Efficient wooden door paint spraying equipment with drying function

A kind of painting equipment and high-efficiency technology, applied in the direction of painting room, spraying device, device for coating liquid on the surface, etc., can solve the problems of troublesome processing personnel, affecting the efficiency of wooden doors, low processing efficiency, etc., to improve efficiency, convenient and fast operation , The effect of improving the uniformity of spray paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

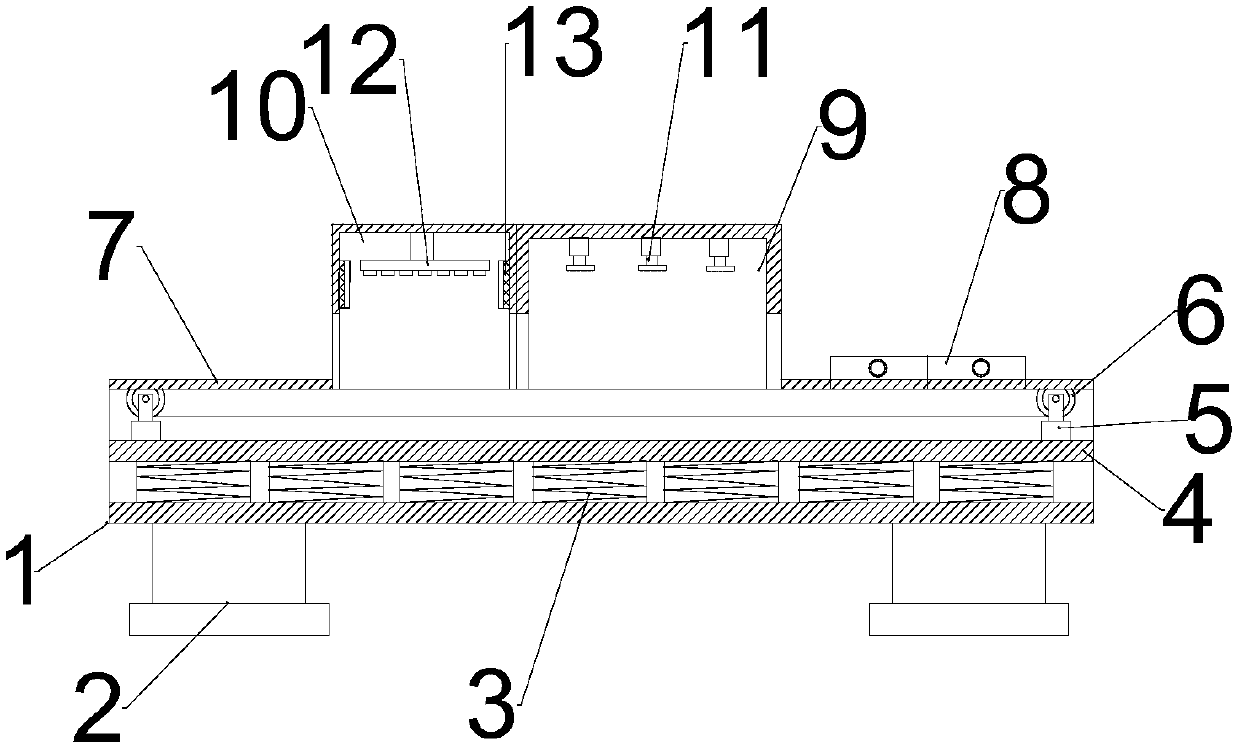

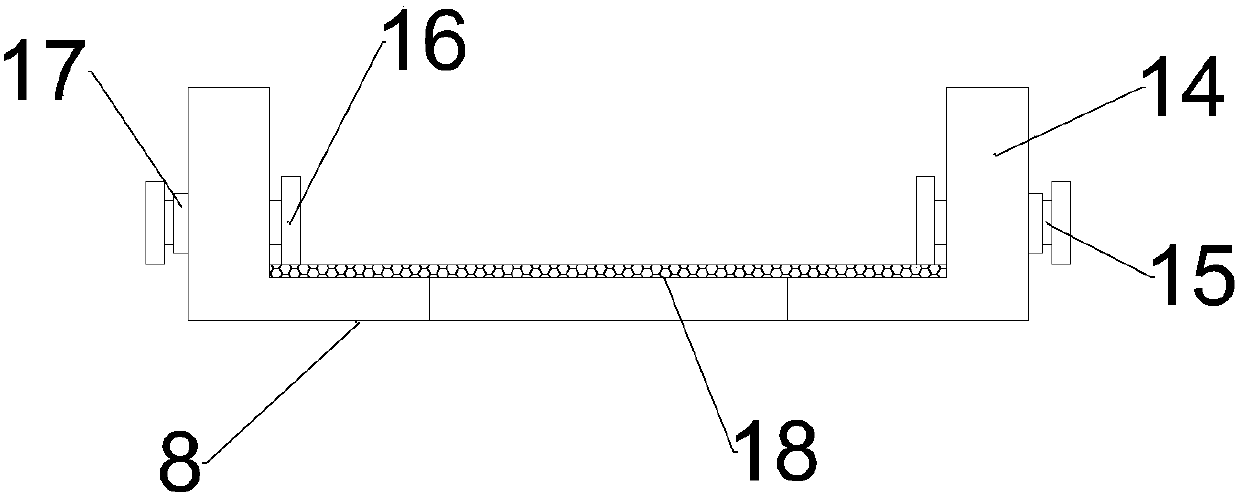

[0013] Such as figure 1 with figure 2 as shown, figure 1 It is a structural schematic diagram of a high-efficiency wooden door painting equipment with drying function proposed by the present invention, figure 2 It is a structural schematic diagram of the fixing device in the high-efficiency wooden door painting equipment with drying function proposed by the present invention.

[0014] refer to figure 1 with figure 2 , a kind of high-efficiency wooden door painting equipment with drying function proposed by the present invention comprises a fixed chassis 1, a fixed base 2 and a shock absorbing device 3, wherein:

[0015] The fixed base 2 is arranged on the lower end of the fixed base frame 1, the lower end of the fixed base 2 is provided with an anti-slip pad, the shock absorber 3 is arranged on the upper end of the fixed base frame 1, and the upper end of the shock absorber 3 is provided with a support plate 4, and the support plate 4 is left and right The upper sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com