Method and die for obtaining variable-intensity hot stamping part

A variable-strength, hot-stamping technology, applied in the field of hot-stamping, can solve problems such as inability to form variable-strength hot-stamped parts, and achieve the effect of improving comprehensive mechanical properties, easy implementation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

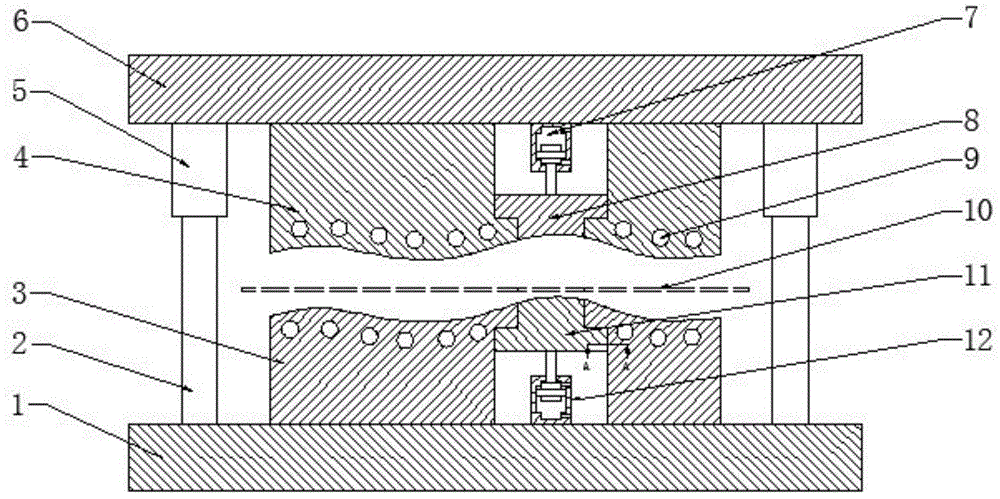

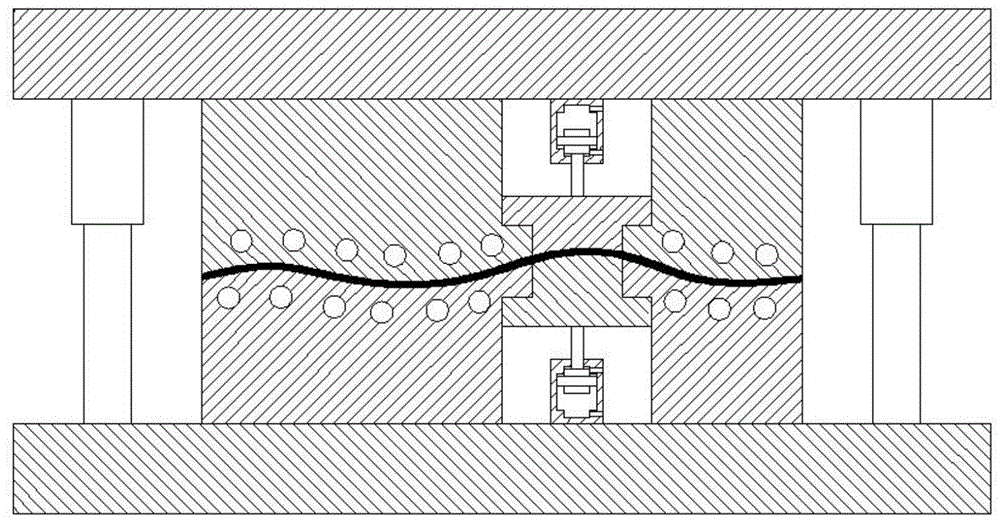

[0037] Let's take the B-pillar parts with variable strength as an example in combination with the attached Figure 1a , 1b ~4, further illustrate the content of the present invention and its specific implementation steps.

[0038] A method for obtaining variable-strength hot stamping parts, comprising the steps of:

[0039] Step 1: Mold preparation.

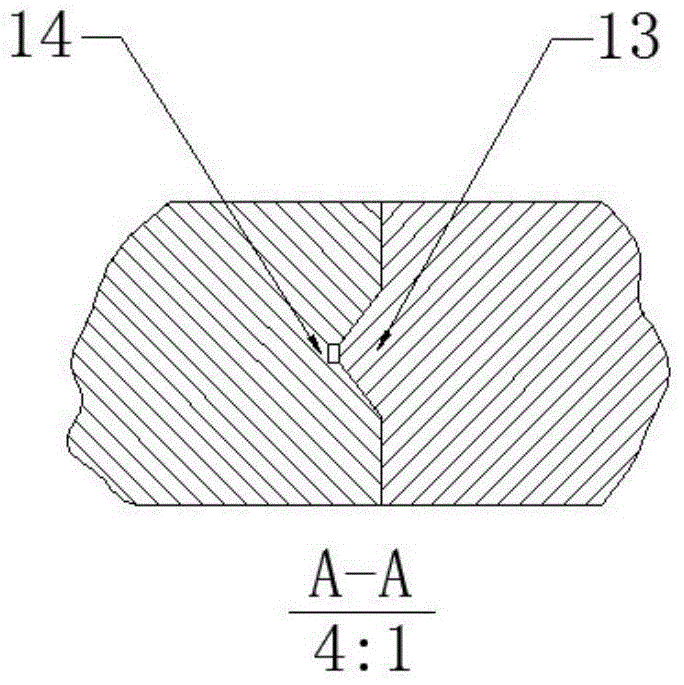

[0040] A mold for obtaining variable-strength hot stamping parts, including an upper mold mounting plate 6, a lower mold mounting plate 1, a guide post 2, a guide sleeve 5, an upper mold fixed insert 4, an upper mold movable insert 8, a lower mold fixed insert Block 3, lower mold movable insert 11, upper hydraulic cylinder 7, lower hydraulic cylinder 12; upper mold fixed insert 4 is fixed on upper mold mounting plate 6, upper mold fixed insert 4 is provided with cooling channel 9 (cooling 9 communicates with the cooling pipe to provide cooling), the fixed insert 4 of the upper die is also provided with a through hole for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com