Patents

Literature

227results about How to "With drying function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

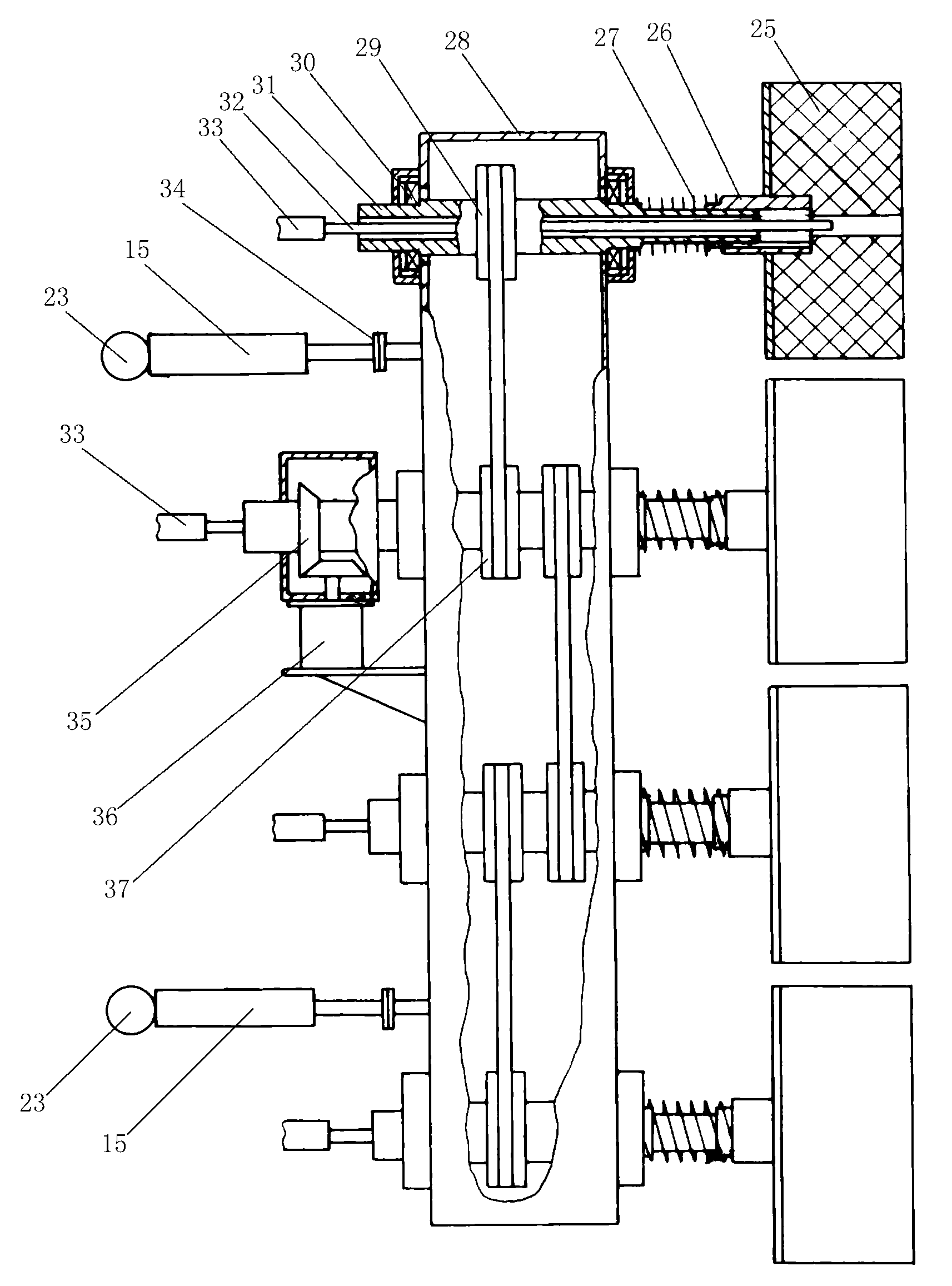

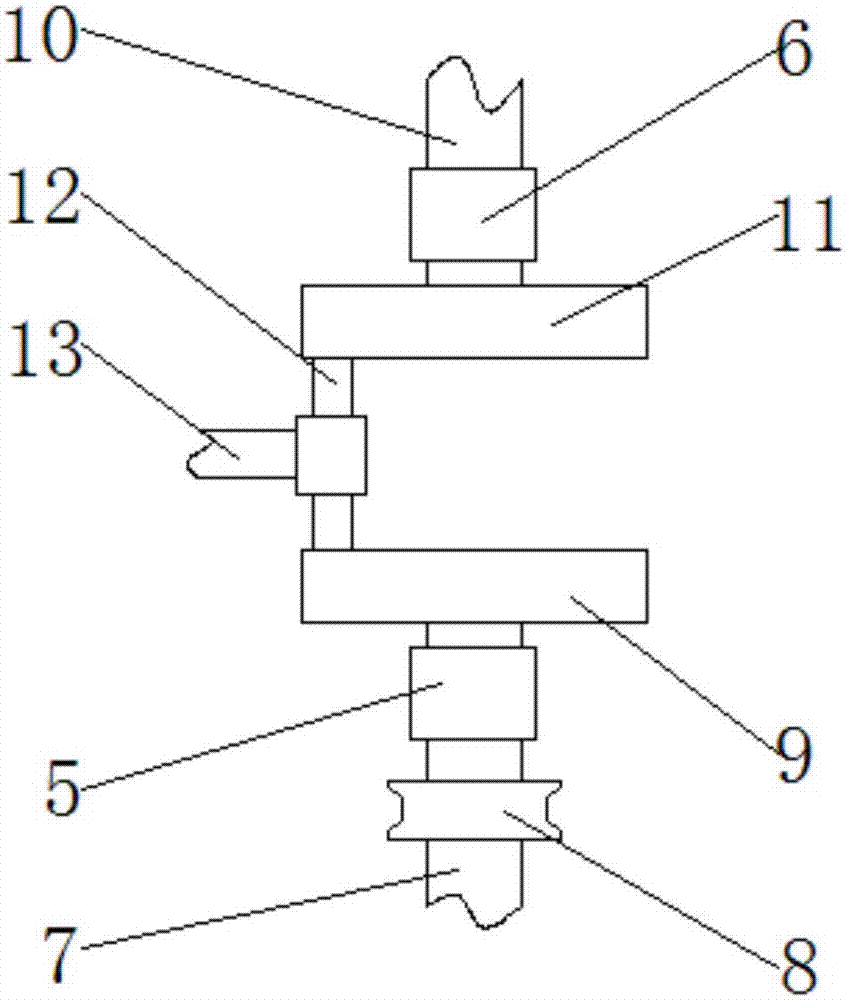

Multi-barrel washing machine capable of controlling number of washing barrels in operation

ActiveCN102080321APrevent rotationRealize the drying functionOther washing machinesTextiles and paperDrive shaftEngineering

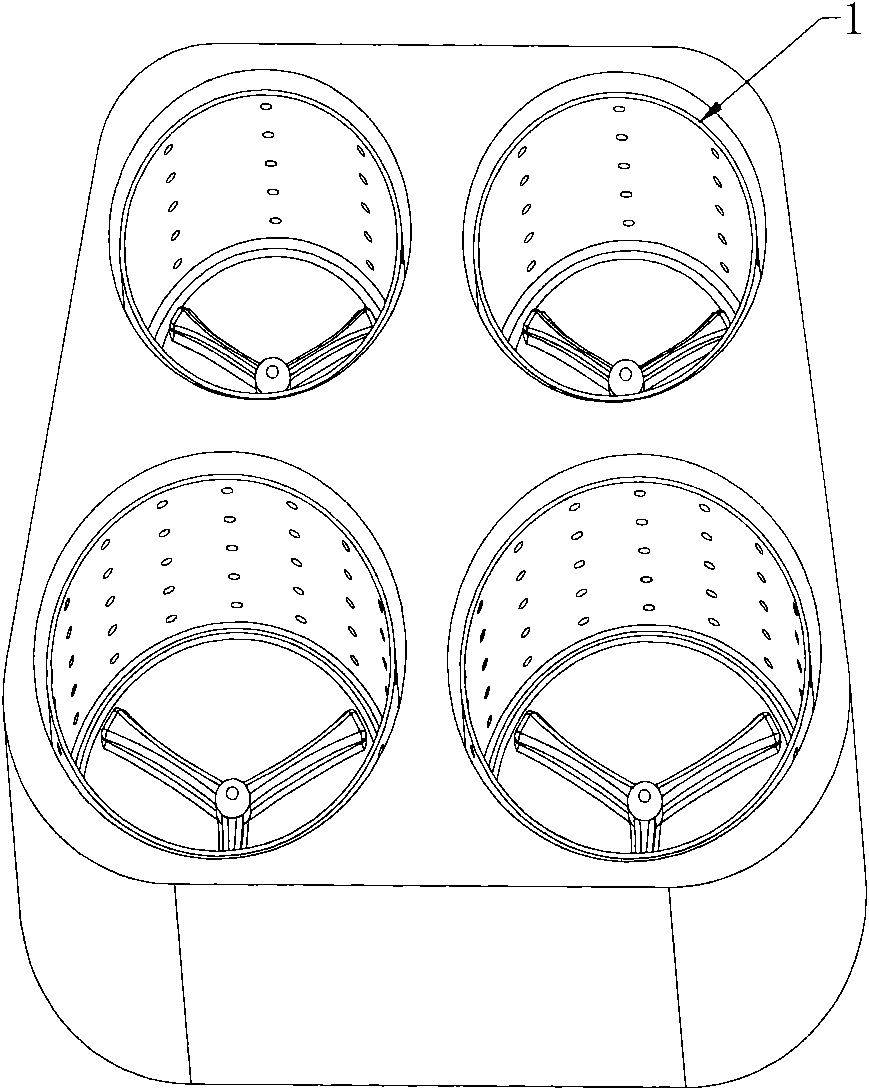

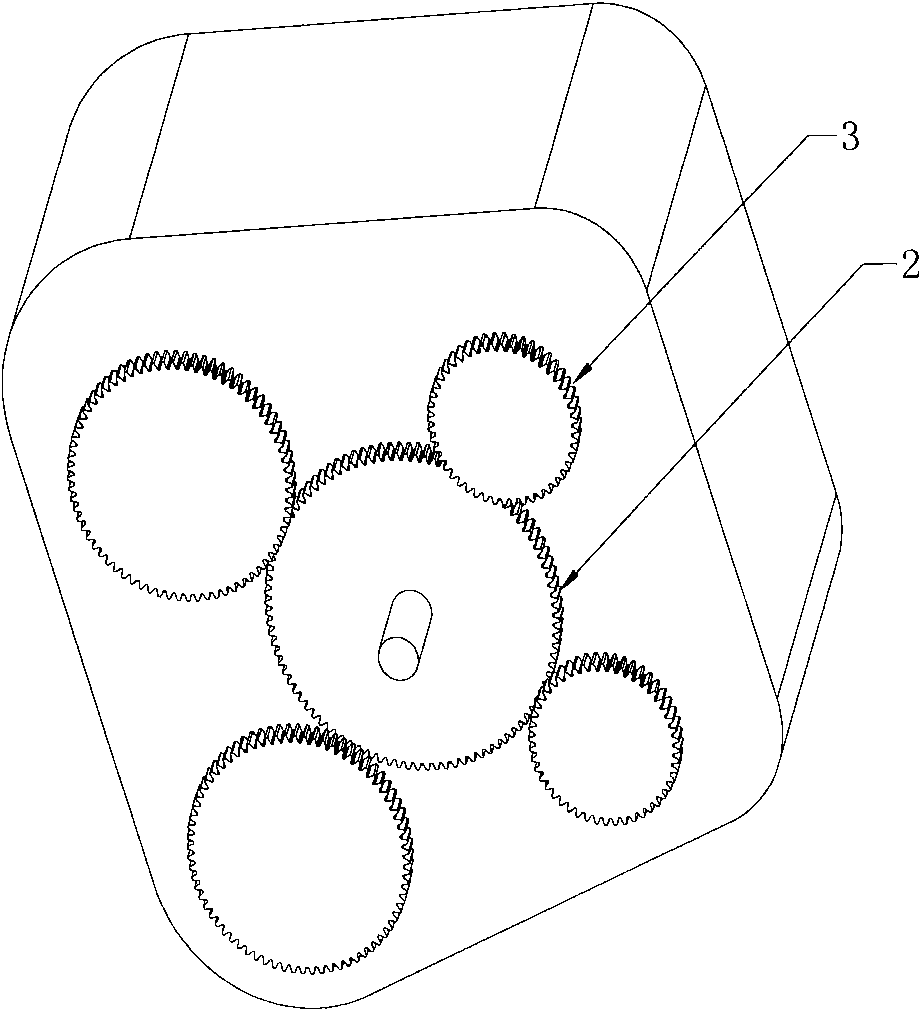

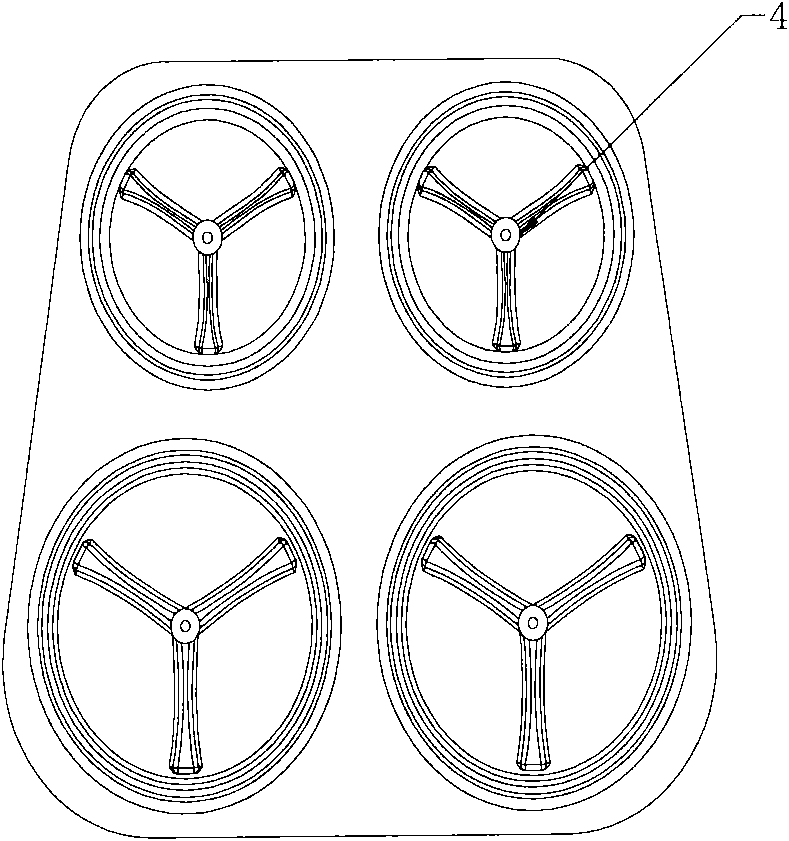

The invention relates to a multi-barrel washing machine capable of controlling the number of washing barrels in operation, belonging to the field of washing machines. The washing machine comprises a motor, a driving gear connected with the motor, multiple washing barrels and driven gears which are respectively connected with the driving shaft of each washing barrel, each driven gear is parallel to the driving gear and is not meshed with the driving gear when the washing barrels are not injected with water, the bottom of each washing barrel is provided with a buoyant chamber, each washing barrel can drive the driving shaft of each washing barrel to move up and down by virtue of buoyancy, and the motion stroke of the driving shaft of each washing barrel is defined by the fact that the driven gear is meshed with the driving gear. In the invention, one driving gear is utilized to drive a plurality of driven gears, the aim of driving multiple washing barrels to simultaneously operate by one motor is achieved, the buoyancy of water is utilized to control each washing barrel to operate or not, and the problems of various cross infections, dyeing and abrasion among clothes are avoided. The locking relation between a baffle collar and an elastic hasp which are arranged on the driving shaft of each washing barrel as well as a locking ring is utilized to realize the drying function of each washing barrel.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE

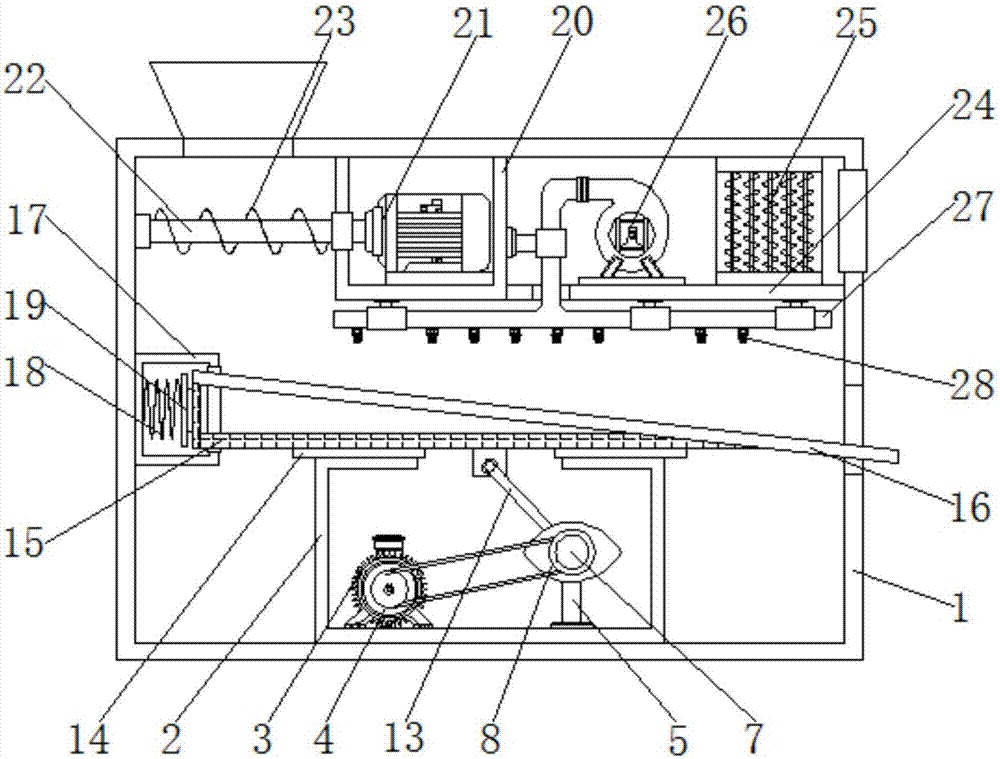

Multilevel energy-saving drying spiral sieve

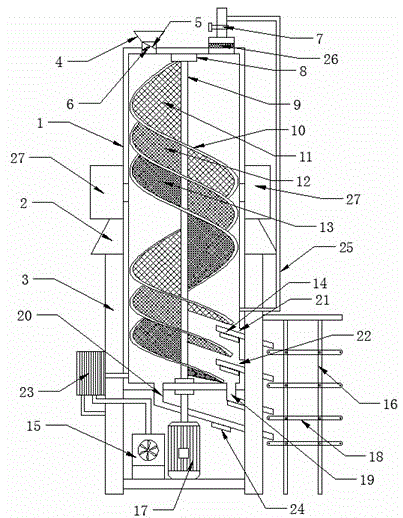

The invention discloses a multilevel energy-saving drying spiral sieve. The multilevel energy-saving drying spiral sieve comprises a sealed barrel, a foundation column, an adjusting-controlling motor, a support and an air blower. A lug seat on the outer wall of the sealed barrel is installed on the foundation column. A microwave generator and an electric heater are installed on the outer wall of the sealed barrel. A rotary shaft connected with the adjusting-controlling motor is arranged between shaft seats in the sealed barrel. A feed hopper with a baffle, and an air outlet pipe with a filter screen are installed at the top end of the sealed barrel. A check valve on the air outlet pipe is connected in the middle of the side wall of the sealed barrel through a heat recovery pipe. A spiral sieve body is arranged between each of three layers of spiral frames and the rotary shaft. The side wall and the bottom end of the sealed barrel are provided with discharge plates and discharge pipes correspondingly, and the discharge plates and the discharge pipes are each provided with a vibrator. Four layers of conveyer belts are installed on the part, close to the foundation column, of the support. The air blower is communicated with the electric heater and the sealed barrel through pipelines. The multilevel energy-saving drying spiral sieve is simple in structure, reasonable in design, good in sealing effect, capable of screening out materials with different grain sizes and meeting the need of actual production, good in screening effect, high in work efficiency and good in energy-saving effect and has a drying function.

Owner:GUIZHOU JIQIAN NETWORK CO LTD

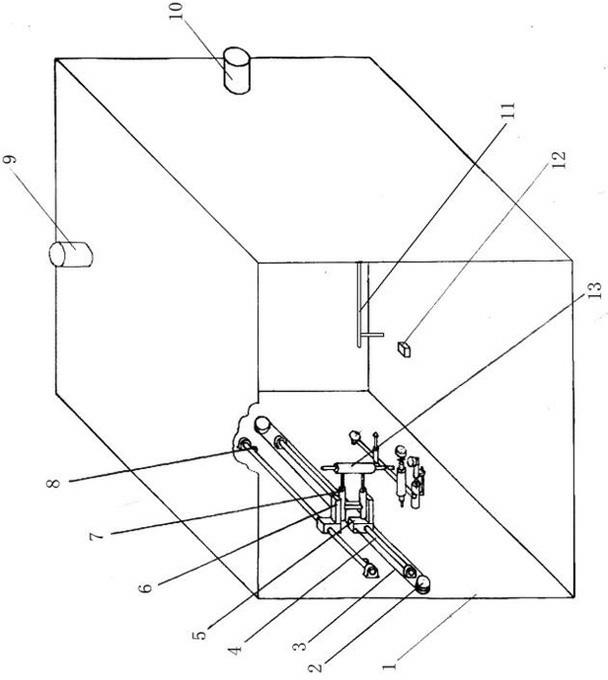

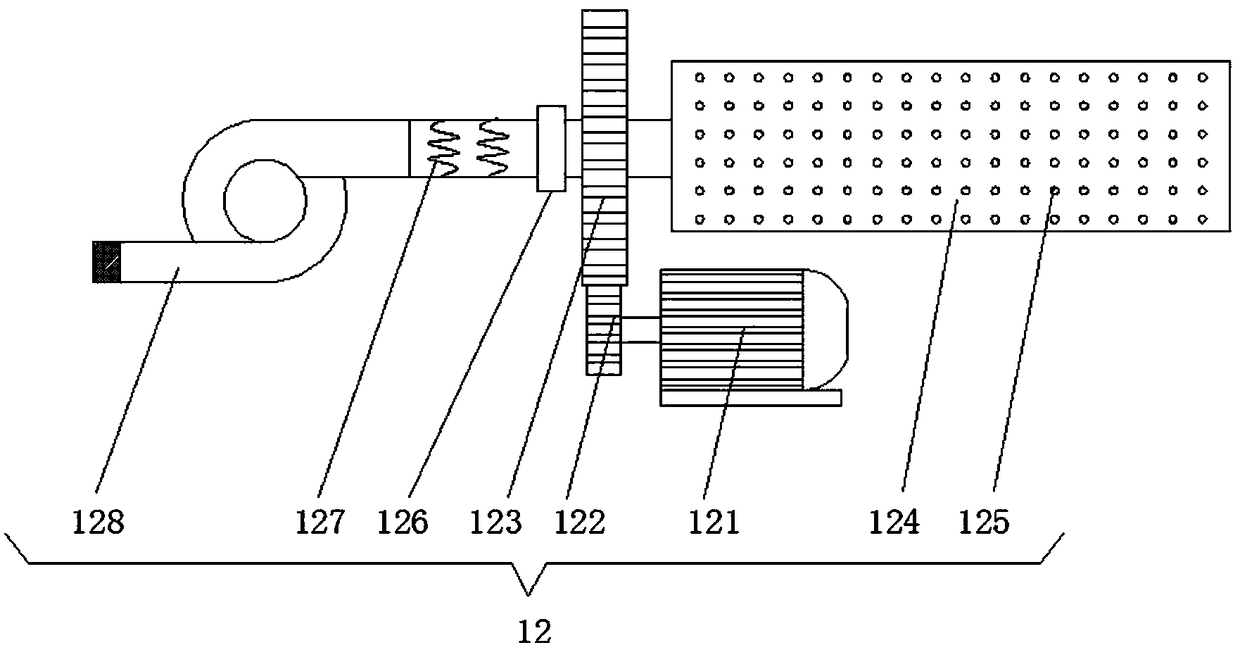

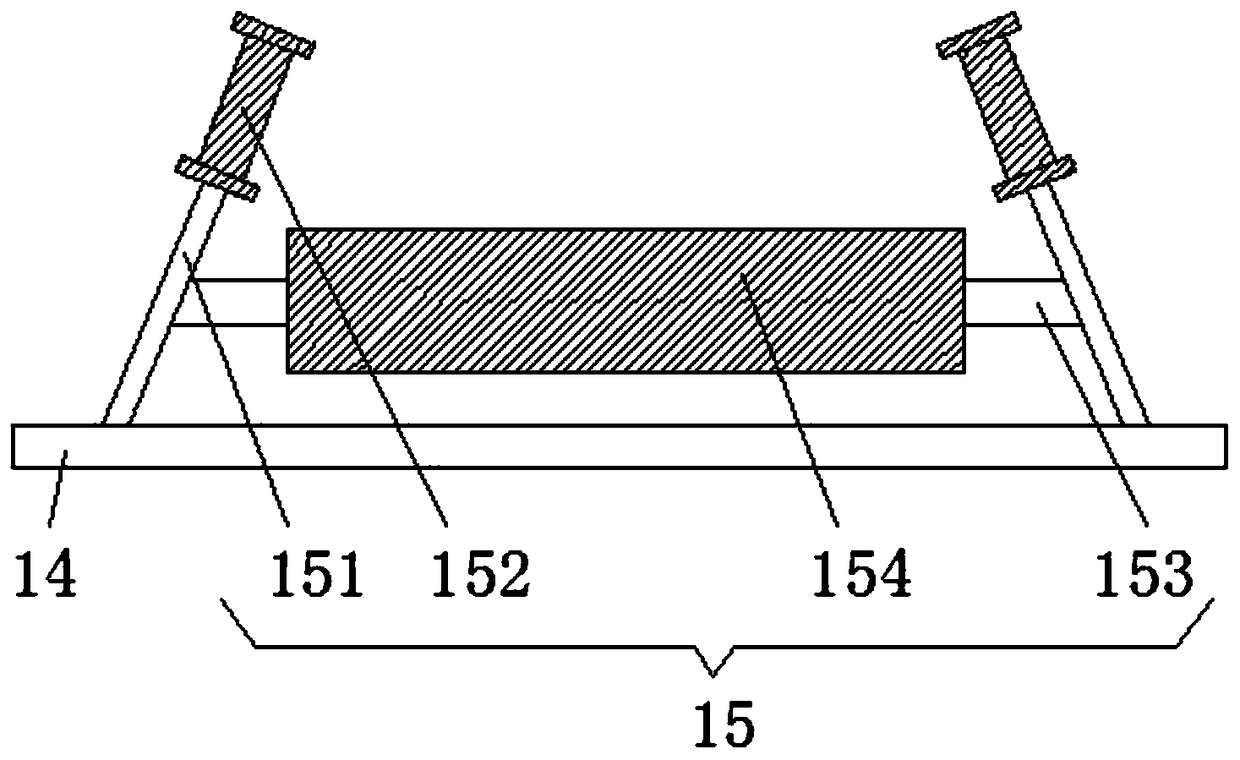

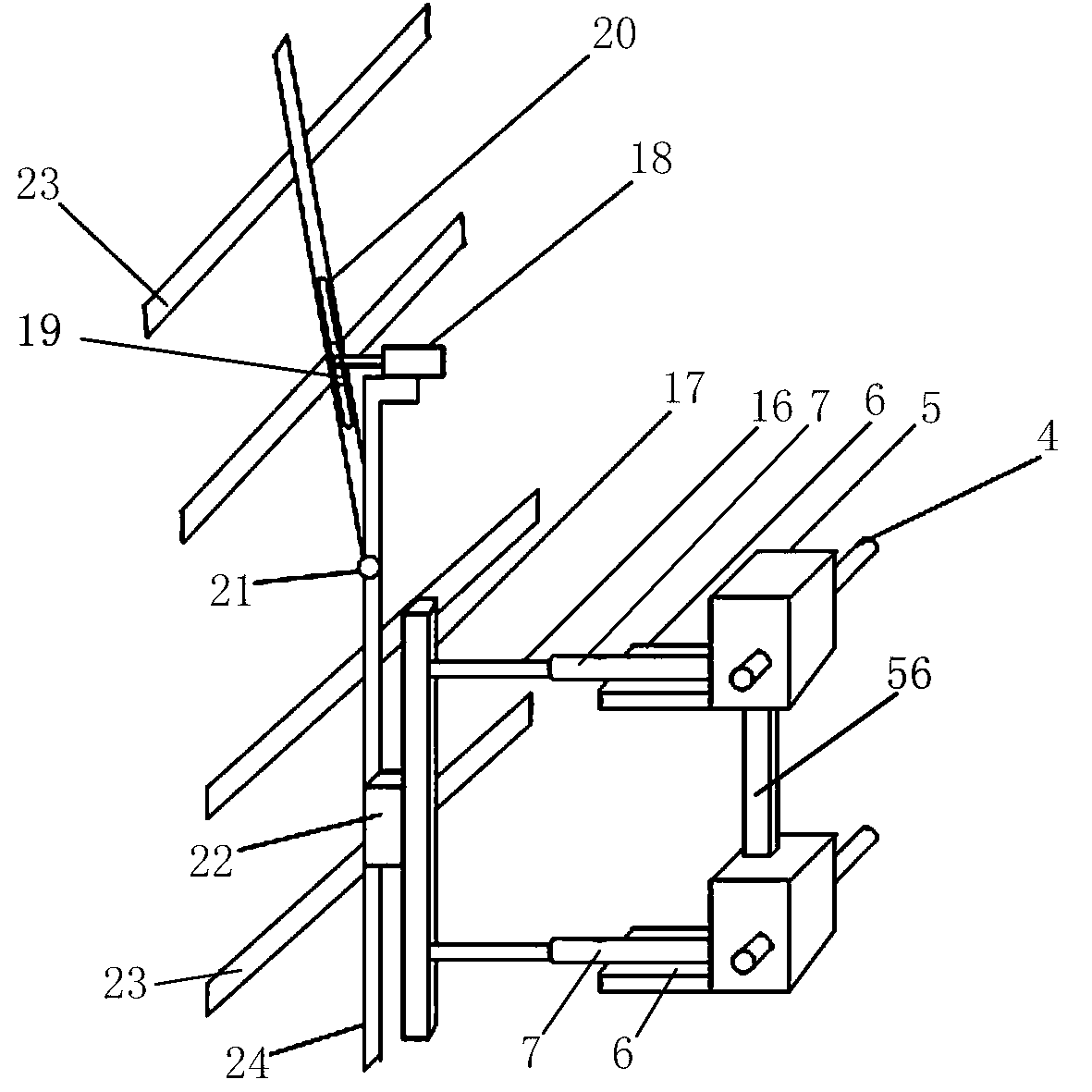

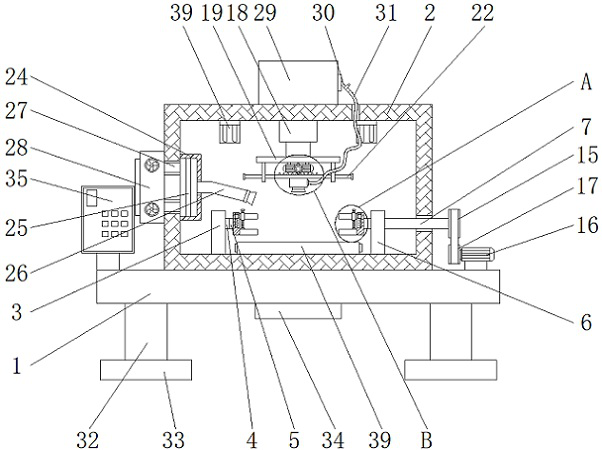

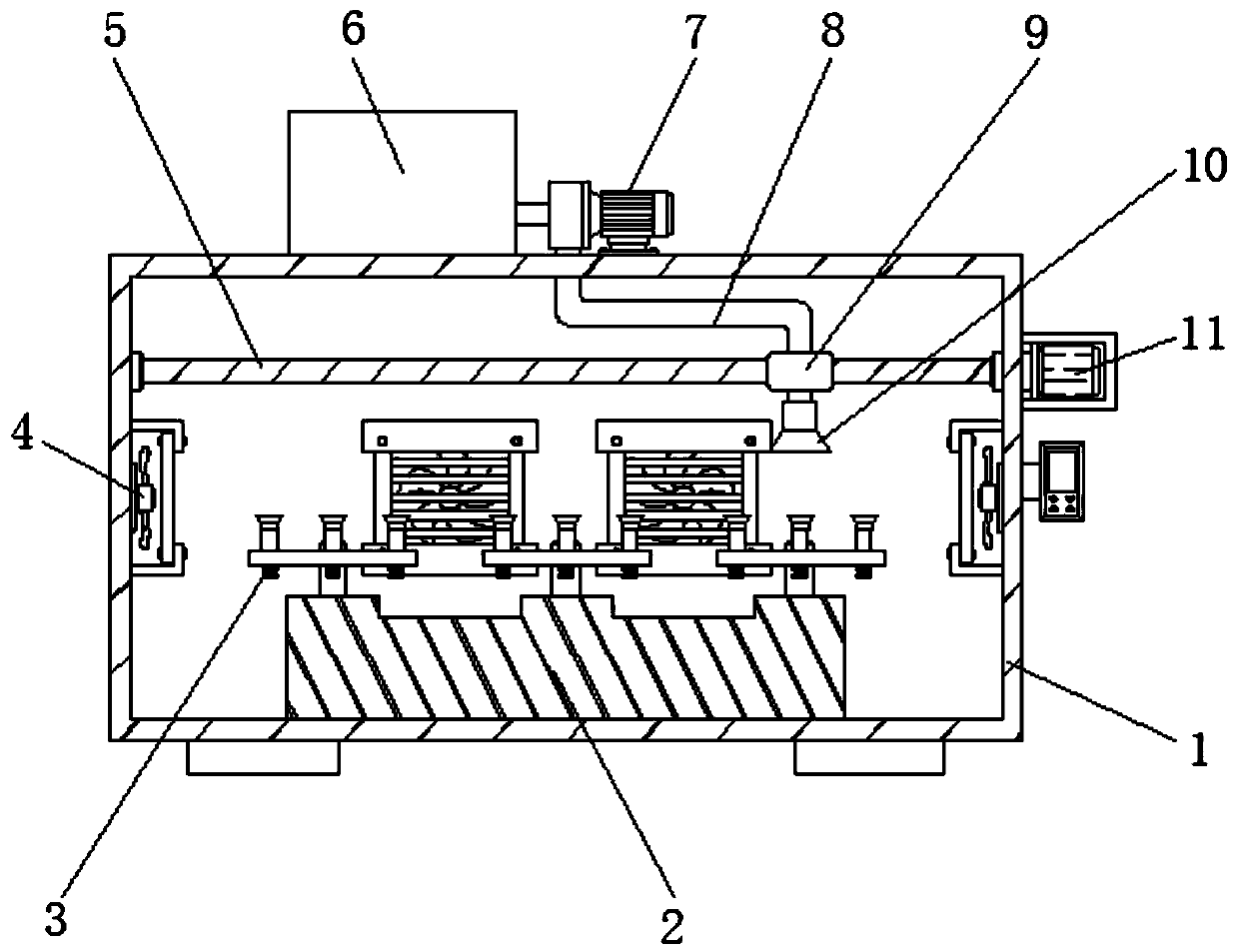

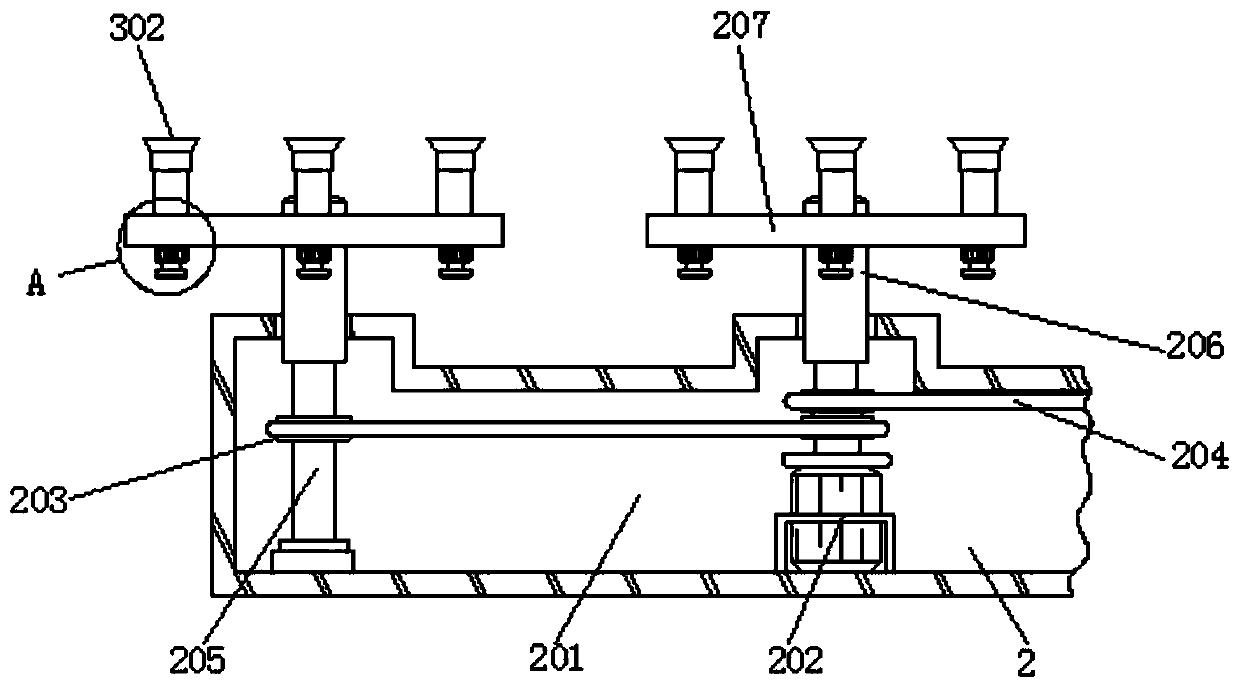

Intelligent fully automatic automobile washing machine

InactiveCN102616214AStrong targetingImprove scrubbing effectCleaning apparatus for vehicle exteriorsProcess optimizationMeasuring instrument

The invention relates to an intelligent fully automatic automobile washing machine, which comprises a PLC (Programmable Logic Controller), a stand, a right washing mechanism, a left washing mechanism, a top washing mechanism and a series starting switch set controlled by a front wheel, wherein the right washing mechanism comprises an X axis traveling mechanism, a Y axis telescopic translation mechanism, a Z axis translation mechanism and a washing unit; the left washing mechanism is structured the same as the right washing mechanism; the left washing mechanism and the right washing mechanism are symmetrically arranged on the middle part of the inner side of the left side wall of the stand; the washing unit comprises a horizontal supporting rod parallel to the plane of the automobile body, a water nozzle, a distance measuring instrument, a washing liquid scrubber and a wiping device; and the water nozzle, the distance measuring instrument, the washing liquid scrubber and the wiping device are orderly fixed to the horizontal supporting rod. According to the intelligent fully automatic automobile washing machine, an automobile washing route can be automatically calculated based on the overall dimensions of different automobiles, so that the specified operations such as automatic water spraying, washing and wiping can be automatically carried out; and human-simulating automobile washing flow and operation can be completely realized. The intelligent fully automatic automobile washing machine has the advantages of optimal washing flow, quick washing and good washing effect; and the automobile body is not damaged.

Owner:王晓晖

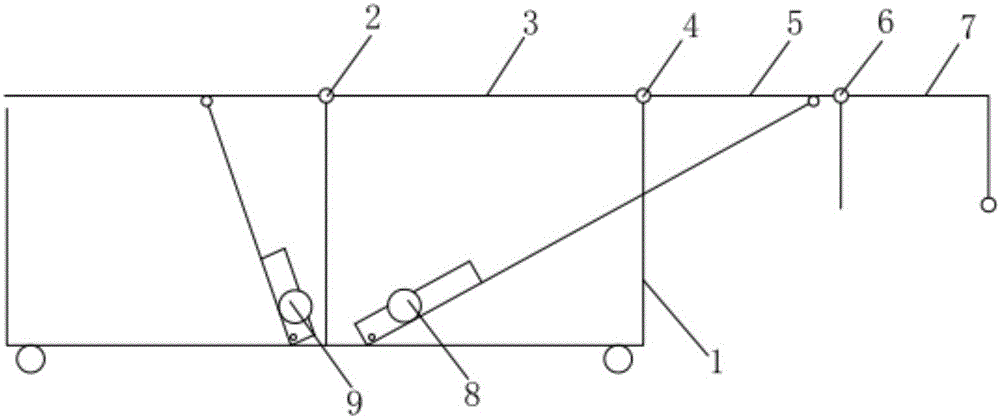

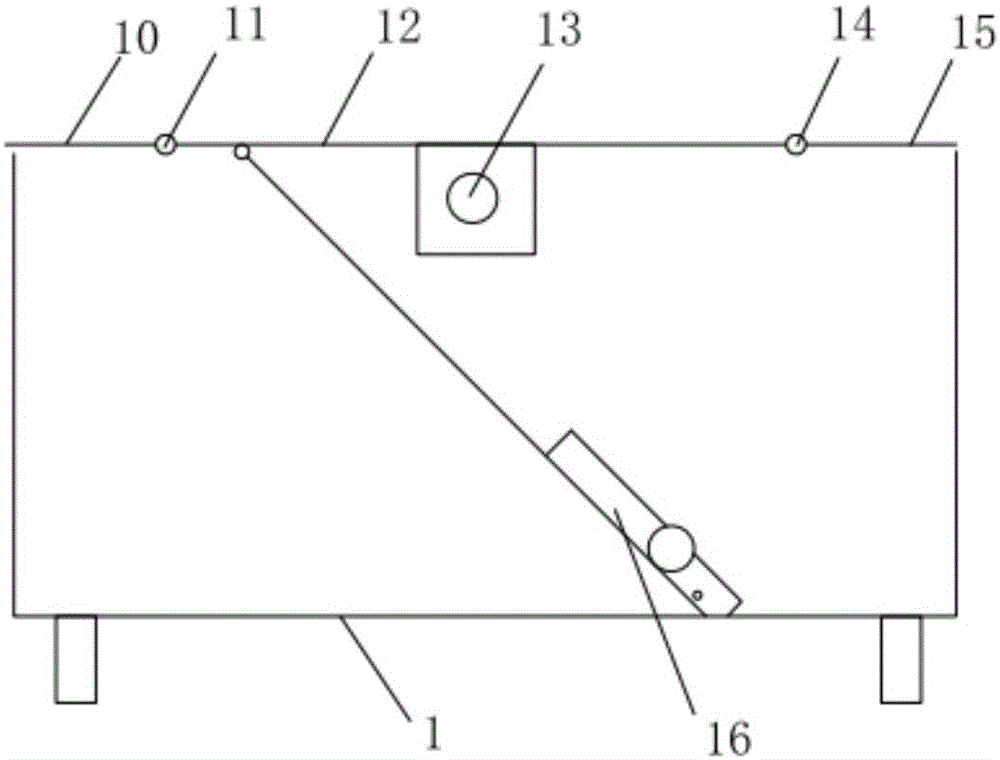

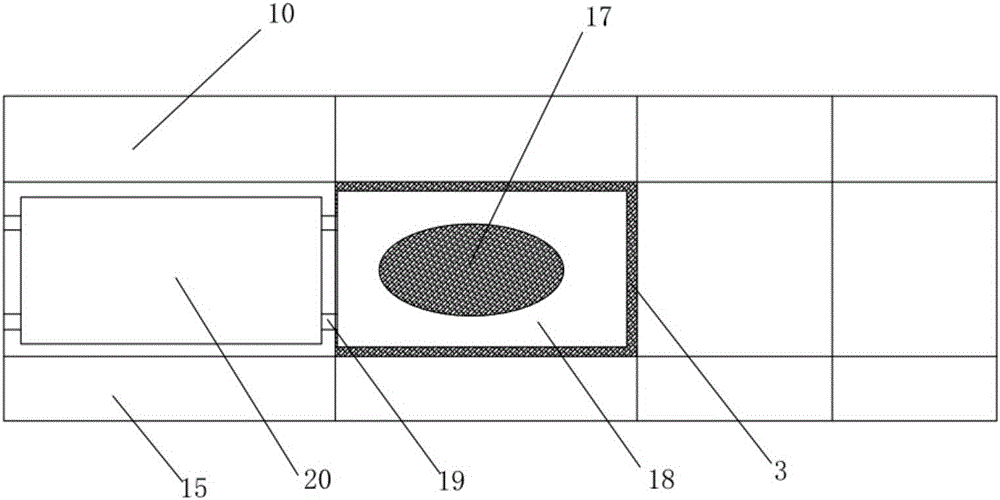

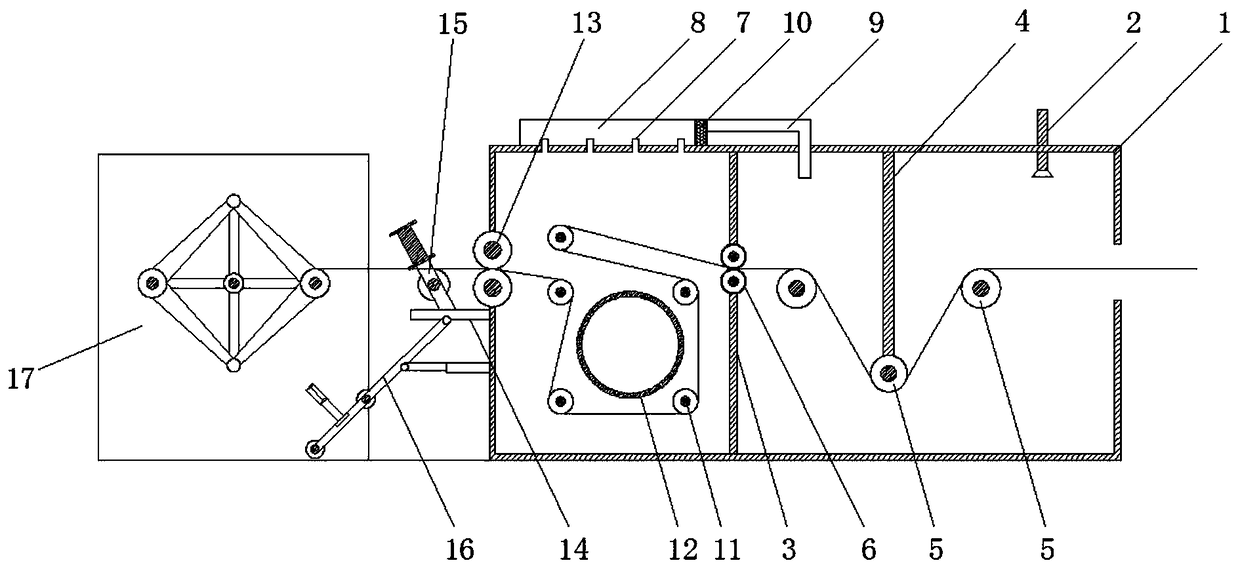

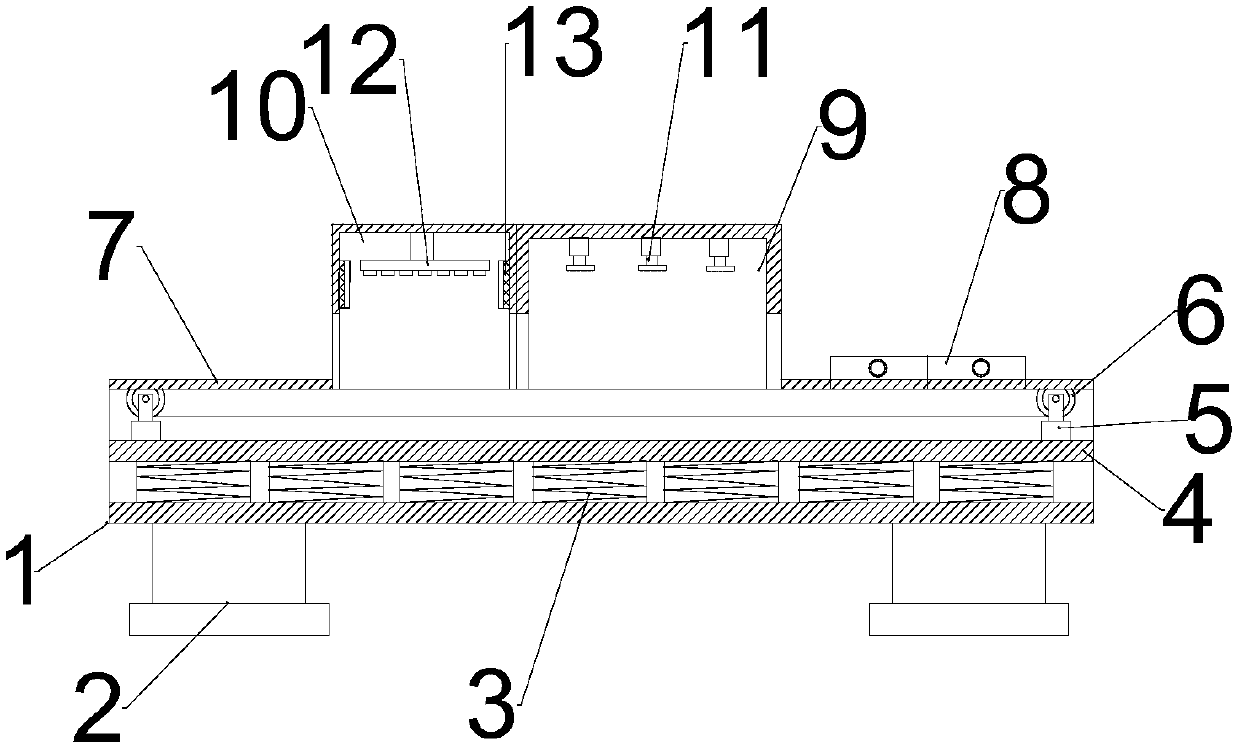

Sign cutting and grinding all-in-one machine capable of conducting cutting and edge grinding simultaneously

InactiveCN106736956AEasy to useImprove grinding efficiencyEdge grinding machinesGrinding feed controlMechanical engineeringWater spray

The invention discloses a sign cutting and grinding all-in-one machine capable of conducting cutting and edge grinding simultaneously. The sign cutting and grinding all-in-one machine comprises a conveying device, a cutting device located on the conveying device, and signs. Two sliding ways are arranged on the conveying device, and grinding devices are arranged at the two ends of the sliding ways; and the grinding devices are used for grinding the edges of the cut signs, and a rotating table body is arranged between the two sliding ways. According to the sign cutting and grinding all-in-one machine, cutting and grinding are integrated, using is more convenient, and the grinding efficiency is higher; the machine is suitable for the signs of different sizes, and the practicability is high; and water spraying and drying functions are achieved, and the quality of the obtained signs is better.

Owner:重庆景登科技有限公司

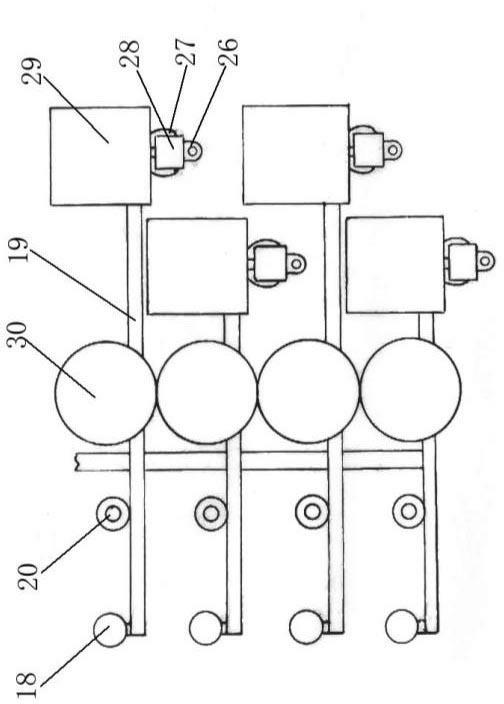

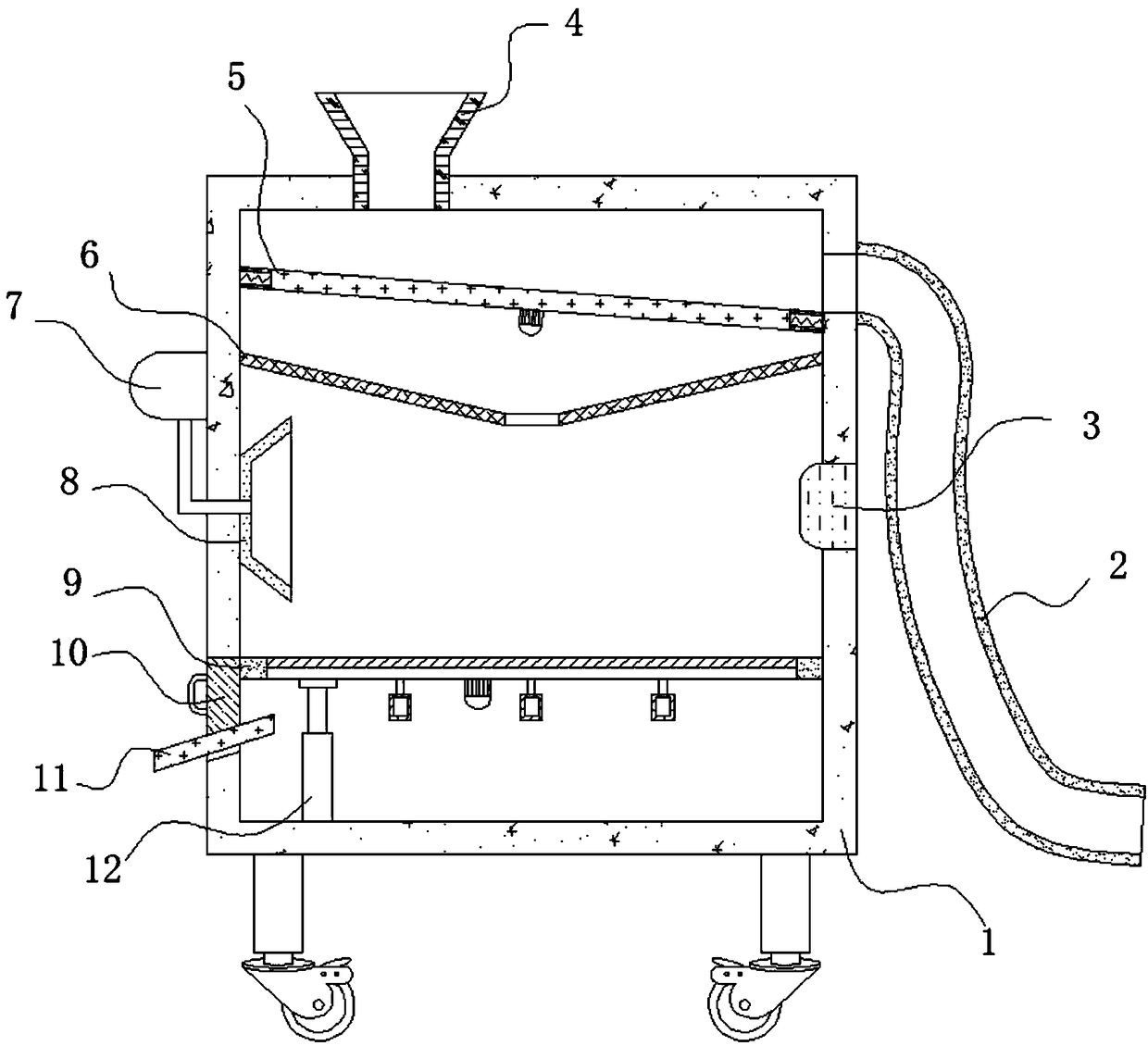

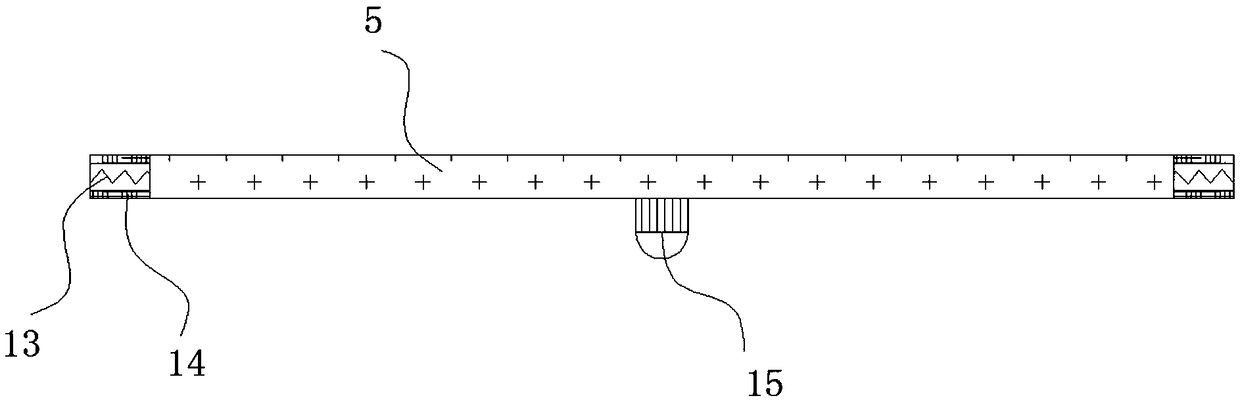

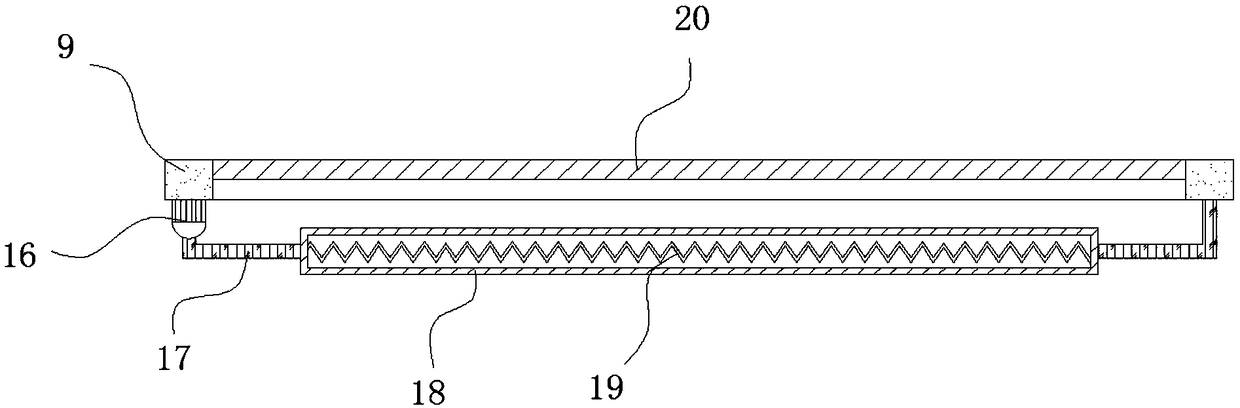

Rice screening device for removing impurities used in agricultural planting

InactiveCN109046980AClean up thoroughlyEasy to operateSievingGas current separationEngineeringImpurity

The invention discloses a rice screening device for removing impurities used in agricultural planting. The rice screening device comprises a box body. A feeding funnel is inserted into one side of theouter wall of the top of the box body. A discharge pipe is arranged at the top of one side of the box body. Connecting sleeves are arranged on the top of the inner wall of both sides of the box body.And the same first sieve plate is arranged on one side of the two connecting sleeves away from the box body. Connecting springs distributed in equidistant are arranged on the intermediate position ofboth sides of the first sieve plate. A first vibration motor is arranged on the intermediate position of the bottom of the first sieve plate. A transition funnel is arranged on the top of the inner wall of the box body, and the transition funnel is located on the bottom of the first sieve plate. A through hole is formed in the intermediate position of the inner wall of one side of the box, and ablower is arranged on the inner wall of the through hole. The rice screening device for removing impurities used in agricultural planting can conveniently screen out large particles and small particles of the rice and light-weight impurities, completely remove the impurities, is convenient and easy to operate, is convenient for discharging rice after the screening, and has a drying function.

Owner:郴州八方农林科技有限公司

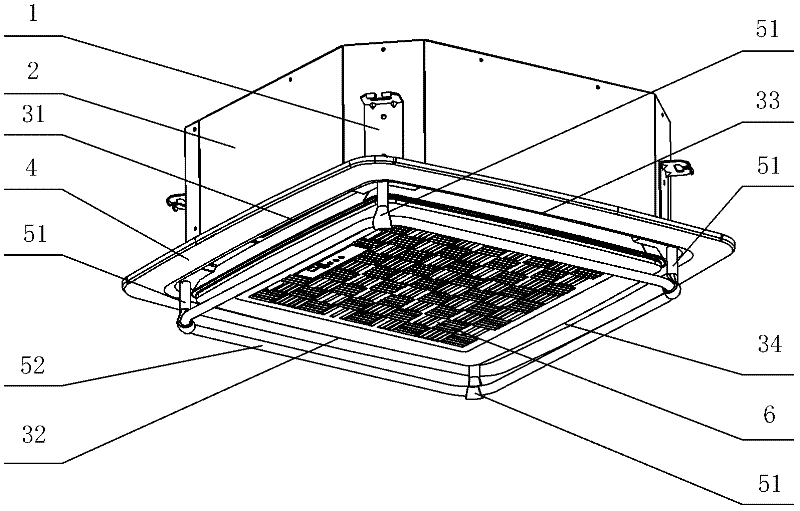

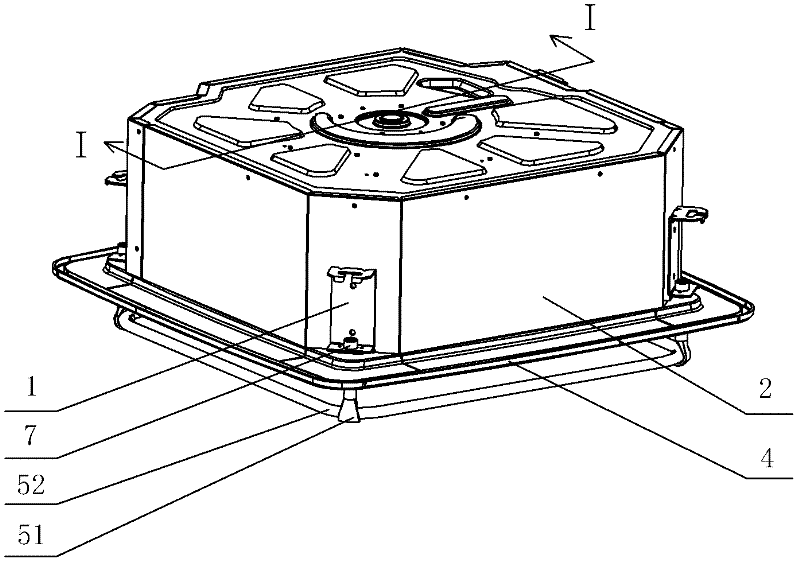

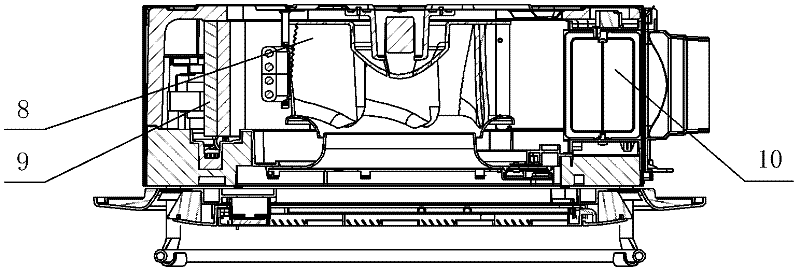

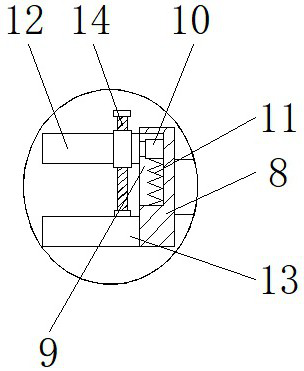

Ceiling embedded air conditioner

InactiveCN102519092AEasy to hangIncrease profitLighting and heating apparatusSpace heating and ventilation detailsScrew threadElectrical and Electronics engineering

The invention relates to a ceiling embedded air conditioner which comprises a housing, a wind wheel, an evaporator, an air interchanger and a panel, wherein the wind wheel, the evaporator and the air interchanger are arranged in the housing; the panel is arranged on the housing; the periphery of the panel is provided with air outlets; an air inlet grille is arranged in the middle of the panel; a clothing hanging device is arranged on the housing; the clothing hanging device is close to the air outlets; the clothing hanging device comprises cloth rods and hooks; one ends of the hooks are connected with the cloth rods; the other ends of the hooks pass through the panel to be connected with the housing; through holes are arranged on the panel; lifting lugs are arranged on the housing; the other ends of the hooks pass through the through holes to be connected with the lifting lugs; the other sides of the hooks are provided with external screw threads; the other ends of the hooks pass through the through holes on the panel to be in threaded connection with nuts arranged on the lifting lugs; or, the other ends of the hooks are provided with protruding buckling hooks. The ceiling embedded air conditioner has simple and reasonable structure, is flexible to operate, has low manufacturing cost, is energy-saving and the characteristics of clothes drying function and wide application range.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD

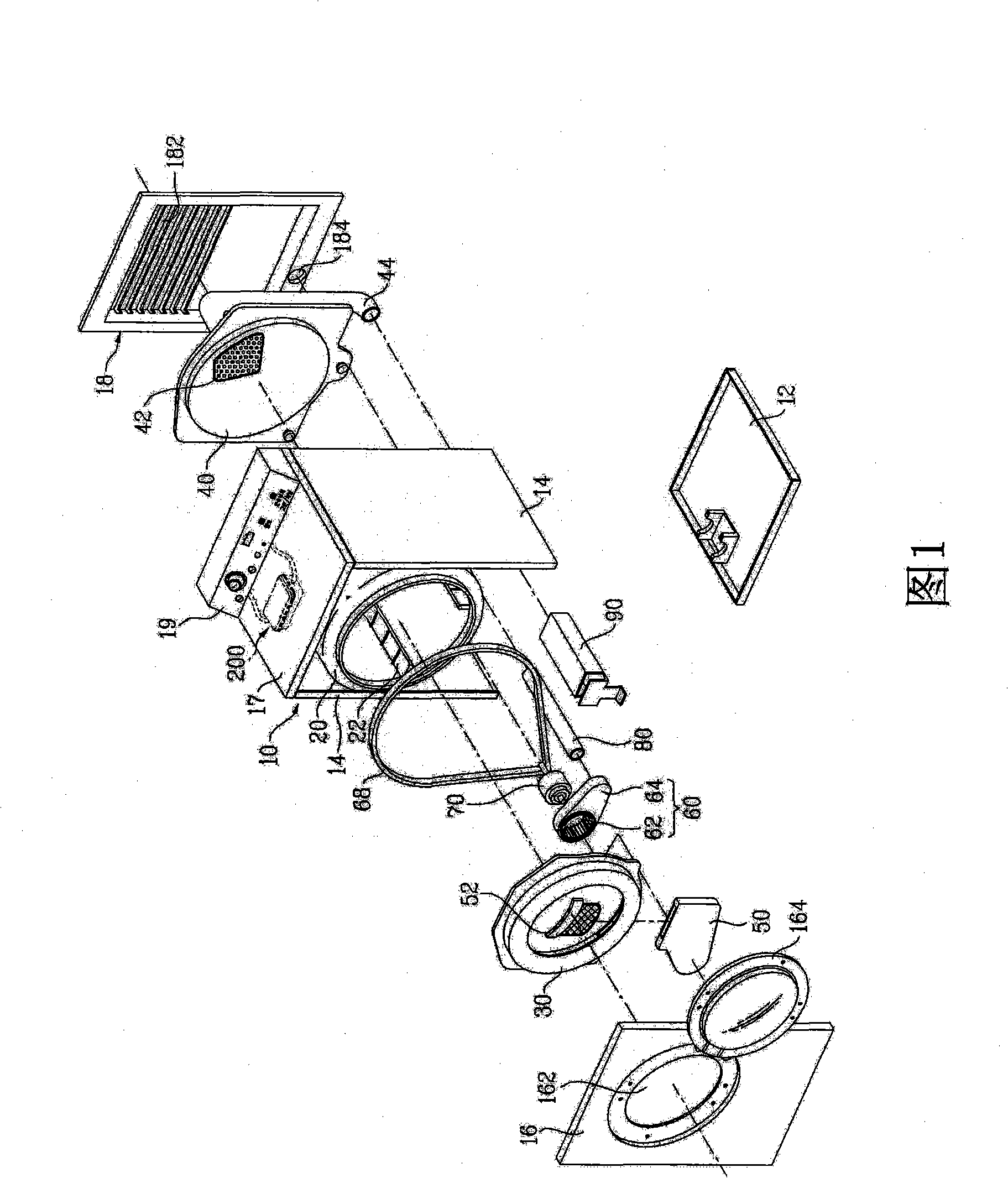

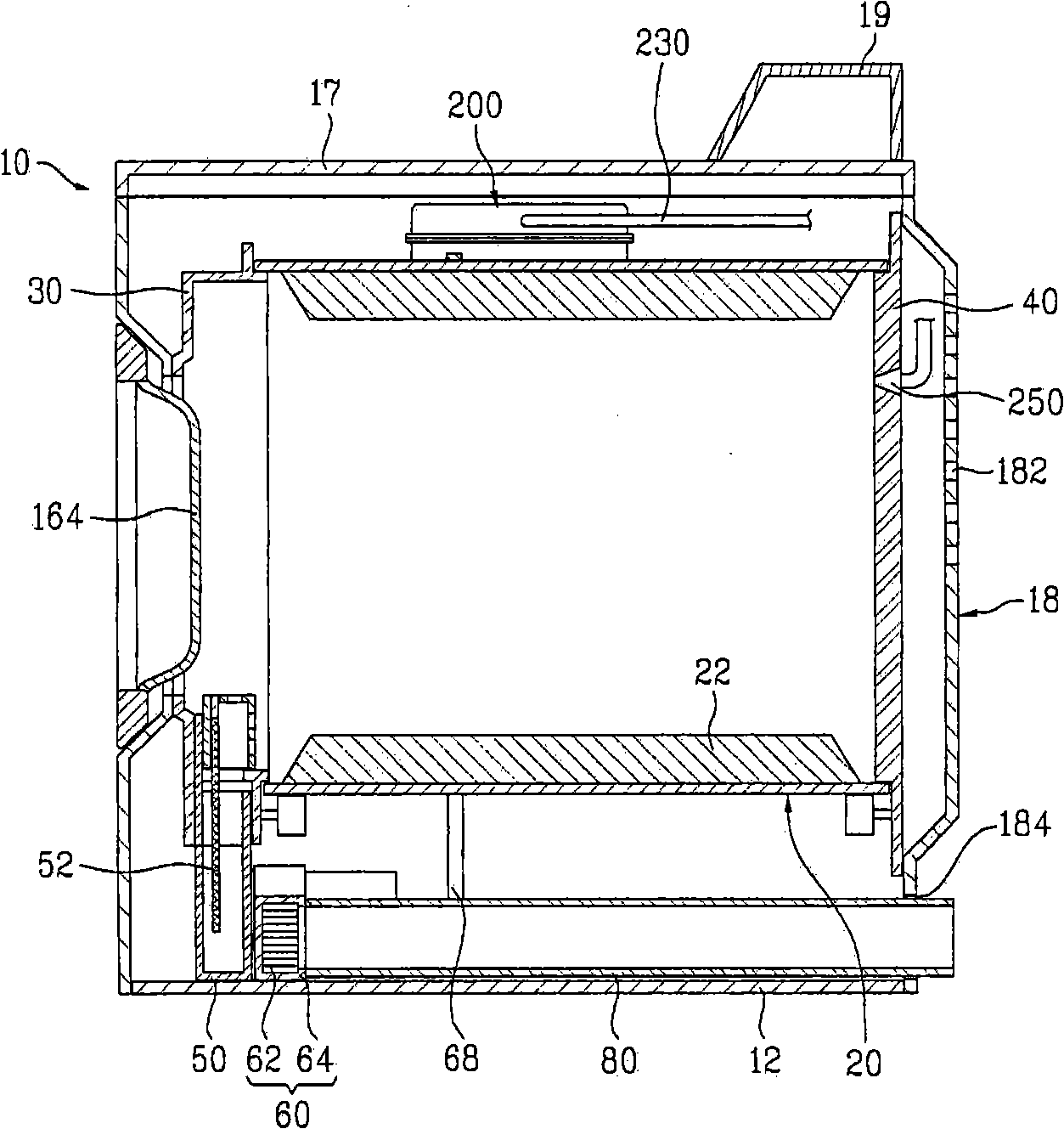

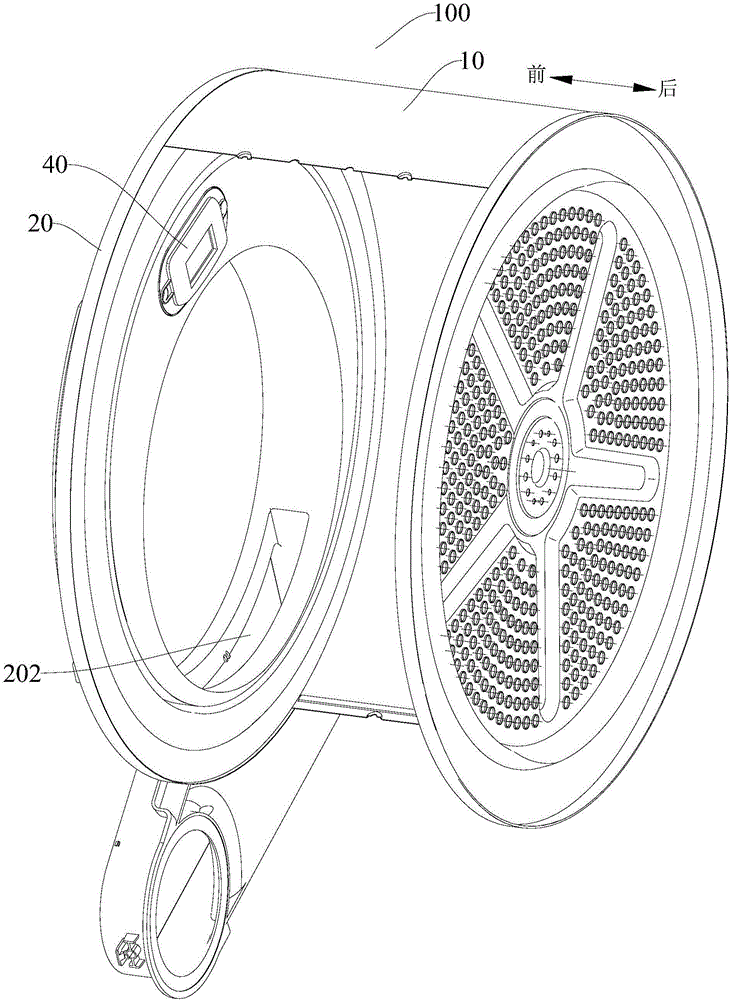

Dryer

ActiveCN101319458AWith drying functionAdditional features with ease of useOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

A laundry machine, in particular, a dryer using steam, is disclosed. The dryer includes an object container for containing an object, a control panel provided as a user interface, and a controller. In the dryer, the control panel comprises a course selector for enabling a user to select one of a steam-enable course, in which a steam cycle for supply steam to the object container is enabled, a steam course, in which the steam cycle is provided, and a steam-off course, from which the steam cycle is excluded, as operation courses. The controller controls an operation of the dryer to execute the selected operation course.

Owner:LG ELECTRONICS INC

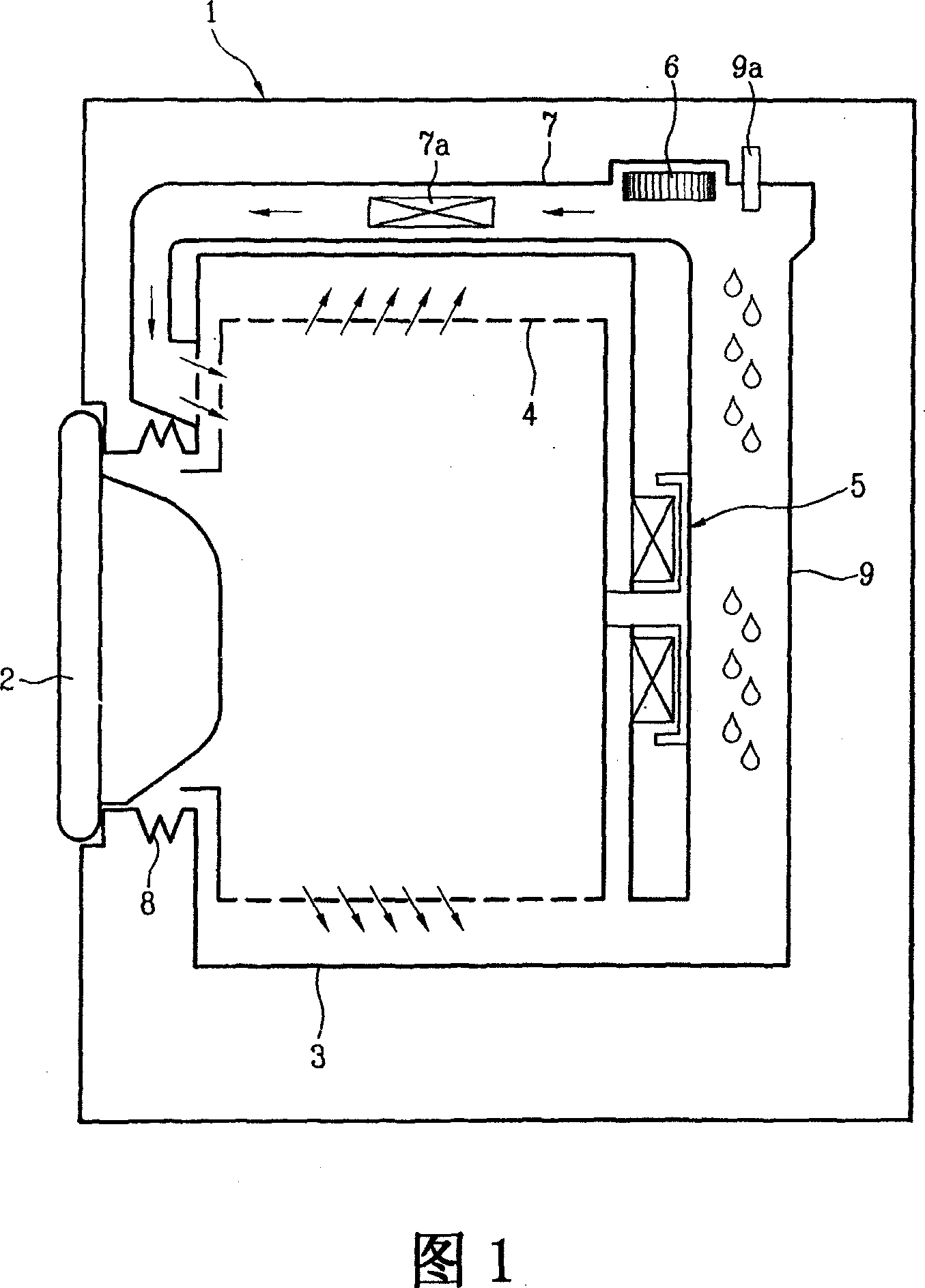

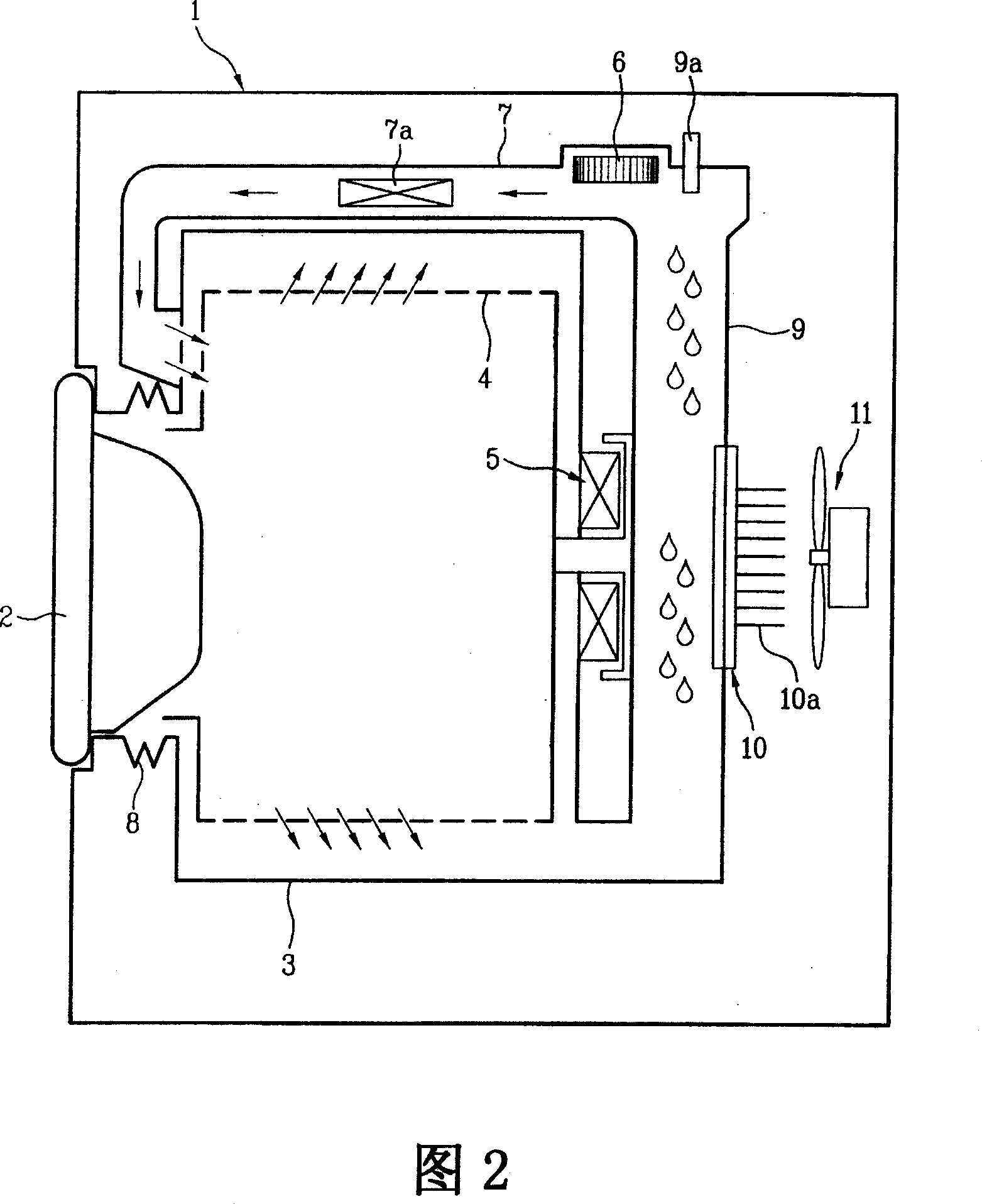

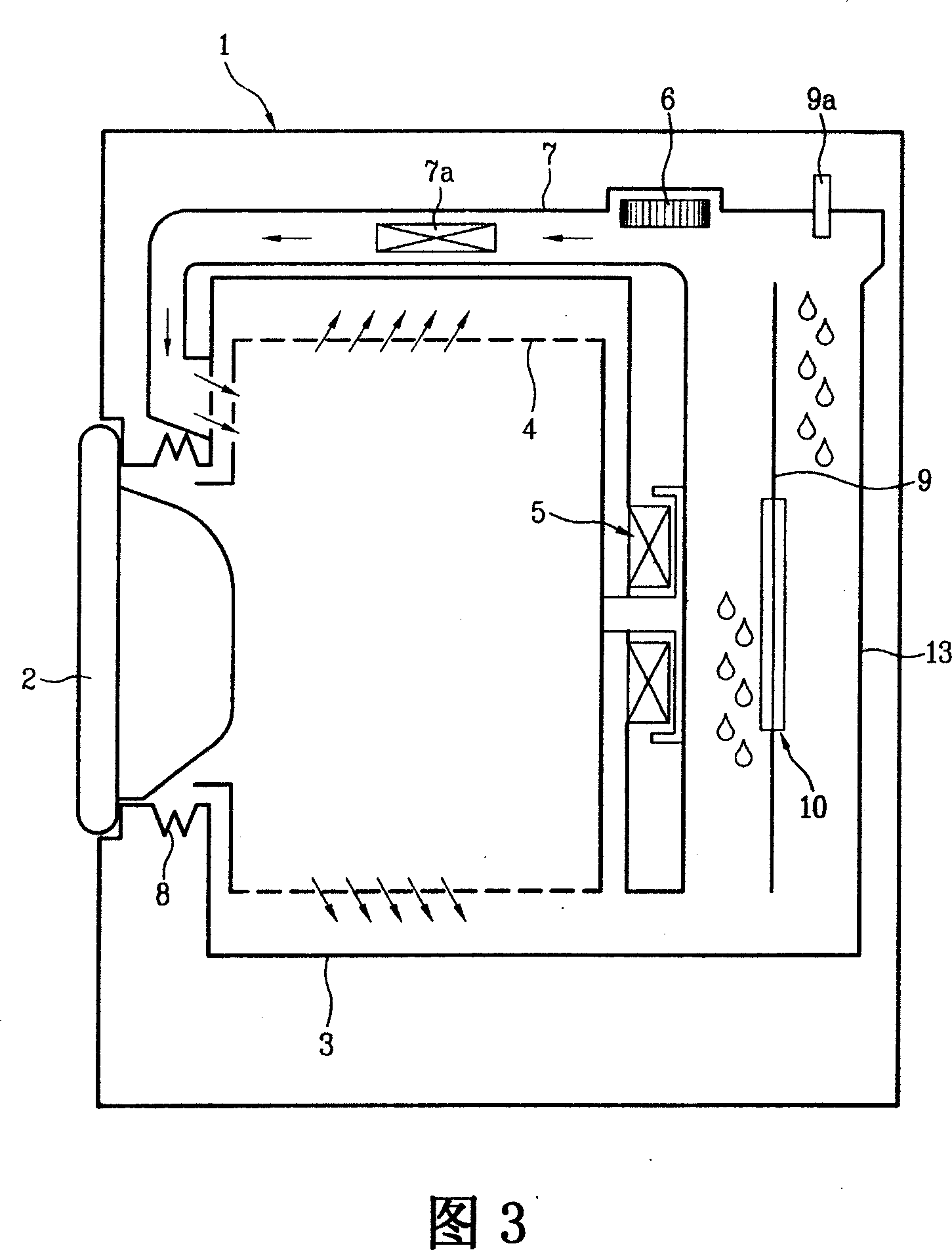

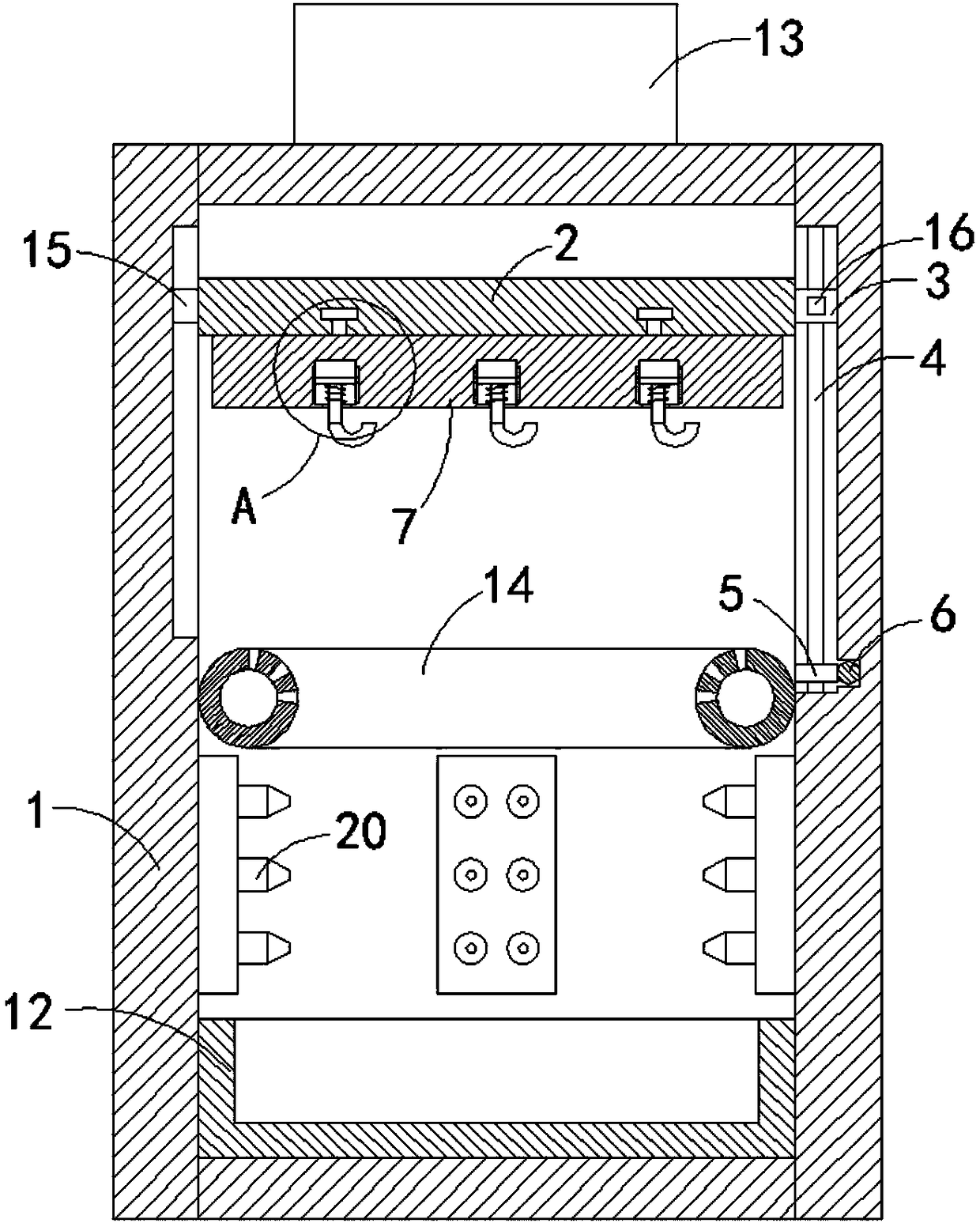

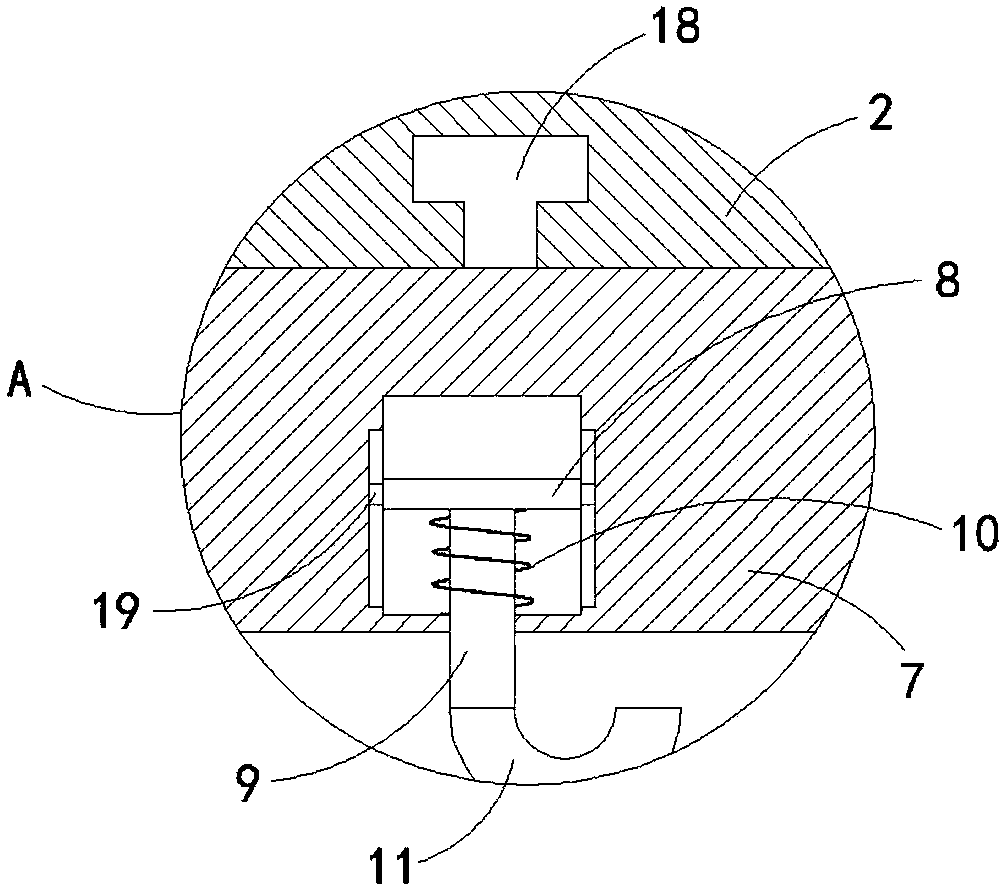

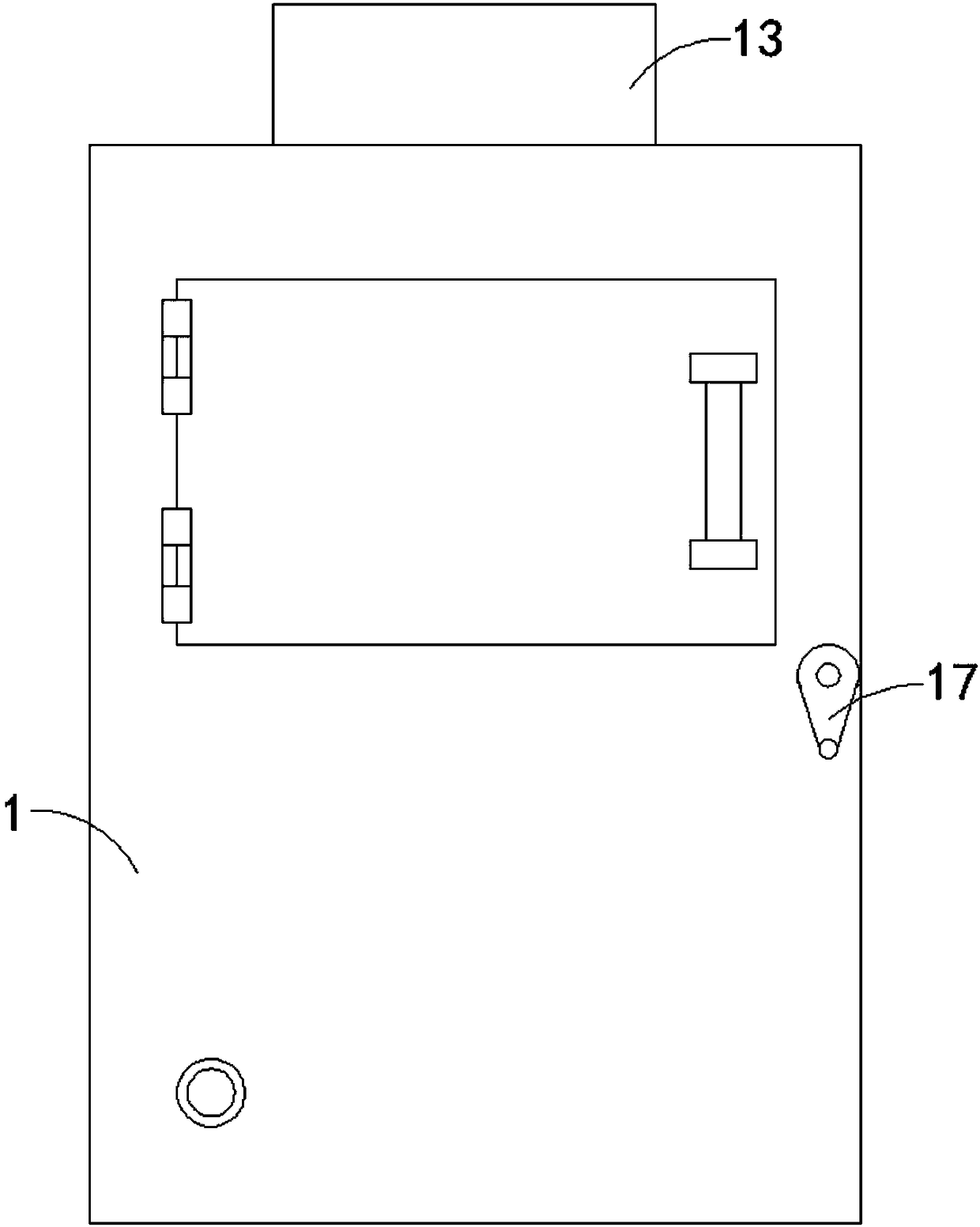

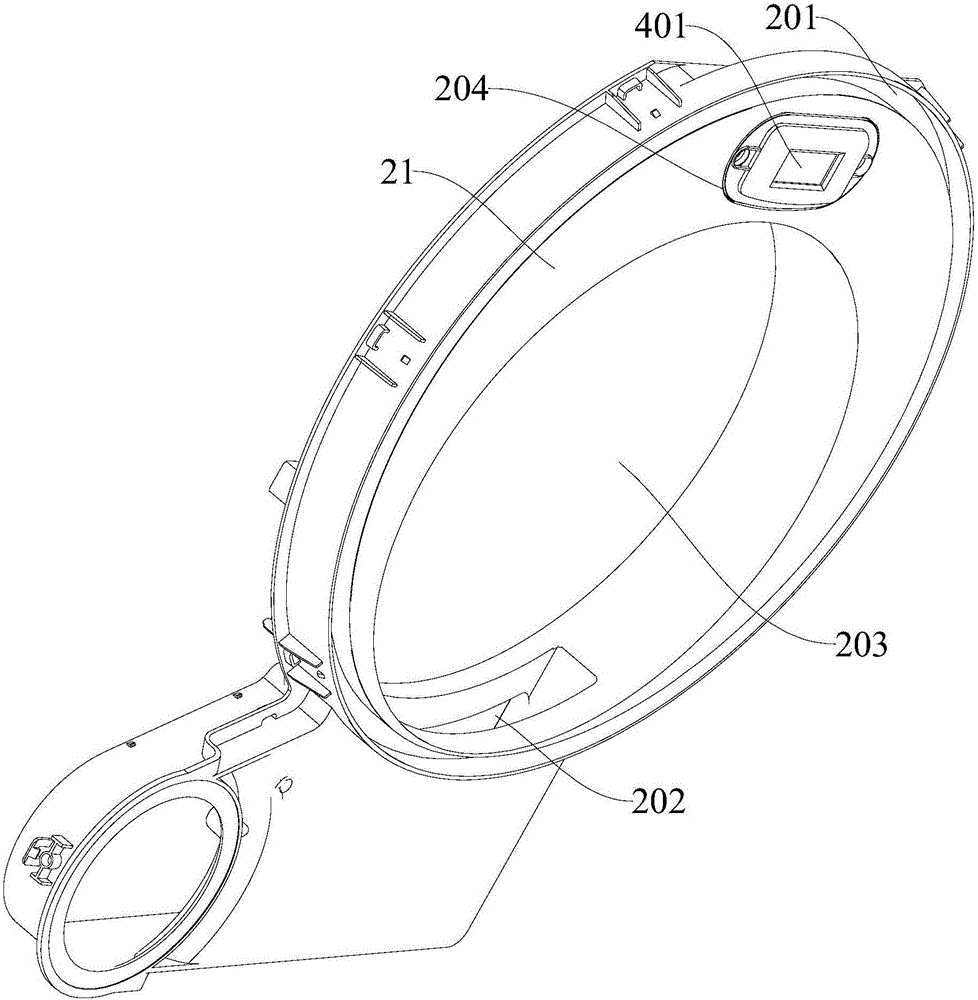

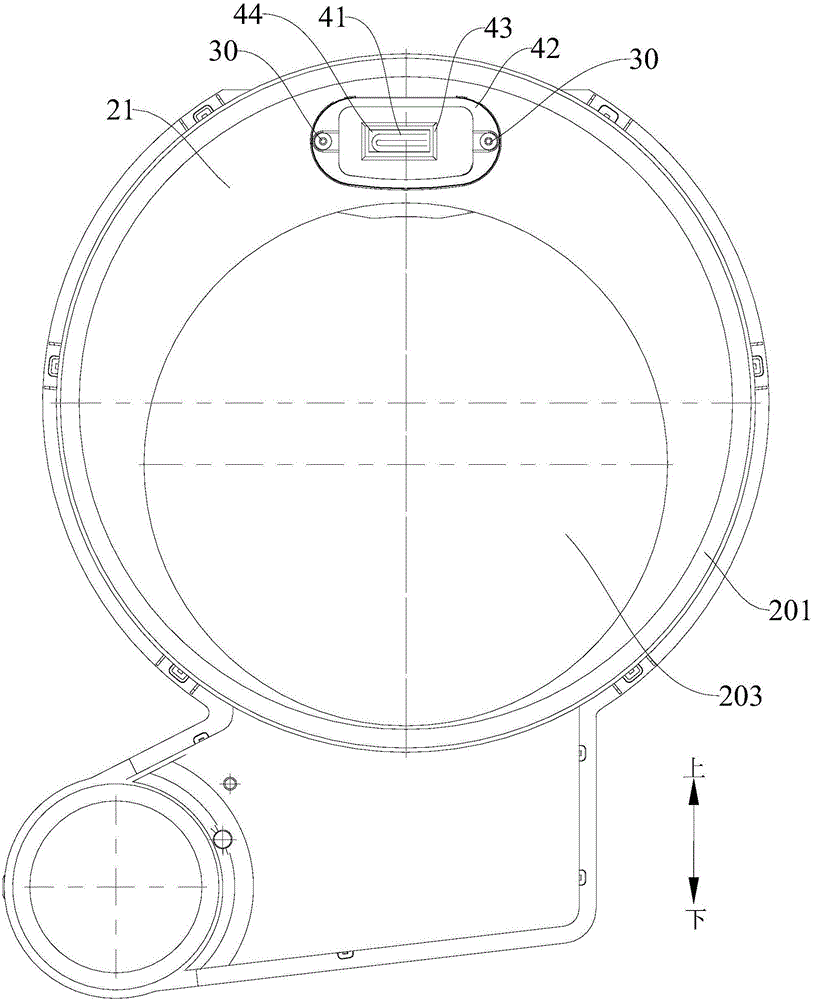

Drum washing machine with drying function

InactiveCN101086112AImprove drying efficiencyImprove energy efficiencyWashing machine with receptaclesTextiles and paperLow noiseElectricity

The invention discloses a drum washing machine with drying function, it includes the components as followings: barrel used for launching drying materials; thermo-electricity modular condenser used for condensing the air discharged from said barrel; circulating flow circuit forming air flow and inflowing the air discharged out said barrel into the circulating air channel of barrel; circulating fan which is connected with and driven by said motor and forces air circulate through said circulating air channel; among them the thermo-electricity module is composed by the thermo-electricity elements which are based on the directionality of current flow running on the adjoiner of two different metals, and the thermo-electricity elements absorbs and release heat, besides said thermo-electricity module is installed for the wet air discharged out said barrel passes through the heat-absorbing surface side of said thermo-electricity module. The invention uses the drying efficiency and the energy use efficiency is higher, and it has the advantages of low noise and meeting the environment-protection requirements.

Owner:NANJING LG PANDA APPLIANCES

Intelligent nursing bed with bedsore prevention function

The invention discloses an intelligent nursing bed with a bedsore prevention function. The intelligent nursing bed comprises a bed frame, a bed surface and an electric push rod, wherein the bed surface is arranged on the bed frame, and comprises a bed surface main board, a bed center board, a thigh board, a shank board, a left board and a right board; a sliding back board is arranged on the bed surface main body by virtue of a slide rail; when the bed surface main board is turned over, the sliding back board moves along the slide rail; furthermore, a defecation collection device is arranged on the bed center board; a massage mattress is arranged on the bed surface; and a health monitor system is integrally arranged on the bed surface. The intelligent nursing bed can realize sitting-up, leg-bending and lateral-overturning of a patient, has functions of defection collection, washing, sealing and drying, can be used for automatically massaging a patient and remotely monitoring the vital signs of a patient in real time, and has multiple control modes.

Owner:薄和秋

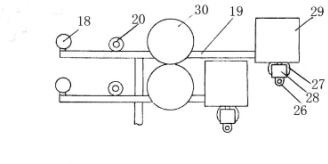

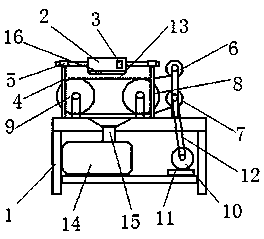

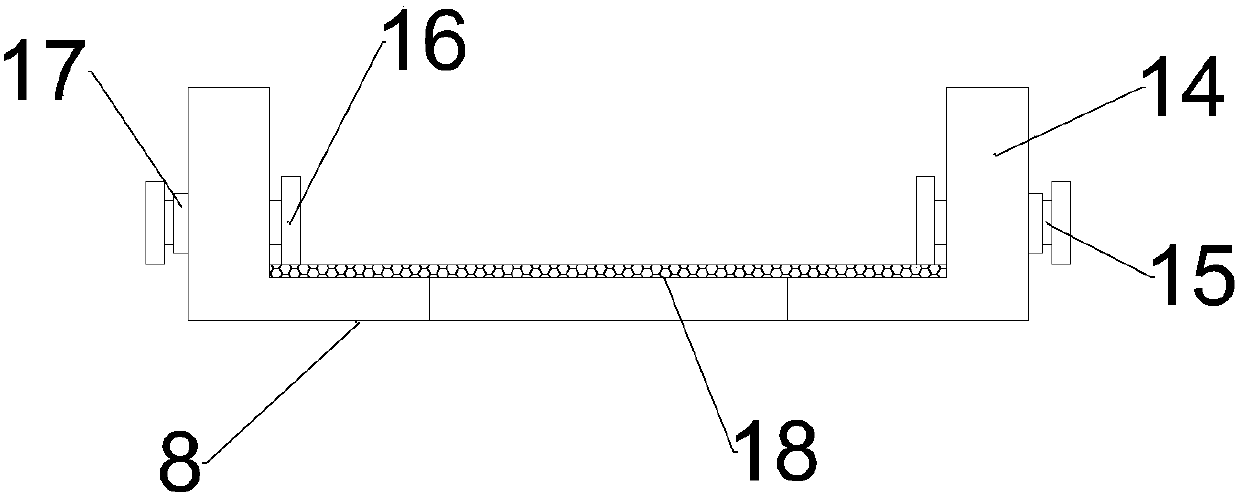

Non-woven fabric winding device with static electricity removal and drying functions

The invention provides a non-woven fabric winding device with static electricity removal and drying functions and relates to the technical field of non-woven fabric winding bundles. The non-woven fabric winding device with the static electricity removal and drying functions comprises a machine box. A partition and a fixing rod are fixedly arranged in the machine box. First pressure rollers are fixedly arranged on the partition. A water mist spray nozzle, exhaust ports and an air cover are fixedly arranged on the top of the machine box. Second conveying rollers and a wind-heat device are arranged on the left side of the partition. Second pressure rollers are arranged on a box body of the machine box. A support table is fixedly arranged on the outer wall on the left side of the machine box.A limiting device is fixedly arranged on the top of the support table. A cutting device is arranged on the bottom of the support table. A winding device is arranged on the left side of the machine box. The non-woven fabric winding device with the static electricity removal and drying functions is easy and convenient to use and high in automation degree and can realize the functions of static electricity removal, material compaction, material heating, material cutting and winding and the like.

Owner:江西美宝利实业有限公司

Novel drying agent and preparation method thereof

InactiveCN106925239ABoth deoxygenationWith drying functionGas treatmentOther chemical processesDeoxygenationIon

The invention discloses a novel drying agent and a preparation method thereof. The novel drying agent comprises the following components in parts by weight: 25-50 parts of minerals, 20-30 parts of silicon dioxide, 35-40 parts of iron powder, 15-20 parts of bamboo charcoal, 2-5 parts of sodium chloride, 10-30 parts of quartz sand and 5-10 parts of fiber. The novel drying agent is prepared by sequentially soaking, sieving, mixing, grinding, concentrating, drying and adding the iron powder and the fiber. The preparation method is simple in process, has low demands on equipment, and is suitable for large-scale industrial production, and the obtained drying agent has deoxygenation and drying functions and is high in cation exchange capacity, significant in deoxygenation and drying effects and high in repeated utilization rate.

Owner:安徽省明美矿物化工有限公司

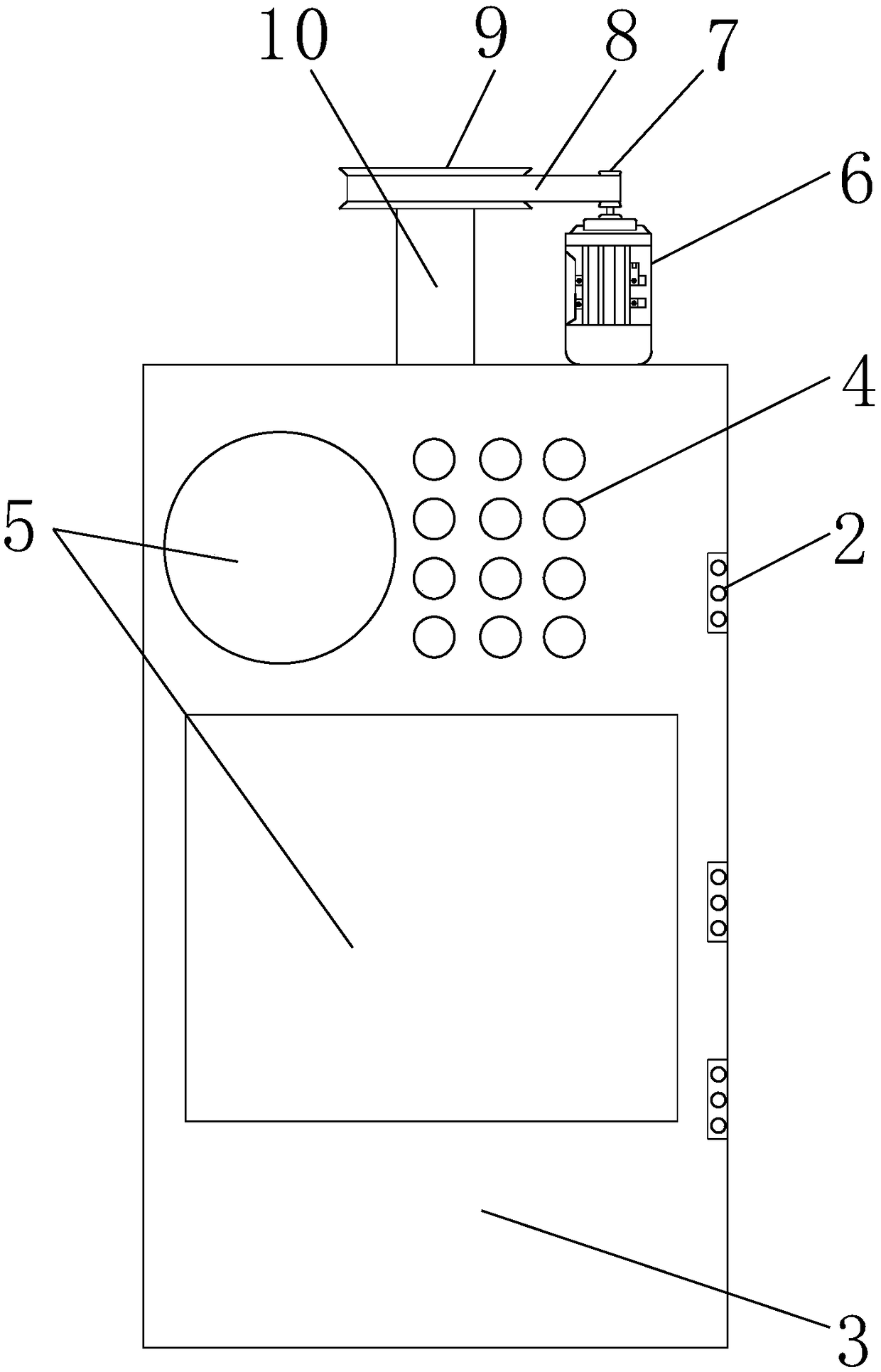

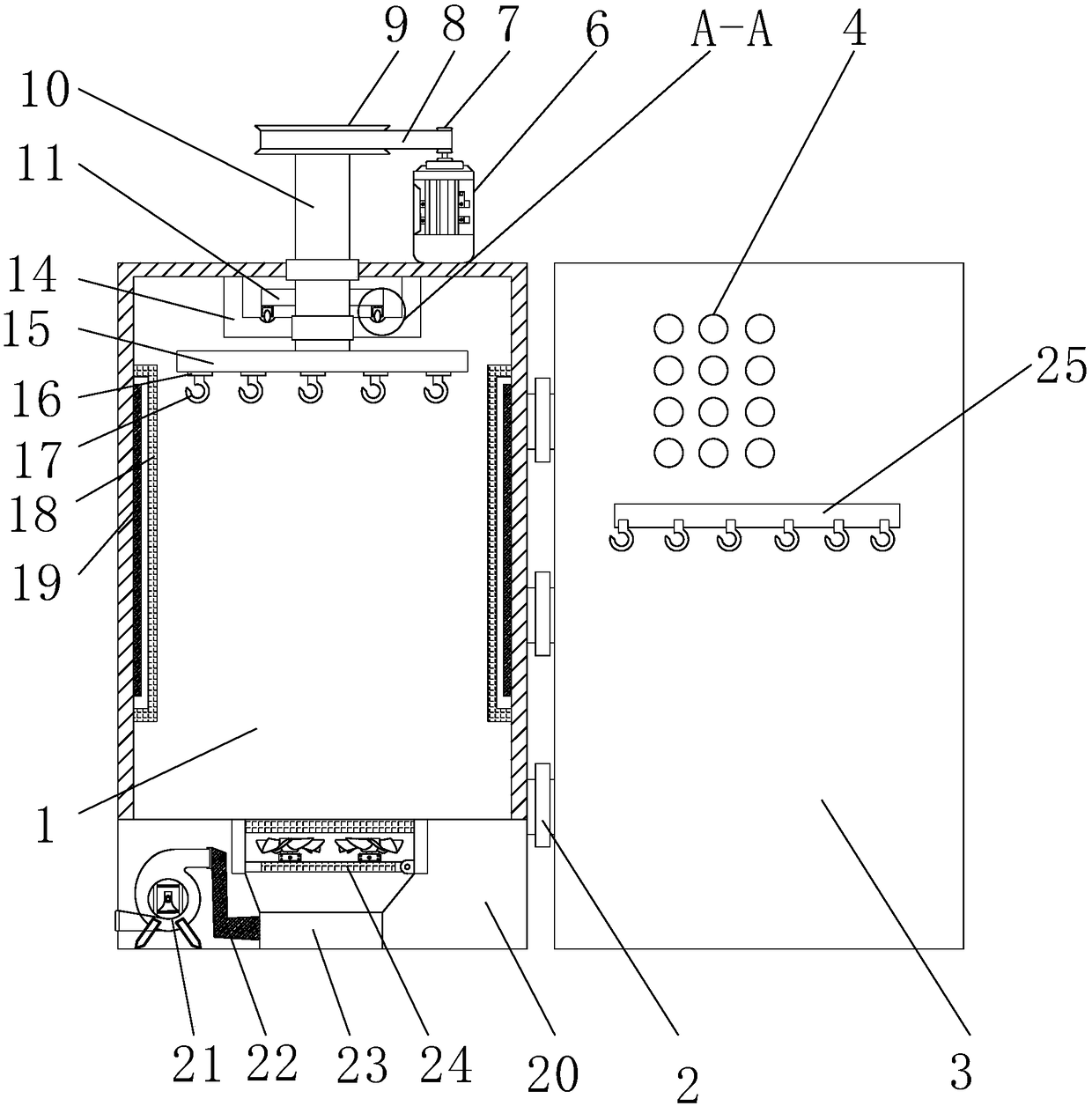

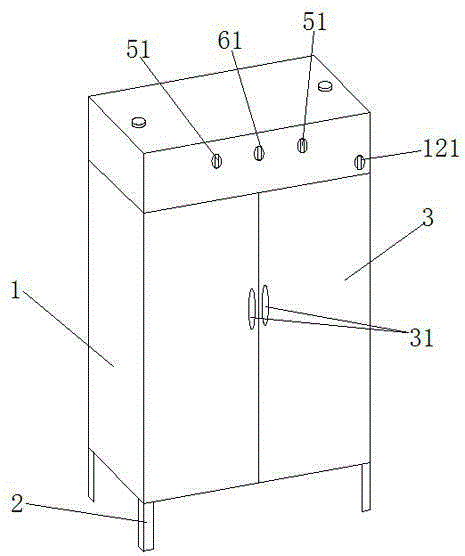

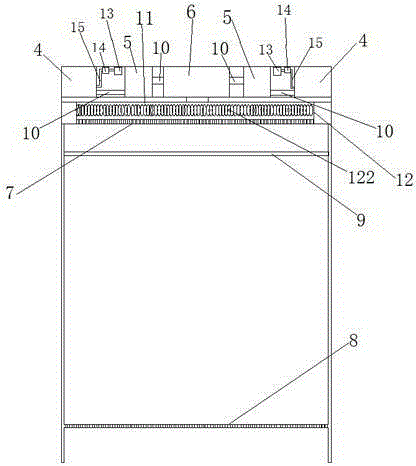

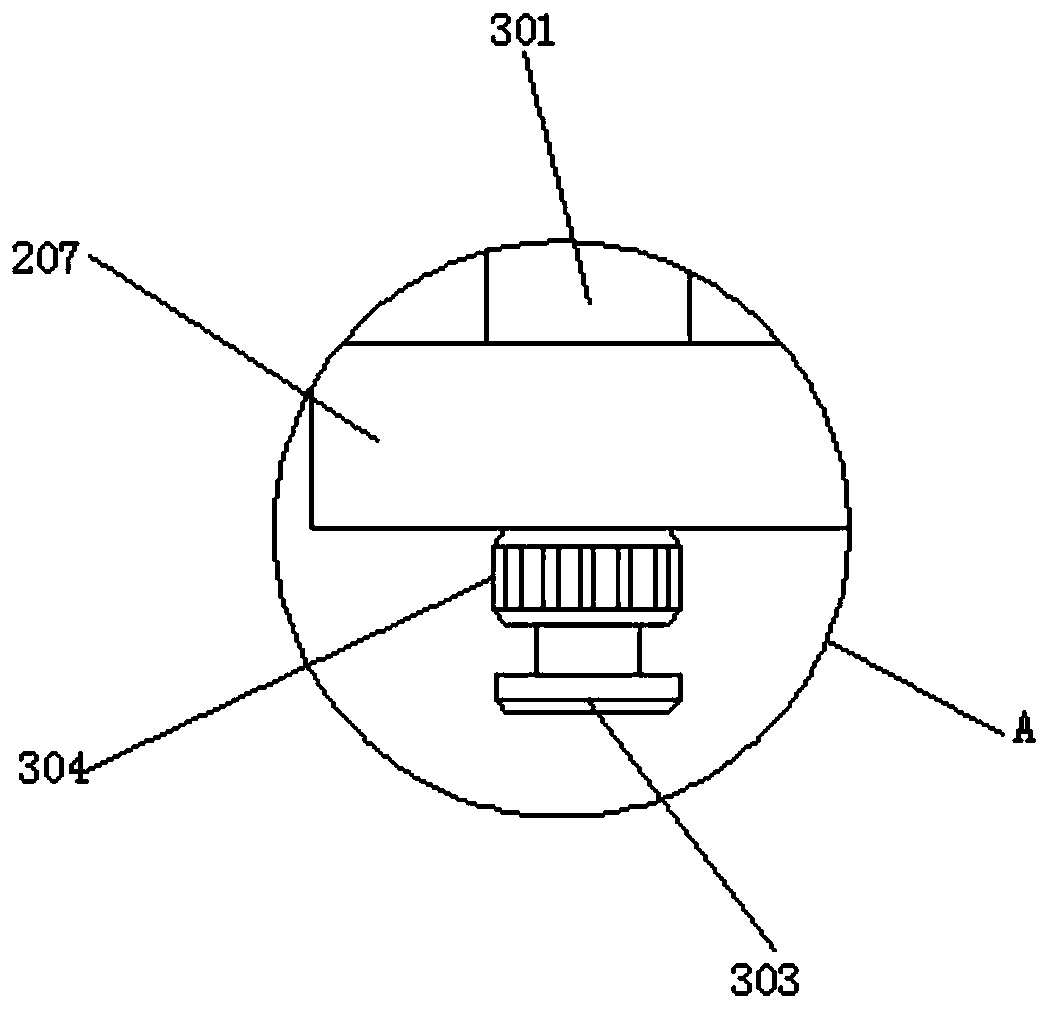

Wardrobe with drying function

InactiveCN108713885AWith drying functionEasy accessWardrobesTextiles and paperEngineeringUltraviolet germicidal light

The invention discloses a wardrobe with a drying function, and relates to the technical field of furniture. The wardrobe comprises a box body, a box door is rotatably connected to the box body throughhinges, a motor is fixedly connected to the top of the box body, a first runner is fixedly connected to an output shaft of the motor and is in transmission connection with a second runner through a belt, and a rotary shaft is fixedly connected to the axis of the second runner and penetrates through and extends to the interior of the box body. By means of the wardrobe with the drying function, thepurposes of putting clothes in the wardrobe to rotate the clothes, bringing convenience for devices to dry and disinfect the clothes and convenience for people to take and put the clothes, and improving the efficiency are achieved; the purposes of drying and disinfecting the clothes on a rotary clothes rack, using fans to blow hot air upwards, guaranteeing the dryness of the clothes, using ultraviolet sterilizing lamps to disinfect the clothes, guaranteeing the comfort of the clothes, reducing breeding of bacteria, and meeting people's requirements for wearing the clothes are achieved.

Owner:安吉睿丰家具股份有限公司

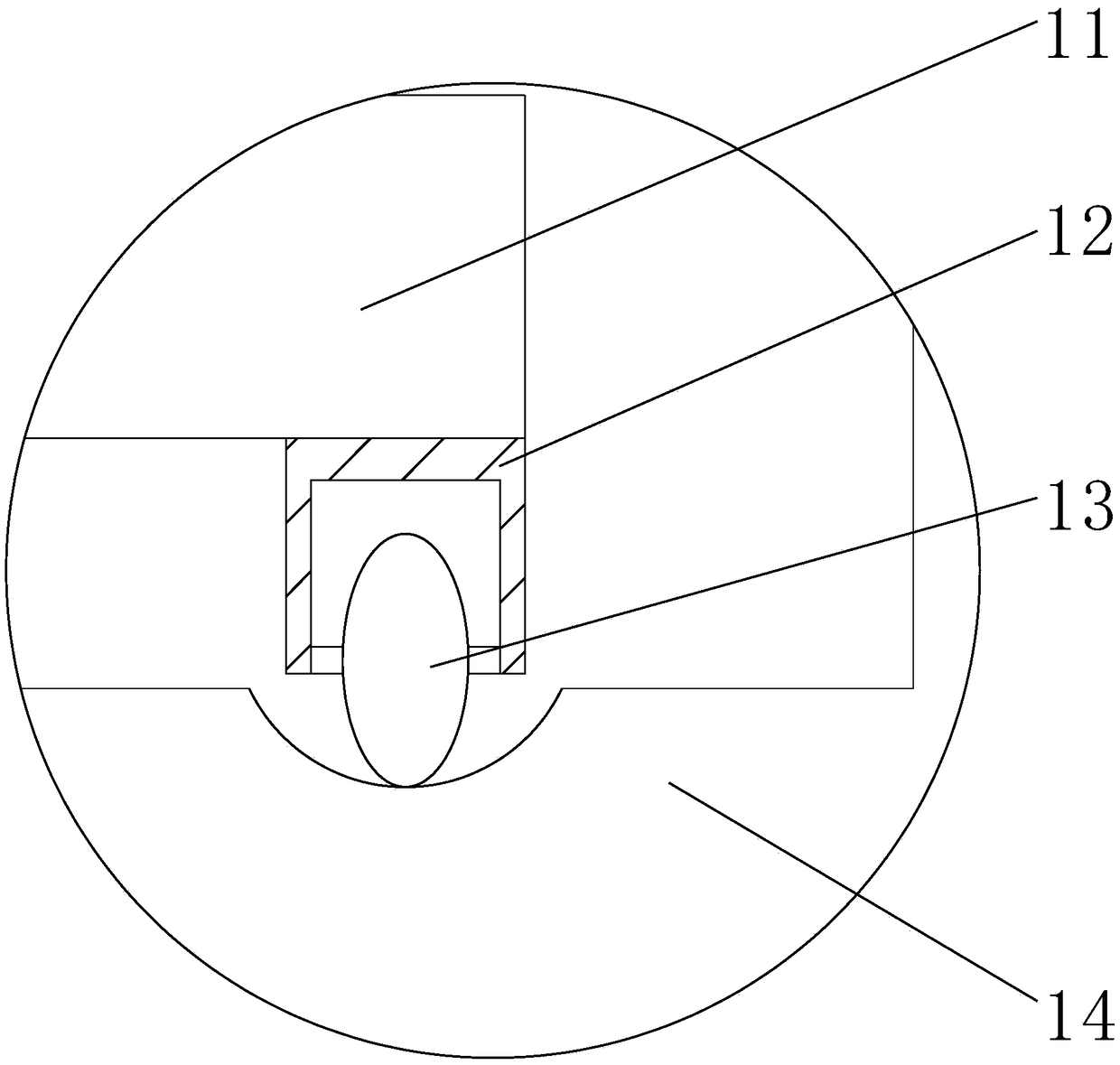

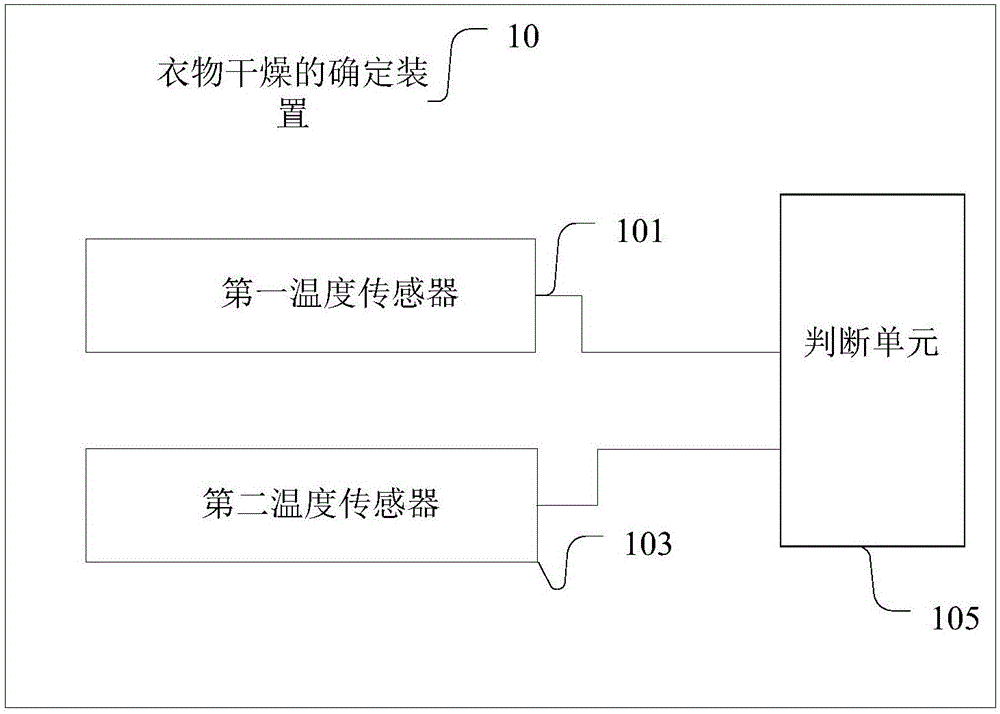

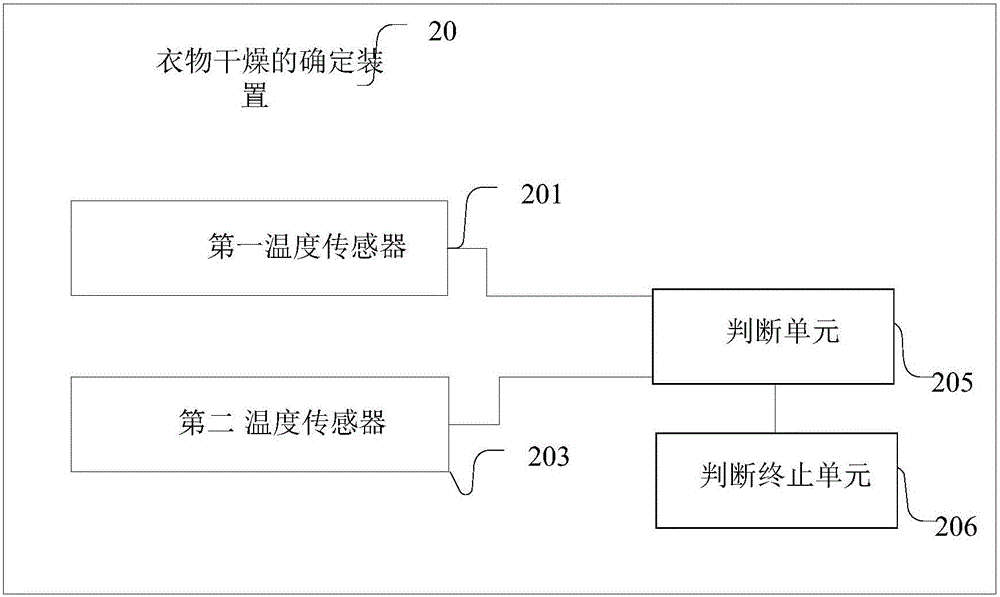

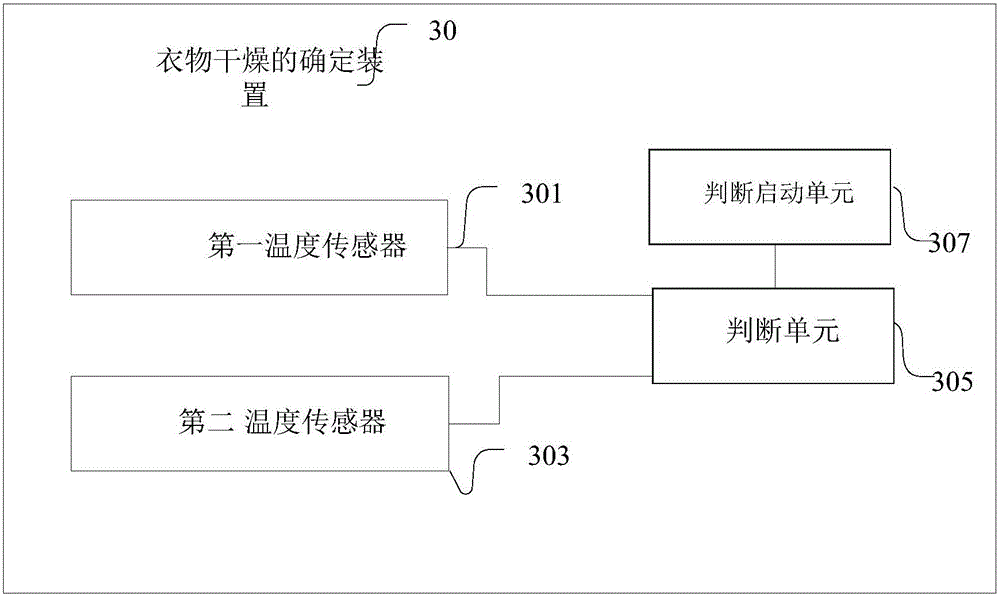

Device and method for determining whether clothes are dry or not and equipment

ActiveCN106567216AWith drying functionSimple structureWashing machine with receptaclesTextiles and paperEngineeringMoisture sensor

The invention provides a device and method for determining whether clothes are dry or not and equipment. The device comprises a first temperature sensor, a second temperature sensor and a judgment unit, and the first temperature sensor is used for acquiring the first temperature of an air outlet of a clothes containing device; the second temperature sensor is used for acquiring the second temperature of an air inlet of the clothes containing device; the judgment unit is used for determining whether the clothes are dry or not according to the first temperature and the second temperature. According to the scheme, whether the clothes are dry or not can be judged without adopting a humidity sensor, and the equipment with a clothes drying function has a simpler structure.

Owner:GREE ELECTRIC APPLIANCES INC

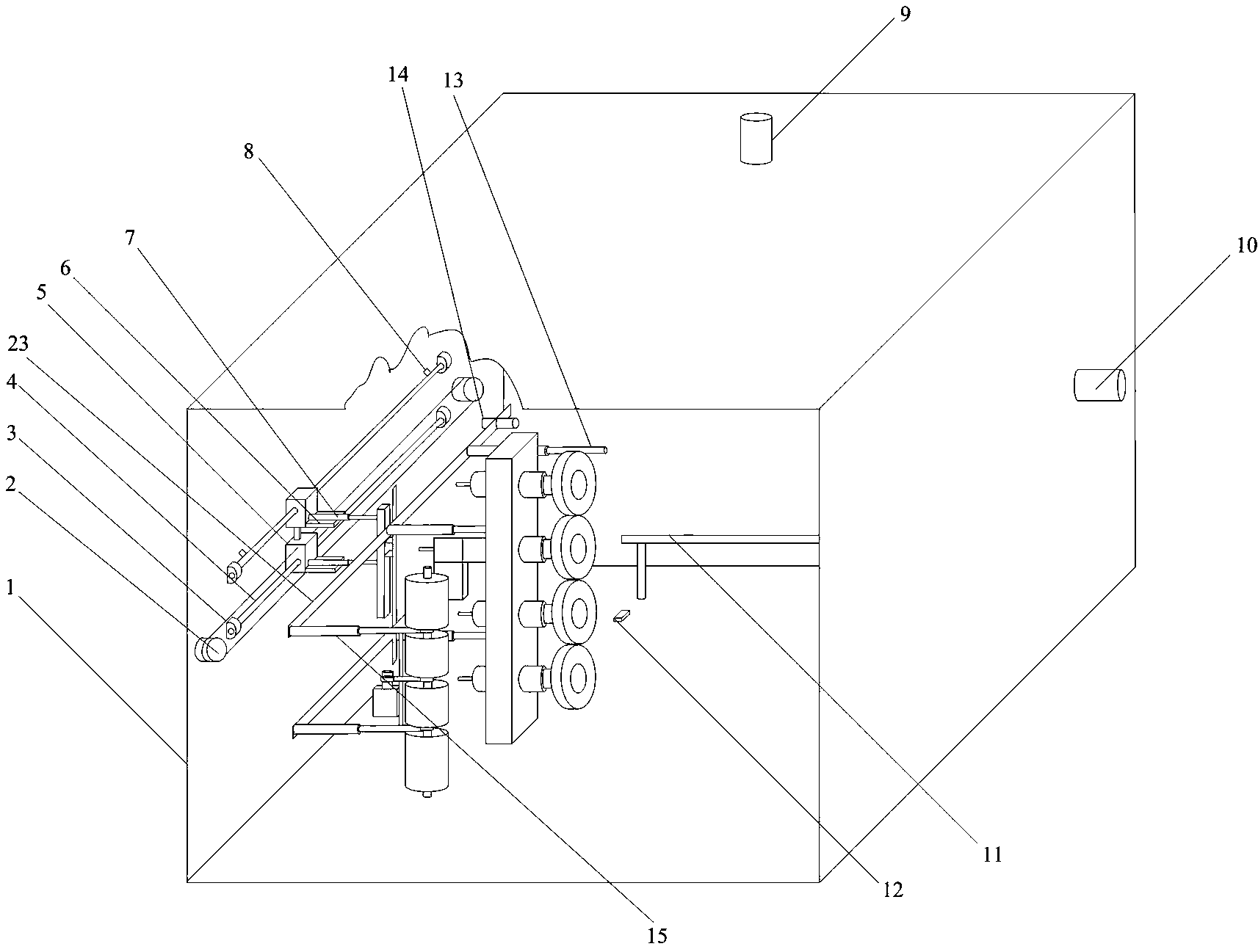

Intelligent full-automatic automobile washing machine on automobile

InactiveCN103072555AConvenient distanceStrong targetingCleaning apparatus for vehicle exteriorsProgrammable logic controllerGroup control

The invention relates to an intelligent full-automatic automobile washing machine on an automobile, which comprises a PLC (Programmable Logic Controller), a frame, a right side cleaning mechanism, a left side cleaning mechanism, a top cleaning mechanism, and a serial start switch group controlled by using a front wheel, wherein the right side cleaning mechanism consists of an X-axis travelling mechanism, a Y-axis telescopic translation mechanism, a Z-axis translation mechanism and a cleaning unit; the left side cleaning mechanism and the right side cleaning mechanism have the same structure, and are symmetrically arranged on the middle part of the inner side of the left side wall of the frame; and the cleaning unit consists of two horizontal support rods, and a water spray nozzle, a range finder, a vertical washing liquid scrubbing mechanism and a vertical scrubbing mechanism which are fixed in sequence on the horizontal support rods. According to the intelligent full-automatic automobile washing machine on the automobile, an automobile washing route can be calculated automatically according to the external dimensions of different automobiles, a series of specified actions such as automatic water spraying, cleaning, scrubbing, wiping and the like are completed, and manual work imitation automobile washing flows and actions are realized completely; and the intelligent full-automatic automobile washing machine has the advantages of optimized cleaning flow, high washing speed and good washing effect, and does not damage automobile bodies.

Owner:王晓晖

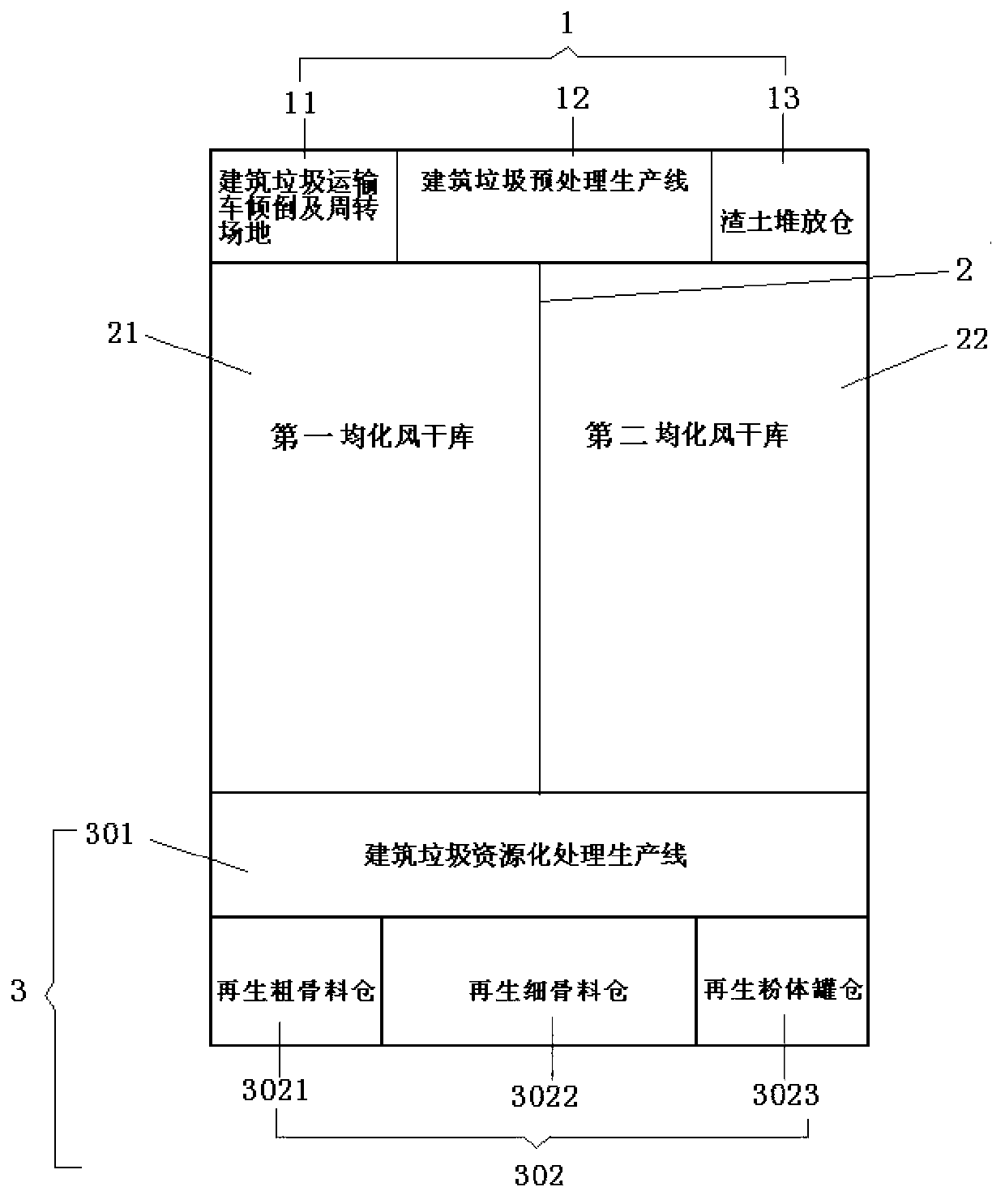

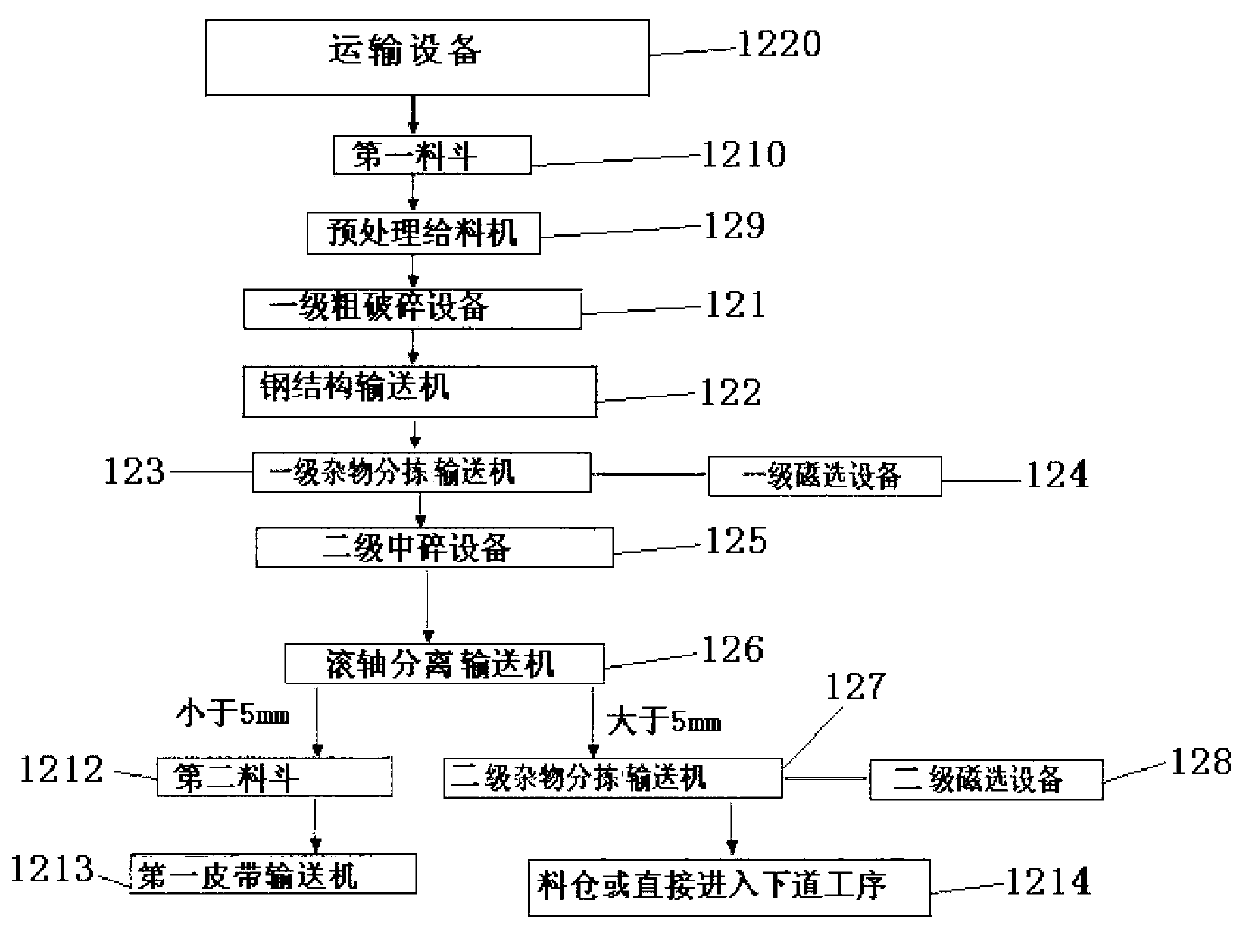

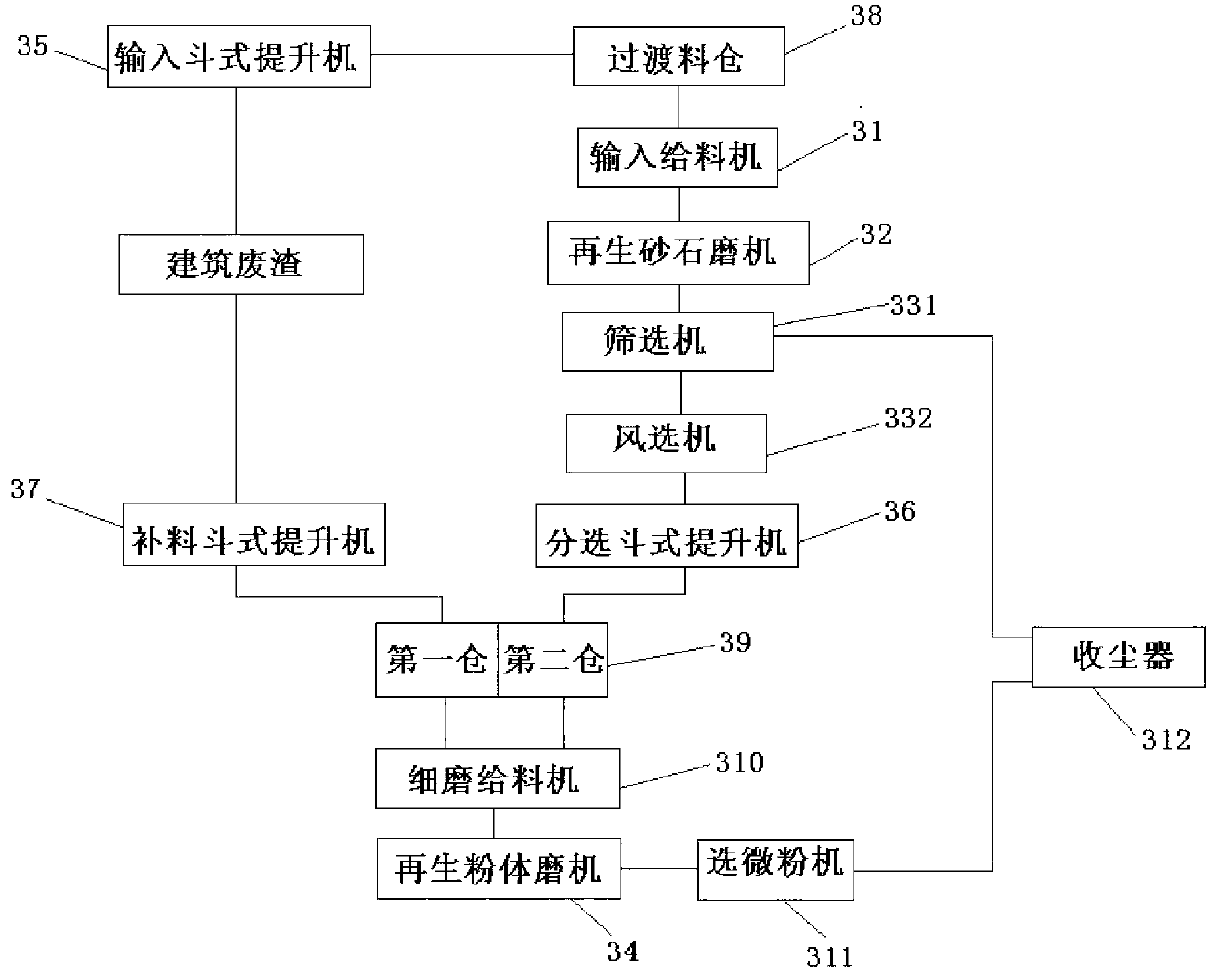

Factory type construction waste resourceful treatment system and technological process thereof

ActiveCN103128094AEasy to absorb waterIncrease moisture contentConstruction waste recoverySolid waste disposalLitterMaterials processing

The invention discloses a factory type construction waste resourceful treatment system and a technological process of the factory type construction waste resourceful treat system and belongs to the technical field of construction waste treatment. The factory type construction waste resourceful treatment system comprises a pretreatment unit, a homogenized drying unit and a recycled material processing production unit which are arranged in sequence. The layout of the technical scheme includes that no matter how the specification and the size of the components and the moisture content of the construction waste change, the normal production of three recycled materials of the construction waste resourceful treatment can not be influenced; and no matter how the three recycled materials of the construction waste resourceful treatment are adjusted, combined and changed, the normal production of the construction waste pretreatment can not be influenced. The processing and production of the recycled materials refer to breaking and grinding of the construction waste residue after harmless treatment, stripping of mishmash, homogenization and drying, the moisture content of the construction residue can be basically controlled below 6%, and therefore smooth production can be achieved.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

Efficient rice drying machine

ActiveCN104990388AWith drying functionWith cooling functionDrying gas arrangementsSeed preservation by dryingProcess engineeringAir blower

The invention discloses an efficient rice drying machine. The efficient rice drying machine comprises a machine shell, multiple rice conveyer belts and a rice storing box. The machine shell is provided with a feeding hopper. The multiple rice conveying belts are arranged in the machine shell from top to bottom in a staggered mode in sequence. The conveying directions of every two adjacent rice conveying belts are opposite so that rice can be conveyed layer by layer from top to bottom. The machine shell is provided with multiple partition plates, wherein each partition plate is located above the corresponding rice conveying belt. The partition plates are divided into an upper group and a lower group. Electric heating devices are arranged on the upper group of partition plates. The electric heating devices are further connected with first air blowers. Second air blowers are arranged on the lower group of partition plates. The rice storing box is arranged in the machine shell and located below the lowest rice conveying belt. The rice output portion, opposite to the lowest rice conveying belt, of the rice storing box is provided with a point portion enabling the dried rice to be distributed to the two sides. The rice drying machine has the drying and cooling functions, and the rice can be rapidly dried and is high in efficiency.

Owner:YANCHENG MAICRETE MACHINERY

Household tableware cleaning device

InactiveCN108042068ATimely dryingAvoid secondary pollutionTableware washing/rinsing machine detailsPulp and paper industrySewage

The invention discloses a household tableware cleaning device. The device comprises a shell body and a base, the inner cavity of the shell body is provided with a tableware net bracket, the middle ofthe inner cavity of the base is provided with a motor, the end portion of the output shaft of the motor is sleeved with blades located in the inner cavity of the shell body, and a steam sterilizing device and a drying device are sequentially arranged from right to left on the side, away from the motor, of the inner cavity of the base. The device has the advantages of light structure and reasonabledesign, has a drying function and a sterilizing function, through the use of the drying device, tableware after washing can be dried in time, secondary pollution caused by residual sewage to the tableware is effectively avoided, through the cooperation of the steam sterilizing device, the tableware can be drastically treated through steam high-temperature sterilization, the content of bacteria and pathogenic bacteria on the surface of the tableware is greatly reduced, effects of tableware washing are improved, and the device is beneficial for safe and reliable reuse of the tableware.

Owner:绍兴市积成包装机械有限公司

Clay drying adsorbent

InactiveCN102941061APromote decompositionWith purification functionOther chemical processesDispersed particle separationMolecular sieveSorbent

The invention relates to a clay drying adsorbent and belongs to the field of drying agents. The clay drying adsorbent comprises a drying agent and an adsorbent, wherein the drying agent is an attapulgite clay drying agent and prepared by the steps of mixing additives with attapulgite clay which is main raw material in proportion and pelletizing and calcination, and the additives include 20-30 percent by weight of molecular sieves and 10-20 percent by weight of chlorides, and the addition of attapulgite clay is 60-80 percent by weight; the adsorbent is a drying agent which is a solid substance with a porous structure; the mixing proportion of the drying agent and the adsorbent is 1:1-1:3, and the mixed drying agent and adsorbent are placed in a container. The clay drying adsorbent disclosed by the invention has purifying and drying functions and can bring more extensive purposes by having two different functions. According to the invention, very good environment friendliness is achieved; selected materials are environmental-friendly and innoxious; and a product generated after the clay drying adsorbent absorbs water is very easy to decompose in nature.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

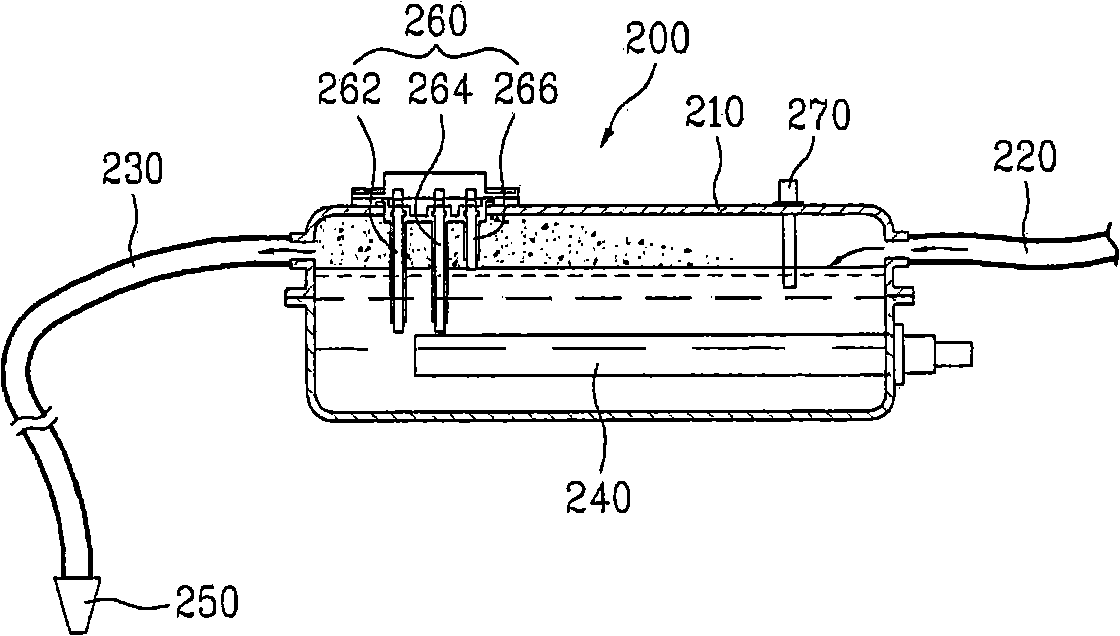

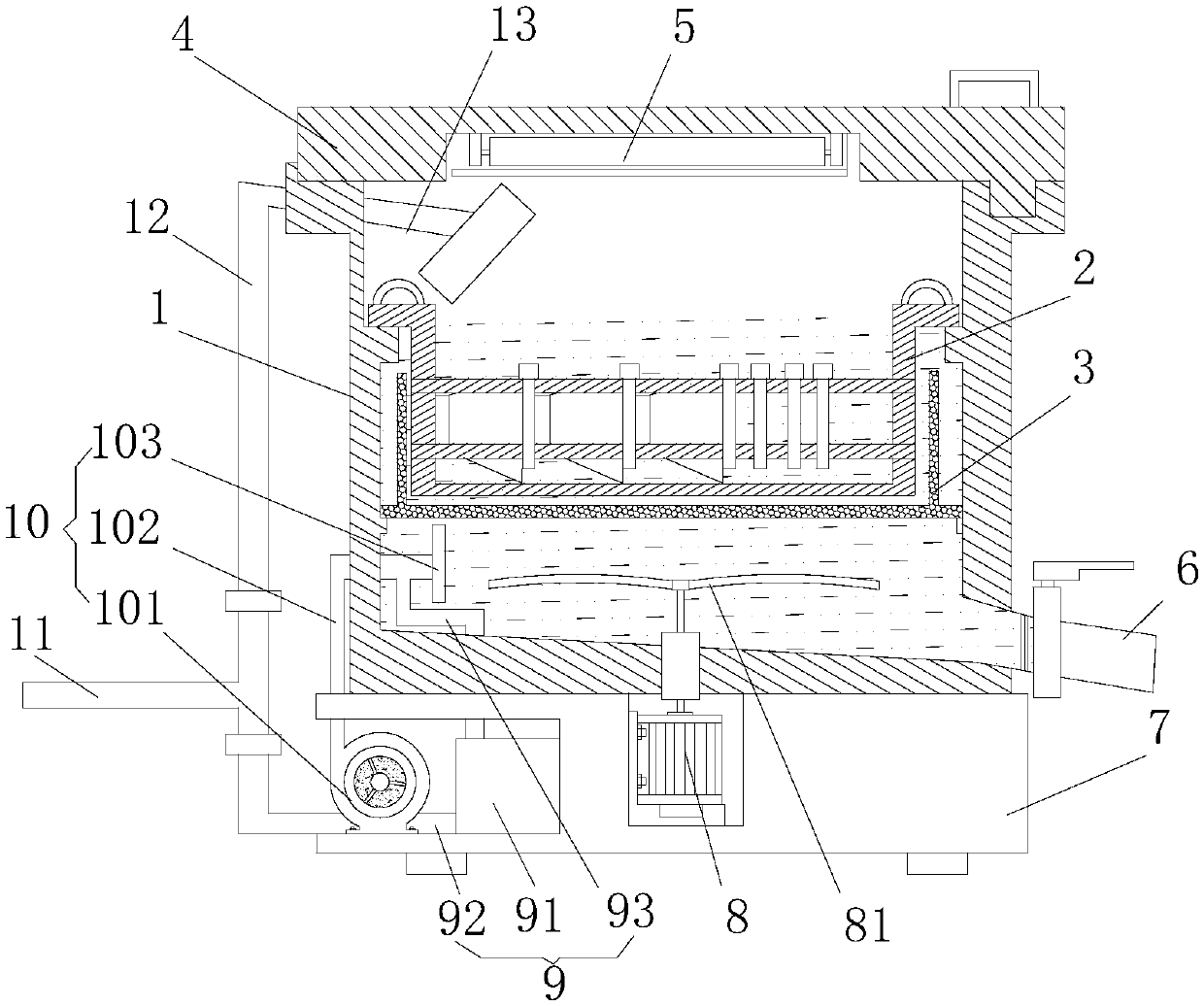

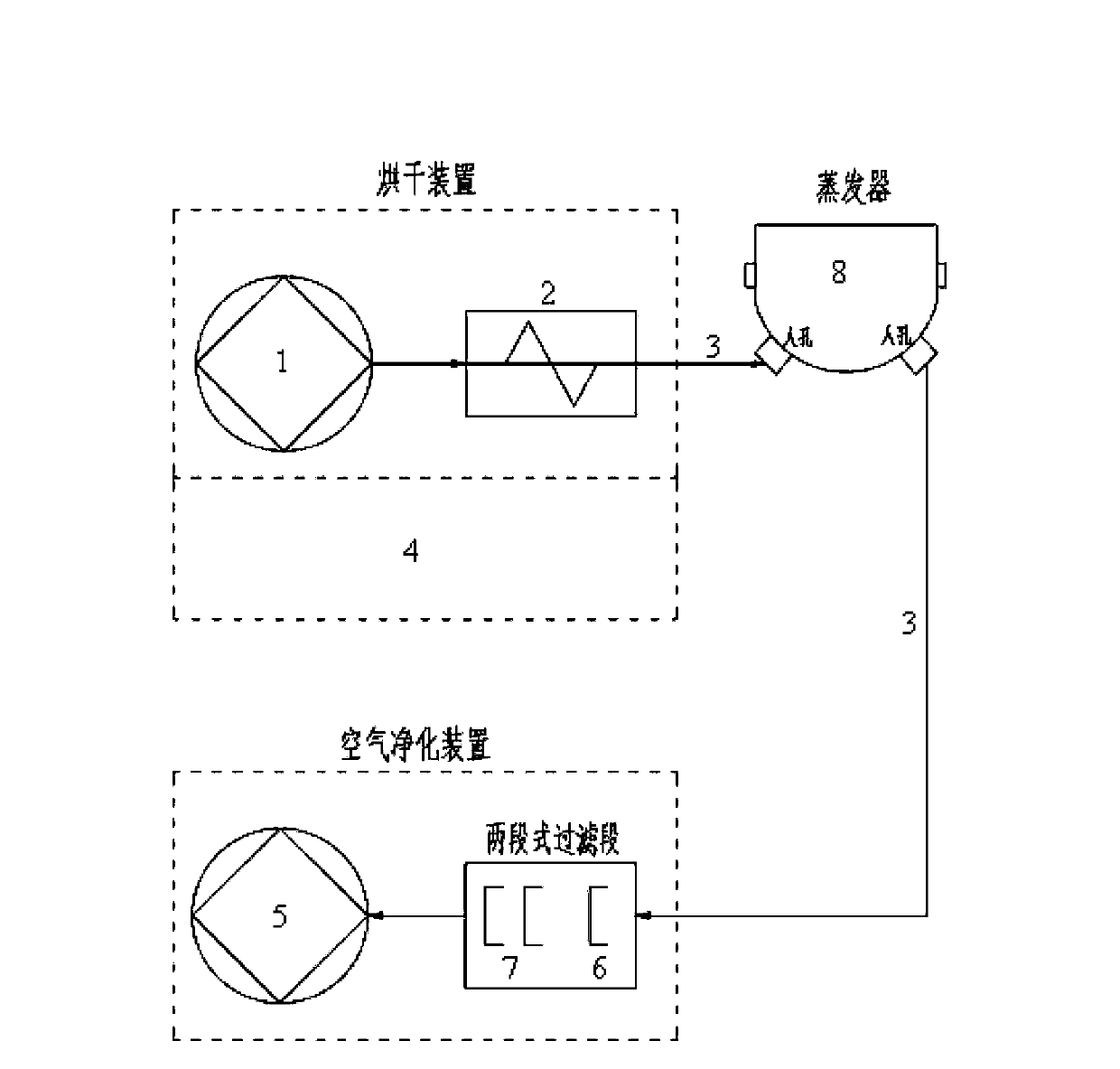

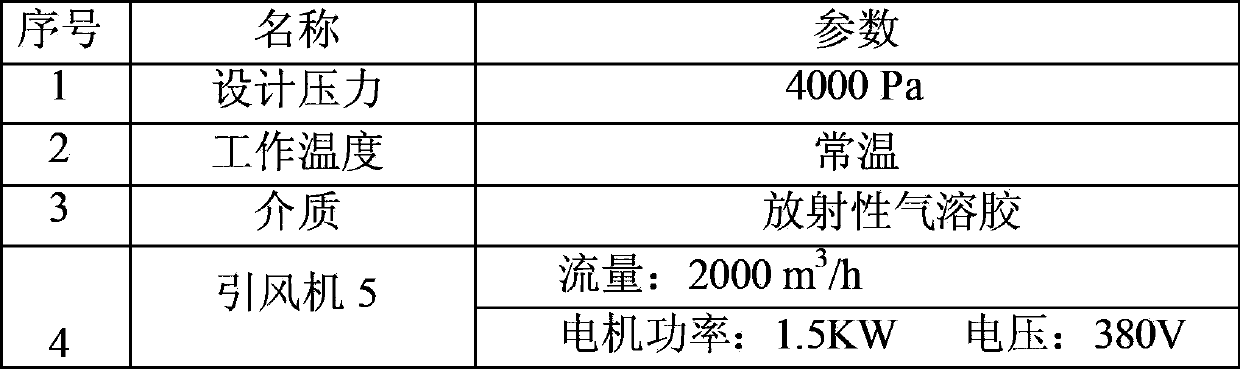

Primary side drying system of steam generator

ActiveCN103868048AWith drying functionLow costDrying gas arrangementsSteam boilersNuclear powerProcess engineering

The invention belongs to the technical field of steam generator drying, and particularly relates to a primary side drying system of a steam generator. The primary side drying system of the steam generator comprises a drying device used for importing heated gas to the steam generator and an air purifying device used for extracting and filtering waste gas generated by the steam generator. The primary side drying system solves the technical problem that the primary side drying system of the steam generator of the existing nuclear power station only has a drying function and has difficulty in extracting and filtering the waste gas generated by the steam generator. The primary side drying system not only has the drying function but also can be used for extracting and filtering the waste gas generated by the steam generator, and the filtered waste gas can be directly discharged to the atmosphere, so that the cost is reduced, and the efficiency is improved.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

Rapid printing device for thin films

InactiveCN108215463AImprove work efficiencySimple structureRotary pressesOther printing apparatusElectric machineryPrinting press

The invention relates to a rapid printing device for thin films. A supporting frame is arranged on one side of the top of a jack, height adjusting mechanisms are arranged on the two sides of the top end of the supporting frame, and a printer is arranged in the middle of the top of the supporting frame. A switch is arranged on the printer, a first guiding wheel is arranged on one side below the printer, and a second guiding wheel is arranged on the side, away from the first guiding wheel, below the printer. A material collecting set is arranged on one side of the supporting frame, a dischargingset is arranged above the material collecting set, and one ends of the thin films are placed on the outer side of the discharging set. The other ends of the thin films sequentially penetrate throughthe first guiding wheel and the second guiding wheel and then collected by the material collecting set, and a motor is arranged on one side of the middle of the rack. A quakeproof cushion is arrangedat the bottom of the motor, and the motor and the material collecting set are connected through a belt. A drying machine is arranged on the side, away from the motor, of the middle of the rack, one end of an air guiding pipe is arranged at the top of the drying machine, and the other end of the air guiding pipe is arranged at the top of the rack and located under the printer. The rapid printing device for the thin films has the beneficial effects that the structure is simple, using is convenient, the drying function is achieved, and the work efficiency of users is effectively improved.

Owner:ZHONGSHAN ZHILIAN BUSINESS INCUBATOR DEV CO LTD

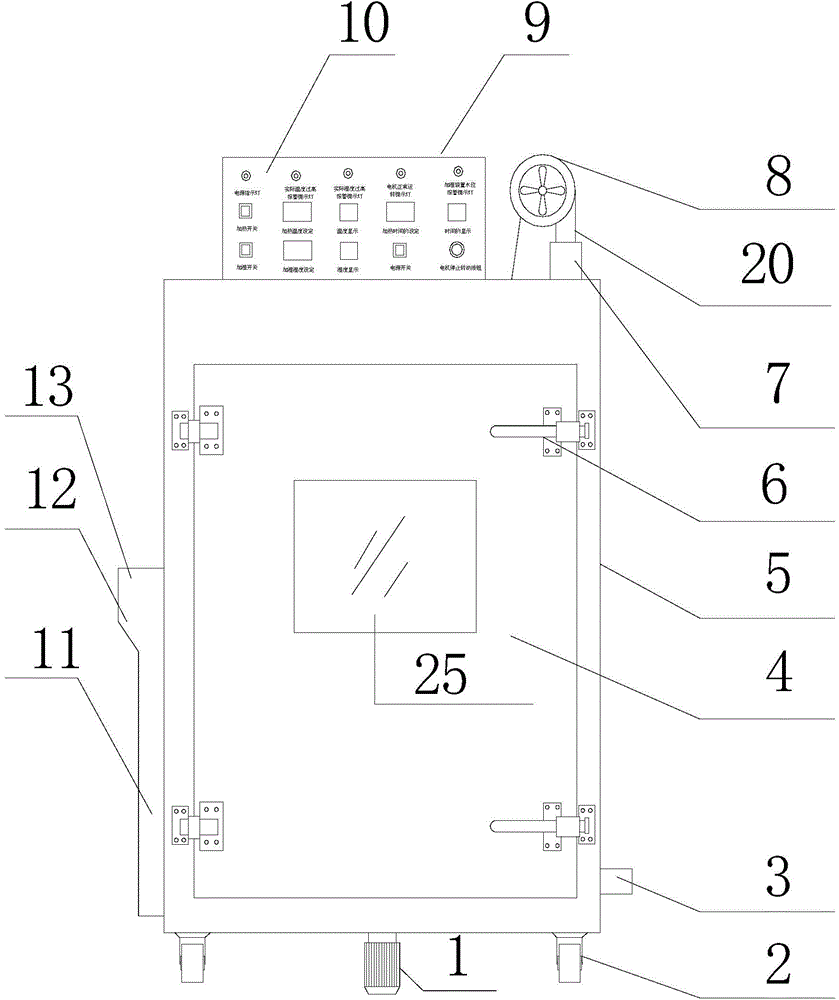

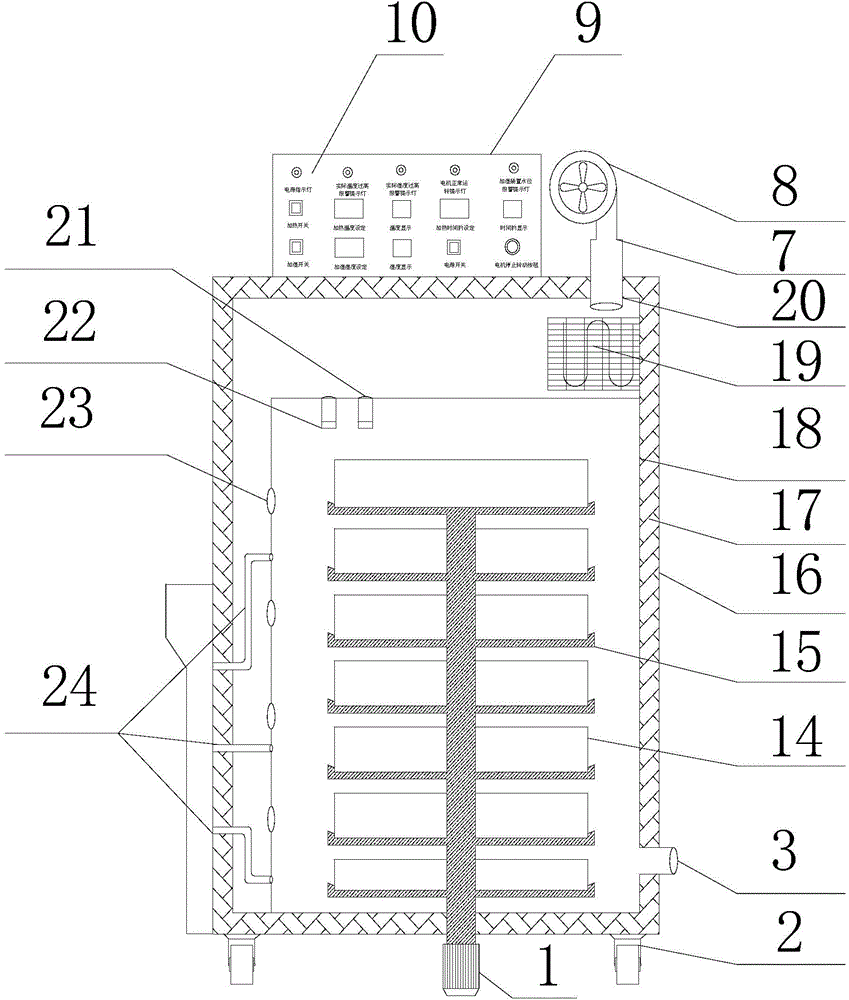

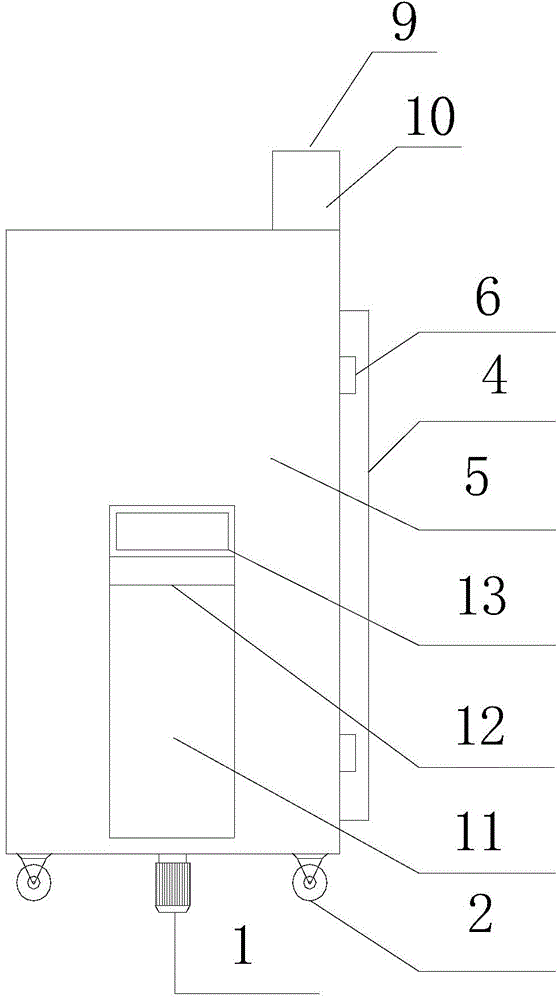

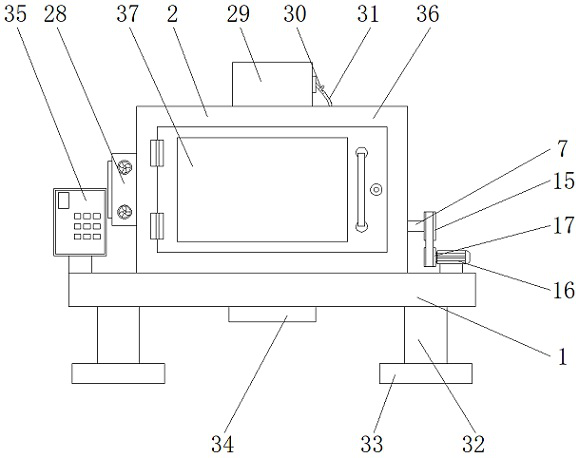

Tea leaf fermenting and oven-drying intelligent integrated machine

InactiveCN104920679AGood ability to control temperature and humidityCompact structurePre-extraction tea treatmentElectric machineryAgricultural engineering

The present invention relates to the technical field of tea leaf processing machinery and discloses a tea leaf fermenting and oven-drying intelligent integrated machine. The machine includes a box body, a control device, a fermentation auxiliary device, a drying auxiliary device, swivel brackets and tea trays. The box body comprises a box door, a visible window, a sealing device, and a fan, a tray rotary electric motor and a control panel are arranged at the box body. The fermentation auxiliary device consists of a steam generator and a steam running pipeline; the drying auxiliary device consists of the external fan, an air inlet pipe and an electric heater, and the external fan and the electric heater are connected by an air inlet; and the swivel brackets are directly connected with the electric motor and the tea trays are put on the swivel brackets. The machine not only integrates the function of fermentation and drying in one, but also can intelligently control the fermentation and drying time and temperature, and thus can be faster and cleaner to complete production tasks with guaranteed quality and quantity.

Owner:ZHEJIANG PROVINCE XINCHANG COUNTY CHENGTAN TEA FACTORY

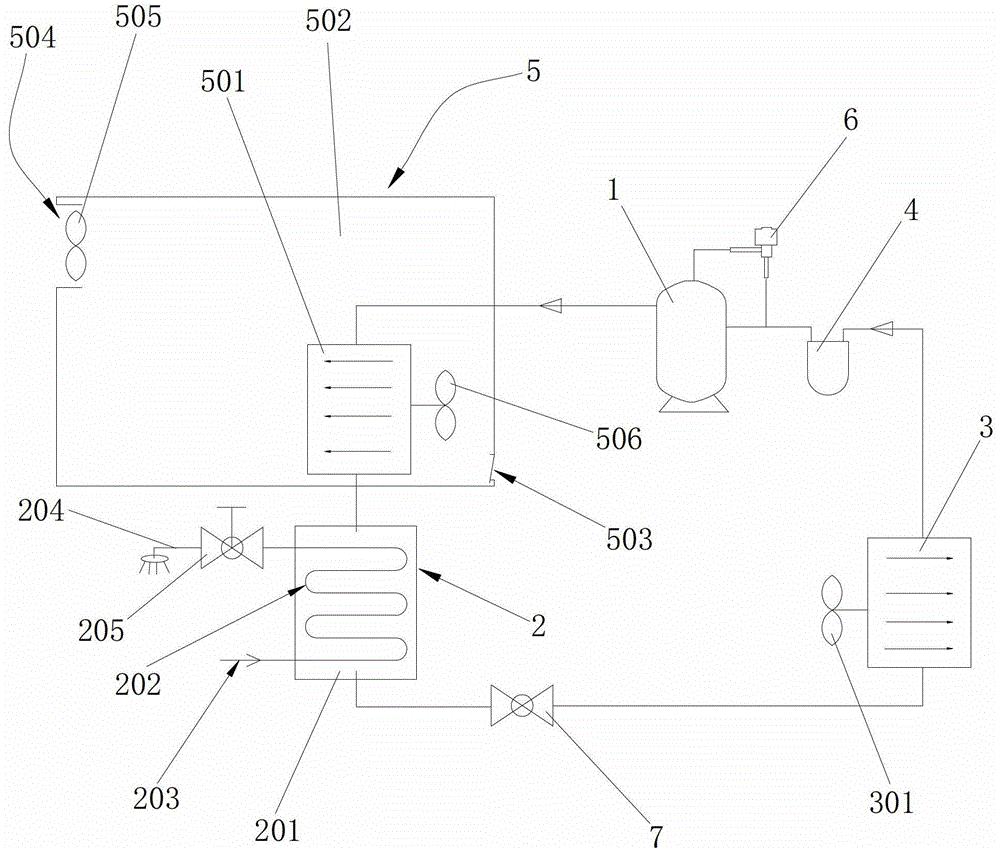

Instant heat pump water heater with drying function

InactiveCN103148588AIncrease profitLow investment costFluid heatersDrying gas arrangementsProcess engineeringThermal water

The invention discloses an instant heat pump water heater with a drying function, which comprises a compressor, a water fluoride heat exchanger, an air heat absorber, and a drying device, wherein the water fluoride heat exchanger and the air heat absorber are sequentially connected with a circulation pipeline of the compressor, and the drying device is connected in series between the compressor and the water fluoride heat exchanger and used for drying a material, so that instant hot water output, drying and instant hot water output precedence can be achieved, the instant heat pump water heater has three functions of the drying, and is multi-purpose, and high in practicability, and the investment cost and the use cost are lowered greatly for a user. In addition, the compressor is a digital scroll compressor and is connected with a pulse width modulation valve, and the pulse width modulation valve can rapidly and steplessly adjust output capacity of the compressor, so that the heating speed of the instant heat pump water heater with the drying function can be high or low, and the instant heat pump water heater is suitable for different hot water temperatures and the drying of different clothes, towels and other materials, and is high in adaptability.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

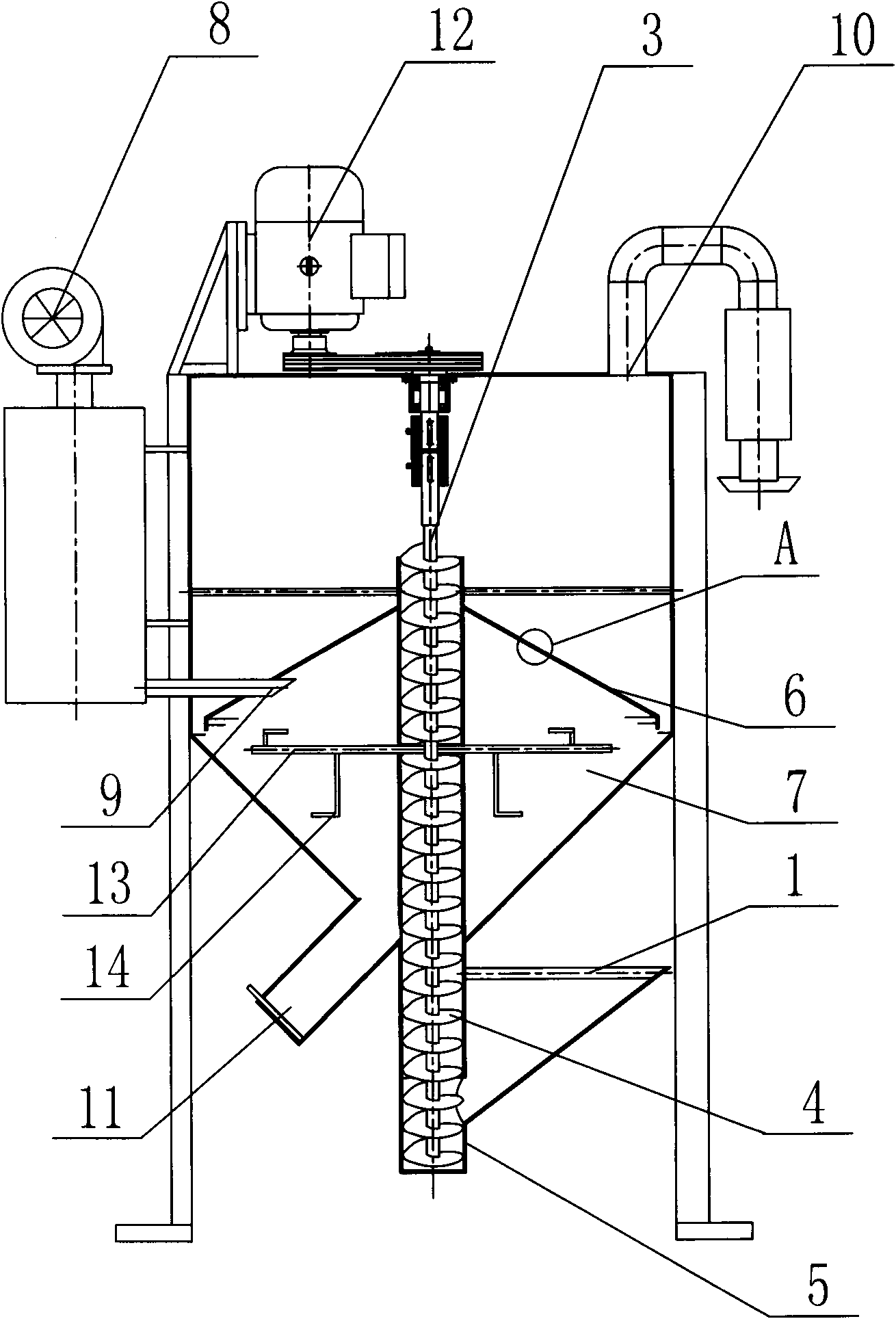

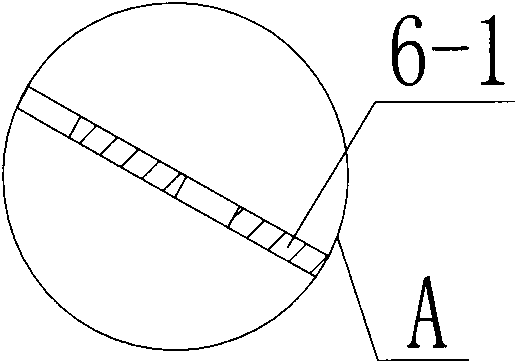

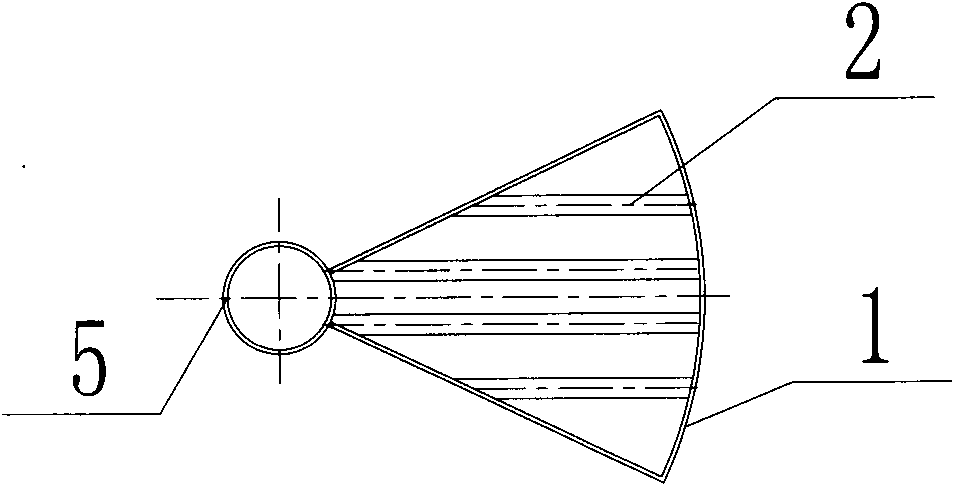

Plastic raw material stirring box

The invention relates to a plastic raw material stirring box, which comprises a feeding hole, supporting rods, a rotary rod, a spiral conveying platform, a hollow tube, a conical cover, a stirring shaft, a blower, an air inlet, an air outlet, a discharge hole and a motor, wherein the spiral conveying platform is fixedly connected with the rotary rod; the spiral conveying platform and the rotary rod are positioned in the hollow tube; the rotary rod is driven by the motor to rotate; holes through which parts of a raw material can pass are formed in the conical cover which is used for dispersing the raw material sliding down from the top of the spiral conveying platform; the blower is connected with the air inlet; the air inlet is positioned in the stirring box; the plastic raw material stirring box also comprises stirring blades and the stirring box; the stirring shaft is fixedly connected with the rotary rod; at least one stirring blade is arranged on the stirring rods; and the feeding hole has at least two supporting rods capable of supporting a raw material package. The plastic raw material stirring box is capable of mixing plastics of various specifications, has a drying function, has a high and uniform mixing speed, improves production efficiency, and is simple in structure and lower in manufacturing cost.

Owner:常州市创信知识产权代理有限公司

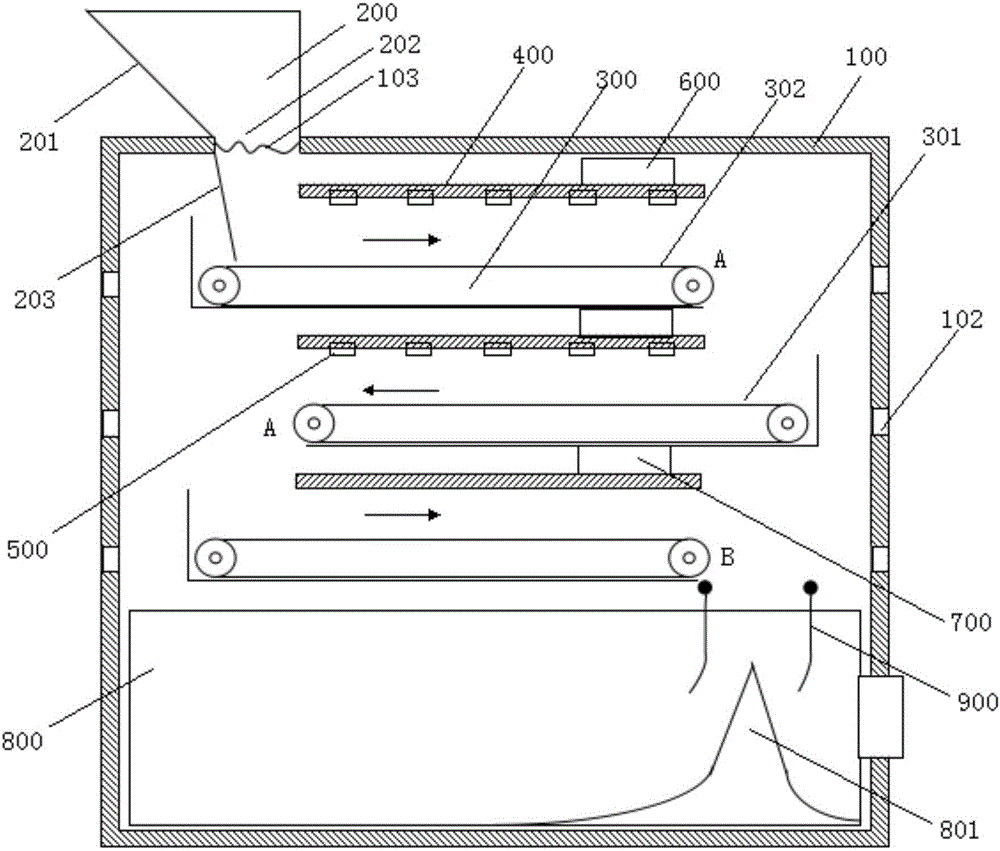

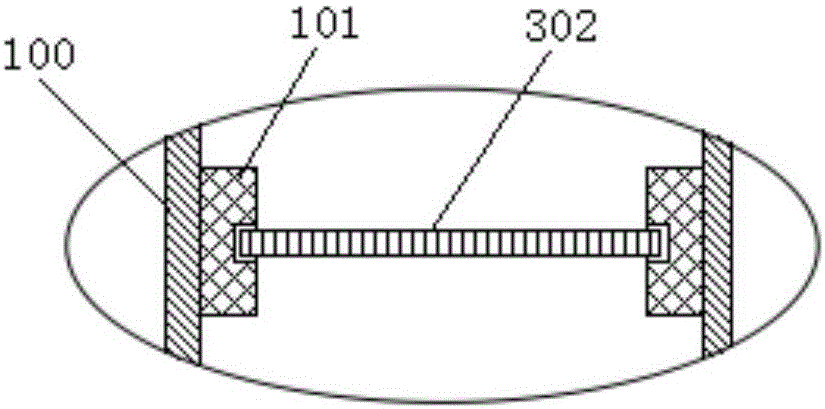

Sand sieving robot with drying function

InactiveCN107511332AWith drying functionTo achieve the purpose of horizontal jitterSievingSand dryingFixed frameEngineering

The invention discloses a sand screening robot with a drying function, which includes a box body, a fixed frame is fixedly connected to the bottom of the inner wall of the box, and a first motor is fixedly connected to the left side of the bottom of the inner wall of the fixed frame. The surface of the output shaft of the first motor is covered with a first pulley, and the right side of the bottom of the inner wall of the fixed frame is fixedly connected with a first support rod and a second support rod in turn from front to back, and the top of the first support rod is rotatably connected with a The first rotating rod, the surface of the first rotating rod is covered with a second pulley and a first cam in sequence from front to back, and the surface of the second pulley is connected to the surface of the first pulley through a belt. The present invention relates to construction machinery equipment technology field. The sand sieving machine with drying function achieves the purpose of horizontally shaking the sieve plate, speeds up the efficiency of sand sieving, improves the drying rate at the same time, and ensures the quality of sand sieving.

Owner:何洁

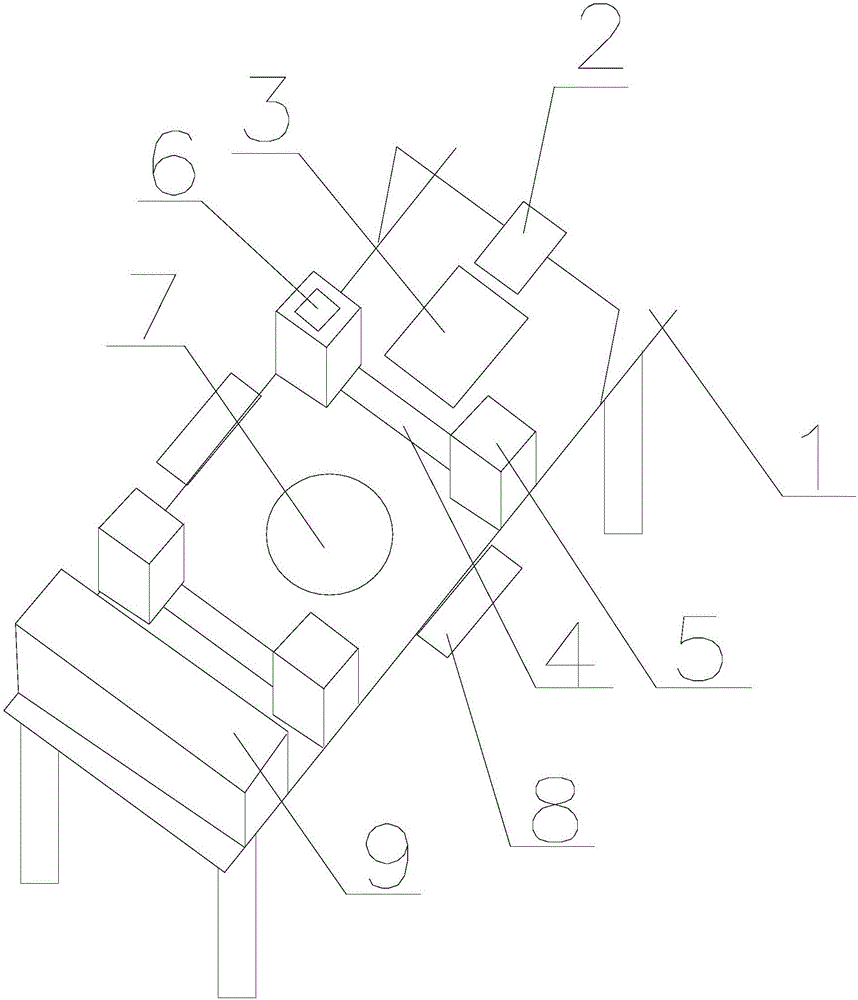

Spraying device with drying function for spline housing transmission shaft production

The invention discloses a spraying device with a drying function for spline housing transmission shaft production. The spraying device comprises a bottom plate, a working box is fixedly connected to the top of the bottom plate, and a first vertical plate is fixedly connected to the left side of the bottom of an inner cavity of the working box. According to the spraying device, the bottom plate, the working box, the first vertical plate, a fixed block, a movable block, a second vertical plate, a rotating rod, a fixed plate, a sliding groove, a sliding block, a spring, a first clamping plate, a second clamping plate, a screw, a first transmission wheel, a first motor, a second transmission wheel, an air cylinder, a connecting plate, a second motor, a gear, a toothed plate, a sprayer, a heating box, a heating pipe, an exhaust pipe, an air inlet pipe, a fan, a paint box, a discharging pipe and a hose are matched, after the spraying device with the drying function for spline housing transmission shaft production completes protective paint spraying work on a spline housing transmission shaft, the drying speed of protective paint can be increased by injecting hot air, and therefore the working efficiency and practicability of the spraying device with the drying function for spline housing transmission shaft production are improved.

Owner:庞江涛

Medical device cleaning and drying device

The invention discloses a medical device cleaning and drying device, which comprises a tank body. A lifting plate is arranged in the tank body; one end of the lifting plate is slidably connected withan inner side wall of the tank body; a connecting block is fixedly connected to the other end of the lifting plate; a first groove is formed in an inner side wall of the tank body; the connecting block is located in the first groove and is slidably connected with the first groove; a threaded rod is rotatably connected into the first groove and penetrates through the connecting block; a threaded hole matched with the threaded rod is formed in the connecting block; a worm wheel is coaxially and fixedly connected onto the threaded rod; a second groove is formed in a side wall of the first groove;a worm meshed with the worm wheel is arranged in the second groove; one end of the worm is rotatably connected with a side wall of the second groove; the other end of the worm penetrates through thetank body; a placement block is slidably connected to the lower end of the lifting plate; and multiple cavities are arranged in the placement block. The medical device cleaning and drying device provided by the invention is good in cleaning effect, capable of drying cleaned devices, simple to operate, and convenient to use.

Owner:南京康翱峰自动化科技有限公司

A sterilizing steam cabinet having a drying function

InactiveCN105239347ASave drying processEasy to useIroning apparatusTextiles and paperOzone generatorWater storage

The invention provides a sterilizing steam cabinet having a drying function. The sterilizing steam cabinet comprises a cabinet body, cabinet feet, an opening / closing door, door handles, water storage tanks, sterilizing holes, steam generators, a steam regulator, an air blower, an air speed adjustor, a steam deflector, an air outlet, a clothes hanging rod, guide pipes, a steam channel, an electric heater, an electro-regulator, an electric heating pipe, ozone generators, air pumps and vent guide pipes. The sterilizing steam cabinet can process multiple pieces of clothes at a time, does not require much manual intervention, saves manpower greatly, has a drying function, saves a clothes airing process, increases the working efficiency, saves time, and thus is convenient to use; the sterilizing steam cabinet is simple in structure, convenient to manufacture and low in production cost; the sterilizing steam cabinet has an ozone generation system which is capable of effectively preventing internal bacterium breeding in the steam cabinet and thus provides guarantee for the health of users.

Owner:CHENGDU MALSS IND CO LTD

Efficient wooden door paint spraying equipment with drying function

InactiveCN107774488ASimple and reasonable designEasy to operatePretreated surfacesCoatingsFixed frameEngineering

The invention discloses efficient wooden door paint spraying equipment with a drying function. The efficient wooden door paint spraying equipment comprises a fixing bottom frame, fixing bases and a damping device. A support plate is arranged at the upper end of the damping device, fixing frames are arranged on the upper sides of the left end and the right end of the support plate, turning wheels are arranged at the upper ends of the fixing frames, conveying devices are arranged at the upper ends of the turning wheels, a paint spraying chamber is arranged at the upper end of the support plate,and a drying chamber is arranged on the left side of the paint spraying chamber. The efficient wooden door paint spraying equipment has the advantages that the efficient wooden door paint spraying equipment is used for paint spraying work on wooden doors, the wooden doors required to be processed are arranged in fixing devices at first, limit screws and fixing nuts can rotate, accordingly, each wooden door can be fixed to a position between two fixing blocks, the efficient wooden door paint spraying equipment can be conveniently and quickly operated, and the wooden doors can be stably fixed; the wooden doors can be driven by the turning wheels to be fed into the paint spraying chamber at first, the paint spraying work can be carried out on the wooden doors, a plurality of air spray nozzlesare uniformly arrayed, accordingly, the paint spraying efficiency and the paint spraying uniformity can be improved, the surfaces of the wooden doors can be flat, and the quality of the processed wooden doors can be improved.

Owner:蚌埠抒阳自动化设备制造有限公司

Clothes dryer with sterilization function

InactiveCN105926249AWith drying functionImprove experienceTextiles and paperLaundry driersControl systemMechanical engineering

The invention discloses a clothes dryer with a sterilization function. The clothes dryer comprises a rear support component, a front support component, an inner drum, a driving assembly, a control system and a sterilization device, wherein the front support component is arranged in front of the rear support component; the inner drum is arranged between the front support component and the rear support component, and the front part and the rear part of the inner drum are pivotally connected with the front support component and the rear support component respectively; the driving assembly is connected with the inner drum to drive the inner drum to pivot; the control system is connected with the driving assembly to control the driving assembly to work; the sterilization device comprises an ultraviolet generator, and the ultraviolet generator is connected with the control system and is suitable for emitting ultraviolet rays directly irradiating the inside of the inner drum under the control of the control system. According to the clothes dryer provided by the embodiment of the invention, clothes in the inner drum can be sterilized and disinfected.

Owner:WUXI LITTLE SWAN CO LTD

Auto part surface coating device with drying function

InactiveCN111250360AWith drying functionWith drying effectPretreated surfacesCoatingsPhysicsElectric machinery

The invention discloses an auto part surface coating device with a drying function. The auto part surface coating device comprises a box, a multi-station mechanism, a paint box, an oil pump and a servo motor. The servo motor is arranged at the top end of one side of the box, the oil pump is arranged at the top end of the box, and the paint box is arranged on one side of the oil pump. The multi-station mechanism is arranged at the bottom end in the box. A mounting block, a drive motor, rolling wheels, a conveying belt, connecting blocks, supporting columns and discs are sequentially arranged inthe multi-station mechanism. The drive motor is arranged at the center position in the mounting block, and the rolling wheels are arranged at the top end of the drive motor. The work efficiency of the auto part surface coating device with the drying function is improved, the auto part surface coating device with the drying function has the drying effect, and the auto part surface coating device with the drying function is convenient to adjust.

Owner:NANTONG RONGRUN AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com