Tea leaf fermenting and oven-drying intelligent integrated machine

A technology of tea fermentation and integrated machine, which is applied in tea processing before extraction, etc., can solve the problems of affecting tea quality and production speed, wasting labor and time, etc., and achieve good temperature and humidity control capabilities, improve quality, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

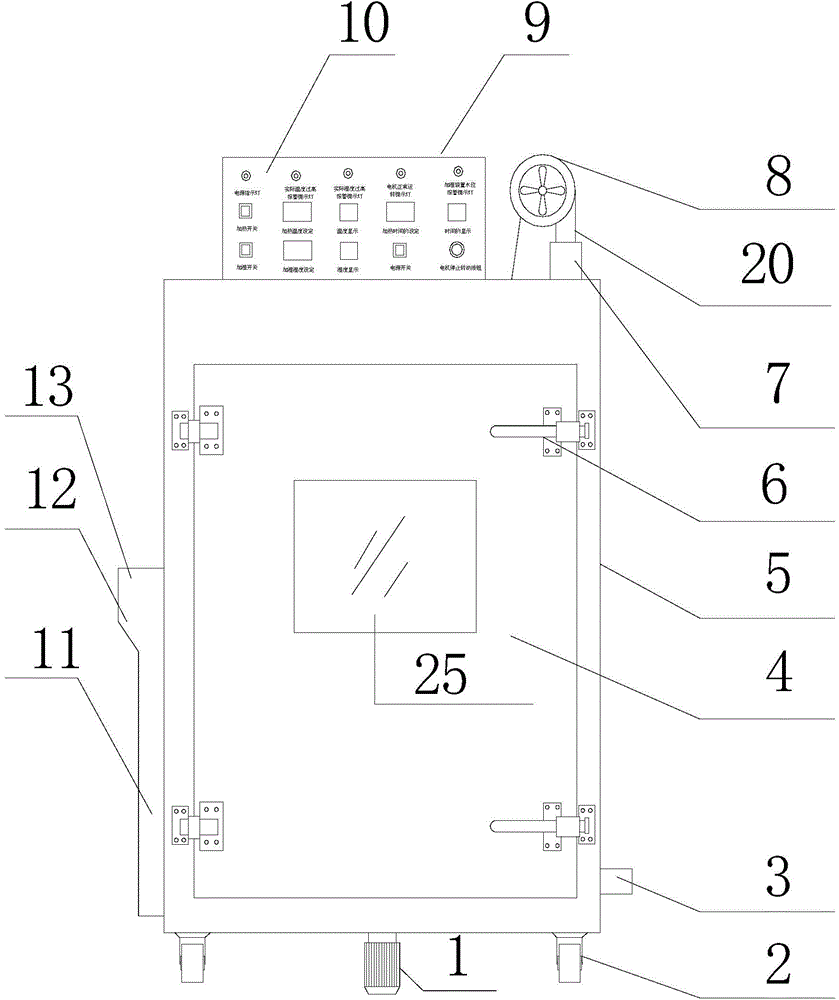

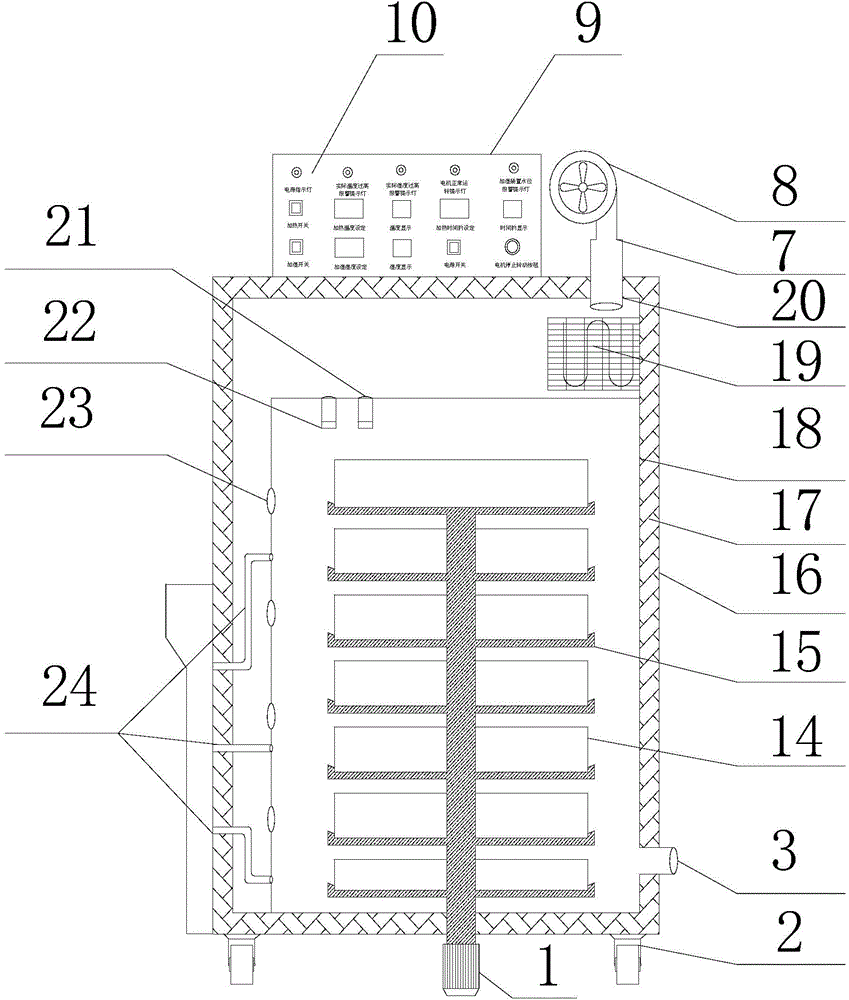

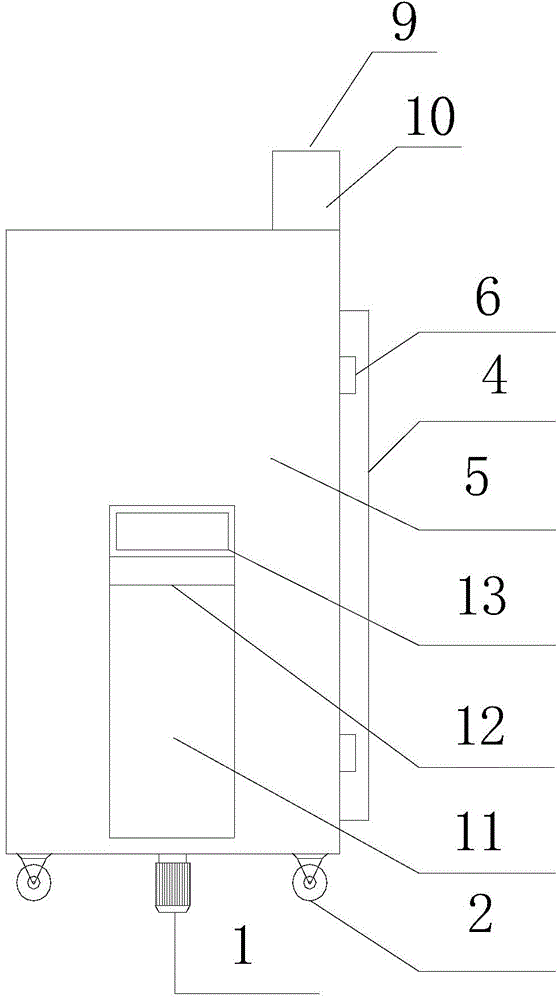

[0017] refer to Figure 1 ~ Figure 4 , an intelligent all-in-one machine for tea fermentation and drying according to the present invention, comprising a box body 5, a control device 9, a fermentation auxiliary device 13, a drying auxiliary device 7, a visual window 25, a warm air blowing port 23, and a steam pipe 24. rack 15 and tea tray 14, the box body 5 is provided with a box door 4, a visible window 25 and a moisture discharge port 3, and an external fan 8 and a control device 9 are installed above the box body, and the side of the box body is installed with Fermentation device 24, rotating bracket motor 1, rubber bottom wheel 2 are installed below the casing; control device 9 is to control steam generator 11 and The electric heater 19; the fermentation auxiliary device 13 is directly connected with the water vapor channel 24; the drying auxiliary device 7 is directly connected with the warm air blowing port 23; the rotating bracket 15 and the tea tray 14 are directly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com