Agricultural product screening device with good screening effect

A screening device and a technology for agricultural products, which are applied in the fields of screening, solid separation, and grids, can solve the problems of poor screening effect and inability to ensure complete screening, and achieve the effects of easy promotion, novel structure, and improved screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

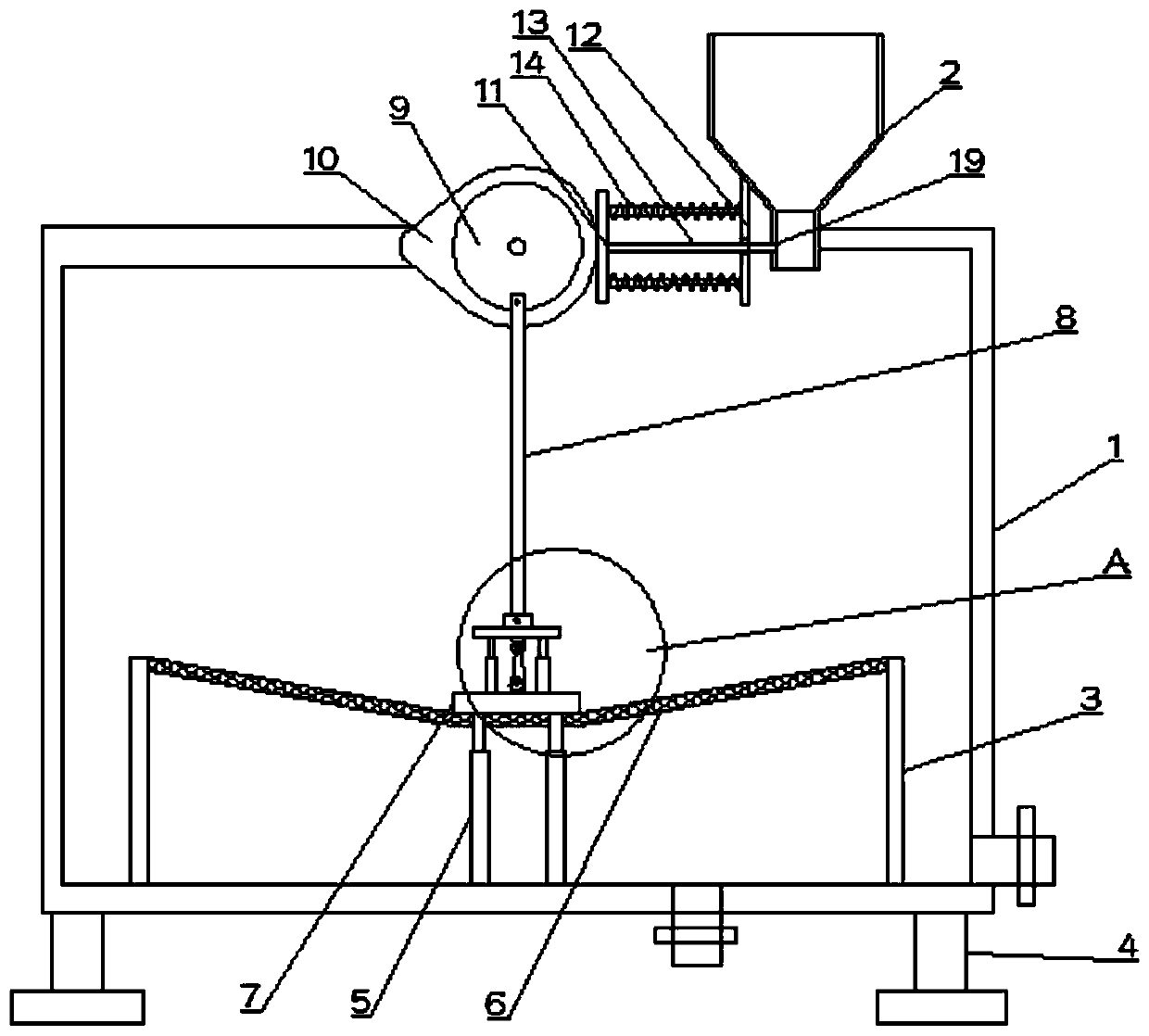

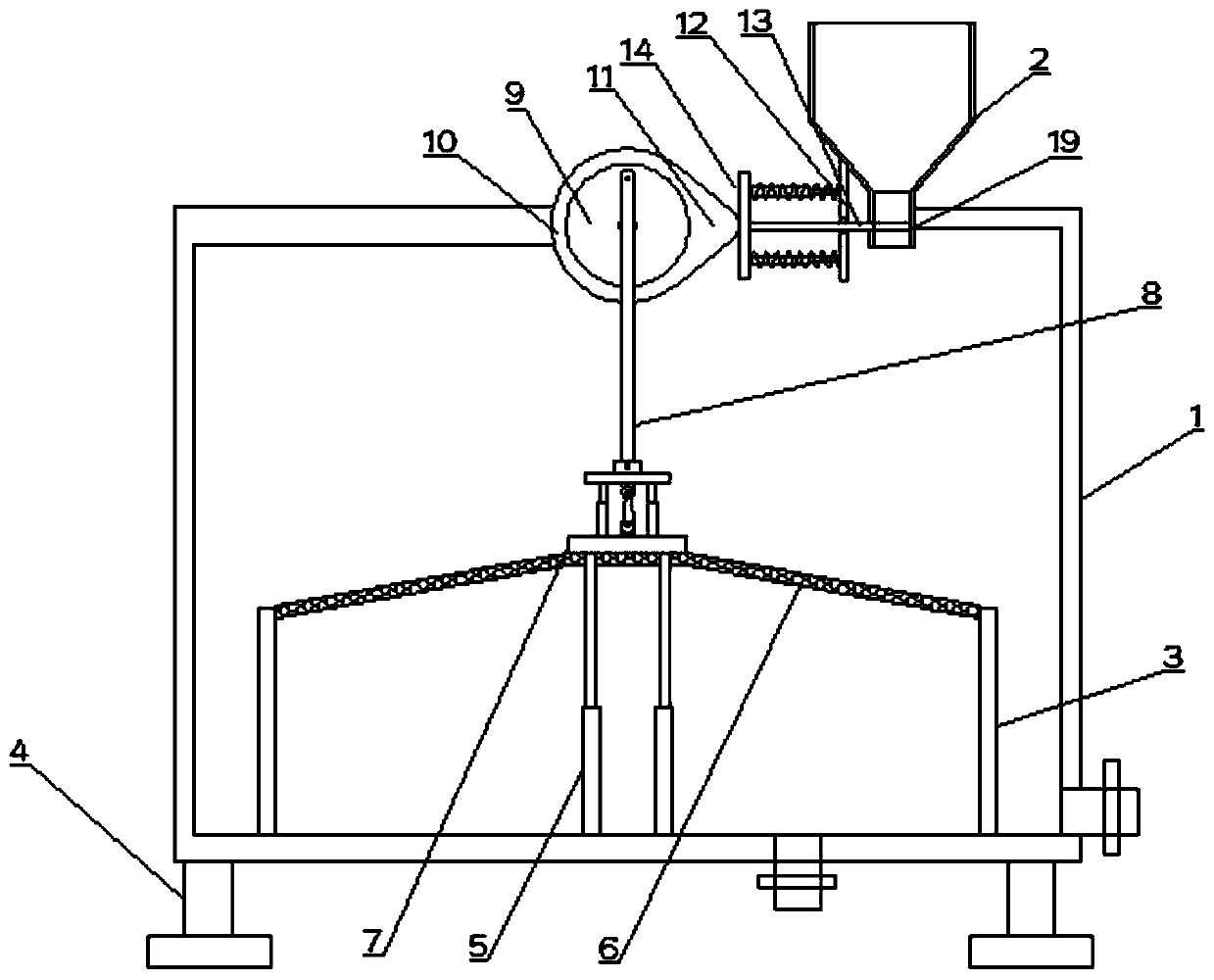

[0022] see Figure 1~2 In Embodiment 1 of the present invention, a screening device for agricultural products with good screening effect includes a main body 1, an inner partition 3 is arranged at the middle position inside the main body 1, and a screen 6 is installed on the upper part of the inner partition 3, so that The middle position of the drive plate 7 is provided with a vibration mechanism to drive its vibration, and the vibration mechanism is fixedly sleeved on the drive plate 9 at the end of the A rotating shaft 20 through the connecting rod 8, and the two ends of the connecting rod 8 are hingedly connected. The cam 10 that drives the flashboard 19 to reciprocate is also set on the A rotating shaft 20. The flashboard 19 is arranged at the outlet of the feeding hopper 2, and the feeding hopper 2 is fixedly installed on the main body 1. It is arranged at a place where materials are convenient to enter into the screen 6; when the shutter 19 is at the left end, the scree...

Embodiment 2

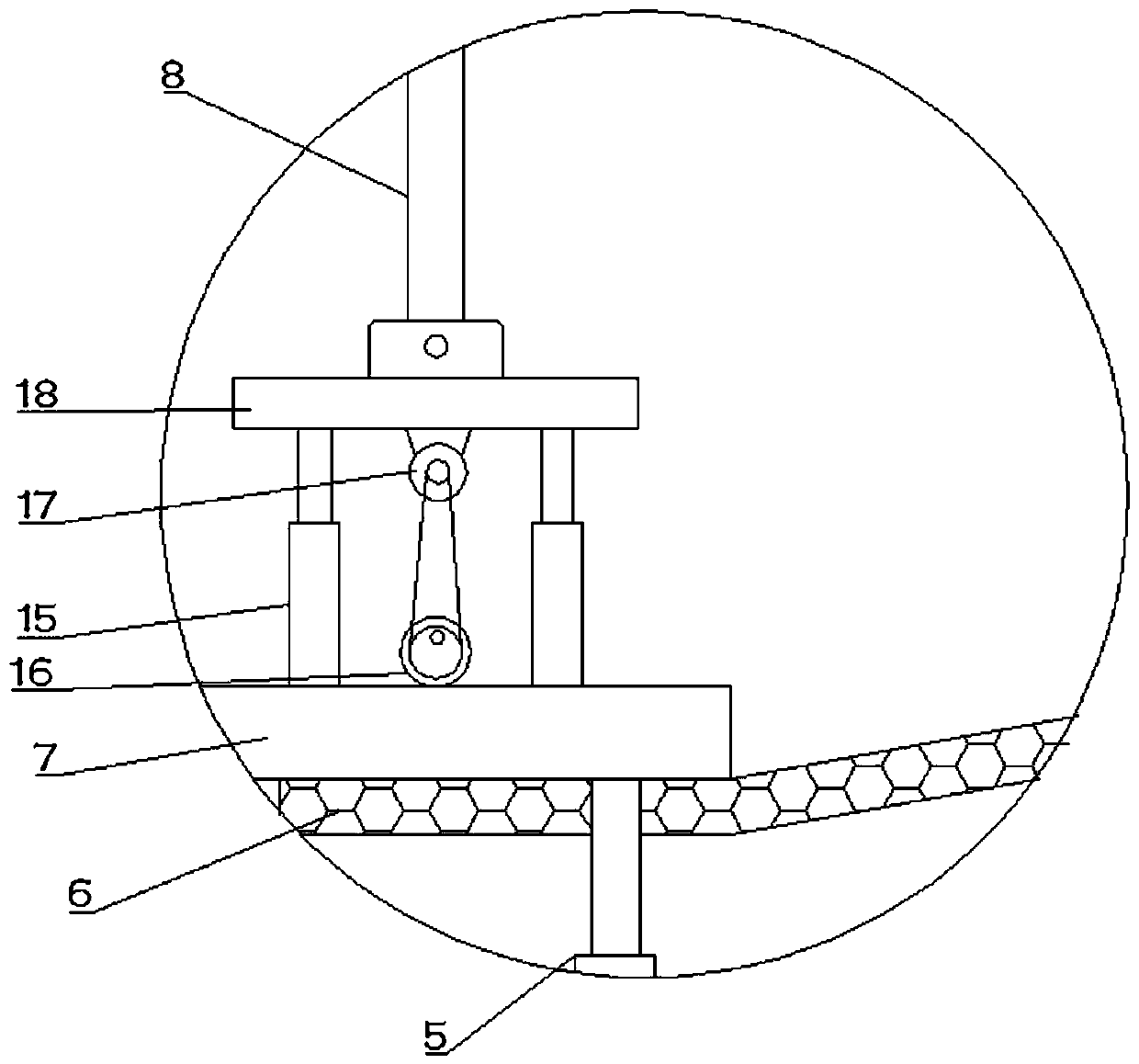

[0025] see Figure 1~4 The main difference between this embodiment 2 and embodiment 1 is that the reciprocating mechanism includes a drive plate 7 fixedly installed in the center of the screen 6, the upper end of the drive plate 7 is in contact with an eccentric wheel 16, and the eccentric wheel 16 passes through the belt Connect with the A motor 17, the A motor 17 is fixedly mounted on the bottom of the mounting plate 18, and the upper and lower ends of the B elastic telescopic rod 15 are respectively fixedly mounted on the drive plate 7 and the mounting plate 18; the eccentric wheel 16 is mounted on the mounting plate by rotating The B rotating shaft on the plate 18 interferes with the drive plate 7 .

[0026] Specifically, A motor 17 is energized to rotate during work, and A motor 17 rotates to drive the eccentric wheel 16 to rotate. Since the eccentric wheel 16 is an eccentric structure, it drives the drive plate 7 to drive the screen cloth 6 to reciprocate up and down, an...

Embodiment 3

[0034] The main difference between Embodiment 3 and Embodiment 1 is that a B spring is fixedly installed at the bottom of the drive plate 7, and the end of the B spring away from the drive plate 7 is fixedly installed on the bottom of the main body 1, and the up and down movement of the drive plate 7 is ensured by setting the B spring. smoothness.

[0035] The working principle of the present invention is:

[0036] When working, put the materials to be screened into the hopper 2, and the A rotating shaft 20 drives the drive plate 9 and the cam 10 to rotate. When the cam 10 drives the shutter 19 to the left position, the screen 6 is at the lowest position, and the materials pass through the hopper 2. The outlet falls onto the screen 6, and at the same time, the A motor 17 rotates to drive the eccentric wheel 16 to rotate. Since the eccentric wheel 16 has an eccentric structure, it drives the drive plate 7 to drive the screen 6 to reciprocate up and down, so that the screen 6 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com