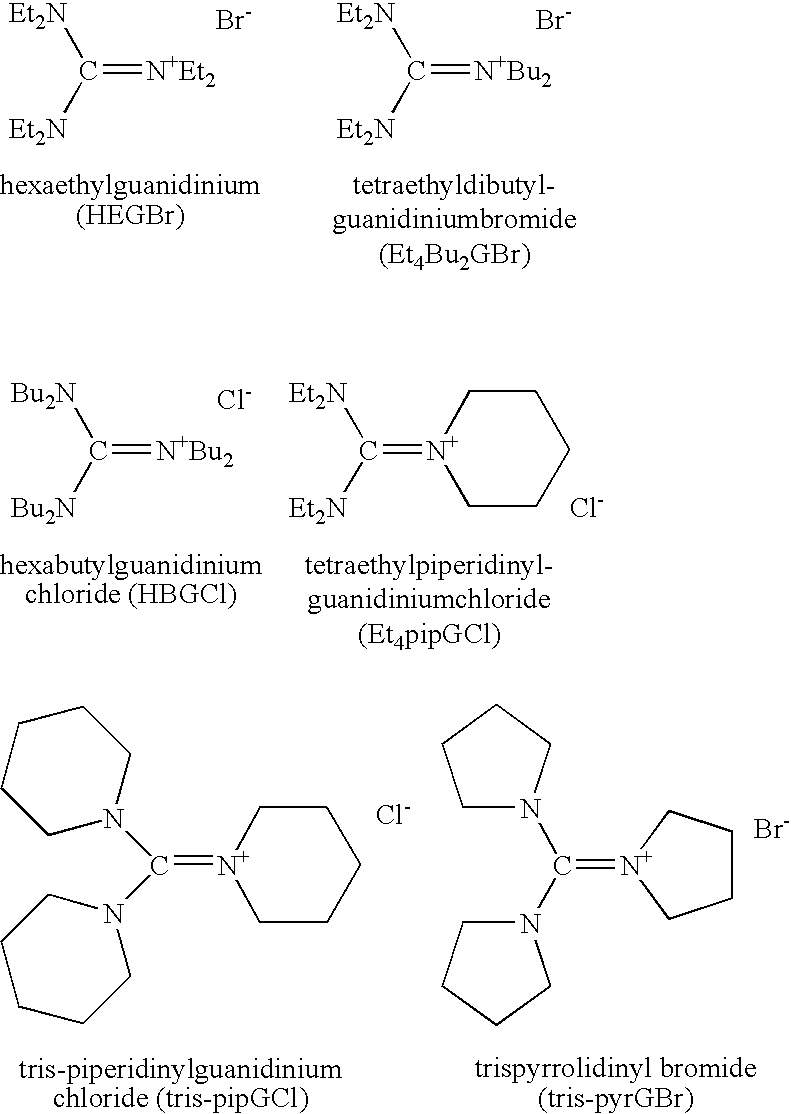

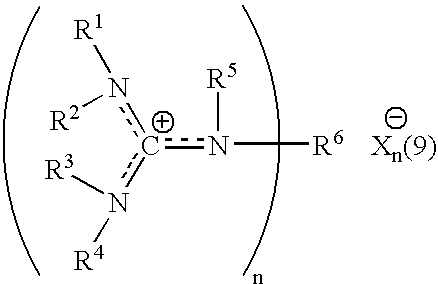

An aqueous process is described in which thiocarboxylate silane is produced from haloalkyl silane by reaction of the haloalkyl silane with an aqueous solution of thiocarboxylate salt in the presence of a catalytically effective amount of alkylguanidinium salt.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Plastic composition and plastic surface metallizing method

ActiveCN101851431AHigh affinityHigh degree of surface activationLiquid/solution decomposition chemical coatingThiocarboxylic acidHigh activation

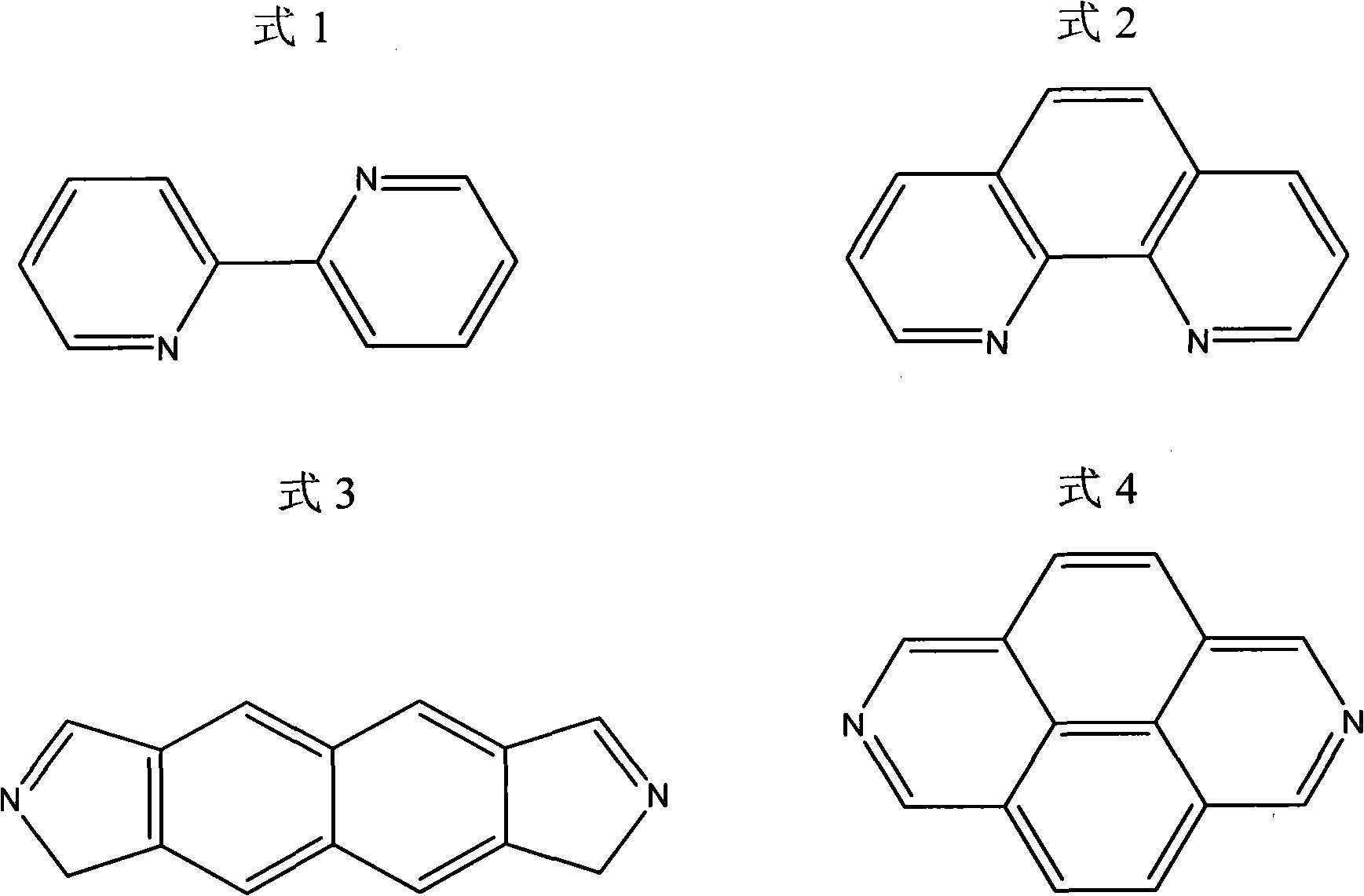

The invention provides a plastic composition and a plastic surface metallizing method. The plastic composition contains plastic matrix resin and metal chelate; the metal chelate is a complex of metal ions and organic chelating agent; and the organic chelating agent is at least one of diketone, aminocarboxylic acid, thiocarboxylic acid, polycarboxylic acid and nitrogen-containing heterocyclic compound with a general formula CnH8N2, wherein n is 10, 12 or 14. The plastic surface metallizing method comprises the following steps of: performing injection molding on the plastic composition provided by the invention to form a plastic piece, then performing laser etching on the plastic piece by adopting laser with wavelength of 1,064 nanometers to 1,000 microns, and chemically plating a laser etching area to form a metal plating layer. The organic chelating agent adopted in the plastic composition has low cost and is sensitive to the laser, so the plastic surface has high activation degree; and when the plastic surface is metallized, the infrared laser with lower cost is adopted so that the metal ions of the metal chelate in the plastic piece are decomposed as an active center of subsequent chemical plating and the precision is very high.

Owner:BYD CO LTD

Polymer-coated perovskite quantum dots and preparation method thereof

InactiveCN109306265AGood dispersionNo coagulationLuminescent compositionsThiocarboxylic acidWater vapor

The invention provides a preparation method of polymer-coated perovskite quantum dots. The preparation method comprises the following steps: supplying perovskite quantum dots, and dispersing the perovskite quantum dots in a solvent to form a perovskite quantum dot solution, wherein ligands on the surfaces of the perovskite quantum dots comprise thiocarboxylic acid ligands; adding a polymer monomerand a photoinitiator into the perovskite quantum dot solution for reacting under an ultraviolet radiation condition in which the water vapor content is less than 30 percent to generate the polymer-coated perovskite quantum dots, wherein the polymer monomer is an unsaturated polymer monomer containing amidogen.

Owner:TCL CORPORATION

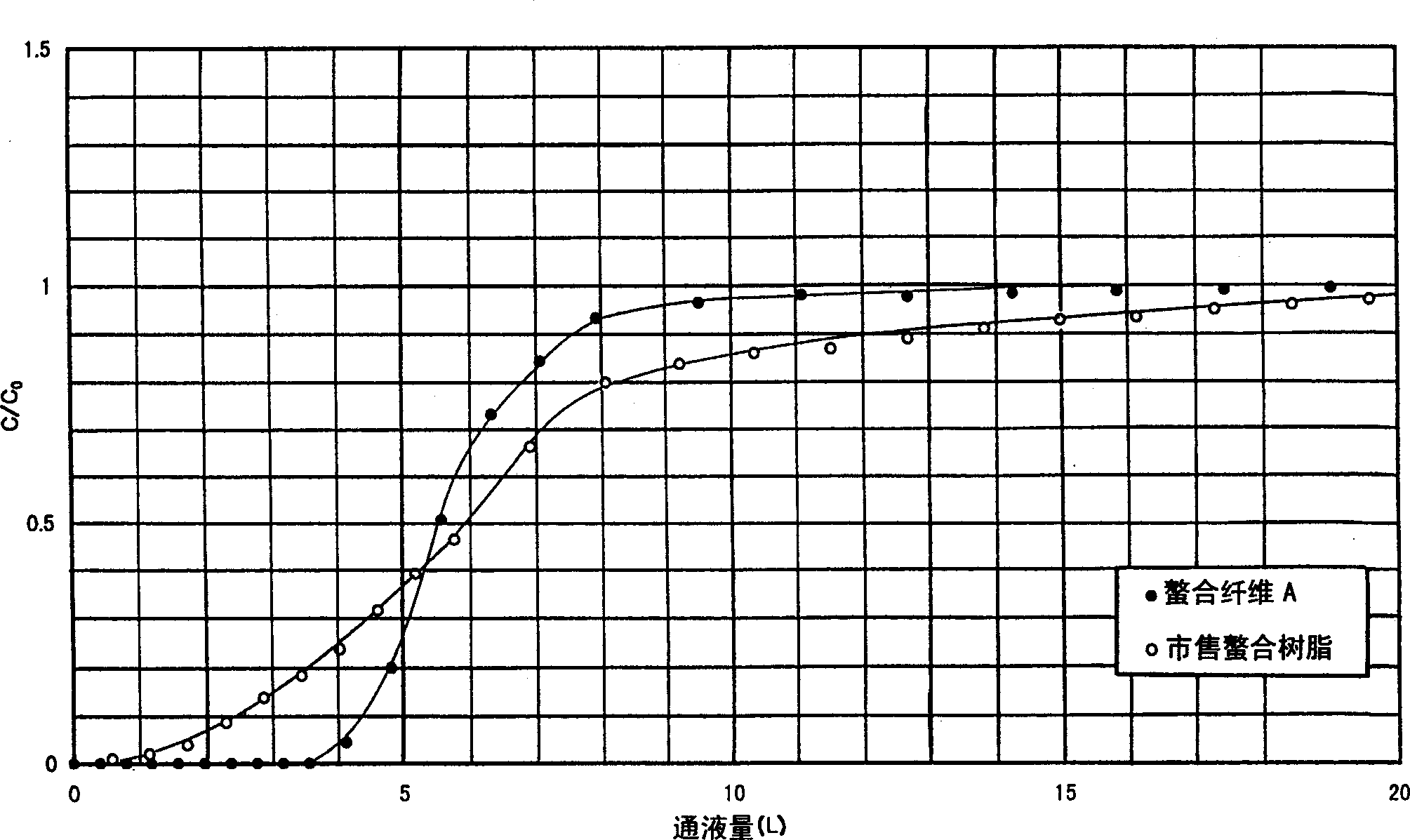

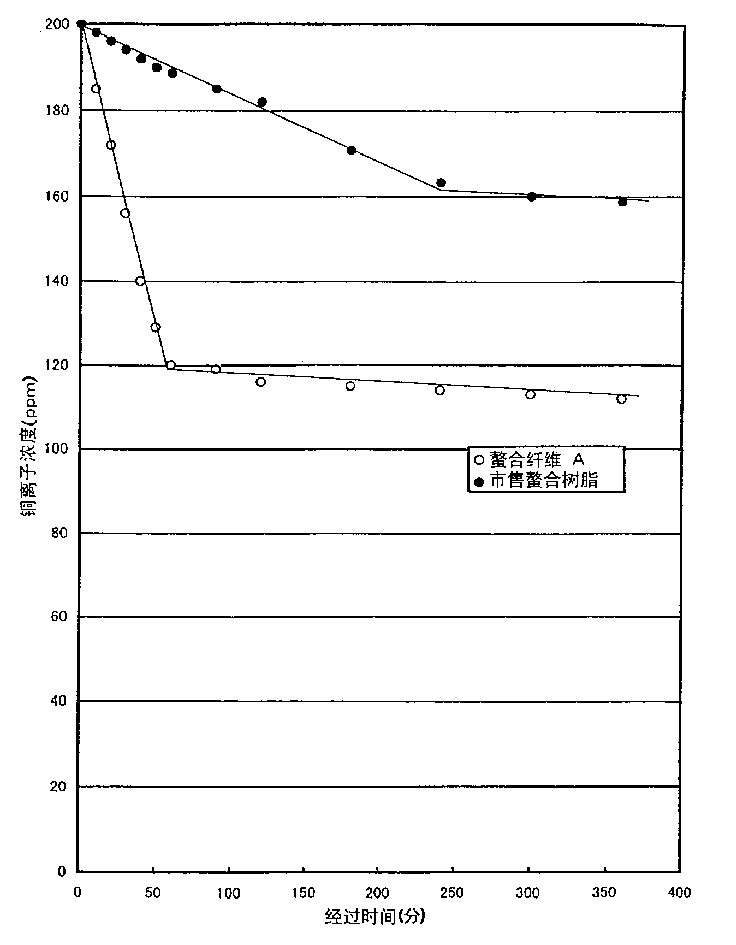

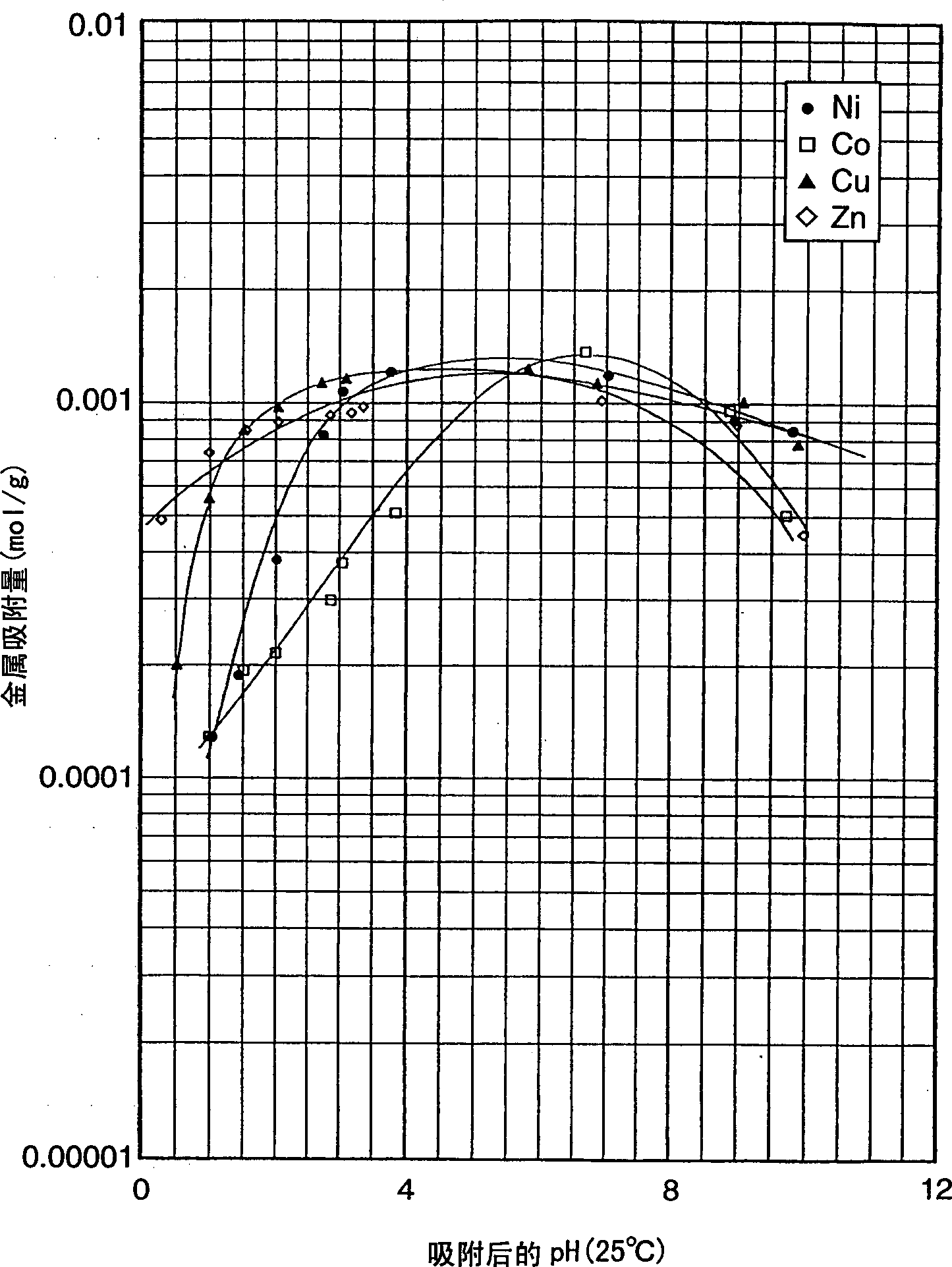

Metal chelate-forming fiber, process for producing the same, method of trapping metal ion with the fiber, and metal chelate fiber

InactiveCN1352713ASimple and Safe ManufacturingManufacture is simple and safe and efficientSynthetic fibresWater contaminantsThiocarboxylic acidPhosphoric acid

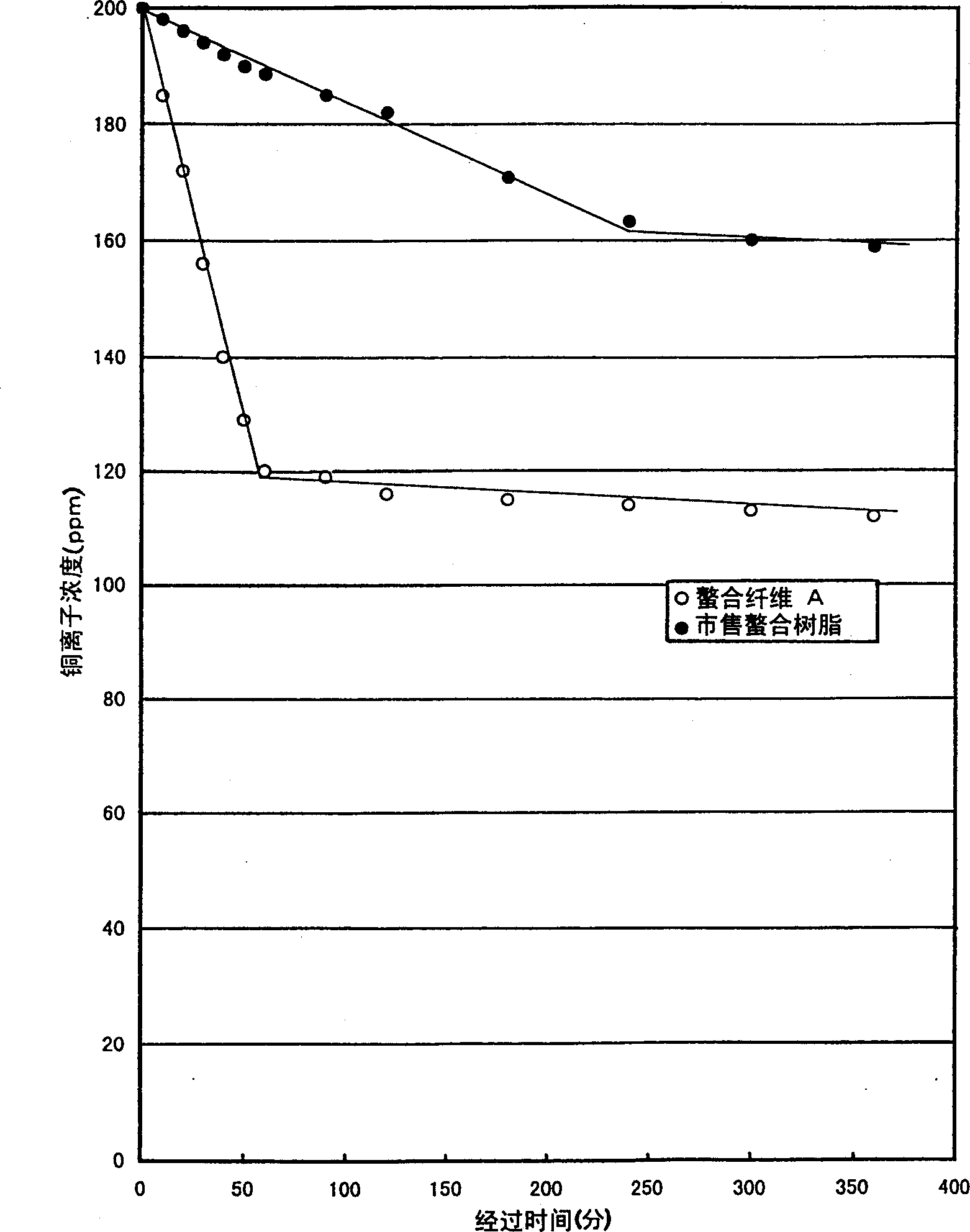

A fiber capable of forming a metal chelate and a process for producing the same are disclosed, wherein the fiber is characterized in that at least one metal chelate-forming compound selected from the group consisting of aminocarboxylic acid. aminocarboxylic acid, thiocarboxylic acid and phosphoric acid. which are reactive with a glycidyl group, is bonded to a molecule of a synthetic fiber through a crosslinkable compound having a reactive double bond and a glycidyl group in its molecule. The chelate-forming fiber is excellent in capturing harmful heavy metal ions and can be easily produced in a simple and safe way at a low cost.

Owner:CHUBU KIRESUTO +1

Polishing system and method of its use

The invention provides a system for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (i) a liquid carrier, (ii) at least one oxidizing agent, (iii) at least one polishing additive that increases the rate at which the system polishes at least one layer of the substrate, wherein the polishing additive is selected from the group consisting of pyrophosphates, condensed phosphates, phosphonic acids and salts thereof, amines, amino alcohols, amides, imines, imino acids, nitriles, nitros, thiols, thioesters, thioethers, carbothiolic acids, carbothionic acids, thiocarboxylic acids, thiosalicylic acids, hydroxylates, carbonylates, carboxylates, and acids thereof, and mixtures thereof, (iv) at least one stopping compound, and (v) a polishing pad and / or an abrasive. The invention also provides a method of polishing a substrate comprising contacting a surface of a substrate with the system and polishing at least a portion of the substrate therewith. Moreover, the invention provides a method for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (a) contacting the first metal layer with the system, and (b) polishing the first metal layer with the system until at least a portion of the first metal layer is removed from the substrate.

Owner:CABOT MICROELECTRONICS CORP

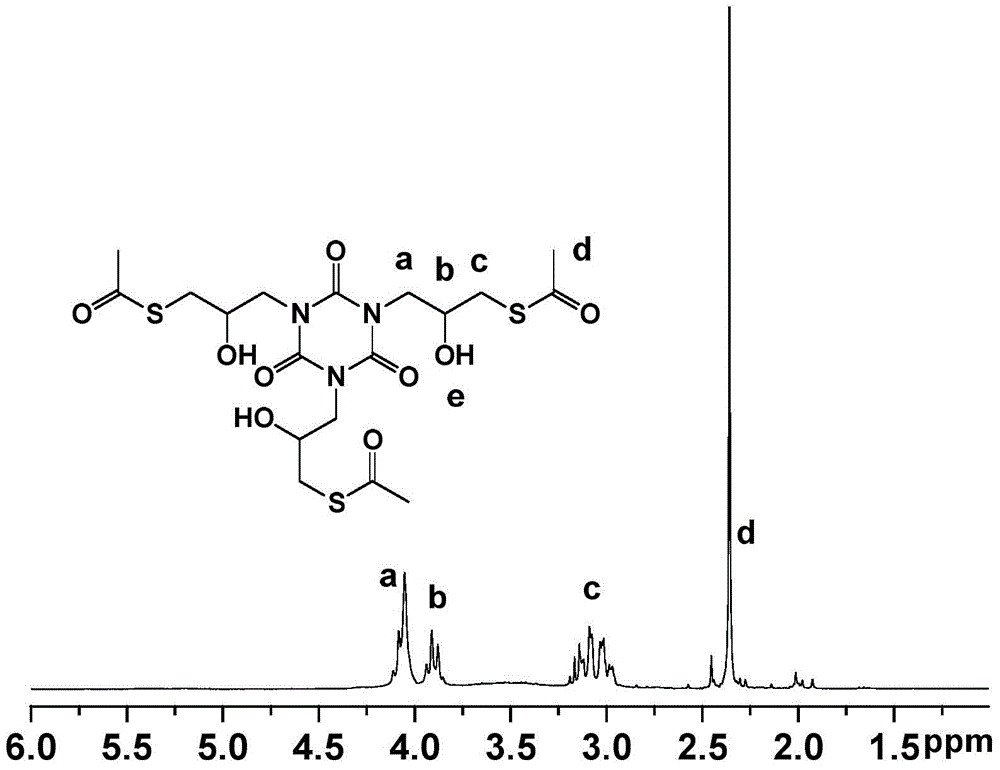

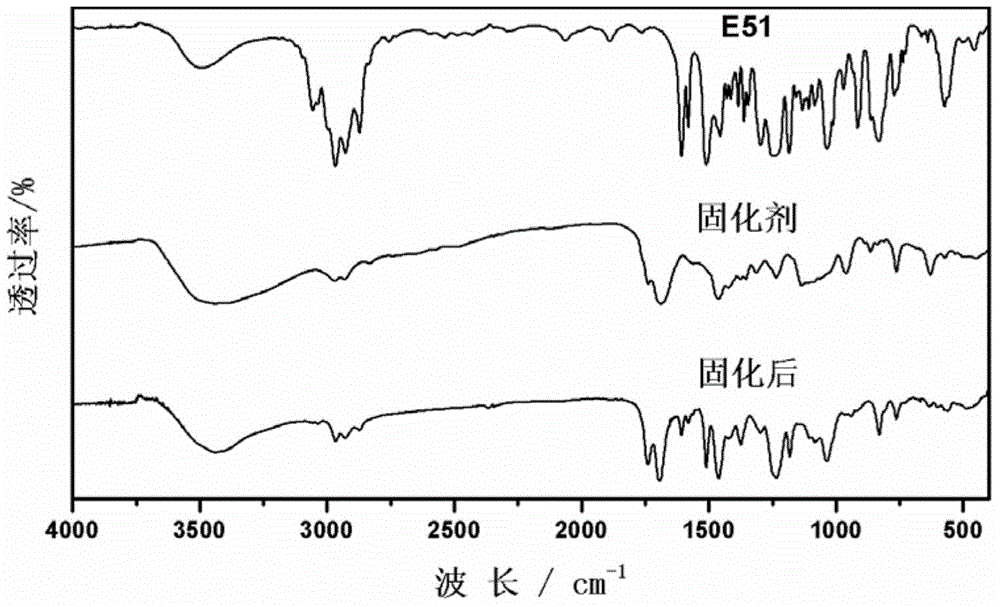

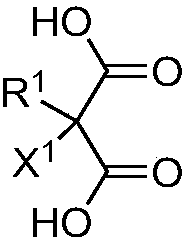

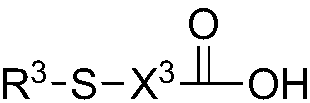

Latent polythiol curing agent, and synthetic method and application of latent polythiol curing agent

The invention discloses a latent polythiol curing agent, and a synthetic method and an application of the latent polythiol curing agent. The molecule of the latent polythiol curing agent comprises more than one beta-hydroxyl carbothioate structural unit shown in the description. In the structural unit, R1 is at least selected from (CH2)nCH3, C(CH3)3, and phenyl, wherein n is any integer selected from 0-6. The synthetic method comprises: taking an epoxy-group-containing compound and carbothioic acid, the mole ratio of which is from 1:1.01 to 1:1.5, performing a reaction at -10 DEG C to 30 DEG C for 1-24 h, and removing excessive carbothioic acid to obtain the latent polythiol curing agent. The latent polythiol curing agent can react with an epoxy resin to form a polymer. The latent polythiol curing agent can be stably stored for a long time and is free of sulfur stink. The synthetic method is simple, fast, and efficient, and is low in cost. The latent polythiol curing agent has bright application prospects in the fields, such as thermosetting plastics, coatings, and elastomer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Quantum dot having organic ligand and application thereof

ActiveCN108624320AImprove oxidation stabilitySolid-state devicesSemiconductor/solid-state device manufacturingThiocarboxylic acidAlcohol

The present invention provides a quantum dot having a ligand layer on a surface thereof, the ligand layer comprises a malonic acid derivative, a thiothiol compound, a thiocarboxylic acid compound, andmore than one of an ester group and sulfur alcohol group-based compounds. The quantum dot is excellent in oxidation stability, and can be effectively applied to various applications such as a quantumdot film, a color filter, and a quantum dot light-emitting diode.

Owner:DONGWOO FINE CHEM CO LTD

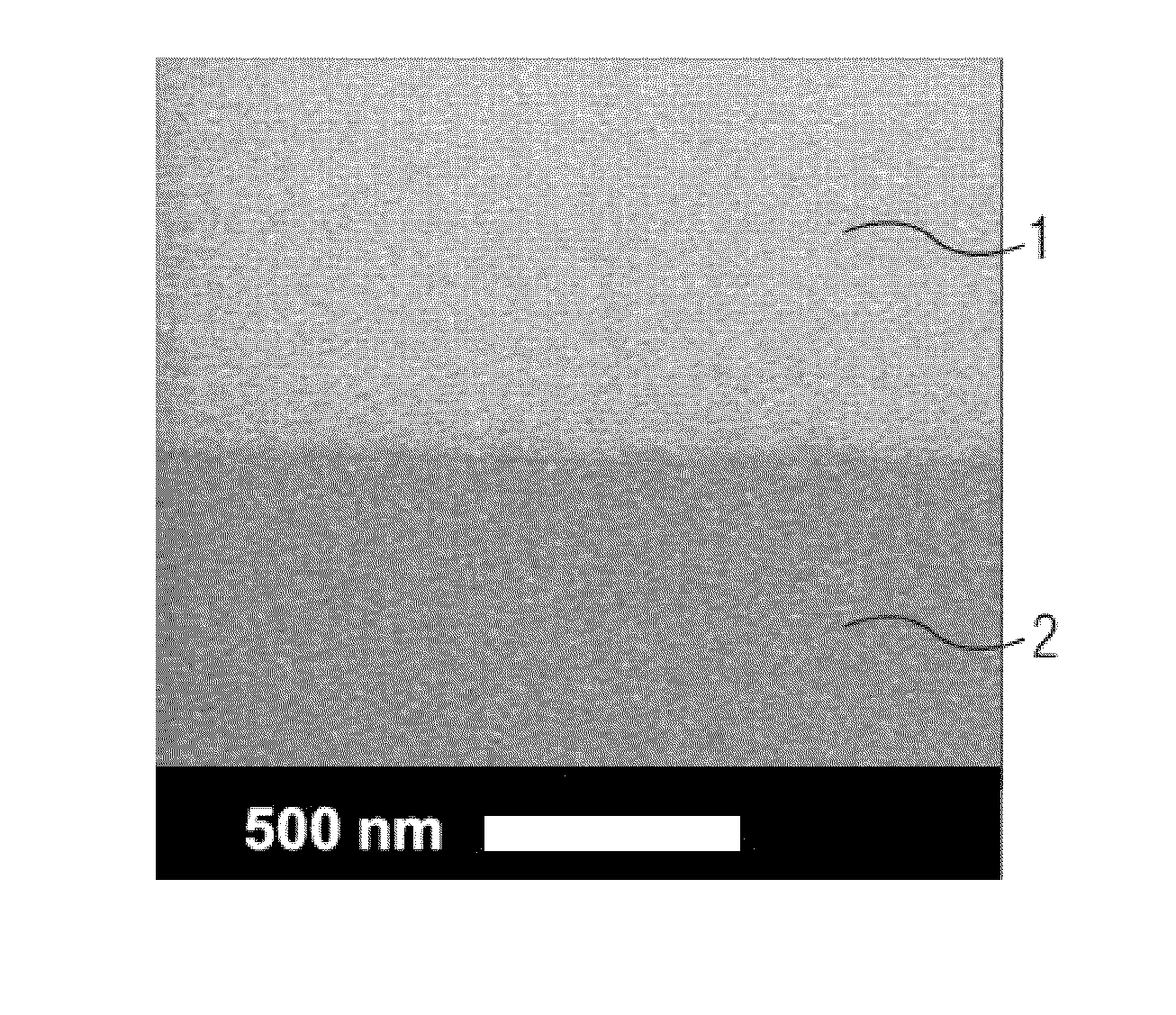

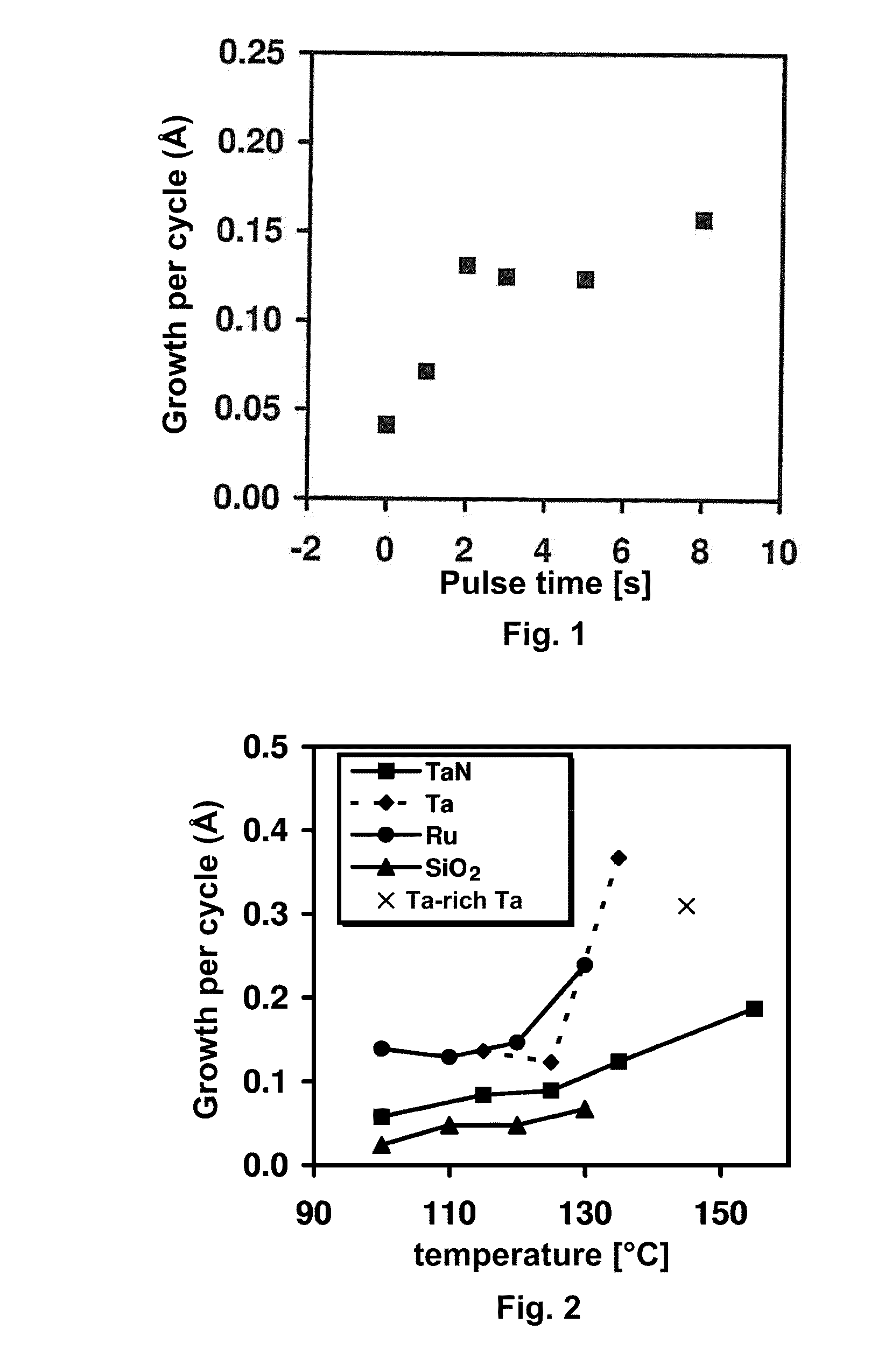

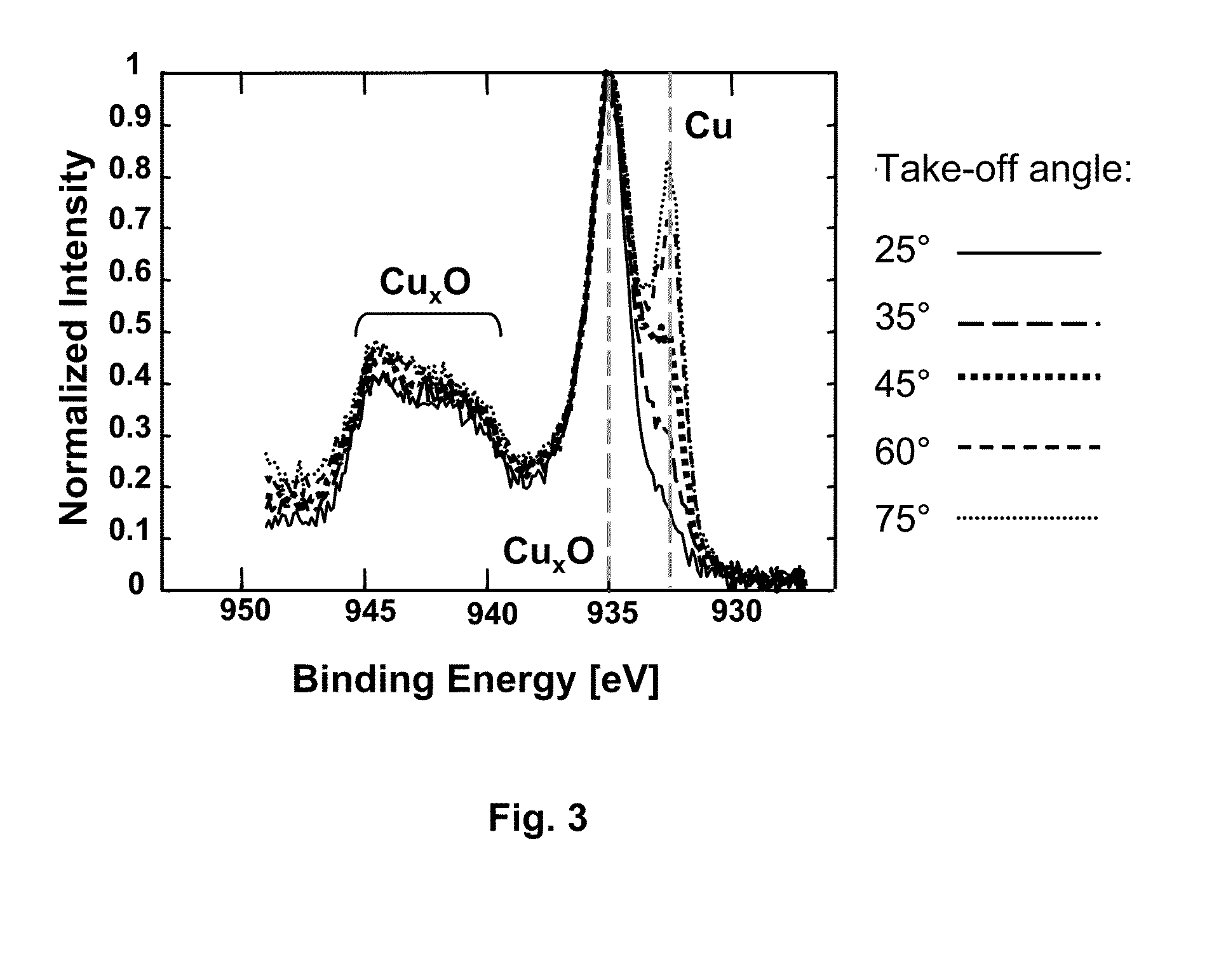

Substrate Having a Coating Comprising Copper and Method for the Production Thereof by Means of Atomic Layer Deposition

ActiveUS20100301478A1Overcome disadvantagesSimple methodGroup 1/11 element organic compoundsSemiconductor/solid-state device detailsCopperAtomic layer deposition

A method can be used for the production of a coated substrate. The coating contains copper. A copper precursor and a substrate are provided. The copper precursor is a copper(I) complex which contains no fluorine. A copper-containing layer is deposited by means of atomic layer deposition (ALD) at least on partial regions of the substrate surface by using the precursor. Optionally, a reduction step is performed in which a reducing agent acts on the substrate obtained in the layer deposition step. In various embodiments, the precursor is a complex of the formula L2Cu(X∩X) in which L are identical or different σ-donor-π acceptor ligands and / or identical or different σ,π-donor-π acceptor ligands and X∩X is a bidentate ligand which is selected from the group consisting of β-diketonates, β-ketoiminates, β-diiminates, amidinates, carboxylates and thiocarboxylates.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

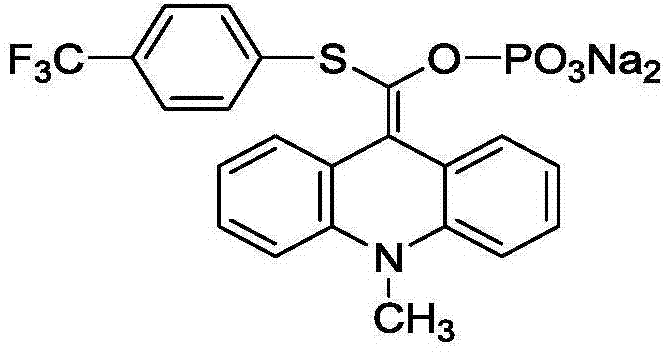

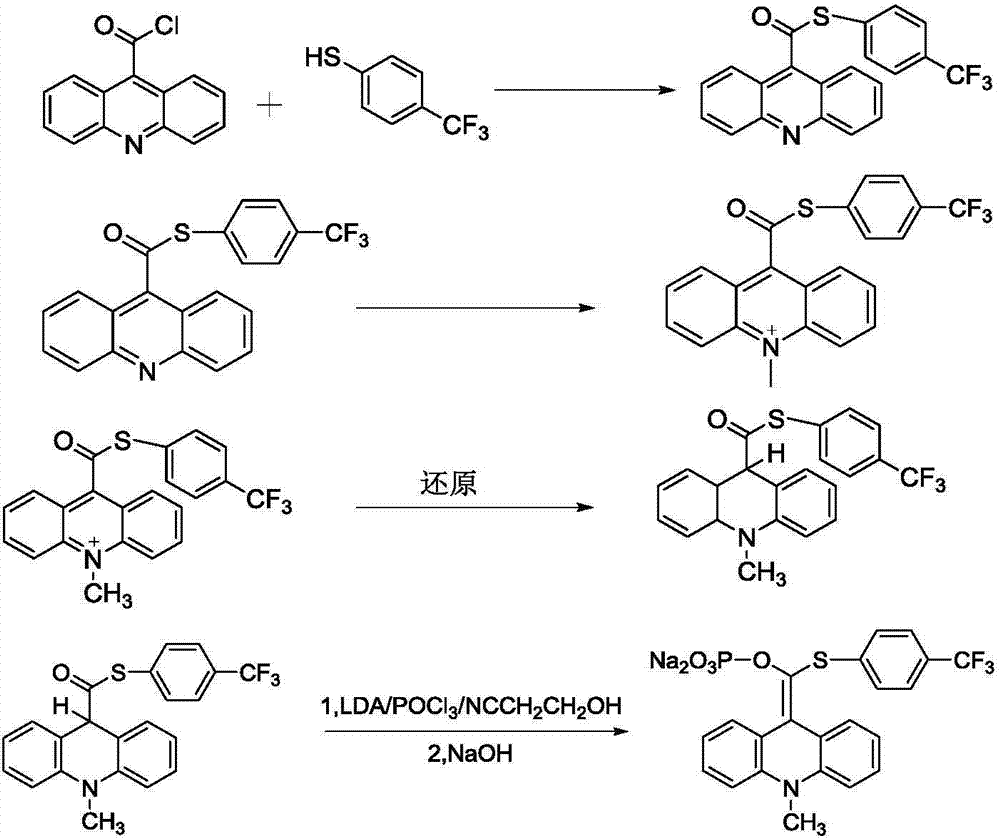

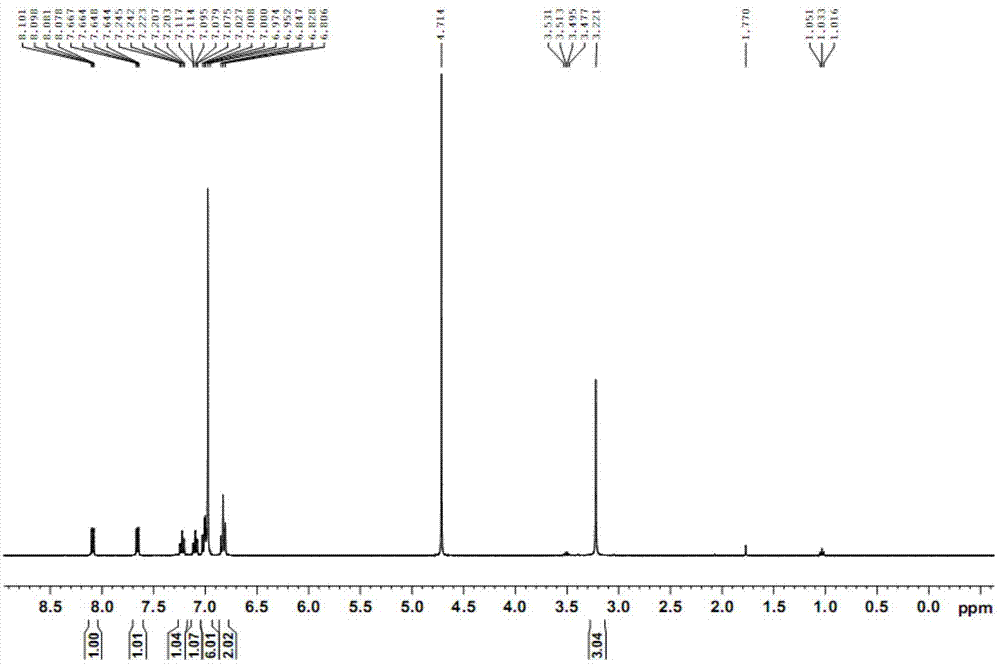

Acridinium ester derivative, synthesis method and application thereof

InactiveCN104761584AEasy to useHigh sensitivityPhosphorus organic compoundsLuminescent compositionsThiocarboxylic acidSynthesis methods

The invention discloses an acridinium ester derivative, a synthesis method and application thereof. The chemiluminescent acridinium ester derivative provided by the invention has a structural formula shown as formula I. The invention further discloses a synthesis method for the compound shown as formula I, and the method includes: (1) synthesizing acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (2) synthesizing 10-methyl-acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (3) synthesizing 10-methyl-9, 10-dihydroacridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; and (4) synthesizing TfS-APS. The acridinium ester derivative provided by the invention can be used as an immunoassay tracer to a chemiluminescence immunoassay reagent system with alkaline phosphatase (ALP) as the marker enzyme. The application effect in a kit proves that the acridinium ester derivative involved in the invention can detect 1*10<-19>mol ALP molecules, and has the advantages of high sensitivity, long luminescence duration, simple use, constant intensity under room temperature condition, and no need for precise temperature control, etc.

Owner:BEIJING LEADMAN BIOCHEM

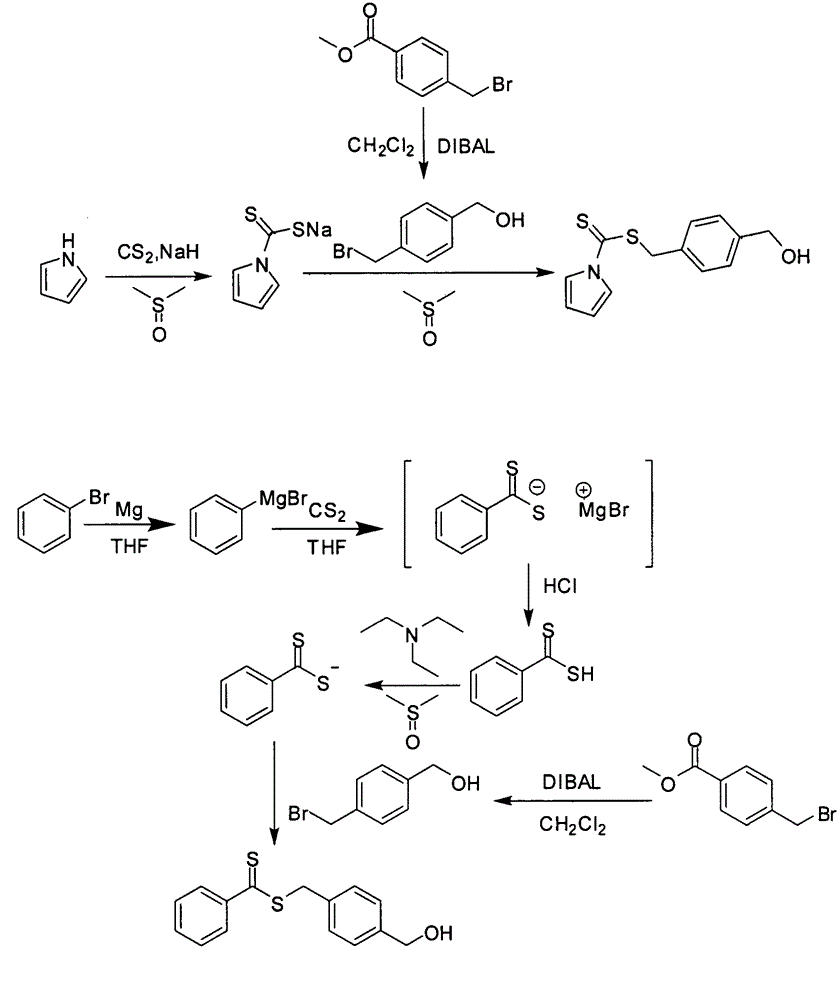

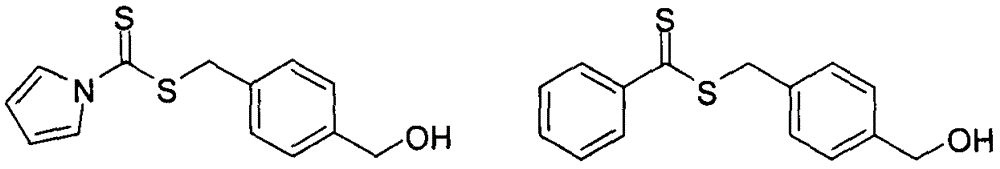

Synthesis method of RAFT chain transfer agent containing terminal hydroxyl

InactiveCN103819390ASimple and mild reaction conditionsIncrease reaction rateOrganic chemistryGrignard reagentSynthesis methods

The invention belongs to the field of organic synthesis, and provides a synthesis method of an RAFT chain transfer agent containing terminal hydroxyl; the synthesis method has the advantages of mild conditions, no need of catalysts and high reaction speed, and is applied to the preparation of segmented copolymers by combining the RAFT polymerization with the hydroxyl-triggered ring opening polymerization. Pyrrole reacts with sodium hydride and carbon disulfide, or a grignard reagent reacts with the carbon disulfide to generate disulfo-carboxylate; the disulfo-carboxylate is reacted with 4-bromine methyl benzyl alcohol for 1 hour at room temperature with dimethyl sulfoxide as a solvent; the generated crude product is implemented with such experimental methods as extraction and column chromatography to finally obtain the RAFT chain transfer agent containing the terminal hydroxyl (see attached drawing). The RAFT chain transfer agent synthesized by the method, provided by the invention, overcomes the defect that only the RAFT polymerization can be implemented in the existing preparation of the RAFT chain transfer agent. The RAFT chain transfer agent containing a trigger radical at the terminal can synchronously realize the combination of the RAFT and the ring opening polymerization (ROP) to prepare the segmented copolymers with certain structures and functions, and has a broad application prospect in a plurality of fields of drug release, bioengineering materials, material separation and immunoassay.

Owner:NANJING UNIV OF TECH

Antimony/ titanium composite catalyst and application thereof in method for preparing polyethylene glycol terephthalate (PET) copolyesters

The invention discloses a high-activity antimony / titanium composite catalyst, which contains the following components: 1 antimony catalysts, 2 titanium catalysts, 3 first catalyst promoters and 4 second catalyst promoters, wherein the antimony catalysts are oxides and salts of antimony, the titanium catalysts are titanates, the first catalyst promoters are phosphoric acids, phosphorous acids and alkyl groups and / or polyaryl ethers of the phosphorous acids, and the second catalyst promoters are benzothiodiazoles. The antimony / titanium composite catalyst can be used in a method for preparing polyethylene glycol terephthalate (PET) copolyesters, which includes the following steps: 1 mixing and adding the antimony / titanium catalyst, the first catalyst promoters, the second catalyst promoters and binary acids into a reaction system, 2 leading the terephthalic acids, esters of the terephthalic acids and excess ethylene glycol to together perform an esterification reaction at temperature of 240-260 DEG C, at pressure of 0.2-0.4MPa and with reaction time of 1-2 hours, and 3 adding copolymerization glycol monomers for a polycondensation reaction to obtain the copolyesters. The antimony / titanium composite catalyst and the application thereof in the method for preparing the PET copolyesters have the advantages that the catalyst can activate the antimony series catalyst and shortens polycondensation time, and the problem of decreasing of polyester heat stability due to the fact that the antimony series catalyst is apt to yellow products is solved.

Owner:MATRIX GUANGZHOU CHEM CORP

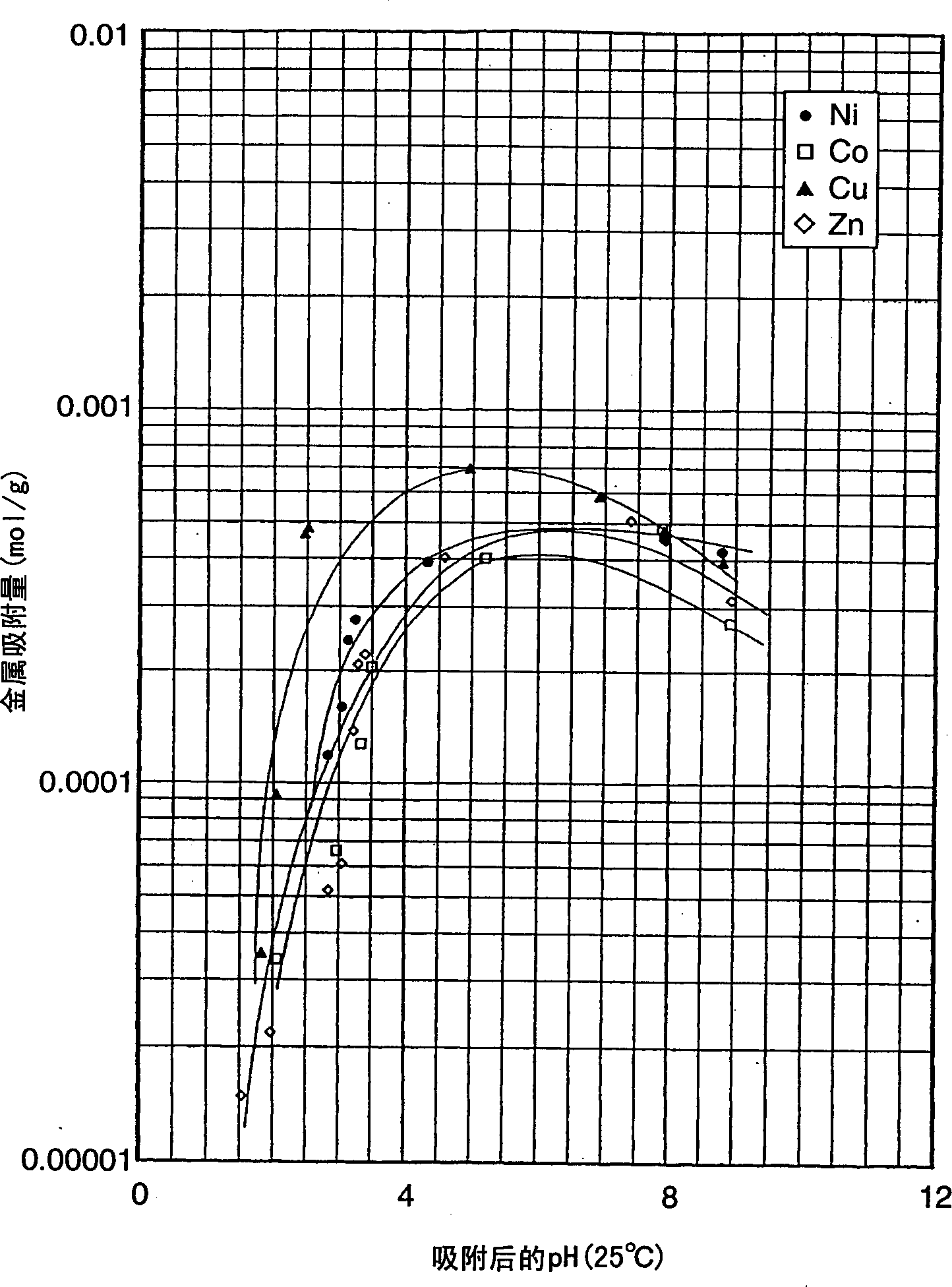

Fiber capable of forming metal chelate process for producing the same, method of trapping metal ion with the fiber, and method chelate fiber

InactiveCN1341176AIon-exchange process apparatusOther chemical processesThiocarboxylic acidRegenerating fibers

A fiber capable of forming a metal chelate and a process for producing the same are disclosed, wherein the fiber is characterized in that at least one metal chelate-forming compound selected from the group consisting of aminodicarboxylic acids, aminocarboxylic acids, thiocarboxylic acids and phosphoric acid, which are reactive with a glycidyl group, is bonded to a molecule of a natural fiber or regenerated fiber through a crosslinkable compound having a reactive double bond and a glycidyl group in its molecule. There are also disclosed a method of capturing metal ions using the fiber and a metal chelate fiber which can effectively make use of the characteristics of the metals and can be easily discarded or incinerated.

Owner:KIRESUTO +1

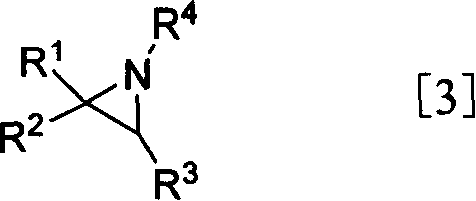

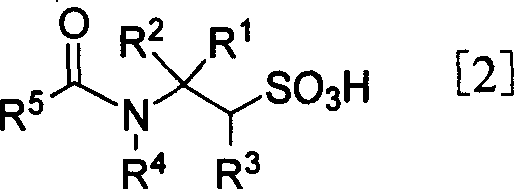

Preparation of taurine and derivatives thereof

InactiveCN101255126AEasy to manufactureHigh purityOrganic chemistryOrganic compound preparationThiocarboxylic acidAziridine

The invention provides a novel preparation method for taurine, substituted taurine and N-acylated derivates. The method comprises taking aziridine and substituted aziridine as raw material, obtaining N-acylated taurine derivates by opening loop and oxygenizing, hydrolyzing N-acylated taurine derivates to obtain taurine or substituted taurine. The raw material of the preparation method is simple and easy to get and prepare, especially convenient to separate and purify, and can be used for the preparation of optical activity substituted taurine and N-acyl group substituted taurine. The obtained compounds can be used as nutrient substance, medicament, enzyme inhibitors, antibacterial agents, surface active agents, plant growth regulators and raw materials for preparing sulfonopeptides.

Owner:PEKING UNIV

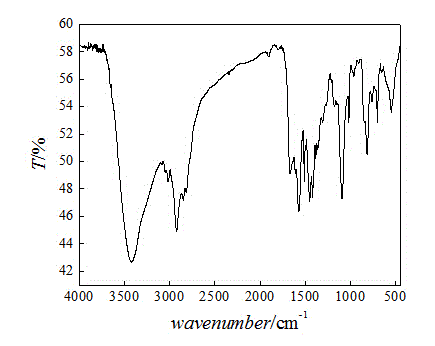

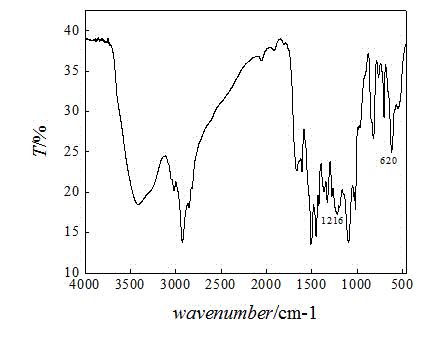

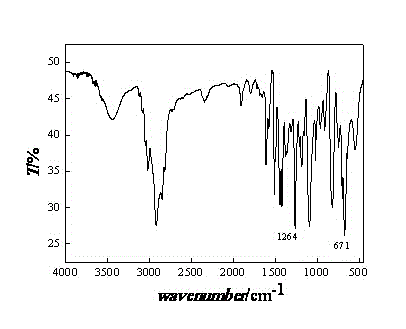

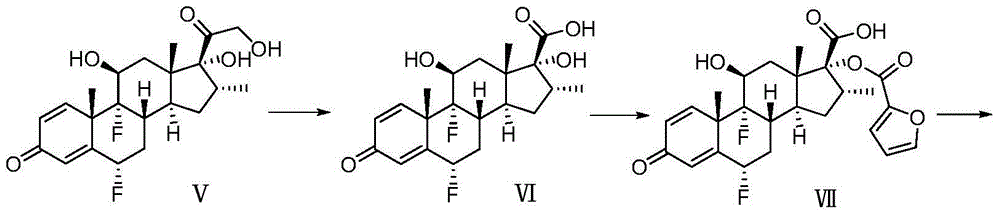

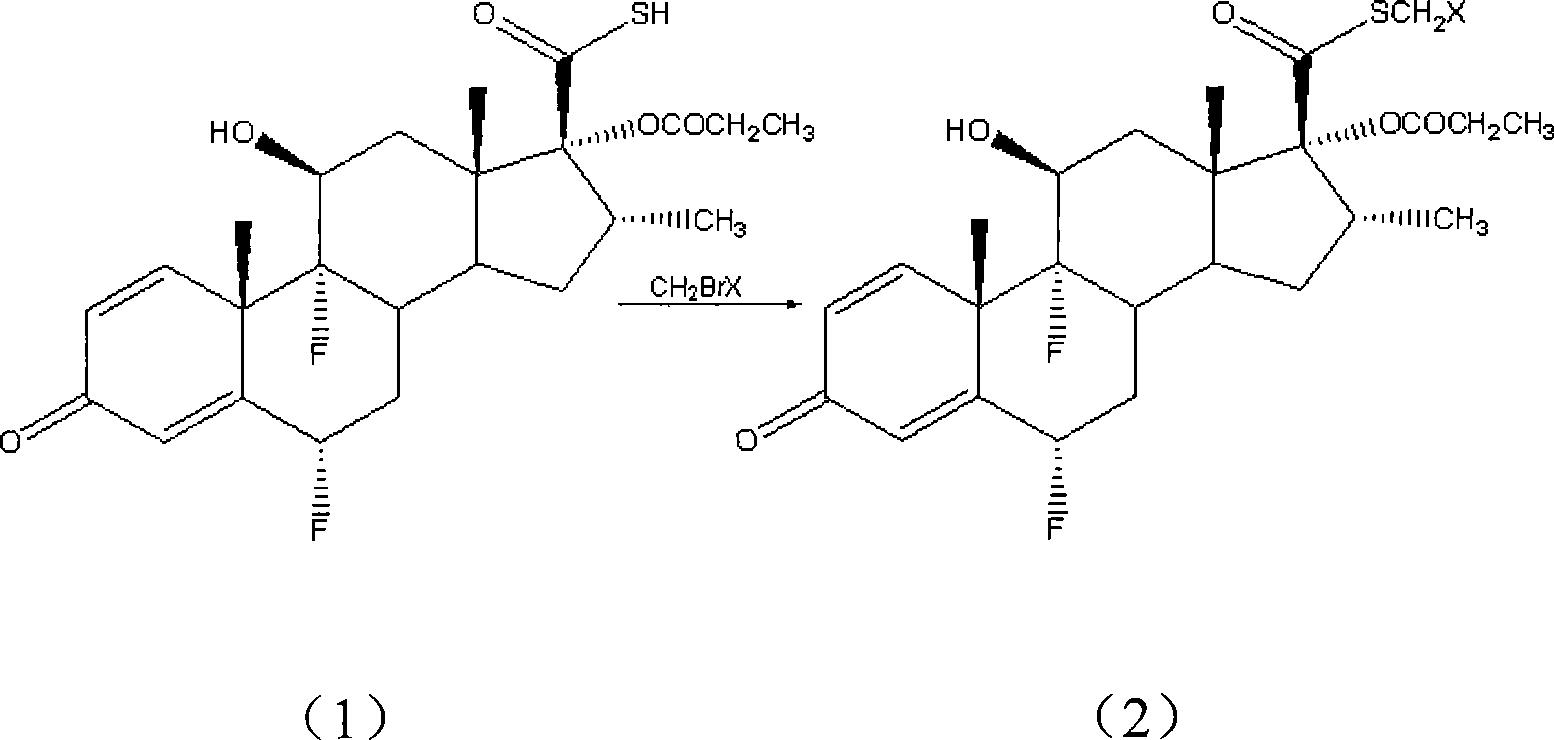

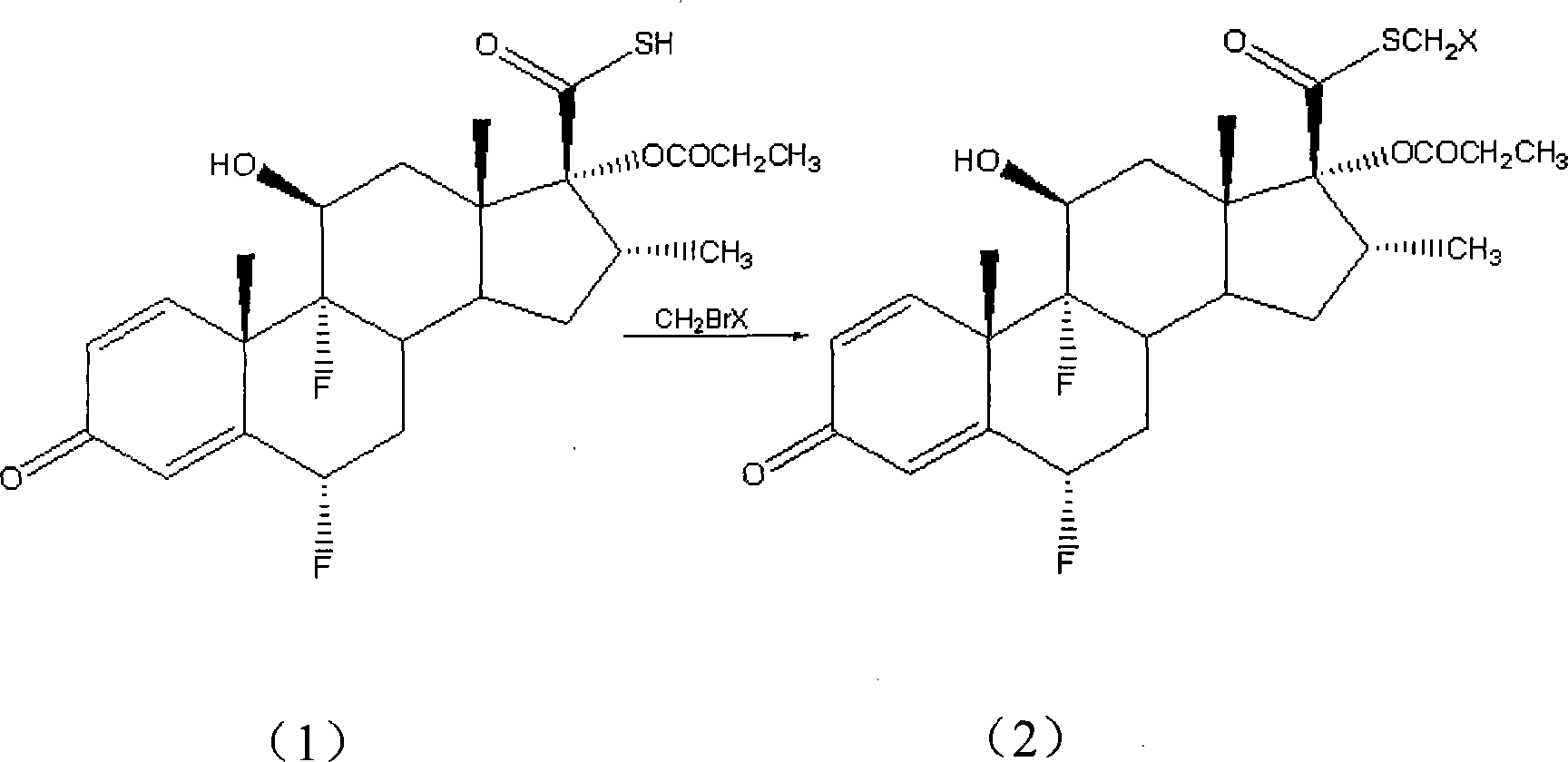

Synthesizing process of fluorine propionate ticasone

The present invention relates to new technological process of converting carboxylic acid into thiocarboxylic acid, and is especially synthesis process of fluticasone acetate. The present invention prepares fluticasone acetate with medicinal level flumethasone as initial material and through one of six technological paths, and has the advantages of short reaction path, high yield, simple reaction condition, high product purity, low cost, etc.

Owner:江苏新海康制药有限公司

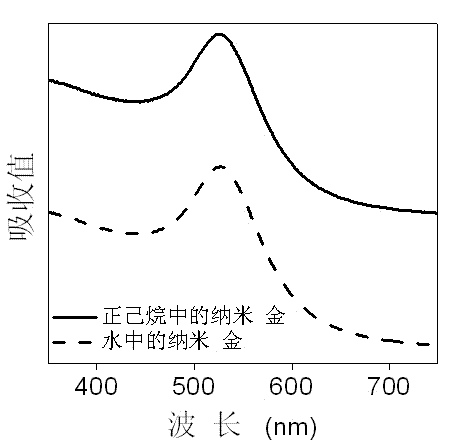

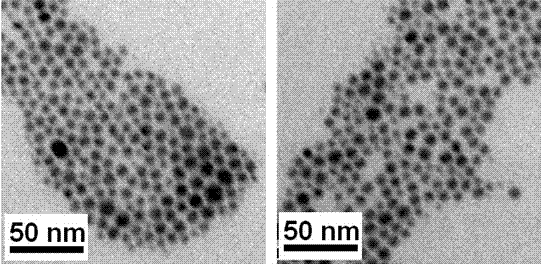

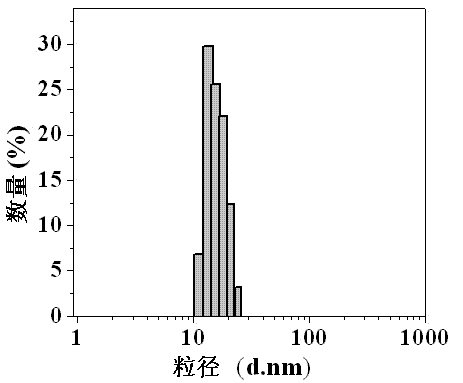

Preparation method of water-soluble nanoparticles

InactiveCN103071806AThe principle is low costEfficient responseMaterial nanotechnologyOxide/hydroxide preparationThiocarboxylic acidIminodiacetic acid

The invention relates to a preparation method for preparing water-soluble nanoparticles by adopting a ligand exchange method. The method comprises the following specific steps of: introducing two water-soluble polyethylene glycol chains onto iminodiacetic acid; reacting the compound with carbon bisulfide to generate a carbon bisulfide derivative which has a thiocarboxylic acid structure and serves as a ligand; and performing ligand exchange on the obtained ligand and oil-soluble nanoparticles to obtain stable water-soluble nanoparticles. The water-soluble nanoparticles prepared by the method can be suitable for a plurality of fields of biology, photoelectric materials, catalysis and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

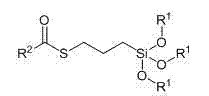

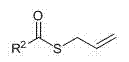

Technology for preparing terminated-type sulfur-containing silane coupling agent through hydrosilation method

ActiveCN103709188AAvoid hydrolysisGood storage stabilityGroup 4/14 element organic compoundsThiocarboxylic acidPtru catalyst

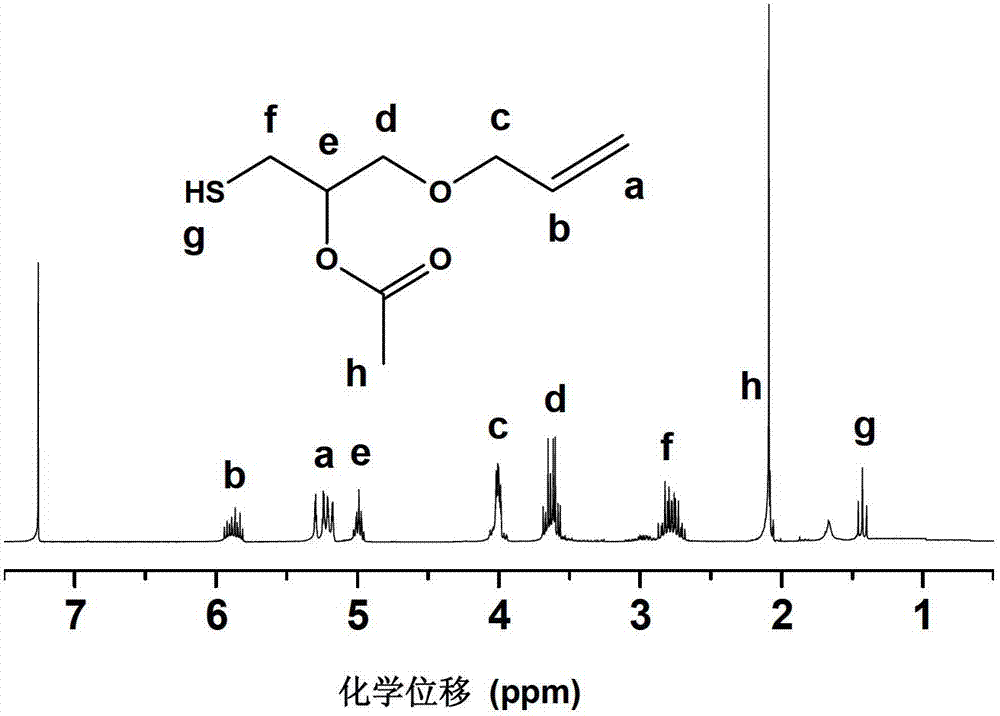

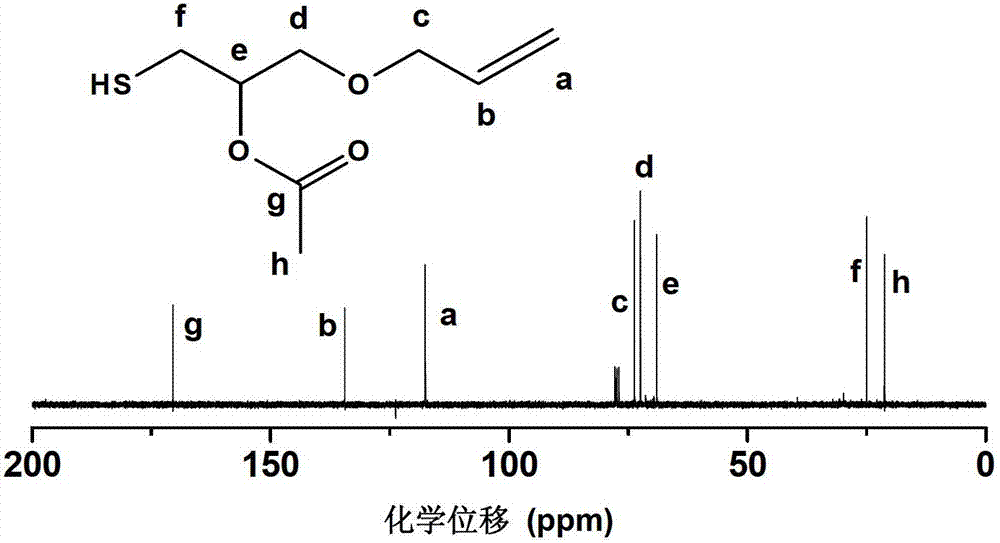

Provided is a technology for preparing a terminated-type sulfur-containing silane coupling agent through a hydrosilation method. First, acyl chloride and sodium sulfide or sodium bisulfide are reacted in a water phase to prepare an aqueous solution of sodium thiocarboxylate; under catalysis of phase-transfer catalysts, the aqueous solution of sodium thiocarboxylate is reacted with chloropropene, and thiocarboxylate allyl ester, liquid separation is carried out, after low-boiling-point substance removal, thiocarboxylate allyl ester and trialkoxysilane are subjected to a hydrosilation reaction under action of platinum catalysts, and after the reaction is over, a finished product silane coupling agent is obtained after low-boiling-point substance removal and decolouring steps. The raw material utilization rate is raised, The hydrosilation reaction process keeps anhydrous state, hydrolysis of alkoxy silane is inhibited, and the storage stability of the silane coupling agent is raised.

Owner:江西晨光新材料股份有限公司

Novel cathode material for lithium secondary batteries and lithium secondary batteries with cathode material

The invention relates to a novel cathode material for lithium secondary batteries and the lithium secondary batteries with the cathode material. The cathode material provided by the invention is a thiocarbonyl compound, at least contains a carbon-sulfur double bond, and is at least one component selected from the group consisting of thiocarboxylic acid, thioamide, thioxo aldehyde, thioxo ketone, thioxo isocyanate, thioxo acid anhydride and thioacyl peroxide, and is prepared by the reaction of metal sulfide, carbonyl-containing carboxylic acid or amide, aldehyde, ketone, isocyanate, acid anhydride and acyl peroxide. When the cathode material is applied in lithium secondary batteries, the first-time discharge capacity of the lithium secondary batteries is greater than 600mAh / g, and the discharge capacity is greater than 150mAh / g after discharging 100 times for 10 C.

Owner:耿世达

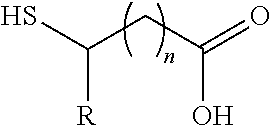

Method for Determining the Concentration of Iron Ions in Hydrocarbon Compositions

ActiveUS20150160179A1Low viscosityWell mixedAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorThiocarboxylic acidFerric ion

The present invention relates to a method for determining the concentration of iron ions in a hydrocarbon composition, as well as reagents and kits for use in such methods. The method utilises a thiocarboxylic acid having formula (I) which reduces the ferric ions and complexes ferrous ions producing a colored solution, which can be analysed to determine the amount of iron ions in the starting sample.

Owner:KITTIWAKE DEV

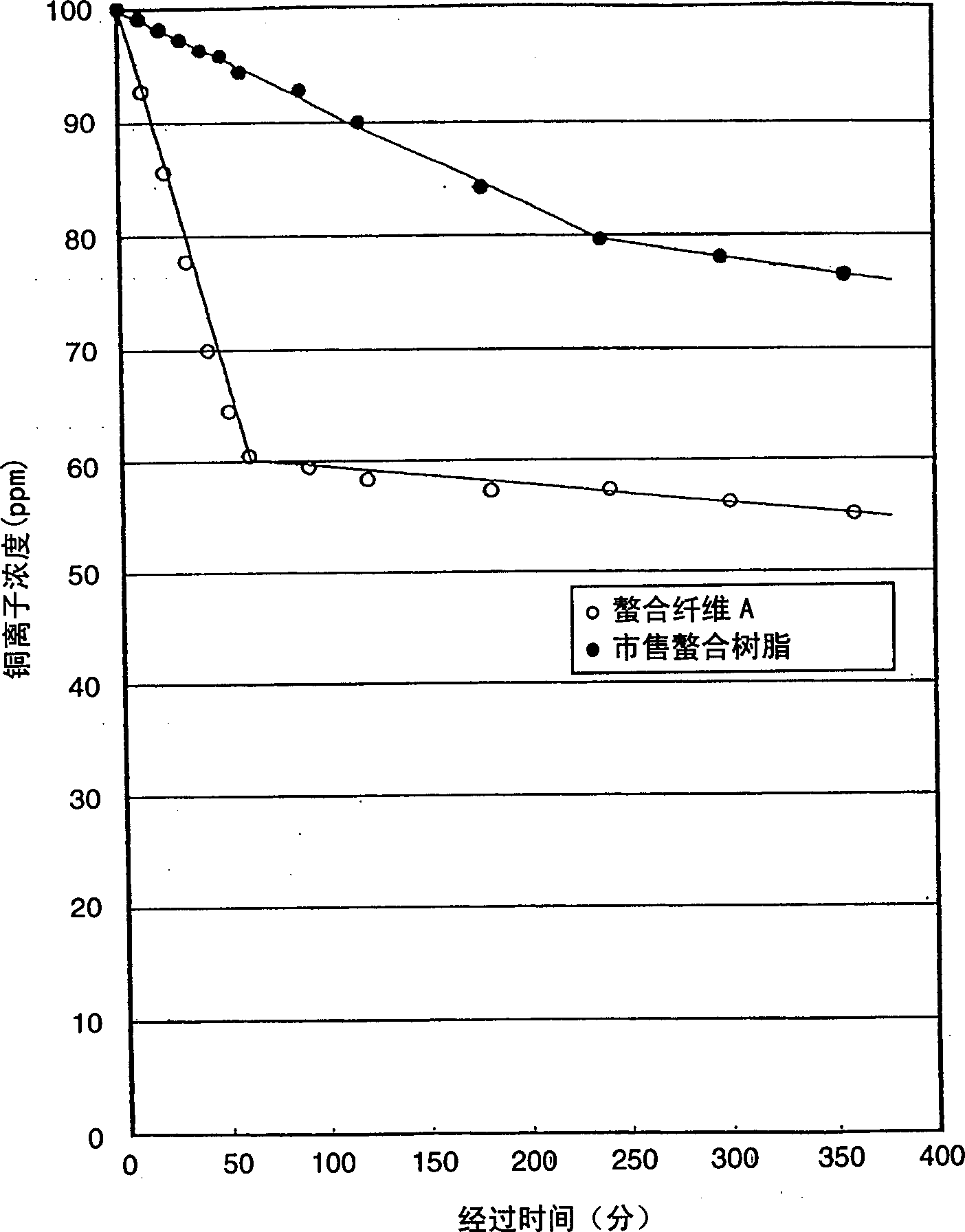

Preparation of carbodithioic acid-modified heavy metal adsorbing material and application of material for removing Cu<2+> in wastewater

InactiveCN104475052AEnsure normal dischargeImprove adsorption capacityOther chemical processesWater contaminantsThiocarboxylic acidMicrosphere

The invention relates to the field of environmental protection, and specifically relates to preparation of a carbodithioic acid-modified heavy metal adsorbing material, and application of the material for removing Cu<2+> in wastewater. The technological process comprises the following steps: (1) pretreatment of chlorine balls; (2) preparation of amino microspheres; (3) modification of amino resin by carbodithioic acid; (4) Cu<2+> adsorption property. The carbodithioic acid-modified chelating resin provided by the invention integrates physical adsorption and chemical adsorption, the preparation steps are simple, and the grafting percent of the amino resin is up to 70%. The resin uses insoluble and infusible crosslinked polystyrene as a matrix, and is good in acid and alkali resistance. The adsorption effect of the resin is higher than that of other types of resin, the 3.17*10<-4> moL.L<-1> Cu<2+> adsorption rate is 96%, the wastewater discharge can reach the primary standard (less than 0.5ppm) in China, and the resin is suitable for recycling a large number of Cu<2+> in wastewater in industrial cities and Cu<2+> salt production enterprises, and has good application prospects.

Owner:UNIV OF JINAN

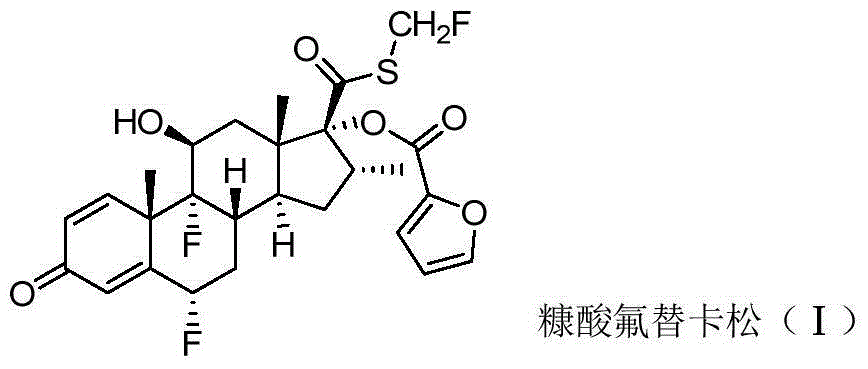

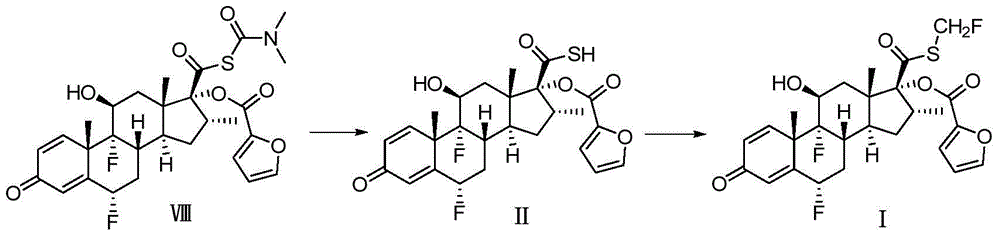

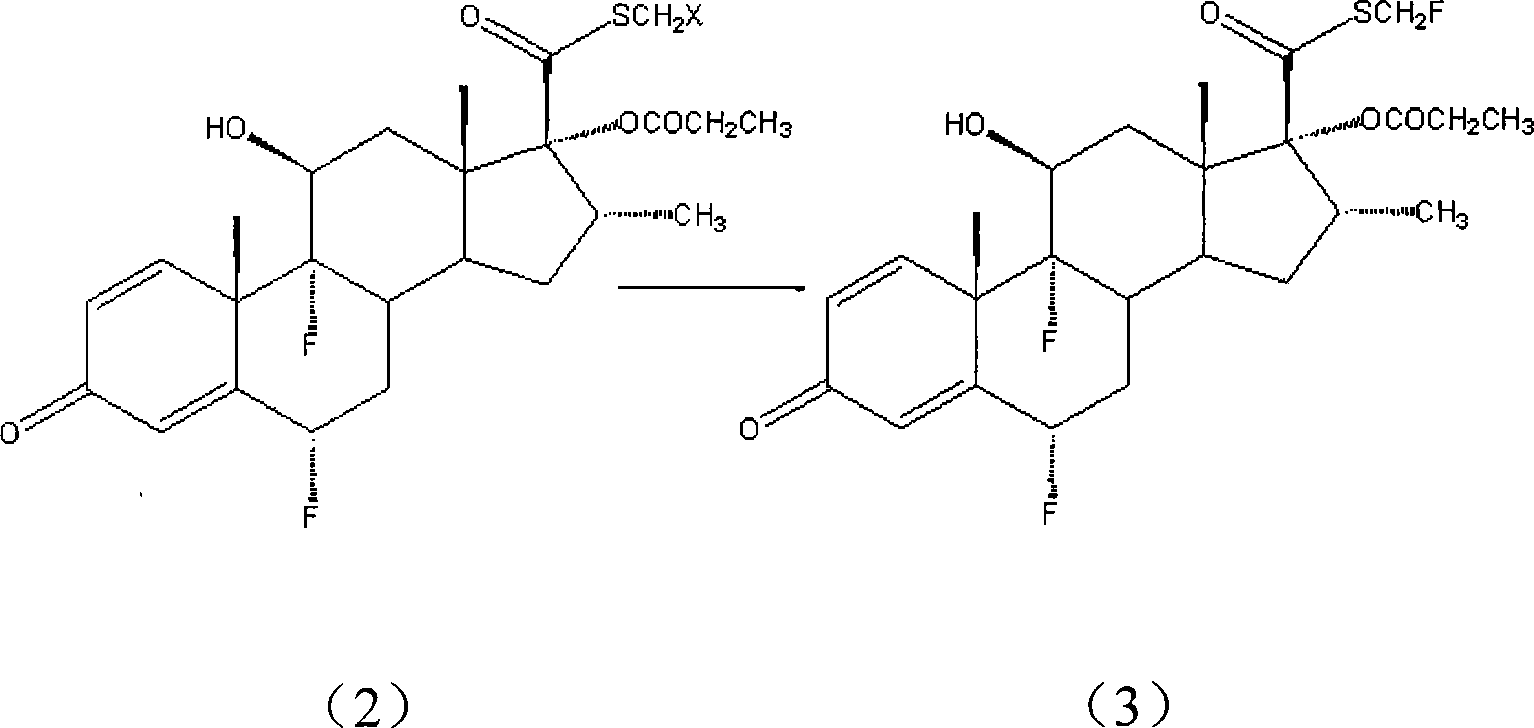

Preparation method of fluticasone furoate

InactiveCN106279341AReduce the difficulty of refiningHigh puritySteroidsThiocarboxylic acidAndrostanes

The invention relates to a preparation method of fluticasone furoate, especially preparation and purification of an intermediate 6alpha, 9alpha-difluoro-17alpha-[(2-furylcarbonyl)oxy]-11beta-hydroxy-16alpha-methyl-3-oxo-androstane-1,4-diene-17beta-thiocarboxylic acid. The preparation method comprises the following steps: in the presence of alkali and alcoholic solvent, a compound as shown in the formula VIII is converted into a mixture containing the compound of formula II; the mixture containing the compound of formula II is mixed with an aqueous solution of inorganic base and an ester solvent; a water phase is separated; pH value of the water phase is regulated by the use of acid until a solid is precipitated out; and the solid is separated. The invention provides a preparation method capable of remarkably raising purity of fluticasone furoate. Safety of drug application is guaranteed.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

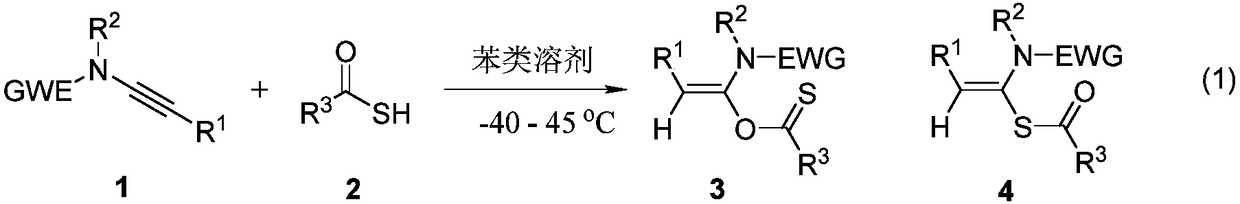

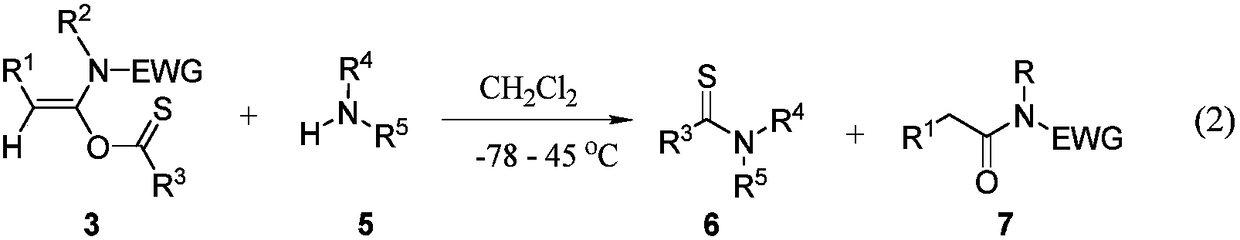

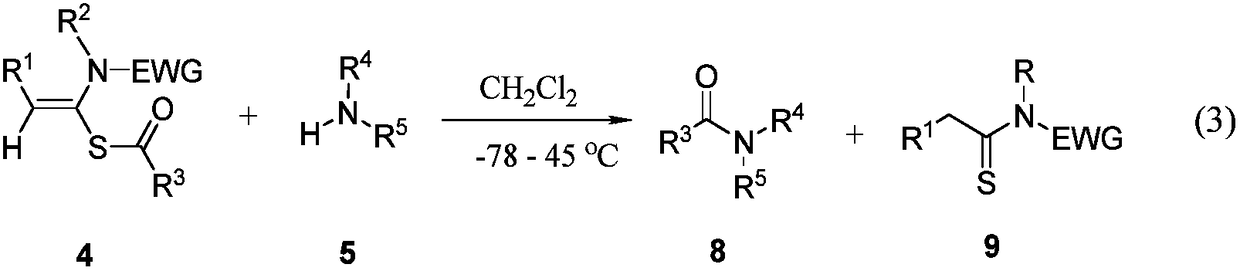

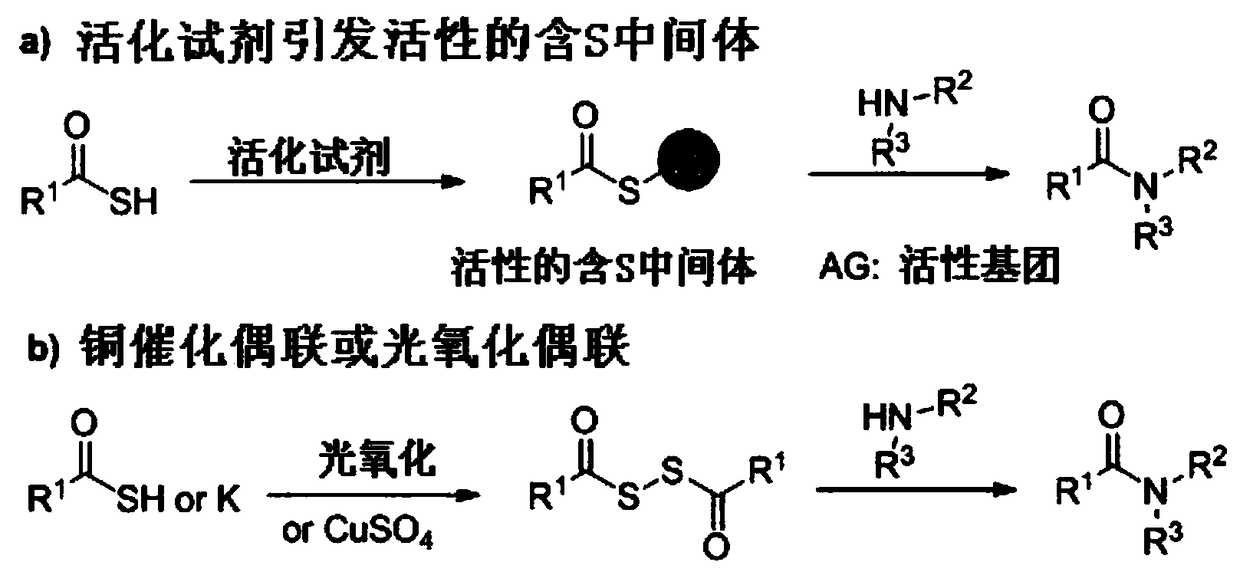

Preparation method of acetylene amide mediated thioacid amide and application of acetylene amide mediated thioacid amide in thiopeptide synthesis

ActiveCN108484461ASynthetic mildSynthesis is direct and conciseOrganic compound preparationPeptidesThiocarboxylic acidThioester

The invention discloses an acetylene amide mediated method for selectively synthesizing carbonyl thioesters and ordinary thioesters. The ordinary thioesters are further used for preparing amides and peptides, and the carbonyl thioesters are used for preparing thioamides and thiopeptides. An addition reaction is carried out between acetylene amide in m-xylene and thiocarboxylic acid to selectivelyobtain the carbonyl thioester and ordinary thioester of which the ratio is 3:1 under the condition of 40 DEG C below zero; the ordinary thioesters can carry out a combination reaction with amines to produce amides and peptides; and the carbonyl can carry out a combination reaction with the amines to produce thioamides and thiopeptides. The method disclosed by the invention is mild in reaction conditions, free of any metal catalyst, high in reaction speed, high in yield, simple in operation and wide in application range. With respect to chiral thiocarboxylic acid in a position alpha of carboxyl, when thioamide bonds or thiopeptide bonds are formed from the carbonyl thioesters or when amido bonds or peptide bonds are formed from the ordinary thioesters, any racemization phenomenon can be avoided.

Owner:广州新肽生物医药科技有限公司

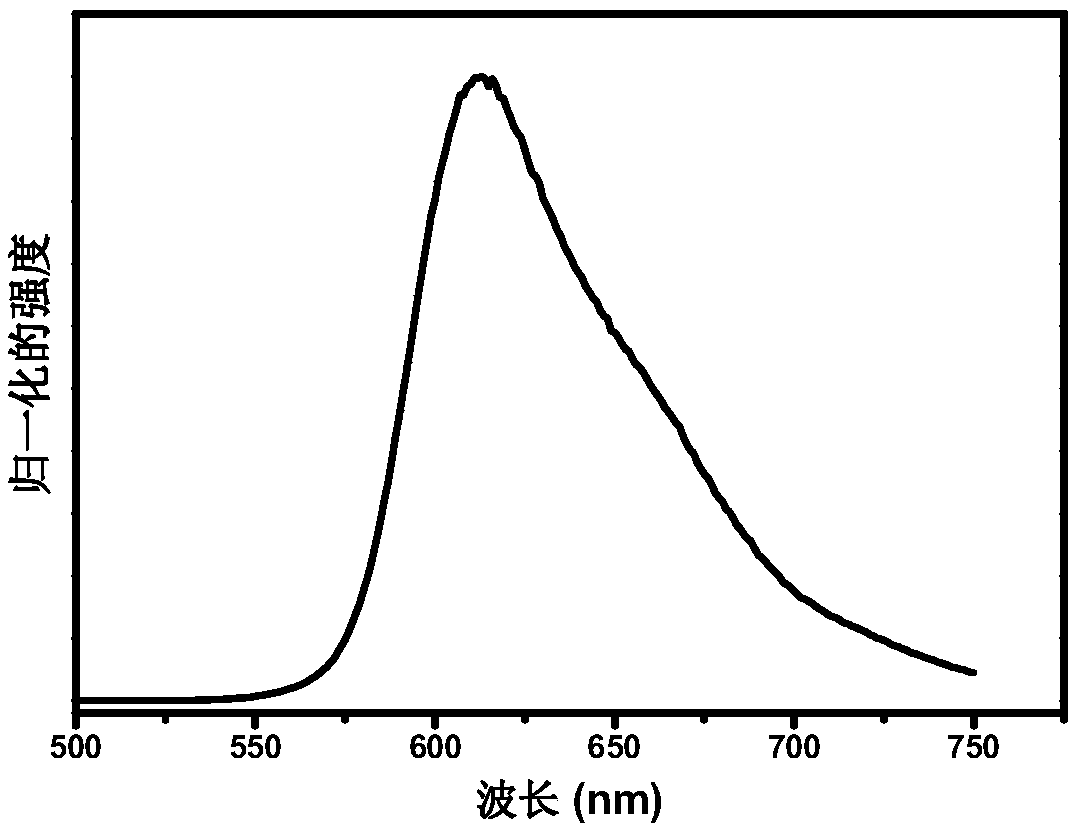

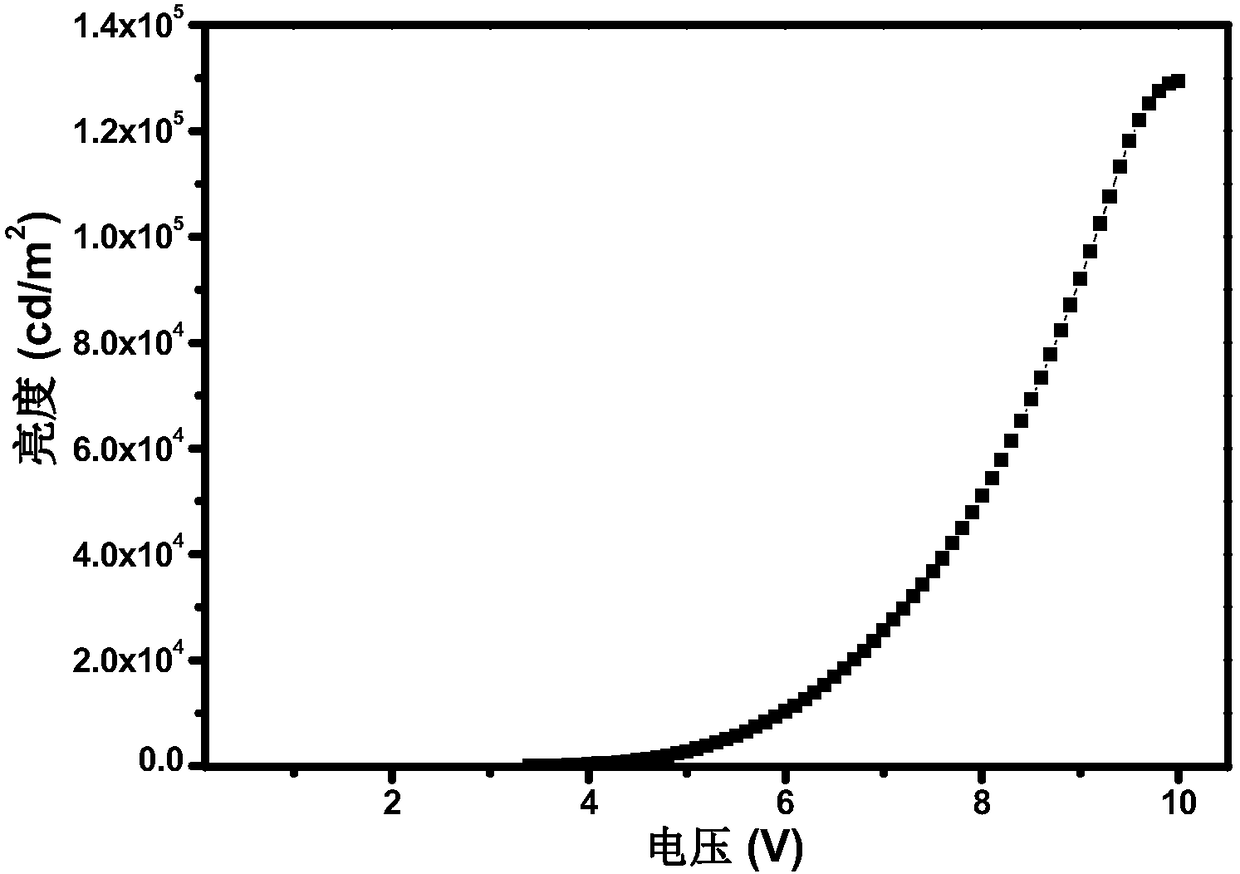

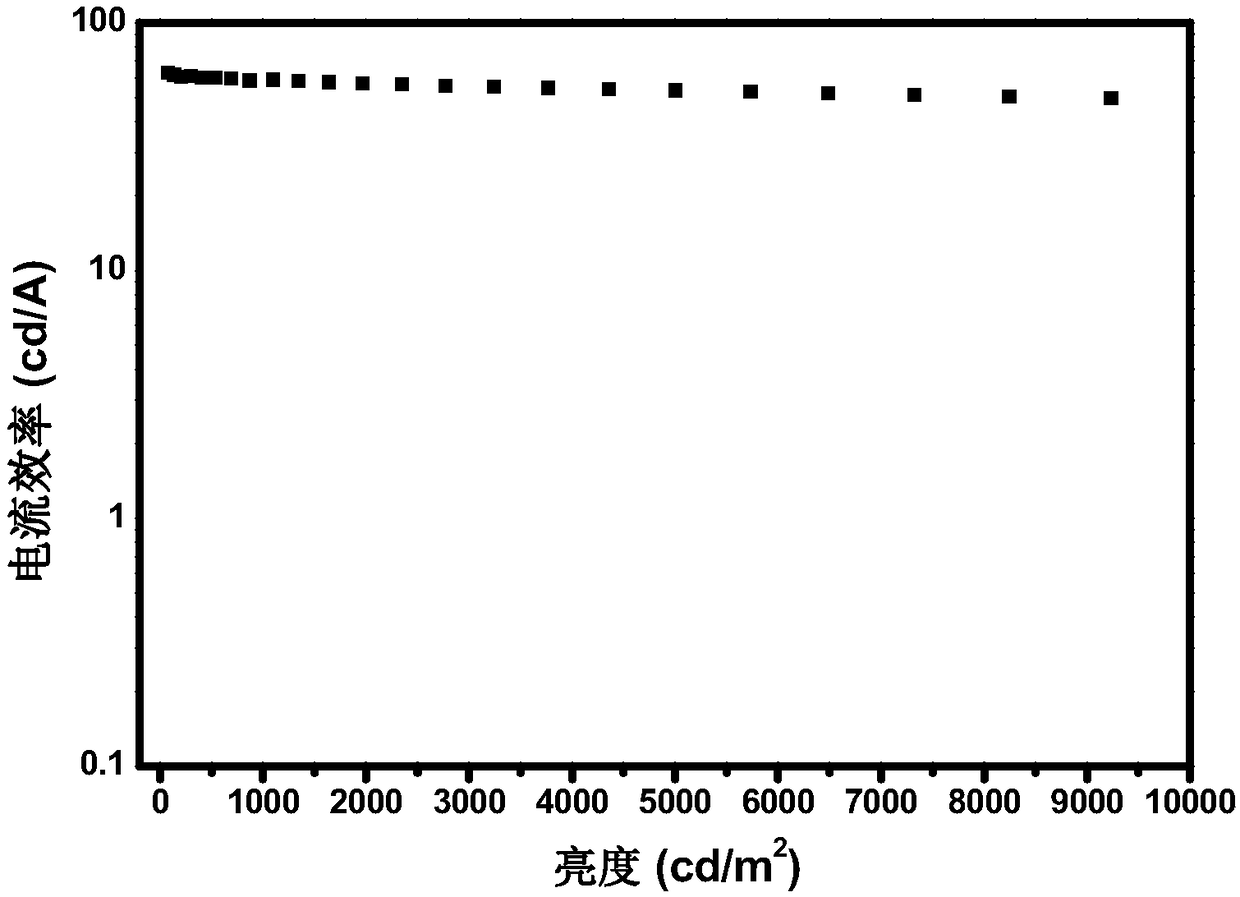

Novel iridium complex with thiocarboxylic acid compound as auxiliary ligand

ActiveCN108358971AHigh electron mobilityEasy to synthesizeIndium organic compoundsSolid-state devicesIridiumThiocarboxylic acid

The invention relates to a novel iridium complex with a nitrogen heterocyclic ring as a main ligand and a thiocarboxylic acid compound as an auxiliary ligand. The nitrogen heterocyclic ring and a carbon-sulfur group in an iridium complex molecule help to improve the electron mobility of the material and control a luminescence color, so the injection and transmission of holes and electrons are balanced, the current carrier recombination region is broadened, the device efficiency is improved and the efficiency roll-off is reduced. The iridium complex has the advantages of simple synthesis, stable chemical property, easy sublimation and purification, and excellent device performance, and provides convenience for the acquisition of high-efficiency organic electroluminescent devices and application in the technical fields of lighting and display.

Owner:马鞍山南京大学高新技术研究院 +1

Method for preparing fluticasone propionate

ActiveCN101125875AImprove stabilityAvoid purification difficultiesSteroidsThiocarboxylic acidFluticasone propionate

Owner:湖南玉新药业有限公司

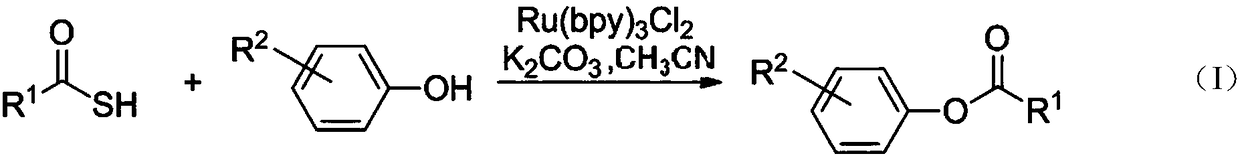

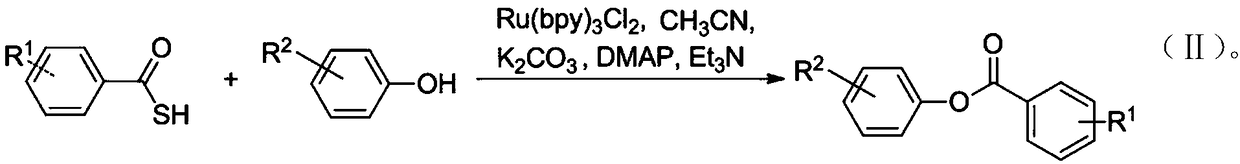

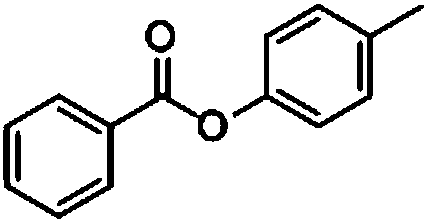

Preparation method for synthesis of phenolic ester through thiocarboxylic acid mediated visible light catalyzed phenol acylation reaction

ActiveCN108191651AHigh yieldImprove toleranceCarboxylic acid nitrile preparationOrganic compound preparationSolventThiocarboxylic acid

The invention discloses a preparation method for synthesis of phenolic ester through a thiocarboxylic acid mediated visible light catalyzed phenol acylation reaction. Thiocarboxylic acid compounds andphenol compounds are subjected to a site specific reaction under certain conditions to produce phenolic ester compounds, wherein the certain conditions are as follows: under the conditions of normaltemperature, normal pressure and visible light, K2CO3 is used as an alkaline catalyst, terpyridyl ruthenium dichloride hexahydrate is used as a photosensitizer and acetonitrile is used as a reaction solvent. Synthesis of phenolic ester under catalysis of visible light is realized, thiocarboxylic acid is used as an acylation reagent, and the site specific phenol esterification reaction is realizedefficiently under mild conditions of normal temperature, normal pressure and visible light. The method has mild reaction conditions, large substrate functional group tolerance, high applicability andhigh yield, and an efficient, reliable and economical preparation method is provided for synthesis of phenolic ester.

Owner:长治学院

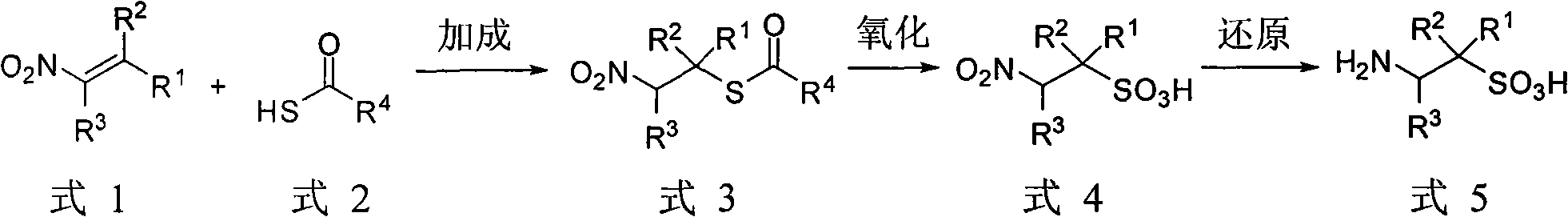

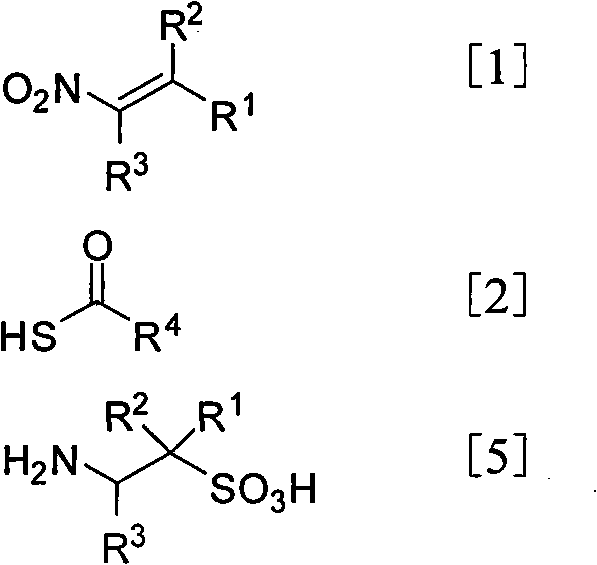

Salt-free preparation method for substituted taurine

InactiveCN101851182AEasy to operateSuitable for large-scale industrial productionSulfonic acid preparationThiocarboxylic acidOrganic synthesis

The invention provides a salt-free preparation method for substituted taurine, and belongs to the technical field of organic synthesis. Nitroolefin and thionocarboxylic acid serving as raw materials are subjected to addition, oxidation and reduction to form the substituted taurine; and particularly, the method can be used for preparing cis and trans disubstituted and trisubstituted taurine. The preparation method has the advantages of simple and readily available raw materials, convenient operation and no troublesome desalting purification process, and suitability for large-scale industrial production. The compounds prepared by the method can be used as nutrient substances, medicaments, enzyme inhibitors, antibacterial agents, surfactants, plant growth regulators, raw materials for preparing sulfonamido peptide and the like.

Owner:BEIJING UNIV OF CHEM TECH

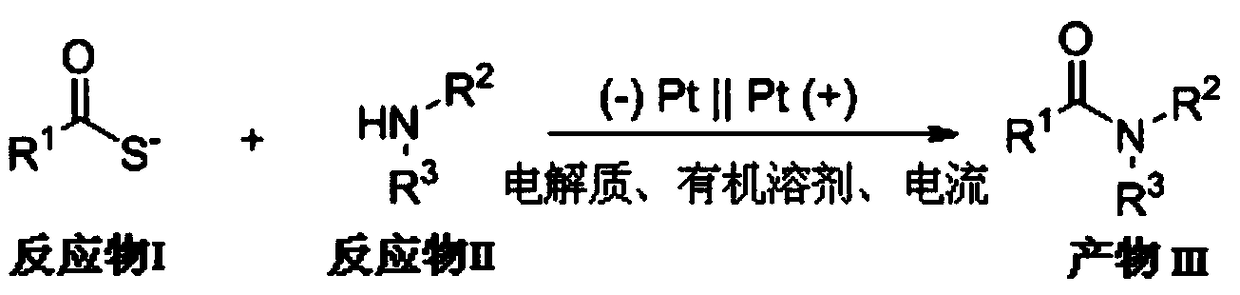

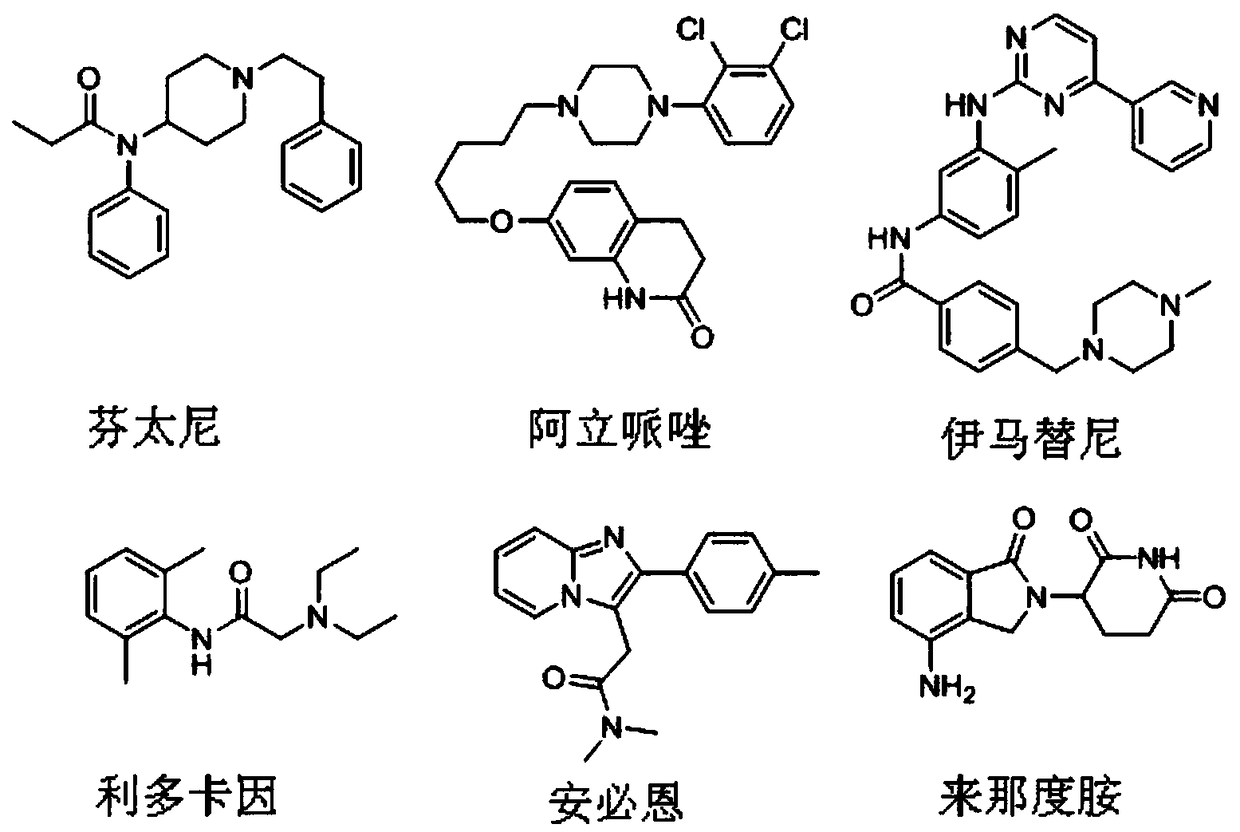

Electrochemical oxidation synthesis method for amide and application thereof

InactiveCN109321940AEasy to synthesizeEasy to purifyElectrolysis componentsElectrolytic organic productionThiocarboxylic acidOrganic synthesis

The invention discloses an electrochemical oxidation synthesis method for amide and application thereof, and belongs to the technical field of electrochemical organic synthesis. According to the synthesis method for the amide, thiocarboxylic acid or thiocarboxylate and amine are adopted as reaction raw materials, firstly, the thiocarboxylic acid or the thiocarboxylate is oxidized through an anodein an electrolytic tank so as to form free radical intermediates, then the two free radical intermediates are coupled so as to form a key intermediate disulfide compound, and then nucleophilic addition-elimination reaction is carried out on the disulfide compound and the reactant amine so as to generate an amide compound. The synthesis method has the advantages that no catalyst needs to be added,in addition, the reaction conditions are mild, by-products are few, synthesis and purification of the amide compound are facilitated, and the method has wide application in preparation of amide drugsin drug synthesis.

Owner:SOUTHWEST UNIVERSITY

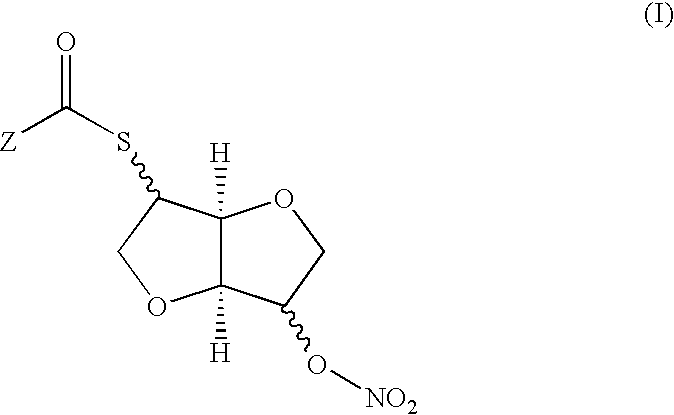

Stereospecific method for the preparation of dioxa-bicyclooctane compounds

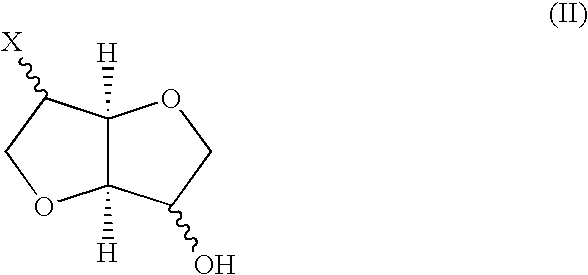

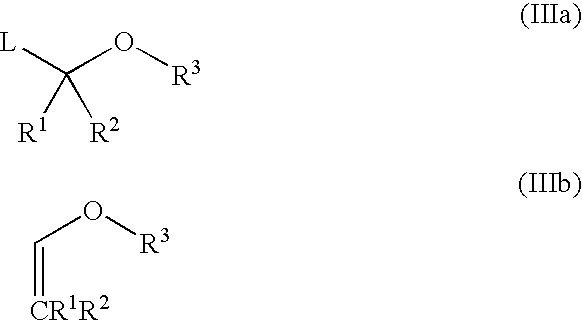

This invention relates to a new method for the stereospecific thiocarboxylation of organic compounds for the preparation of compounds according to formula (I):wherein a compound of formula (II):is reacted with a compound of formula (IIIa) or (IIIb):then treating the obtained product with a thiocarboxylic acid or a salt thereof, and subsequently carrying out a nitration reaction.

Owner:LACER SA

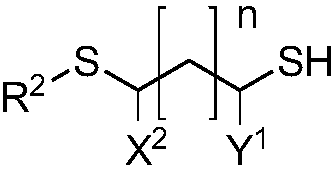

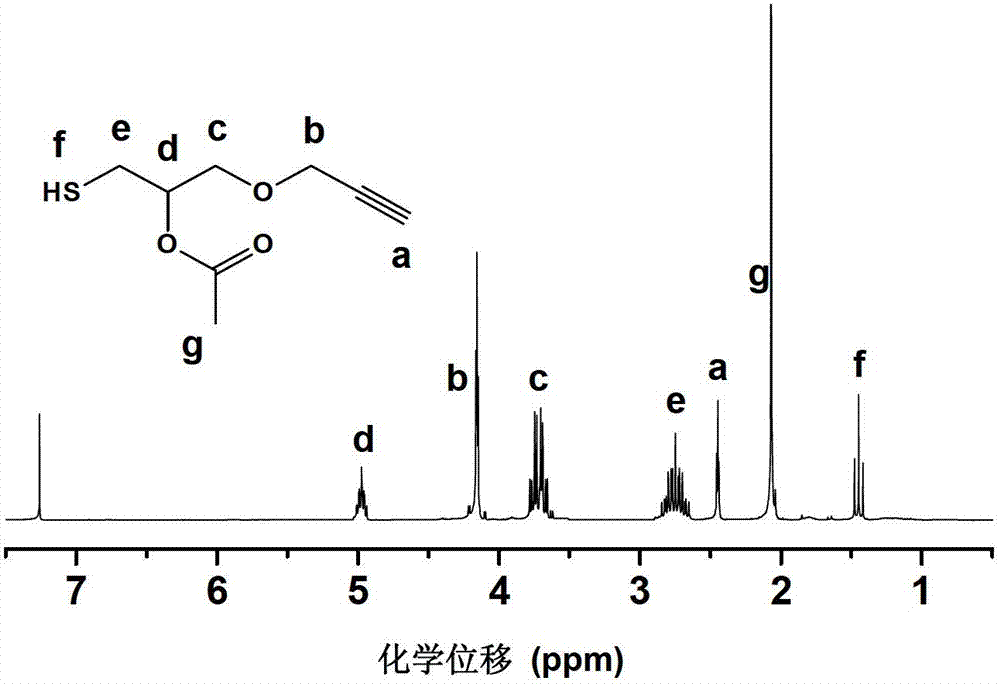

Sulfhydryl compound containing beta-ester groups and acetyl-transferred synthesis method thereof

The invention discloses a sulfhydryl compound containing beta-ester groups and an acetyl-transferred synthesis method thereof. The method comprises the following steps of: under the protection of nitrogen gas, adding a compound or epoxy resin containing 1mol of epoxy groups, 5-100mol of solvent, 0.5-2mol of organic amine and 1.01-1.5mol of monothiocarboxylic acid into a reactor in sequence and reacting for 1-24h at -10 DEG C to 30 DEG C; washing by dilute hydrochloric acid; evaporating to remove the solvent; and, removing the excessive monothiocarboxylic acid by the vacuum evaporation or the column chromatography to obtain the sulfhydryl compound containing the beta-ester groups. The method provided by the invention has the advantages of rapidness, high efficiency and simple and convenient process. A lot of epoxy resins can be converted into the sulfydryl resin. The application prospects of the sulfhydryl compound in the functional macromolecular materials, the thermosetting high-performance materials and the additives and the like are wide.

Owner:杭州德烯科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com