Patents

Literature

200results about How to "Guaranteed screening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

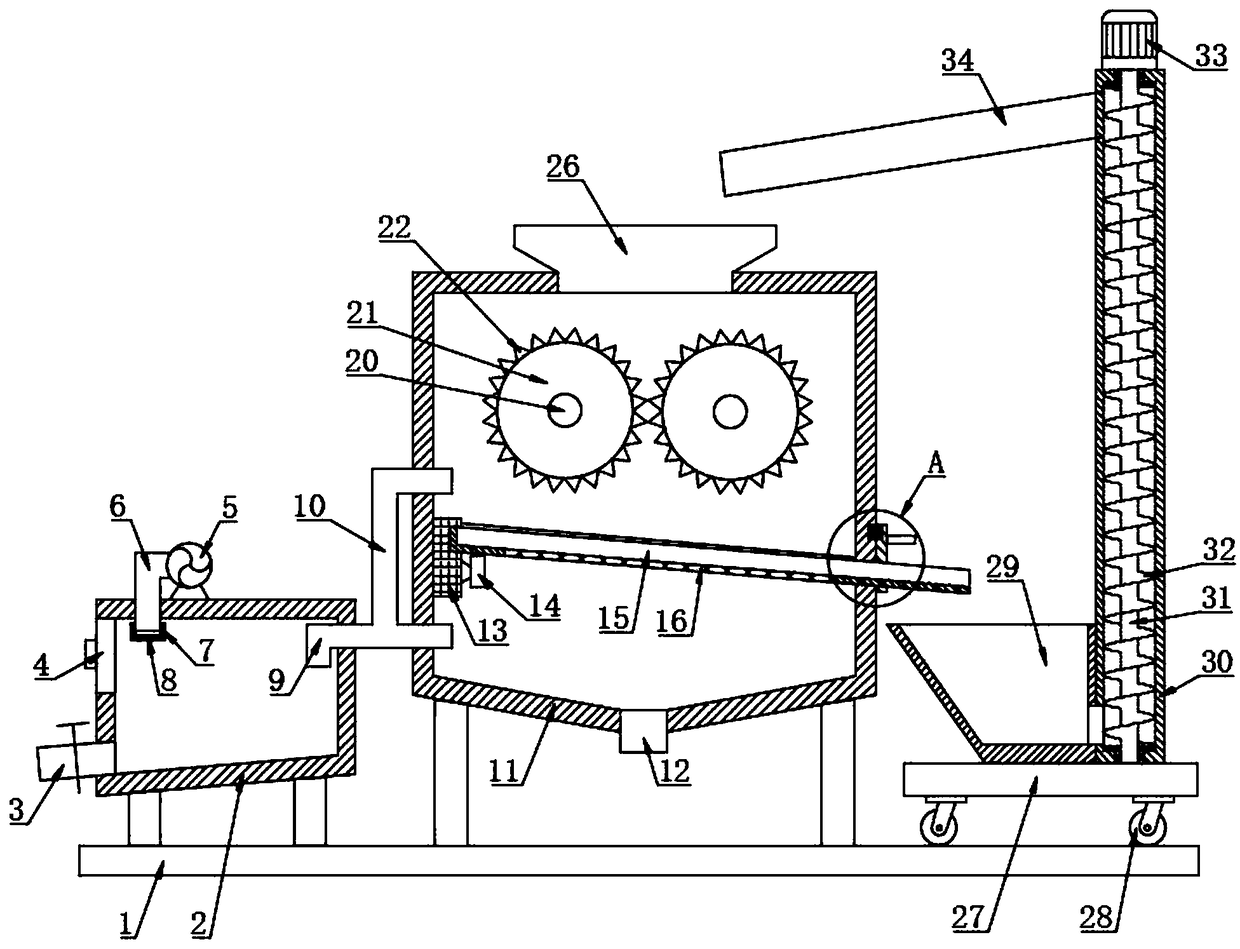

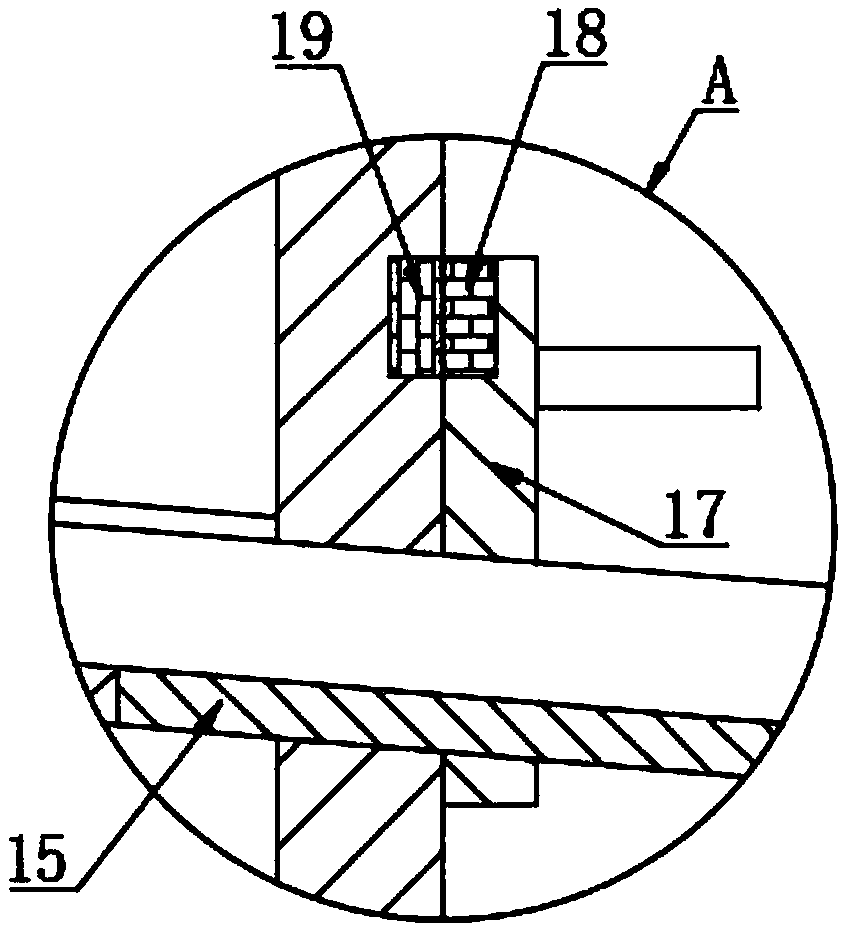

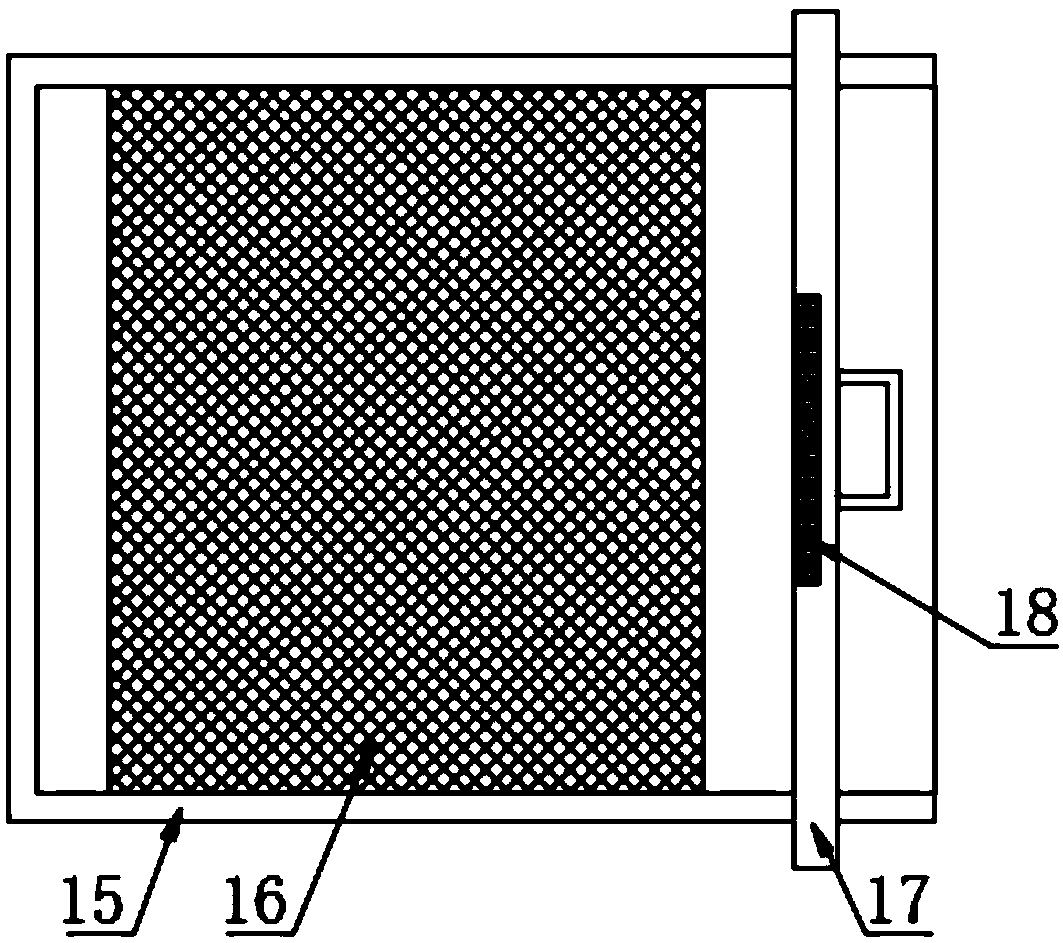

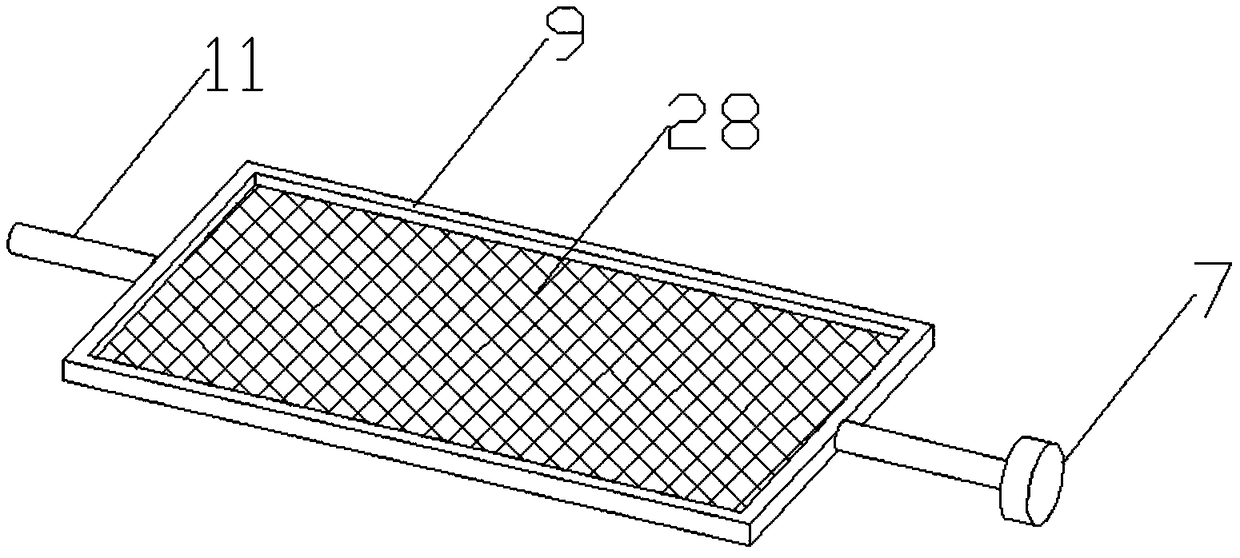

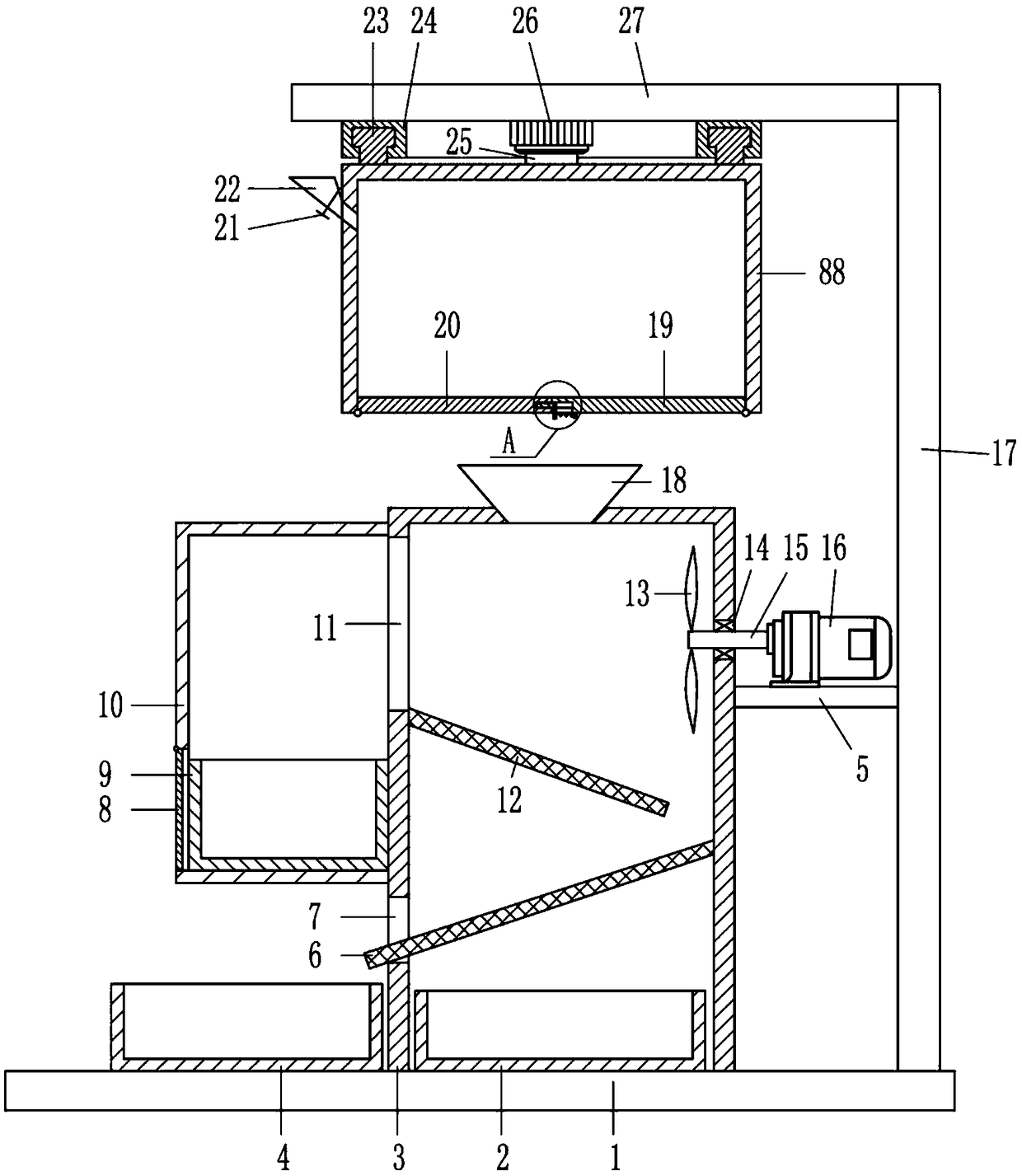

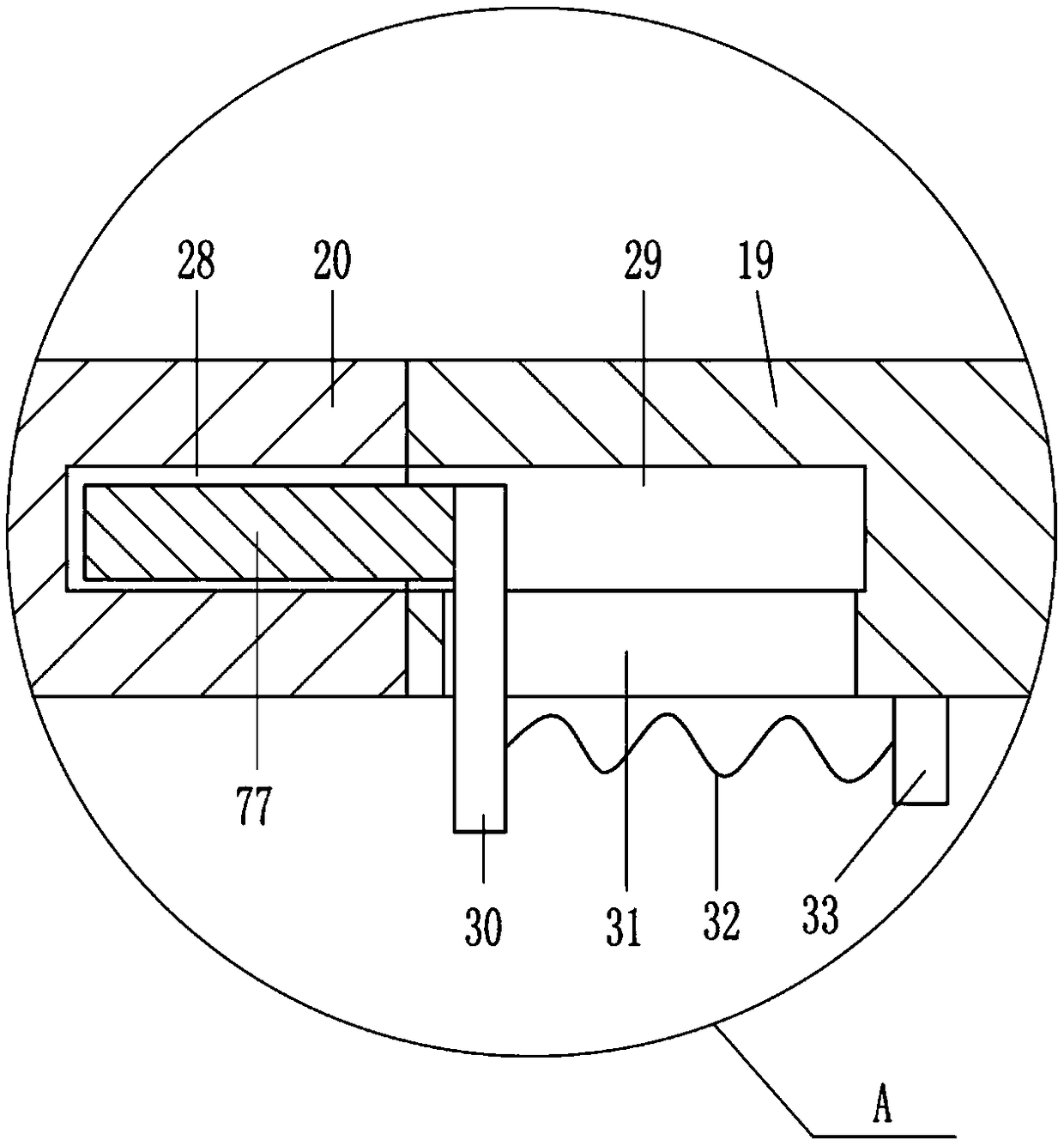

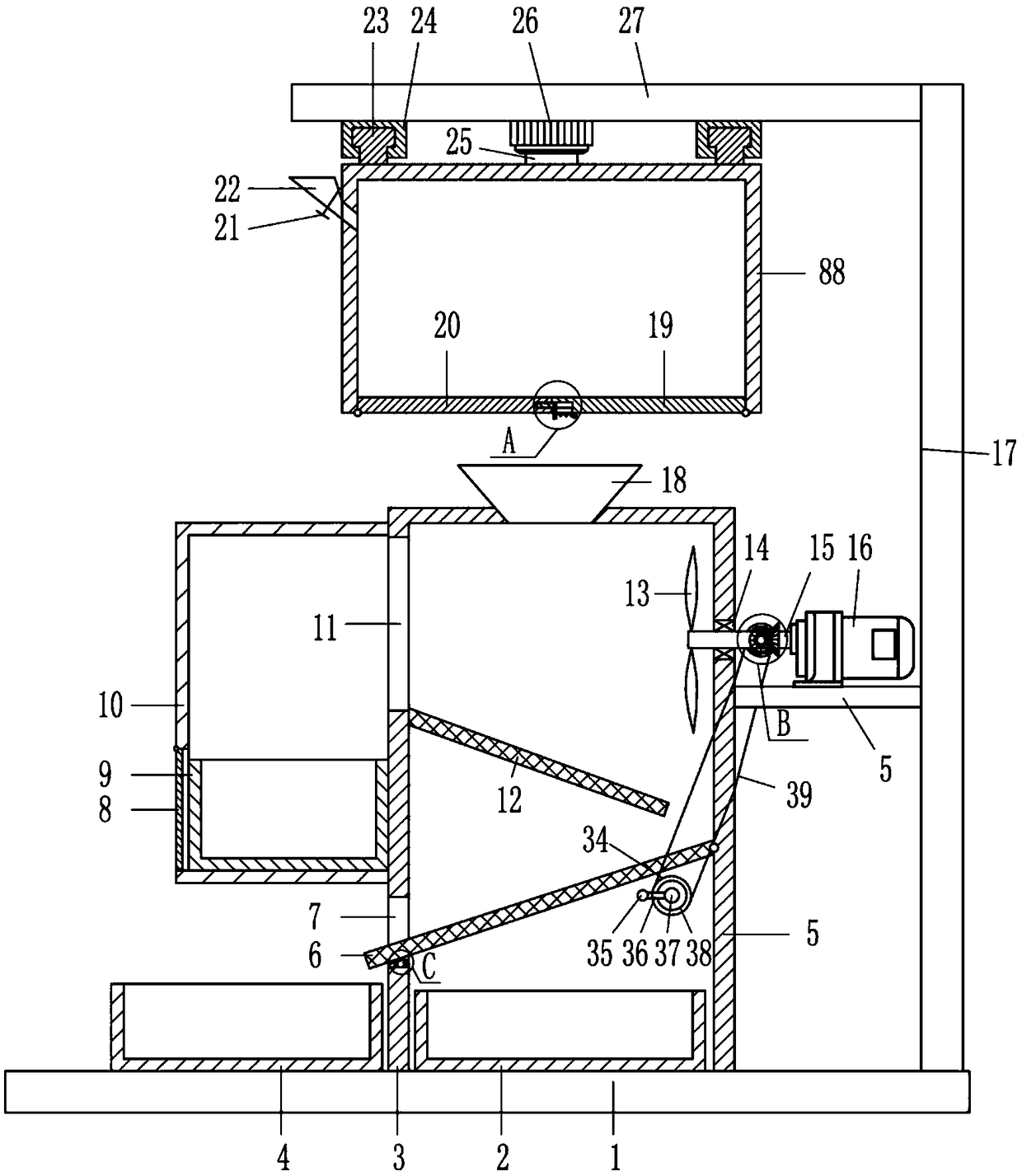

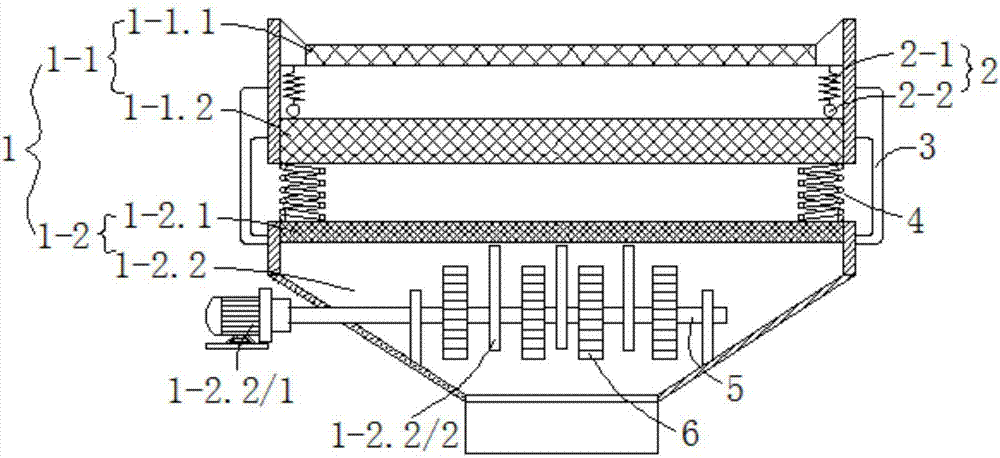

Environmentally-friendly construction waste crushing device with dedusting function

InactiveCN108772132ASmall particlesEasy to cleanDirt cleaningGrain treatmentsArchitectural engineeringLeft wall

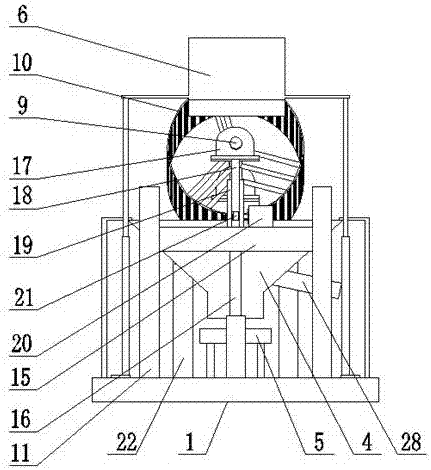

The invention discloses an environmentally-friendly construction waste crushing device with a dedusting function. The device comprises a pedestal, a working box is fixedly arranged at the top of the pedestal through a bracket, a left first rotating shaft and a right first rotating shaft are arranged in the top of the working box in an anteroposterior manner, the left first rotating shaft and the right first rotating shaft are respectively rotatably connected with the front wall and the rear wall of the working box, and a crushing roller is fixedly mounted on a part, positioned in the working box, of each of the left first rotating shaft and the right first rotating shaft; the internal left wall of the working box is fixedly connected with an elastic plate, a drawer is arranged at the rightside of the elastic plate, and the drawer is downwards obliquely arranged from the inside to the outside; and the bottom of the drawer is provided with an opening, and the opening is fixedly connected with a screen. Construction wastes are crushed by the relative rotation of the crushing rollers, so the crushing efficiency is high; the construction wastes fall into the drawer after being crushed,and the construction wastes are screened through the screen, so it is ensured that the construction wastes have small enough particles and can be easily used lately; and the elastic plate is driven by a vibration motor to vibrate in order to drive the drawer and the screen to vibrate, so screening is accelerated.

Owner:HEFEI CAREER TECHNICAL COLLEGE

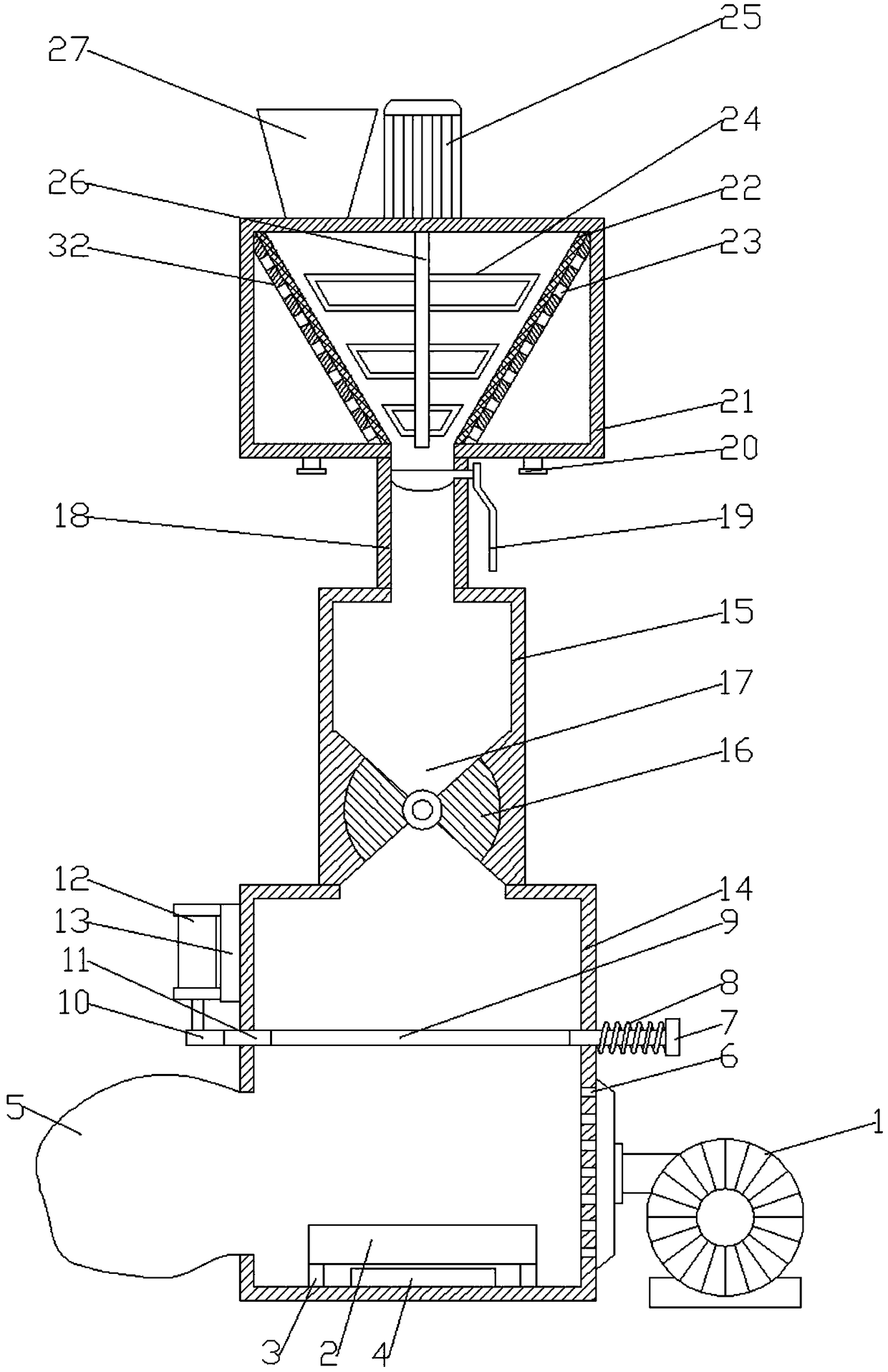

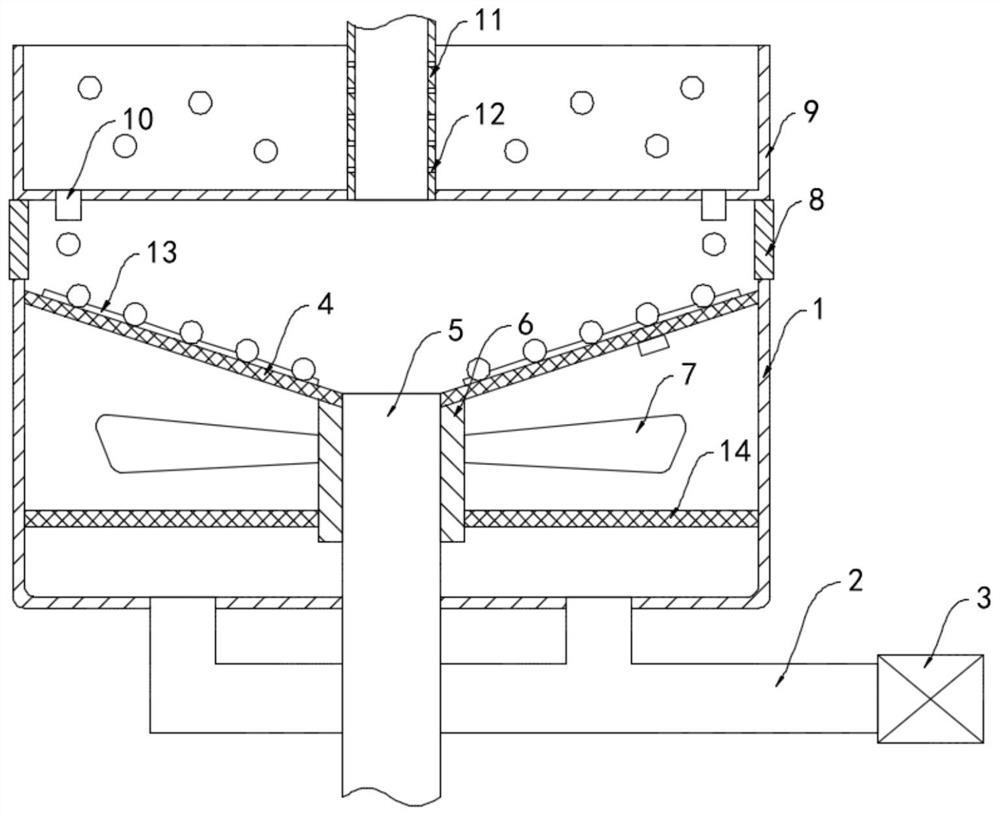

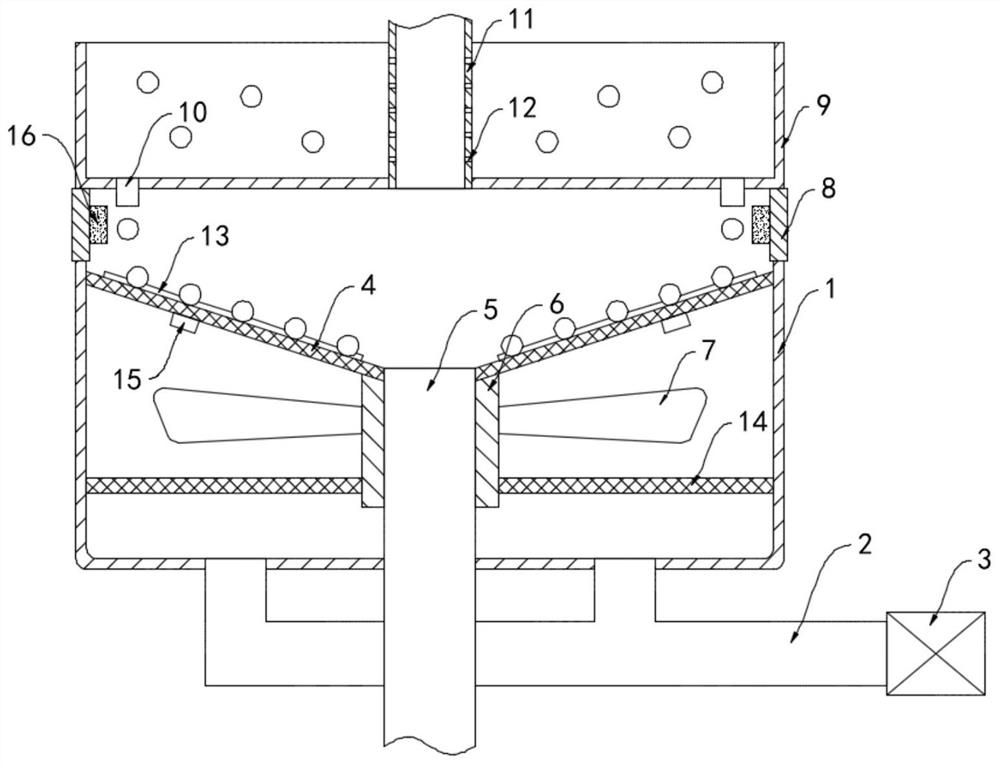

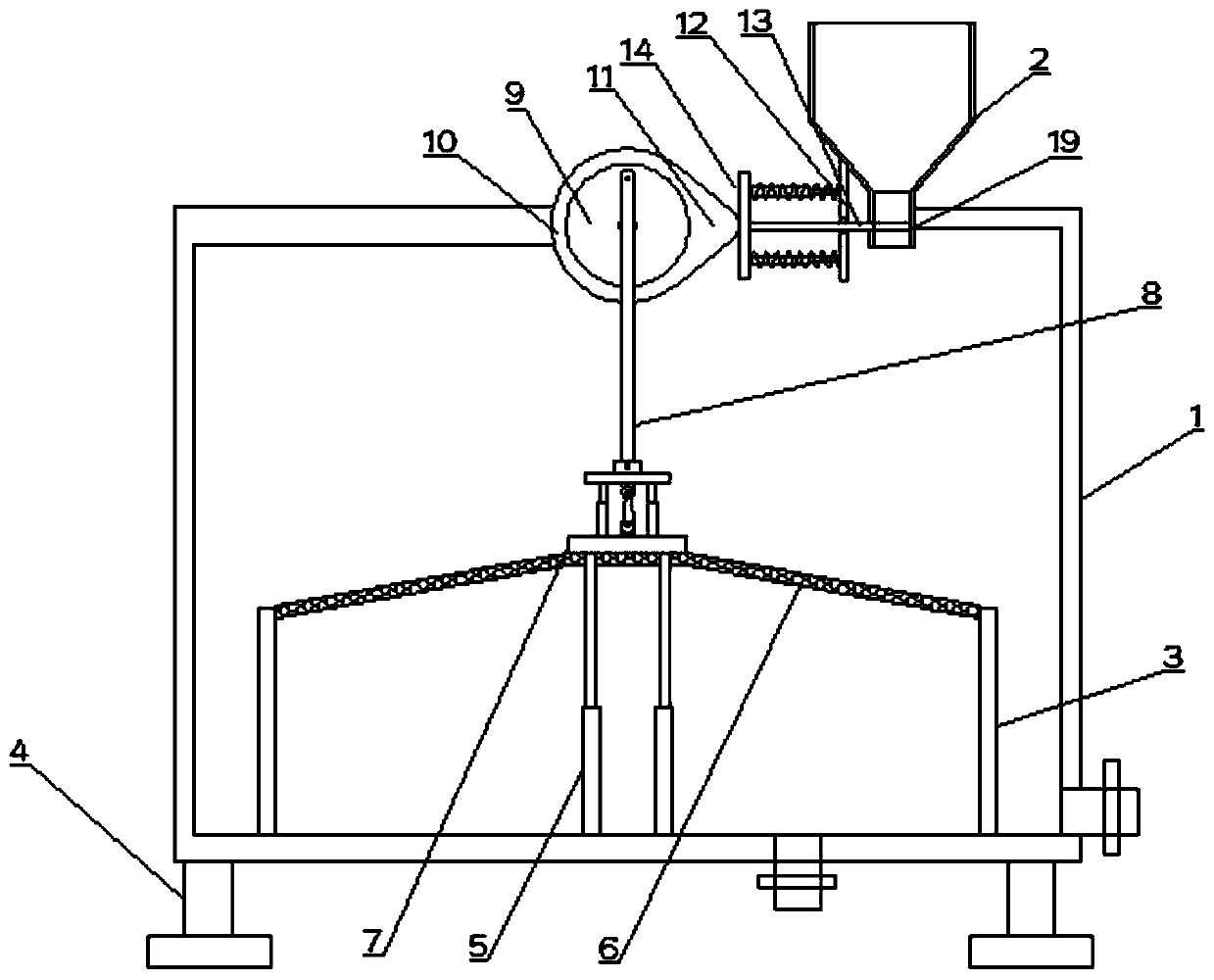

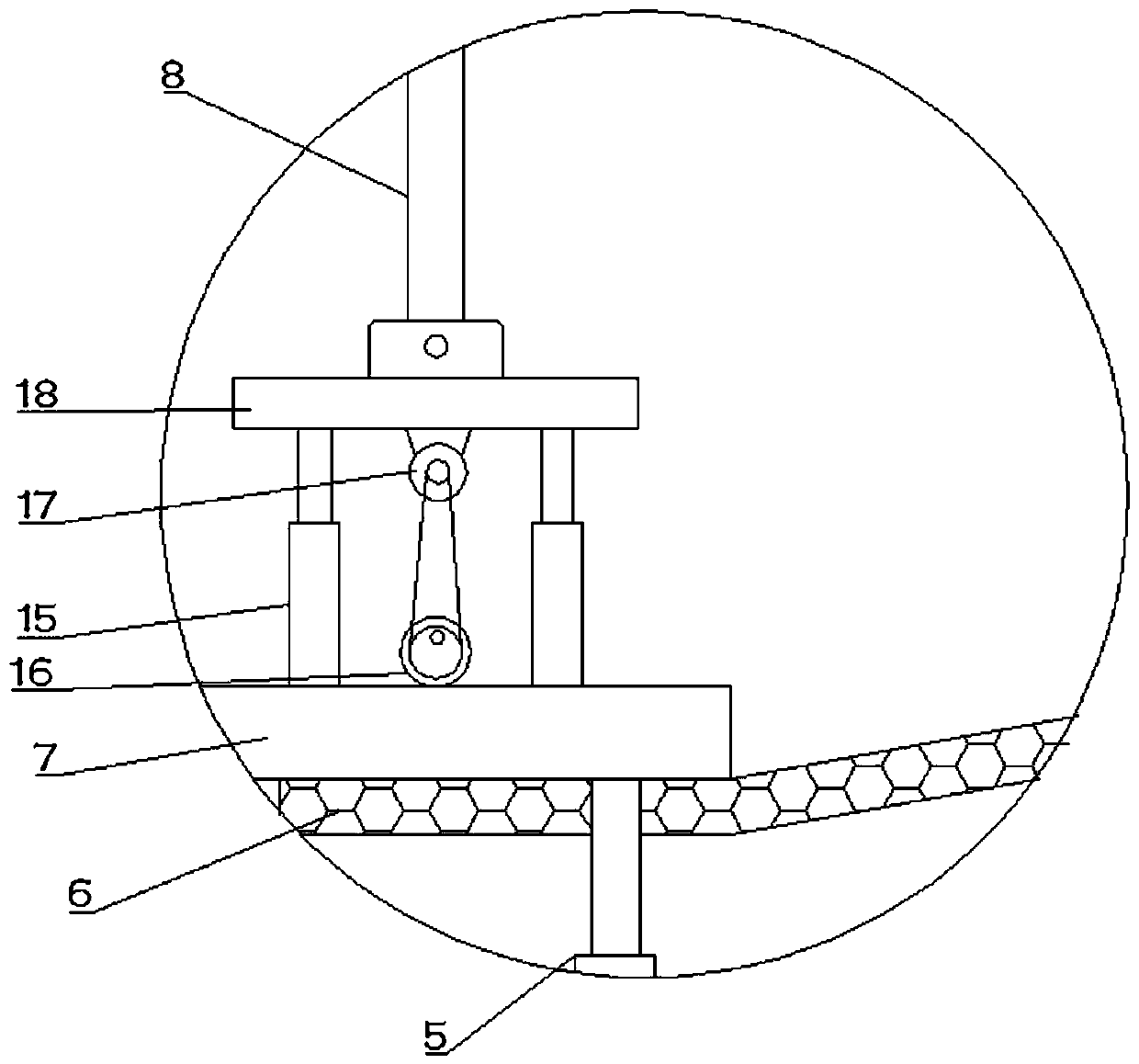

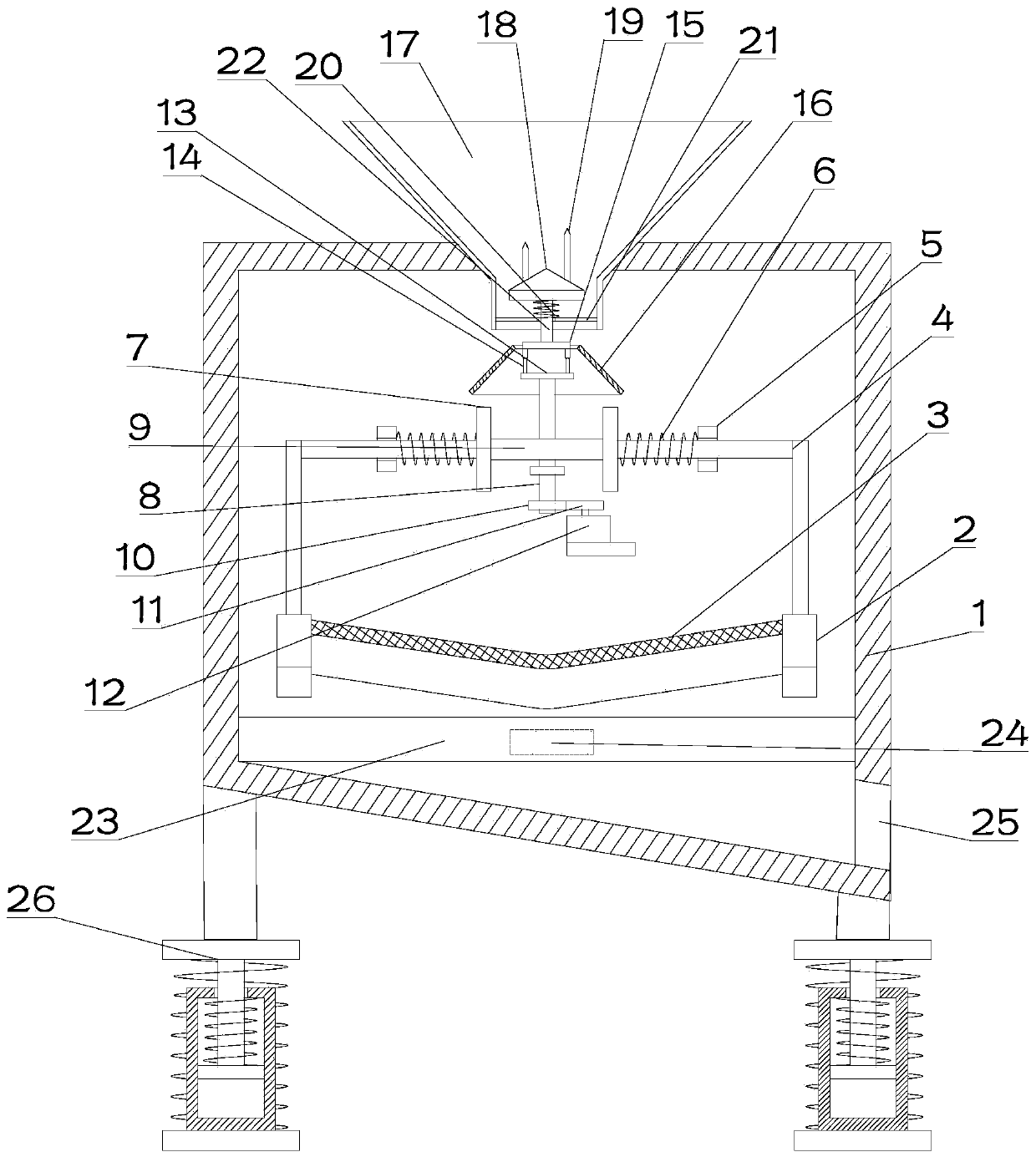

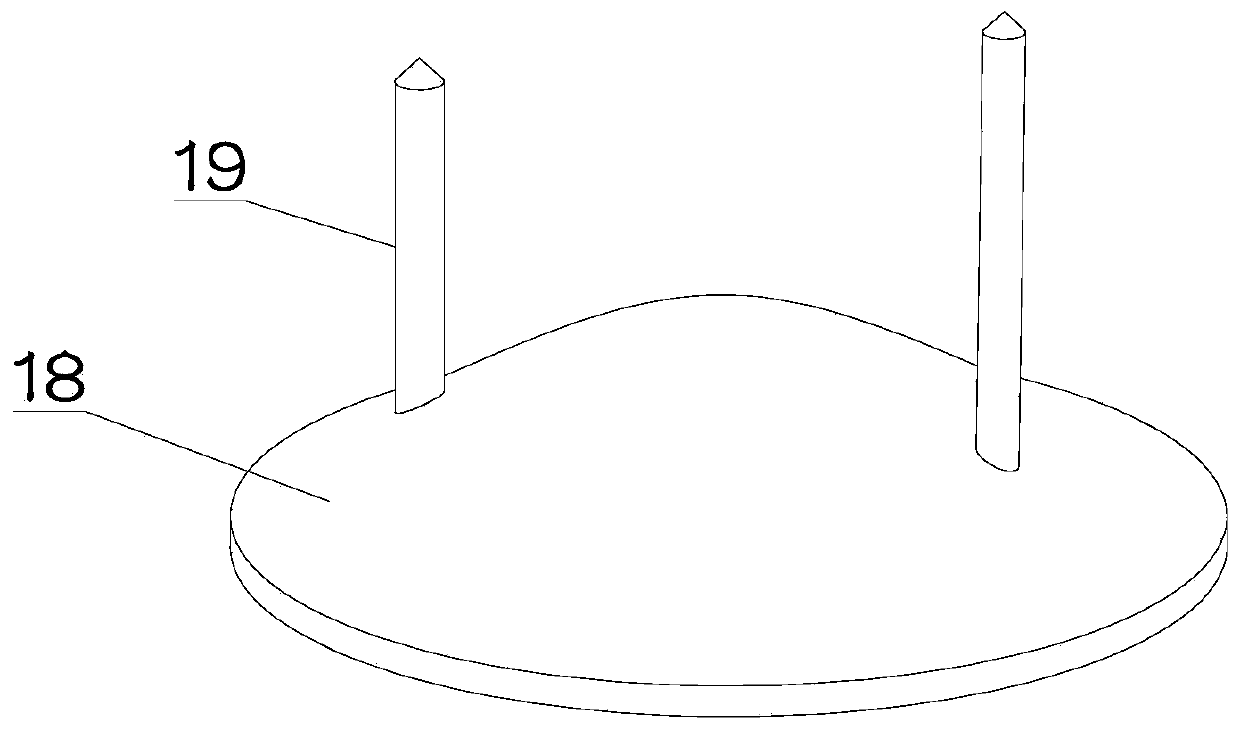

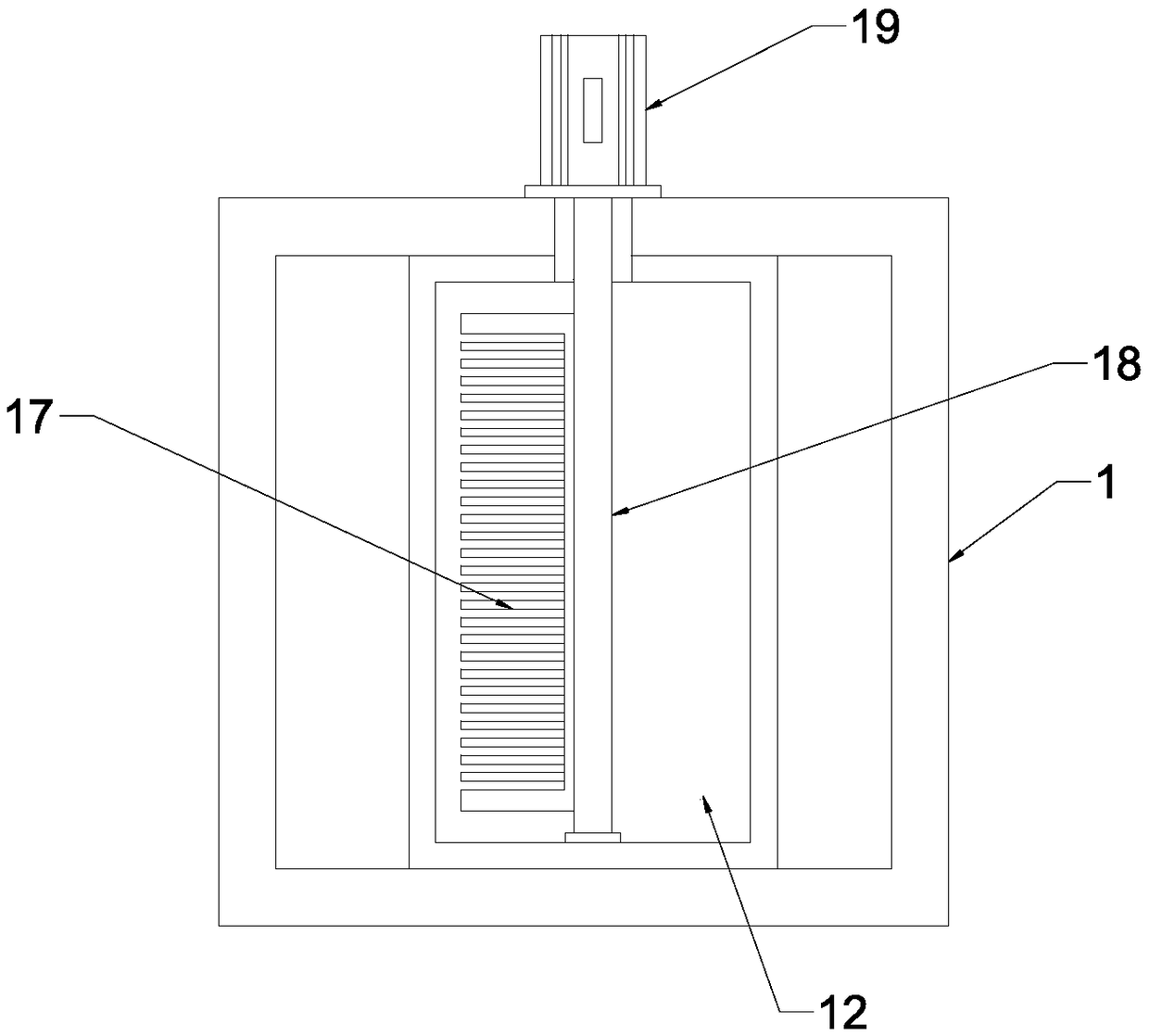

Working method of vibratory screening equipment with intermittent feeding function for granular material

ActiveCN108639786ASolve the accumulationGuaranteed to proceed normallySievingScreeningEngineeringMechanical engineering

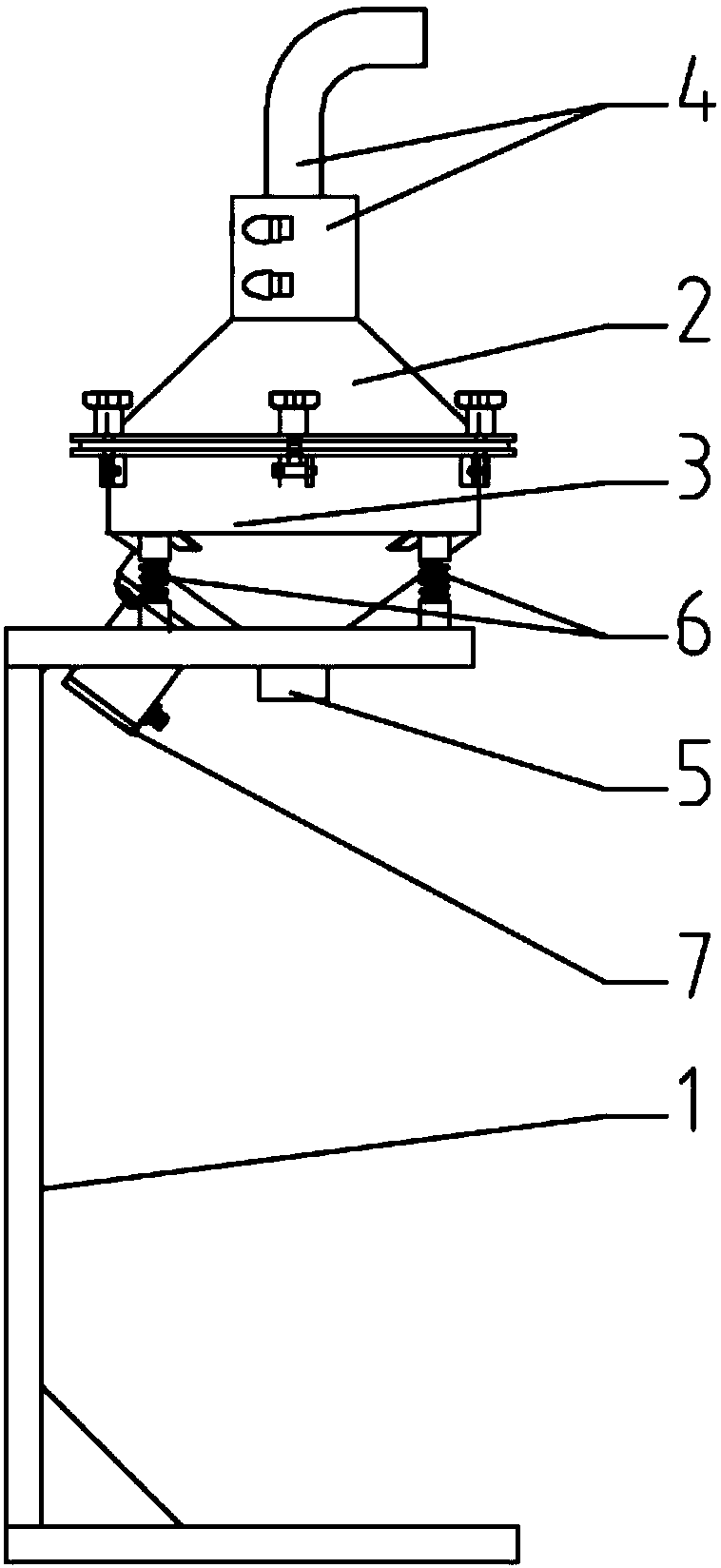

To achieve the purpose, the invention provides a working method of vibratory screening equipment with an intermittent feeding function for a granular material. The vibratory screening equipment comprises an enclosure, wherein an annular support plate is arranged in the enclosure; a sieve is fixedly connected to the bottom of the annular support plate and connected with the inner bottom of the enclosure through a sieve vibrating device; a material disturbance device is arranged at the upper side of the sieve and comprises a first rotating shaft; and the top end of the first rotating shaft penetrates the enclosure and extends upwards and is fixedly connected to an output shaft of a first motor. The following beneficial effects are achieved: first, the first rotating shaft drives a disturbance bulge to rotate through a coordinating rod, and the disturbance bulge disturbs the material on the sieve to guarantee normal proceeding of sieving, so that the problem of material accumulation is effectively solved; and second, a first spring arranged here can enable the rotating coordinating rod to move up and down so as to adapt to the sieve which moves up and down.

Owner:JIANGSU JINENGDA ENVIRONMENTAL ENERGY SCI & TECH

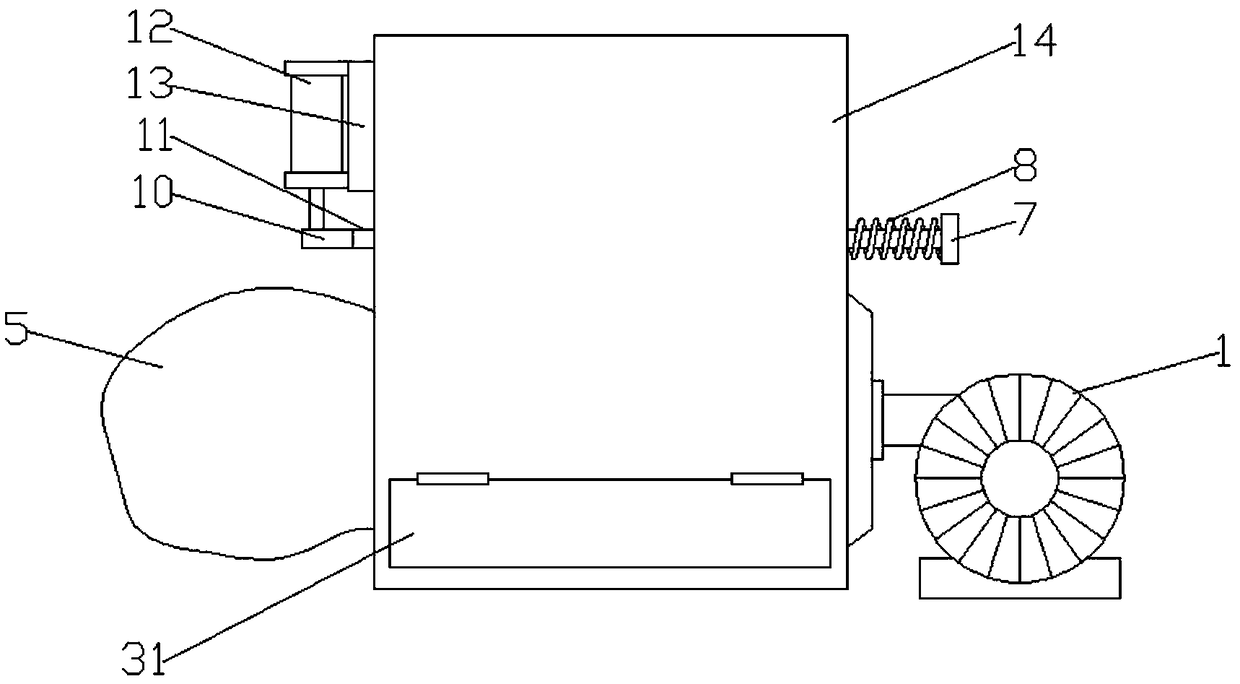

Aggregate screening device for buildings

InactiveCN107803338AReasonable structural designGood filtering effectSievingScreeningRotational axisEngineering

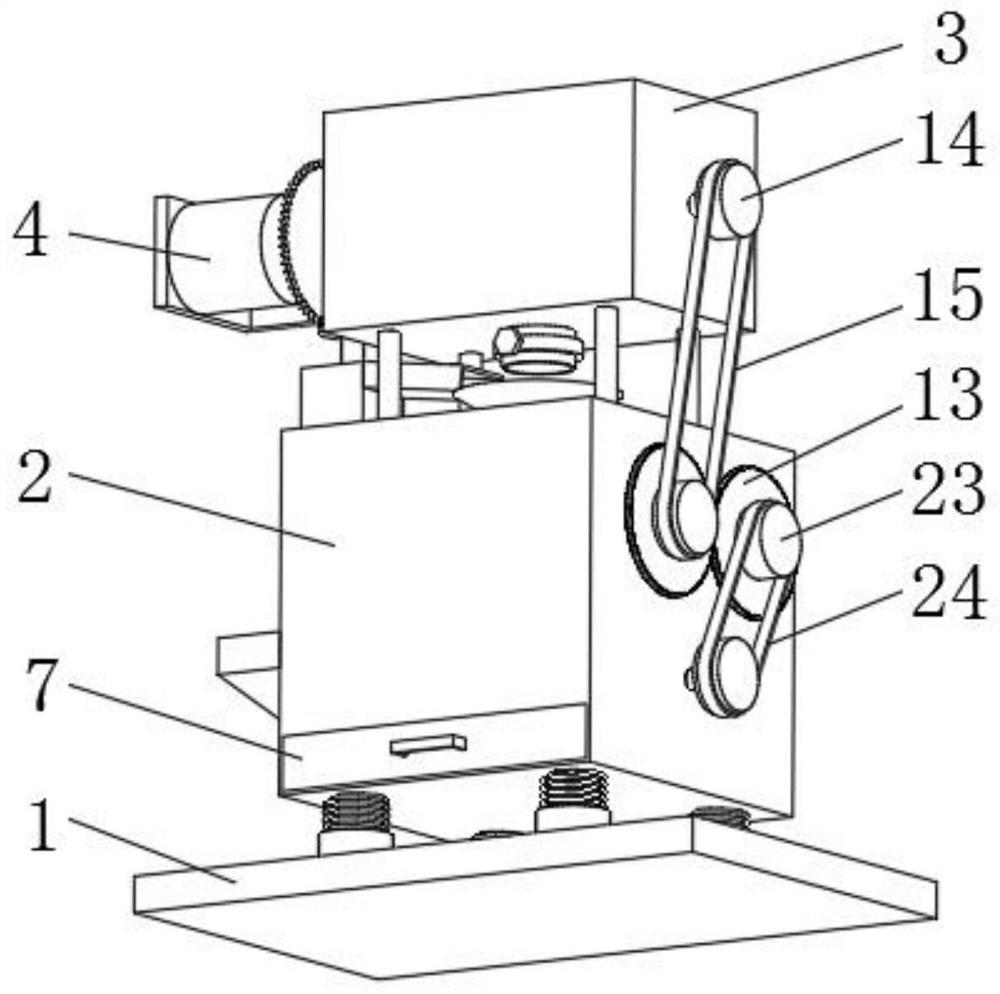

The invention discloses an aggregate screening device for buildings. The aggregate screening device comprises a base and a screening box, wherein a plurality of iron blocks are arranged on the upper side of the base; a spring is arranged on the upper side of each of the iron blocks; an electromagnet is connected to the upper end of each of the springs; a support platform is arranged on the upper sides of the electromagnets; a sliding rail is arranged on the upper side of the support platform; support plates are arranged at the lower end of the screening box symmetrically; the lower ends of thesupport plates are connected with the sliding rail; a motor is arranged at the right end of the upper side of the support platform; a rotating disc is arranged at the output end of the motor; a rotating shaft is arranged on the periphery of the front side of the rotating disc; a connecting seat is arranged on the right side of the support plate on the right side; a connecting rod is arranged between the connecting seat and the rotating shaft; a dust collection box is arranged at the right part of the upper end of the screening box; a fan is arranged at the upper end of the dust collection box; a dust collection pipe is arranged at the output end of the fan; and a dust collection cover is arranged at one end of the dust collection pipe. The aggregate screening device for buildings has thebenefits of being simple in structure, convenient to use, good in screening effect, long in service life, good in dust collection effect, and energy-saving and environment-friendly.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

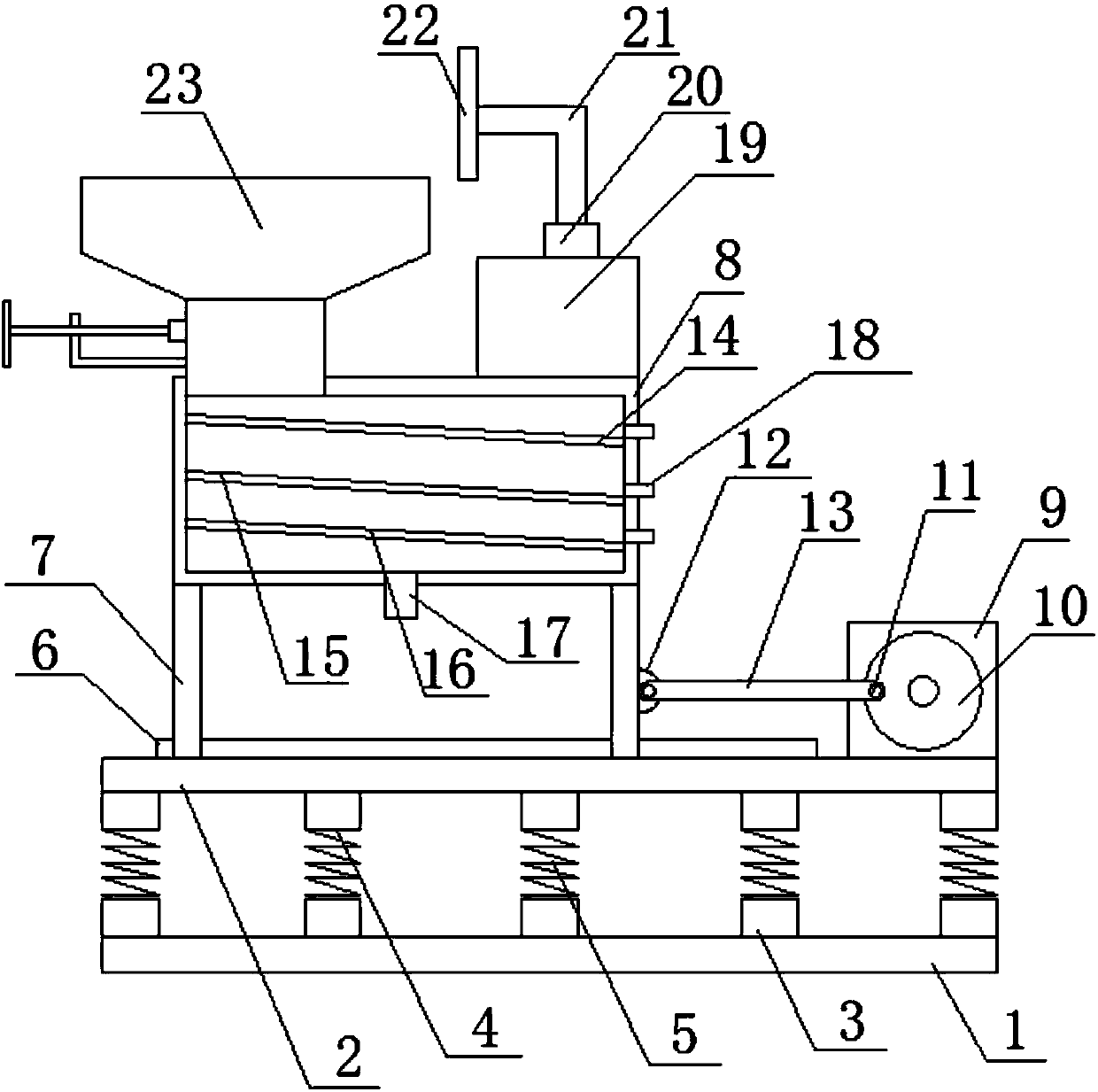

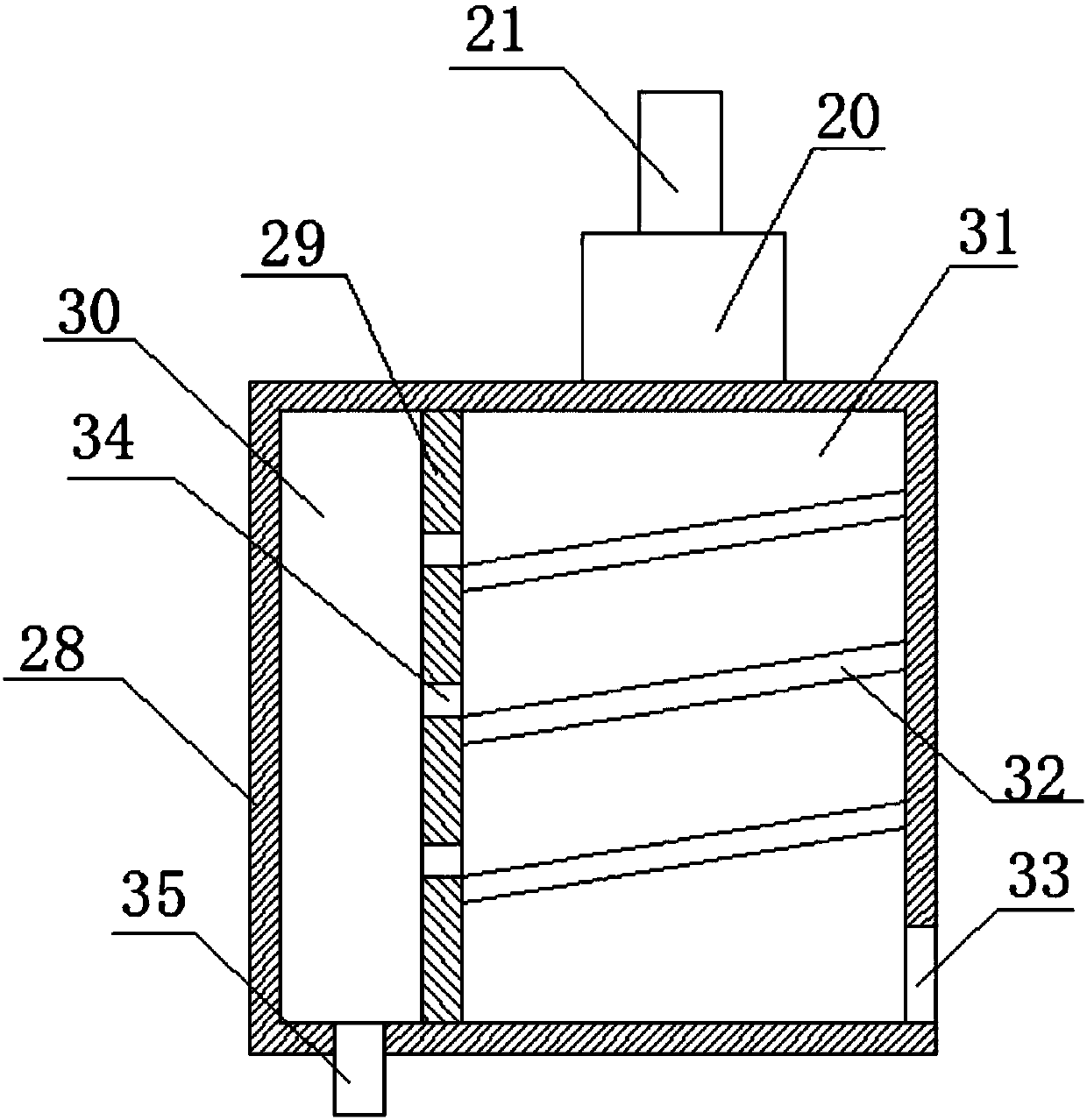

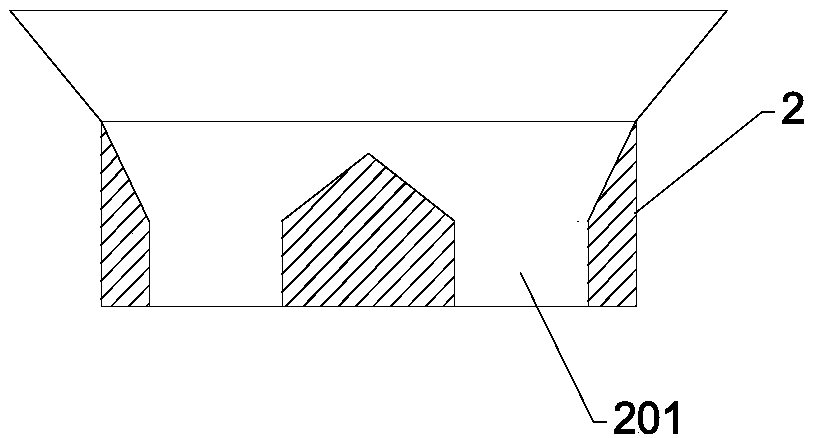

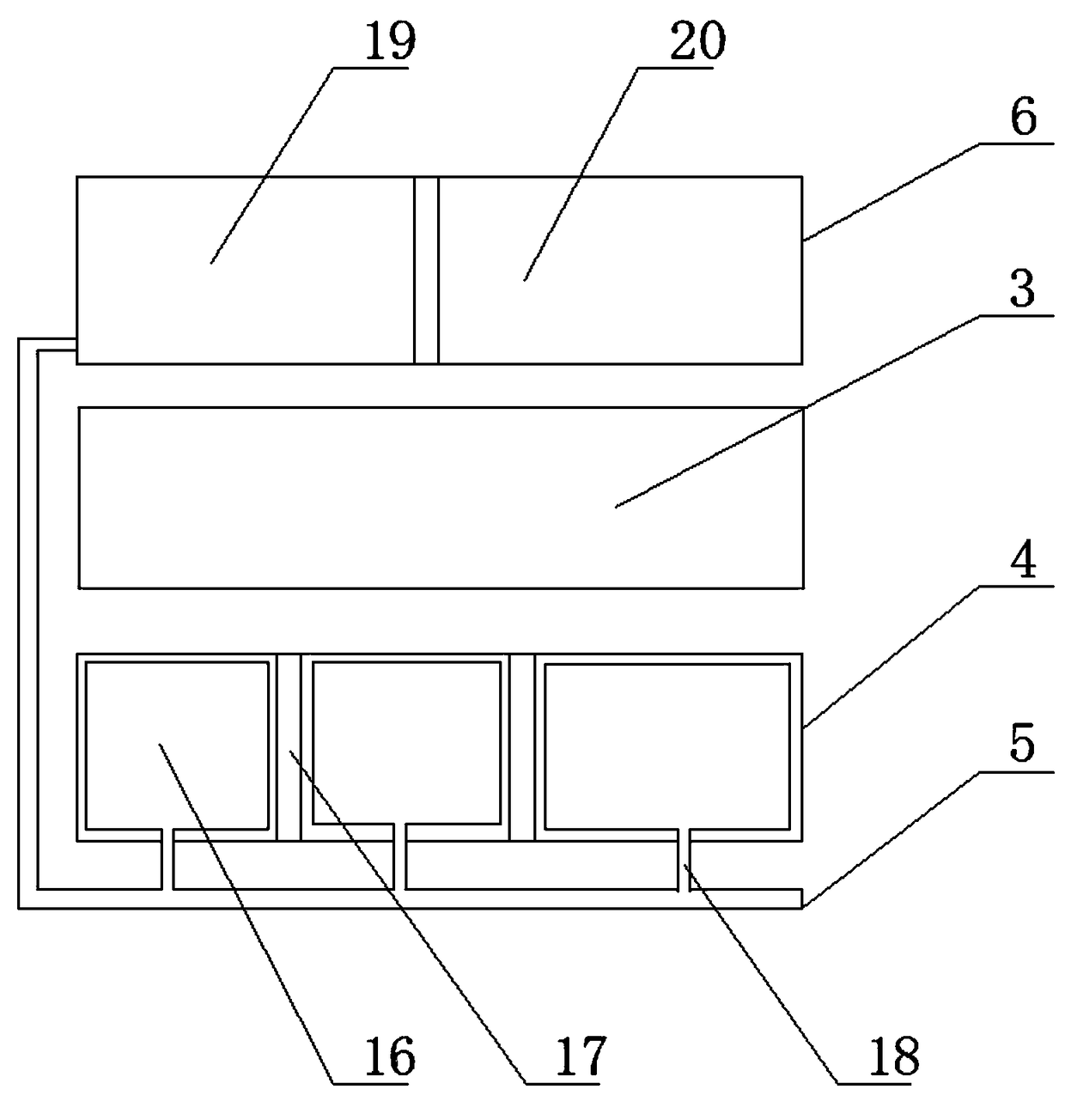

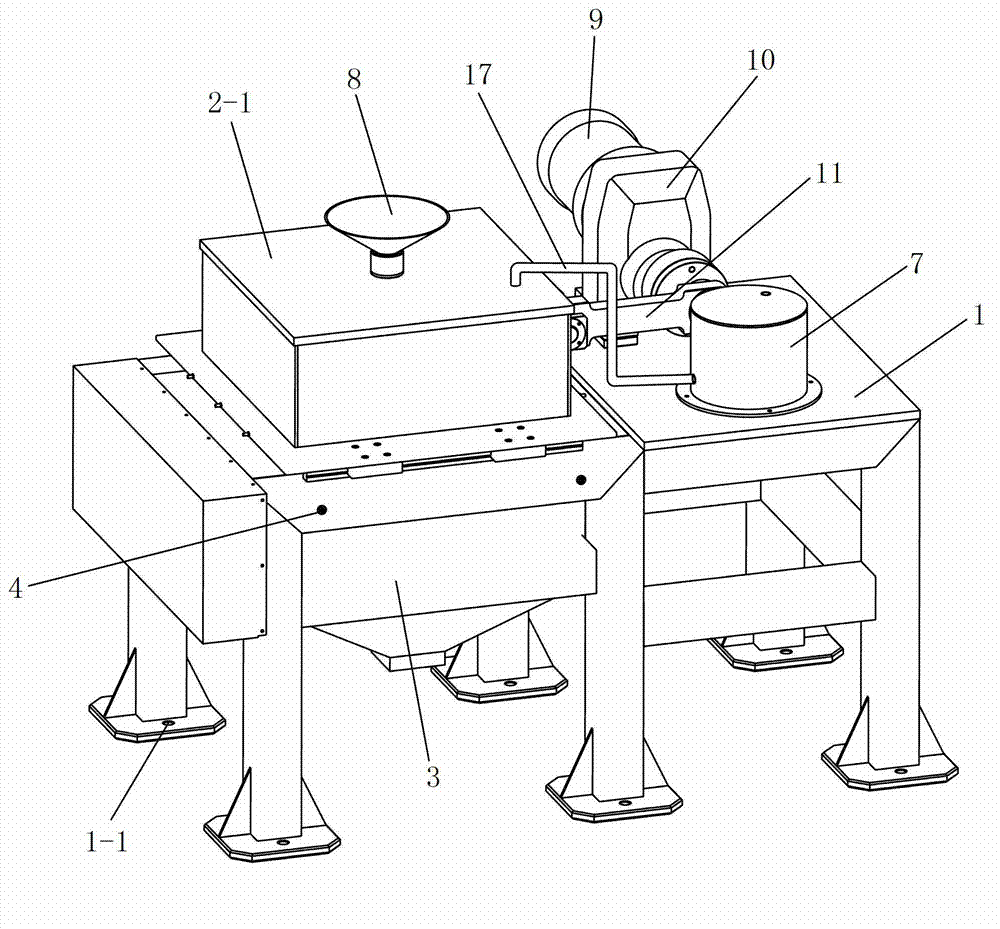

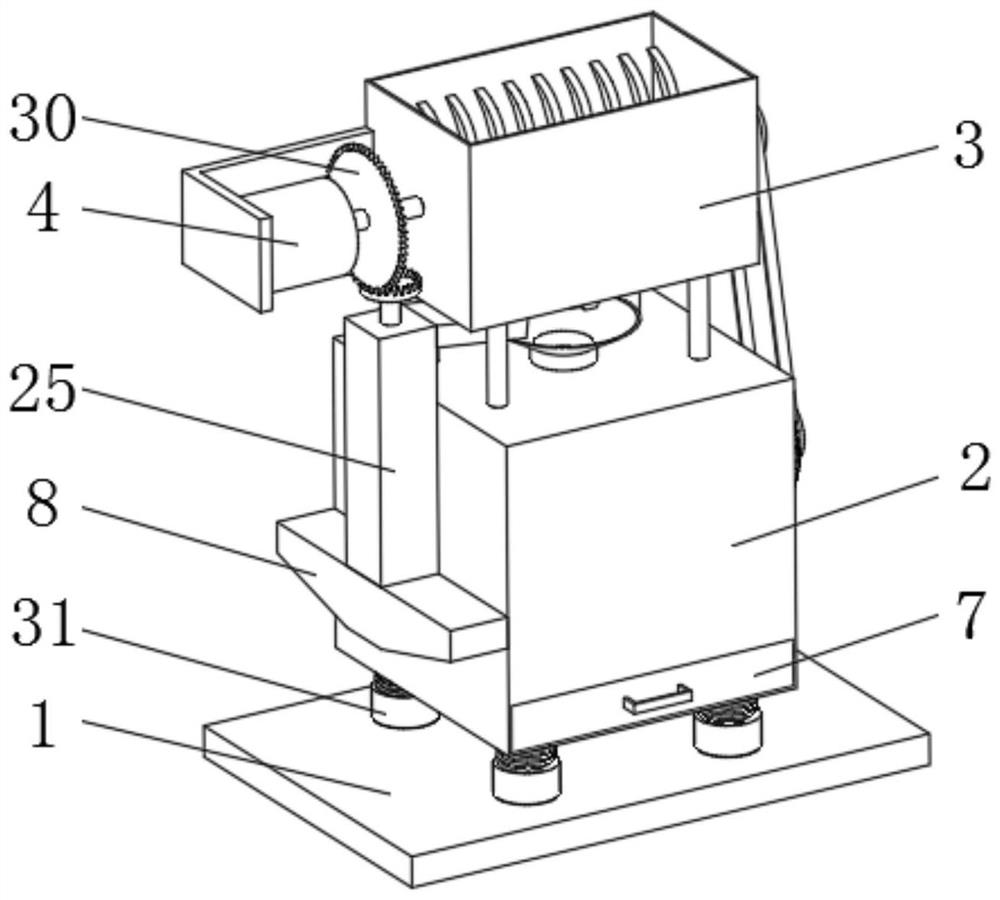

Sieving and drying device for metal powder

ActiveCN108889608ATo achieve the screening effectRealize quantitative screeningSievingTransportation and packagingScreening effectEngineering

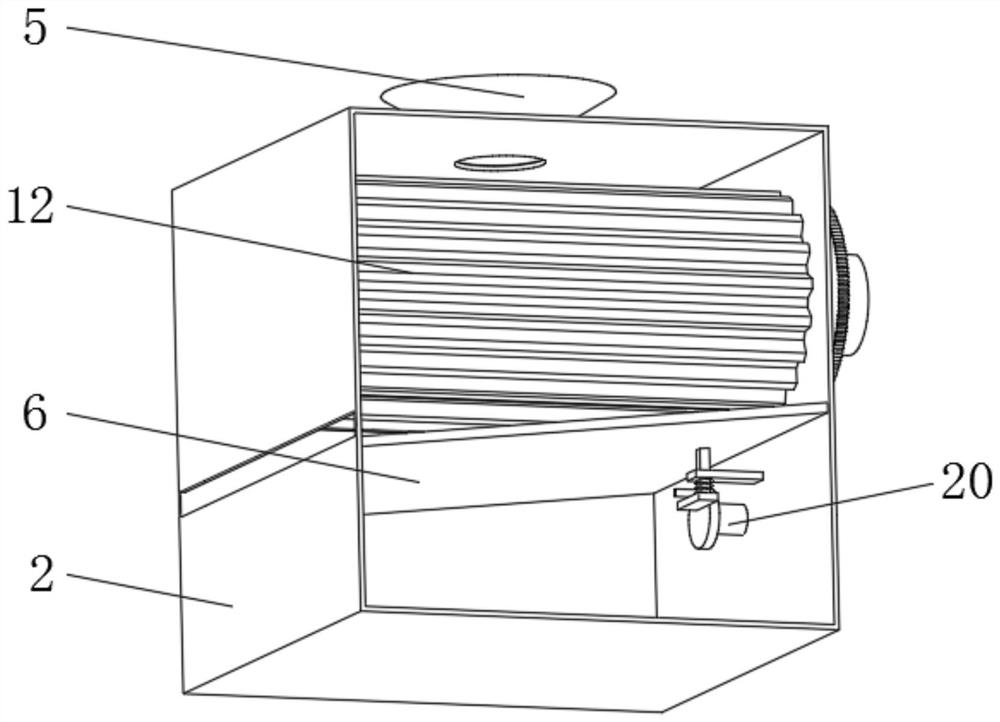

The invention discloses a sieving and drying device for metal powder, include a hot air fan, sieve powder box, distribution box and dispersing box, An upper end of that dispersion box is provide witha motor 2 and a feeding port, A taper stirring drum is arrange in that dispersion box, the main shaft of the motor 2 is provided with a stirring shaft, the lower end of the conical stirring drum is provided with a blanking pipe, A low end of that blanking pipe is communicate with the distribution box, A control valve is arranged on the feeding pipe, A run wheel is arranged in the material distribution box, two grooves are symmetrically arranged on the runner, the upper end side of the sieve powder box is provided with a mounting seat, A motor 1 is arranged on the mounting seat, the main shaftof the motor is provided with an eccentric wheel, A screen net frame is arranged in the screen powder box, a screen net is arranged on the inner side of the screen net frame, a bracket is arranged onthe bottom of the screen powder box, and a recovery box is arranged on the upper end of the bracket. The device realizes the quantitative screening of the powder, ensures the screening effect and efficiency of the screen net, and the treated powder contains less impurities and the water content of the powder is low.

Owner:芜湖市晨睿建材有限公司

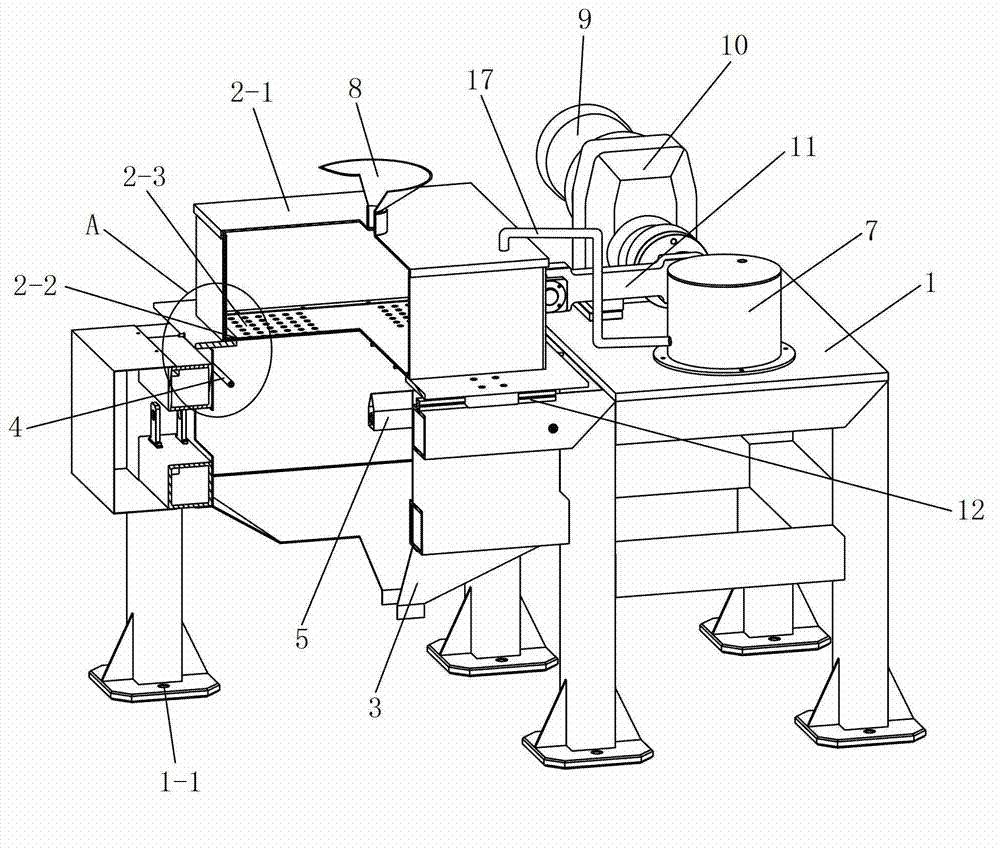

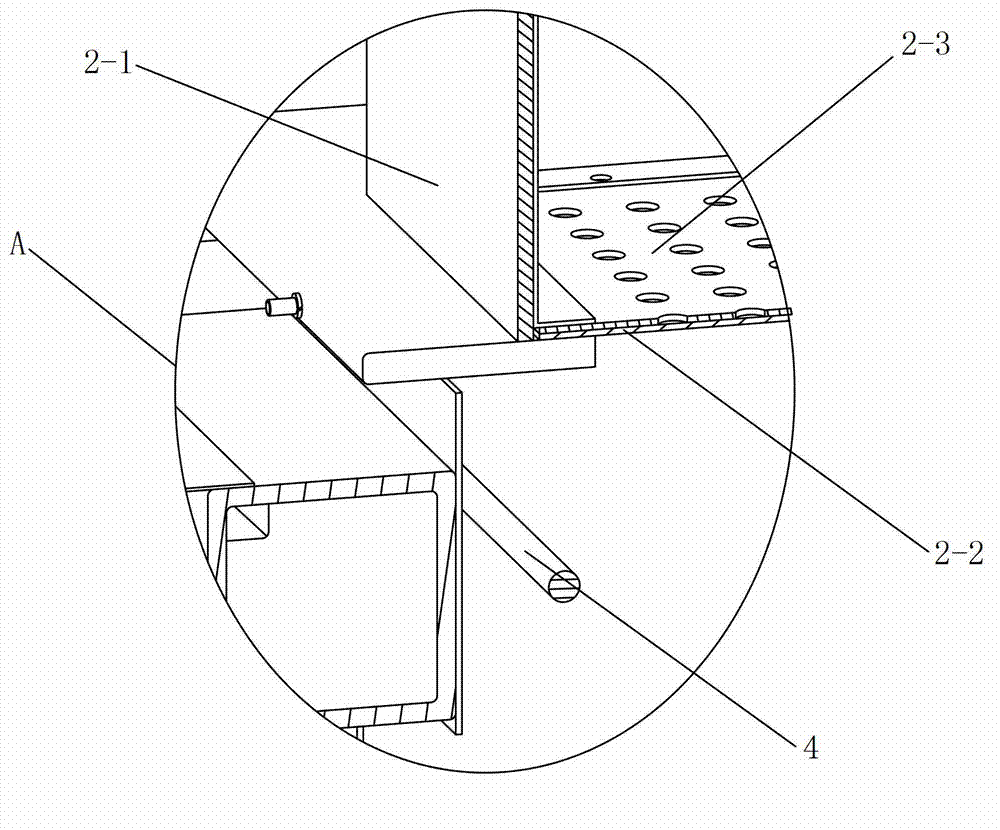

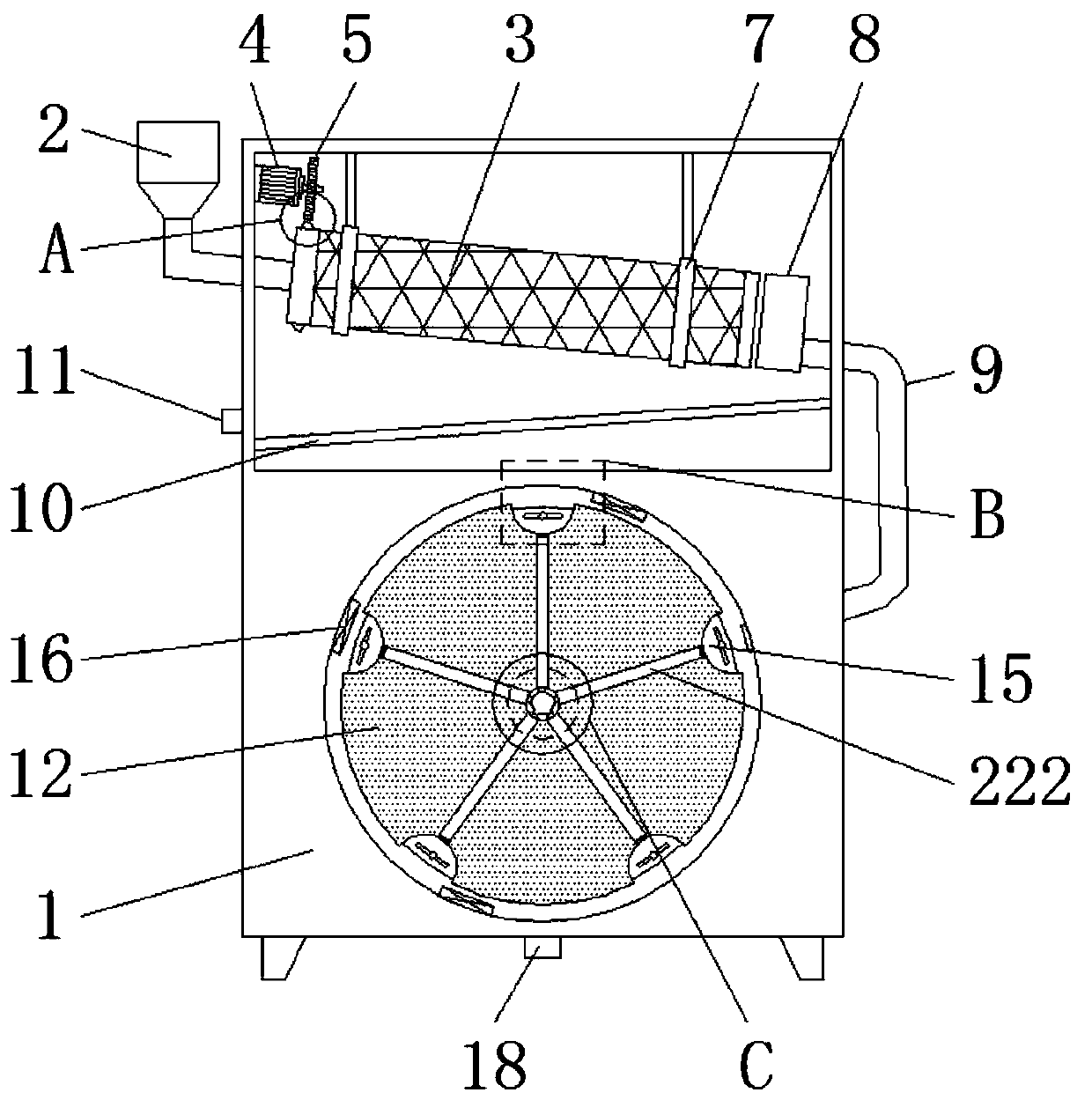

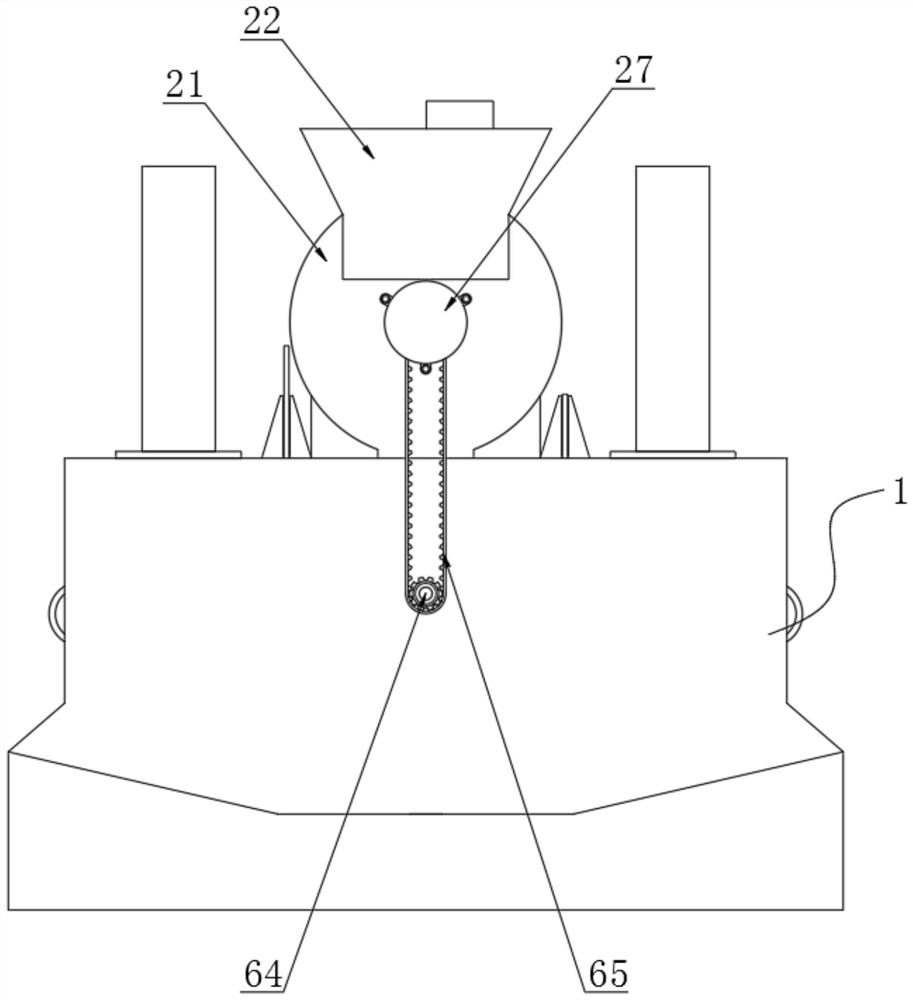

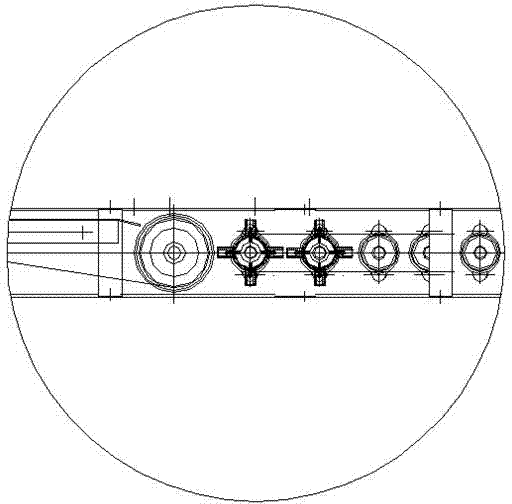

Integrated machine for grading production of anti-radiation mortar

ActiveCN105921248ASimple structureScreening boundaries are clearSievingDischarging apparatusRotational axisCrusher

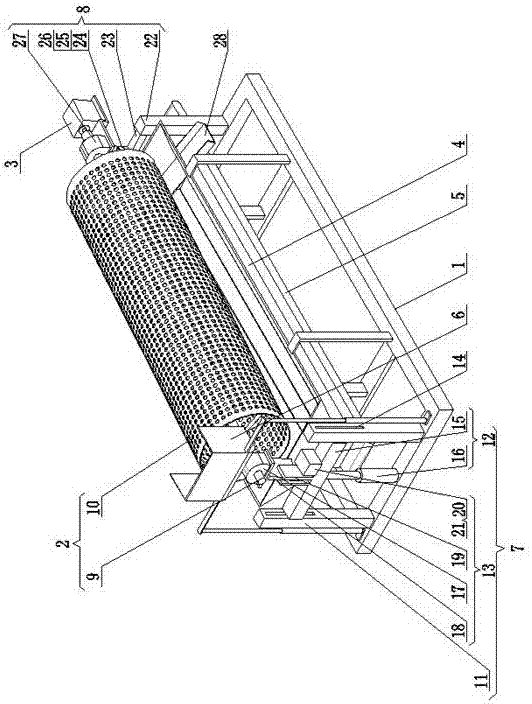

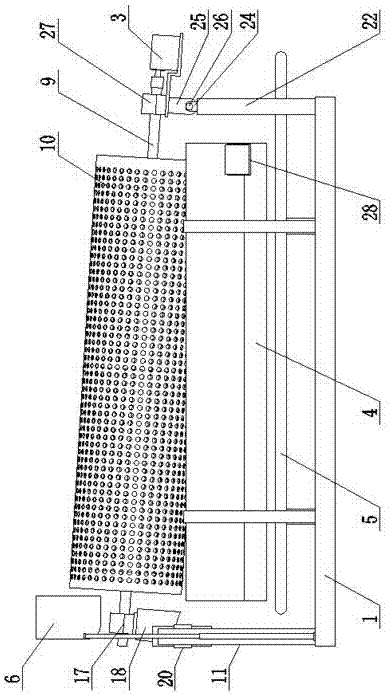

The invention relates to an integrated machine for grading production of anti-radiation mortar. The integrated machine comprises a screening and grading device connected to a crushing machine, a quantitative conveying device, a material mixing device and a raw material box, wherein the screening and grading device comprises a screening drum; a screen mesh is arranged at an upper part in the screening drum and a mounting tube is arranged at a bottom center of the screening drum; turnover shafts penetrating through the screening drum are arranged on the two sides of the screen mesh; the turnover shafts on the two sides are respectively mounted on a bearing pedestal and a turnover motor; partition plates are evenly arranged between the mounting tube and the screening drum; material collection cavities are formed between adjacent partition plates; a rotary cover is arranged above the mounting tube; a notch matched with the material collection cavity is formed in the rotary cover; the rotary cover is connected to a rotary shaft; and the rotary shaft is connected to a rotary motor. According to the screening and grading device, by screening by the simple screen mesh, the limit for screening is obvious, the structure is simple, meanwhile, the classified collection is facilitated, then the anti-radiation mortar of different grades is produced via the quantitative conveying device and the simple material mixing device, and further the economic effects are improved.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

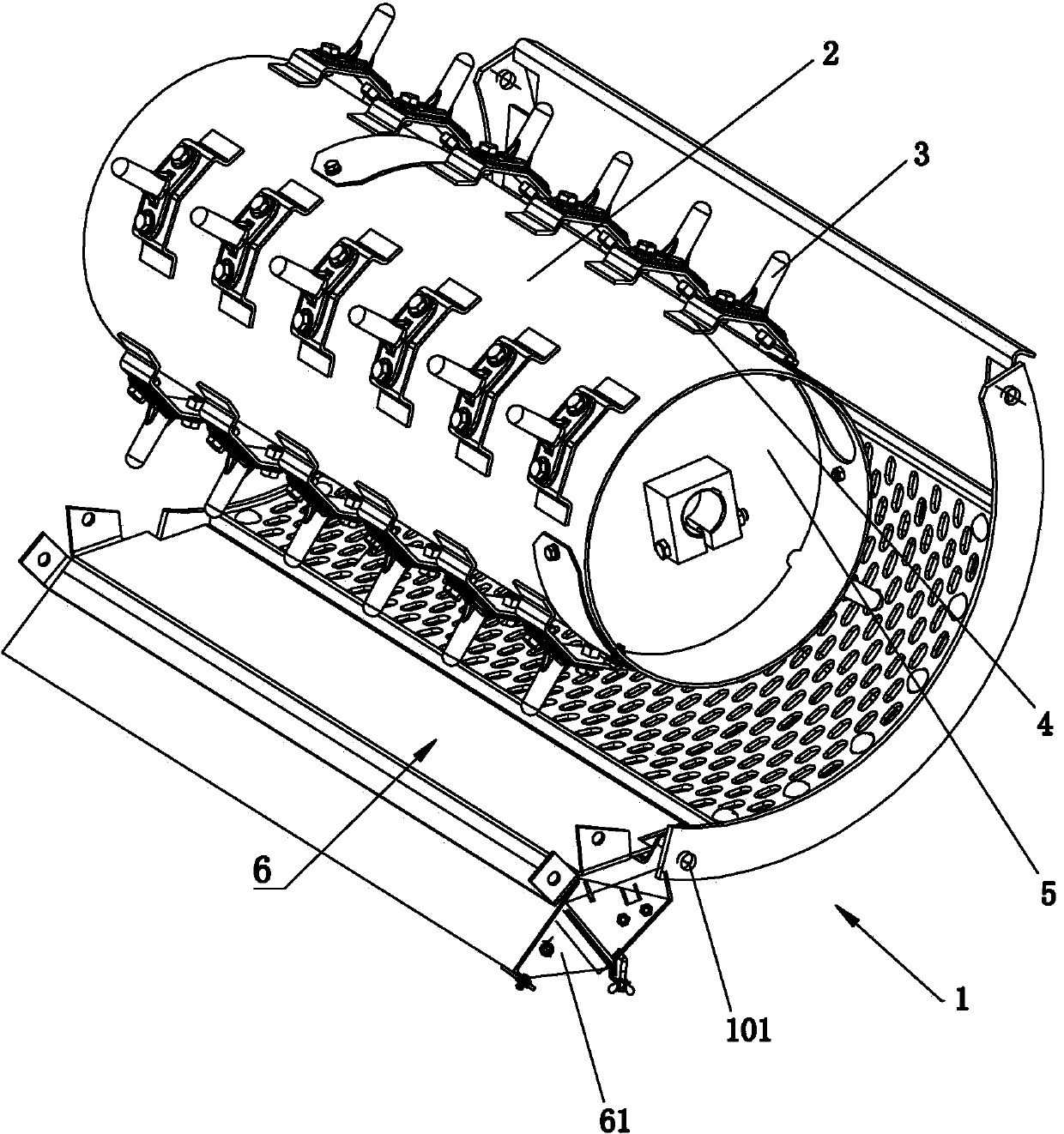

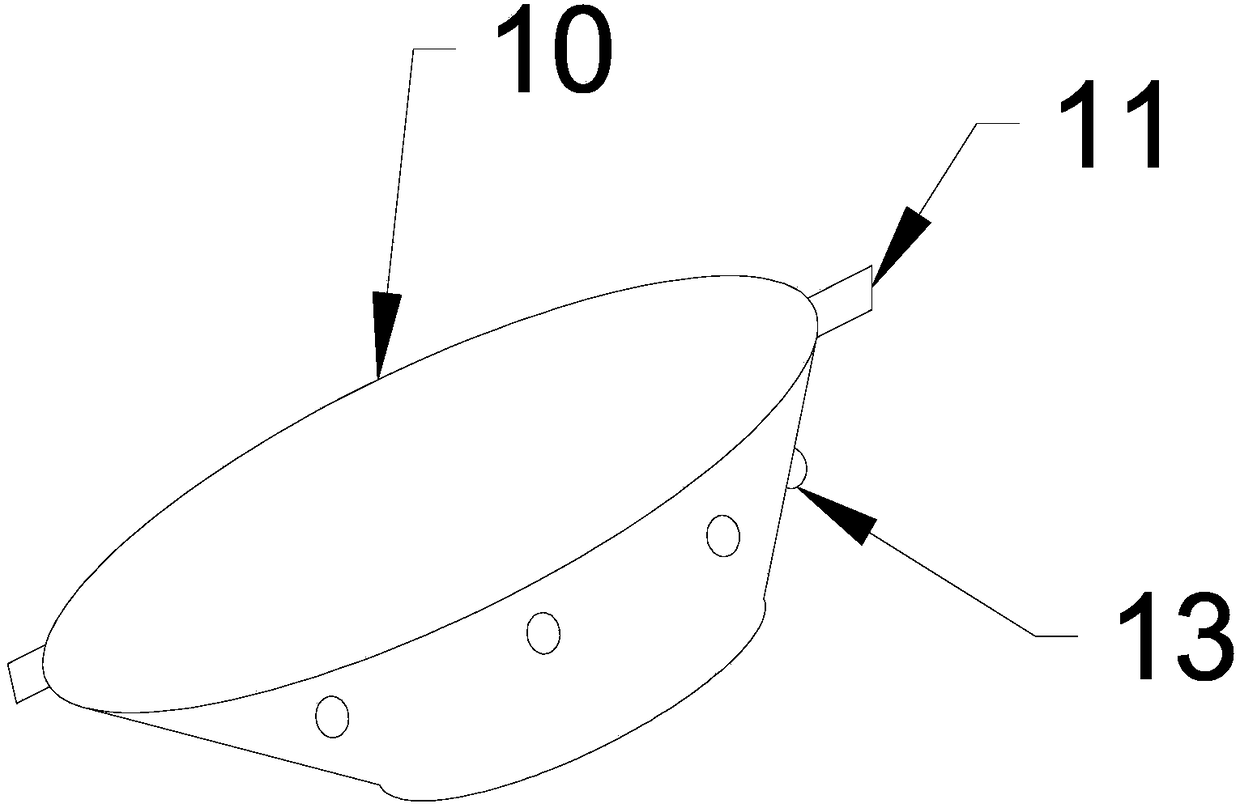

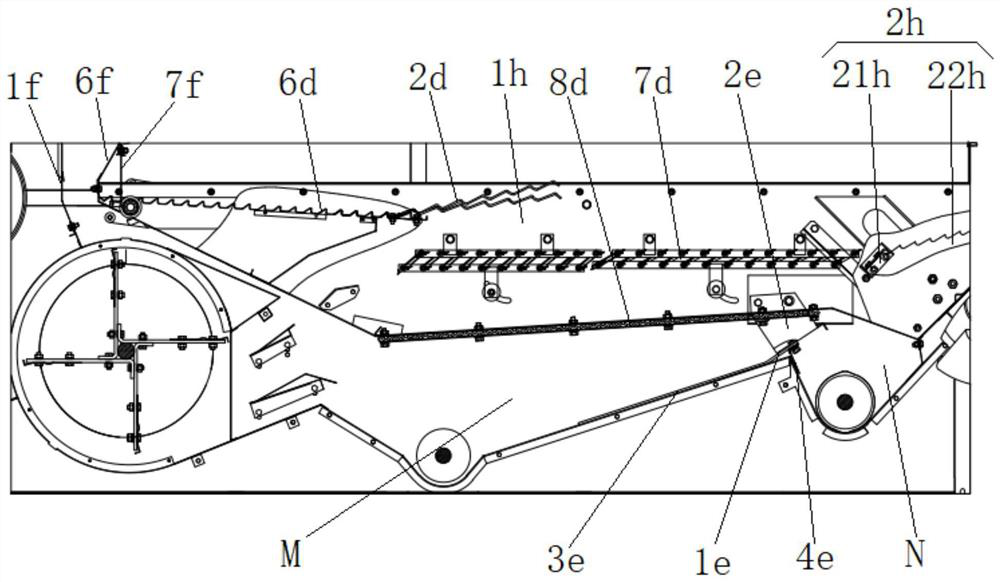

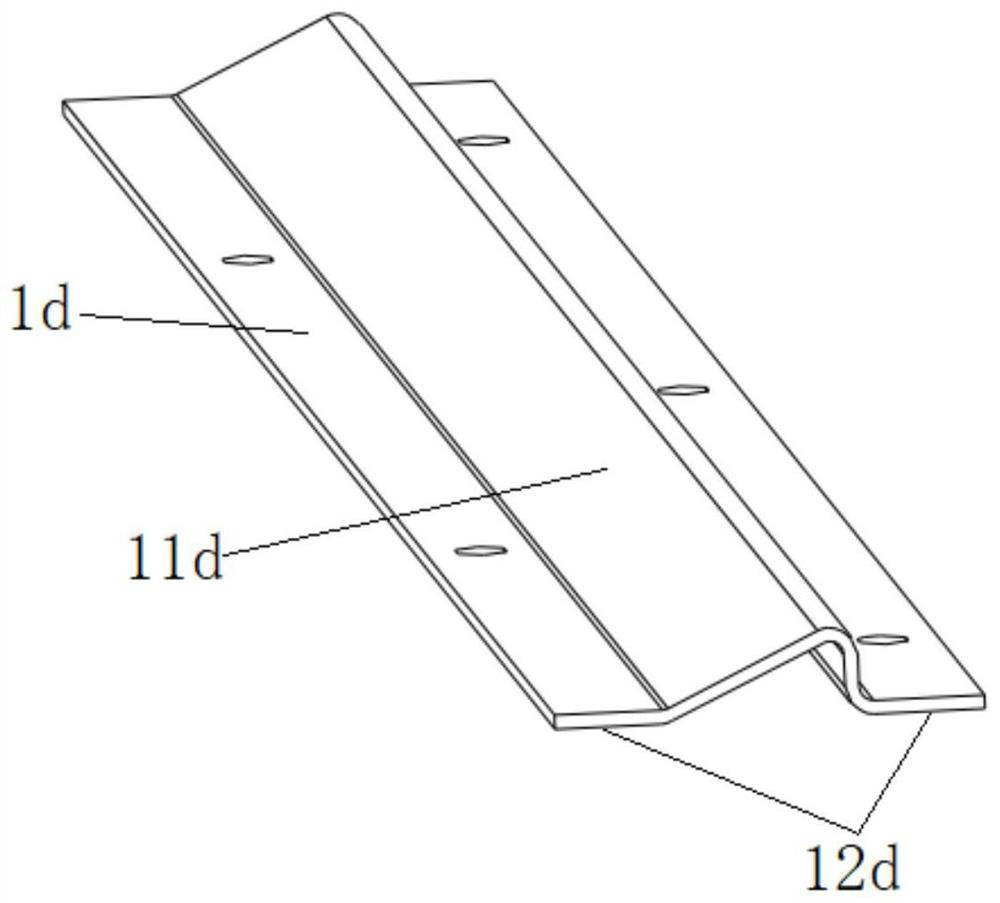

Corn grain threshing and separating device and combine harvester with separating device

The invention discloses a corn grain threshing and separating device and a combine harvester with the separating device. The corn grain threshing and separating device comprises a threshing roller which is provided with threshing teeth with ball-headed top ends, wherein a threshing concave plate is arranged below the threshing roller and is arranged on a mounting rack, and multiple columns of staggered elliptical holes are formed in the threshing concave plate; a stone collecting tank is arranged at one side, close to a corncob source, of the mounting rack, and a stone collecting tank cover plate is arranged above the stone collecting tank. Through the threshing teeth, grains are prevented from being crushed, and the threshing effect is enhanced; the threshing teeth are matched with the threshing concave plate, so that under the condition of guaranteeing low grain crushing rate, high threshing performance, screening performance and passing characteristic, the working strength, reliability and stability are improved through the mounting rack, and mounting and repair / maintenance are facilitated; the stone collecting tank is closed by the stone collecting tank cover plate, so that corncobs are prevented from falling into the stone collecting tank; meanwhile, through replacing a threshing and separating attachment, on the basis of realizing rice / wheat harvesting, the effect of harvesting corn crops is realized, and the use ratio of the harvester is increased.

Owner:LOVOL HEAVY IND

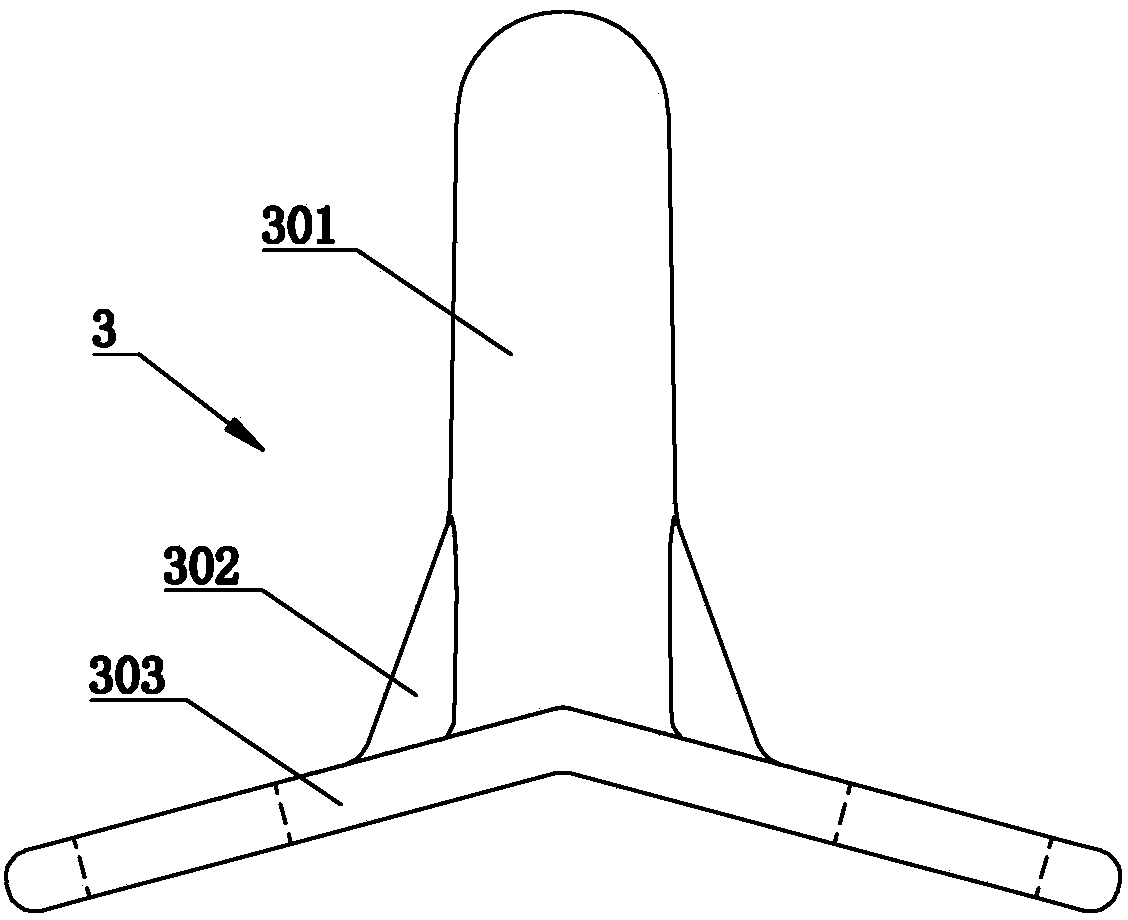

Sand screening device for efficiently separating waste residues

ActiveCN108421691AUniform intermittent feedingAvoid accumulationSievingScreeningScreening effectSlag

The invention discloses a sand screening device for efficiently separating waste residues. The sand screening device comprises a box body, a feeding hopper and a driving motor. The top of the box bodyis communicated with the feeding hopper. A partition is arranged in the box body, and scraping plates distributed in a cross shape are arranged in the portion, above the partition, in the box body. Arotating shaft is positioned below the partition and fixedly connected with a scattering disc, a conical screen cylinder is arranged below the scattering disc, and a slag discharge pipe is communicated with the lower end of the conical screen cylinder. According to the sand screening device, by arranging the scraping plates and the partition, uniform intermittent blanking of coarse sand is realized, and the coarse sand is uniformly scattered on the inner wall of the conical screen cylinder through the arrangement of the scattering plate, so that accumulation of the coarse sand on the screen surface is avoided, the screening effect is ensured, and the screening efficiency is improved; and fine sand entering the slag discharge pipe is blocked and centrifugally separated through the slag discharge pipe with sieve holes in the upper end and a spiral plate, so that the screening effect is improved.

Owner:湖州高强新材料有限公司

Multi-stage screening device

InactiveCN107803241AIncrease profitGuaranteed screening qualitySievingScreeningEngineeringMechanical engineering

The invention discloses a multi-stage screening device, which relates to the technical field of traditional Chinese medicine processing equipment. The invention includes a sieve hopper. The sieve hopper includes a primary screening mechanism and a secondary screening mechanism. A reciprocating rolling assembly is arranged above the primary screening mechanism. The rolling assembly includes a pressing roller and a moving assembly. A load-bearing plate parallel to the feeding screen is arranged above the feeding screen. The moving assembly includes a moving bracket and a driving cylinder. The moving bracket includes a horizontal connecting plate fixedly connected to the piston rod of the driving cylinder. And the two mounting frames symmetrically arranged on the lower surface of the horizontal connecting plate, two grooves corresponding to the two mounting frames are dug on the load-bearing plate, the ends of the two mounting frames are respectively connected to the rotating shaft through the two grooves, and the pressure roller is sleeved on the On the rotating shaft, the powder of the present invention passes through the three-stage screening of the feeding screen, the secondary screen and the third screen in order to ensure the screening quality of the powder, and through rolling and vibration, the screening and circulation of the powder are ensured. , which improves the screening efficiency.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

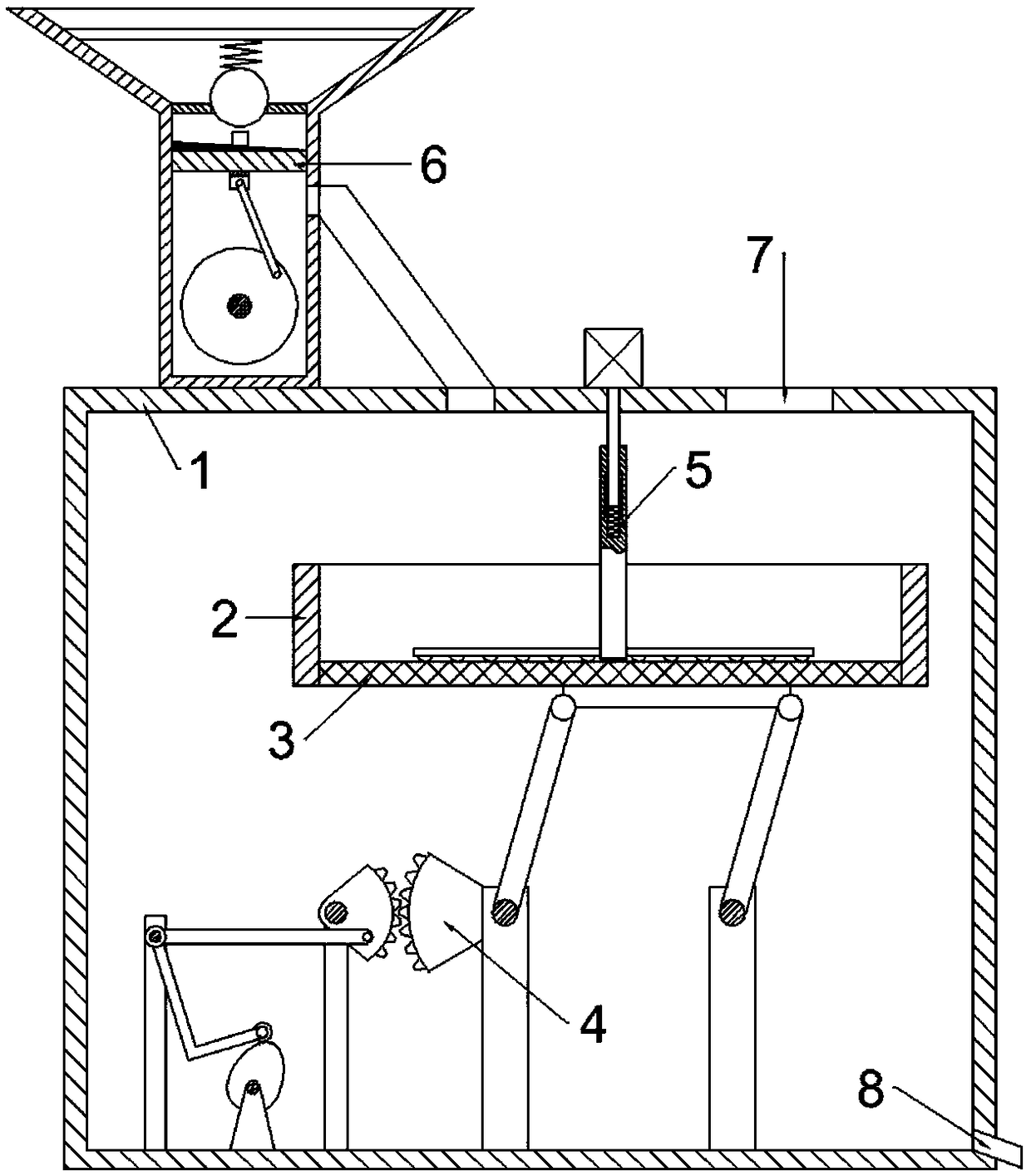

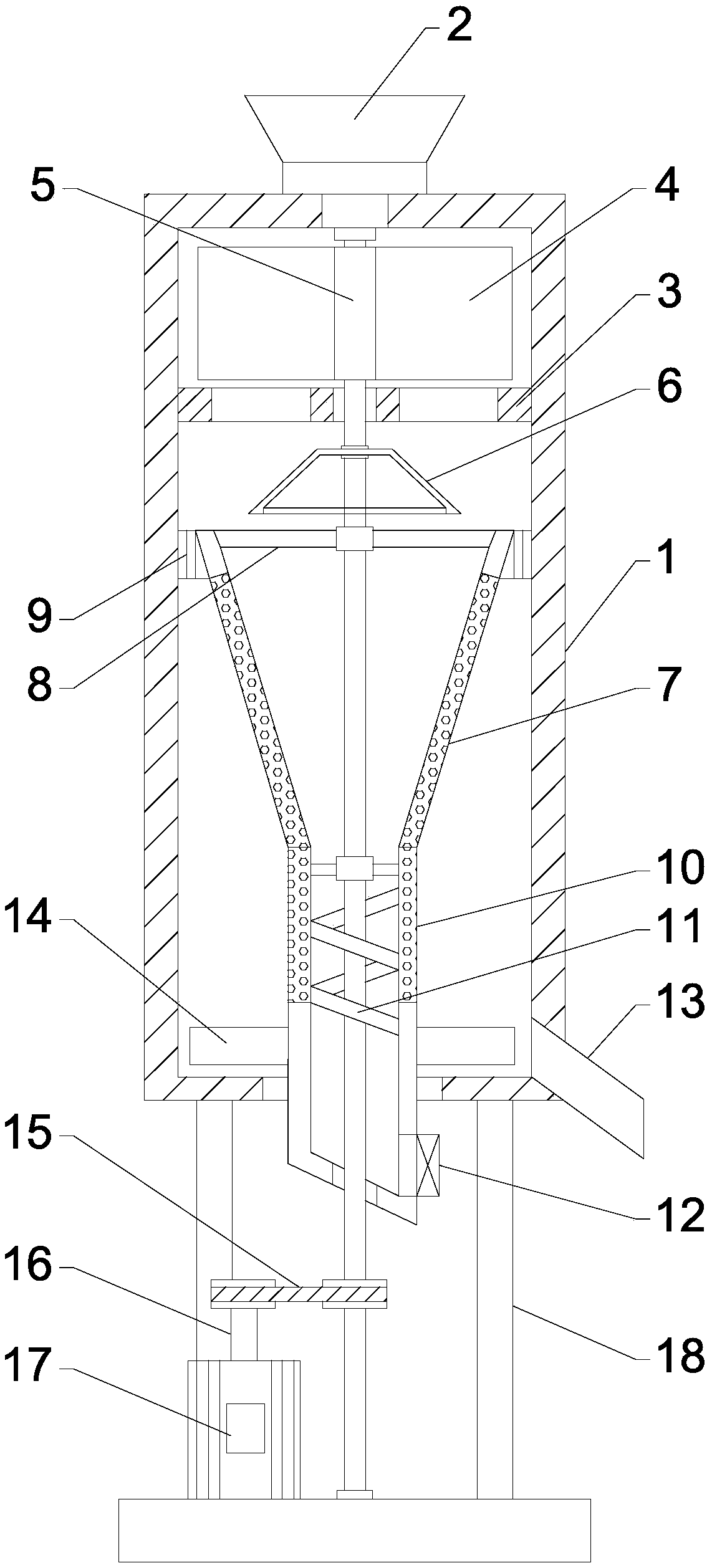

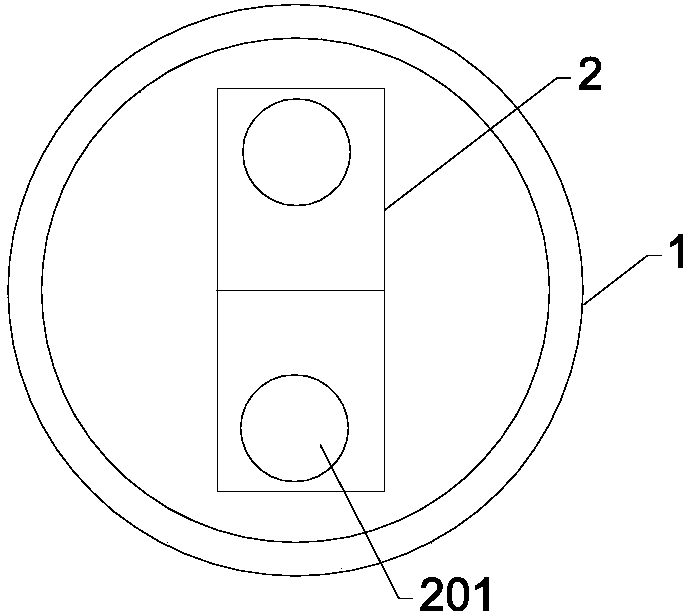

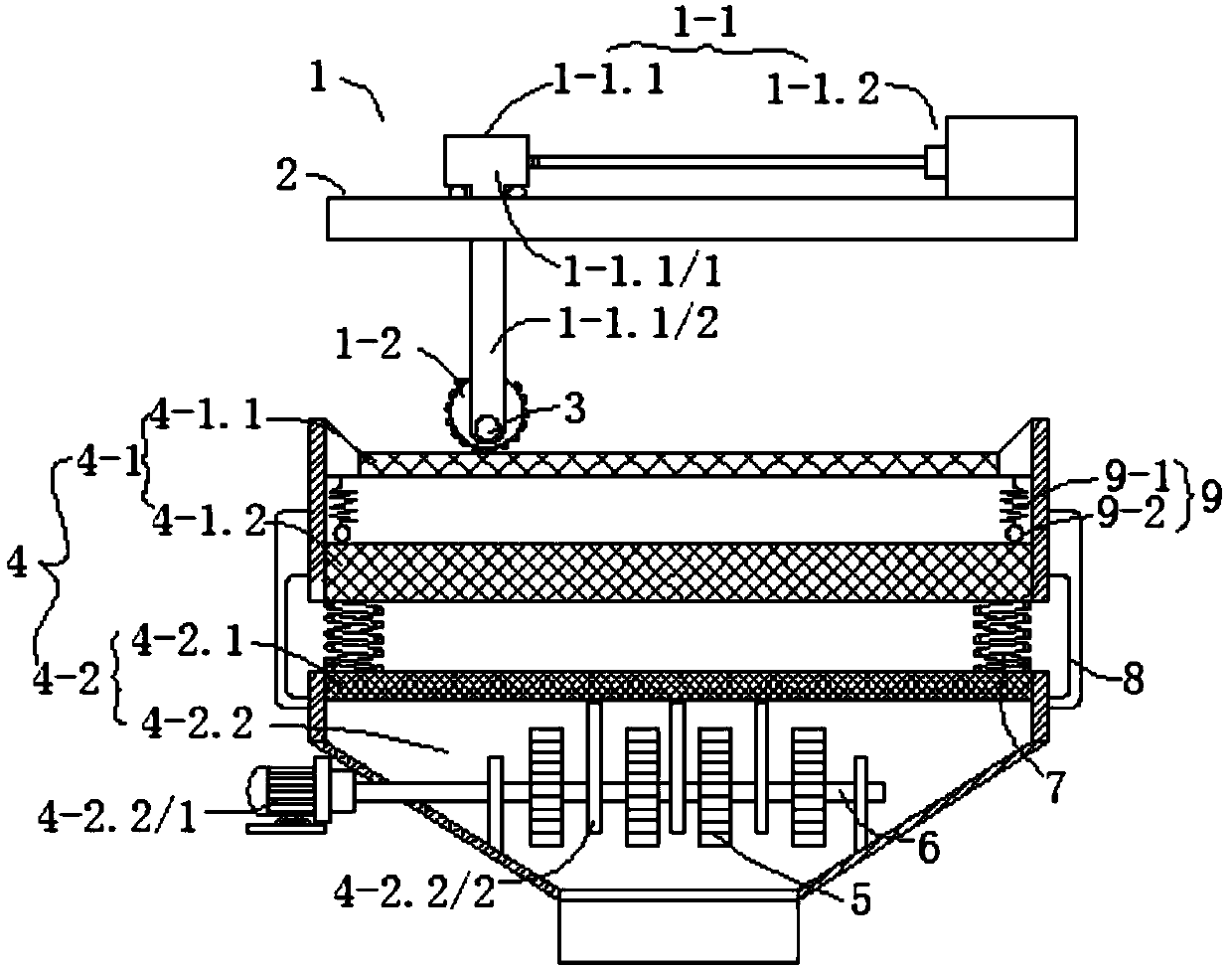

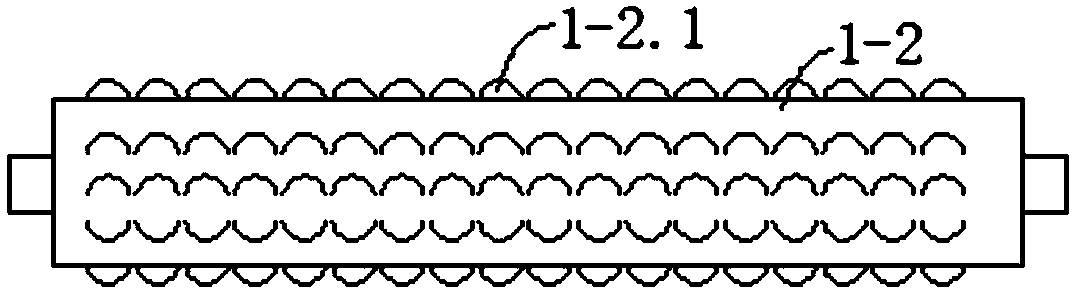

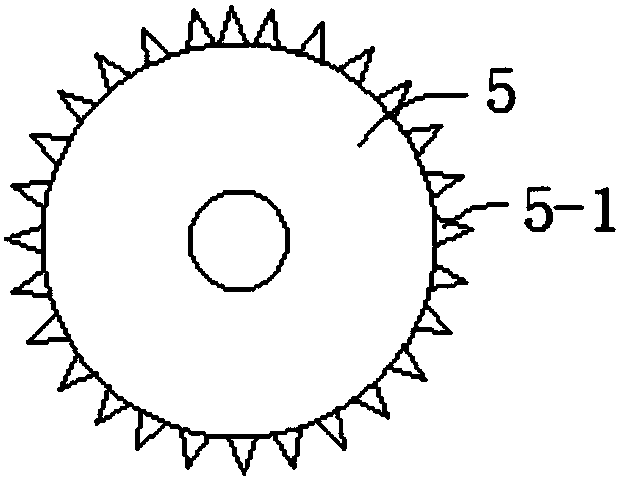

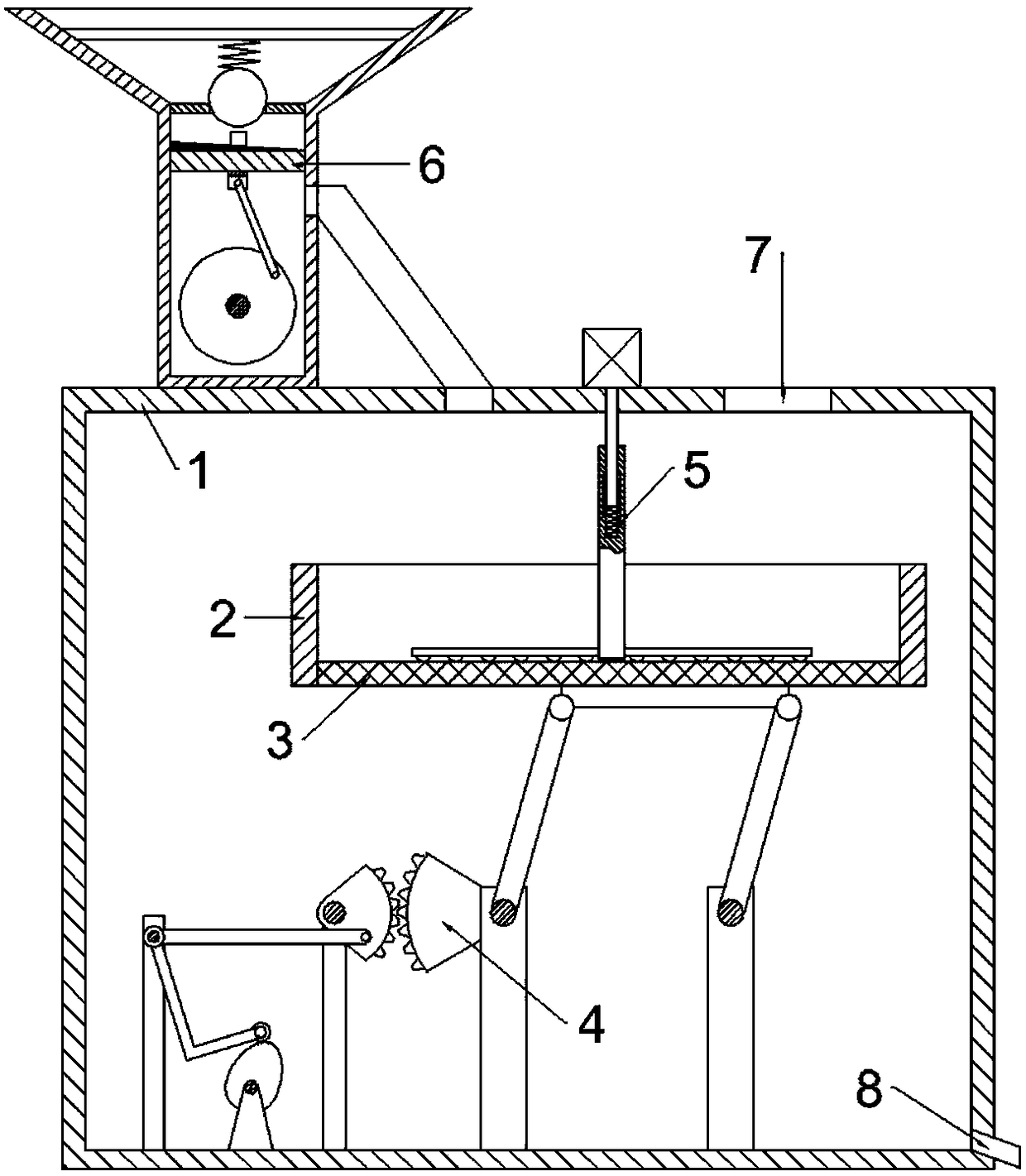

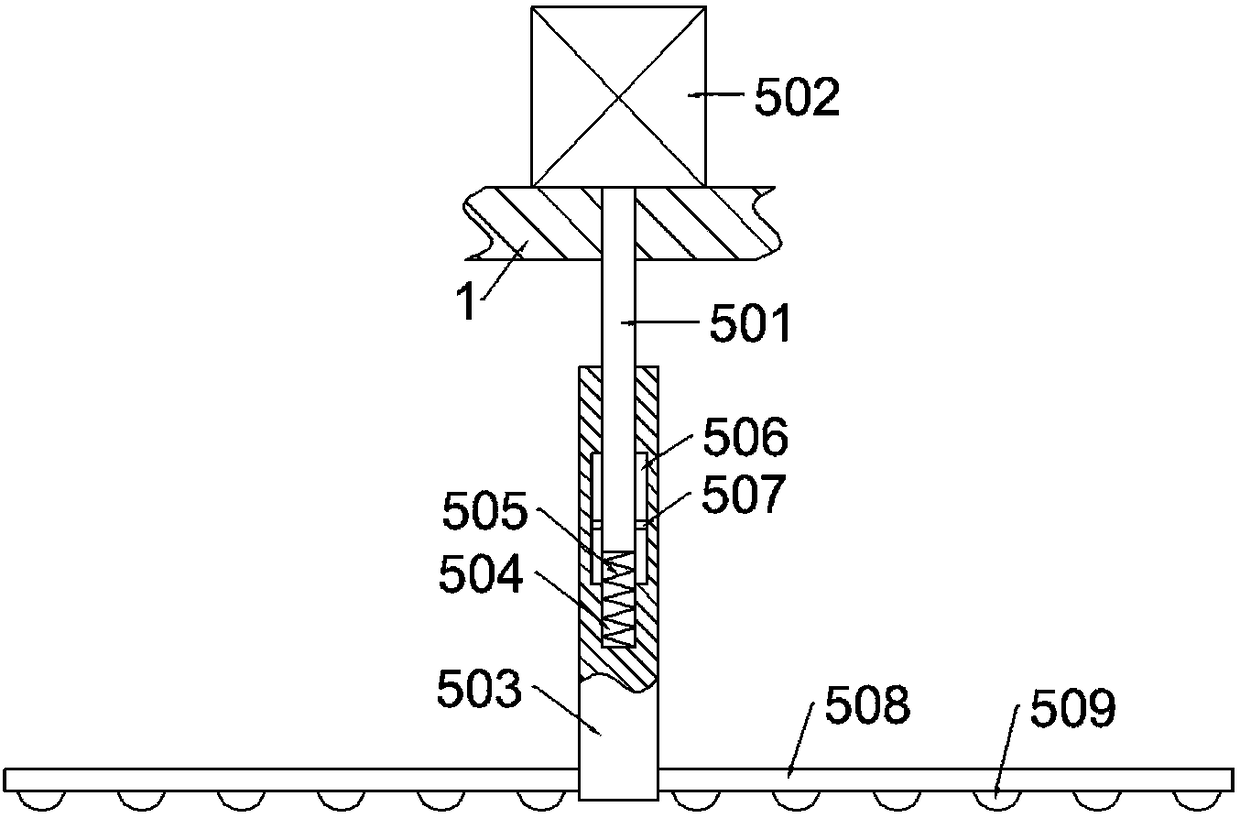

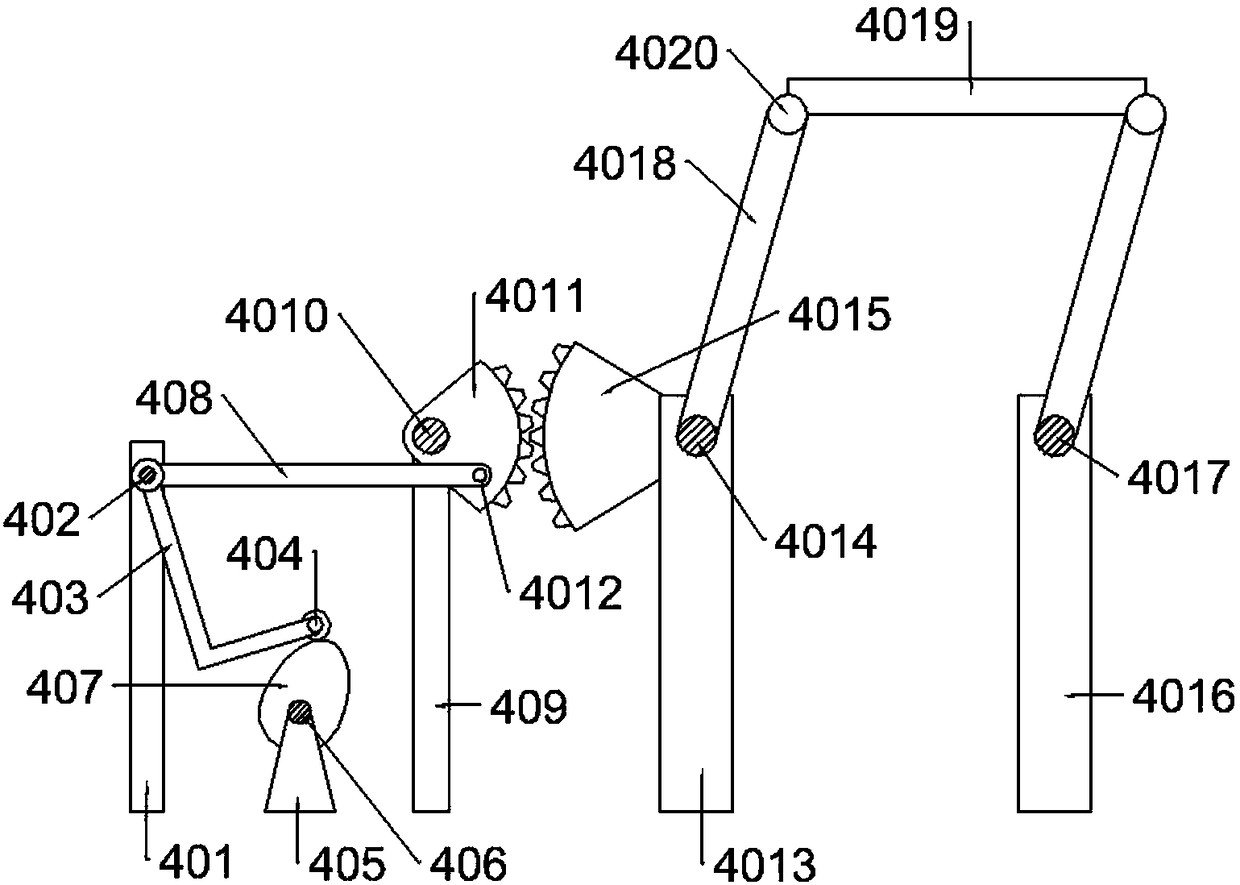

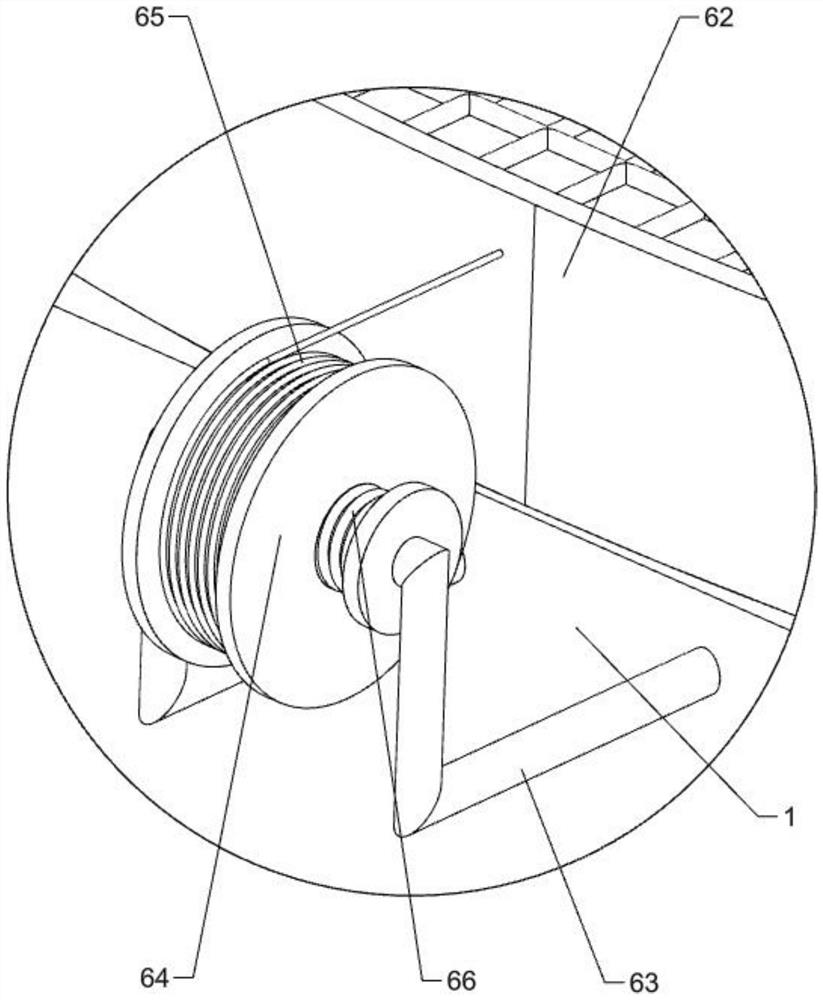

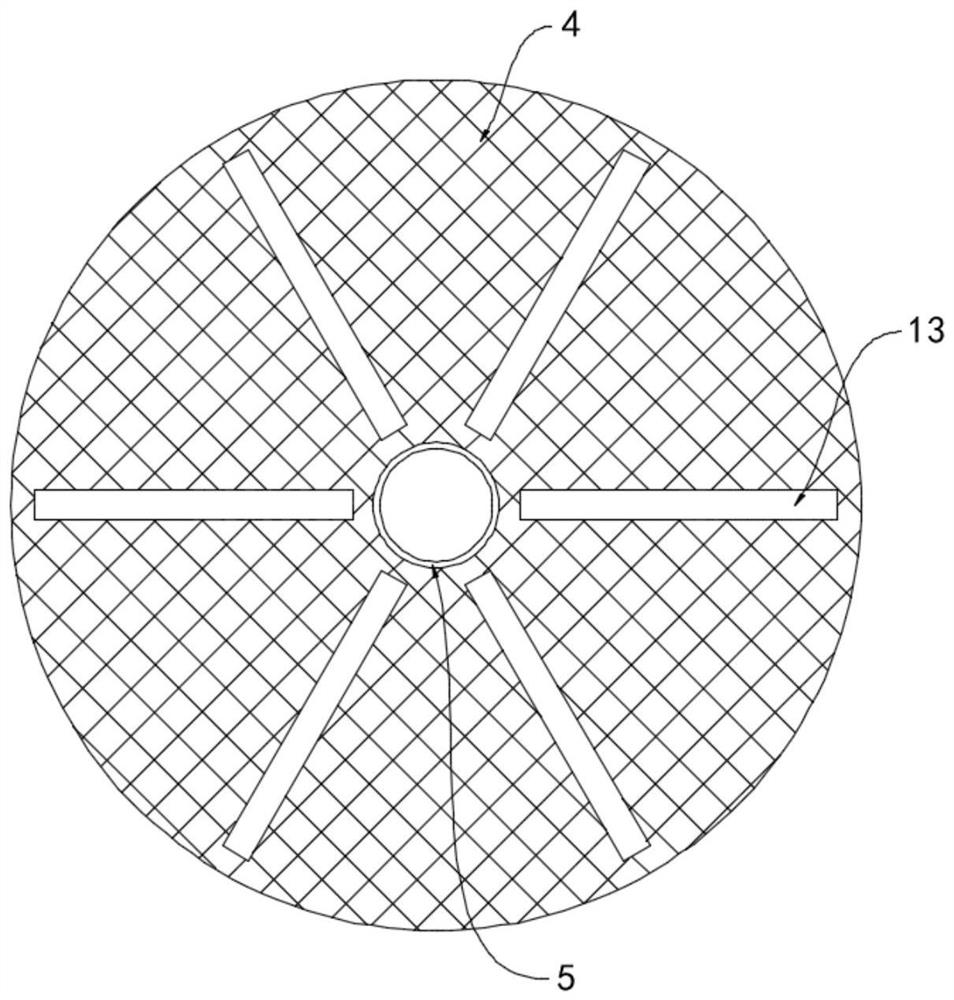

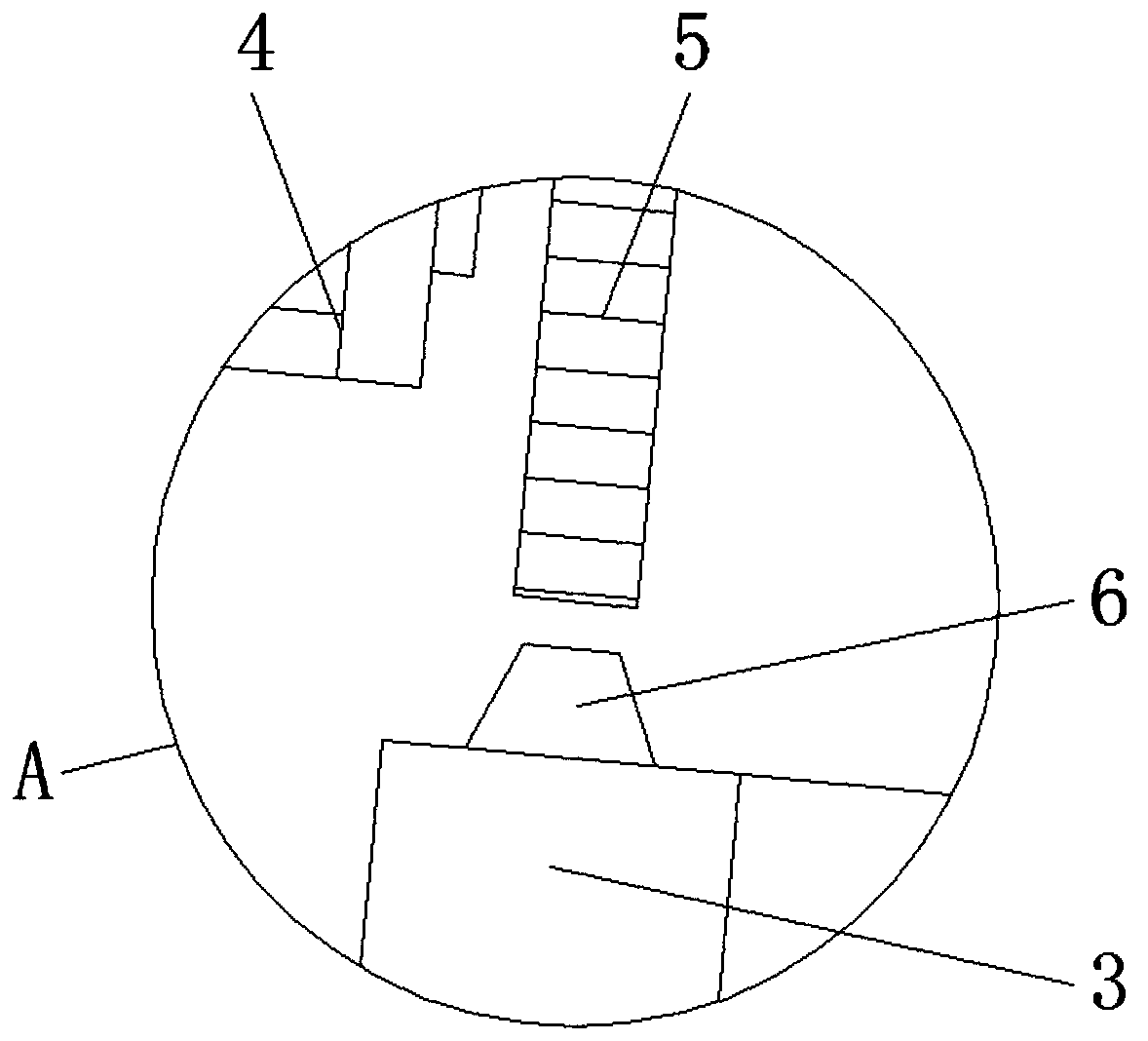

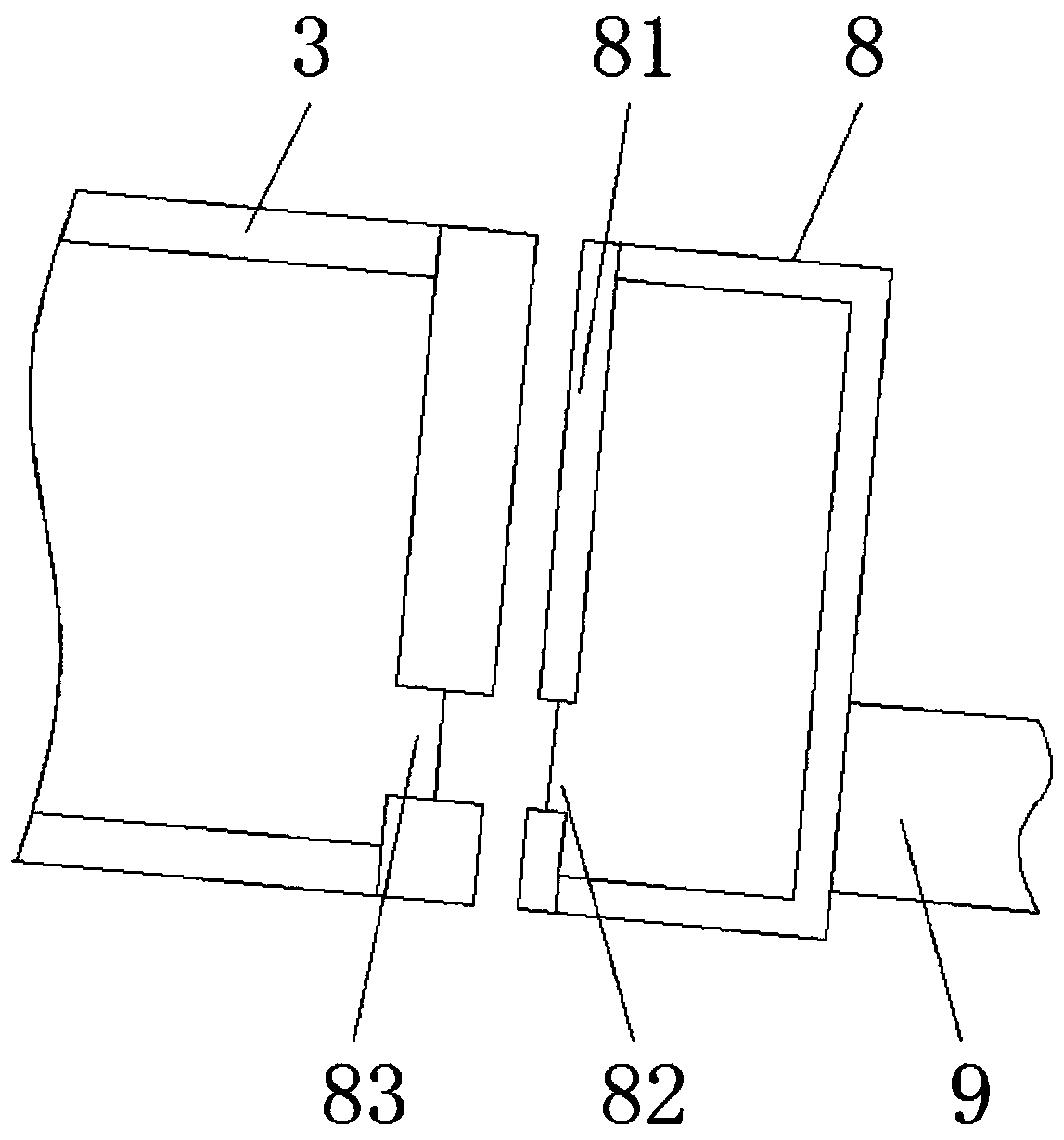

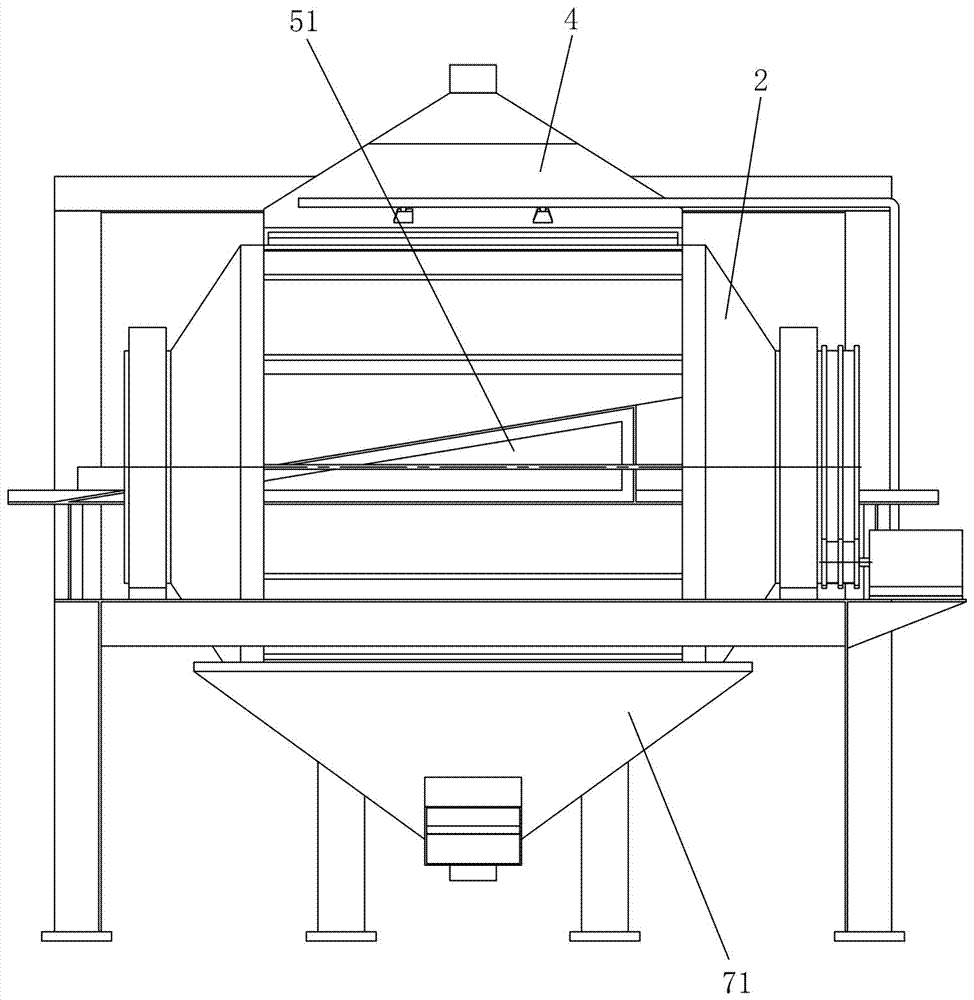

Vibrating screening equipment which has intermittent feeding function and is used for granulate materials

PendingCN108526005ASolve the accumulationGuaranteed to proceed normallySievingScreeningEngineeringMechanical engineering

The invention provides vibrating screening equipment which has an intermittent feeding function and is used for granulate materials so as to achieve the purpose. The vibrating screening equipment comprises a machine shell. A ring-shaped supporting plate is arranged in the machine shell. A screen is fixedly connected to the bottom of the ring-shaped supporting plate. The screen is connected with the inner bottom of the machine shell through a screen vibrating device. A material disturbance device is arranged on the upper side of the screen and comprises a first rotating shaft. The top end of the first rotating shaft penetrates the machine shell and extends upwards. The top end of the first rotating shaft is fixedly connected with an output shaft of a first motor. The equipment has the following beneficial effects that the first rotating shaft drives a disturbance protrusion to rotate through a matching rod, the disturbance protrusion disturbs the materials on the screen so as to ensurenormal processing of the screening work, and the problem about material piling is effectively solved; and by means of a first spring arranged on the portion, the matching rod can move up and down in the rotating process, and thus the matching rod can adapt to the screen moving up and down.

Owner:张慧芳

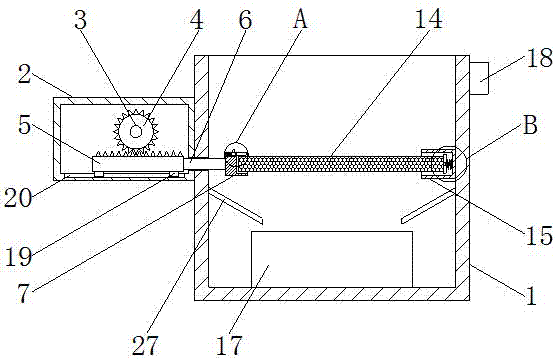

Rice processing chaff sifting device

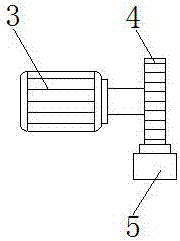

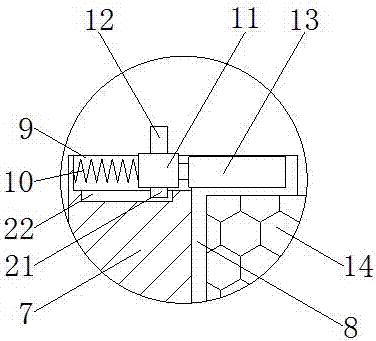

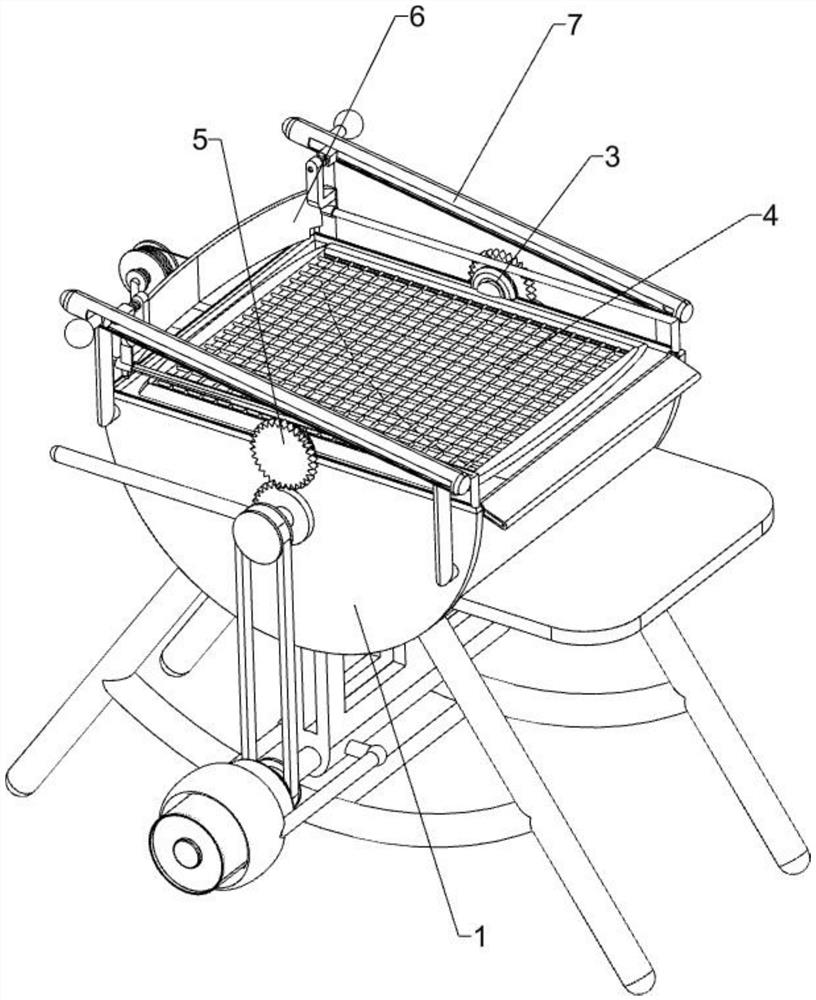

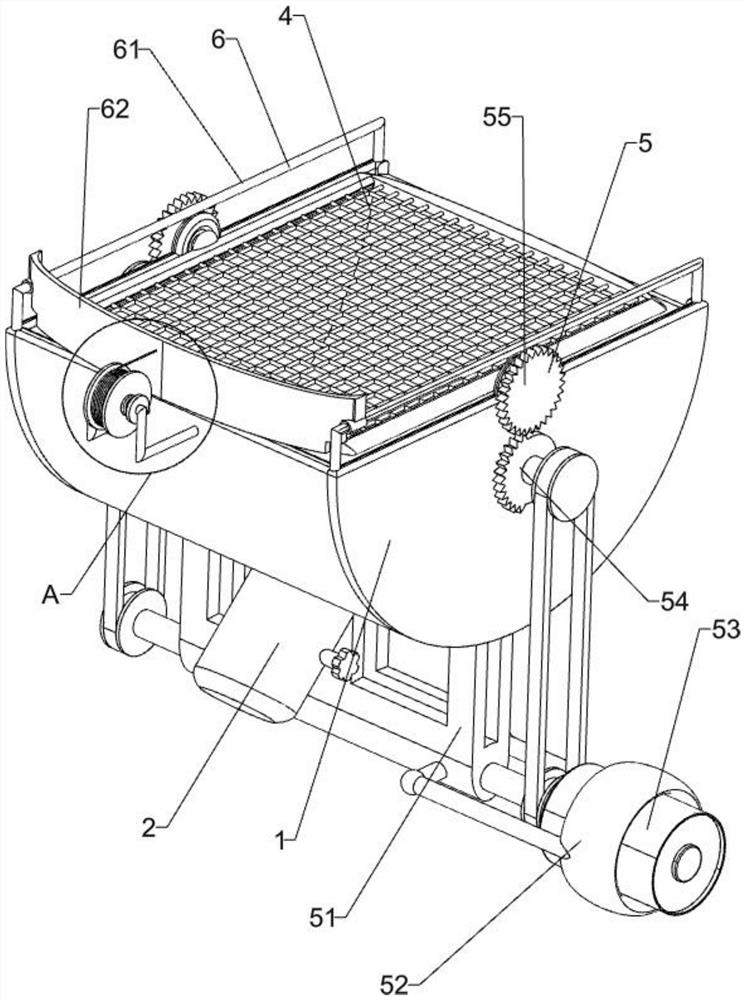

InactiveCN107029991AAchieve the effect of rotationTo achieve the mobile effectSievingScreeningGear wheelEngineering

The invention discloses a rice processing chaff sifting device. The rice processing chaff sifting device comprises a tank body. A holding tank is fixedly connected to the left side of the tank body. A motor is fixedly connected to the back surface of an inner cavity of the holding tank. A gear is fixedly connected with a rotary shaft of the motor. A toothed plate matched with the gear for use is arranged in the inner cavity of the holding tank. The gear is engaged with the toothed plate. A connecting rod is fixedly connected with the right side of the toothed plate. By arranging the motor, the effect of driving the gear to rotate is achieved, through the gear and the toothed plate, the effect of driving a filtering net to move is achieved, rice chaff can be sifted, through a first groove and a second groove, the effect of placing the filtering net is achieved, through a baffle, the effect of fixing the filtering net is achieved, through a first spring and a connecting block, the effect of fixing the baffle is achieved, the filtering net can be dismounted, impurities and rice chaff in the filtering net can be cleared conveniently, and the sifting effect is ensured.

Owner:HUNAN LVHAI RICE & OIL LIMITED

Fry screening device for aquaculture

ActiveCN111869611ATo achieve the screening effectSave human effortClimate change adaptationPisciculture and aquariaEngineeringDrainage tubes

A fry screening device for aquaculture comprises a frame body, two bearing seats, a driving device and a pushing device, wherein the bottom of the frame body is connected with a drainage pipe; the twobearing seats are connected to the two sides of the top of the frame body respectively, and a screen is rotationally connected between the bearing seats on the two sides; the driving device is arranged between the frame body and the screen; and the pushing device is arranged on the frame body. Fry is screened through cooperative operation of the driving device, the pushing device and the screen,and therefore the effect of screening the fry is achieved; the pushing device is assisted to operate through a transmission device, the pushing device does not need to be manually operated to operate,and manpower is effectively saved; and when the fry screening device is operated, the screen can conduct comprehensive screening in the frame body, the screening effect is guaranteed, and the technical problems existing in above patents are effectively solved.

Owner:湖北大场科技有限公司

Rotary screen sand box

ActiveCN108262255AReduce the blanking speedGuaranteed screening effectGas current separationGrain treatmentsEngineeringScreening effect

The invention discloses a rotary screen sand box. The box comprises a box body; a feeding hopper communicates above the box body, and a throwing roller is arranged in the box body and below the feeding hopper; conical toothed plates are arranged on the right side of the throwing roller in the box body; material shaking plates are arranged below the throwing roller in the box body, and conical screen cylinders are arranged below the material shaking plates. According to the box, the throwing roller and the conical toothed plates are arranged, so that the hardened sand blocks are subjected to impact crushing, subsequent screening is facilitated, and the trouble of manual grinding is avoided. The material shaking plates with the upper vibration and the lower vibration is arranged, the crushedscreen is vibrated to carry out slowly blanking, the blanking speed is reduced, and the screening effect is guaranteed; a conical screen cylinder and an annular screen mesh are arranged, the separation of the stones and the fine sand is accelerated by a centrifugal force effect, and the screening efficiency and the screening effect are improved.

Owner:安徽嘉诚建设工程有限公司

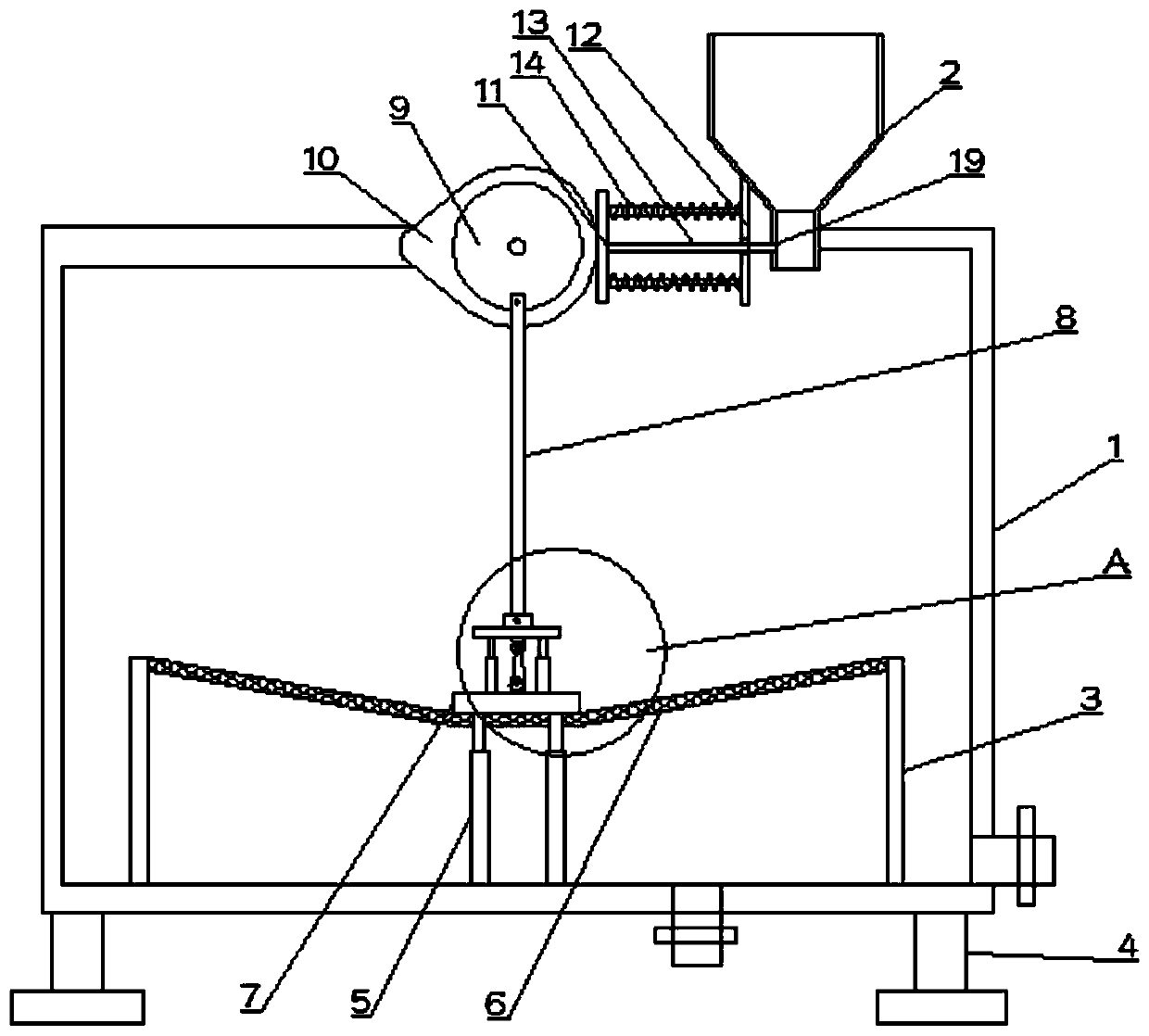

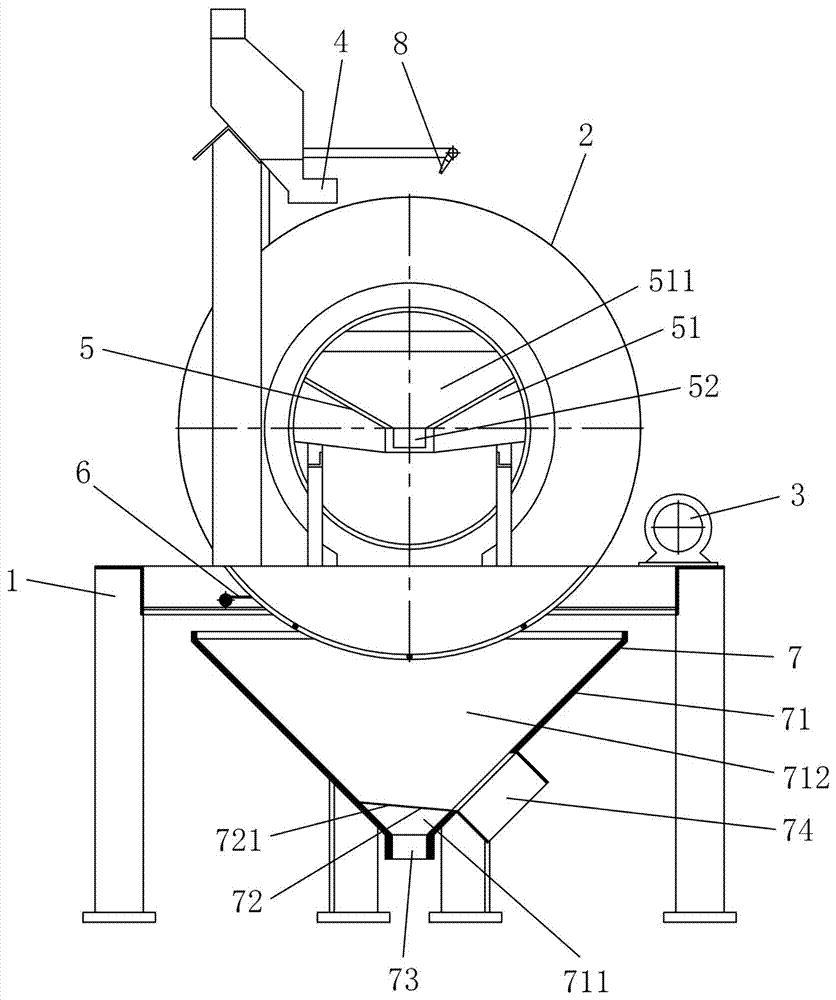

Novel centrifugal granulated fertilizer dryer

InactiveCN111811218AReduce manufacturing costFully dryDrying solid materials without heatDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of dryers, and particularly relates to a novel centrifugal granulated fertilizer dryer. The novel centrifugal granulated fertilizer dryer comprises a shell, wherein the lower end of the shell fixedly communicates with an air inlet pipe, the other end of the air inlet pipe fixedly communicates with an air heater, the upper end of the shell is open, the inner side wall of the upper end of the shell is rotationally connected with a drying net plate, the drying net plate is arranged in a downwards-concave conical face shape, the center of the bottom face of the drying net plate fixedly communicates with a conveying pipe, the lower end of the conveying pipe penetrates through the bottom face of the shell and extends out of the shell, the conveying pipe is in sleeve joint with a sliding sleeve in a rotating mode, and the upper end of the sliding sleeve is fixedly connected with the drying net plate. The novel centrifugal granulated fertilizer dryer can be flatly laid on the surface of the drying net plate according to different water contents and different centrifugal forces of spherical granulated fertilizers, the contact area between the spherical granulated fertilizers and hot air flow is large, the drying effect is good, the dried fertilizers can automatically fall off and be discharged from the conveying pipe, and sufficient and uniform drying is guaranteed.

Owner:王永成

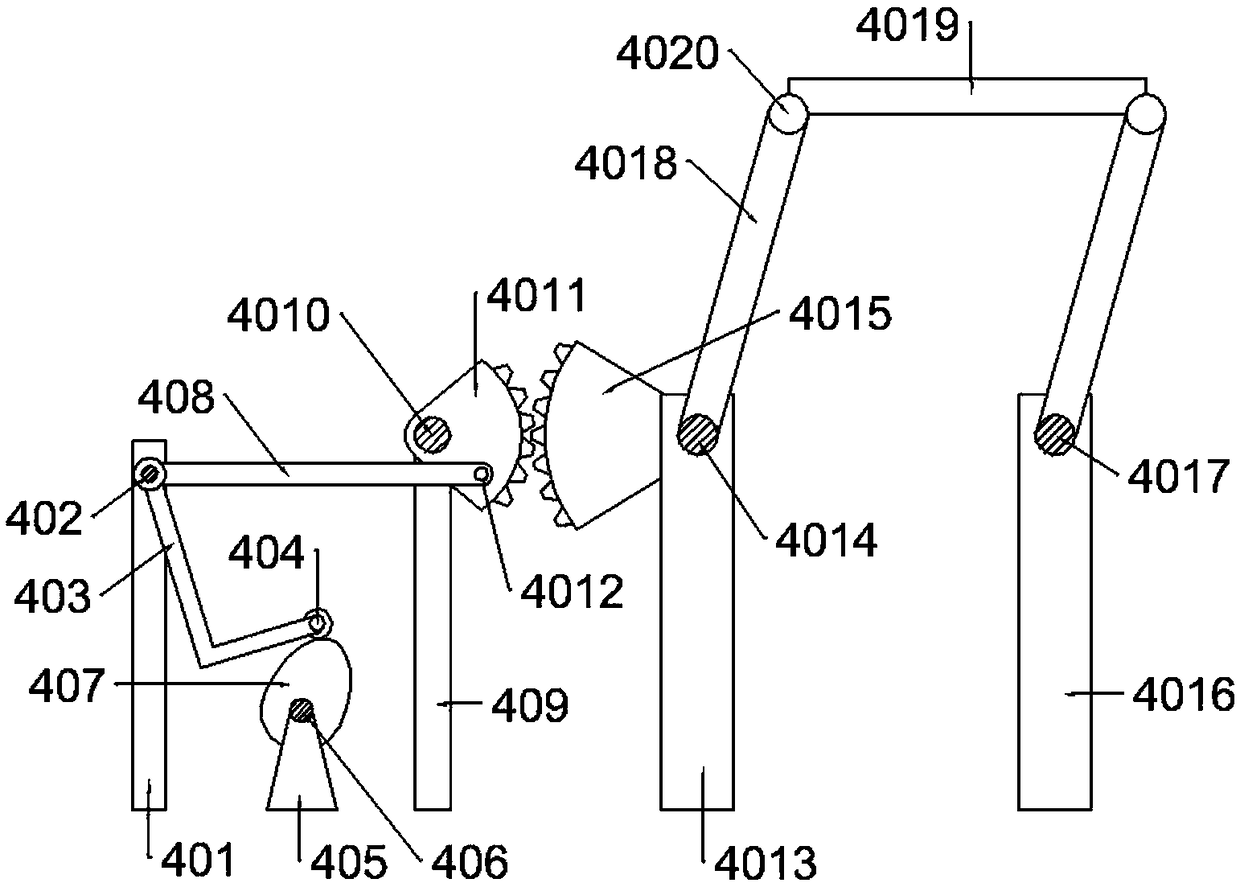

Agricultural product screening device with good screening effect

InactiveCN110302959AGuaranteed screening effectImprove filtering effectSievingScreeningAgricultural engineeringCam

The invention discloses an agricultural product screening device with the good screening effect, and relates to the technical field of agricultural production equipment. The device comprises a main body, wherein an inner separating plate is arranged in the middle of the interior of the main body, a screen is arranged on the upper portion of the inner separating plate, a vibrating mechanism for driving a driving plate to vibrate is arranged in the middle of the driving plate, the vibrating mechanism is connected with a driving disc fixedly sleeving the end part of a rotating shaft A through a connecting rod, the two ends of the connecting rod are connected in a hinged mode, a cam for driving a gate plate to reciprocate is further arranged on the rotating shaft A, the gate plate is arrangedat the outlet of a feeding hopper, the feeding hopper is fixedly arranged on the main body, the outlet of the feeding hopper is arranged at the position convenient for materials to enter the screen, the gate plate is positioned at the left end, the screen is in a low position, and the rotating shaft A is driven by a motor B. The device is good in screening effect, novel in structure and convenientto popularize.

Owner:苏州艾捷尔斯生物科技有限公司

Screening device for building coating production

InactiveCN111530737AExpedited screeningSynchronous feed speedSievingScreeningReciprocating motionConstruction engineering

The invention belongs to the technical field of building material production equipment, and provides a screening device for building coating production. The screening device comprises a device body, ascreening component and a feeding hopper. The interior of the device body is arranged in a hollow manner, and the device body is used for screening. The screening component is arranged in the devicebody and comprises an obliquely-arranged screen and side plates arranged on the two sides of the screen, L connecting rods doing reciprocating motion at the same time are fixedly mounted at the upperends of the side plates on the two side plates, the L connecting rods are used for driving the screen to do stretching motion, and a drive assembly for driving the L connecting rods to reciprocating motion is further included. The feeding hopper is fixedly mounted above the device body and communicates with the interior of the device body. A smashing assembly vibrating up and down is arranged at adischarging opening of the feeding hopper, the smashing assembly is in transmission connection with the drive assembly, and the drive assembly provides power for the smashing assembly. According to the screening device, raw material screening is accelerated, meanwhile, the feeding speed and the screening speed are synchronous, screening is carried out smoothly, stacking is avoided, and the screening effect is guaranteed.

Owner:济南艾博经贸有限公司

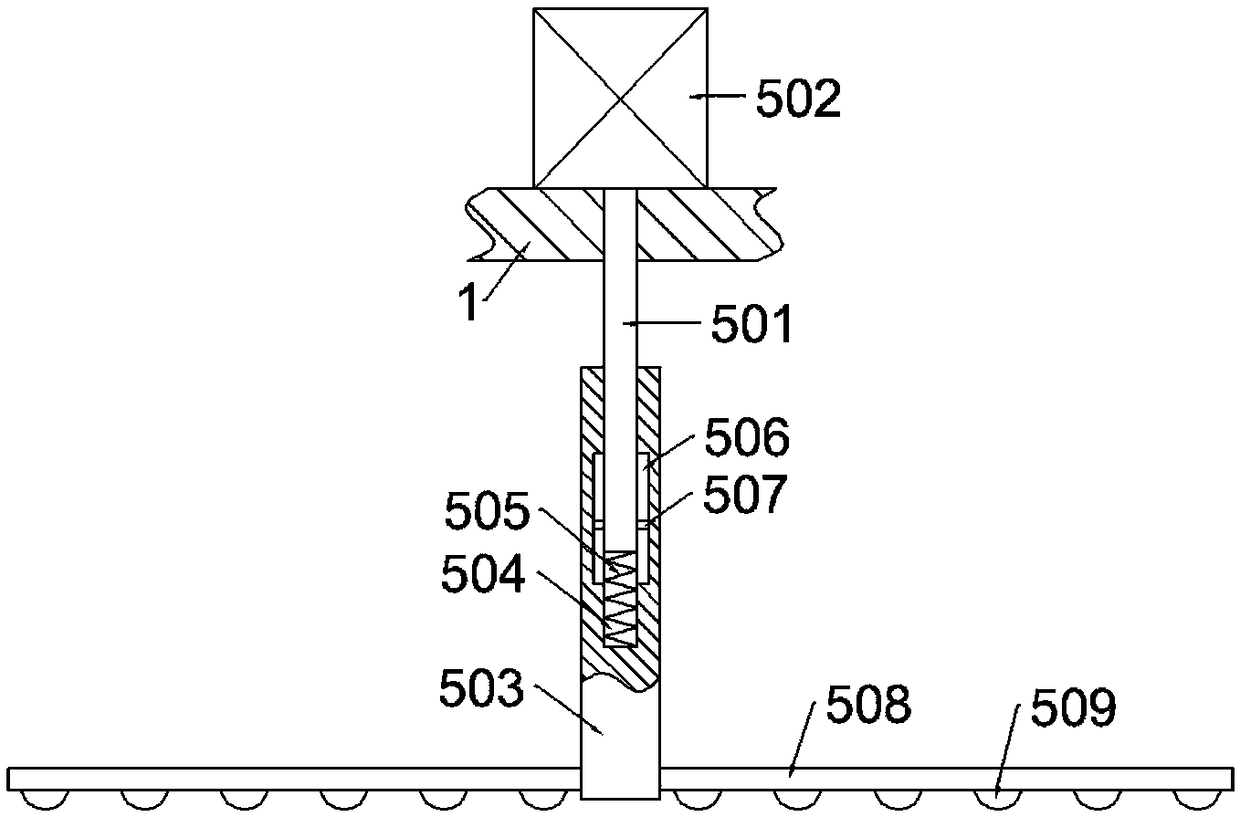

Small powder coating mixing and vibrating screen

InactiveCN108405317AGuaranteed screening effectWell mixedSievingShaking/oscillating/vibrating mixersEngineeringPowder coating

The invention discloses a small powder coating mixing and vibrating screen. The small powder coating mixing and vibrating screen comprises a frame. A screen box is arranged at the upper end of the frame. A vibrating motor is connected to the bottom of the screen box. The vibrating motor is fixed on the frame. The screen box comprises an upper box cover and a lower box body which are oppositely arranged. The upper end of the upper box cover is connected with multiple feed pipes. A screen body is arranged in the lower box body. A discharging pipe is connected to the bottom of the lower box body.Multiple springs are evenly fixed to the lower end of the lower box body. The screen box is fixedly connected with the frame through the springs. According to the vibrating screen for powder coatingmixing and filtering, multiple coating raw materials can be mixed and screened according to the matching, the screening effect is ensured, full mixing under the vibrating effect is realized, and the working efficiency is greatly improved.

Owner:浙江安吉朝辉新材料有限公司

Coal ash roller screen

PendingCN107185798AQuick filterEfficient screeningSievingScreeningScreening effectElectric machinery

The invention discloses a coal ash roller screen. The coal ash roller screen comprises a base, a roller screen body, a rotary drive motor, a funnel, a belt conveyor and a feeding slot, and further comprises a swing drive frame and a hinged supporting frame; the swing drive frame and the hinged supporting frame are separately arranged at the two ends of the base; the roller screen body comprises a rotary shaft and a screen barrel fixedly arranged on the outer periphery of the rotary shaft; one end of the rotary shaft is connected with the swing drive frame, and the other end of the rotary shaft is connected with the hinged supporting frame; the rotary drive motor is connected with the other end of the rotary shaft; the funnel is fixedly arranged on the base and is positioned below the screen barrel; the belt conveyor is fixedly arranged on the base and is positioned below the funnel; and the feeding slot can be detachably formed in the base and is positioned above the swing drive frame. The coal ash roller screen is reasonable in structural design; the swing drive frame and the hinged supporting frame can be connected with the roller screen body, so that the roller screen body swings up and down; and in a coal ash screening process, a better screening effect can be obtained, so that screening efficiency can be promoted to be improved.

Owner:甘肃天碁新型建材有限公司

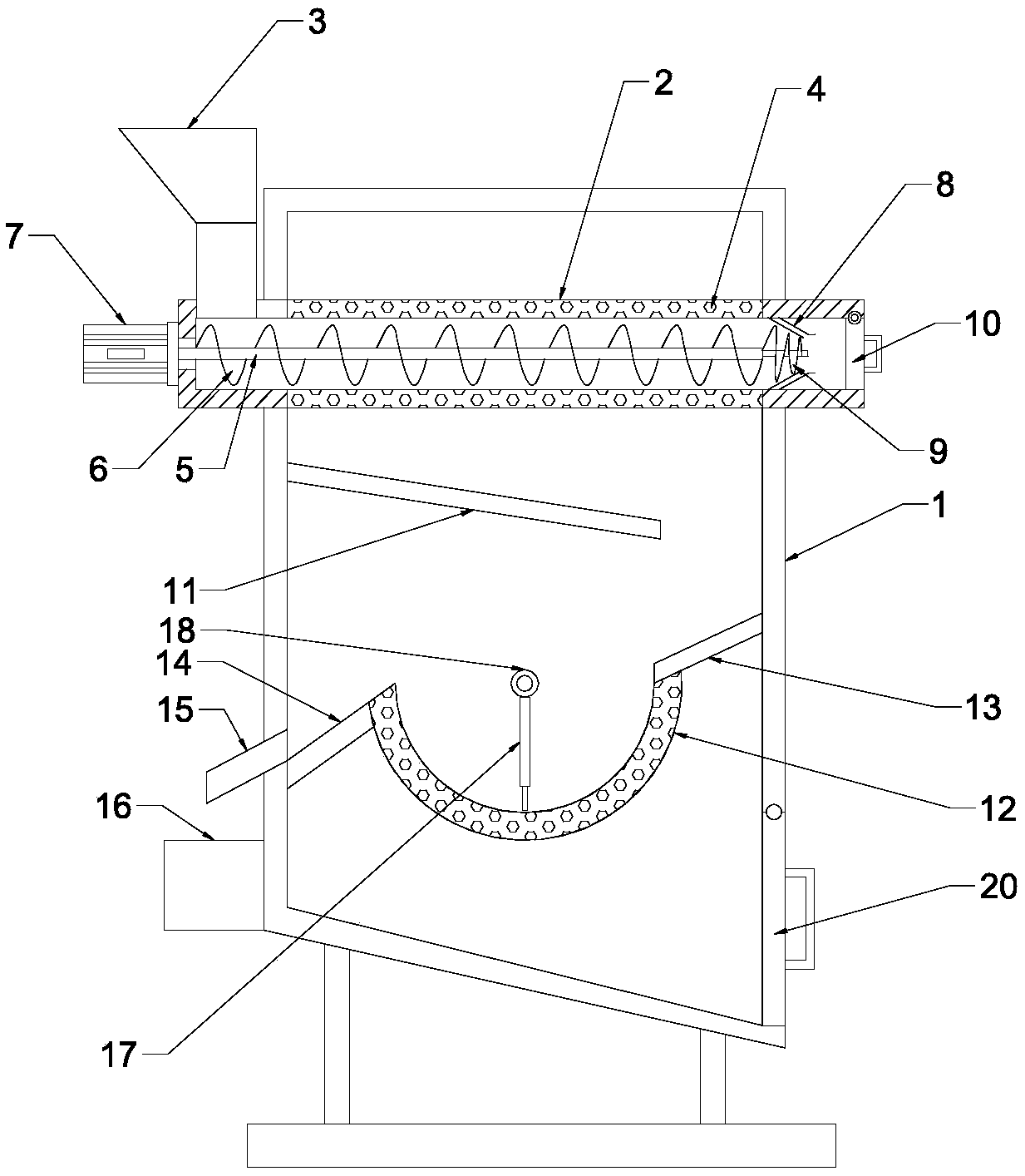

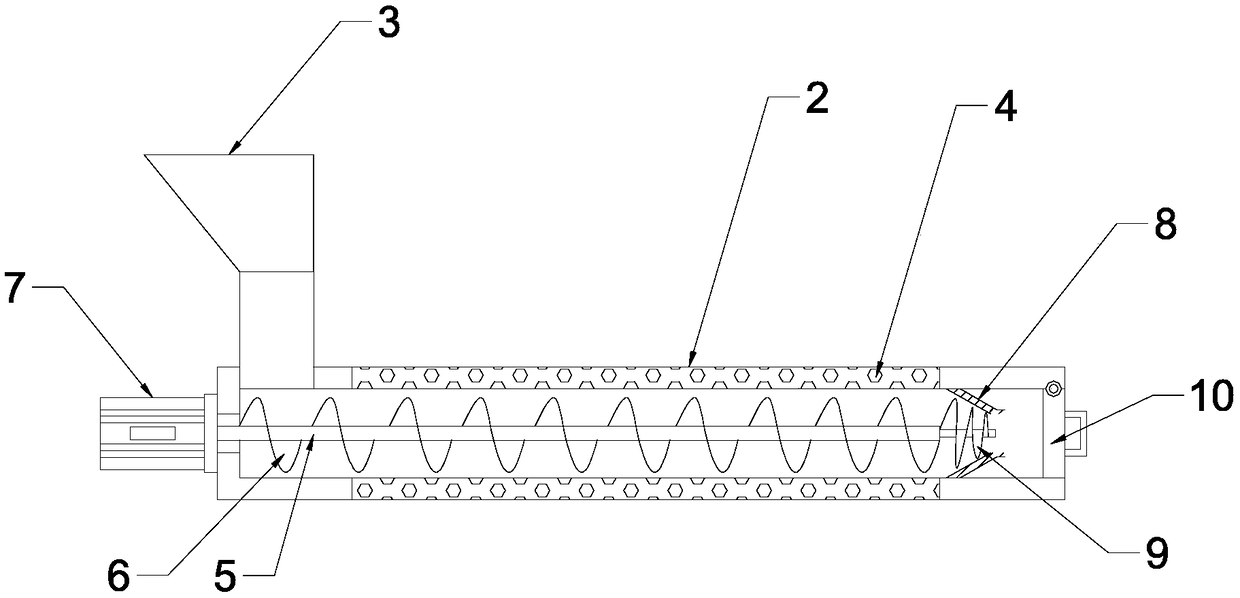

Grain fine screening device

InactiveCN107457181AGuaranteed purityLittle outside influenceSievingGas current separationFixed bearingScreening effect

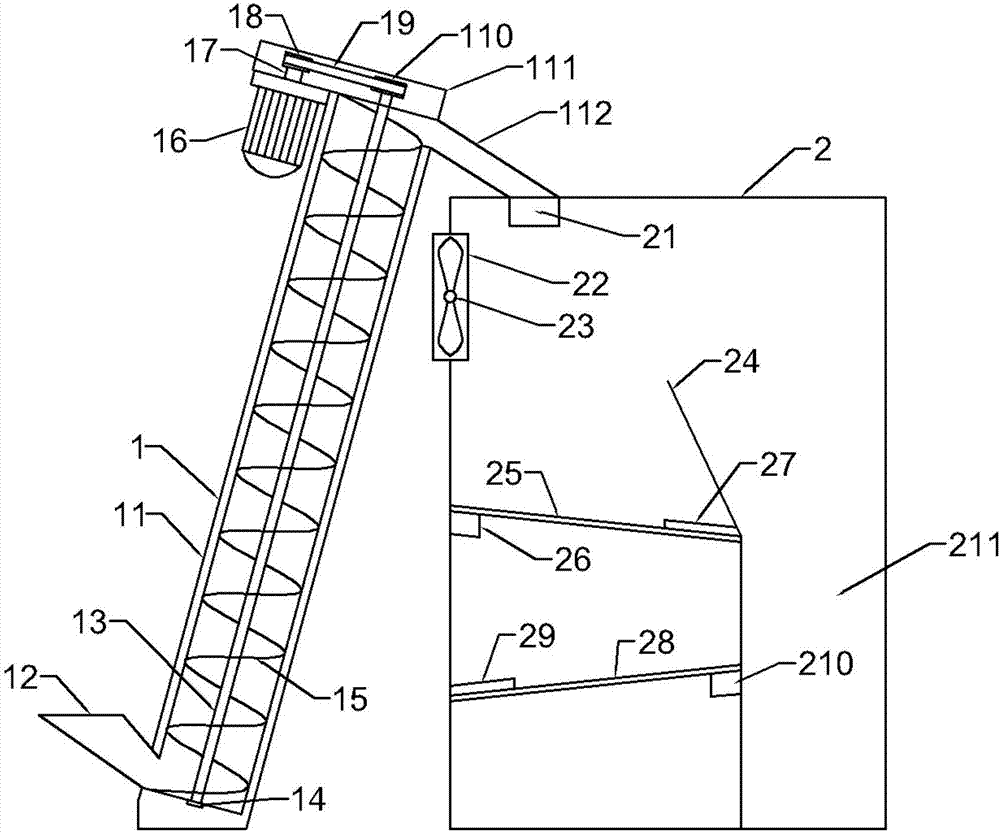

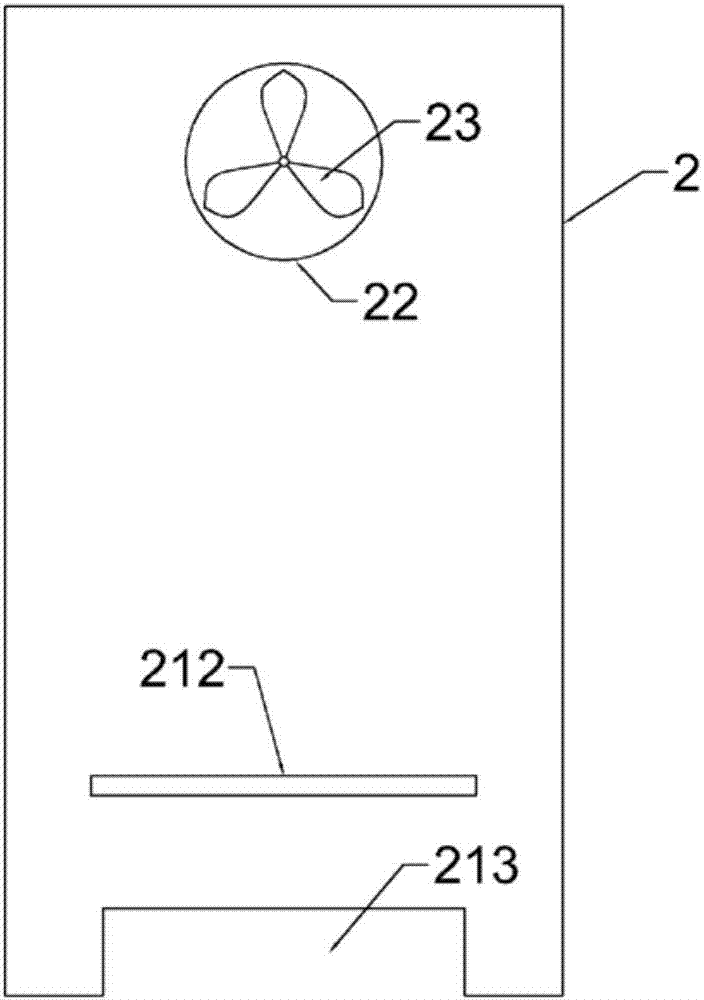

The invention discloses a grain fine screening device. The grain fine screening device comprises a feeding device and a separating screening bin chamber; the feeding device comprises an inclined feeding cylinder; a feed port is mounted on one side of the bottom of the inclined feeding cylinder; a transmission bin is mounted at the top of the inclined feeding cylinder; a conveying shaft is mounted in the inclined feeding cylinder; a conveying spiral plate is mounted on the conveying shaft; the conveying shaft is connected with a power motor on one side of the inclined feeding cylinder through the transmission bin; a conveying outlet is formed in the side, near the separating screening bin chamber, of the top of the inclined feeding cylinder; the conveying outlet is connected with a top opening of the separating screening bin chamber through a conveying channel; and one end of the bottom of the conveying shaft is mounted on the bottom surface of the inner side of the inclined feeding cylinder through a fixed bearing. Through mutual cooperation between the feeding device and the separating screening bin chamber, the grain fine screening device can finely screen grains, and can remove dust, bran, gravels and sand contained in the grains; the influence of the outside on the whole device in the working process is low; the working state is constant; and the screening effect can be effectively guaranteed.

Owner:陈珊珊

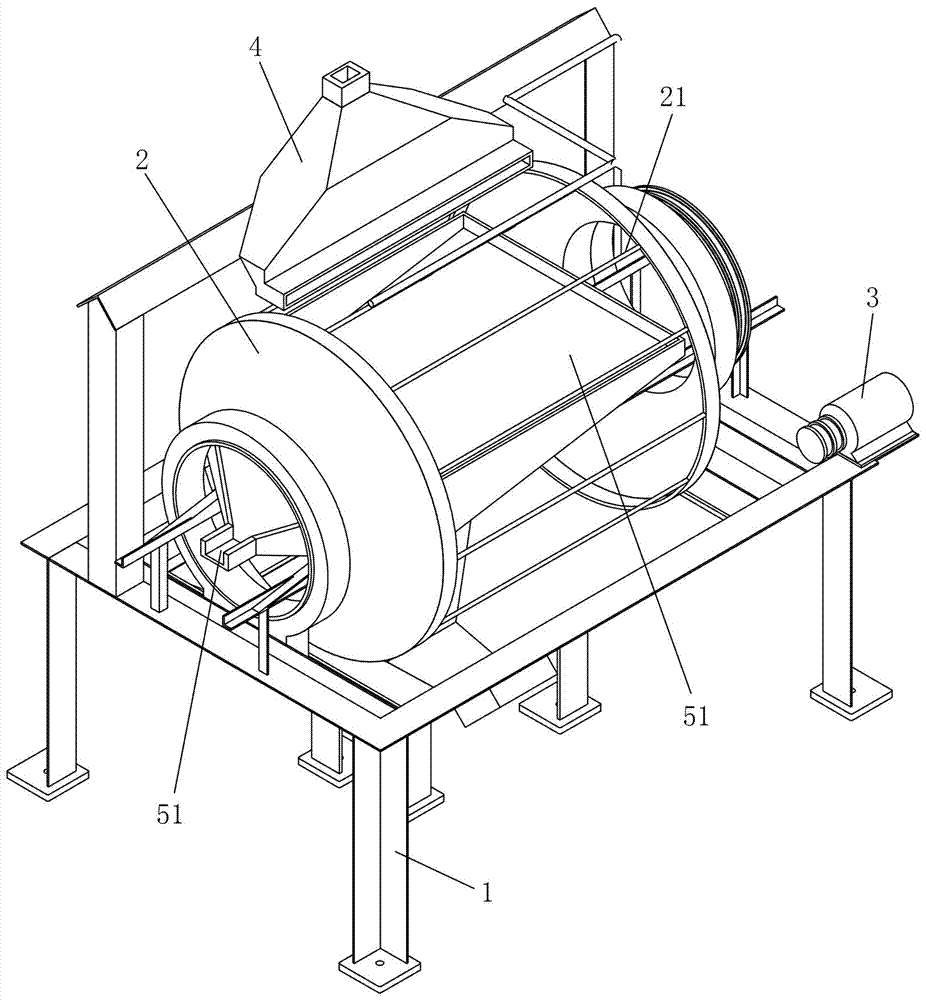

Gravel screening device with sludge cleaning function

InactiveCN108745616AAdd sieving pathFully screenedWater/sewage treatment by flocculation/precipitationWet separationScreening effectSludge

The invention discloses a gravel screening device with a sludge cleaning function. The device comprises a sand loading hopper, a conveying device for conveying sand in the sand loading hopper to a high place, a multistage sand filter device, a sand stacking room, a drainage ditch, a waste water recovery pool and a sand washing device. Through arrangement of spiral blades on the inner wall of a roller, the gravel motion path is effectively prolonged, and full gravel screening is promoted; the gaps of the spiral blades are reasonably arranged according to the particle sizes of gravels to guarantee the screening effect; a water tank is formed in the ground of the sand stacking room for achieving a buffer effect on falling gravels to protect the ground; through a detachable separation plate, the capacity of a compartment is reasonably adjusted according to the gravel screening conditions to guarantee the space utilization rate; waste water is purified through the waste water recovery poolto improve the water utilization rate; and a precipitation pool is cleaned through a sand-water separator to guarantee continuous operation of the waste water recovery pool.

Owner:浦馨月

Efficient powder sieving equipment

ActiveCN102814276AEliminate the "arch bridge effect"Simple structureSievingScreeningReciprocating motionAir knife

The invention discloses efficient powder sieving equipment which comprises a support, a discharge bin, a sieving box and a sieving box swing system. The sieving box comprises a box body and a sieve, the box body is arranged on the support and capable of reciprocating along a rail mounted on the support, a compressed gas blowback system is arranged below the box body and comprises two polish rods, a gas knife, a servo motor, a first synchronous pulley, a second synchronous pulley and a synchronous belt, the two polish rods are parallelly mounted on the support, the servo motor and the second synchronous pulley are mounted on the support, the first synchronous pulley is mounted on an output shaft of the servo motor, the first synchronous pulley and the second synchronous pulley are connected by the aid of the synchronous belt, the gas knife is positioned below the sieve, mounted between the two polish rods through linear bearings and capable of reciprocating along the polish rods and blowing the sieve, and one end of the gas knife is fixedly connected with the synchronous belt. The efficient powder sieving equipment is simple in structure, reasonable in design, convenient to operate, no easy to block meshes of the sieve, accurate in sieving and high in efficiency.

Owner:JINDUICHENG MOLYBDENUM CO LTD

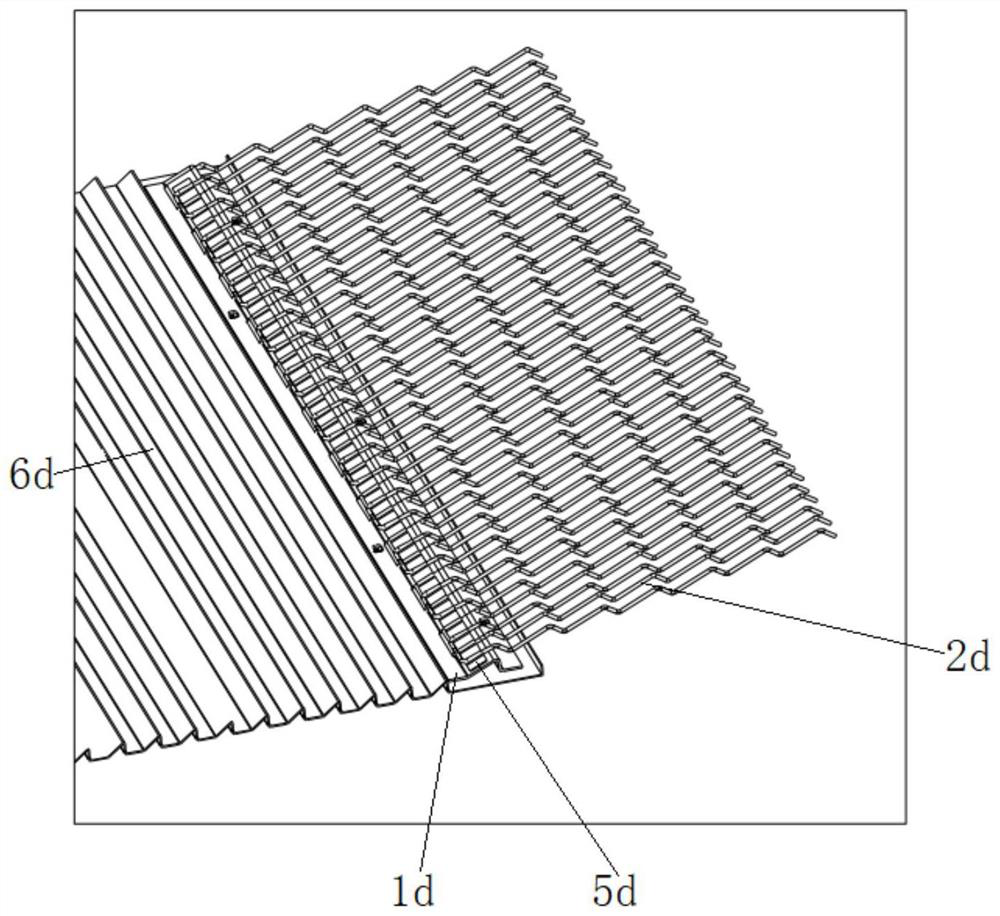

Screening system and combine harvester

PendingCN112690107AAvoid wastingPrevent throwingMowersThreshersAgricultural scienceAgricultural engineering

The invention provides a screening system and a combine harvester. The screening system comprises a vibrating screen, a front sealing structure, a grain separating structure and a driving structure. The vibrating screen is provided with an upper screen area and a lower screen area, a lifting structure is arranged at the tail end of a corrugated plate in the upper screen area to increase the fall between the corrugated plate and a scaly screen, two-section lifting is formed in cooperation with a tail screen at the tail end, clustered crops are fully shaken to be scattered and loosened, and waste caused by the fact that crop straw carries grains to be discharged is avoided. Meanwhile, the front sealing structure is arranged at the front end of the corrugated plate to prevent the grains from being thrown out by the vibrating screen. The grain separating structure is arranged at the position, between a grain collecting area and an impurity collecting area, below the vibrating screen, so that clean grains are effectively separated from impurities such as straw, the grains are collected more completely and cleanly, waste is avoided, and the screening efficiency is improved.

Owner:JIANGSU WORLD AGRI MACHINERY

Rice processing screening device

InactiveCN109290205AEfficient separationImprove screening efficiencySievingGas current separationGratingScreening effect

The invention discloses a rice processing screening device. The rice processing screening device comprises a tank, a primary screening mechanism and a secondary screening mechanism. The primary screening mechanism comprises a screen drum. The left end of the screen drum communicates with a feed hopper. A conical cover is nested in the right end of the screen drum. The secondary screening mechanismis arranged in the tank. The secondary screening mechanism comprises a screen net. A grating plate is arranged above the screen net. The rice processing screening device conducts high-efficiency preliminary screening on a rice material through the screen drum provided with a first spiral blade set, conducts high-efficiency separation on waste residues through the conical cover and a second spiralblade set to improve the screening effect, conducts secondary screening on the rice material and separates residues through the arc-shaped screen net and the grating plate to improve the screening effect and conducts separation and collection on dust particles in the rice material through an air blower, a blowing head, a dust collection cover and a cyclone sedimentation cylinder to ensure the screening effect.

Owner:南县三缘米业有限公司

Multifunctional camellia seed screening device

InactiveCN109046993AReduce workloadGuaranteed screening effectSievingGas current separationEngineeringMultiple function

The invention belongs to the field of camellia oil processing and particularly relates to a multifunctional camellia seed screening device in order to achieve the technical effects that the multifunctional camellia seed screening device can rapidly separate shells of oil-tea camellia from camellia seeds, no manual work is required in separating and screening processes, and the working load is reduced. The multifunctional camellia seed screening device comprises an inserting plate, an annular sliding rail, a second rotating shaft, a second motor, a second mounting plate, a moving rod, a first elastic piece and a fixing block lamp; a screening frame is fixedly connected with the top of a bottom plate; a side plate is fixedly connected with one side of the bottom plate; a first collection frame is placed at the top of the bottom plate and located in the screening frame; and a discharge port is formed in one side of the screening frame. The effects that the shells of oil-tea camellia are removed, the camellia seeds are screened based on the size, and no manual work is required in the processes and the working load is reduced are achieved.

Owner:王宁

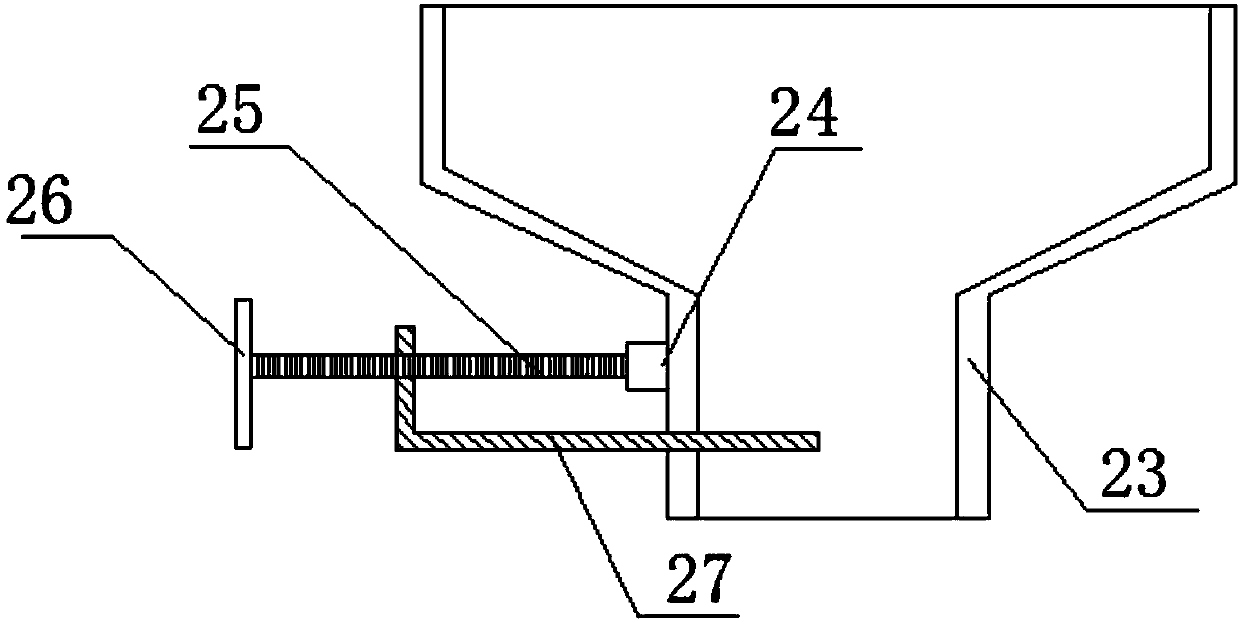

Screening and drying device for bract of globe artichoke

The invention discloses a screening and drying device for the bract of globe artichoke. The screening and drying device comprises a machine body, a feeding hopper a sliding plate, a slag discharging pipe and a discharging pipe, wherein the feeding hopper is mounted on the side of the machine body; a horizontally distributed cross shaft is arranged inside an accommodating groove; the two ends of the cross shaft are rotationally connected with a drying disk; the discharging pipe is mounted at the bottom end of the machine body; a power box is fixedly mounted on the surface of the outer part of the machine body; the end of a rotating shaft penetrates through the side wall of the machine body and extends into the power box; a fan shaft and a transmission shaft which are parallel to each otherare fixed into the power box; and a cavity is formed in the rotating shaft. According to the screening and drying device, a screening and drying structure in an all-in-one machine is redesigned, so that the quantitative screening and drying operation of the bract is ensured, the bract is synchronously and gently stirred by the self rotation of the drying disk in the drying process, the drying efficiency is ensured, and the treatment effect is good.

Owner:HUNAN UNIV OF ARTS & SCI

Vibration screening feeding hopper

InactiveCN107971213AGuaranteed screening qualityEnsure screening flowSievingScreeningElastomerThree stage

The invention discloses a vibration screening feeding hopper and relates to the technical field of Chinese medicinal herb processing equipment. The vibration screening feeding hopper comprises a hopper body, wherein the hopper body comprises a primary screening mechanism and a secondary screening mechanism sequentially arranged from top to bottom; an elastomer is connected between the primary screening mechanism and the secondary screening mechanism; the primary screening mechanism comprises a feeding screen and a second screen sequentially arranged from top to bottom; a striking assembly is arranged between the feeding screen and the second screen; the secondary screening mechanism comprises a third screen and a vibrating assembly arranged below the third screen and used for driving the third screen to vibrate; one end of the elastomer is connected with the second screen; and the other end of the elastomer is connected with the third screen. According to the vibration screening feeding hopper, powder sequentially passes through the feeding screen, the second screen and the third screen for three-stage screening, so that the screening quality of the powder is ensured; and in addition, through vibration, the screening circulation of the powder is ensured and the screening efficiency is improved.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

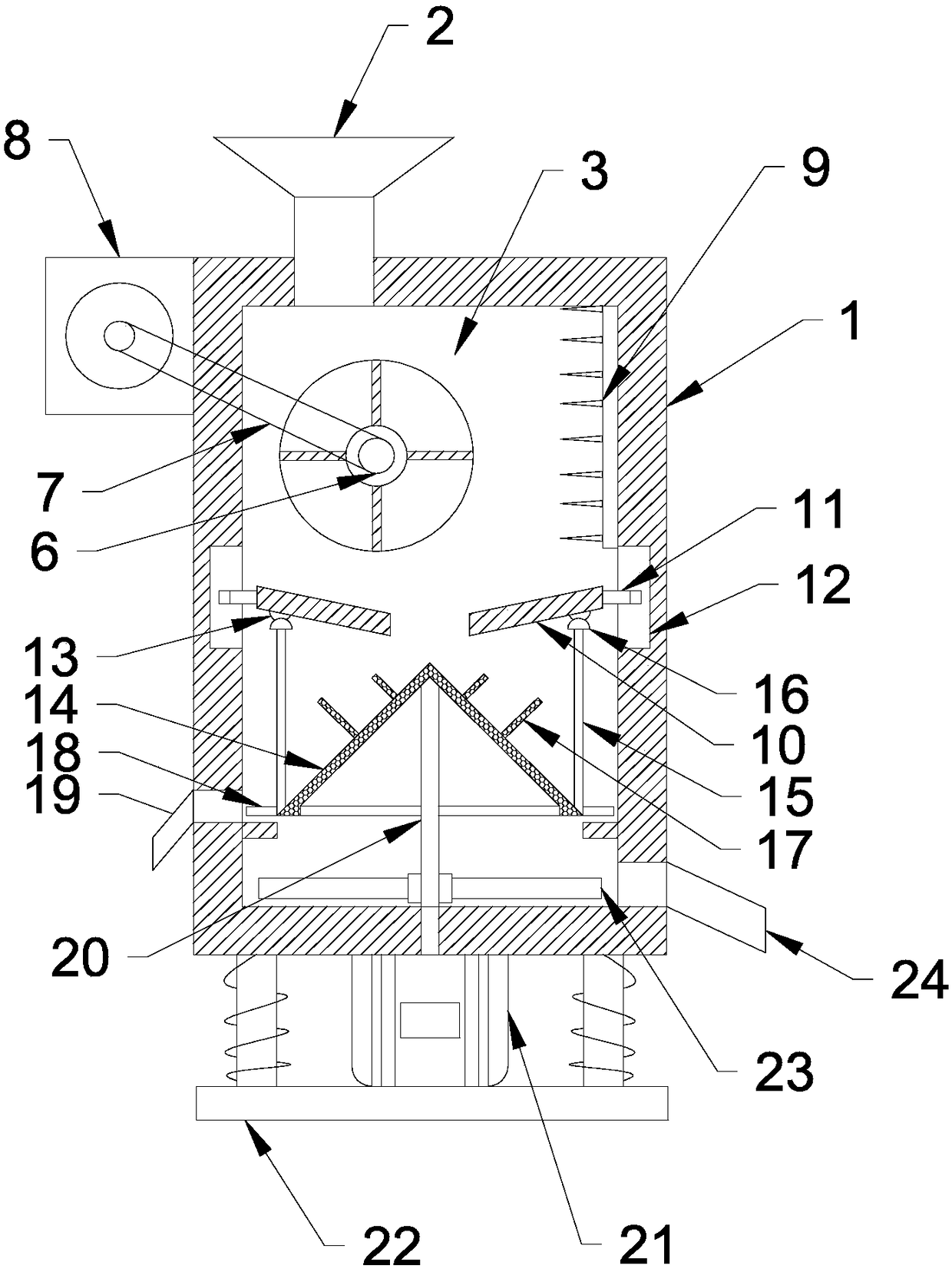

Raw material pulverizer for polyurethane foam plastic production and pulverizing method

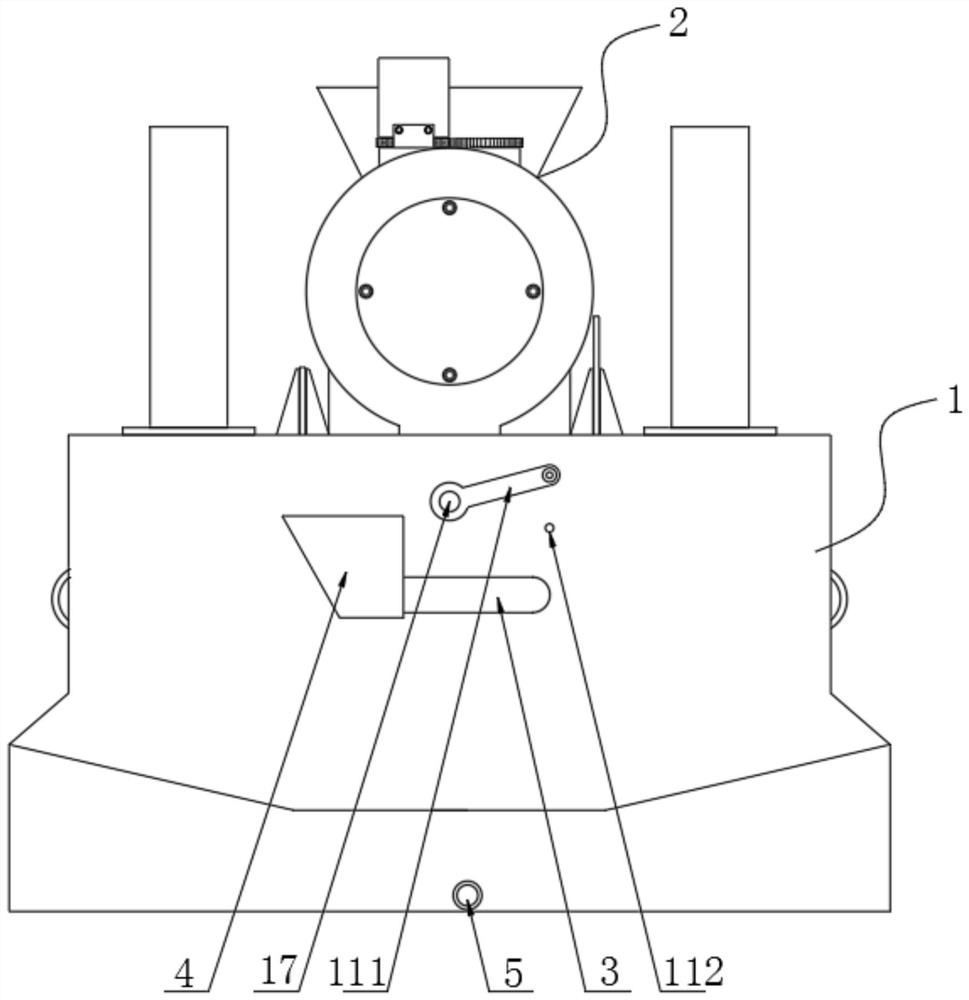

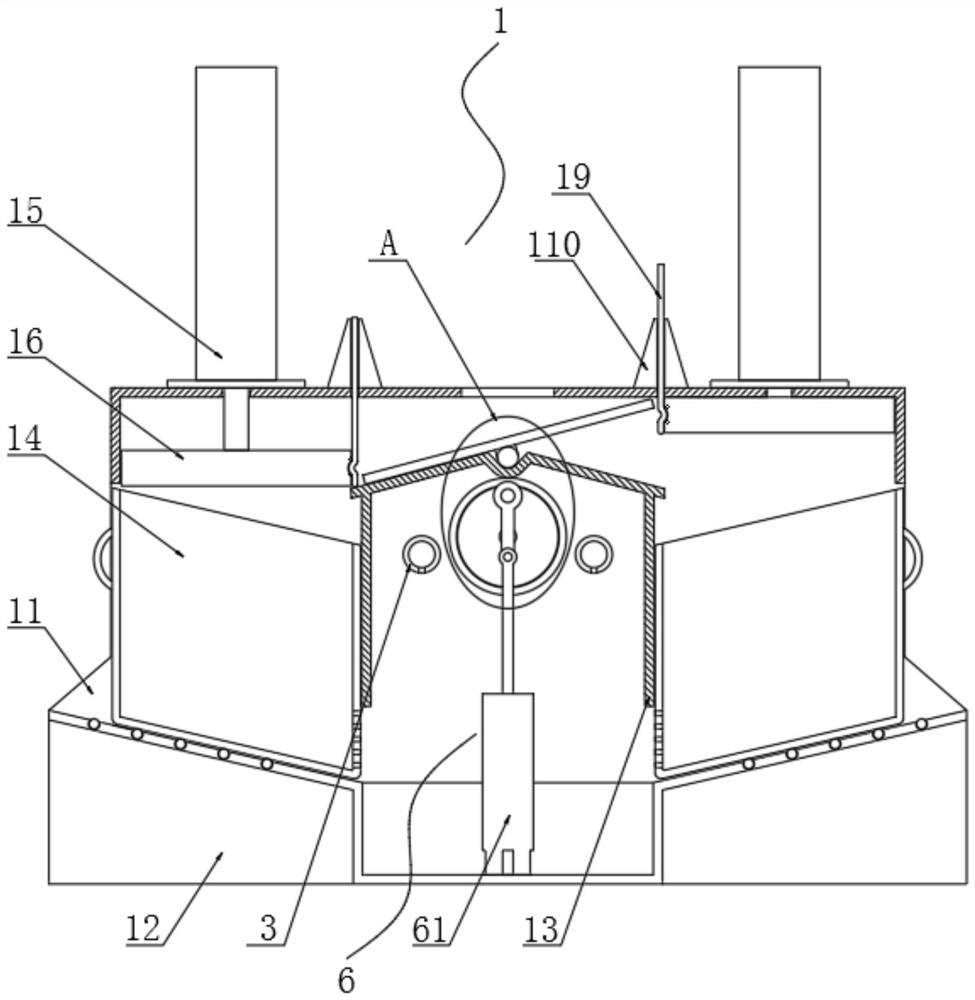

InactiveCN113102068AAvoid damageReasonable structureGrain treatmentsVibration suppression adjustmentsSpiral bladeElectric machinery

The invention discloses a raw material pulverizer for polyurethane foam plastic production and a pulverizing method, and relates to the field of polyurethane foam plastic production. The raw material pulverizer comprises a base, the top of the base is connected with a pulverizing box through a plurality of damping assemblies, and the top of the pulverizing box is fixedly connected with a cutting box through a plurality of stand columns. An L-shaped machine base is fixedly installed on one side of the cutting box, a driving motor is fixedly arranged on one side of the L-shaped machine base, a discharging pipe is fixedly connected to the bottom side of the cutting box, and a control valve is fixedly arranged on the discharging pipe. The raw material pulverizer is reasonable in structure, when the driving motor is started, cutting blades can be driven to rotate for preliminary pretreatment, two crushing tooth rollers can also be driven to rotate oppositely for crushing treatment, meanwhile, a conveying spiral blade can also be driven to rotate to convey unqualified raw materials for repeated crushing again, finally, all the raw materials can be crushed to be qualified, manual screening and investment are not needed any more, and the labor intensity of workers is relieved.

Owner:董政

Environment-friendly solid waste treatment device

ActiveCN111804700APlay a screening effectGuaranteed screening effectDrying solid materials without heatTransportation and packagingDrive shaftWaste treatment

The invention relates to the technical field of waste treatment, and discloses an environment-friendly solid waste treatment device which comprises a filter press box and a crushing box fixedly connected to the top of the filter press box. The crushing box comprises an outer cylinder, the bottom of the outer cylinder is provided with a falling opening communicating with the top of the filter pressbox, the top of the back of the outer cylinder fixedly communicates with a feeding hopper, the front side and the rear side of an inner cavity of the outer cylinder are each rotatably connected witha rotary drum, a plurality of groups of material leakage grooves are formed in the surface of the rotary drum at equal intervals, and the inner side of the rotary drum is fixedly connected with a driving shaft through a tripod. According to the environment-friendly solid waste treatment device, the rotary drum which rotates continuously is arranged, so that the solid waste can be continuously brought to a high position to fall down, the solid waste can be repeatedly cut and crushed by a plurality of blades on two groups of tool holders, the solid waste can be effectively crushed into small blocks, the material leakage grooves on the surface of the rotary drum can also achieve a screening effect, the thorough crushing of the solid waste is guaranteed, the subsequent treatment is facilitated, and the treatment efficiency can be improved.

Owner:河北总友环保科技有限公司

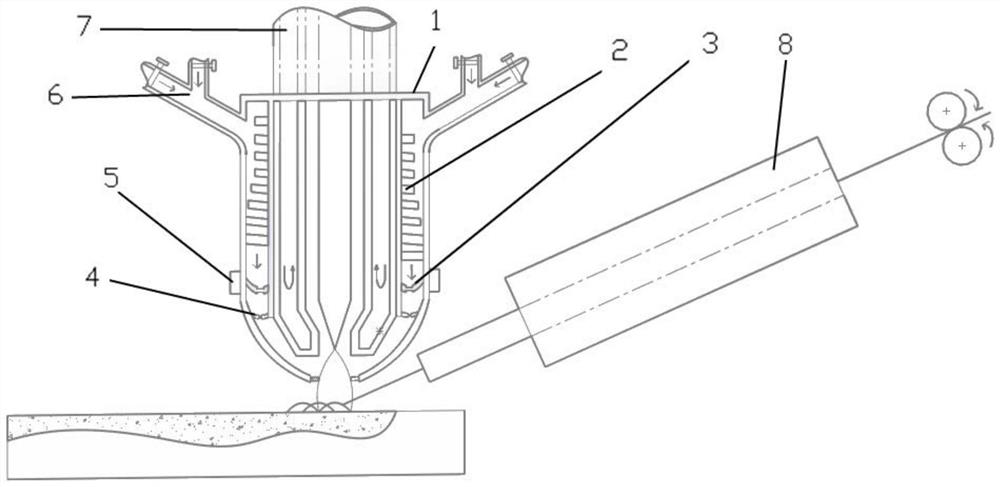

Ultra-high strength steel in-situ wire-powder composition-adjustable composite additive device

ActiveCN112139492AGuaranteed screening effectWell mixedAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAlloy

The invention provides an ultra-high strength steel in-situ wire-powder composition-adjustable composite additive device. The device comprises a plasma arc generating mechanism, a paraxial air powderconveying mechanism, a wire feeder and a vibrating mechanism, wherein the paraxial air powder conveying mechanism comprises a paraxial air powder cover, a spiral air powder groove is formed in the airpowder cover, an annular funnel filter is arranged in the air powder cover, and an aperture adjusting switch valve is arranged at the lower end of the air powder cover. According to the composite additive device, a set vibration and airflow composite mode is adopted in a gun body, quantitative opening of a plurality of preset alloy powders is achieved, the powders are spirally mixed in an decelerated mode, sieved and uniformly mixed, and the uniform powders are sent out of the gun body; and through the vibration and air flow composite powder feeding and the plasma flow force composite driving, the preset alloy uniformly-mixed powders and a conventional wire material with a set wire feeding speed are compounded below the gun body and then conveyed into a molten pool through a paraxial shaft, and additively manufactured into multi-component alloy materials under the stirring force of the molten pool. The device can produce composite components with adjustable composition in different areas of a metal matrix according to different requirements through additive manufacturing.

Owner:NANJING UNIV OF SCI & TECH

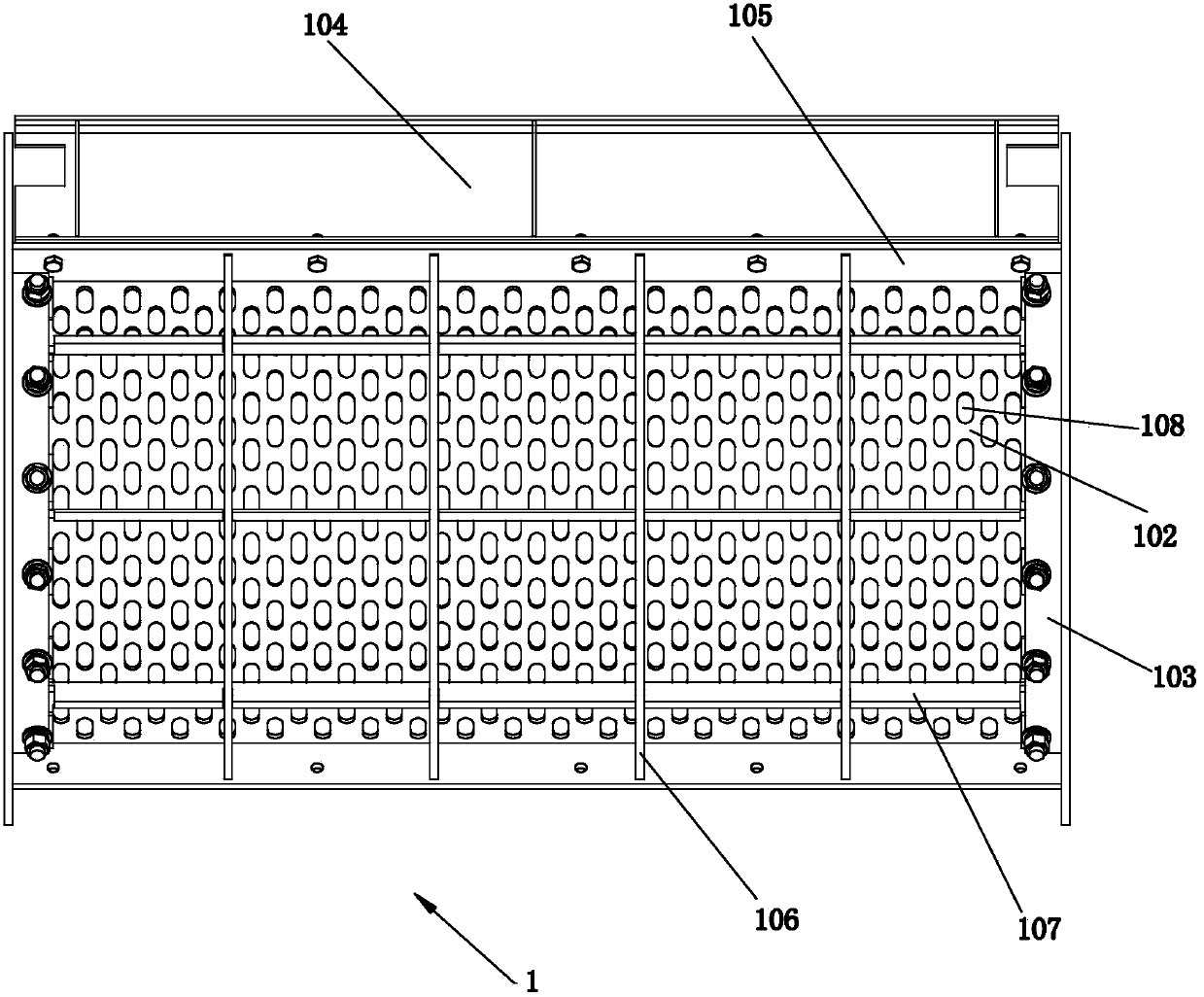

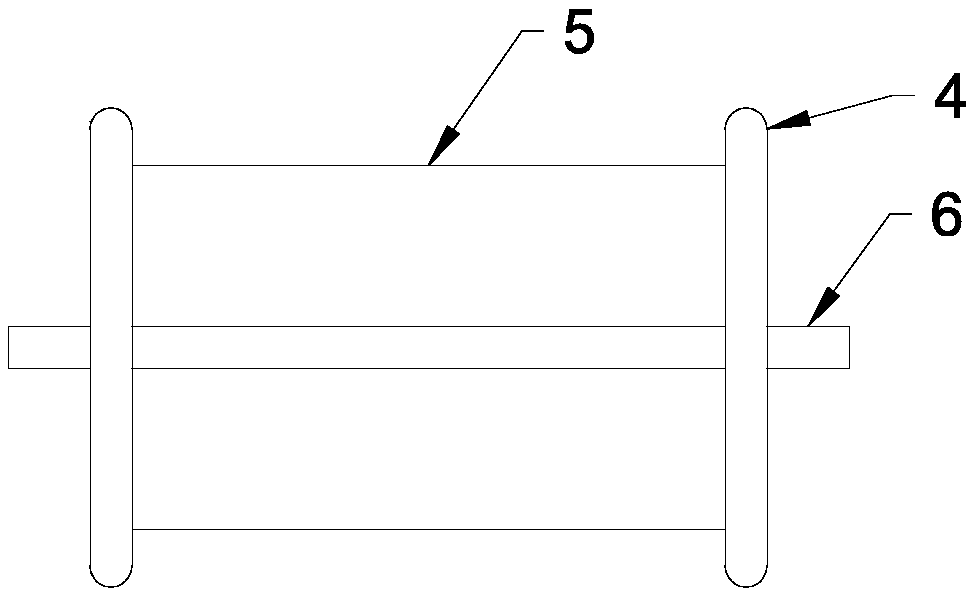

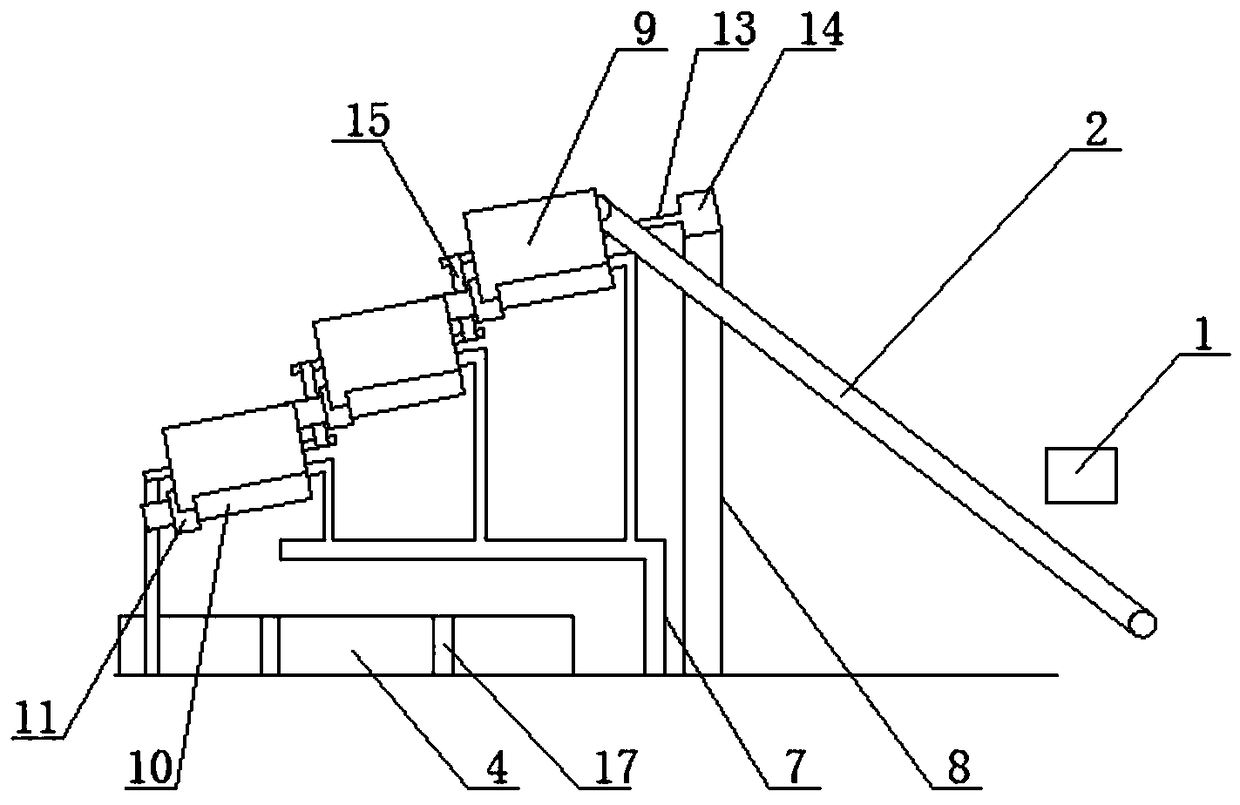

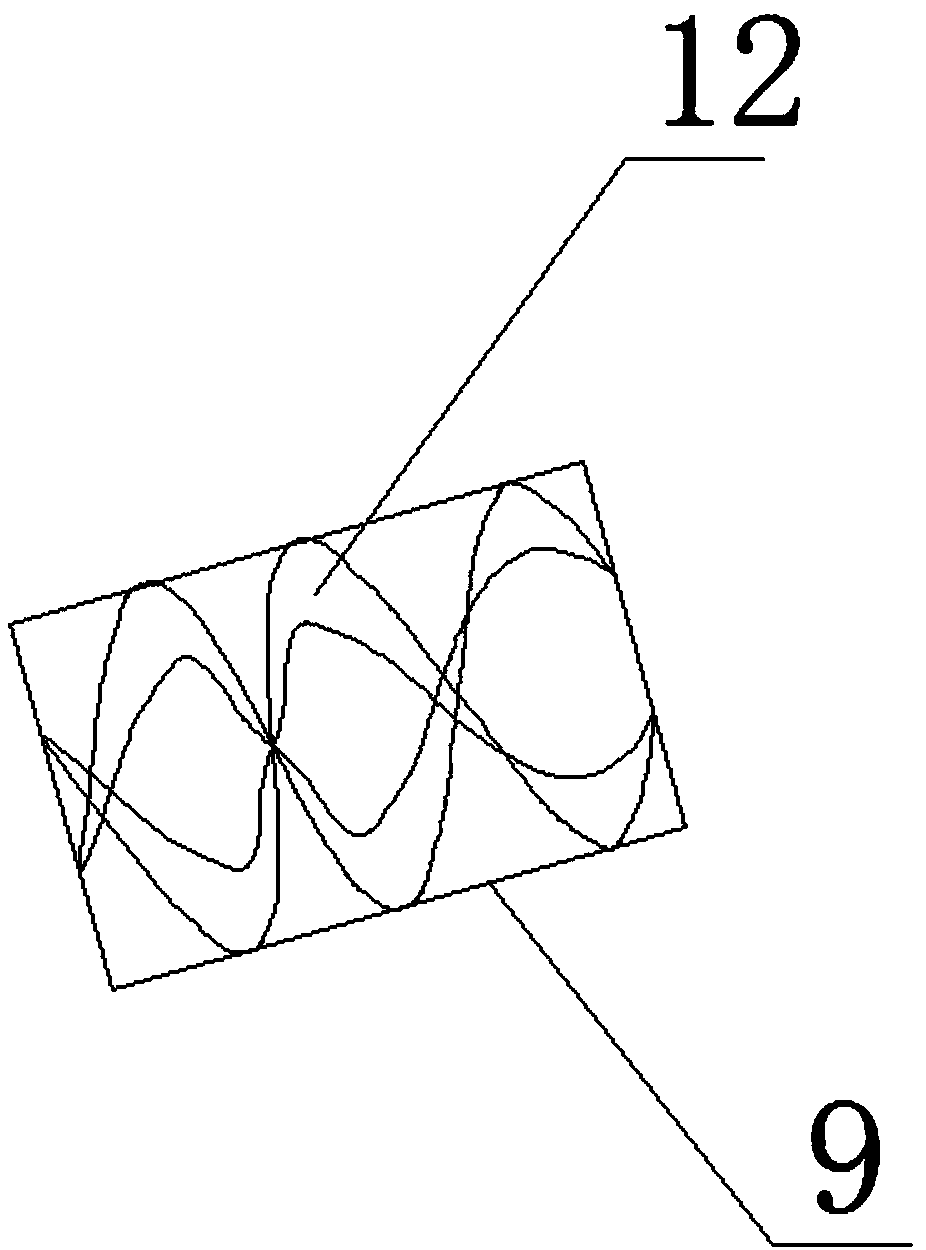

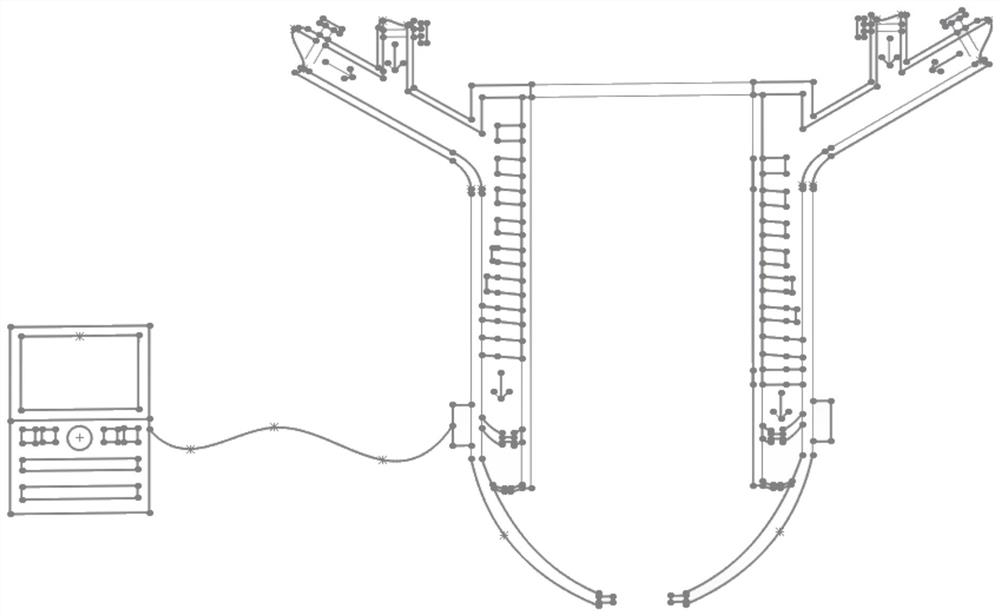

Method and device for removing impurities of tobacco leaves in pre-processing stage of threshing and redrying

ActiveCN102389159AReduce breakageEfficient removalTobacco preparationSmall footprintPulp and paper industry

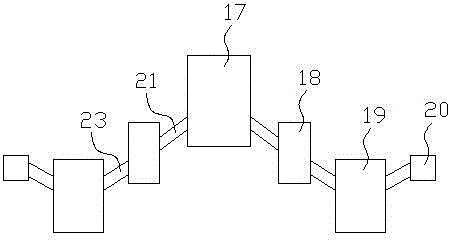

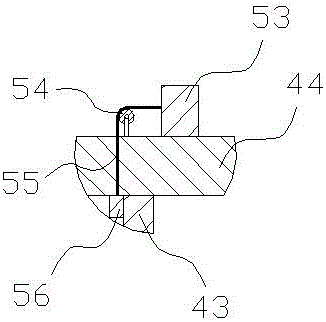

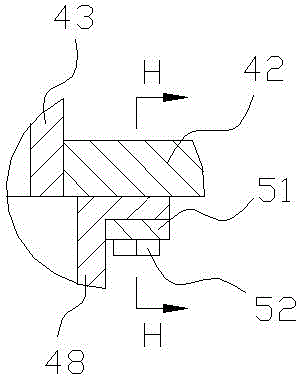

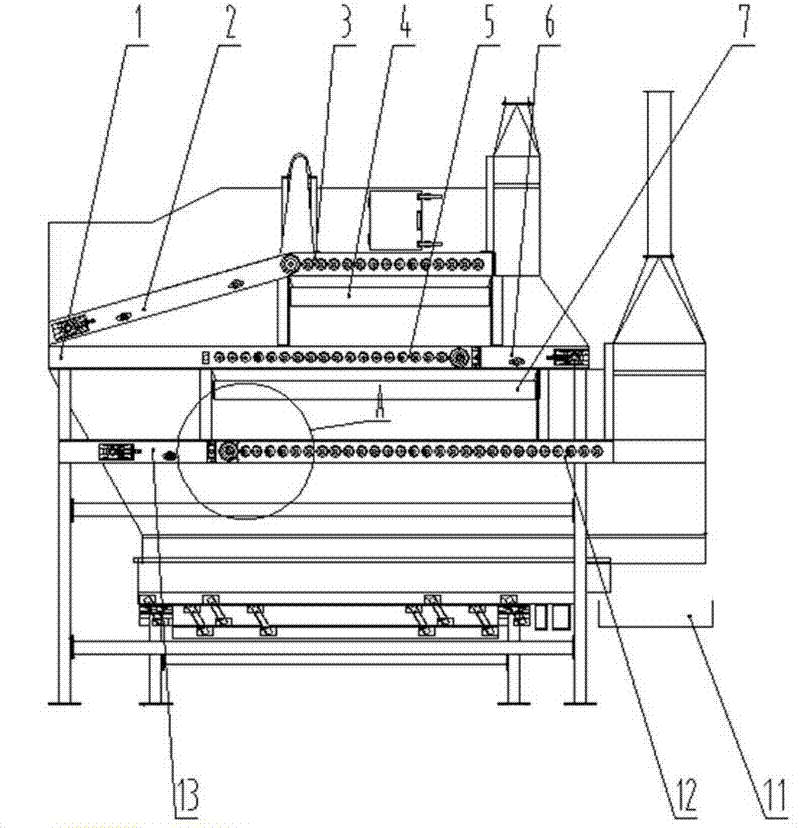

The invention discloses a method and a device for removing impurities of tobacco leaves in the pre-processing stage of threshing and redrying. The method comprises the following steps: conveying the tobacco leaves for a certain distance by a horizontal top screening roller channel conveying device; turning the tobacco leaves for 180 degrees, and conveying a certain distance by a middle screening horizontal roller channel conveying device; later turning the tobacco leaves for 180 degrees, and conveying a certain distance by a bottom screening horizontal roller channel conveying device; removing the impurities adhered on the upper surfaces and the lower surfaces of the tobacco leaves from the gaps among the roller channels, and separating the impurities from the tobacco leaves; and simultaneously arranging impurity collecting devices at the lower sides of the top screening roller channel conveying device, the middle screening roller channel device, and the bottom screening roller channel device, and collecting the dropped impurities. The invention can effectively separate the impurities and fragments, such the sand, dust and hemp thread, from the tobacco leaves in the pre-processing stage of threshing and redrying, and can effectively reduce the broken tobacco. The device has a compact structure and small taken area.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

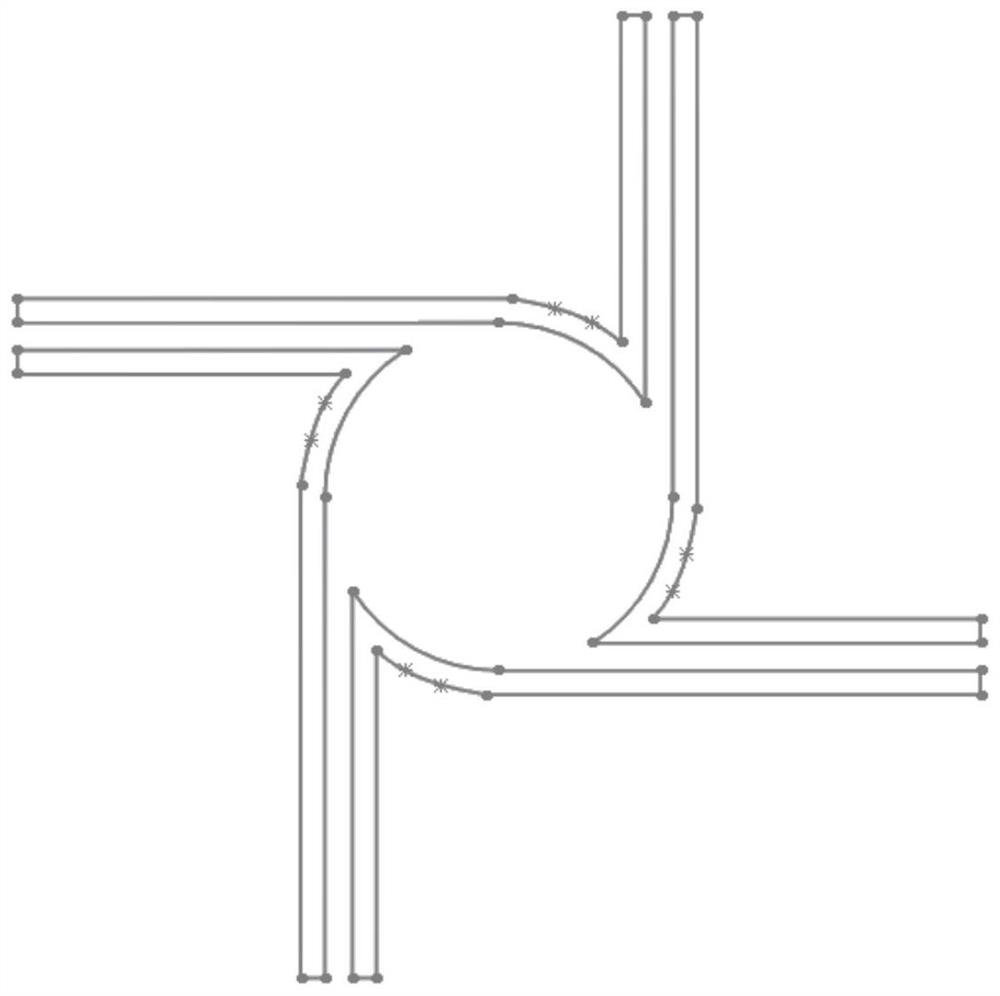

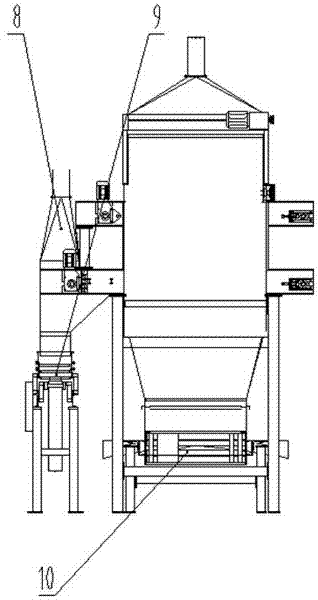

External type cylindrical residue isolating screen

PendingCN107185800ACompact structureEasy to manufactureSievingScreeningMechanical engineeringEngineering

The invention discloses an external type cylindrical residue isolating screen which comprises a machine frame, a screen cylinder rotationally installed on the machine frame and a rotary driving assembly installed on the machine frame and used for driving the screen cylinder to rotate. A feeding assembly used for feeding materials to be screened to the outer surface of the upper portion of the screen cylinder is arranged above the screen cylinder. A receiving assembly used for collecting screened materials and guiding out the screened materials is arranged in the screen cylinder. A residue removing assembly used for removing unscreened materials attached to the outer surface of the screen cylinder is arranged outside the screen cylinder. The external type cylindrical residue isolating screen has the advantages of being simple and compact in structure, easy to manufacture, convenient to assemble and maintain, capable of reducing the labor intensity, saving the labor cost, improving the screening efficiency and ensuing production continuity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com