Fume emission continuous monitoring method and system

A flue gas emission and monitoring system technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of damage to the gas chamber gas pipeline, not being heated by an electric heating device, and temperature drop, etc., to reduce Corrosion, maintainability and stability, slow cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

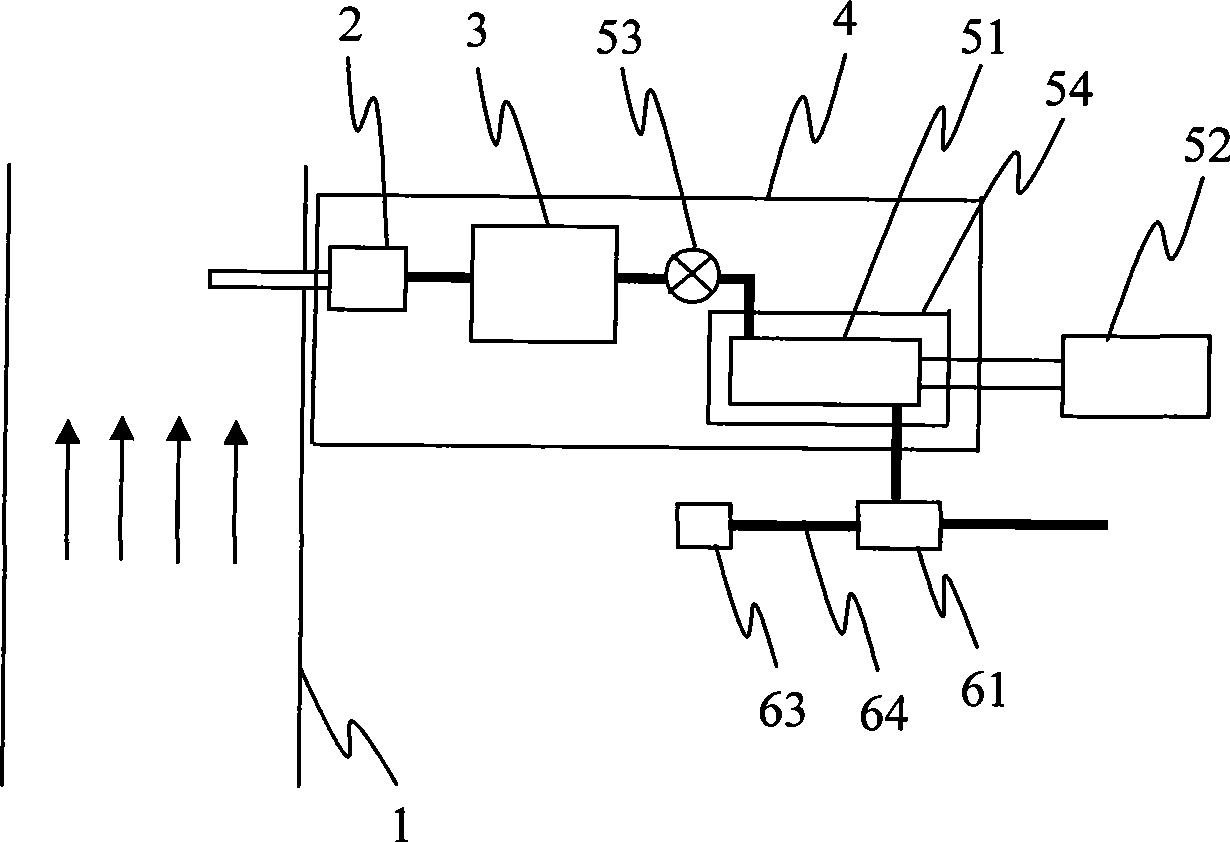

[0041] Such as figure 1 As shown, a continuous monitoring system for flue gas emission includes a flow path heating device 4, a measuring device 52, a sequentially connected sampling device 2, a pretreatment device 3, a valve 53, a gas chamber 51 and a jet device, wherein the sampling The device 2 , the pretreatment device 3 , the valve 53 and the gas chamber 51 are arranged in the flow path heating device 4 .

[0042] The sampling device 2 is installed on the flue 1 , and the measuring device 52 is connected with the gas chamber 51 .

[0043] The gas chamber 51 is set in the heat preservation device 54, and the inlet end of the gas chamber 51 is provided with a valve 53, which is opened when the power is turned on, so that the sampled flue gas can pass into the gas chamber 51, and is closed when the power is turned off.

[0044] The jet device provides power to sample the flue gas from the flue, and also plays the role of displacing the flue gas in the gas chamber after a po...

Embodiment 2

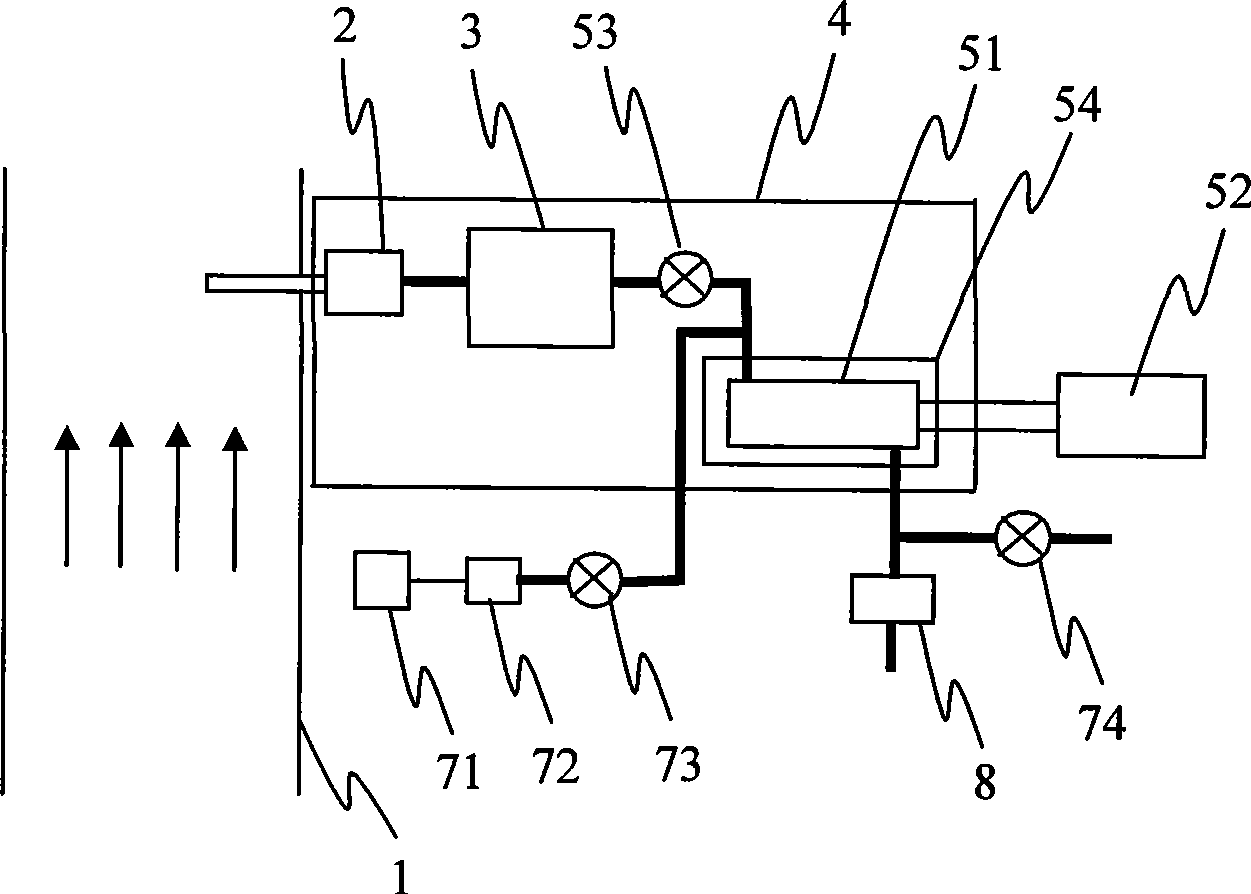

[0057] Such as figure 2 Shown, a kind of flue gas emission continuous monitoring system is different from embodiment 1:

[0058] 1. Use an ordinary air pump 8 to replace the jet device.

[0059] 2. The gas replacement device includes a gas source 71, a filter device 72, valves 73, 74, the gas source 71, filter device 72 and valve 73 connected in sequence are arranged at the inlet end of the gas chamber 51, and the valve 74 is arranged at the end of the gas chamber 51. export port. Valves 73, 74 are closed when energized and opened when de-energized.

[0060] This embodiment also discloses a method for continuous monitoring of flue gas emissions, which is different from Embodiment 1 in that:

[0061] When energized, the exhaust pump 8 works to extract the flue gas in the flue 1 for measurement.

[0062] When the system is powered off, the air pump 8 stops working and disconnects the communication between the gas chamber 51 and the outside world. At this moment, the valves 7...

Embodiment 3

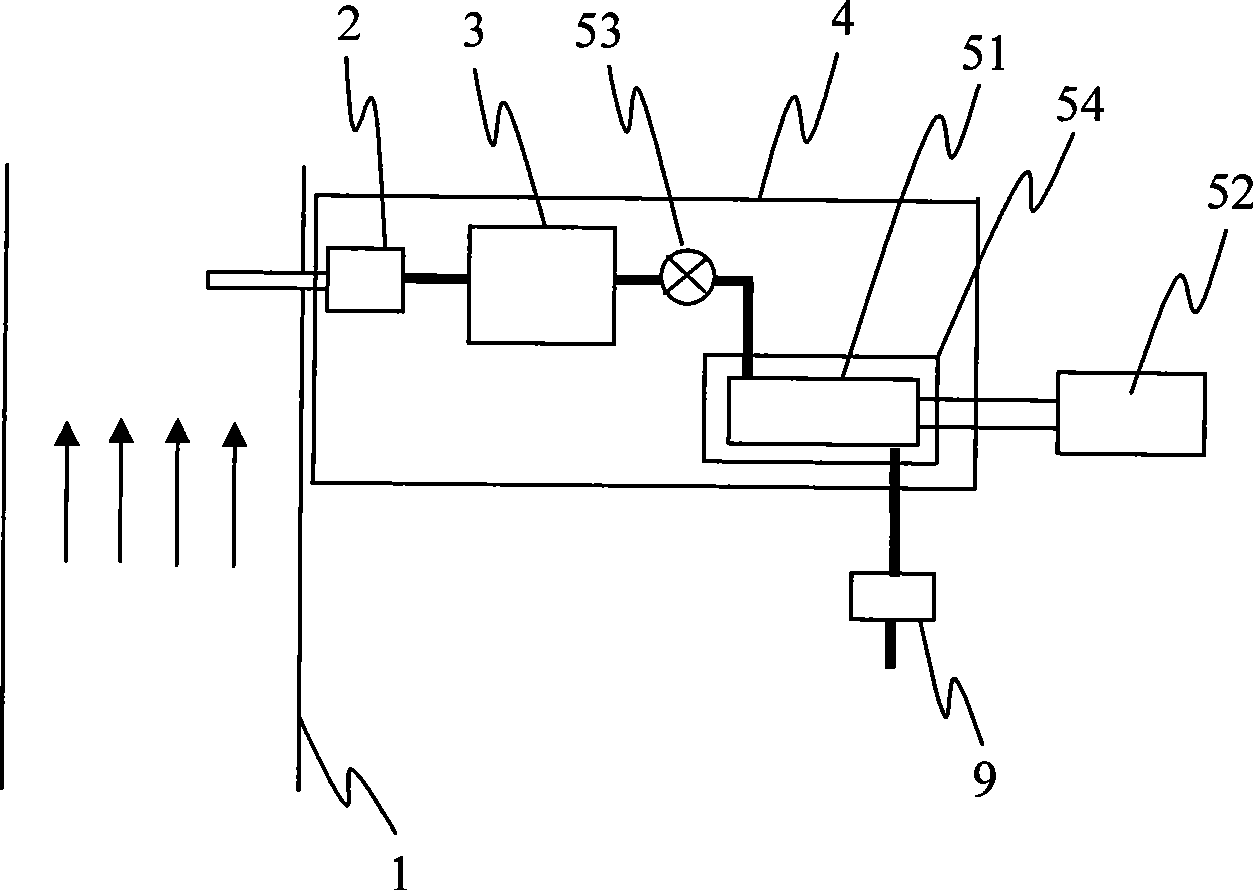

[0065] Such as image 3 Shown, a kind of flue gas emission continuous monitoring system is different from embodiment 2:

[0066] Remove the gas source 71, filter device 72, valves 73, 74, and set a diaphragm pump 9 at the outlet of the gas chamber 51 that still communicates the gas chamber 51 with the outside world when the power is cut off.

[0067] This embodiment also discloses a method for continuous monitoring of flue gas emissions, which is different from Embodiment 2 in that:

[0068] When energized, the diaphragm pump 9 works to extract the flue gas in the flue 1 for measurement.

[0069] When the system is powered off, the diaphragm pump 9 stops working, but the gas chamber 51 is still communicated with the outside world. At this time, the residual gas in the gas chamber 51 is slowly replaced with the clean air (without corrosive components and little moisture content) from the outside. During the replacement process, the heat preservation device 54 ensures that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com