Sign cutting and grinding all-in-one machine capable of conducting cutting and edge grinding simultaneously

A technology of cutting and grinding, integrated machine, applied in the direction of machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problem of low grinding efficiency, achieve high grinding efficiency, good quality, and high practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

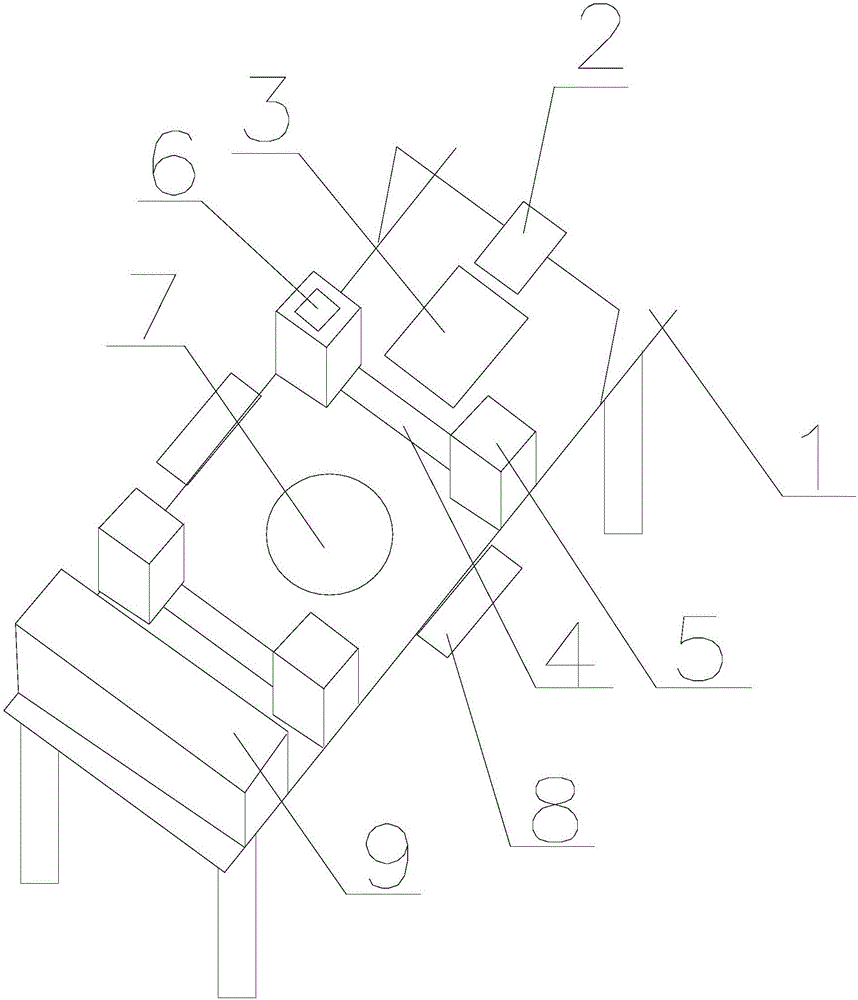

[0022] Such as figure 1 As shown, the label cutting and polishing integrated machine for cutting and polishing edges of the present invention includes a conveying device 1, a cutting device 2 and a label 3 on the conveying device 1. There are two slides 4 on the conveying device 1, the slide 4 There is a polishing device 5 at both ends of the, and the polishing device 5 polishes the cut edge of the sign 3, and there is a rotating table 7 between the two slideways 4.

Embodiment 2

[0024] On the basis of Example 1, the integrated label cutting and polishing machine for cutting and polishing the edges at the same time, the conveyor 1 has a water sprayer 8, a dryer 9, and the water sprayer 8 is installed on the dryer 9 and the cutting Between the device 2 and the slide 4 between the dryer 9 and the cutting device 2.

[0025] In the label cutting and polishing integrated machine for cutting and polishing edges at the same time, a pressure sensor 6 is provided on the polishing device 5, and a rotatable polishing machine is provided on the opposite surfaces of the two polishing devices 5.

Embodiment 3

[0027] On the basis of the second embodiment of the label cutting and polishing integrated machine for cutting and polishing the edges, the conveyor on the conveyor 1 has a number of holes.

[0028] In the label cutting and polishing integrated machine for cutting and polishing edges, there is a dust collecting chamber under the conveyor belt of the conveying device 1, and the dust collecting chamber is connected with a water sprayer 8, which has a water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com