Preparation method of water-soluble nanoparticles

A nanoparticle, water-soluble technology, applied in the field of preparation of nanomaterials, can solve problems such as limiting the application of nanocrystals and hindering contact, and achieve the effect of low cost, good repeatability, fast and efficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In parts by weight, the formula is as follows:

[0030] IA-dPEG 10 parts

[0031] Oil-soluble nano gold 1000 parts

[0032] Preparation Process:

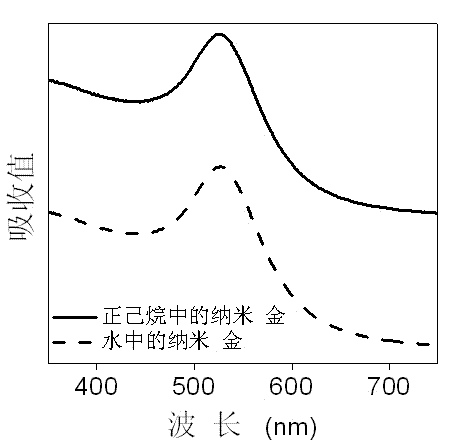

[0033] a. Synthesis of compound IA-dPEG: In parts by weight, 440 parts of iminodiacetic acid (IA) was suspended in water at 5°C, and then 110 parts of benzyl chloroformate (Cbz) and 10000 parts of benzyl chloroformate (Cbz) and 10000 parts of Parts of NaOH aqueous solution (concentration is 2 M). The above mixture was stirred at room temperature for 1 hour, diethyl ether was added to the reaction liquid to separate layers to remove excess benzyl chloroformate, and the aqueous phase was collected. Use 1M hydrochloric acid to adjust the pH of the aqueous phase to about 2, add ethyl acetate to the extraction reaction solution, separate the ethyl acetate layer, dry over sodium sulfate, filter, and concentrate in vacuo to obtain compound 1 as an oily substance. 200 parts of compound 1, 860 parts of monomethyl ether-capped poly...

Embodiment 2

[0038] In parts by weight, the formula is as follows:

[0039] IA-dPEG 5 parts

[0040] Oil-soluble CdSe / CdS / ZnS quantum dots 400 parts

[0041] Preparation Process:

[0042] a. Prepare IA-dPEG-DTC in the same manner as in Example 1.

[0043] b. Add 5 parts of IA-dPEG-DTC to 400 parts of oil-soluble quantum dot solution, stir for 20 minutes and then add water to obtain an aqueous solution of quantum dots. Acetone is added to the aqueous solution, and after centrifugal purification, the water-soluble quantum dots modified by IA-dPEG-DTC can be obtained.

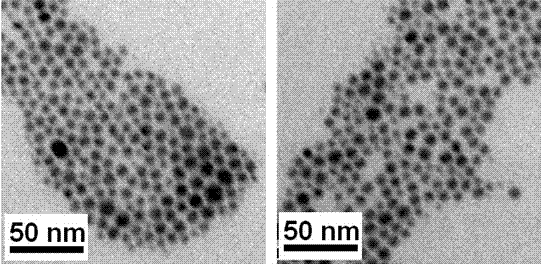

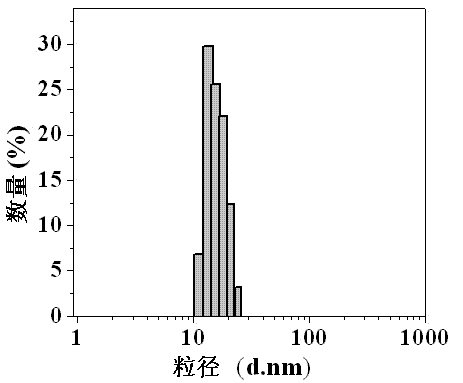

[0044] After ligand exchange, the obtained quantum dots can be uniformly dispersed in aqueous solution. After the ligand exchange, the UV-visible absorption curve of the quantum dots hardly changes, the shape and size of the quantum dots do not change, and the good monodispersity is maintained.

Embodiment 3

[0045] Embodiment 3: by weight, the formula is as follows:

[0046] IA-dPEG 10 parts

[0047] Oil-soluble nano iron oxide 1500 parts

[0048] Preparation Process:

[0049] a. Prepare IA-dPEG-DTC in the same manner as in Example 1.

[0050] b. Add 5 parts of IA-dPEG-DTC to 1500 parts of oil-soluble quantum dot solution, stir for 20 minutes and then add water to obtain an aqueous solution of nanometer iron oxide. Acetone is added to the aqueous solution, and after centrifugal purification, the water-soluble nano iron oxide modified by IA-dPEG-DTC can be obtained.

[0051] After the ligand exchange, the obtained nano-iron oxide can be uniformly dispersed in the aqueous solution. After ligand exchange, the UV-visible absorption curve of the quantum dots hardly changed, the morphology and size of the nano-iron oxides did not change, and the good monodispersity was maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com