External type cylindrical residue isolating screen

A slag screen and cylinder technology, applied in screen, solid separation, grid and other directions, can solve the problems of poor fluidity of plastic products, high labor intensity, inability to continuous production, etc., to achieve simple and compact structure, easy assembly and maintenance , to ensure the effect of production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

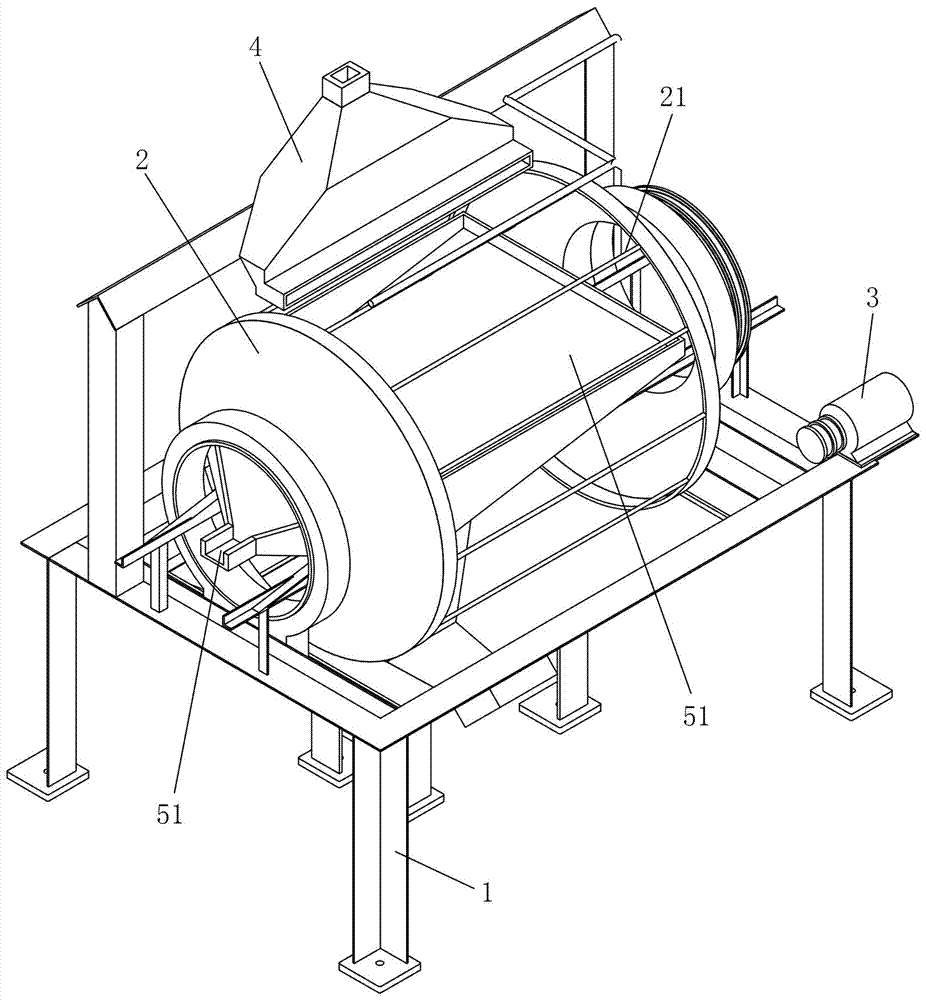

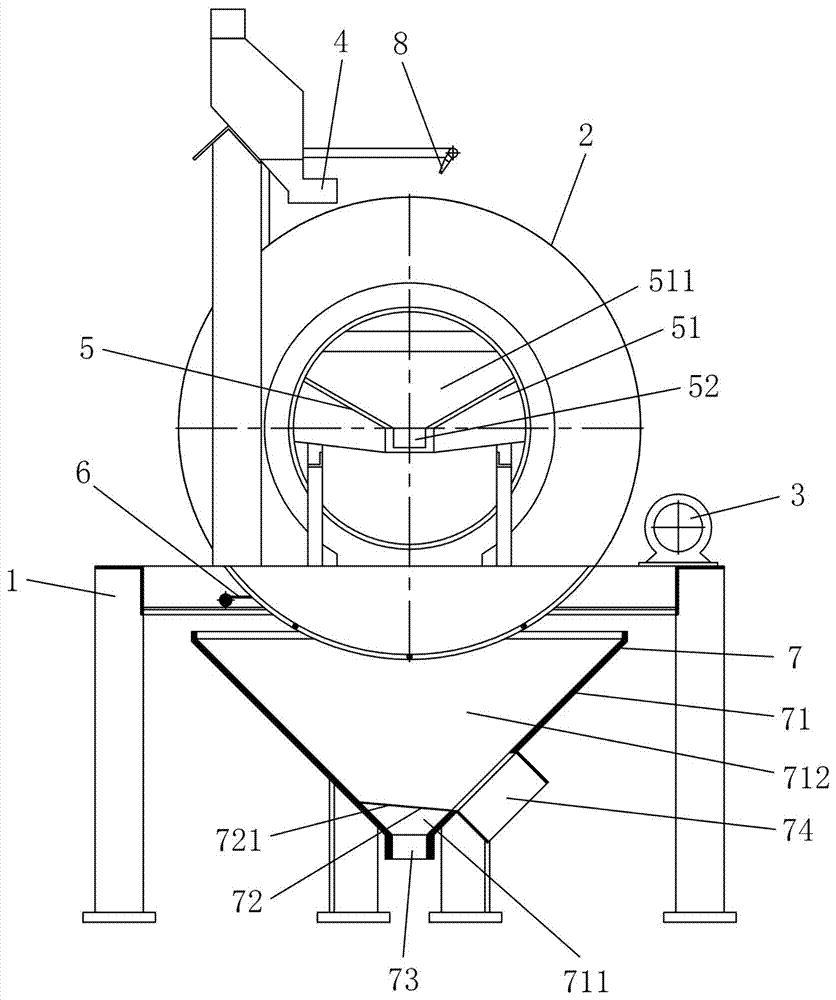

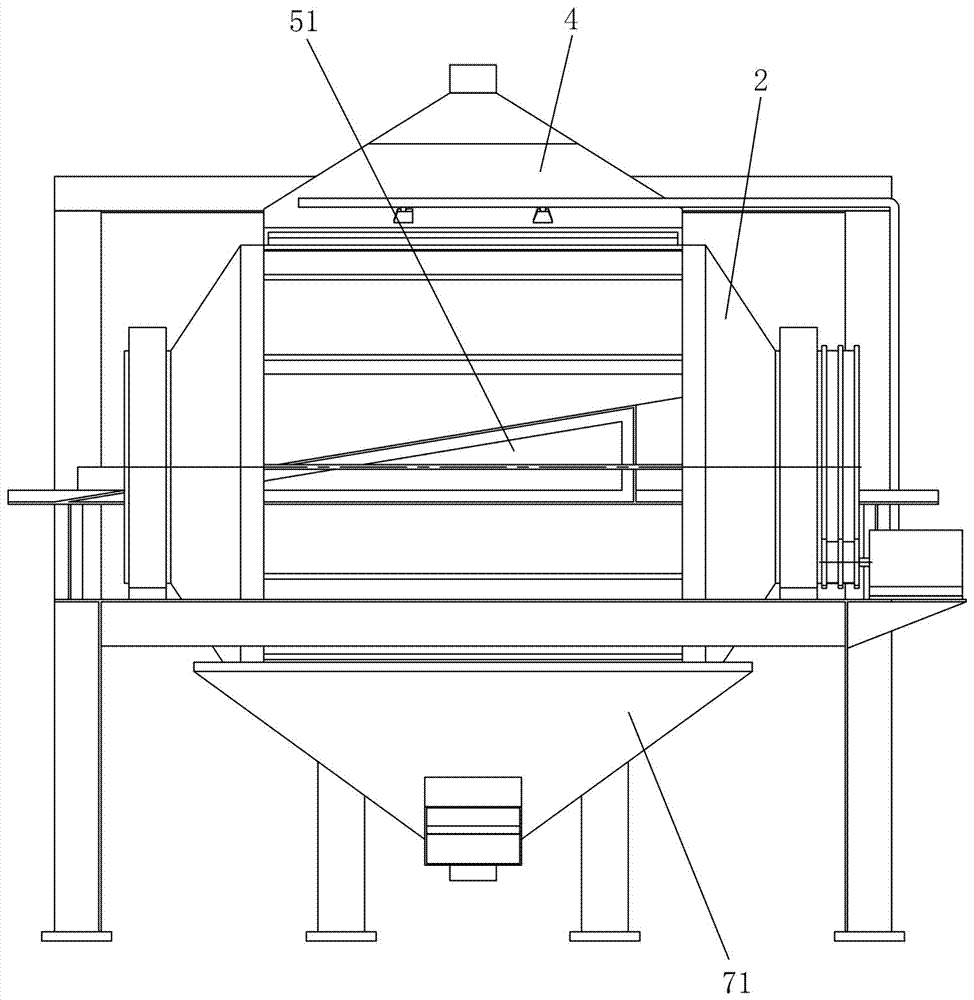

[0022] Such as Figure 1 to Figure 3 As shown, the external-entry cylindrical slag screen of this embodiment includes a frame 1, a sieve cylinder 2 rotatably mounted on the frame 1, and a rotary drive mounted on the frame 1 for driving the sieve cylinder 2 to rotate. Component 3, above the screen cylinder 2, there is a feeding component 4 for feeding the materials to be screened to the upper outer surface of the screen cylinder 2, and inside the screen cylinder 2 is a set for collecting the screened materials (materials passing through the screen cylinder 2) and The material receiving component 5 that guides the sieved material out, and the outside of the sieve cylinder 2 is used as a slag cleaning component to remove the unscreened material (material that has not passed through the sieve cylinder 2) attached to the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com