Patents

Literature

111results about How to "Improve screening rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

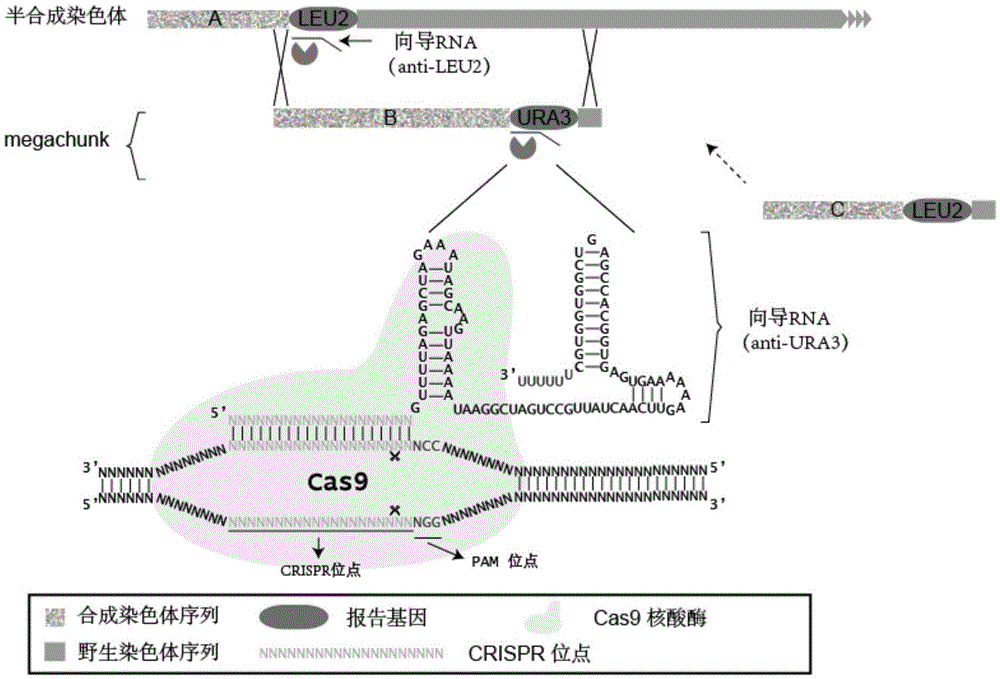

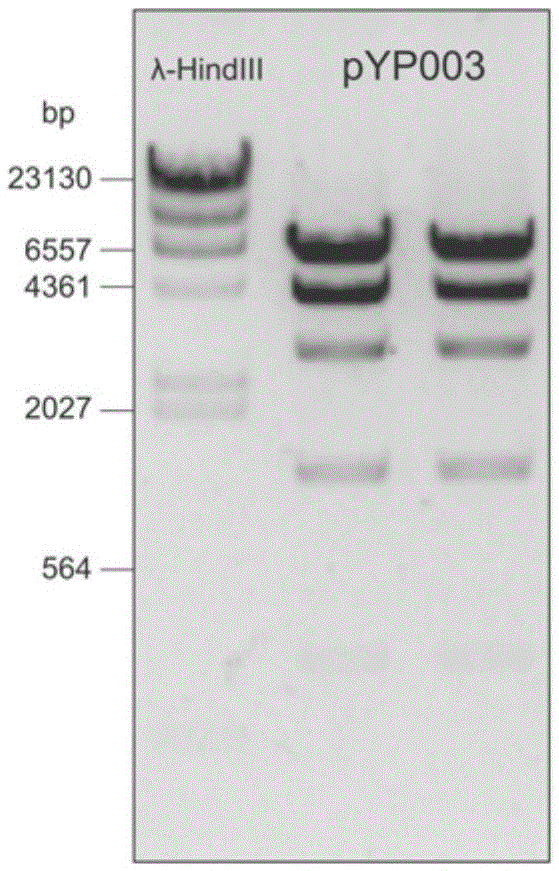

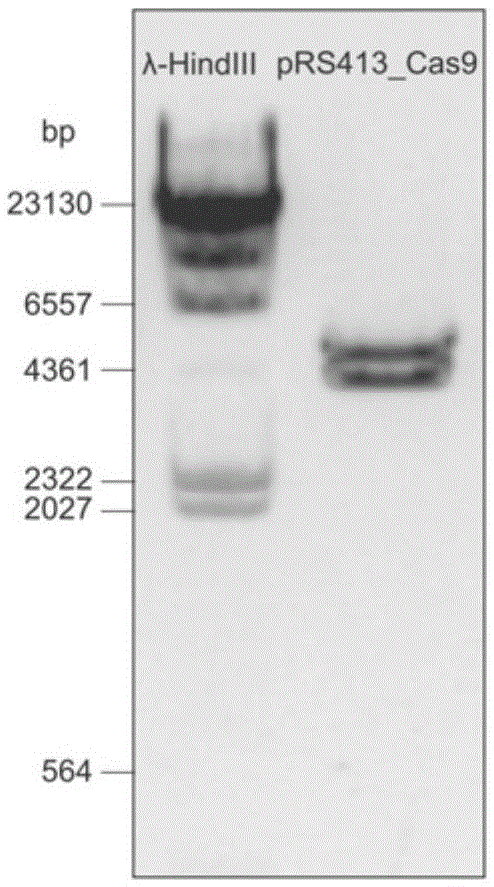

CRISPR-Cas9 system used for assembling DNA and DNA assembly method

InactiveCN105821072ARepeatableSuccessfully synthesizedFungiMicroorganism based processesReporter geneGuide RNA

The invention discloses a CRISPR-Cas9 system used for assembling DNA and a DNA assembly method. The CRISPR-Cas9 system includes the following parts: a plasmid used for expressing Cas9 gene, a first guide RNA, and / or a plasmid used for expressing the first guide RNA, wherein the first guide RNA has a CRISPR site. The CRISPR site is combined with a first reporter gene carried by a semisynthetic chromosome used for assembling according to base complementation pairing rule. The CRISPR-Cas9 system has advantages of high replacement success rate of homologous recombination, less species of guide RNA which needs to design and use, less harmful effect subjected by the genomic sequence, and low off-target rate.

Owner:SHENZHEN HUADA GENE INST

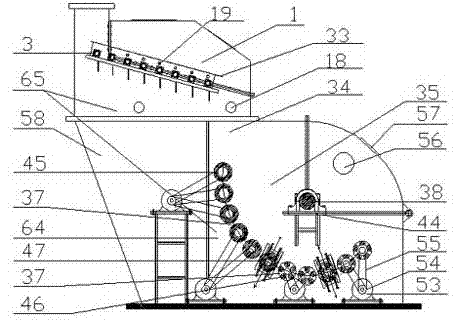

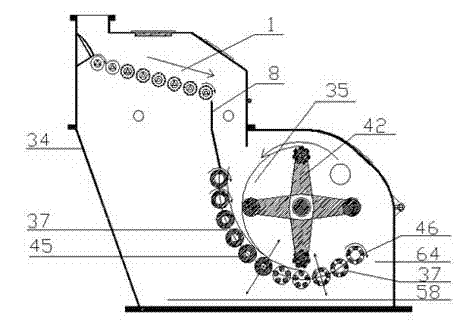

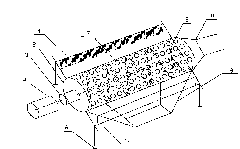

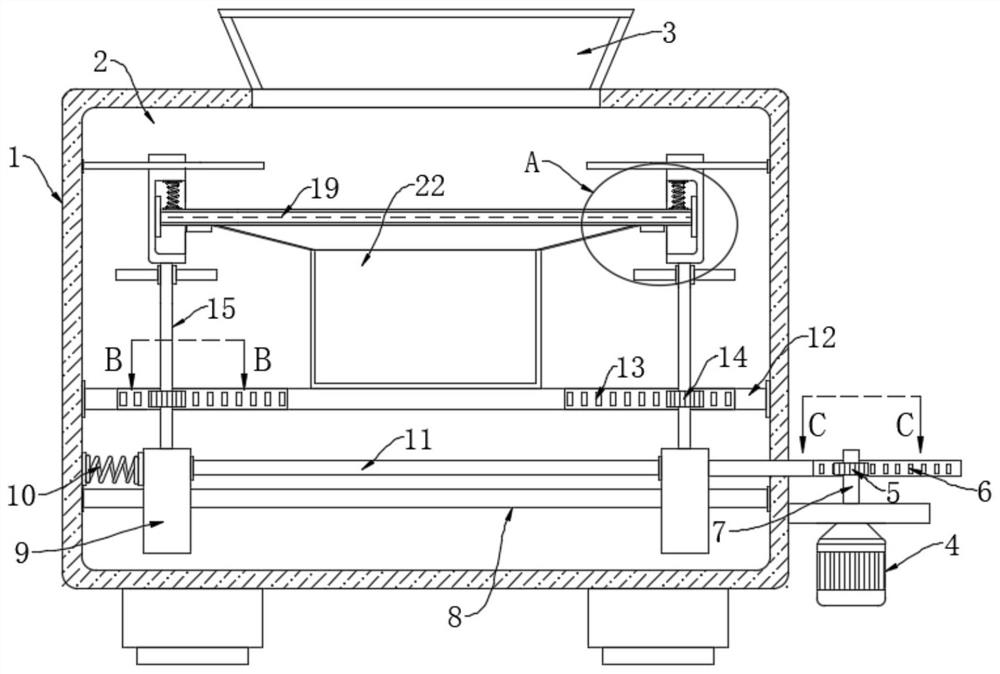

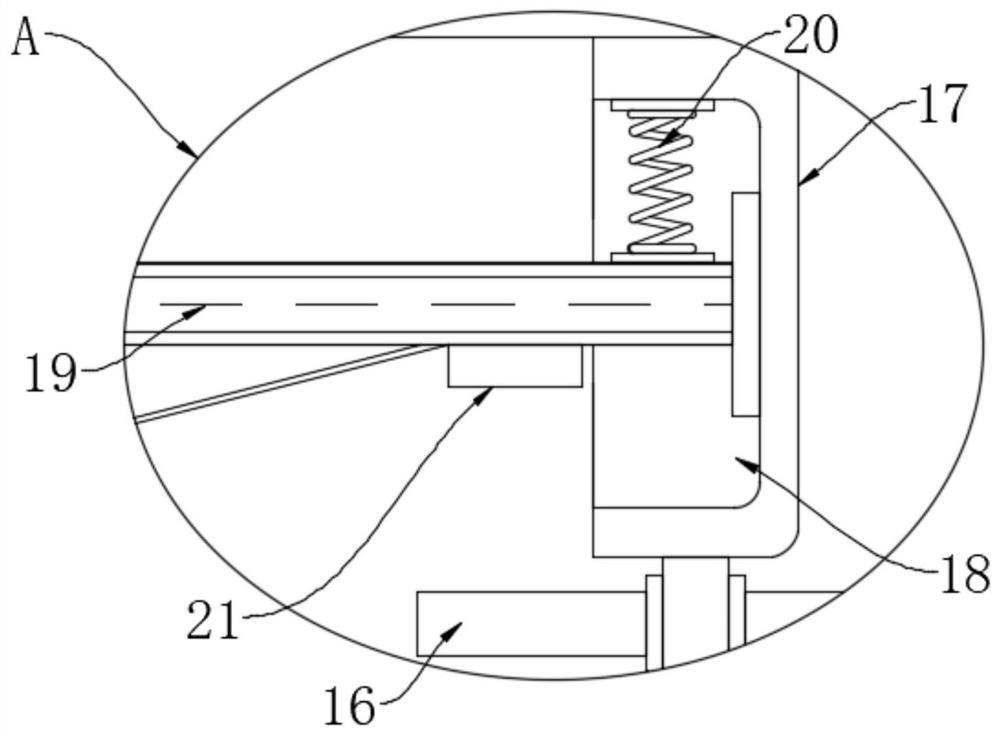

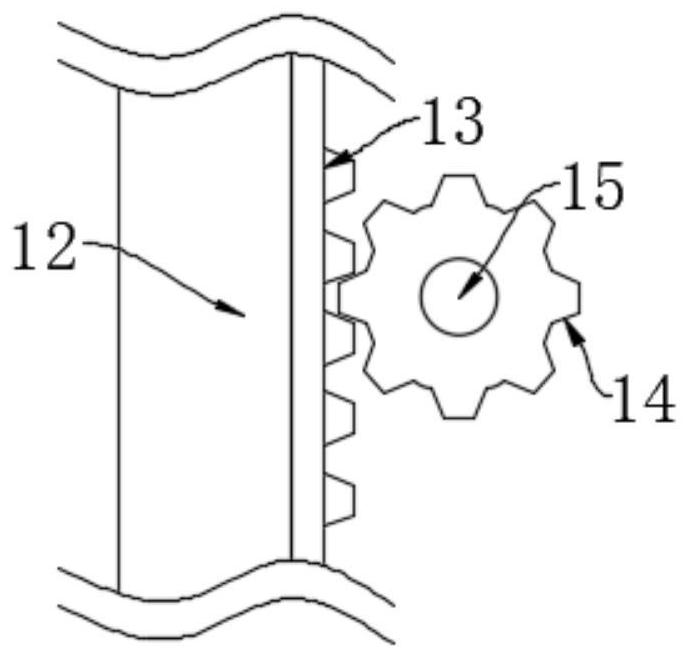

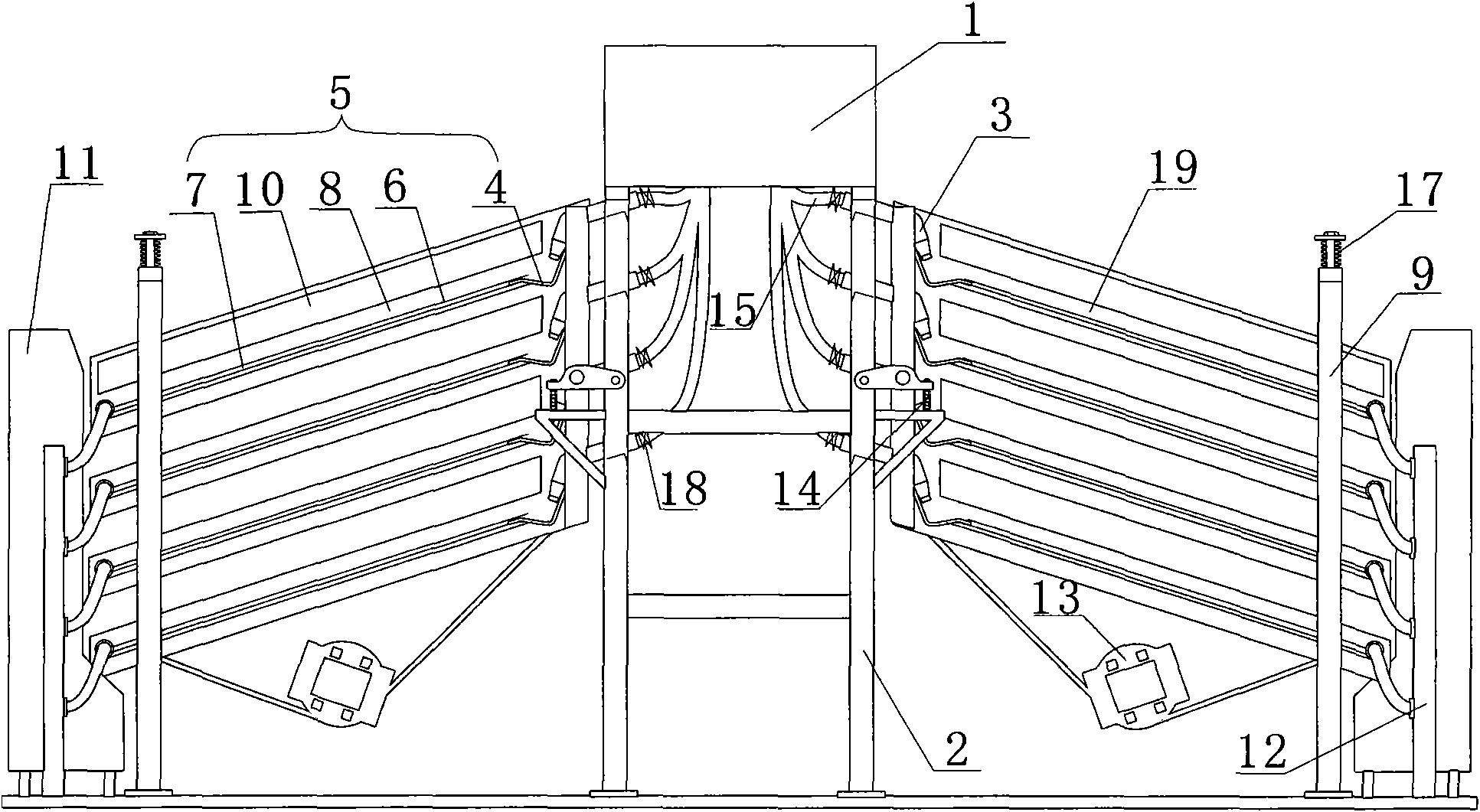

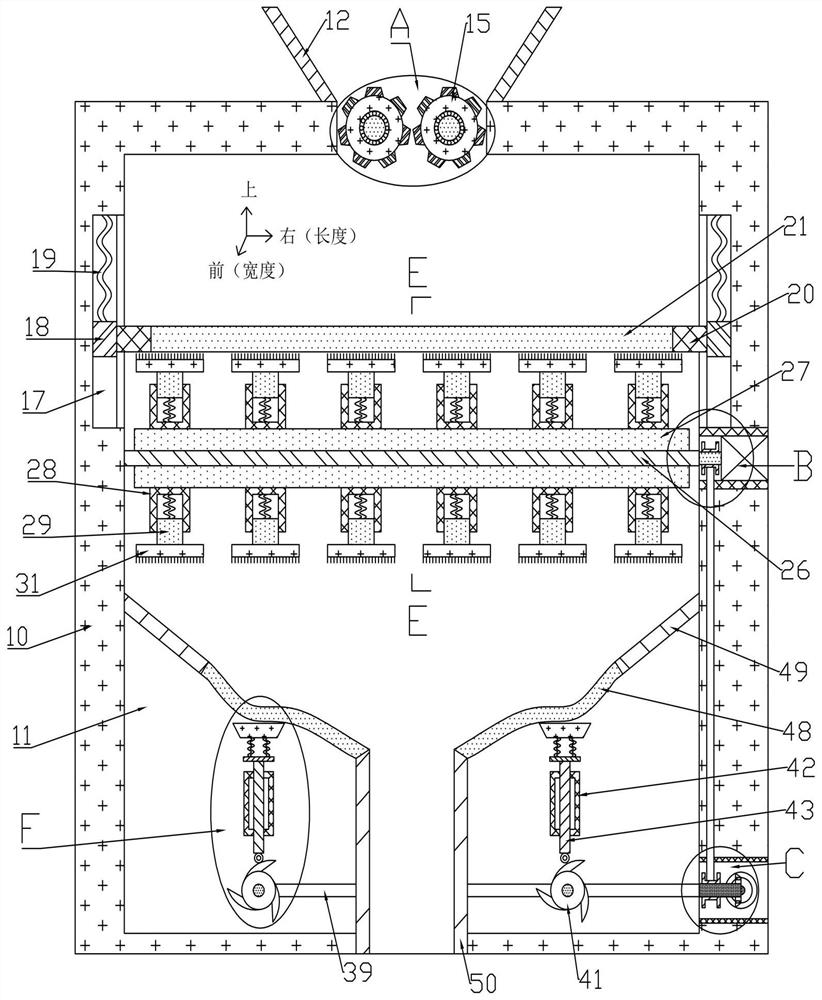

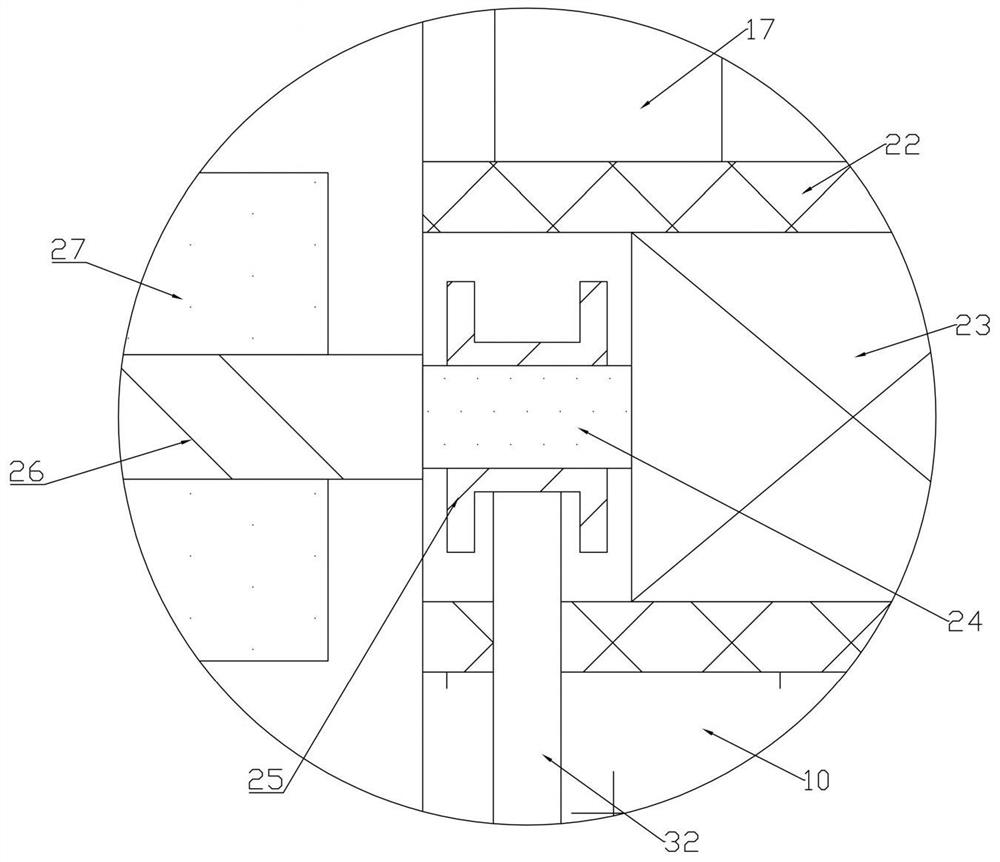

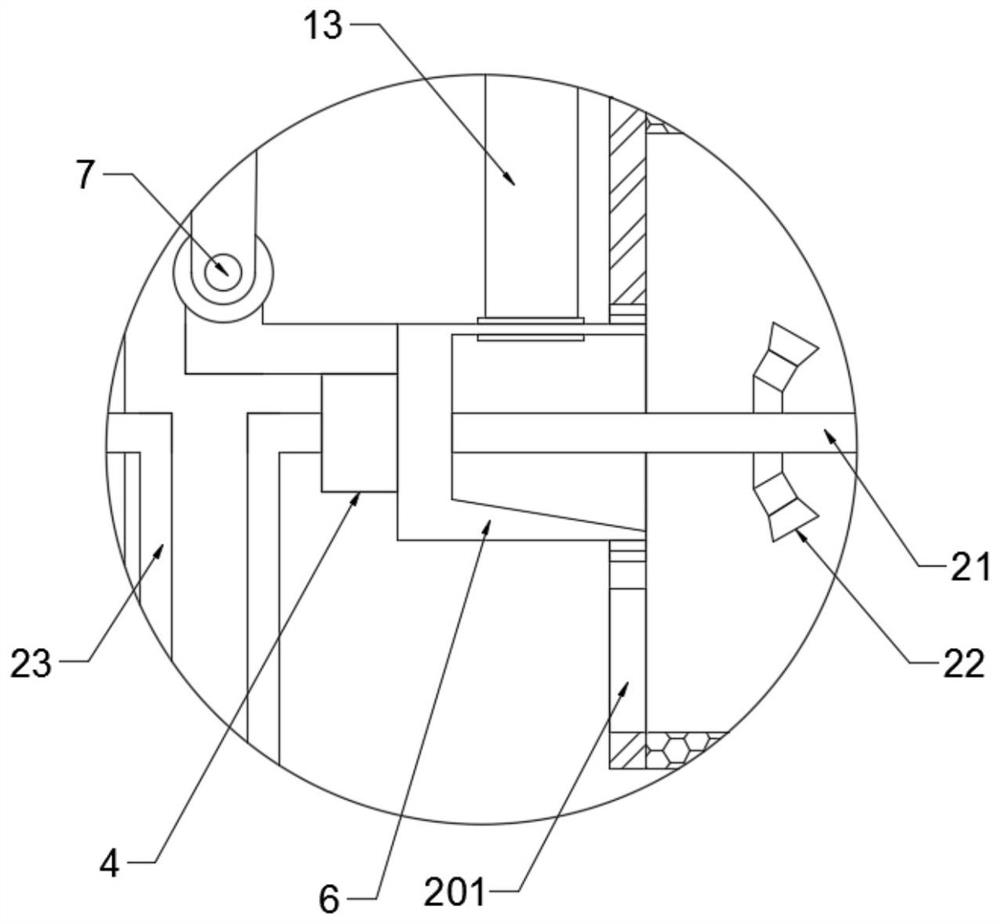

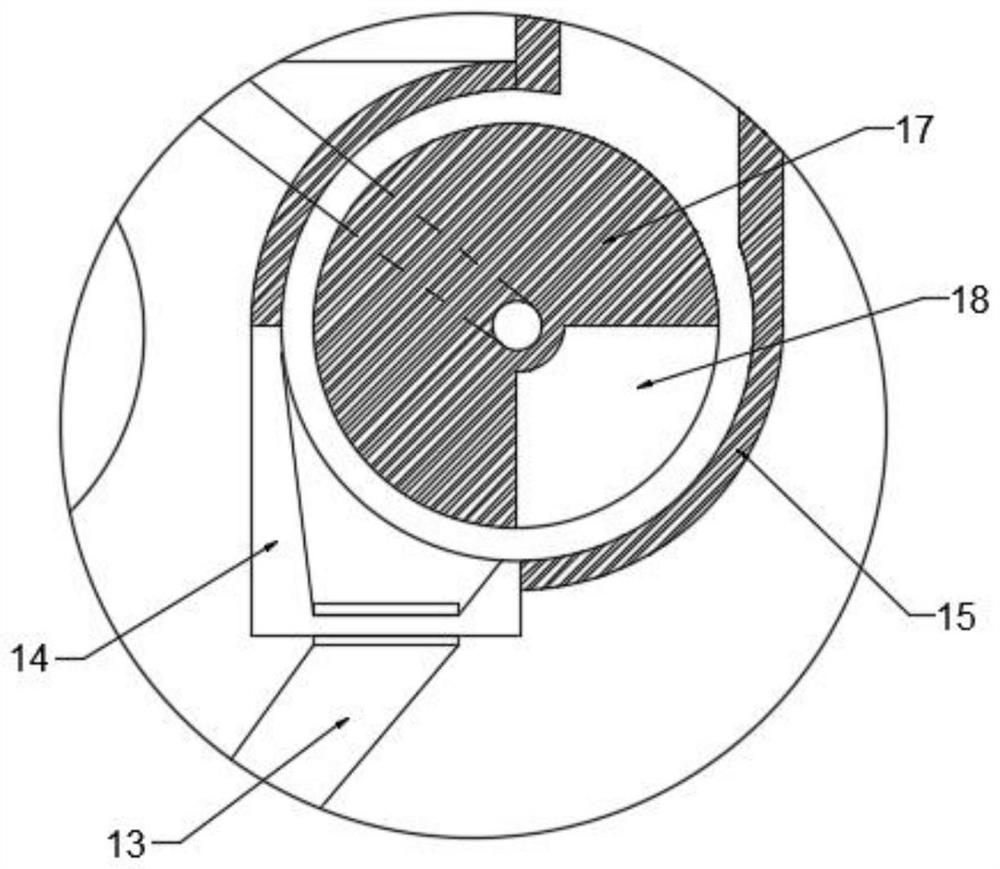

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

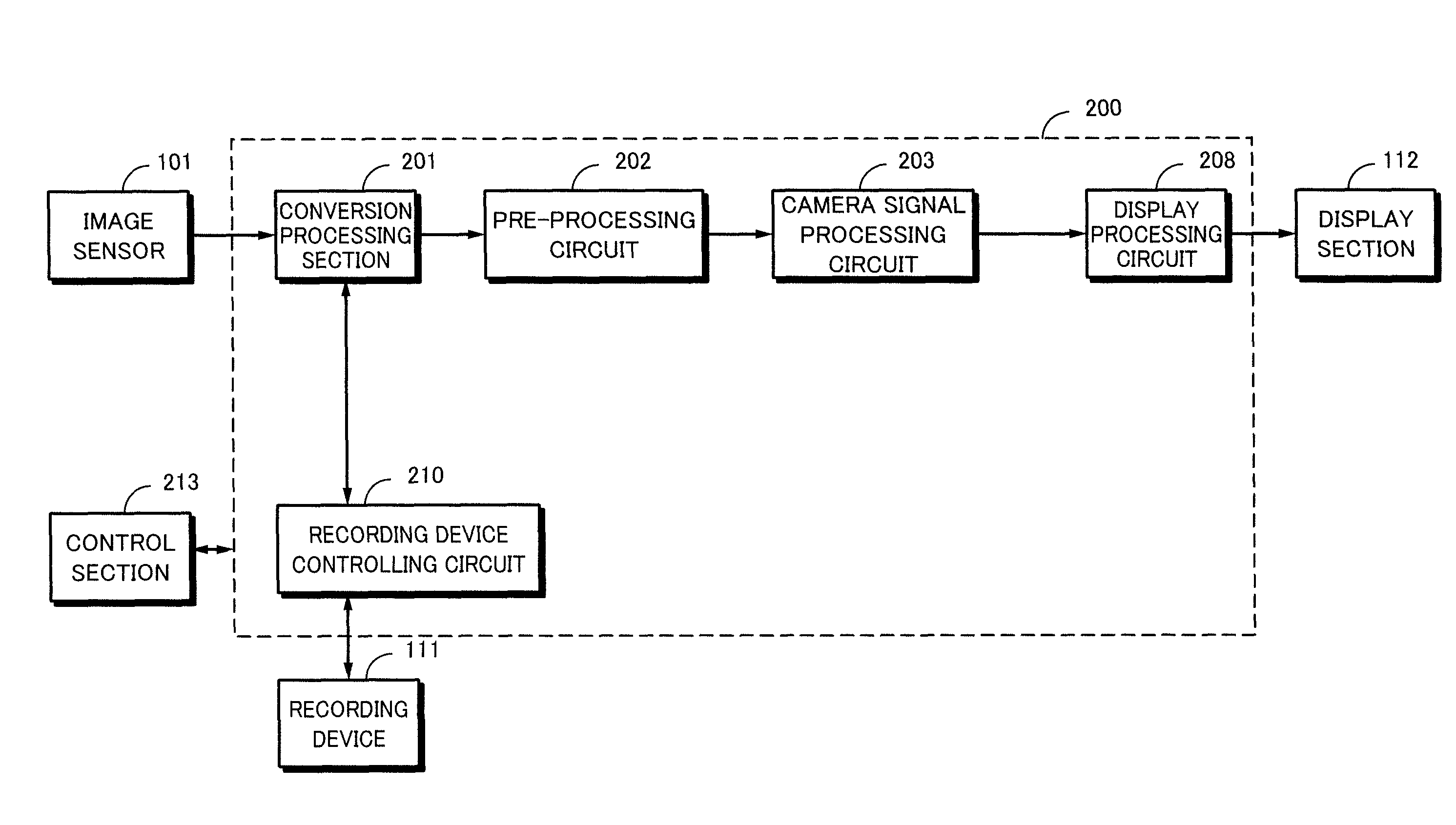

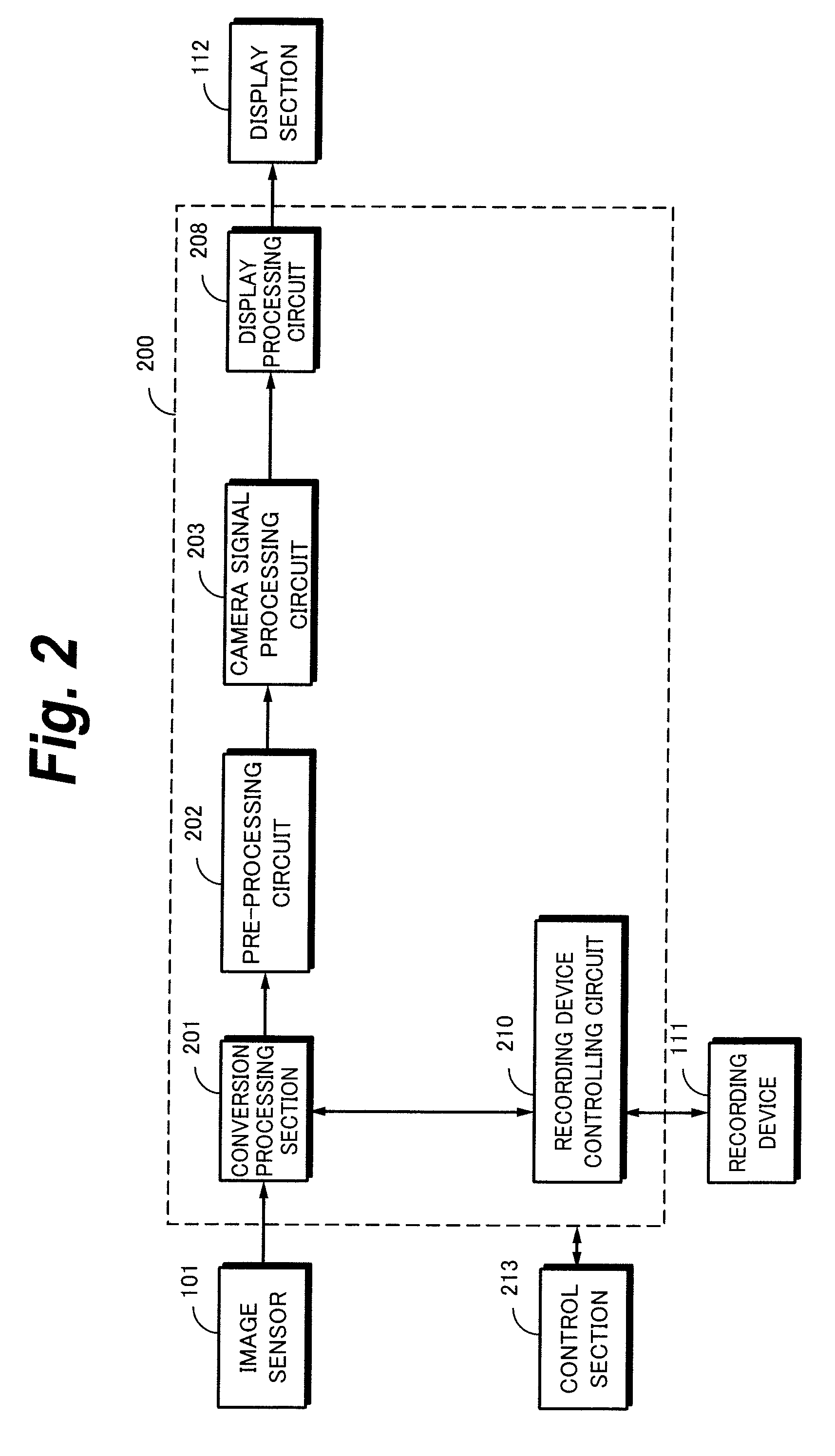

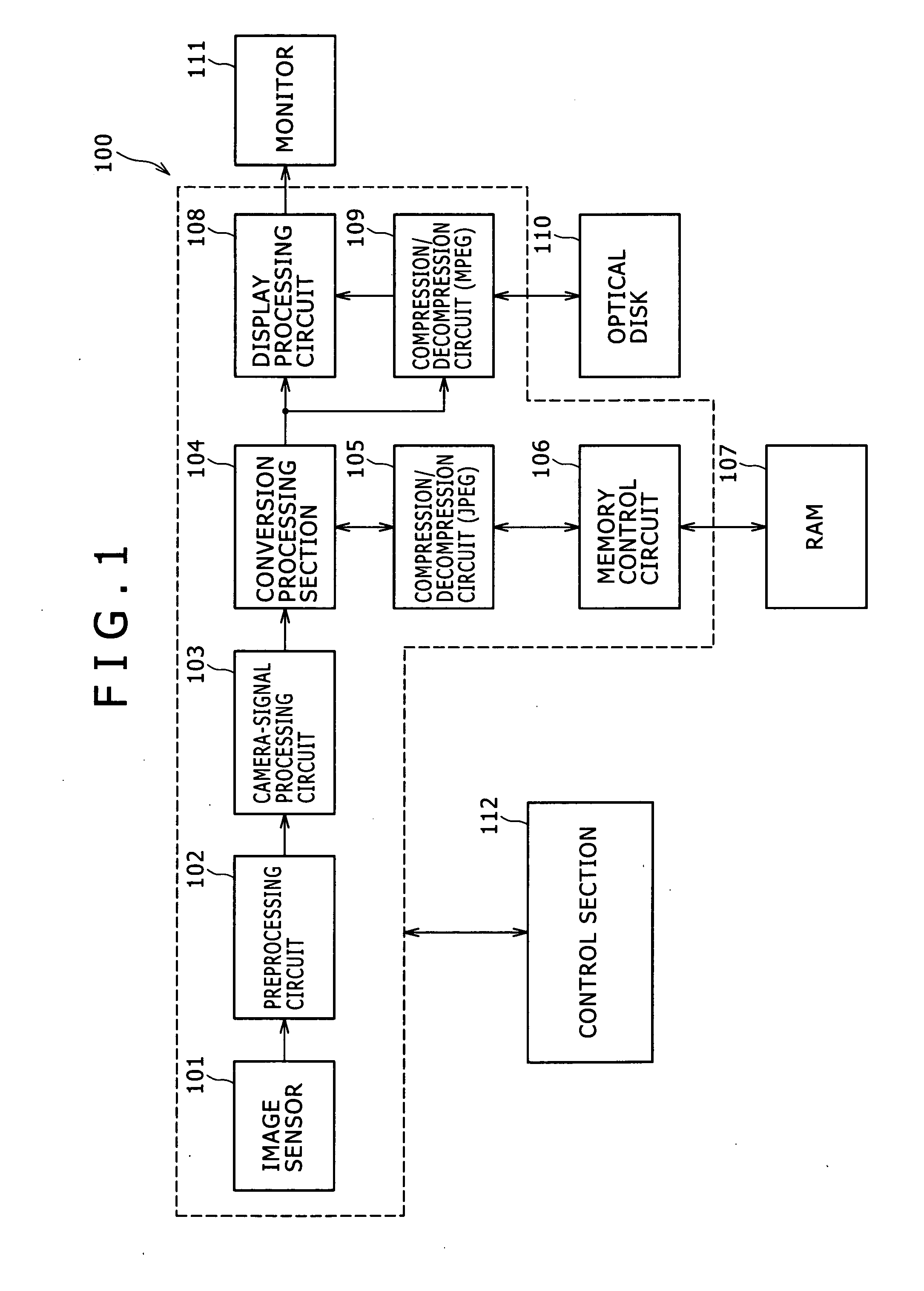

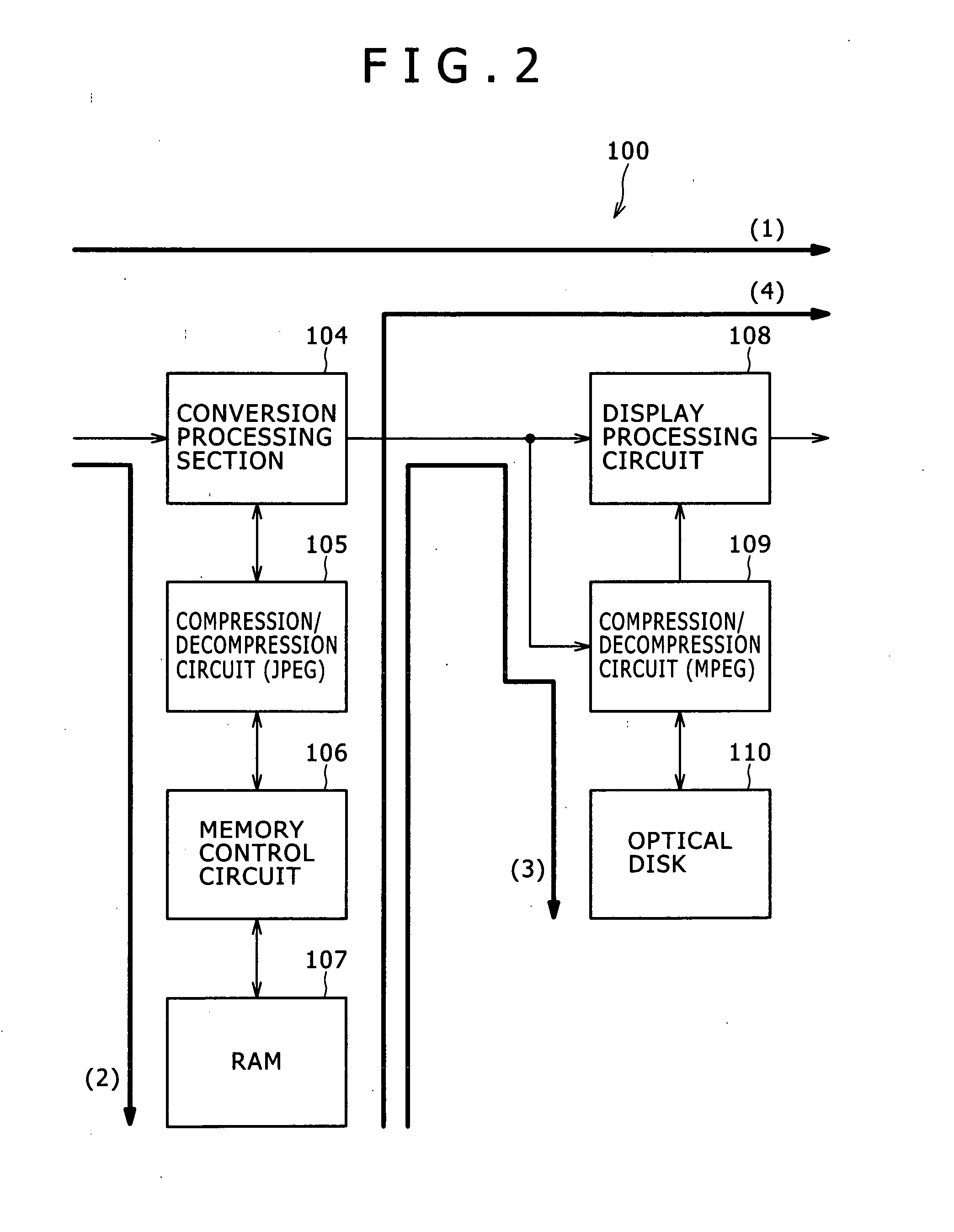

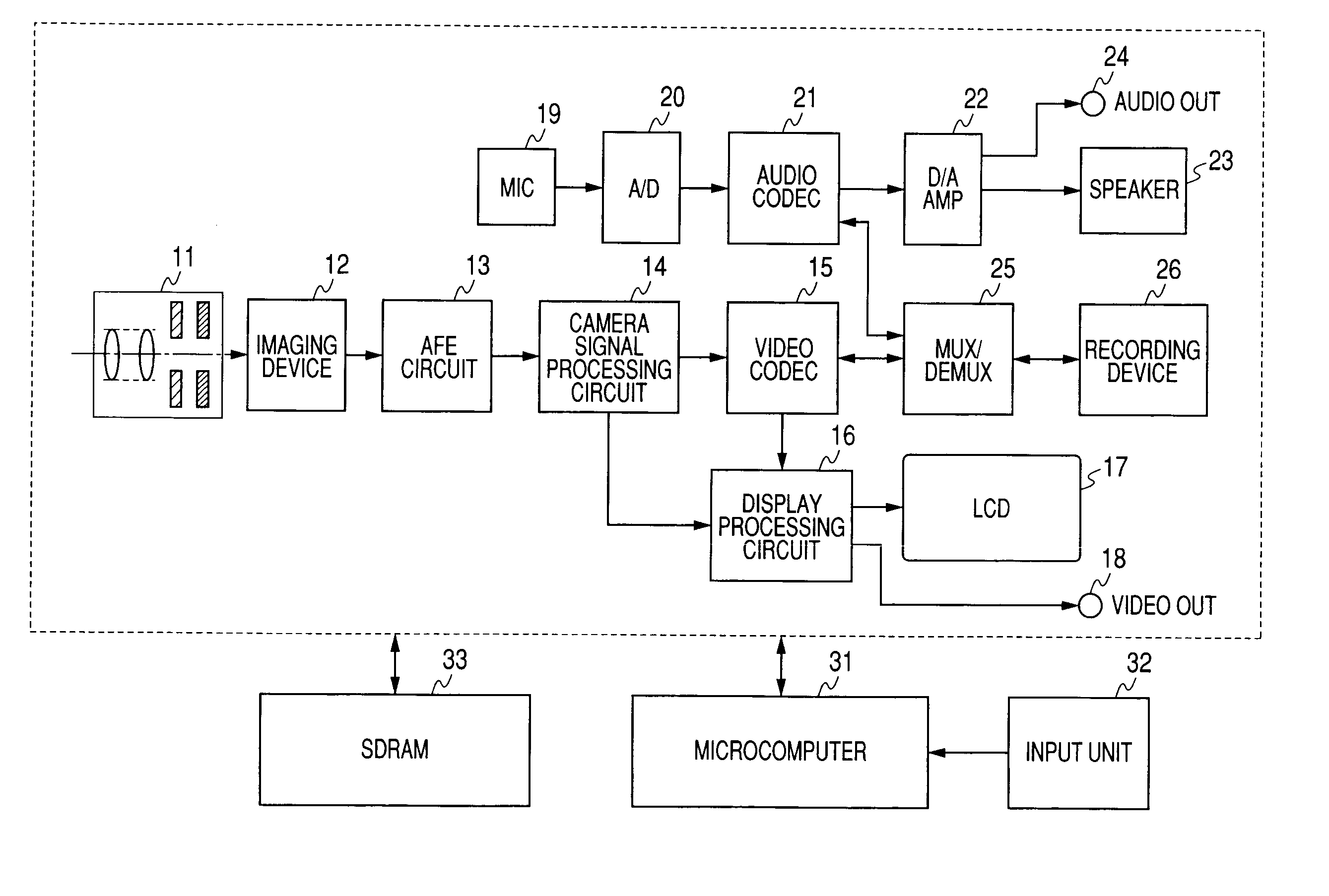

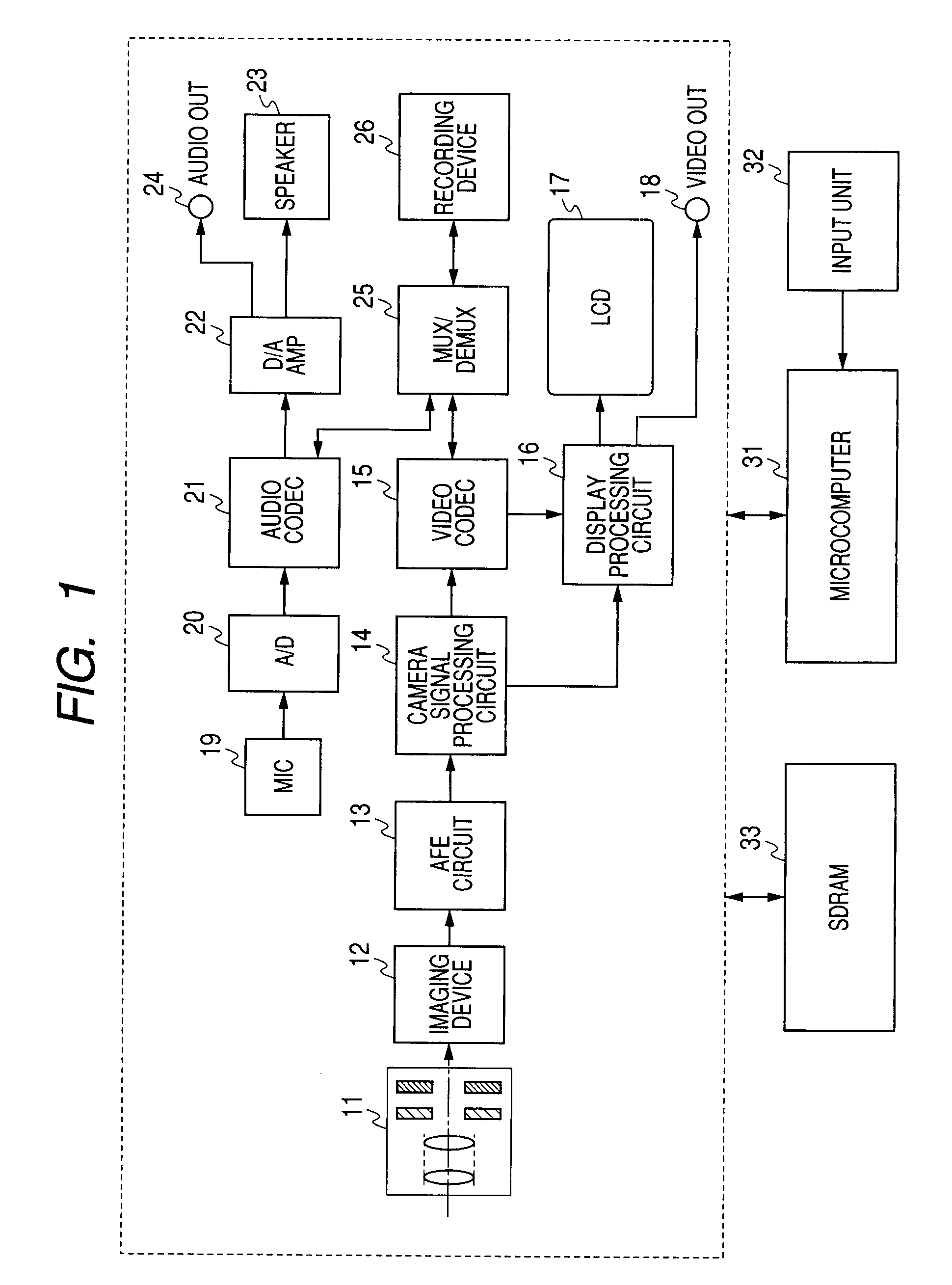

High speed image capturing apparatus and method

ActiveUS8849090B2Easy to operateLow costTelevision system detailsColor signal processing circuitsComputer hardwareSignal processing circuits

In a high speed image capturing state, a camera signal processing circuit is not needed to perform a signal process at a high screen rate, but at a regular screen rate. In the high speed image capturing mode, raw data of 240 fps received from an image sensor 101 are recorded on a recording device 111 through a conversion processing section 201 and a recording device controlling circuit 210. Raw data that have been decimated and size-converted are supplied to a camera signal processing circuit 203 through a pre-processing circuit 202 and an image being captured is displayed on a display section 112 with a signal for which a camera process has been performed. In a reproducing state, raw data are read from the recording device 111 at a low screen rate according to a display performance of the display section 112 and the raw data that have been read are processed are processed by the pre-processing circuit 202 and the camera signal processing circuit 203 and a reproduced image is displayed by the display section 112.

Owner:SONY CORP

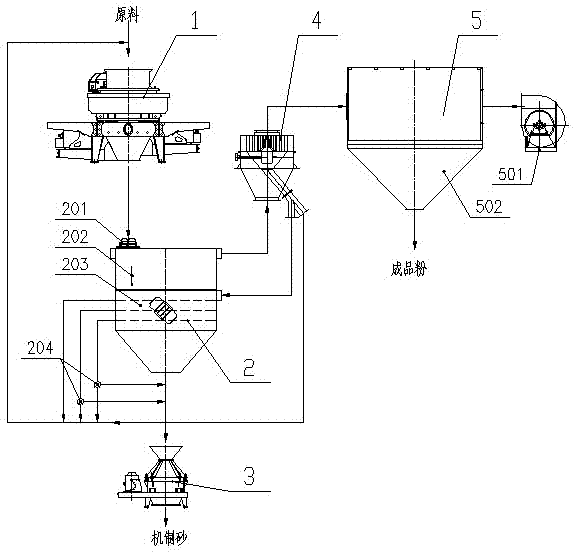

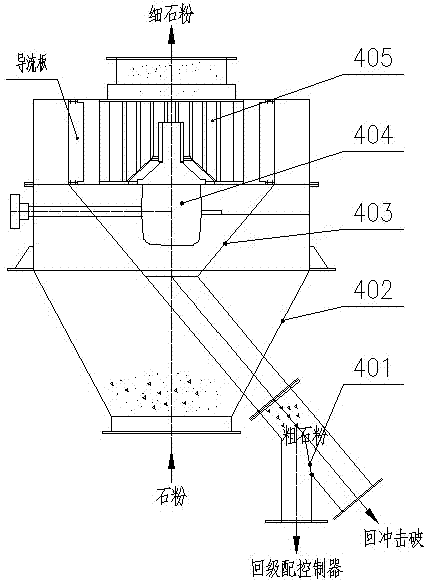

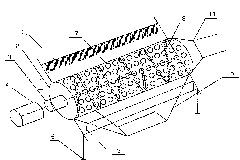

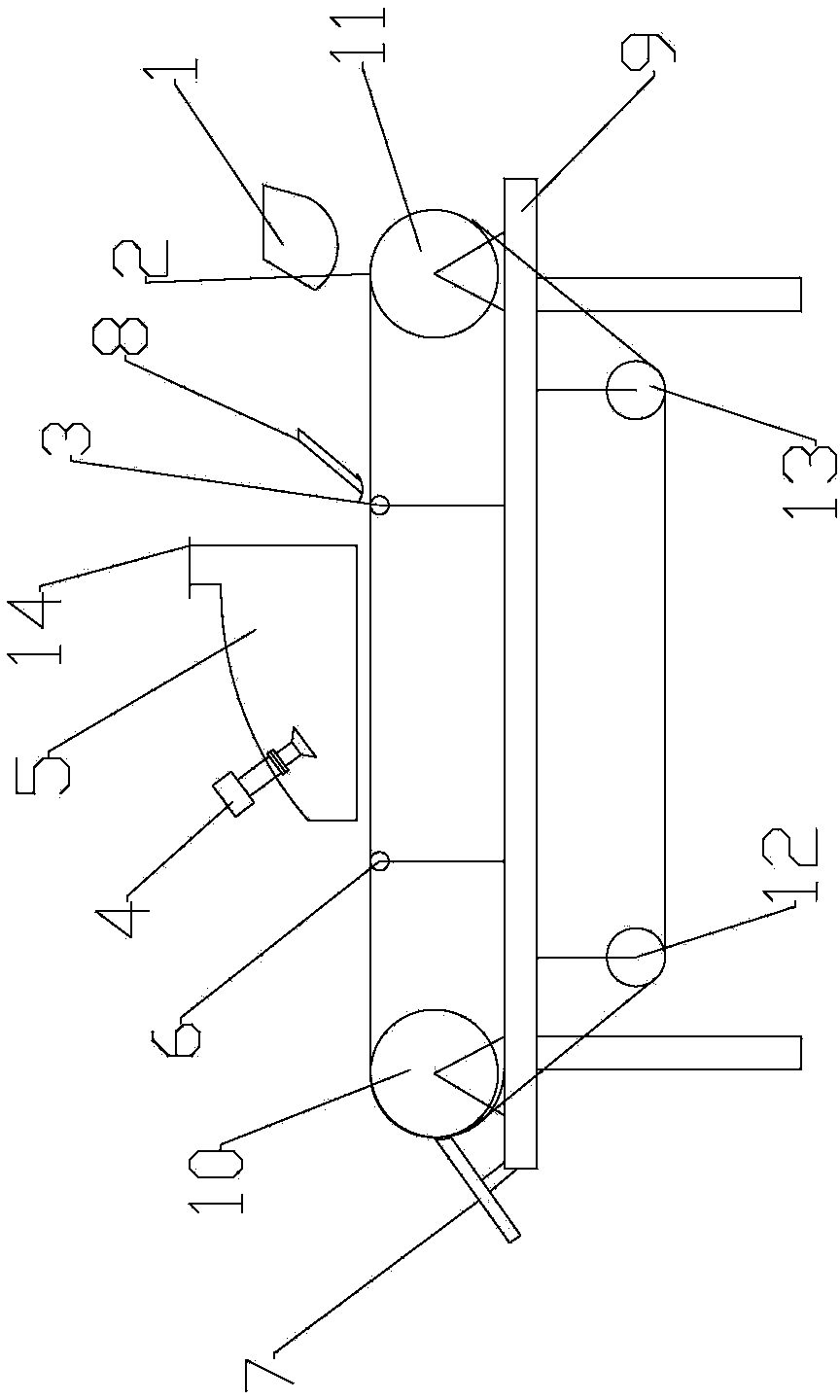

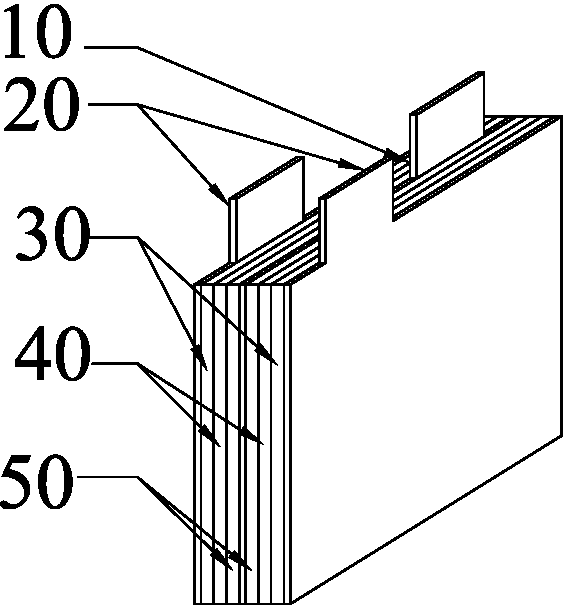

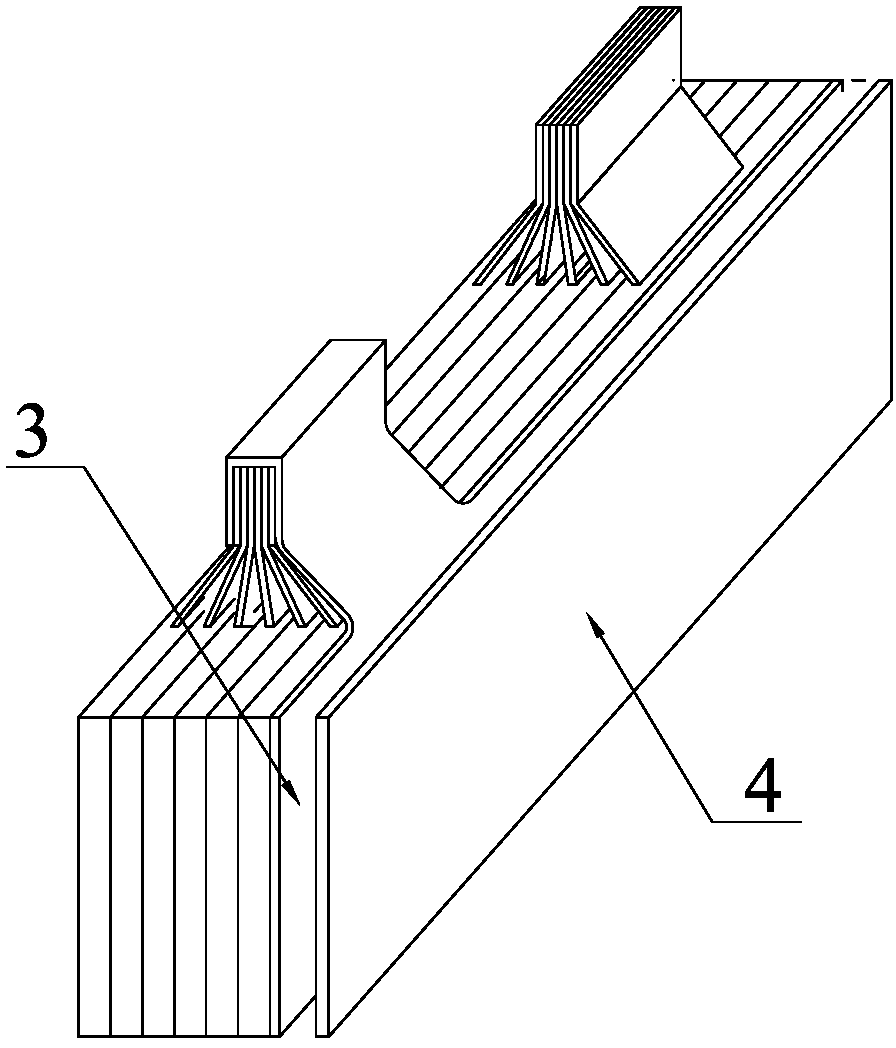

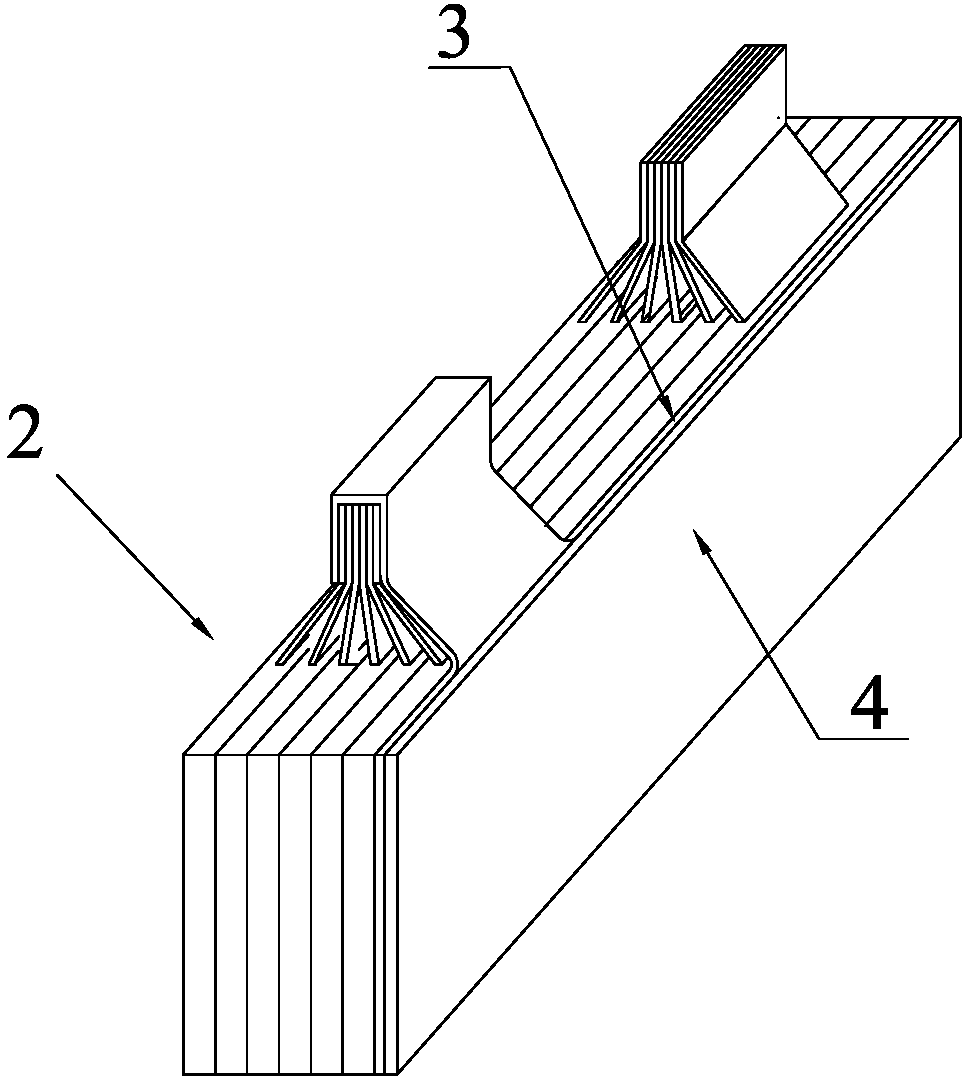

Production system and method for high-grade machine-made sand and high-grade rock flour

InactiveCN103801444AExpand the scope of applicationImprove efficiencyGas current separationGrain treatmentsGrain shapeRock flour

The invention discloses a production system and method for high-grade machine-made sand and high-grade rock flour and solves the problems that the fineness of the rock flour cannot be accurately controlled and the use ratio of the rock flour is low in a conventional machine-made sand system. The production system comprises a crusher (1), a grading controller (2), a grain-shape optimization machine (3), a fine-powder selecting device (4), a negative-pressure recycling device (5) and a conveying device. The production method is characterized in that after being crushed by the crusher (1), rubbles are conveyed to the grading controller (2), and the grading of the machine-made sand is finely controlled, unqualified materials are returned to the crusher (1) to be crushed again, and meanwhile, the rock flour in the machine-made sand is sucked by the negative pressure generated by the negative-pressure recycling device (5); the fine-powder selecting device (4) is arranged between the grading controller (2) and the negative-pressure recycling device (5) and be used for accurately controlling the fineness of the rock flour entering the negative-pressure recycling device, and the rock flour which cannot meet the fineness requirement enters the grading controller (2) for regulating the grading of the machine-made sand or enters the crusher (1) to be crushed again.

Owner:SHANGHAI ZENITH MINING & CONSTR MACHINERYCO

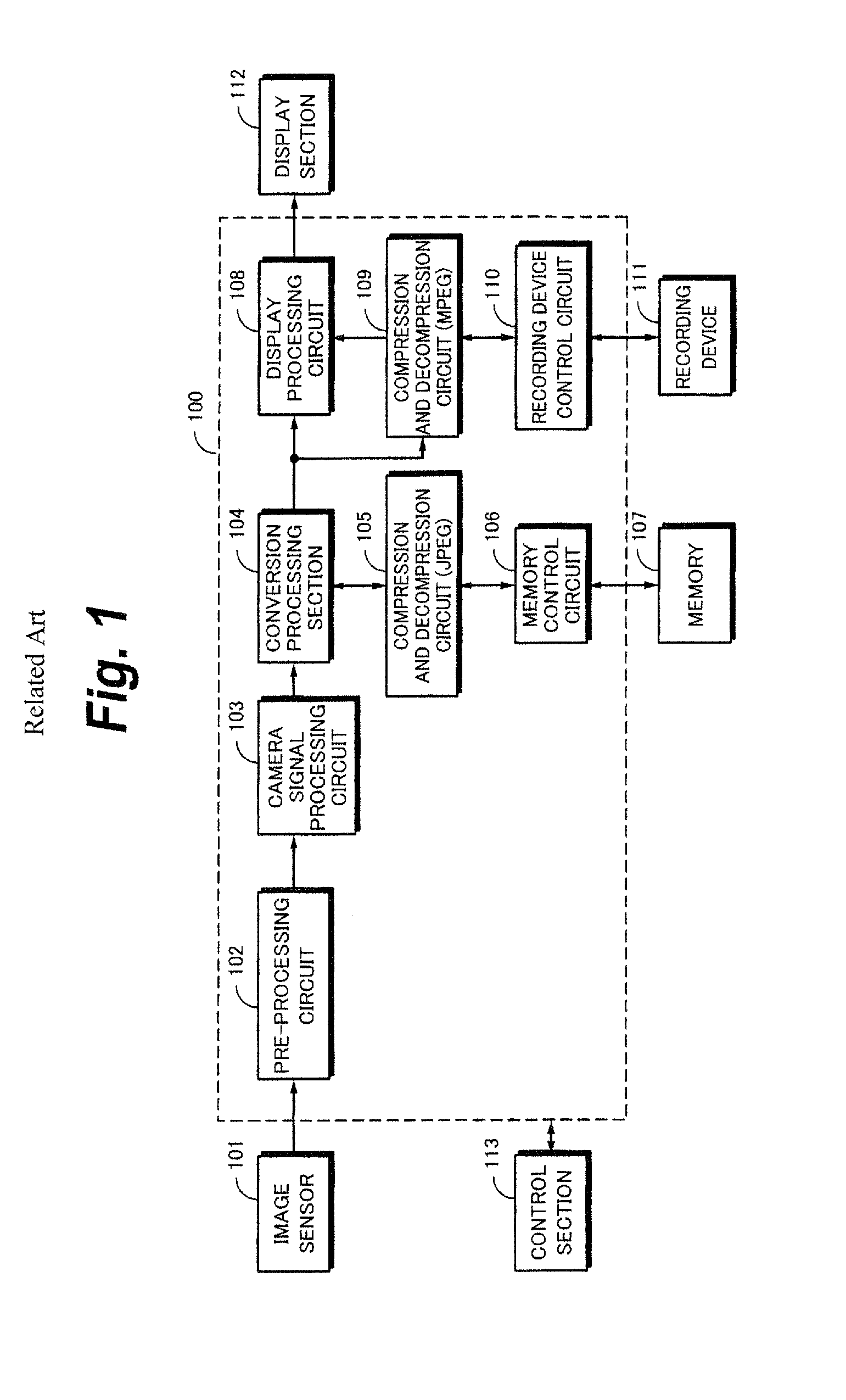

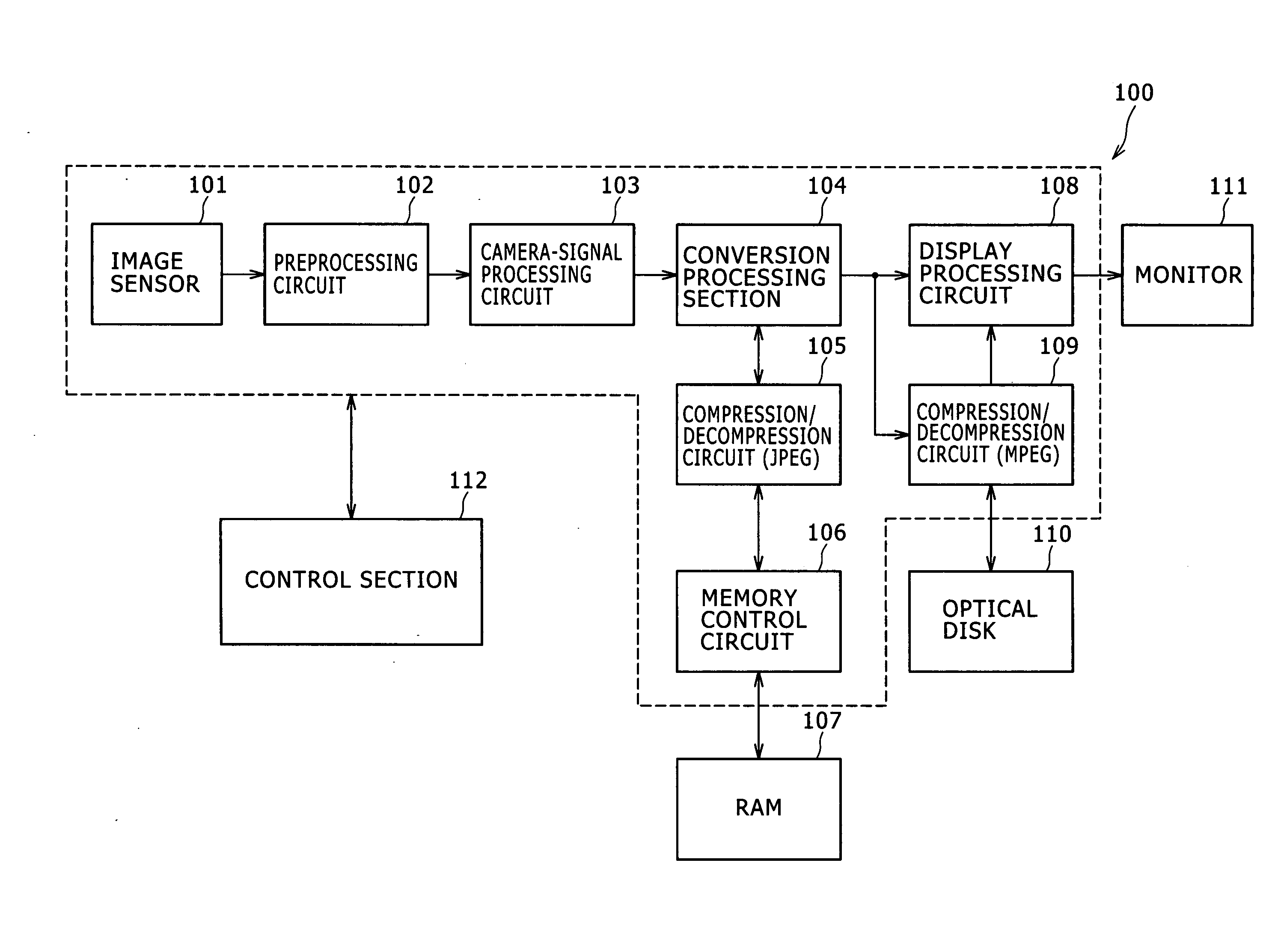

Image-Taking Apparatus and Image-Taking Method

ActiveUS20080049121A1Reduce storage capacityReduce manufacturing costTelevision system detailsColor television detailsComputer hardwareImaging data

An image obtained as a result of an image-taking process carried out at a screen rate higher than a standard screen rate is stored in a recording medium in the contemporary video format. To put it more concretely, the image obtained as a result of an image-taking process is supplied at a first screen rate to first compression / coding means for carrying out a compression / coding process at the first screen rate and image data obtained as a result of the compression / coding process is temporarily stored in temporary storage means. After image data output by the first compression / coding means during a predetermined period of time is stored in the temporary storage means, decompression / decoding means reads out the image data from the temporary storage means at a second screen rate lower than the first screen rate, carries out a decompression / decoding process on the image data and stores a result of the decompression / decoding process in recording means.

Owner:SONY CORP

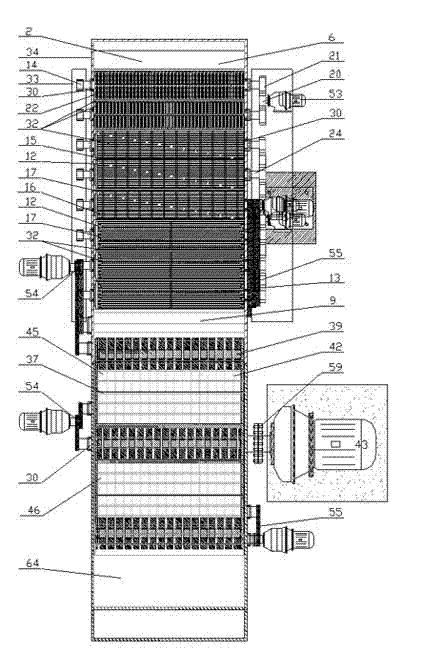

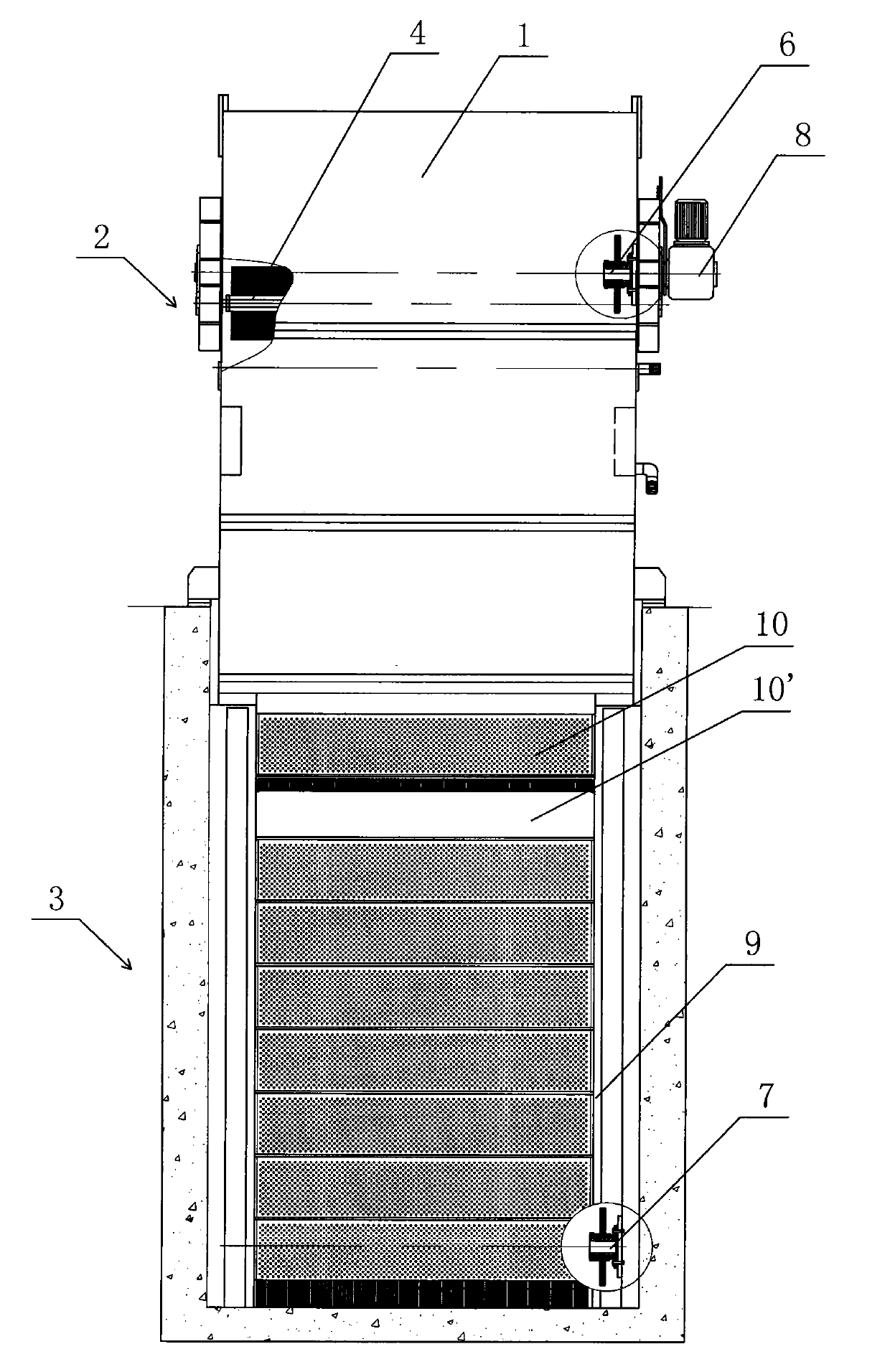

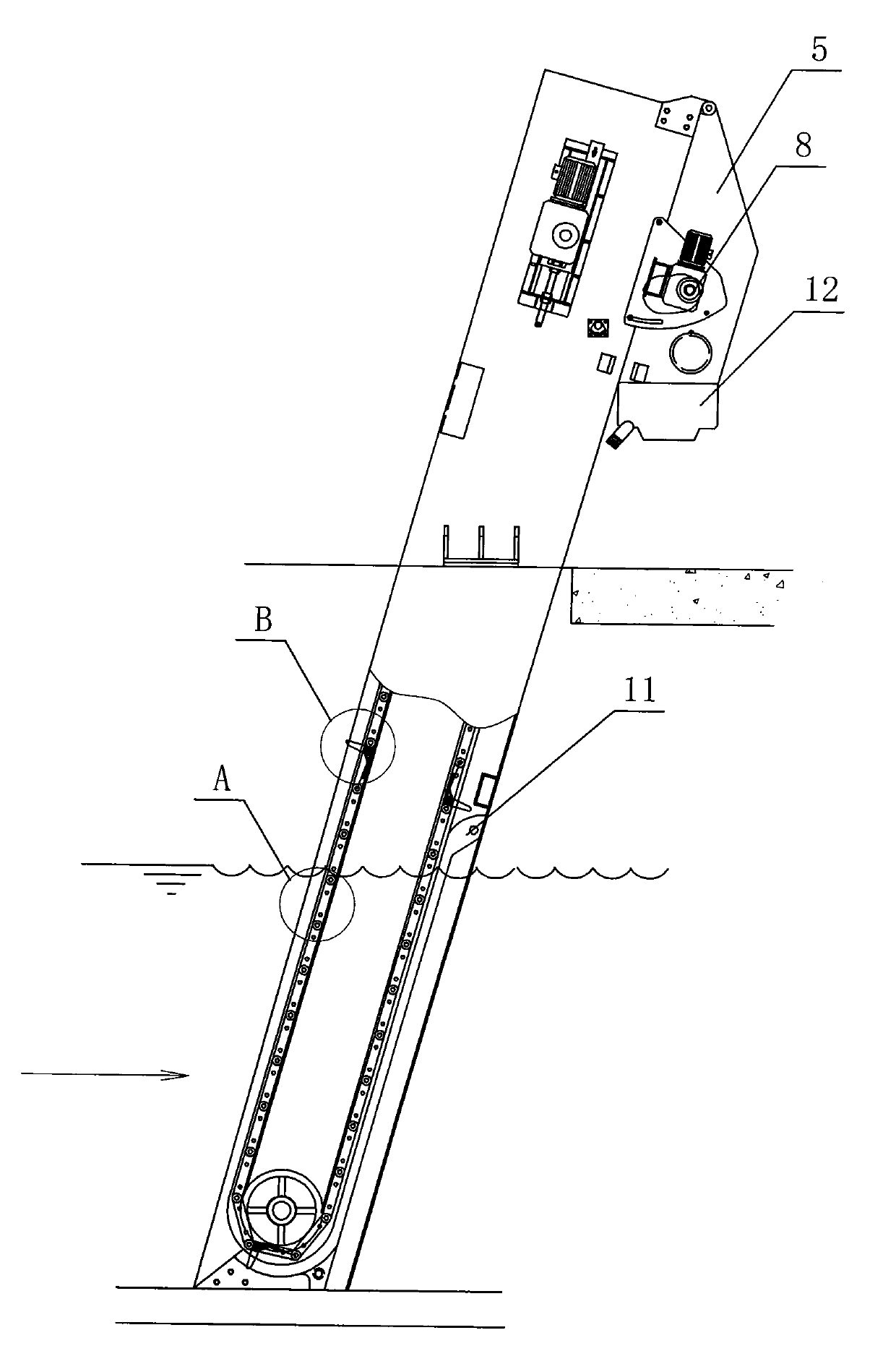

Trash cleaning device for grating of plane sieve plate

ActiveCN102000456AStop stuckImprove sealingWater cleaningMoving filtering element filtersGratingDrive motor

The invention relates to a trash cleaning device for a grating of a plane sieve plate. The trash cleaning device comprises a frame type machine rack arranged in a titling mode, and a rotating device and a rotating hairbrush device which are arranged in the machine rack. The rotating hairbrush device comprises a hairbrush roller arranged at the upper part of inner side of the machine rack and a rotating hairbrush driving motor connected with the hairbrush roller. The rotating device comprises an upper guide wheel and a lower guide wheel. The upper guide wheel is connected with a sieve plate driving motor. Chains and sieve plates are arranged between two guide wheels. The trash cleaning device for the grating of the plane sieve plate is characterized in that: the surface of each sieve plateis plane; the sieve plates are connected to form a plane; and a rabble blade is arranged on one of a plurality of sieve plates. The device can enhance solid floater so as to effectively solve the problem of trash clamped in the centre joint of the sieve plates, clean the dead corner and improve the grating trash rate.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

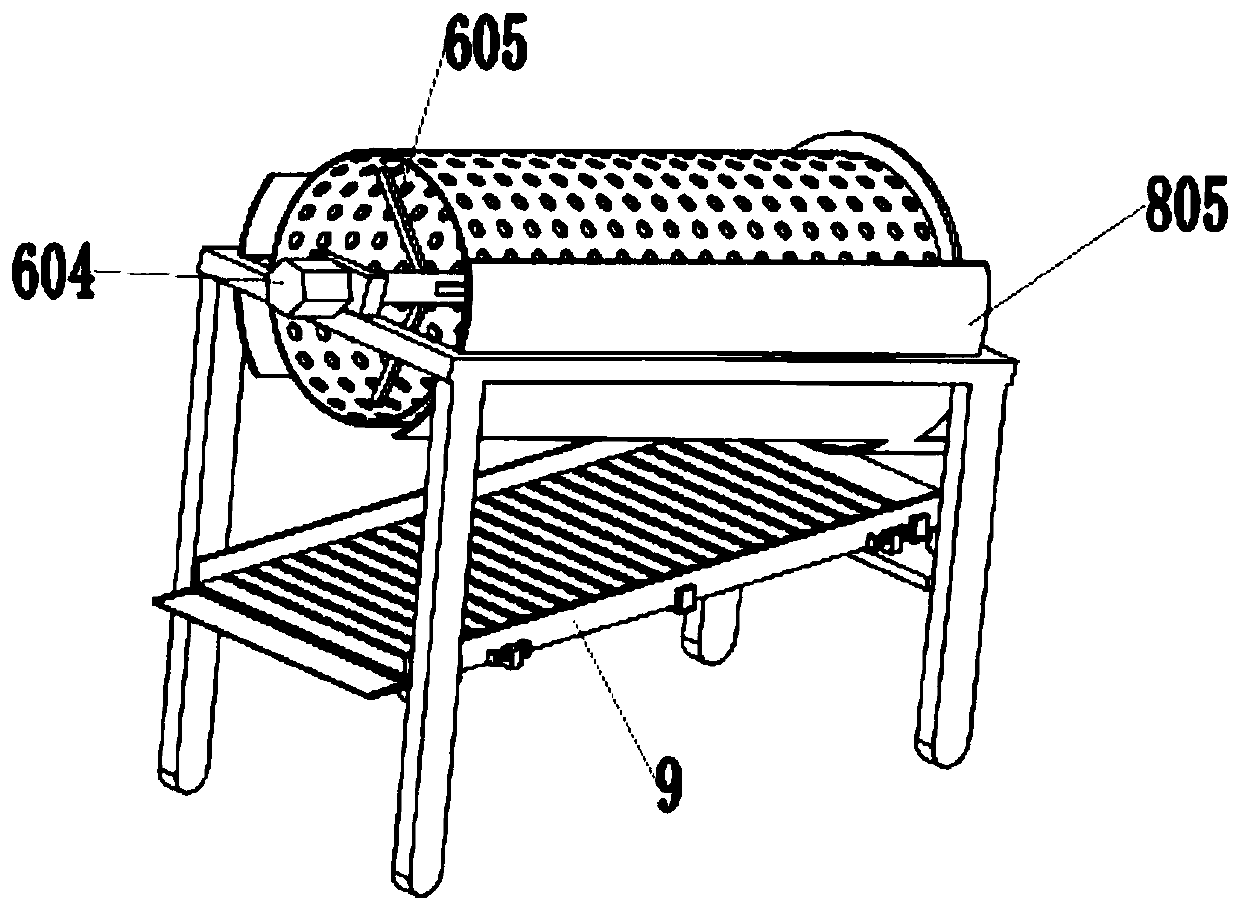

Garbage sorting device and method

The invention relates to a trommel screen device and a method used for sorting domestic garbage. The device comprises a roller brush, a roller, a speed reducer, a motor, a scraping plate, a base, screen meshes, a guide plate, a screening hopper and a riddling outlet, wherein the screen meshes are circular holes, the aperture is 80mm, and the aperture ratio is 75 to 85 percent; both sides of equipment are respectively provided with the telescopic roller brush and the scraping plate, which can clear obstacles in the screen meshes and burs outside the roller; and the entire trommel screen deviceis horizontally arranged, the guide plate is arranged inside the roller, and the domestic garbage in the roller turns and moves forward along the guide plate. When the device is used for sorting the domestic garbage, the rotational speed of the trommel screen is controlled to be 10 to 20r / min, and the sorting efficiency of the domestic garbage with the grain diameter below 80mm is as high as 93 percent. The domestic garbage sorting method involved with the invention has high efficiency, low energy consumption and easy maintenance.

Owner:BEIJING HAOHAI TIANJI TECH +1

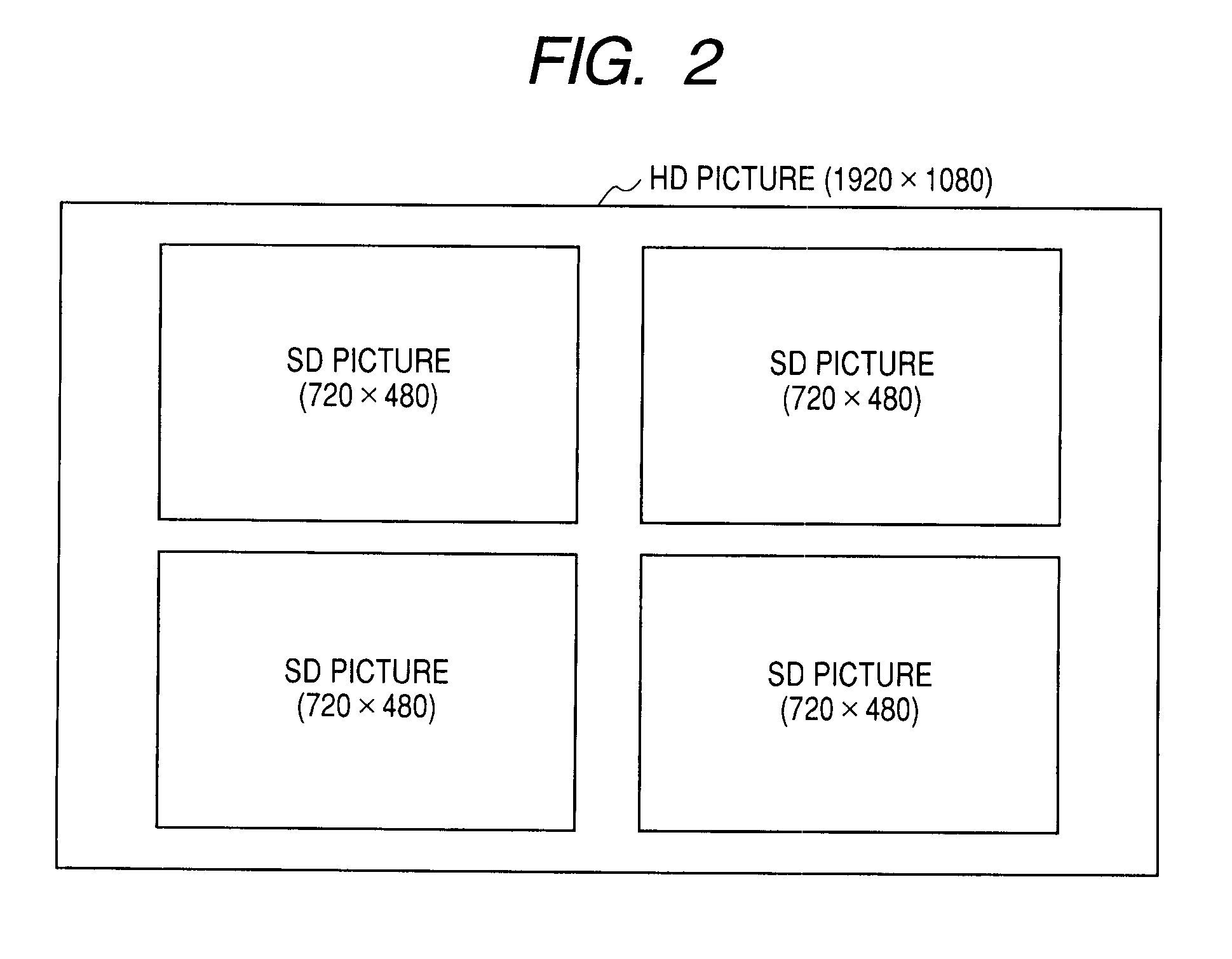

Picture processing apparatus, imaging apparatus and method of the same

InactiveUS20070296826A1Suppress manufacturing costMiniaturizationTelevision system detailsColor television detailsLow speedComputer graphics (images)

An imaging apparatus which images pictures using a solid-state imaging device includes a picture conversion unit converting pictures imaged at a high-speed screen rate by the solid-state imaging device into a picture in which n-pieces (“n” is an integer of 2 or more) of continuous imaged pictures are arranged in one screen and outputting the converted picture at a low-speed screen rate which is 1 / n of the high-speed screen rate, a signal processing unit performing predetermined picture-quality compensation processing to the picture from the picture conversion unit, a display picture cutting unit cutting one of n-pieces of imaged pictures from pictures processed by the signal processing unit and outputting the picture at the low-speed screen rate, and a display processing unit generating picture signals for displaying the picture outputted from the display picture cutting unit at a display device.

Owner:SONY CORP

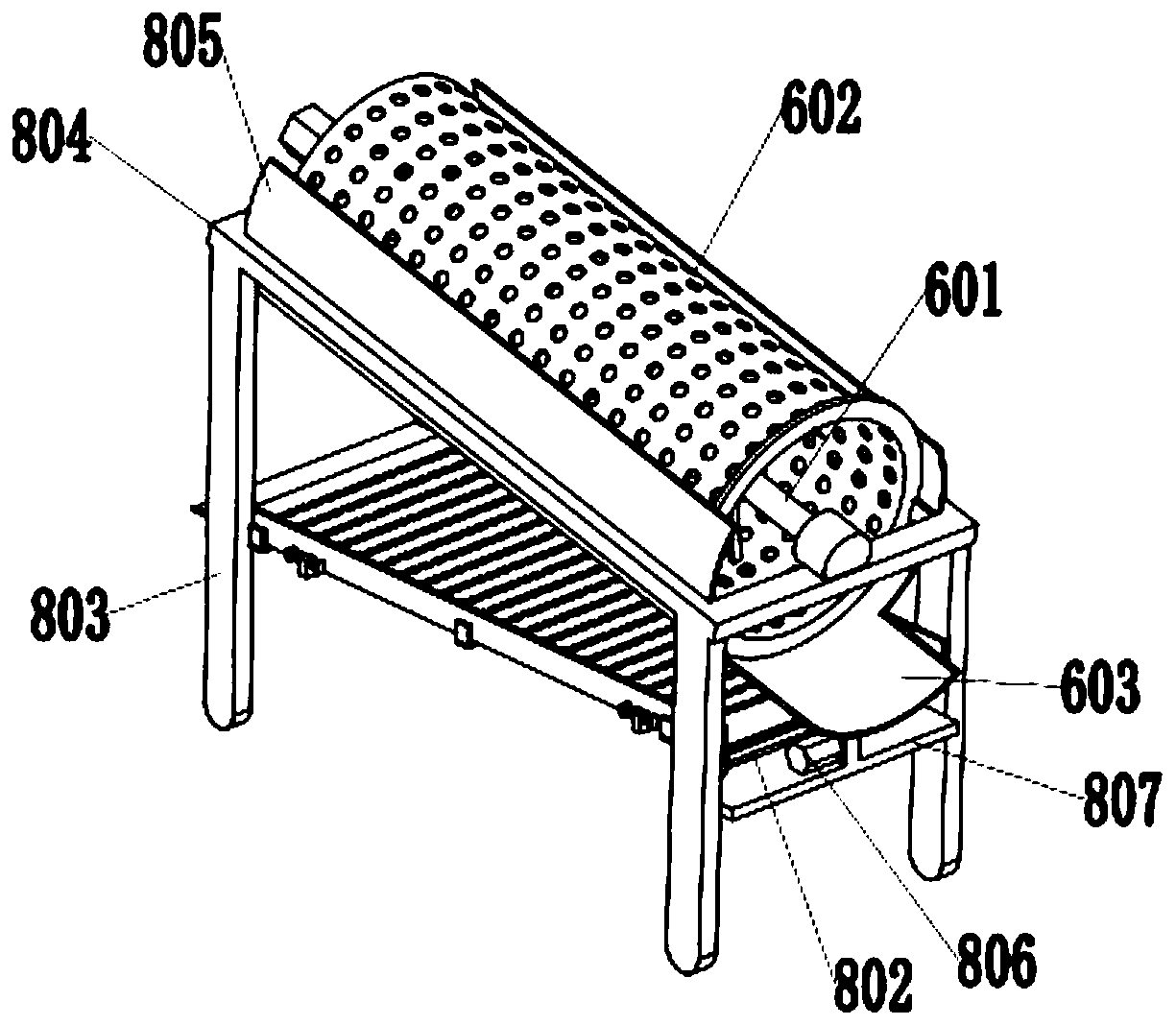

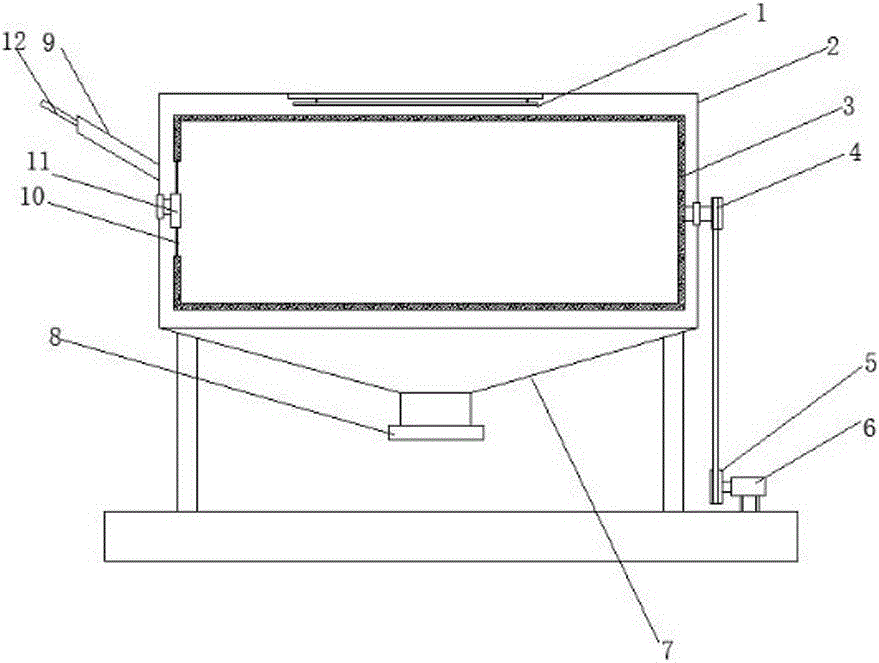

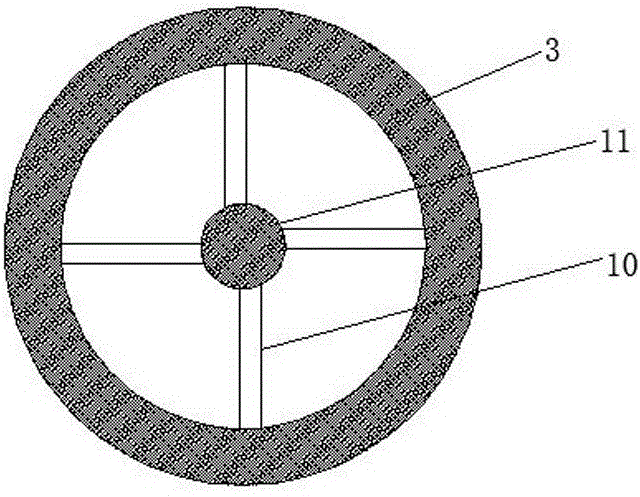

River sand screening device for construction

ActiveCN111054631ASmooth slidingIncrease profitSievingSand dryingEnvironmental engineeringSand filter

The invention discloses a river sand screening device for construction. The sand screening device comprises a sand feeding hopper, a drying cylinder, a primary screening device and a secondary sand screening device, the drying cylinder is mounted at the upper end of a bracket; the drying cylinder is of a double-layer hollow structure, a heating block is arranged between the outer cylinder wall andthe inner cylinder wall of the drying cylinder; one end of the drying cylinder is connected with a sand inlet hopper; the other end of the drying cylinder is communicated with the primary screening device; the primary screening device is a sand screening barrel; the sand screening barrel is installed on a supporting frame, first screening holes are formed in the side wall of the sand screening barrel, the second-stage sand screening device comprises a swing frame and a sand filtering plate, a sand screening plate is fixed to the upper end of a swing frame, second screening holes are formed inthe sand screening plate, the swing frame is connected with the supporting frame and located below the sand screening barrel, and the sand screening plate and the sand screening barrel are opposite in inclination direction. The problem that wet sands with small particles are mutually adhered is solved, the working efficiency is improved, the screening effect is improved, the utilization rate of the sand is increased, waste is avoided, and the construction cost is reduced.

Owner:济南工程职业技术学院

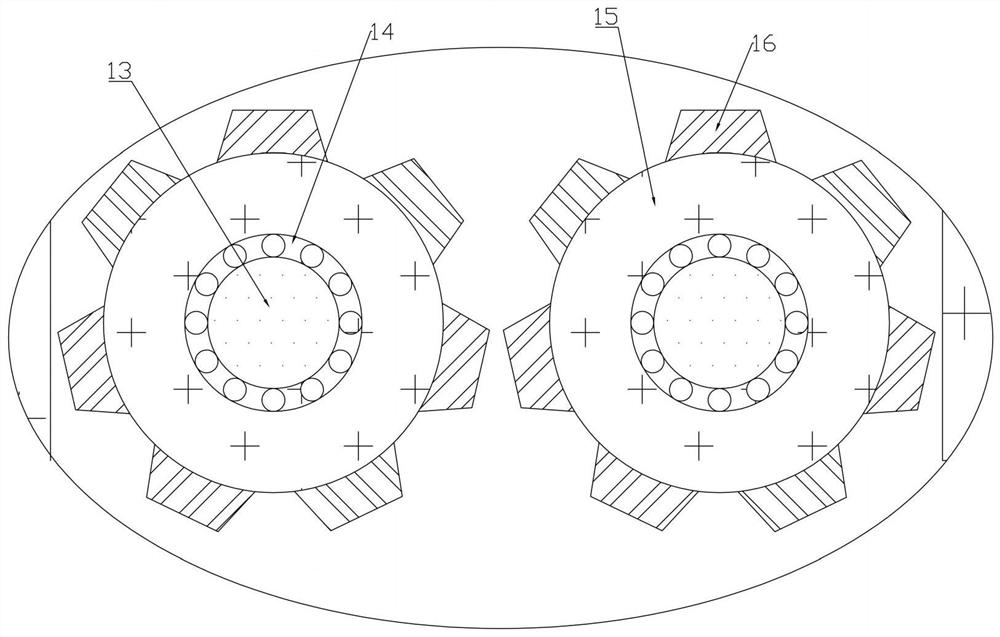

Magnetic separation device for iron ore powder

InactiveCN104028373AContinuous workingSimple structureDirt cleaningMagnetic separationIronstoneEngineering

The invention relates to an ore screening device, in particular to a magnetic separation device for iron ore powder. The magnetic separation device comprises a frame, wherein belt wheels are arranged at the left and right ends of the frame; a conveying belt with magnetism is coated on the two belt wheels; a dust collecting cover with an air blower is arranged above the conveying belt, and is positioned in the middle position between the two belt wheels; an inclined scraper is arranged at the left side of the left belt wheel; the upper end of the scraper is contacted with the outer surface of the conveying belt; and a feeder for conveying iron ore materials onto the conveying belt is arranged above the right belt wheel. The magnetic separation device has the advantages of simple structure, easy maintenance, strong controllability, strong practicability, obvious separation effect, low operation cost and high ore separation rate.

Owner:TAIZHOU BEIYANG METAL MATERIAL

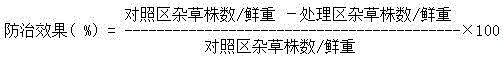

Weeding composition containing isoxaflutole and imazapic and application of weeding composition

ActiveCN106818786AImprove securityReduce dosageBiocideDead animal preservationMedicineBULK ACTIVE INGREDIENT

The invention discloses a weeding composition containing isoxaflutole and imazapic and application of the weeding composition. The weeding composition compounds the isoxaflutole and imazapic and achieves an excellent synergetic effect, wherein a weight ratio of the isoxaflutole to imazapic is (1 to 10):(1 to 10). The composition disclosed by the invention can achieve the effects of improving the drug efficacy, reducing the dosage, reducing the economic cost, greatly reducing the administration dose of a single active ingredient, improving the safety on crops, reducing residues of the agents in the environment, retarding drug resistance of weeds, prolonging the service life of the agents, and controlling most of broadleaf weeds, annual gramineous weeds and cyperaceous weeds in sugarcane fields.

Owner:SHANDONG WEIFANG RAINBOW CHEM

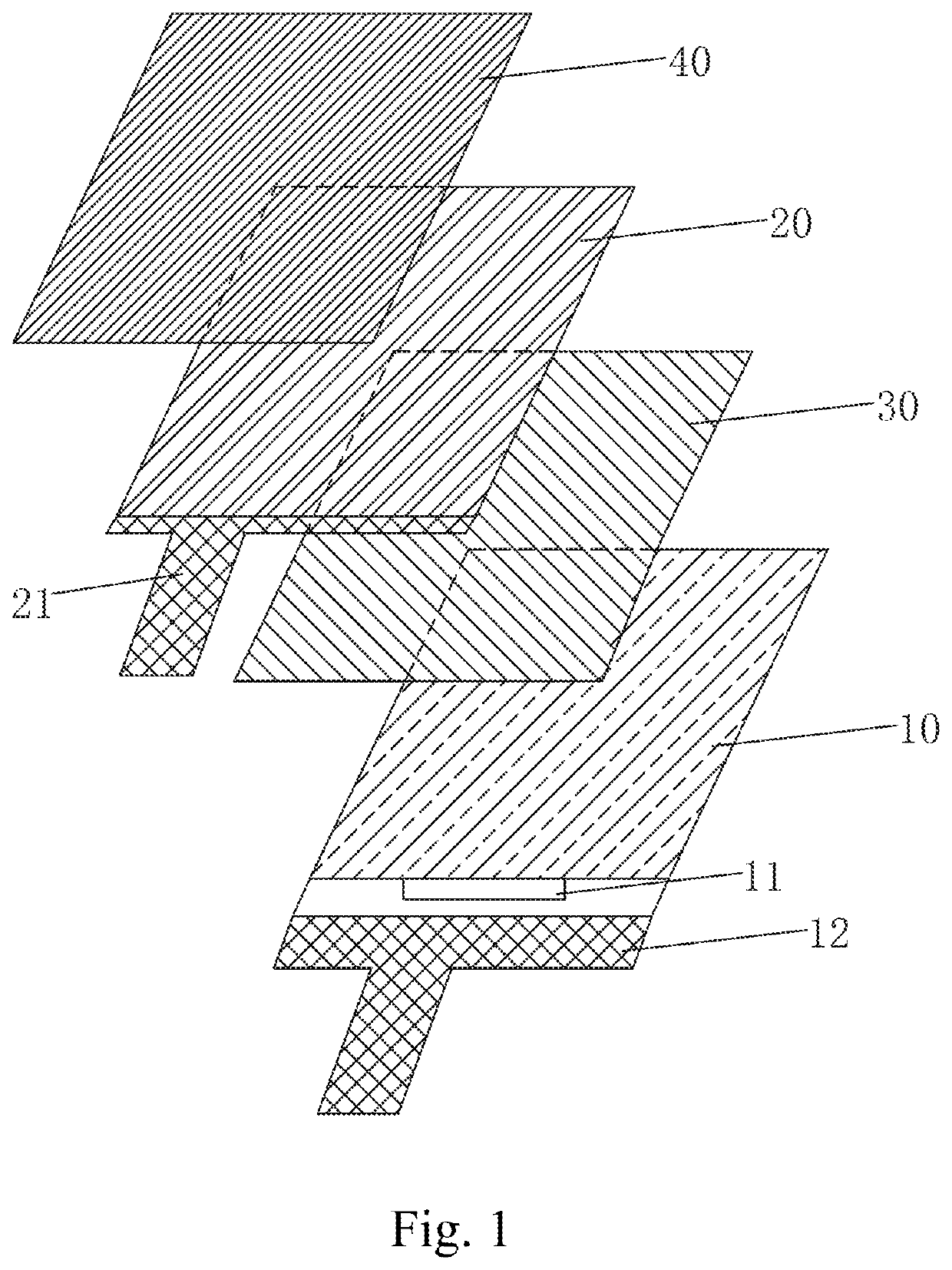

Poly lithium battery structure with high capacity and high output ratio power

ActiveCN102842700AImprove polarization performanceImprove polarization effectSecondary cellsCell component detailsElectrical batteryWorking temperature

The invention mainly discloses a poly lithium battery structure with high capacity and high output ratio power. The poly lithium battery structure comprises a plurality of single battery pole pieces, wherein all single battery pole pieces are equally divided into a plurality of small single piece groups, polar lugs, which have same polarity, of single battery pole pieces in the same single piece group, are reshaped by pressing and clamped by a positive clamp and a negative clamp through welding; positive auxiliary electrode aluminum conductive metal sheets and polytetrafluoroethylene clapboard sheets are stacked between two adjacent groups; clamps with same polarity in each group are connected by an output connector in a unified manner; and the poly lithium battery structure is finally formed by packaging an aluminum-plastic packaging film. The poly lithium battery structure disclosed by the invention breaks through the bottleneck of application of high output ratio power and high current discharge of the traditional polymer lithium ion battery. According to the poly lithium battery structure, the accumulation of the polarization effect and the heat effect of the high-capacity battery under the condition of high output ratio power and high current discharge is greatly improved, the working temperature of the battery is reduced by 30 percent and the output capacity of the battery is improved by 38 percent than those of the traditional polymer lithium ion battery structure, the polarization effect of the battery is reduced and the temperature of a thermal runway platform is improved by 80-95 DEG C.

Owner:厦门太和动力电源科技有限公司

Plant seed screening device

The invention discloses a plant seed screening device. The plant seed screening device comprises a screen pond, a telescopic device, a telescopic rod, a push plate, a separation plate, a stirring plate, a collector, a water outlet valve and a water outlet pipe, and is characterized in that: the telescopic device and the collector are symmetrically arranged on the outer wall of the screen pond, one end of the telescopic rod runs through the telescopic device to be arranged on the telescopic device, the other end is connected with the push plate, the separation plate and the stirring plate are arranged on the push plate, the water outlet valve is arranged on the bottom of the screen pond, and the water outlet pipe is arranged on the water outlet valve. The push plate is arranged in the screen pond, the outer wall of the screen pond is provided with the telescopic device and the collector, the telescopic device pushes the push plate to go forward through the telescopic rod, the push plate and a baffle plate push the floated incomplete seeds into the collector, the stirring plate below the push plate can stir the seeds, the incomplete seeds can be adequately floated, the screening rate of the seeds can be increased, and the working efficiency can be improved.

Owner:鲁蓉蓉

Method and device for screening, diagnosing or risk grading of ovarian cancer

InactiveCN110880356AHigh degree of automationHigh degree of integrationMicrobiological testing/measurementBiostatisticsBenign tumoursParanasal Sinus Carcinoma

The invention relates to a method and a device for screening, diagnosing or risk grading of ovarian cancer. Specifically, the invention relates to a method and a device for screening, diagnosing or risk grading of ovarian cancer by constructing a decision tree model by using high-throughput sequencing and CA-125 level; and more specifically, the invention relates to construction of the decision tree model by using high-throughput sequencing and CA-125 level, and training of the model for screening and detection of ovarian cancer; and therefore, the clinical problems of difficult discovery of the ovarian cancer due to hidden early ovarian cancer symptoms, difficulty in judging whether masses are ovarian cancer or benign ovarian tumors due to undetermined ovarian masses in property, and thepossibility of negative tumor markers accompanied by malignant pelvic cavity masses are solved from the molecular biology level. According to the method and the system, the possible ovarian cancer canbe found through one-time detection.

Owner:NANJING GEZHI GEMONICS CO LTD

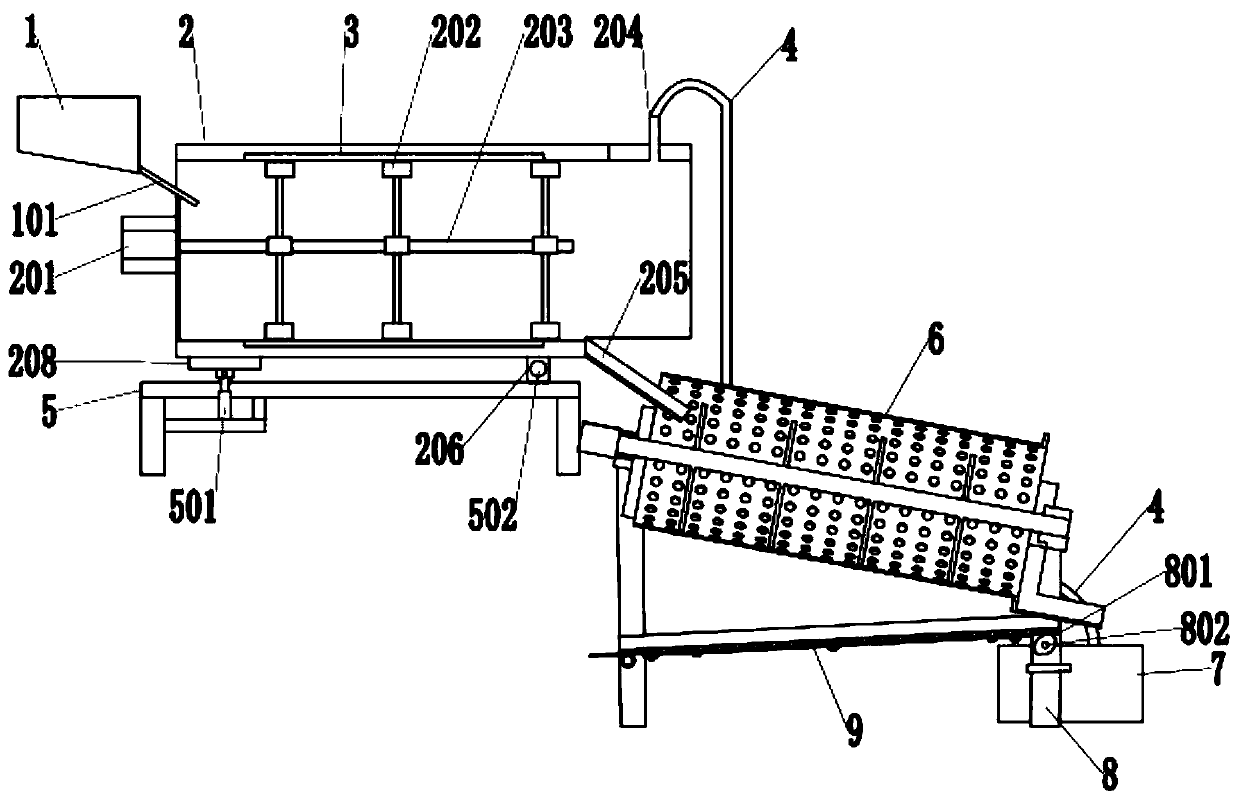

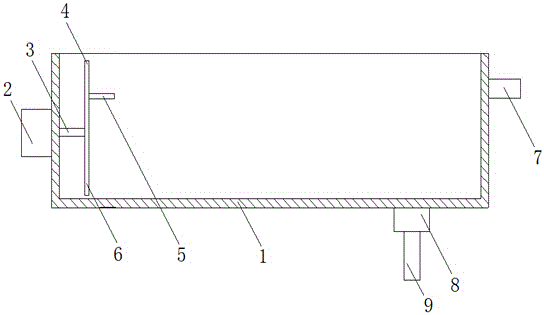

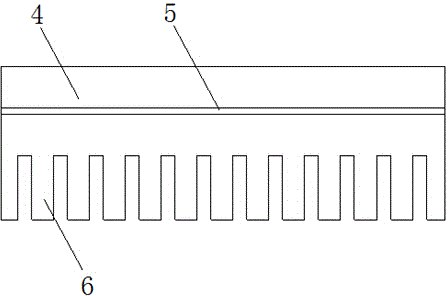

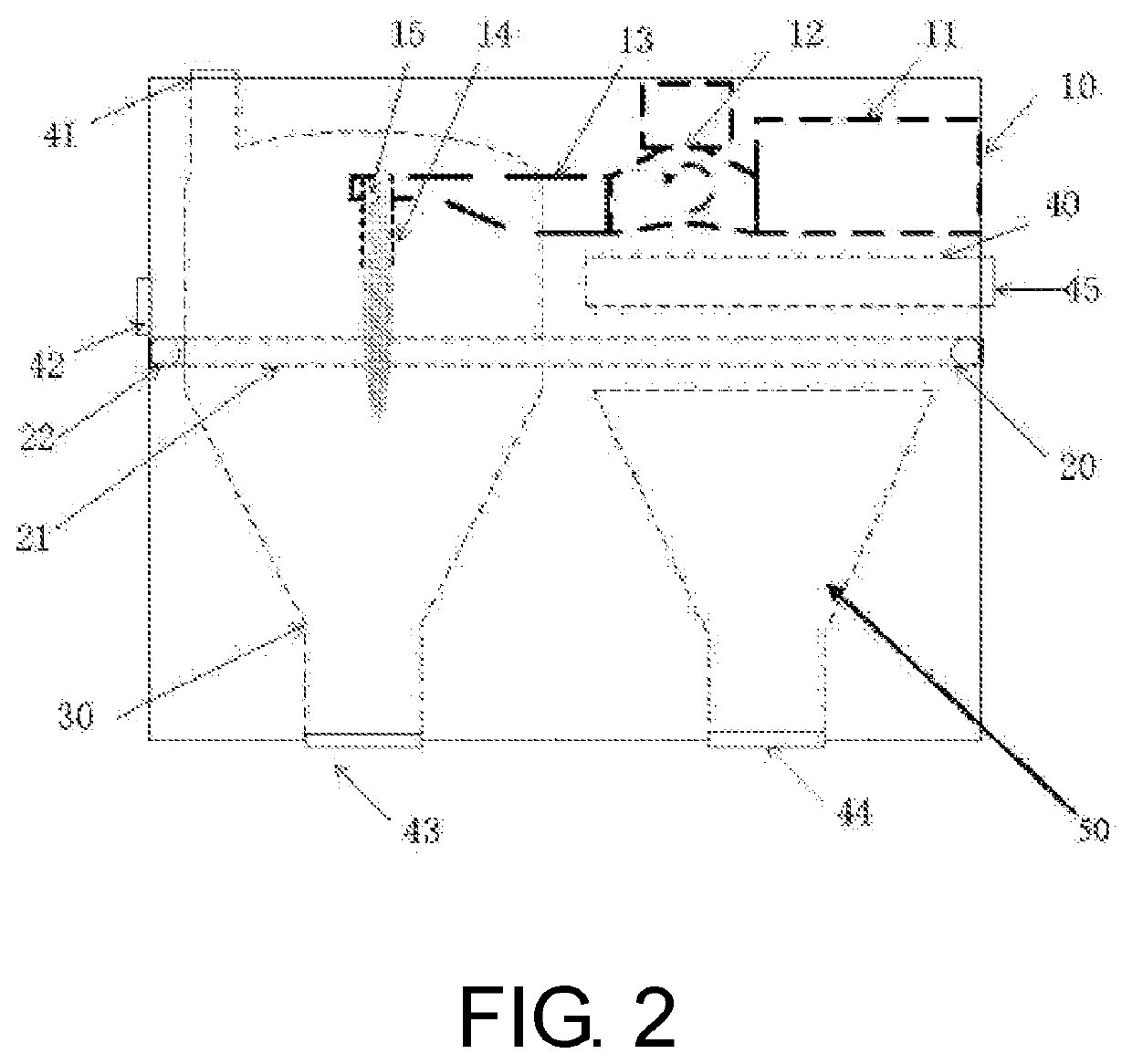

Ore sand screening device

ActiveCN103949391AEvenly distributedImprove screening effectSievingScreeningScreening effectEngineering

The invention discloses an ore sand screening device which comprises a conveyer belt used for feeding material to a screening machine and a screen used for ore sand screening, wherein the screen is arranged in an inclined manner; a distribution groove is formed in the upper end of the screen and arranged in a manner of being inclined and next to the screen; the distribution groove is arranged corresponding to the discharging end of the conveyer belt; the conveying direction of the conveyer belt intersects with or is perpendicular to the flowing direction of material in the screen; a first flow equalization board component which enables ore sand conveyed by the conveyer belt to be uniformly distributed is arranged at the bottom of the distribution groove; first ore sand outlets are uniformly formed in the first flow equalization board component in the length direction. Through the first flow equalization board component, ore sand conveyed on the conveyer belt can be uniformly distributed on the screen, so that the screening effect and the screening rate can be improved.

Owner:SHANGHAI BAILI NEW BUILDING MATERIALS CO LTD +1

Leakage detection device and leakage detection method for lithium ion battery

PendingCN113218589ASimple structureEasy to useDetection of fluid at leakage pointEngineeringWeld seam

The invention provides a leakage detection device for a lithium ion battery, which comprises a loading disc structure, a battery is loaded on the loading disc structure, the loading disc structure is detachably mounted on a test platform, a test hole corresponding to the battery is formed in the test platform, and test paper is arranged in the test hole. The loading disc structure loaded with the battery is mounted on the test platform after being positively mounted or turned over, so that the battery is in contact with and clings to the test paper after being inverted, and the test paper is used for detecting whether a leak hole exists in a welding seam of the battery to cause electrolyte leakage or not. The leakage detection device is used for conveniently, quickly and efficiently screening the lithium ion batteries subjected to laser welding and screening the unqualified lithium ion batteries with leakage holes in welding seams, so that the risk of combustion or explosion caused by electrolyte leakage is avoided.

Owner:湖南领湃科技股份有限公司 +4

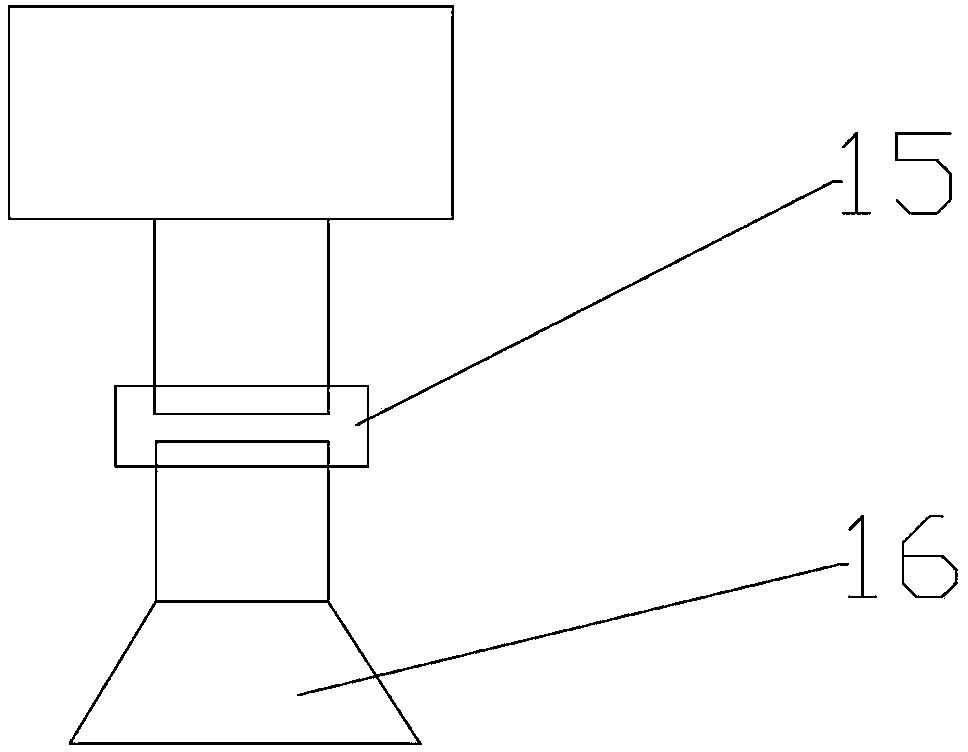

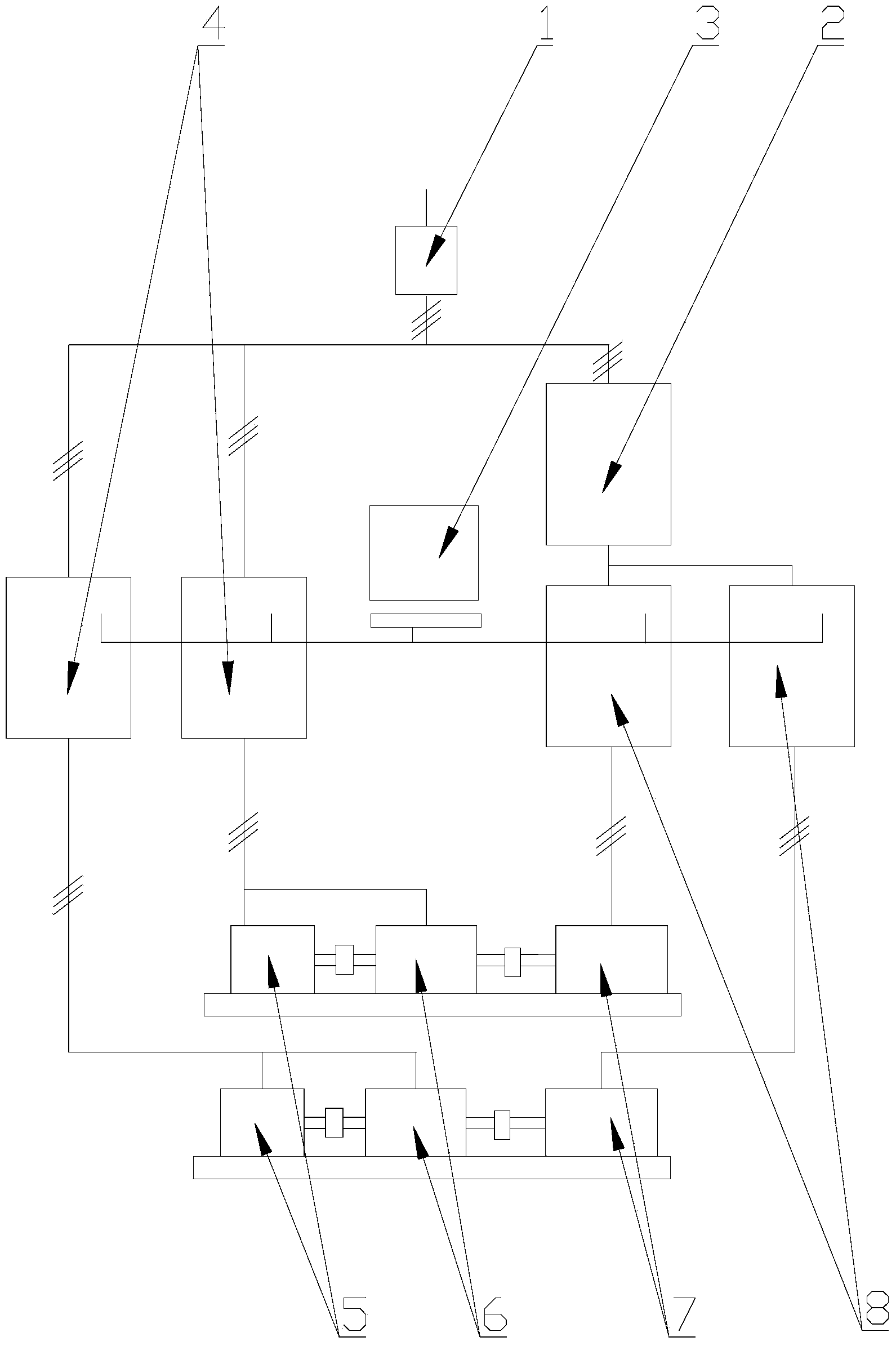

Three-motor-combined frequency converter full-load aging test device

ActiveCN104297603AReduce usageImprove screening rateElectrical testingMeasurement instrument housingElectricityFrequency changer

The invention discloses a three-motor-combined frequency converter full-load aging test device. The three-motor-combined frequency converter full-load aging test device comprises an incoming wire breaker, an energy feedback unit, an industrial computer, tested frequency converters, first tested motors, second tested motors, test-accompanying electric generators and test-accompanying frequency converters. The incoming wire breaker is electrically connected with a mains supply. The incoming wire breaker is electrically connected with the tested frequency converters and the energy feedback unit respectively. The tested frequency converters are electrically connected with the corresponding first tested motors and the corresponding second tested motors respectively. The first tested motors and the second tested motors are connected in the axial direction. The second tested motors are connected with the test-accompanying electric generators in the axial direction. The test-accompanying electric generators are electrically connected with the test-accompanying frequency converters. The test-accompanying frequency converters are electrically connected with the energy feedback unit. The tested frequency converters and the test-accompanying frequency converters are electrically connected with the industrial computer. Since the three-motor-combined frequency converter full-load aging test device is equipped with the motors in different combinations, the three-motor-combined frequency converter full-load aging test device can be used for testing frequency converters at various power sections, thereby saving cost; the device conducts feedback to a power grid through the energy feedback unit, thereby lowering energy consumption.

Owner:SUZHOU SUMING AUTOMATION EQUIP

Tea leaf screening device for agricultural production

InactiveCN112495777AEasy to scatterEasy to filterSievingScreeningAgricultural scienceElectric machine

The invention discloses a tea leaf screening device for agricultural production. The tea leaf screening device comprises a shell and a trigger mechanism. A screening chamber is formed in the shell, and the inner top of the screening chamber communicates with the outside through a feeding hopper. The trigger mechanism comprises a motor installed on one side of the shell, the tail end of an output shaft of the motor is fixedly connected with a first rotating rod, and the first rotating rod is sleeved with a first gear. A sliding rod is horizontally arranged in the screening chamber, and the leftend and the right end of the sliding rod are fixedly connected with the inner wall of the screening chamber. When the equipment is used, only the motor needs to be started, a filter screen can be shaken left and right and up and down, and the filter screen can better screen tea leaves; and meanwhile, only one motor is used when the equipment is used, and energy consumption is reduced.

Owner:河南能祥建筑机械有限公司

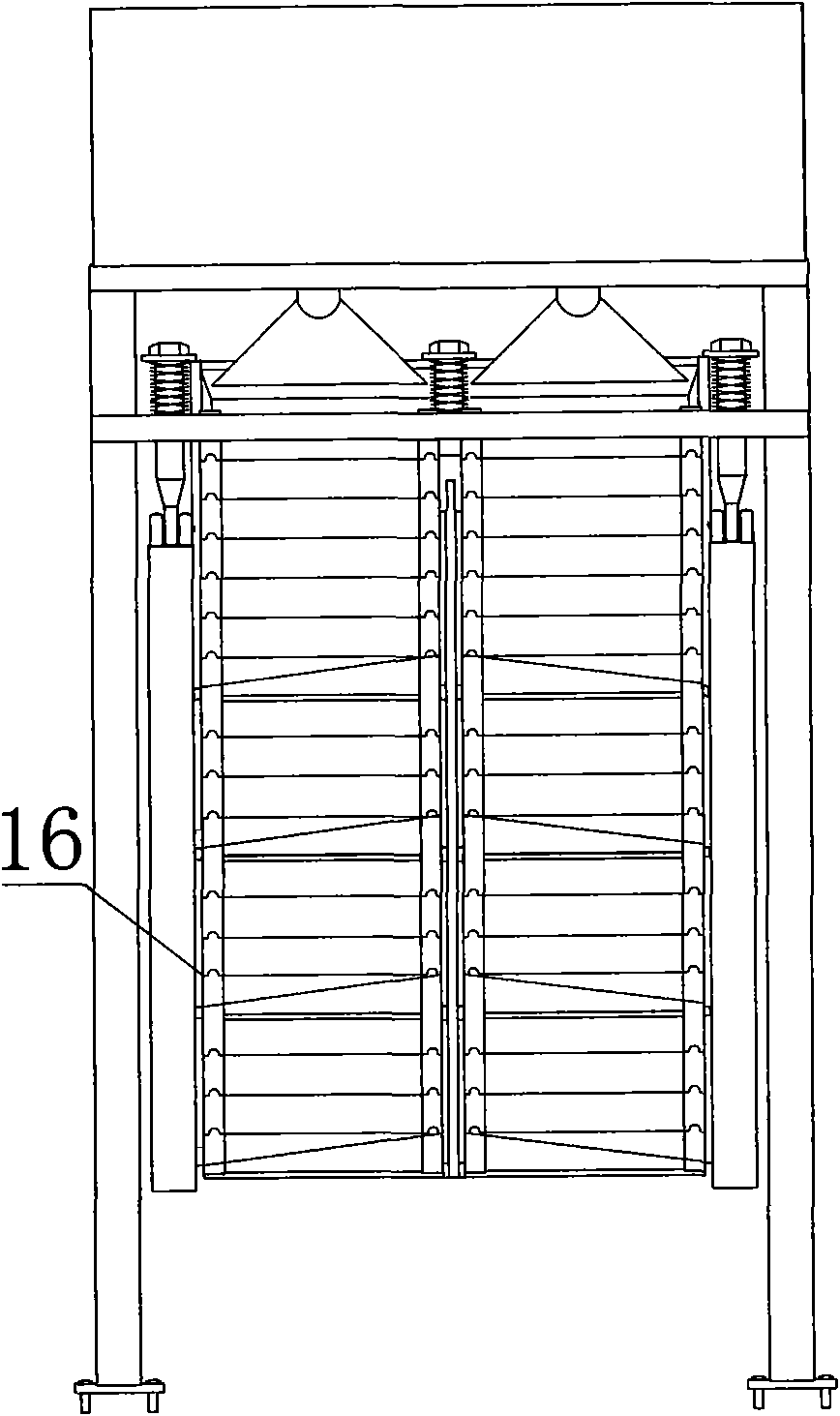

Multilayer high-frequency vibrating screen

InactiveCN101653762AEasy to replaceSimple structureSievingScreeningEngineeringMechanical engineering

The invention relates to the screening field, in particular to a multilayer high-frequency vibrating screen of superfine material screening such as oreconcentrate, medicine and the like, which is characterized in that a plurality of multilayer screen groups are arranged on a lower part bracket and a tail bracket of a main splitter; the lower parts of the multilayer screen groups are provided withvibration motors; a spring one is hinged and arranged between a high end and a bracket of the multilayer screen group; a spring two is arranged between a low end and the tail bracket of the multilayerscreen group; shunt pipes are arranged between the main splitter and splitters; a plurality of screen bodies are arranged on the multilayer screen groups in parallel; the splitters are respectively arranged at the entrance of each screen body; oversize products and undersize products enter a trough through the tail part of the screen body; an upper screen piece of the screen body is connected with a screen frame through a screen piece platen; a buffer slot is arranged at the end part of the screen piece; an isolation hood is arranged at the upper part of the whole screen frame; and valves arearranged at the shunting pipes. The invention has the beneficial effects of simple structure, convenient operation, reduced occupied area, improved screening ratio, low energy consumption and convenient screen piece replacement and maintenance.

Owner:李斌

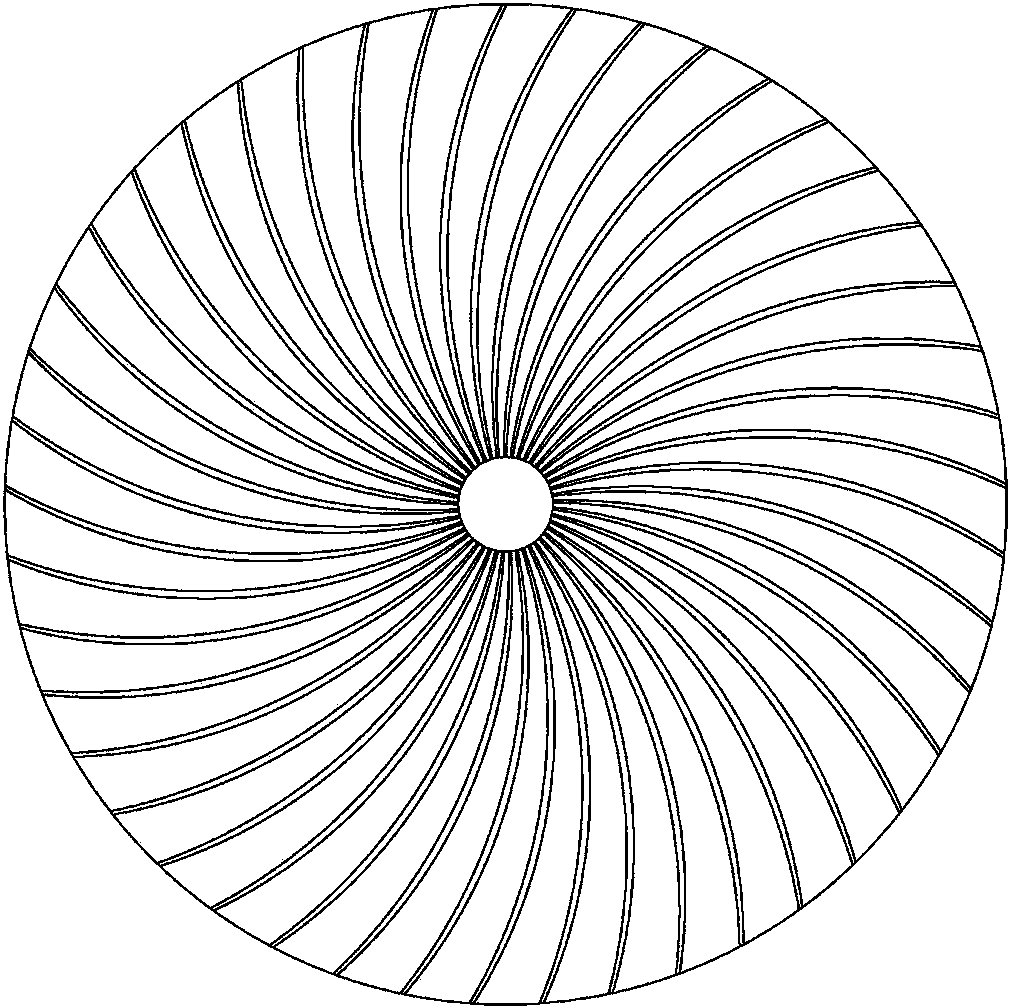

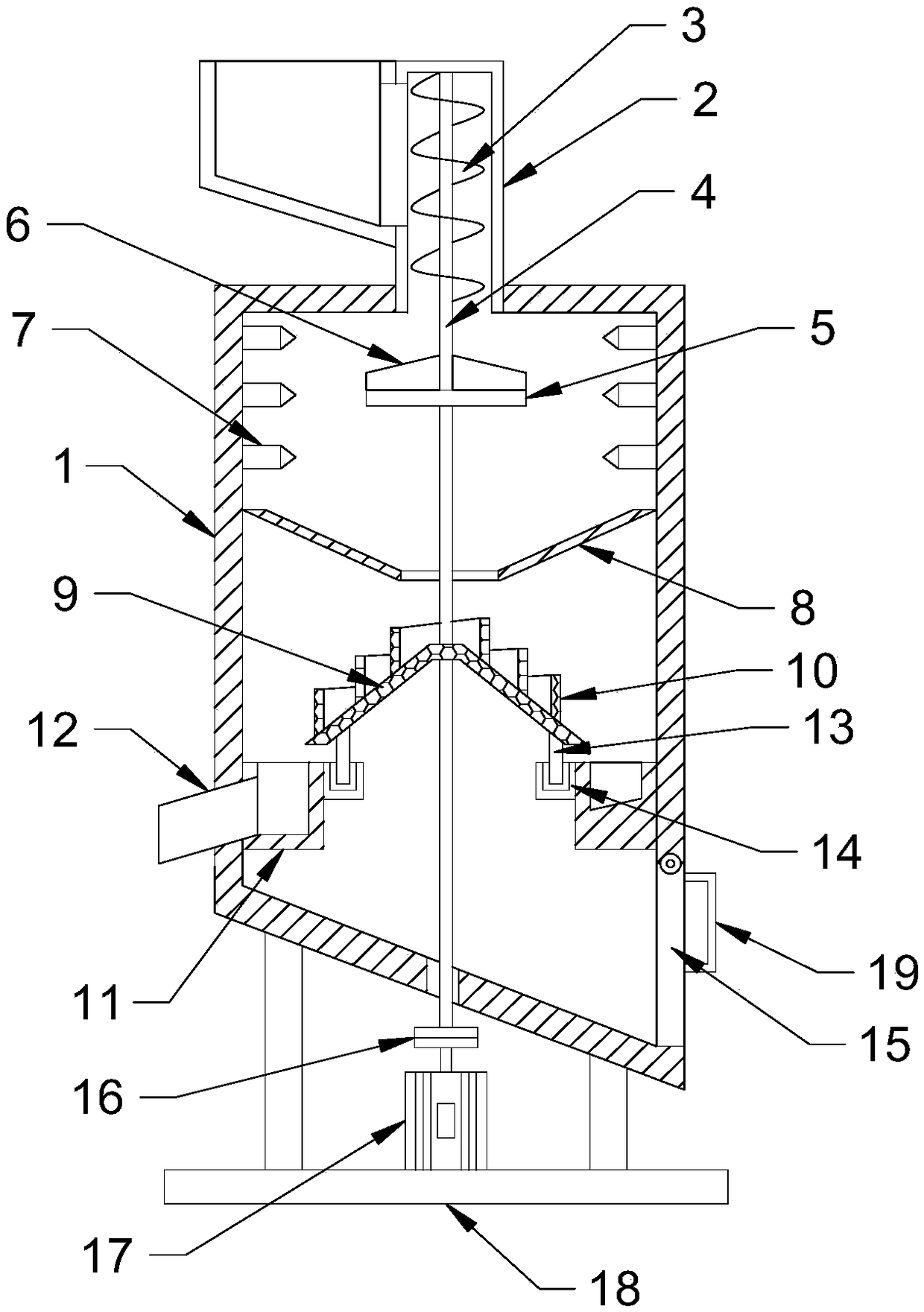

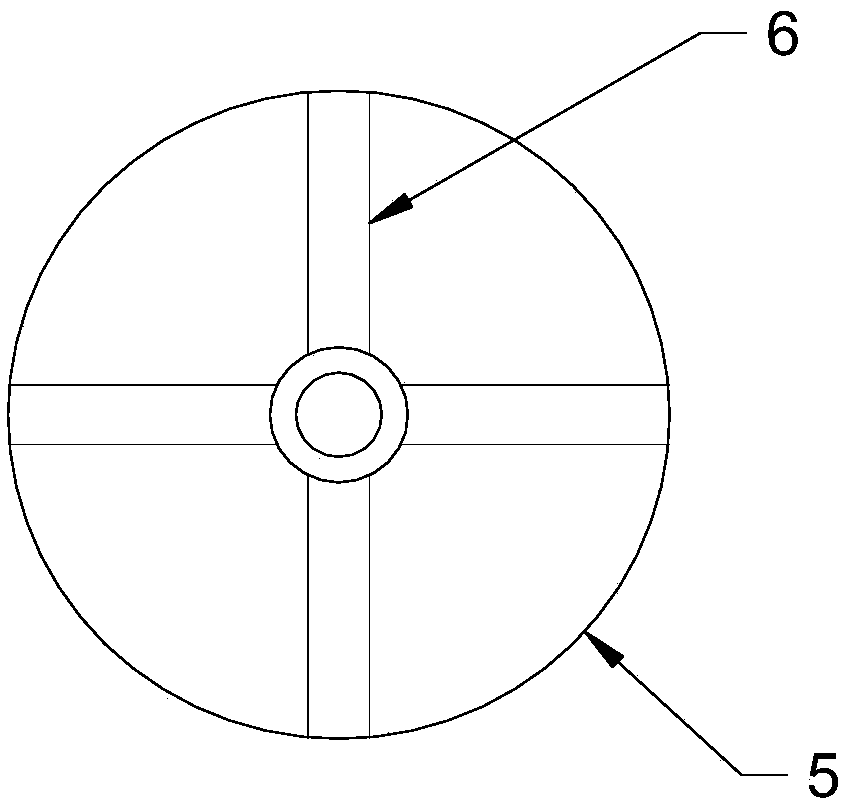

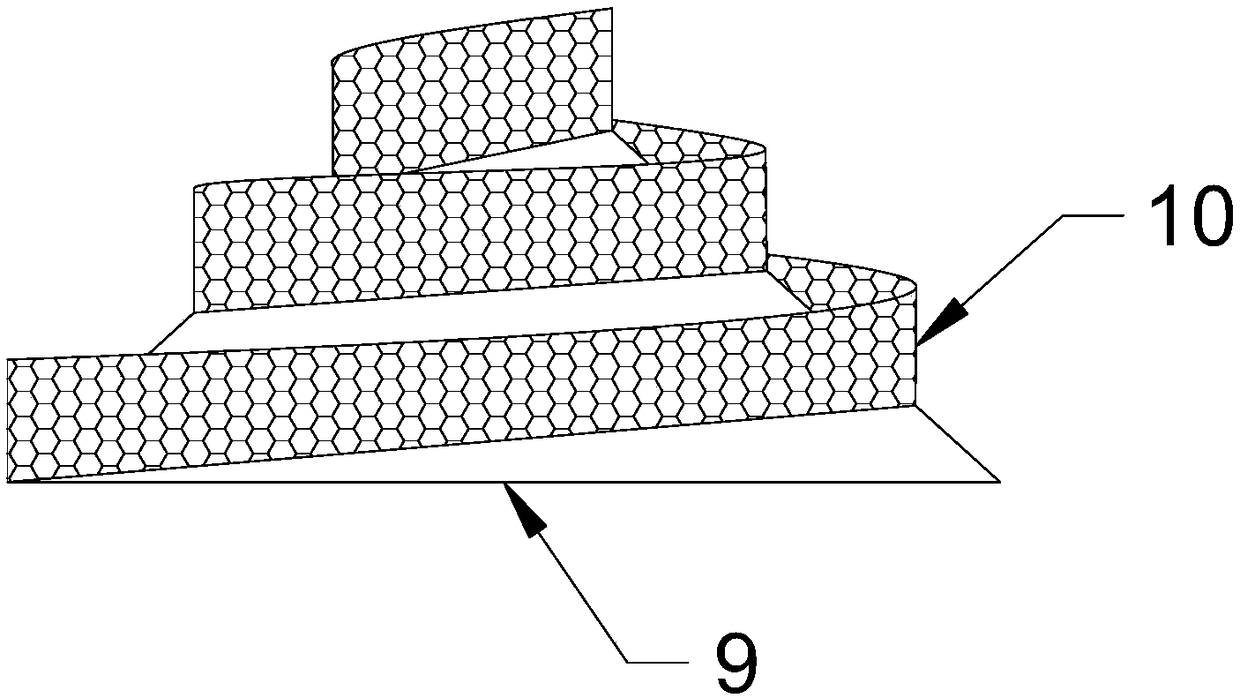

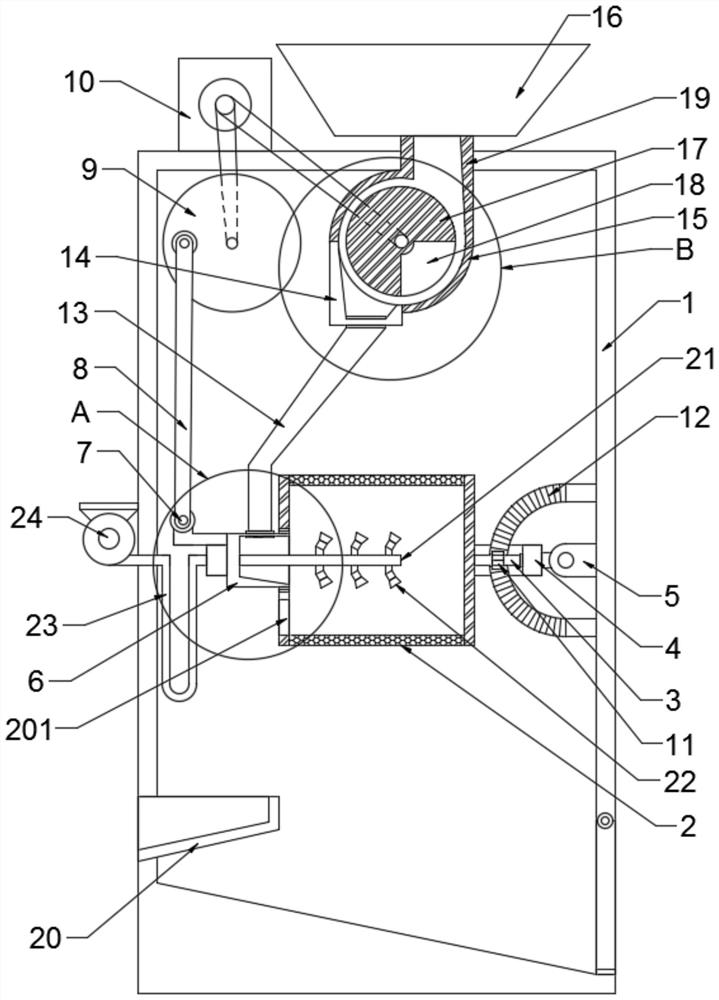

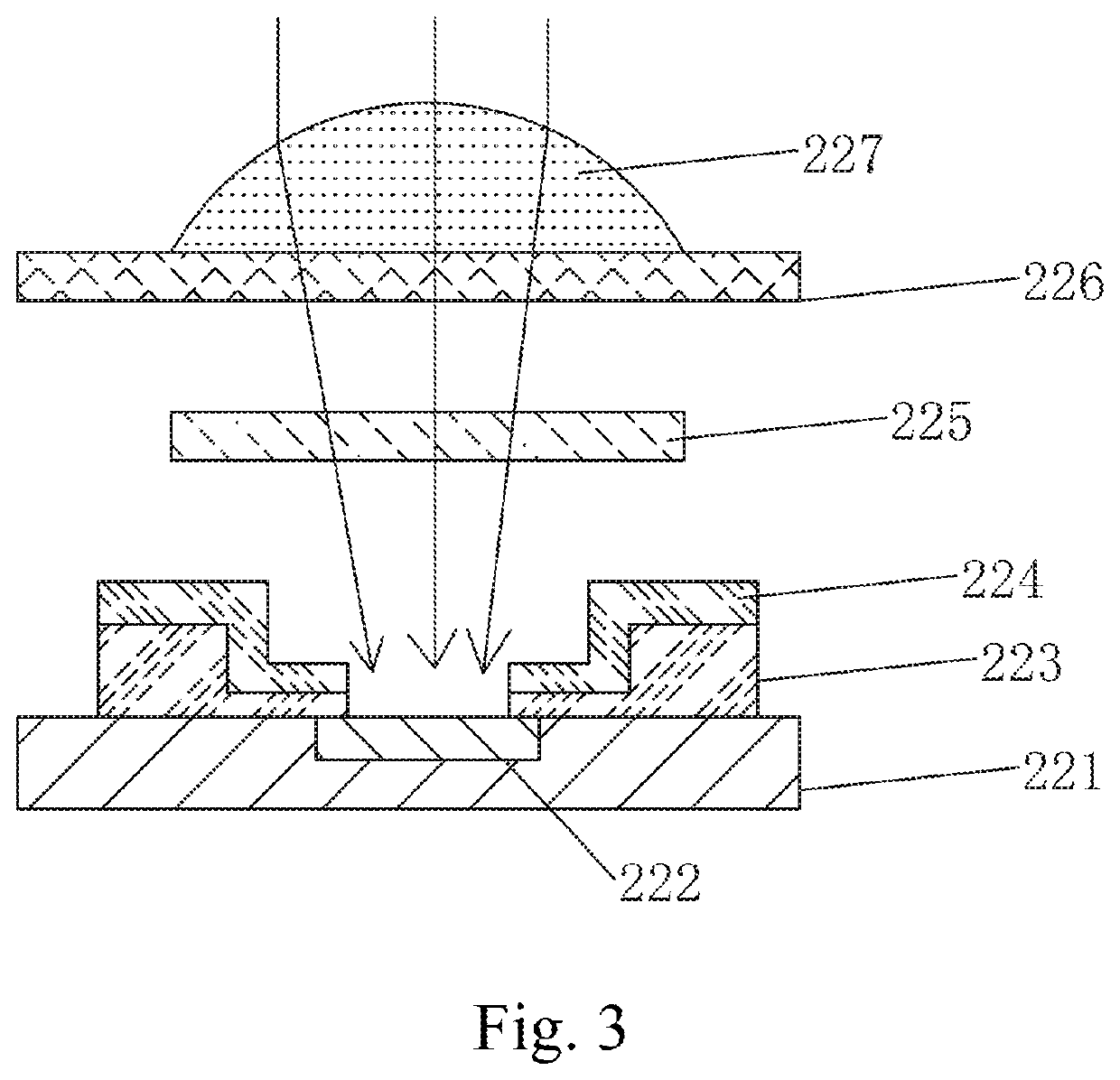

Fine sand screening device

InactiveCN109482309AHigh removal rateImprove screening rateSievingScreeningImpact toothScreening effect

The invention discloses a fine sand screening device. The fine sand screening device comprises a box body, an impacting mechanism and a screening mechanism; the impacting mechanism is arranged in thebox body, and the impacting mechanism comprises a scattering disc and impacting teeth; tooth plates with circumferential distribution are perpendicularly and fixedly connected to the upper end surfaceof the scattering disc, a center shaft is fixed to the scattering disc in a sleeving mode, and the impacting teeth with circumferential distribution are uniformly distributed at the positions, located on the inner wall of the outer side of the scattering disc, of the box body; and the screening mechanism comprises a collection cover and a screening cover, the screening cover is arranged below thecollection cover, the screening cover is fixedly connected with a spiral screen plate in a spiral rising shape, and a slag collecting groove is formed below the screening cover. Sand blocks and the impacting teeth are impacted and crushed by arranging the scattering disc and the impacting teeth, and subsequent screening is facilitated; and the tapered screening cover and the spiral screen plate in a spiral rising shape are arranged to enable sand material comprising waste slag to roll in a spiral waste slag channel, sufficient screening is achieved, the removal rate of the waste slag is improved, the screening out rate of fine sand is improved, and thus, the screening effect is improved.

Owner:王亮

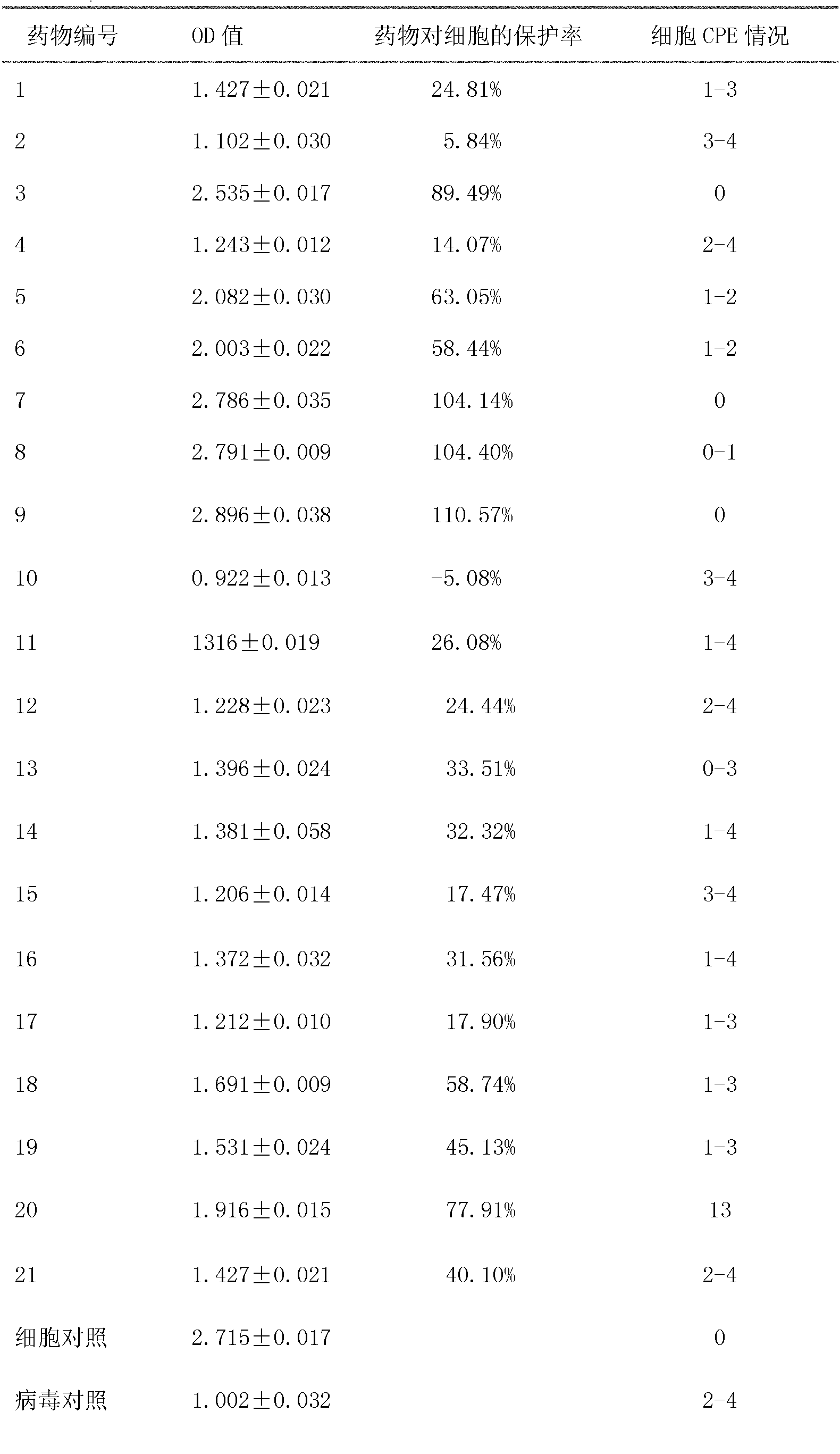

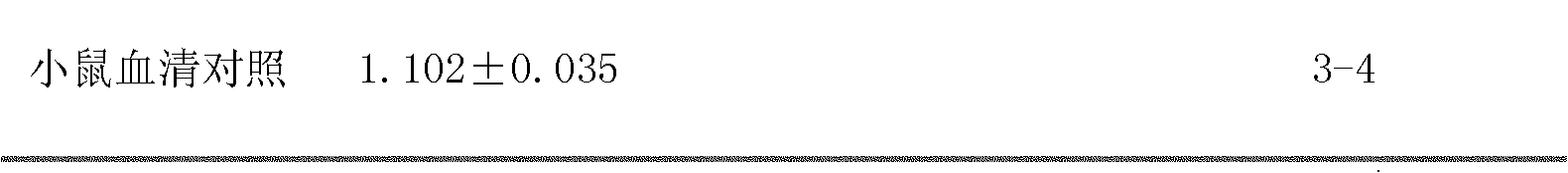

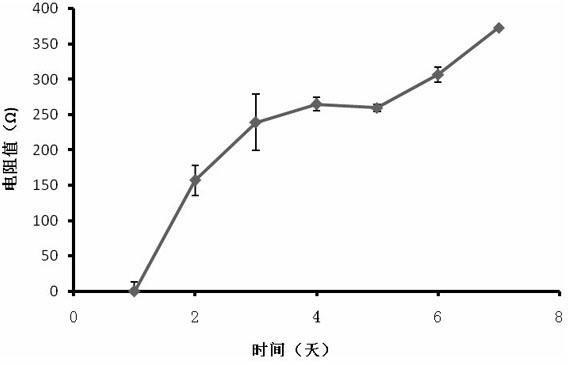

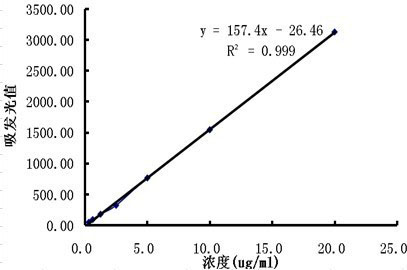

Rapid high-throughput screening model for antiviral drugs

ActiveCN101983724AImprove the effective screening rateImprove screening rateMicrobiological testing/measurementAntiviralsCytopathic effectHigh-Throughput Screening Methods

A establishment method of a novel high-throughput screening model is provided in the invention, which aims to solve the problems of nondeterminacy and incorrespondence exsiting in general in vitro high-throughput screening method. The model provided by the invention furthest simulates animal physiological environment, thus the accuracy of drug screening is increased and the results obtained by the method of in-vitro screening are closer to that of clinical application. The technical scheme of the present invention is as follows: Animal medicated serum is obtained by absorpting and separating drug active ingredients during the process of in vivo circulation of animals, thereby the medicated serum is added to cell culture media or maintenance media after drug is subject to the process of in vivo metabolism of animals. Cell activity is calculated by utilizing micro cell culture method, cytopathic effects (CPE) measurement and MTT method.

Owner:HUNAN DANWEI BILOGICALTECH

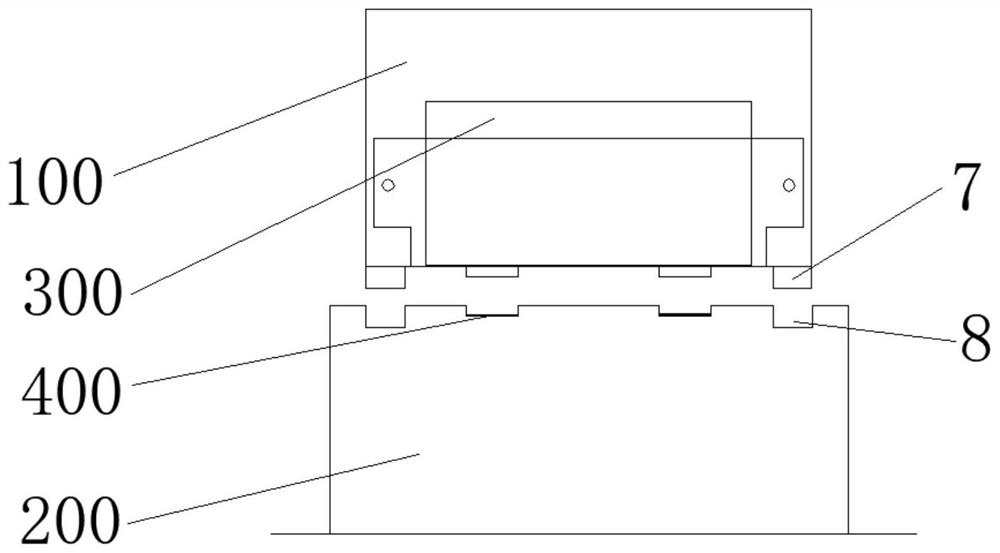

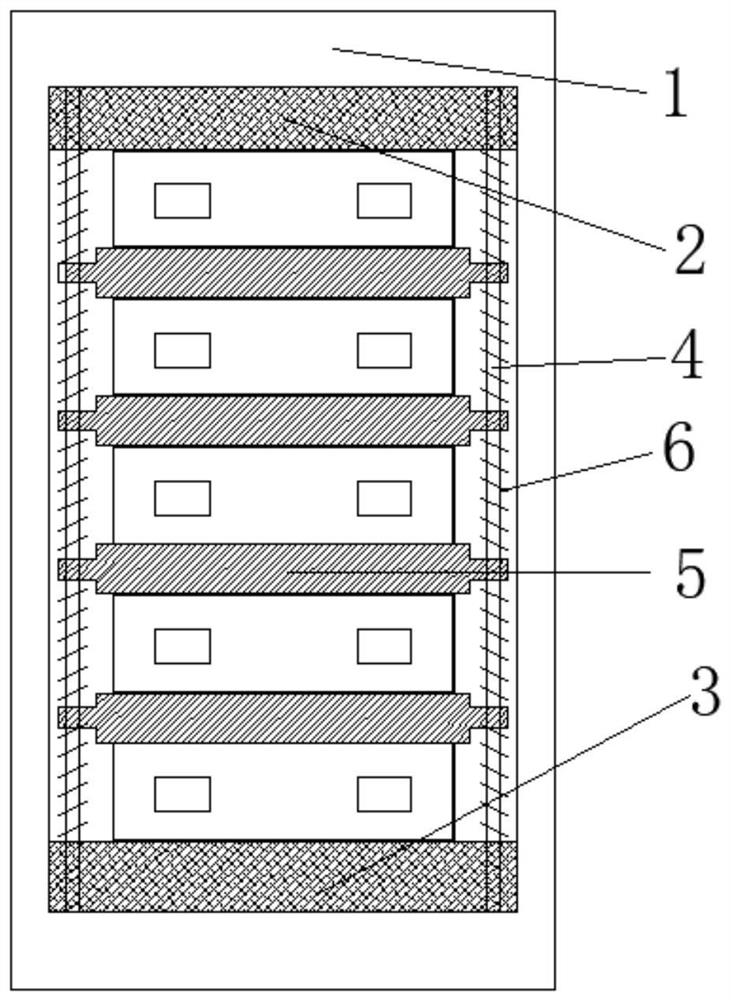

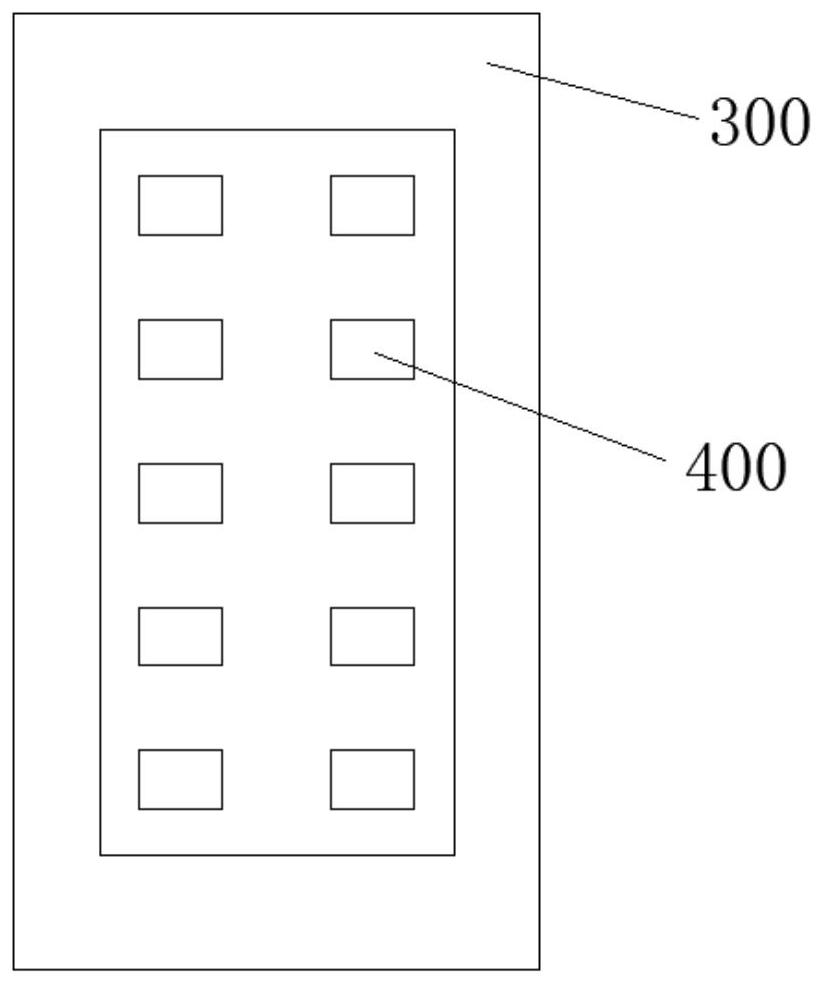

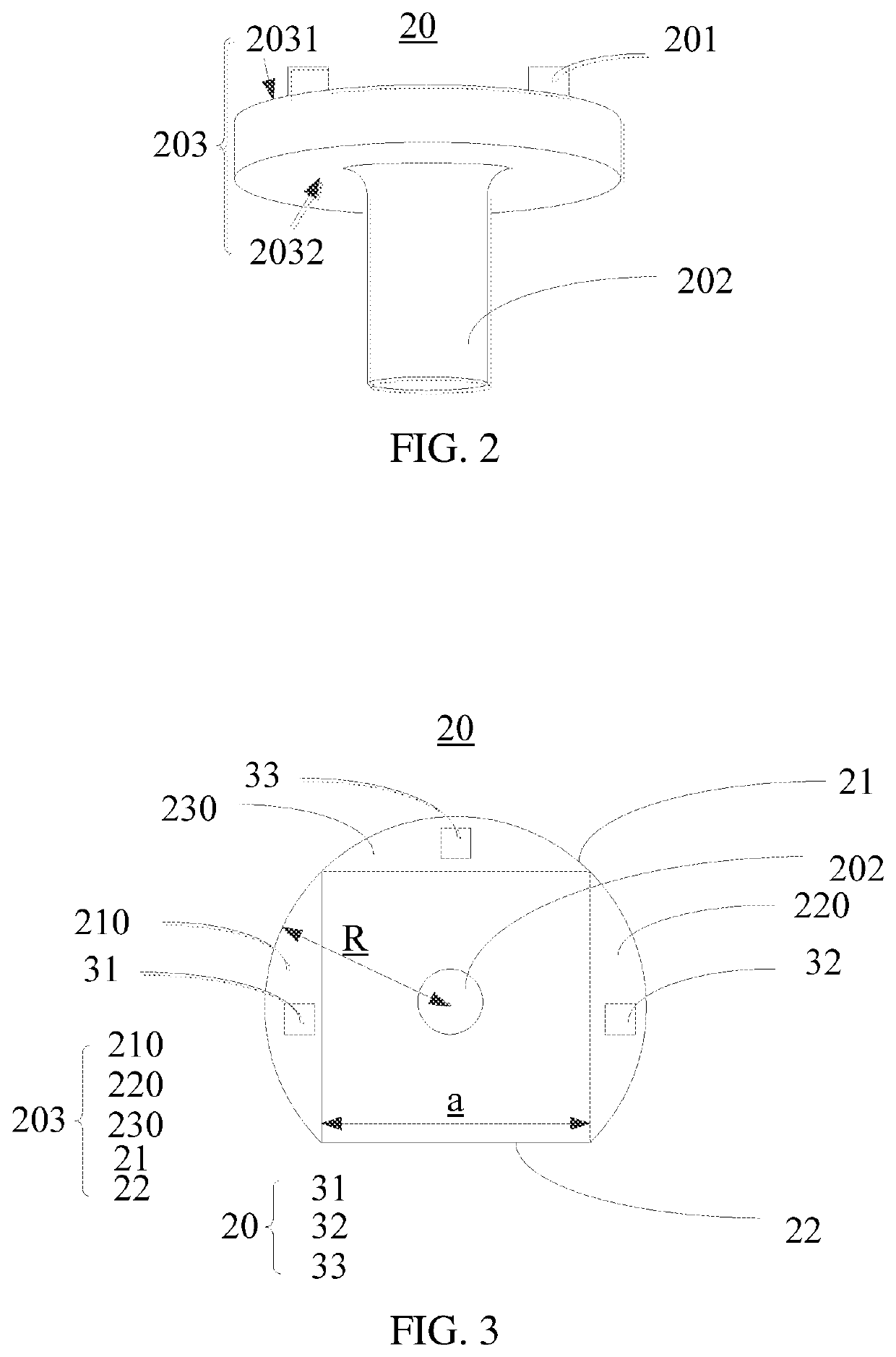

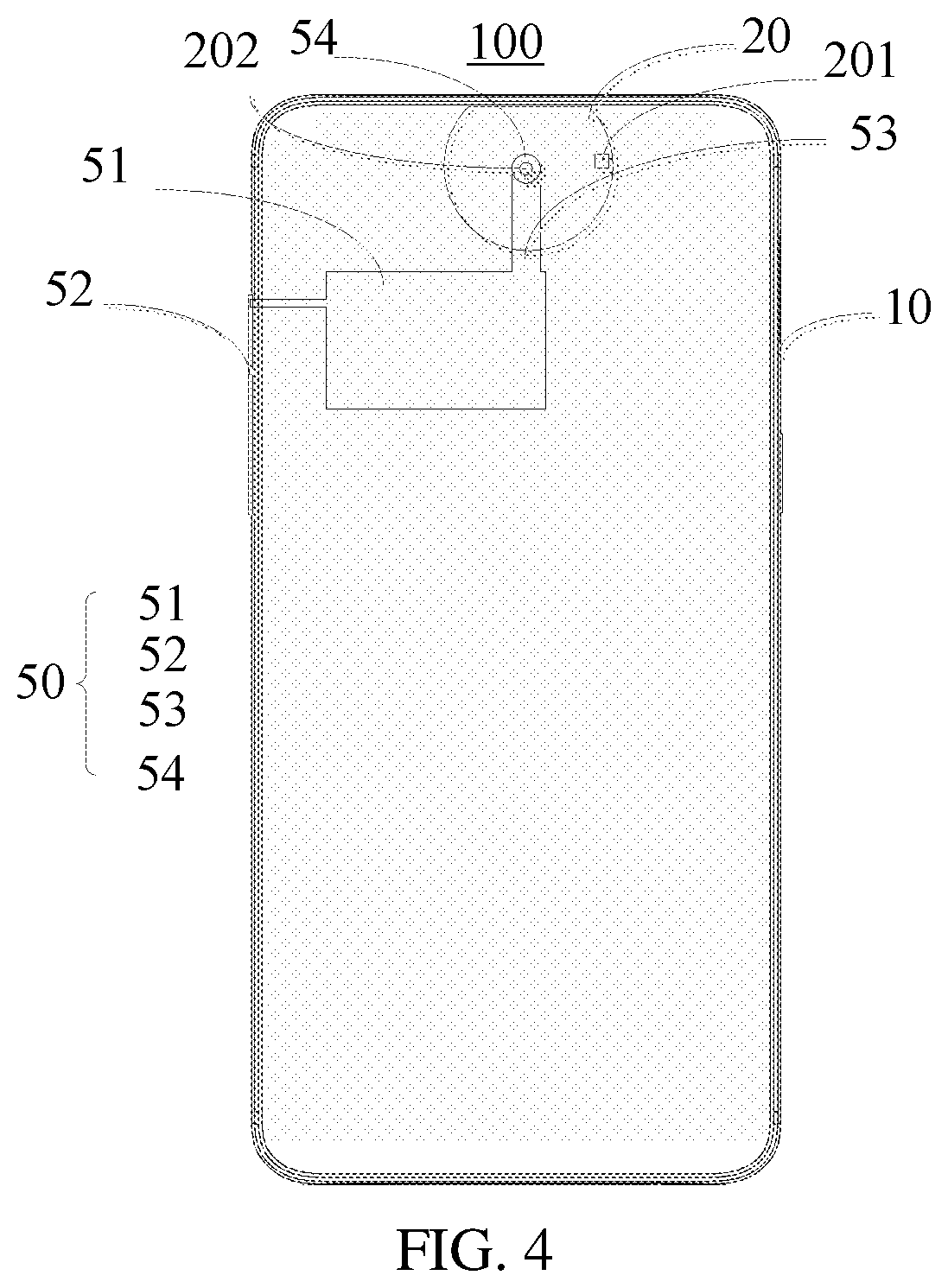

Housing assembly and electronic device

ActiveUS11324132B2Improve screening rateDevices with rotatable cameraDigital data processing detailsStructural engineeringMechanical engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

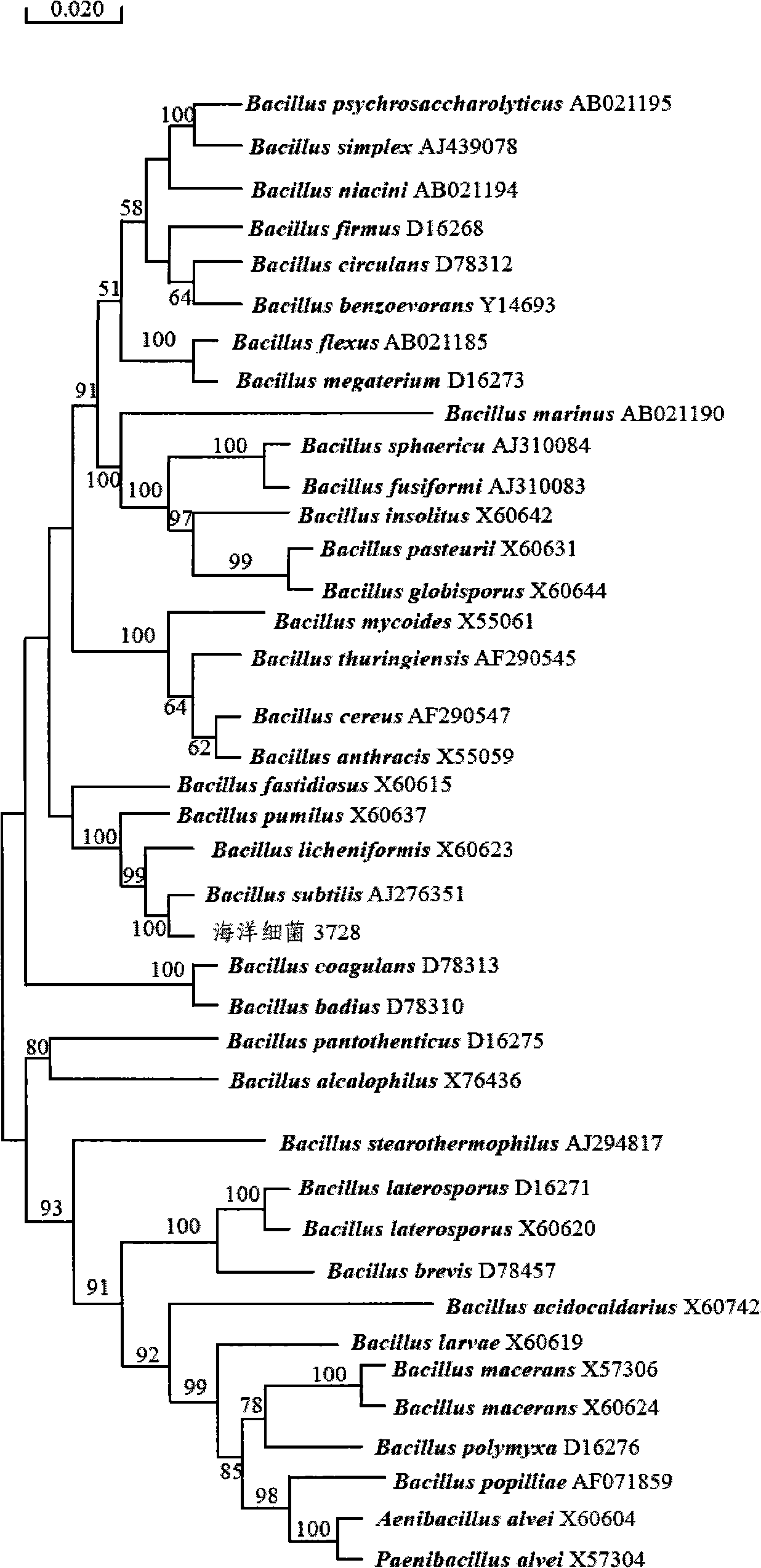

Sea bacillus subtilis and screening method thereof

InactiveCN101298597AThe screening method is simple and easyHigh screening rateBacteriaMicroorganism based processesRhizosphereToxicity

The invention relates to an application technology of marine microorganism and a disease control method for fungi in the rhizosphere soil in Chinese fir plantation, in particular to a type of marine bacillus subtilis and a screening method thereof. The microorganism refers to the bacillus subtilis 3728C, the number for preservation of which is CCTCC No. M207052. The method combines a screening model with mutually antagonized plates and directional screening. By the screening method, strains of the marine bacillus subtilis for controlling the harmful fungi in the rhizosphere soil in Chinese fir plantation are used as one of the major components to develop a type of disease-preventing and toxicity-decreasing ecological agent, which solves the problems of continuous planting of Chinese firs. The disease-preventing and toxicity-decreasing ecological agent is a type of microbial preparation with high efficiency, safe and free of toxicity and residues, which can enhance the development of the green ecosystem of the Chinese fir plantation. With satisfactory application and test results in Hunan Huitong Chinese Fir Plantation, the disease-preventing and toxicity-decreasing ecological agent has bright development prospects.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Ground flour wheat husk screening device

InactiveCN112317311AGuaranteed Screening VolumeImprove screening rateSievingScreeningAgricultural scienceAgricultural engineering

The invention provides a ground flour wheat husk screening device, and belongs to the technical field of rice and flour machinery. The problems that, during screening of ground flour, wheat bran, grains and other impurities remain in the flour, a screen is blocked and consequently the screening efficiency is affected is solved. The ground flour wheat husk screening device comprises a shell with openings formed in the upper end face and the lower end face, and a working space is defined in the shell; a discharging device for controlling flour to intermittently enter the working space for screening is arranged at the opening in the upper end of the shell; and a screening device for screening wheat husks remaining in the flour is mounted in the working space. The ground flour wheat husk screening device is more convenient in use and higher in efficiency.

Owner:HANGZHOU QIZHI ENVIRONMENTAL PROTECTION TECH CO LTD

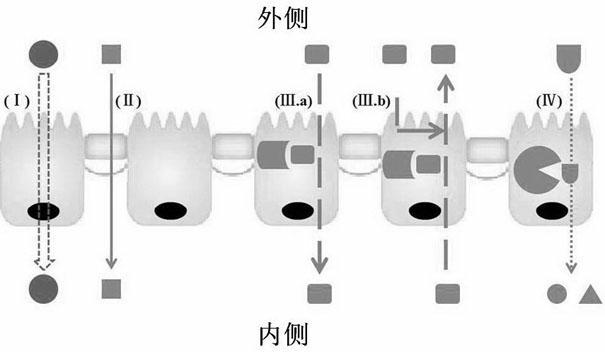

Method for building drug-oral-taking absorption forecasting and screening models

InactiveCN102533927ADetermine tightnessDetermine integrityMicrobiological testing/measurementHigh-Throughput Screening MethodsBiochemical engineering

The invention relates to a method for building drug-oral-taking absorption forecasting and screening models. On the basis of a 21-day Caco-2 cell model built in early days forecasting compound absorption, a forecasting method of a 7-day Caco-2 cell model is further built, optimized and verified, and the testing index and the cell morphology of the model are optimized and verified, so that a most fitting Caco-2 cell model with drug-oral-taking absorption and high throughput screening is obtained. According to the method, the culture time of the cell model can be greatly shortened, so that the possibility of appearing pollution in the 21-day long-term culture of cells can be greatly reduced, the labor strength is reduced, and the oral-taking absorption forecasting and screening of a lot of lead compounds existing today are responded.

Owner:SUN YAT SEN UNIV

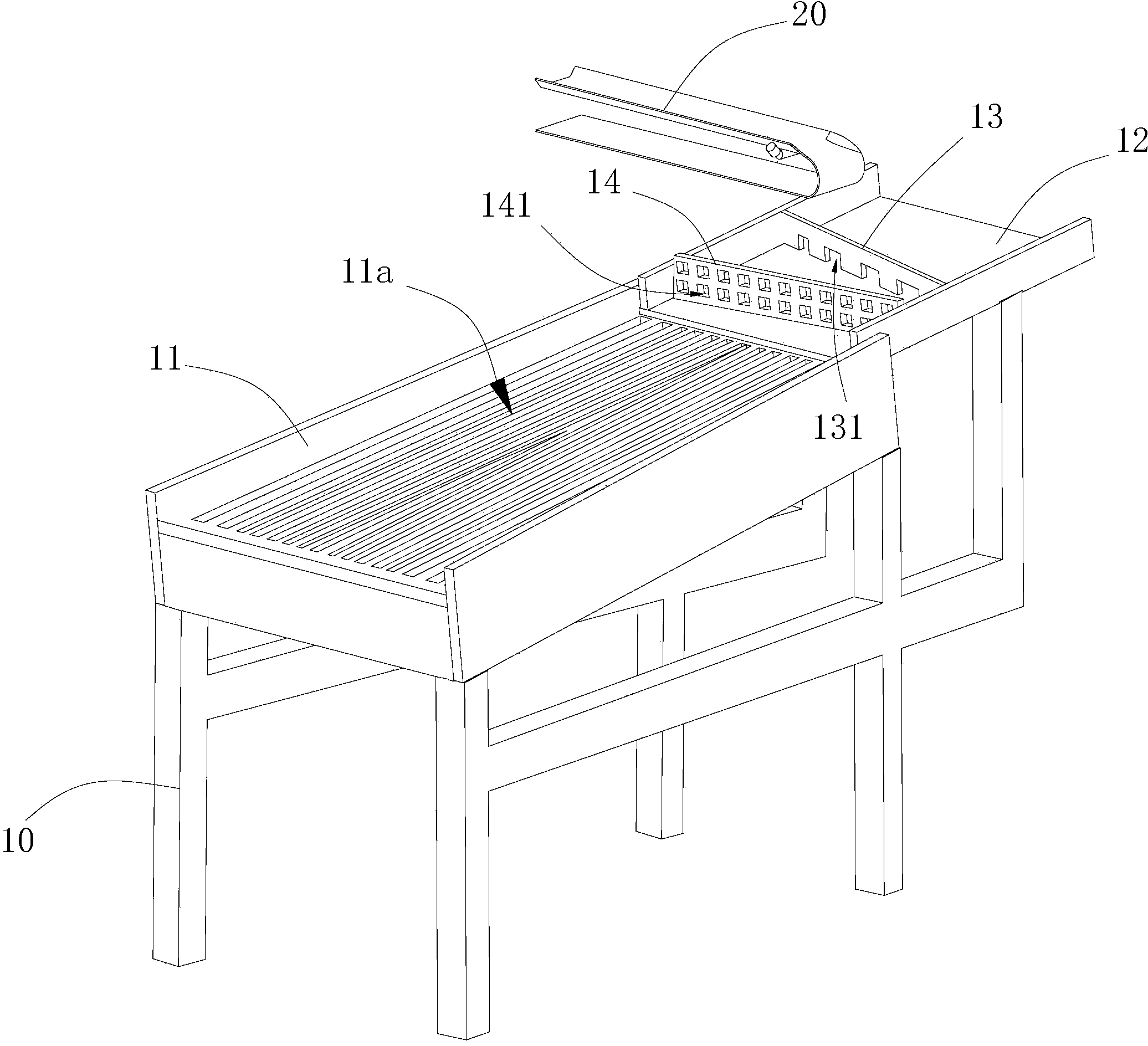

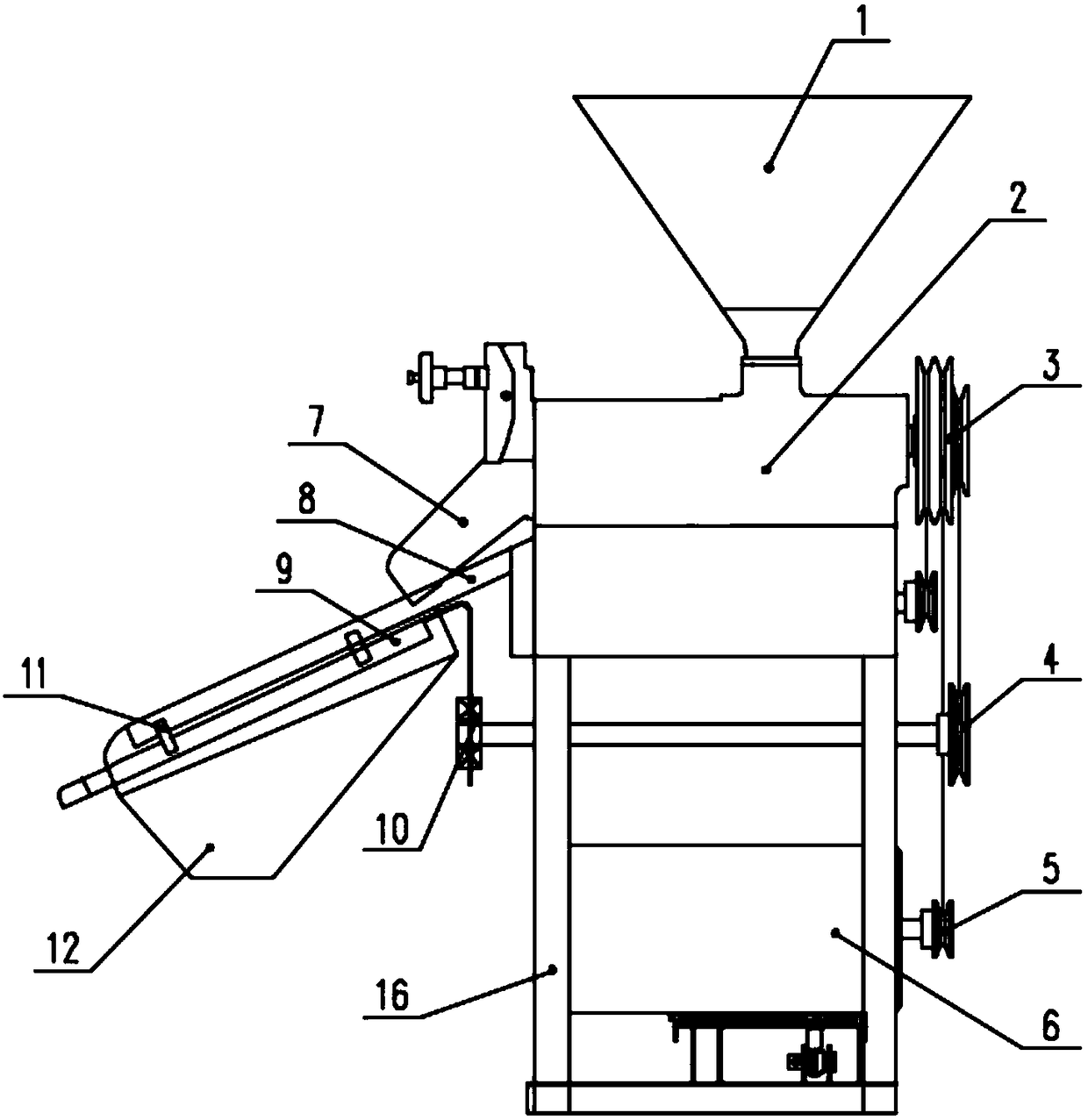

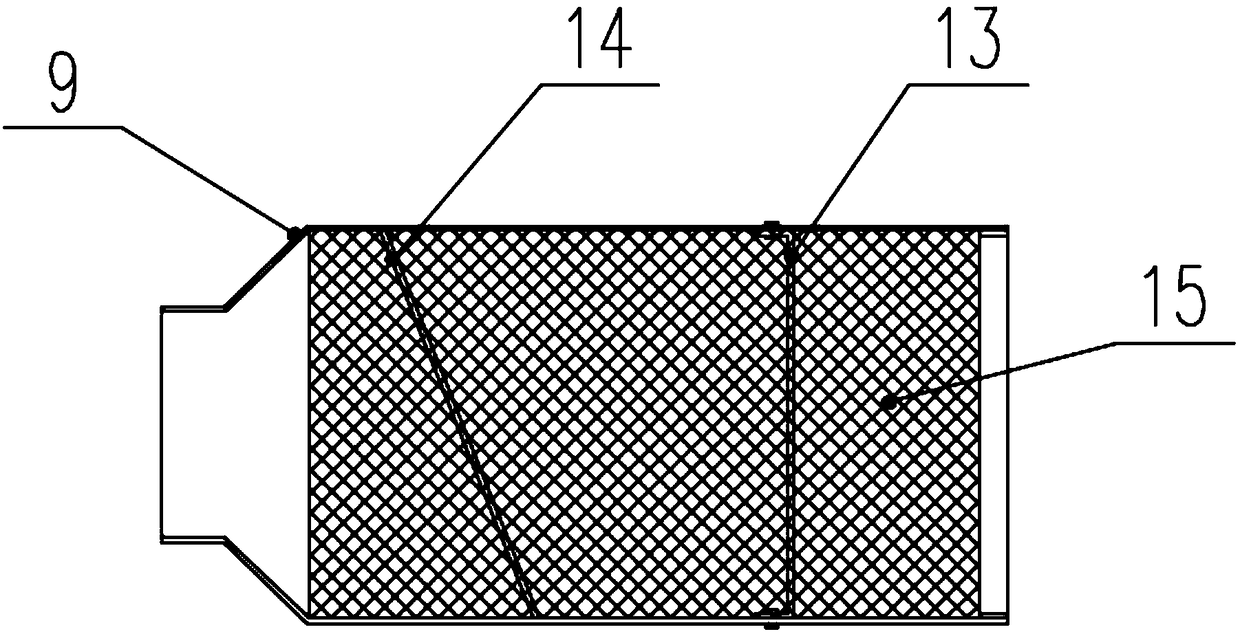

Small rice machine with efficient screening device

InactiveCN108745453AIncrease drop travelImprove screening rateSievingScreeningAgricultural engineering

The invention discloses a small rice machine with an efficient screening device. The small rice machine comprises a rice machine body, and is characterized in that the rice machine body is arranged ona rice machine frame, the upper end of the rice machine body is provided with a rice feeding hopper, the left side of the rice machine body is provided with a rice outlet, a reciprocating screen is arranged at the lower end of the rice outlet, a reciprocating vibrating mechanism support is arranged at the upper end of the reciprocating screen, the reciprocating screen and the reciprocating vibrating mechanism support are connected through a connecting piece, the connecting piece is a swingable connecting piece, a screen plate is arranged on the reciprocating screen, a rice flow speed adjusting plate and a rice flow speed adjusting fixing plate are arranged on the reciprocating screen, the rice flow speed adjusting plate is movably hinged to the reciprocating screen, the lower end of the reciprocating screen is provided with a broken rice and broken stone receiving hopper, and the lower end of the reciprocating screen is connected with an eccentric wheel. According to the small rice machine with the efficient screening device, the rice rolls and falls in a straight line free falling body mode originally and is turned to roll and fall in zigzag-shape free falling body mode presently, so that the falling stroke of the rice is increased, moreover, the rice can turn over while rolling downwards under the action of swinging, so that the screening rate of the broken rice and the broken stone is greatly improved.

Owner:贺啸雄

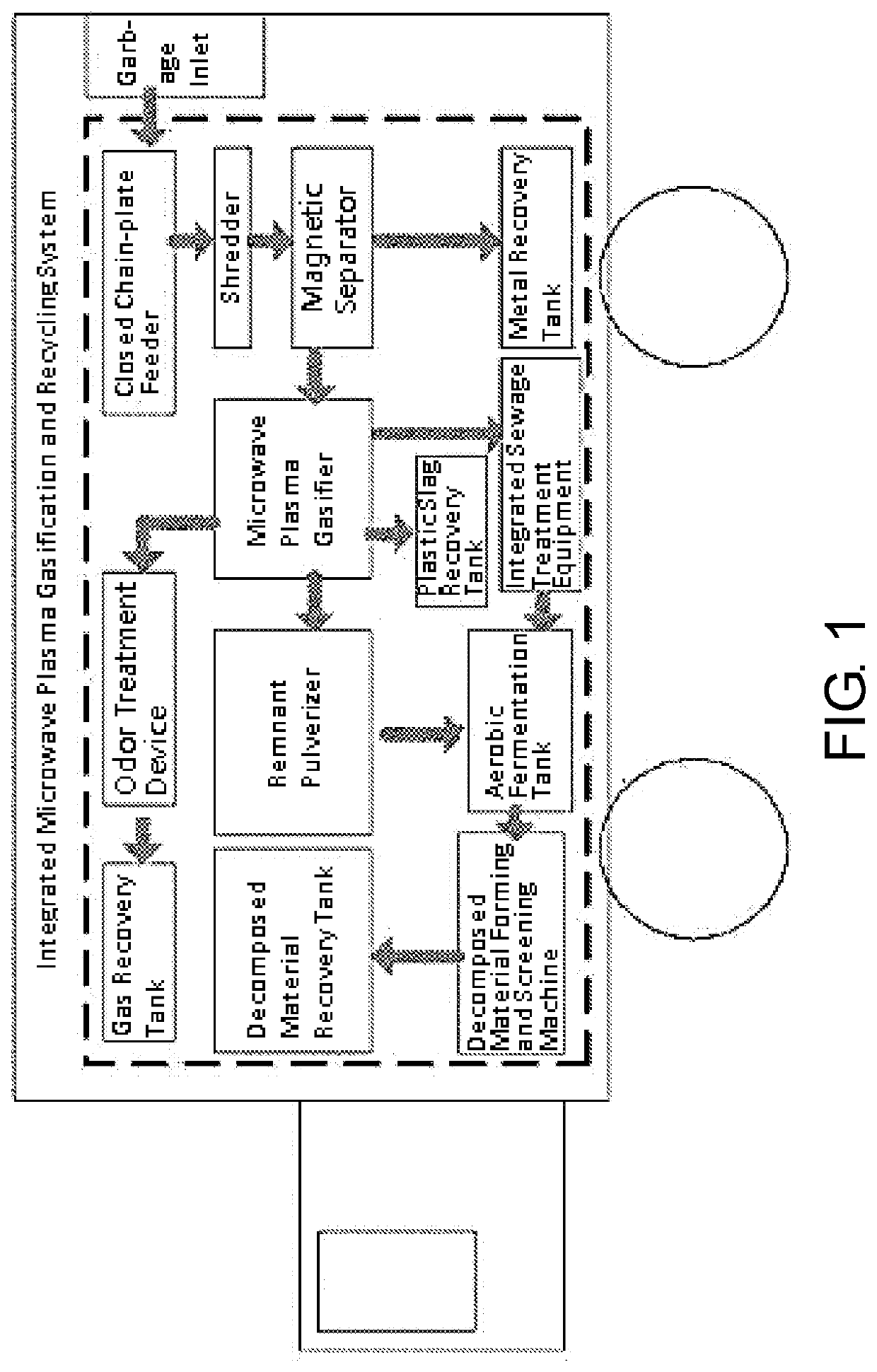

Microwave plasma gasification and recycle integrated system for domestic garbage

ActiveUS20200238350A1Good effectReduce difficultySolid waste disposalMedical waste disposalThermodynamicsMagnetic separator

A microwave plasma gasification and recycle integrated system for domestic garbage. The system is fixed in a garbage truck compartment with a garbage inlet, and includes a closed chain-plate type feeder, a shredding machine, and a closed magnetic separator which are connected in sequence. The magnetic separator is further separately connected to a microwave plasma gasification furnace and a metal recycle tank. The microwave plasma gasification furnace is further separately connected to a stink processor, a plastic residue recycle tank, an integrated sewage treatment device, and a residue smashing machine. The stink processor is connected to a gas recycle tank. Both the residue smashing machine and the integrated sewage treatment device are connected to an aerobic fermentation tank. The aerobic fermentation tank is connected to a decomposed material recycle tank by means of a decomposed material forming and screening machine.

Owner:TSINGHUA UNIV

Sweet watermelon seed screening machine

InactiveCN106000860AImprove screening rateSimple structureSievingScreeningAgricultural engineeringDrive motor

The invention discloses a sweet watermelon seed screening machine, which comprises a drive motor, a first pulley is installed on the output shaft of the drive motor, the first pulley is connected with a second pulley through a transmission belt, and the second pulley is installed on the rotating shaft At one end, the end of the rotating shaft away from the second pulley passes through the side wall of the box body and is connected to one end of the screening tank. The end of the screening tank away from the second pulley has a through hole, and a bracket is installed in the through hole. The bracket and the fixing plate, The fixed plate is connected with the box body through the rotating shaft. There are screening holes on the side wall of the screening tank. The feed pipe is installed on the side wall of the box body at one end away from the second pulley. The sweet watermelon seed sorting machine has a simple structure and a high screening rate, and an electric heating tube is arranged on it, which can dry seeds. The utility model has the advantages of simple structure, low manufacturing cost, convenient use and easy popularization.

Owner:安徽富牧通生物科技有限公司

Sand screening device for building engineering

InactiveCN111744764AAchieve dischargeAvoid wastingSievingScreeningGear wheelArchitectural engineering

The invention discloses a sand screening device for building engineering. The sand screening device for building engineering comprises a box body; the box body is internally provided with a screen cylinder, a left side plate of the screen cylinder is provided with a slag discharge opening, the outer side of the screen cylinder is sleeved with a swinging frame, and the left side of the swinging frame is connected with an up-and-down traction mechanism. According to the sand screening device for building engineering, through the screen cylinder provided with the slag discharge opening, the swinging frame, a fixed hinged seat, a rotating shaft, a rolling gear, a semicircular rack plate and the up-and-down traction mechanism, screening of up-and-down swinging and rotating composite actions ofthe screen cylinder is realized, waste residues are conveniently separated and discharged, and screening efficiency is improved; through the arrangement of a synchronous feeding mechanism, the periodic quantitative feeding of coarse sand is realized, the compound screening action of the screen cylinder is matched, the screening effect is guaranteed, and the sand waste is avoided; and through the arrangement of a spray pipe and a spray head opposite to the slag discharge opening, sand particles adhering to the surface of the waste residues are dried and sprayed, meanwhile, the sand particles are prevented from being discharged from the slag discharge opening, and the screening rate of the sand particles is improved.

Owner:庄锦辉

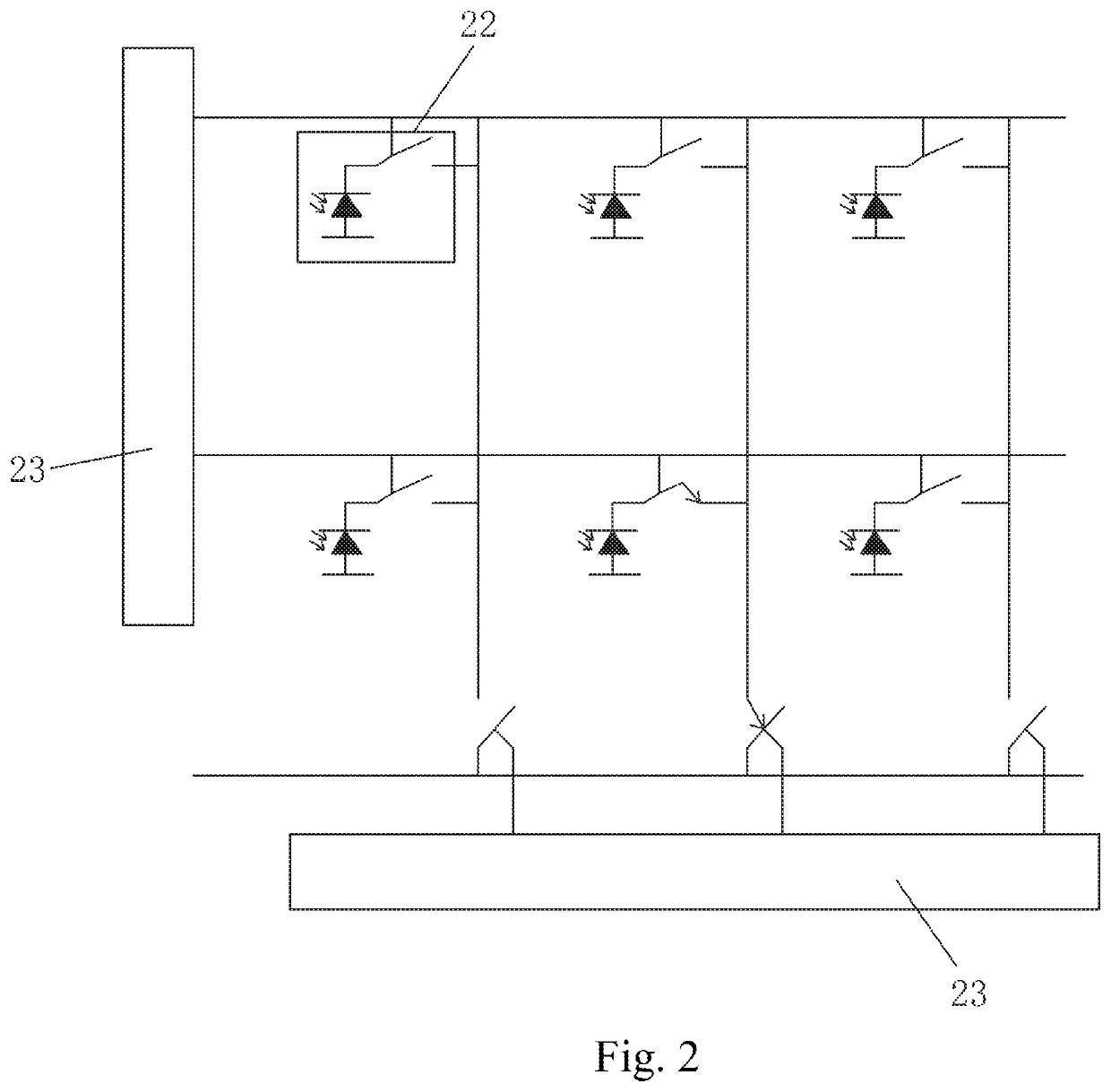

Full screen module and smartphone

ActiveUS10712595B2Increase the screen ratioImprove screening rateStatic indicating devicesPrinted circuit aspectsFlexible circuitsData signal

The present disclosure relates to a full screen module and a smartphone. The full screen module includes a display panel, a driving chip electrically connected to the display panel, a first flexible circuit board electrically connected to the driving chip, a photoreceptor panel configured on the display panel, and a second flexible circuit board electrically connected to the photoreceptor panel and the first flexible circuit board. The photoreceptor panel is configured to receive light signals, to transform the light signals into digital signals, and to transmit the digital signals to the driving chip. The driving chip is configured to transform the digital signals into data signals, and to drive the display panel to display images. The photoreceptor panel may replace the front camera module of the conventional smartphone. As such, the screen ration of the smartphone may be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com