Primary side drying system of steam generator

A technology of steam generator and drying system, applied in steam generation, drying, dryer and other directions, can solve the problems of increasing research and development cost, reducing work efficiency, difficult exhaust gas extraction and filtration, etc., to improve efficiency and versatility Good, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

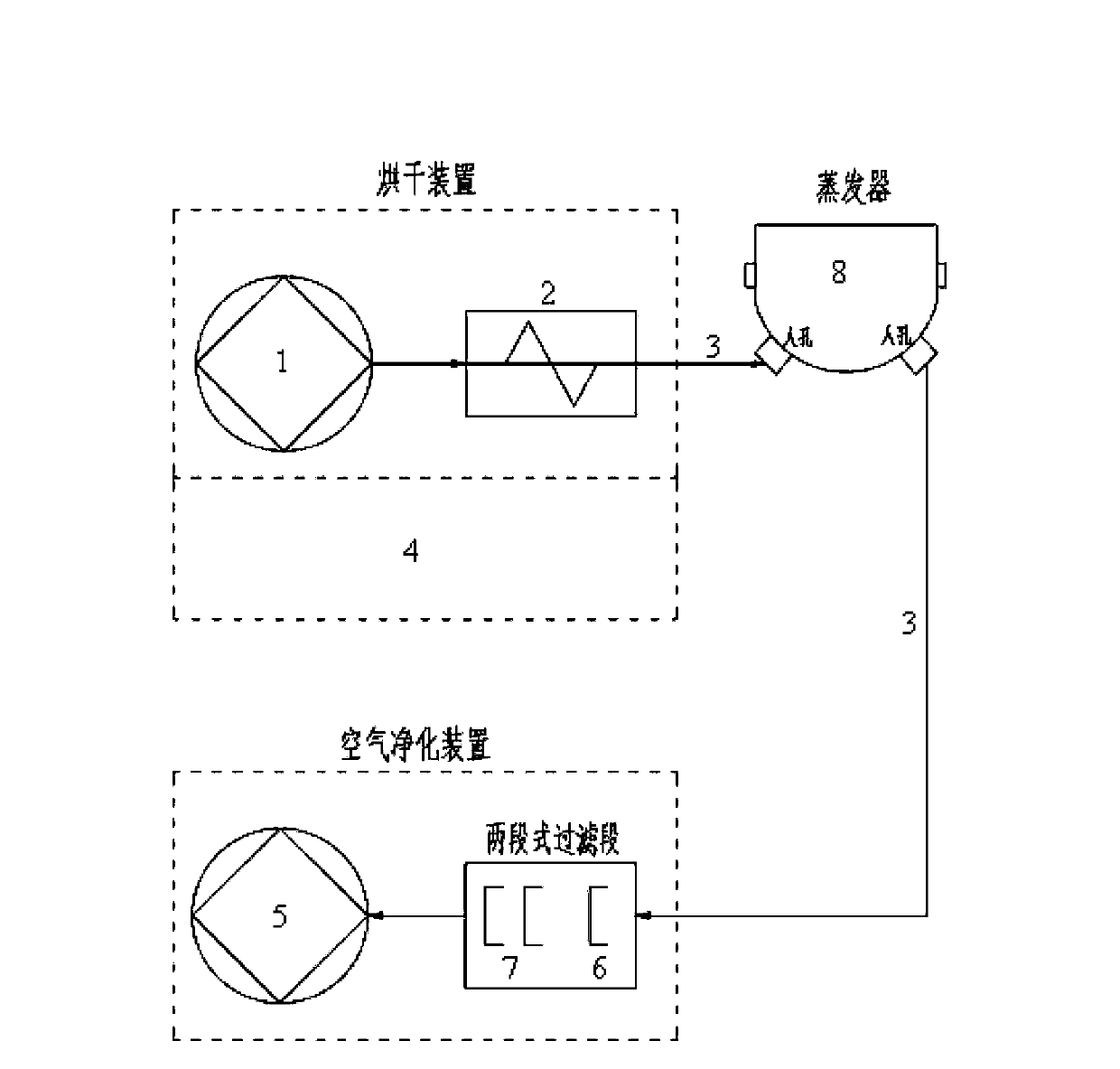

[0022] The steam generator primary side drying system of the present invention will be described in detail below with reference to the drawings and embodiments.

[0023] The steam generator primary side drying system of the present invention includes a drying device and an air cleaning device, the drying device is used to input the heated gas to the steam generator 8, and the air cleaning device is used to treat the waste gas generated by the steam generator 8 Vent and filter.

[0024] The drying device includes a drying module and a drying control module 4 .

[0025] Wherein, the drying module includes a blower 1 and a heater 2 , and the gas generated by the blower 1 is heated by the heater 2 and input to a manhole of the steam generator 8 .

[0026] In this embodiment, the blower 1 and the heater 2 are interlocked, and when the blower 1 stops, the heater 2 stops, so as to avoid overheating damage of the heating section.

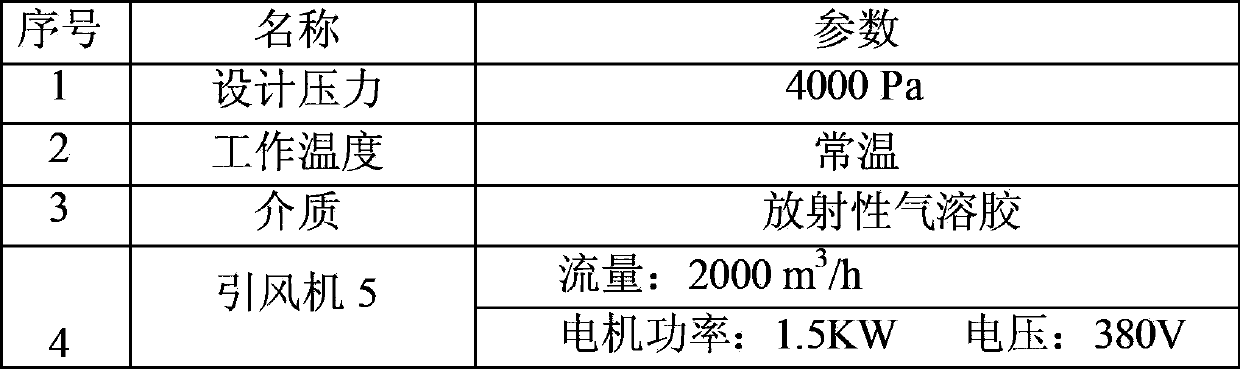

[0027] In this embodiment, the main technical param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com