Raw material pulverizer for polyurethane foam plastic production and pulverizing method

A technology of foam plastics and polyurethane, applied in mechanical equipment, grain processing, springs/shock absorbers, etc., can solve the problems of reducing the crushing accuracy and service life of the pulverizer, increasing the labor intensity of the staff, and being inconvenient for users to use, etc. , to achieve the effect of good crushing effect, improved service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

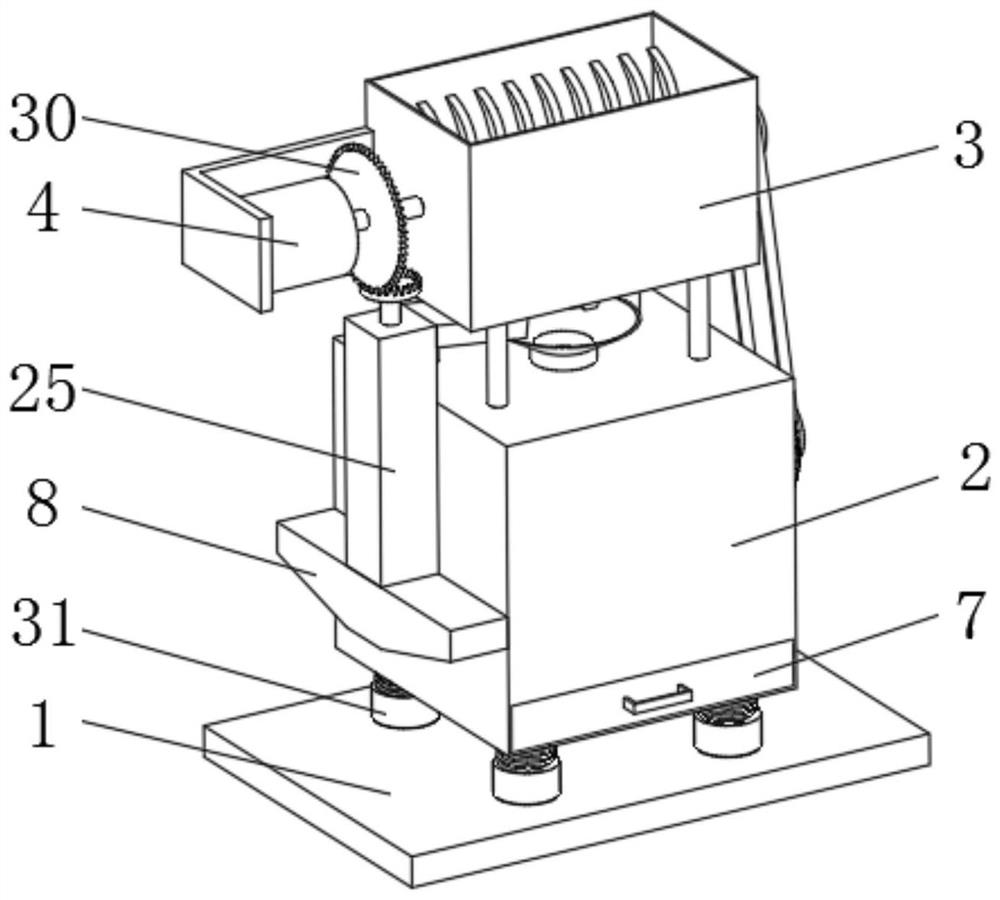

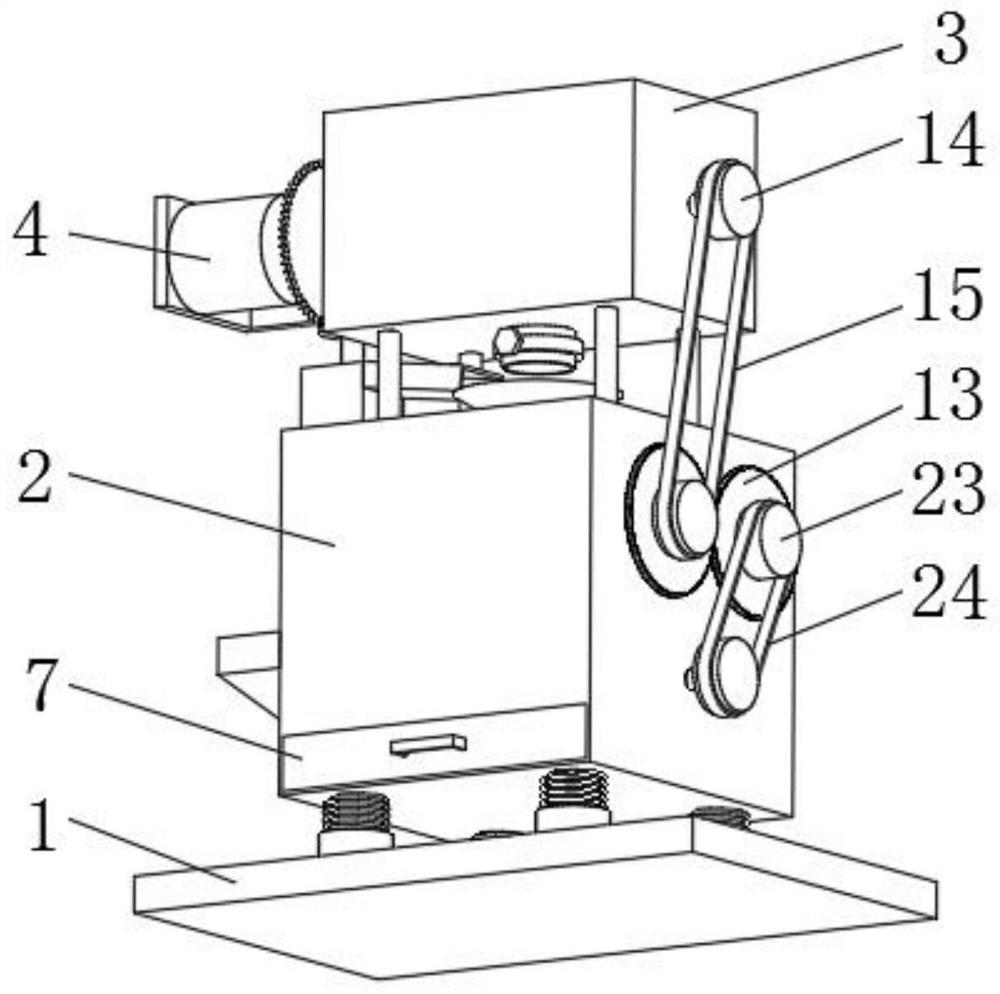

[0041] Example: Reference Figure 1-8 The raw material pulverizer for polyurethane foam production shown includes a base 1, and the base 1 can be any base structure in the prior art, such as a metal bottom plate.

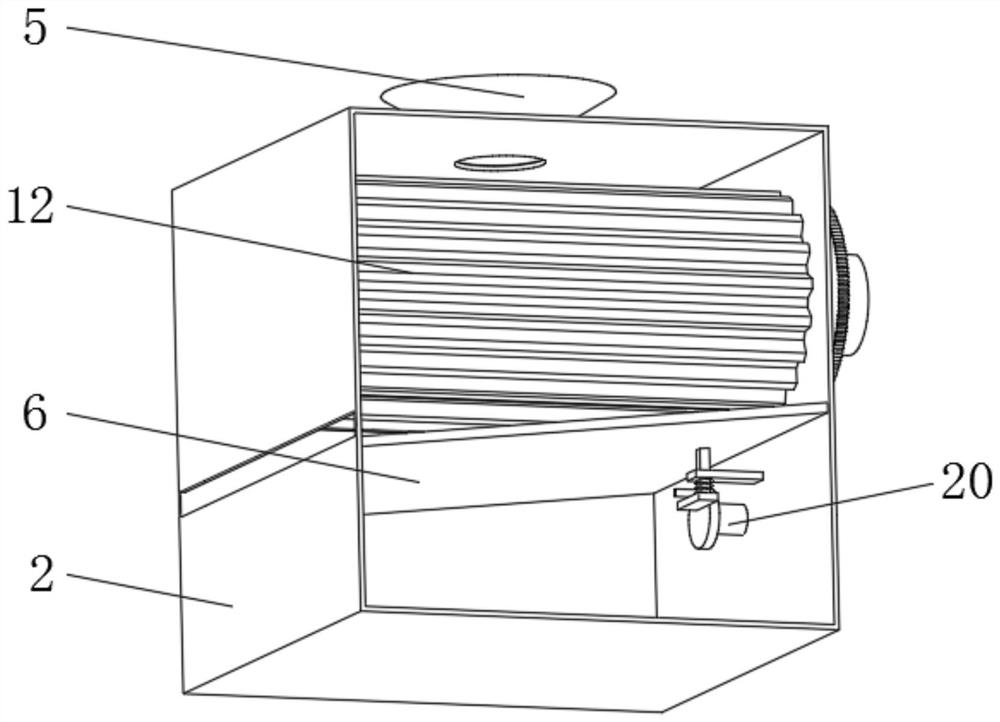

[0042] A crushing box 2 is connected to the top of the base 1 through a plurality of shock absorbing components, and the crushing box 2 may be any box structure in the prior art, such as a metal box. It should be noted that the number of shock absorbing assemblies can be two, three, four, five, etc. In this embodiment, four shock absorbing assemblies are arranged on the top of the base 1 .

[0043] The top of the crushing box 2 is fixedly connected with a cutting box 3 through a plurality of columns, and the cutting box 3 can be any metal box with an upper opening in the prior art, which is carried out by screwing the top of the crushing box 2 through a plurality of columns. fixed.

[0044] One side of the cutting box 3 is fixedly equipped with an L-shaped support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com