River sand screening device for construction

A screening device, a technology for construction, applied in heating devices, separation of solids from solids by air flow, sieving, etc., can solve the problems of mutual adhesion of wet sand, achieve smooth sliding, increase distance, and facilitate transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

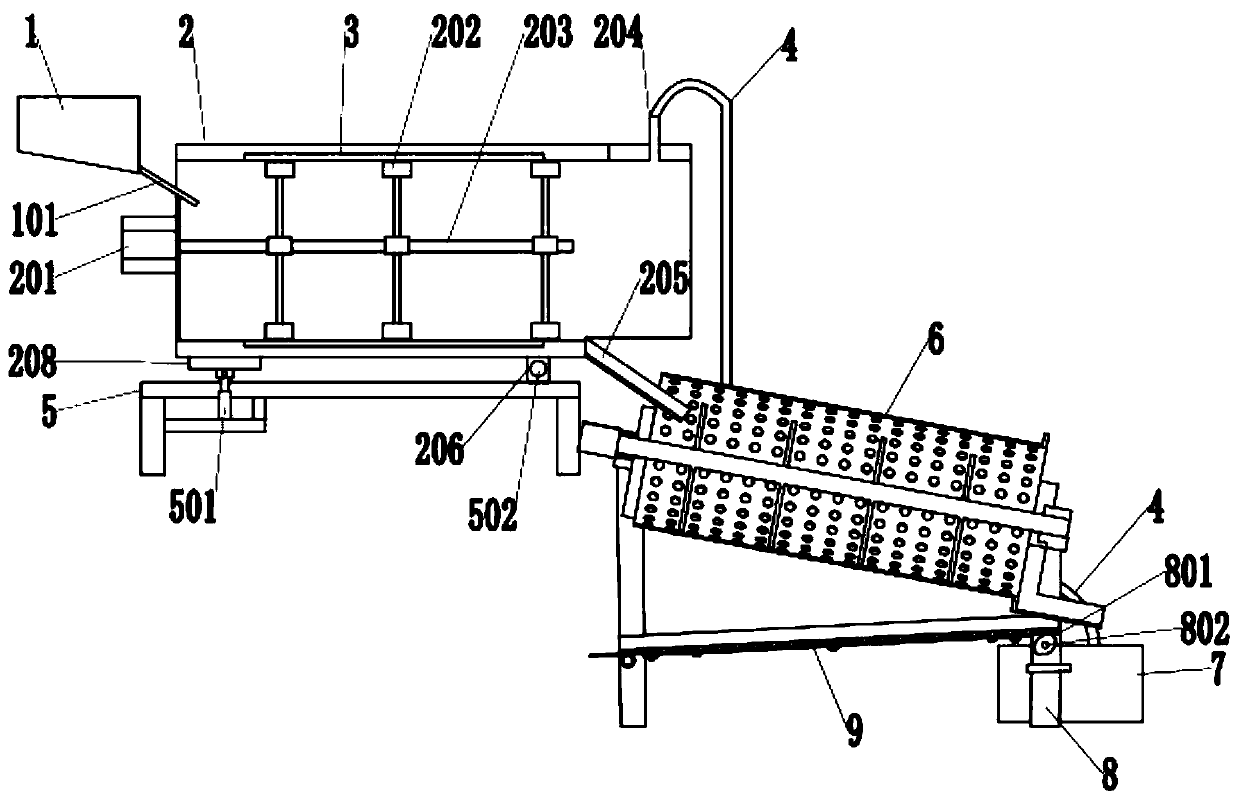

[0040] Such as figure 1 As shown, a river sand screening device for construction includes a sand inlet bucket 1, a drying cylinder 2, a primary screening device and a secondary sand screening device 9, and the drying cylinder 2 is installed on the upper end of the bracket 5 for To dry wet sand, the drying cylinder 2 is a double-layer hollow structure. A heating block 3 is arranged between the outer cylinder wall and the inner cylinder wall of the drying cylinder 2. The heating block 3 is fixed to the inner wall of the drying cylinder 2. The heating block 3 is a cast aluminum heating block 3, the inside of the heating block 3 is a heating wire, the heating wire is connected to the power supply, and the heating wire generates heat after being energized, and the heat is transferred to the inner wall of the drying cylinder 2 through the heating block 3, and one end of the drying cylinder 2 is connected with a The sand inlet 1 and the other end of the drying cylinder 2 are connecte...

Embodiment 2

[0052] The temperature inside the drying cylinder 2 is relatively high, which can evaporate the water on the surface of the sand, forming water vapor loss, in order to realize the collection and utilization of water resources.

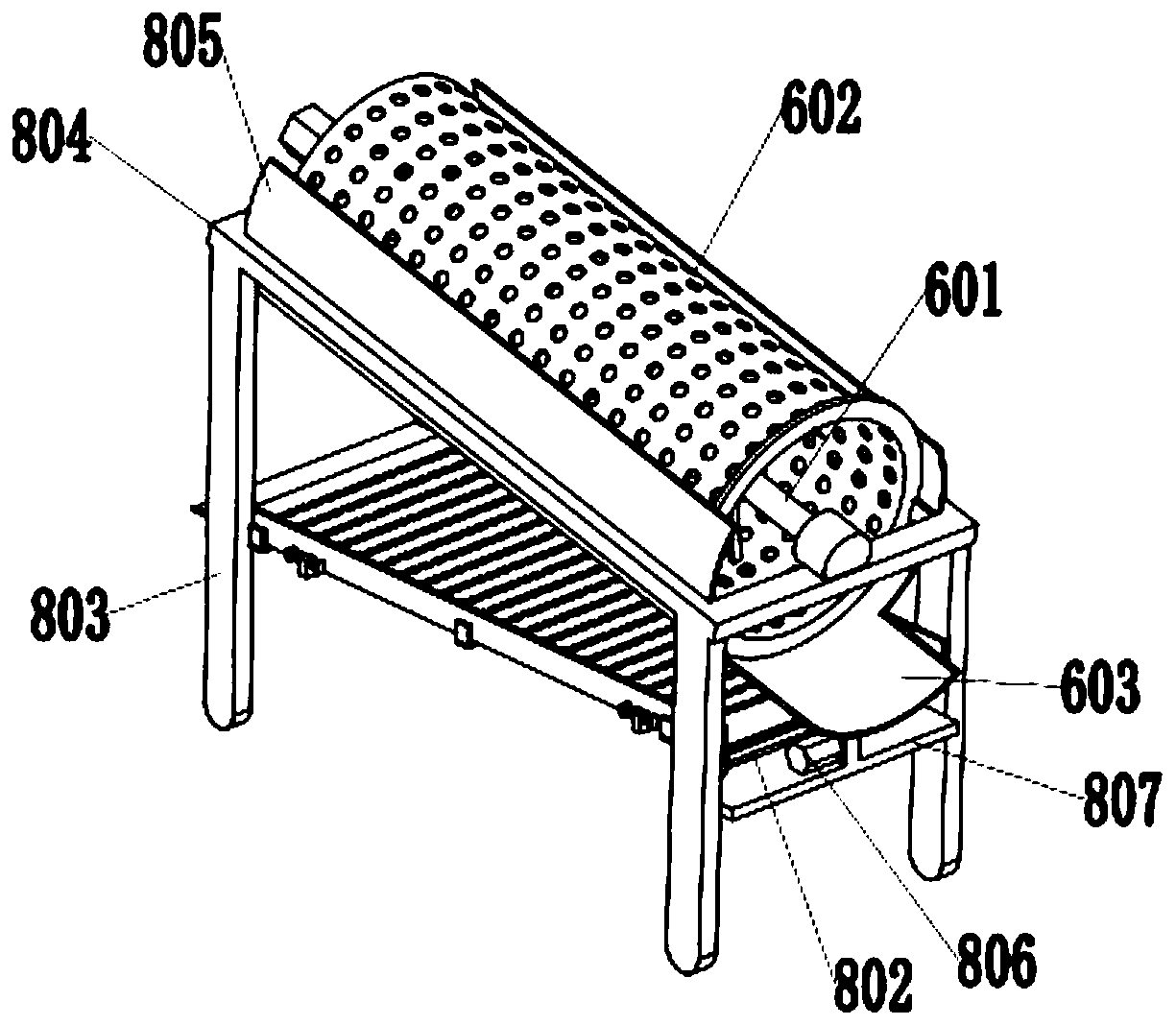

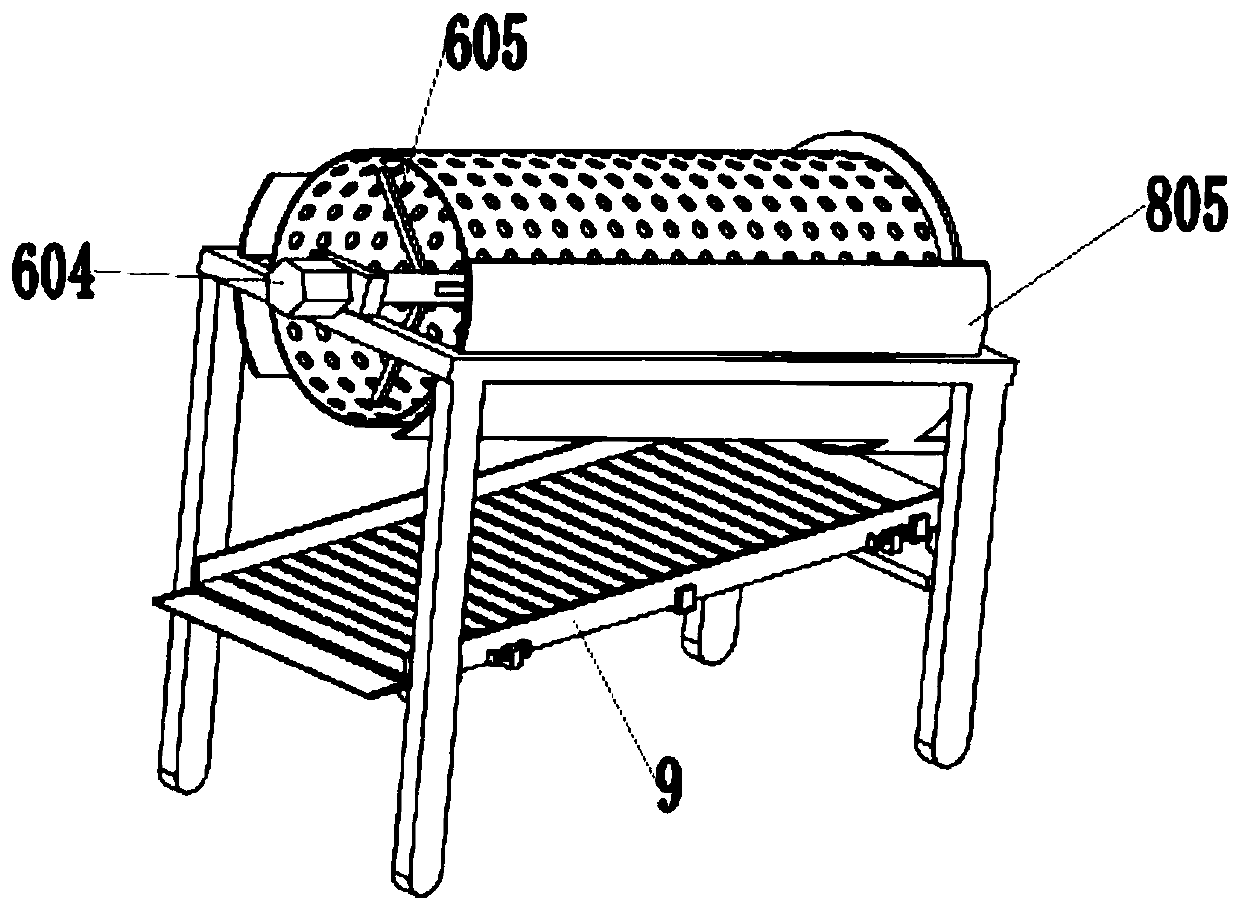

[0053] Such as figure 1 As shown, the upper end of the side wall of the drying cylinder 2 is provided with a steam outlet pipe 204, and the steam outlet pipe 204 is connected with a steam collecting pipe 4, as Figure 5 As shown, the steam collecting pipe 4 is fixed on the inner wall of the first sand shield 805 through buckles 401 and arranged in a serpentine shape, and the end of the steam collecting pipe 4 is connected with the water collecting tank 7 .

[0054] The water vapor with a higher temperature enters the steam collecting pipe 4 and flows through the first sand baffle 805, which can increase the temperature at the first sand baffle 805, achieve the effect of secondary drying, and realize the utilization of waste heat. The curved steam coll...

Embodiment 3

[0057] On the basis of Embodiment 1 or 2, in this embodiment, in order to meet the requirements of different constructions on the diameter of sand, in order to realize the adjustment of the diameter of the second screen hole 903, in this embodiment,

[0058] Such as Figure 7-11 As shown, the adjustment grid 10 is slidingly connected to the bottom of the sand screening plate. The adjustment grid 10 includes a shutter 1003 and a connecting plate 1004. The shutter 1003 is attached to the lower end surface of the sand screening board and cooperates with the second screen hole 903. In this embodiment In the example, the second screen hole 903 is a square hole, and the shutter 1003 is used to shield the second screen hole 903, so as to realize the adjustment of the opening size of the second screen hole 903, and the multiple shutters 1003 are connected through the connecting plate 1004 , the bottom of the connecting plate 1004 is provided with a supporting plate 1001 and a pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com