Patents

Literature

72 results about "Constant intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The intensity of a sound wave is its power/unit area. In one dimension the intensity is constant as the wave travels. In two or three dimensions, however, the intensity decreases as you get further from the source.

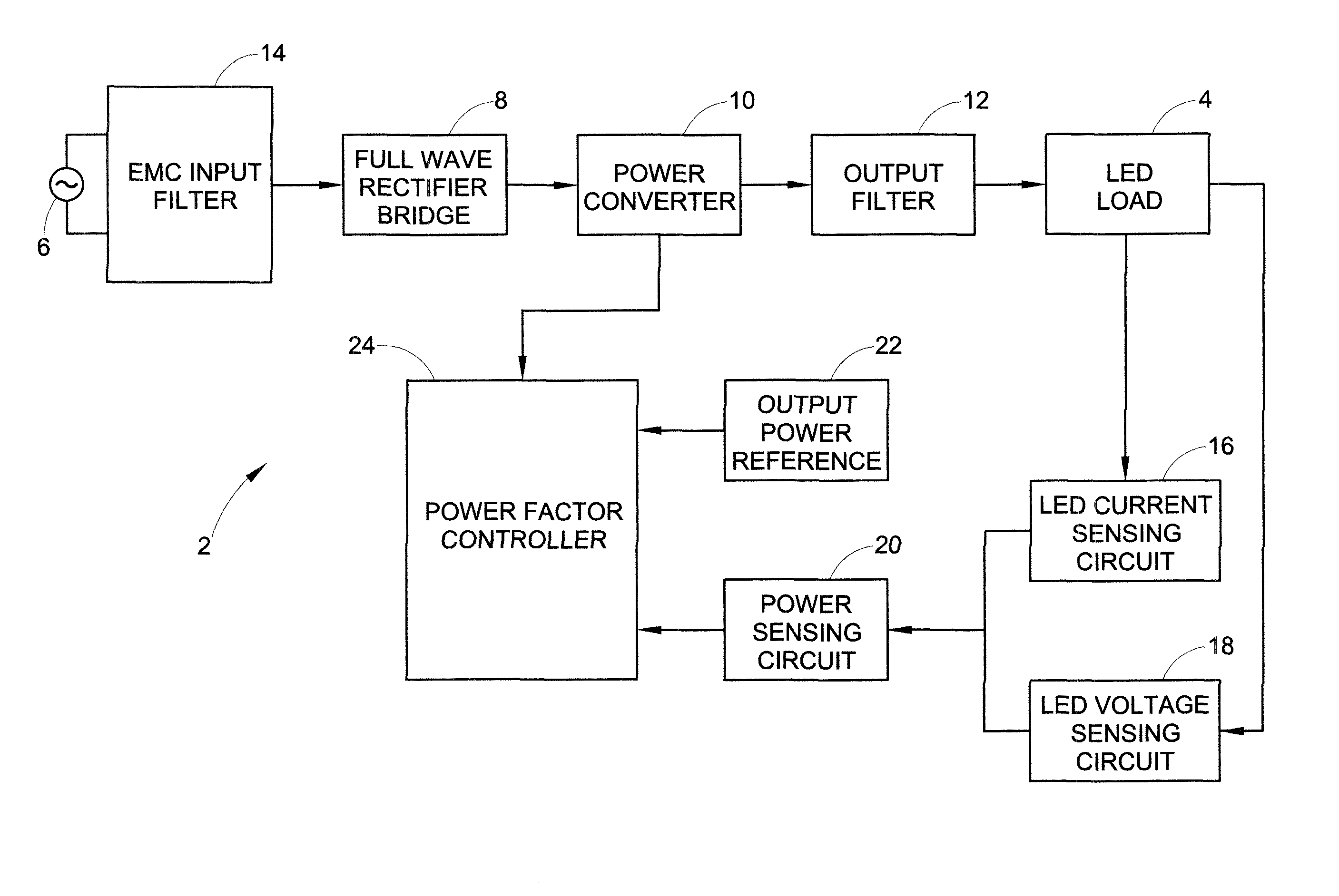

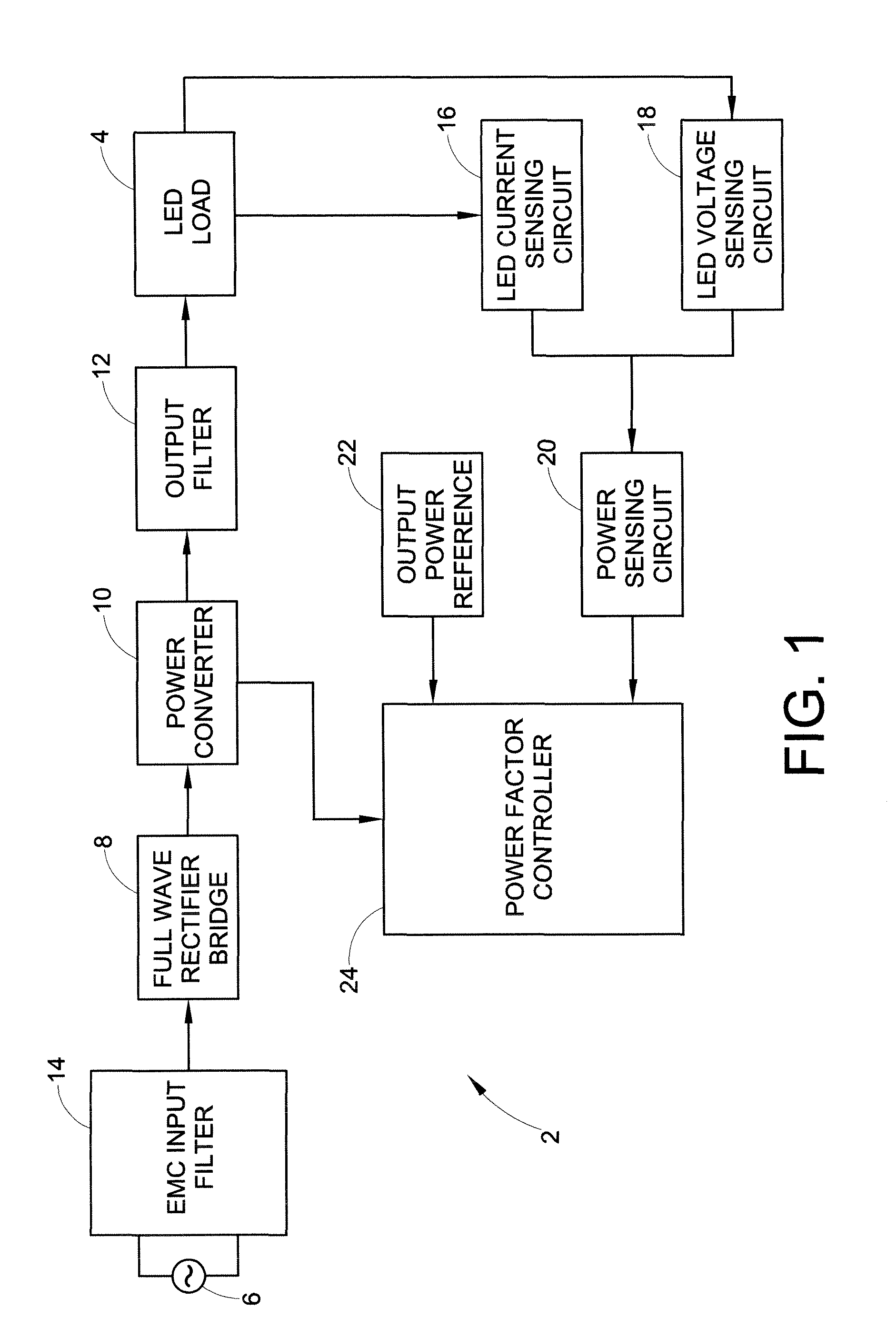

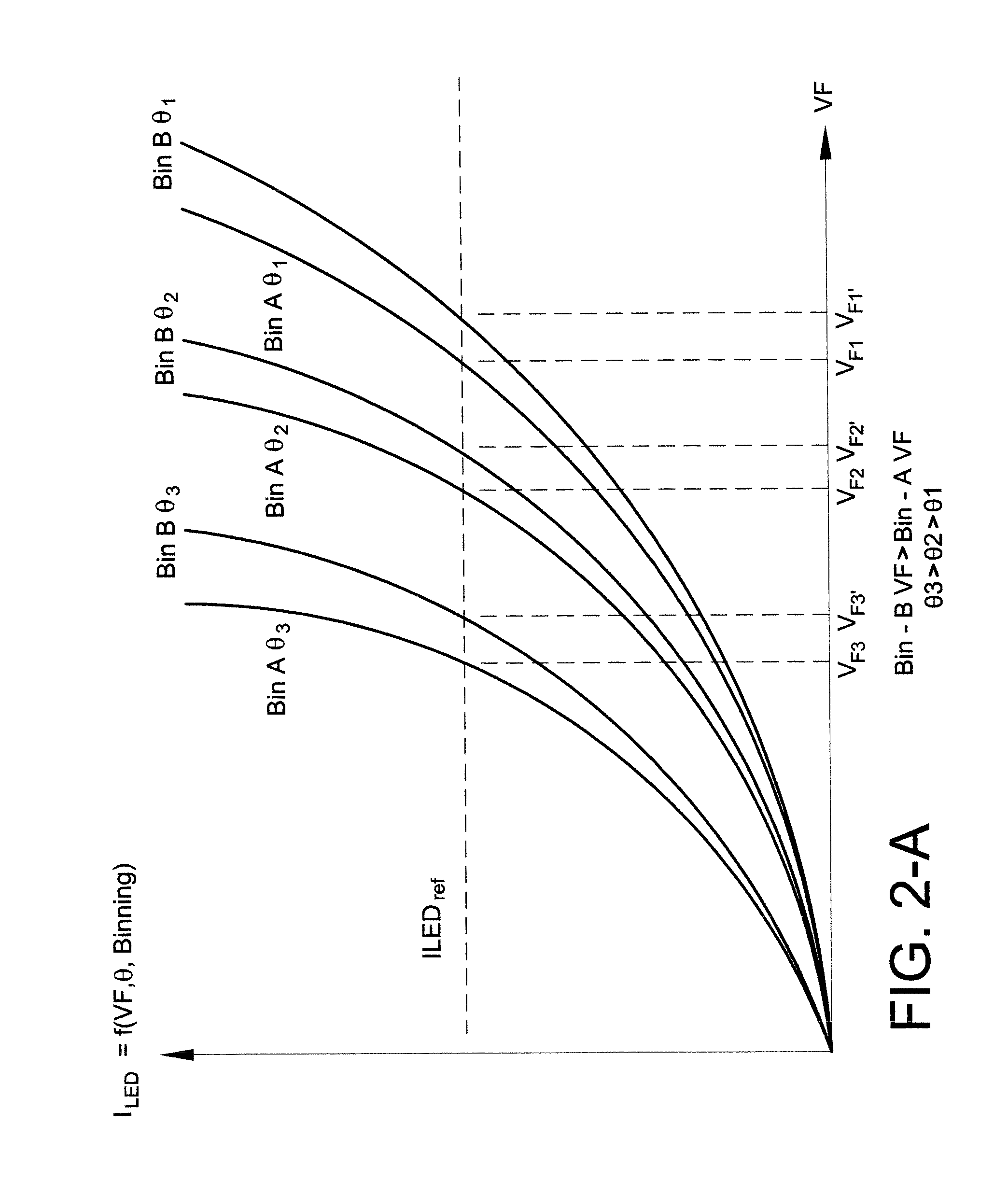

Power control circuit and method

ActiveUS8174197B2Light intensityPower consumption of lightDischarge tube incandescent screensElectric discharge tubesFeedback circuitsControl circuit

A light source with substantially constant intensity and power consumption is provided. The light source includes a controllable dc voltage and current source; a non-linear light-emitting load supplied with dc voltage and current from the controllable dc voltage and current source; a current sense circuit connected in series with the non-linear light-emitting load; a variable LED forward voltage (varying with temperature, binning batch, aging) sensor circuit; a multiplier operative to measure a power-representative signal; and a power consumption control feedback circuit through which the dc voltage and current source is controlled in relation to the variable forward voltage representative signal to adjust the dc voltage and then a current to amplitudes that keep the light intensity and power consumption produced by the light source substantially constant.

Owner:GE LIGHTING SOLUTIONS LLC

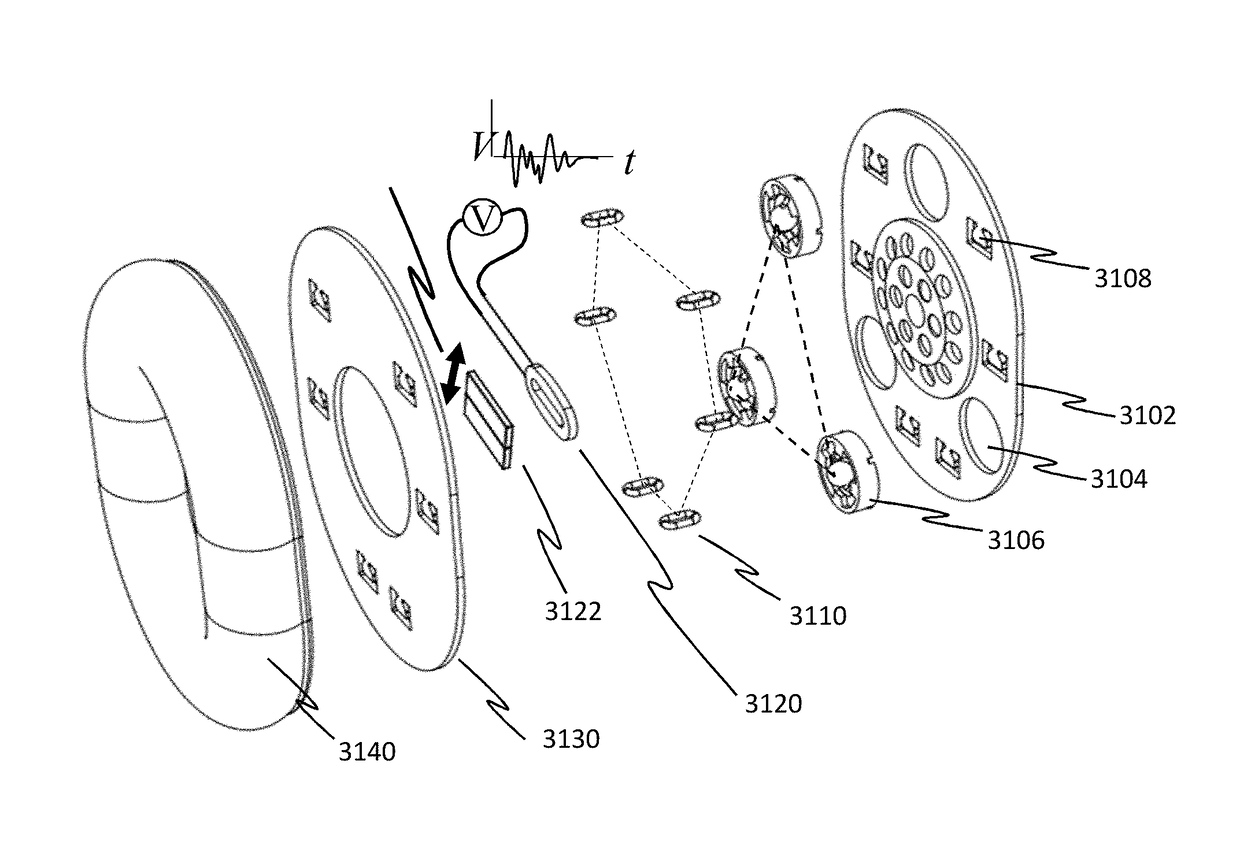

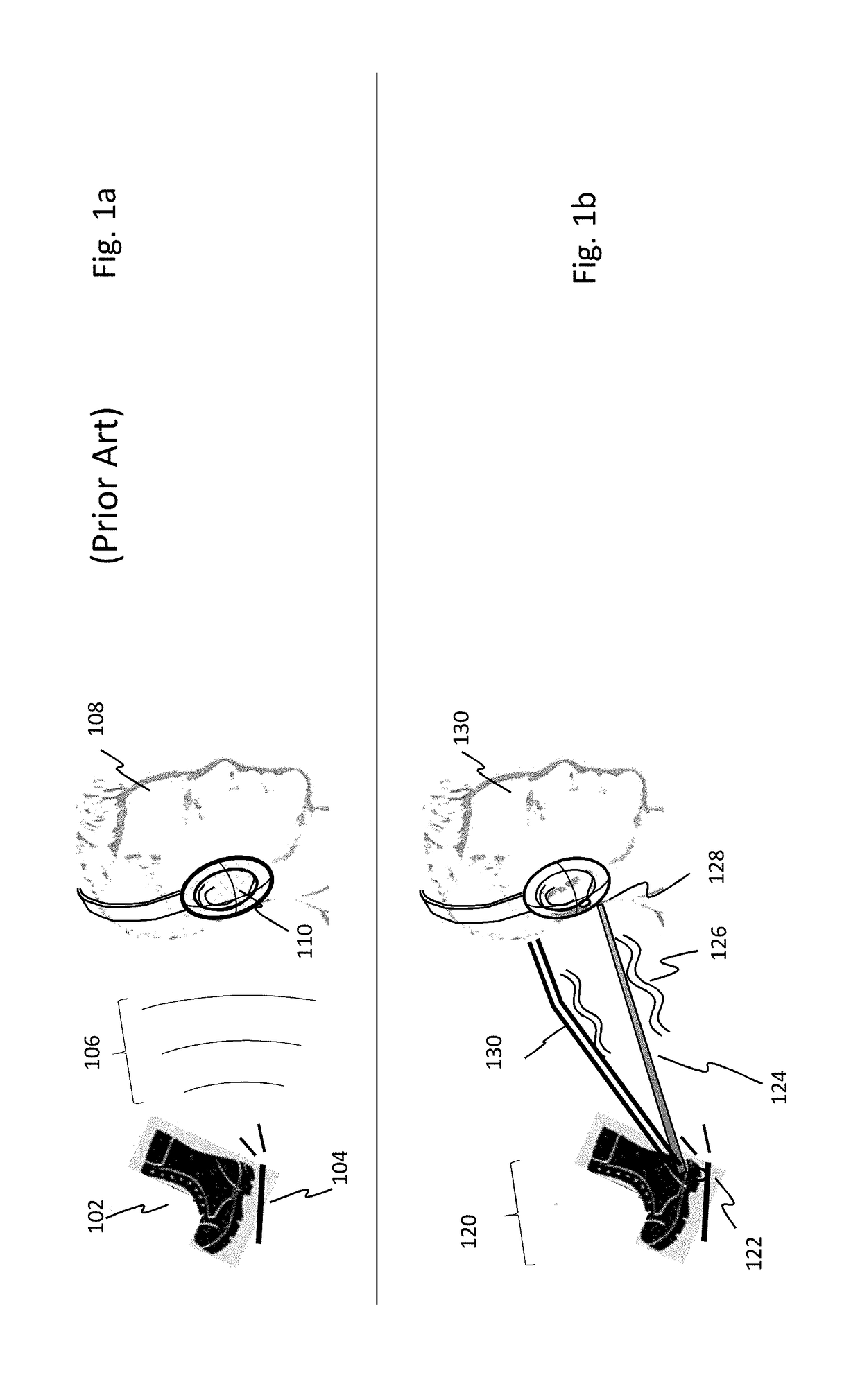

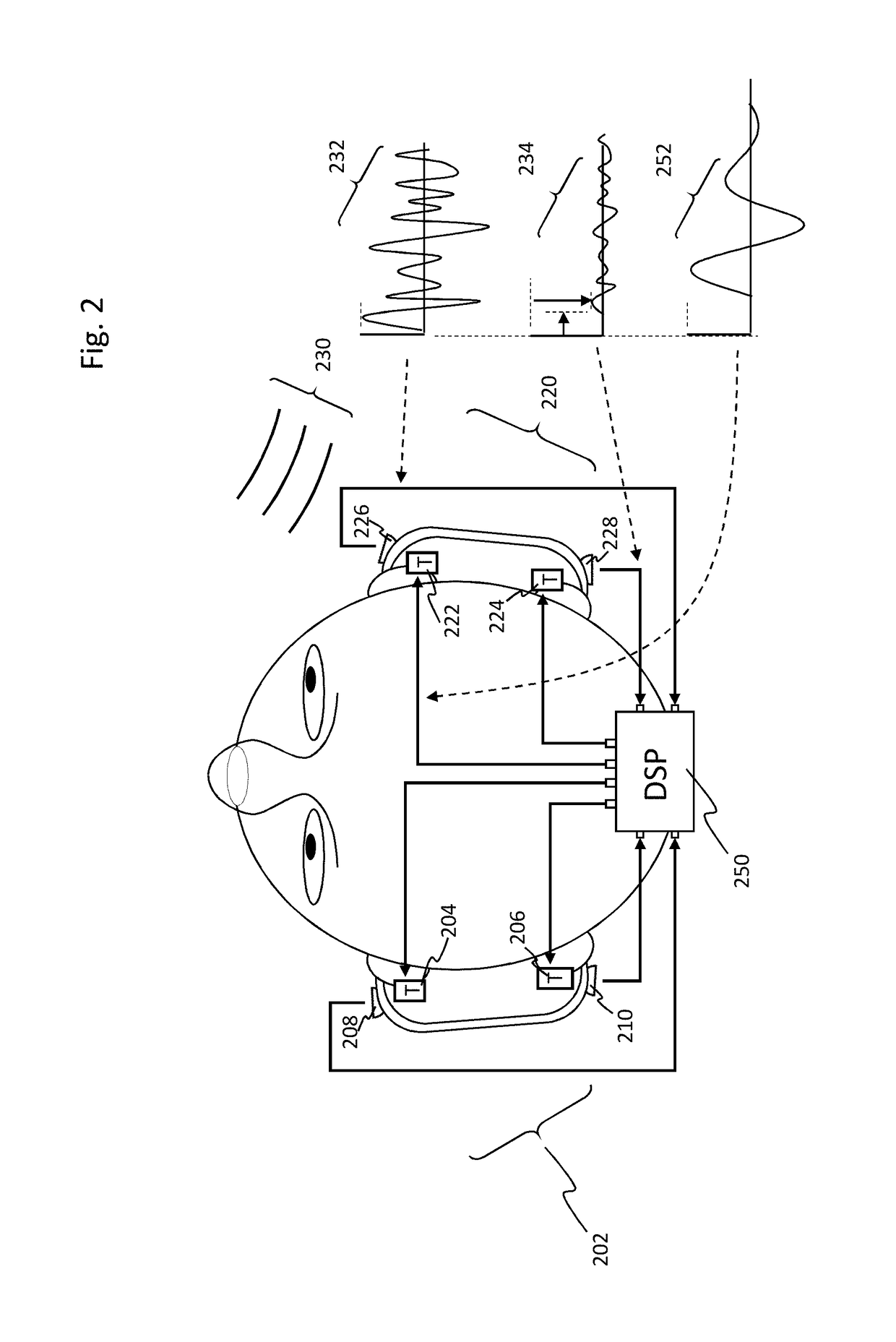

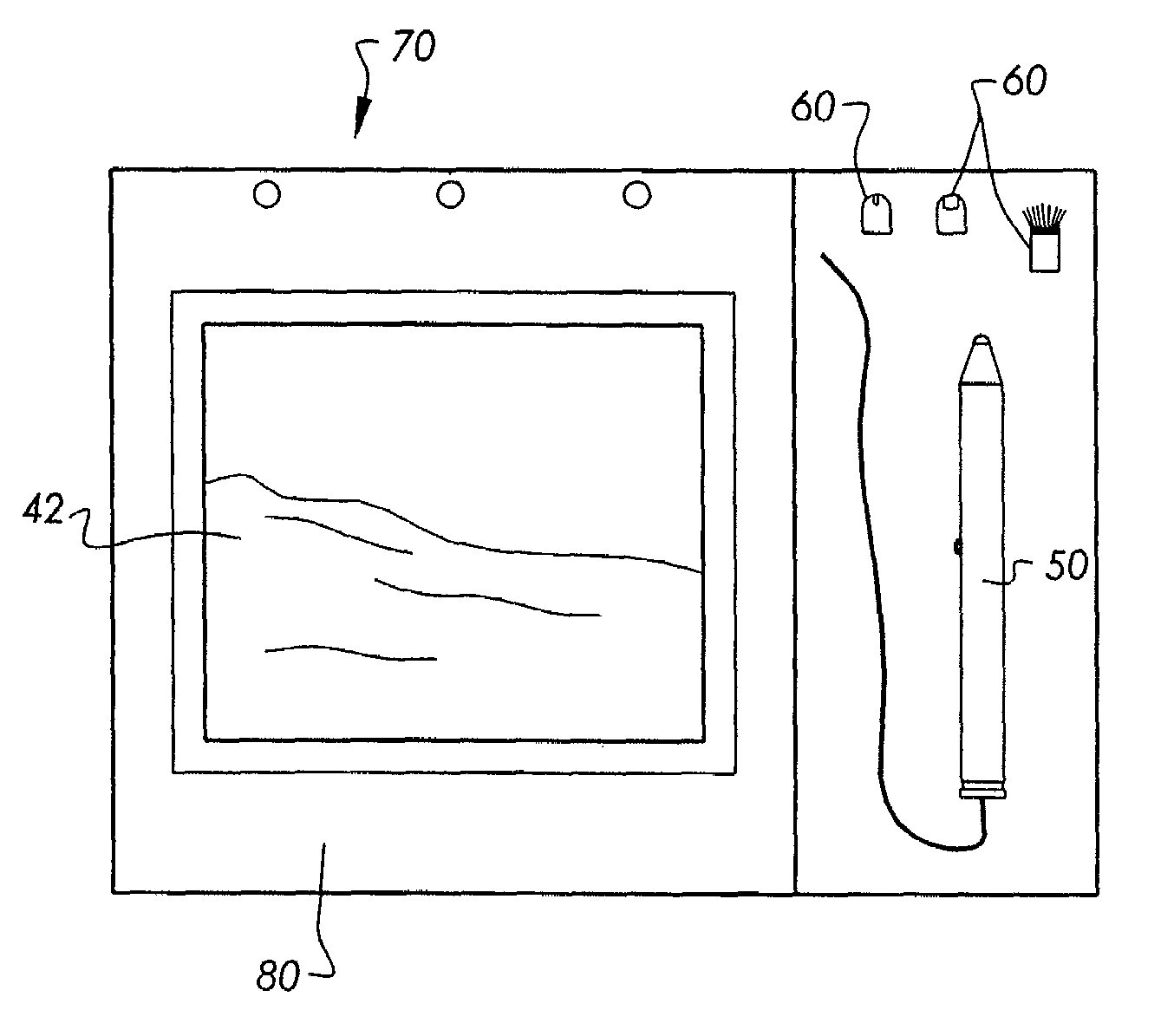

Apparatus and methods for audio-tactile spatialization of sound and perception of bass

ActiveUS20170180863A1Accurately produce wide range of tactile frequencyImprove user experienceHeadphones for stereophonic communicationBone conduction transducer hearing devicesImage resolutionTactile illusions

The apparatus and methods of the present invention provide quiet, compact, robust hardware that can accurately produce a wide range of tactile frequencies at a perceptually constant intensity. For greater expressiveness, some apparatus for moving the skin in multiple axes are also disclosed. Signal processing methods are presented to enhance the user's experience of audio spatialization. The methods transform audio signals into directional tactile cues matched to the time resolution of the skin, and which exploit directional tactile illusions.

Owner:TACTION TECH

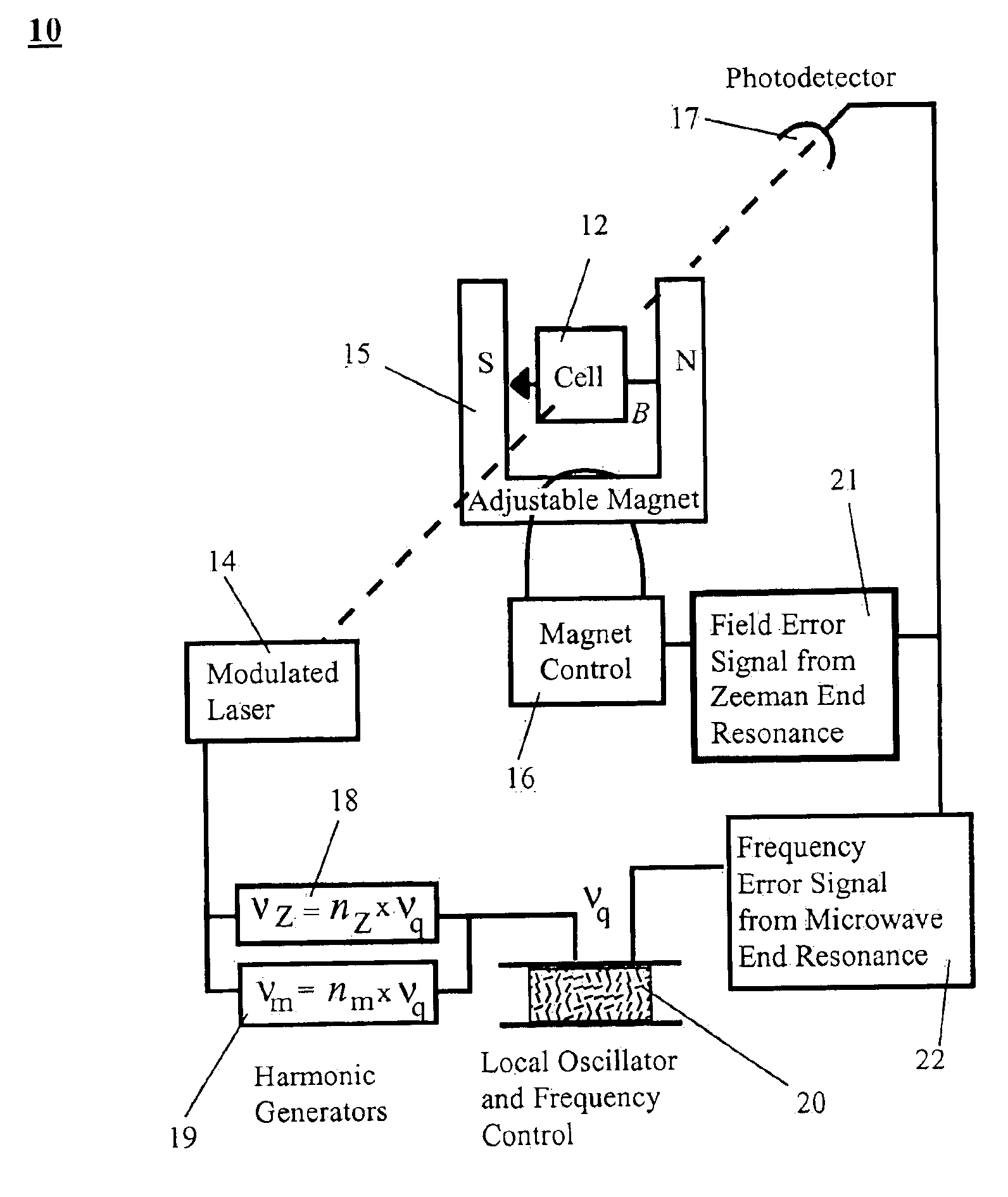

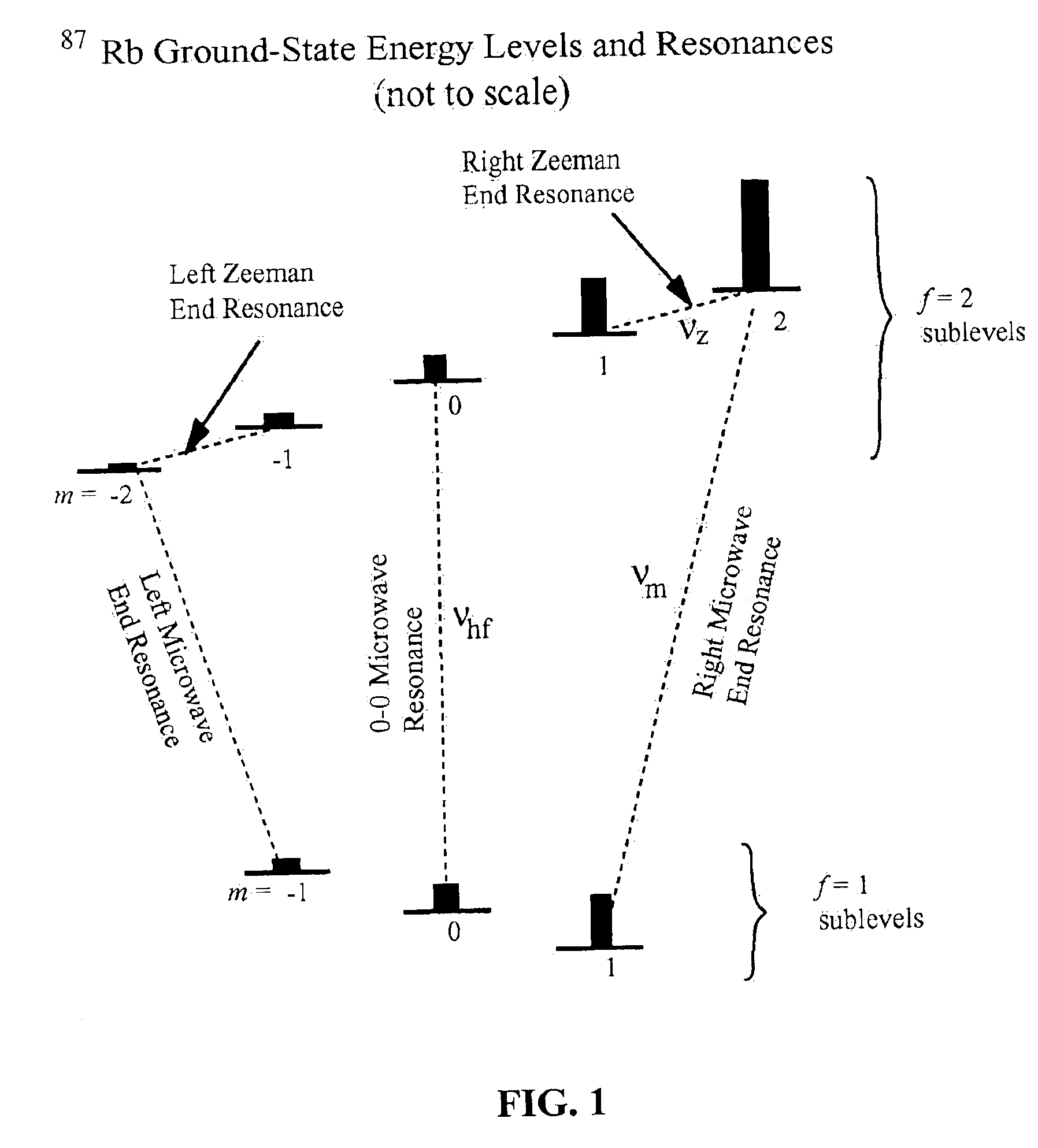

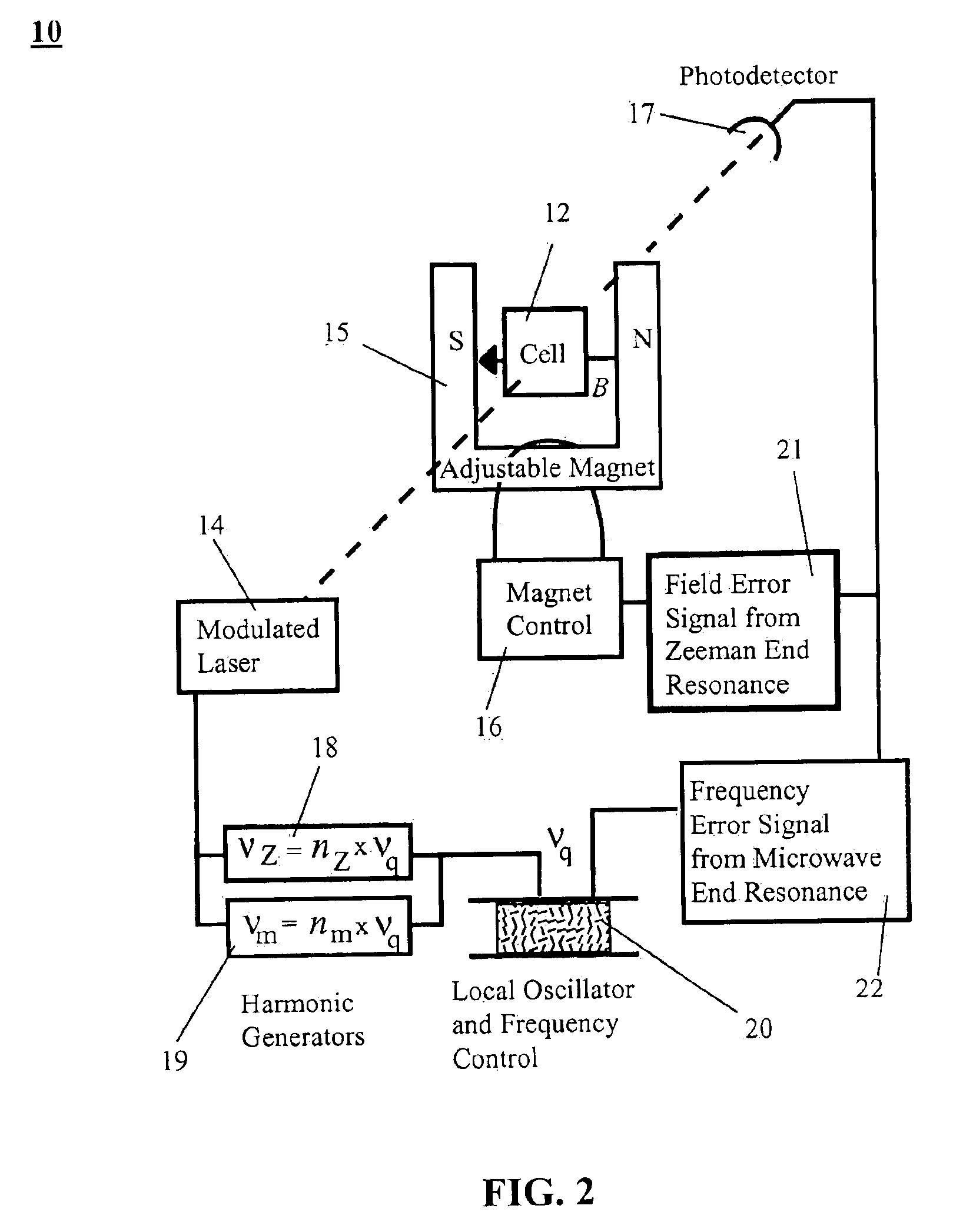

Method and system for operating an atomic clock with simultaneous locking of field and frequency

InactiveUS6888780B2Eliminates concern about magnetic-field dependenceHigh light transmittanceMechanical clocksPulse automatic controlTrappingLaser light

The present invention provides a method and system to simultaneously use the microwave and Zeeman end resonances associated with the same sublevel of maximum (or minimum) azimuthal quantum number m to lock both the atomic clock frequency and the magnetic field to definite values. This eliminates the concern about the field dependence of the end-resonance frequency. In an embodiment of the system of the present invention, alkali metal vapor is pumped with circularly-polarized D1 laser light that is intensity-modulated at appropriate resonance frequencies, thereby providing coherent population trapping (CPT) resonances. In another embodiment, pumping with constant-intensity circularly-polarized D1 laser light enhances magnetic resonances that are excited by alternating magnetic fields oscillating at appropriate resonance frequencies. In both embodiments, the resonances are greatly enhanced by concentrating most of the atoms in the initial state of the resonances, and by diminishing the spin-exchange broadening of the resonances. This leads to greater stability of optically pumped atomic clocks. This invention can also be used to operate an atomic magnetometer, where the feedback signal used to stabilize the magnetic field at the alkali-vapor cell can serve as a sensitive measure of the ambient magnetic field.

Owner:PRINCETON UNIV

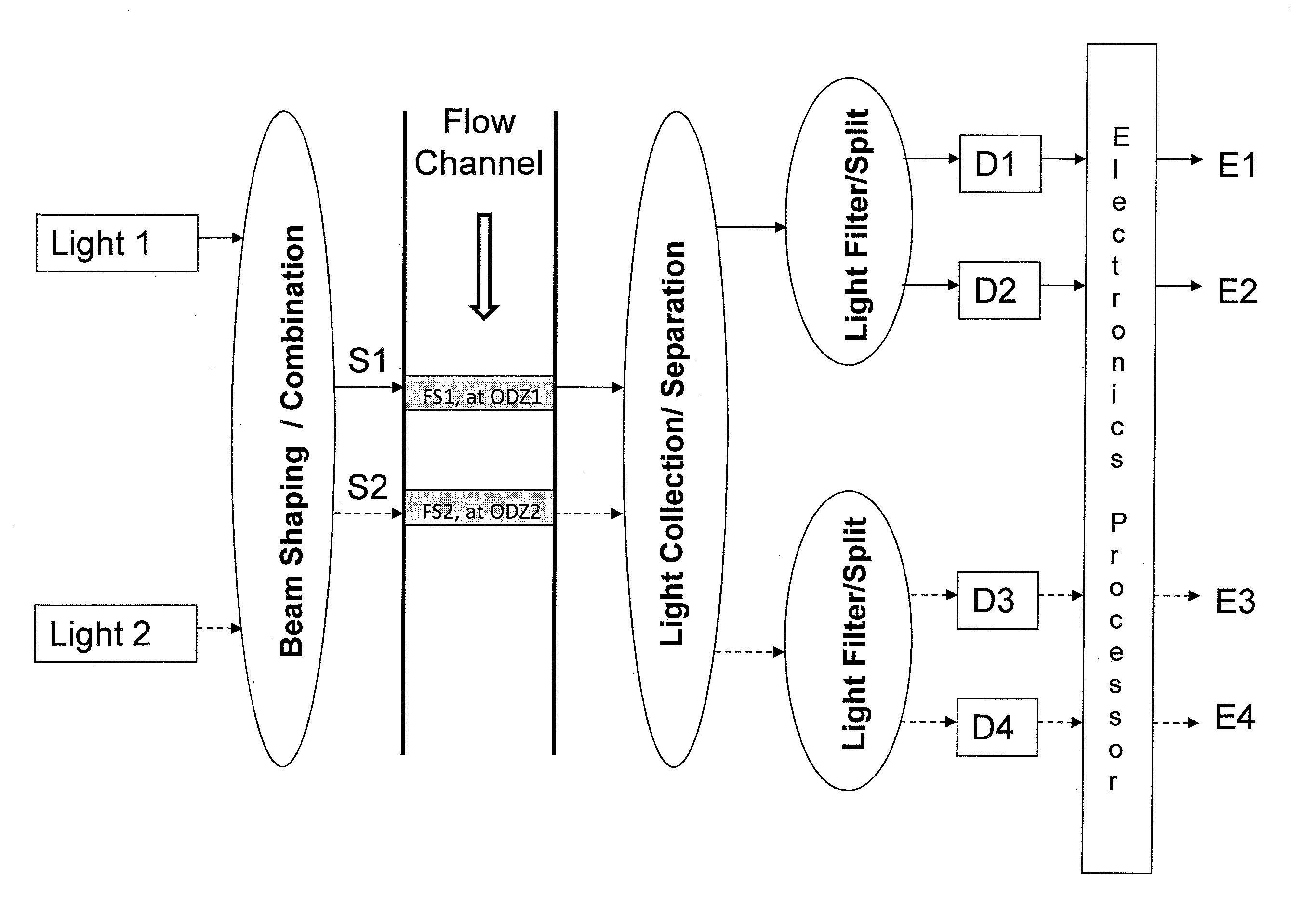

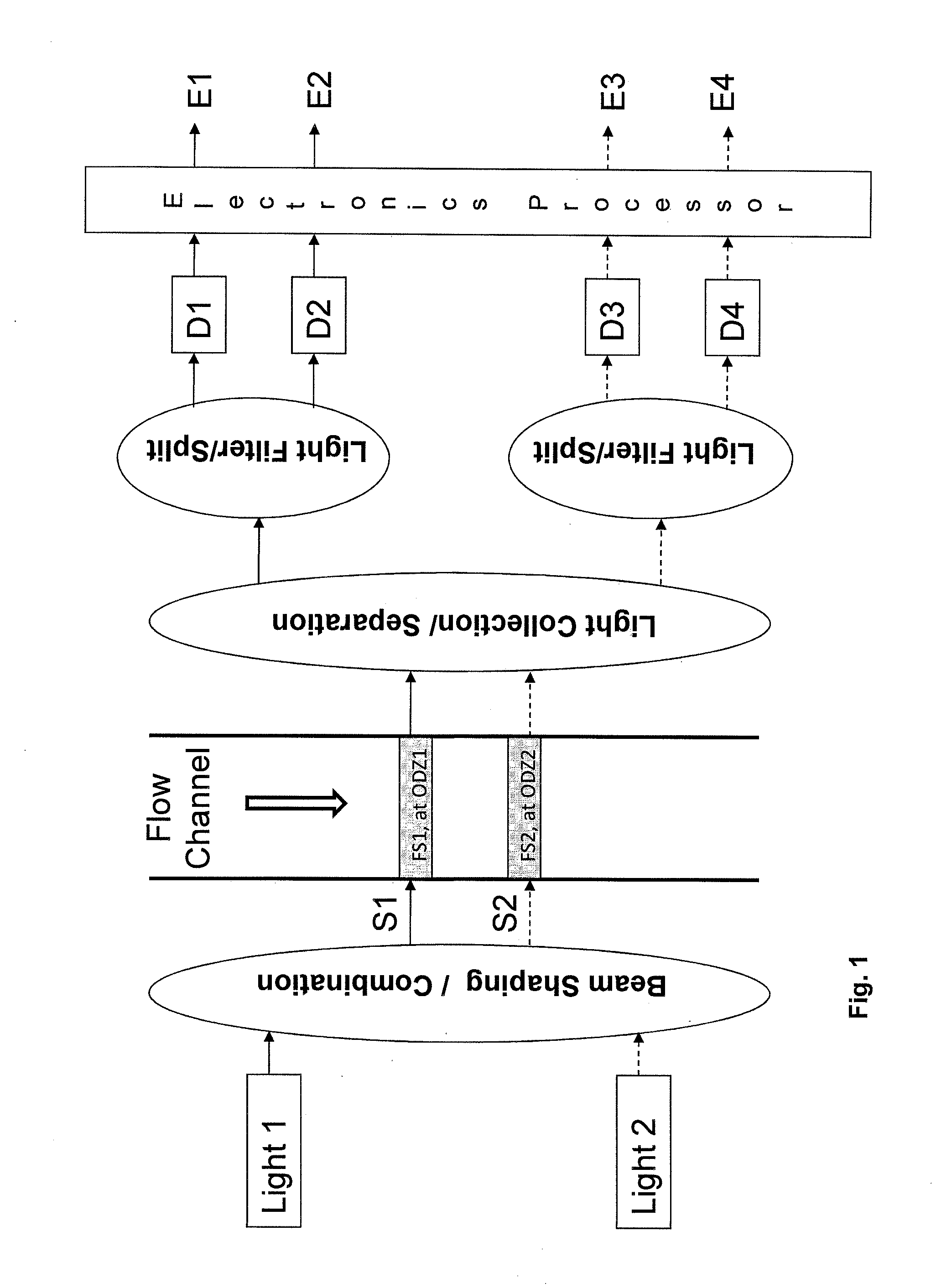

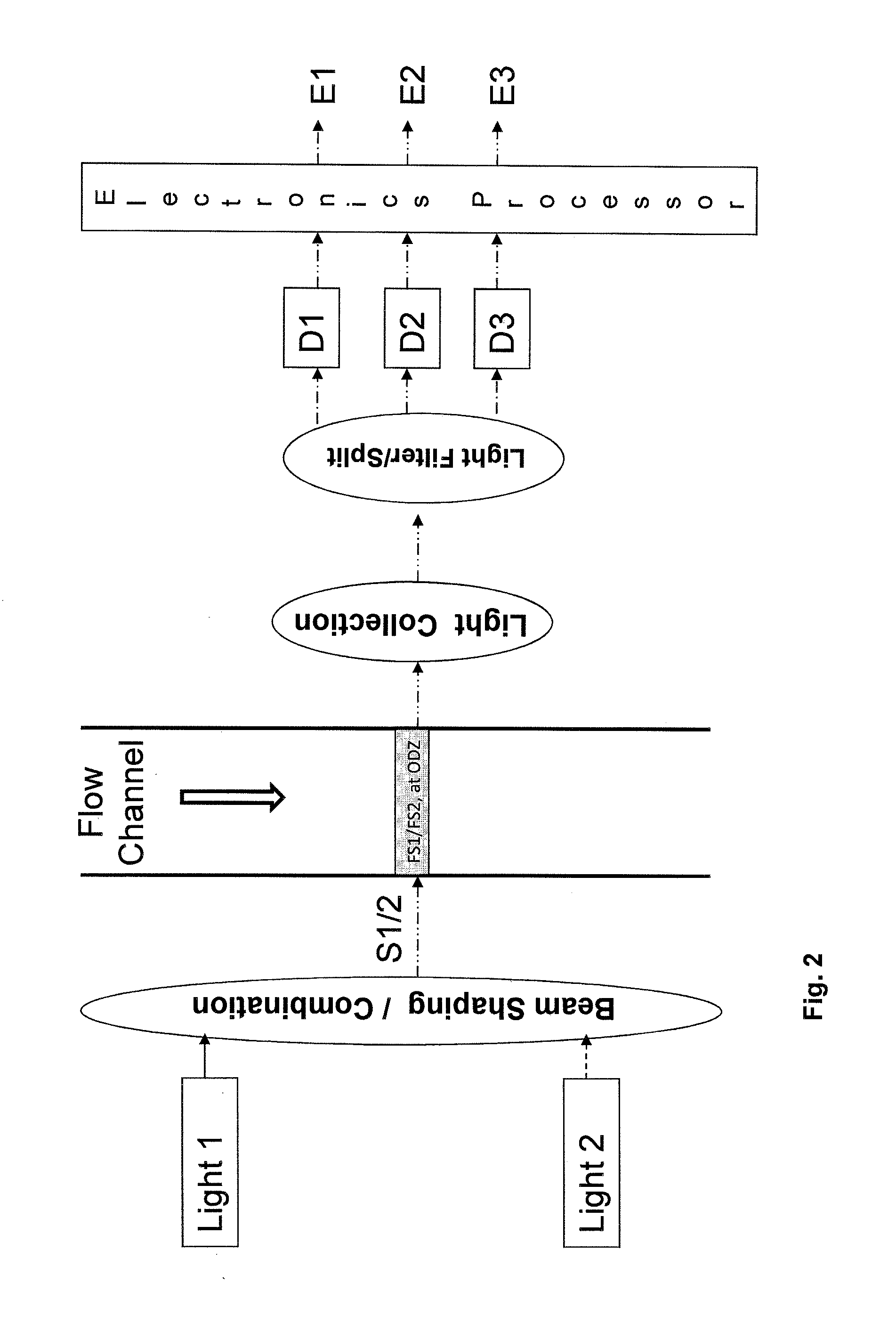

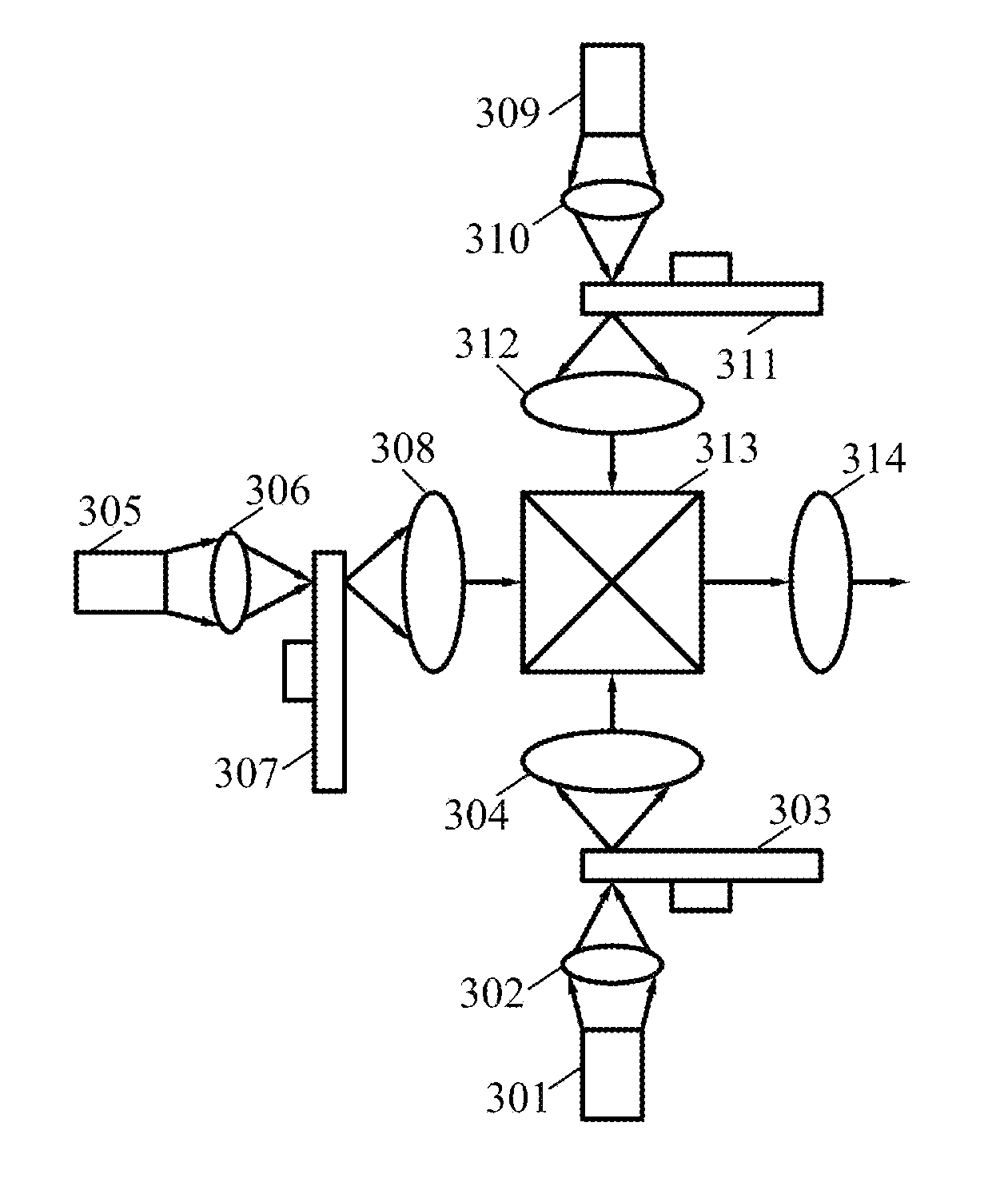

System and method for detecting multiple-excitation-induced light in a flow channel

ActiveUS20130200277A1Reduce probabilityInterference minimizationLuminescent dosimetersPhotoelectric discharge tubesElectricityParticle flow

A system for detecting signal components of light induced by multiple excitation sources including: a flow channel including at least two spatially separated optical interrogation zones; a non-modulating excitation source that directs a light beam of a first wavelength at a near constant intensity onto a first of the optical interrogation zones; a modulating excitation source that directs a light beam of a second wavelength with an intensity modulated over time at a modulating frequency onto a second of the optical interrogation zones; a detector subsystem comprising a set of detectors configured to detect light emitted from particles flowing through the at least two optical interrogation zones and to convert the detected light into a total electrical signal; and a processor that determines signal components from the light detected from each of the optical interrogation zones.

Owner:AGILENT TECH INC

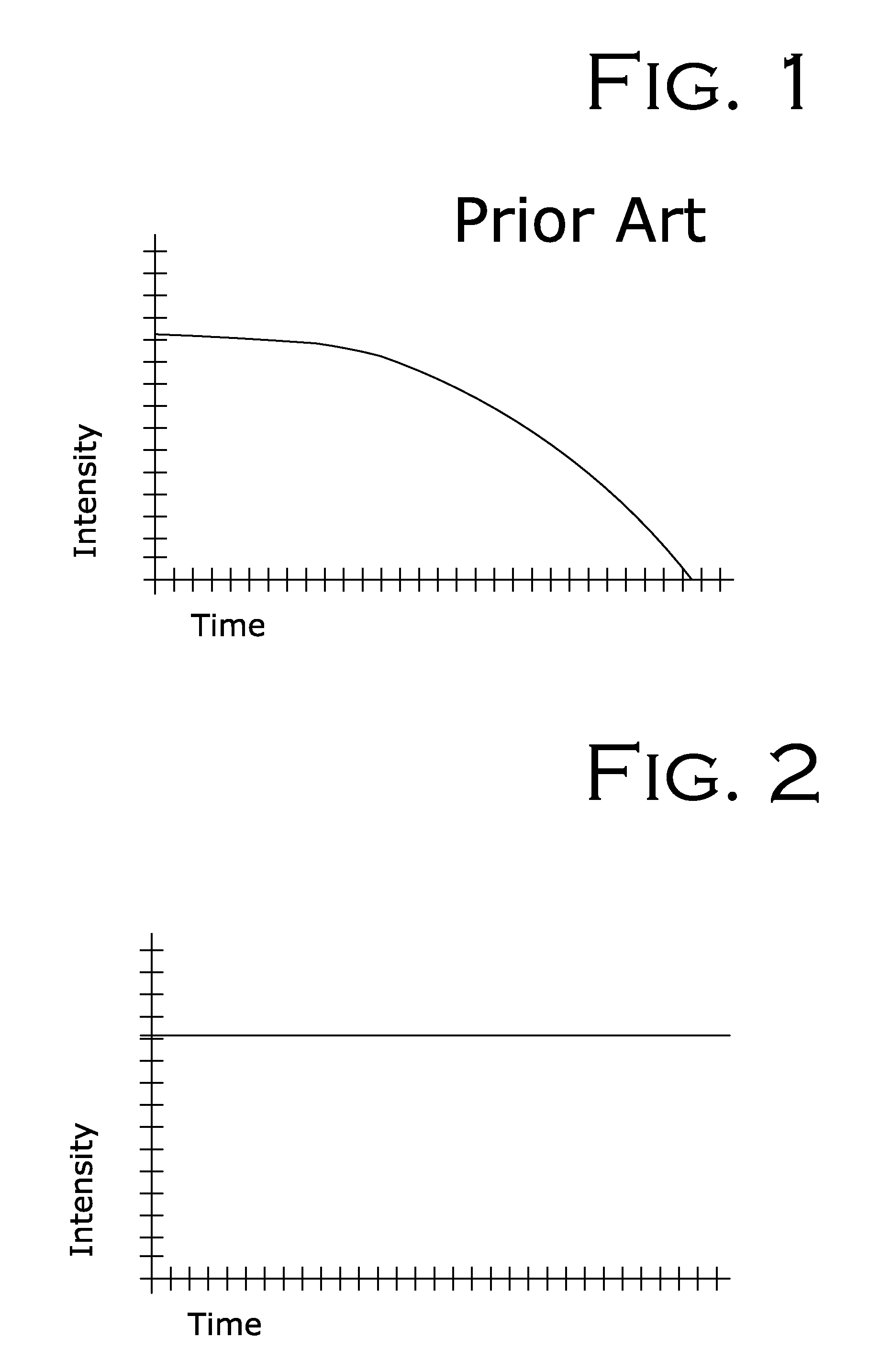

Method and apparatus for a solid state light source

A solid state light source device for generating a constant broad band light useful in multiple SLM projectors. The light source device includes a blue or UV / near UV excitation light and a moving plate carrying wavelength conversion materials to convert the excitation light into a broad band light. The wavelength conversion materials include red, green, yellow and / or blue phosphors, and may pass some of the blue excitation light. The broad band light outputted by the phosphor plate includes at least two primary color components and has a constant intensity and spectrum as a function of time. The solid state light source device further includes a second light source such as a blue light source, and a light combination device which combines the output light of the moving phosphor plate and the light from the second light source into one beam of constant, broad band light.

Owner:APPOTRONICS CORP LTD

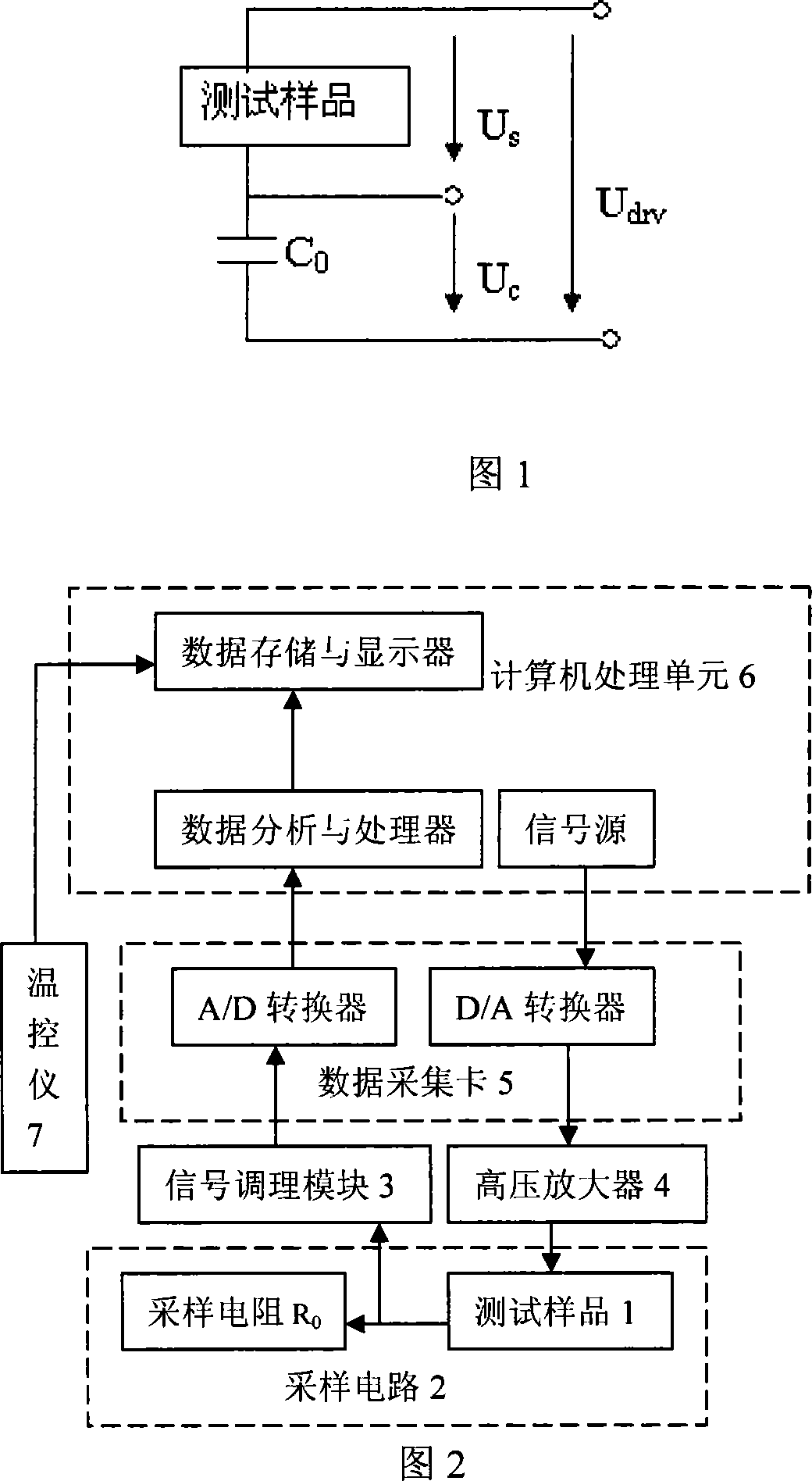

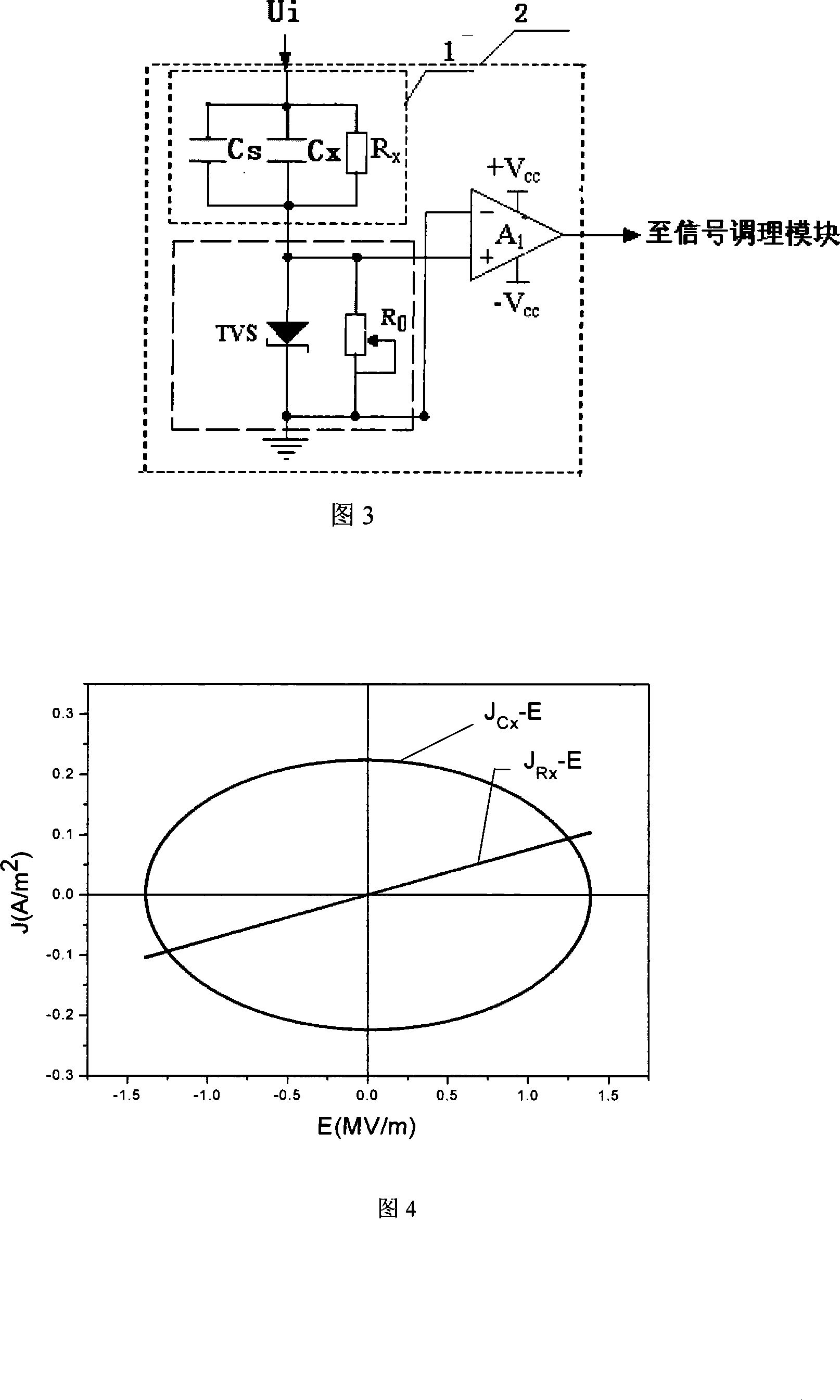

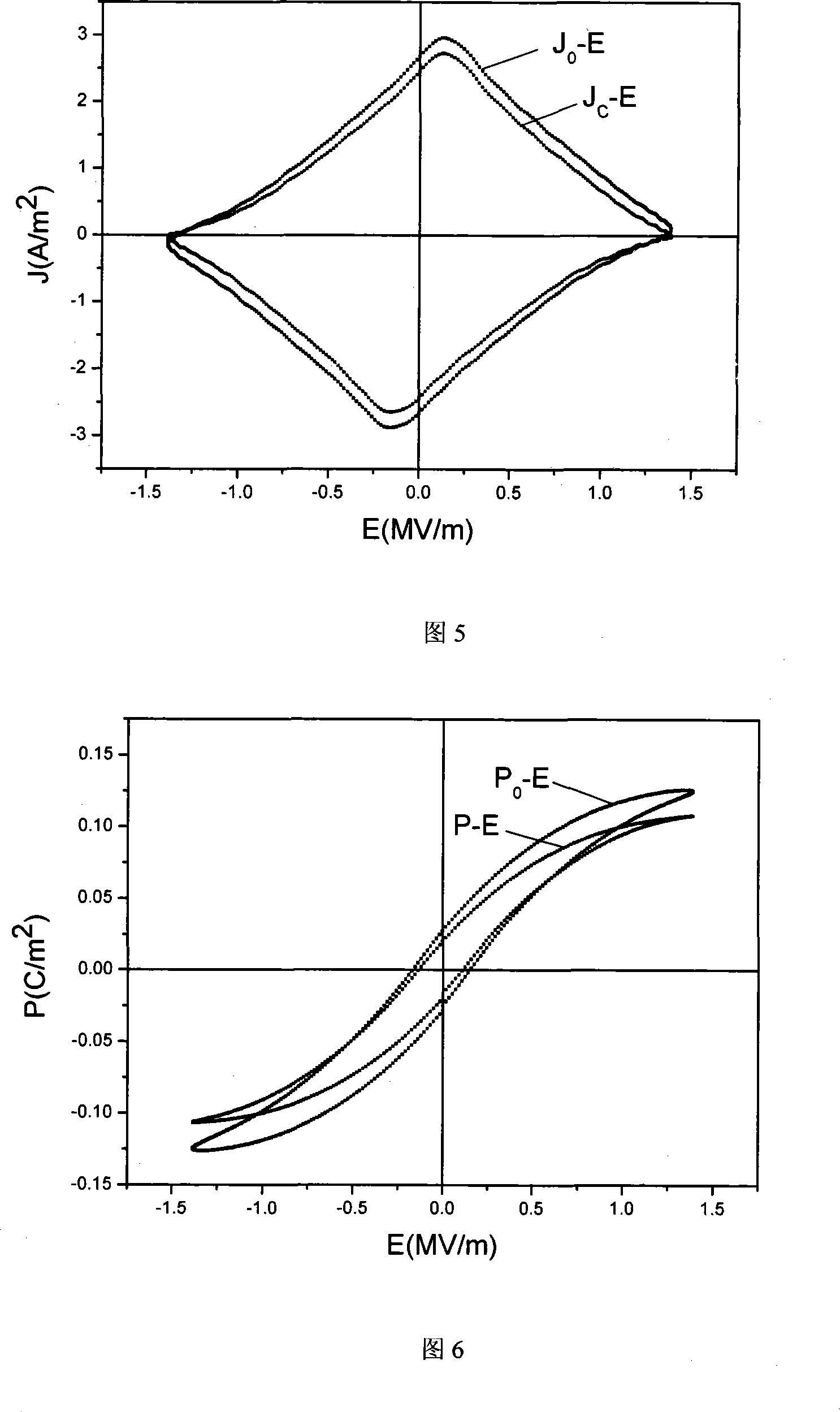

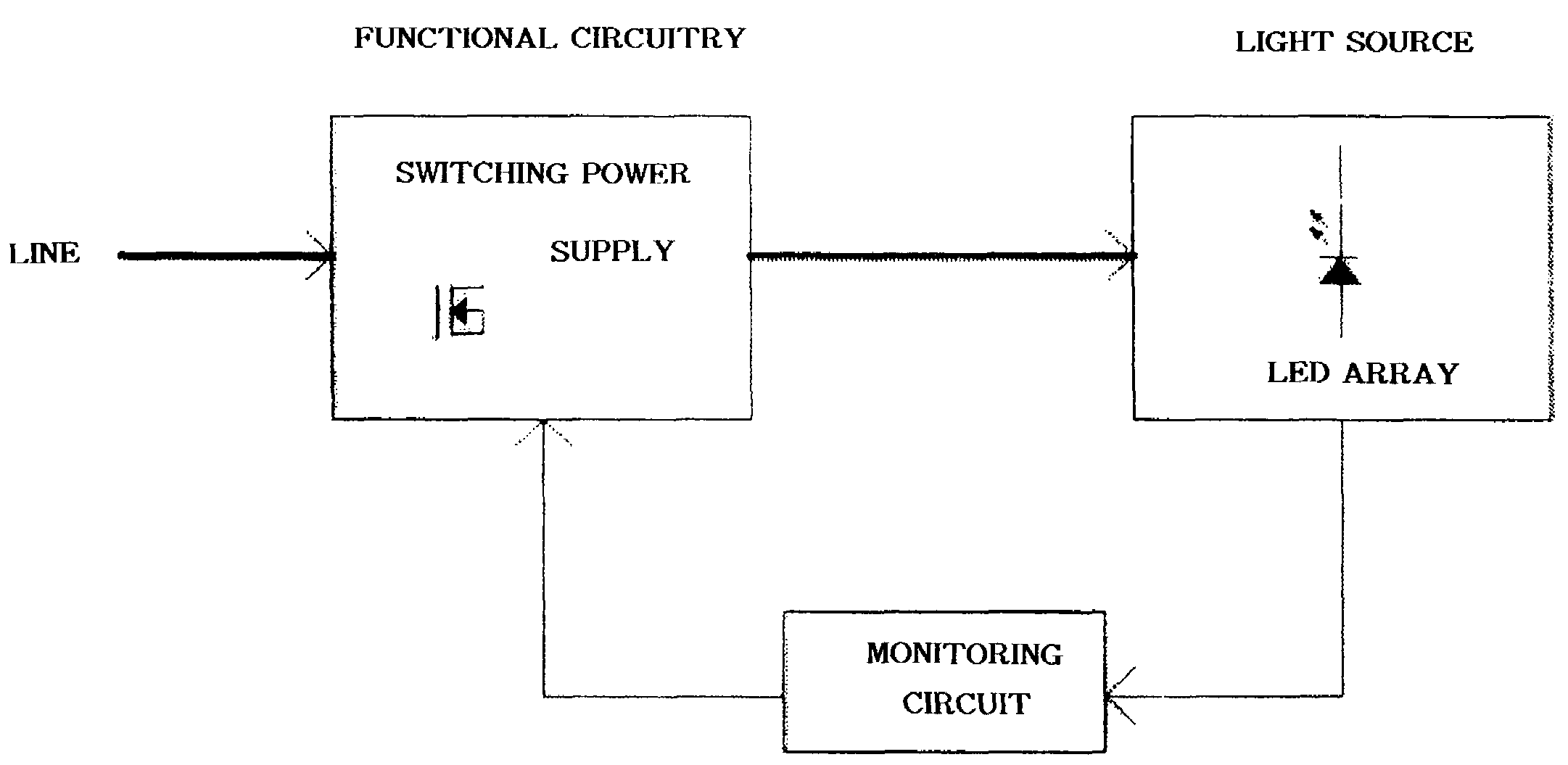

Measurement mechanism and measurement method of ferroelectric materials electric hysteresis loop wire

InactiveCN101158712AGuaranteed accuracyResistance/reactance/impedenceCurrent density measurementsHysteresisMeasurement device

The invention discloses an apparatus for measuring the ferroelectric hysteresis of ferroelectric materials which is based on a current measurement circuit, as well as a measurement method thereof. The invention inputs a simulated output signal generated by a computer processing unit into a high voltage amplifier through a signal source and a data acquisition board, thus giving excitation voltage to a sample being tested, and then through a sampling resistance R0, sampled current signal is input into a signal regulating module through an operational amplifier, and then the sampled current signal is transmitted back into the computer processing unit through the data acquisition board. By separating the current signal acquired from the measurement into three parts as linear polarization, non-linear polarization and electric loss, the measurement system is provided with not only the function of measuring the P-E relationship, but also the function of acquiring the relationship between the real spontaneous polarization and induced polarization of the dielectric substance being tested and the field intensity. Furthermore, by superimposing actuating signal of a small alternative electric field to a bias electric field with constant intensity and synchronously collecting the corresponding change information of the polarization intensity of the sample being tested, then the reversible permittivity can be acquired.

Owner:XI AN JIAOTONG UNIV

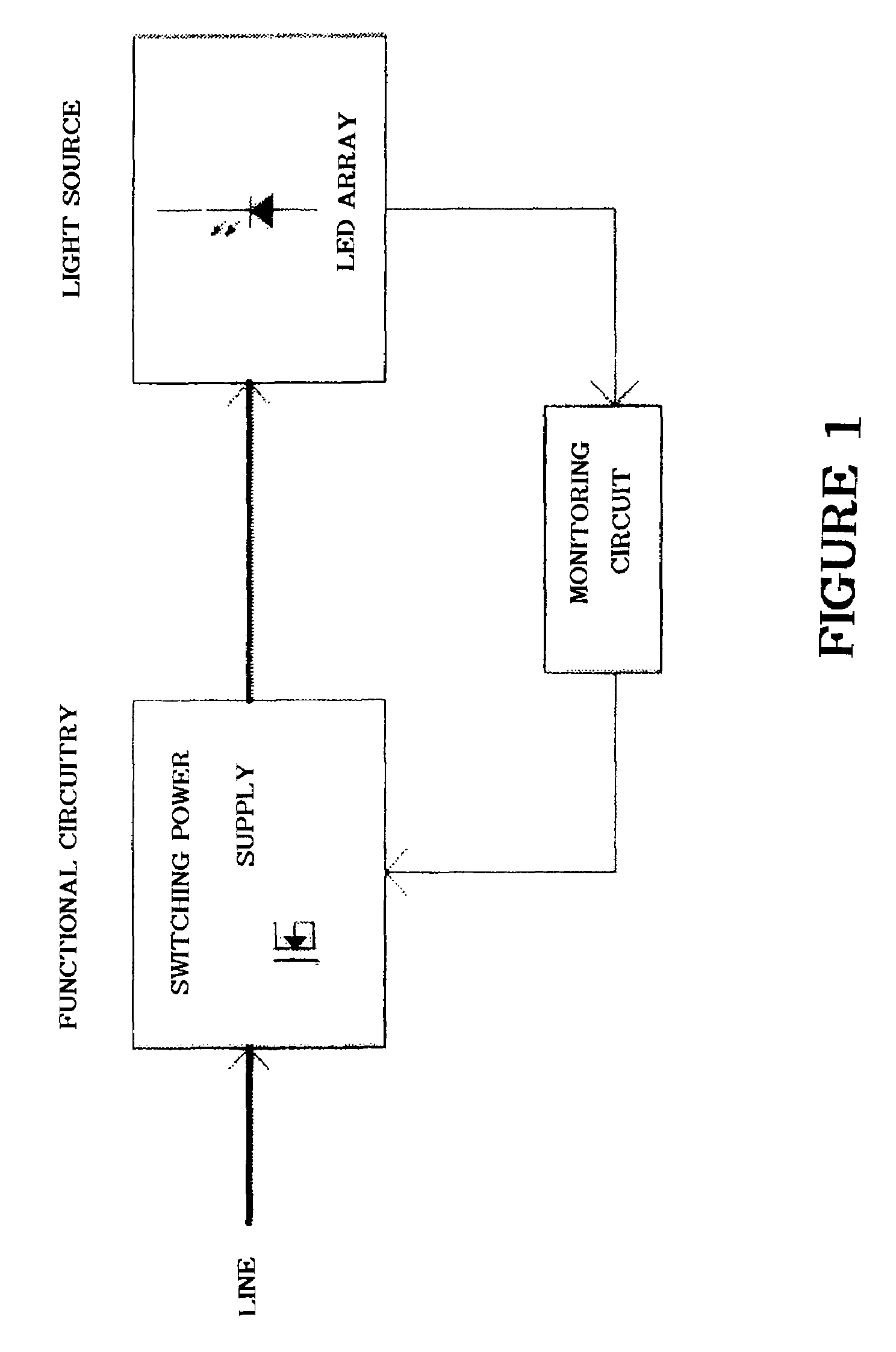

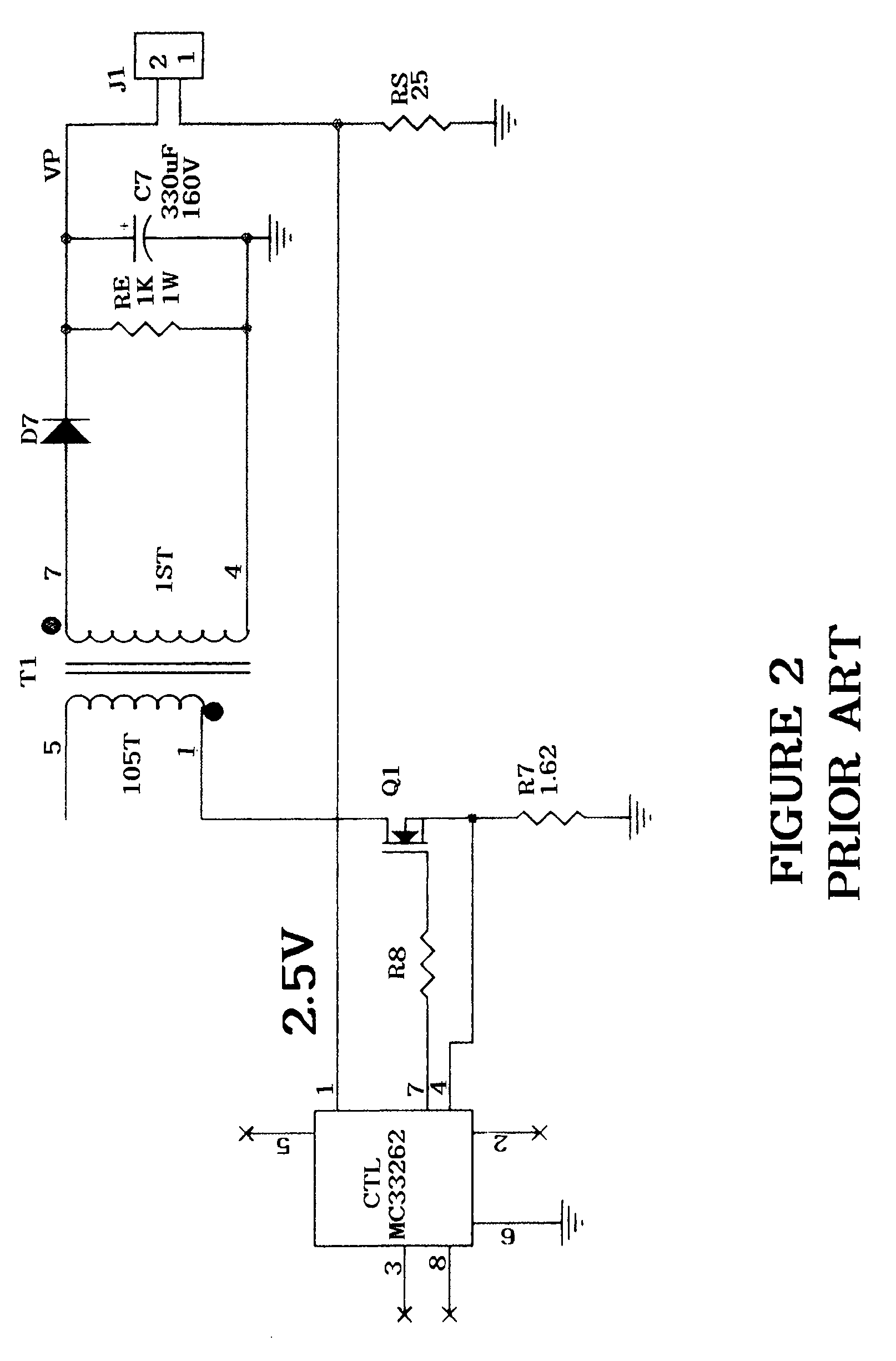

LED matrix current control

ActiveUS7233258B1Low costSimple low-cost circuitRoad vehicles traffic controlElectroluminescent light sourcesAudio power amplifierLow-pass filter

A system is employed to provide a substantially constant intensity light source via functional circuitry, the functional circuitry comprises a switching power supply. At least one signal is part of a matrix of LEDs connected in series and parallel and configured for redundancy. A monitoring circuit comprises a current sense circuit, wherein the current sense circuit includes an amplifier and at least one resistor in series with the amplifier. The current sense circuit includes a power converter circuit that senses a current of a flyback diode, recovers a dc component of a waveform via a low pass filter, and provides feedback control of the at least one signal.

Owner:GE LIGHTING SOLUTIONS LLC

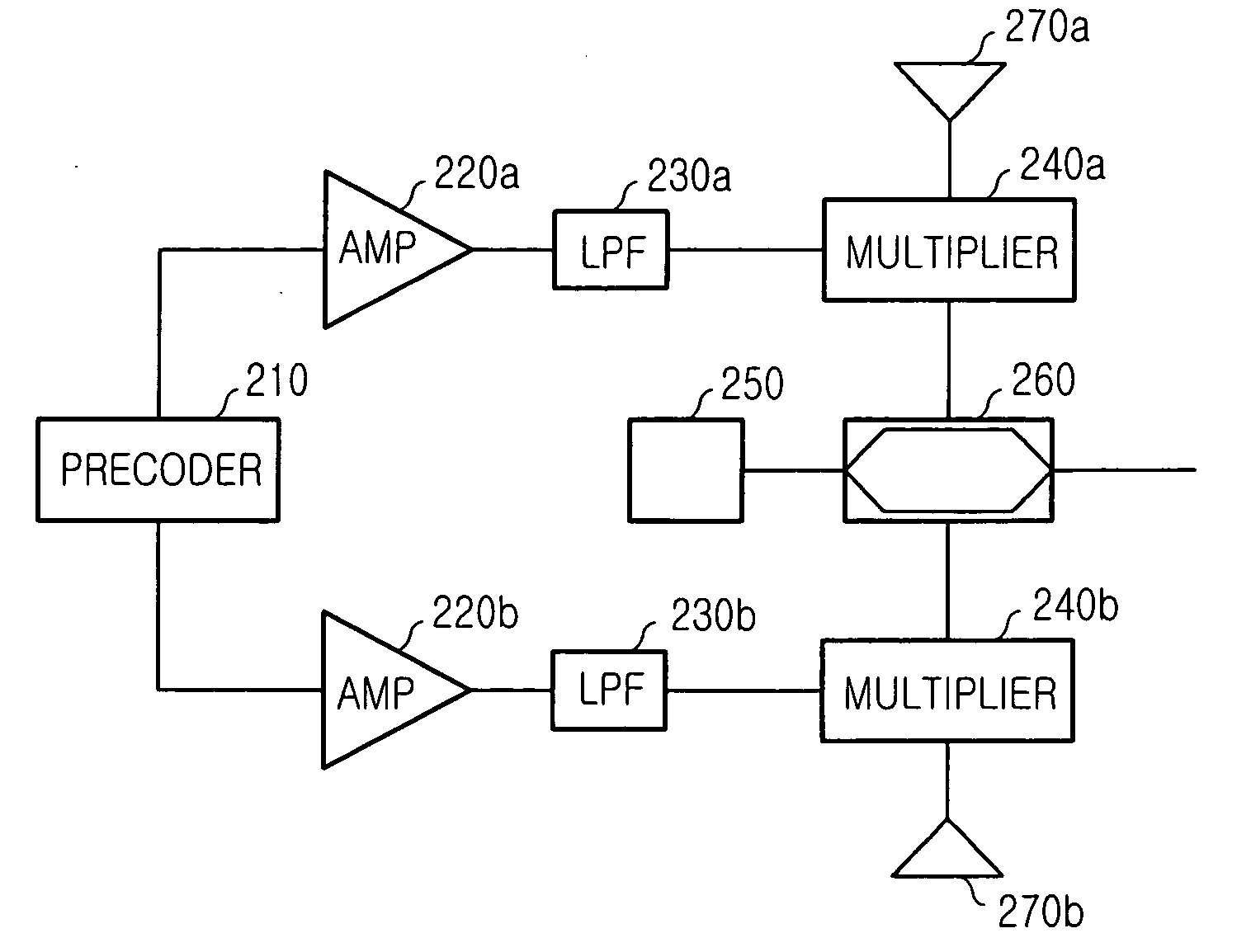

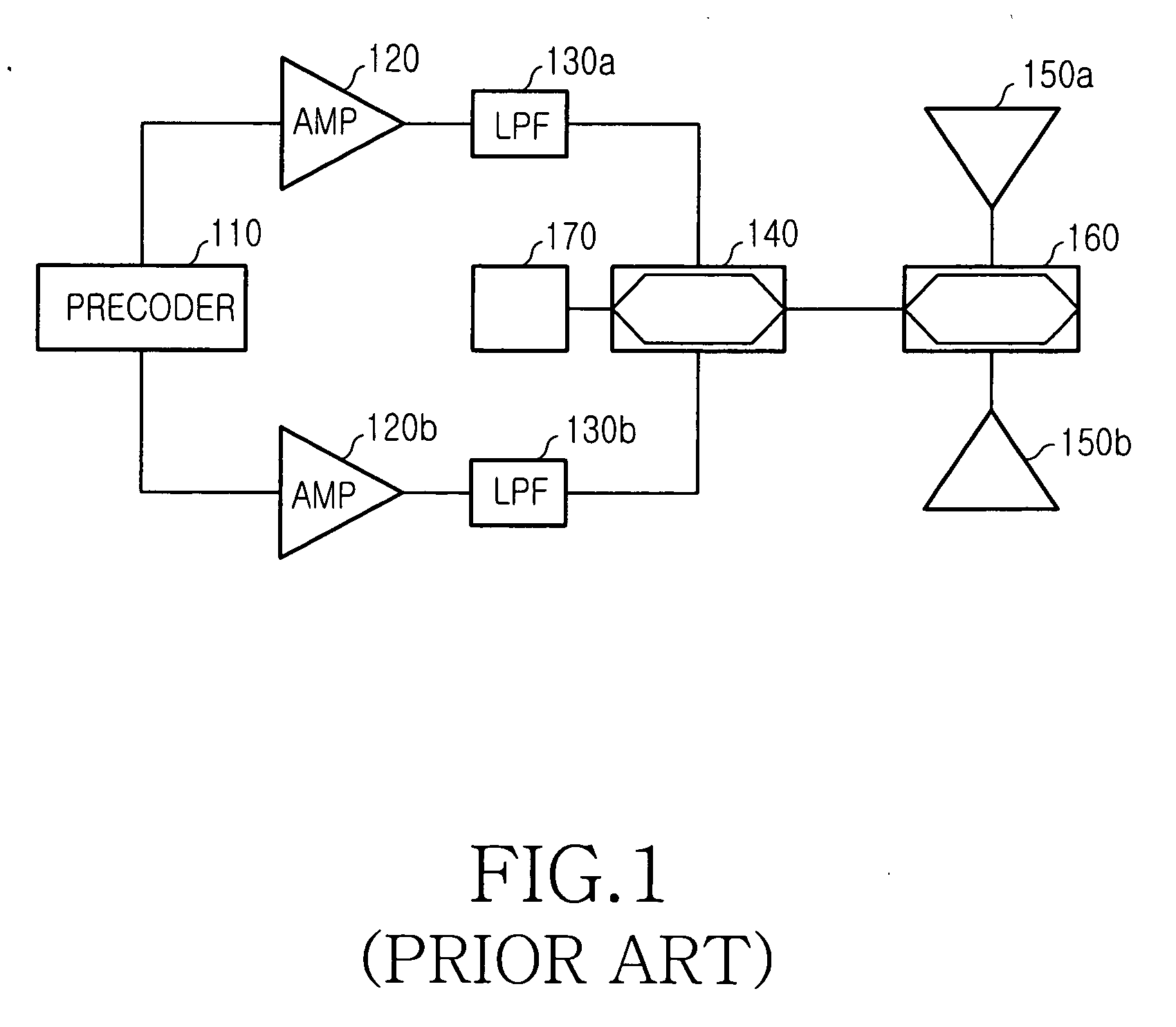

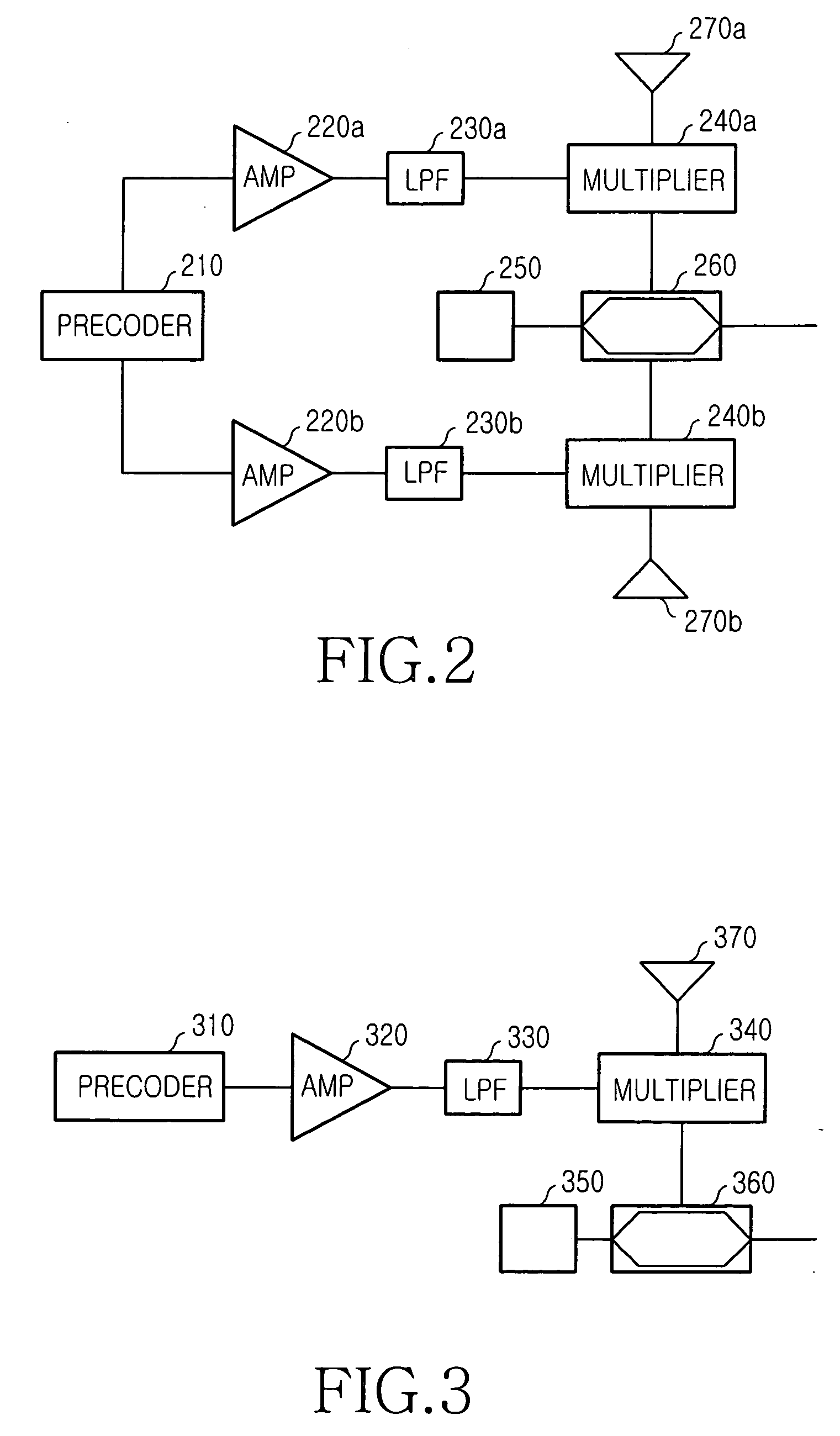

RZ-AMI optical transmitter module

InactiveUS20050078965A1Electromagnetic transmittersElectromagnetic receiversAudio power amplifierOptical transmitter

Disclosed is an optical transmitter module comprising: a precoder to generate an encoded binary signal from an electric signal; an amplifier to amplify the binary signal; a converter to convert the amplified encoded binary signal into a limited ternary signal; a frequency generator to generate a sine wave having a predetermined frequency; a multiplier to multiply the ternary signal using the sine wave; a light source to generate a coherent CW light having a constant intensity; and a Mach-Zehnder modulator to modulate the CW light according to the ternary signal from the multiplier.

Owner:SAMSUNG ELECTRONICS CO LTD

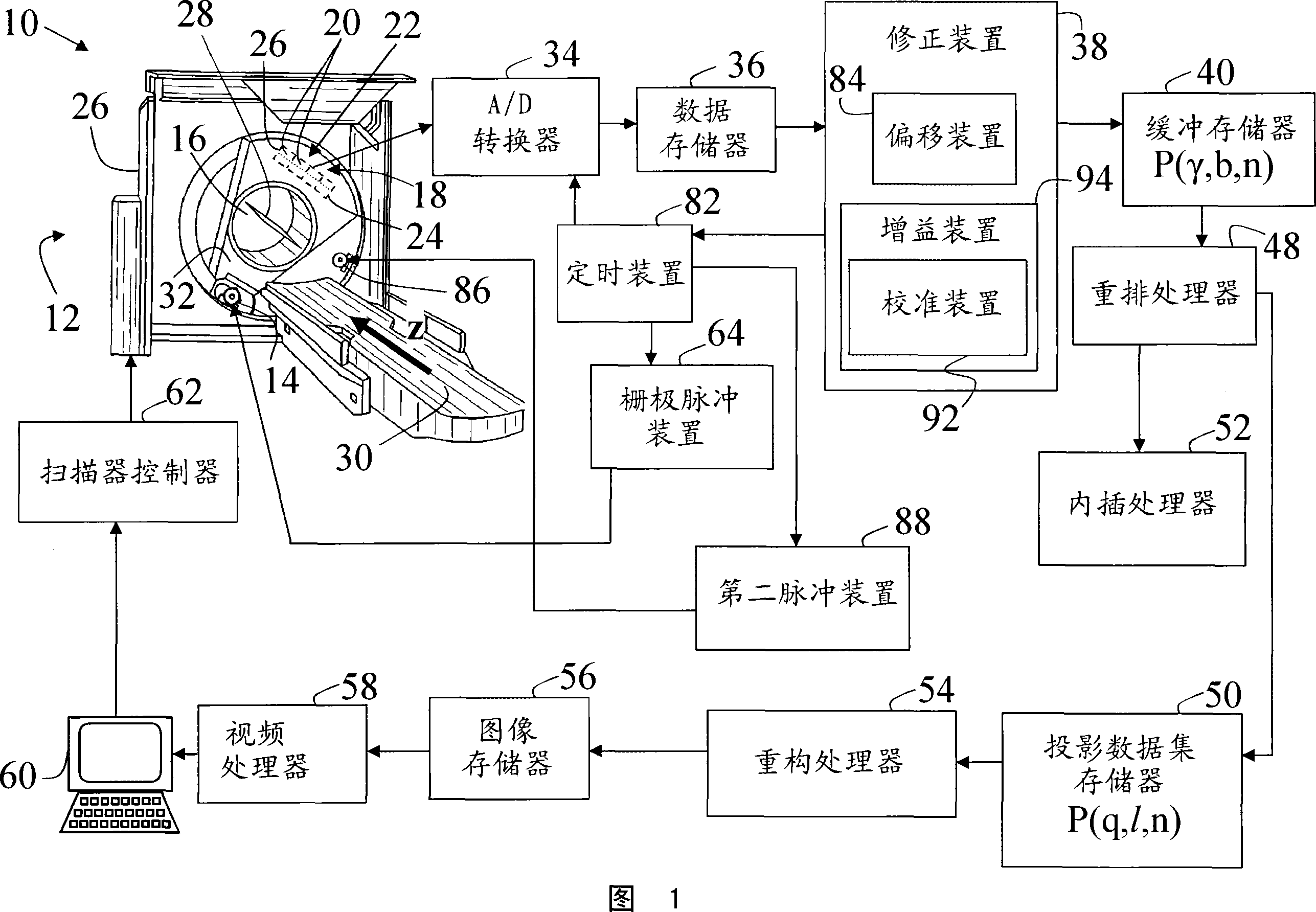

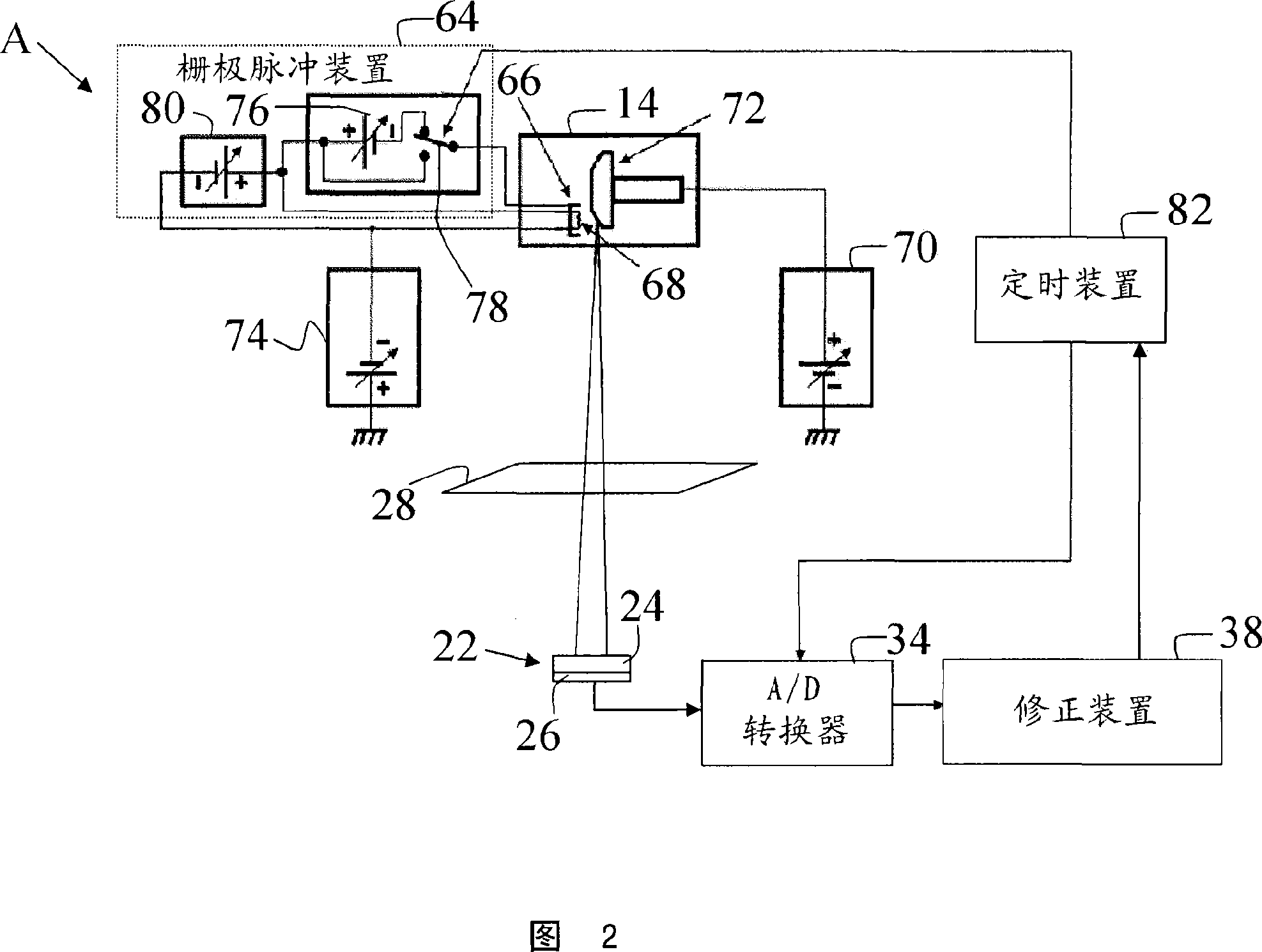

Pulsed X-ray for continuous detector correction

InactiveCN101080653AReduce scan timeAvoid artifactsTomographyRadiation diagnosticsX-rayUltimate tensile strength

A radiographic imaging apparatus (10) including a first radiation source (14) emitting a radiation beam to an examination region (16). The detector (18) converts the detected radiation passing through the examination area (16) into an electrical detector signal representative of the detected radiation. The detector (18) has at least one characteristic that changes in time, such as offset B(t) or gain A(t). The gate pulsing device (64) switches the first radiation source (14) on and off at a rate of 1000 to 5000 pulses per second, so that the offset B(t) is remeasured at least between 1000 and 5000 times per second, and Corrections are made many times during the detector signal generation process. The gain A(t) is measured using a second pulsing device (88) by pulsing a second pulsed source (86, 100, 138) of constant intensity (XRef). The gain A(t) is remeasured and corrected multiple times per second during detector signal generation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

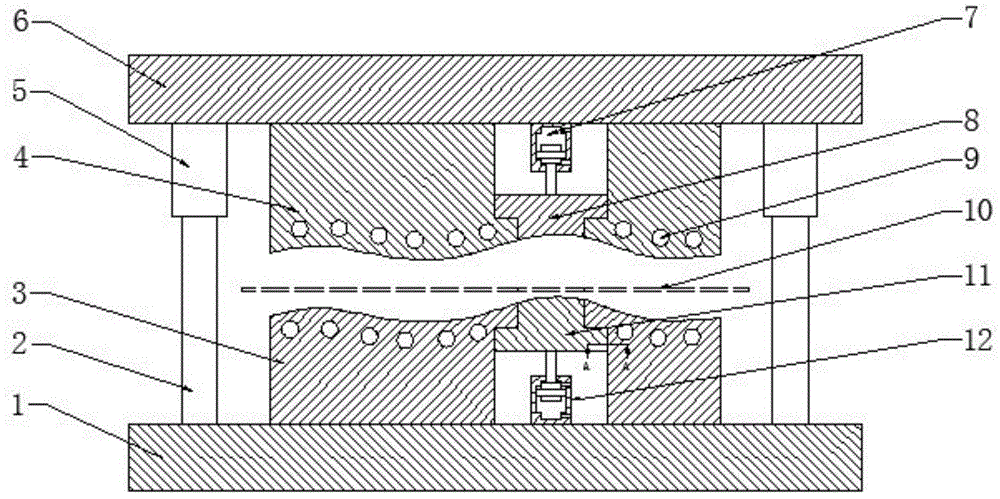

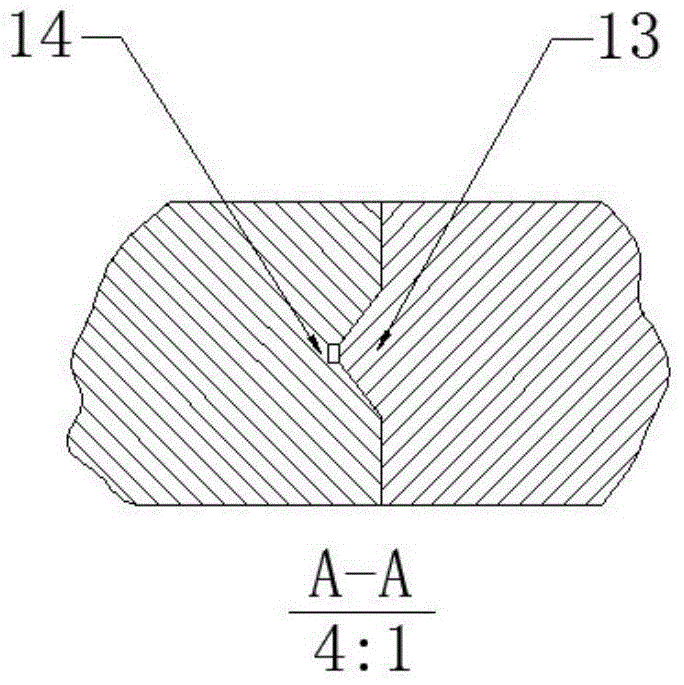

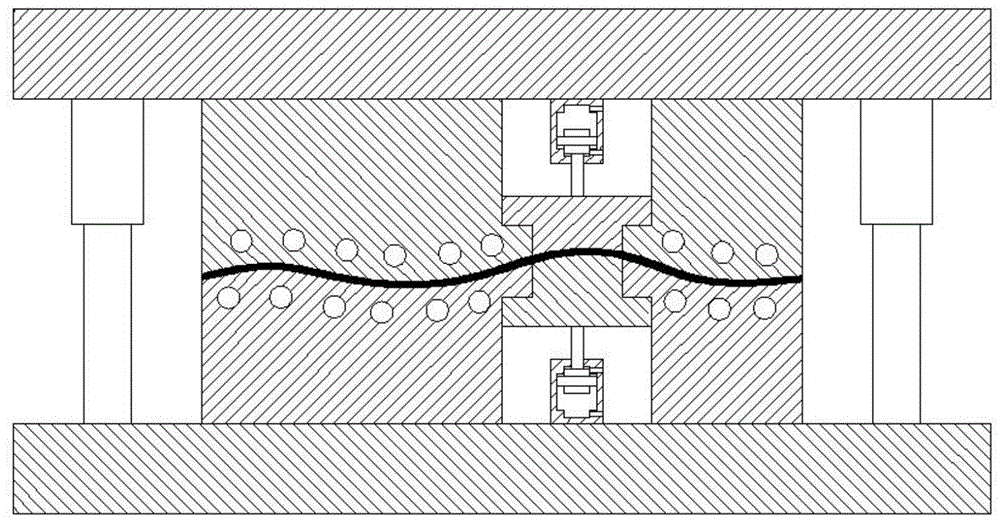

Method and die for obtaining variable-intensity hot stamping part

ActiveCN104889218AReduce cooling rateImprove mechanical propertiesShaping toolsFurnace typesHot stampingEngineering

The invention relates to the field of hot stamping forming and discloses a method and a die for obtaining a variable-intensity hot stamping part. The method for obtaining the variable-intensity hot stamping part is characterized by including steps that 1) preparing the die; 2) preparing; 3) stamping, to be specific, quickly moving a completely austenitized part blank to the die from a heating furnace; enabling a fixed insert of an upper die and a movable insert of the upper die to synchronously move downward till the die is closed, and finishing the hot stamping forming; 4) maintaining pressure and quenching, to be specific, quenching the constant-intensity region of the part by means of a die cooling system, and enabling the austenite to completely convert into a martensitic structure; enabling the movable insert of the upper die and a movable insert of a lower die corresponding to the variable-intensity region of the part to separate from the surface of the variable-intensity region of the part after maintaining a closed pressure maintaining state for 1 to 3 seconds, and forming a clearance; 5) returning and taking the part, to be specific, enabling the fixed insert of the upper die and the movable insert of the upper die to synchronously move towards the upside, opening the die, and taking out the part. The method for obtaining the variable-intensity hot stamping part can make different regions of the hot stamping part have different structures and intensities, and the multi-performance requirement of a single part is realized.

Owner:WUHAN UNIV OF TECH

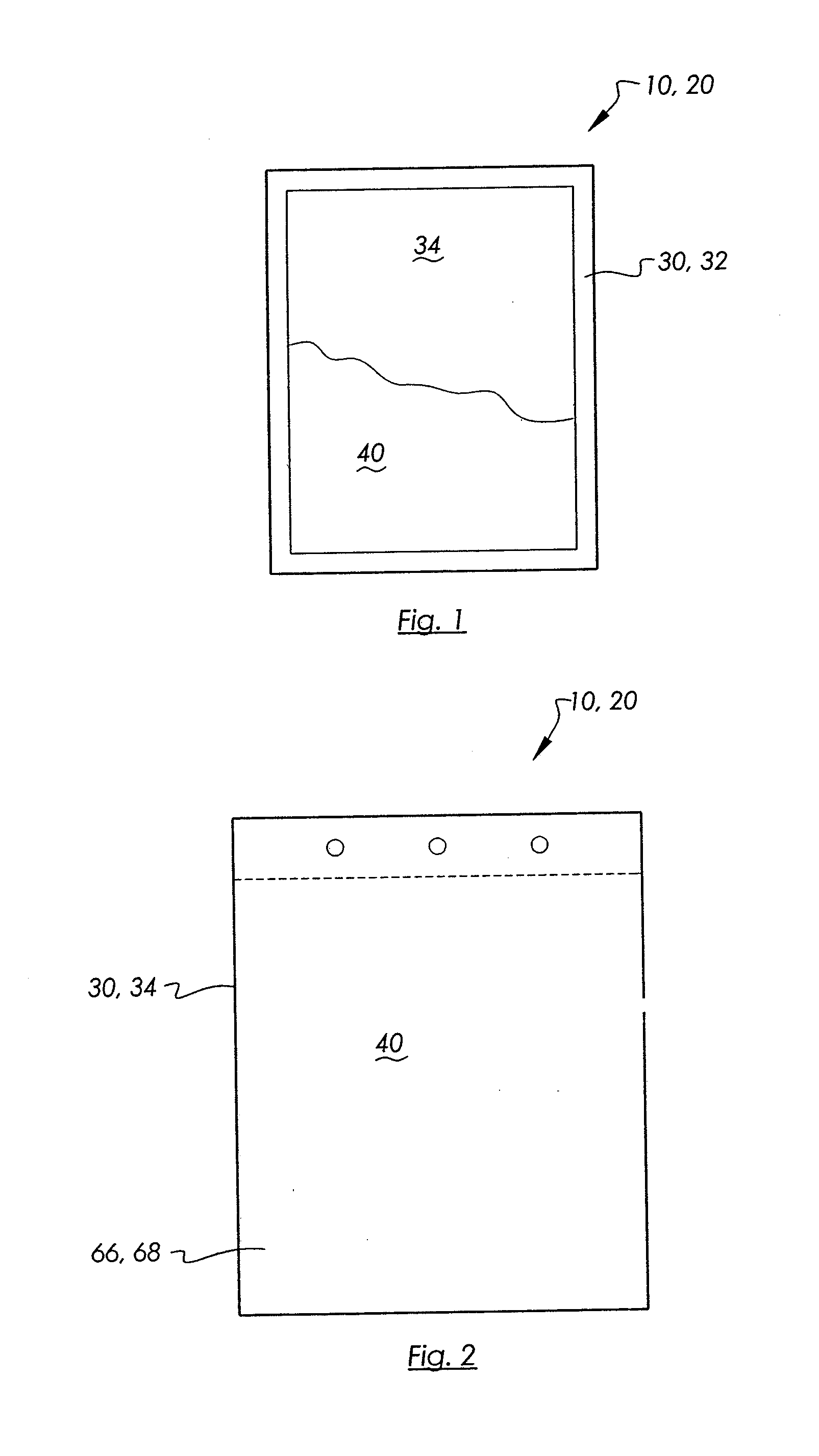

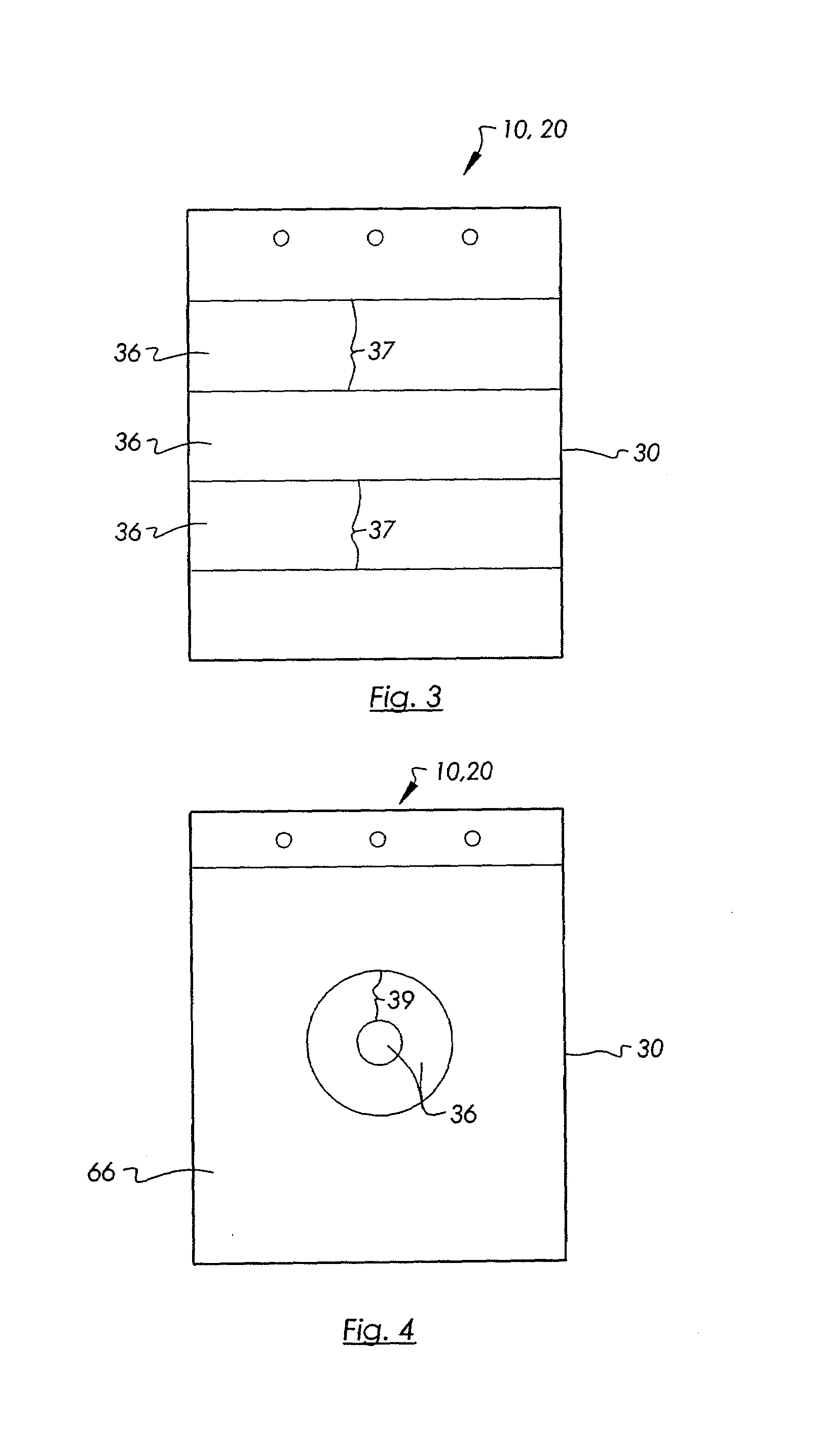

Light-activated illuminating device

A light-activated illuminating member having a support member and a phosphorescent material supported thereby. The phosphorescent material can form a luminescent image having a varying luminescent effect after the phosphorescent material is exposed to a light of constant intensity. One or more such light-activated illuminating members can be assembled with a light source, such as a UV-LED pen, and be formed into a book-type writing / drawing toy which is capable of providing a varying luminescent effect. When a plurality of such illuminating members are used in the book-type toy, such a toy is capable of providing a different, combined luminescent effect.

Owner:ROSE WILLIAM +1

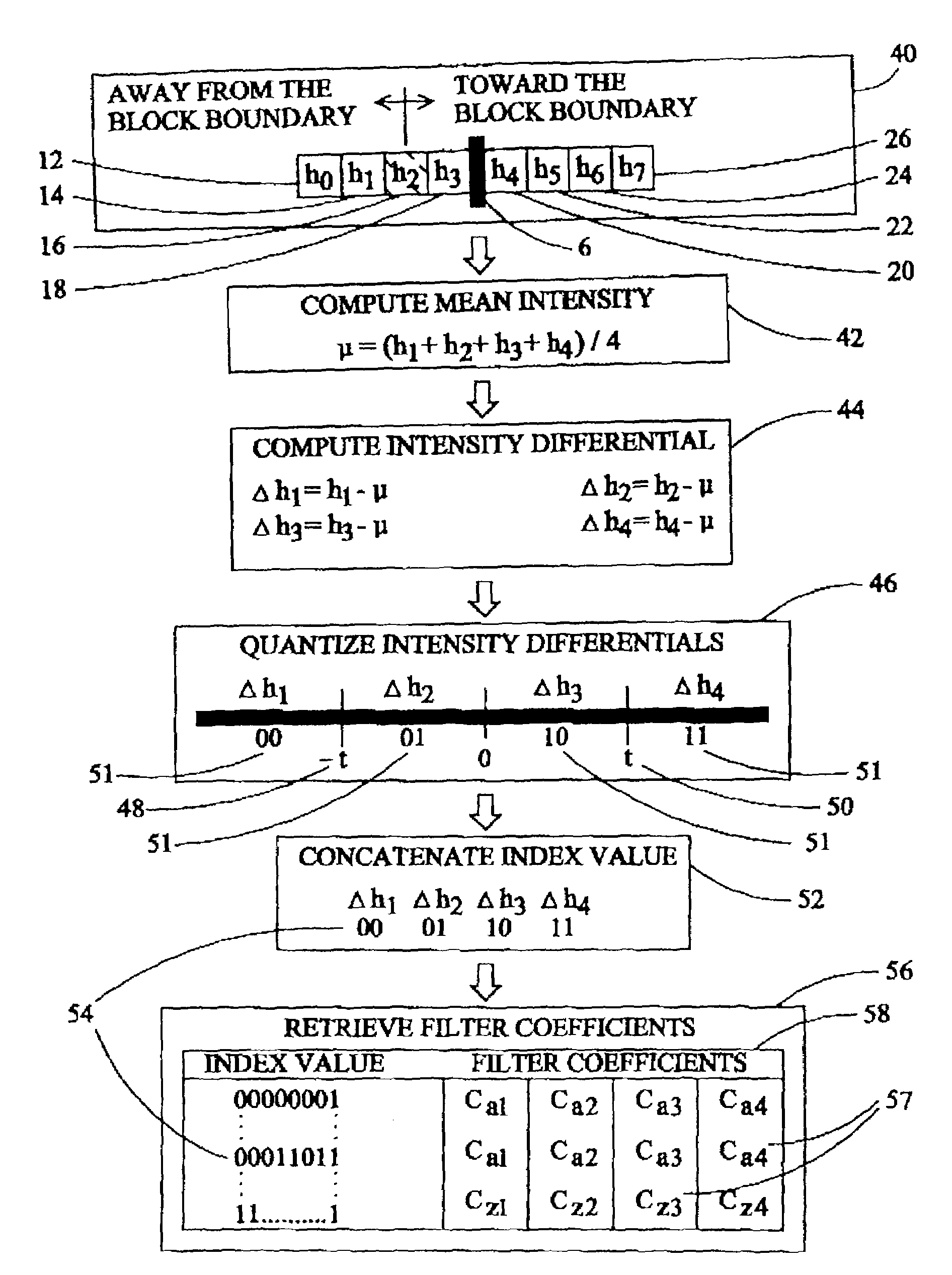

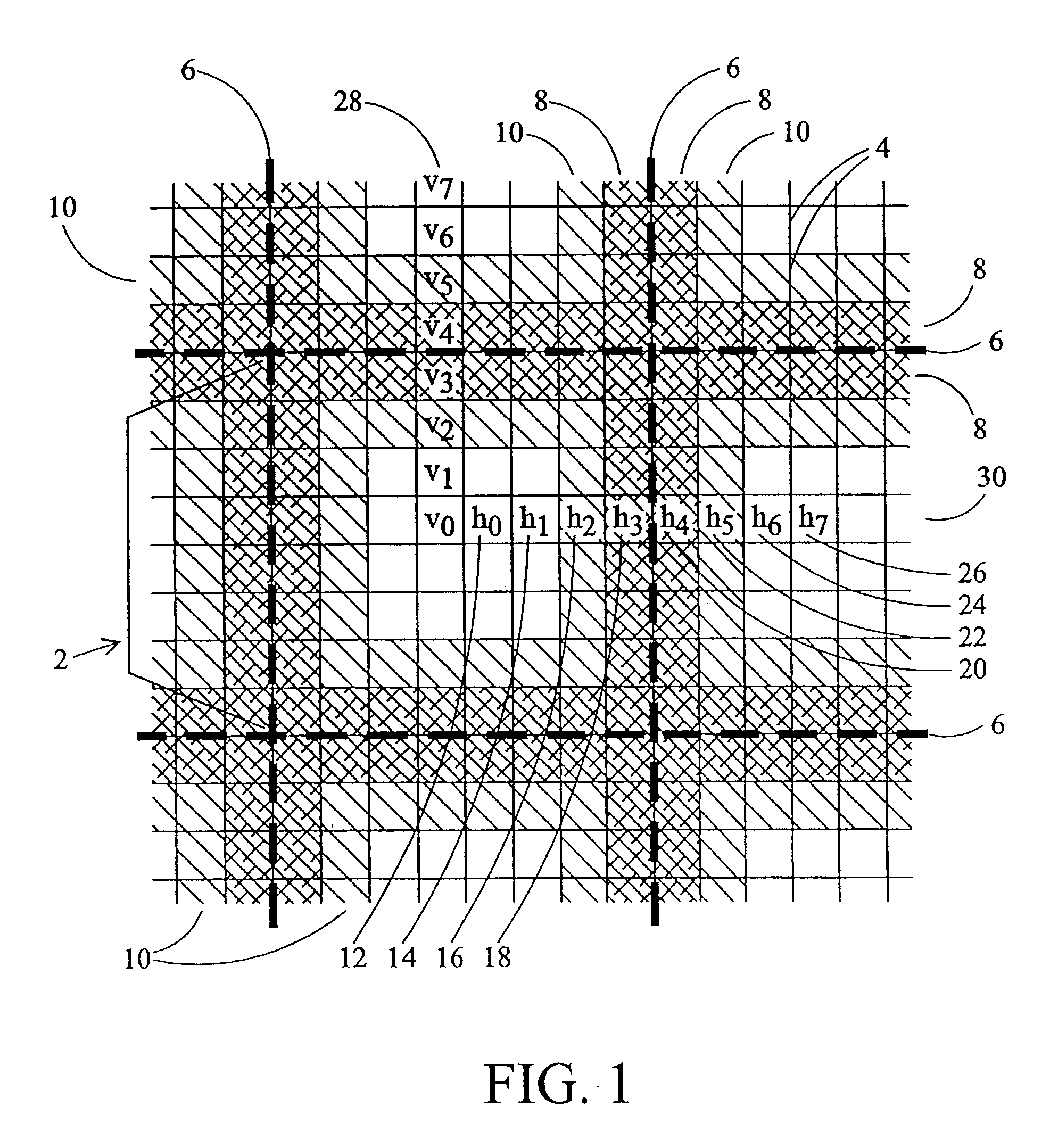

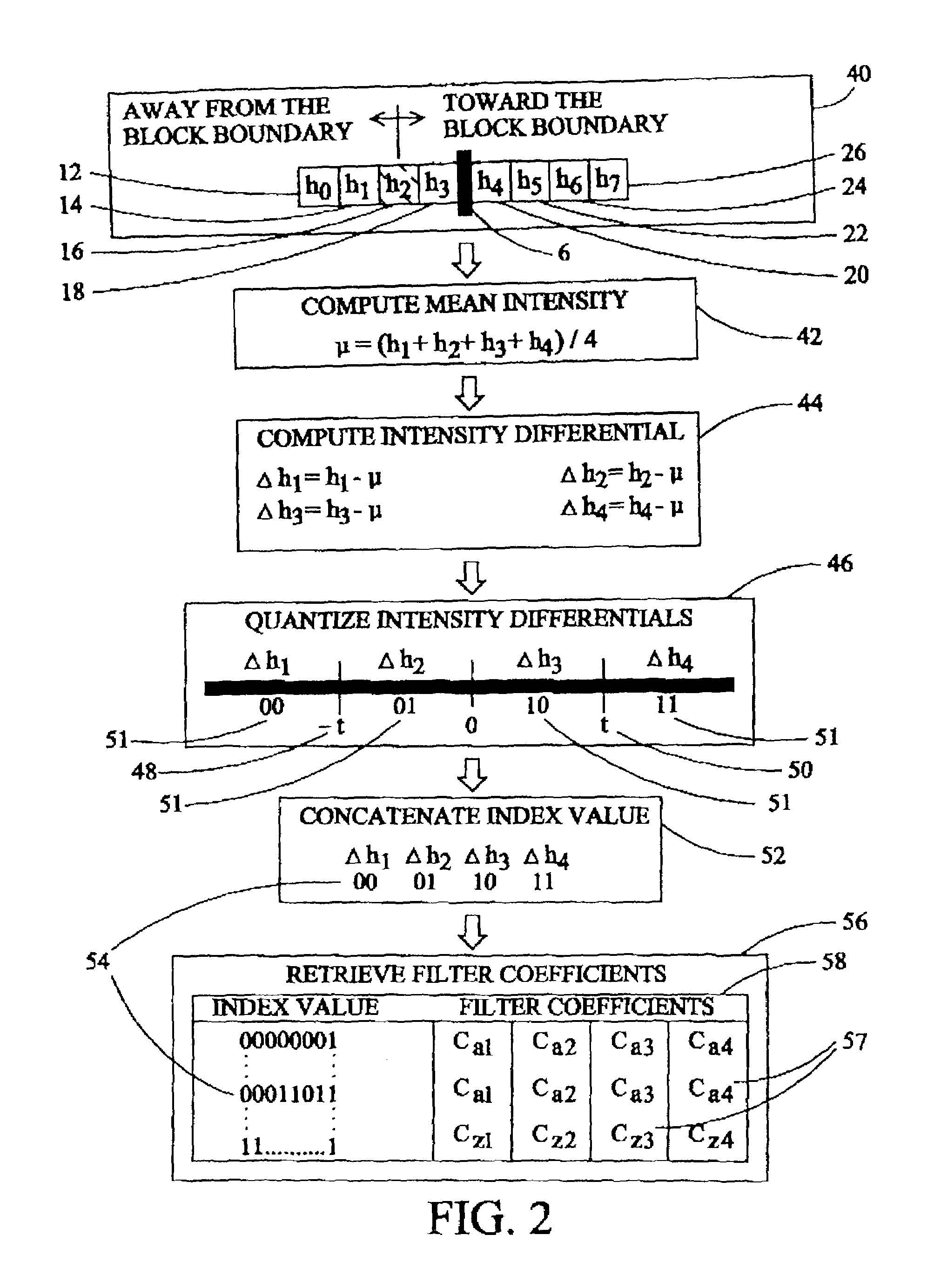

Block boundary artifact reduction for block-based image compression

InactiveUS7076114B2Reduce suddennessImproves block boundary artifact reductionPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningImage compressionDigital image

Block boundary artifact reduction in decompressed digital images is accomplished by filtering the intensity of pixels in the vicinity of the block boundary. The filter utilizes filter coefficients selected from tables on the basis of the distribution of a scalar quantity describing the pixels neighboring the pixel to which the intensity adjustment is to be applied. The intensities of pixels at the boundary and one pixel removed from the boundary are adjusted. If interpolation pixels in each of neighboring blocks are of relatively constant intensity, the intensities of additional pixels, more remote from the boundary, are adjusted. Filter coefficients can be selected from different arrays for pixels on the boundary or removed from the boundary or if the pixel intensity adjustment is based on the intensities of pixels in a horizontal row or vertical column of interpolation pixels.

Owner:RAKUTEN GRP INC

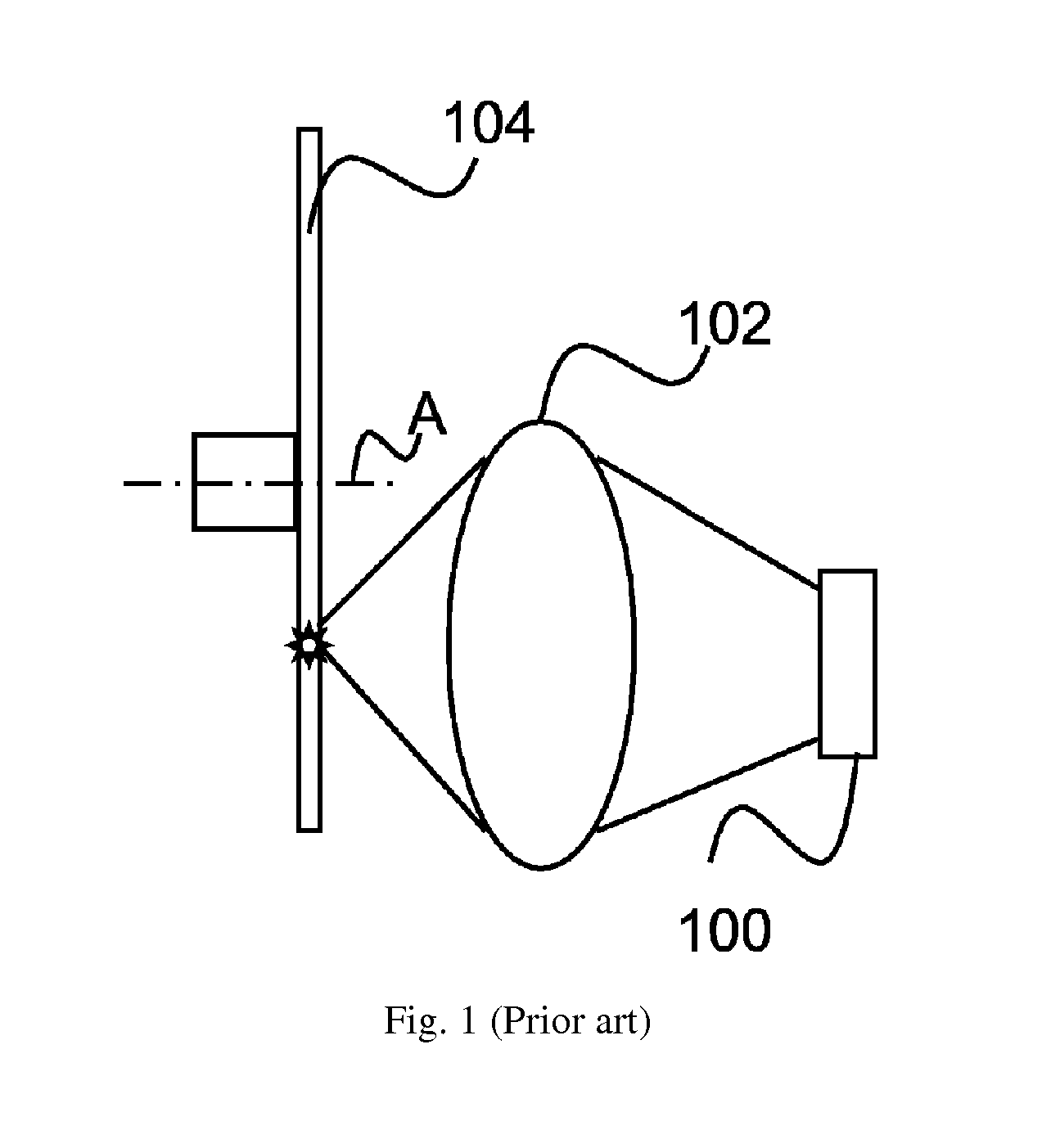

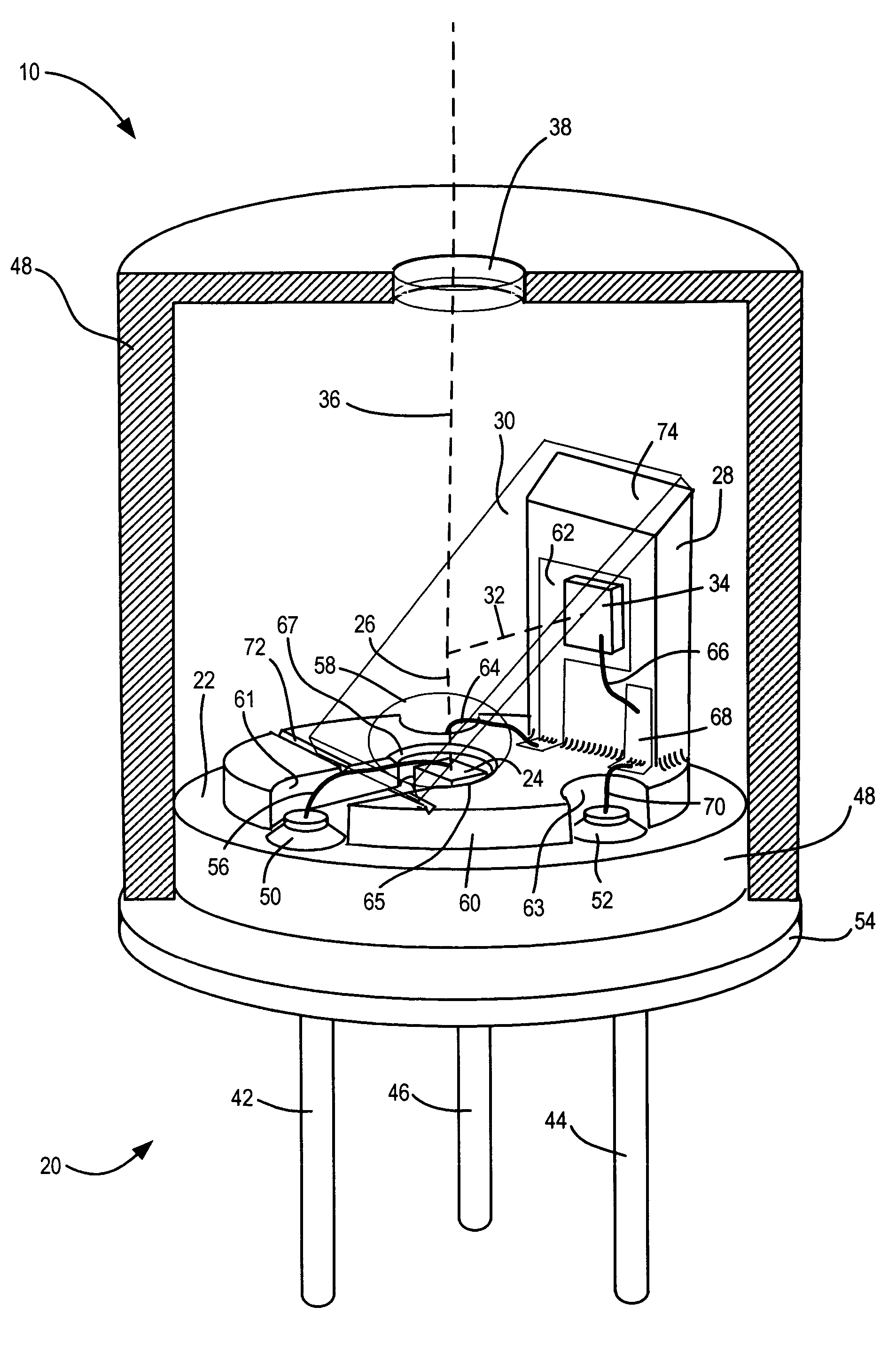

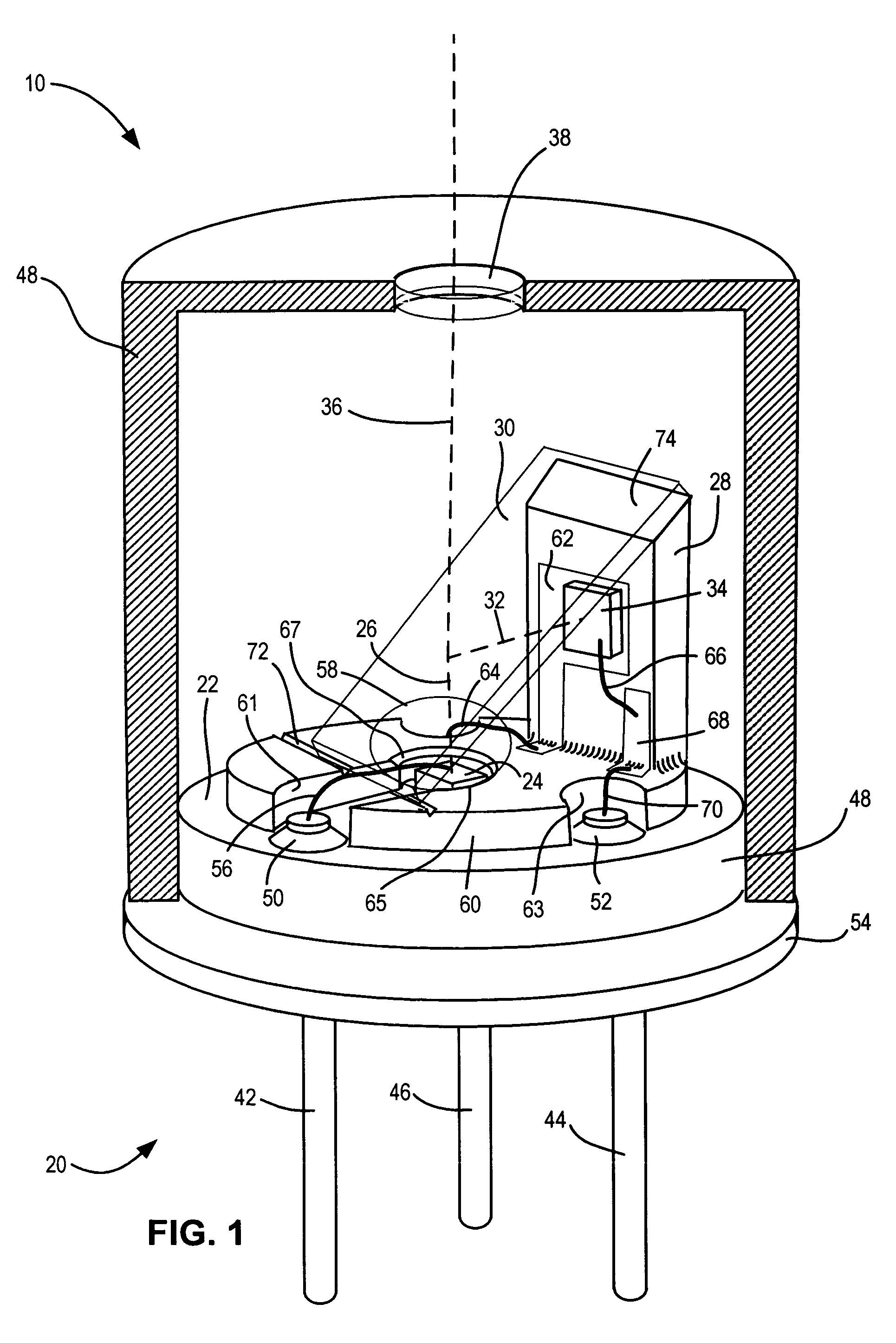

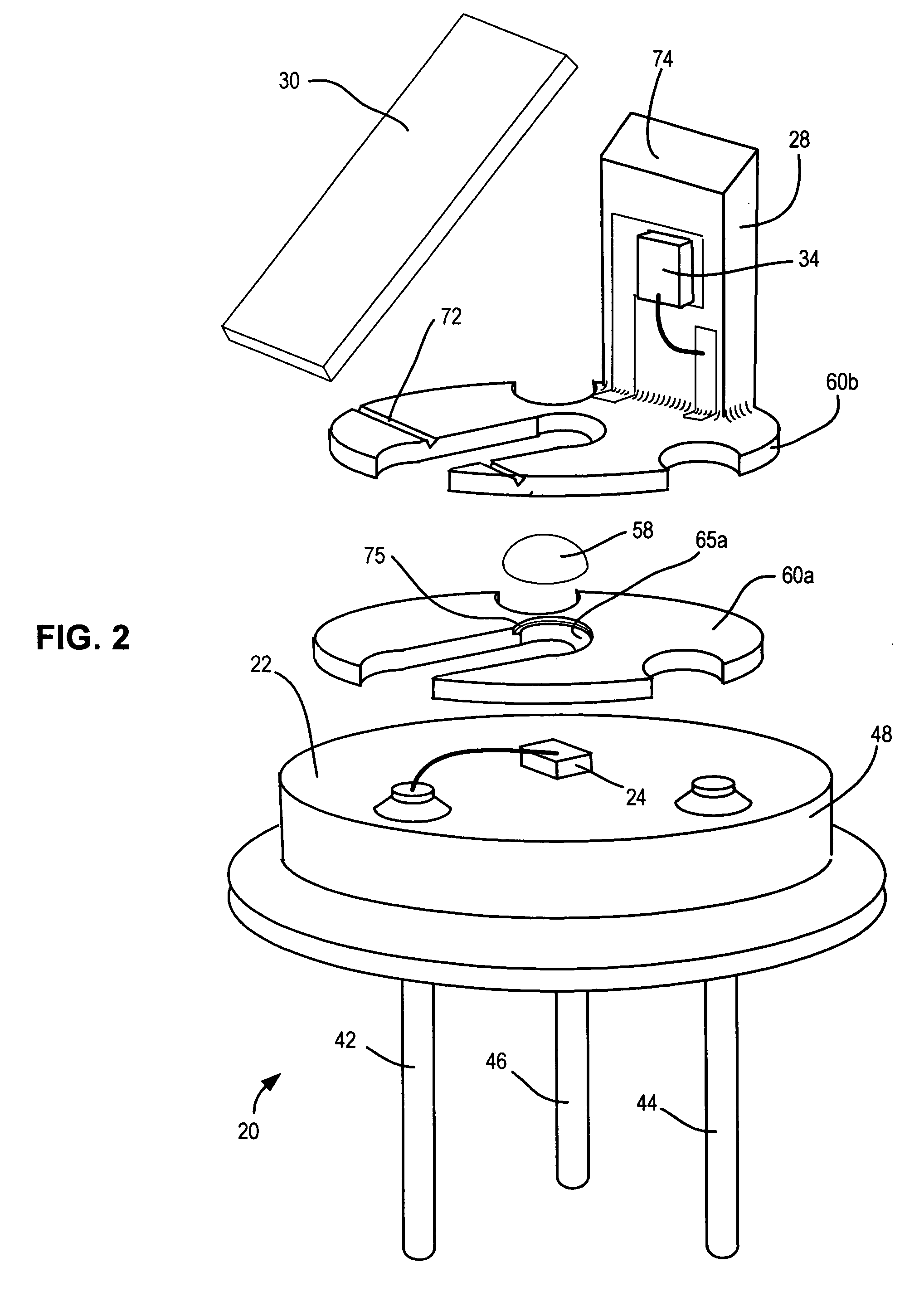

Semiconductor light source with optical feedback

InactiveUS20070063125A1Avoid mistakesReduce sensitivityPhotometry using reference valueLaser detailsBeam splitterPhotodiode

A semiconductor light source with optical feedback includes a vertical member extending upward from an upper horizontal surface of a header parallel to a vertical beam projected from a semiconductor light-emitting element mounted on the horizontal surface of the header wherein the vertical member supports a light-sensing element for receiving light reflected transversely from the vertical beam by a beam splitter supported by the vertical member. The vertical beam passing through the beam splitter passes through a window or filter in a cap mounted on the header and covering the light-emitting element, the light-sensing element, the beam splitter, and the vertical member. Substantially all of the transversely reflected light impinges on the light-sensing element and can be used to control the power to the light-emitting element. A simple lens can by used to collimate the beam. Interior portions of the unit are formed from light absorbing materials such as black ceramic, black plastic, anodized aluminum, etc. The combined effect of the non-reflective interior of the assembly, the orientation of the photo-diode to have an acceptance cone perpendicular to the beam axis, the small entrance pupil, and the optical filter reduces ambient radiation in the unit by as much as −75 dB of the level outside the device. This reduces noise and drift in the automatic power control loop to produce constant intensity in the output light beam.

Owner:USL TECH

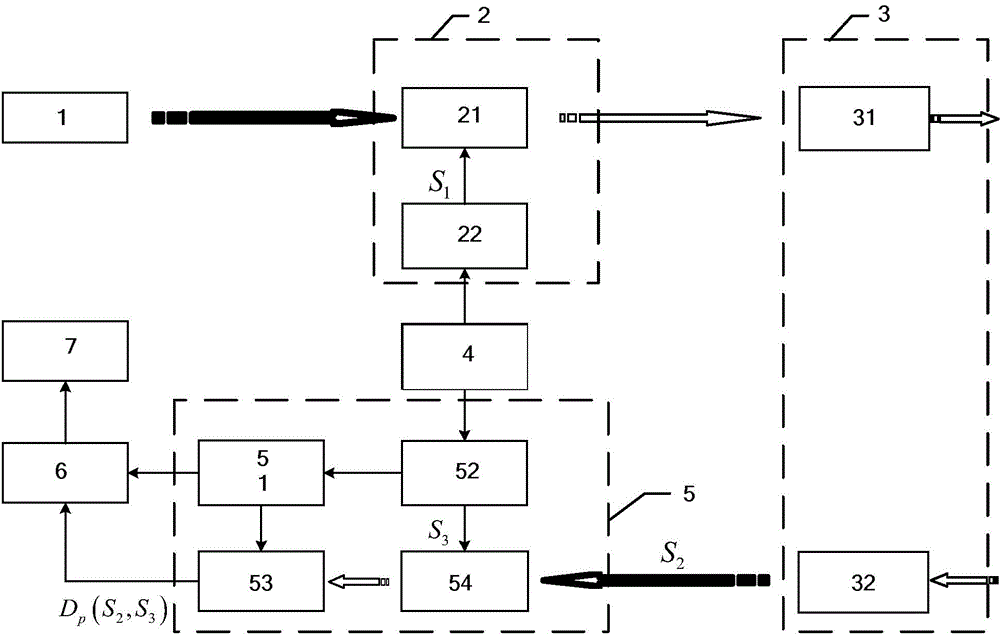

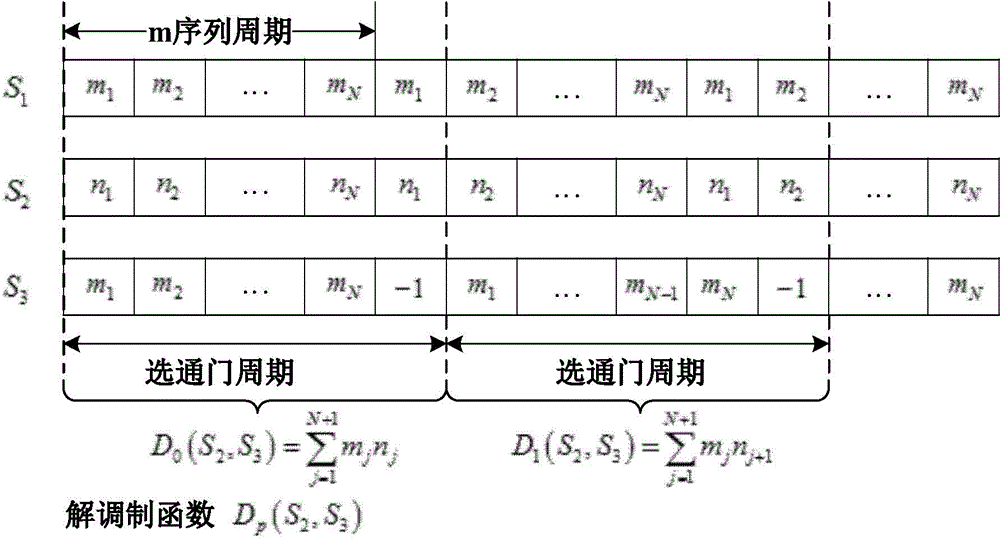

Asymmetric phase encoding ranging method applied to laser radar system

ActiveCN104931973ADownsamplingExtended sampling timeElectromagnetic wave reradiationRadar systemsMode control

The invention discloses an asymmetric phase encoding ranging method applied to a laser radar system. The laser radar system uses a typical phase encoding method and has high system hardware demands. The method provided by the invention comprises the steps that a laser in the laser radar system emits a laser signal with constant intensity; a modulator carries out intensity modulation according to a modulation signal sequence; the modulation signal sequence is an m sequence; a demodulator carries out intensity demodulation on an echo signal according to a demodulation signal sequence; a strobe mode is used to control cumulative detection time and output of a detector; the detector outputs cumulated signals to a signal processor; the signal output order of the detector shows a correlation peak position, so that the signal processor directly determines phase difference between a demodulation signal and the echo signal; and according to the phase difference, target distance is calculated. According to the invention, the asymmetric phase encoding method is used to measure the target distance; the sampling rate requirement of the system on the detector is reduced; and the calculation amount of signal processing is reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Apparatus and methods for audio-tactile spatialization of sound and perception of bass

ActiveUS10390139B2Accurately produce wide range of tactile frequencyImprove user experienceInput/output for user-computer interactionHeadphones for stereophonic communicationImage resolutionPattern perception

The apparatus and methods of the present invention provide quiet, compact, robust hardware that can accurately produce a wide range of tactile frequencies at a perceptually constant intensity. For greater expressiveness, some apparatus for moving the skin in multiple axes are also disclosed. Signal processing methods are presented to enhance the user's experience of audio spatialization. The methods transform audio signals into directional tactile cues matched to the time resolution of the skin, and which exploit directional tactile illusions.

Owner:TACTION TECH

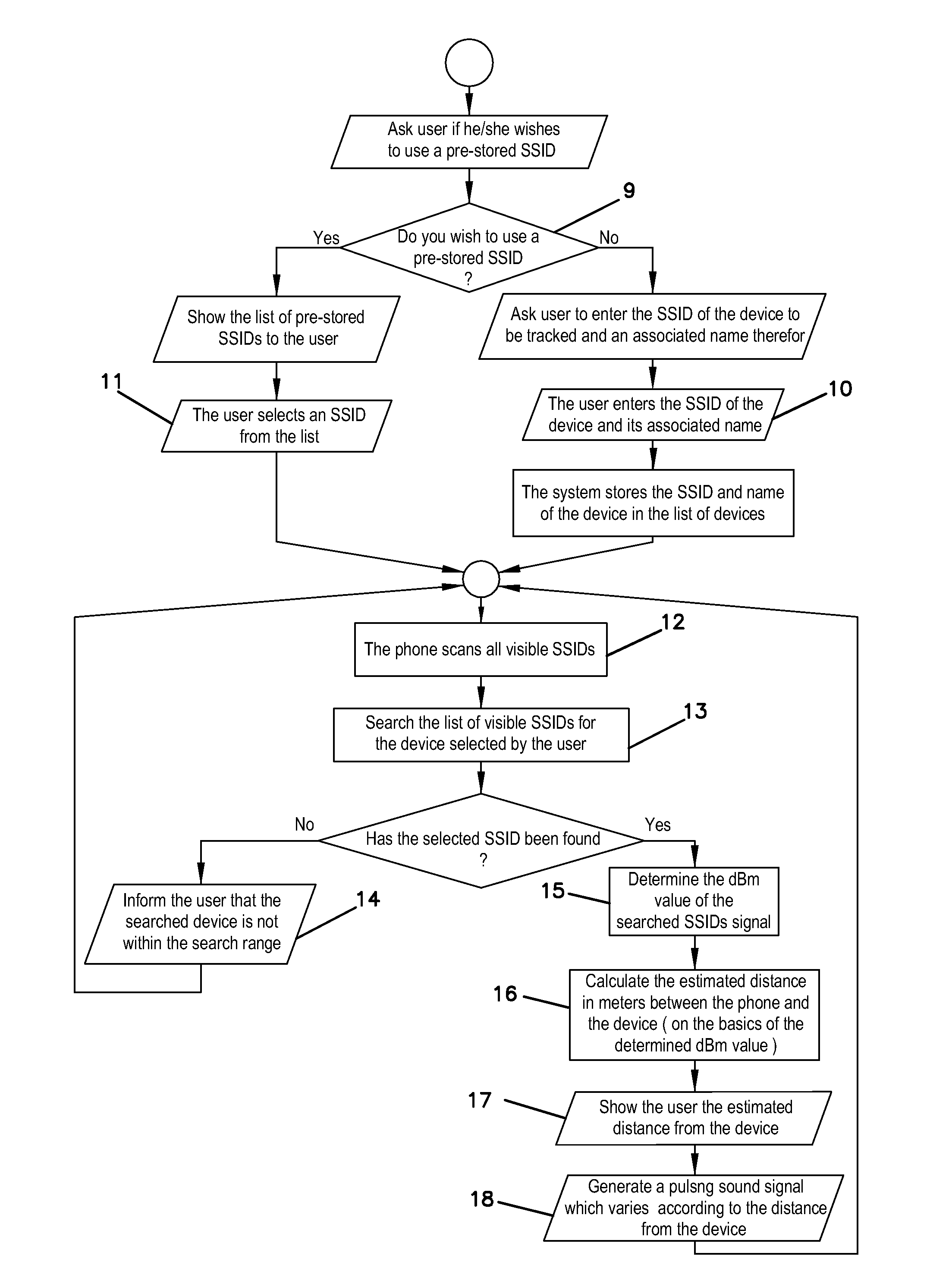

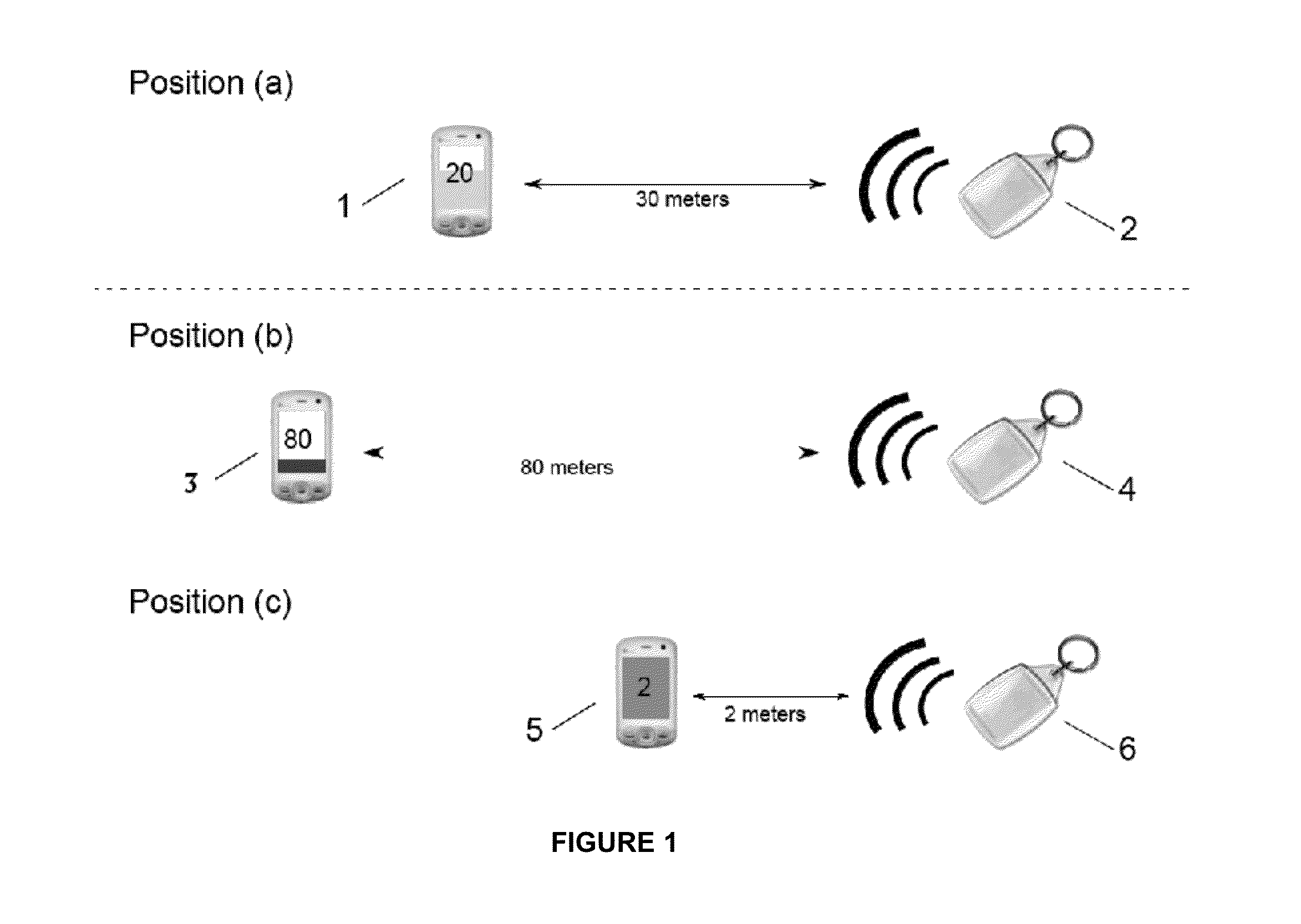

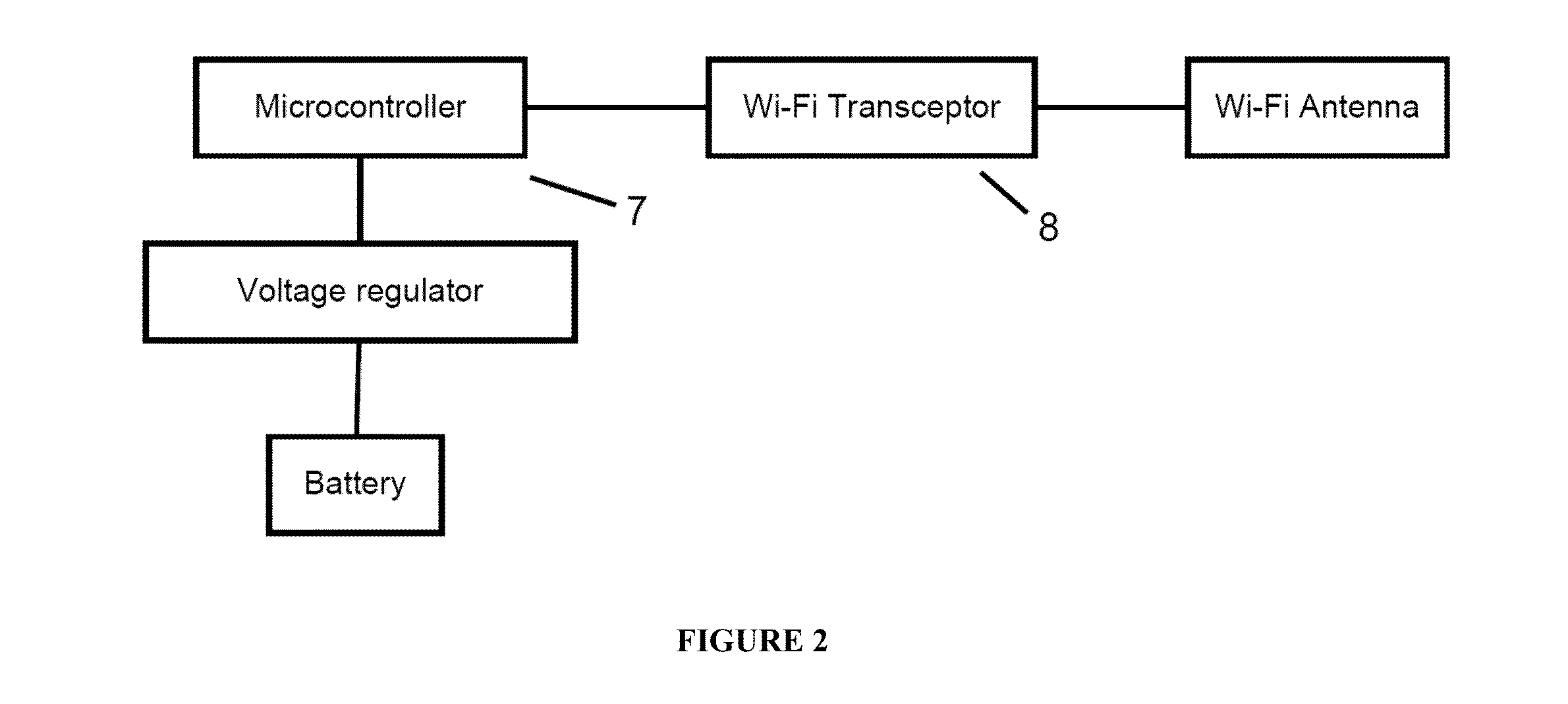

Wi-fi tracker system for persons and objects

The present invention refers to a new short-distance tracking system for persons or objects consisting in the use of a Wi-Fi—emitting device (for example a key fob) carried by the person or object to be tracked, and the Wi-Fi receptor of a smart mobile phone as tracker unit. Smartphones have a function capable of measuring the intensity of a received Wi-Fi signal. The signal transmitted by the device has a constant intensity and frequencies within the range established by protocol IEEE 802.11 b / g / n (Wi-Fi), and is identified by a unique SSID. In this way the application running on the mobile phone can show the distance of the specific device emitting the wireless signal (for example, a key fob), depending on the detected attenuation level. When distance increases, the signal will show an attenuation and the application running on the phone will prompt the user to move towards the direction in which the signal intensifies. As the mobile phone approaches the device, the signal will intensify and the application will prompt the user to continue moving in the same direction.

Owner:DECO JUAN JOSE +1

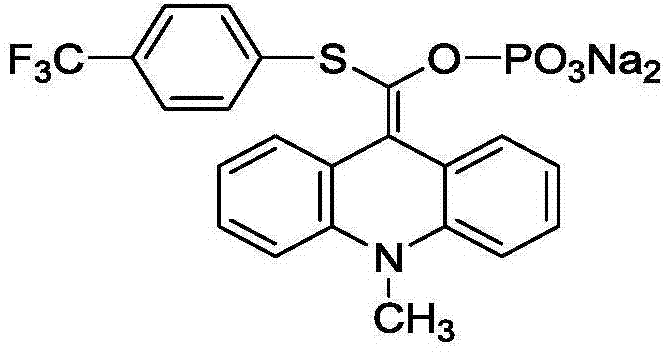

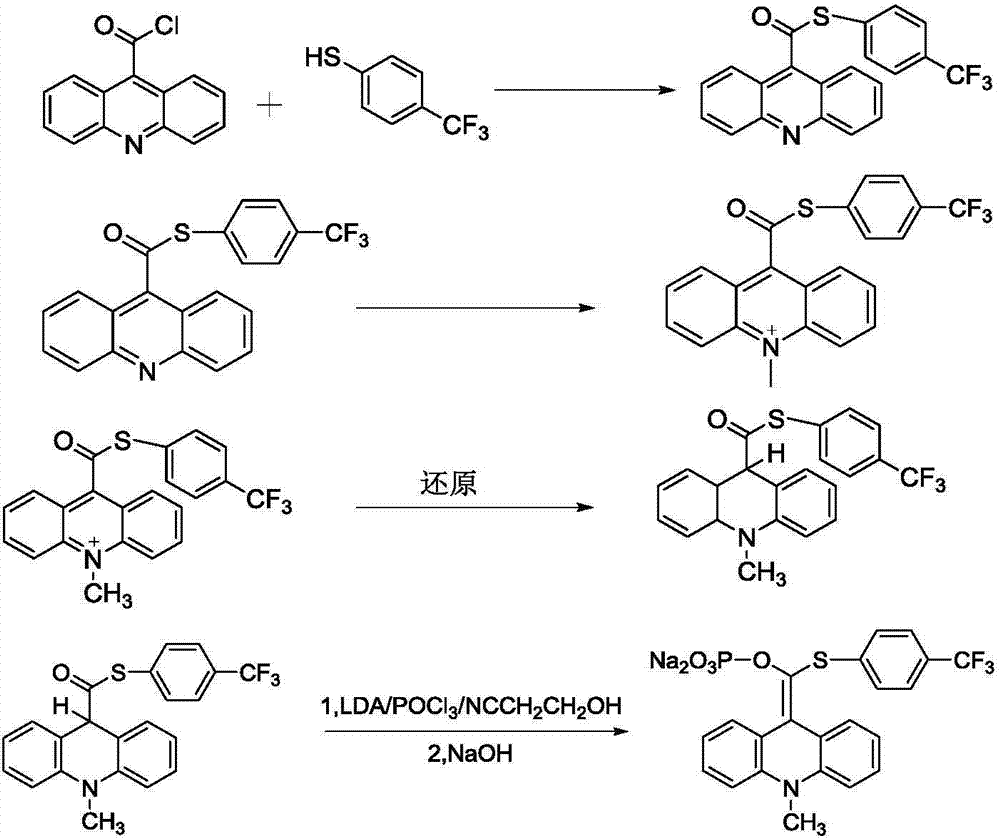

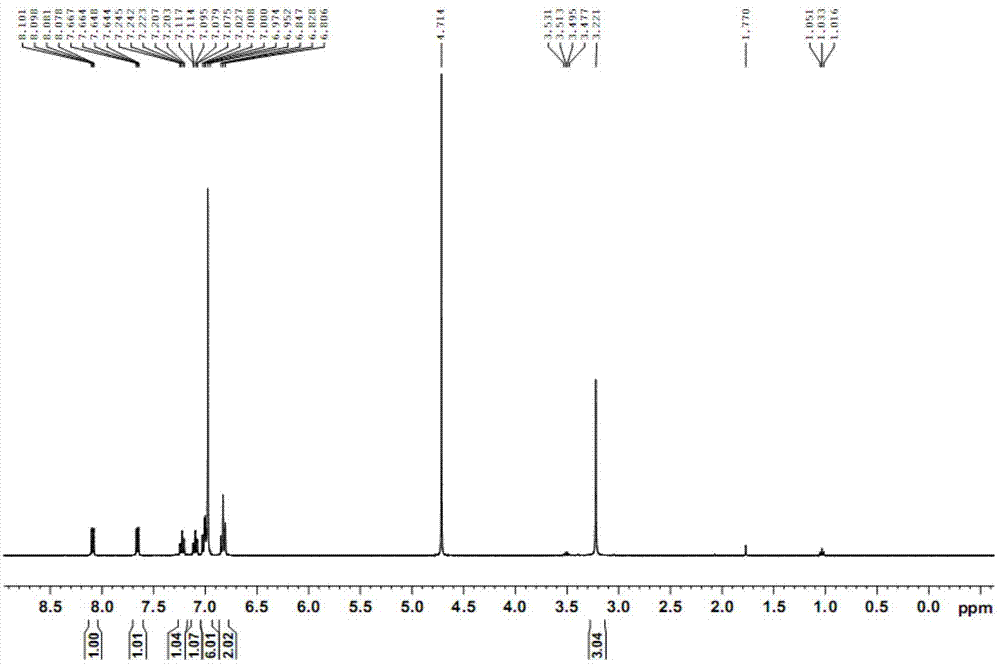

Acridinium ester derivative, synthesis method and application thereof

InactiveCN104761584AEasy to useHigh sensitivityPhosphorus organic compoundsLuminescent compositionsThiocarboxylic acidSynthesis methods

The invention discloses an acridinium ester derivative, a synthesis method and application thereof. The chemiluminescent acridinium ester derivative provided by the invention has a structural formula shown as formula I. The invention further discloses a synthesis method for the compound shown as formula I, and the method includes: (1) synthesizing acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (2) synthesizing 10-methyl-acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (3) synthesizing 10-methyl-9, 10-dihydroacridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; and (4) synthesizing TfS-APS. The acridinium ester derivative provided by the invention can be used as an immunoassay tracer to a chemiluminescence immunoassay reagent system with alkaline phosphatase (ALP) as the marker enzyme. The application effect in a kit proves that the acridinium ester derivative involved in the invention can detect 1*10<-19>mol ALP molecules, and has the advantages of high sensitivity, long luminescence duration, simple use, constant intensity under room temperature condition, and no need for precise temperature control, etc.

Owner:BEIJING LEADMAN BIOCHEM

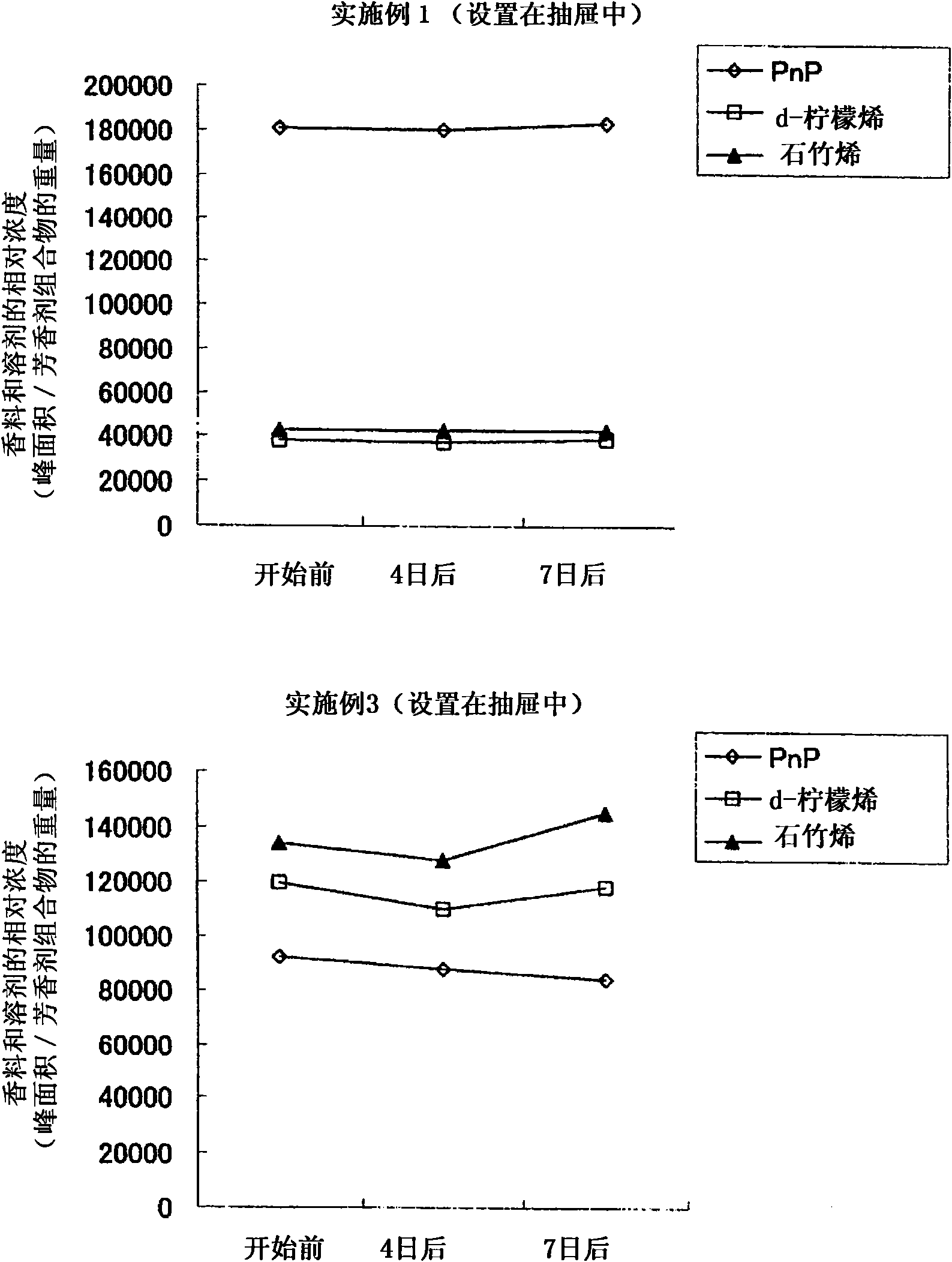

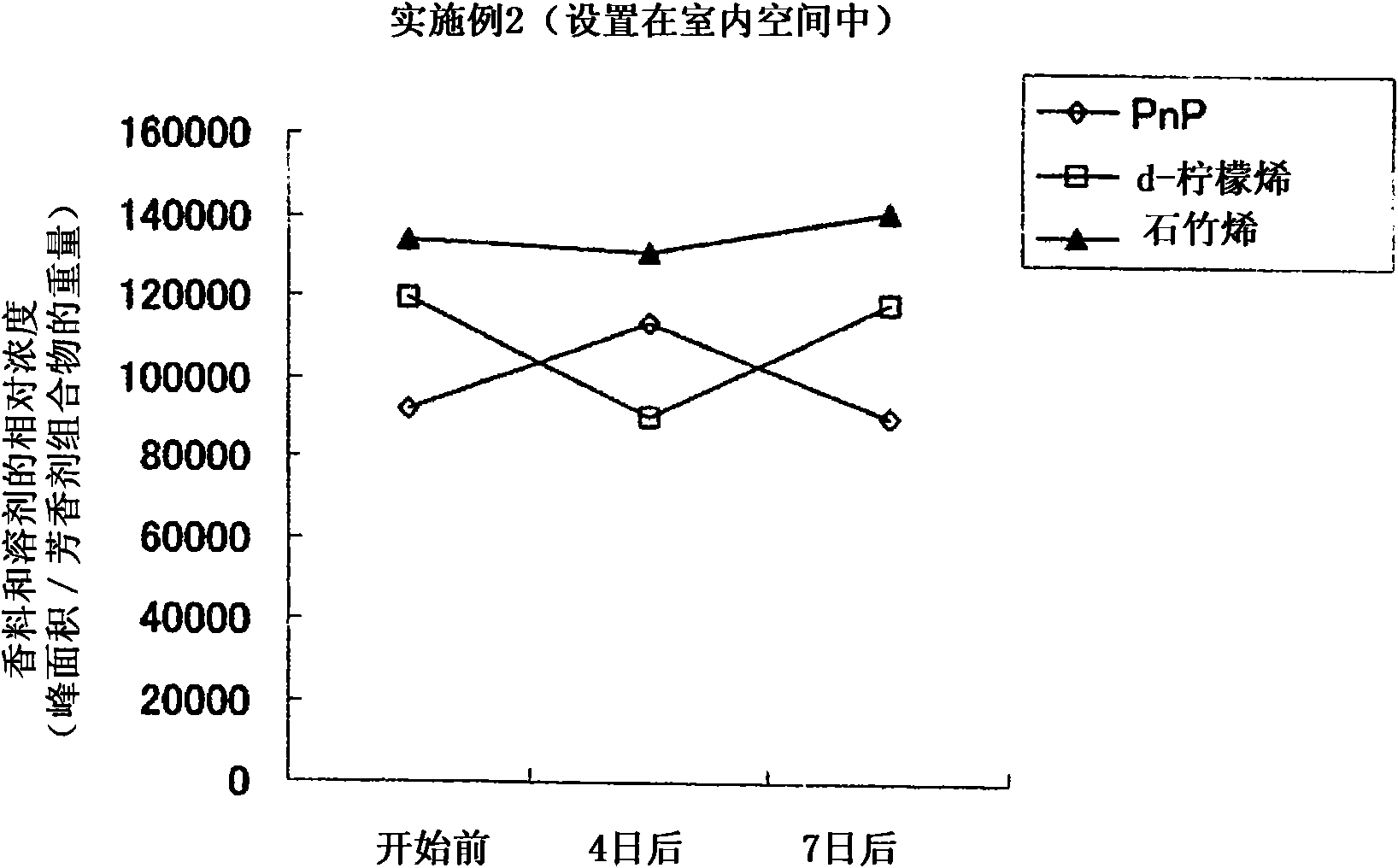

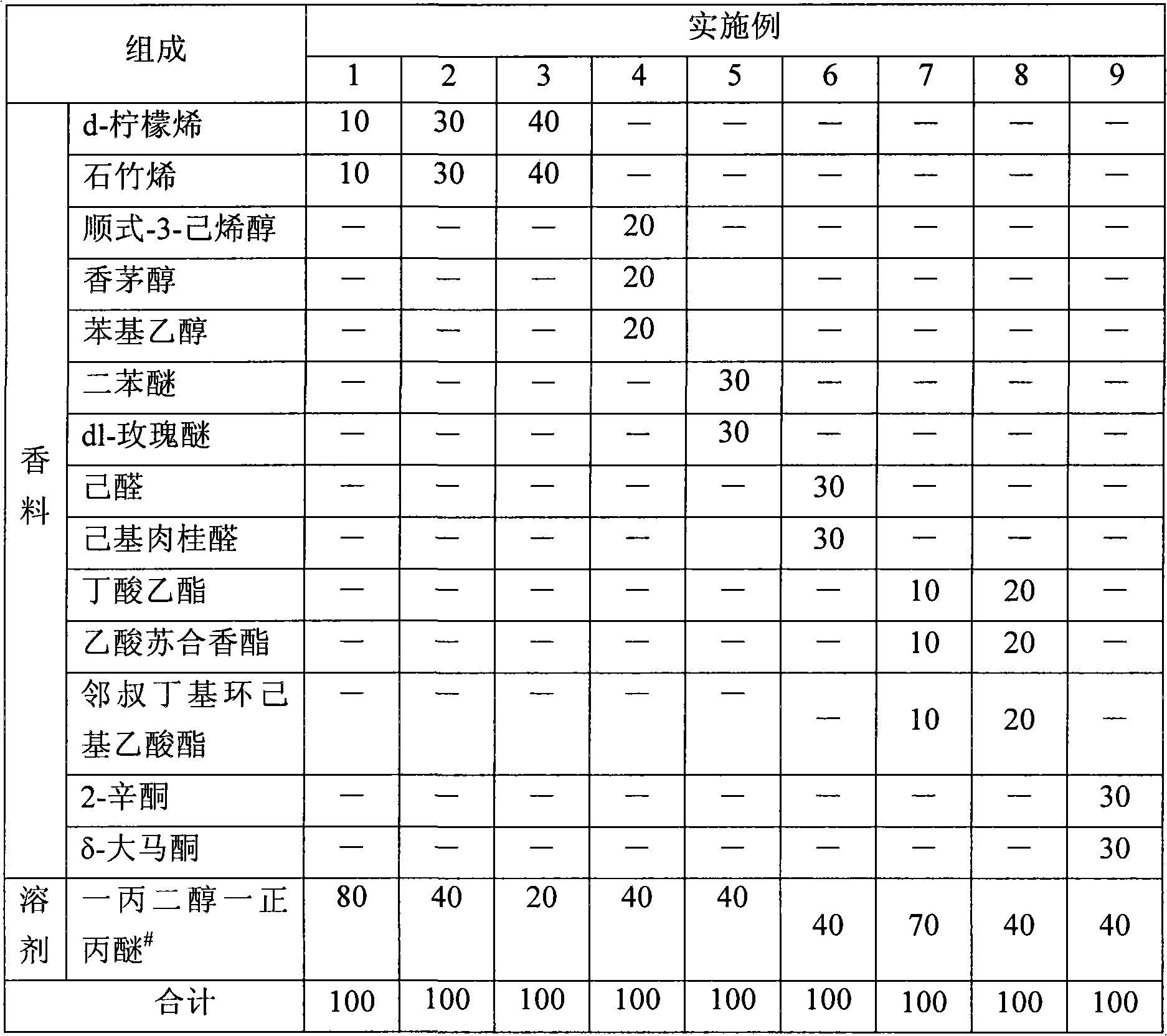

Aromatic agent composition for openable storage space

Owner:KOBAYASHI PHARMA CO LTD

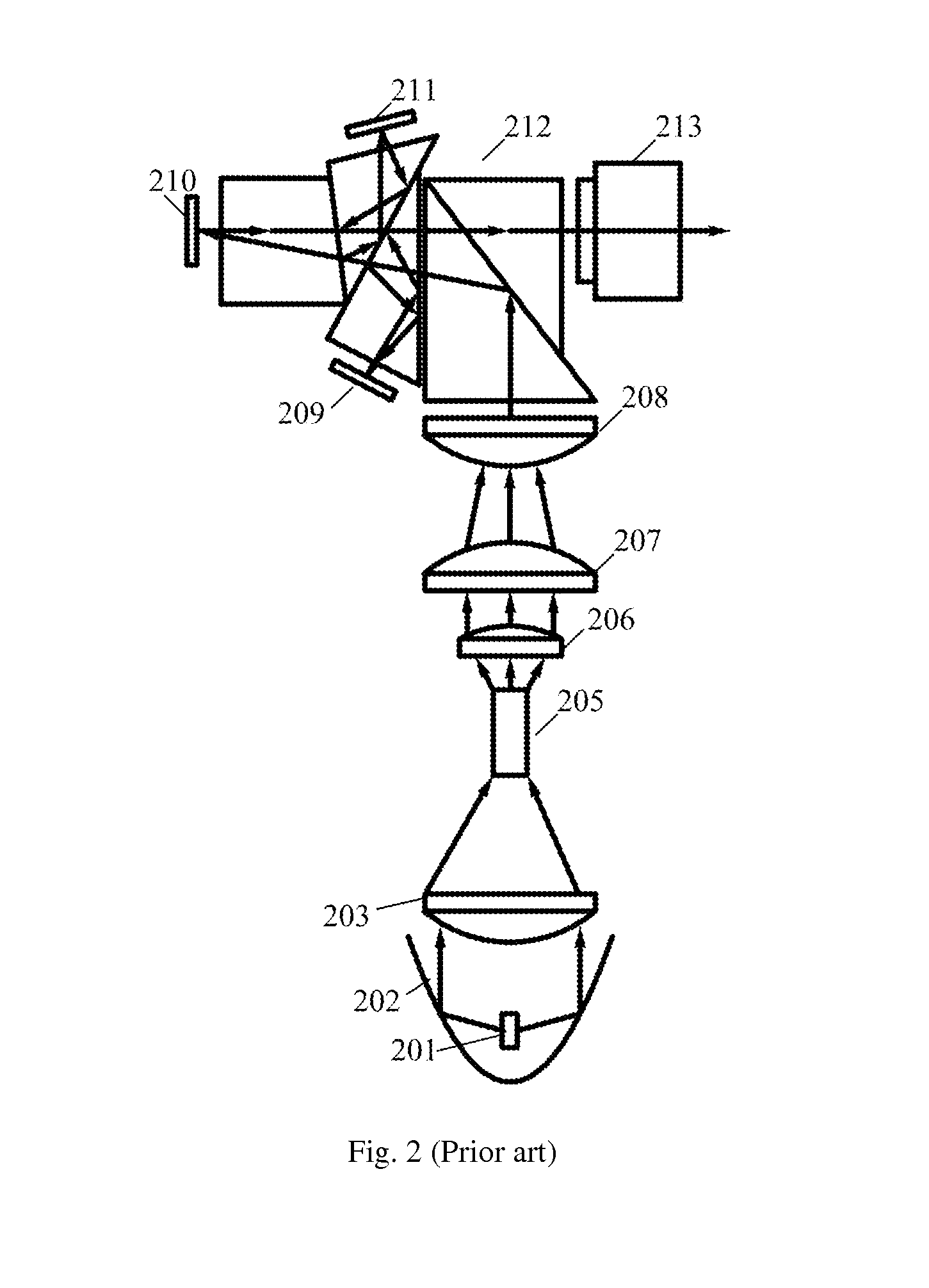

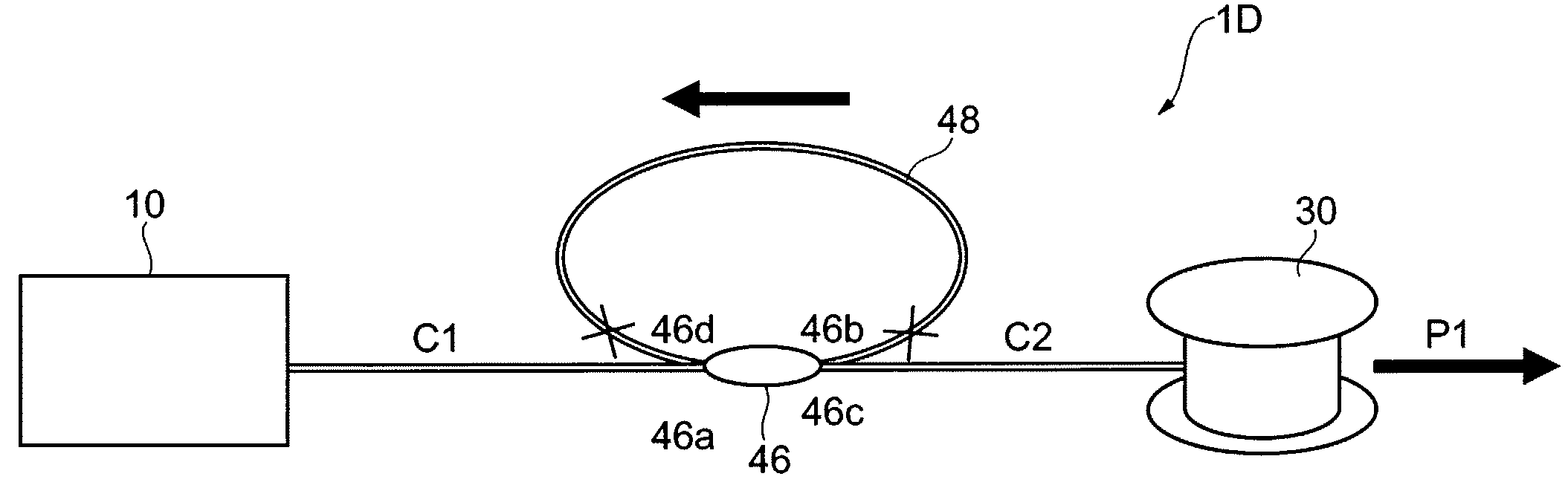

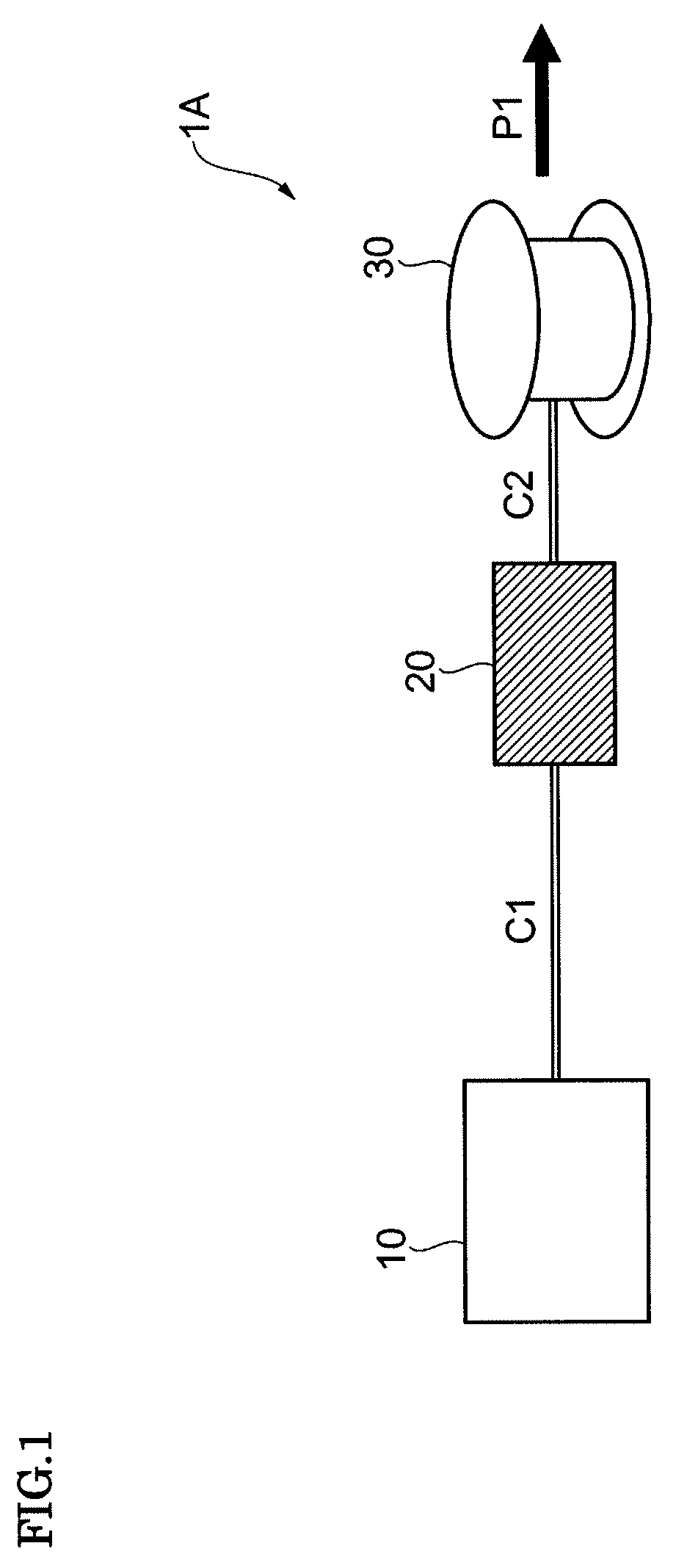

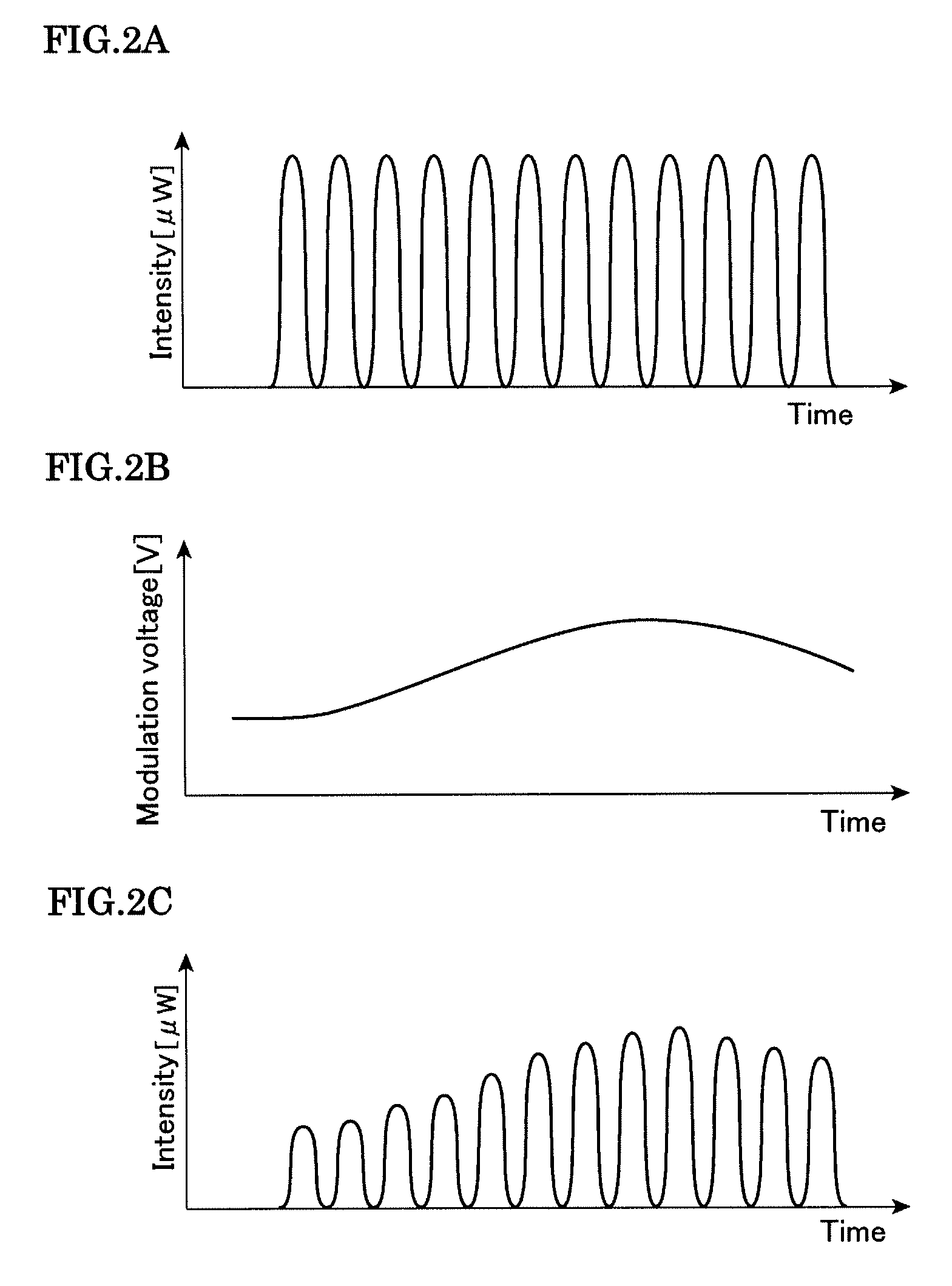

Broadband light source unit and optical analyzer

ActiveUS20090095890A1Photometry using reference valueRadiation pyrometryBroadband light sourceBroadband

The invention offers a broadband light source unit that produces using a simple system a supercontinuum lightwave having a flat spectral form and an optical analyzer using the unit. The broadband light source unit has a light source that outputs a first source lightwave, which is a pulse lightwave having periodic pulses with a constant intensity, a conversion means that receives the first source lightwave, produces a second source lightwave having pulses whose intensities are different from one another, and outputs it, and a nonlinear optical medium section that receives the second source lightwave, produces a supercontinuum lightwave having a wavelength band broadened through a nonlinear optical phenomenon, and outputs it. The optical analyzer has the foregoing broadband light source unit, a light-applying section that applies a supercontinuum lightwave outputted from the broadband light source unit to a light-receiving region of a measurement-undergoing object, and an image pickup section that receives a lightwave generated at the light-receiving region by the application of the supercontinuum lightwave and picks up an image of the measurement-undergoing object.

Owner:SUMITOMO ELECTRIC IND LTD

Compensating for effects of topography variation by using a variable intensity-threshold

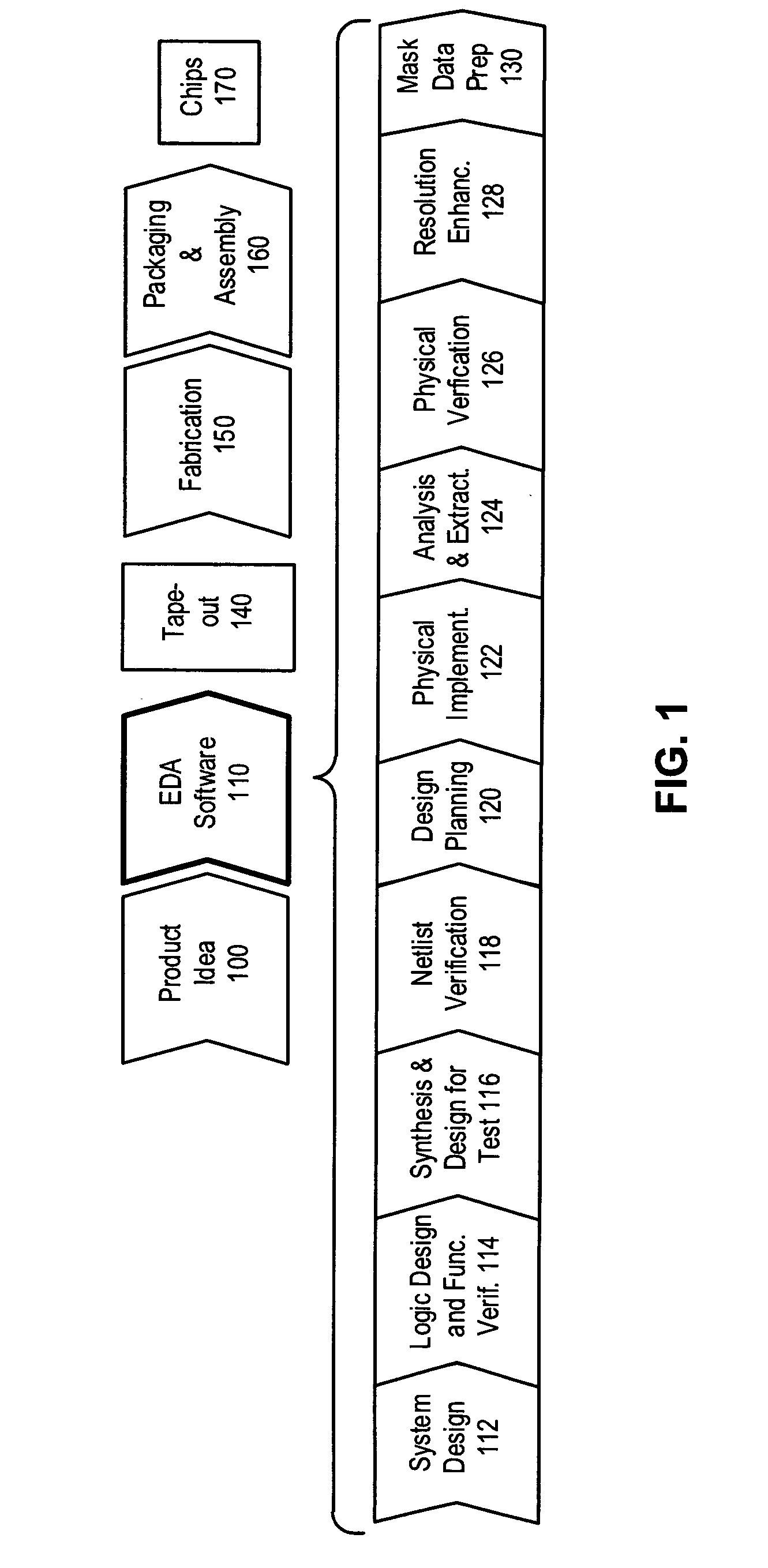

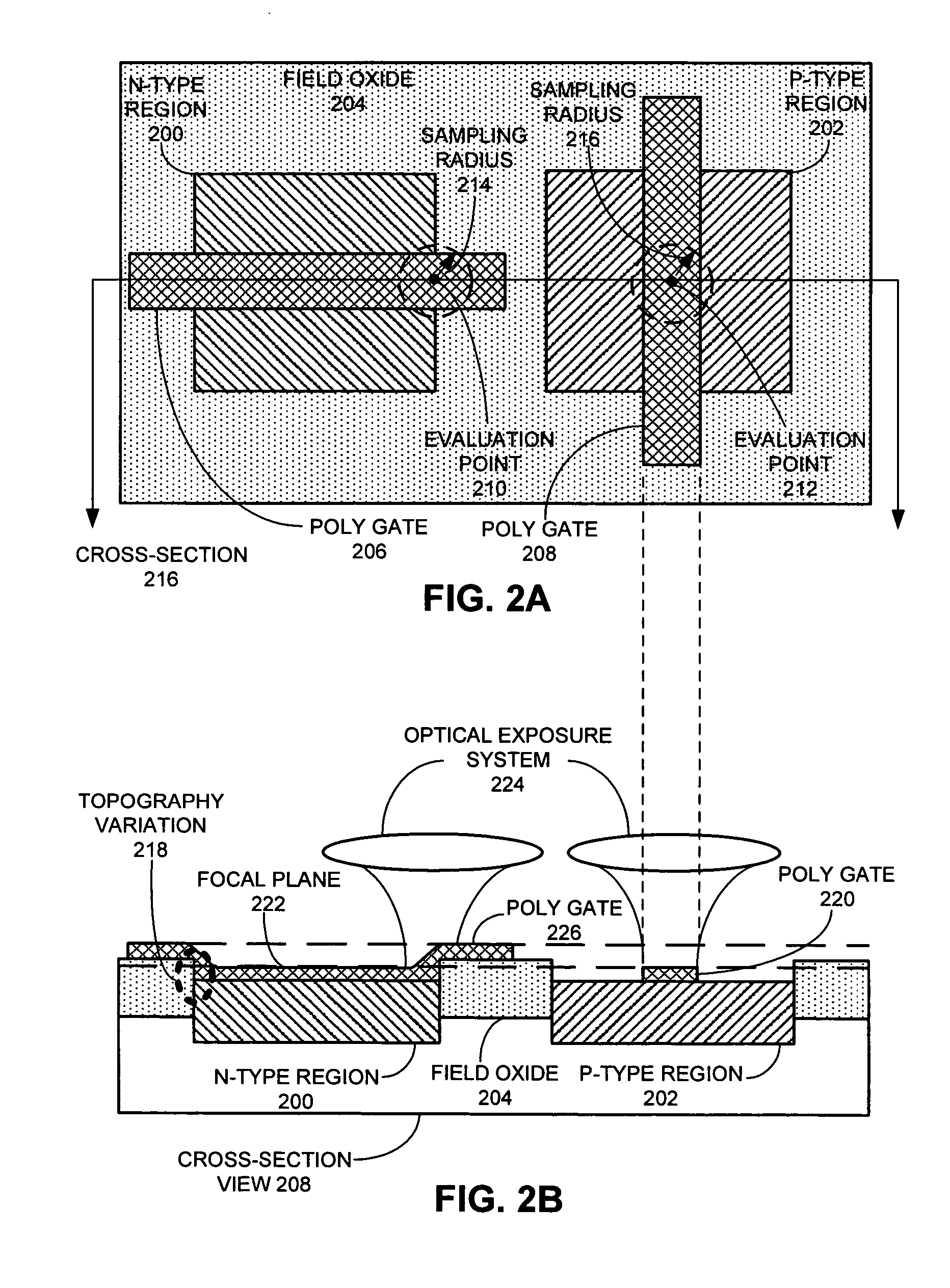

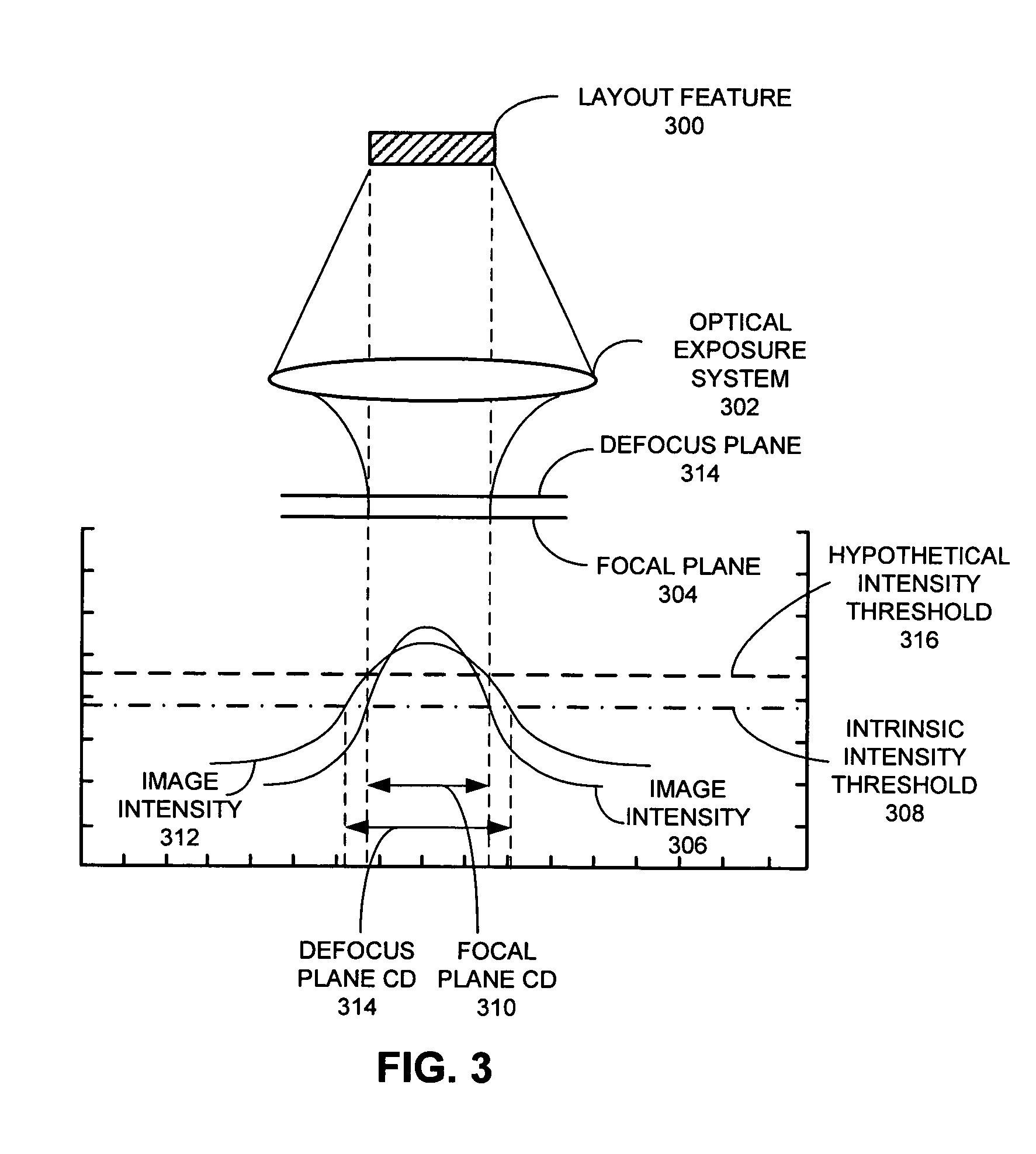

ActiveUS20070082281A1Accurately determineAccurately determinedPhoto-taking processesCharacter and pattern recognitionLithography processEngineering

One embodiment of the present invention provides a system that accurately determines a critical dimension of a feature in a layout by compensating for the effects of topography variation on the performance of an optical lithography process. During operation, the system first receives a layout. Next, the system computes an aerial-image intensity at an evaluation point in the layout using an optical lithography model that models the optical lithography process. Note that the aerial-image intensity is typically compared with a constant intensity threshold to determine a critical dimension of a feature in the layout. The system then computes an intensity threshold based on features in the proximity of the evaluation point, which compensates for the effects of topography variations on the performance of the optical lithography process. Next, the system determines the critical dimension of the feature by comparing the aerial-image intensity with the computed intensity threshold, instead of comparing the aerial-image intensity with the constant intensity threshold.

Owner:SYNOPSYS INC

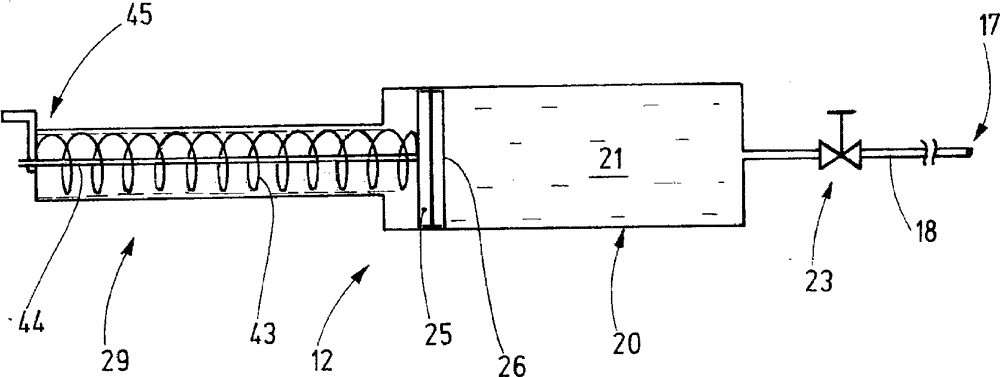

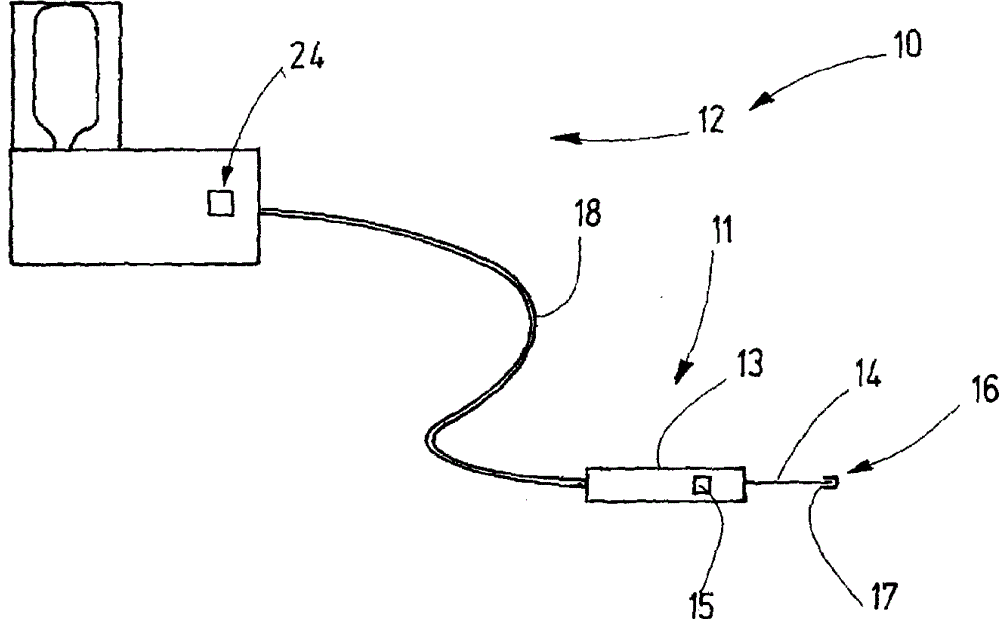

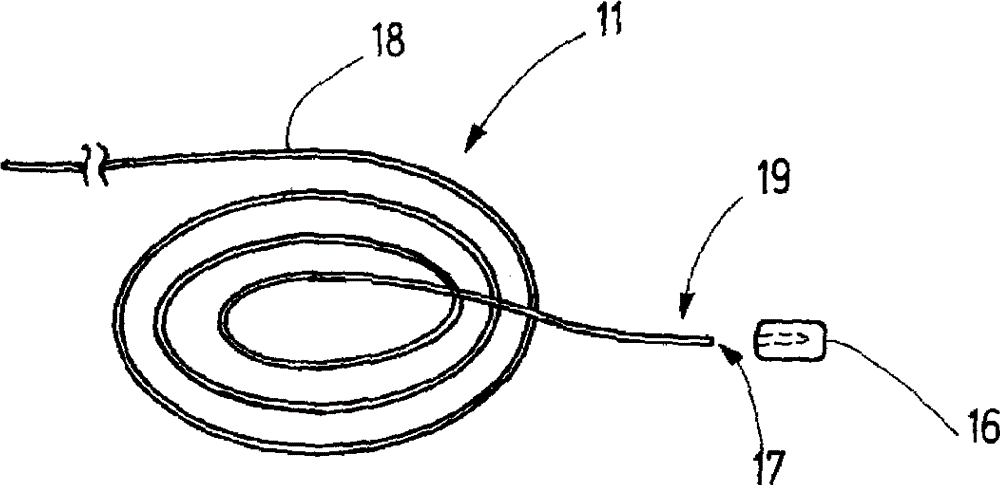

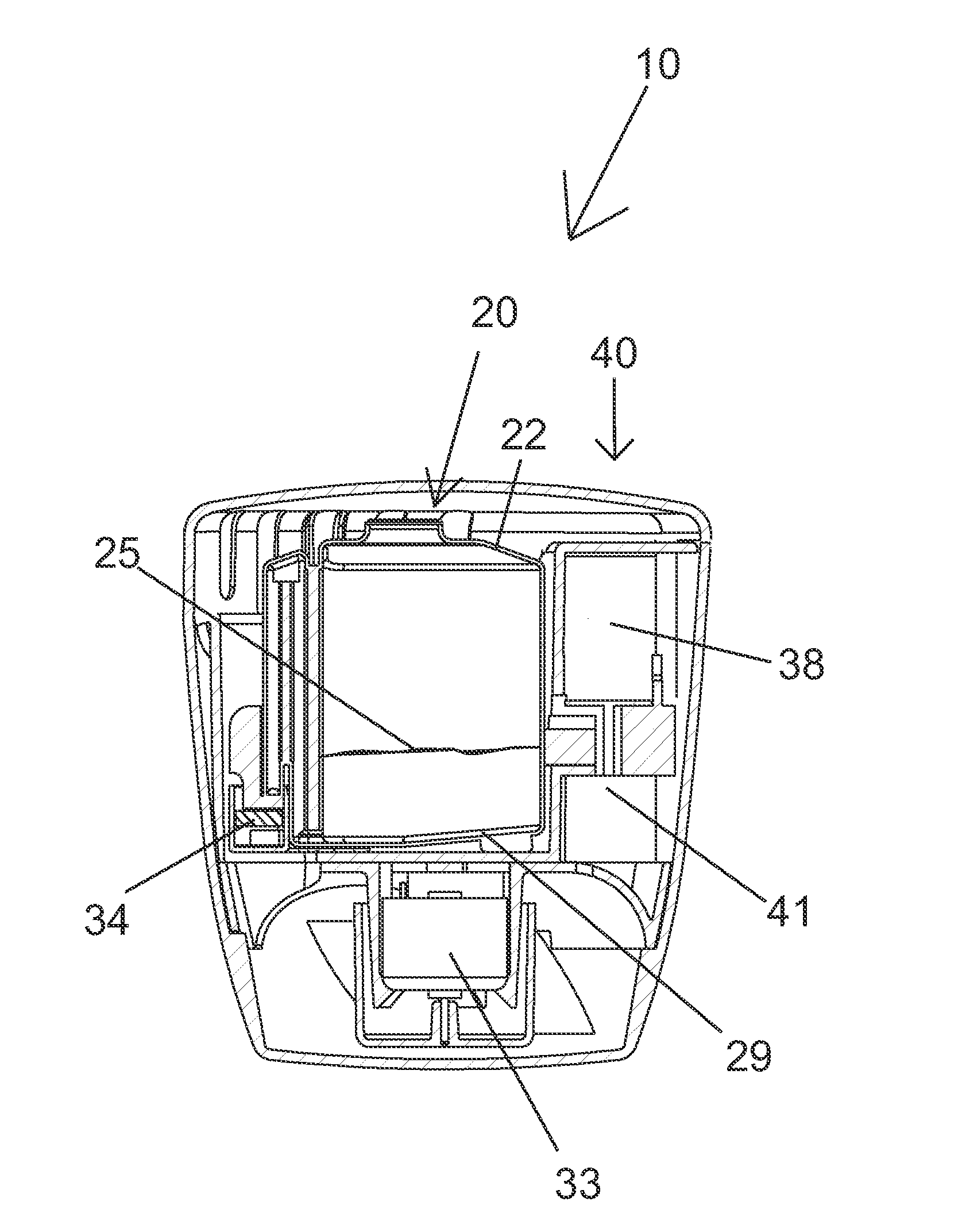

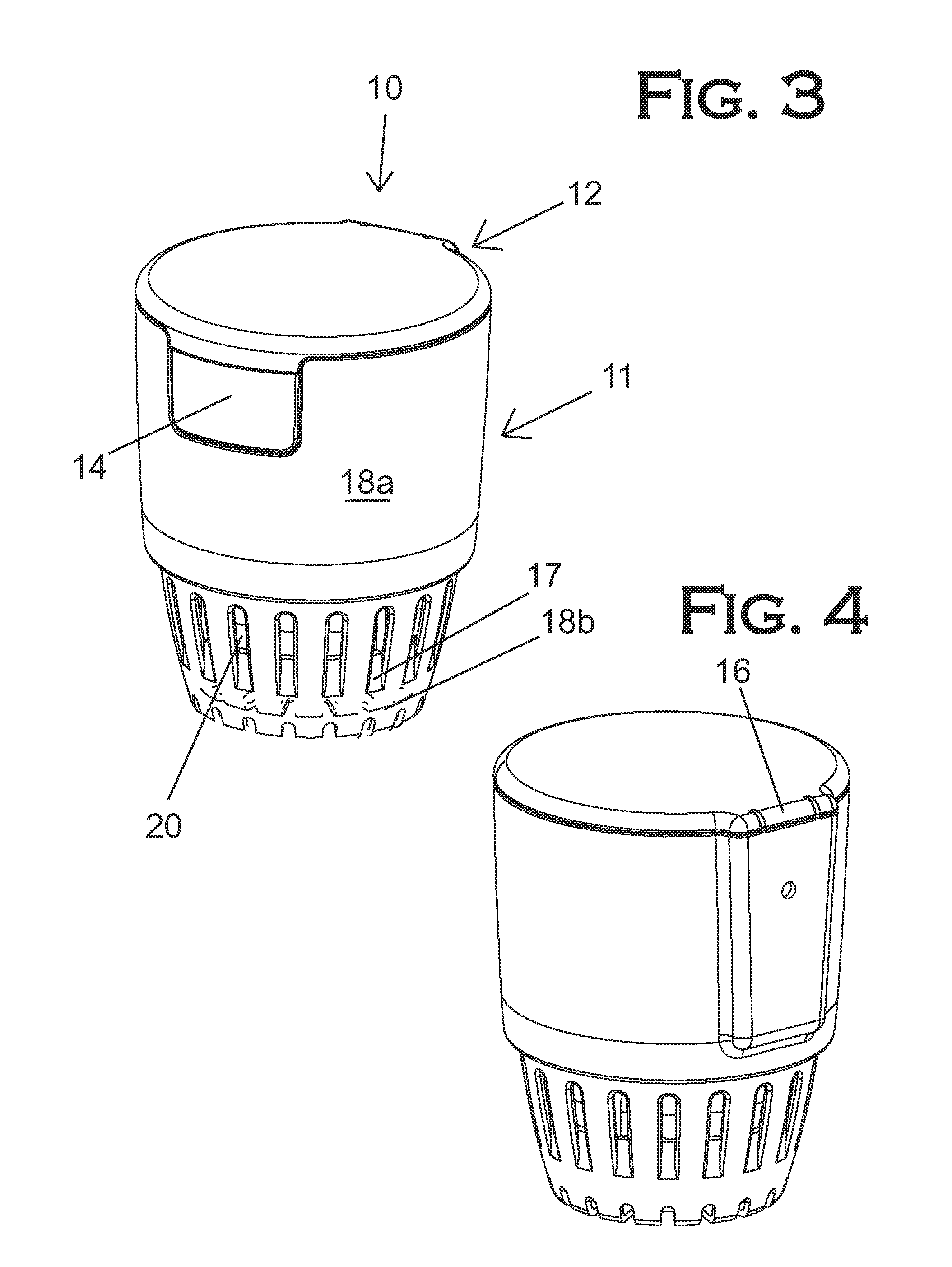

Needleless injection device

An injection device 10 has a fluid applicator 11 that is fed by a fluid delivery arrangement 12 containing an energy storage 29 such as a pressure vessel 36. The gas pressure obtained by the pressure vessel 36 directly or indirectly acts on a container that has been prefilled with the ejection fluid, such as the isosmotic NaCl solution, so that the fluid to be ejected is thus subject to constant pressure. With a valve 23, the user can initiate the ejection of the desired amount of fluid with constant intensity. A check valve 23 may also be a regulating valve which can be used by the user to vary the intensity of the effect. The basic characteristic of the present invention is that the ready-to-use injection device can be produced in a very high cost benefit manner. A user need only release the system, e.g., by puncturing the pressure vessel, to then be able to directly inject the fluid in a defined or metered manner via the probe, i.e., the fluid applicator. the check valve or regulating valve 23 can be disposed, released and actuated easily and visually. It is also possible to configure the entire injection device 10 as a single-use system and to prefill the fluid applicator up to its fluid exit opening. A aseptic sealing member can be arranged at the far-end of the fluid applicator via a protection cap 16.

Owner:ERBE ELEKTROMEDIZIN GMBH

Defogging method for video camera

InactiveCN104378537ASimple structureEasy to useTelevision system detailsColor television detailsLight signalComputer science

The invention discloses a defogging method for a video camera. A light transmitter and a light receiver are arranged in the video camera, and a heating module and a fan are arranged nearby window glass of the video camera. Light is transmitted to the inner wall of the window glass of the video camera at constant intensity through the light transmitter; the light receiver receives the light reflected by the inner wall of the window glass of the video camera after being transmitted by the light transmitter. A light signal received by the light receiver is converted into an electric signal, and then the electric signal is filtered; afterwards, the intensity of the filtered electric signal is compared with a preset intensity threshold value, and whether the heating module and the fan are controlled to work or not is controlled according to the comparison result. According to the defogging method, whether the window glass of the video camera fogs or not can be judged intelligently, and meanwhile defogging can be performed automatically when the window glass fogs.

Owner:LICERAM ELECTRONICS TECH

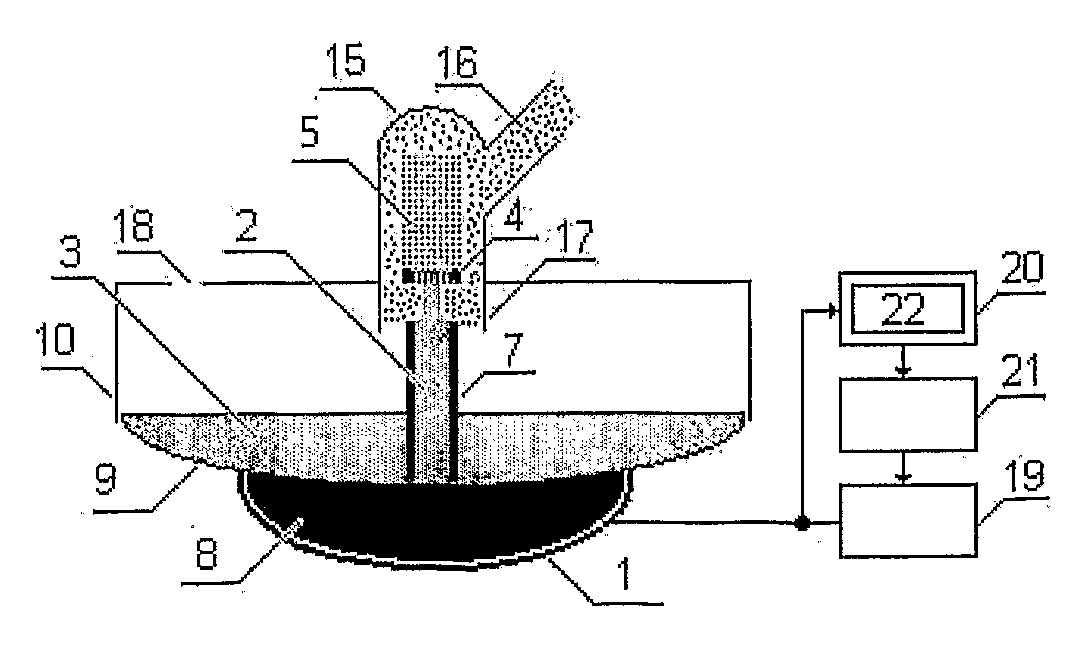

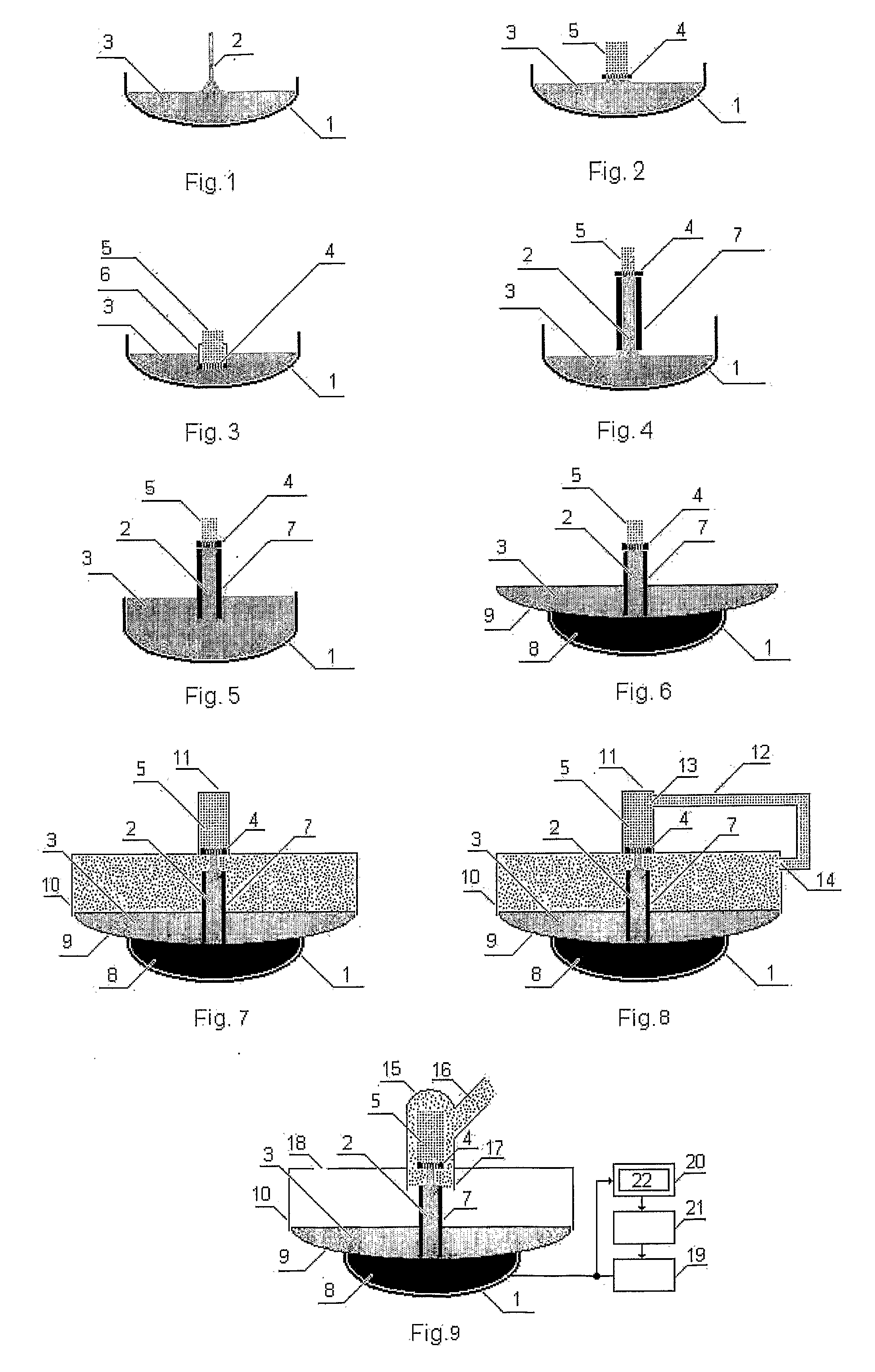

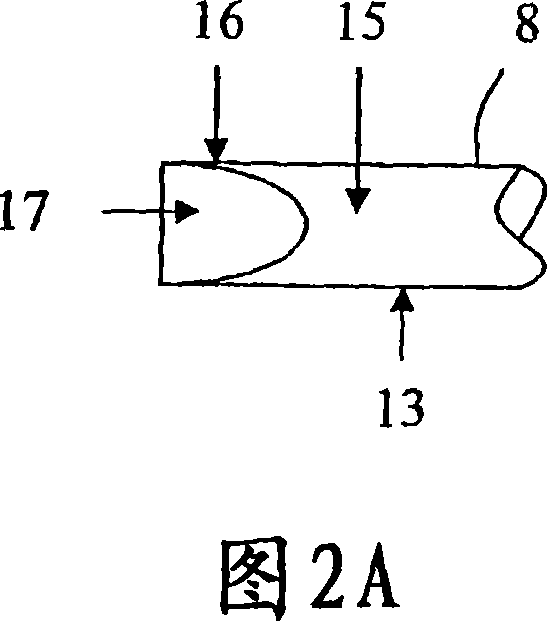

Apparatus for atomisation and liquid filtration

ActiveUS20090200397A1Improve efficiencyEasy to disinfectMovable spraying apparatusSpray nozzlesUltrasound attenuationNebulizer

The invention relates generally to a mesh type apparatus for liquid atomising and filtration, for example, of the atomiser having a concave ultrasonic transducer, which also forms a part of the liquid container (1). This transducer is emitted an ultrasonic energy which created a spout (2) of the liquid (3) to be atomised. The liquid (8) plays a role of the transmission media. The container (9) with liquid (3) is set up on the top of the container (1). The liquid (3) is separated from the transmission media (8) through the bottom of the container (9) by a material that has minimum attenuation of ultrasonic energy. This separation could be temporary of permanent. The focal zone extender (5) is placed in the vicinity of the bottom of container (9). In this case all liquid above the bottom of the focal zone extender will be forced up to the top of the focal zone extender and atomized at the constant intensity of acoustical energy conveyed from the bottom of the focal zone extender. This new technology author named for Dynamic Mesh Technology.

Owner:BIOSONIC AUSTRALIA

Constant-rate volatile material dispensing device

InactiveUS7597309B1Avoid flowReduce manufacturing costMixing methodsUsing liquid separation agentBiomedical engineeringAtmosphere

A volatile material dispensing device is provided, including a volatile material, a replaceable canister including a U-shaped outlet tube and a reservoir to hold the volatile material, and a generally cylindrical external housing sized and configured to receive the replaceable canister. The U-shaped outlet tube includes a tube inner leg, a tube crosspiece, and a tube outer leg, with the tube inner leg fluidly connected to the cavity and with the tube outer leg open to the atmosphere. The external housing includes a powered actuating unit configured to apply pressure to the flexible outer wall of the reservoir. Thereby a portion of the volatile material is forced up the inner tube, over the tube crosspiece, and down the outer tube to be received by a porous pad, providing a time-release dispersing mechanism delivering a controlled, consistent flow and producing a constant intensity of vapor release over time.

Owner:STUCKI ANDRE

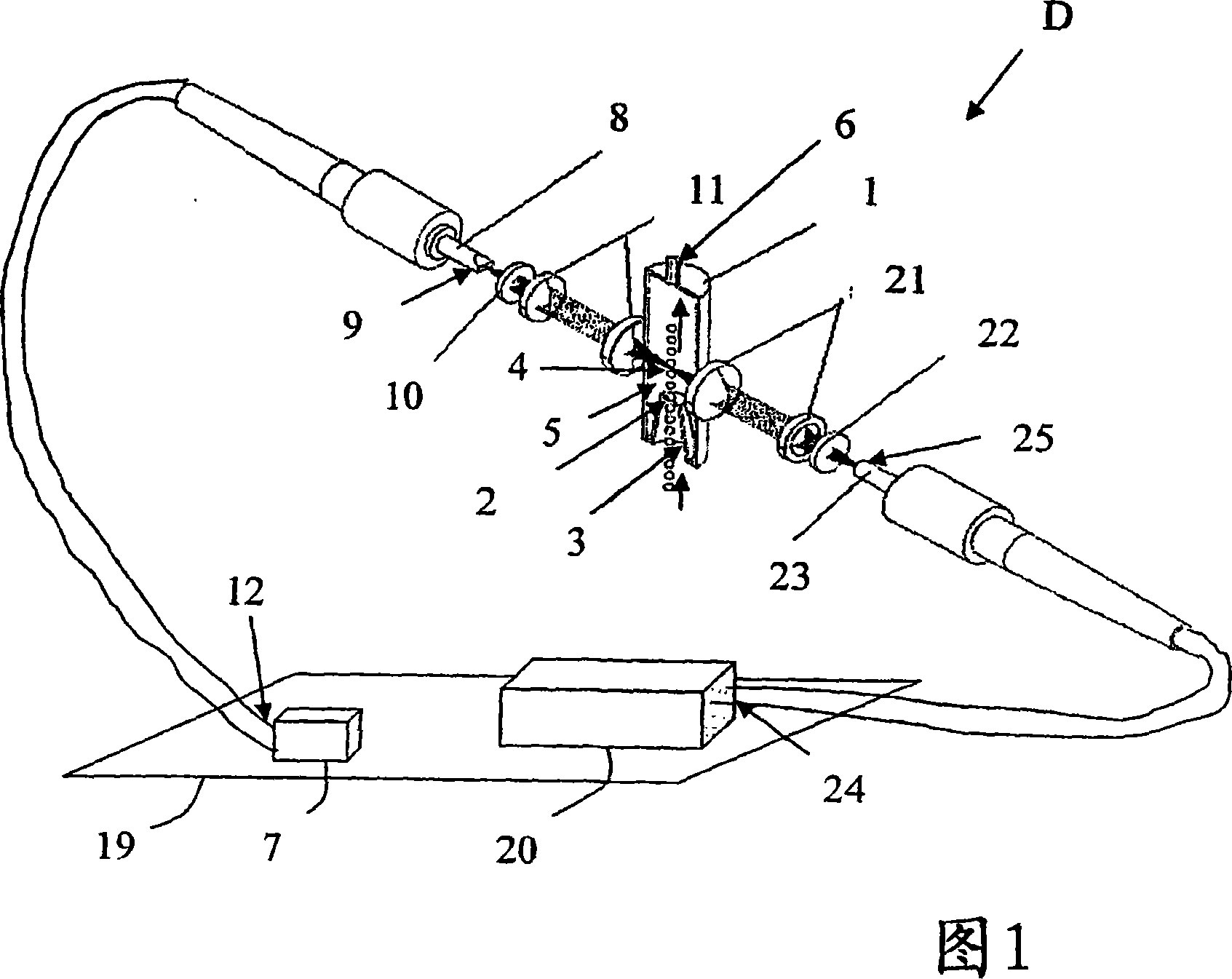

Device for examining a fluid by uniform illumination using a configured light guide

InactiveCN101061381AScattering properties measurementsIndividual particle analysisLight guideUltimate tensile strength

The invention concerns an optical device for examining a fluid (D) comprising a measuring space (4) including a compulsory passage (5) for the fluid to be examined, at least one source (7) delivering a selected light to optical illuminating means (21-25) serving to collect at least part of the light having traversed the compulsory passage (5) and to deliver same to means (20) serving to analyze the collected light so as to deliver signals representing data borne by same. The optical illuminating means (8-12) comprise first light guiding means (8) including one end (9), opposite the source (7), and configured to deliver the light, derived from the source (7), in accordance with a selected geometry so that it illuminates the compulsory passage (5) in a substantially uniform manner and under a substantially constant intensity.

Owner:HORIBA ABX SAS

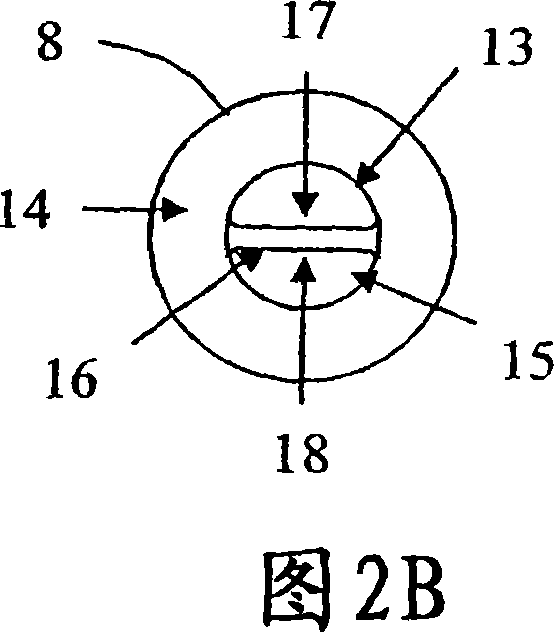

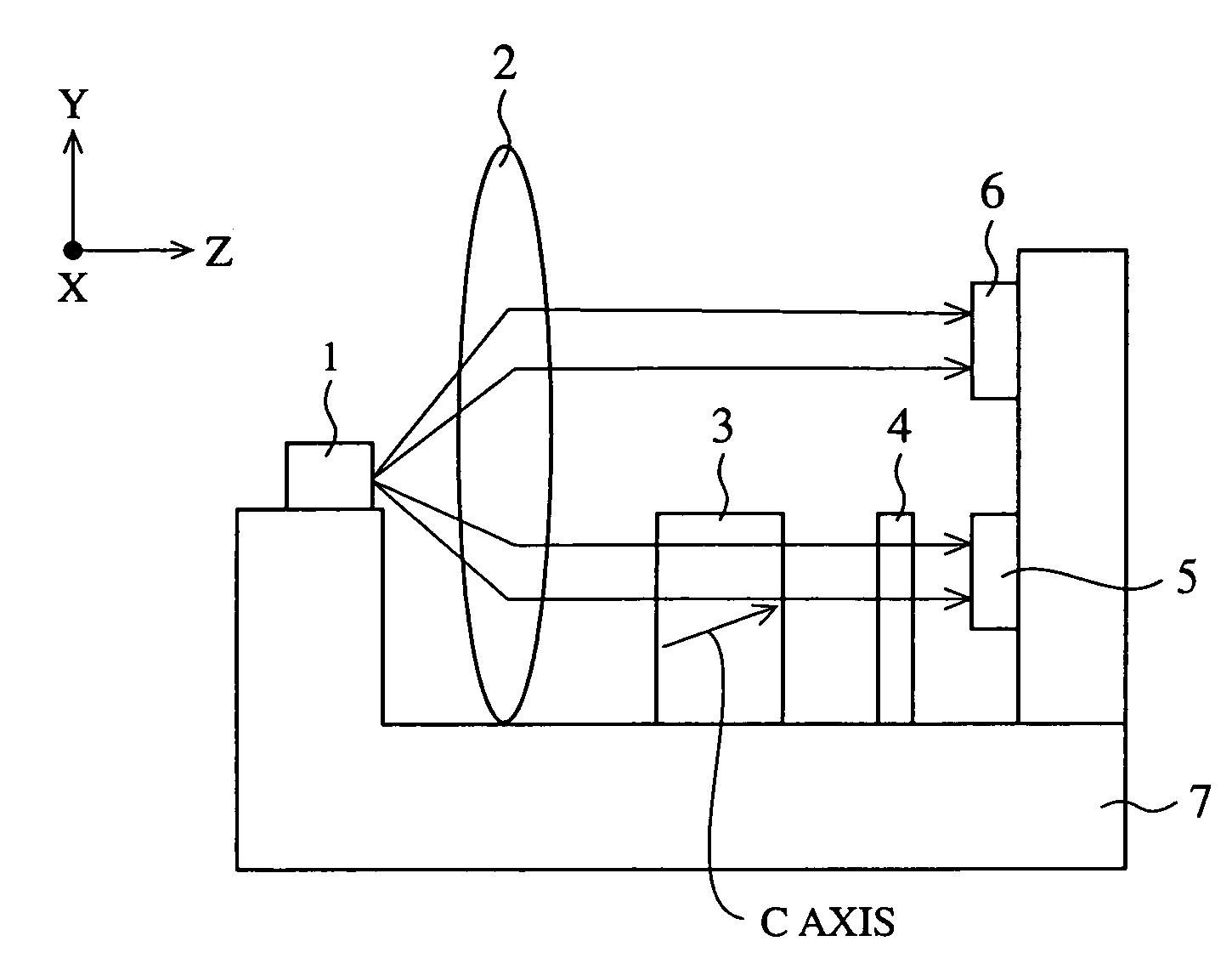

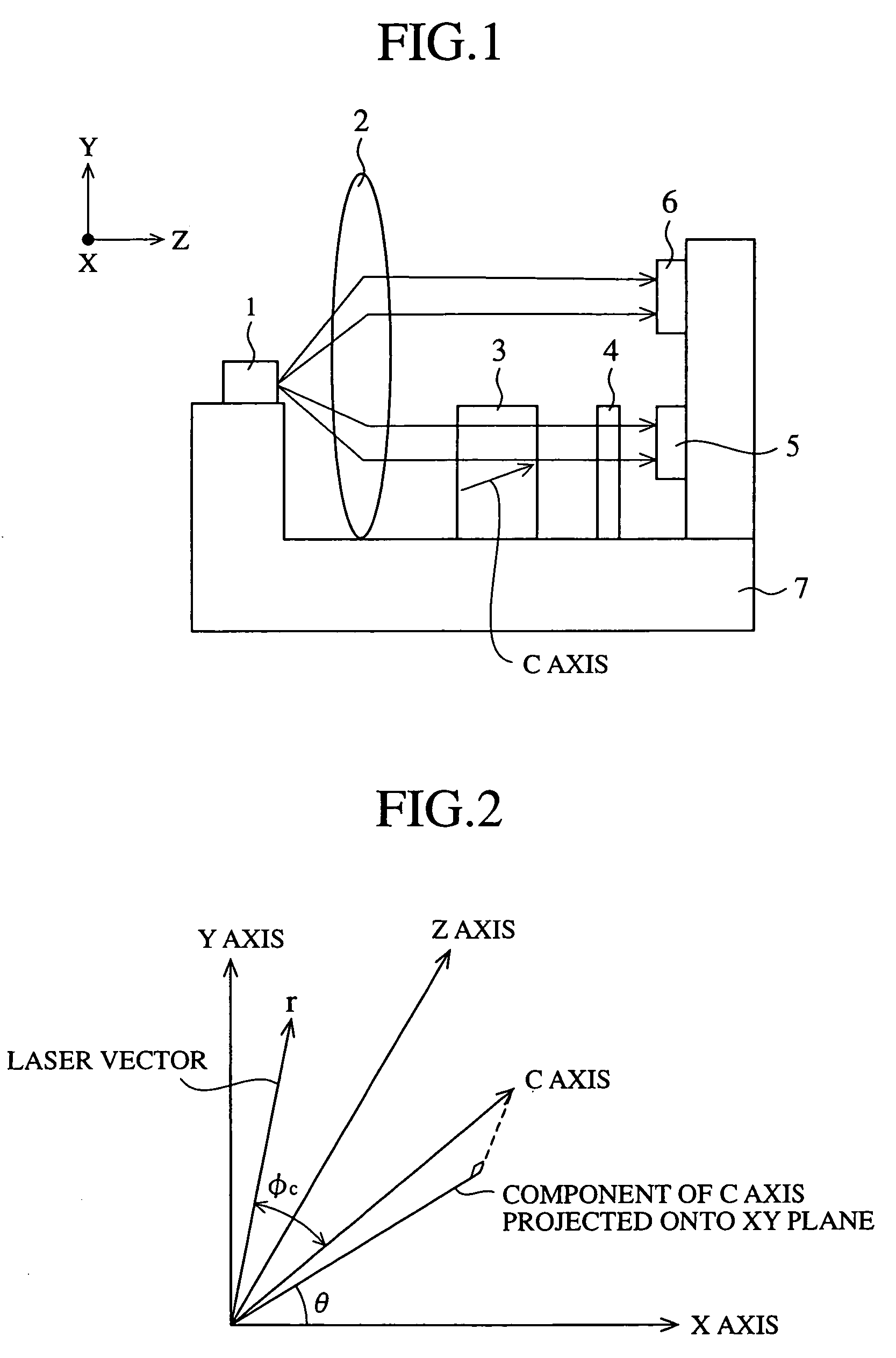

Wavelength monitoring apparatus

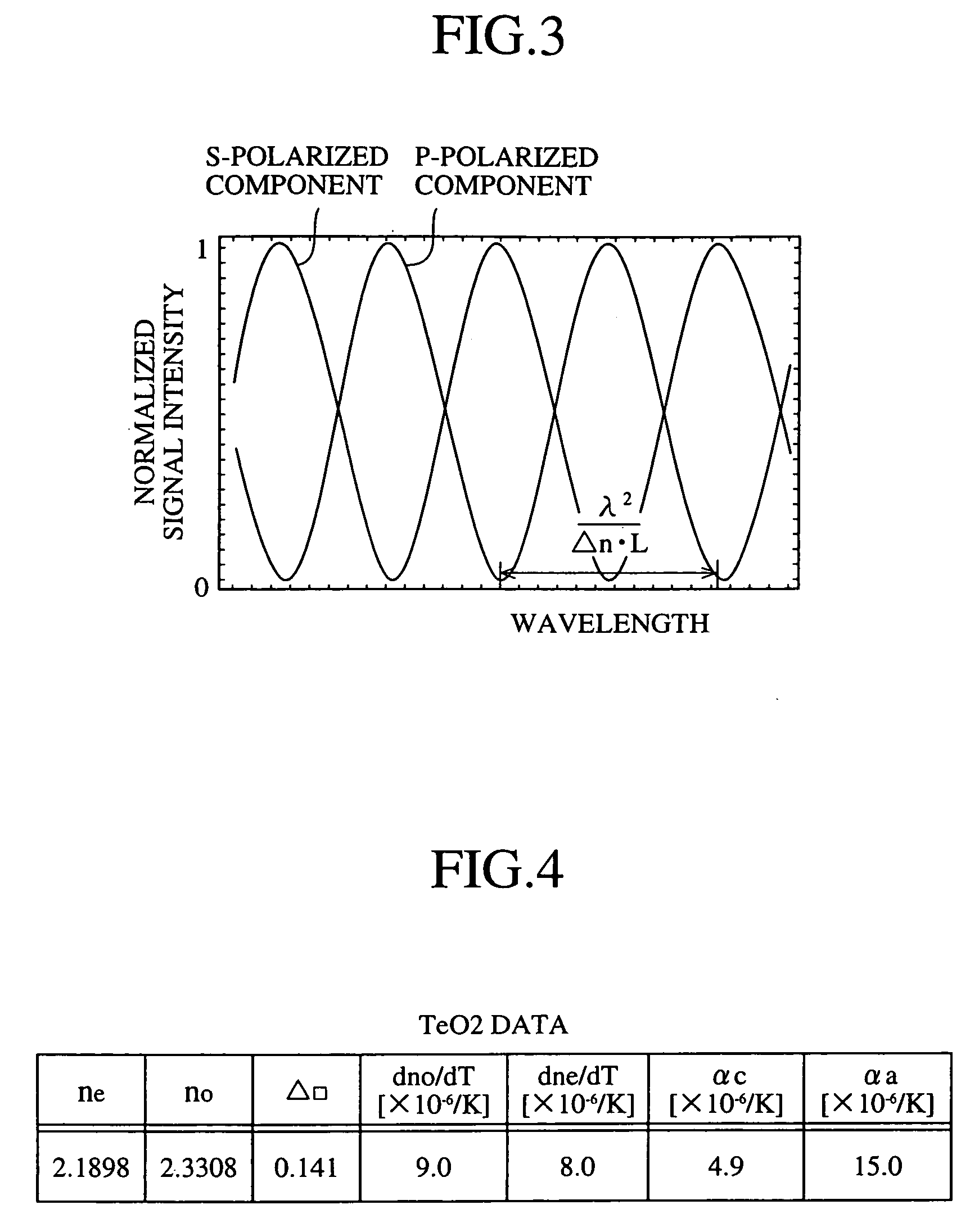

InactiveUS7301974B2Easy to provideEasily discriminatedOptical measurementsOptical resonator shape and constructionBirefringent crystalOptical axis

An optical signal emitted from a semiconductor laser is converged by a lens and then received by a single uniaxial birefringent crystal having a C axis that is inclined at an angle other than 90 degrees against a laser optical axis to output an optical signal having a polarized wave component of constant intensity corresponding to the wavelength of the optical signal regardless of temperature changes. The optical signal has an ordinary ray vibrating in a direction perpendicular to a plane including both the C axis and the laser optical axis, and an extraordinary ray vibrating in a direction perpendicular to both the ordinary ray and the laser optical axis. A first main photo detector detects the intensity of a p-polarized component of the optical signal that has passed through a polarizer and a second photo detector directly receives the optical signal converged by the lens.

Owner:MITSUBISHI ELECTRIC CORP

Defogging system for camera

InactiveCN104391419ASimple structureEasy to useTelevision system detailsColor television detailsLight signalElectric signal

The invention discloses a defogging system for a camera. The defogging system for the camera comprises a light emitter, a light receiver, a photoelectric converting module, a filter module, a control module, a heating module and a fan; the light emitter is used for emitting light to the inner wall of window glass of the camera at a constant intensity; the light receiver is used for receiving the light emitted by the light emitter and reflected by the inner wall of the window glass of the camera; the photoelectric converting module is used for converting a light signal received by the light receiver into an electrical signal; the filter module is used for filtering the converted electrical signal; the heating module is used for heating air close to the window glass of the camera; the fan is used for blowing the heated to the window glass of the camera; the control module is used for comparing the strength of the received electrical signal with the preset intensity threshold, and controlling the heating module and the fan to work or not work according to the comparing result from the comparing unit. With the adoption of the defogging system for the camera, whether the window glass of the camera is fogged can be intelligently determined; in addition, the fog can be automatically removed in case of fogging.

Owner:LICERAM ELECTRONICS TECH

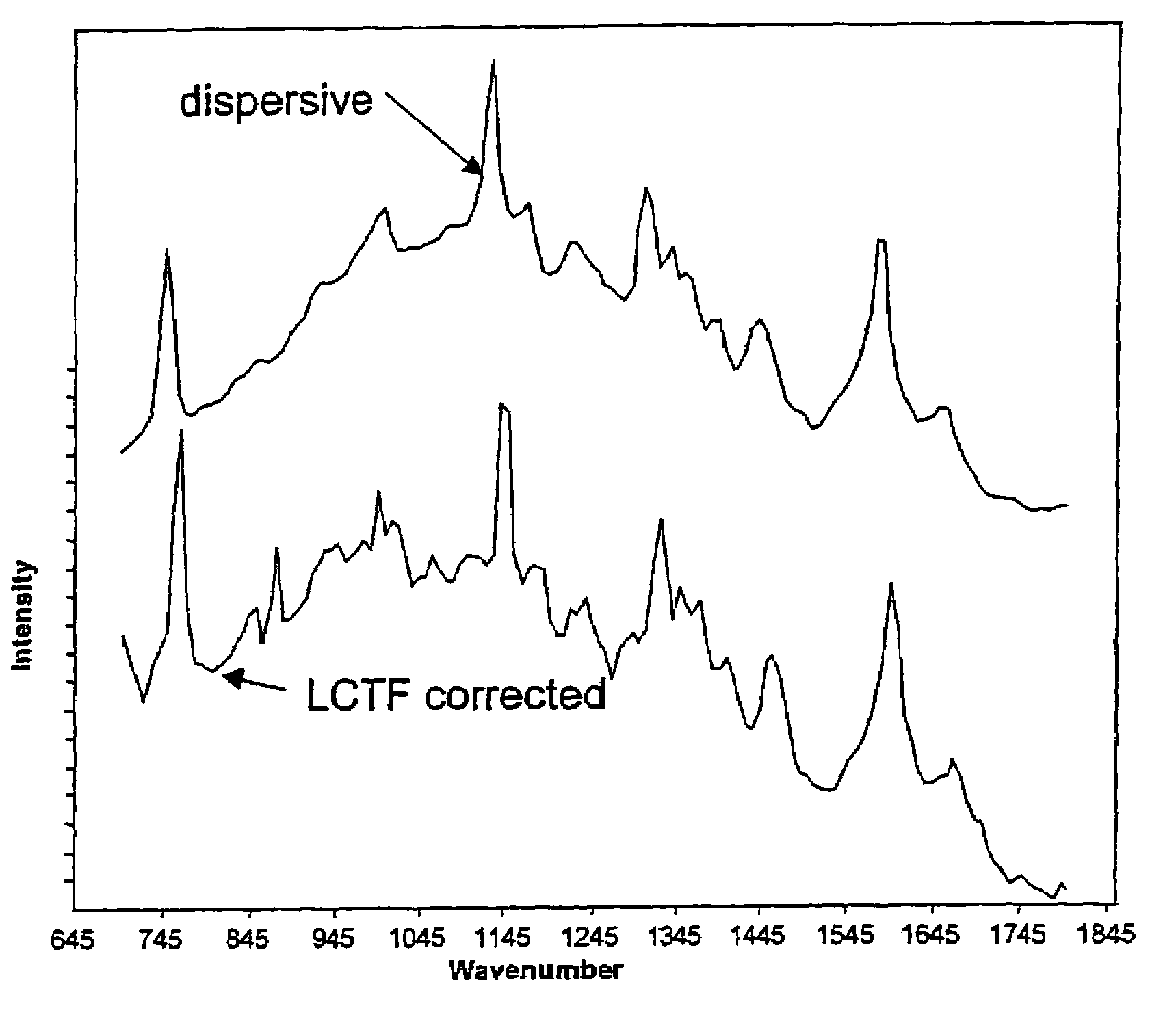

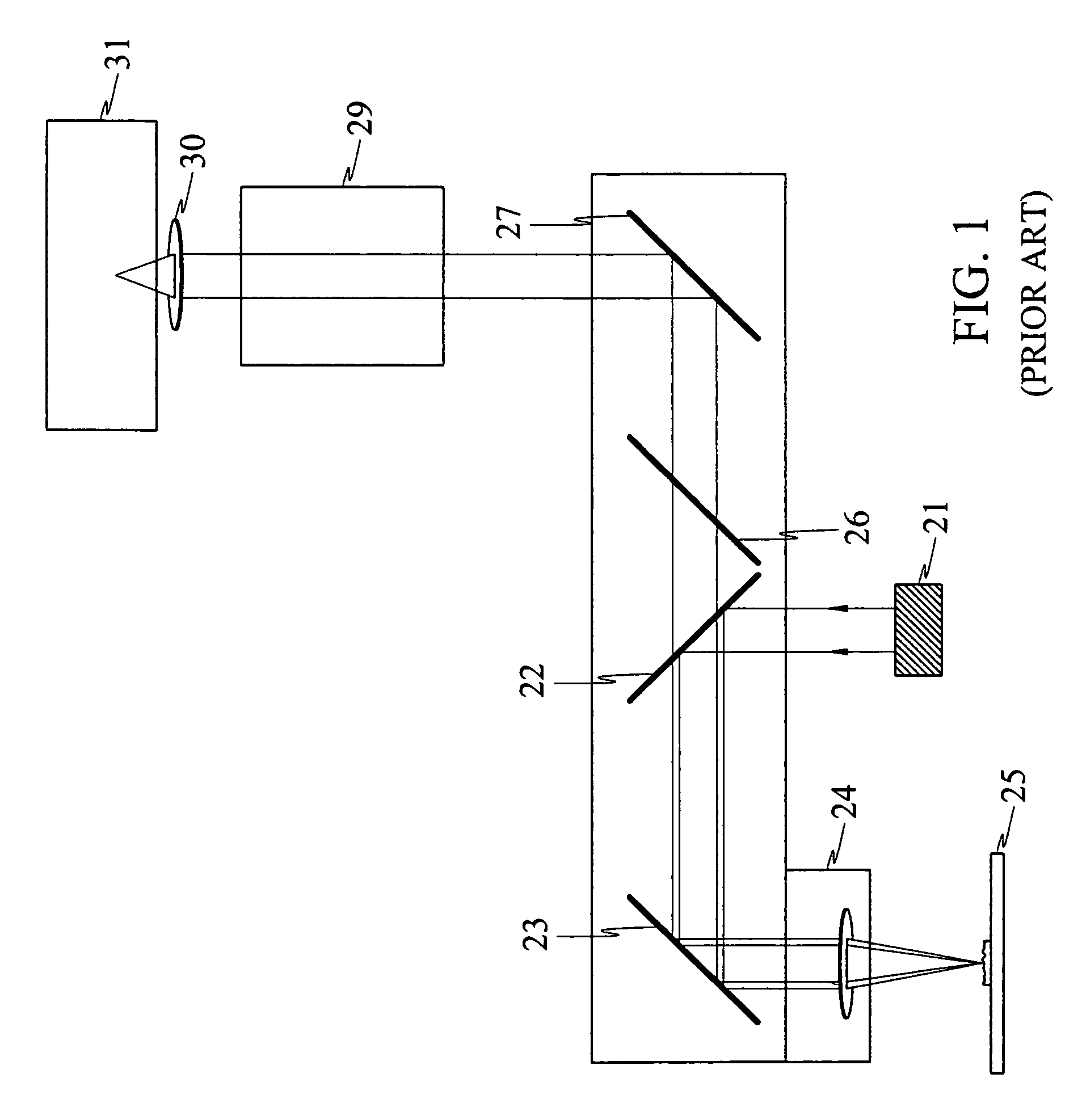

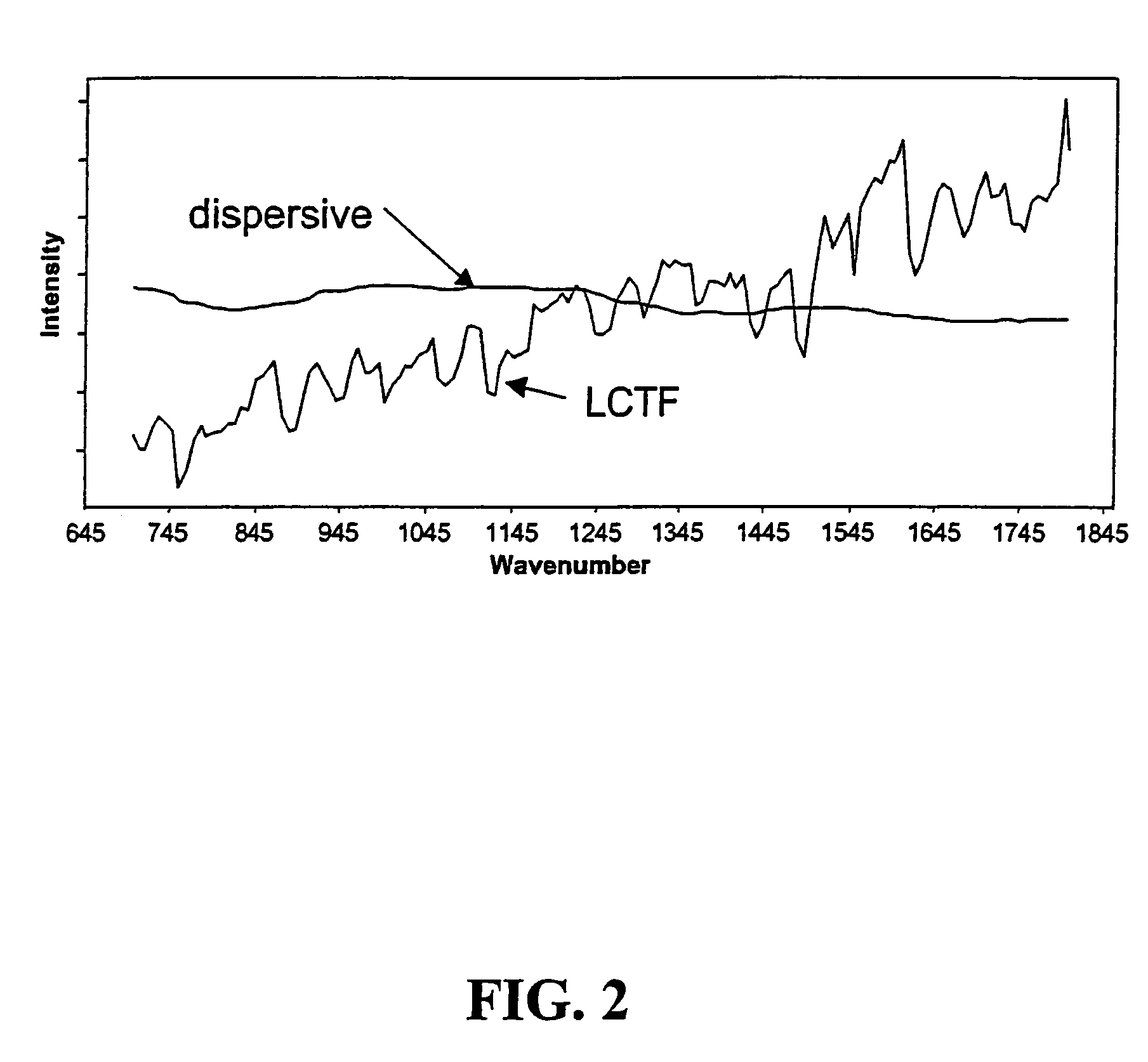

Method and apparatus for spectral modulation compensation

ActiveUS7239383B2Narrow bandwidthRadiation pyrometrySpectrum investigationFrequency spectrumLength wave

The embodiments disclosed herein generally relate to identifying and removing background noise in spectroscopic imaging of a sample. Because white-light has essentially constant intensity at every wavelength, background noise caused by white light can be identified and removed from spectroscopic measurements including Raman spectroscopy. Thus, once the Raman spectrum for a sample is obtained, it may be corrected to remove the white-light dispersive spectrum in accordance with the embodiments disclosed herein.

Owner:CHEMIMAGE TECH LLC

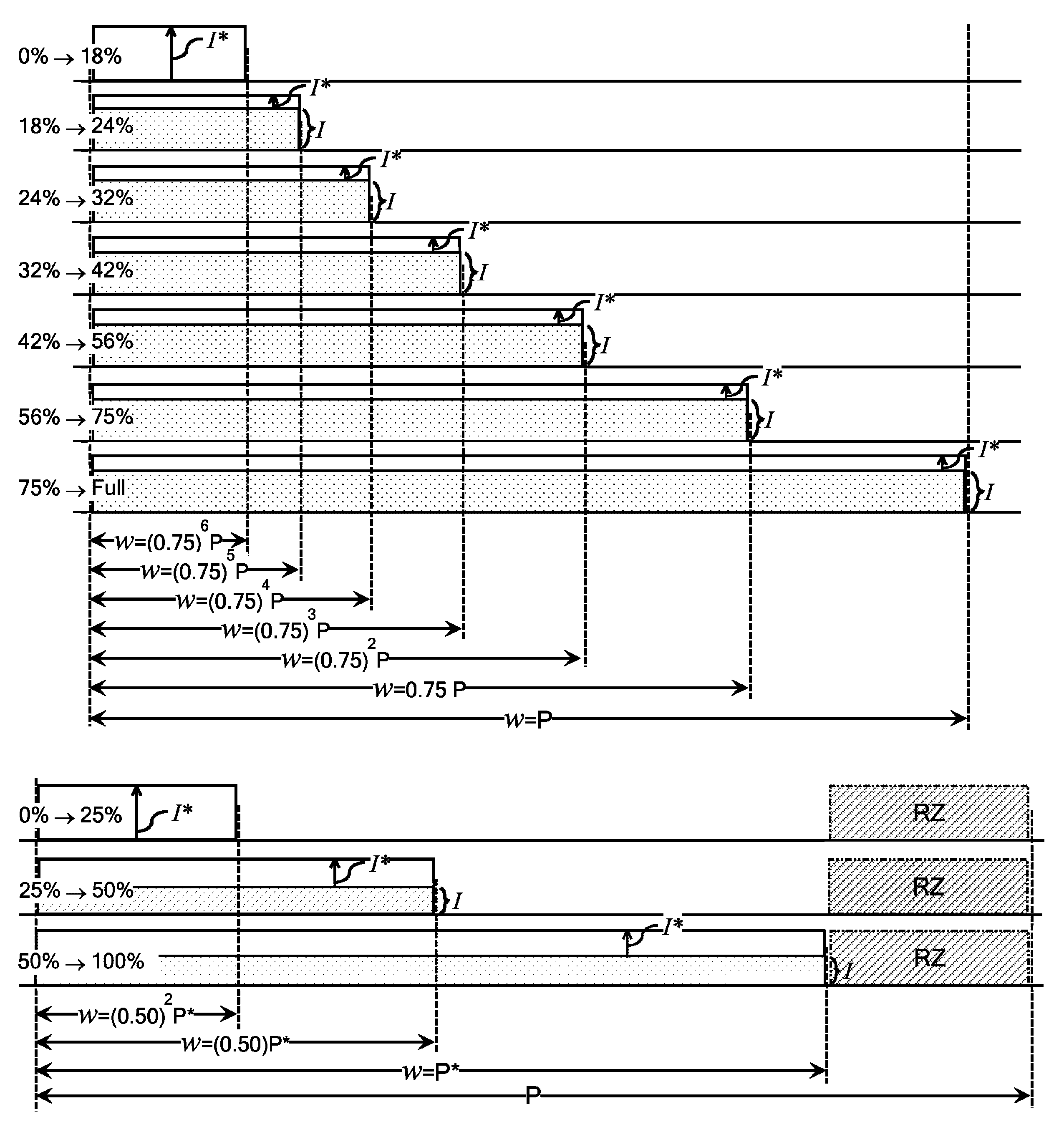

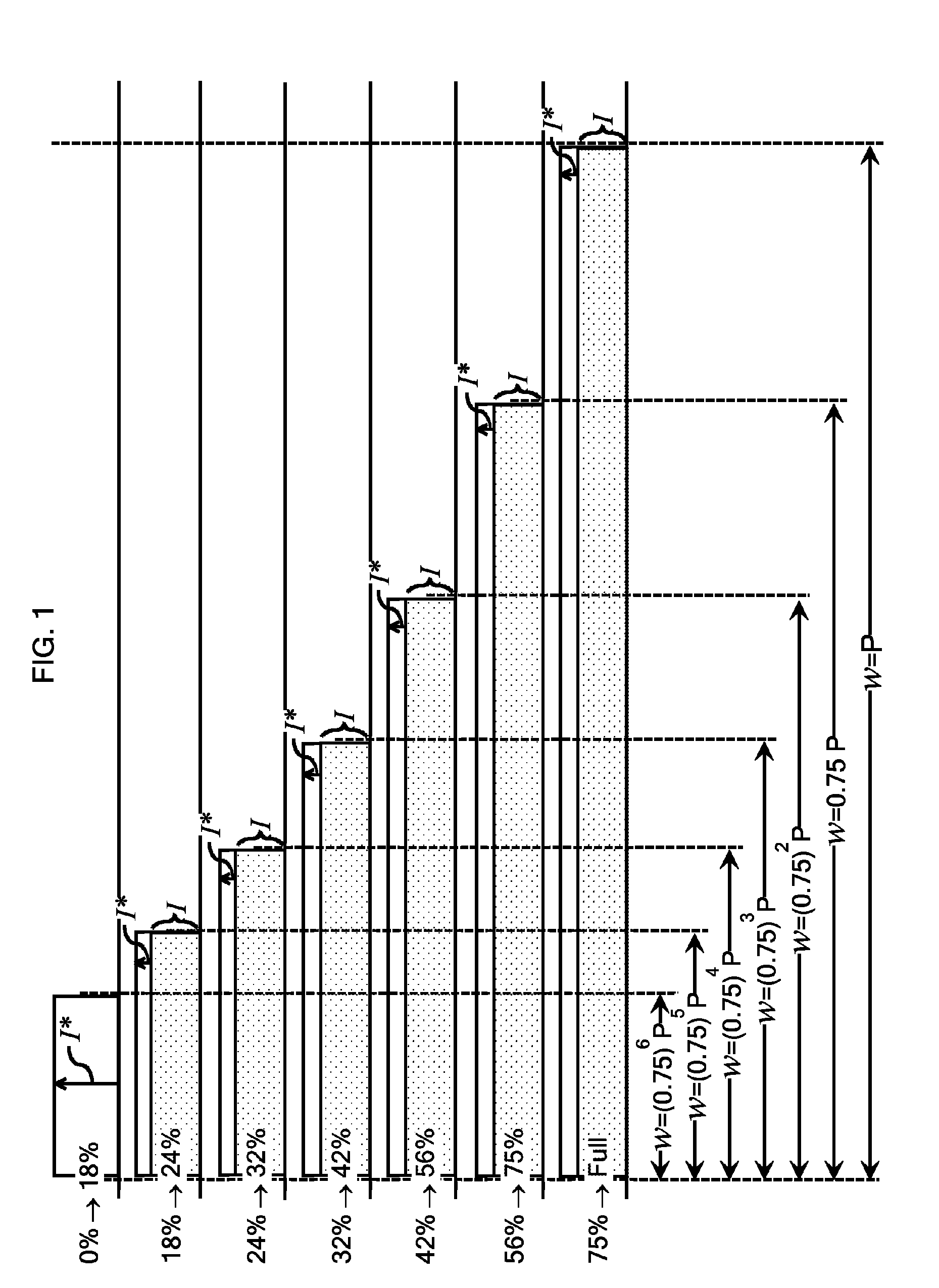

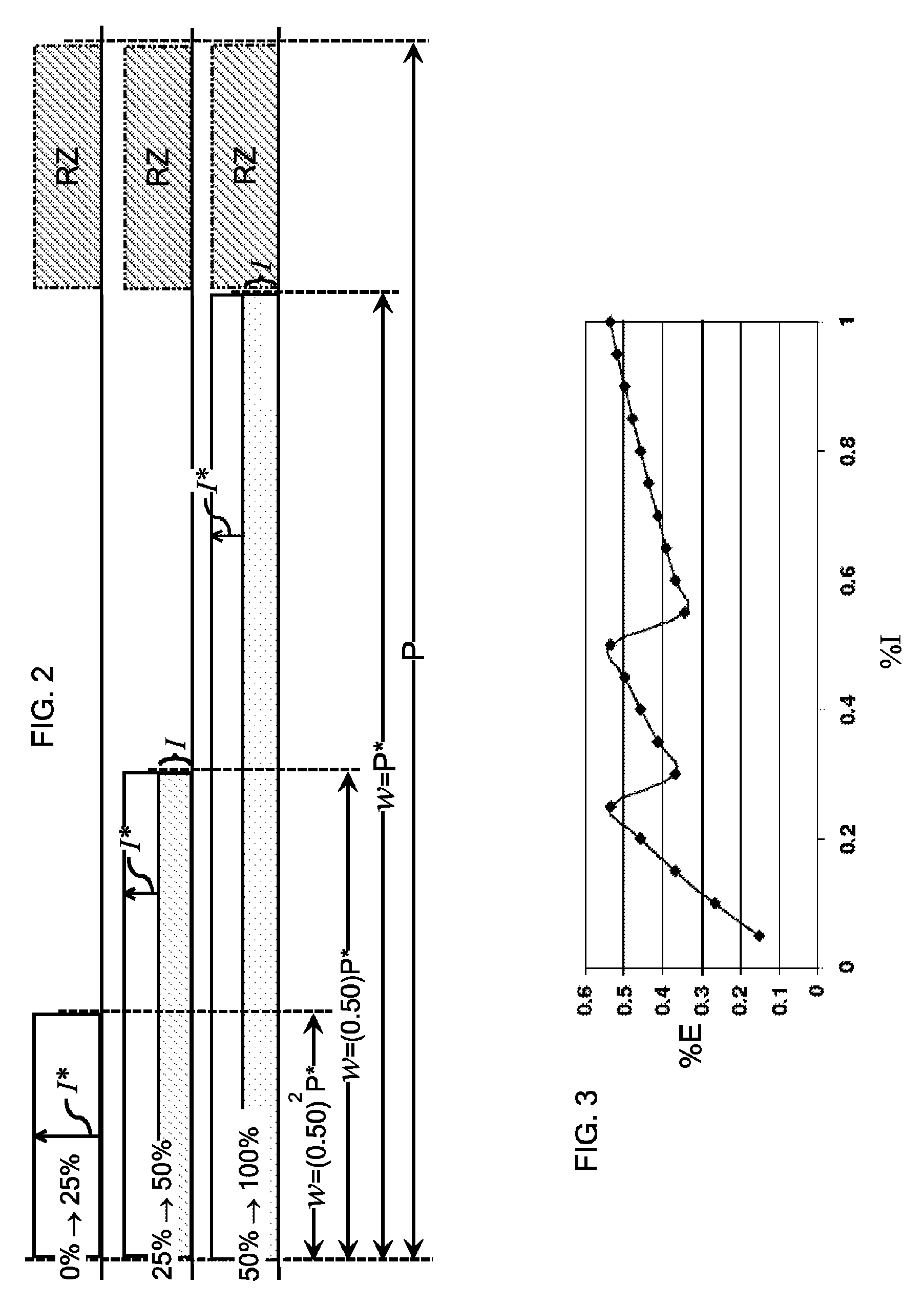

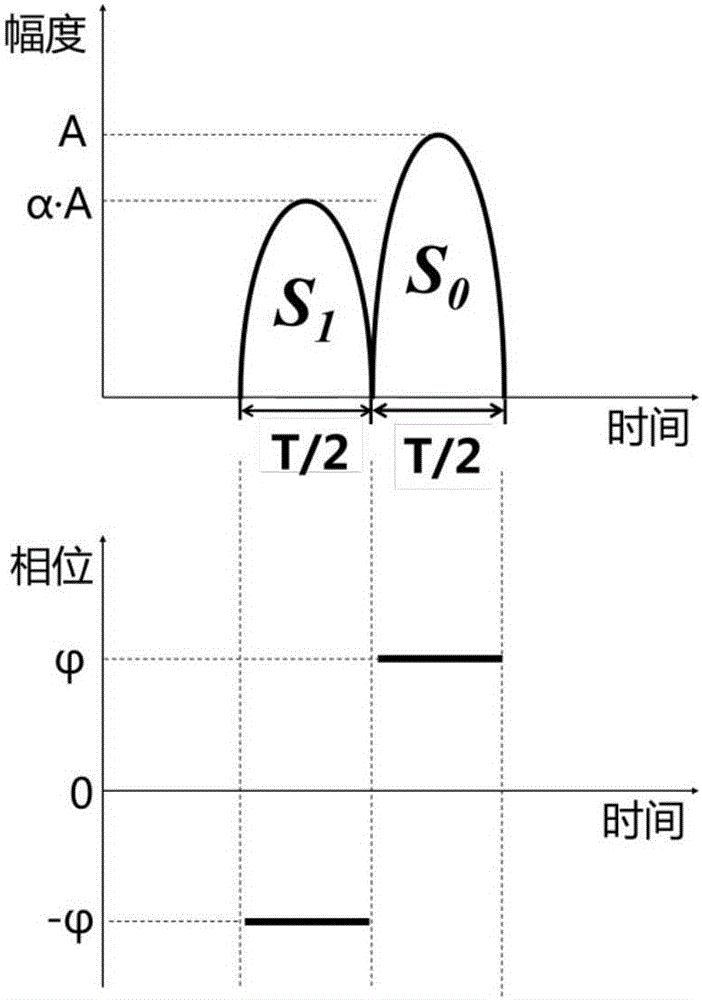

Pulse mode modulation in frequency converted laser sources

InactiveUS7920610B2Improve electricity efficiencyHigh modulationLaser detailsProjectorsControl signalPulsed mode

Methods of operating a frequency-converted laser source are disclosed. According to particular disclosed embodiments, a laser diode is driven in a pulsed mode to define pixel intensity values corresponding to desired gray scale values of image pixels in an image plane of the laser source. The pixel intensity values are a function of a laser control signal comprising a discontinuous pulse component, a relatively constant intensity component I, and a continuously variable intensity component I*. The pulse width w of the discontinuous pulse component is selected from a set of discrete available pulse widths according to a desired pixel gray scale value. A low-end pulse width w of the set of available pulse widths is established for a range of low-end pixel gray scale values and progressively larger pulse widths w are established for ranges of progressively higher pixel gray scale values. The relatively constant intensity component I makes a relatively insignificant contribution to pixel intensity at the low-end pulse width w for the range of low-end pixel gray scale values and assumes a non-zero value for enhanced conversion efficiency at the progressively larger pulse widths w established for the higher pixel gray scale values. The continuously variable intensity component I* varies according to the desired gray scale value of the selected pixel and the contributions of the relatively constant intensity component I and the pulse width w to pixel intensity.

Owner:CORNING INC

Light transmission system and method for reducing fiber non-linearity effects

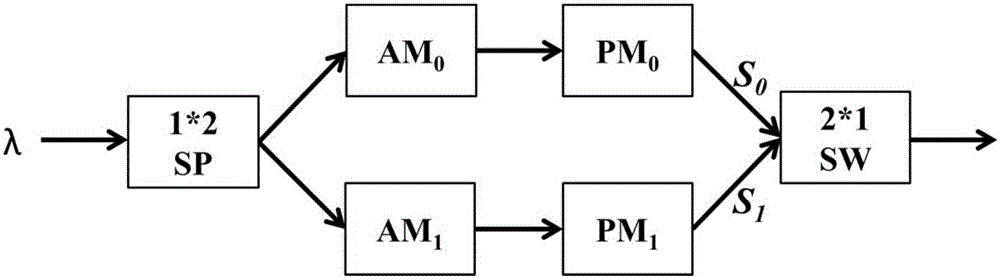

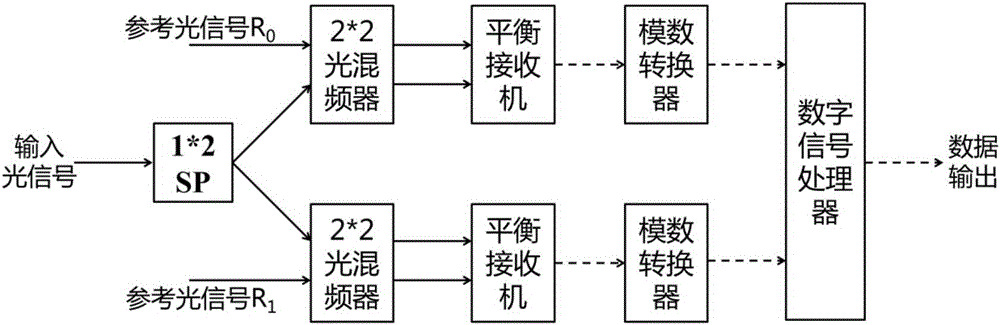

ActiveCN106059670AImprove transmission performanceImprove transmission distanceElectromagnetic transmissionContinuous lightFiber

The invention discloses a light transmission system and method for reducing fiber non-linearity effects, and relates to the field of fiber communication. The system includes a single carrier transmitter and a single carrier receiver. The single carrier transmitter divides a continuous light signal transmitted by a subcarrier light source into two equal paths with each path provided with one intensity modulator and one phase modulator. The two paths of light signals after the modulation have the same center frequencies, constant intensity ratio, and opposite phases. A light switch is intended for switching the two paths of light signals. The single carrier receiver is intended for receiving the light signals in the two paths. Each path of optical mixer conducts frequency mixing on the corresponding path of light signal and one continuous narrow band reference light signal having the same center frequency and is orthogonal, conducts light / electrical conversion on the light signals after frequency mixing, converts an analog signal to a digital electrical signal. A digital electrical signal processor is intended for processing the two paths of digital electrical signals, and extracts loaded data. According to the invention, the system reduces influence of fiber non-linearity effects, reduces complexity of cost and controlling, and reduces power consumption and time delay.

Owner:FENGHUO COMM SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com