Sand screening device for building engineering

A technology for construction engineering and sand screening, applied in the field of sand screening devices for construction engineering, can solve the problems of easy clogging of sieve plates, affecting operation efficiency, and troublesome cleaning of waste residues, so as to improve the screening rate, avoid waste, and ensure the screening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

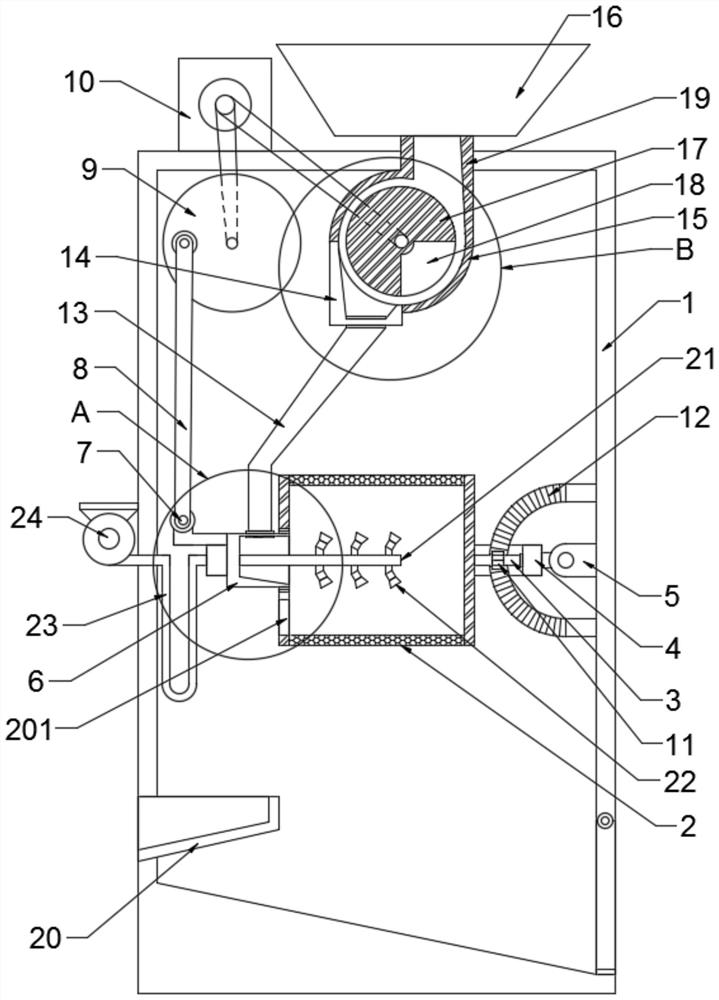

[0020] see Figure 1-4 , in the embodiment of the present invention, a sand screening device for construction engineering includes a box body 1; a screen cylinder 2 is arranged in the box body 1, and the screen cylinder 2 is a hollow cylindrical cylinder arranged horizontally, and the circumference surface of the screen cylinder 2 is arranged There are evenly distributed sieve holes, and the left side plate of the screen cylinder 2 is provided with a slag discharge port 201; the outer side of the screen cylinder 2 is provided with a swing frame 4, and the left side plate of the screen cylinder 2 is penetrated by a feed pipe 6, and the feed pipe 6 The tube 6 is rotationally connected with the left side plate of the screen drum 2 through a bearing, and the feed pipe 6 is fixedly connected with the inner wall of the swing frame 4; the right side of the screen drum 2 is fixedly connected with a rotating shaft 3, and the rotating shaft 3 is connected to the swing frame 4 through a b...

Embodiment 2

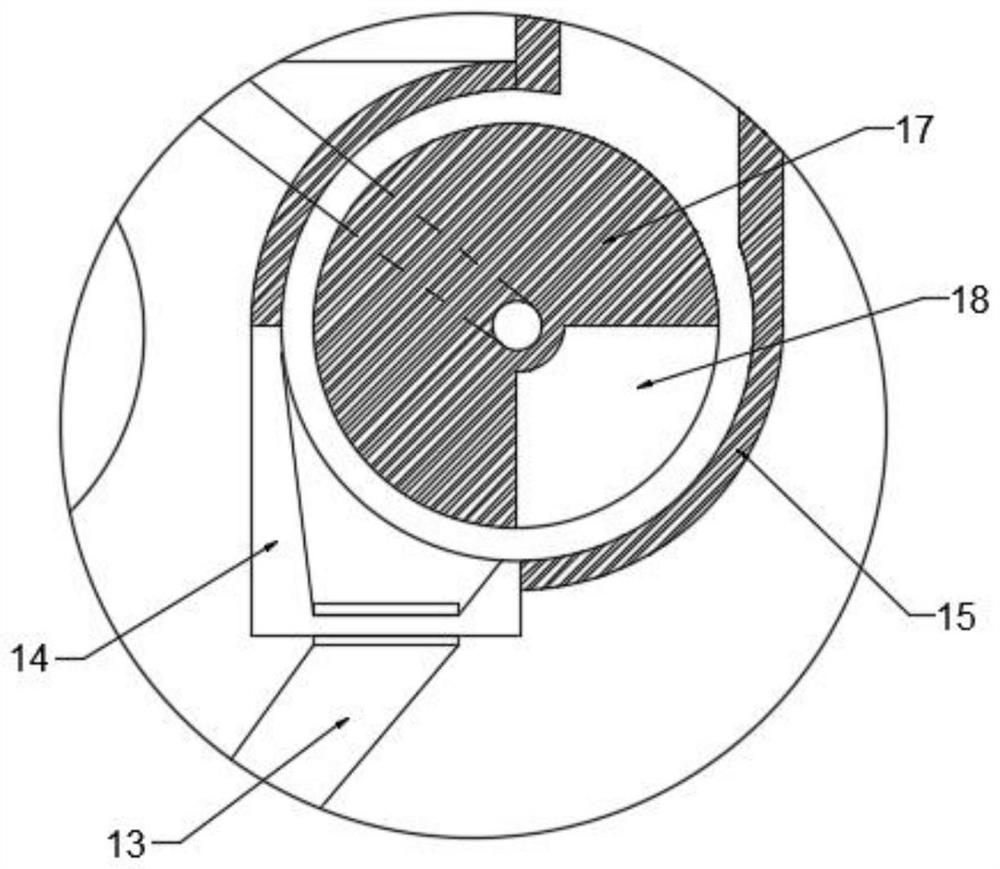

[0023] The difference between this embodiment and Embodiment 1 is: in order to adapt to the swing action of the screen cylinder 2, to realize the feeding of coarse sand raw materials, that is, to complete the feeding during the upward swing of the screen cylinder 2 from the horizontal position; The synchronous feeding mechanism, the synchronous feeding mechanism includes the lower material cylinder 15, the lower material cylinder 15 is a hollow cylinder arranged vertically, the lower material cylinder 15 is nested with the lower material roller 17, the lower material roller 17 is provided with a fan-shaped groove 18, and the fan-shaped groove The radian of 18 is 0.5π, and the unloading roller 17 is connected with the unloading barrel 5 through the rotation shaft and extends to the outside of the casing 1, and the revolving shaft of the unloading roll 17 is connected to the output shaft of the driving motor 10 through a transmission belt; the unloading The upper part of the barr...

Embodiment 3

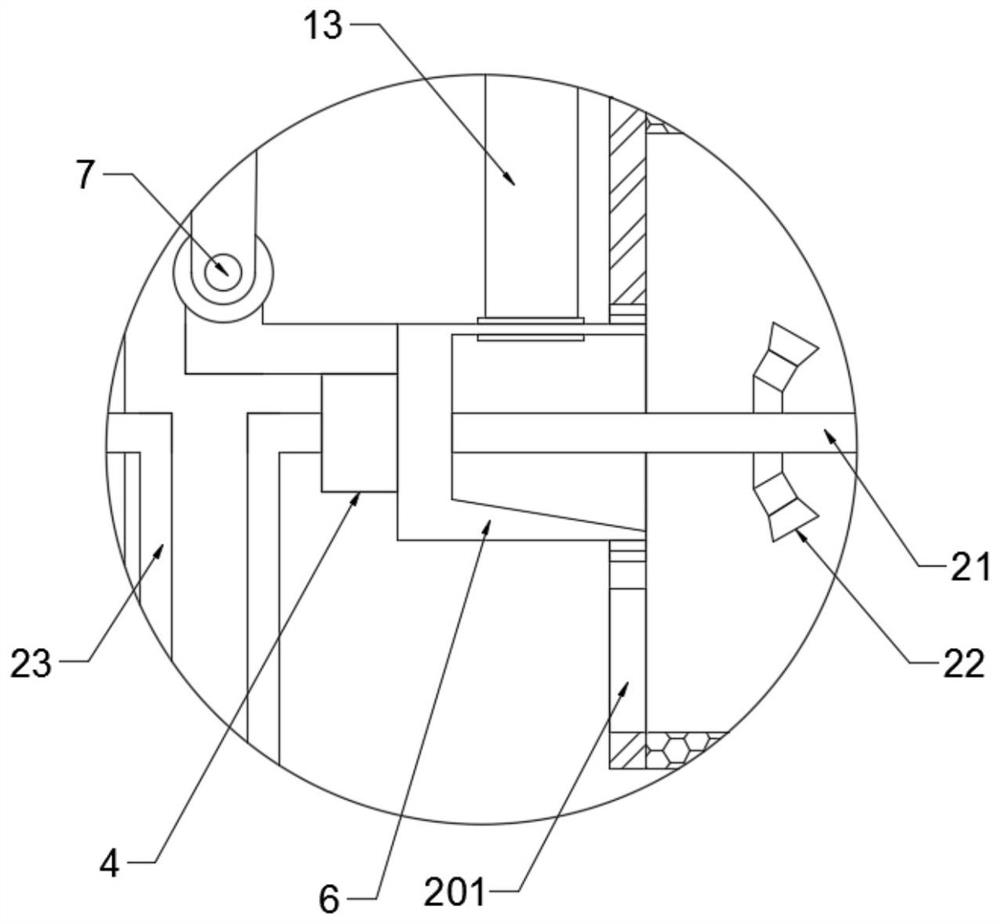

[0025] The difference between this embodiment and embodiment 2 is: in order to improve the screening effect and avoid more sand particles sticking to waste residues such as stones; Evenly distributed nozzles 22, the nozzles 22 uniformly face the opposite direction of the slag discharge port; the nozzle 21 runs through the feed pipe 6 and the swing frame 4 and is fixedly connected with the swing frame 4, and the nozzle 21 is connected to a hot air blower through the ventilation pipe 23 24. The hot air blower 24 is fixedly connected to the outer wall of the box body 1; specifically, the hot air generated by the hot air blower enters the nozzle pipe 21 through the ventilation pipe 23 and is sprayed out from the nozzle 22 to spray the sieve holes of the sieve cylinder 2 to avoid the sieve At the same time, dry and spray the surface of the falling stone waste to make the sticky sand separate from the stone waste, and prevent a small amount of sand from rolling out of the slag outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com