Patents

Literature

117results about "Sand drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

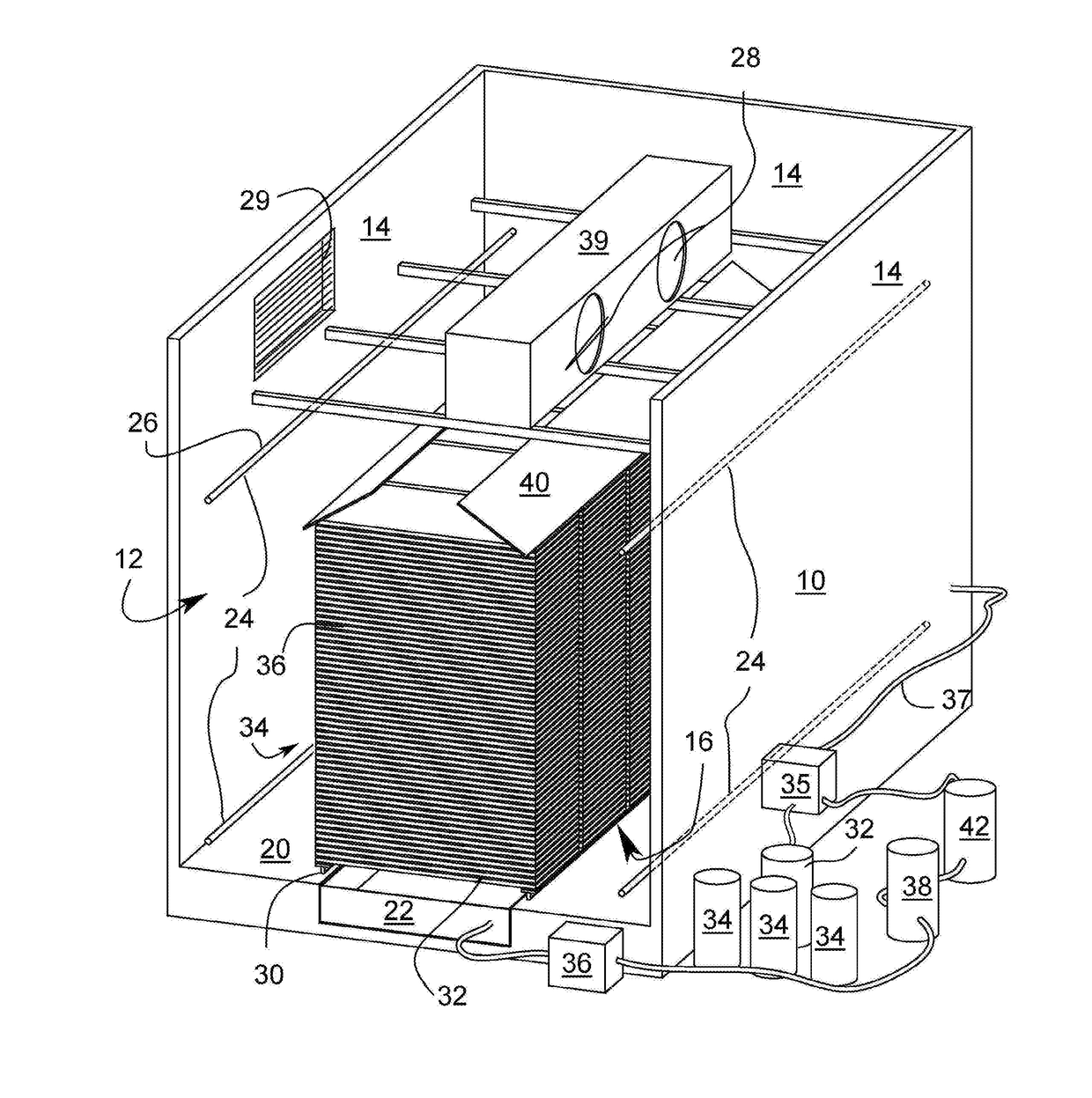

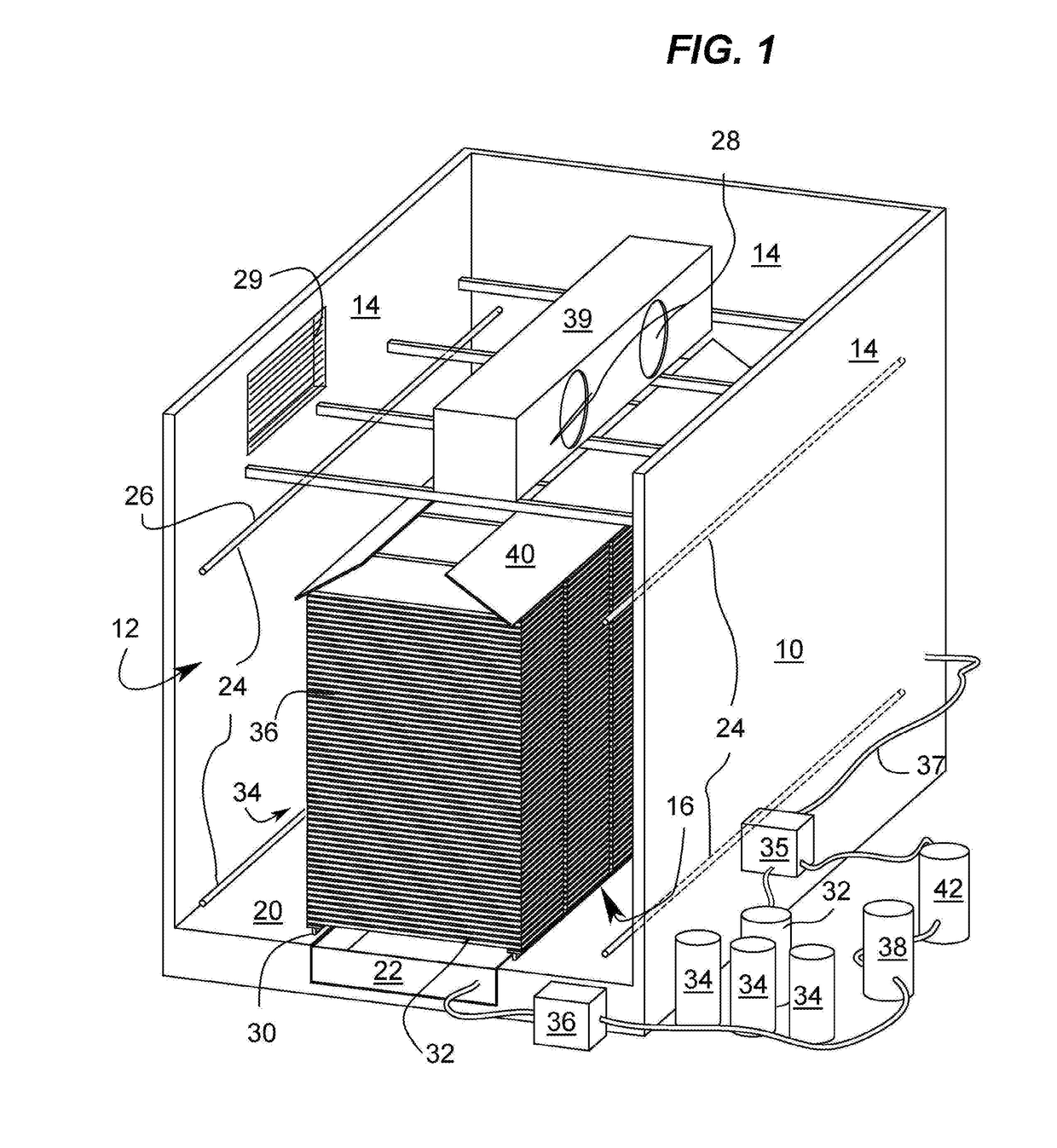

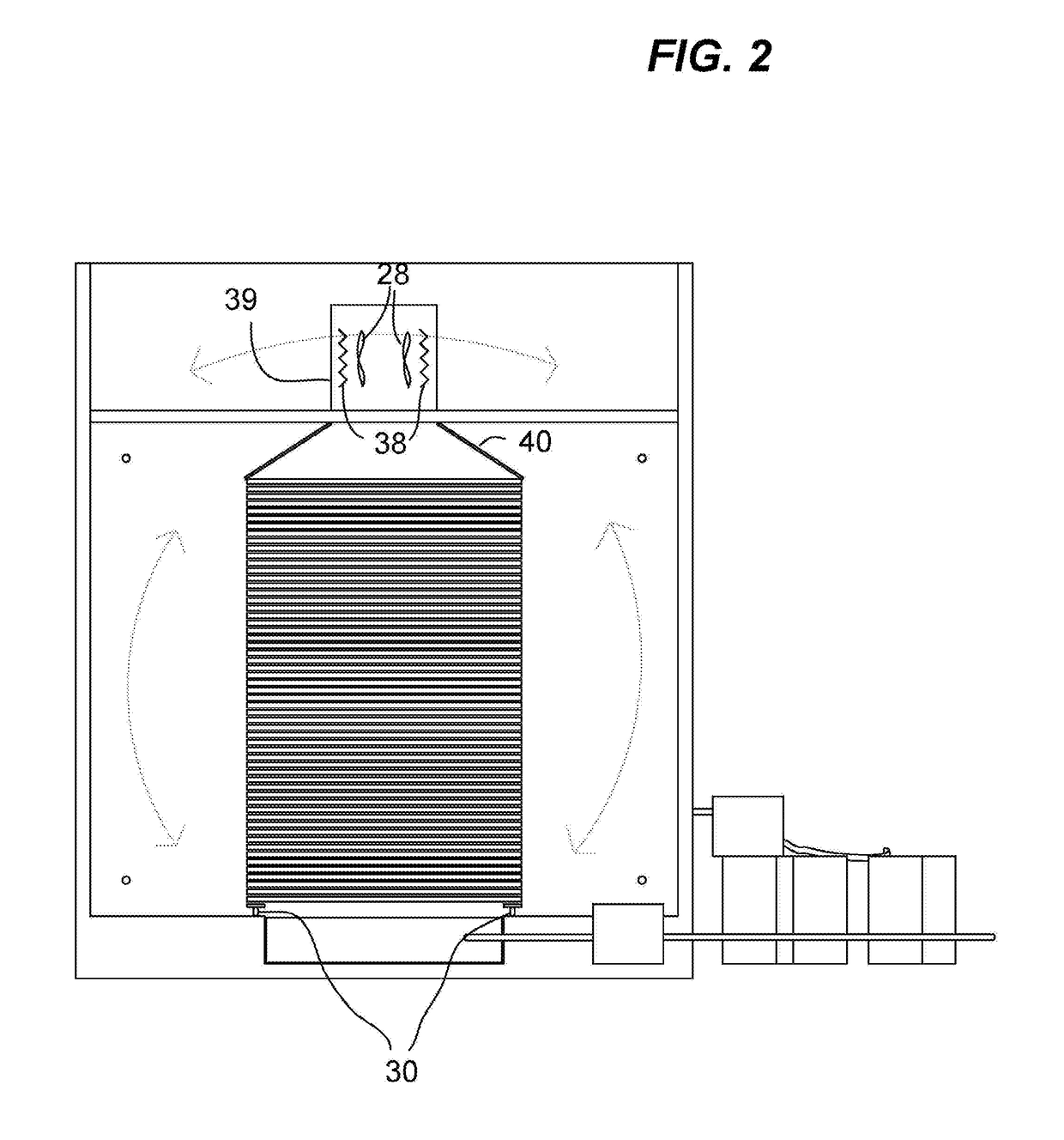

Heat and Water Recovery From Oil Sands Waste Streams

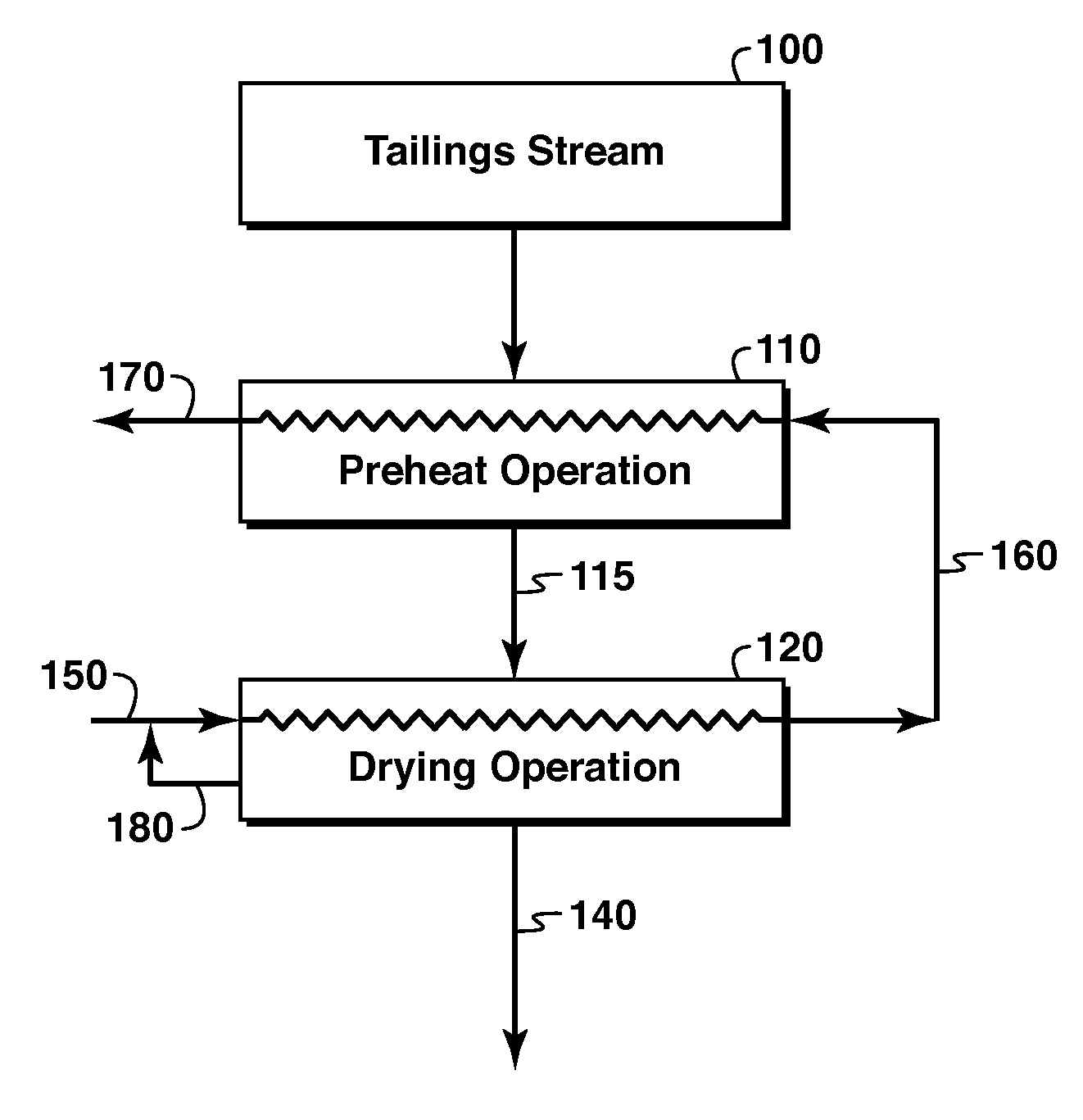

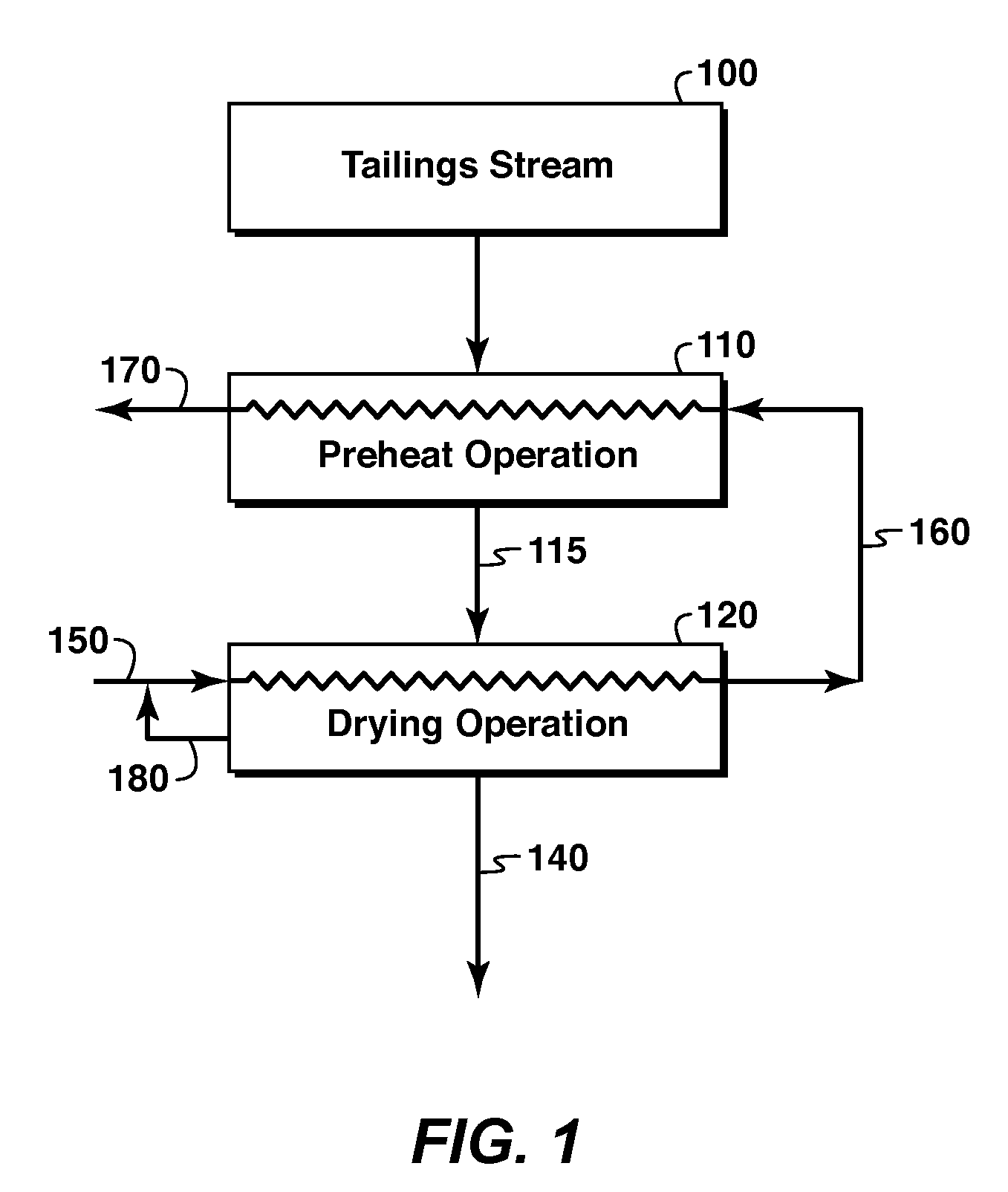

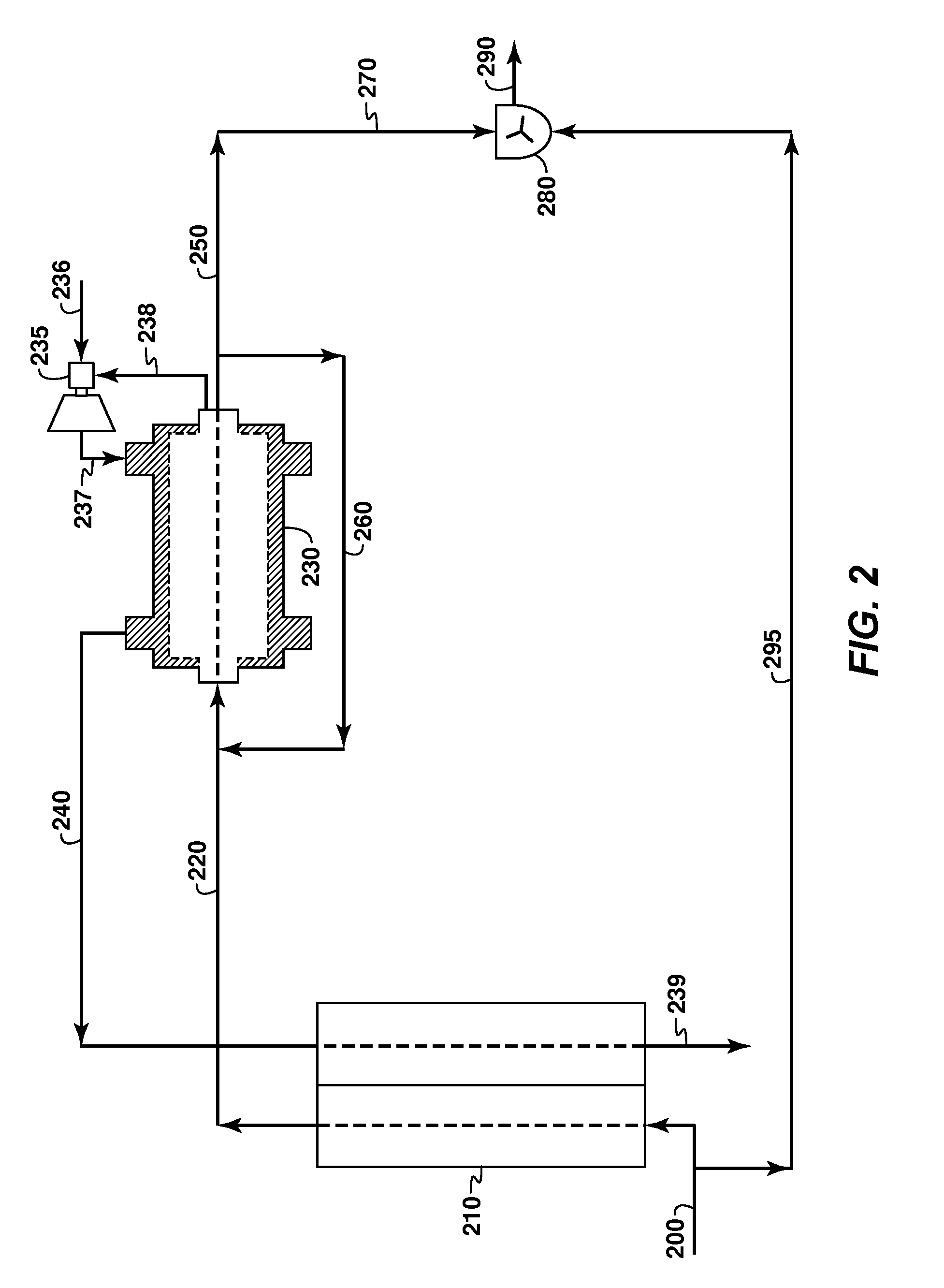

InactiveUS20110061610A1Lower energy requirementsReduce heatSand dryingLiquid hydrocarbon mixture productionWaste streamProcess engineering

Methods and systems for recovering heat and water from waste streams produced during oil sands extraction to form dry, stackable tailings. A tailings stream is preheated in a heat exchanger, thereby reducing the energy required to dry the tailings. The preheated tailings are then dried, thereby reducing the tailings to dry stackable tailings or thickened tailings suitable for mine backfill. Heat and high-quality water are recovered from the drying operation and re-used in the preheat operation, or in other steps of oil sands extraction or treatment processes, thereby reducing the overall heat and water requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

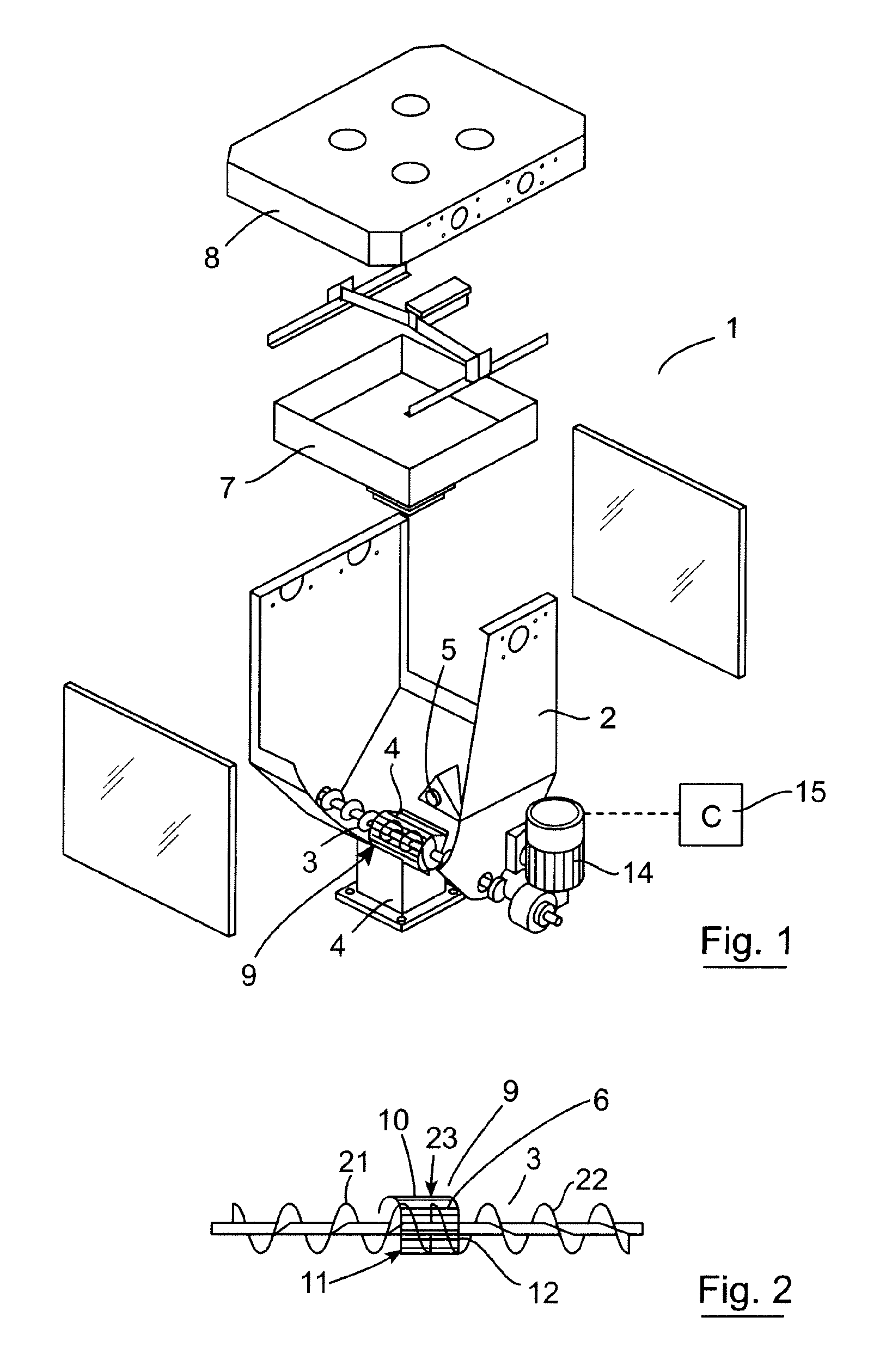

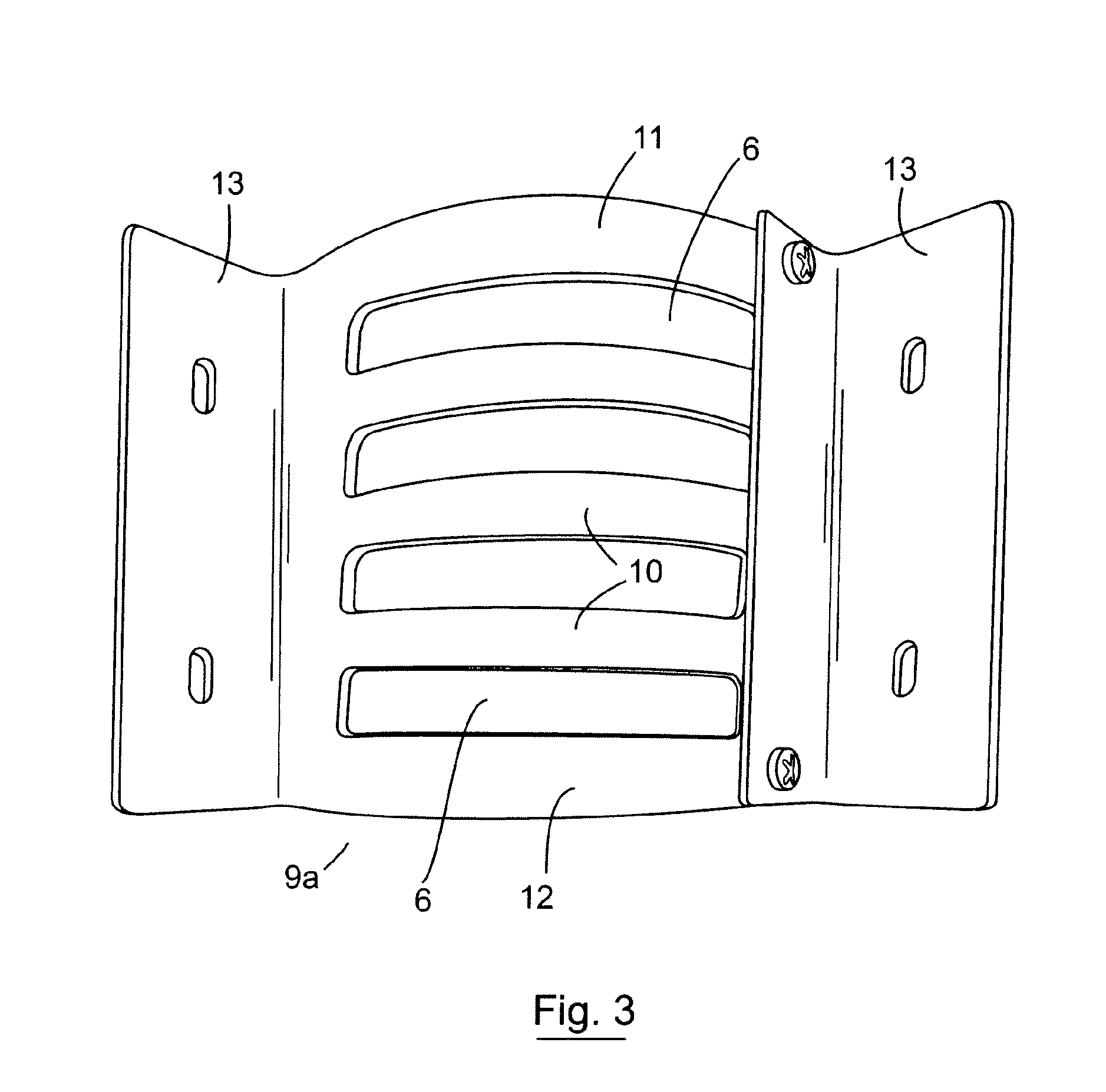

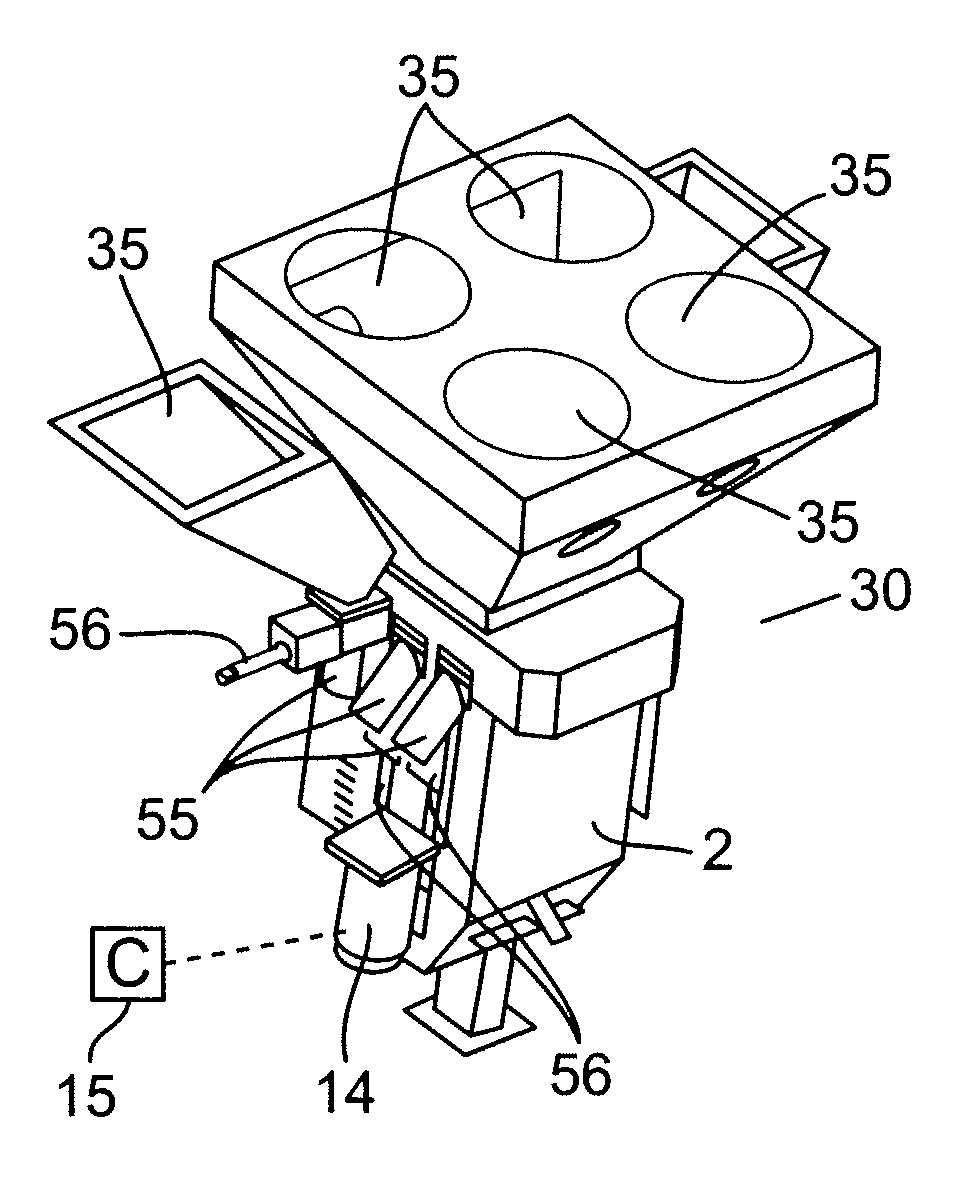

Blenders

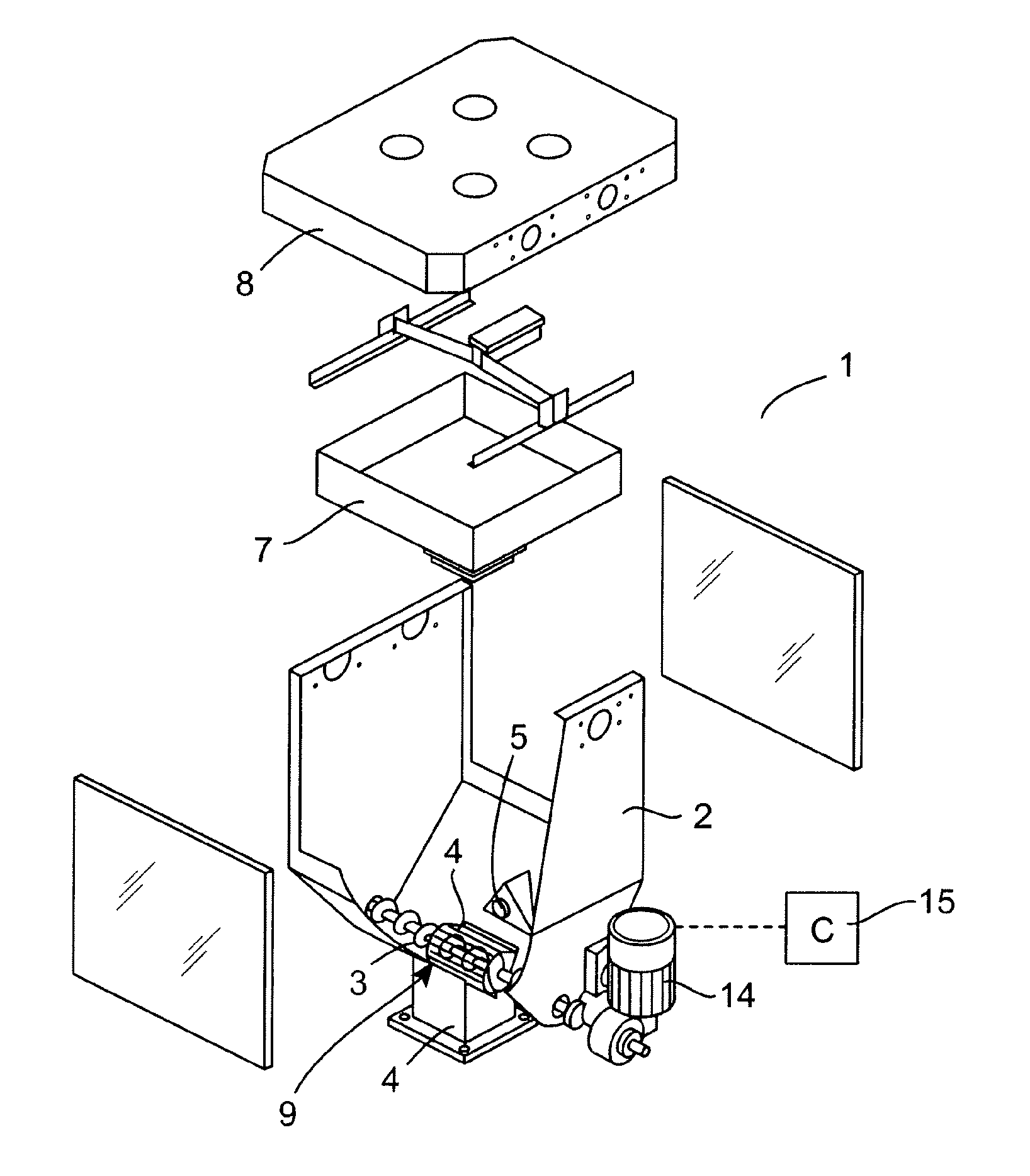

ActiveUS20130135958A1Clean thoroughlySand dryingDrying solid materials with heatMixed materialsEngineering

A blender has a mixing chamber for reception of materials to be blended. A mixing screw is mounted at a bottom of the mixing chamber for mixing materials within the mixing chamber and delivering mixed materials to an outlet feeding a processing line. A baffle is mounted at the outlet extending about the mixing screw. The baffle inhibits upward movement of material at the outlet tending to cram material into the outlet.

Owner:VERVANT

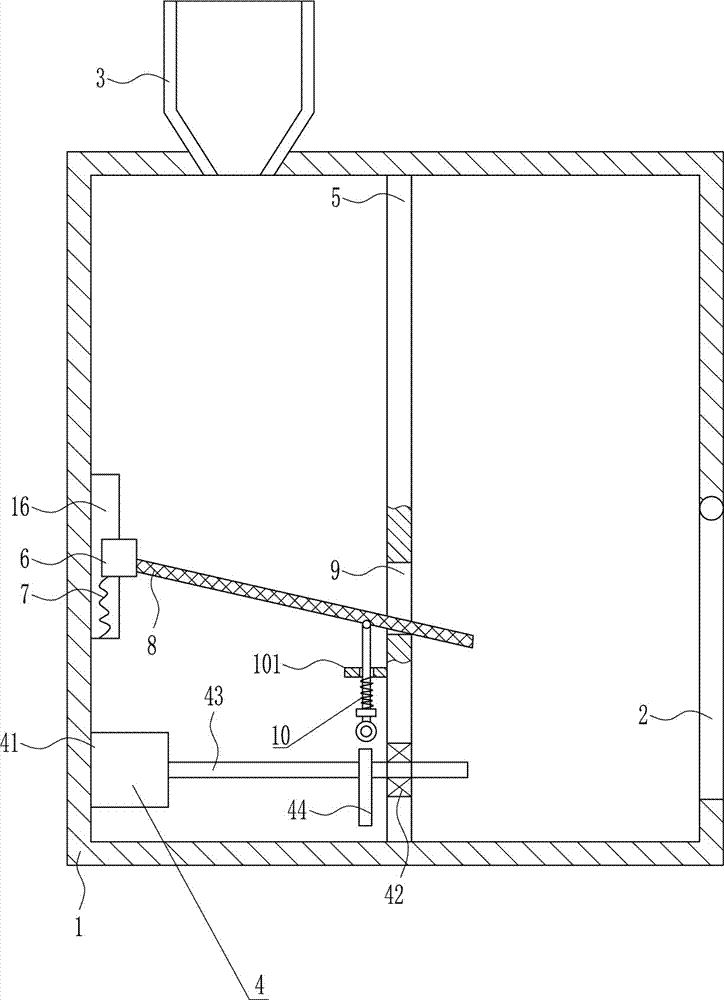

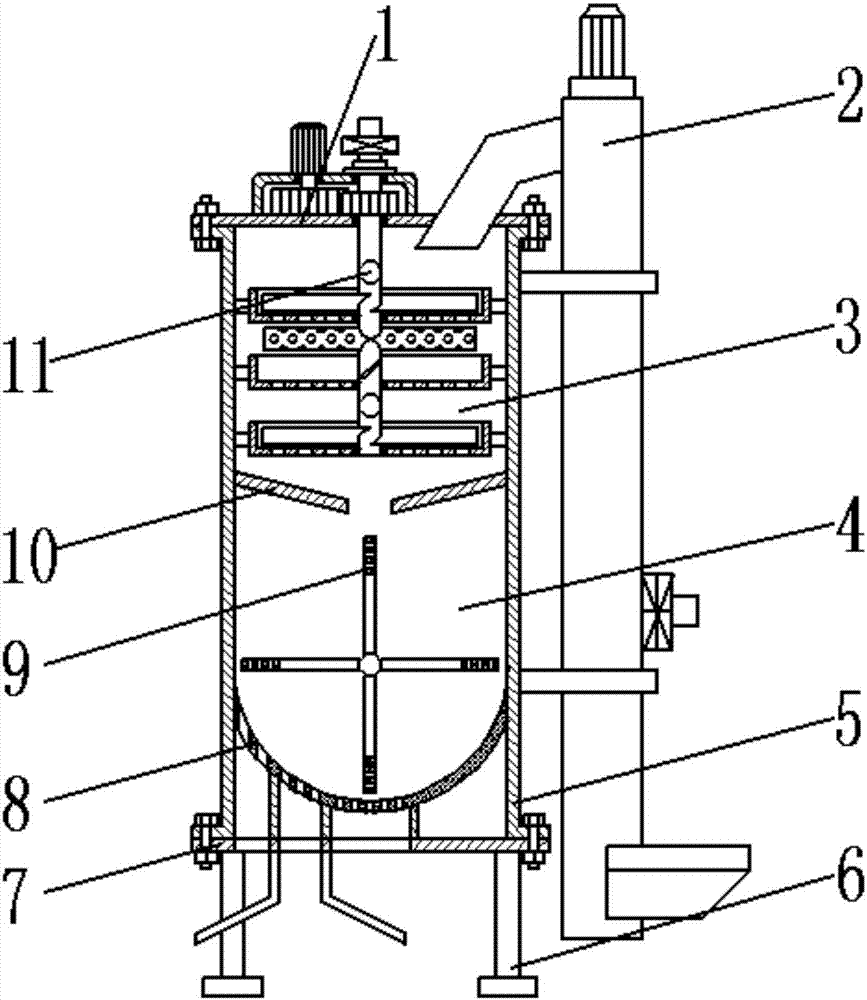

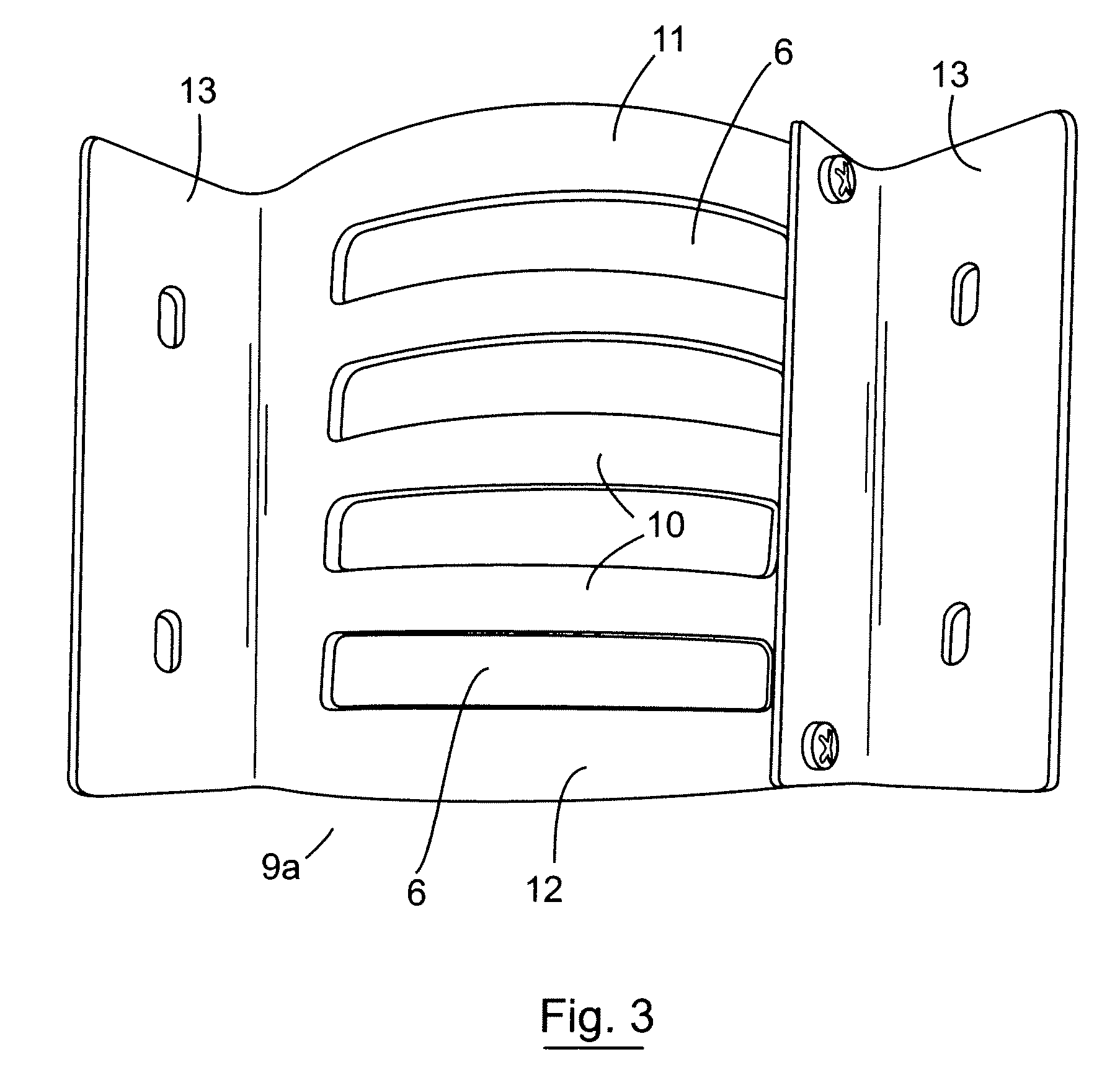

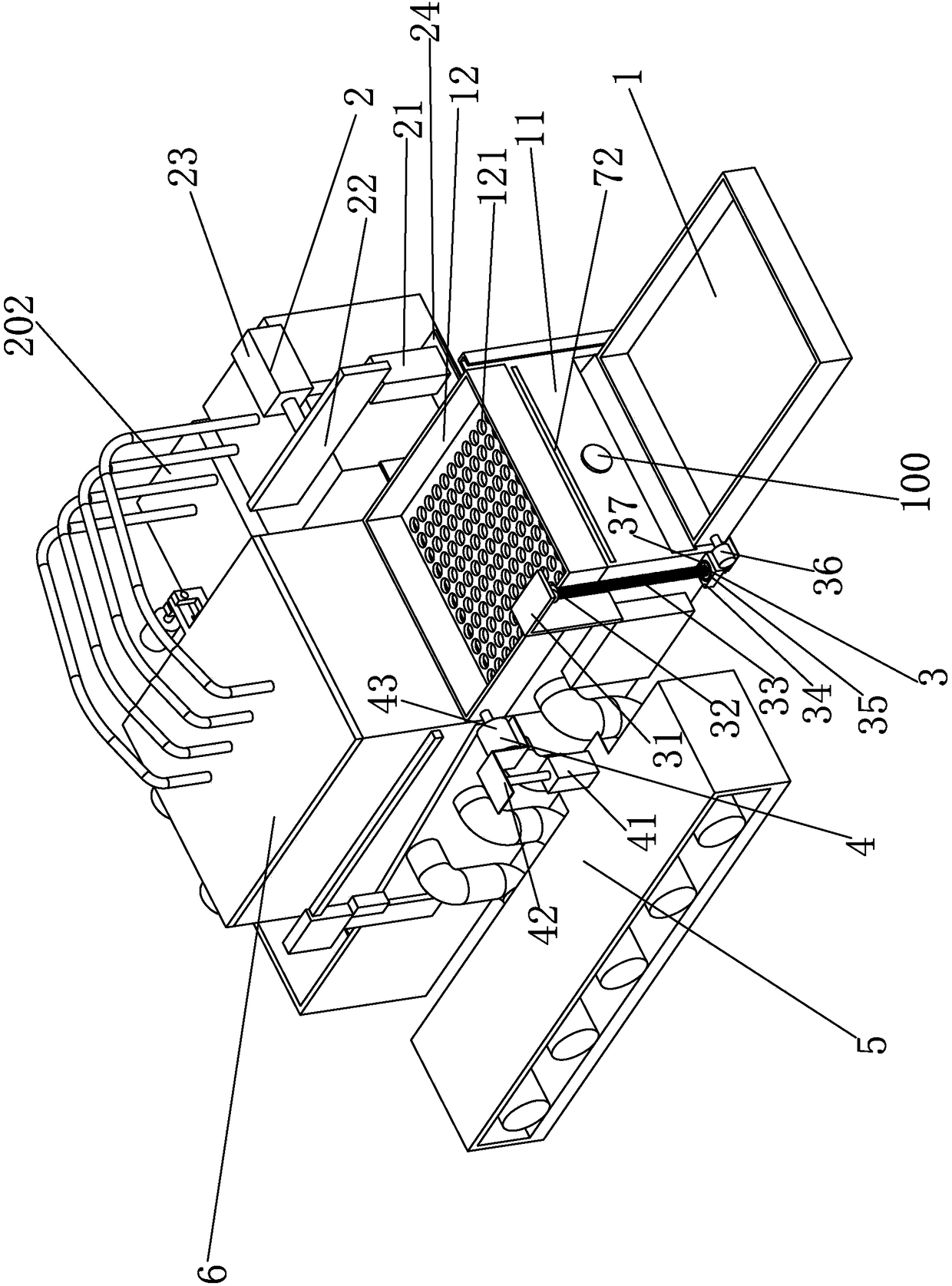

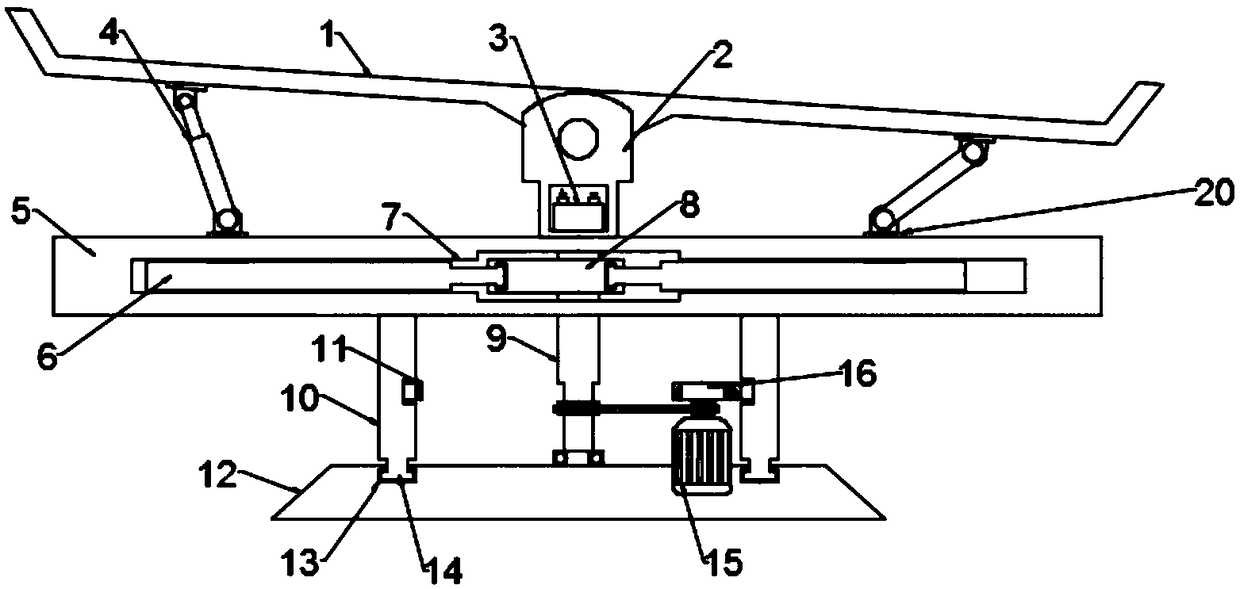

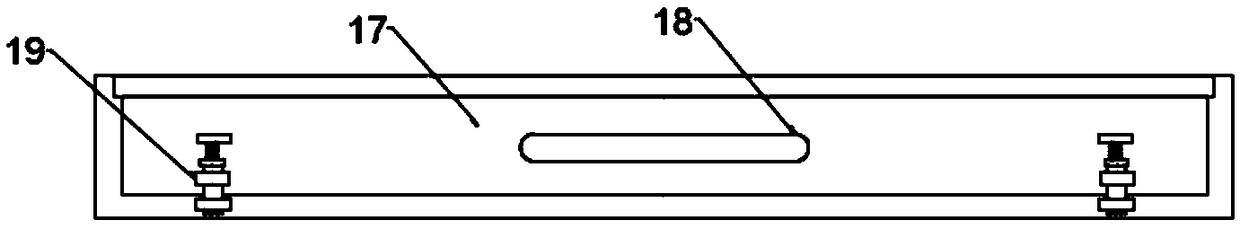

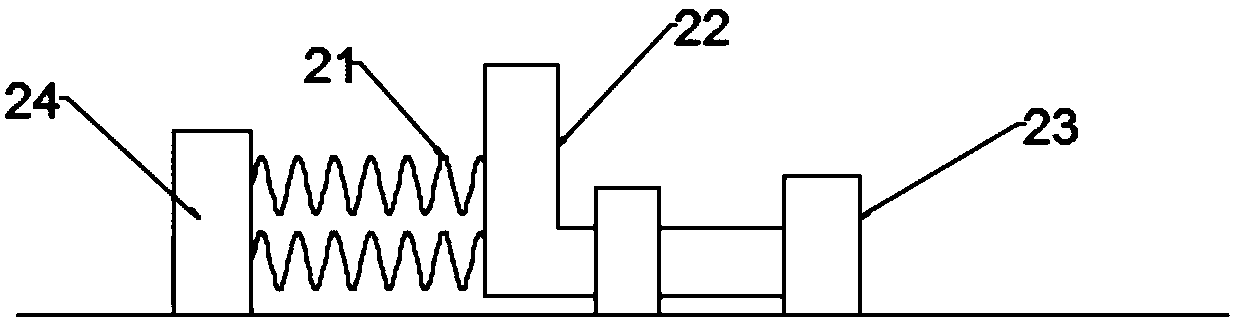

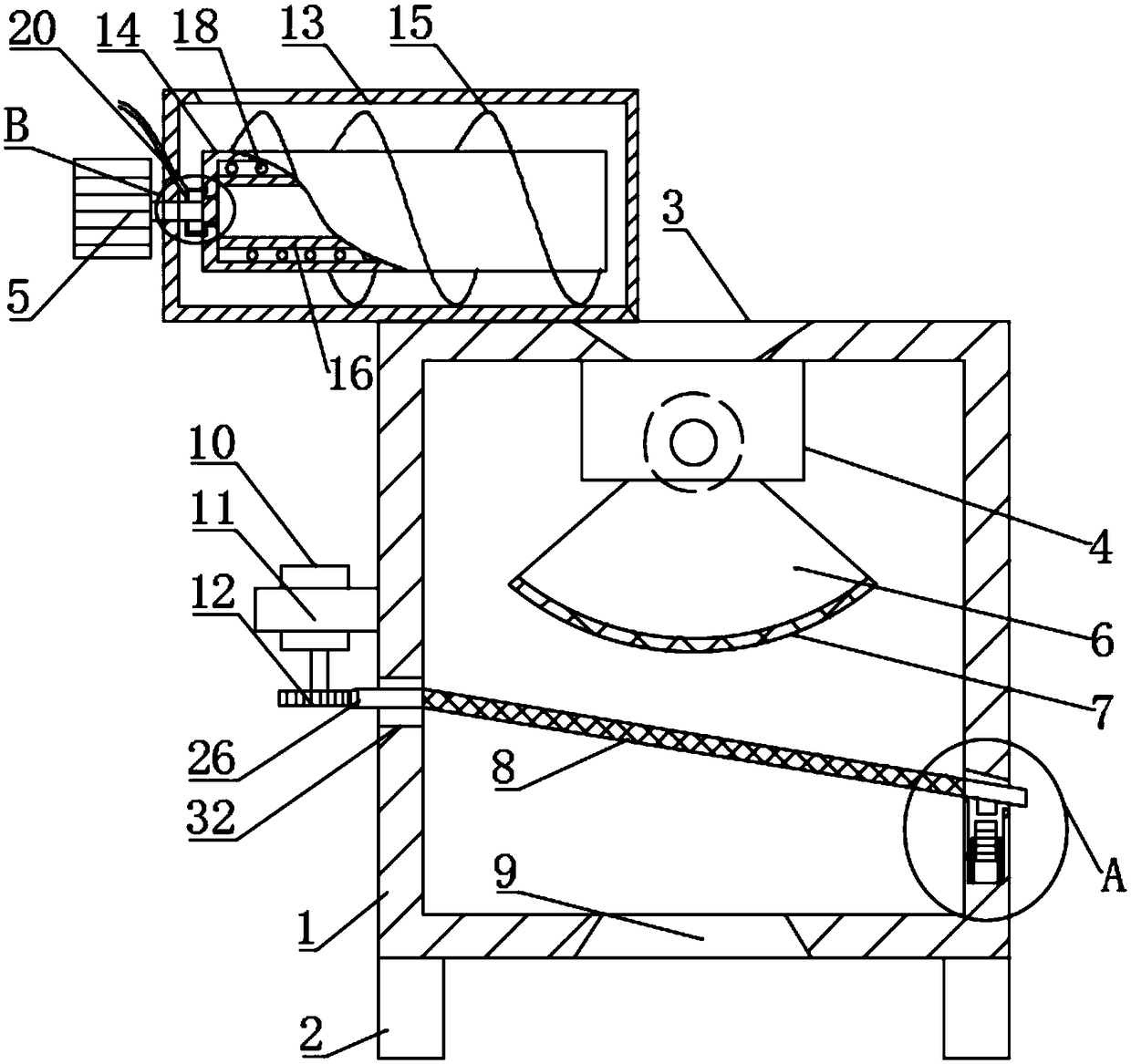

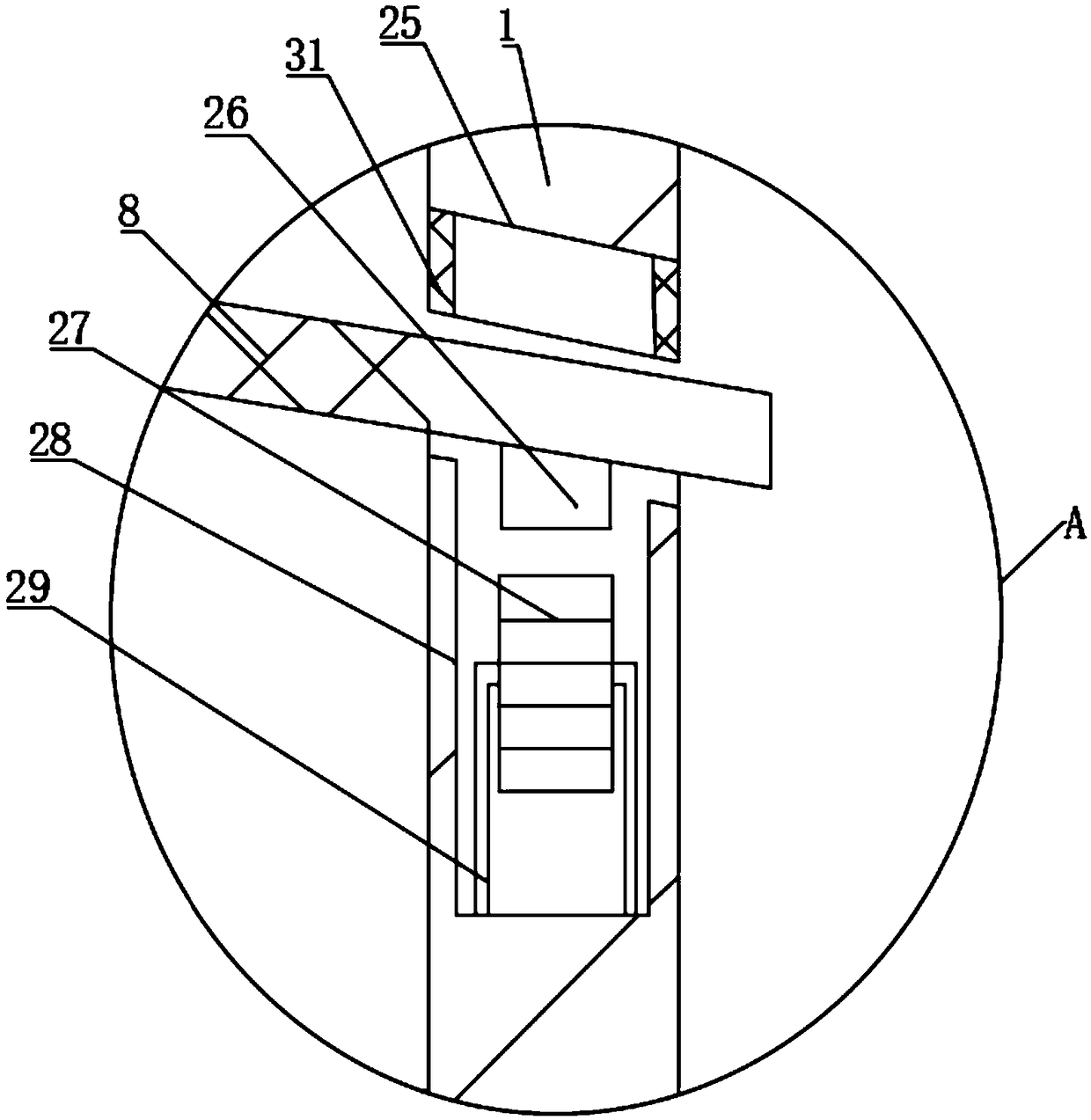

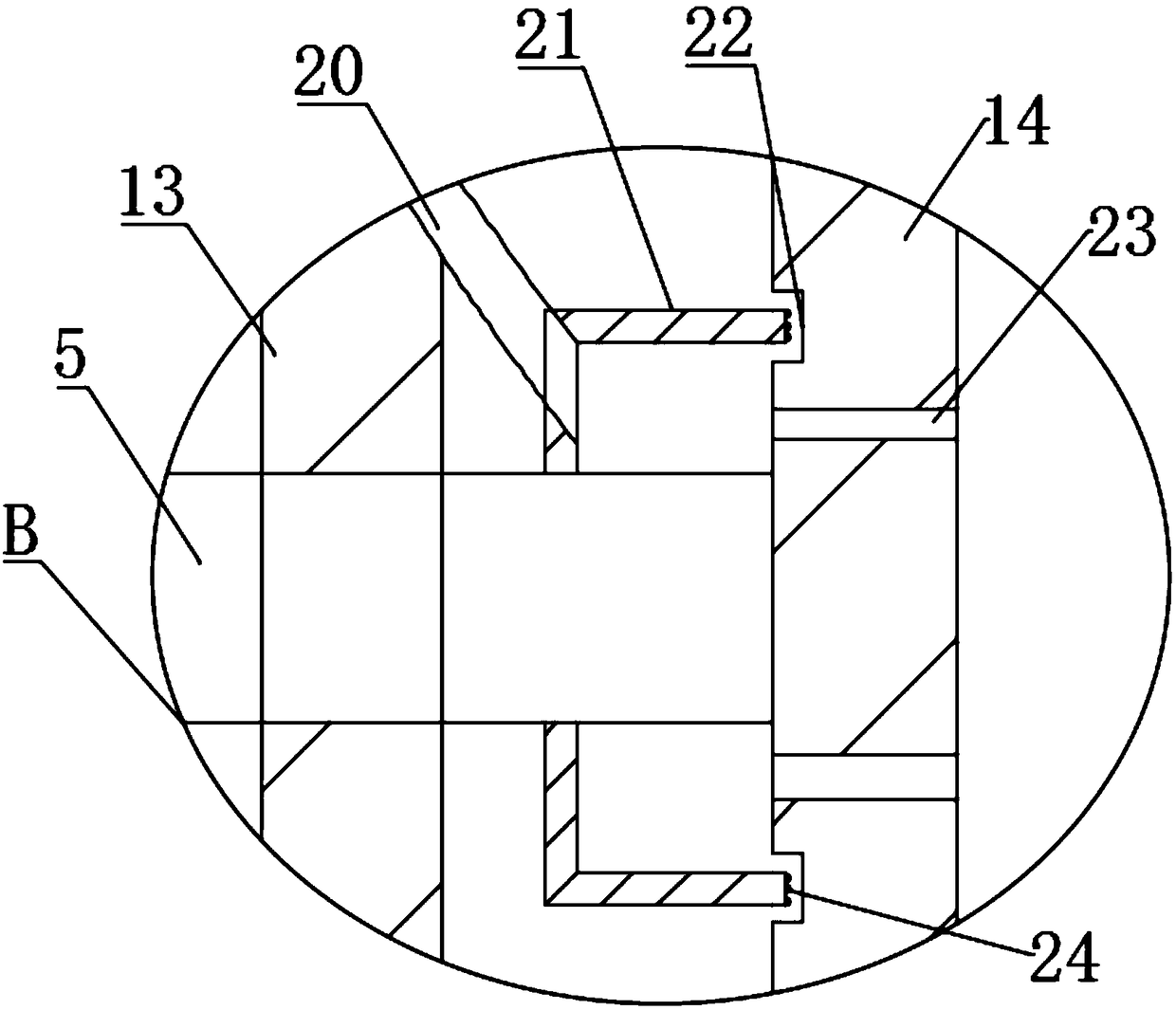

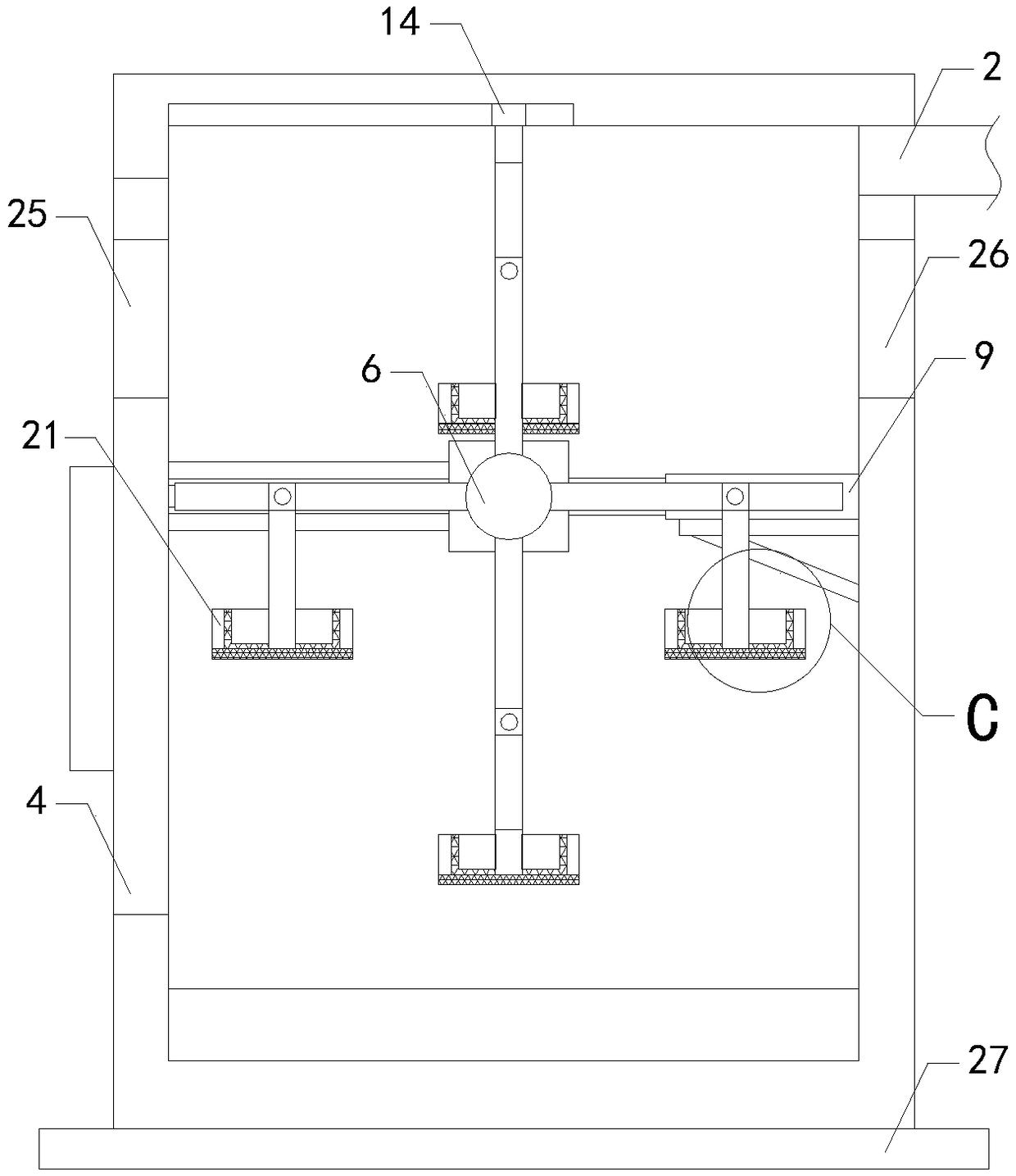

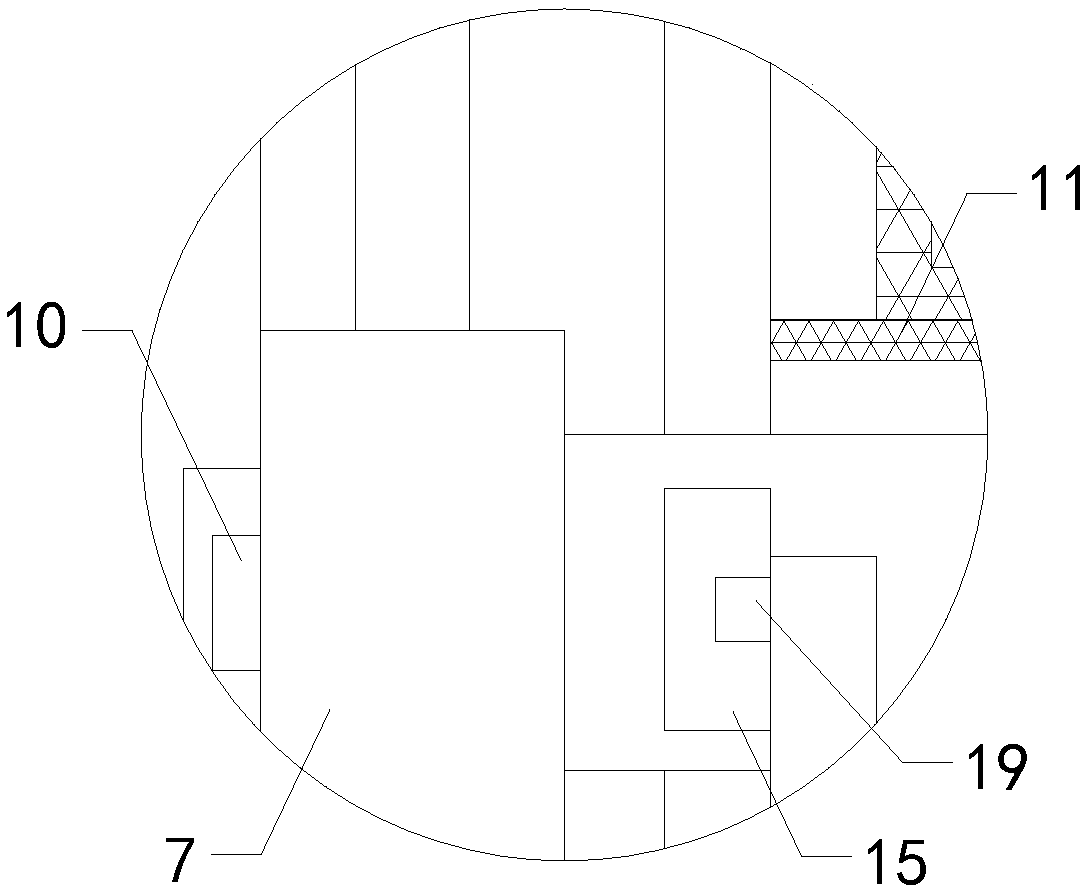

Efficient sand screening equipment having dustproof function for road and bridge construction

InactiveCN107234061AAvoid flyingImprove work efficiencySievingFouling preventionEngineeringUltimate tensile strength

The invention belongs to the technical field road and bridge construction, and particularly relates to efficient sand screening equipment having a dustproof function for road and bridge construction, in order to achieve the effects that the manpower and time can be saved, the labor intensity is low, the probability of fine sand flying in a screening process is low and the working efficiency can be improved. The efficient sand screening equipment having the dustproof function for the road and bridge construction comprises a box body, a baffle, a discharge hopper, a first driving device, a partition plate, a first sliding block and the like; the lower part of the right side surface of the box body is hinged with the baffle through a pin shaft; the baffle is matched with the box body; and the discharge hopper is arranged on the left side of the top of the box body. The efficient sand screening equipment achieves the effects that the manpower and time can be saved, the labor intensity is low, the probability of the fine sand flying in the screening process is low and the working efficiency can be improved.

Owner:肖述盛

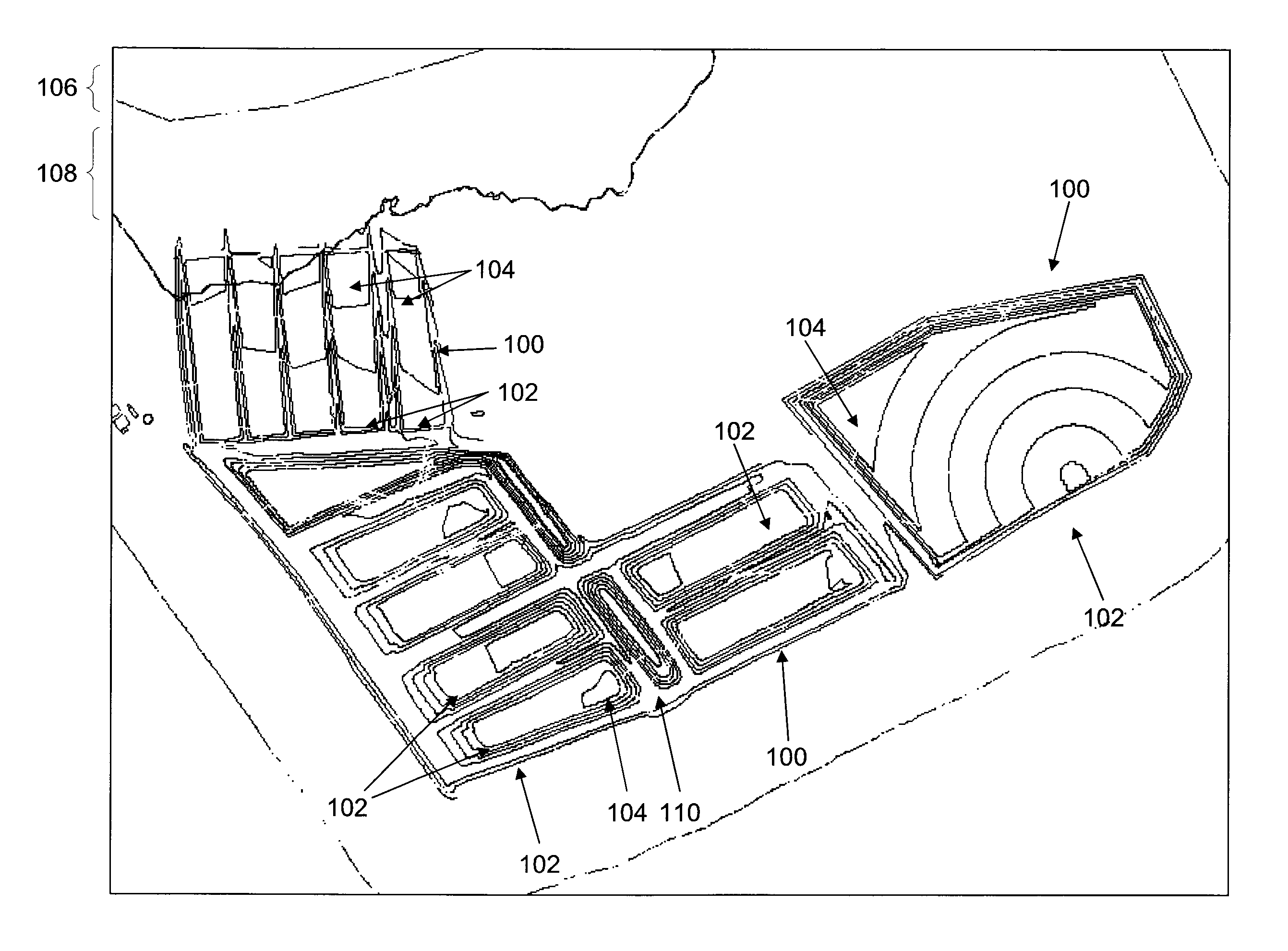

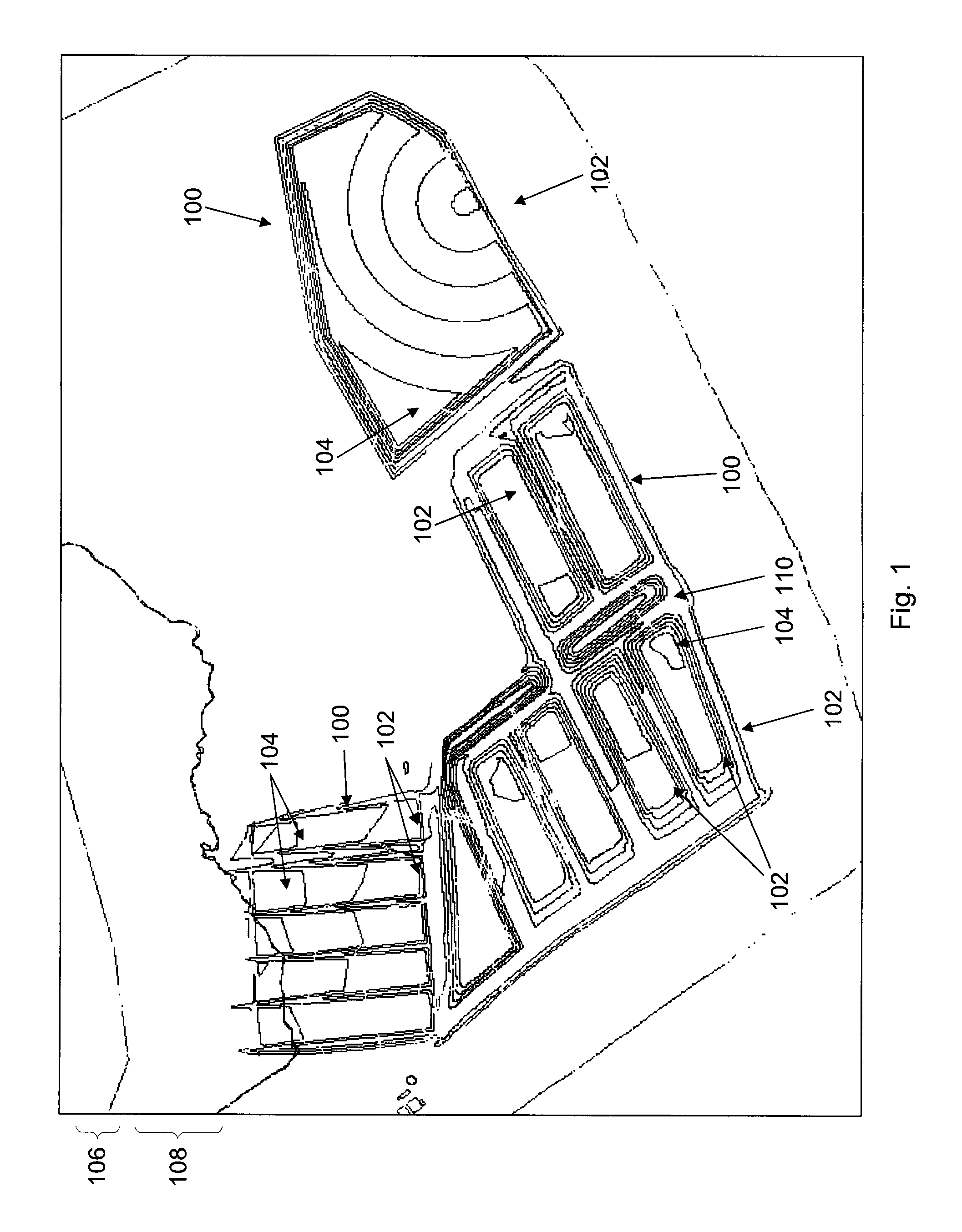

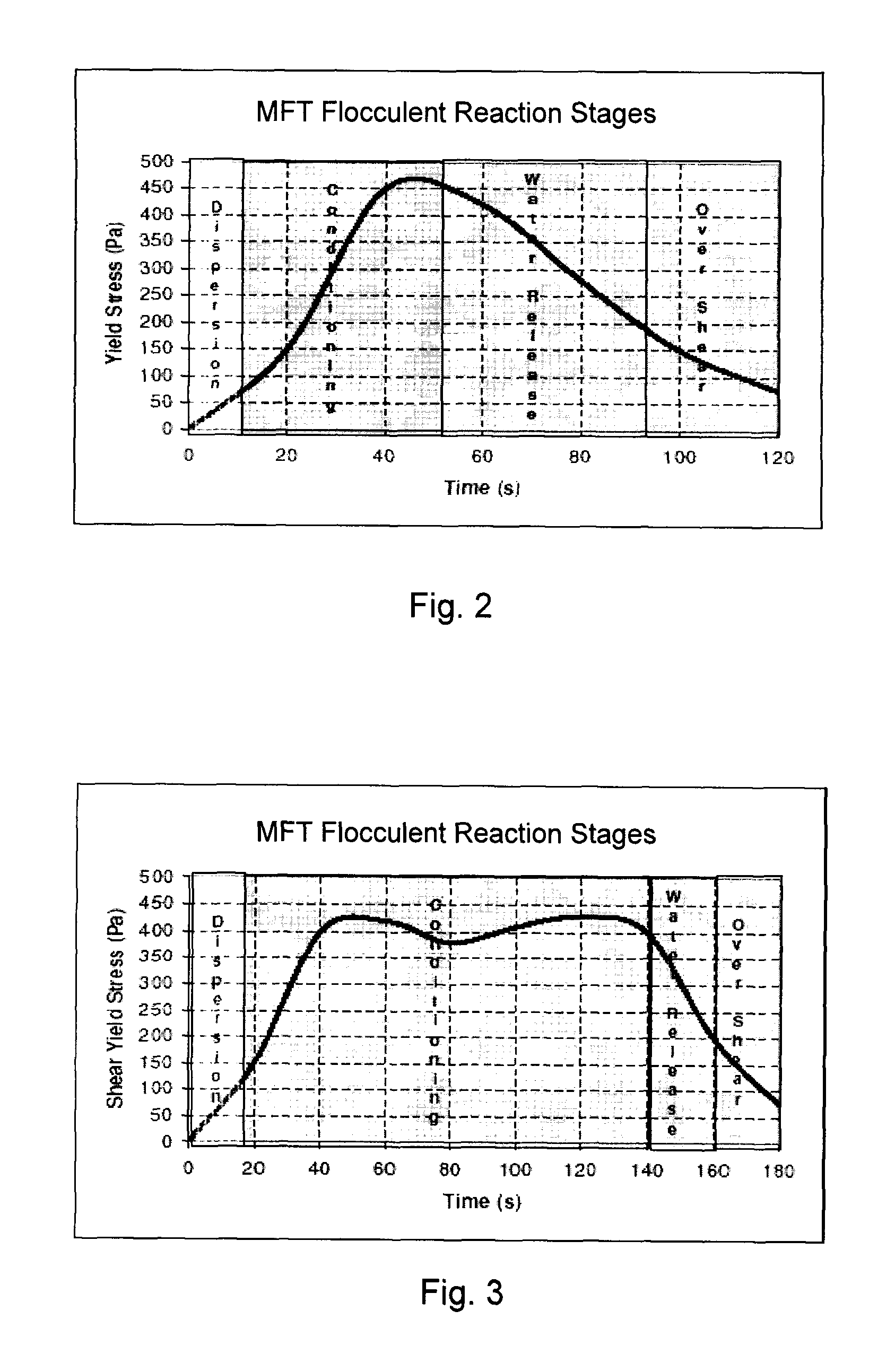

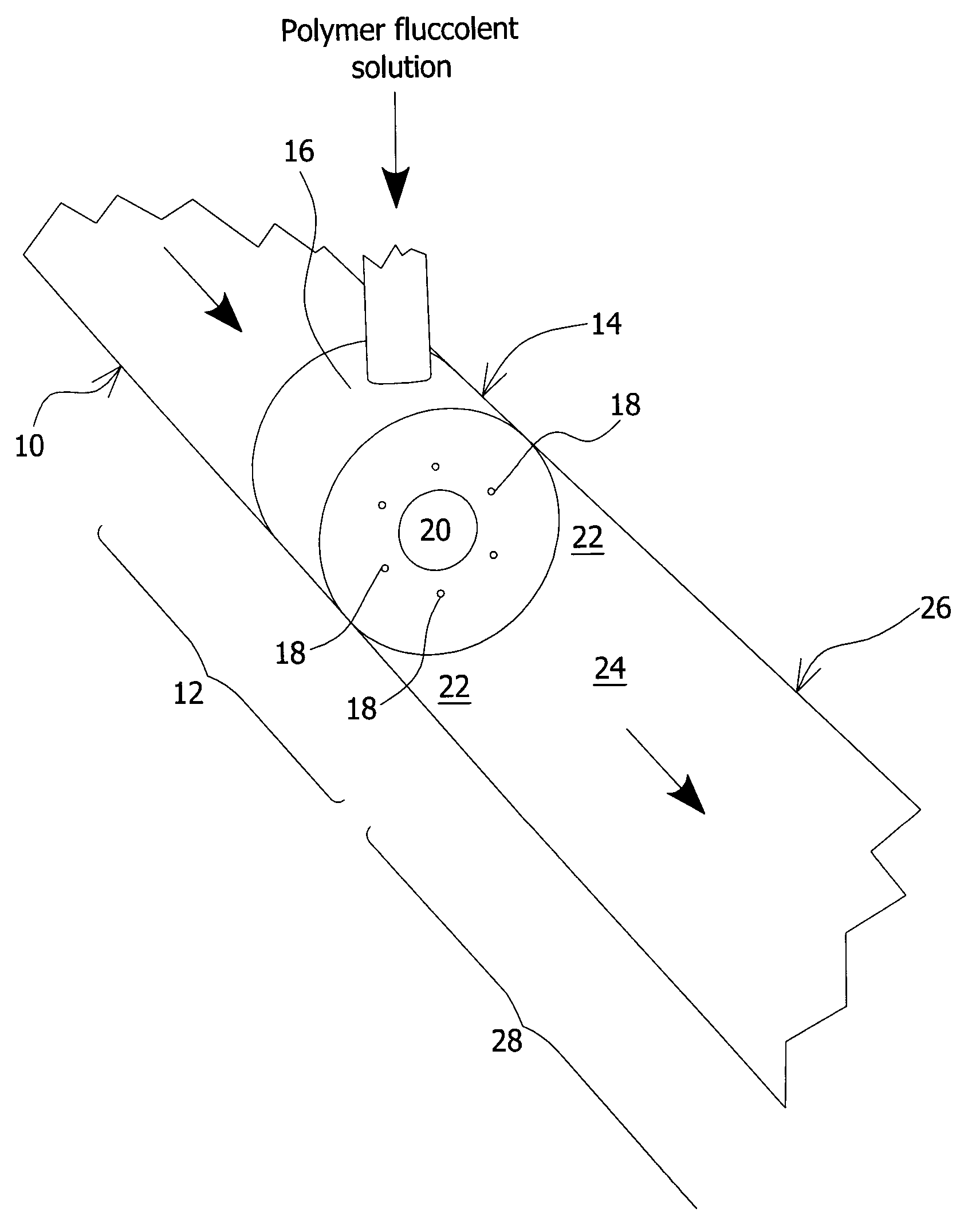

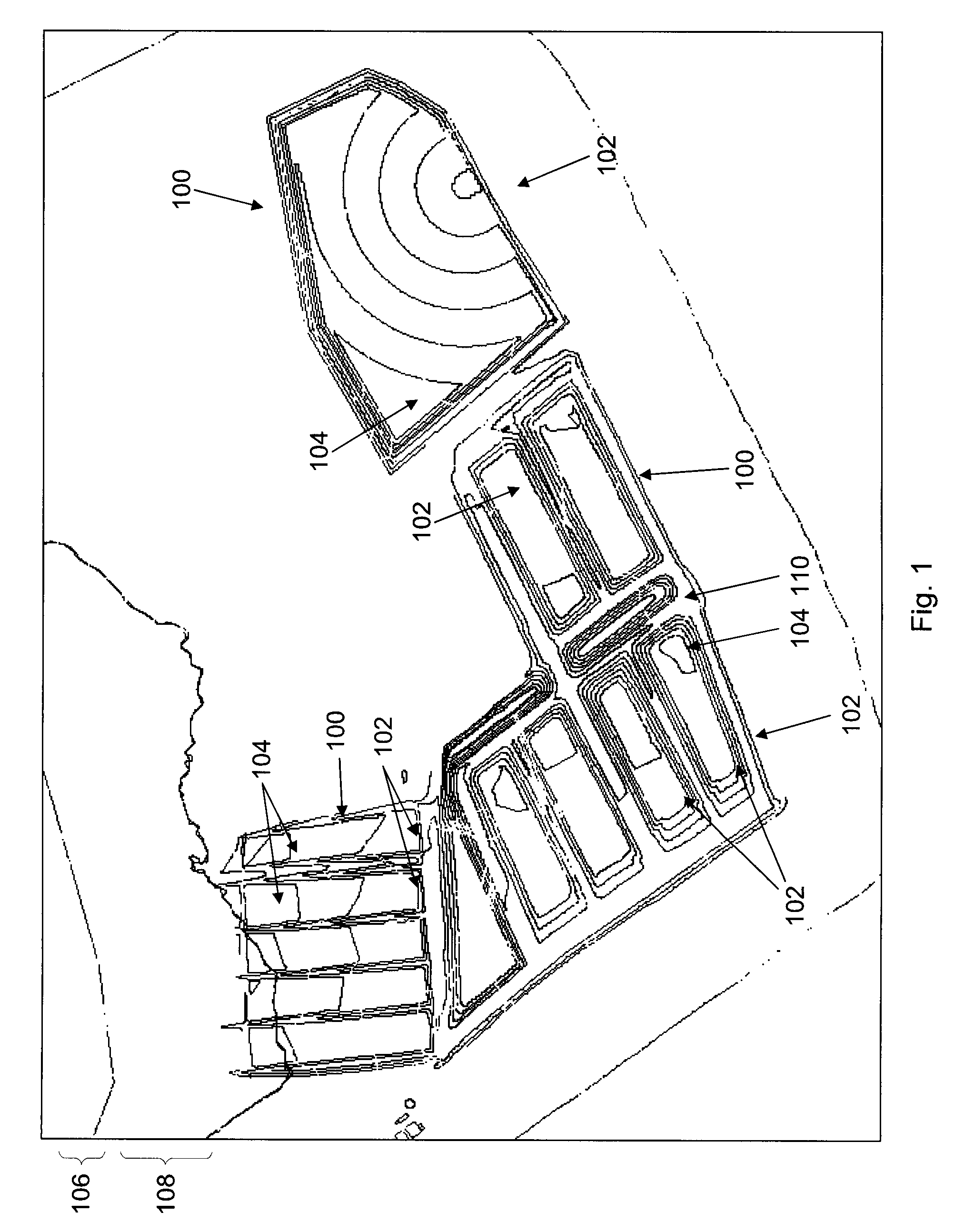

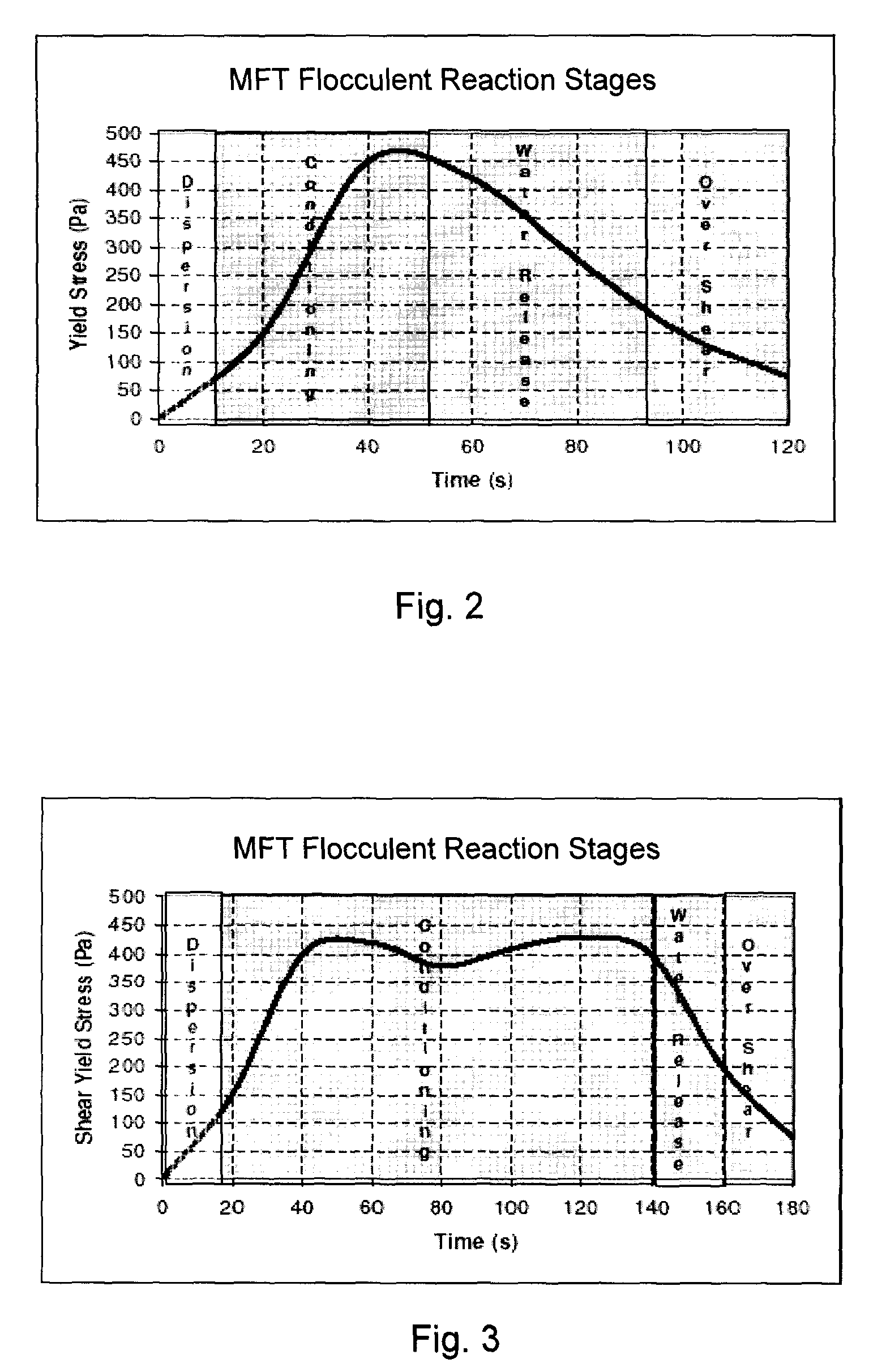

Depositing and Farming Methods for Drying Oil Sand Mature Fine Tailings

InactiveUS20130081298A1Improve initial dewateringAccelerated dryingDrying using combination processesSand dryingUpper crustEngineering

Methods for drying oil sand fine tailings treated to comprise flocculated fine tailings, by deposition and farming techniques, are provided. A deposition cell is provided with a sloped bottom surface and the flocculated fine tailings are deposited to undergo channelless advancement in the cell while allowing drainage of release water. When the deposit is uneven, the deposit may be plowed while wet for spreading and ensuring water release conditioning is imparted thereto, while avoiding over-shearing, and maintaining sufficient shear strength to allow standing. Once a dried upper crust forms, the deposit may be harrowed to break up the crust, expose wet regions there-beneath and create furrows in the standing deposit. The methods improve the dewatering and drying of mature fine tailings in oil sands.

Owner:SUNCOR ENERGY INC

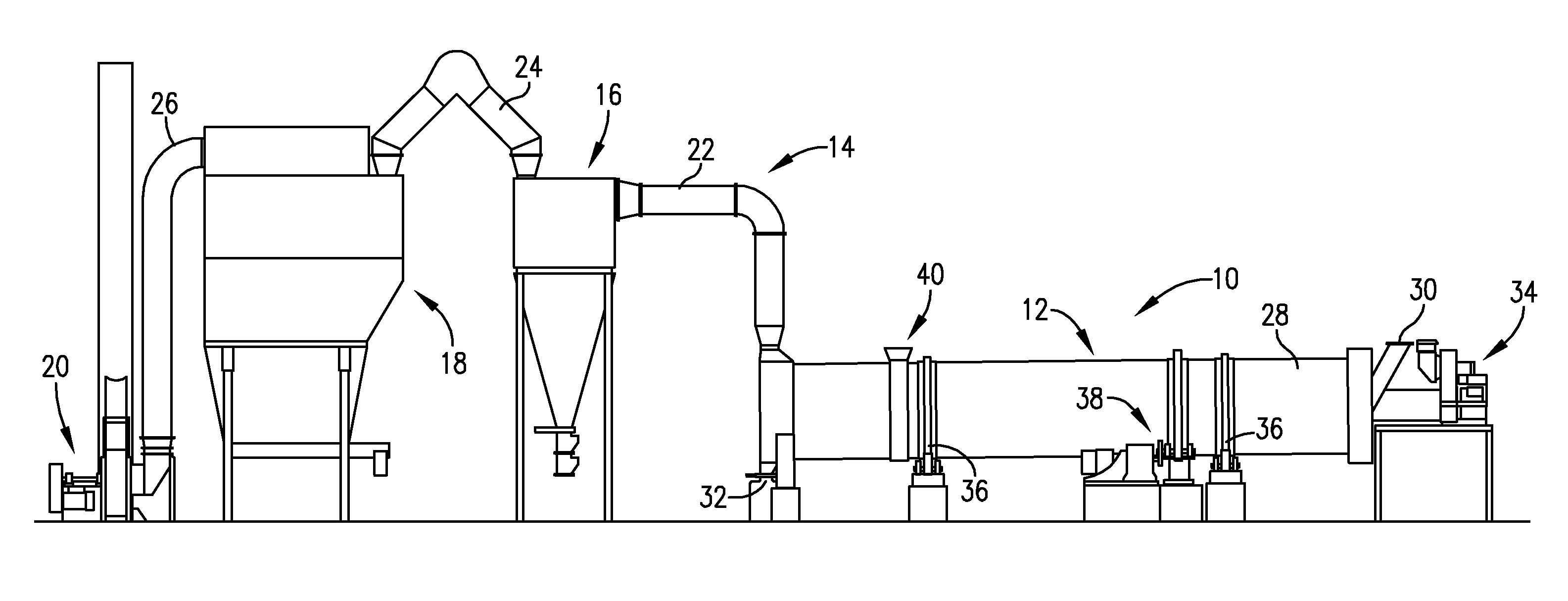

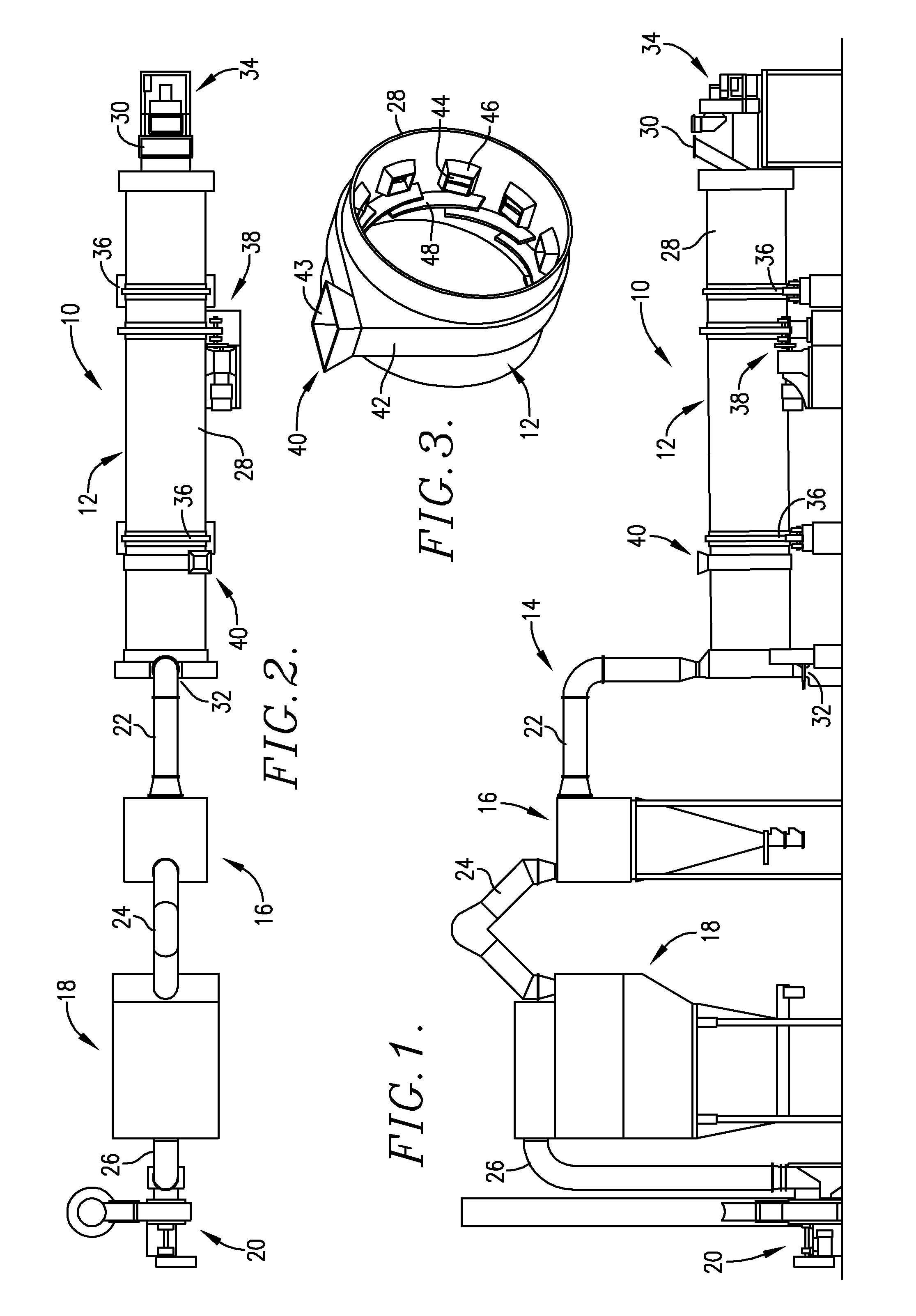

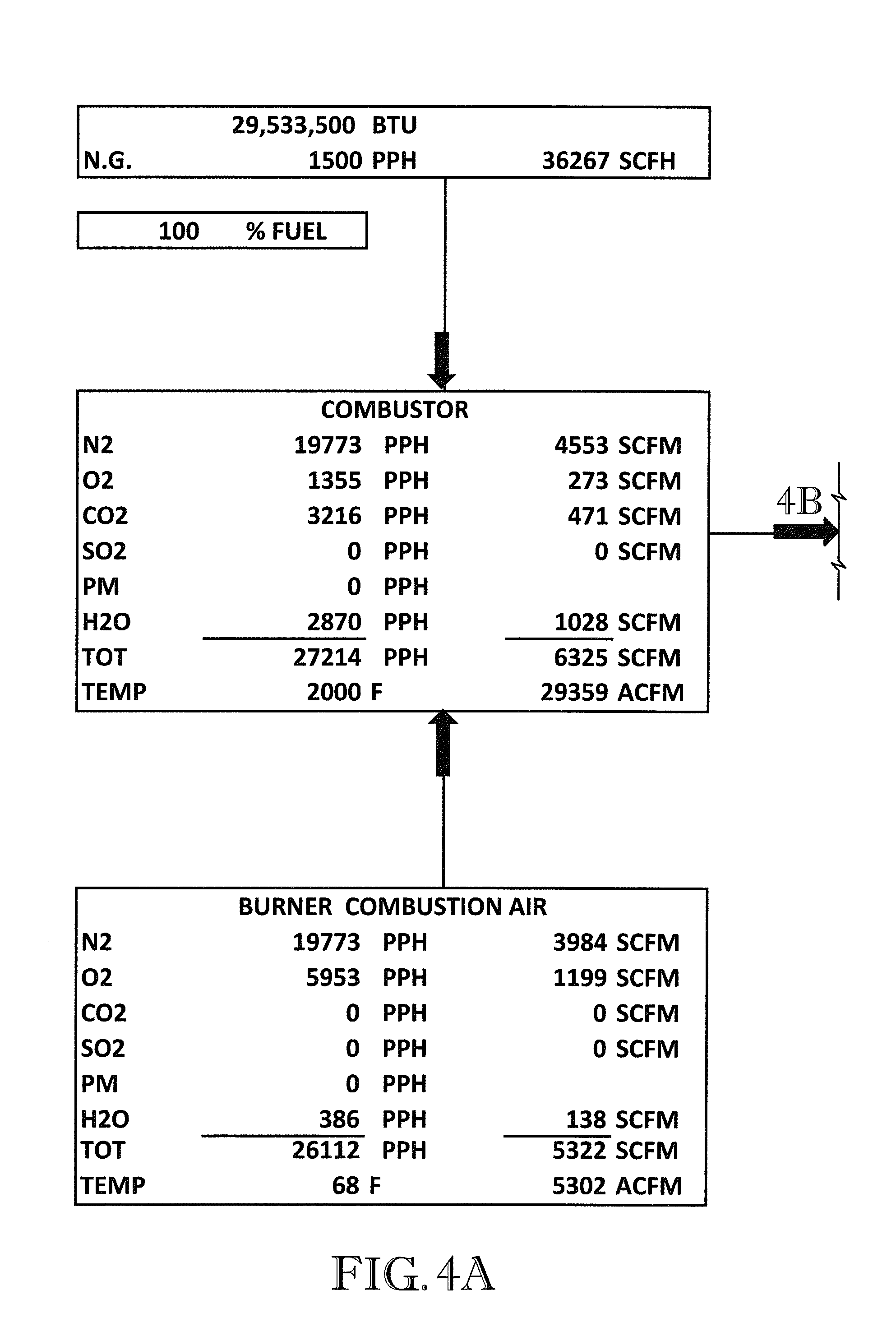

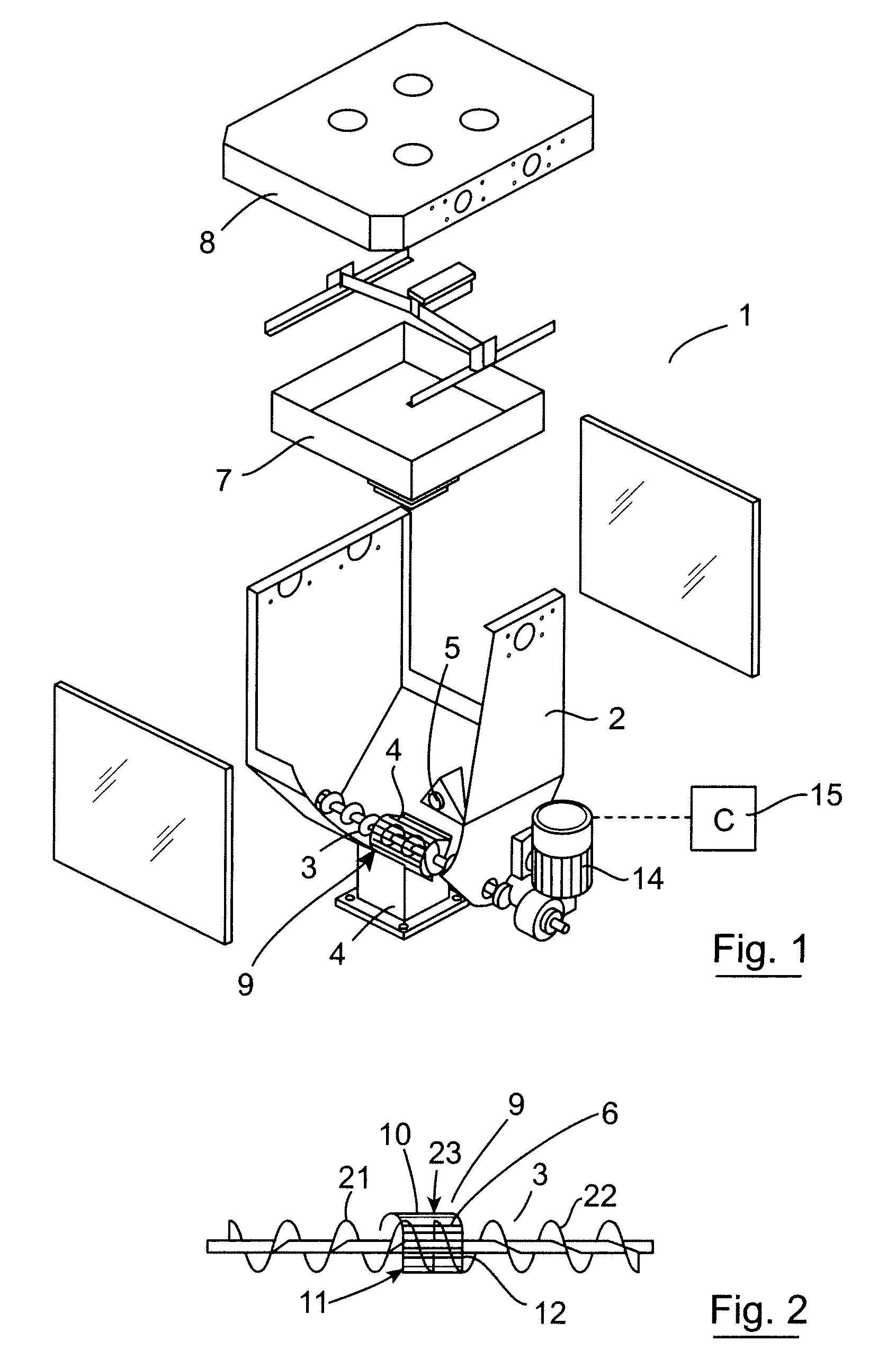

Method and apparatus for conditioning of fracturing sand

ActiveUS9322595B1Low costReduce equipmentSand dryingDrying solid materials without heatMaterials science

An improved, energy efficient method and apparatus for conditioning of fracturing sand provides an elongated, rotatable drying / cooling shell with co-current flow of heated air and sand through the shell. Structure operable to deliver additional quantities of wet sand into the shell is provided at a zone between the shell inlet and outlet, and downstream of the point where the initial quantity of wet sand is substantially dry. The additional quantities of wet sand mix with the initial quantities of substantially dry sand in order to evaporatively dry the additional quantity of wet sand, and to cool the initial and additional quantities of wet sand.

Owner:INDAL ACCESSORIES

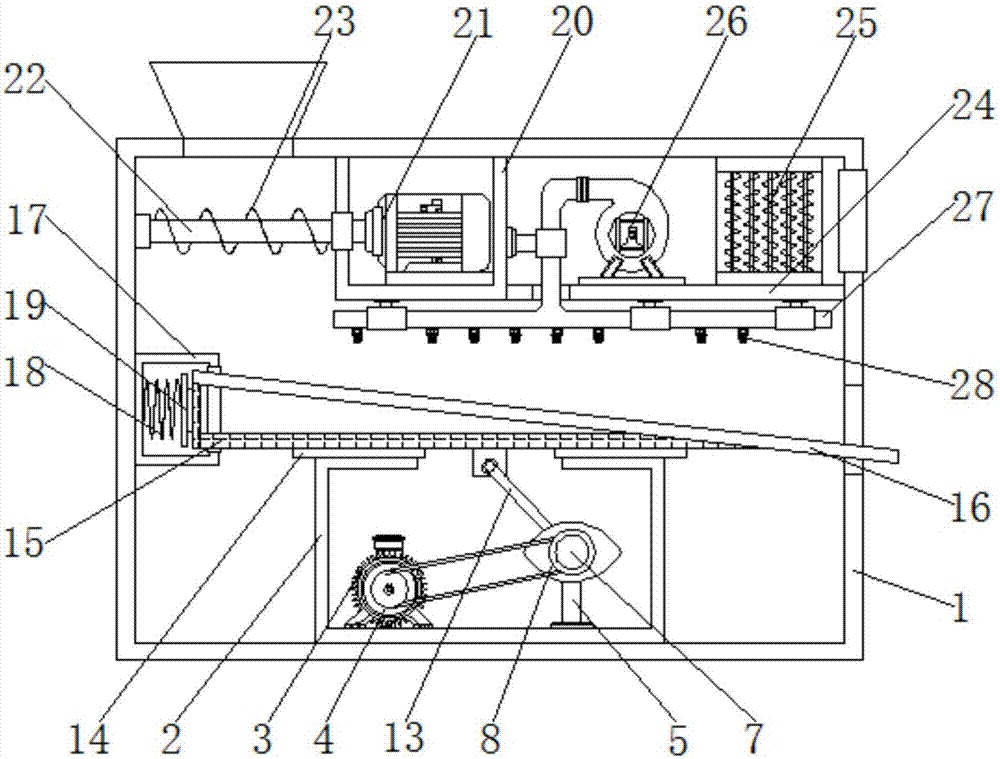

Grading sand screening device for building construction

InactiveCN107252765AKeep dryEasy to move with each otherSievingSand dryingSquare cross sectionEngineering

The invention provides a kind of grading and sand screening equipment for building construction, which comprises a tank body; the tank body is set as a hollow cuboid with a square cross section, an upper cover is set at the top opening of the tank body, and a bottom opening is set at the bottom opening of the tank body. cover; the middle part of the tank body is divided into a drying chamber and a screening chamber by a partition; a drying device is provided in the drying chamber; a screening plate and a screening device are provided in the screening chamber; feeding device; the present invention adds the sand added by the feeding hopper into the tank body at a uniform speed through the feeding device, which is also beneficial to reduce the labor intensity of the workers; through the setting of the drying device, the three-layer rotating material guide plate is used to control the sand falling on the guide The sand in the material tray is turned over, and the hot air blown by the hot air blower is used to evenly distribute the hot air blown in by the three-layer rotating air distribution pipe, so as to facilitate the full drying of the sand; The sand is graded and screened to improve the screening quality.

Owner:合肥多智科技开发有限公司

Blenders

InactiveUS20100065149A1Clean thoroughlyLiquid fillingDrying solid materials with heatMixed materialsEngineering

A blender has a mixing chamber for reception of materials to be blended. A mixing screw is mounted at a bottom of the mixing chamber for mixing materials within the mixing chamber and delivering mixed materials to an outlet feeding a processing line. A baffle is mounted at the outlet extending about the mixing screw. The baffle inhibits upward movement of material at the outlet tending to cram material into the outlet.

Owner:VERVANT

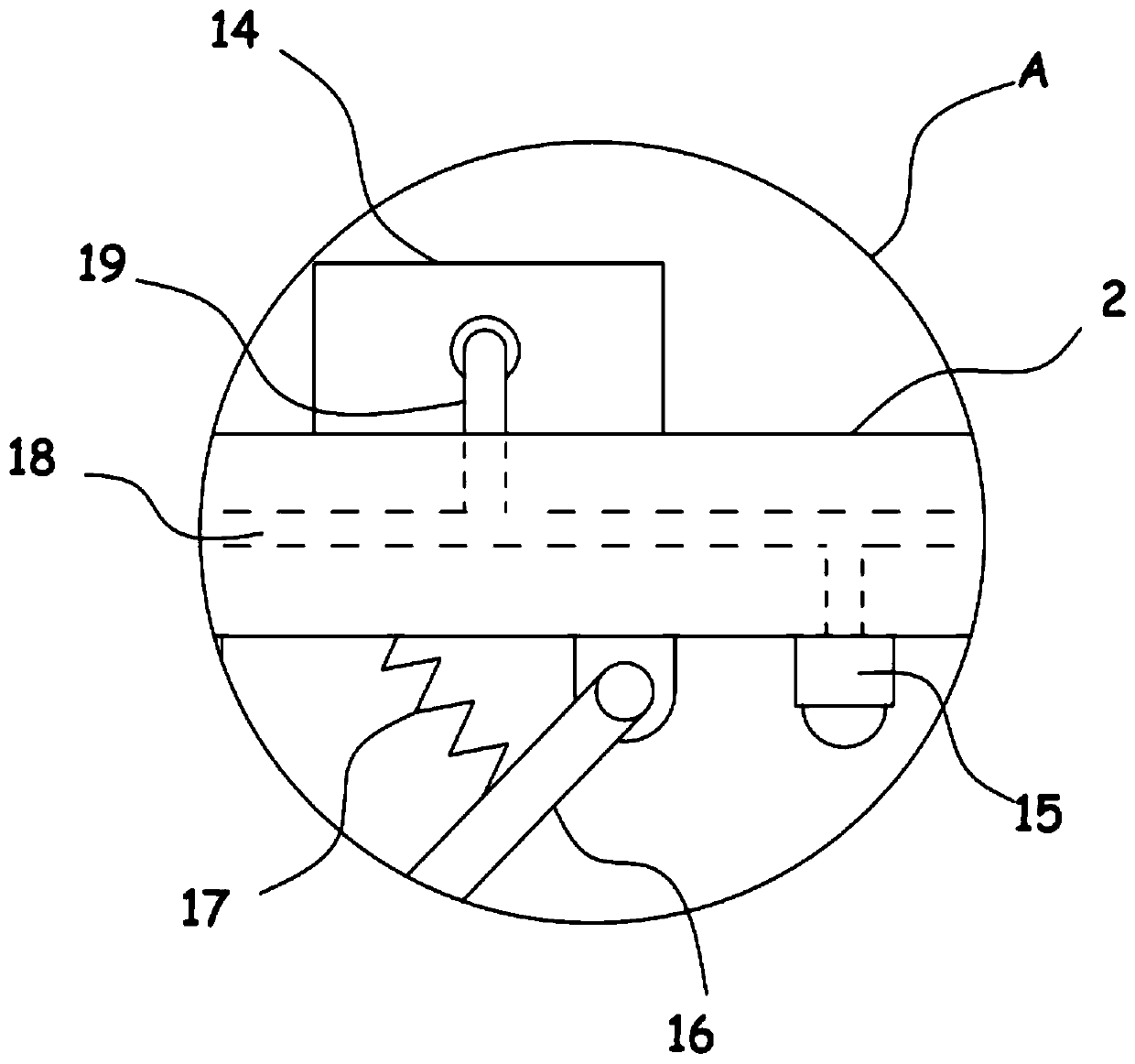

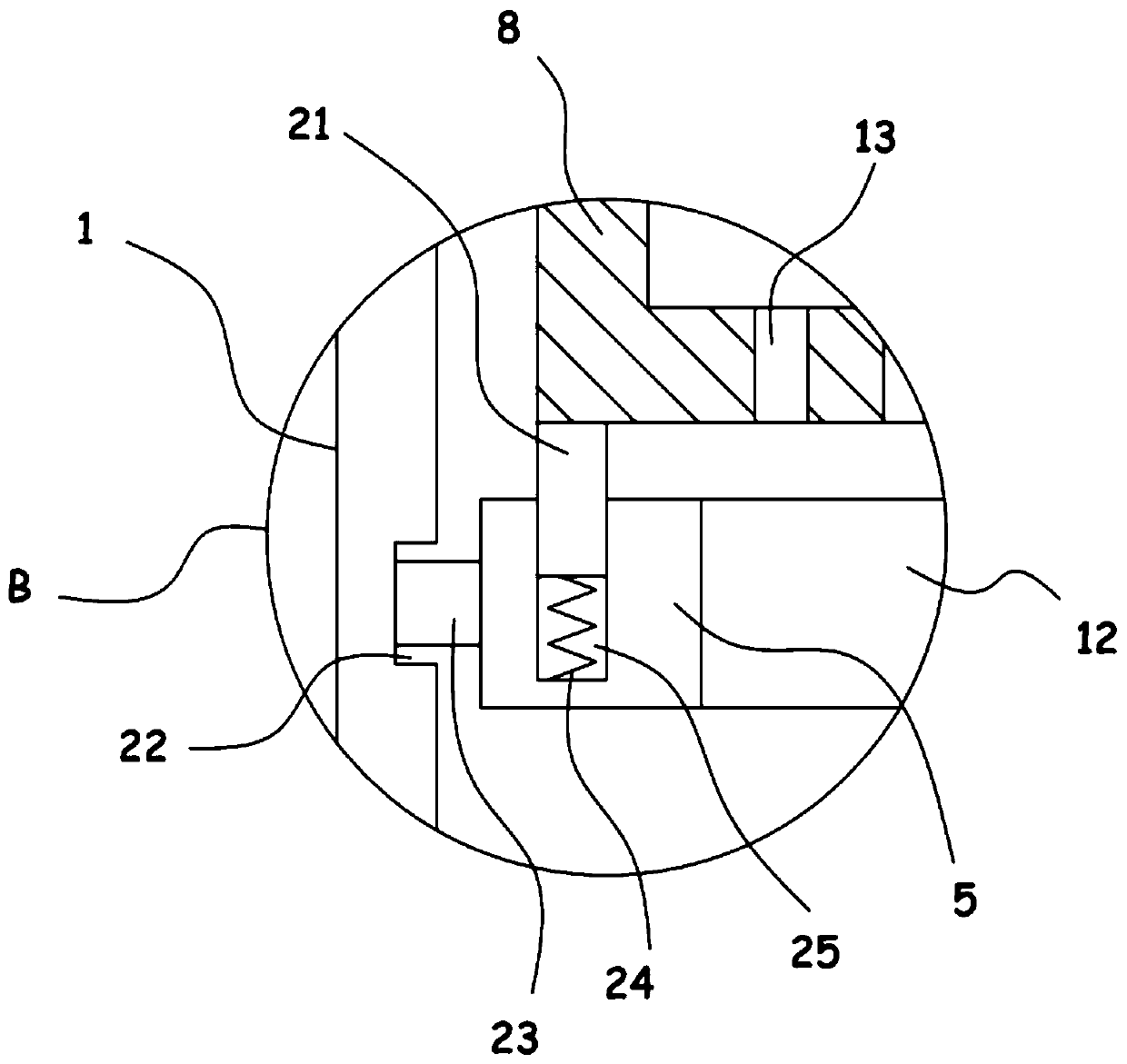

Sand screening device for bridge construction

Owner:赣州市兴顺辉科技有限公司

Sand screening device with heating dehumidifying function

The invention discloses a sand screening device with the function of heating and dehumidification, which includes a heating block, an exhaust fan, a turning motor, a turning through hole, a conveying device, a filter screen and a vibrating motor. The sand is heated, and the exhaust fan is used to discharge the moisture generated by heating the wet sand in the heating dehumidification box through the dehumidification pipe, and the turning motor is used to rotate to drive the turning blades on the turning shaft to rotate the wet sand in the heating dehumidification box. Flip, by setting the flip through hole to reduce the resistance when the flip shaft rotates, use the conveying device to transport the dehumidified sand to the top of the material funnel, set the filter to filter the impurities in the sand, and use the vibration motor The vibration further drives the sieve plate to vibrate, thereby speeding up the screening speed of the sieve plate for sand and improving the practicability of the equipment.

Owner:王先华

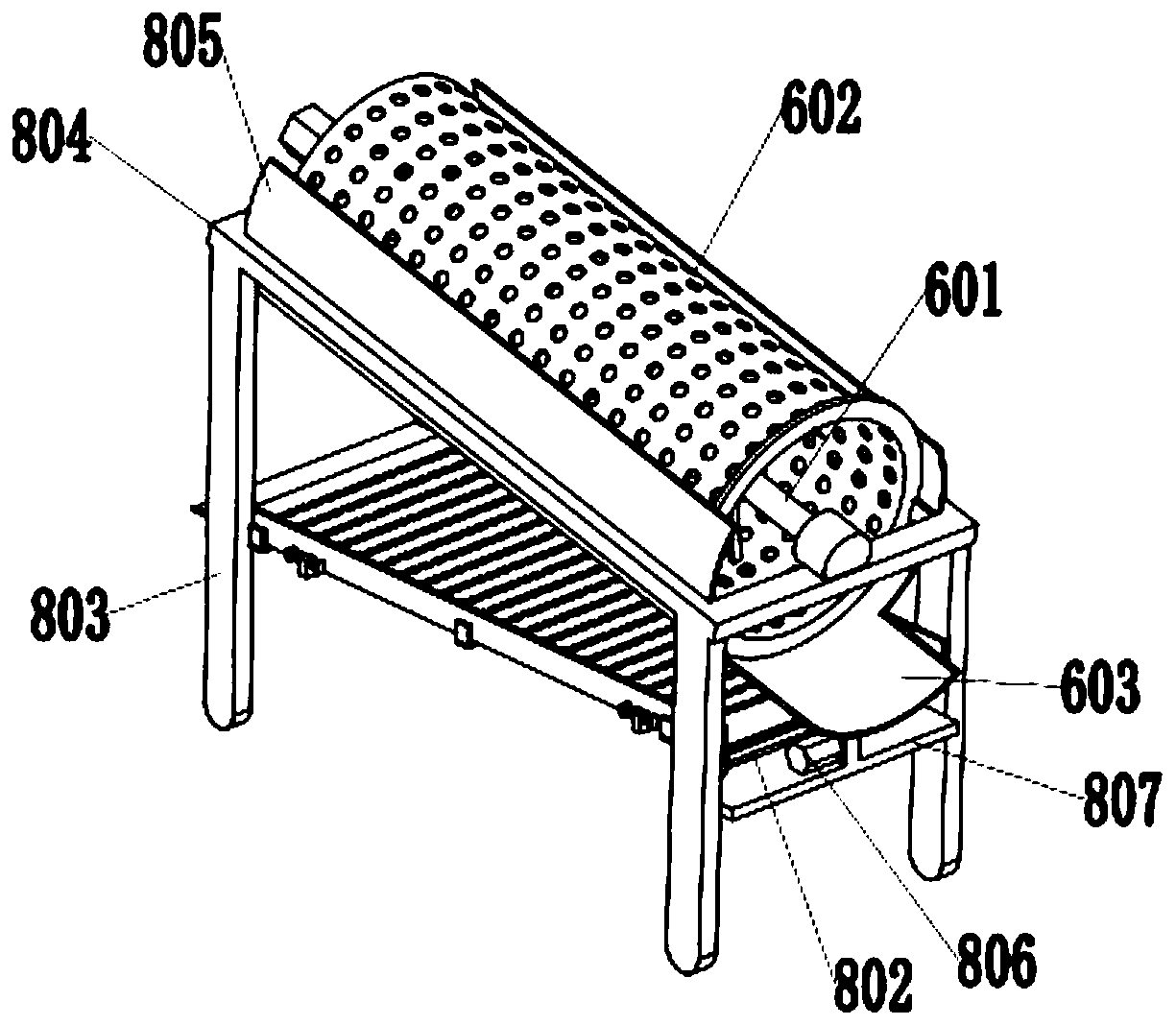

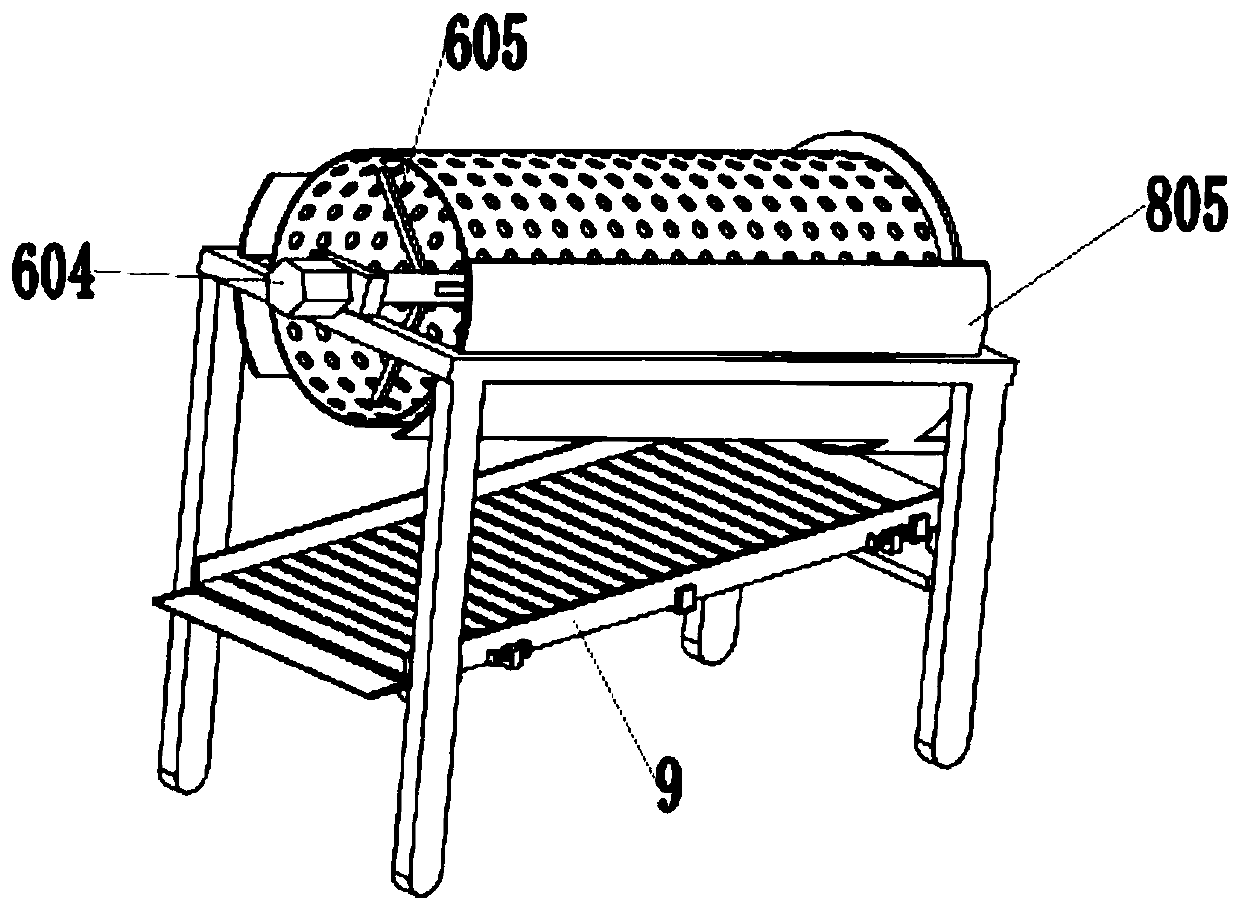

River sand screening device for construction

ActiveCN111054631ASmooth slidingIncrease profitSievingSand dryingEnvironmental engineeringSand filter

The invention discloses a river sand screening device for construction. The sand screening device comprises a sand feeding hopper, a drying cylinder, a primary screening device and a secondary sand screening device, the drying cylinder is mounted at the upper end of a bracket; the drying cylinder is of a double-layer hollow structure, a heating block is arranged between the outer cylinder wall andthe inner cylinder wall of the drying cylinder; one end of the drying cylinder is connected with a sand inlet hopper; the other end of the drying cylinder is communicated with the primary screening device; the primary screening device is a sand screening barrel; the sand screening barrel is installed on a supporting frame, first screening holes are formed in the side wall of the sand screening barrel, the second-stage sand screening device comprises a swing frame and a sand filtering plate, a sand screening plate is fixed to the upper end of a swing frame, second screening holes are formed inthe sand screening plate, the swing frame is connected with the supporting frame and located below the sand screening barrel, and the sand screening plate and the sand screening barrel are opposite in inclination direction. The problem that wet sands with small particles are mutually adhered is solved, the working efficiency is improved, the screening effect is improved, the utilization rate of the sand is increased, waste is avoided, and the construction cost is reduced.

Owner:济南工程职业技术学院

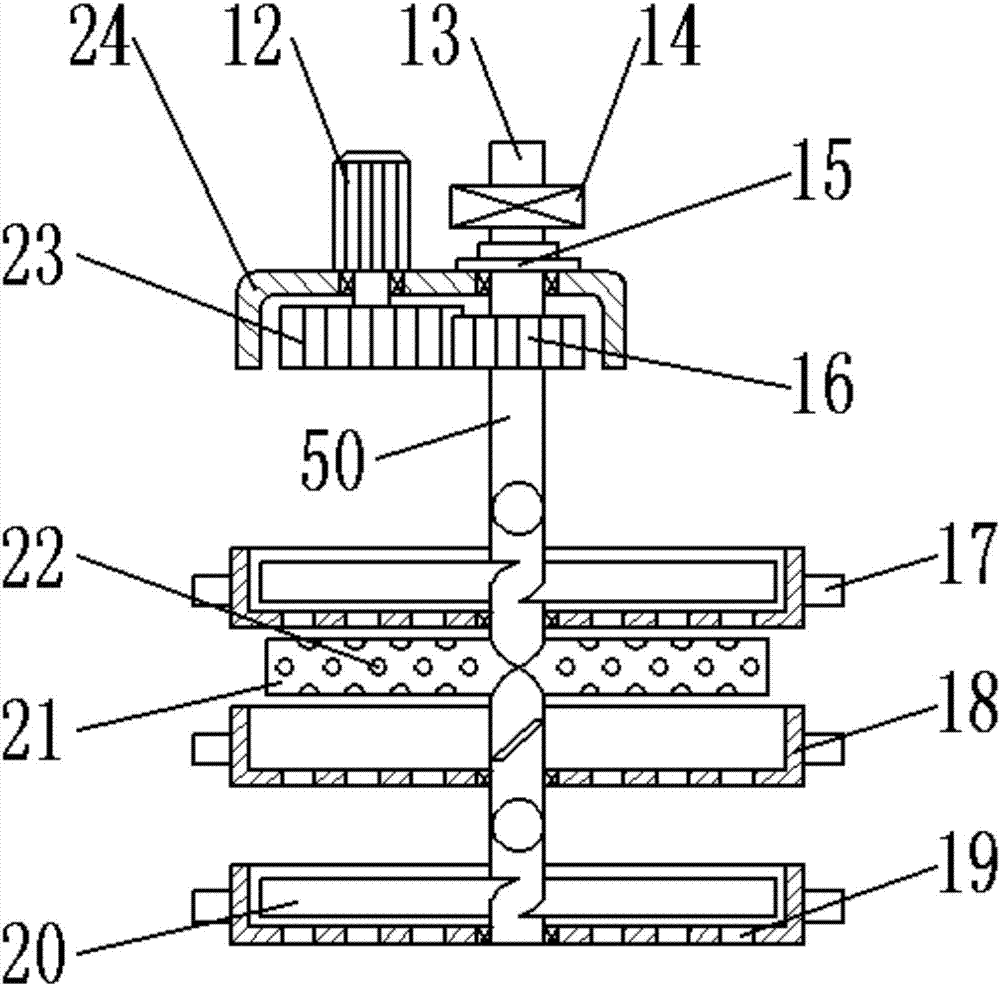

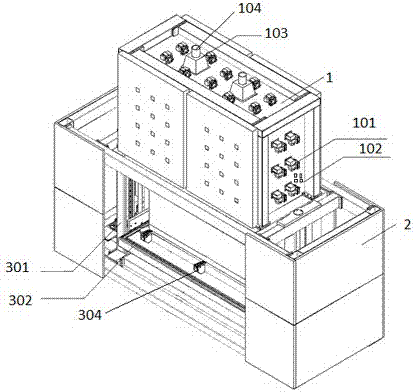

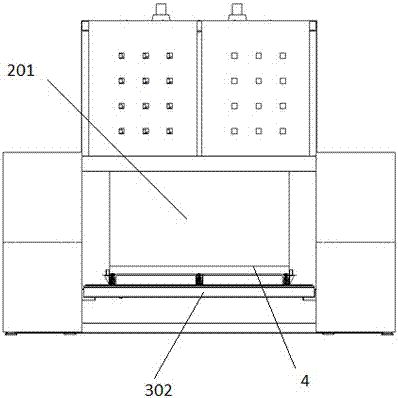

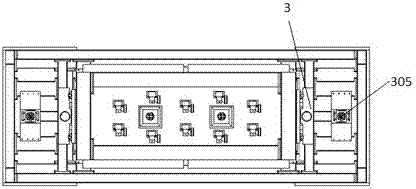

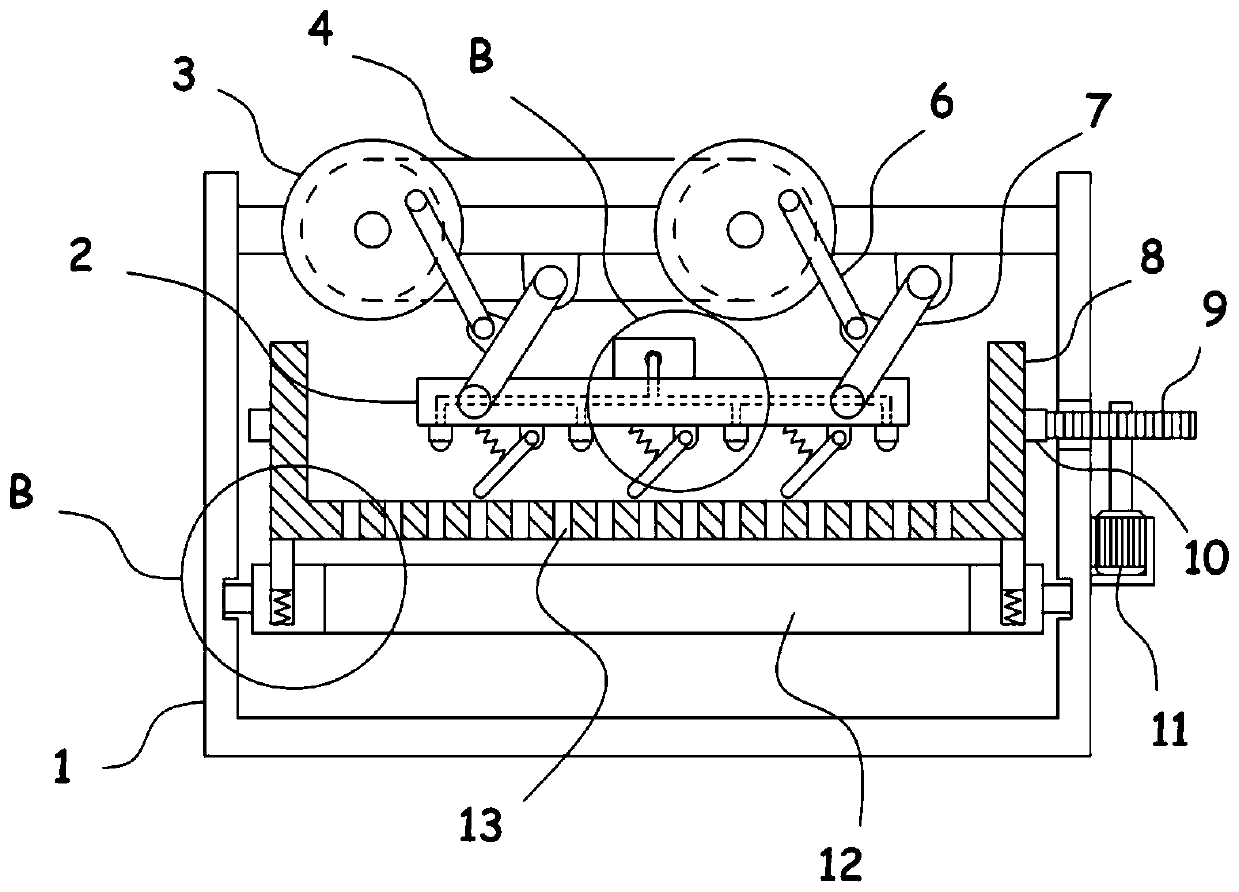

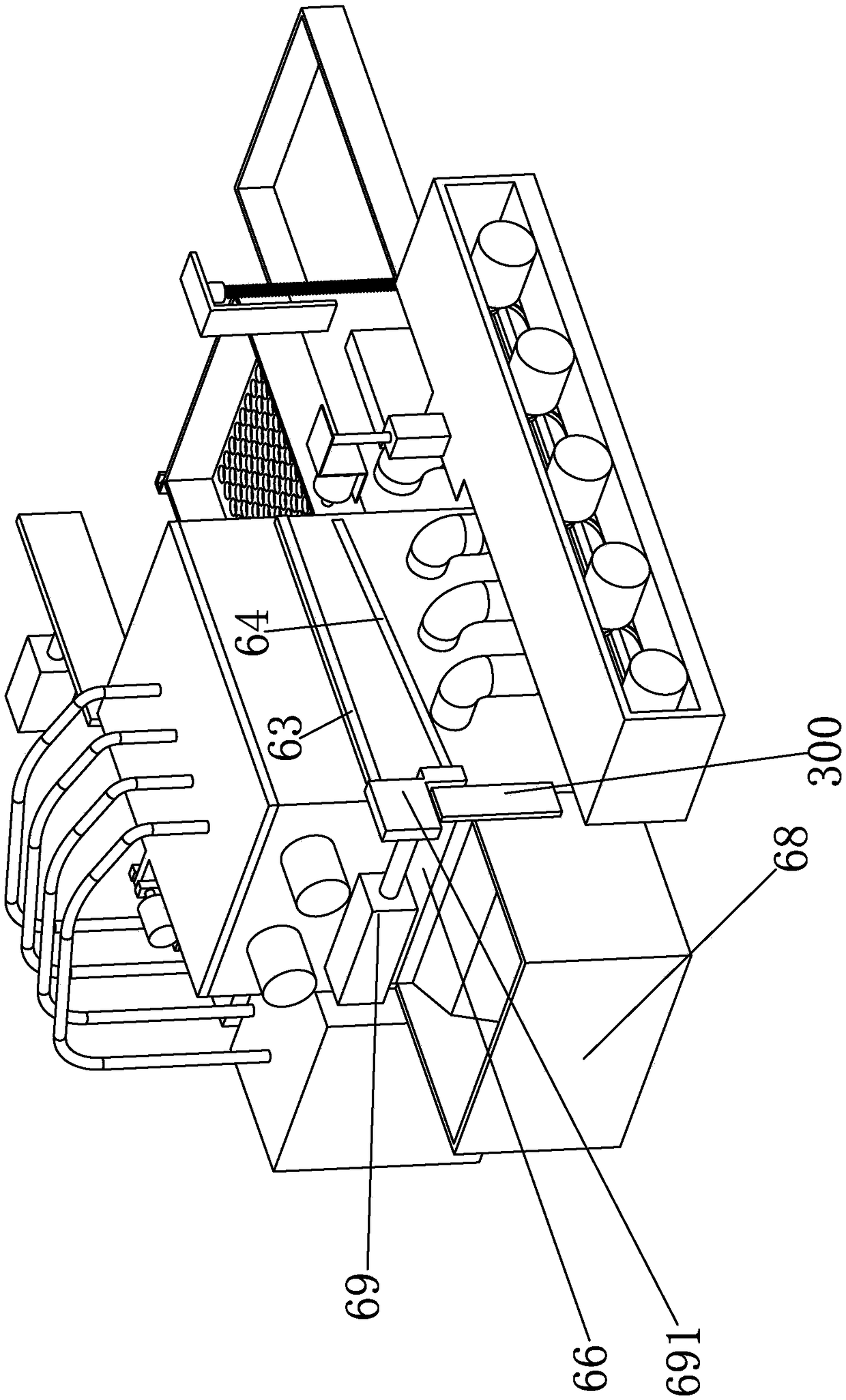

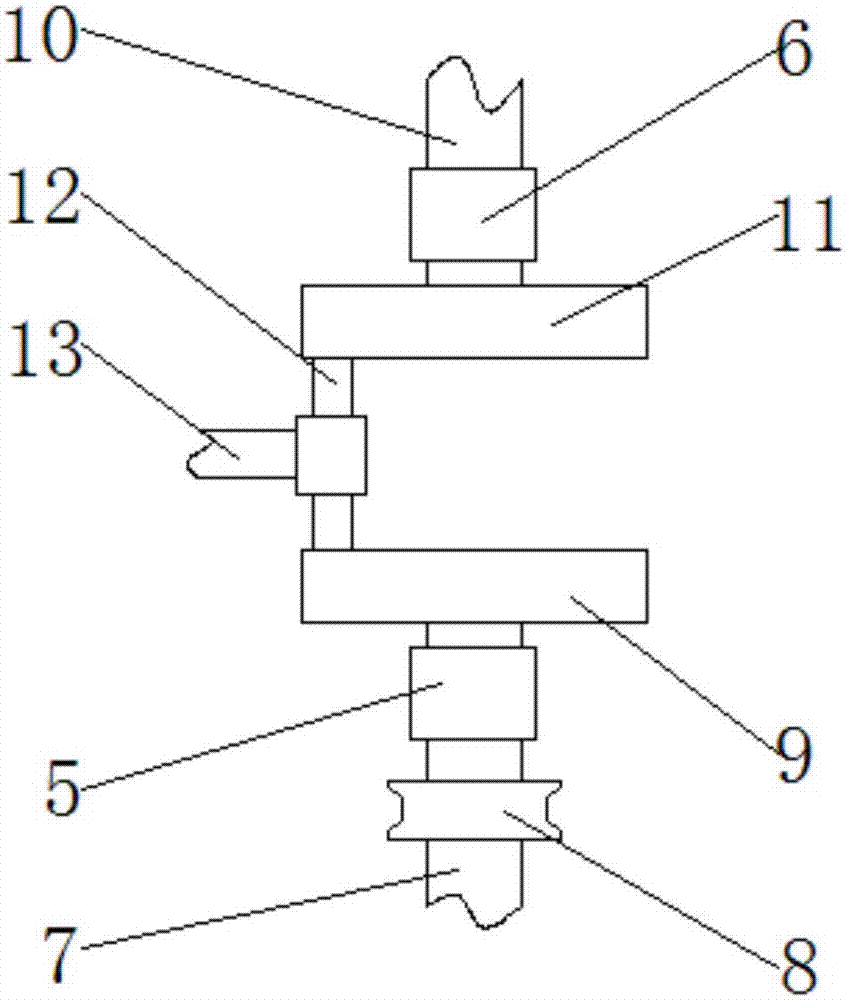

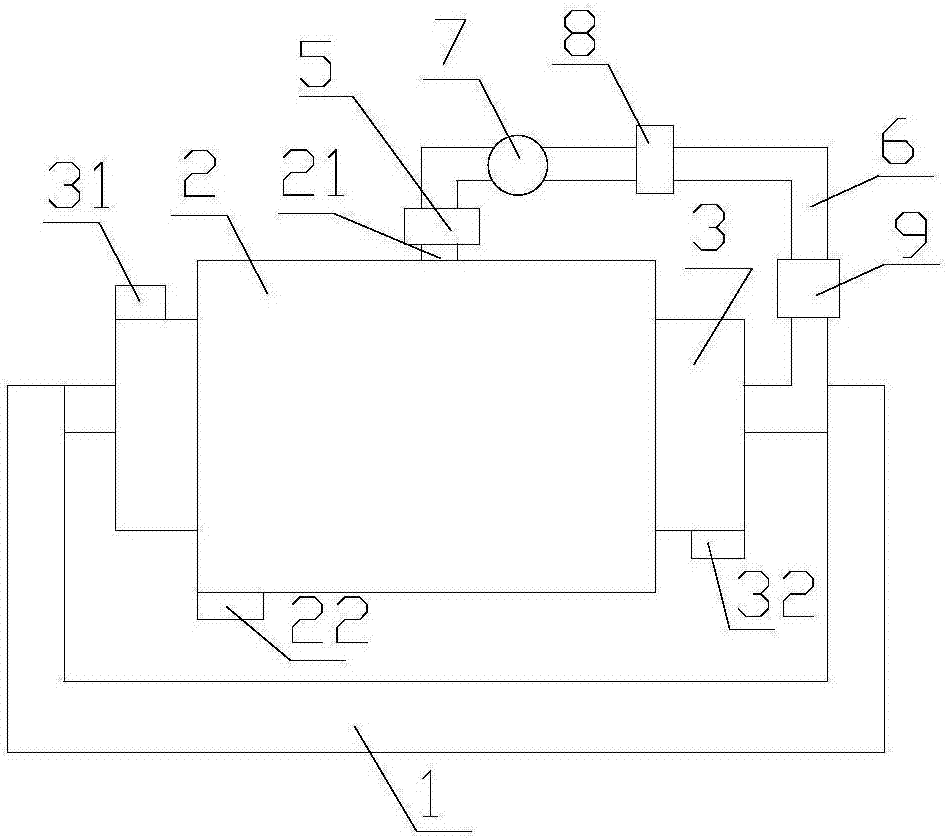

Jacking type sand core microwave drying device

InactiveCN108007096AAvoid Sealing DefectsPrevent leakageSand dryingDrying solid materials with heatMicrowaveEngineering

The invention relates to a jacking type sand core microwave drying device. The drying device mainly comprises a microwave drying cavity, a jacking assembly and a sand core tray, wherein the jacking assembly comprises two supporting stand columns and a jacking sealing bracket arranged between the two supporting stand columns; a vertical linear rail is arranged on each supporting stand column; the jacking sealing bracket is jacked and descended on the supporting stand columns through the vertical linear rails; an inner roller way is arranged on the jacking sealing bracket, and is used for beingmatched with a outer roller way to carry and transport the sand core tray; the microwave drying cavity is located above the supporting stand columns; the bottom of the microwave drying cavity is provided with a feeding opening; when the jacking sealing bracket ascends, the jacking sealing bracket is in sealing connection with the feeding opening. Through matching and sealing of the jacking sealingbracket and the upper microwave drying cavity, microwave leakage prevention is carried out, the problem of microwave leakage is effectively solved, and 3D printing sand core flow coating and automatic drying after dip coating are efficiently realized.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Efficient sand screening device for bridge construction

InactiveCN110355100AAchieve decentralizationImprove screening efficiencySievingSand dryingReciprocating motionAgricultural engineering

The invention discloses an efficient sand screening device for bridge construction, and relates to the technical field of construction machinery. The efficient sand screening device comprises a screening chamber, the screening chamber is internally provided with a screening groove used for screening sand, the bottom of a swinging plate is provided with a scraping mechanism used for scraping the screening groove, a supporting plate used for supporting the screening groove is rotationally installed in the screening chamber, and a rotating mechanism used for driving the screening groove to rotateis arranged on the screening chamber. According to the efficient sand screening device, the scraping mechanism is driven by the swinging mechanism to carry out transverse reciprocating motion, a scraping plate in the scraping mechanism can keep the abutting connection with the inner bottom surface of the screening groove under the elastic action of a reset spring, so that the dispersing effect onthe sand and the scraping cleaning effect on sieve pores in the screening groove are achieved, the blockage of the sieve pores is avoided, the screening efficiency of the sand is improved, the rotating mechanism can drive the screening groove to rotate, so that the dispersing effect of the scraping mechanism can be obtained at different positions in the screening groove, and the screening efficiency of the sand is remarkably improved.

Owner:戴俊

Integrated unit for treatment and drying lignocellulosic material

InactiveUS20170320090A1Allow useLow costDrying solid materials with heatSpraying apparatusCelluloseHigh humidity

An integrated boiler-dryer consisting in a sealable vessel capable of sustaining high humidity and variable gas pressures and into which is placed a lignocellulosic material, and a compound in mist form. The sealable vessel provides dry heat so as to dry the lignocellulosic material while the compound is impregnated within the lignocellulosic material.

Owner:ROY JACQUES

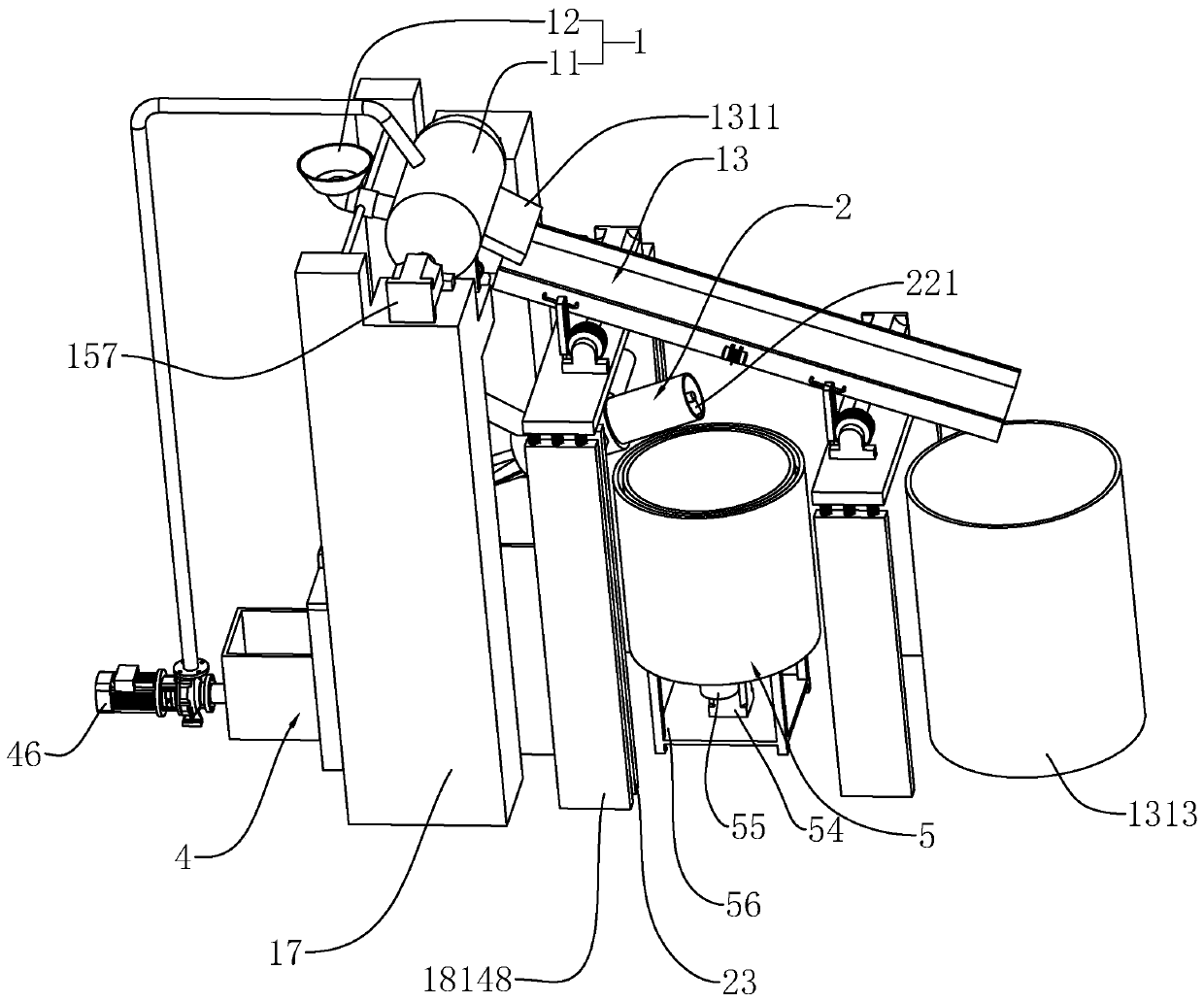

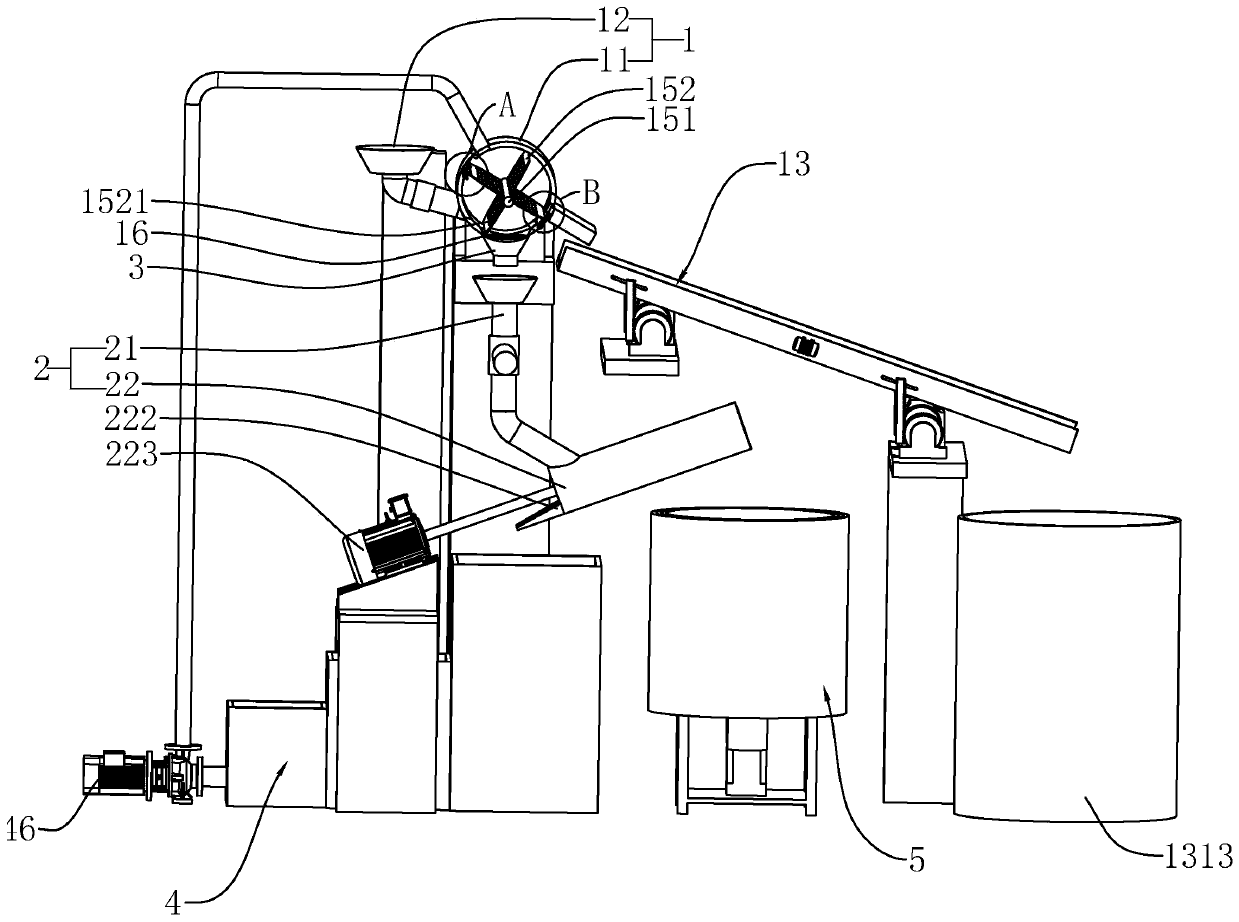

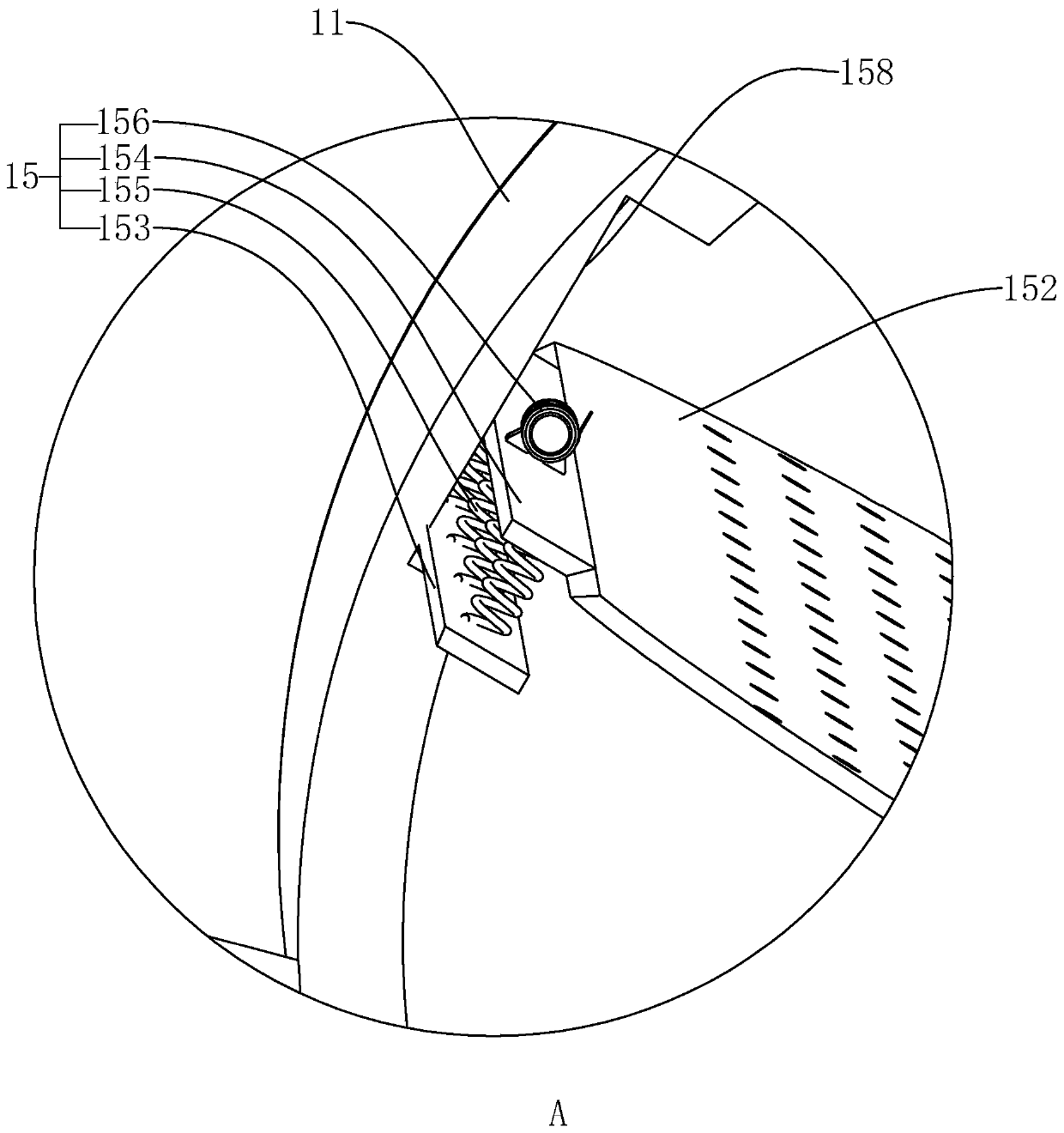

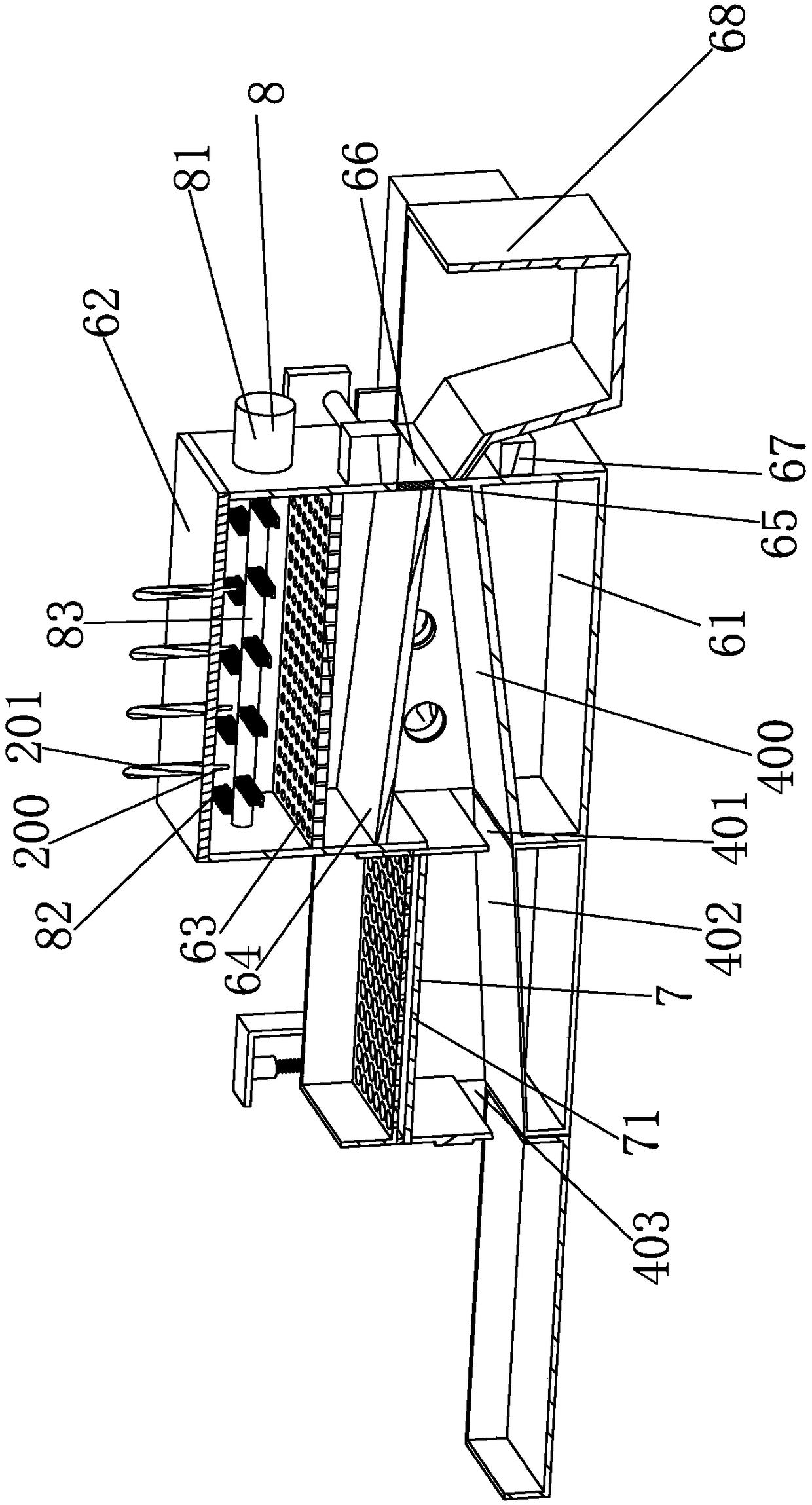

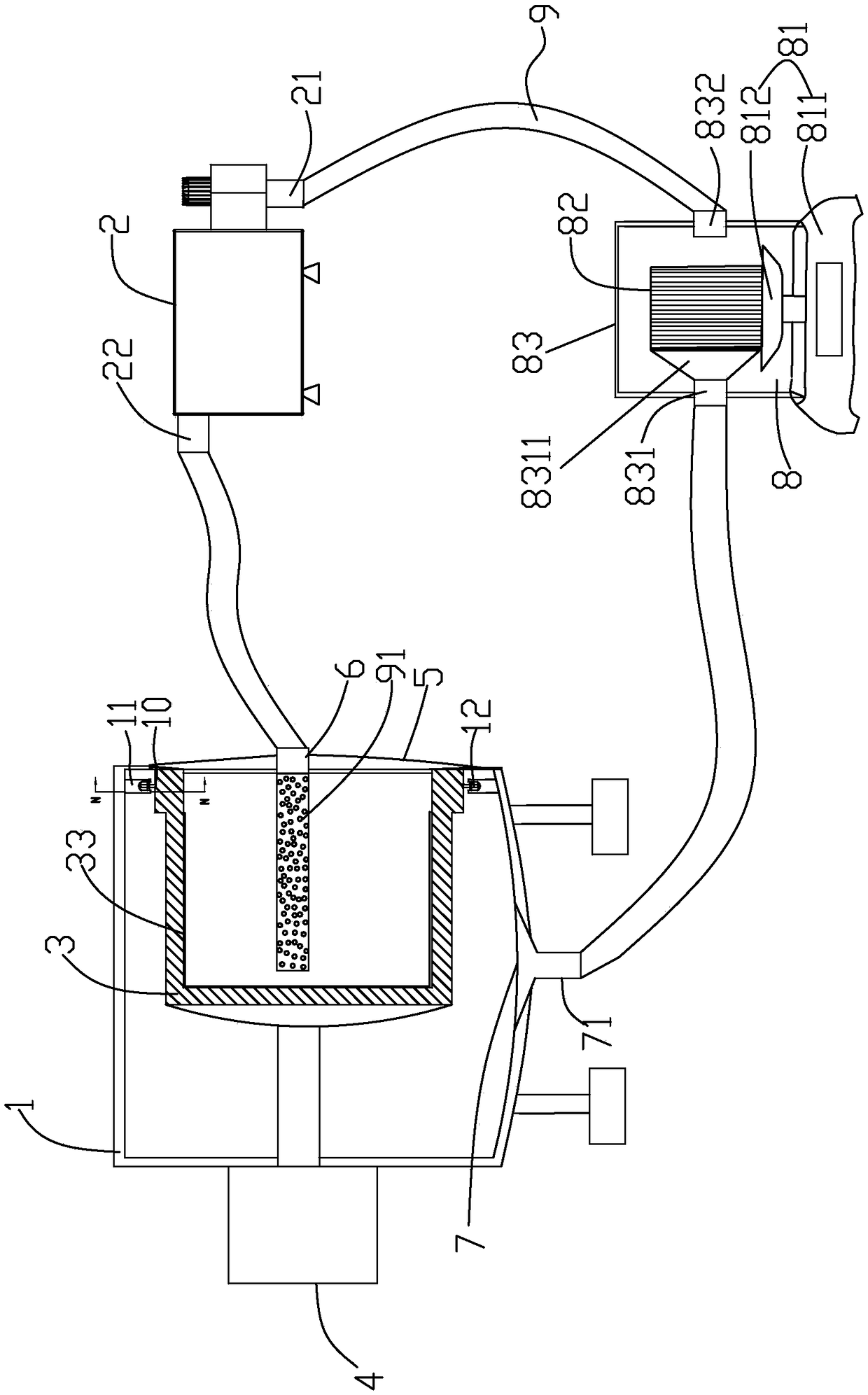

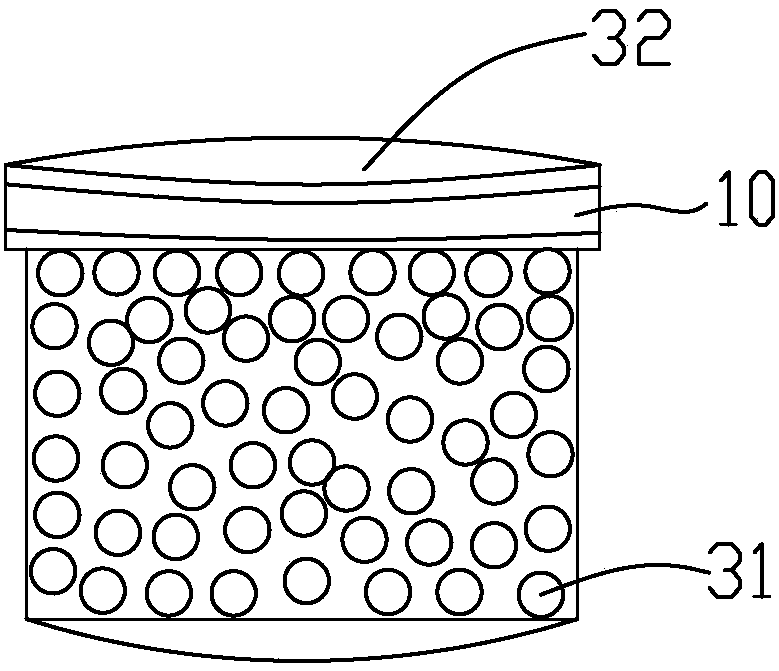

Mud recycling and separating system and using method thereof

InactiveCN111408185AAvoid combiningAchieve separationSand dryingDrying gas arrangementsHelical bladeElectric machinery

The invention relates to a mud recycling and separating system. The system comprises a stone separation device and a sand-water separation device, the sand-water separation device is positioned belowthe stone separation device; the lower part of the stone separation device is communicated with a communicating pipe; the sand-water separation device comprises a material bearing hopper located belowthe communicating pipe, a circular pipeline which communicates with the outlet end of the material bearing hopper and is obliquely arranged, and a second support used for supporting the circular pipeline. Spiral blades are arranged in the circular pipeline, a water output port is formed in the lower end of the circular pipeline, and a driving motor for driving the spiral blades to rotate is arranged at one end of the circular pipeline. The mud recycling and separating system has the effects that stones, sand and water are separated, the separation degree of the stones, the sand and the wateris enhanced, and the water is recycled.

Owner:杭州金鼎实业有限公司

Cat litter cleaning device

The invention discloses a cat litter cleaning device which comprises a cat litter placing disc. The cat litter cleaning device is characterized in that a fixed frame is arranged at the rear end of thecat litter placing disc, wherein the upper end of the fixed frame is equipped with a filter frame; a plurality of filter holes are formed in the bottom surface of the filter frame; a sealing device capable of sealing the upper end of the fixed frame is arranged on the fixed frame at the lower end of the filter frame; a first through slot is formed in the front end of the fixed frame; a first inclined plate which tilts towards the first through slot is arranged in the fixed frame; a drive device capable of driving the cat litter placing disc to move for pouring cat litter in the cat litter placing disc into the filter frame is arranged at one side of the fixed frame; a scraping device capable of scrapping cat litter in the filter frame for dropping perfect cat litter into the fixed frame is arranged at one side of the fixed frame; and a cleaning device capable of cleaning used cat litter and conveying the cleaned cat litter back into the cat litter placing disc is arranged at the rearend of the fixed frame.

Owner:嘉兴琦玥装饰材料有限公司

Depositing and farming methods for drying oil sand mature fine tailings

InactiveUS9068776B2Improve initial dewateringAccelerated dryingDrying using combination processesSand dryingUpper crustEngineering

Methods for drying oil sand fine tailings treated to comprise flocculated fine tailings, by deposition and farming techniques, are provided. A deposition cell is provided with a sloped bottom surface and the flocculated fine tailings are deposited to undergo channelless advancement in the cell while allowing drainage of release water. When the deposit is uneven, the deposit may be plowed while wet for spreading and ensuring water release conditioning is imparted thereto, while avoiding over-shearing, and maintaining sufficient shear strength to allow standing. Once a dried upper crust forms, the deposit may be harrowed to break up the crust, expose wet regions there-beneath and create furrows in the standing deposit. The methods improve the dewatering and drying of mature fine tailings in oil sands.

Owner:SUNCOR ENERGY INC

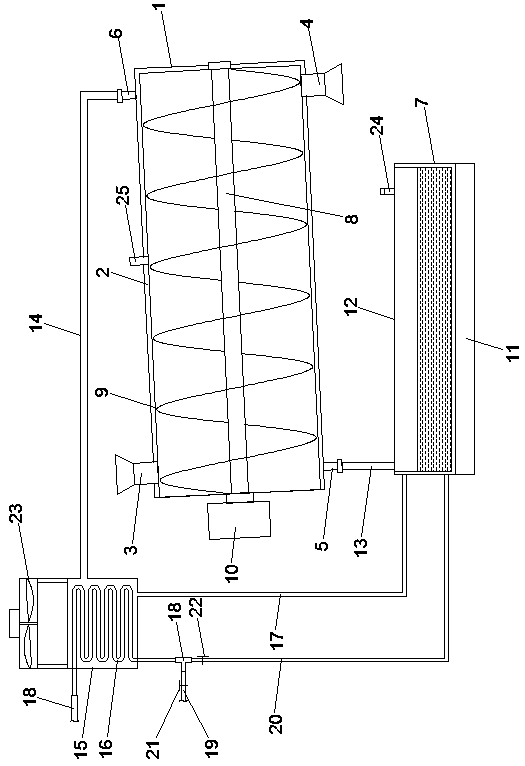

Wet sand drying device

InactiveCN110296589AEfficient heatingSave resourcesSand dryingDrying machines with non-progressive movementsWater vaporPropeller

Disclosed is a wet sand drying device. The wet sand drying device comprises a drying cylinder. The drying cylinder is composed of two-layer cylinder walls. A heating chamber is formed between the inner side wall and the outer side wall. The right side of the drying cylinder is inclined upwards. A feeding inlet is formed in the upper portion of the left side of the drying cylinder, and a discharging outlet is formed in the lower portion of the right side of the drying cylinder; a steam inlet is formed in the lower portion of the left side of the drying cylinder, a steam outlet is formed in theupper portion of the right side of the drying cylinder, and the steam inlet is connected with a steam generator; a stirring shaft is arranged inside the drying cylinder, a spiral propeller is arrangedon the stirring shaft, and a motor for driving the stirring shaft to rotate is arranged at one side outside of the drying cylinder. According to the wet sand drying device, steam is adopted for heating the drying cylinder, the lowest temperature of the steam is higher than 100 DEG C, the drying cylinder can be efficiently heated, condensed water can continue to be used, resources are saved, heatexchange is completed, and heat energy can be supplied to other devices.

Owner:湖北恒诚建设有限公司

Sand sieving robot with drying function

InactiveCN107511332AWith drying functionTo achieve the purpose of horizontal jitterSievingSand dryingFixed frameEngineering

The invention discloses a sand screening robot with a drying function, which includes a box body, a fixed frame is fixedly connected to the bottom of the inner wall of the box, and a first motor is fixedly connected to the left side of the bottom of the inner wall of the fixed frame. The surface of the output shaft of the first motor is covered with a first pulley, and the right side of the bottom of the inner wall of the fixed frame is fixedly connected with a first support rod and a second support rod in turn from front to back, and the top of the first support rod is rotatably connected with a The first rotating rod, the surface of the first rotating rod is covered with a second pulley and a first cam in sequence from front to back, and the surface of the second pulley is connected to the surface of the first pulley through a belt. The present invention relates to construction machinery equipment technology field. The sand sieving machine with drying function achieves the purpose of horizontally shaking the sieve plate, speeds up the efficiency of sand sieving, improves the drying rate at the same time, and ensures the quality of sand sieving.

Owner:何洁

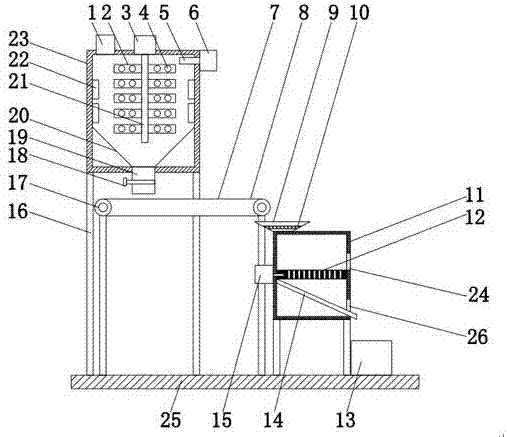

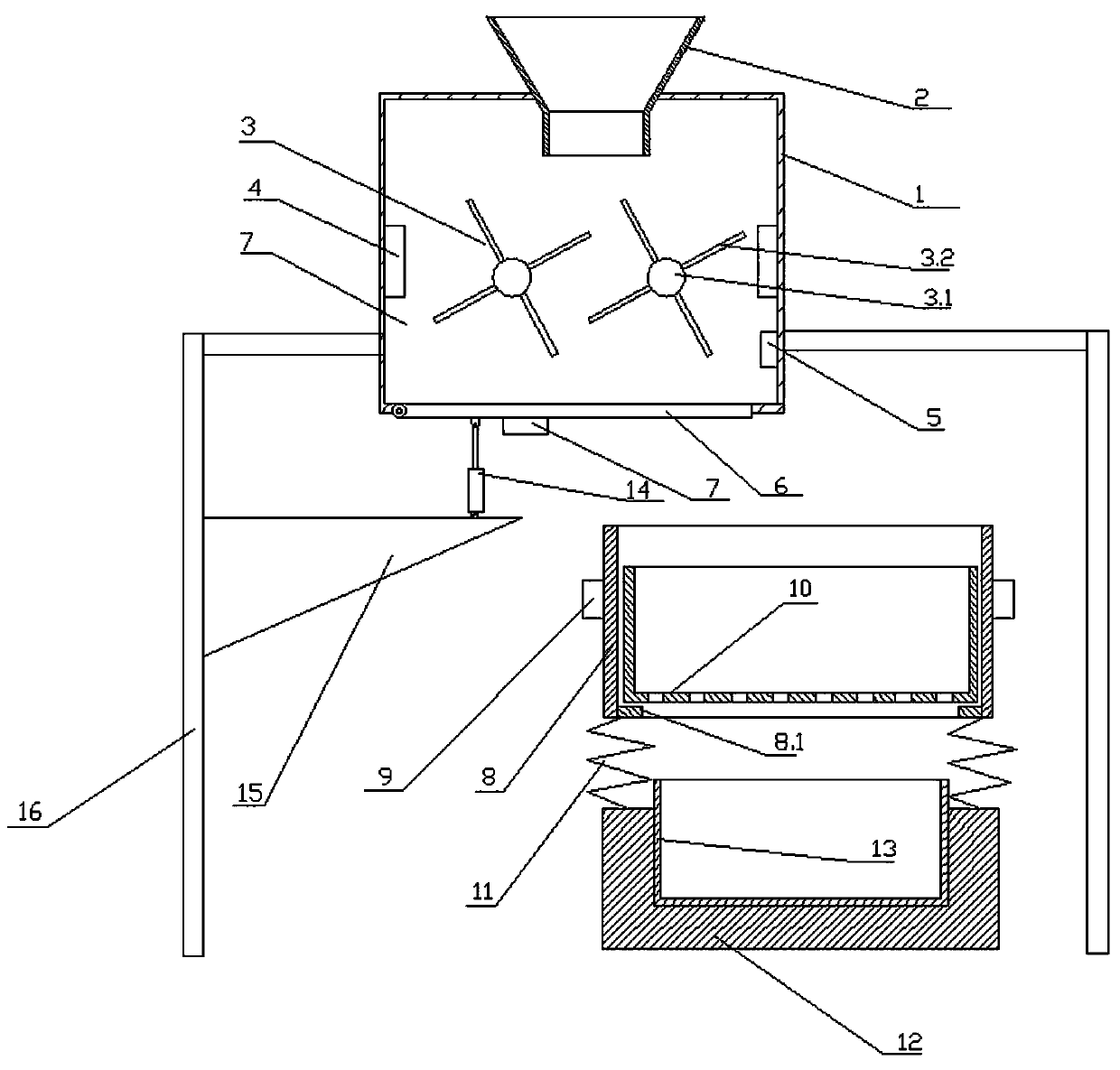

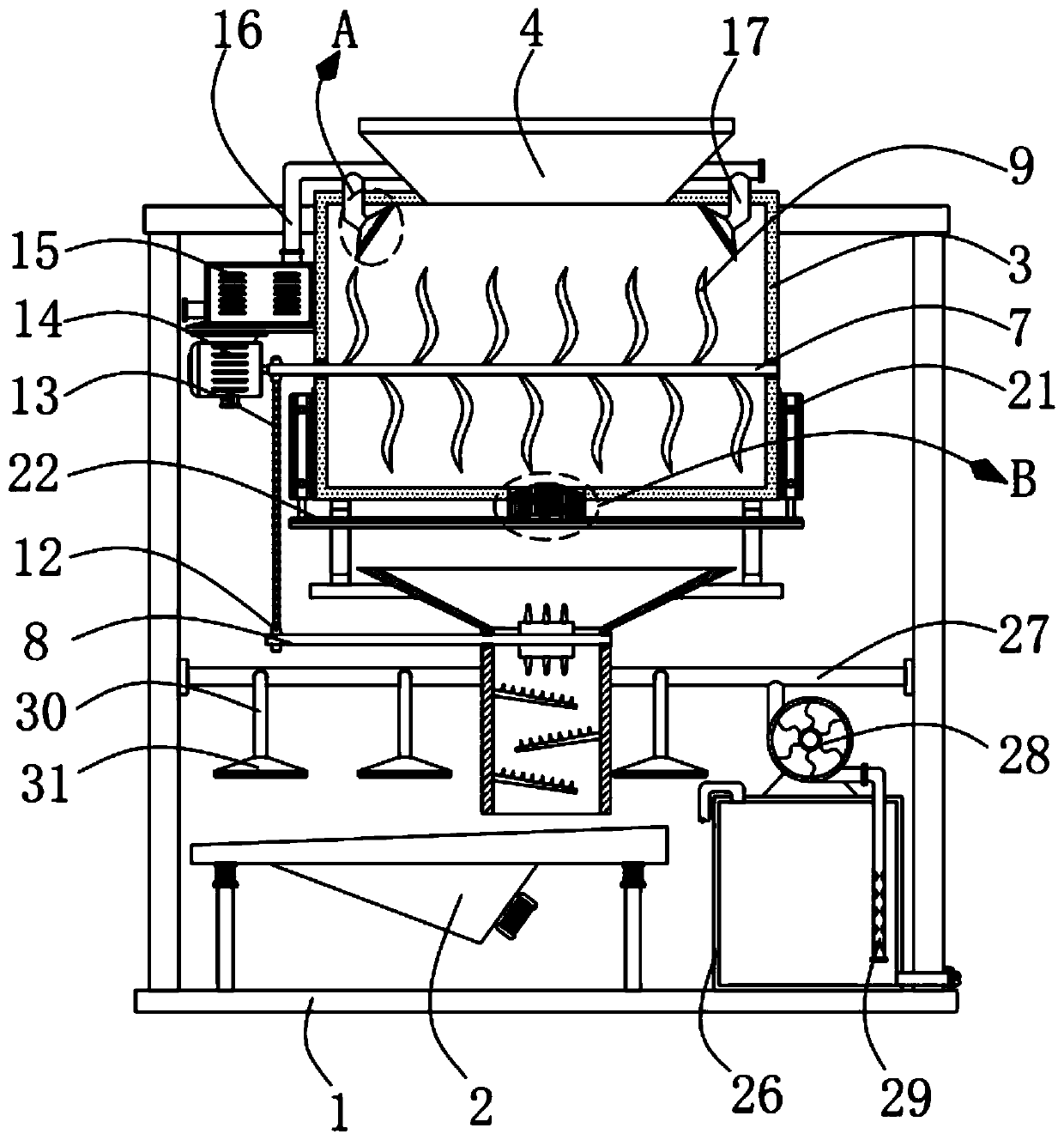

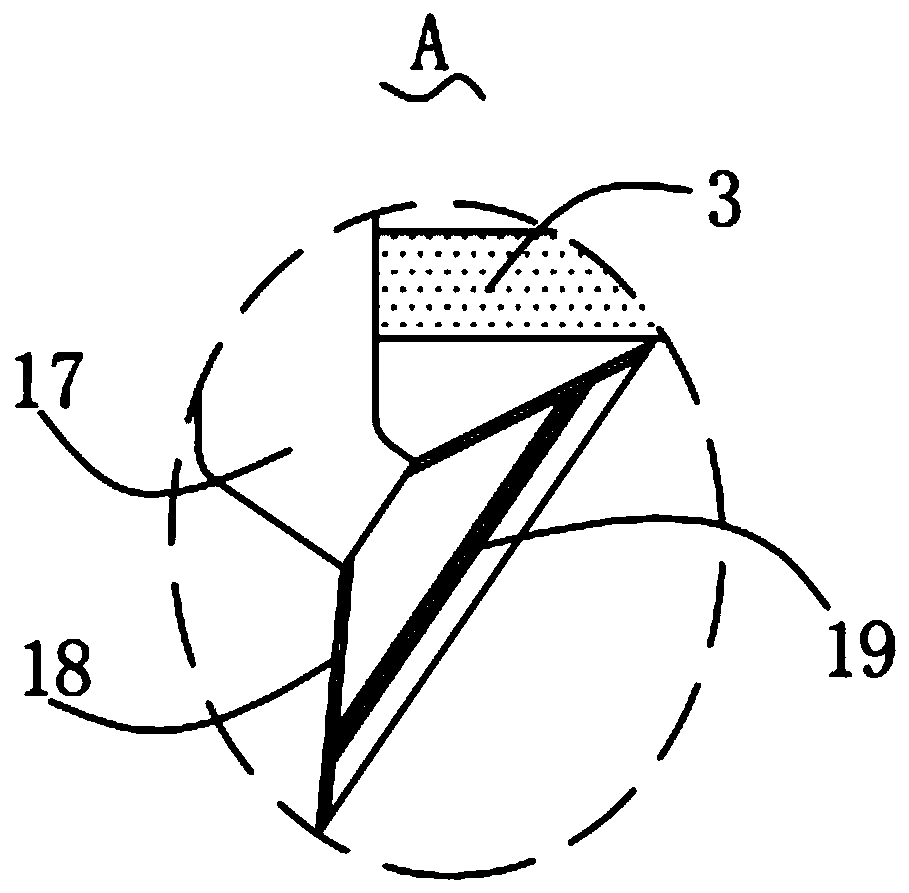

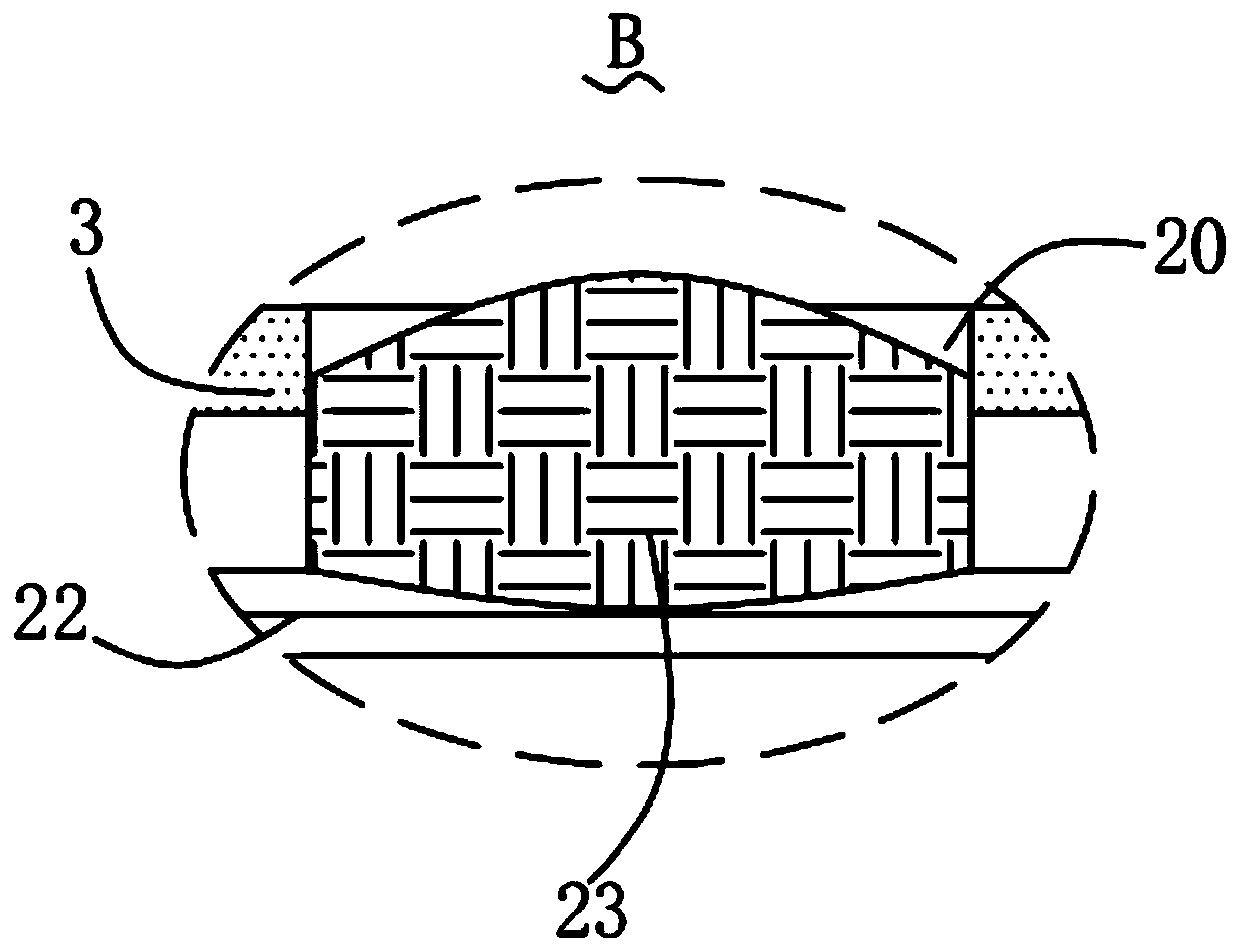

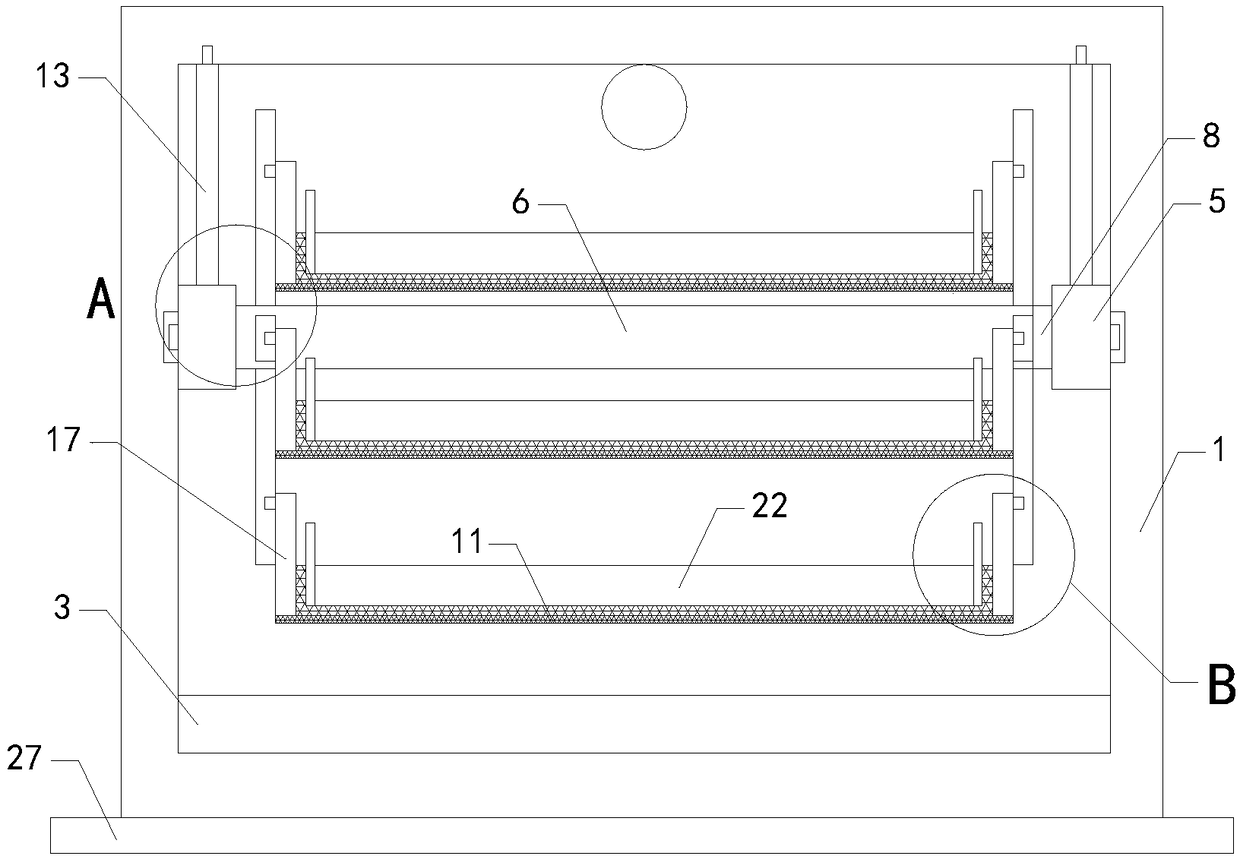

Sand drying device

The invention discloses a sand drying device, and belongs to the technical field of pre-mixing mortar equipment. The upper end of the device is provided with a feeding port 1. An air outlet 12 is formed in the right side of the feeding port 1. A drying chamber 2 is arranged at the lower end of the feeding port 1. A pulverizing chamber 7 is arranged at the upper end in the drying chamber 2. Pulverizing rollers 8 are arranged in the pulverizing chamber 7. A first screen 9 is arranged at the lower end of the pulverizing chamber 7. Drying pipes 10 are arranged at the lower end of the first screen9. A second screen 11 is arranged at the lower ends of the drying pipes 10. A first sand outlet 5 is formed in the left side of the lower end of the second screen 11, and a second sand outlet 6 is formed in the right side. A first air heater 13 is arranged on the left side of a box of the drying chamber 2, and a second air heater 14 is arranged on the right side. The provided sand drying device has excellent drying efficiency, the drying time is saved, and the quality of sand is not influenced after drying.

Owner:孙祎

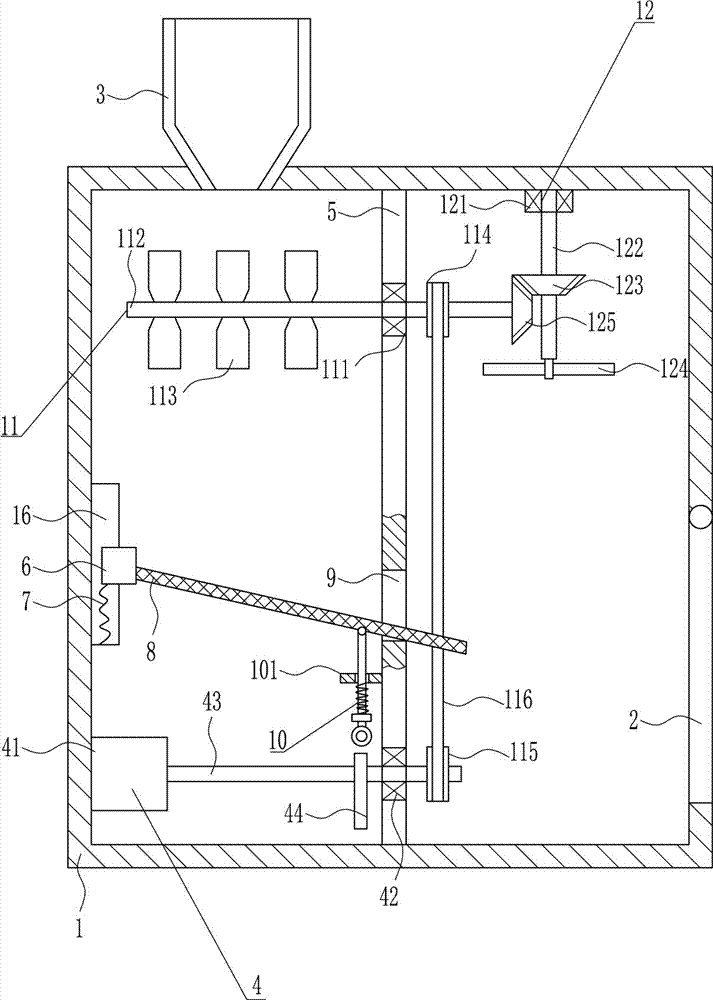

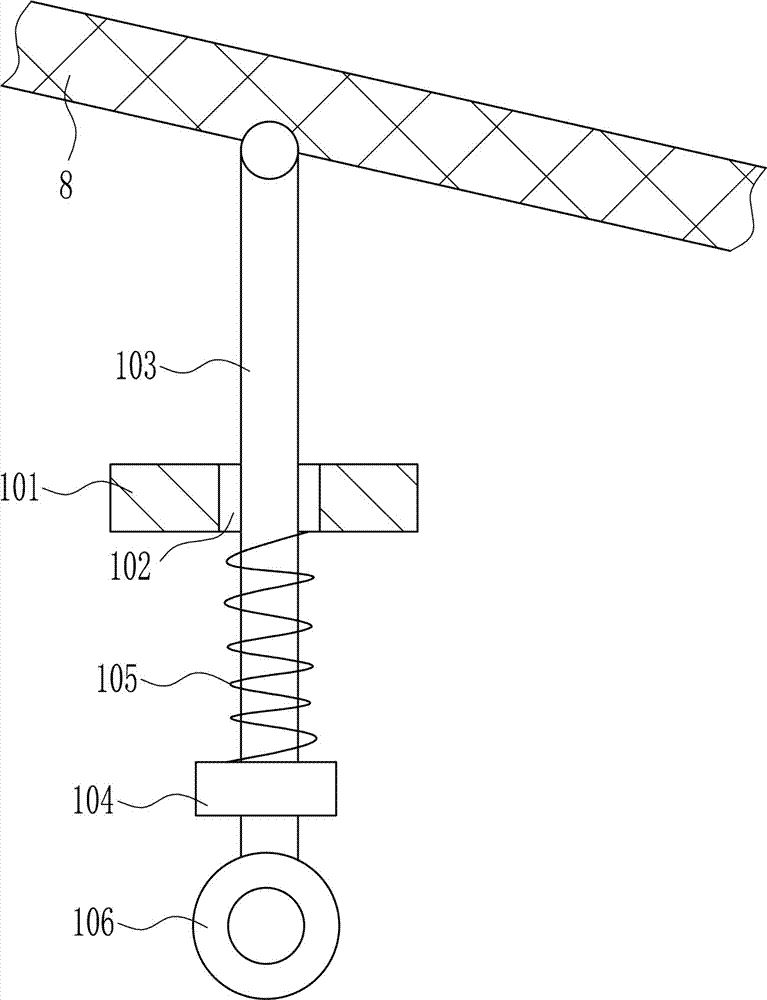

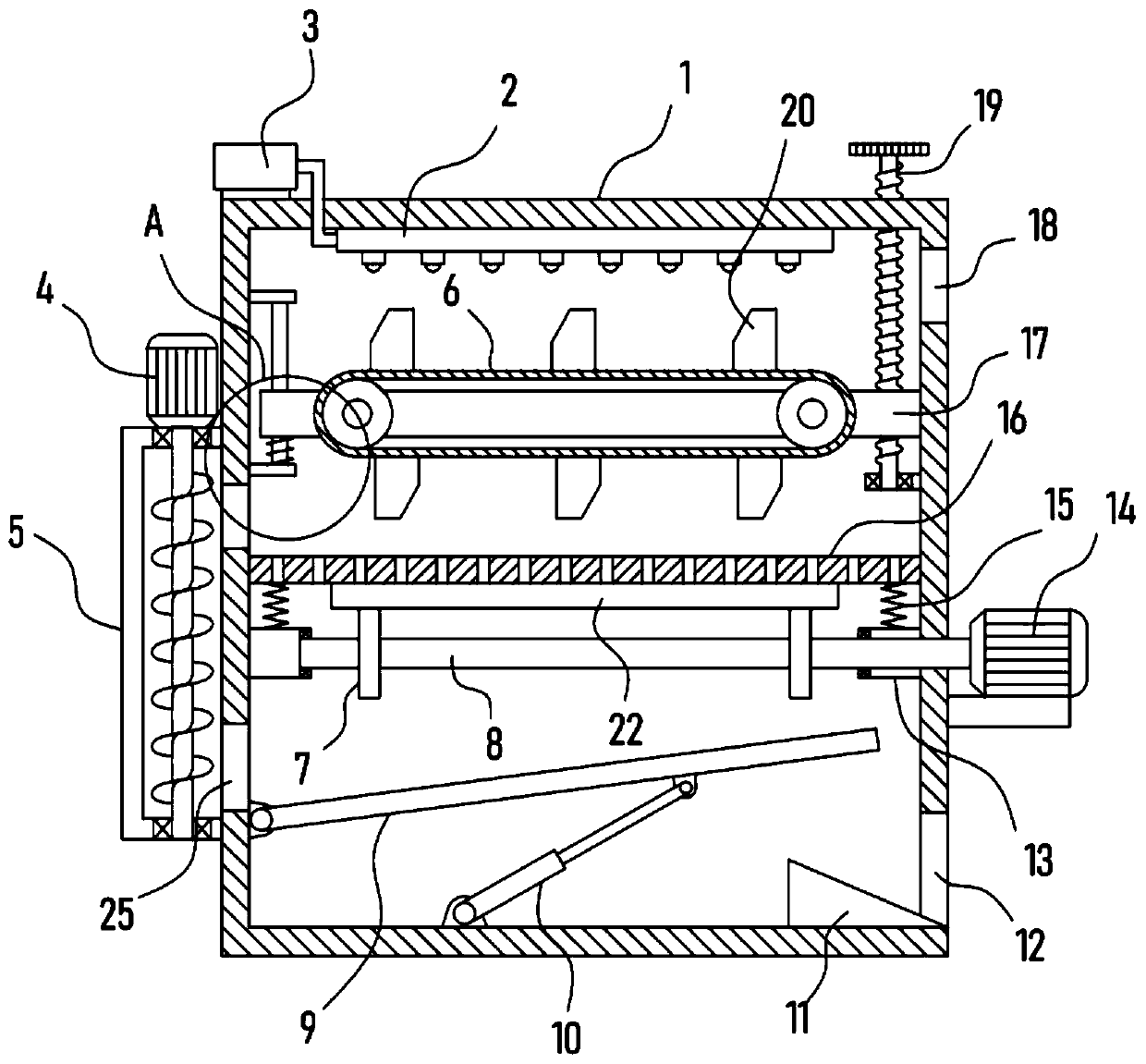

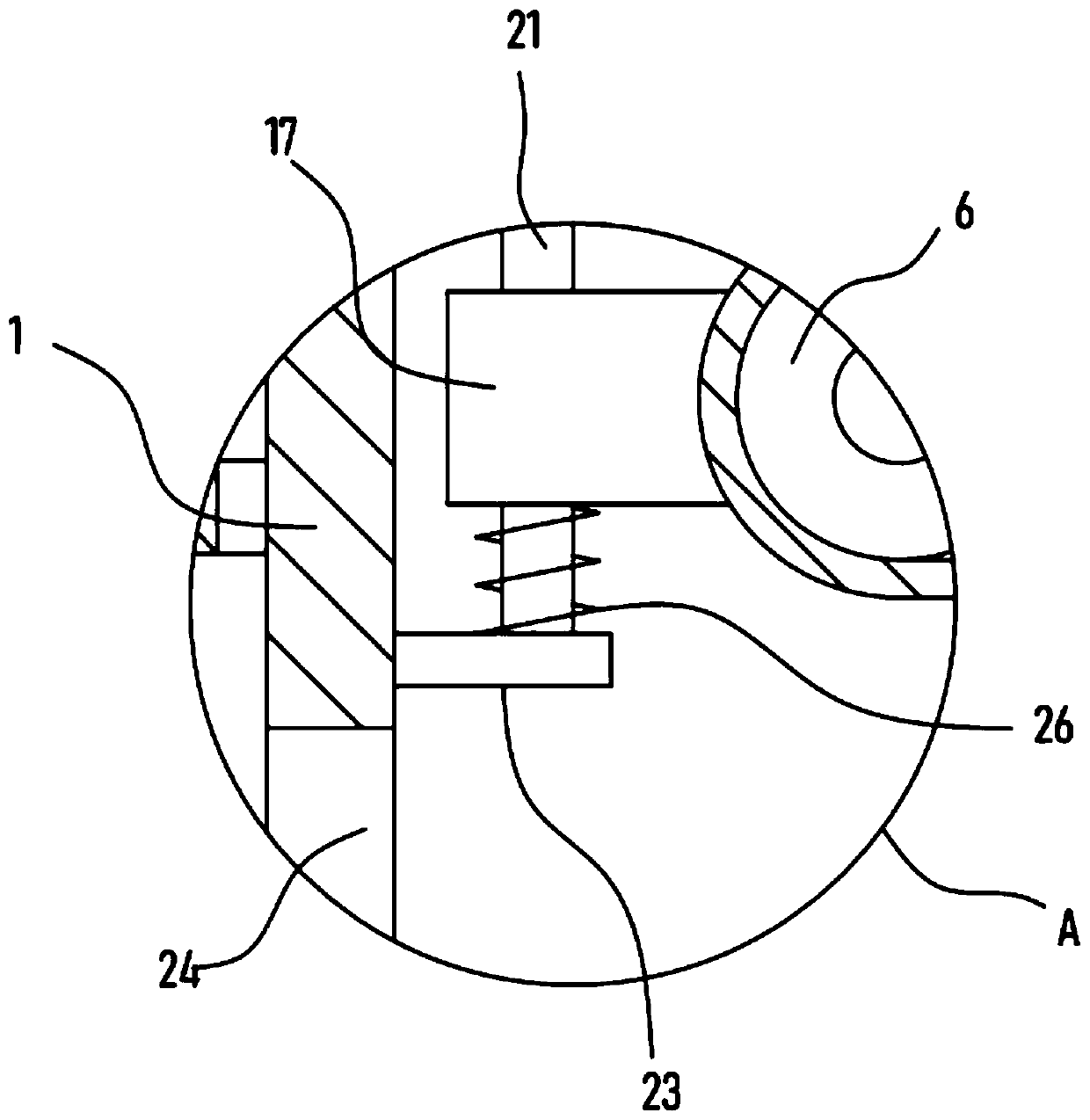

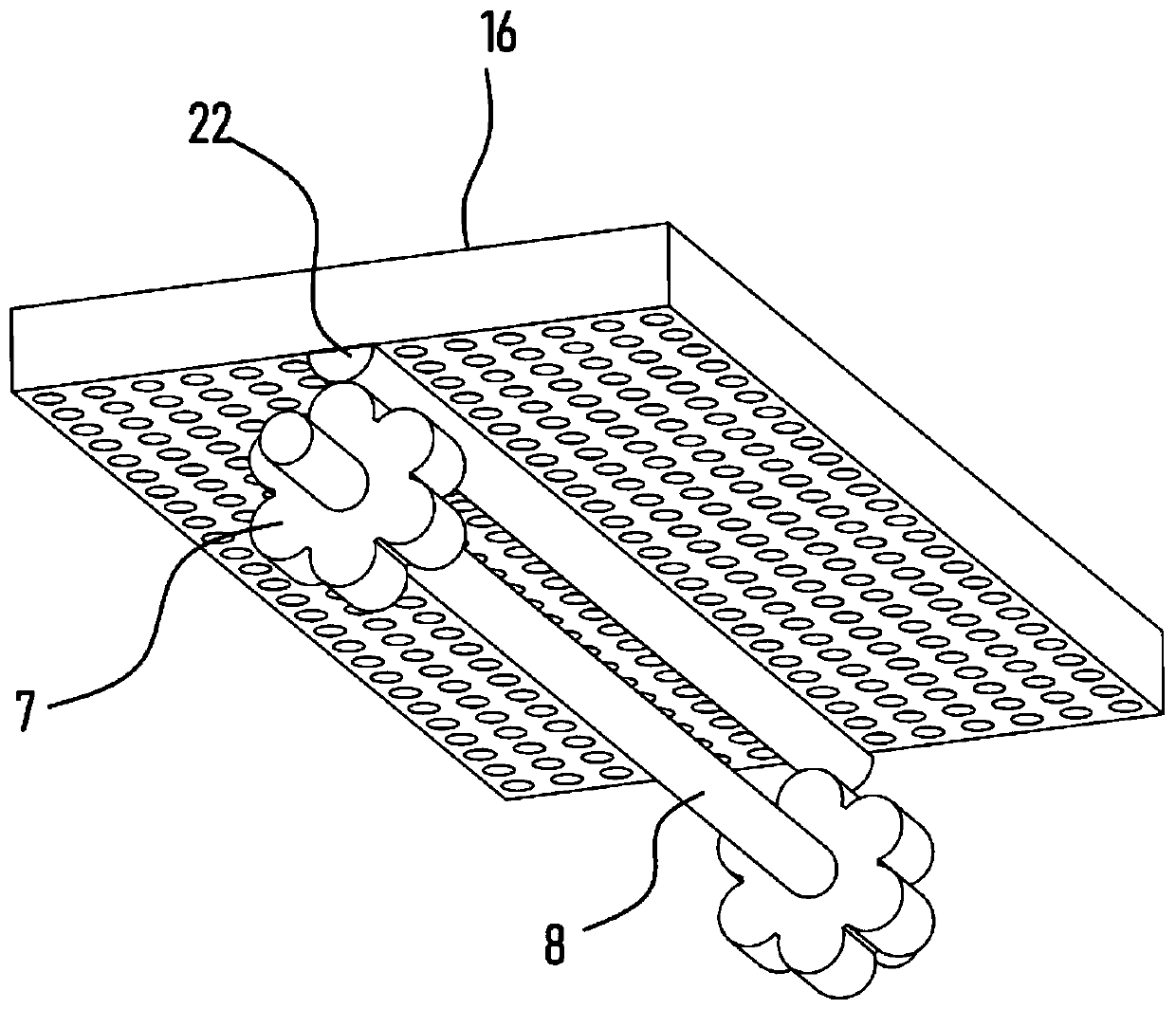

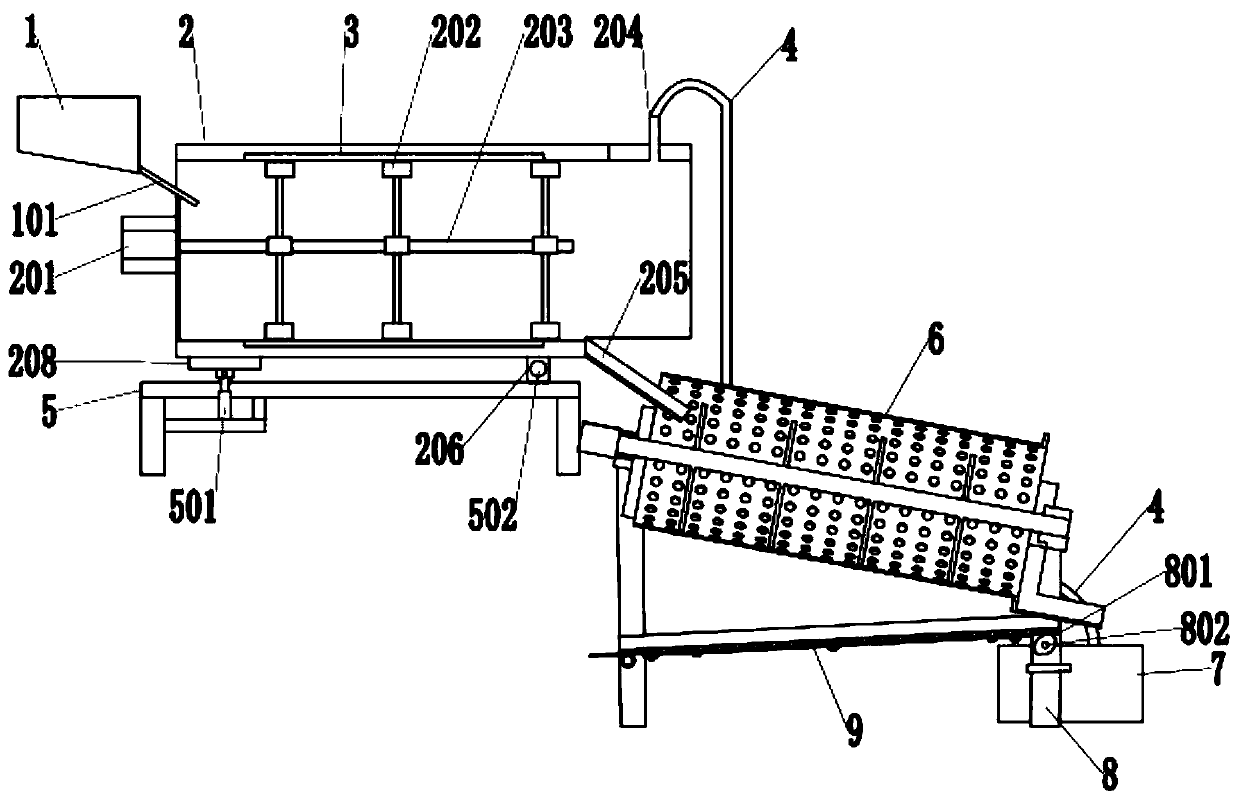

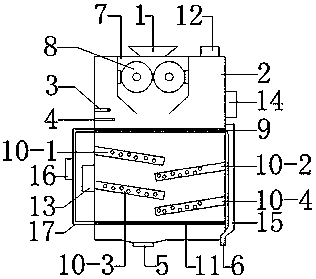

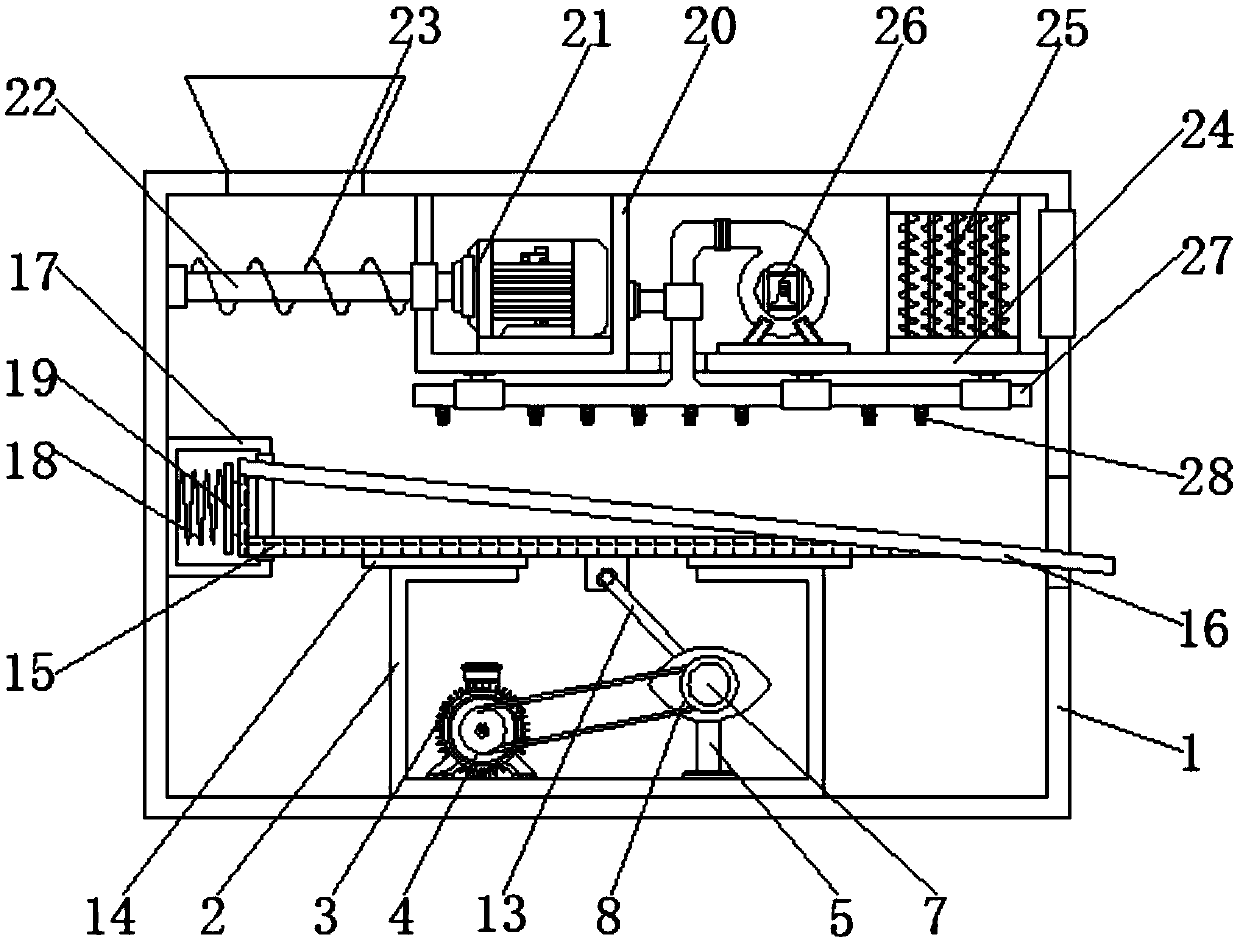

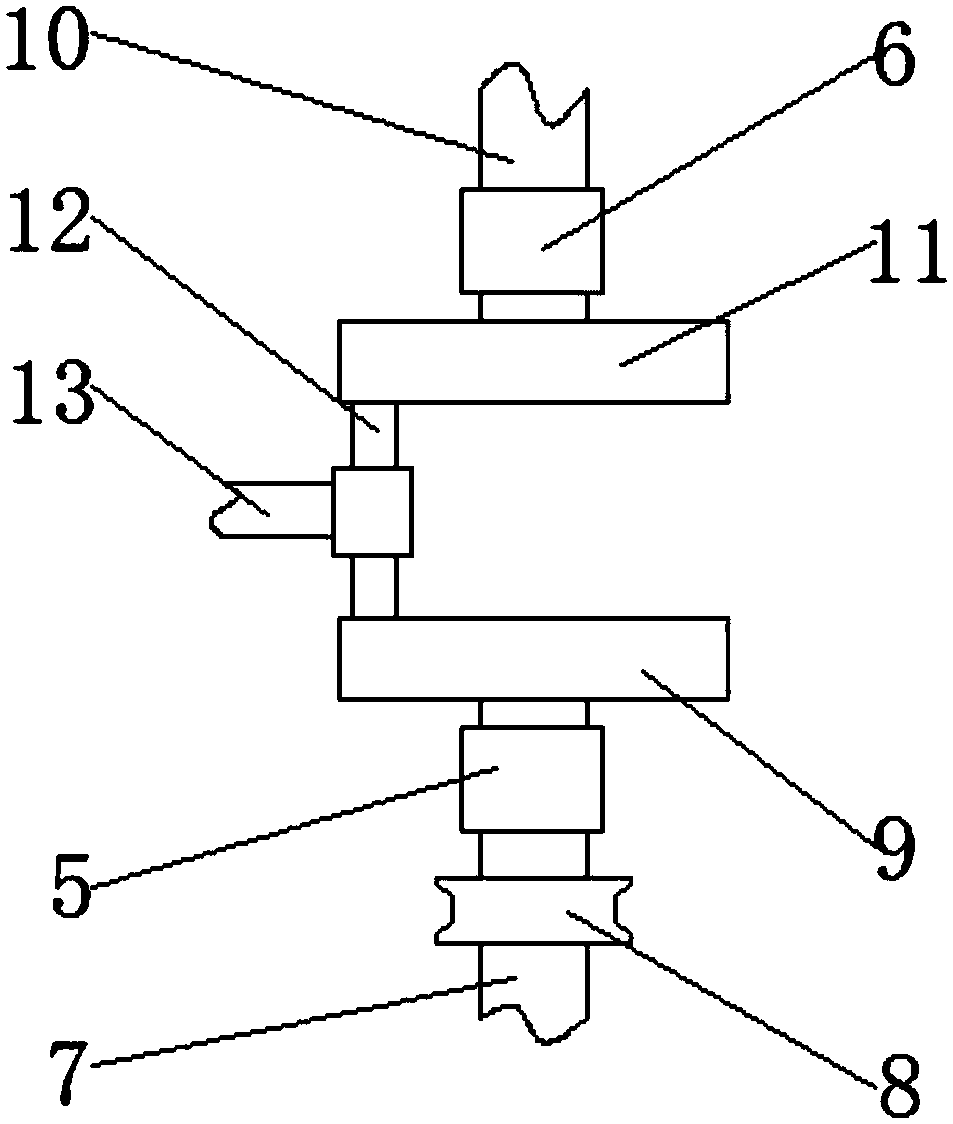

Sand drying and grading device for building construction

InactiveCN110270500AReduce labor intensityAvoid clumpingSievingSand dryingEngineeringUltimate tensile strength

The invention discloses a sand drying and grading device for building construction. The device comprises a drying box body, wherein a feed hopper is arranged at the top of the drying box body; a double-shaft stirring device is arranged in the drying box body; an electric heater and a humidity sensor are arranged on the inner side wall of the drying box body; a discharge plate is hinged to the bottom of the drying box body; a first vibrating motor is arranged at the bottom of the discharge plate; an annular vibrating basket is arranged at a position obliquely below the discharge plate; a second vibrating motor is arranged on the annular vibrating basket; a screen mesh is arranged in the annular vibrating basket; the bottom of the annular vibrating basket is connected with the top of a fixing groove through a spring; and a collecting basket is arranged in a notch of the fixing groove. According to the device, the sand can be dried and graded, the phenomenon of agglomeration is effectively avoided, the sand with proper water content and proper mesh number is finally obtained, the sand screening efficiency is improved, and the labor intensity of workers is reduced.

Owner:湖北乾奥建设工程有限公司

Construction site sand airing device capable of conveniently pouring material

InactiveCN108931125ASpeed up dryingIncrease mobilitySand dryingDrying chambers/containersArchitectural engineeringRotating disc

The invention discloses a construction site sand airing device capable of conveniently pouring a material. The construction site sand airing device comprises an airing tray, a rotating disc and a base; the middle position of the lower end of the airing tray is hinged to the upper end of a fixing column, the lower end of the fixing column is fixedly installed on the rotating disc, rotating rings are fixedly connected to the lower end of the rotating disc, annular sliding blocks are fixedly connected to the lower ends of the rotating rings, the annular sliding blocks are arranged in annular sliding grooves formed on the base in a sliding mode, an inner cavity is formed in the inner side end of the rotating disc, and an eccentric wheel is arranged at the middle position of the inner cavity. The device has the advantages that design is novel, movable rods drive the airing tray to swing leftwards and rightwards in a reciprocating mode through a connecting rod and an electric telescopic rodwhen the movable rods move left and right, when the airing tray moves left and right, the sand on the airing tray can slide under the action of gravity, so that the sand on the lower layer is exposed,then the airing speed of the sand is accelerated, the inclination angle of the airing tray can be increased when the electric telescopic rod is started to extend, so that the dried screen can be conveniently emptied, the use is convenient, and the practicability is high.

Owner:刘辉辉

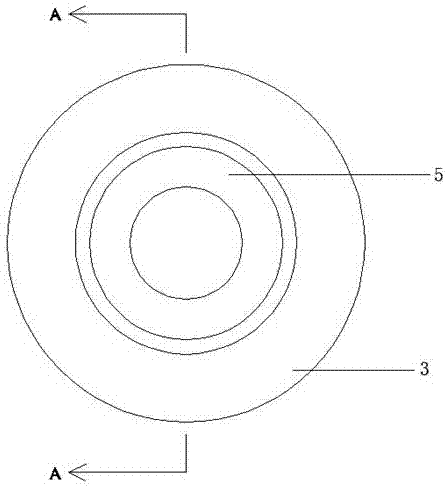

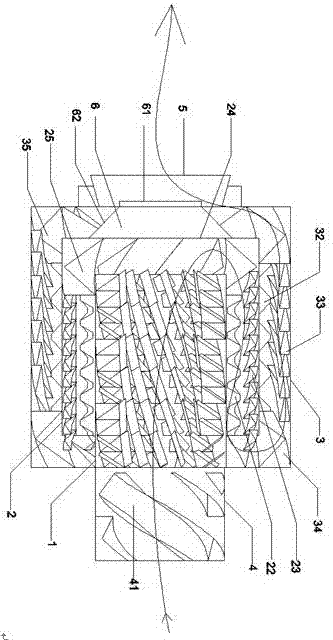

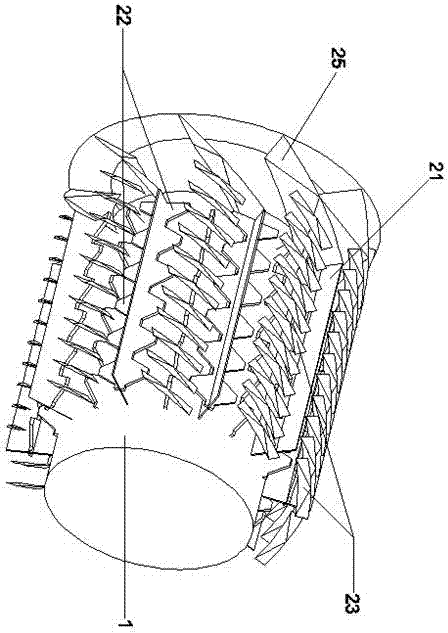

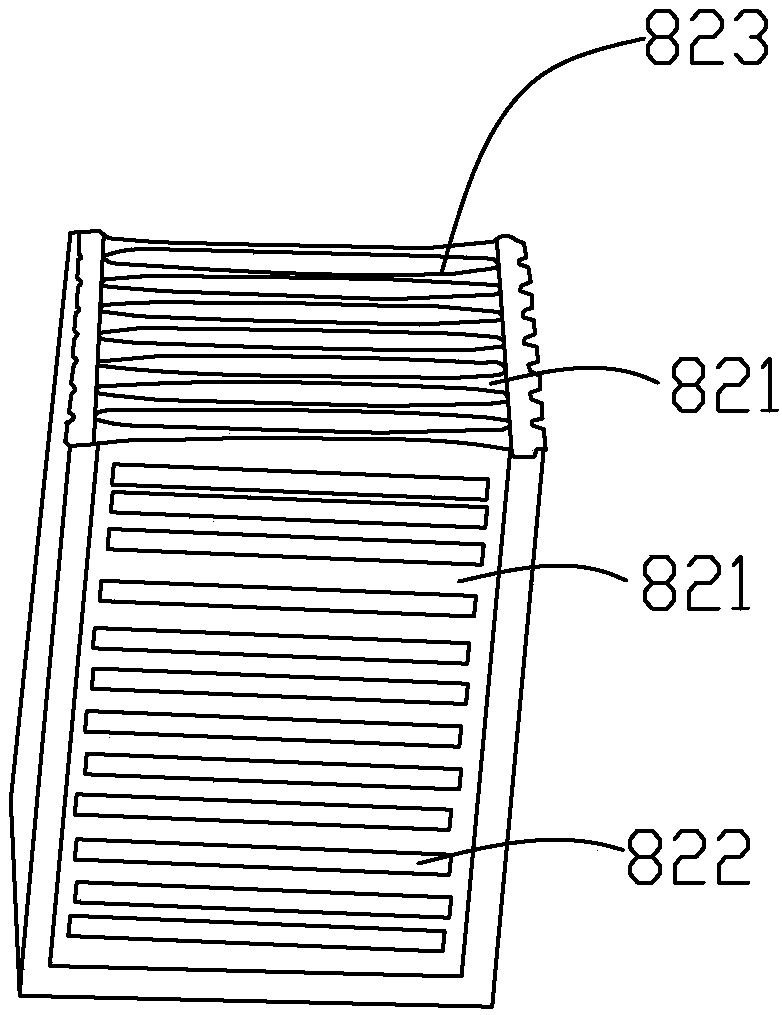

Sawtooth-shaped sand raising plate type sand drying machine

ActiveCN107990694AEasy to measure flow rateIncrease the effective heat transfer areaSand dryingDrying chambers/containersPulp and paper industrySlide plate

The invention discloses a sawtooth-shaped sand raising plate type sand drying machine. The machine comprises an inner cylinder, a middle cylinder and an outer cylinder, wherein the inner cylinder, themiddle cylinder and the outer cylinder are coaxially sleeved with one another from inside to outside; the feeding end of the inner cylinder is provided with a feeding cylinder, the discharging end ofthe outer cylinder is provided with an external connection cone, an inner cylinder sand raising combined plate is arranged on the inner wall of the inner cylinder, a middle cylinder partition plate and a middle cylinder sand sliding plate are arranged between the inner cylinder and the middle cylinder in the axial direction, the two sides of the middle cylinder partition plate are arranged on theouter wall of the inner cylinder and the inner wall of the middle cylinder correspondingly, middle cylinder sand raising plates are arranged on the two sides of the middle cylinder partition plate, the middle cylinder sand sliding plate is arranged on the inner wall of the middle cylinder, and a middle cylinder baffle plate is arranged at the discharging end of the middle cylinder; an outer cylinder partition plate and an outer cylinder sand sliding plate are arranged between the middle cylinder and the outer cylinder in the axial direction, the two sides of the outer cylinder partition plateare arranged on the outer wall of the middle cylinder and the inner wall of the outer cylinder correspondingly, outer cylinder sand raising plates are arranged on the two sides of the outer cylinderpartition plate, and the outer cylinder sand sliding plate is arranged on the inner wall of the outer cylinder. According to the machine, in the middle cylinder and the outer cylinder, most hot air can be effectively acted on the thrown wet sand, the effective heat exchange area of sand and hot air is increased, the damp and hot moisture in the sand is taken away, and the energy consumption loss is reduced.

Owner:ZHENGZHOU TONGDING MASCH EQUIP CO LTD

Sand screening machine with drying function

ActiveCN107649381ATo achieve the purpose of horizontal jitterImprove screening efficiencySievingSand dryingMechanical equipmentEngineering

The invention discloses a sand screening machine with a drying function, and relates to the technical field of building mechanical equipment. The sand screening machine comprises a box body, a fixingframe is fixedly connected to the bottom of the inner wall of the box body, a first motor is fixedly connected to the left side of the bottom of the inner wall of the fixing frame, and a first belt wheel is arranged on the surface of an output shaft of the first motor in a sleeving mode; a first supporting rod and a second supporting rod are fixedly connected to the right side of the bottom of theinner wall of the fixing frame from front to back in sequence, and the top end of the first supporting rod is rotationally connected with a first rotating rod; and the surface of the first rotating rod is sequentially sleeved with a second belt wheel and a first cam from front to back, and the surface of the second belt wheel is in transmission connection with the surface of the first belt wheelthrough a belt. According to the sand screening machine with the drying function, the purpose of horizontally shaking a screening plate is achieved, the efficiency of screening sand is improved, meanwhile, the drying speed is increased, and the quality of screening the sand is guaranteed.

Owner:广州恒龙建设工程有限公司

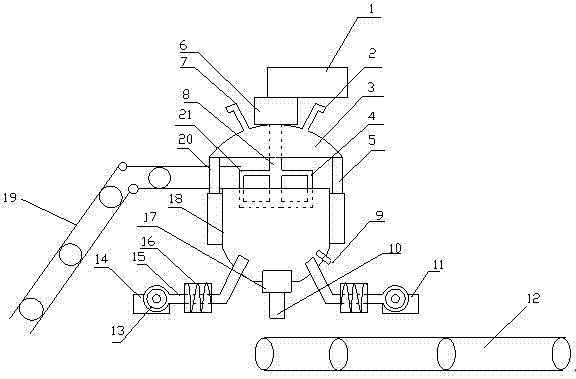

River sand screening device for concrete mixing on construction site

The invention discloses a river sand screening device for concrete mixing on a construction site. A supporting frame is arranged at the bottom of a machine box. A feeding port is formed at the top ofthe machine box. A rectangular through groove is formed in the interior, below the feeding port, of the machine box. Vertical through grooves are formed on the two sides of the rectangular through groove. A fan-shaped box body is arranged in each vertical through groove. A second-level screening device is arranged in the interior, located below a rough filter screen, of the machine box. A fine sand outlet is formed at the bottom of the machine box. A drying conveying device is arranged at the top, located above the feeding port, of the machine box. According to the river sand screening devicefor concrete mixing on the construction site, river sands can be dried (wind-blowing and heating) before screening is conducted; thus the screen is prevented from being blocked by the river sands in the screening process; and screening can be conducted smoothly. By means of the river sand screening device, rough screening is conducted on the river sands first, and big pebbles and impurities in theriver sands are filtered out; then screening is conducted again on the river sands by means of an inclined fine filter screen, and river sands of small size are filtered out; and thus river sands ofmedium particle size and excellent property are acquired.

Owner:王红燕

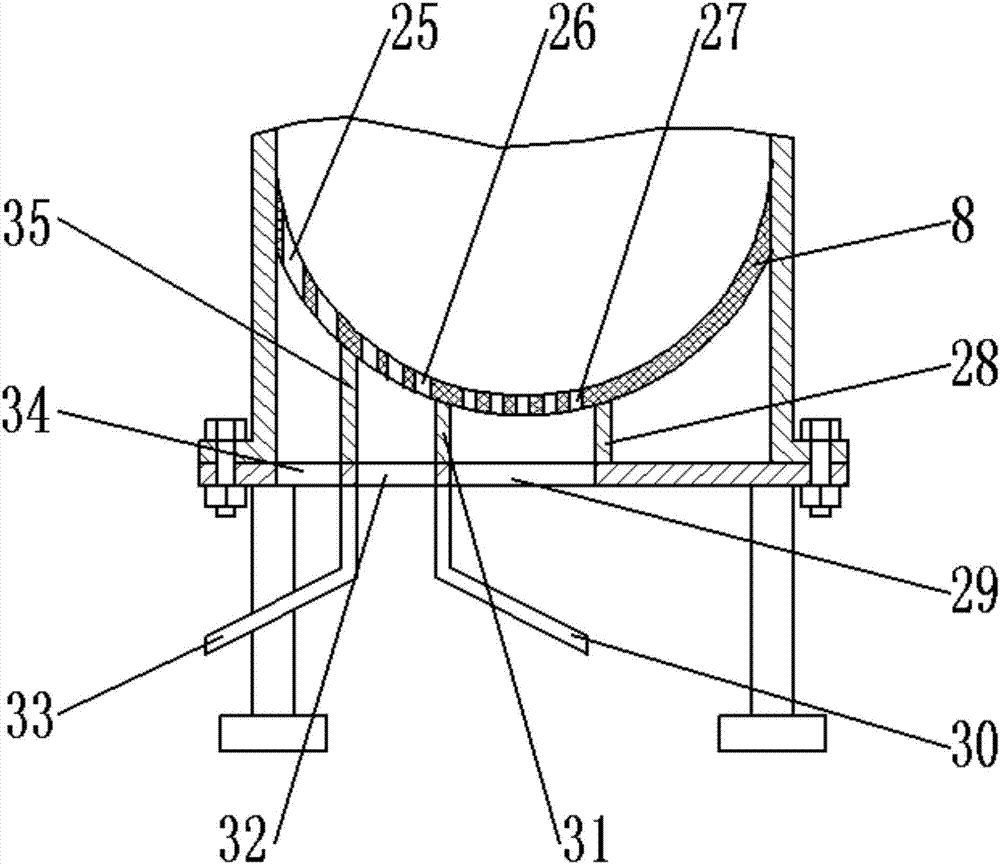

Vertical yellow sand dryer

InactiveCN107014183AIncrease productivityStir wellSand dryingDrying gas arrangementsEngineeringHumidity

The invention discloses a vertical yellow sand dryer. The vertical yellow sand dryer comprises a tank body, a tank cover, a stirring device, hydraulic lifting rods, a conveying belt and drying devices; the tank body is set as a cylinder structure; the tank cover is set as a semicircular structure; the tank cover is supported through a left hydraulic lifting rod on the left side of the tank body and a right hydraulic lifting rod on the right side of the tank body, and is fixed above the tank body; the stirring device is arranged in middle of the tank cover; the drying devices are arranged on the left and right sides of the tank body; an outlet is formed below the tank body, and is provided with a valve; an outlet pipeline is arranged below the valve; the conveying belt includes a discharge conveying belt and a feed conveying belt; and a humidity induction probe is arranged on the tank body. The vertical yellow sand dryer can quickly dry yellow sand, and is widely applied to the field of yellow sand drying.

Owner:胡川

High-efficiency building sand screening equipment

InactiveCN111570266AUnobstructed whereaboutsReduce health threatsSievingSand dryingArchitectural engineeringStructural engineering

The invention provides high-efficiency building sand screening equipment. The high-efficiency building sand screening equipment comprises a base, a vibrating screen, a pretreatment box, a sand discharging hopper, a material guiding hopper, a rectangular leakage pipe, and a first rotating rod, wherein the vibrating screen is arranged at the top of the base; the pretreatment box is arranged above the vibrating screen; the sand discharging hopper is fixedly arranged at the top of the pretreatment box; the material guiding hopper is arranged below the pretreatment box; the rectangular leakage pipeis fixedly arranged at the bottom of the material guiding hopper, and the rectangular leakage pipe is matched with the vibrating screen; and the first rotating rod is rotationally arranged on the inner walls of the two sides of the pretreatment box, and one end of the first rotating rod extends out of the pretreatment box. The high-efficiency building sand screening equipment has the advantages that sand can be evenly scattered and dewatered, the sand screening efficiency and quality are improved, and the sand screening environment is improved.

Owner:甘肃一安建设科技集团有限公司

Energy-saving gravel drying device for screening of intelligent control module gravel

InactiveCN108645135AEasy to placeImprove contact effectSand dryingDrying gas arrangementsElectric machineUsability

The invention relates to the technical field of environment-friendly energy-saving drying devices, in particular to an energy-saving gravel drying device for screening of intelligent control module gravel. Gravel can be placed conveniently, and the usability is improved; meanwhile, the available drying amount of gravel each time can be increased, the energy is saved, and the use effect is improved; moreover, the gravel can be uniformly dried, the drying effect is improved, and the use reliability is improved. The device includes a working box, a bracket, a venting pipe and an electric heater;a taking port is formed in the front end of the working box, and a box door is arranged on the taking port; the device also includes a servo motor and two reinforcing components, and the bracket comprises a connecting shaft and a fixing block; the device further includes two electric retractable rods and two lower sliding blocks, and the output ends of the two electric retractable rods are connected to the fixing block and the rear end of the servo motor respectively. The device also includes four connectors, four placing plates and four placing boxes, the four placing plates are arranged at output ends of the four connectors respectively, and the four placing boxes are placed on the four placing plates respectively.

Owner:JIANGSU JINENGDA ENVIRONMENTAL ENERGY SCI & TECH

Centrifugal soil test soil rapid drying instrument

PendingCN108072239ADry fastShorten the timeSand dryingDrying solid materials without heatEngineeringAir heater

The invention discloses a centrifugal soil test soil rapid drying instrument. The centrifugal soil test soil rapid drying instrument comprises a shell and further comprises an air heater, an inner container, a work motor, a cover and a water collecting device. The air heater is provided with an air inlet air port and an air outlet air port which is connected with the shell. The inner container isarranged in the shell and used for containing soil test soil. Filter holes for water-soil separation are formed in the inner wall of the inner container. The inner container comprises an inner container opening. The work motor is detachably connected with the inner container and can drive the inner container to centrifugally rotate. The cover is arranged on the shell and is in sealed connection with the inner container opening. The cover is provided with an air inlet communicating with the interior of the inner container. The air outlet air port communicates with the air inlet. The shell is provided with an air outlet. The water collecting device is connected between the air outlet and the air inlet air port. The provided centrifugal soil test soil rapid drying instrument can rapidly dry the soil test soil, and the content of water in soil can be conveniently and rapidly calculated.

Owner:YUNNAN INST OF BUILDING RES +1

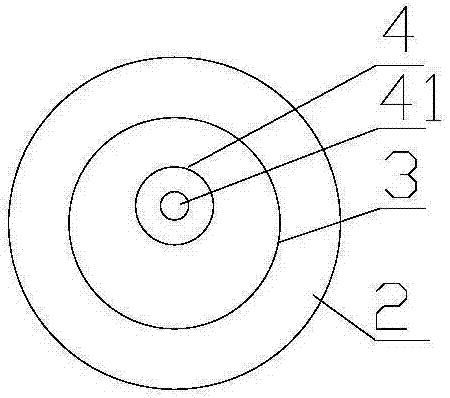

Sleeve type silica sand drying device

InactiveCN107462027AStir wellImprove drying and dust removal effectSand dryingDrying gas arrangementsPulp and paper industryConvection

The invention discloses a sleeve type silica sand drying device. The sleeve type silica sand drying device comprises a support, an outer cylinder, a rotating cylinder and an inner cylinder. The rotating cylinder is rotationally arranged on the support and connected with a drive mechanism, the rotating axis of the rotating cylinder is parallel to the center axis of the rotating cylinder and is eccentrically arranged from the center axis, and the outer cylinder is arranged on the periphery of the rotating cylinder in a sleeving manner and is in sealed connection with the rotating cylinder. According to the sleeve type silica sand drying device, by means of the eccentric rotation of the rotating cylinder, silica sand in the rotating cylinder can rotate along with the rotating cylinder, the silica sand is sufficiently stirred in the rotating cylinder, and agglomeration is avoided. Hot air is exhausted into the rotating cylinder through first exhaust holes in the inner cylinder, the directions that the hot air is emitted into the rotating cylinder are increased, the pressure that the hot air is emitted into the rotating cylinder is also increased, and therefore by increasing the intense degree of convection between the silica sand and the hot air, the hot air and the silica sand are mixed more sufficiently, and the drying and dedusting effects of the hot air on the silica sand are improved.

Owner:望江县金峰矿产品科技有限公司

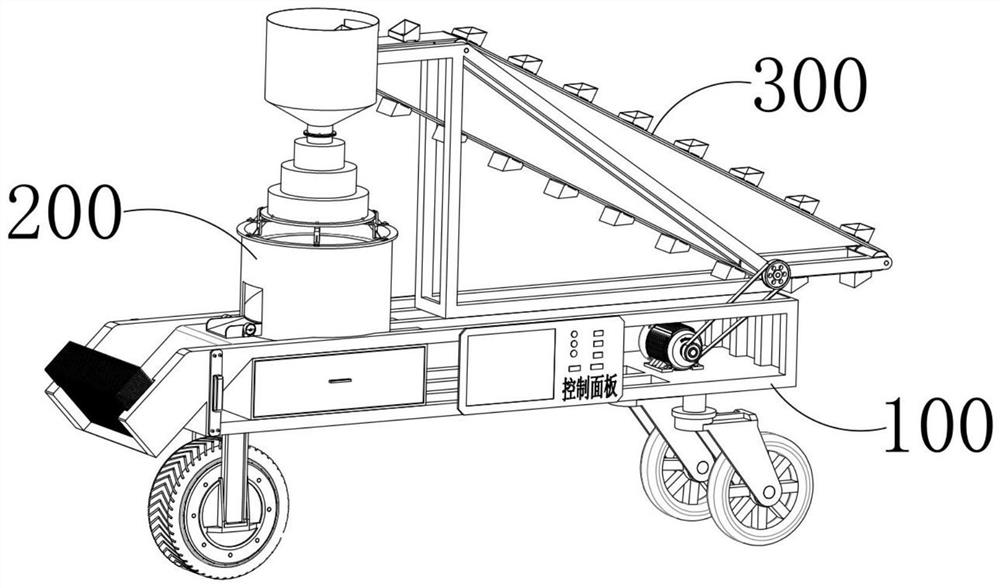

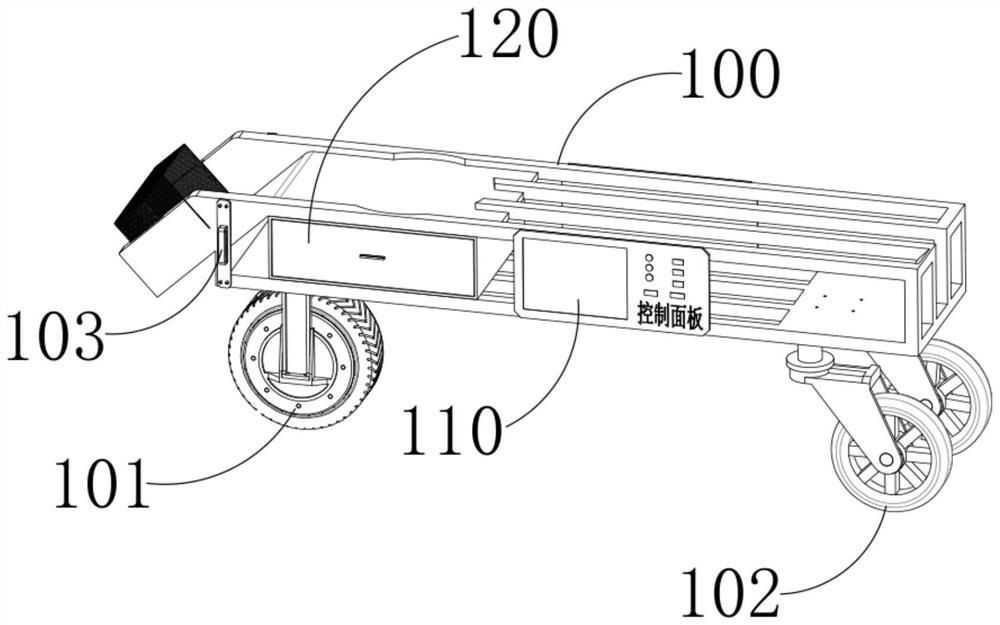

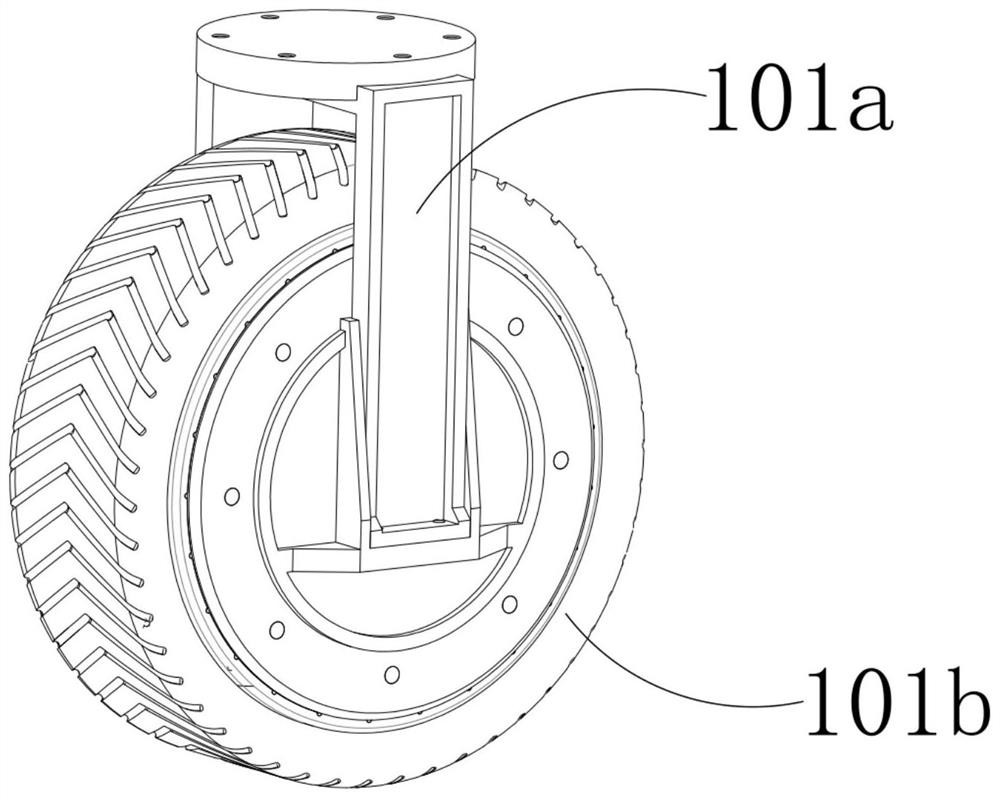

Sand and stone centrifugal screening equipment for constructional engineering

ActiveCN111687044AAvoid problems with insufficient filter separationThe principle is simple and reliableSand dryingGas current separationStructural engineeringMechanical engineering

The invention provides a sand and stone centrifugal screening equipment for constructional engineering. The sand and stone centrifugal screening equipment for constructional engineering comprises a rectangular hollowed-out rack capable of advancing, a separating device and a conveying device, wherein one end of the rack in the length direction is the front end in the advancing direction, the otherend of the rack in the length direction is the rear end in the advancing direction, the separating device is fixedly arranged on the upper end face of the rack and close to the front end of the rack,the conveying device is fixedly arranged on the upper end face of the rack and close to the rear end of the rack, the conveying device is used for supplying sand and stones to the separating device,the separating device is used for drying and centrifugally separating the sand and the stones, firstly discharging the sand outwards and then discharging the stones outwards, the separating device comprises a sieve tray with the tray bottom capable of being opened in an upward floating mode, the sieve tray is driven to rotate to screen out the sand and enable the sand to be discharged outwards, then the tray bottom of the sieve tray is opened to discharge the stones, and meanwhile, an air-drying mechanism and a heater can dry the sand-stone mixture. The sand and stone centrifugal screening equipment has the beneficial effect that the situation that the sand and the stones are difficult to separate due to moist caking is avoided.

Owner:塔江建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com