Coal ash roller screen

A rolling screen, fly ash technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of affecting production efficiency, the fly ash cannot be effectively screened, the screening effect is not good, etc., to achieve high-efficiency screening, The effect of promoting the improvement of screening efficiency and ensuring the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

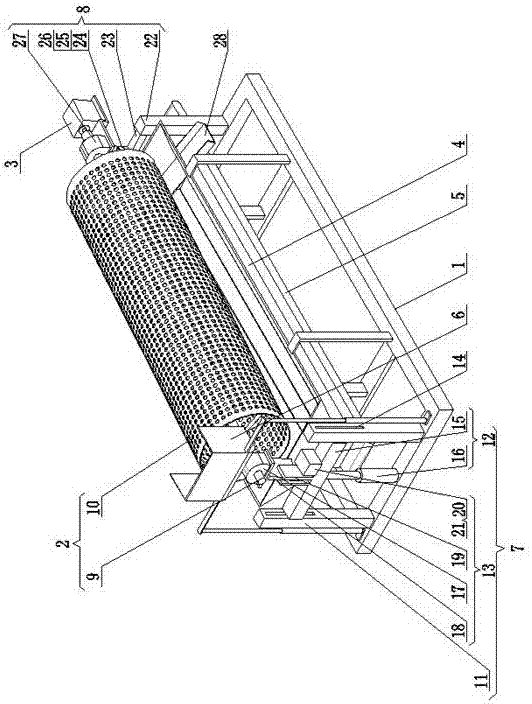

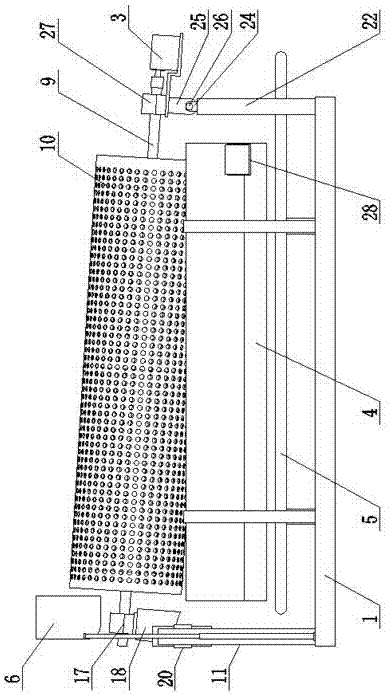

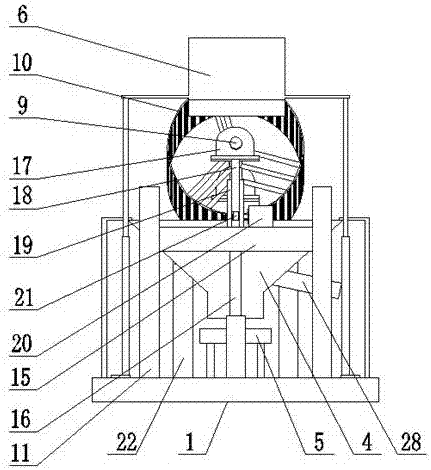

[0019] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described:

[0020] Such as Figures 1 to 4 As shown, a fly ash rolling screen includes a base 1, a rolling screen body 2, a rotary drive motor 3, a funnel 4, a belt conveyor 5, and a feeding trough 6, and also includes a swing drive frame 7 and a hinged support frame 8. The swing drive frame 7 and the hinged support frame 8 are respectively arranged at both ends of the base 1. The rolling screen body 2 includes a rotating shaft 9 and a screen cylinder 10 fixed on the outer circumference of the rotating shaft 9. One end of the rotating shaft 9 is connected to the swing driving frame 7. The other end is connected to the hinged support frame 8, the rotary drive motor 3 is connected to the other end of the rotating shaft 9, the funnel 4 is fixed on the base 1 and is located below the screen cylinder 10, and the belt conveyor 5 is fixed on the base On the base 1 and below the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com