Cr-Mo ASTM A387 Gr22CL2 pressure vessel steel and production method thereof

A technology of a pressure vessel and a production method, which is applied in the field of wide and thick steel plate production, can solve the problems of aggravating the segregation and segregation of steel ingots, affecting the center feeding effect of the steel ingot body, and being difficult to meet the demand of product delivery time, and achieving high cooling strength. , the effect of shortening the cooling rate solidification time, solidification time and demolding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An ASTM A387 Gr22CL2 pressure vessel steel with a limit thickness of Cr-Mo, comprising the following mass percentage components (unit, wt%): C: 0.10, Si: 0.30, Mn: 0.50, P: 0.010, S: 0.002, Als: 0.029 , Cr: 2.2, Mo: 0.98, others are Fe and residual elements.

Embodiment 2

[0025] An ASTM A387 Gr22CL2 pressure vessel steel with a limit thickness of Cr-Mo, comprising the following mass percentage components (unit, wt%): C: 0.09, Si: 0.32, Mn: 0.45, P: 0.011, S: 0.003, Als: 0.025 , Cr: 2.1, Mo: 1.0, others are Fe and residual elements.

[0026] The aforementioned limit thickness Cr-Mo is ASTM A387 Gr22CL2 pressure vessel steel, and the thickness of the steel plate is 120-150 mm.

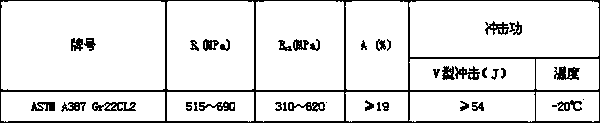

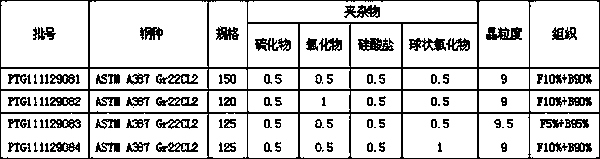

[0027] The chemical composition and mechanical properties are implemented in accordance with ASTM A387 / A387M-06a, as shown in the table.

[0028]

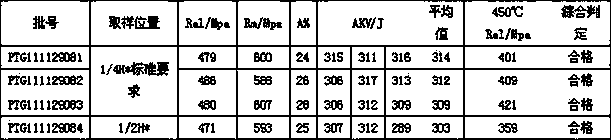

[0029] The test results of mechanical properties of ASTM A387 Gr22CL2 steel plate are shown in the table.

[0030]

[0031] *H represents the thickness of the steel plate, 1 / 4H or 1 / 2H is the performance of sampling and testing at 1 / 4 or / 1 / 2 of the thickness direction of the steel plate.

[0032] In terms of performance testing, the average yield strength is 479MPa, a surplus of 169Mpa compared with the standard, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com