Mud recycling and separating system and using method thereof

A separation system and mud technology, applied in the field of sand and gravel separators, can solve the problems affecting the reuse and separation of sand, and achieve the effect of preventing the combination of sand and water and enhancing the separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

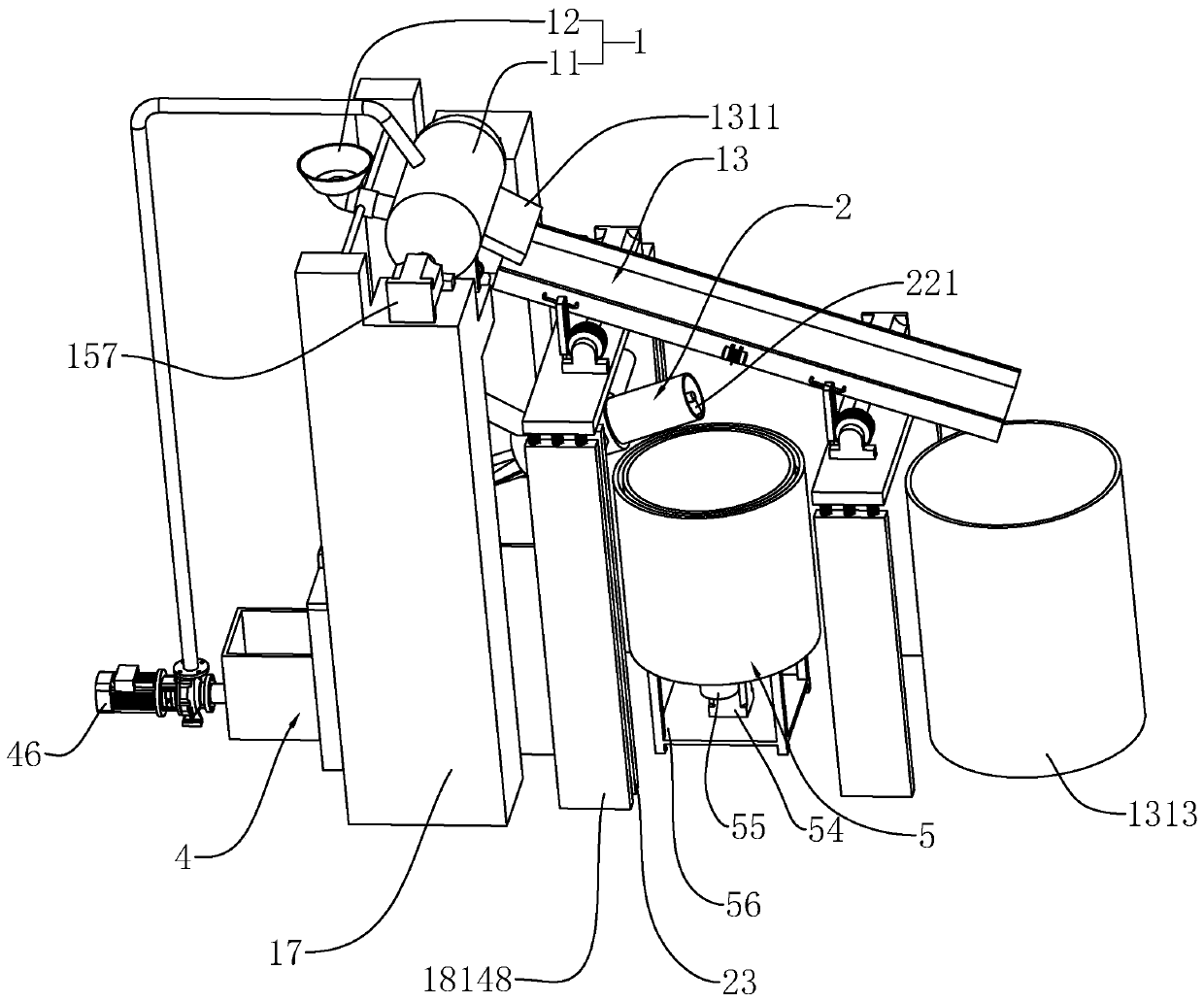

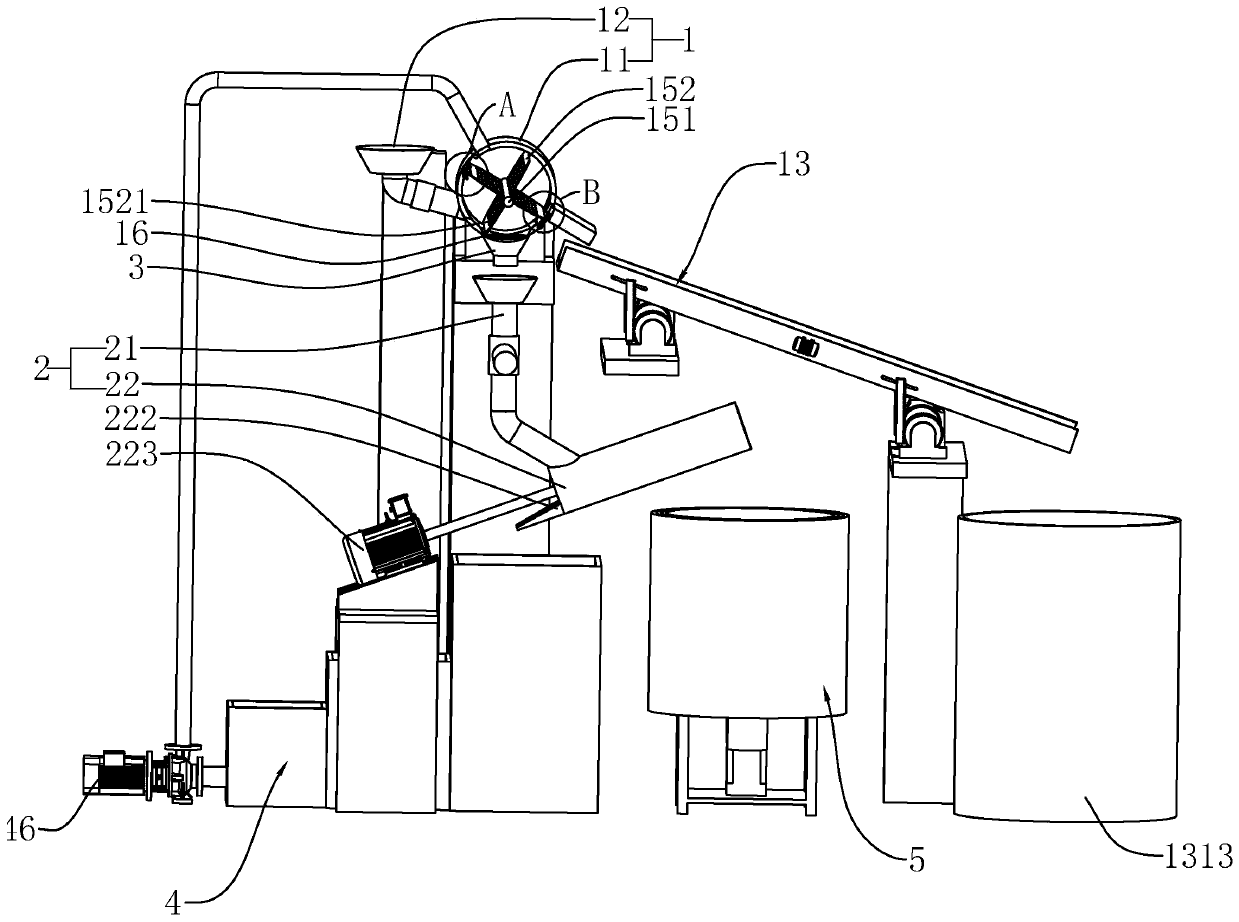

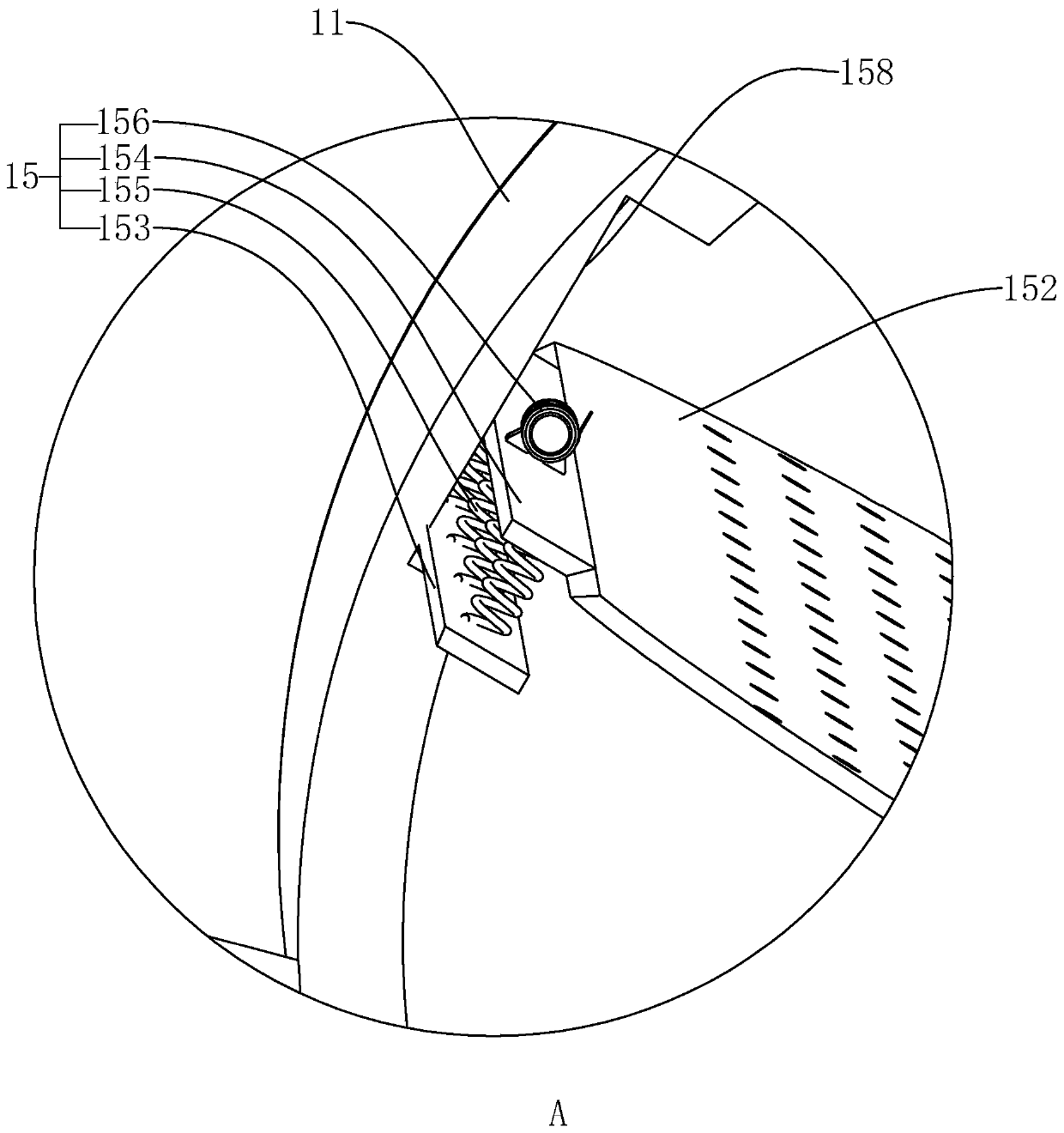

[0048] refer to figure 1 and figure 2 , is a mud reuse separation system disclosed in the present invention, comprising a stone separation device 1 and a sand-water separation device 2, the sand-water separation device 2 is located below the stone separation device 1, and a connecting pipe 3 is connected to the bottom of the stone separation device 1, and the sand-water separation device The two ends of the separation device 2 are respectively provided with a settling tank group 4 and a drying cylinder 5 . After the sand and water are separated by the stone separation device 1, they are sent to the sand and water separation device 2 through the connecting pipe 3 to separate the sand and water. The separated water enters the settling tank group 4 for impurity precipitation, and the separated sand enters the drying process. Carry out drying treatment in cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com