Mercaptan-alkene light-cured resin for 3D printing and preparation method of mercaptan-alkene light-cured resin for 3D printing

A light-curing resin, 3D printing technology, applied in the field of 3D printing, can solve the problems of hardness and other performance degradation, polymerization inhibition, affecting the accuracy of parts, etc., to achieve the effect of easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

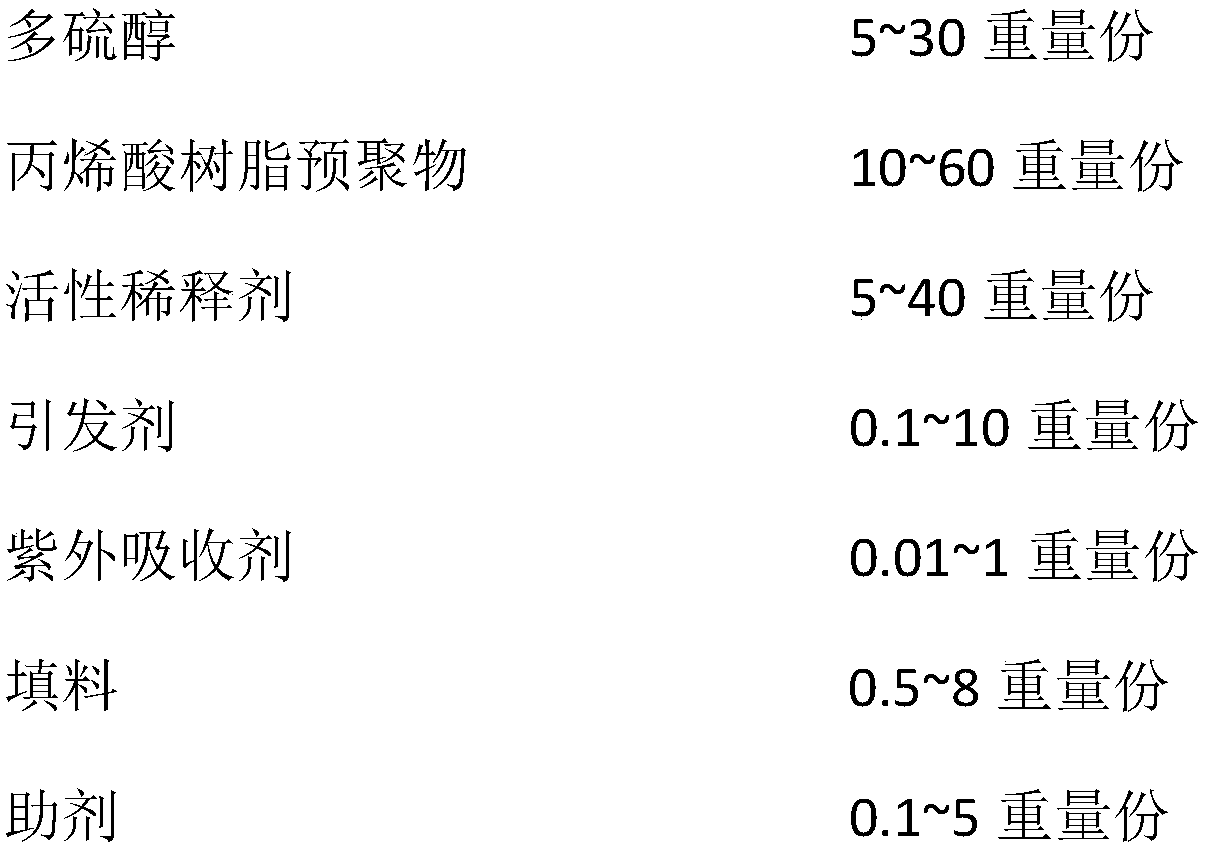

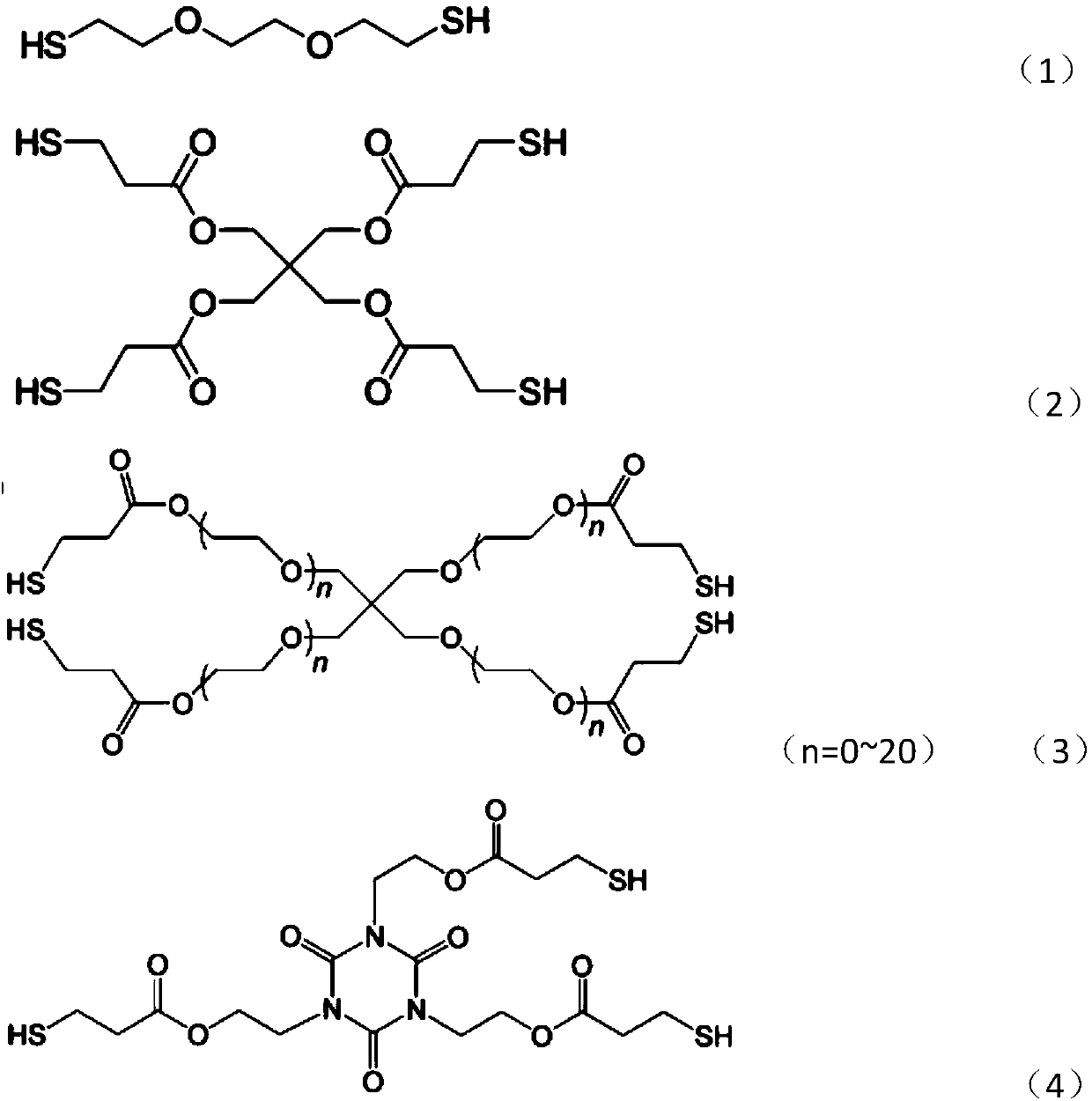

Method used

Image

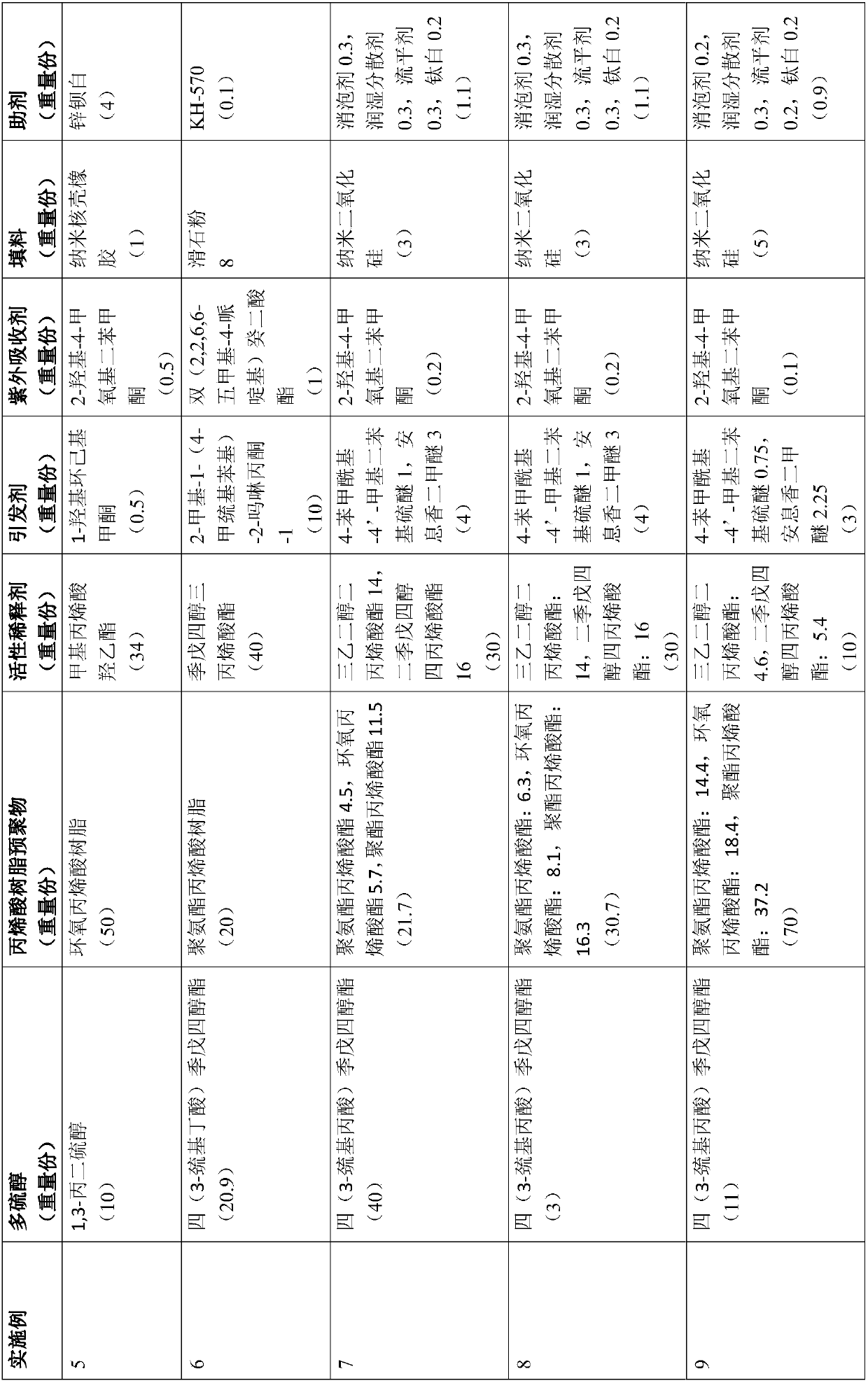

Examples

Embodiment 1

[0031] A thiol-ene photocurable resin that can be applied to 3D printing, wherein the mass percentages of each component are: 13% of 1,4-benzenedimethanol, 12% of tetrakis (3-mercaptopropionic acid) pentaerythritol ester, Epoxy acrylate 15%, polyester acrylate 21%, dicyclopentadiene (meth) acrylate 20%, hydroxyethyl acrylate 10%, benzoin dimethyl ether 3%, nano silicon dioxide 5%, 2 -Hydroxy-4-methoxybenzophenone 0.1%, defoamer 0.2%, wetting and dispersing agent 0.3%, leveling agent 0.2%, KH-560 coupling agent 0.2%. The stirring temperature was 25°C, and the stirring time was 90 minutes.

Embodiment 2

[0033] A thiol-ene photocurable resin that can be applied to 3D printing, wherein the mass percentages of each component are: 20% of mercapto silicone oil, 6% of tetrakis (3-mercaptobutyric acid) pentaerythritol ester, 15% of polyether acrylic resin, Polyurethane acrylic resin 15%, 1,6-hexanediol diacrylate 30%, benzoin dimethyl ether 5%, nano core-shell rubber 8%, 2-hydroxy-4-methoxybenzophenone 0.1%, disinfectant Foaming agent 0.3%, wetting and dispersing agent 0.3%, leveling agent 0.3%. The stirring temperature is 30°C, and the stirring time is 60 minutes.

Embodiment 3

[0035] A thiol-ene photocurable resin that can be applied to 3D printing, wherein the mass percentages of each component are: 10% of 4,4'‐thiobisthiophenol, 12.85% of 2,4,6‐trimercaptotriazine %, polyester acrylate 20%, epoxy acrylate 15%, dipentaerythritol tetraacrylate 15%, 2-phenoxyethyl methacrylate 20%, 2‐hydroxy‐2‐methyl‐1‐benzene Base‐1‐acetone 4%, superfine calcium carbonate 2%, 2-hydroxy-4-methoxy-5-sulfonic acid benzophenone 0.2%, defoamer 0.3%, wetting and dispersing agent 0.3%, leveling Agent 0.3%, fluorescent whitening agent 0.05%. The stirring temperature was 40°C, and the stirring time was 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com