Factory type construction waste resourceful treatment system and technological process thereof

A construction waste and treatment system technology, applied in the field of comprehensive utilization of resources, to achieve the effects of easy water absorption, low resource treatment cost, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

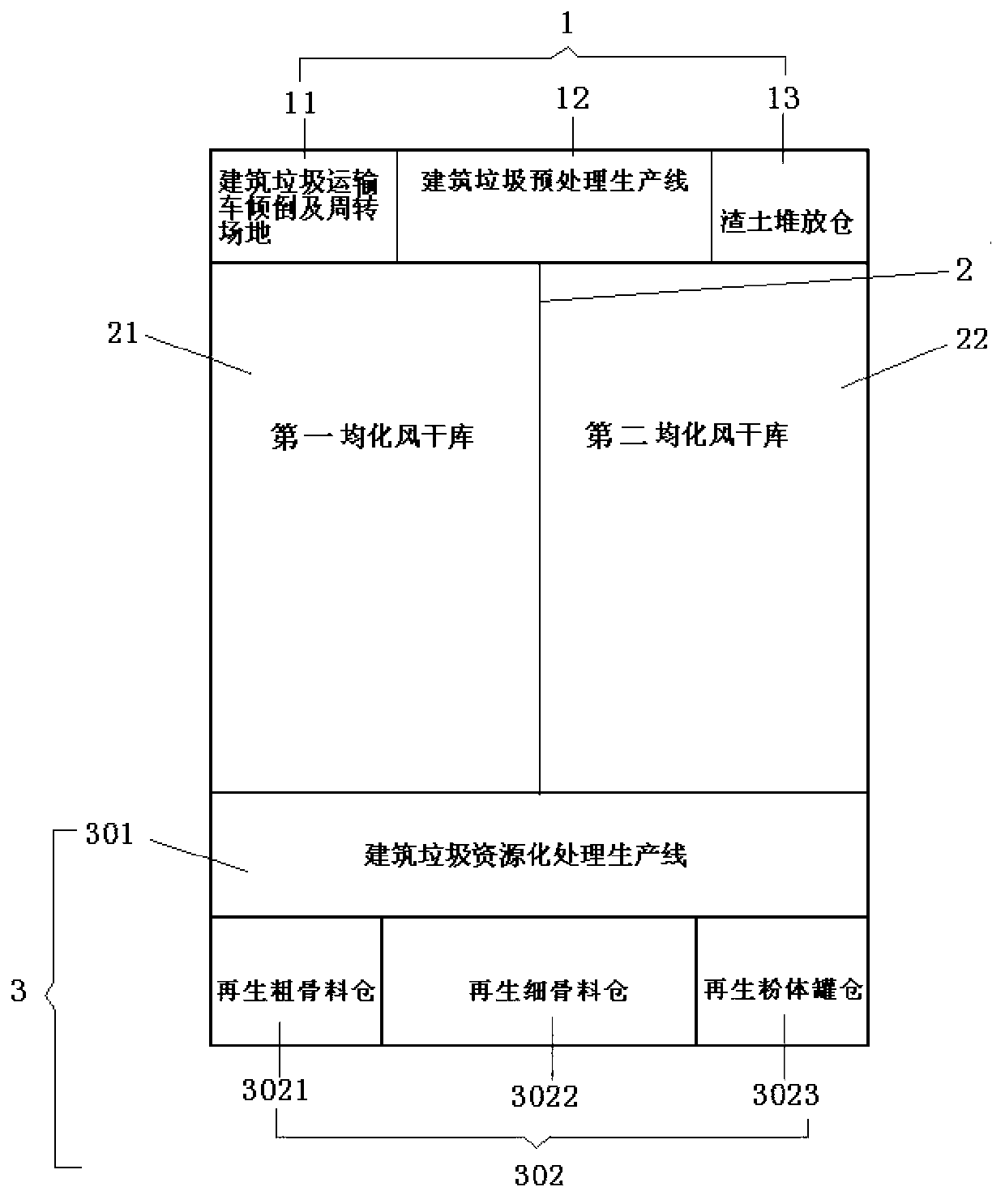

[0084] Embodiment 1. The process layout of the in-line factory type construction waste resource treatment system

[0085] Such as figure 1 As shown, a factory-style construction waste resource treatment system in this embodiment includes a pretreatment unit 1 , a homogenizing air-drying unit 2 and a recycled material processing and production unit 3 arranged in sequence.

[0086] The pretreatment unit 1 includes a construction waste transport vehicle dumping and turnover site 11 , a construction waste pretreatment production line 12 and a muck storage bin 13 arranged in sequence.

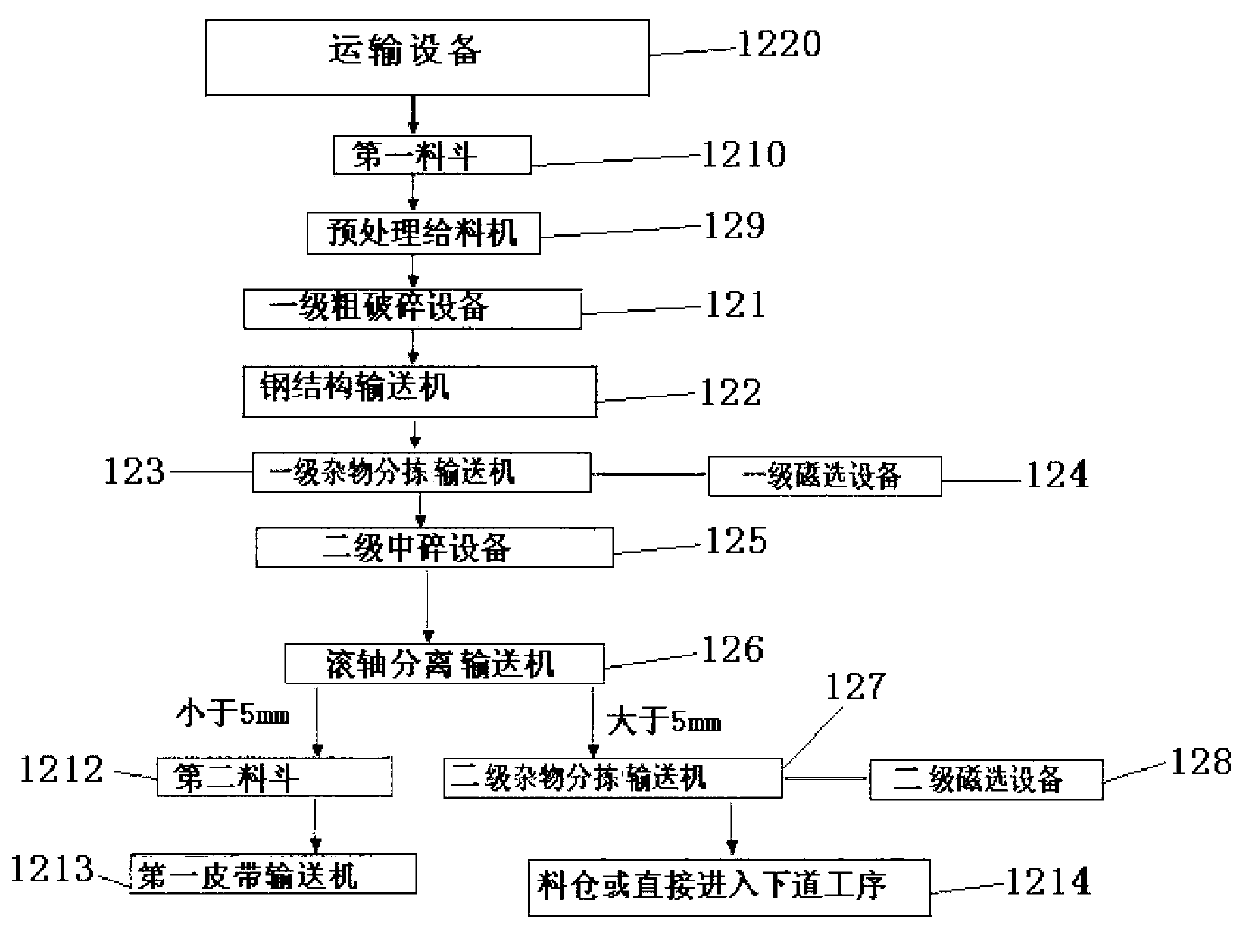

[0087] Such as figure 2 As shown, the construction waste pretreatment production line 12 is a construction waste joint extrusion harmless treatment system, and the construction waste joint extrusion harmless treatment system includes a primary coarse crushing equipment 121, a steel structure conveyor 122, a The first-level debris sorting conveyor 123 and the first-level magnetic separation equipm...

Embodiment 2

[0110] Embodiment 2, process layout of L-shaped factory-style construction waste recycling system

[0111] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the two vertical sides of the homogenization air-drying unit 52 of the present embodiment are respectively provided with a pretreatment unit 51 and a recycled material processing production unit 53, and the pretreatment unit 51 and the homogenization The position of the air-drying unit 52 forms a first L-shaped layout, and the positions of the pretreatment unit 51 and the recycled material processing and production unit 53 form a second L-shaped layout. The two L-shaped layouts are suitable for the implementation of construction waste recycling in square plots. When the factory-style construction waste resource processing system constitutes two L-shaped layouts, the construction waste pretreatment production line 512 and the muck storage bin 513 are adjacent to the first homogeniz...

Embodiment 3

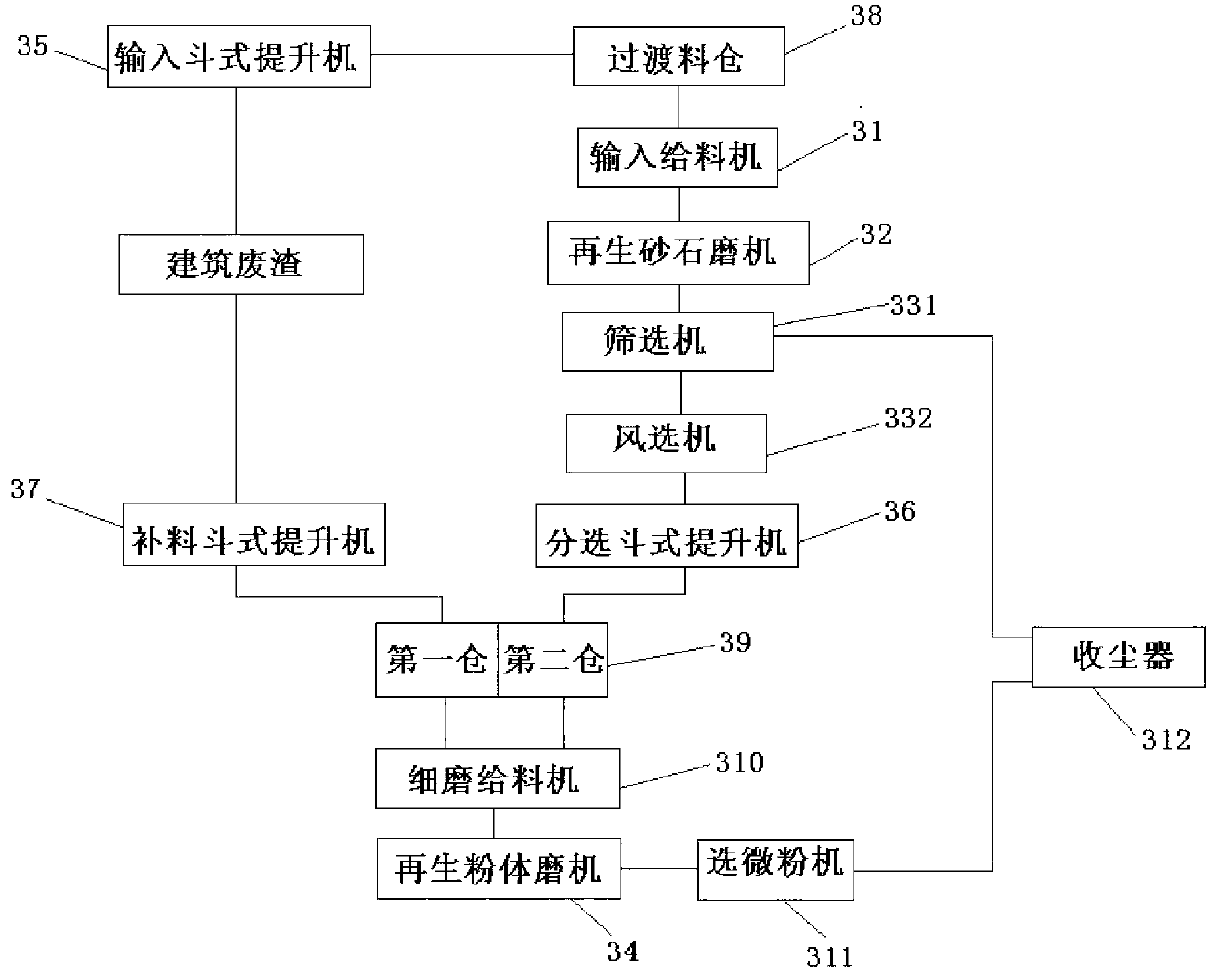

[0112] Embodiment 3, the process flow of the factory-style construction waste resource treatment system

[0113] The process flow of the factory type construction waste recycling system of the present invention, the steps are as follows:

[0114] Such as figure 2 As shown, step 1, feeding: construction waste transport vehicles or loaders, both of which are transport equipment 1220, and the transport equipment pours construction waste into the first hopper 1210, and enters the feeder through the hopper. The feeder 129, the feeder 129 sends the construction waste into the primary extrusion crushing equipment 121;

[0115] Step 2, first-level coarse crushing of construction waste: the first-level extrusion and crushing equipment 121 squeezes, splits, and crushes the construction waste to crush the construction waste to a particle size below 200mm;

[0116] Step 3, first-level separation of impurities: construction waste is discharged from the lower outlet of the first-level ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com