Efficient sand screening device for bridge construction

A bridge construction and high-efficiency technology, applied in the directions of filter screen, dry gas arrangement, lighting and heating equipment, etc., can solve the problems of poor sand dispersion, clogging of screen holes, low sand screening efficiency, etc., to avoid clogging and screening. Efficiency improvement and the effect of improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

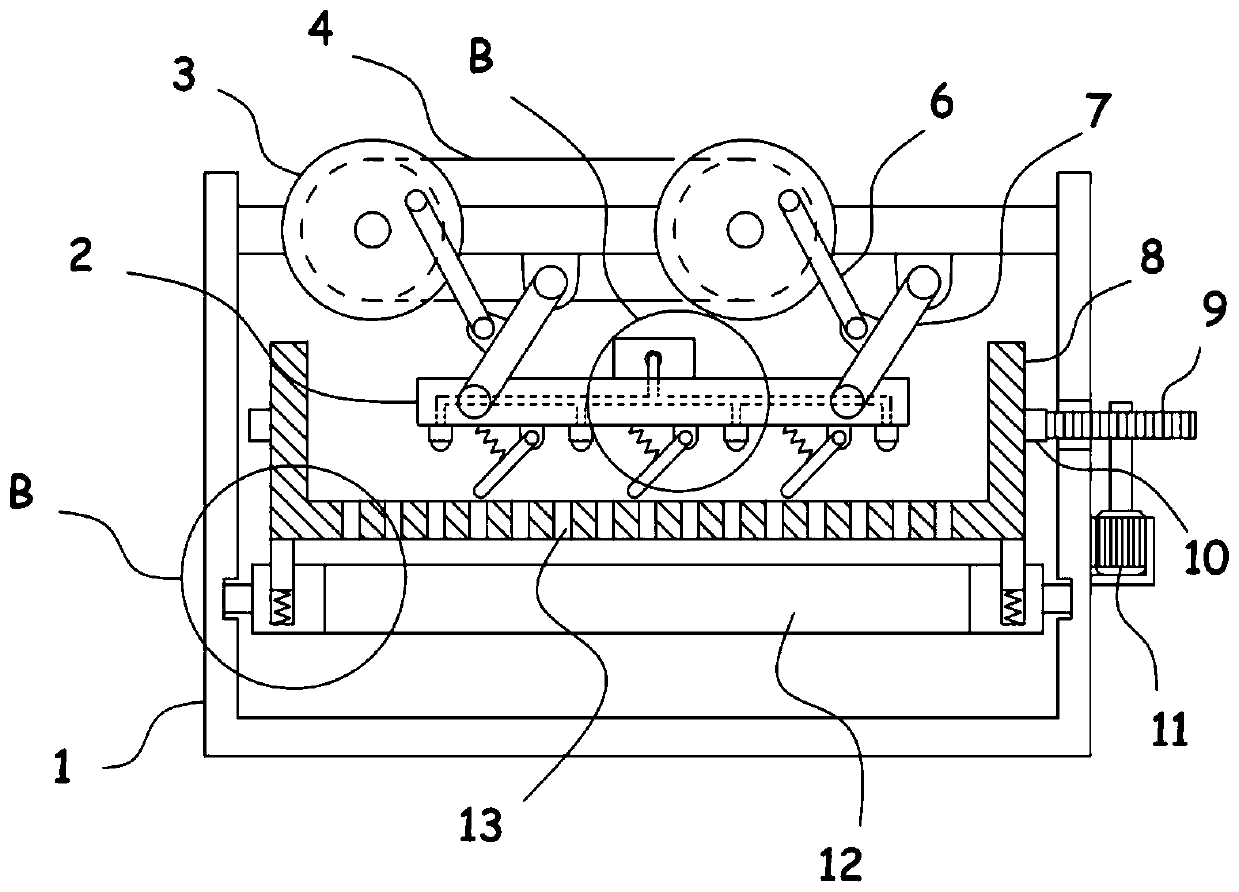

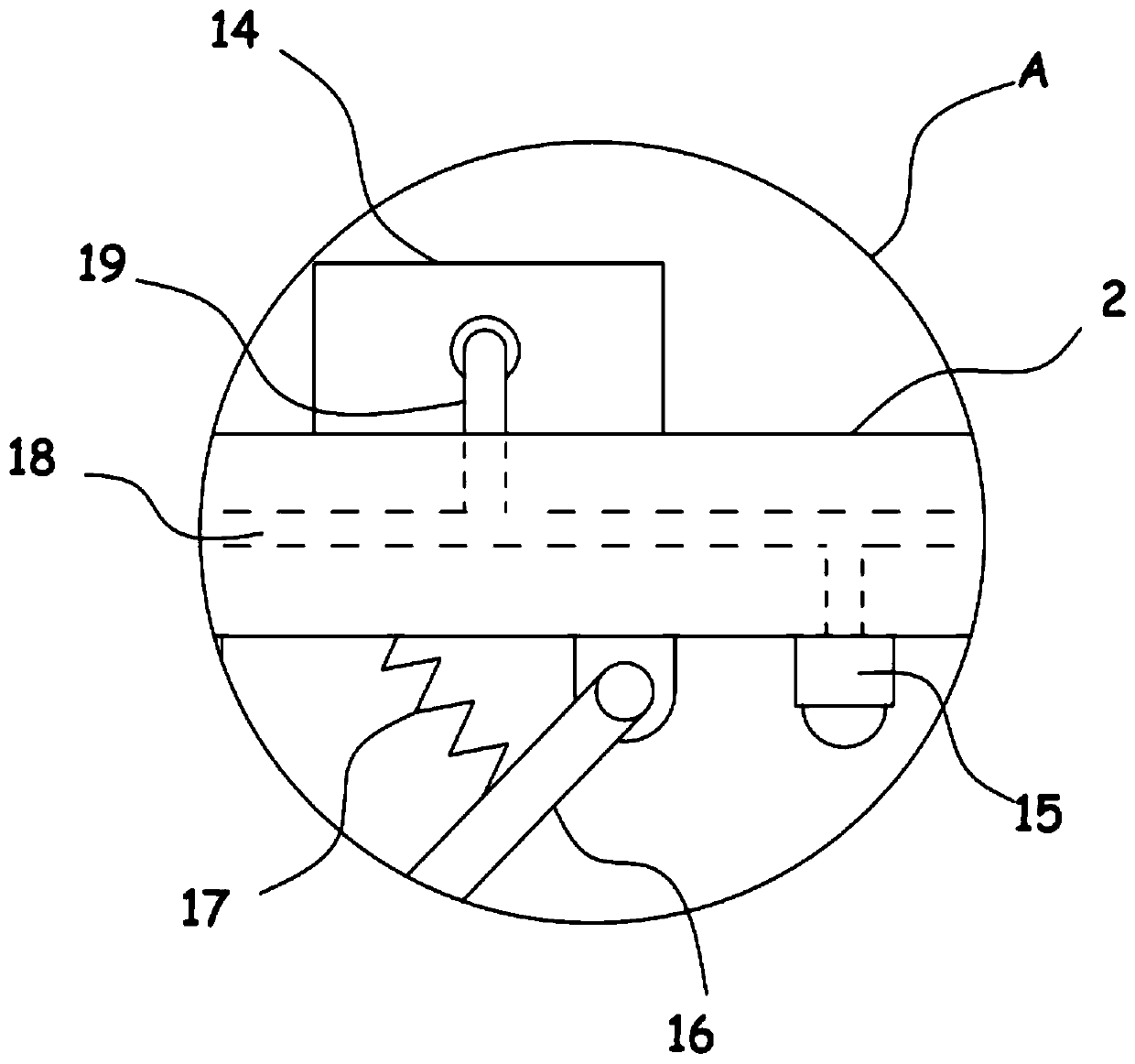

[0023] see Figure 1-5 , a bridge construction high-efficiency sand screening device, comprising a screening chamber 1, the screening chamber 1 is provided with a screening tank 8 for screening sand, the bottom of the screening tank 8 is evenly opened with a number of sieve holes 13, the screening tank 8 is There is a oscillating plate 2 driven by a oscillating mechanism, the bottom of the oscillating plate 2 is provided with a scraping mechanism for scraping the screening tank 8, and a support plate 5 for supporting the screening tank 8 is installed in rotation in the screening chamber 1, The screening chamber 1 is provided with a rotating mechanism for driving the screening tank 8 to rotate.

[0024] When carrying out bridge engineering construction, sand is placed in the screening tank 8, and the scraping mechanism driven by the provided swing mechanism is used to disperse the sand inside the screening tank 8 to improve the screening efficiency of the sand. Specifically, T...

Embodiment 2

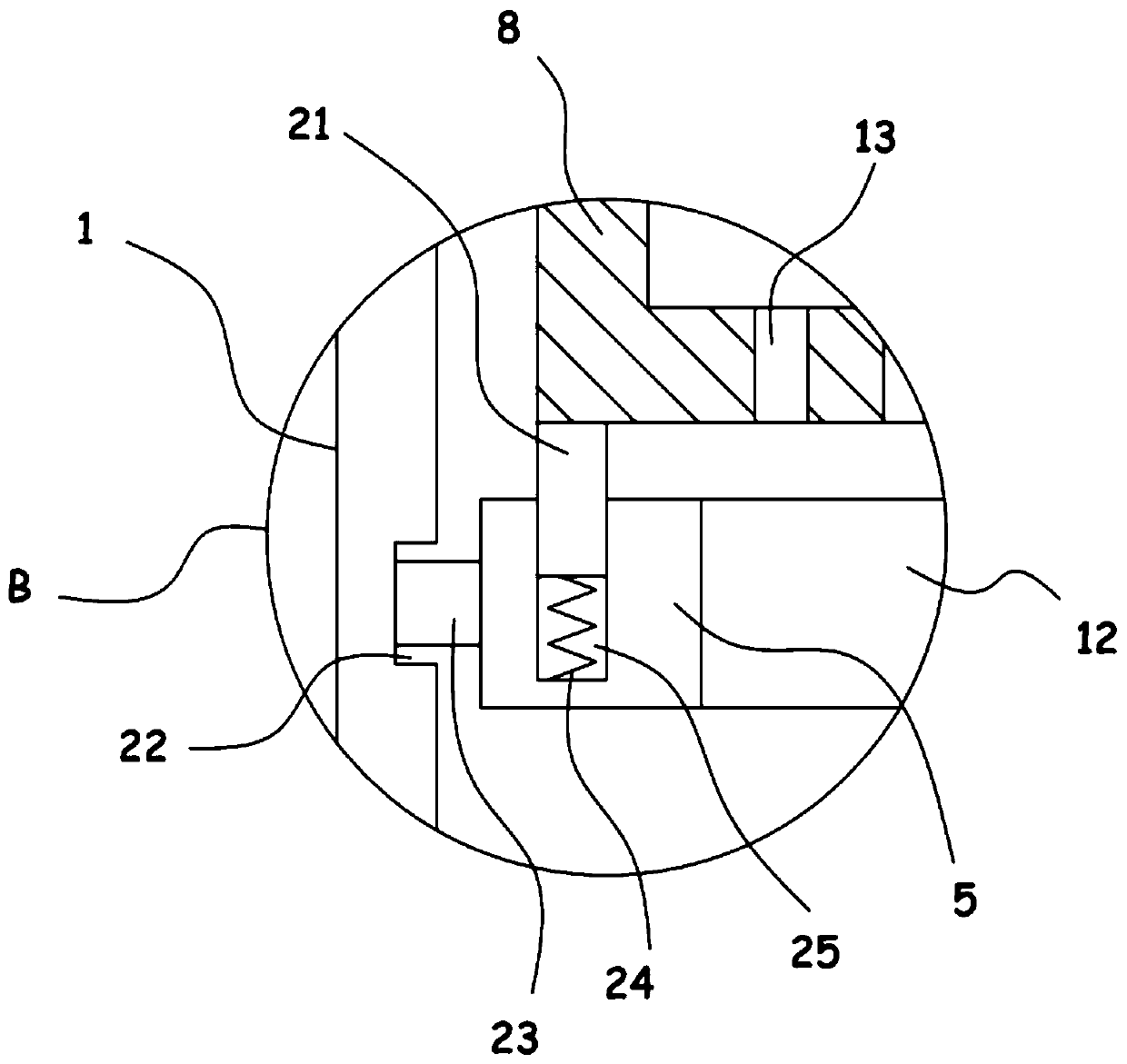

[0028] On the basis of Embodiment 1, in order to further enhance the degree of dispersion of sand in the screening tank 8, in addition, the rotating mechanism includes a servo motor I11, the output shaft of the servo motor I11 is coaxially fixed with a drive gear 9, and the drive gear 9 is meshed and connected There is an outer ring gear 10 sheathed and fixed on the screening tank 8 .

[0029] The provided servo motor I11 is used to drive the drive gear 9 to rotate, and the drive gear 9 drives the screening tank 8 to rotate through the external ring gear 10 meshed with it, and the screening tank 8 and the scraping mechanism at the bottom of the oscillating disk 2 produce relative rotation. Furthermore, the scraper 16 fully turns and disperses the sand in the screening tank 8, and the sand screening effect is remarkable.

[0030] In addition, a blanking hole 12 vertically corresponding to the sieve hole 13 is provided on the support plate 5, and a sliding cavity 25 is verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com