Flexible stretchable shielded conductor and preparation method thereof

A shielded wire, flexible conductive technology, applied in the directions of extensible conductors, extensible conductor cables, bendable conductors, etc., can solve the problems of poor bending resistance of metals, easy damage and failure of the shielding layer, etc., to achieve easy application, Excellent shielding properties and tensile properties, the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The embodiment of the second aspect of the present invention provides a method for preparing a flexible and stretchable shielded wire, comprising the following steps:

[0050] a. According to the formulas of the flexible conductive layer, flexible inner insulating layer, flexible shielding layer and flexible outer insulating layer of the flexible and stretchable shielded wire according to the embodiment of the first aspect of the present invention, the flexible conductive layer, The flexible inner insulating layer, the flexible shielding layer and the flexible outer insulating layer materials are respectively added with a solvent to stir and mix each layer; preferably, the solvent used for the flexible conductive layer is water, ethylene glycol, ethanol or N,N-dimethylformamide The amount added is 6-50 times the weight of the resin used in the conductive layer; the solvent used for the flexible shielding layer is water, ethylene glycol, ethanol or N,N-dimethylformamide, ...

Embodiment 1

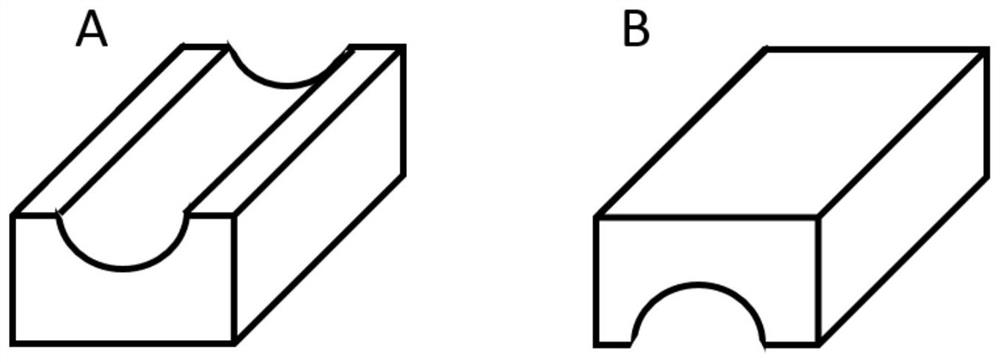

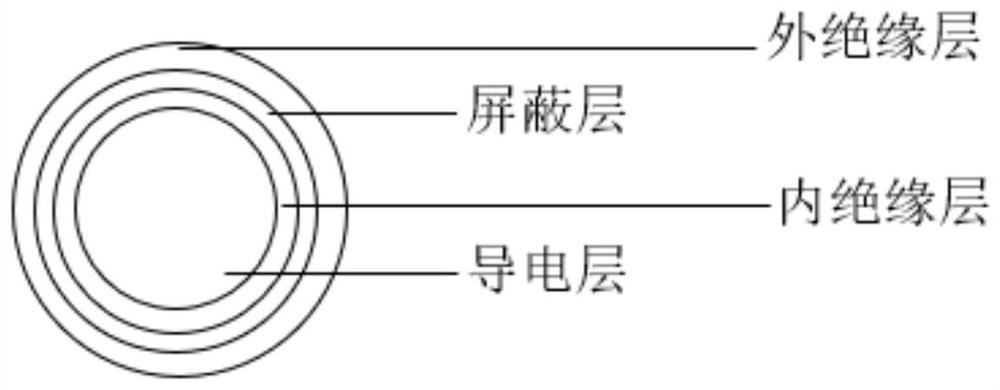

[0065] Example 1 Preparation of Flexible and Stretchable Shielded Conductors by Mold Forming

[0066] Prepare conductive layer: prepare conductive layer according to the formula of 5wt% gallium indium alloy, 10wt% silver nanowire and 85wt% hydroxypropyl methylcellulose, add 20 times the water of hydroxypropylmethylcellulose weight as solvent, and Each material is weighed, mixed evenly by mechanical stirring, and then set aside;

[0067]Prepare the inner insulating layer: the inner insulating layer is polydimethylsiloxane, the solvent added is N,N-dimethyl, the amount of solvent added is twice the weight of polydimethylsiloxane, and the mixture is evenly mixed by mechanical stirring reserve;

[0068] Prepare the shielding layer: Prepare the shielding layer according to the formula of 4wt% carbon nanotubes, 8wt% nickel nanoparticles and 88wt% water-based acrylic resin, add water 30 times the weight of the water-based acrylic resin as a solvent, weigh each material, and mix by m...

Embodiment 2

[0074] Example 2 Preparation of Flexible and Stretchable Shielded Conductors by Mold Forming

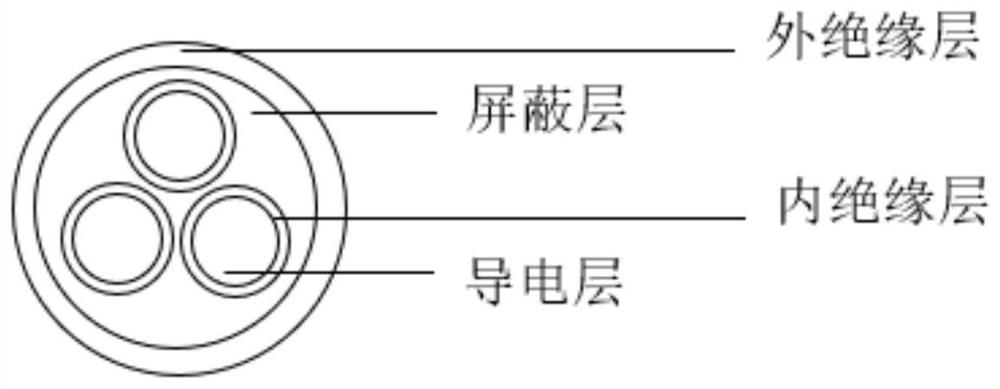

[0075] The method is the same as in Example 1, except that the multi-strand formed flexible conductive layer coated with a flexible inner insulating layer is placed in the center of the second mold, and the uniformly mixed flexible shielding layer material is placed in the mold at 85°C After heating for 15 minutes to solidify and form, the mold is taken off to obtain a formed flexible conductive layer that is sequentially covered with a flexible shielding layer and a flexible inner insulating layer from the inside to the outside. The multiple strands in this embodiment are preferably three strands.

[0076] The stretchable shielding wire prepared in this embodiment is three strands of wires, and the outside of each formed flexible conductive layer is covered with a flexible inner insulating layer, and the outer side of the three strands is covered with a flexible inner insulating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com